Page 1

Rhein Tech Laboratories Client: M/A COM, Inc.

360 Herndon Parkway Model: MastrIII w/Sitepro Base Station

Suite 1400 Standards: FCC Part 90/IC RSS-119

Herndon, VA 20170 Report Number: 2003083

http://www.rheintech.com

Date: June 6, 2003

APPENDIX G: MANUAL

Please refer to the following pages.

48 of 52

Page 2

Installation Manual

Preliminary

LBI-38636S

MASTR

Conventional Base Station

III

Page 3

LBI-38636S

NOTE

Repairs to this equipment should be made only by an authorized service technician or facility designated by the supplier.

Any repairs, alterations or substitution of recommended parts made by the user to this equipment not approved by the

manufacturer could void the user’s authority to operate the equipment in addition to the manufacturer’s warranty.

NOTICE!

The software contained in this device is copyrighted by M/A-COM Private Radio Systems, Inc. Unpublished rights are

reserved under the copyright laws of the United States.

This manual is published by

typographical errors, inaccuracies of current information, or improvements to programs and/or equipment, may be made by

Systems, Inc.,

reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, for any purpose, without the

express written permission of

Copyright 1992-2002 M/A-COM Private Radio Systems, Inc. All rights reserved.

at any time and without notice. Such changes will be incorporated into new editions of this manual. No part of this manual may be

2

M/A-COM Private Radio Systems, Inc.,

M/A-COM Private Radio Systems, Inc.

without any warranty. Improvements and changes to this manual necessitated by

M/A-COM Private Radio

Page 4

LBI-38636S

TABLE OF CONTENTS

Page

PRODUCT SPECIFICATION FOR CE MARKED EQUIPMENT ..................................................................................4

MAXIMUM PERMISSIBLE EXPOSURE (MPE) LIMITS.............................................................................................. 5

DETERMINING MPE RADIUS.................................................................................................................................... 5

SAFETY TRAINING INFORMATION ............................................................................................................................ 5

STATION SPECIFICATIONS (GENERAL) .................................................................................................................... 7

PUBLICATIONS INDEX.................................................................................................................................................. 8

SAFETY SUMMARY........................................................................................................................................................ 9

GROUND THE EQUIPMENT ...................................................................................................................................... 9

REPLACEMENT OF PLUG-IN CIRCUIT MODULES ............................................................................................... 9

CAUTION .......................................................................................................................................................................... 9

ELECTROSTATIC DISCHARGE - SENSITIVE COMPONENTS ............................................................................. 9

DO NOT SUBSTITUTE PARTS OR MODIFY PRODUCT ...................................................................................... 10

INTRODUCTION ............................................................................................................................................................ 10

CABINET..................................................................................................................................................................... 10

STATION POWER SUPPLY ...................................................................................................................................... 10

TRANSMITTER/RECEIVER SHELF......................................................................................................................... 10

TRANSMITTER POWER AMPLIFIER ..................................................................................................................... 10

UNPACKING EQUIPMENT........................................................................................................................................... 10

SITE PREPARATION AND INSTALLATION.............................................................................................................. 10

CABINET INSTALLATION....................................................................................................................................... 10

Single 37-inch Cabinet Installation........................................................................................................................... 10

Double Stacked 37-inch Cabinet installation............................................................................................................ 11

ELECTRICAL CONNECTIONS................................................................................................................................. 12

AC Power ................................................................................................................................................................. 12

Microphone............................................................................................................................................................... 12

Antenna..................................................................................................................................................................... 12

TELEPHONE LINE CHARACTERISTICS................................................................................................................ 12

Telephone Lines ....................................................................................................................................................... 12

Types Of Voice Grade Lines .................................................................................................................................... 12

Tone Remote Control Systems ................................................................................................................................. 14

Voting System Considerations.................................................................................................................................. 15

Ordering Voice Grade Telephone Lines................................................................................................................... 15

Telephone Company Ordering Information.............................................................................................................. 16

TELEPHONE LINE INSTALLATION ....................................................................................................................... 16

DC Remote Installation ............................................................................................................................................16

E & M Signaling....................................................................................................................................................... 16

Tone Remote Installation.......................................................................................................................................... 17

STATION SETUP............................................................................................................................................................ 21

SETUP PROCEDURE ................................................................................................................................................. 21

ALIGNMENT PROCEDURE...................................................................................................................................... 23

AUDIO ROUTING AND ADJUSTMENTS ................................................................................................................... 26

TX AUDIO LEVEL ADJUSTMENT .......................................................................................................................... 26

REMOTE CONTROLLER TO STATION CONTROL PANEL ADJUSTMENTS ................................................... 30

LINE OUT LEVEL ADJUSTMENT ...........................................................................................................................30

LINE IN LEVEL ADJUSTMENT ............................................................................................................................... 30

DSP LEVEL ADJUSTMENTS .................................................................................................................................... 30

REPEATER PANEL INSTALLATION ......................................................................................................................31

CSI Model 32 Repeater Panel................................................................................................................................... 31

Zetron 38A Repeater Panel....................................................................................................................................... 31

ACCESSORIES................................................................................................................................................................ 33

3

Page 5

LBI-38636S

TABLE OF CONTENTS

Page

ILLUSTRATIONS

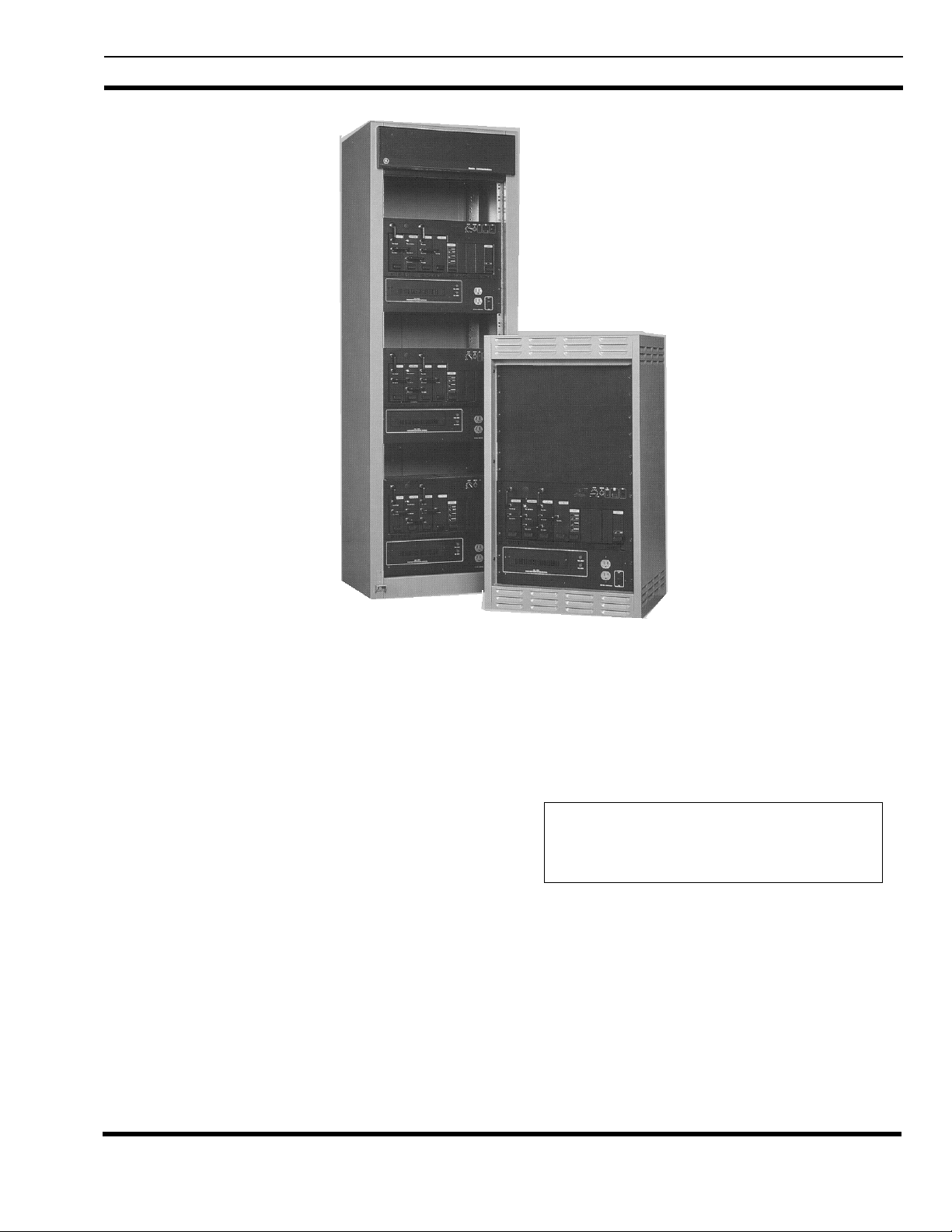

Figure 1 - Typical 37-inch MASTR III Stations................................................................................................................. 9

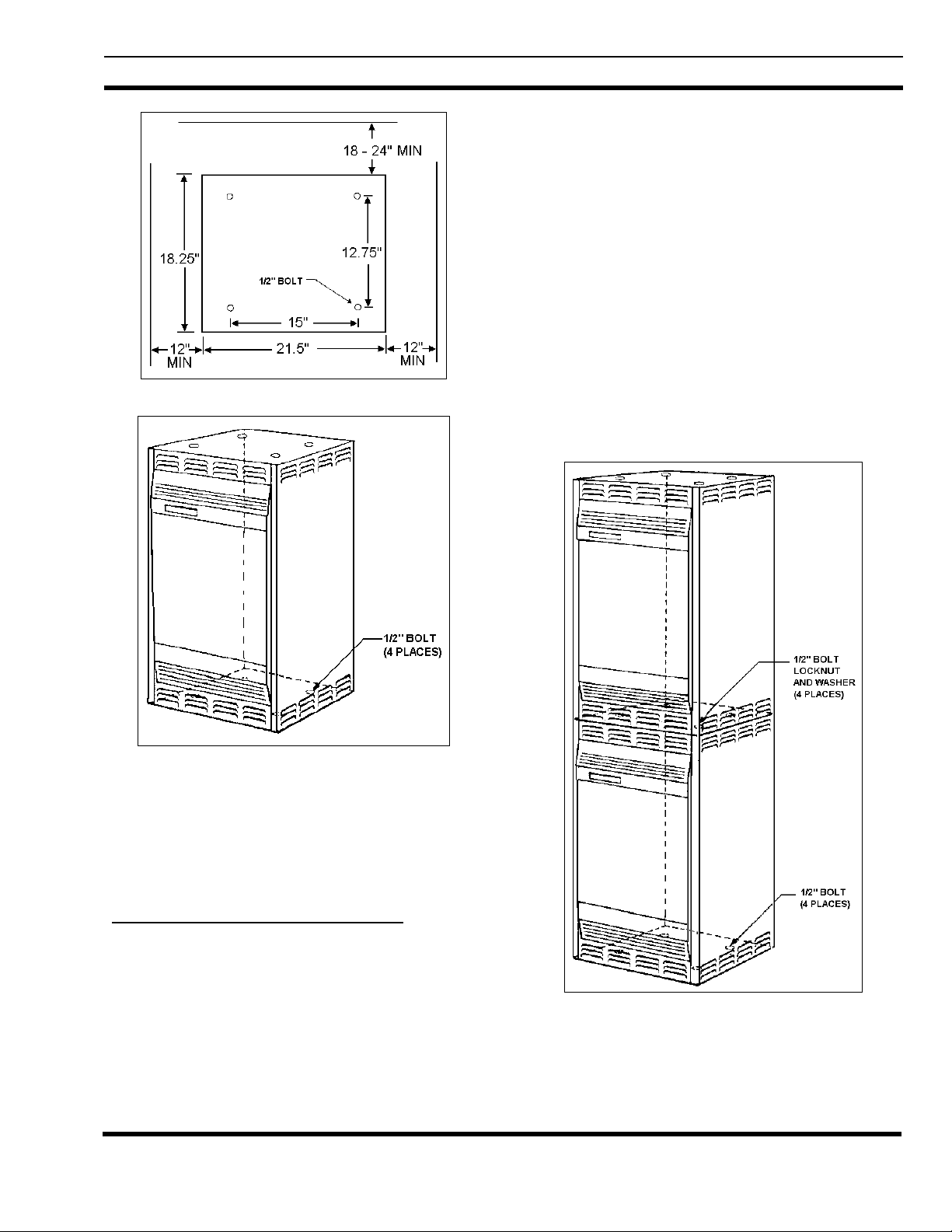

Figure 2 - 37 Inch Mounting Footprint............................................................................................................................. 11

Figure 3 - 37-Inch Cabinet................................................................................................................................................ 11

Figure 4 - Stacked 37-Inch Cabinets 11

Figure 5 - Microphone Connections .................................................................................................................................12

Figure 6 - T/R Shelf Connections .....................................................................................................................................13

