Page 1

Suite 1400

Herndon, VA 20170

http://www.rheintech.com

360 Herndon Parkway

APPENDIX E: INSTALLATION MANUAL

Com-Net Ericsson Critical Radio Systems, Inc. Model: Panther 300M VHF (136-155 MHz)

FCC ID: OWDTR-00011-A 2001056 REV 1 / QRTL01-030 Page 42

FCC and Canadian Certification Report

Page 2

MM101031V2 R1A

P

ANTHER

™

300M VHF

Mobile Radio

Installation Manual

Page 3

NOTICE!

Repairs made to this equipment should be made only by an authorized

service technician or facility designated by the supplier. Any repairs,

alterations, or substitution of recommended parts made by the user to this

equipment not approved by the manufacturer could void the user’s

authority to operate the equipment in addition to the manufacturer’s

warranty.

NOTICE!

The software contained in this device is copyrighted by Com-Net Ericsson

Critical Radio Systems, Inc. Unpublished rights are reserved under the

copyright laws of the United States.

This manual i s published by

warranty. Improvements and changes to this manual necessitated by typographical errors,

inaccurac ies of current informat ion, or improvement s to programs and/or eq uipment, may b e

made by

Such changes will be incorporated into new editions of this manual. No part of this manual

may be reproduced or transmitted in any form or by any means, electronic or mechanical,

including photocopying and recording, for any purpose, without the express written permission

of

Copyright © 2001, Com-Net Ericsson Critical Radio Systems, Inc. All rights reserved.

Com-Net Ericsson Critical Radio Systems, Inc.

Com-Net Ericsson Critical Radio Systems, Inc.

Com-Net Ericsson Critical Radio Systems, Inc.

, at any time and without n otice.

, without any

2

Page 4

TABLE OF CONTENTS

Page

SAFETY INFORMATION...................................................................4

SAFETY TRAINING INFORMATION..............................................5

INTRODUCTION .................................................................................7

UNPACK AND CHECK THE EQUIPMENT....................................7

OPTIONS AND ACCESSORIES ........................................................8

INSTALLATION...................................................................................9

STEP 1 - PLAN THE INSTALLATION.............................................9

STEP 2 - LOCATE THE TOOLS REQUIRED...................................9

STEP 3 – EQUIPMENT PREPARATION........................................10

STEP 4 – PROGRAM THE RADIO .................................................15

STEP 5 – INSTALL CABLES...........................................................16

STEP 6 – INSTALL OPTIONS AND ACCESSORIES....................22

FIGURES

Figure 1 – Typical Connection Diagram................................................11

Figure 2 – Removing Top Cover ...........................................................12

Figure 3 – Factory Default Internal Speaker Jumper Setting (Enabled) 13

Figure 4 – Factory Default Settings For Jumper JP600.........................14

Figure 5 – Removing Plastic Cover.......................................................15

Figure 6 – Power Cable RPM 113 7674/10...........................................17

Figure 7 – Mounting Bracket and Mounting Bracket Hardware Kit......20

Figure 8 – Mounting Bracket Installation..............................................21

Figure 9 – Mounting Radio to Bracket..................................................22

Figure 10 - Mounting the External Speaker...........................................25

Figure 11 – External Speaker Option.....................................................26

Figure 12 – Internal/External Speaker Relay.........................................27

Figure 13 - External Car Alert...............................................................29

Figure 14 - External Alarm Relay..........................................................29

Figure 15 – Ignition Sense Option.........................................................30

TABLES

Table 1 - P

ANTHER

300M Mobile Radio Options and Accessories.........8

Table 2 – Radio Option Connector P3 Interface Description ................23

3

Page 5

SAFETY INFORMATION

The operator of any mobile radio should be aware of certain hazards

common to the operation of vehicular radio transmissions.

possible hazards is given:

A list of several

1.

Explosive Atmospheres

the motor running, similar hazards exist when operating a mobile radio,

be sure to turn the radio off while fueling the vehicle. Do not carry

containers of fuel in the trunk of the vehicle if the radio is mounted in

the trunk.

2.

Interference to Vehicular Electronics Systems

injection systems, electronic anti-skid braking systems, electronic

cruise control systems, etc., are typical electronic systems that may

malfunction due to the lack of protection from radio frequency energy

present when transmitting. If the vehicle contains such equipment,

consult the dealer and enlist their aid in determining the expected

performance of electronic circuits when the radio is transmitting.

3.

Dynamite Blasting Caps

explode by operating a radio within 500 feet of the blasting caps.

Always obey the

dynamite is being used.

When transporting blasting caps in your vehicle:

a. Carry the blasting caps in a closed metal box with a soft lining.

