Page 1

Rhein Tech Laboratories, Inc. Client: M/A-Com, Inc.

360 Herndon Parkway Model: VIDA

Suite 1400 Standard: FCC Part 90

Herndon, VA 20170 FCC ID: BV8VMXBA

http://www.rheintech.com

Report Number: 2006072

MAX

Base Station

Appendix J: Manual

Please refer to the following pages for the installation manual and see also the separate user manual document.

57 of 64

Page 2

Installation and Configuration Manual

MM-009804-001

May-06

MAX

VIDA

Base Station

4.9 GHz Broadband Distribution System

Page 3

MM-009804-001

MANUAL REVISION HISTORY

REVISION DATE REASON FOR CHANGE

- May 2006 Initial Release.

M/A-COM Technical Publications would particularly appreciate feedback on any errors found in this document and

suggestions on how the document could be improved. Submit your comments and suggestions to:

Wireless Systems Business Unit fax your comments to: (434) 455-6851

M/A-COM, Inc. or

Technical Publications e-mail us at: techpubs@tycoelectronics.com

221 Jefferson Ridge Parkway

Lynchburg, VA 24501

CREDITS

NOTICE!

Repairs to this equipment should be made only by an authorized service technician or facility designated by th e supplier.

Any repairs, alterations or substitution of recommended parts made by the user to this equipment not approved by the

manufacturer could void the user’s authority to operate the equipment in addition to the manufacturer’s warranty.

NOTICE!

This manual covers M/A-COM, Inc. products manufactured and sold by M/A-COM, Inc.

This device made under license under one or more of the following US patents: 4,590,473; 4,636,791; 5,148,482;

5,185,796; 5,271,017; 5,3 77,229, 5,377,229; 4,71 6,407; 4,972460; 5,502,767; 5,146,497; 5,164,986; 5,185,795.

The voice coding technology embodied in this product is protected by intellectual property rights including patent rights,

copyrights, and trade secrets of Digital Voice Systems, Inc. The user of this technology is explicitly prohibited from

attempting to decompile, reverse engineer, or disassemble the Object Code, or in any way convert the Object Code into

human-readable form.

NOTICE!

This product conforms to the European Union WEEE Directive 2002/96/EC. Do not dispose of this product in a public

landfill. This product should be taken to a recycling center at the end of its life.

NOTICE!

The software contained in this device is copyrighted by M/A-COM, Inc. Unpublished rights are reserved under the

copyright laws of the United States.

This manual is published by M/A-COM, Inc., without any warranty. Improvements and changes to this manual

necessitated by typographical errors, inaccuracies of current information, or improvements to programs and/or equipment,

may be made by M/A-COM, Inc., at any time and without notice. Such changes will be incorporated into new editions of

this manual. No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, for any purpose, without the express written permission of M/A-COM,

Inc.

Copyright © 2006, M/A-COM, Inc. All rights reserved.

2

Page 4

MM-009804-001

TABLE OF CONTENTS

Page

1 REGULATORY AND SAFETY INFORMATION .............................................................................7

1.1 SAFETY CONVENTIONS......................................................................................................7

1.2 REGULATORY......................................................................................................................8

1.2.1 Maximum Permissible Exposure Limits.................................................................... 8

1.2.2 Determining MPE Radius......................................................................................... 8

1.2.3 Safety Training Information ....................................................................................10

2 SPECIFICATIONS.........................................................................................................................11

2.1 GENERAL SPECIFICATIONS.............................................................................................11

2.2 TRANSMITTER...................................................................................................................13

2.3 RECEIVER ..........................................................................................................................13

3 INTRODUCTION............................................................................................................................14

3.1 ABOUT THIS MANUAL........................................................................................................14

3.2 CUSTOMER SERVICE..............................................................................................................15

3.2.1 Technical Support................................................................................................... 15

3.2.2 Customer Resource Center....................................................................................15

4 DESCRIPTION...............................................................................................................................16

4.1 VIDA

MAX

SYSTEM OVERVIEW ...........................................................................................16

4.2 THE VIDA NETWORK SOLUTION......................................................................................16

4.3 THE VIDA

4.4 VIDA

4.5 4.9 GHZ VIDA

MAX

NETWORK....................................................................................................17

MAX

NETWORK COMPONENTS/FEATURES.............................................................18

MAX

BASE STATION.......................................................................................20

4.5.1 Summary of Key Features......................................................................................21

4.6 VIDA

MAX

BASE STATION INTERFACES............................................................................. 22

4.6.1 Standard Base Station (AC Powered)....................................................................22

4.6.2 Special Hardened Base Station (DC Powered)......................................................23

4.7 VIDA

MAX

BASE STATION ANTENNA OPTIONS...........................................................................24

5 UNPACKING AND CHECKING EQUIPMENT.............................................................................. 26

5.1 UNPACKING EQUIPMENT.................................................................................................26

5.2 INSPECTING AND INVENTORYING EQUIPMENT............................................................26

6 PLANNING THE INSTALLATION................................................................................................. 27

6.1 ENVIRONMENTAL EVALUATION...................................................................................... 27

6.2 POLE-MOUNT INSTALLATIONS........................................................................................27

6.3 ELECTRICAL POWER........................................................................................................28

6.3.1 AC Power................................................................................................................28

6.3.2 DC Power ...............................................................................................................28

6.4 SITE GROUNDING..............................................................................................................28

3

Page 5

MM-009804-001

TABLE OF CONTENTS

Page

7 INSTALLATION.............................................................................................................................29

7.1 TOOLS AND TEST EQUIPMENT REQUIRED....................................................................29

7.2 CUSTOMER SUPPLIED MATERIALS................................................................................29

7.3 BEFORE BEGINNING THE INSTALLATION......................................................................30

7.4 MOUNTING THE BASE STATION......................................................................................30

7.4.1 Attaching the Mounting Bracket..............................................................................31

7.4.2 Attaching the Base Station to a Pole......................................................................32

7.5 POWER CABLES................................................................................................................32

7.5.1 AC Power................................................................................................................32

7.5.2 DC Power ...............................................................................................................32

7.6 GROUNDING STUDS.........................................................................................................32

7.7 NETWORK/DATA CONNECTION.......................................................................................33

7.8 ANTENNA CONNECTIONS................................................................................................33

7.8.1 Installing an omni-directional antenna....................................................................33

7.8.2 Installing a Directional Antenna..............................................................................34

7.9 GPS ANTENNA ......................................................................................................................35

7.9.1 Installing Optional GPS Antenna............................................................................35

7.10 RADIO CHASSIS AND CABLING........................................................................................36

7.10.1 Attaching Base Station Cables...............................................................................36

8 OPERATION..................................................................................................................................37

8.1 LOGGING INTO THE VIDA

8.2 TESTING THE VIDA

MAX

BASE STATION .................................................................37

MAX

BASE STATION............................................................................37

9 TROUBLESHOOTING AND SERVICING..................................................................................... 39

9.1 TUNING AND CALIBRATION PROCEDURE......................................................................39

9.1.1 Transmit Frequency Accuracy Calibration..............................................................39

9.1.2 Transmit Power Level Calibration...........................................................................39

10 RADIO CHASSIS.................................................................................................................40

11 CABLE FABRICATION.......................................................................................................41

11.1 ETHERNET CABLE PLUG KIT............................................................................................41

11.1.1 Tools Required .......................................................................................................41

11.1.2 Cable Selection.......................................................................................................42

11.1.3 Cable Preparation...................................................................................................42

11.1.4 Termination.............................................................................................................45

11.1.5 Assembly ................................................................................................................46

TABLE OF FIGURES

Page

4

Page 6

MM-009804-001

TABLE OF FIGURES

Page

Figure 4-1: VIDA

Figure 4-2: VIDA Network Solution................................................................................................... 17

Figure 4-3: VIDAMAX Broadband Network ..................................................................................... 18

Figure 4-4: Network diagram of small VIDA

Figure 4-5: VIDA

Figure 4-6: VIDA

Figure 6-1: Pole Mounting the VIDA

Figure 7-1: Mounting the VIDA

Figure 7-2: Brackets attached to the VIDA

Figure 7-3: VIDA

Figure 7-4: Mounting a Directional Antenna to the VIDA

Figure 13-1: Tyco/Electronics Industrial Circular Ethernet Connector Plug Kit (1738607-2)...........41

Figure 13-2: Cable Preparation ........................................................................................................... 43

Figure 13-3: Cable Preparation Continued..........................................................................................44

Figure 13-4: Termination Requirements............................................................................................. 45

Figure 13-5: Assembly Detail ............................................................................................................. 47

MAX

Wireless Broadband Video and Data Services ................................................16

MAX

MAX

Base Station...................................................................................................... 20

MAX

Base Station Interface Diagram........................................................................22

MAX

Base Station Antenna with External Lightning Protection............................... 34

MAX

MAX

Base Station........................................................................28

Base Station on Horizontal or Vertical Poles.............................31

system ................................................................... 19

MAX

Base Station (vertical pole mounting) ...................... 31

MAX

Base Station ......................................35

TABLE OF TABLES

Page

Table 4-1: Recommended Antenna.....................................................................................................24

5

Page 7

MM-009804-001

6

Page 8

1 REGULATORY AND SAFETY INFORMATION

1.1 SAFETY CONVENTIONS

The following conventions may be used in this manual to alert the user to general safety precautions that

must be observed during all phases of operation, service, and repair of this product. Failure to comply

with these precautions or with specific warnings elsewhere in this manual violates safety standards of

design, manufacture, and intended use of the product. M/A-COM, Inc. assumes no liability for the

customer's failure to comply with these standards.