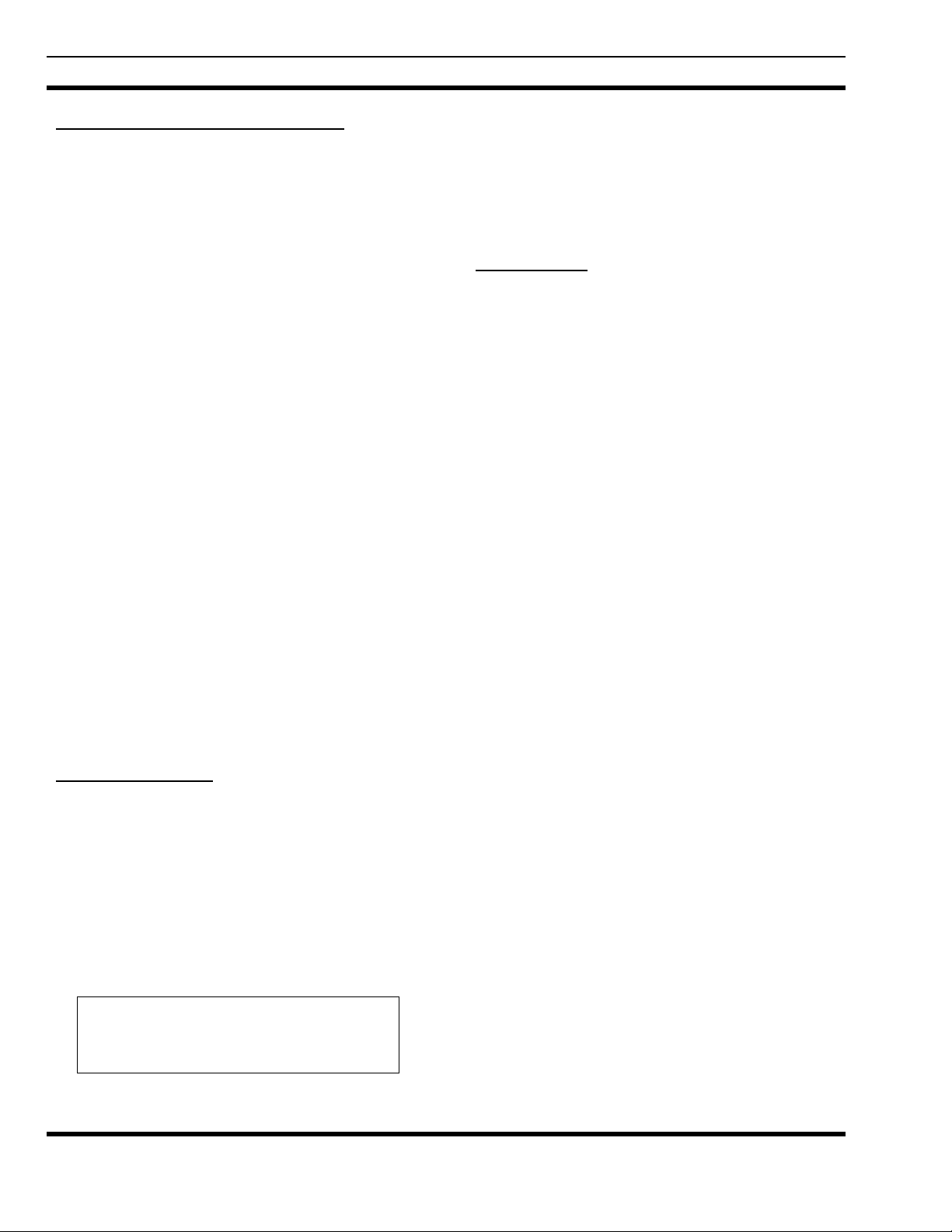

Figure 7 - Typical E & M Signaling Application..............................................................................................................18

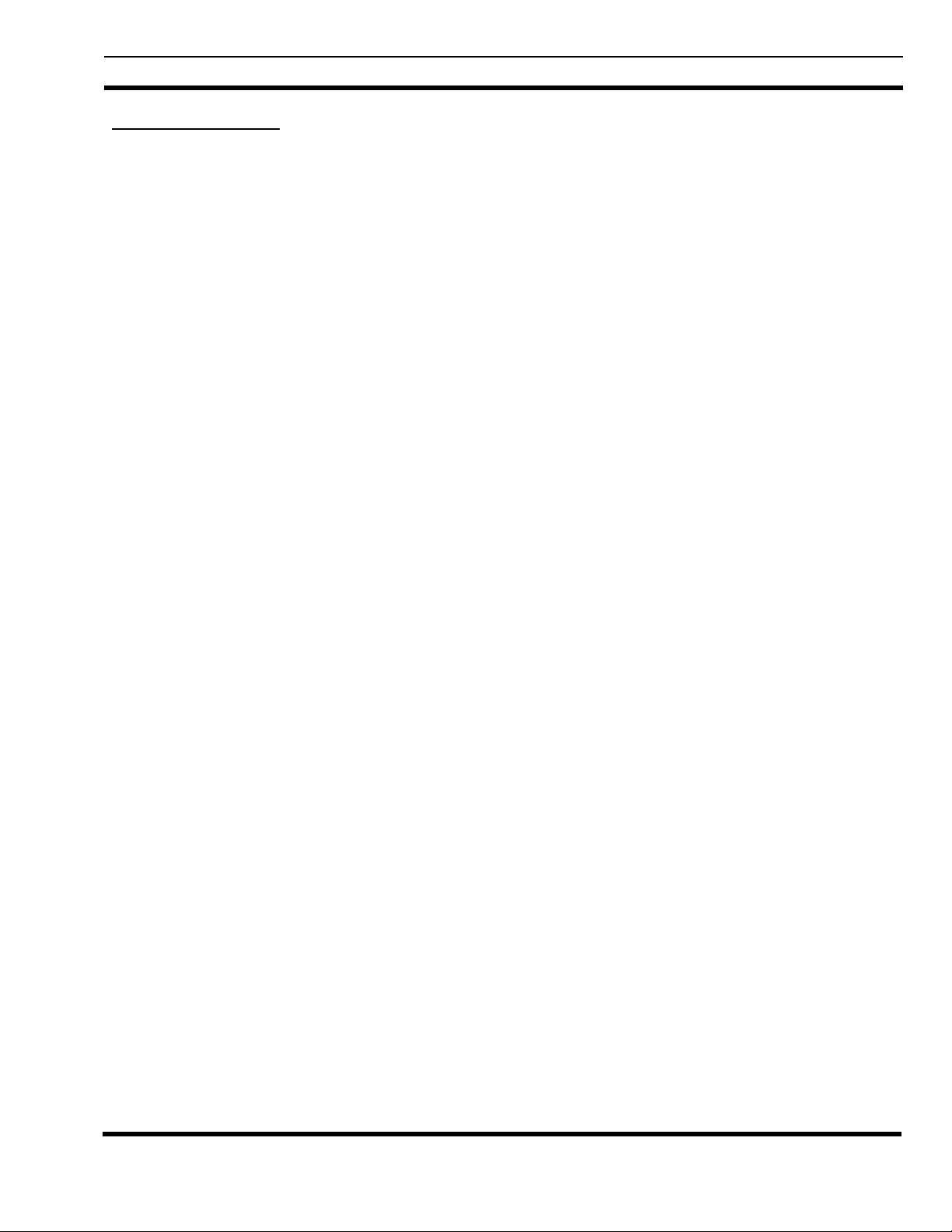

Figure 8 - METHOD 1 (Single Metallic Pair) ..................................................................................................................19

Figure 9 - METHOD 2 (Single Metallic, Earth Ground)..................................................................................................19

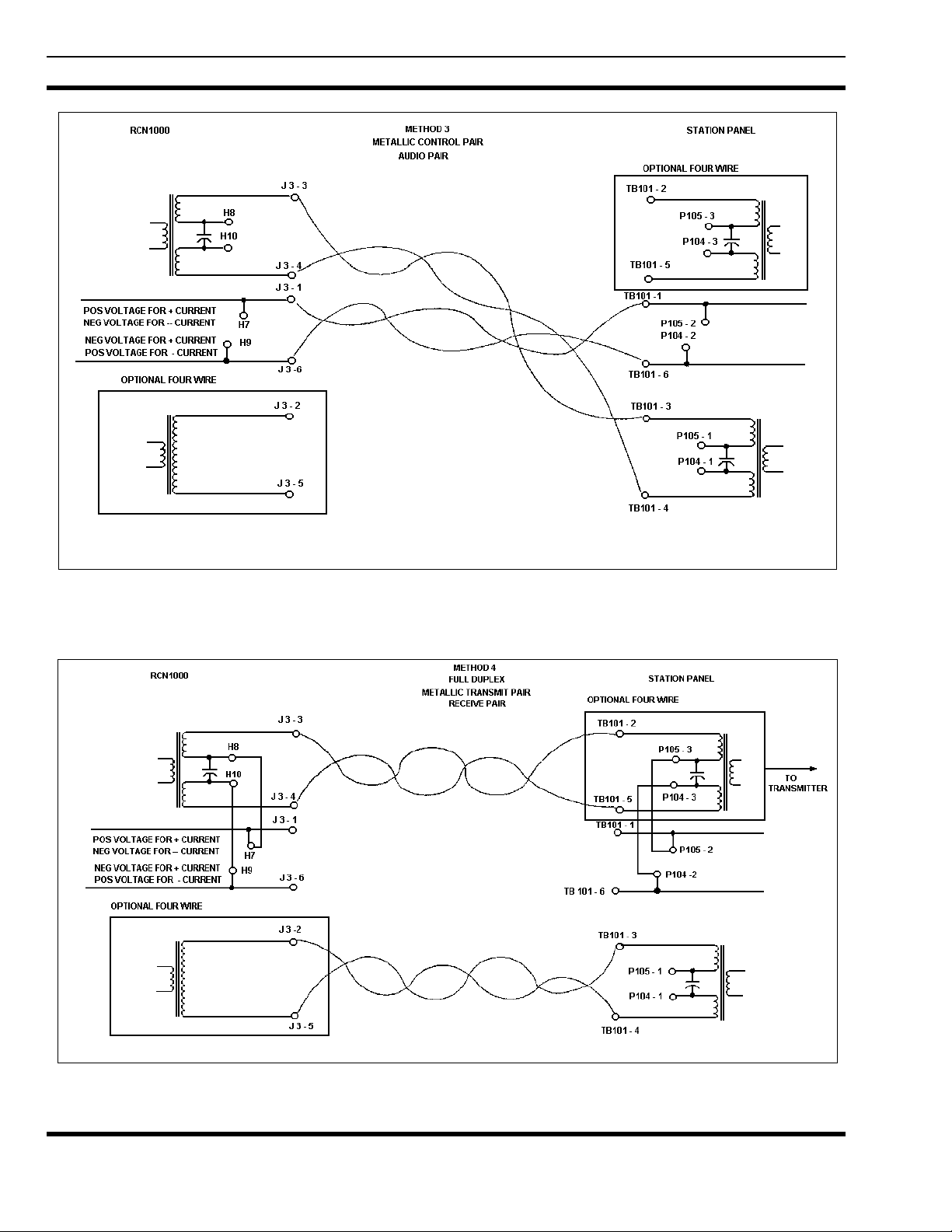

Figure 10 - METHOD 3 (Metallic Control Pair, Audio Pair)...........................................................................................20

Figure 11 - METHOD 4 (Full Duplex Metallic TX Pair) ................................................................................................. 20

Figure 12 - Telephone Line Connections..........................................................................................................................21

Figure 13 - 3-Wire Adapter...............................................................................................................................................21

Figure 14 - Antenna Installation .......................................................................................................................................22

Figure 15 - MASTR III System Module Pot Alignment................................................................................................... 24

Figure 16 - T/R Shelf Interface Board ..............................................................................................................................27

Figure 17 - T/R Shelf Interface Board (Rev. A) ...............................................................................................................28

Figure 18 - T/R Shelf Interface Board ( Rev. C)...............................................................................................................29

PRODUCT SPECIFICATION FOR CE MARKED EQUIPMENT

The MASTR® III Base Station and Auxiliary Receiver conform to the following Product Specifications.

EUROPEAN STANDARDS:

Safety: EN60065 (220 VAC applications only)

EMC: prETS 300 279 (August 1995)

TTD: Not Applicable

SUPPLEMENTARY INFORMATION:

The MASTR III Base Station and Auxiliary Receiver may be used in both trunked and conventional applications. Neither the

MASTR III Base Station nor the Auxiliary Receiver may be connected to leased lines in Europe without an additional linebarrier protection device.

4

Page 6

LBI-38636S

MAXIMUM PERMISSIBLE EXPOSURE (MPE) LIMITS

Do not transmit with this basestation and antenna when persons are within the MPE Radius of the antenna. The MPE Radius

is the minimum distance from the antenna axis that ALL persons should maintain in order to avoid RF exposure higher than

the allowable MPE level set by the FCC.

FAILURE TO OBSERVE THESE LIMITS MAY ALLOW ALL PERSONS WITHIN

THE MPE RADIUS TO EXPERIENCE RF RADIATION ABSORPTION, WHICH

EXCEEDS THE FCC MAXIMUM PERMISSIBLE EXPOSURE (MPE) LIMIT. IT IS

THE RESPONSIBILITY OF THE BASESTATION OPERATOR TO ENSURE THAT

THE MAXIMUM PERMISSIBLE EXPOSURE LIMITS ARE OBSERVED AT ALL

WARNING

DETERMINING MPE RADIUS

THE MAXIMUM PERMISSIBLE EXPOSURE RADIUS HAS BEEN ESTIMATED TO BE A RADIUS OF 24 FEET

MAXIMUM ASSUMING THE HIGHEST EFFECTIVE RADIATED POWER (ERP) ALLOWABLE UNDER FCC

RULES FOR BASESTATION ANTENNA INSTALLATIONS. THIS ESTIMATE IS MADE ASSUMING

MAXIMUM ALLOWABLE ERP LEVEL BY THE FCC AND 100 PERCENT DUTY CYCLE. THE MPE

CALCULATIONS WERE MADE ASSUMING WORST CASE IN EACH BAND WITH RESPECT TO

FREQUENCY, ERP AND LIMIT. THE MAXIMUM ALLOWABLE ERP WAS DETERMINED FROM THE

APPLICABLE PART 90 RULES REGARDING POWER LIMITATION ( 90.205, 90.309, 90.635 ). THE LIMIT

USED WAS FOR UNCONTROLLED EXPOSURE. THE FORMULA USED WAS DERIVED FROM OET 65,

SECTION 2, EQUATION 4.