"Turn Off Two-Way Radios"

- Just as it is dangerous to fuel a vehicle with

- Electronic fuel

- Dynamite blasting caps may be caused to

signs posted where

b. Leave the radio OFF whenever the blasting caps are being put into

or removed from the vehicle.

4.

Liquefied Petroleum (LP) Gas Powered Vehicles

installations in vehicles powered by liquefied petroleum gas with the

LP gas container in the trunk or other sealed-off space within the

interior of the vehicle must conform to the National Fire Protection

Association standard (NFPA) 58 requiring:

a. The space containing the radio equipment shall be isolated by a

seal from the space containing the LP gas container and its fittings.

b. Outside filling connections shall be used for the LP gas container.

c. The LP gas container shall be vented to the outside of the vehicle.

- Mobile radio

4

Page 6

SAFETY TRAINING INFORMATION

Your Com-Net Ericsson radio generates RF

electromagnetic energy during transmit mode. This radio

is designed for and classified as “Occupational Use Only,”

meaning it must be used only during the course of

employment by individuals aware of the hazards and the

WARNING

This radio has been tested and complies with the FCC RF exposure limits

for “Occupational Use Only.” In addition, your Com-Net Ericsson radio

complies with the following Standards and Guidelines with regard to RF

energy and electromagnetic energy levels and evaluation of such levels for

exposure to humans:

•

FCC OET Bulletin 65 Edition 97-01 Supplement C, Evaluating

Compliance with FCC Guidelines for Human Exposure to Radio

Frequency E l ectromagnetic Fields.

ways to minimize such hazards. This radio is NOT

intended for use by the “General Population” in an

uncontrolled environment.

•

American National Standards Institute (C95.1 – 1992), IEEE Standard

for Safety Level s wit h Re sp e ct to Hu ma n E xp osur e to Ra di o Fr eq ue nc y

Electromagnetic Fields, 3 kHz to 300 GHz.

•

American National Standards Institute (C95.3 – 1992), IEEE

Recommended Practice for the Measurement of Potentially Hazardous

Electromagnetic Fields – RF and Microwave.

To ensure that your exposure to RF electromagnetic

energy is within the FCC allowable limits for

occupational use, always adhere to the following

CAUTION

•

DO NOT operate the radio without a proper antenna attached, as this

guidelines:

may damage the radio, and may also cause you to exceed FCC RF

exposure limits. A proper antenna is the antenna supplied with this

radio or an antenna specifically authorized by Com-Net Ericsson for

use with this radio.

•

DO NOT transmit for more than 50% of total radio use time (50% duty

cycle). Transmitting more than 50% of the time can cause FCC RF

exposure compliance requirements to be exceeded. The radio is

transmitting when the “TX” LED in the radio’s display is illuminated.

5

Page 7

Pressing the “PTT” button on the microphone will cause the radio to

transmit.

•

ALWAYS use Com-Net Ericsson authorized accessories (antennas,

speaker/mics, etc.). Use of unauthorized accessories may cause the

FCC Occupational/Controlled Exposure RF compliance requirements

to be exceeded.

•

ALWAYS keep at least 25 cm (10 inches) between the antenna and

user/bystanders while transmitting. This radio has been tested and

found to be compliant with Specific Absorption Rate (SAR) limits for

uncontrolled exposure at a distance of 25 cm (10 inches) or more using

a 50% duty cycle.

The information listed above is provided to make the user aware of an RF

exposure and what to do to assure that this radio operates within the FCC

RF exposure limits of this radio.

6

Page 8

INTRODUCTION

The P

ANTHER™

300M mobile radio is designed for installation as a front

mount radio. This manual provides the mobile installation instructions and

includes the instructions to install the external horn or external speaker

options.

UNPACK AND CHECK THE EQUIPMENT

Carefully unpack the equipment and verify the items listed below are

included in the shipping container. If damage has occurred to the

equipment during shipment, file a claim with the carrier immediately.

Table 1 on page 8 provides a complete list of the options and accessories

available for the P

ANTHER

P

•

P

•

Power Cable.......................................................RPM 113 7674/10

•

Mounting Bracket..............................................KG6903

•

Mounting Bracket Hardware Kit.......................52B6032

300M Radios Are Shipped With The Following:

ANTHER

ANTHER

300M mobile radio.

300M Mobile Radio..........................KRD 103 154/(1-7)

•

Operator's Manual..............................................MM101030V1

•

Installation Manual............................................MM101031V1

7

Page 9

OPTIONS AND ACCESSORIES

The following table lists the options and accessories available for the

Panther 300M Mobile Radio.