The WARNING symbol calls attention to a procedure, practice, or the like, which,

if not correctly performed or adhered to, could result in personal injury. Do not

proceed beyond a WARNING symbol until the conditions identified are fully

understood or met.

The CAUTION symbol calls attention to an operating procedure, practice, or the

like, which, if not performed correctly or adhered to, could result in a risk of

CAUTION

danger, damage to the equipment, or severely degrade the equipment performance.

MM-009804-001

The NOTE symbol calls attention to supplemental information, which may improve

system performance or clarify a process or procedure.

The ESD symbol calls attention to procedures, practices, or the like, which could expose

equipment to the effects of Electro-Static Discharge. Proper precautions must be taken

to prevent ESD when handling circuit modules.

The electrical hazard symbol is a WARNING indicating there may be an electrical

shock hazard present.

This symbol indicates the presence of a potential RF hazard.

7

Page 9

MM-009804-001

1.2 REGULATORY

1.2.1 Maximum Permissible Exposure Limits

DO NOT TRANSMIT with this base station and antenna when persons are within the MAXIMUM

PERMISSIBLE EXPOSURE (MPE) Radius of the antenna. The MPE Radius is the minimum distance

from the antenna axis that ALL persons should maintain in order to avoid RF exposure higher than the

allowable MPE level set by the FCC.

FAILURE TO OBSERVE THESE LIMITS MAY ALLOW ALL PERSONS WITHIN

THE MPE RADIUS TO EXPERIENCE RF RADIATION ABSORPTION, WHICH

EXCEEDS THE FCC MAXIMUM PERMISSIBLE EXPOSURE (MPE) LIMIT. IT IS

THE RESPONSIBILITY OF THE BASE STATION LICENSEE TO ENSURE THAT

THE MAXIMUM PERMISSIBLE EXPOSURE LIMITS ARE OBSERVED AT ALL

TIMES DURING BASE STATION TRANSMISSION. THE BASE STATION

LICENSEE IS TO ENSURE THAT NO BYSTANDERS ARE WITHIN THE RADIUS

LIMITS.

1.2.2 Determining MPE Radius

THE MAXIMUM PERMISSIBLE EXPOSURE RADIUS is unique for each site and is determined

based on the complete installation environment (i.e. co-location, antenna type, transmit power level, etc.).

Determination of the MPE distance is the responsibility of the VIDA

radius is required as part of the installation. The Limit for Uncontrolled Exposure Power Density (P

is 10 W/m

The M/A-COM 4.9 GHz VIDA

2

for fixed mounted device.

MAX

Base Station is a fixed mounted radio. After installation and

MAX

user. Calculation of the MPE

)

d

commissioning, the safe distance from the 9 dBi omni-directional antenna is greater than 20 cm

(8-inches).

1.2.2.1 MPE Calculation for omni-directional Antenna

This MPE Minimum Distance Calculation is based on using a 9 dBi gain omni-directional antenna

mounted directly to the base station RF port.

Basic M/A-COM 4.9 GHz VIDA

P: Maximum Peak Conducted Power = 27 dBm

G: Maximum Omni Antenna Gain = 9 dBi

Frequency Range = 4.94 to 4.99 GHz

R: Minimum Distance between User and Antenna = 0.2 m

MAX

Base Station specifications:

8

Equation from FCC:

Pd = P * G / ( 4 * π * R 2 )

= 0.5 W * 7.94 / (4 * 3.1415926 * 0.2 2) = 7.89 W / m2 < 10 W / m

P

d

2

Page 10

MM-009804-001

The calculation indicates that the minimum 0.2 meter distance between user and the omni-directional

antenna (directly mounted to the base station RF port) is required when operating the M/A-COM 4.9 GHz

MAX

VIDA

Base Station.

1.2.2.2 MPE Calculation for Directional Antenna

This MPE Minimum Distance Calculation is based on using a directional antenna with more than 9 dBi

antenna gain.

Basic M/A-COM 4.9 GHz VIDA

MAX

Base Station specifications:

P: Maximum Peak Conducted Power = 27 dBm;

G: Maximum Omni Antenna Gain – Cable Loss = 27 dBi – 1 dB = 26 dBi; (Use numerical G

for the calculation ): G

= 10 ^ (G /10)); For G = 26 dBi, GN = 10 ^ (26 /10) = 398

N

value

N

Frequency Range = 4.94 to 4.99 GHz;

: Minimum Distance between user and antenna to comply with FCC MPE Level (10 W / m2 );

R

min

Equation from FCC:

Pd = P * G / ( 4 * π * R

= SQRT( 0.5 W * GN / (4 * 3.1415926 * 10 ) )= SQRT ( 3.9789E-3 * GN )

R

min

= 1.26 m, for G =26 (i.e., GN = 398 )

R

min

The calculation provides guidelines for users to estimate the minimum safe distance when a high gain

antenna is connected to the M/A-COM 4.9 GHz VIDA

safe distance from antenna greater than 20 cm or SQRT (3.9789E-3 * G

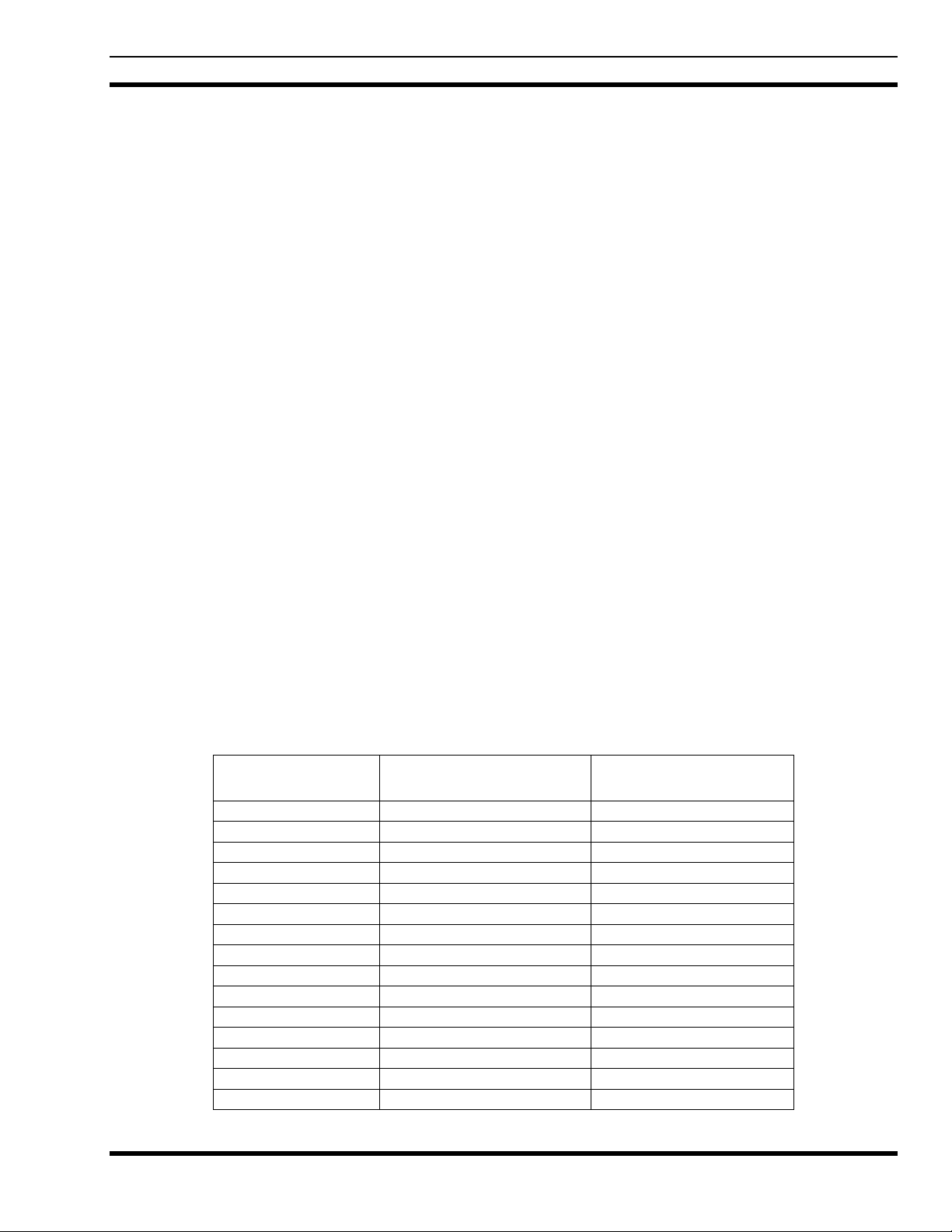

The following table lists the minimum distance for Different Effective Antenna Gain Levels (Antenna

Gain – Feeder Cable Loss)

Minimum Safe Distance Calculation Based for Directional Antennas

min

2

)

MAX

Base Station. The user should always keep a

).