TIMES DURING BASESTATION TRANSMISSION. THE BASESTATION

OPERATOR IS TO ENSURE THAT NO BYSTANDERS COME WITHIN THE

RADIUS OF THE MAXIMUM PERMISSIBLE EXPOSURE LIMITS SHOWN BELOW.

SAFETY TRAINING INFORMATION

YOUR M/A-COM MASTR III BASESTATION GENERATES RF

ELECTROMAGNETIC ENERGY DURING TRANSMIT MODE. THIS BASESTATION

IS DESIGNED FOR AND CLASSIFIED AS “OCCUPATIONAL USE ONLY”

MEANING IT MUST BE USED ONLY IN THE COURSE OF EMPLOYMENT BY

INDIVIDUALS AWARE OF THE HAZARDS AND THE WAYS TO MINIMIZE SUCH

HAZARDS. THIS BASESTATION IS NOT INTENDED FOR USE BY THE “GENERAL

POPULATION” IN AN UNCONTROLLED ENVIRONMENT. IT IS THE

WARNING

This basestation has been examined and complies with the FCC RF exposure limits when persons are beyond the MPE radius

of the antenna. In addition, your M/A-COM basestation complies with the following Standards and Guidelines with regard to

RF energy and electromagnetic energy levels and evaluation of such levels for exposure to humans:

•

FCC OET Bulletin 65 Edition 97-01 Supplement C, Evaluating Compliance with FCC Guidelines for Human

Exposure to Radio Frequency Electromagnetic Fields.

•

American National Standards Institute (C95.1 – 1992), IEEE Standard for Safety Levels with Respect to Human

Exposure to Radio Frequency Electromagnetic Fields, 3 kHz to 300 GHz.

RESPONSIBILITY OF THE BASESTATION OPERATOR TO ENSURE THAT THE

MAXIMUM PERMISSIBLE EXPOSURE LIMITS DETERMINED IN THE PREVIOUS

SECTION ARE OBSERVED AT ALL TIMES DURING TRANSMISSION. THE

BASESTATION OPERATOR IS TO ENSURE THAT NO BYSTANDERS COME

WITHIN THE RADIUS OF THE MAXIMUM PERMISSIBLE EXPOSURE LIMITS.

5

Page 7

LBI-38636S

•

American National Standards Institute (C95.3 – 1992), IEEE Recommended Practice for the Measurement of

Potentially Hazardous Electromagnetic Fields – RF and Microwave.

TO ENSURE THAT YOUR EXPOSURE TO RF ELECTROMAGNETIC ENERGY IS

WITHIN THE FCC ALLOWABLE LIMITS FOR OCCUPATIONAL USE, ALWAYS

ADHERE TO THE FOLLOWING GUIDELINES:

CAUTION

DO NOT operate the basestation with an antenna that would cause an ERP in excess of that

allowable by the FCC.

6

Page 8

STATION SPECIFICATIONS

(GENERAL)

CABINET 37-INCH 69-INCH

Height 37.0 inches 69.1 inches

Width 21.5 inches 23.1 inches

Depth 18.25 inches 21.0 inches

Weight (note 1) 150 lbs (68 kg)

Rack Units (RU) (note 2)

Cabinet capacity 17 RU 33 RU

Radio 8 RU 8 RU

Duty Cycle (EIA) Tx and Rx at 100%

(continuous)

Operating Temperature -30°C to +60°C

Humidity (EIA) 90% at 50°C

AC Input Power 5 Amps at 120 Vac (-20%) 60 Hz

or

3 Amps at 230 Vac (-15%) 50 Hz

DC Input Power 33 Amps at 13.8 Vdc (transmit, full power)

25 Amps at 13.8 Vdc (transmit, half power)

1.6 Amps at 13.8 Vdc (receive only, standBy)

1.75 Amps at 13.8 Vdc (receive only, 1 watt at

service speaker)

Service Speaker 1 watt at 8 ohms

Service Microphone Dynamic

Notes:

1. Typical station consists of:

a. One T/R Shelf with plug-in modules.

b. One Power Amplifier.

c. One power supply unit.

d. One cabinet with doors.

2. One rack unit equals 1.75 inches.

LBI-38636S

INTERFACE

Line Interface

Line Interface 2-wire or 4-wire (programmable)

Line Cancellation (2-wire) 20 dB amplitude only (programmable)

Line Input (line to transmitter)

Line Terminating Impedance 600 ohms (2-wire or 4-wire)

Line Input Level (adjustable) -20 dBm to +11 dBm

Frequency Response 300 Hz to 3000 Hz

Line Input (receiver to line)

Line Terminating Impedance 600 ohms (2-wire or 4-wire)

Line Output Level (adjustable) zero output to +11 dBm (ref at 1 kHz)

Frequency Response 300 Hz to 3000 Hz, ±1 dB

Remote Control (Tone)

Control Tones (Hz) 1050, 1150, 1250, 1350, 1450, 1550, 1650, 1750,

1850, 1950, 2050, & 2175

Secur-it 2175 Hz

Function Programmable

Hold 2175 Hz

DC Remote Control

Control currents -2.5 mA, ±6.0 mA, ±11.0 mA

7

Page 9

LBI-38636S

PUBLICATIONS INDEX

MASTR III BASE STATION Systems Combination Package .............................................................. LBI-38775

T/R Shelf..........................................................................................................................................LBI-38637

System Module ................................................................................................................................ LBI-38764

Power Module..................................................................................................................................LBI-38752

MASTR III PC Programmer...................................................................................................................... TQ-3353

MASTR III Installation Manual..............................................................................................................LBI-38636

RF Module Test Fixture..........................................................................................................................LBI-38805

MASTR III Utility Handset ....................................................................................................................LBI-38599

RF Package: High Band (136 - 174 MHz)..............................................................................................LBI-38754

Transmit Synthesizer Module..........................................................................................................LBI-38640

Receive Synthesizer Module............................................................................................................LBI-38641

Receiver Front End Module.............................................................................................................LBI-38642

IF Module ........................................................................................................................................LBI-38643

Power Amplifier ..............................................................................................................................LBI-38531

Duplexer ..........................................................................................................................................LBI-38763

RF Package: UHF (380 - 512 MHz).......................................................................................................LBI-38675

Transmit Synthesizer Module..........................................................................................................LBI-38671

Receive Synthesizer Module............................................................................................................LBI-38672

Receiver Front End Module.............................................................................................................LBI-38673

IF Module ........................................................................................................................................LBI-38643

Power Amplifier ..............................................................................................................................LBI-38674

Duplexer ..........................................................................................................................................LBI-38763

RF Package: 800 MHz............................................................................................................................LBI-39025

Transmit Synthesizer Module..........................................................................................................LBI-39026

Receive Synthesizer Module............................................................................................................LBI-39027

Receive RF Module .........................................................................................................................LBI-39028

IF Module ........................................................................................................................................LBI-39029

Power Amplifier ............................................................................................................... (100 W)LBI-39030

AE/LZB 119 3521/1

Power Amplifier ................................................................................................................ (110 W)LBI-39127

Power Supply................................................................................................................................... LBI-38550

Power Supply (800 MHz).......................................................................................................................LBI-38551

Emergency Power (Battery Charger)...................................................................................................... LBI-38625

Auxiliary Receiver VHF.........................................................................................................................LBI-39114

UHF .................................................................................................................................................LBI-39115

800 ...................................................................................................................................................LBI-39113

Voice Guard System Manual..................................................................................................................LBI-31600

Voice Guard/Aegis .................................................................................................................................LBI-38879

Adaptive Multipath Pop Filter (AMPF)................................................................................... AE/LZT 123 3244/1

Antenna Systems.....................................................................................................................................LBI-38983

NOTE: Indented maintenance manuals are included with the header (cover) maintenance manual.

LBI-39176

LBI-39123

LBI-39129

LBI-39123

LBI-38880

LBI-38881

8

Page 10

LBI-38636S

Figure 1 - Typical 37-inch MASTR III Stations

SAFETY SUMMARY

The following general safety precautions must be

observed during all phases of operation, service, and

repair of this product. Failure to comply with these

precautions or with specific warnings elsewhere in this

manual violates safety standards of design, manufacture,

and intended use of the product. M/A-COM assumes no

liability for the customer’s failure to comply with these

standards.

GROUND THE EQUIPMENT

To minimize shock hazard, the station equipment

cabinet must be connected to an electrical ground. The

equipment supplied is equipped with a three-conductor

AC power cord. The power cord must be plugged into an

approved three-contact electrical outlet with the

grounding wire firmly connected to an electrical ground

(safety ground) at the power outlet. The power cord meets

International Electrotechnical Commission (IEC) safety

standards.

REPLACEMENT OF PLUG-IN CIRCUIT

MODULES

Component or module replacement and internal

adjustments must be made by qualified maintenance

technicians.

CAUTION

Do Not replace components or modules with

power applied.

ELECTROSTATIC DISCHARGE SENSITIVE COMPONENTS

This station contains CMOS and other circuit

components, which may be damaged by electrostatic

discharge. Proper precaution must be taken when

handling circuit modules. As a minimum, grounded wrist

straps should be used at all times when handling circuit

modules.

9

Page 11

LBI-38636S

DO NOT SUBSTITUTE PARTS OR

MODIFY PRODUCT

Because of the danger of introducing additional

hazards, do not install substitute parts or perform any

unauthorized modifications to the product.

INTRODUCTION

This manual describes the installation and

connections for a typical MASTR III station combination.

Information provided includes suggested locations and

installation of equipment and hardware, interconnection

and assembly diagrams, alignment instructions, and

troubleshooting suggestions.

The MASTR III cabinet normally includes the

Transmitter/Receiver Shelf, the Transmitter Power

Amplifier, and a Station Power Supply. The assemblies

are mounted in a 37-inch cabinet. Optional 69- inch or

two stacked 37-inch cabinets are available.

CABINET

The system is contained in a 37-inch cabinet with

improved ventilation for greater reliability. The cabinet

can also house optional equipment such as a Duplexer,

Charger, Gell Cell batteries, or Auxiliary Receiver.

STATION POWER SUPPLY

The Station Power Supply provides all necessary

power to run the station. It provides 13.2 volts at 33 amps

to the station from an AC source. The source voltage

depends on the particular area and power sources

available. The power supply is normally mounted beneath

the T/R Shelf.

UNPACKING EQUIPMENT

Unpack the station and carefully inspect each item. If

any damage has occurred to the equipment during

shipment, immediately file a claim with the freight

carrier. AC power adequate to meet system requirements,

environmental control, and digital or voice grade phone

lines must be available at the site prior to installation.

SITE PREPARATION AND

INSTALLATION

CABINET INSTALLATION

The MASTR III station cabinet is designed for

servicing from the front. However, the system may also

be serviced from the rear when adequate space is

available. The cabinet should be mounted on a level, solid

surface.

If rear servicing is desired, cabinets should be setup

with a minimum of 24-inches of clearance in the rear and

between cabinets or wall to permit ventilation and room

for the service-man to move between and behind the

cabinets.

If space is at a premium or if servicing is to be made

from the front only, then cabinets should be setup with a

minimum of 18-inches of clearance in the rear and 12inches between cabinets to permit ventilation. However,

access to the rear of the cabinets may still be necessary in

order to install or repair antenna or power cables.

Single and double stacked 37-inch cabinets must be

securely anchored to the floor according to the footprint

shown in Figure 2 and following single or double stacked

installation instructions.

TRANSMITTER/RECEIVER SHELF

The MASTR III Transmitter/Receiver (T/R) Shelf

contains the station control electronics for dc/tone remote,

re-mote/repeater, or repeater only applications. The

station control electronics consists of a Backplane board,

Power Module, System Module, and an Interface Board.

The back-plane also connects the RF Section which

consists of the Receiver Synthesizer Module, First IF

Module, Second IF Module, and the Transmit Synthesizer

Module.

TRANSMITTER POWER AMPLIFIER

The Transmitter Power Amplifier is mounted directly

behind the T/R Shelf. Cabling from the output of Power

Amplifier will depend on the system configuration.

10

Single 37-inch Cabinet Installation

The station provides for front and rear door servicing

or front door only servicing in tight space situations. The

front and rear of the station must be kept clear of

obstructions so that the serviceman can easily remove the

front and rear doors for servicing. Also, the front and rear

air vent louvers and rear cable outlets must be free of

obstructions.

Page 12

Figure 2 - 37 Inch Mounting Footprint

LBI-38636S

serviceman can easily remove the front and rear doors for

servicing. Also, the front and rear air louvers and rear

cable outlets must be free of obstructions. Leave a

minimum of 12-inches of space on each side of the

cabinets to avoid obstructing the louver air vents. With

the bottom cabinet in position, secure it to the floor as

shown in Figure 2 with 1/2-inch bolts and anchors.

Remove the four plastic plugs in the top surface of the

bottom cabinet (by squeezing the plastic retaining barbs

together from the inside of the cabinet and pushing the

plug up and out).

Position the top cabinet on the bottom cabinet. Align

the fixing holes and bolt the cabinets securely together

using 1/2 inch bolts, washers, and locknuts (supplied in

hardware kit 344A3450G7) as shown in Figure 4.

It will be necessary to remove the front and rear

covers and some internal components to allow access to

the top and bottom securing holes.

Figure 3 - 37-Inch Cabinet

Using the four holes are provided in the bottom

surface of the cabinet, the cabinet must be securely bolted

to the floor with 1/2" bolts and anchors as shown in

Figures 2 and 3. It will be necessary to remove the front

and rear door covers and some internal components to

allow access to the bottom securing holes.