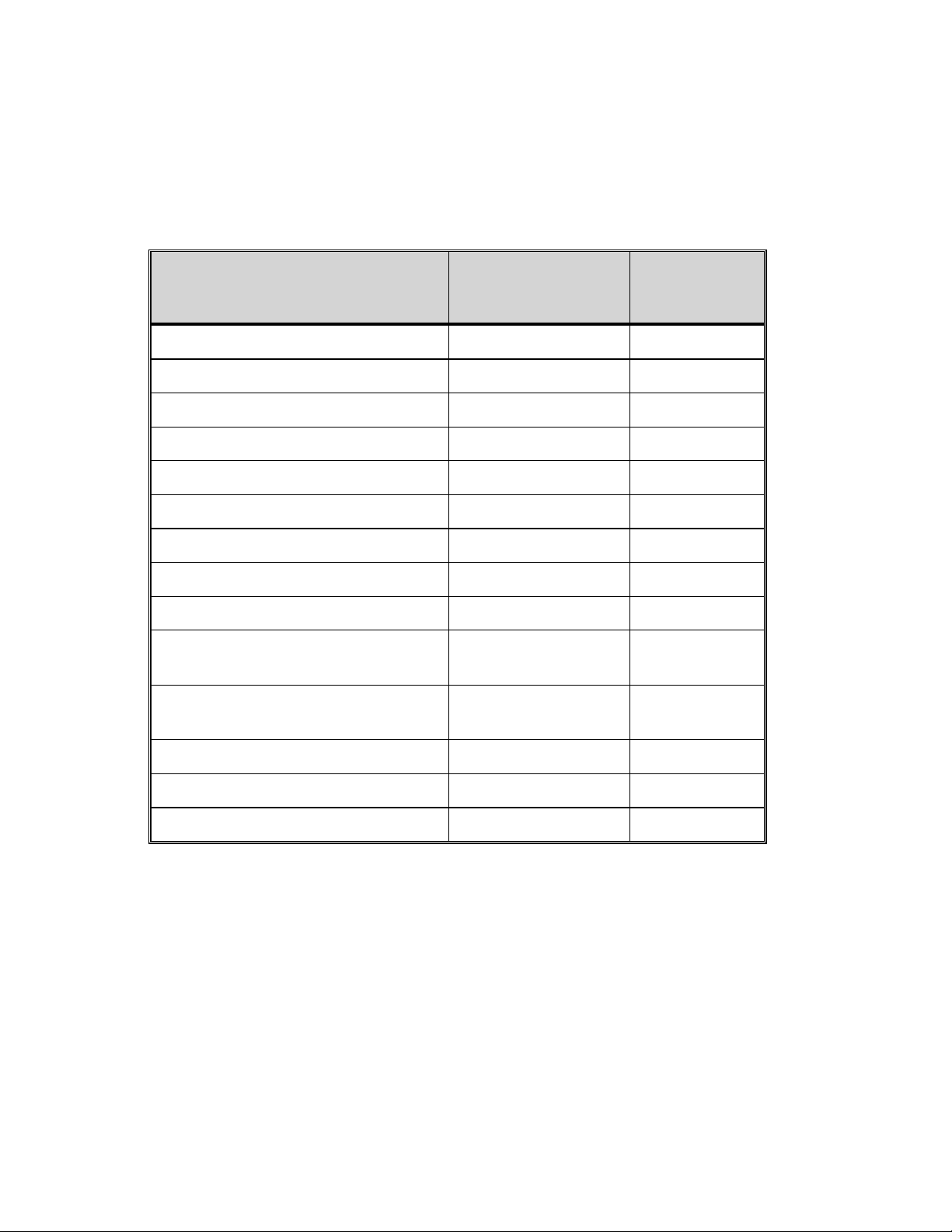

Table 1 - P

ANTHER

300M Mobile Radio Options and Accessories

DESCRIPTION PART NUMBER OPTION

NUMBER

Microphone, Standard KRY 101 1654/1 KAMC7J

Microphone, DTMF

Microphone Hanger 344A4678P1 KAMN1A

External Speaker (4 ohm, 10W) 19A149590P11 KALS1H

Option Cable RPM 113 7674/1 KACJ7G

External Relay Kit 19A705499P1 KASU1C

Noise Suppression Kit 19A148539G1 KAPD1A

Power Cable RPM 113 7674/10 KACJ7H

Audio Test Cable RPM 113 2472/48

Conventional ProGrammer SoftwareorAE/LZY 213 766/5 TQ3389 R9A

KRY 101 1654/10 KAMC7K

or later

ProGrammer Software AE/LZY 213 766/1 TQ3385 R9A

or later

Radio Programming Interface Cable RPM 113 2472/47 TQ3393

Copy CatTM Cable, 300M-to-300M RPM 113 2472/42 TQ3394

Copy CatTM Cable, 300M-to-300P RPM 113 2472/41 TQ3395

8

Page 10

INSTALLATION

STEP 1 - PLAN THE INSTALLATION

Figure 1 shows an example of a typical connection diagram. Before

beginning, plan the radio installation carefully so that it will:

¾

Be safe for the operator and passengers,

¾

Be convenient for the operator to use,

¾

Be neat in appearance,

¾

Be protected from water damage,

¾

Be easy to service,

¾

Be out of the way of auto mechanics,

¾

Be out of the way of passengers, and

¾

Allow for good air flow around the unit’s cooling fins.

For passenger safety, mount the radio securely so the unit will not break

loose in the event of a collision. This is especially important in station

wagons, vans and similar type installations where a loose radio could be

extremely dangerous to the vehicle occupants.

The procedures in this section provide a guideline for installing the mobile

radio. In some applications, it may be necessary to deviate slightly from the

recommended procedure and the order in which the equipment is installed.

To assure the feasibility of the cable routes you p lan to use, it is suggested

that you run the cables before installing the radio. Be sure to leave some

slack in each cable so that the radio may be pulled out for servicing with the

power applied.

It is recommended the unit be installed by one of the many Com-Net

Ericsson Authorized Service Centers located throughout the United States.

Personnel at these centers are experienced in installations of this type and

can provide a safe, neat, and functional installation.

STEP 2 - LOCATE THE TOOLS R EQUIRED

The following tools are required to install the P

ANTHER

300M Mobile

Radio:

•

Electric drill for drilling mounting holes

•

Drills and circle cutters as follows:

¾

No. 31 (1/8-inch) drill

9

Page 11

¾

1/2-inch drill or circle cutter

¾

3/4-inch circle cutter, hole saw or socket punch

•

Phillips and flat-blade screwdrivers

•

No. 10 Torx driver

Torx is a registered trademark of CAMCAR Division TEXTRON, Inc.

STEP 3 – EQUIPMENT PREPARATIO N

Mounting

This section describes the radio preparation for installation. In most

applications, the following procedures should be completed before the radio

is mounted. Depending upon the mounting location, these procedures could

become very difficult after the radio is mounted. The preparation list

includes:

•

Configuring the Internal Speaker Jumper

•

Configuring the Ignition Sense Line Jumper

•

Connecting the Option Cable to the Radio

Read through the procedures provided in this section. If you are satisfied

with the default factory jumper settings and your installation does not

require an option cable, skip this section and go to STEP 4 – PROGRAM

THE RADIO on page 15.

Removing the Top Cover and Shield

The top cover and shield must be removed to change the Internal Speaker

jumper (JP701) or the ignition sense line jumper (JP600), to connect the

option cable to the radio.

1. The top cover is secured with three screws from the bottom of the

radio. Using a No. 10 Torx driver, loosen the three screws on the

top of the radio as shown in Figure 2.

2. Remove the two control knobs from the front of the radio.

3. Pry the cover loose from the two tabs on the bottom of the radio.

10

Page 12

Figure 1 – Typical Connection Diagram

11

Page 13

4. Remove the top cover by lifting the back and slid ing it forward away

from the chassis.

12

Figure 2 – Removing Top Cover

Page 14

Figure 3 – Factory Default Internal Speaker Jumper Setting (Enabled)

Configure the Internal Radio Speaker Jumper (JP701)

The P

ANTHER

300M radio is shipped from the factory with the internal

radio speaker jumper (JP701) set to 1-2 as shown in Figure 3. This setting

enables the internal radio speaker. Set the jumper to 2-3 if 1) only the

External Speaker is to be enabled or 2) the Internal/External Sp eaker option

is to be enabled.

Configure Ignition Sense Jumper (JP600)

The Ignition Sense line enables or disables transmit or car horn alert option

through the vehicle ignition switch. If the Ignition Sense option is desired,

Ignition Sense jumper JP600 must be set to 2-3. The P

ANTHER

300M radio

is shipped from the factory with the Ignition Sense jumper (JP600) set to 12 as shown in Figure 4. This default setting disables the Ignition Sense

option. If your installation will not take advantage of the Ignition Sense

line, skip this section and proceed to the next section.

To use the Ignition Sense line in any application, the option cable must be

13

Page 15

wired accordingly, see the section Connect To Ignition Sense on page 17.

There are three parameters that define how the Ignition Sense feature will

operate - a jumper on the radio (as described above), and two programmable

parameters in the personality.