N

Effective Antenna

Gain (dBi)

< 9 0.20 0.65

10 0.20 0.65

11 0.22 0.73

12 0.25 0.82

13 0.28 0.92

14 0.32 1.04

15 0.35 1.16

16 0.40 1.31

17 0.45 1.47

18 0.50 1.64

19 0.56 1.84

20 0.63 2.07

21 0.71 2.32

22 0.79 2.61

23 0.89 2.92

9

Minimum Safe Distance

(Meters)

Minimum Safe Distance

(Feet)

Page 11

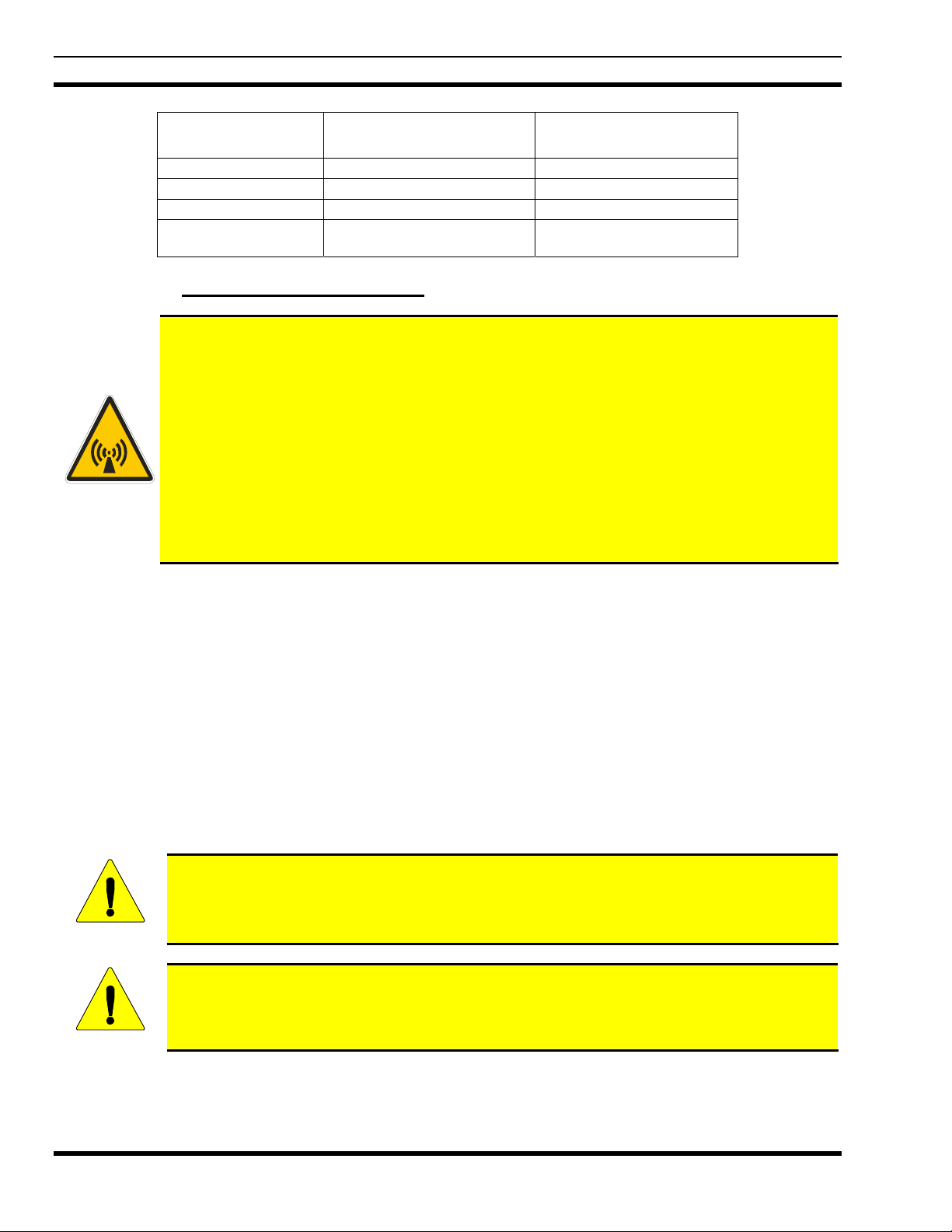

MM-009804-001

Effective Antenna

Gain (dBi)

24 1.00 3.28

25 1.12 3.68

26 1.26 4.13

>26

Minimum Safe Distance

(Meters)

Reduce Transmit Power is

required by FCC

Minimum Safe Distance

(Feet)

1.2.3 Safety Training Information

YOUR M/A-COM VIDA

MAGNETIC ENERGY DURING TRANSMIT MODE. THIS BASE STATION IS

DESIGNED FOR AND CLASSIFIED AS “OCCUPATIONAL USE ONLY” MEANING

IT MUST BE USED ONLY IN THE COURSE OF EMPLOYMENT BY INDIVIDUALS

AWARE OF THE HAZARDOUS RF ENERGY AND THE WAYS TO MINIMIZE

EXPOSURE. THIS BASE STATION IS NOT INTENDED FOR USE BY THE

“GENERAL POPULATION” IN AN UNCONTROLLED ENVIRONMENT. IT IS THE

RESPONSIBILITY OF THE LICENSEE TO ENSURE THAT THE MAXIMUM

PERMISSIBLE EXPOSURE LIMITS ARE OBSERVED AT ALL TIMES DURING

TRANSMISSION. THE BASE STATION LICENSEE IS TO ENSURE THAT NO

BYSTANDERS COME WITHIN THE RADIUS OF THE LIMITS

MAX

BASE STATION GENERATES RF ELECTRO-

When licensed by the FCC, this base station complies with the FCC RF exposure limits when persons are

beyond the MPE radius of the antenna. In addition, your M/A-COM base stations installation complies

with the following Standards and Guidelines with regard to RF energy and electromagnetic energy levels

and evaluation of such levels for exposure to humans:

FCC OET Bulletin 65 Edition 97-01 Supplement C, Evaluating Compliance with FCC Guidelines

for Human Exposure to Radio Frequency Electromagnetic Fields.

American National Standards Institute (C95.1 – 1992), IEEE Standard for Safety Levels with

Respect to Human Exposure to Radio Frequency Electromagnetic Fields, 3 kHz to 300 GHz.

American National Standards Institute (C95.3 – 1992), IEEE Recommended Practice for the

Measurement of Potentially Hazardous Electromagnetic Fields – RF and Microwave.

To ensure that your exposure to RF electromagnetic energy is within the FCC allowable

limits for occupational use, do not operate the base station in a manner that would create

CAUTION

an MPE distance in excess of that allowable by the FCC.

Changes or modifications not expressly approved by M/A-COM Inc. could void the

user’s authority to operate the equipment.

CAUTION

10

Page 12

2 SPECIFICATIONS

2.1 GENERAL SPECIFICATIONS

Physical Characteristics:

Electrical Power: +24 ±3 VDC or

Power Consumption: 60 Watts nominal

Size (H x W x D): 14.5 in. x 8.0 in. x 4.25 in.