Double Stacked 37-inch Cabinet installation

For limited floor space situations, two 37-inch

MASTR III cabinets may be stacked one upon the other.

This requires that the bottom cabinet be securely bolted to

the floor surface and the top cabinet securely bolted to the

top surface of the bottom cabinet, as shown in Figure 4.

Ensure first that the floor is strong enough to support

the weight of the two cabinet configuration and that

adequate ceiling height is available. Ensure the front and

rear, of the station cabinets are clear of obstructions so

Figure 4 - Stacked 37-Inch Cabinets

11

Page 13

LBI-38636S

ELECTRICAL CONNECTIONS

AC Power

The station will be received with the power cord

bundled and stored in the bottom of the cabinet. Remove

the twist tie from the AC power cord, unravel and feed the

cord through one of the rear cable holes. It may be helpful

to remove the grommet from the hole before passing the

cord through and reinstalling it afterwards.

A separate 15 to 20 Ampere, 120 Vac, 60 Hertz

electrical circuit should be provided for the station. A 120

volt grounded AC outlet for the station should be located

within six feet of the lower rear of the cabinet. The power

cord for the 120 Vac Power Supply comes with a

grounded 120 Vac molded plug attached. Check the

electrical code to ensure the power outlet complies with

local ordinances.

If a 240 Vac, 60 Hz source is used for the station, an

external step-down transformer (similar to 19C307148P1)

must be used.

For 230 Vac, 50 Hz applications, the station power

supply is equipped with a power cord, less connector, to

permit connection to an acceptable electric circuit. A plug

meeting local electrical codes must be supplied by the

customer. Make sure the station power supply is

connected to an outlet having the same configuration as

the plug. No adapters should be used in this configuration.

The equipment should be connected to a good earth

ground using a ground wire of adequate size. A ground

stud is provided for a separate cabinet ground. Use No. 14

or larger wire (depending on local ordinances and system

requirements) for connecting the cabinet to a good

building ground. After the ground lead from the power

cable is connected to the building ground, check for

continuity between building ground and the cabinet.

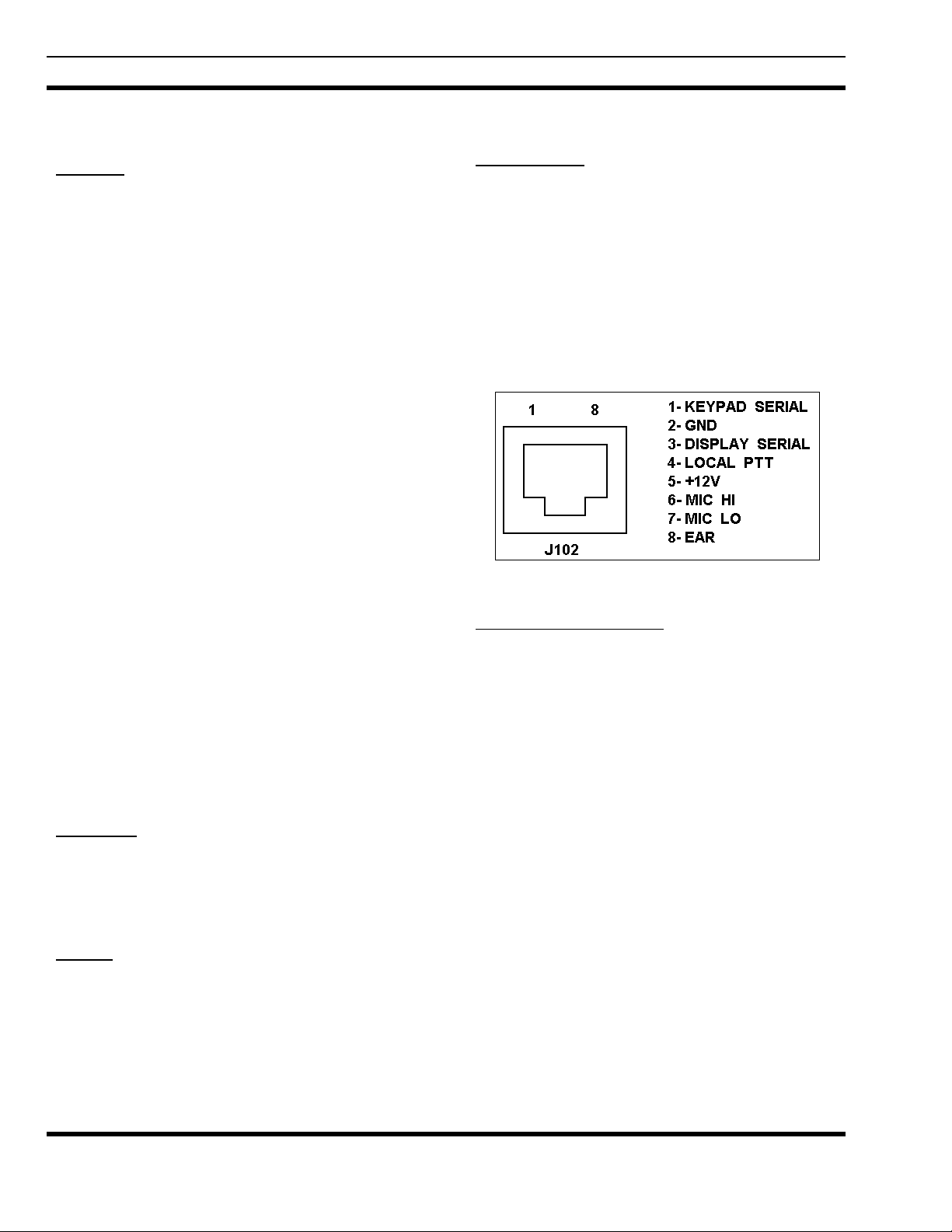

Microphone

The local microphone or utility handset may be

attached to the station through the MIC port on the front

of the T/R Shelf (Figure 6), the connections are shown in

Figure 5.

Antenna

The antenna cable may be routed through the top rear

or bottom rear of the cabinet directly to the appropriate

connector within the station, depending upon the

configuration.

TELEPHONE LINE CHARACTERISTICS

Telephone Lines

The type of telephone lines required for the

installation will depend on how the station is controlled

and if it is being used for simplex or duplex operation.

Generally, both 4-wire Audio and E & M Signaling

options are used to interface between the radio and carrier

systems. However, 2-wire Audio can be used in the twoway radio portion of the control system if hybrids are

installed to provide transition between the 2-wire and 4wire connections. Usually the E & M Signaling is

separated from the audio (separate line) in both 2-wire

and 4-wire installations.

Figure 5 - Microphone Connections

Types Of Voice Grade Lines

Telephone lines are normally obtained from a

communications common carrier ("telephone company"

for our purposes here). When a voice grade (as contrasted

to a "data line") telephone line is requested, there is no

way of knowing just what type of line will be received

from the phone company.

In addition, the telephone company may supply one

type of line first, and later change it to another type

without any notification to the user. One of the following

types of telephone line can be expected:

1. Wire lines with no amplifiers

2. Wire lines with amplifiers added to compensate

for line loss

3. Facilities derived from carrier (multiplex)

These lines have different operating characteristics,

and each must be treated differently. In large systems, all

three types of lines can be provided. In long haul

applications, a system can consist of two or three of these

types of lines in tandem (tied together end-to-end).

The first type is WIRE LINE WITH NO

AMPLIFIERS. These are the same lines that have been

used for years to control dc systems. These are the easiest

to work with since they include no problem-causing

electronic equipment. These lines are normally found in

12

Page 14

LBI-38636S

less populated areas where the phone company has not yet

switched to carrier systems. These lines have a fixed

amount of loss, which varies with frequency, temperature,

from deterioration of splices, and from moisture getting

into the cables. When these cables get old, the phone

company sometimes applies DC current to improve the

joints and lower the line loss. In this case, the line is not

usable for DC control.

Normally, a +10 dBm test tone can be applied to

these lines. These lines do not normally include any type

of voice limiters.

The second type of line is a WIRE LINE WITH

AMPLIFIERS. These lines are normally supplied when

the loss of available lines is too high. An amplifier or

several amplifiers are added to the line to make up for the

loss.

One commonly used amplifier is the E-6 repeater.

This amplifier will pass DC current and they have been

used on DC lines for years. These amplifiers include

limiters, which start limiting at somewhere around 0 dBm

input to the amplifier. The limiters do not cause any real

problems on DC systems since only the voice peaks are

clipped. However, special care must be used when

applying them to tone remote control systems.

Each amplifier can be adjusted for up to 12 dB of

gain. If the loss is more than 12 dB, one or more

amplifiers may be added. The amplifier(s) can be placed

at any point in the line.

The third type of telephone line is a Derived Facility

using carrier equipment. Since this is the most

complicated, more care is required when connecting radio

equipment. This type of line will be available more often

in the future.

The telephone company supplies two wires at each

end of the circuit. Each two-wire end goes to some point

in the circuit where it is converted to a four-wire circuit

and then connected to the carrier equipment. A four-wire

circuit can be ordered if that is what is required. At the

other end, it is taken out of the carrier equipment and

converted back to the two-wire circuit. The carrier

equipment has a transmit path and a receive path. The

gain is adjustable each way.

Figure 6 - T/R Shelf Connections

13

Page 15

LBI-38636S

The telephone company wants to see a maximum

three-second level of -13 dBm at the carrier equipment as

measured on a modified Western Electric 3-type Noise

Measuring Set. The telephone equipment will limit the

audio if the signal is above -13 dBm at the carrier input.

This does not mean that the maximum that can be applied

into the two-wire end is -13 dBm. If the radio equipment

is a good distance from the carrier equipment, there will

be some line loss. If the loss is 5 dB, for instance, then -8

dBm could be applied into the two-wire end. Therefore,

the telephone company will have to be asked in each case

what level is allowed to be applied at the two-wire end.

If the telephone company checks and finds that too

much audio is being applied into the carrier equipment,

they will put a pad into the circuit to cut the audio down.

When the phone company is asked what levels can be

applied to the line, they will either provide a level in

Volume Units (VU) or test tone. VU is average voice,

which is generally considered to be 10 dB below test tone.

Test tone is a 1000 or 1004 Hz tone used to line up the

circuit. Test tone is normally given in dBm. If the radio

installer isn’t careful, he and the phone company will be

talking 10 dB apart. If the phone company says the limit

is 0 VU, use +10 dBm for the line-up.

The two wire ends of these lines are normally

designed to work with a 600 ohm impedance in and out.

The transmit and receive carrier equipment gains are set

up for 600 ohm terminations. If the line to the carrier

equipment is fairly long, the impedance at which at the

two-wire end is not very critical.

If the two-wire end is close to the carrier equipment,

however, then the impedance is critical. If the impedance

is not 600 ohms, it can cause the gain of the carrier

equipment to go up or down. In some cases, feedBack

(oscillations) from the receive path to the transmit path

will be present. A common problem that causes

oscillations in the carrier equipment is gain change,

whether from misalignment or other reasons.

American Telephone and Telegraph Company has

published a reference for Voice Grade Lines entitled,

"Private Line Interconnections, Voice Applications"

(Publication Number 43201). It covers several types of

private line interfaces. There is no publication that covers

radio control alone. However, there are several

parameters provided in the publication that are important

to note.

The 1000 Hz loss design objective is 0 to 10 dB. If

the loss is not specified, there will be a loss of 10 dB at

1000 Hz in most cases. The phone company allows itself

a SHORT-TERM fluctuation of 3 dB and a LONG-

TERM variation of 4 dB. If a 10 dB loss line at 1000 Hz

is specified, up to 14 dB loss can be expected, and the

phone company would still be within their design limits.

The loss between 500 and 2500 Hz can be +2 dB and

-8 dB relative to 1000 Hz loss. Note that the phone man

may refer to this as -2 and +8 in the telephone company

way of talking. The loss between 300 and 3000 Hz can be

+3 dB to -12 dB relative to the 1000 Hz loss. This says

that if there is a line with 10 dB of loss at 1000 Hz, a loss

of as much as 18 dB at 2500 Hz, and 22 dB of loss at

3000 Hz can be expected. A loss 4 dB of long-term

variation should be added to this.

Noise on this type of line is measured at each end

with a Western Electric 3-type Noise Meter. The

allowable level of a line from 0 to 50 miles is 31 dBrnC,

and for a line from 51 to 100 miles is 34 dBrnC. If this

type meter is not available, an AC- VTVM can be used. If

there is a noise reading of -50 dBm or less, generally this

is considered an acceptable circuit.

Tone Remote Control Systems

In contrast with DC systems, where audio level

setting is not as critical, it is important that levels in tone

applications be set properly. Failure to do so results in the

control function not working properly. For example, after

the installation when the user has gained a little

experience, the user may find that they are not always

picking up the function selected. A little extra time spent

at the installation will save many problems of this type

later.

This equipment is designed so that the tone sequence

consists of either two or three parts. The first part is the

"Secur-it" tone (2175 Hz) which is sent at the highest

level for approximately 125 milliseconds. This is

followed by the "Function" tone which is sent at a level

10 dB lower for approximately 40 ms. In the case of a

transmit function, the "Function" tone is followed by

2175 Hz "Hold" tone at a level 30 dB down from the

"Secur-it" tone burst (therefore, it is 20 dB down from the

"Function" tone burst). This tone continues for the

duration of the transmit function. The average voice (0

VU) is sent at the same level as the "Function" tone,

therefore, the test tone for the voice is sent at the same

level as the "Secur-it" tone.