The programmable parameters enable/disable Transmission and/or Horn

Alert with respect to the vehicle ignition switch. For more information on

the personality parameters, see the On-Line Help in Conventional

ProGrammer (TQ-3389 R9A or later) or ProGrammer (TQ-3385 R9A or

later).

14

Figure 4 – Factory Default Settings For Jumper JP600

Page 16

Connect Option Cable

This section applies to installations that require an option cable. The option

cable (RPM 113 7674/1) is required if you are installing:

•

External Speaker

•

Car Horn Alert

•

External Modulation

•

Internal/External Speaker Option

•

Ignition Se nse

•

External Demodulation

To connect the option cable to the radio:

1. Remove the two Phillips screws holding the plastic cover in place, from

the back of the radio, see Figure 5.

Figure 5 – Removing Plastic Cover

2. Insert the option cable through the hole left by removing the plastic

cover. This will allow the connector to fit through the hole in the back

of the radio.

3. Plug the option cable connector into J3 on the radio circuit board.

4. Finally, attach cable with the two Phillips scre ws.

STEP 4 – PROGRAM THE RADIO

All radios must be programmed with a radio personality. There are many

parameters in the P

ANTHER

300M mobile radio that need to be setup and

defined for the radio to operate appropriately for each application.

Conventional ProGrammer (TQ-3389 R9A or later) or ProGrammer (TQ3385 R9A or later) is the software used to create the personality for the

ANTHER

P

300M radio. The radio personality is a computer file that defines

all the operating parameters for the radio. For more information on

programming the P

ANTHER

300M radio, see the On-Line Help provided

with Conventional ProGrammer (TQ-3389 R9A or later) or ProGrammer

(TQ-3385 R9A or later). Typically, the radio is programmed before it is

installed in a vehicle.

15

Page 17

STEP 5 – INSTALL CABLES

The P

ANTHER

300M Mobile Radio is installed as a front mount radio. The

location of the mount, the application, and the options to be installed should

be considered when planning the cable runs. The cable diagram in Figure 1

should be referenced throughout the installation process.

Power Cable

The power cable RPM 113 7674/10 consists of a two-wire cable, see Figure

6. The red fused lead supplies power to the radio directly from the vehicle

battery. Ignition Sense lead, through the separate option cable, is used by

the radio electronics to determine when the ignition switch is turned on.

The black lead is the radio ground connection.

To install the power cable:

1. Remove the fuse from the power cable.

2. When the power cable is wired directly to the vehicle’s battery, it is

necessary to route the red power lead through the vehicle’s firewall. If

an existing hole is not conveniently located in the firewall, drill a 1/2inch hole in the firewall for the cable run and insert a rubber grommet.

This grommet is required to prevent lead chaffing. Additional

grommets may be required if the leads must pass through shields or

guards in the engine compartment.

16

Page 18

Figure 6 – Power Cable RPM 113 7674/10

Route the lead away from high heat sources in the engine compartment

that may cause lead damage and introduce a fire hazard. In addition, the

lead should not be routed near electrical noise sources such as

electronic ignition modules or cruise control modules.

3. Secure the cable at several locations within the engine compartment to

prevent possible damage to the cable.

4. Connect the BLACK lead to the vehicle chassis. Connect the lead as

close to the radio as possible. DO NOT connect the BLACK lead to

the “NEG” or “-“ battery post. Connect the RED lead to the positive

(“POS” or “+”) battery post. See Figure 6.

The power source must have a minimum current supply

NOTE

capability of 13 amps.

17

Page 19

Connect To Ignition Sense

The ignition sense line is used to enable or disable transmit or the Car Horn

Alert option through the vehicle ignition switch. For a detailed description

on how to configure the Ignition Sense line, see the section Configure

Ignition Sense Jumper on pa ge 13. Rega rdless of how t he ignitio n sense

line is configured, the option cable must be wired as described below for the

feature to work.

Connect Pin 13 of the option cable to an ignition “ON” sense point

(preferably an “Accessory” point in the vehicle fuse panel) that is switched

on when the vehicle ignition switch is in the ACCESSORY and RUN

positions. This lead should be connected so the vehicle fuse protection is

used. See Figure 6.

The DB-25 male connector that connects to the option cable is

NOTE

user-supplied.

18

Page 20

CAUTION

The “Accessory” point should drop to ZERO volts when

cranking the engine and return to +12 volts after the

engine is started. If a point is chosen that drops to a

voltage between zero and +12 volts, the radio may

execute a power-up cycle several times during start up. It

is recommended that the terminal be measured with a

voltmeter to be sure it shuts OFF (goes to zero volts)

during the cranking of the engine.