Weight: 13.5 lbs (6.12 kg)

Environmental Specifications

Operating Temperature: -22 - +140 F (-30 to +60 C)

Storage Temperature: -40 - +185 F (-40 to +85 C)

MM-009804-001

110 VAC +/- 15%, 50-60 Hz

(36.8 cm x 20.3 cm x 10.8 cm)

Environmental: NEMA4

Altitude: 15000 ft

System Interfaces

Data Plane: 100Base-FX (RJ-45)

Management: 100Base-FX (RJ-45)

4.9 GHz RF Connector: Type N (F) into 50 ohms

GPS RF Connector: SMA (F) into 50 ohms

Power: 110V VAC

Security Features

Authentication: X.509 Digital Certificate

Authorization: RSA Public Key Encryption

Encryption: DES, 3-DES, AES 128 bit

Network Features

Management: SNMP

Convergence: IPv4 over IEEE 802.3/Ethernet

IEEE 802.3/Ethernet

Configuration: DHCP, TFTP

11

Page 13

MM-009804-001

PHY Characteristics

PHY: OFDM 256 FFT

Channel Bandwidth: 5 MHz

Modulation Rates: BPSK, QPSK (1/2, 3/4),

Duplexing: Time Division Duplexing (TDD)

Frame Durations: 2.5 msec, 5 msec, 10 msec, 20 msec

CP: 1/32, 1/16, 1/8, 1/4

Throughput: 4-19 Mbps

MAC Characteristics

Duplexing: Time Division Duplexing (TDD)

Service Classes Supported: Real-Time Polling Service (rtPS)

16QAM (1/2, 3/4), 64QAM (1/2, 3/4)

Non-Real-Time Polling Service (nrtPS)

Unsolicited Grant Service (UGS)

Best Efforts (BE)

Payload Header Suppression: Supported

Automatic Repeat Request (ARQ): Supported

Connections/Client: Up to 16

12

Page 14

2.2 TRANSMITTER

Frequency Band: 4940 - 4990 MHz

Channel Step Size: 1 MHz

Channel Bandwidth: 5 MHz

Frequency Stability (-30 to 60 C): 1.5 PPM over temperature range

MM-009804-001

Output Power into a 50 Ω Load:

Power Adjustment: 0.5 – 0.005 W (27 to 7 dBm adjustable with 1 dB

Duty Cycle: 50% Maximum

Emission Designator:

Spurious and Harmonic Emissions: FCC Part 90

PHY: OFDM 256 FFT

Available Modulation Mode: BPSK, QPSK (1/2, ¾), 16QAM (1/2, ¾), 64QAM

Duplexing: Time Division Duplexing (TDD)

Spectrum Mask: FCC Mask M (90.210)

2.3 RECEIVER

Frequency Band: 4940 - 4990 MHz

Channel Step Size: 1 MHz

0.5 Watts (27 dBm ) Maximum

step)

5M00X7D

(1/2, ¾)

Channel Bandwidth: 5 MHz

Frequency Stability: 1.5 PPM

Sensitivity at BER 10

E-6

:

BPSK -1/2 -96 dBm

QPSK -3/4 -91 dBm

16QAM – 3/4 -85 dBm

Max RX Input Power: -30 dBm

ST

Adjacent Channel Selectivity: 20 dBc Minimum

1

nd

Adjacent Channel Selectivity: 50 dBc Minimum

2

13

Page 15

MM-009804-001

3 INTRODUCTION

3.1 ABOUT THIS MANUAL

This manual is written for the communications professional responsible for maintaining the VIDA

Base Station equipment installed as part of a VIDA

This manual provides an overview and description of the VIDA

network, equipment specifications, and instructions for installing VIDA

MAX

4.9 GHz Broadband Network.

MAX

Base Station equipment used in the

MAX

Base Stations and auxiliary

equipment.

MAX

14

Page 16

3.2 CUSTOMER SERVICE

3.2.1 Technical Support

M/A-COM’s Technical Assistance Center (TAC) resources are available to help you with overall system

operation, maintenance, upgrades, and product support. TAC is your point of contact when you need

technical questions answered.

Product specialists, with detailed knowledge of product operation, maintenance, and repair, provide

technical support via a toll-free telephone number (in North America). Support is also available through

mail, fax, and e-mail.

For more information about technical assistance services, contact your sales representative, or call the

Technical Assistance Center directly at:

North America: 800-528-7711

International: 434-385-2400

FAX: 434-455-6712

MM-009804-001

e-mail:

tac@tycoelectronics.com

3.2.2 Customer Resource Center

If any part of the system equipment is damaged on arrival, contact the shipper to conduct an inspection

and prepare a damage report. Save the shipping container and all packing materials until the inspection

and the damage report are completed. In addition, contact the Customer Resource Center to make

arrangements for replacement equipment. Do not return any part of the shipment until you receive

detailed instructions from a M/A-COM representative.

Contact the Customer Resource Center at:

North America:

Phone Number: 800-368-3277 (toll free)

Fax Number: 800-833-7592 (toll free)

E-mail:

International:

Asia Pacific: 434-455-9223

Latin America & Middle-East: 434-455-9229

Europe: 434-455-9219

customerfocus@tycoelectronics.com

Fax Number: 434-455-6685

E-mail:

15

InternationalCustomerFocus@tycoelectronics.com

Page 17

MM-009804-001

4 DESCRIPTION

The VIDA

applications, such as video surveillance, broadband hot spots, remote precinct connectivity, and LMR

backhaul.

M/A-COM’s new VIDA

broadband communications protocol of 802.16 to the 4.9 GHz band, thereby providing true Quality-ofService (QoS) while operating on contention-free licensed frequencies.

The VIDA

COM’s 4.9 GHz VIDA

4.1 VIDA

VIDA

critical applications. VIDA

band with robust 802.16 technology to create a true public safety broadband network. With this state-ofthe-art network, public safety customers can implement applications such as streaming video, web

applications, economical licensed LMR backhaul, and other bandwidth intensive applications. Since the

network provides guaranteed Quality of Service (QOS), it is especially suited for applications such as

video surveillance, perimeter control, and mobile command. VIDA

VIDA network allowing seamless sharing of network management and administration.

MAX

system delivers public safety grade wireless broadband data services for mission critical

MAX

broadband network applies the open standard IEEE-based wireless

MAX

Base Station provides hardened, public safety grade base station infrastructure for M/A-

MAX

SYSTEM OVERVIEW

MAX

provides integrated public safety grade wireless broadband video and data services for mission-

MAX

broadband network.

MAX

combines the security of the licensed 4.9 GHz public safety frequency

MAX

is integrated with M/A-COM’s

Figure 4-1: VIDA

MAX

Wireless Broadband Video and Data Services

4.2 THE VIDA NETWORK SOLUTION

By leveraging advances in standards-based Information Technology, M/A-COM has developed a unique

IP-based network solution to solve the many challenges that critical communications users are confronted

with. These challenges include delivering different types of information reliably, ensuring technology

does not become quickly obsolete, and being able to acquire equipment from multiple vendors.

MAX

VIDA

Interoperability, Data, and Access). VIDA

communications customers to obtain access to information that its users need today and into the future.

16

addresses these challenges and is part of a total network solution called VIDA (Voice,

MAX

is fast, secure and standards based and will allow critical

Page 18

MM-009804-001

Figure 4-2 depicts a picture of the VIDA Network Solution and how many different communications

systems are built on the solid foundation of a wide-area IP network. This provides an open architecture

for the integration of public safety voice and data airlink protocols including OpenSky, EDACS, and

IP

P25

. This open architecture enables mission critical communications customers to have one integrated

solution to meet numerous voice and data needs.

4.3 THE VIDA

MAX

VIDA

serve as the airlink to the user, as well as a wireless extension of the core IP network upon which the

VIDA network is based (

VIDA

(WiMAX) protocol with the licensed protection of the 4.9 GHz public safety band to provide public

safety grade wireless broadband data services for mission critical applications.

is the broadband extension of VIDA and as a complete broadband distribution system, can

MAX

integrates the sophisticated Quality-of-Service (QoS) and solid security of the 802.16-2004

MAX

NETWORK

Figure 4-2).

Figure 4-2: VIDA Network Solution

17

Page 19

MM-009804-001

Figure 4-3 illustrates a typical deployment scenario of the VIDA

provides secure, public safety grade broadband services to both fixed and mobile clients. Conceptually,

the system can be seen as extending the enterprise WAN to remote locations using the licensed 4.9 GHz

public safety band. Some common applications for this system include:

• Remote surveillance video

• Mobile

• Connection of remote precincts to the enterprise and/or VIDA network

• Backhaul of IP based LMR traffic

4.4 VIDA

The basic architecture of the 4.9 GHz VIDA

consists of one or more base station(s) and at least one client (

of client devices; fixed and mobile. Fixed client devices are usually mounted outdoors with directional

antennas and have a range of up to 10 miles. Mobile clients are vehicle mounted and use an omnidirectional antenna. The range of a mobile client to base station is a few hundred meters.