The "Secur-it" tone must arrive at the base station at

no less than -20 dBm. The transmit "Hold" tone must

arrive at the base station at no less than -50 dBm. The test

tone for the voice must arrive at the base station at no less

than -20 dBm. Therefore, the limits of system operation

are usually established by only three things:

1. The maximum level at 2175 Hz that the phone

company will allow to be sent from the most

distant point in the system. Normally this will

not be higher than 0 dBm. In some cases it can

even be less, or on rare occasions it can be +5 or

+10 dBm.

14

Page 16

LBI-38636S

2. The loss of the circuit at 2175 Hz. Do not forget

the long-term variation of up to 4 dB more.

3. The requirement that the "Secur-it" burst must

arrive at the base station at no less than -20 dBm.

Normally, most systems will not crowd these limits.

However, if the result is a few dB short, consider adding

C-1 conditioning (at an added cost). Resist the natural

desire to just turn up the tone sending level as this will

cause improper system operation.

Increasing the level will cause the "Secur-it" tone

burst to go into limiting in the phone company equipment.

The limited tone causes the "Secur-it" tone filter in the

base station to ring. This will result in picking up or

dropping out functions, which were not selected. NEVER

allow the "Se-cur-it" tone to be in limiting.

There is an easy way to check and see if the "Secur-

it" tone is in limiting. With the phone lines connected to

the equipment at both ends connect an AC voltmeter

across the phone line at the base station. Arrange to send a

burst of "Secur-it" tone long enough to measure the

incoming level on the AC voltmeter. Then arrange to send

a burst of 1950 Hz "Function" tone long enough to

measure the incoming level on the AC voltmeter. If the

1950 Hz tone does not arrive 10 dB (1 dB) less than the

"Secur-it" tone, then the "Secur-it" tone is in limiting. It

will become necessary to lower the sending level at the

remote controller until it is below limiting.

If the audio is high enough to cause the telephone

equipment to go into limiting, it will cause amplitude

distortion. On a high loss line the amplitude distortion

will cause the "Hold" tone (2175 Hz) to vary and the

transmitter to drop out.

On remote systems using tone control, care must be

used when connecting two telephone lines in tandem. For

example, for a base station and two remotes, a phone line

is ordered to connect the station to the first remote, and a

second line to connect the second remote to the first

remote. The loss of each line is now added together and

the tones from the second remote can not operate the base

station. The installer can either specify a low loss on each

line, or run each line directly to the base station.

A check with the phone company can determine

which approach is the least expensive over a period of

time; i. e., an analysis of non-recurring costs versus

recurring costs over the expected length of time the circuit

will be used.

selector 3 dB lower than the 1000 Hz test tone level. Most

telephone lines have a frequency response which

attenuates the 1950 Hz tone with respect to a 1000 Hz test

tone, therefore care should be taken to ensure that the

correct levels are received at the voting selector.

If the telephone company will not allow a continuous

tone as high as -8 dBm to be sent, then a lower loss circuit

should be requested or C-1 conditioning added.

When ordering phone lines for a voting system, if

possible, all lines should be of the same type. Different

telephone line responses will cause the voter to prefer one

signal over others.

It is improper system design to have the received

signal selection biased by a "poorer" telephone circuit.

Many telephone companies will add pads to build out the

lines. If this is considered when the lines are ordered, it

should not be difficult to build all of the lines out to have

the same frequency response.

Ordering Voice Grade Telephone Lines

If a standard voice grade circuit is ordered, and the loss is

not specified, the following will normally result:

1. Loss at 1000 Hz will be 5 to 10 dB; normally 10

dB

2. Long-term variation 4 dB

3. Amplitude distortion (frequency response)

Referenced to 1000 Hz; + = more loss 300 to

3000 Hz: -3 to +12 dB 500 to 2500 Hz: -2 to + 8

dB

4. Noise: 31 dBrnC maximum

5. Frequency translation error: 5 Hz

6. Normal impedance: 600 ohms

7. Maximum permitted signal into the line: -6 dBm

to -13 dBm in-band three second average (the

level arriving at the carrier equipment cannot be

more than -13 dBm).

By adding C-1 conditioning, the loss changes to:

Amplitude distortion (frequency response) Referenced to

1000 Hz; higher frequency = more loss 300 to 2700 Hz: 2 to +6 dB 1000 to 2400 Hz: -1 to +3 dB

One added advantage to C-1 conditioning is that the

voice quality will be improved by boosting the high

frequency components.

Voting System Considerations

A voting system uses a continuous 1950 Hz tone on

the telephone line when the receiver is squelched. This

voting tone is normally sent from the station to the voting

15

Page 17

LBI-38636S

Telephone Company Ordering Information

When ordering a telephone line, the following must

be considered:

1. Type of circuit:

Voice grade, 2-wire termination, for radio

control, and tone remote system - send/

receive; voting system - receive only.

2. DC continuity not required

3. Impedance: 600 ohms 20%

4. Line Loss:

Tone remote system:

Sends 2175 Hz tone for 125 milliseconds, and

it must arrive at the base station at no less than

-20 dBm including long-term variation.

Average voice is 10 dB below the 2175 Hz

tone burst.

Voting system:

Sends a continuous 1950 Hz tone when the

receiver is squelched, and it must arrive at the

voting selector at no less than -30 dBm

including the long-term variation.

5. C-1 conditioning if necessary. (If two phone

lines are to be tied in tandem, it is usually proper

to specify C-1 conditioning.)

6. If more than one phone line is to be used, a block

diagram showing locations and type of

equipment to be used should be provided the

telephone company.

TELEPHONE LINE INSTALLATION

DC Remote Installation

Two-Wire Operation

For two-wire operation, connect the pair to TB101-3

and -4. If the remote control unit at the other end is an

RCN 1000, use J3-3 (red) and -4 (green). Refer to

Methods 1 and 2 in Table 1 and associated illustration for

examples (Figures 8 & 9). Jumpers should be placed on

P104-1 to P104-2 and P105-1 to P105-2 on the Interface

Board. Figures 15 & 17 shows the location of Interface

Board connectors and jumpers.

NOTE

Polarity must be maintained, if the metallic

control pair is being used for DC control.

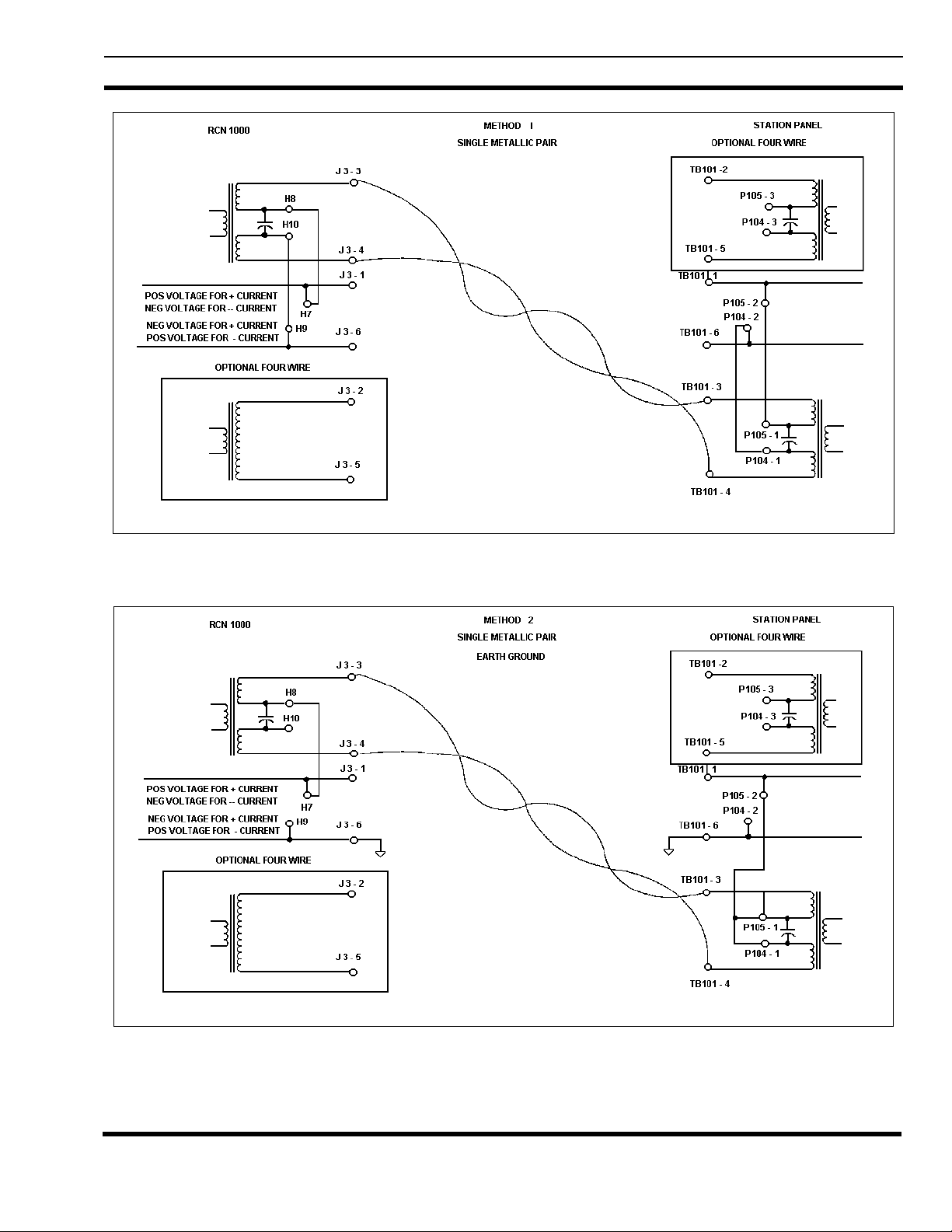

Four-Wire Operation

For examples, refer to Methods 3 and 4 in Table 1,

and the associated illustrations showing the different

methods (Figures 10 & 11). Jumpers should be installed

on P104-2 to P104-3 and P105-2 to P105-3 on the

Interface Board.

E & M Signaling

E & M lead signaling systems derive their name from

certain historical designations of the signaling leads on

circuit drawings. An "M" lead is associated with the

transMit function or Mouth, while the "E" lead is

associated with the recEive function or Ear. In two-way

radio systems with remote control, E & M Signaling can

be the only type of control offered by the available carrier

circuits.

Generally, both 4-Wire Audio and E & M Signaling

options are used to interface between the radio and carrier

systems. However, 2-Wire Audio can be used in the twoway radio portion of the control system if hybrids are

installed to provide transition between the 2-Wire and 4Wire connections. Usually the E & M Signaling is

separated from the audio (separate line) in both 2-Wire

and 4-Wire installations.

Figure 7 illustrates a typical interface between a twoway radio system and a multiplex/microwave system. The

Remote Control Console and Base Station are equipped

with the E & M Signaling Option and the 4-Wire Audio

Option. The console provides a regulated -48 Vdc output

(or -24 Vdc with minor modifications) to the "M" lead

when the TRANSMIT switch is pressed. This -48 Vdc

activates a tone encoder (usually 3825 Hz) in the

multiplex rack. The tone encoder modulates the carrier

frequency, which is transmitted over the microwave link.

At the station end of the microwave link, the signal is

demodulated and the 3825 Hz tone operates a tone

decoder in the multiplex rack. The output of the decoder

results in a contact closure, which applies +48 Vdc (or

+24 Vdc) to the control shelf. This voltage should be

connected between TB101-1 and TB101-6 on the

Interface board. Jumpers on P104 and P105 of the

Interface Board should also be removed. If +48 Vdc is

being used, resistors R116 and R118 on the Interface

Board should also be removed.

When the system is configured in this manner,

approximately +8 milliamperes flows through the DC

control decode circuitry on the backplane. This will cause

the T/R Shelf to decode a +6mA control current to key the

transmitter and route line audio to the transmitter.