Certain problems may be encountered when accessory

equipment is connected to the ignition or accessor y lines

of the vehicle, where these lines may have large filter

capacitors and a leakage path present. If the radio does

not turn OFF within a reasonable amount of time after the

ignition is turned off, first try a different accessory or

ignition A+ pick up point in the vehicle. Many vehicles

have more than one circuit that is switched by the ignition

switch, and one may be available that does not have large

filter capacitors or a leakage path present.

If a different pickup point cannot be found, then add a

470-ohm, 1-watt resistor from the ignition A+ pick point

to ground. This will discharge the capacitor(s) or reduce

the leakage voltage to a low value. Current drain through

this resistor will be minimal (less than 0.03A) when the

ignition is switched ON.

19

Page 21

Figure 7 – Mounting Bracket and Mounting Bracket Hardware Kit

Radio Mounting Procedures

The following procedures are used to mount the radio.

1. Using the bracket as a template, mark and drill the mounting holes

using a No. 31 (1/8) drill bit. Be sure to leave enough room at the rear

of the radio unit for the cable connections and airflow.

Be careful to avoid damaging some vital part (fuel tank,

transmission housing, etc.) of the vehicle when drilling

mounting holes. Always check to see how far the

mounting screws will extend below the mounting surface

before installing.

CAUTION

If pilot holes must be d rilled, remove all metal shavings

from drilling holes before installing scre ws.

2. Mount the bracket using the four 3/4” Phillips sheet metal screws and

spacers provided in the mounting bracket hardware kit. (Refer to

Figure 8.)

20

Page 22

Figure 8 – Mounting Bracket Installation

3. Place the radio into the mounting bracket and secure with the four 3/8”

Phillip’s screws supplied. The radio can be fastened in any of three

different positions: parallel to the mounting surface or tilted slightly

from the parallel position. (Refer to Figure 9.)

4. Connect antenna coaxial cable to antenna connector (TNC).

5. Insert power cable into power connector running from rear of radio unit

and push until the connectors snap together.

6. Recheck all connections and then reinsert fuse into the fuse assembly

on the power cable.

21

Page 23

Figure 9 – Mounting Radio to Bracket

STEP 6 – INSTALL OPTIONS AND ACCESSORIES

Radio Option Cable

The radio option cable (RPM 113 7674/1) is required if you are installing:

•

External Speaker

•

Car Horn Alert

•

External Modulation

•

Internal/External Speaker Option

•

Ignition Se nse

•

External Demodulation

The section STEP 3 – EQUIPMENT PREPARATION, on page 10,

describes how to connect the option cable to the radio. The other end of the

option cable consists of a standard female DB-25 connector, which is used

to connect to the optional accessories listed above. Table 2 provides a

description for each input and output on the radio option connector J603.

22

Page 24

Table 2 – Radio Option Connector P3 Interface Description

DB-25

PIN

NO

PIN

NO

(P3)

I/O DESCRIPTION

(J100)

2 1 ---

52I

63O

18 4 O

19 5 I

76I

20 7 O

88I

21 9 I

910O

22 11 ---

Ground:

Audio Ground

Internal Speaker Input #1:

5W across Internal Speaker

Audio Amp Output #1:

Vo ≈ 6.6 VDC

Audio Amp Output #2

Vo ≈ 6.6 VDC; 10W maximum across Ext ernal Speaker

External Mic Input:

300- 3000 Hz

Input level @ 1kHz for 60% of RSD: 82 ± 28 mV

(if external audio source has Ro=600Ω)

Input level @ 1kHz for 60% of RSD: 41 ± 14 m V

(if external audio source has Ro<1Ω)

External Mod Input:

5-10,000 Hz (3 db BW)

Modu lation-Sensitivity: 4.2 kH z/Vrms ± 3dB

Switched DC Output:

Icc=500 mA Max

Push To Talk:

TX ON: Low

TX O FF: Open

Mic Hookswitch:

“Disable” or “Enable” is selected by PC Programmer

Hookswitc h ON: Low

Hookswitc h OFF: Open

Rx Discriminator Detect Audio:

20-4,000 Hz (3 dB Bandwidth)

75 m V

Ground

±3 dB into a 10K ohm load

RMS

to Internal or External Speaker

RMS

RMS

10 12 I

23 13 O

11 14

Internal Mic Mute:

Mute ON: Low

Mute OFF: Open

Radio UnSquelch:

Squ elch Open: Low

Squ elch Close: High

RL = 4.7 kohms

Spare

23

Page 25

Table 2 - Radio Option Connector P3 Interface Description Cont’d

DB-25

PIN NO

PIN NO

(P3)

(J100)

24 15 O

I/O DESCRIPTION

(1) HORN CONTROL At Signaling Mode

Display In Menu Action

On Enable

Off Disable

When select “ON”(enable) and a correct T99 Individual Call

is received , the output of pi n 15 is “low.”