Figure 4-3: VIDAMAX Broadband Network

broadband access to vehicles (“Hot Spots”)

MAX

NETWORK COMPONENTS/FEATURES

MAX

network is a point-to-multipoint network. A system

MAX

4.9 GHz broadband network. It

Figure 4-3). There are two configurations

18

Page 20

MM-009804-001

Figure 4-4: Network diagram of small VIDA

MAX

system

The base station implements the 802.16-2004 protocol in a 5 MHz channel, delivering an over-the-air

throughput from 4 to 19 Mbps. All communication over this channel is scheduled by the base station,

with contention slots provided for subscriber stations to request bandwidth. This coordinated scheduling

feature of the protocol provides significant advantages such as:

• Minimizes contention between clients

• Maximizes channel utilization

• Maximizes ability to coordinate frequency usage among users

• Enables guaranteed bandwidth services for critical multimedia applications.

The use of a scheduling protocol also makes the network more resilient to simple denial of service attacks

that can disable other broadband networks.

To allow for great flexibility when designing a network, up to 16 “connections” can be established

between the base station and each client, with a different QoS for each connection. Low priority

processes (such as email) can be mapped to best effort services while high priority processes (such as

19

Page 21

MM-009804-001

streaming video or LMR backhaul) can be mapped to Unsolicited Grant Services (UGS) to provide

guaranteed throughput.

4.5 4.9 GHz VIDA

The VIDA

COM’s 4.9 GHz VIDA

2004 protocol to deliver an over-the-air throughput from 4 to 19 Mbps. All communication over the

wireless channel is scheduled by the base station, with contention slots provided for subscriber stations to

request bandwidth. Up to 16 “connections” can be established between the base station and each

subscriber in the network, with different QoS for each connection, allowing for great flexibility when

designing a network. Low priority processes (such as email) can be mapped to best effort services while

high priority processes (such as streaming video or LMR backhaul) can be mapped to unsolicited grant

services (UGS) which offer guaranteed throughput. Network convergence is provided in the form of

802.16 classifier rules that ensure network level QoS over the airlink.

Base station configuration and management is provided via a browser interface to M/A-COM’s Unified

Administration System (UAS). The base station additionally supports localized SNMP management for

single/limited site deployments. SNMP attributes are defined in the MIB II, the 802.16 and the M/ACOM using an open MIB. Base stations may optionally be configured as DHCP and/or TFTP servers.

All subscriber station management can be performed over the air. The VIDA

strong protection against unauthorized network access through the use of certificates for subscriber

authentication. Authentication keys are distributed using RSA Public Key encryption. The cryptographic

methods provided by the security sub layer use DES, 3-DES, and AES algorithms.

The VIDA

outdoor deployments. The base station is designed with flexible mounting configuration to allow for both

pole mount and fixed structure mounting. To provide for flexible RF deployment configurations, the base

station provides options for (1) direct mounting of an omni-directional antenna on the base station (2)

direct mounting of a directional antenna on the front face of the base station and (3) remote mounting of

an antenna through the connection of an RF cable to the base station. The base station comes in two

power/network configurations: one with 110 VAC power and RJ-45 Gigabit Ethernet configuration and

one with +24 VDC power and 100-BaseFX fiber configuration.

MAX

Base Station provides hardened, public safety grade base station infrastructure for M/A-

MAX

Base station is housed in a hardened, outdoor enclosure that satisfies IP66 requirements for

MAX

BASE STATION

MAX

broadband network. The VIDA

MAX

base station implements the IEEE 802.16-

MAX

base station provides

20

Figure 4-5: VIDA

MAX

Base Station

Page 22

4.5.1 Summary of Key Features

4.5.1.1 Airlink Features

MM-009804-001

The VIDA

from 4 to 19 Mbps. All communication over the wireless channel is scheduled by the base station, with

contention slots provided for the VIDA

MAX

Base Station implements the 802.16-2004 protocol to deliver an over-the-air throughput

MAX

Client to request bandwidth. A protocol with coordinated

scheduling provides significant advantages such as:

• minimizing contention between clients

• maximizing channel utilization

• enabling guaranteed bandwidth services for critical multimedia applications.

The use of a scheduling protocol also makes the network more resilient to simple denial of service attacks

that can disable other broadband networks.

Up to 16 “connections” can be established between the base station and each client in the network, with

different QoS for each connection, allowing for great flexibility when designing a network. Low priority

processes (such as email) can be mapped to best effort services while high priority processes (such as

streaming video or LMR backhaul) can be mapped to unsolicited grant services (UGS) which offer

guaranteed throughput.

4.5.1.2 Network Features

Network convergence is provided in the form of 802.16 classifier rules that ensure network level QoS

over the airlink.

Network management is provided via a browser interface to M/A-COM’s UAS. The base station

additionally supports localized SNMP management using an open MIB. Base stations may optionally be

configured as DHCP and/or TFTP servers. All VIDA

MAX

Client management can be performed over the

air.

4.5.1.3 Security Features

The VIDA

use of certificates for client authentication. Authentication keys are distributed using RSA Public Key

encryption. The cryptographic methods provided by the security sublayer use DES, 3-DES, and AES

algorithms.

MAX

base station provides strong protection against unauthorized network access through the

21

Page 23

MM-009804-001

4.6 VIDA

MAX

BASE STATION INTERFACES

MAX

Figure 4-6: VIDA

Base Station Interface Diagram

4.6.1 Standard Base Station (AC Powered)

RF Antenna Port:

• Connector: N-type Female

• Impedance: 50 Ohm

110 V AC Power Port:

• Industrialized 3-Pin Connector (Conxall Part No. 4180-3PG-3XX)

DATA Ports:

• Two Industrialized RJ-45 Connectors

• One port for Service only

GPS Antenna Port:

• Connector: SMA Female

• Impedance: 50 Ohm

22

Page 24

4.6.2 Special Hardened Base Station (DC Powered)

RF Antenna Port:

• Connector: N-type Female

• Impedance: 50 Ohm

• Internal Lightning Suppressor

24 V DC Power Port:

• Industrialized 3-Pin Connector (Conxall Part No. 4180-3PG-3XX)

• Internal Lightning Suppressor

DATA Ports:

• LC Industrialized Fiber Optic Connector

• One port for Service only

GPS Antenna Port:

MM-009804-001

• Connector: SMA Female

• Impedance: 50 Ohm

• External Lightning Suppressor (optional)

23

Page 25

MM-009804-001

4.7 VIDA

The VIDA

requirements. Depending on the location and site planning, a directional antenna can significantly extend

the effective coverage area of the base station. For example, one can choose a high gain directional

antenna to effectively cover a long strip of highway, in the meantime avoiding the area further away from

the highway (where coverage is no longer needed) to reduce the total number of base stations. Another

example could be using a 90-degree sectional antenna to effectively cover a town-center area while

avoiding rural regions where no coverage is required. The user can directly mount an omni-directional

antenna to base station RF antenna port. Additionally, four mounting holes are provided on the VIDA

Base Station chassis to allow a directional antenna to be mounted on an optional bracket. Finally, the user

can choose other industry means for mounting a directional or omni-directional antenna separate from

base station. In this case, however, the total length of cable should not exceed 5 feet. Choose high

quality 50-Ohm cable with the lowest loss at 5 GHz.

CAUTION

Basic Antenna Requirements:

MAX

Base Station Antenna Options

MAX

Base Station allows users to choose many different antenna types to meet their application

The four antenna mounting holes on VIDA

force of 100 mph (160 km/h) sustained wind and survive wind gusts to 136 mph

(220 km/h). It is the user’s responsibility to estimate the force induced by antenna

to ensure the integrity of the product.

MAX

base station can sustain a pulling

MAX

Omni Antenna: Vertical Polarization

9 dBi Maximum Gain

Directional Antenna: Linear Vertical

26 dBi Maximum Gain

(Reduction of Transmitter Power is required if the Effective Maximum Antenna

Gain is greater than 26 dBi.)

The following antennas have been tested and approved for use with the VIDA

Table 4-1: Recommended Antenna

Part Number Manufactur

er

MT-444003 MTI 15 Vertical

MT-466003

(Note 1)

MTI 27 Vertical or

Gain

(dBi)

Polarization Azimuth

Beamwidth

Horizontal

MAX

Base Station:

Size Weight

(Degree)

120

3 600x600x51 (mm^3) 11 lbs

550 x250x17 (mm^3) 3.3 lbs

(1.5 kg)

(5 kg)

MT-465005

24

MTI 21 Vertical or

Horizontal

9 305x305x14 (mm^3) 3.3 lbs

(1.5 kg)

Page 26

MM-009804-001

Part Number Manufactur Gain Polarization Azimuth Size Weight

er (dBi) Beamwidth

(Degree)

MT-464003

MT-464002

MT-462002

MFB49009

MP24581820PT

MA-WA49-1X

Note 1: Based on guidelines from FCC Regulations, the MT-466003 27 dBi Directional Antenna can only be used with a

cable that provides at least 1 dB of insertion loss. It is recommended that this antenna be installed with a minimum of 10

feet of LMR-400-UF antenna feeder cable (Cable Loss = 1.1 dB at 5 GHz). The effective Antenna Gain in this case will

thereby be less than 26 dBi. Also, due to its size, the MT-466003 needs to be individually mounted on the pole.