16

Page 18

LBI-38636S

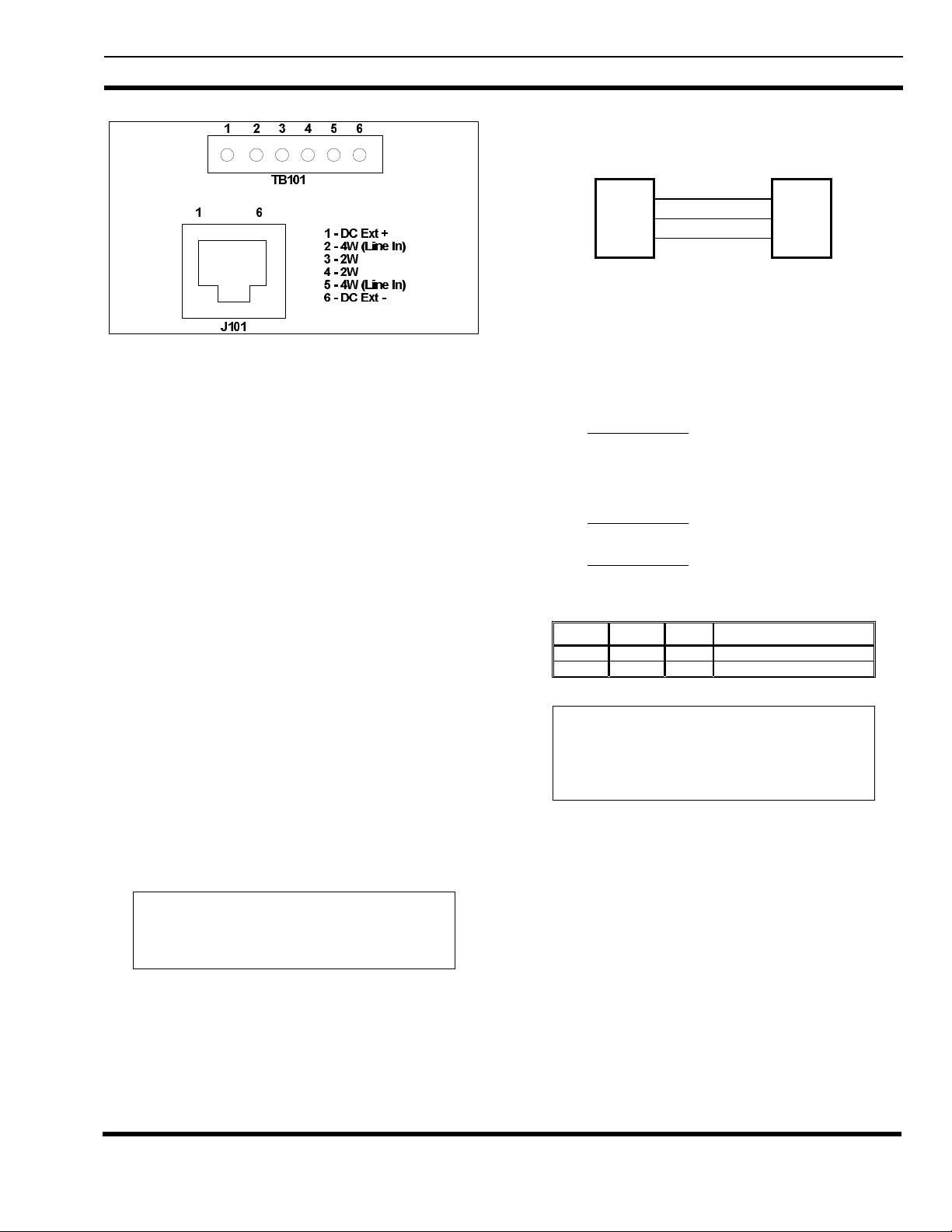

Tone Remote Installation

Jumpers P104 and P105 located on the Interface

Board are not required and should be removed. Refer to

the sections on TELEPHONE LINE

CHARACTERISTICS and LEVEL ADJUSTMENTS for

additional installation information. Line connections are

made to TB101 or J101 on the T/R Shelf’s Interface

Board. TB101 and J101 are connected together and each

has the same pin out.

Two Wire Tone Remote

When the control shelf is used with a two wire tone

re-mote/console, the remote control pair should be

connected to TB101-3 and TB101-4.

Four Wire Tone Remote

When the control shelf is used with a four wire tone

re-mote/console, the remote control transmit pair (which

modulates the transmitter) should be connected to TB1012 and -5. The remote control receive pair (which listens to

the receiver) should be connected to TB101-3 and TB101-

4.

Connections

Telephone line connections may be made on the

terminal block (TB101) or with an RJ11 connector to

J101. The telephone line cable may be routed through the

top rear or bottom rear of the cabinet (Assembly

Diagram). The telephone line connections are shown in

Figure 12.

17

Page 19

LBI-38636S

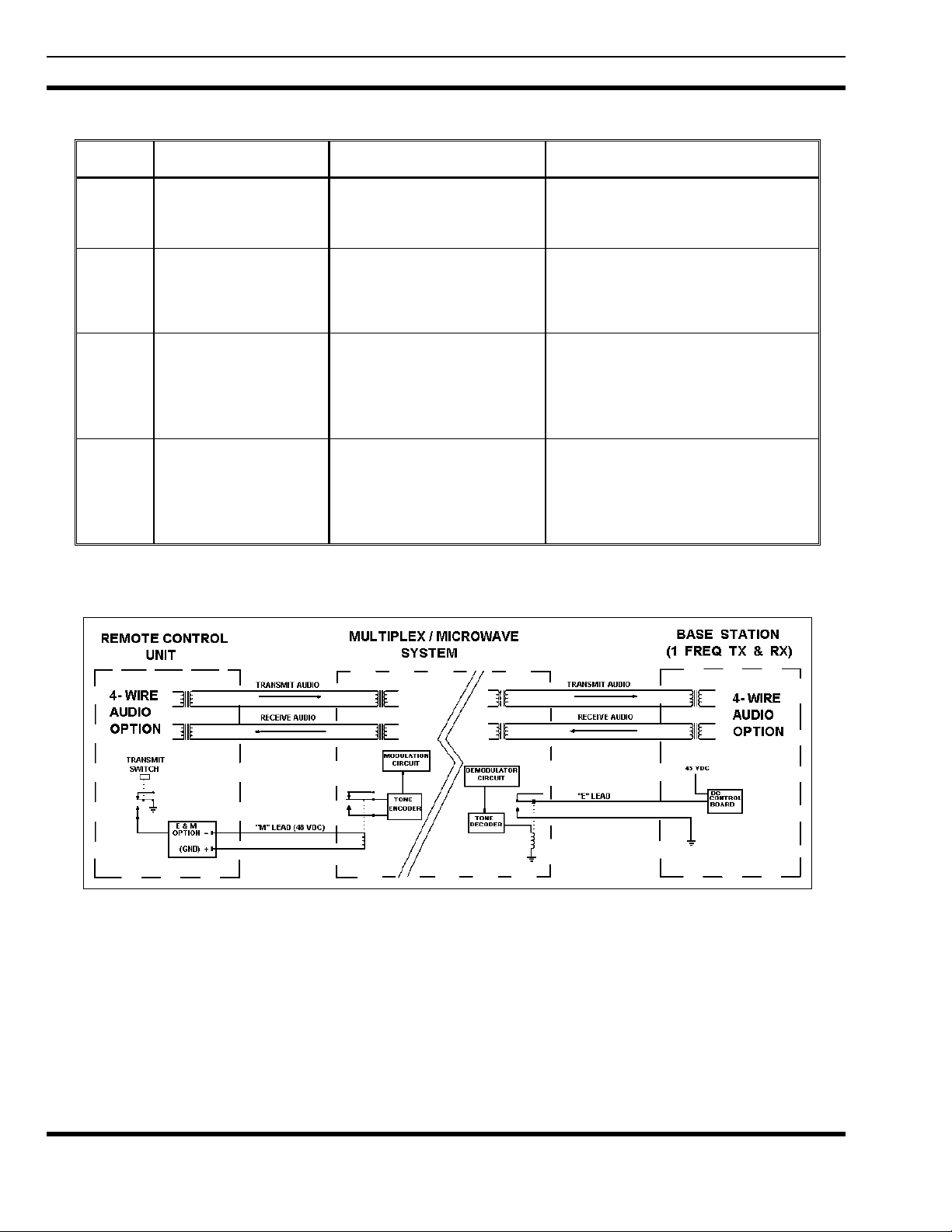

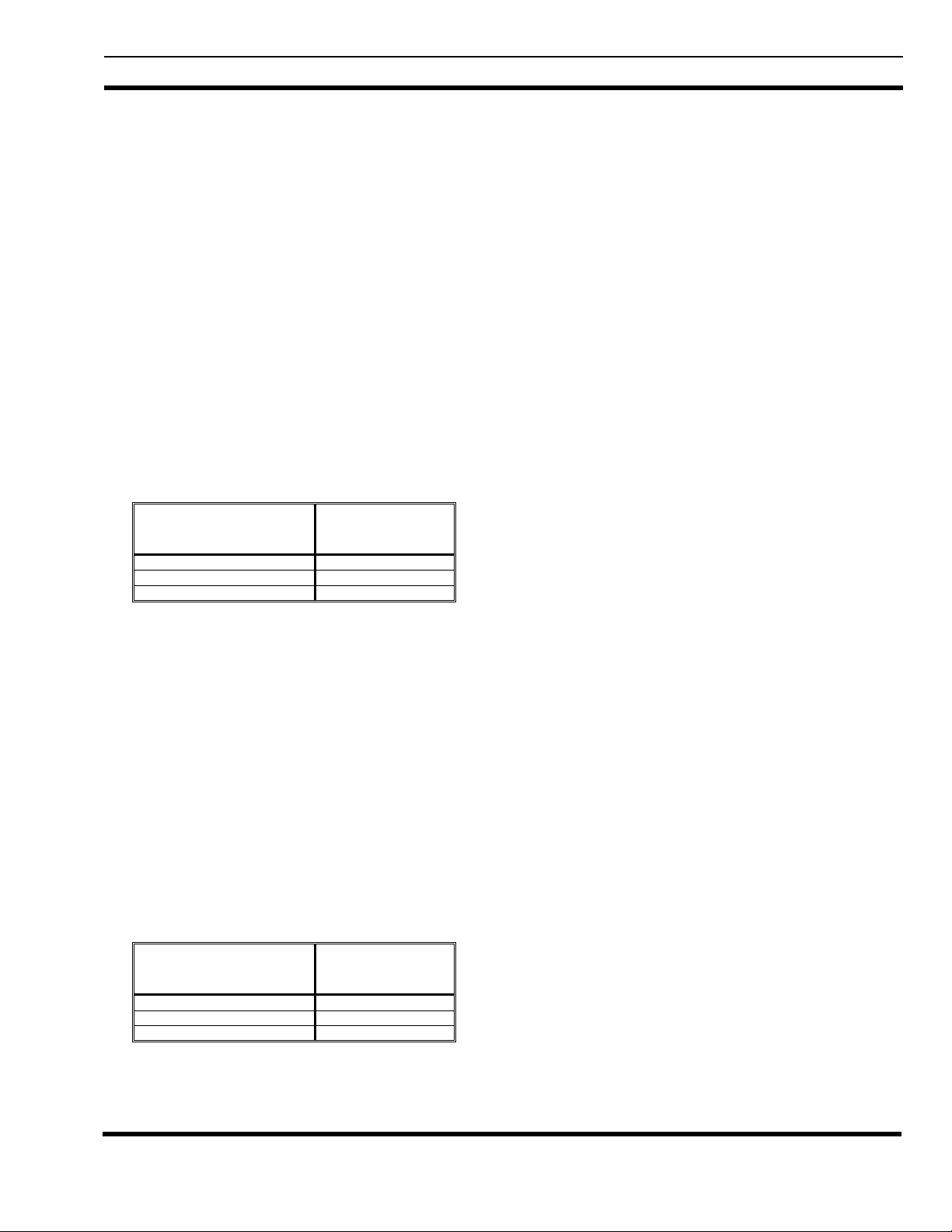

Table 1 - Wire Line Installation Methods

METHOD DESCRIPTION PROCEDURE

1 Single metallic pair (the

control currents are simplexed

to line, a two wire cable is

required).

2 Single metallic pair (the

control currents are simplexed

line to earth ground, a two wire

cable is required).

3 One voice grade circuit for bi-

directional audio and the other

a metallic pair of control

voltages.

4 Single metallic pair for

transmit audio and control

Currents. Single voice grade

circuit for receive audio. A

four wire line is required.

a. Connect the metallic pair to TB101-3

and -4.

b. Jumper P105-1 to P105-2, and P104-

1 to P104-2 on the Interface Board.

a. Connect the metallic pair to TB101-3

and -4.

b. Jumper P105-1 to P105-2 to P104-1

on the Interface Board and connect

TB101-6 to earth ground.

a. Connect audio pair to TB101-3 and

TB101-4.

b. Remove jumpers from P104 and

P105 on Interface Board.

c. Connect control metallic pair to

TB101-1 and -6 on Interface Board.

a. Connect the transmit metallic pair to

TB101-2 and -5 on Interface Board.

b. Connect a jumper from P104-3 to

P104-2, and P105-3 to P105-2.

c. Connect the remote receive pair to

TB101-3 and -4

ADVANTAGES OR

DISADVANTAGES

Economical: Dependable where earth ground

currents may be large or good earth grounds cannot

be obtained. The keying clicks will be heard on

parallel remotes.

Economical: Minimizes keying clicks in paralleled

remotes but large ground currents may result in

interference with control function if located near

sub-stations.

Provides excellent performance by eliminating

keying clicks and providing no path for ground

loop current, but requires two pair.

Provides full duplex operation in which the remote

can operate in receive and transmit simultaneously.

But, requires two pair.

18

Figure 7 - Typical E & M Signaling Application

Page 20

LBI-38636S

Figure 8 - METHOD 1 (Single Metallic Pair)

Figure 9 - METHOD 2 (Single Metallic, Earth Ground)

19

Page 21

LBI-38636S

Figure 10 - METHOD 3 (Metallic Control Pair, Audio Pair)

20

Figure 11 - METHOD 4 (Full Duplex Metallic TX Pair)

Page 22

LBI-38636S

manufactured. Making your own requires only

three wire connections (Figure 13).

DB9 DB25

Figure 12 - Telephone Line Connections

STATION SETUP

The MASTR III station comes pre-programmed and

ready to install, the only adjustments needed are the

required Line Output Level, the Line Input Level

necessary to produce Standard Deviation, and the Line

Cancellation for 2-wire Tone Remote Orientation. These

adjustments can be made using the PC Programming

option TQ-3353, or Utility PC software TQ-0619 with the

Utility Handset SPK9024.