Horn Alarm ON : Low

Horn Alarm OFF: Open

(2) SPEAKER SELECT INTERNAL/EXTERNAL

Enab lin g or di sab lin g of th e Intern al/ E xtern a l Speak er op ti on

is done by proper setting of an internal jumper in the mobile

radio.

Intern a l: Low

External: Open

For relay control Io_max = 150mA

12 16 I

25 17 O

13 18 I

Internal Mic Mute (DB25-10) must be grounded when

applying audio to external Mic Input (DB25-19).

External Mic Input (DB25-19) has the same audio

NOTE

characteristics as the Front Panel Mic Jack. External Mod

Input (DB25-7) has no pre-emphasis or modulation limiting.

**“HORN CONTROL” or “SPEAKER SELECT” is

selected by PC ProGrammer.

Note

: Internal and external speaker do not operate

simultaneously.

Data Communication Input (Test Mode)

TTL Lev e l

Data Communication Output (Test Mode)

TTL Lev e l

Ignition Sense

13.6VDC

Io_max = 100 mA

24

Page 26

External Speaker – 19A149590P11

The external speaker kit includes a 4-ohm, 10 Watt rated speaker and a

radio option cable. To connect an external speaker, the radio option cable

(RPM 113 7674/1) must be installed and connected to the radio.

1. Mount the speaker so it is directed at the operato r but d oes not interfere

with the operator’s vision. It also should not present a hazard in the

event of an accident. The speaker may be mounted on the lower edge of

the instrument panel, the firewall, or above the windshield in some

trucks.

2. Use the mounting bracket as a template for locating the mounting

holes, and mount the speaker as shown in Figure 10.

3. Refer to Figure 9 for instructions on connecting the External Speaker

option and Figure 10 for instructions on connecting the

Internal/External Speaker option.

Figure 10 -

MOUNTING

BRACKET

FLAT WASHER

LOCK WASHER

MACHINE

SCREW

Mounting the External Speaker

25

Page 27

AUDIO IN

RADIO AUDIO

AMP

uP PORT

JUMPER POSITIONS

1-2 USED WHEN THERE IS NO

EXTERNAL SPEAKER OPTION

2-3 USED WHEN THERE IS AN

EXTERNAL SPEAKER OPTION

SPKR 2

INTERNAL

SPEAKER

SPKR 1 1

-

+

SPKR 2

SPKR 1

OPEN COLLECTOR

TRANSISTOR

3 PIN

JUMPER

INT SPKR 1

300M RADIO

8 OHM

5 WATT

2

3

SPKR 2 4

INT SPKR 1 2

SPKR 1 3

HORN/SPKR 15

PANTHER 300M EXTERNAL

SPEAKER OPTION

WHEN THE EXTERNAL SPEAKER OPTION IS APPLIED,

AUDIO FROM THE SPEAKER AMP LEAVES THE RADIO

ON OPTION CONNECTOR PINS 3 AND 4 AND GOES TO

J101. THE EXTERNAL SPEAKER'S CABLE IS

CONNECTED TO J101.

INT

EXT

P3 J100

4

2

3

15

RADIO

CONNECTOR

J101

RPM 113 7674/1

OPTION CABLE

SPKR 1

SPKR 2

DB 25

CONNECTOR

4 OHM

10 WATT

18

5

6

24

Figure 11 –

External Speaker Option

26

Page 28

Figure 12 – Internal/

JUMPER POSITIONS

1-2 US ED WHEN THER E IS NO INTERN AL/

EXTERNAL SPEAKER OPTION

2-3 US ED WHEN THER E IS AN INTERNAL/

EXTERNAL SPEAKER OPTION

PANTHER 300M INTERN AL/EX TERNAL

(THIS SCHEMATIC ALSO APPLIES TO PUBLIC ADDRESS)

WHEN THE INTERNAL/EXTERNAL SPEAKER OR PUBLIC ADDRESS OPTIONS ARE APPLIED. AUDIO FROM THE SPEAKER AMP

LEAVES THE RADIO ON OPTION CONNECTOR PIN 3 AND GOES TO THE COMMON SIDE OF AN SPDT RELAY.

WHEN INTERNAL SPEAKER IS SELECTED, THE RELAY FLOATS. THE NORMALLY CLOSED RELAY CONTACT APPLIES AUDIO

BACK INTO THE RADIO TO THE INTERNAL SPEAKER ON OPTION CONNECTOR PIN 2. (IT IS ASSUMED THE INTERNAL 3-PIN

JUMPER IS ON PINS 2 & 3.)