MTI 15.5 Vertical 90 530x260x11 (mm^3) 5.5 lbs

(2.5 kg)

MTI 16 Vertical 60 350x150x30 3.3 lbs

(1.5 kg)

MTI 9 Vertical Omni 18 in.

(460 mm)

MAXRAD 9 Vertical Omni 20.2 in 0.5 lbs

MAXRAD 20 Vertical 60 384x353x48 (mm^3) 3.9 lbs

Mars 21 Vertical 10.5 305x305x15 (mm^3) 3.3 lbs

1.3 lbs

(0.6 kg)

(0.23 kg)

(1.8 kg)

(1.5 kg)

25

Page 27

MM-009804-001

5 UNPACKING AND CHECKING EQUIPMENT

Before unpacking, installing or operating the VIDA

thoroughly. It contains detailed unpacking and handling instructions, and safety precautions to protect

users and equipment.

5.1 UNPACKING EQUIPMENT

The VIDA

accessories for each unit, if any, may also be shipped in separate containers.

When unpacking the equipment, check the contents against the packing list. Contact your M/A-COM

VIDA

MAX

equipment may be shipped in separate transit packages. The associated cabling and

MAX

equipment representative and the carrier if any discrepancies are noted.

Save the shipping cartons and packing materials in case the equipment needs to be shipped

back to the M/A-COM for service.

There are no user serviceable components within the VIDA

assemblies. These assemblies contain ESD sensitive components and should only be

serviced by M/A-COM qualified personnel.

MAX

equipment, read this section of the manual

MAX

radio equipment

5.2 INSPECTING AND INVENTORYING EQUIPMENT

Carefully unpack the equipment and examine each item. If there is any damage to the equipment, contact

the carrier immediately and have their representative verify the damage. If you fail to report the shipping

damages immediately, you may forfeit any claim against the carrier.

After removal from the carton, examine the VIDA

damaged, loose, or missing parts. Examine the RF connector(s), circular power

connector and ground lug for cracks, bent or damaged threads, or damage to any

paint or seals. If any are noted, contact the M/A-COM Customer Resource Center

CAUTION

immediately. Any unauthorized attempts to repair or modify this equipment will

void the warranty and could create a safety hazard.

MAX

equipment for broken,

26

Page 28

6 PLANNING THE INSTALLATION

6.1 ENVIRONMENTAL EVALUATION

MM-009804-001

Before installing the VIDA

selection before attempting to install the base station. Since high frequencies do not readily pass through

trees or buildings, consideration should be given to the following:

• Ensure there are no obstructions (such as buildings or trees) in the radio path between base station

and fixed client units

• Ensure the any future building construction or tree growth will not obstruct the radio path

• Ensure there is sufficient clearance around the Fresnel Zone so there is minimal interference from

obstacles along the radio propagation path

• Ensure the installation adheres to any local building codes and permits

• Ensure sufficient electrical power is available at the installation site

• When using directional antennas, align the base station antenna to maximize the received signal

strength indication (RSSI)

• Ensure area around an omni-directional antenna is clear (at least 30 inches) so as not to distort the

RF pattern

• Locate the base station away from any sources of interference that could degrade the performance

of the base station

MAX

Base Station, the System Engineer and installer should plan the site

• Ensure the base station and fixed clients are within maximum coverage range of reception

• Maximum standard CAT-5 cable length connecting the base station to the Ethernet LAN is 100

meters and maximum antenna cable length is 5-feet

6.2 POLE-MOUNT INSTALLATIONS

The VIDA

mounting the base station on a light post (horizontally) or telephone pole (vertically) as shown in

6-1

. A kit containing two mounting brackets and hardware for attaching the base station to a pole can be

optionally purchased. The bracket accommodates mounting on a pole with a diameter in the range of one

(1) to six (6) inches. The installer must provide straps necessary to secure the base station brackets to the

pole.

CAUTION

MAX

Base Station is designed to accommodate pole mounting. Typically, pole mounting means

When mounting the base station on a pole, the installer must ensure the mounting

bands are strong enough (resistance to rotation) so the base station can withstand 100

mph (160 km/h) sustained wind and survive 136 mph (220 km/h) wind gusts.

Figure

27

Page 29

MM-009804-001

Figure 6-1: Pole Mounting the VIDA

MAX

Base Station

6.3 ELECTRICAL POWER

There are two configurations of the base station. The AC version is configured to accept 110 VAC power

from standard U.S. utility power distribution. The DC Hardened version of the base station accepts

+24 VDC (negative ground) power from a power supply or battery.

6.3.1 AC Power

An AC powered VIDA

MAX

base station requires at least 2 amperes of electrical service:

6.3.2 DC Power

A DC powered base station requires a +24-volt (nominal) DC power source. This source must have a

continuous-duty current rating of at least 3 amperes. Refer to Section

information.

6.4 SITE GROUNDING

Installers should review the recommended grounding procedures in the Site Grounding and Lightning

Protection Guidelines manual, AE/LZT 123 4618/1 and ensure a suitable ground is installed between the

base station ground lug and earth ground. Grounding must also be in compliance with any local and

national electrical codes.

2, Specifications for additional

28

Page 30

7 INSTALLATION

MM-009804-001

The VIDA

conditions. The user can choose different antenna types (omni-directional or directional) depending on

the application. It is preferred that the user specifies 50-Ohm low loss (@5GHz) cable with minimum

length (5-feet maximum) between the antenna connector and antenna port on the base station to avoid

further loss of RF power.

The base station is available as either as +24 VDC (hardened) or 110 VAC version. The total power

consumption is less than 60 Watts.

For the AC version, the radio uses weatherproof RJ-45 for connector as data and network connections.

M/A-COM recommends using the DC hardened version of the VIDA

experience frequent thunderstorms. In this version, weatherproof LC fiber-optic connections are

employed, and lightning protection is internally provided within the base station for the RF antenna and

DC power ports. Additional external lightning protection for the GPS antenna port may optionally be

installed.

MAX

Base Station resides in a Die Casting Metal Chassis to meet tough environmental

MAX

base station in the areas that

Both the RJ-45 and LC fiber-optic connectors achieve weatherproof properties only when

properly mated with M/A-COM approved cabling. For the Service port, the dust cap is to

be installed in normal operation.

7.1 TOOLS AND TEST EQUIPMENT REQUIRED

The following tools and test equipment are recommended for installing and testing the VIDA

Station:

• Common hand tools, including screwdrivers, wire cutters, pliers, etc.

• Modular Plug Tool, 3-231652-0 (Tyco/Electronics-AMP)

Includes; Hand Tool, 2-231652-0 and Die Set, 1-853400-0

• Digital Voltmeter (DVM), capable of measuring AC and DC voltage

• Agilent E4440A, PSA series high-performance spectrum analyzer

• Laptop Computer

• Linux operating system

7.2 CUSTOMER SUPPLIED MATERIALS

The customer or designated installer must provide the following:

• Ethernet Cable, length as required, not to exceed 100 ft. (refer to Section

specifications)

11.1.1 for cable

MAX

Base

• RF coaxial cable (directional or remotely mounted antenna), i.e. LMR-400 Low loss coaxial cable

29

Page 31

MM-009804-001

• Pole mounting straps, i.e. Band-It® bands and buckles

• Power source (110 VAC 50/60 Hz or 24 VDC)

• Ethernet connection to network

7.3 BEFORE BEGINNING THE INSTALLATION

Before beginning the installation, collect information from the Site Deployment Order (SDO)

specific to the site access such as:

• Permission to access the site

• Important contact names and telephone numbers

• Location of and directions to the site

• Keys and/or lock combinations to access the site and equipment shelter (if any), or points of

contact to obtain them

• Site entry alarm system pass-codes and/or disable keys

• Information about work practices needed to work safely at the site

Other important information that may or may not be included on the SDO includes:

• Type of mounting—metal pole, wooden pole, tower base, exterior wall, etc.

• Drawing or description of each site showing how the equipment is to be installed

• Applicable inspections completed (pole installation, electrical, local build code, etc.)

7.4 MOUNTING THE BASE STATION

As shown in Figure 7-1, pole-mounting brackets can be installed onto the mounting surface of the base

station so it to be mounted (a) horizontally, for instance, on the arm of a light post, or on a vertical (b)

post. In both cases, two metal straps (not included) are inserted into slots on the brackets and tightened to

the pole using industry strapping equipment.