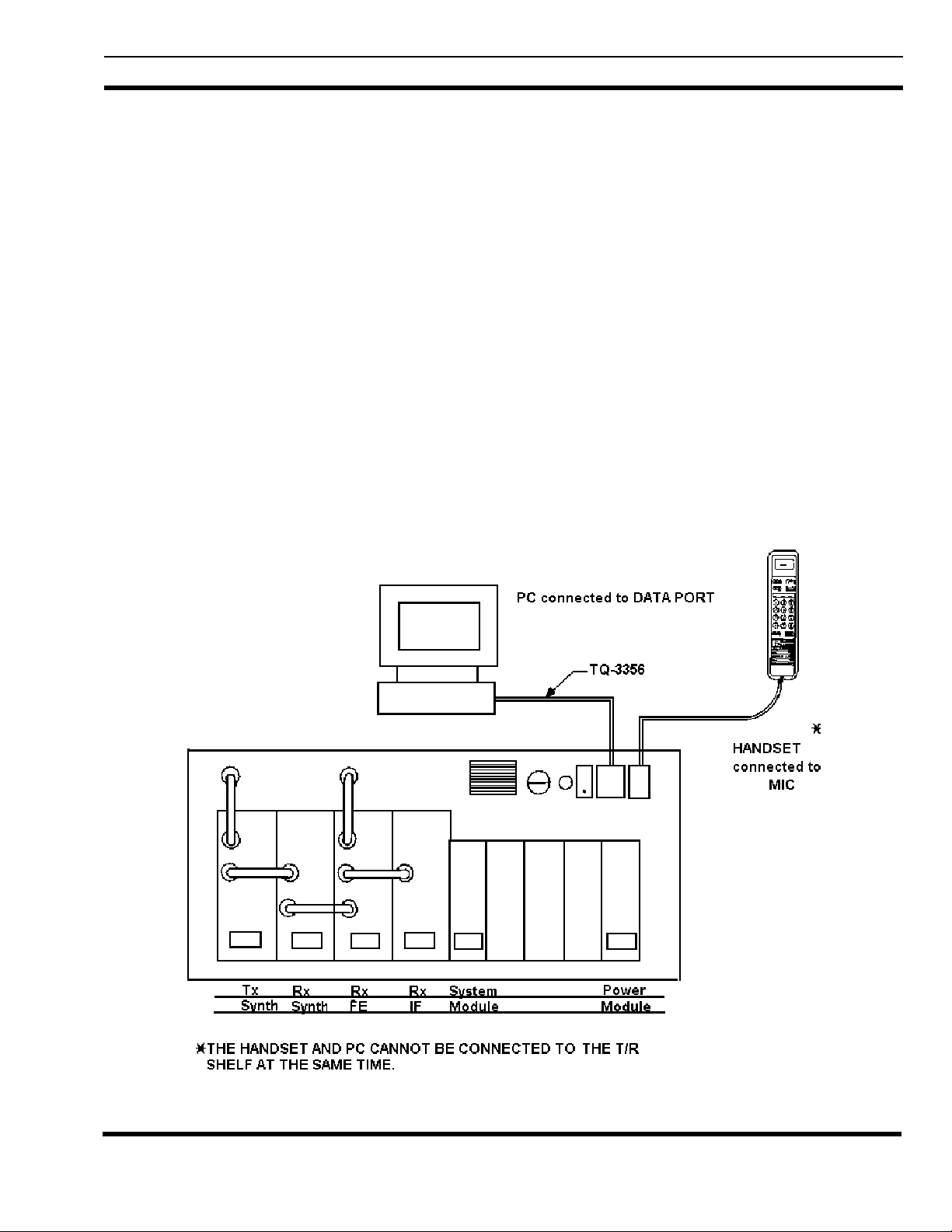

SETUP PROCEDURE

Use the following procedures when setting up the

station using a Personal Computer (PC). If the Utility

Handset is plugged into the MIC connector, it must be

removed prior to resetting the system and using the PC

Programming software. Levels may be adjusted using the

MASTRUTL program supplied with the PC

Programming package. A RESET (on the Power Module)

should be initiated before programming starts.

1. Ensure proper connections are made to receive

and transmit antenna(s). See interconnect

diagram.

2. Plug the power cord from the base station into a

120 Vac, 60 Hz power source.

NOTE

If a 230 volt, 50 Hz source is used, connect the

locally required plug.

3. Connect the PC computer’s serial COM port and

the DATA PORT on the front of the T/R Shelf

using the TQ-3356 Interconnect cable

(19B801348P2).

If the computer has a 25-pin connector instead of

a 9-pin connector, an adapter must be installed.

The adapter may be either purchased or locally

Pin 2

Pin 3

Pin 5

Pin 2

Pin 3

Pin 7

Figure 13 - 3-Wire Adapter

4. If the system requires control by a remote unit,

the following interconnection must be made.

Connect the wires from the remote unit to the

six-pin terminal block (TB101). Use the

following information when making

connections:

TB101, Pins 3,4 - Line Input/Output for 2-wire

DC and Tone control.

or

Line Output for 4-wire DC and Tone control.

TB101, Pins 2,5 - Line Input for 4-wire DC and

Tone control.

TB101, Pins 1,6 - Line Inputs for E & M

signaling, DC Remote Control.

Table 2 - DC Remote Control

P104 P105 COMMENTS

2-wire 1 to 2 1 to 2 Both jumpers back

4-wire 2 to 3 2 to 3 Both jumpers forward

NOTE

P104, Pin 1 and P105, Pin 1 are on the far side

of the connector if you are facing the front of the

base station. Refer to Figures 16 thru 18.

5. The SQUELCH and VOLUME adjustments

should be made for proper operation. Unsquelch

the receiver by turning the SQUELCH

adjustment counter-clockwise. (If your base

station has Channel Guard, also activate the CG

switch.) Verify that unsquelched noise is going

to the speaker by increasing the VOLUME

(clockwise). Adjust the SQUELCH pot for

critical squelch (squelch just closes).

6. Following the initial setup, the MIC port may be

used for one of the following purposes:

a. Connecting the local microphone

equipped with a modular connector.

b. Connecting the multi-purpose Utility

Handset.

21

Page 23

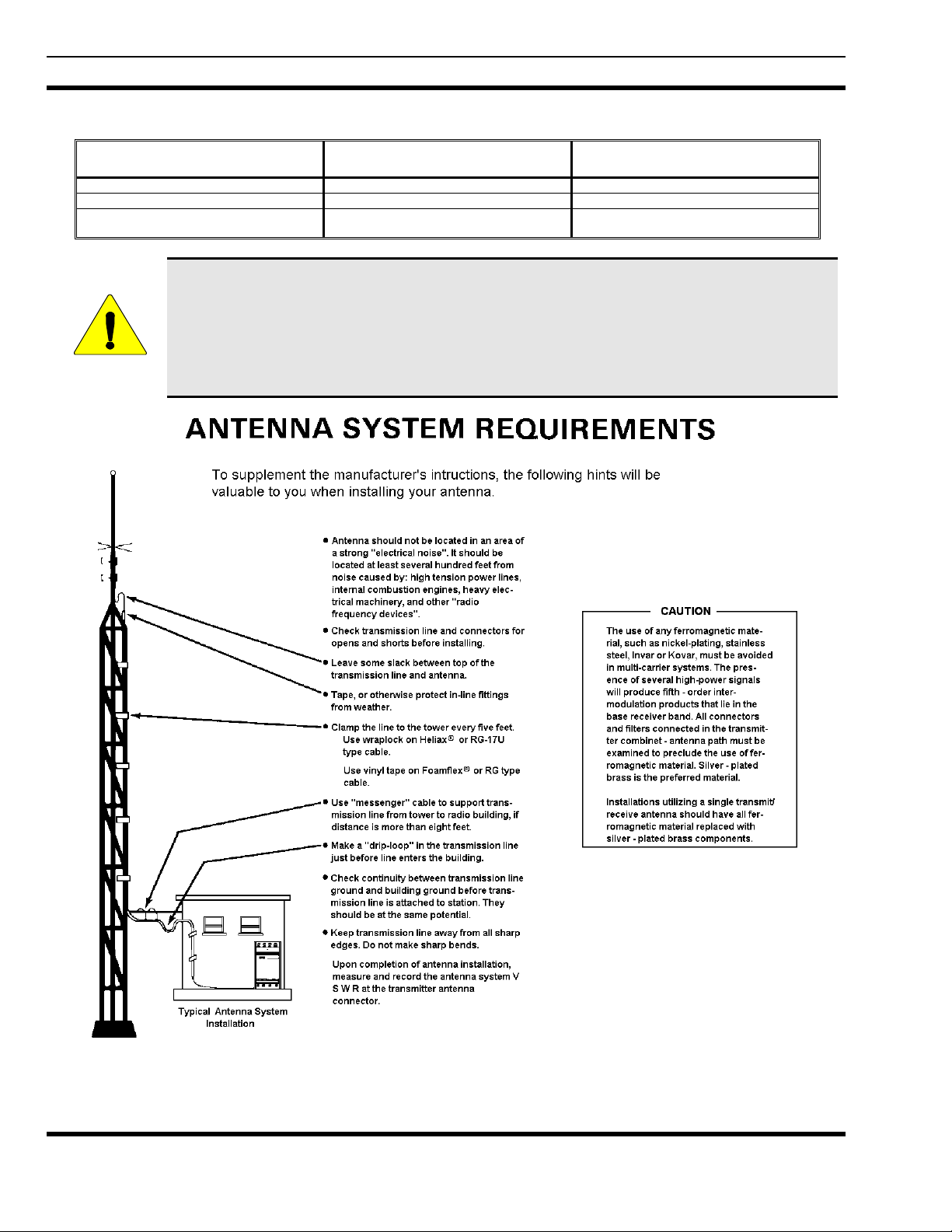

LBI-38636S

Simplex (T/R Relay) N-Type Female Antenna Switch

Duplex (Internal Duplexer) N-Type Female Duplexer

Duplex (External Duplexer) BNC Female (Rx)

Table 3 - Station Connectors

CONFIGURATION

STATION TERMINATING

CONNECTOR

N-Type Female (Tx)

LOCATION

T/R Shelf

Low Pass Filter

TO ENSURE THAT YOUR EXPOSURE TO RF ELECTROMAGNETIC ENERGY IS

WITHIN THE FCC ALLOWABLE LIMITS FOR OCCUPATIONAL USE, ALWAYS

ADHERE TO THE FOLLOWING GUIDELINES:

CAUTION

DO NOT operate the basestation with an antenna that would cause an ERP in excess of that

allowable by the FCC.

22

Figure 14 - Antenna Installation

Page 24

LBI-38636S

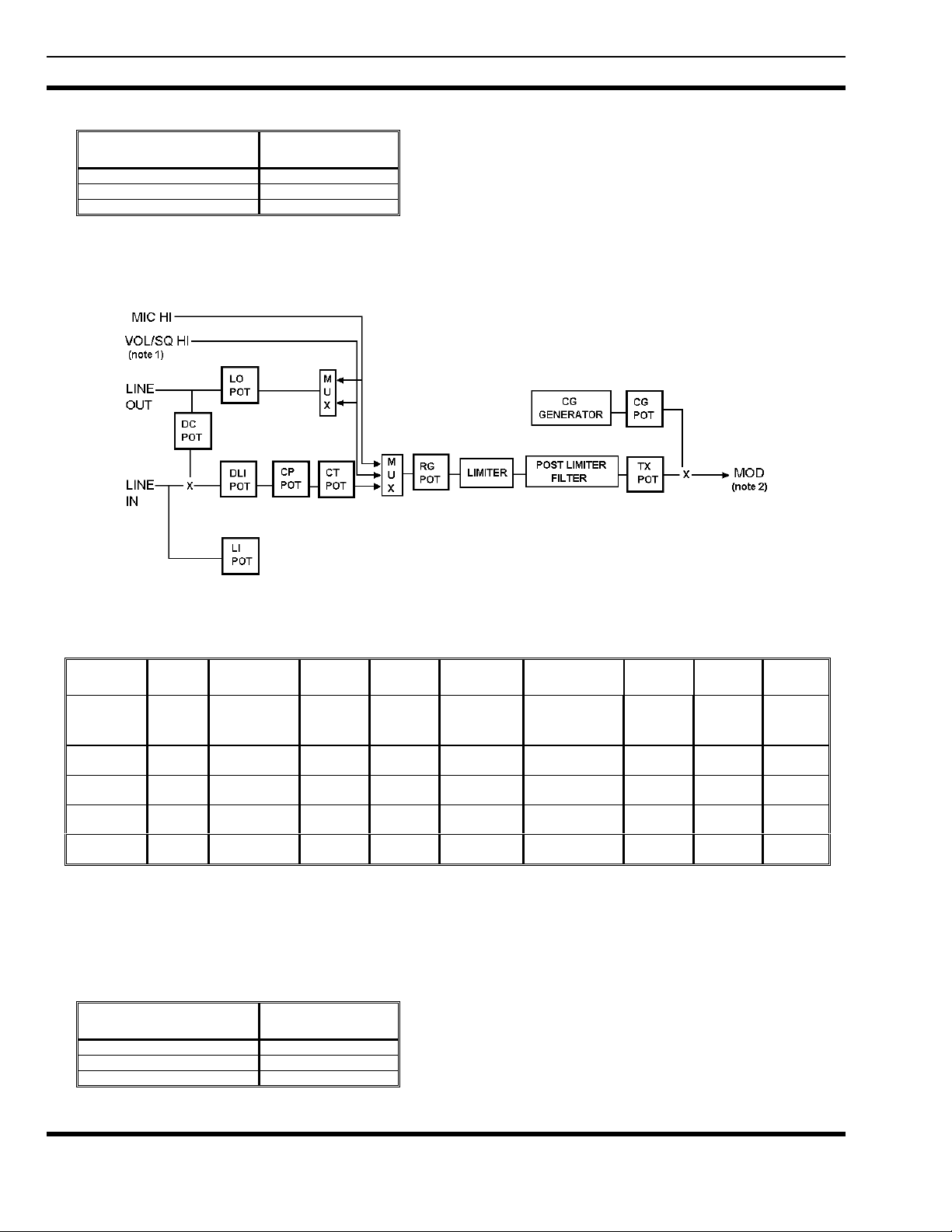

ALIGNMENT PROCEDURE

Alignment of the MASTR III base station was

performed prior to shipment. The factory assumed the

following characteristics:

1. There is no loss or gain for repeated audio

deviation.