It is important to mount the base station so that its fins are positioned vertically, as

shown in Figure 7-1 (a) and (b). This gives the base station the best thermal

performance, allowing air to move naturally through the fins

Mounting the base station with the fins vertically also allows the RF antenna port to be in the best

position for mounting the omni-directional antenna, as shown in

Figure 7-1.

30

Page 32

MM-009804-001

a. Horizontal Mounting b. Vertical Mounting

Figure 7-1: Mounting the VIDA

MAX

Base Station on Horizontal or Vertical Poles

7.4.1 Attaching the Mounting Bracket

1. Orient the brackets so when the base station is mounted on a pole, the fins are vertical. This position

provides the best thermal convection (vertical fins) and shields the multiple connectors from rain.

2. Attach mounting brackets to base station using the flat washer, lock washer, and hex head bolt

included with the brackets. (Ensure lock washer is closest to the bolt’s head.)

Figure 7-2: Brackets attached to the VIDA

31

MAX

Base Station (vertical pole mounting)

Page 33

MM-009804-001

3. The preferable mounting scheme is to have omni-directional antenna pointing straight up.

7.4.2 Attaching the Base Station to a Pole

Strap the base station to pole using Band-It bands and buckles (not supplied). Follow the manufacturer’s

guidelines for proper equipment and techniques.

7.5 POWER CABLES

Power is supplied to the base station through a 3-pin connector. Both AC and DC base stations use the

same power connector, although they require different cables, available for purchase through M/A-COM.

The mating connector is Conxall Multi-Con-X

7.5.1 AC Power

®

3-pin connector #4180-3SG-3xx).

The AC powered VIDA

MAX

Base Station requires 110 VAC, 50-60 Hz power applied to the following

contacts.

Connection Pin Wire Color VIDA

MAX

Base

Station

Connector

Ground 3 Green

Neutral 2 White/Grey

Hot 1 Black

7.5.2 DC Power

A DC powered VIDA

Connection Pin Wire Color VIDA

+24 VDC (PWR+) 1 Red

MAX

requires 24 ±3 VDC applied to the following contacts:

Station

Connector

MAX

Base

Return (PWR-) 2 Black

7.6 GROUNDING STUDS

Mounting studs for grounding the base station are located on two sides of the base station. For safety

purposes, earth ground and lightning protection electrical connections should be made at either location.

32

Page 34

7.7 NETWORK/DATA CONNECTION

The AC version of the base station connects to the network using standard Ethernet RJ-45 protocol. The

DC hardened version connects to the network through a standard LC multimode fiber optic connector.

The proper connection in both cases is on the port that does not have the dust cap installed.

Recommended Ethernet mating connectors:

MM-009804-001

For AC powered VIDA

• Tyco/Electronics, Industrial Circular Ethernet Connector

Part number: 1738607-2

For DC powered VIDA

• Tyco/Electronics, LC multimode fiber optic connector

Part number: 1828618-1

All connections are weatherproof, and the service port has a dust cap which is normally installed to

provide the sealing. Sealing of all other ports on the base station is provided through mandatory usage

connections.

MAX

base station:

MAX

base station:

7.8 ANTENNA CONNECTIONS

The omni-directional antenna should be mounted vertically directly onto the antenna port. There is also a

mounting feature on the base station to support the mounting a directional antenna.

7.8.1 Installing an omni-directional antenna

The omni-directional antenna can be mounted directly to the base station using the following procedure:

1. Connect an N-type male to male RF adapter (not included) to the omni-directional antenna. Hand

tighten the connector.

Recommend using Amphenol 82-100 or RF Industries RFN-1014-1.

2. For the AC version of the base station, if external lightning protection is required, connect the

optional lightning suppressor to the antenna assembly as shown in

Recommend using M/A-COM # PT-009560.

3. Connect the completed antenna assembly to the base station antenna connector.

33

Figure 7-3.

Page 35

MM-009804-001

Figure 7-3: VIDA

MAX

Base Station Antenna with External Lightning Protection

7.8.2 Installing a Directional Antenna

The directional antenna (weight less than 5 lb and size less than 350x350 mm^2) can be mounted on the

base station using the universal mounting bracket. This mounting bracket is located on the antenna

mounting face (cover) of the base station. The universal mounting bracket can then be adjusted to point

the beam of the antenna in the direction needed for network connectivity. An antenna weighing more than

5 lb cannot be mounted directly on the base station. A separated mounting bracket is required to mount

the antenna directly on the pole while an antenna feeder cable connects the base station to the antenna.

A low loss RF cable (not included) is needed to connect between the base station antenna connector and

the Directional Antenna.

To mount the directional antenna to the base station:

1. Using the four bolts, lock washers and flat washers included in the optional antenna mounting kit,

attach the universal antenna mounting bracket to the base station as shown in

2. Attach the antenna panel bracket assembly to the antenna panel.

3. Attach the two bracket assemblies together with the universal knuckle.

Figure 7-4.

34

Page 36

MM-009804-001

4. Attach the short RF cable between the antenna and the base station antenna port.

Recommend using < 5 ft. long LMR-400 Low loss coaxial cable with field installable N Type Male

connectors, M/A-COM # MAMROS0095.

Figure 7-4: Mounting a Directional Antenna to the VIDA

7.9 GPS Antenna

The Base Station performs time synchronization through GPS. An external GPS antenna connection is

required. Various antennas are available in the marketplace. One offered by M/A-COM can be mounted

directly onto the base station, or alternatively attached to the pole.

7.9.1 Installing Optional GPS Antenna

To connect GPS cable to base station:

Connect the SMA-type plug of the GPS antenna cable to the SMA receptacle on the base station. Route

the cable to the GPS antenna location. This will be a temporary connection until the installation is

complete.

To install the GPS Antenna:

The GPS antenna kit (M/A-COM # MAMROS0023) includes the GPS antenna (part number ANPC185B-Y-180-SM) and various mounts.

MAX

Base Station

Based on how the base station is physically positioned, the mounting location that is uppermost is where

the antenna can be mounted in order to have best access to the satellites in the sky. Connection to the

antenna port is made through the SMA female connector on the base station. Optionally, for lightning

protection, a protection device can be externally installed.

After installing the antenna, dress and secure the cable.

35

Page 37

MM-009804-001

7.10 RADIO CHASSIS AND CABLING

7.10.1 Attaching Base Station Cables

To connect power to Base Station

1. Connect the M/A-COM power cable to the proper power source.

2. Mate the other end of the power cable’s connector to the 3-pin power connector on the base station by

visually aligning the key and firmly push and turn the outer locking ring clockwise until it stops. A

click will be sensed to confirm proper mating.

3. For added protection against long-term exposure to weather, industry techniques for sealing the data

connection may optionally be performed.

To connect data cable to Base Station

1. Fabricate the Ethernet (AC base station) or Fiber Optic cable (DC base station) as described in

Section

2. Connect one end of the cable to the LAN connection.

11 or the manufacturer’s instructions.

3. Mate the other end of the power cable’s connector to the 3-pin power connector on the base station by

visually aligning the key and firmly push and turn the outer locking ring clockwise until it stops. A

click will be sensed to confirm proper mating.

4. Ensure the dust cap is fully seated on the service port.

5. For added protection against long-term exposure to weather, industry techniques for sealing the data

connection may optionally be performed.

Upon connection, verify that all cabling is not under any stress, a service loop is

maintained, and the cabling is restrained according industry techniques.

CAUTION

36

Page 38

8 OPERATION

MM-009804-001

To operate the VIDA

required and described in the following sections.

MAX

Base Station, a Linux-based computer using Category 5 Ethernet cable is

8.1 LOGGING INTO THE VIDA

To login to the VIDA

1. Connect the base station to a Linux-based computer using a Category 5 cable.

2. Power up the base station. Once powered up, the base station takes about 2-3 minutes to boot.

3. After 2-3 minutes, begin a Telnet session to communicate with the base station by entering the

following command at the prompt:

pico@pico:~$ telnet IP address of base station

4. This will make the following prompt appear:

login@IP address of base station:

5. At the above prompt, enter the command shown below:

login@IP address of base station: root

MAX

Base Station:

MAX

BASE STATION

Enter

Enter

6. With the above command, the user is logged into the base station as the root, which is seen by the

prompt shown below:

root@IP address of base station:

7. Enter the next step to load the necessary drivers into the digital board and run Picotools:

root@IP address of base station: cd /ixa

ixa@IP address of base station: ./pc102start

8.2 TESTING THE VIDA

To run the Test Program

1. Open a new terminal window and change the director to the working directory:

pico@pico:~$ cd TXRX_Test

2. Once in the working directory, start the test program named TXRX_Test:

FCC_Test@pico:~$ ./TXRX_Test

MAX

BASE STATION

Enter

Enter

Enter

Enter

37

Page 39

MM-009804-001

3. The program causes a menu-driven screen to appear as illustrated below:

0 : Exit

1 : Change Channel :

2 : Transmit ON / OFF :

Enter Your Choice :

4. To change the channel, type “1” and at the succeeding prompt enter the desired channel number:

0 : Exit

1 : Change Channel :

2 : Transmit ON / OFF :

Enter Your Choice : 1 Enter

Enter Channel Number : 10

5. To make the radio transmit, type “2” and at the succeeding prompt enter “1”:

0 : Exit

1 : Change Channel :

2 : Transmit ON / OFF :

Enter Your Choice : 2

Turn Transmit ON/OFF : 1

6. When transmit is turned on, an OFDM signal is transmitted continuously.

Enter

Enter

Enter

To run the “TXRX_Test” program on a different base station

1. Power up the new base station and login as root using the new base station’s IP address.

2. Modify the “Setup.txt” file with the IP address of the new base station.

38

Page 40

9 TROUBLESHOOTING AND SERVICING

9.1 TUNING AND CALIBRATION PROCEDURE

MM-009804-001

Every VIDA

compliance with FCC requirements. No further tuning is required by the customer or installer during the

installation process.

MAX

Base Station is fully calibrated for frequency and power before shipment to ensure

9.1.1 Transmit Frequency Accuracy Calibration

The accurate frequency setting is a key parameter for VIDA

accuracy is guaranteed by a Voltage Controlled Temperature Compensated Crystal Oscillator (VCTCXO)

with 1.5 ppm frequency drift over full temperature range. The factory calibration procedures calibrate the

default VCTCXO setting to minimize the frequency error. This minimizes the frequency variation from

base station to base station. The base station will automatically use default value after each reboot.

MAX

Base Station. Base station frequency

9.1.2 Transmit Power Level Calibration

The power level calibration is performed at CH1, CH5, CH10 (lowest, middle, and highest) to ensure the

over-band performance. An Agilent PSA E4440A under spectrum emission mask mode is used to

perform the calibration. A standard baseband OFDM QPSK 3/4 Signal (Downlink Burst, 50% duty, 10

msec. frame) is used for the calibration. The on board 30 dB/ 1 dB step attenuator is used to adjust power

level. The cable loss (radio antenna port to PSA input) is calibrated out so the PSA can measure channel

power at the antenna port. After the TX power level calibration step, the FCC emission mask is used to

check TX spectrum at CH1, CH5 and CH10 to ensure the compliance. After calibration, the base station

uses the calibrated TX power as a default value to initialize the radio.

39

Page 41

MM-009804-001

10 RADIO CHASSIS

40

Page 42

11 CABLE FABRICATION

11.1 ETHERNET CABLE PLUG KIT

For the AC version of the base station, the Ethernet cable connected to the base station uses a RJ-45

connector protected by an Industrial Circular Ethernet plug assembly that protects the RJ-45 connector

from the elements.

MM-009804-001

The Stranded Wire Plug Kit (Tyco Electronics # 1738607-2), shown in

8-position Category 5e RJ-45 plug, load bar, and plug assembly. The load bar is used to hold the cable

wires for insertion into the RJ-45 plug. The RJ-45 plug must be terminated and then installed into the

plug assembly. The RJ-45 plug is held in the plug assembly by the locking tab. The cable fitting holds

the RJ-45 plug in the plug assembly and seals the plug at the cable end. When engaged, the connectors

are held together by a locking mechanism (coupling ring and bayonet lock), which prevents accidental

disconnection. The engaged connectors are sealed by the interfacial seal.

Figure 11-1, consists of an

Figure 11-1: Tyco/Electronics Industrial Circular Ethernet Connector Plug Kit (1738607-2)

11.1.1 Tools Required

• Modular Plug Hand Tool, 3-231652-0 (Tyco/Electronics-AMP)

Includes; Hand Tool, 2-231652-0 and Die Set, 1-853400-0

41

Page 43

MM-009804-001

11.1.2

Cable Selection

The RJ-45 plug will accept Category 5e, 100–ohm unshielded round cable with the following

specifications:

• Cable type: 8–conductor

• Conductor size: 24 AWG

• Conductor type: 7–strand copper

• Conductor insulation diameter: 0.039 in. (0.99 cm) maximum

• Cable jacket diameter range:

RJ-45 plug accepts: 0.190 through 0.220 in. (4.83 through 5.59 cm) OD (single jacket)

Cable fitting accepts: 0.18 through 0.31 in. (4.6 through 7.9 cm) OD (double jacket)

11.1.3 Cable Preparation

Prepare the cable using the following procedure:

42

Reasonable care must be taken not to scrape or nick any part of the cable during

the stripping operation.

CAUTION

1. Slide the plug assembly (cable fitting end first) onto the cable. See Figure 11-2, Detail A.

2. Proper strip length is necessary to insert the conductors into the contact slots. The recommended strip

length is given in

Figure 11-2, Detail B.

Page 44

MM-009804-001

Insulation of individual conductors must not be cut or removed. This could result in

shorted or open connections.

Figure 11-2: Cable Preparation

3. Conductor pairs must be oriented side–by–side in the order shown in

Figure 11-3, Detail A. The end

of the cable jacket must be flattened so that the conductor pairs lay side–by–side.

4. Properly sequenced conductor pairs should extend into the cable jacket to the dimension given in

Figure 11-3, Detail B, creating an oblong shape.

5. The conductor tips must be trimmed evenly to the dimension shown in Figure 11-3, Detail C. Proper

orientation of conductors must be maintained.

6. The conductor pairs must be untwisted and arranged according to EIA/TIA T568A or T568B (defined

in

Figure 11-3, Detail D). IT IS CRITICAL that the pairs are NOT untwisted inside the cable jacket.

When arranging conductor pairs, IT IS IMPORTANT that Conductor 6 be crossed over Conductors 4

and 5 as shown in

Figure 11-3, Detail C.

43

Page 45

MM-009804-001

44

Figure 11-3: Cable Preparation Continued

Page 46

MM-009804-001

11.1.4 Termination

Terminate the RJ-45 plug to the cable end using the following procedure:

1. The conductors (maintaining arrangement) must be inserted into the load bar (oriented so that the

cable notch will align with the contacts) until the cable jacket rests against the cable notch. The

conductor twist must not enter the front of the load bar. The conductors must be trimmed evenly and

square with the front edge of the load bar to the dimension given in

Figure 11-4, Detail A.

Figure 11-4: Termination Requirements

45

Page 47

MM-009804-001

2. The conductors must be retracted from the load bar so that the conductors protrude from the end of

the load bar to the dimension given in

deformed.

3. The load bar (oriented so that the cable notch is aligned with the contacts) must be inserted into the

RJ-45 plug until it butts against the mating feature of the RJ-45 plug, and the conductors are bottomed

on the wire circuits. The cable jacket must be against the cable notch after the load bar is fully seated.

The conductors must not be exposed between the cable jacket and cable notch. The ends of the

conductors must be clearly visible through the front of the RJ-45 plug. See

4. The RJ-45 plug must be terminated to the cable according to the instructions included with the

tooling.

Figure 11-4, Detail B. The top of the load bar must not be

If the load bar is deformed, the conductor twist entered the front of the load bar

Figure 11-4, Detail C.

If the conductors do not bottom on the wire circuits, they must be re-trimmed (after

removing the load bar/cable assembly from the RJ-45 plug), and re-inserted into the

RJ-45 plug. If the conductors are too short, the cable must be re-stripped.

11.1.5 Assembly

Assemble the RJ-45 connector into the plug assembly using the following procedures:

1. Align the locking tab of the RJ-45 plug with the wide slot at the front (end opposite the cable fitting)

of the plug assembly. See

2. Depress the locking tab, and insert the RJ-45 plug into the plug assembly. Gently pull the cable until

the RJ-45 plug is fully seated. There should be approximately 12.7 mm [.50 in.] of the RJ-45 plug

protruding from the front of the plug assembly. See

To avoid damage to the connection, the cable must be pulled GENTLY when

seating the RJ-45 plug.

CAUTION

3. While holding the RJ-45 plug in position, rotate the cable fitting as shown in Figure 11-5, Detail B

until tightened to a torque of 1.13 N–m [10 lbf–in.].

The given torque must be met in order for the cable fitting to seal the plug at the cable

end.

Figure 11-5, Detail A.

Figure 11-5, Detail B.

46

Page 48

MM-009804-001

Figure 11-5: Assembly Detail

47

Page 49

M/A-COM Wireless Systems

221 Jefferson Ridge Parkway

Lynchburg, Virginia 24501

(Outside USA, 434-385-2400) Toll Free 800-528-7711

www.macom-wireless.com Printed in U.S.A.

Loading...

Loading...