2. If a remote exists, it is connected to the base

station through a telephone line with 10 dB of

loss.

3. The base station drives the line output at -10

dBm with nominal receive deviation.

The base station should deliver –10 dBm to the line

with a signal applied with 3kHz deviation. A –10 dBm

audio signal applied to the Station Line In should result in

transmitter deviation of 3 kHz.

These values may be altered by following one of the

alignment procedures as provided. For minor adjustments

you may want to adjust only one or two digital

potentiometers or leave the setting as set. In any case, it is

important to carefully examine the ALIGNMENT

DIAGRAM (Figure 15) which follows:

NOTE

It is a good idea to record the potentiometer

settings on paper, until you’re familiar with all

the digital potentiometer setting tools.

Test Equipment Required

The following test equipment is required to align the

MASTR III base station:

•

Audio Oscillator

•

AC Voltmeter

•

RF Signal Generator

•

Deviation Monitor

•

Handset or PC Computer (with diagnostic utility

TQ-0619)

Procedure

Terminate both the Line Input (T101-3,4) and Line

Output (T101-2,5) with a 600 ohm load. This step must be

completed for all parts of the alignment to ensure proper

level setting (Table 4).

1. Line In

•

Set Line Input digital potentiometer (Pot) LI

to 0.

Table 4 - Normal System Deviation

System Deviation

Standard (25 Hz kHz Bandwidth 3.0 kHz

NPSPAC 2.4 kHz

Narrow (12.5 kHz Bandwidth) 1.5 kHz

2. Channel Guard (GC)

•

If the station is not programmed for CG, set

CG Pot to 0.

For a station programmed with CG encode follow

these steps:

•

Execute a REMOTE PTT on the System

Module by flipping the REM PTT switch

on the front panel.

•

Adjust the CG Pot as needed (Table 5).

Table 5 - Channel Guard Deviation

Channel Guard

Deviation

Standard (25 Hz kHz Bandwidth 0.750 kHz

NPSPAC 0.600 kHz

Narrow (12.5 kHz Bandwidth) 0.500 kHz

•

Repeat for each channel.

Disable CG decode and encode for the

•

remainder of the station alignment.

3. TX Limiter

•

Preset the following digital potentiometer

values:

Repeater Gain (RG) 1023

Compressor Threshold (CT) 5000

Compressor Gain (CP) 1023

DSP Line In (DLI) 100

•

Apply a 1000 Hz tone, at the maximum

system audio level, across the 600 ohm load

termination to the Line Input.

This level is the secur-it level, and is

usually 0 dBm across 600 ohms, (775

mVrms). The "maximum system audio

level" is the absolute highest signal level

that will be present on the line and must be

10 dB higher than average voice audio level.

•

Execute a REMOTE PTT on the System

Module by flipping the REM PTT switch

on the front panel.

•

Adjust the TX Pot to maximum system

deviation (Table 6).

23

Page 25

LBI-38636S

Table 6 - System Deviation

System

Deviation

Standard (25 Hz kHz Bandwidth 3.75 kHz

NPSPAC 3.0 kHz

Narrow (12.5 kHz Bandwidth) 1.75 kHz

Remove the 1000 Hz tone from the Line

•

Input and the REMOTE PTT.

Repeat this step for every channel.

•

4. Repeater Gain

If the station is not a repeater, leave the

•

Repeater Gain pot RG at 1023.

If the station is a repeater, apply an "on

•

channel" RF signal modulated with a 1000

Hz tone at 60% of system deviation to the

receiver.

Adjust RG pot for 60% of system deviation

•

(Table 8).

Figure 15 - MASTR III System Module Pot Alignment

Table 7 - Digital Potentiometer Settings

HANDSET

NUMBER

POT PAGE

(Note 3)

HANDSET

DISPLAY

DEFAULT

VALUES

LO

POT

Line

Out

15 367 2 221

P_1 P_1 P_1 P_1 P_1 P_2 P_3 P_1 P_1

P LO P DC P LI P DI CP CT RG P TX P CG

45 75 (2W)

DC

POT

DSP Line

Cancellations

0 (4W)

LI

POT

Line

In

034 (2W)

DLI

POT

DSP

Line In

28 (4W)

CP

POT

DSP

Compressor

Gain

1023 1890 1023 127

CT

POT

Comp

Threshold

POT

Repeater

Gain

*no Channel Guard

NOTES: 1) VOL/SQ sensitivity: 1000 mV rms = 3 kHz peak deviation (System Module, Pin, B2)

2) MOD sensitivity: 1000 mV rms = 5 kHz peak deviation (System Module, Pin, C3)

3) Refer to Handset manual, LBI-38599, for instructions on page selection.

Table 8 - 60% of System Deviation

Remove the signal from the receiver.

60% of System

Deviation

Standard (25 Hz kHz Bandwidth 3.0 kHz

NPSPAC 2.4 kHz

Narrow (12.5 kHz Bandwidth) 1.5 kHz

•

RG

TX

POT

Transmit Channel

150*

CG

POT

Guard

123

0*

24

Page 26

LBI-38636S

5. Line Input Sensitivity and Compression

•

If not a remote station, set the DSP Line In

DLI Pot to 0.

•

If a remote station, do the following:

Apply a 1 kHz tone at the average voice

audio level across 600 ohms to the line

input. (This level is the function tone level,

and is usually -10 dBm across 600 ohms, or

245 mVrms. This level MUST be 10 dBm

below the "maximum system audio level"

even if your actual secur-it tone and function

tone are at the same level.)

•

Execute a REMOTE PTT on the System

Module by flipping the REM PTT switch on

the front panel.

•

Adjust the DSP Line In DLI Pot for 60% of

maximum system deviation if operating with

compression. (Table 9).

Table 9 - Deviation For Setting Line In Pot With

Compression

Deviation For Setting

Line In Pot With

Compression

Standard (25 Hz kHz Bandwidth 2.8 kHz

NPSPAC 2.2 kHz

Narrow (12.5 kHz Bandwidth) 1.4 kHz

•

If no compression is desired, set DLI pot to

60% of maximum system deviation (Table

8).

•

If compression is desired, adjust the DLI Pot

for 60% of maximum system deviation

(Table 8).

•

Increase the audio input level to the

maximum system audio level. (This level is

the secur-it level, and is usually 0 dBm

across 600 ohms, or 775 mVrms. This level

must be 10 dB higher than the average voice

audio level.)

•

Adjust the Compressor Threshold CT pot for

desired compression deviation level (Table

10).

Table 10 - Deviation For Setting Compressor

Threshold Pot

Deviation For Setting

Line In Pot With

Compression

Standard (25 Hz kHz Bandwidth 4.0 kHz

NPSPAC 3.2 kHz

Narrow (12.5 kHz Bandwidth) 2.0 kHz

6. Line Out

•

If not a remote station, set the Line Out LO

Pot to 0.

•

If the station is a remote station, apply an

"on Channel" RF signal modulated with a 1

kHz tone at 60% of system deviation to the

receiver. (60% of system deviation is

usually 3 kHz.)

•

Adjust the Line Out LO Pot for the desired

output level as measured across 600 ohms.

The line out level must never rise above 7

dBm, as measured across 600 ohms.

•

Re-enable Channel Guard decode.

7. DSP cancellation

•

If the station is a 4 wire station, set the DSP

Line Cancellation DC Pot to 0. If the station

is 2 wire, do the following:

•

Apply a RF signal to the receiver modulated

by a 1000 Hz tone at 60% of rated system

deviation and monitor the remote’s Line

Out. The level of the Line Out should be

between +7 dBm and -19 dBm.

•

Put the System module on an extender card

and meter TP1 on the DSP board. On

stations with Group 6 or later T/R shelf, the

TPI signal can be observed at J5-28A on the

backplane. An oscilloscope may be more

helpful than an analog meter. Adjust the

DSP Cancellation DC Pot for a null at TP1.

8. Tone Remote timing

You must have PC Programmer for base stations,

version 9.0 or later, to affect the timing of Tone

Remote Decoding.

If you have two wire tone remote, do the

following:

•

In the timing screen of the option screen,

ENABLE Timed Tone Remote. The

default values of 100ms and 150ms will

appear for Secur-it minimum time and

Secur-it maximum time. Change these

values as your system requires.

25

Page 27

LBI-38636S

AUDIO ROUTING AND

ADJUSTMENTS

Once the T/R Shelf is installed and programmed

properly, audio level adjustments may be made for proper

system operation. Level adjustments must be made with a

handset (LBI-38599). THERE ARE NO MANUAL

MECHANICAL ADJUSTMENTS IN THE T/R SHELF.

Integrated circuits (IC's) U35 and U36 on the System

Board are dual electronic potentiometers that are

controlled by the microprocessor. IC U15 on the DSP

Board is also a dual electronic potentiometer controlled

by the DSP.

TX AUDIO LEVEL ADJUSTMENT

U36-0 is used to set the transmitter deviation by

adjusting the TX AUDIO output level. Analog switch

U15 selects, which audio source is routed to the

transmitter. Possible sources are LOCAL MIC, REPEAT

AUDIO, DSP LINE/TX AUDIO, DSP TX AUDIO,

EXTERNAL High Speed Data, LINE IN AUDIO, OPEN

(used for Morse code ID), and GROUND (used for no

transmission. A battery alarm tone may also be summed

in with whichever source is selected with the exception of

GROUND.

Normally, LOCAL MIC, REPEAT AUDIO, DSP TX

AUDIO, LINE IN AUDIO, OPEN, or GROUND will be

selected. The gains in the circuitry are set such that 100

mVrms in the MIC HI or 1 Vrms (3 kHz deviation) in on

VOL/SQ HI (REPEAT AUDIO) will produce the same

out-put level on TX AUDIO HI. The gains for Morse

code ID and battery alarm are also designed to provide the

proper levels without adjustments. The TX AUDIO HI

output level should be adjusted with a 100 mVrms, 1 kHz

signal in on MIC HI or a 1 Vrms, 1 kHz signal in on

VOL/SQ HI.

26

Page 28

LBI-38636S

Figure 16 - T/R Shelf Interface Board

27

Page 29

LBI-38636S

28

Figure 17 - T/R Shelf Interface Board (Rev. A)

Page 30

LBI-38636S

Figure 18 - T/R Shelf Interface Board ( Rev. C)

29

Page 31

LBI-38636N

REMOTE CONTROLLER TO STATION

CONTROL PANEL ADJUSTMENTS

Although audio levels should be considered on a

system basis, it is appropriate to set the levels of the

remote controller and the control station panel by

themselves with reference to the levels required by the

transmission path and then connect the controller(s) and

station to the path. The transmission path, if it is more

than just a simple twisted pair, is usually set up with a

"test tone". The "average voice" level is defined as being

a certain number of decibels below the test tone. The test

tone is normally the maximum level that can be sent

through the path without clipping or being regulated.

Although there is no definite agreement on the difference

between the test tone and average voice levels, 10 dB is

an appropriate level.

In order to align the RCN 1000 Remote Controller

and T/R Shelf properly, it will be necessary to have some

information on the transmission path. This will help to

determine the levels at each end required by the system.

Specifications needed include:

1. Loss at 1 kHz

2. Test tone or maximum level

3. Average voice level (if defined)

4. Loss at 2175 Hz (if tone remote)

The DSP Board performs tone detection in a tone

remote installation. The "Secur-it" tone Decoder on this

board has a dynamic range of approximately 9 dB. The

system must be set up such that the "Secur-it" tones from

all remotes in the system arrive at the T/R Shelf within

this 9 dB window.

LINE OUT LEVEL ADJUSTMENT

U36-1 is used to set the line out level. Analog switch

U14 selects which audio source is routed to the line.

Possible sources are LOCAL MIC, VOL/SQ, auxiliary

receiver audio, auxiliary receiver audio summed with

VOL/SQ (simultaneous monitor), DSP LINE/TX

AUDIO, MODEM LINE data, OPEN (used for battery

alarm), GROUND (used for no transmission, and LINE

IN audio (used for four wire loop around). A battery

alarm tone and/or VG ALERT tone may also be summed

in with whichever source is selected with the exception of

GROUND. Typically LOCAL MIC, VOL/SQ, DSP

LINE/TX AUDIO, OPEN, GROUND, or LINE IN

AUDIO will be selected.

The gains in the circuitry are set such that 100

mVrms in on MIC HI or 1 Vrms (3 kHz deviation) in on

VOL/SQ HI (REPEAT AUDIO) will produce the same

line output level. The gains for VG ALERT tone and

battery alarm are also designed to provide the proper

levels without adjustments. The LINE output level should

be adjusted with a 100 mVrms, 1 kHz signal in on MIC

HI or a 1 Vrms, 1 kHz signal in on VOL/SQ HI.

LINE IN LEVEL ADJUSTMENT

Typically, the TX AUDIO and LINE OUT levels

should be adjusted prior to adjusting the LINE IN level.

DSP TX AUDIO and DSP LINE/TX AUDIO are

typically line audio or VOL/SQ HI audio that has been

processed by the DSP Board.

A DSP Board is always present, this DSP processed

line in audio will normally be selected by analog switches

U14 (DSP LINE/TX AUDIO to line out) and U15 (DSP

TX AUDIO to transmit audio) on the System Module

when line in audio is selected. The level for DSP TX

AUDIO and DSP LINE/TX AUDIO must be adjusted on

the DSP Board.

DSP LEVEL ADJUSTMENTS

The LINE IN level into the DSP must be adjusted

using U15-0 (DSP line cancellation level) and U15-1

(DSP line input level) located on the DSP Board. If twowire audio is used then both electronic pots must be