SPEAKER OPTION

SPKR 2

8 OHM

5 WATT

WHEN THE EXTERNAL SPEAKER IS SELECTED, THE RELAY IS ENGAGED. AUDIO IS APPLIED TO THE NORMALLY OPEN

CONTACT THAT THEN CONNECTS TO THE EXTERNAL SPEAKER.

ONLY THE SPKR_1 SIDE OF THE AUDIO AMP'S OUTPUT IS SWITCHED. THE SPKR_2 SIDE OF THE AUDIO AMP IS

INTERNAL

SPEAKER

SPKR 1 1

External Speaker Relay

SPKR 2

2

3

3 PIN

CONNECTED TO BOTH SPEAKERS.

OUR SPEAKER RELAY KIT INCLUDES THE 19A149299P1 RELAY, WIRE, AND A FUSE. THE CUSTOMER IS RESPONSIBLE FOR

INSTALLING AND PROVIDING POWER TO T HE RELAY.

INT

EXT

JUMPER

AUDIO IN

-

+

INT SPKR 1

EXT SPEAKER AUDIO

P3 J100

RPM 113 7674/1

SPKR 2

EXTERNAL

SPEAKER

4 OHM

10 WATT

OPTION CABLE

RADIO AUDIO

AMP

uP PORT

SPKR 1

OPEN COLLECTOR

TRANSISTOR

SPKR 2 4

INT SPKR 1 2

SPKR 1 3

HORN/SPKR 15

4

2

3

15

RADIO

CONNECTOR

DB 25

CONNECTOR

18

AUDIO OUT (SPK R_ 2 SID E OF A UDIO A MP)

5

INTERNAL AUDIO BA CK INTO RA DIO

6

AUDIO OUT (S PK R_1 S IDE OF A UD IO AMP)

24

RELAY CON TROL LINE

(LOW FOR EXTERNAL SP EA KE R)

NO

COM

NO

SPDT RE LA Y

(19A149299P1)

SPEAKER RELAY

FUSE

1A

BATTERY A+

OR

IGNITION A+

300M RADIO

Page 29

Alarm (Horn) Relay Kit - 19A705499P1

To connect the alarm relay kit, the radio option cable (RPM 113 7674/1)

must be installed and connected to the radio. The alarm relay kit option

consists of the following items:

•

Relay (19A149299P1)

•

Fuse holder

•

Fuse, 1 amp, 250 volt

•

4 feet red wire, AWG #18 with Ring Tongue Terminal for 3/ 8 stud

•

6 feet black wire, AWG #18 with Molex #39- 00- 0060 terminal

•

(5) Insulated 1/ 4 inch spade tab receptacles

•

Ring Tongue Terminal for 3/ 8 inch stud

•

#8 x 3/ 4 long Type A sheet metal screw

•

Nut Plate for #8 screw

To install the Alarm (Horn) Relay Kit

1. Fasten the relay in the desired location, close to the voltage source,

using one #8 x 3/ 4 inch self- tapping screw.

2. Crimp an insulated 1/ 4 inch spade tab receptacle to one end of the #18

red wire.

3. Connect the receptacle to relay lug #86. Cut the red lead so the fuse

assembly is close to the voltage source. Install the fuse holder. Attach

the other end of the fuse lead to the voltage source with appropriate

hardware. See Figure 14.

4. From the radio option cable, take the green/white wire and crimp an

insulated 1/ 4 inch spade tab receptacle. Connect the receptacle to relay

lug #85.

5. Connect the horn or light circuit to lugs #30 and #87 (not 87a) using the

insulated 1/ 4 inch spade tab receptacles.

The relay contact make/break current and voltage rating is 30

NOTE

amps at 16 volts.

28

Page 30

OPTION CABLE

RPM 113 7674/1

P3

PIN 15

ON

BATTERY A+

18 PIN CONNECTOR

FUSE (1A)

J100

PIN 24

(FEMALE)

DB-25 CONNECTOR

DB-25 CONNECTOR (MAL E)

TO BE SUPPLIED BY CUSTOMER

FUSE

(1A)

BATTERY A+

Figure 13 - External Car Alert

86

COM

85

86

RELAY

19A149299P1

87

To Horn Circuit

NO

30

To Horn Circuit

87a

87

30

85

TO HORN CIRCUIT

Figure 14 - External Alarm Relay

TO RADIO OPTION CAB LE

GREEN/WHITE WIRE

29

Page 31

OPTION CABLE

RPM 113 7674/1

P3

PIN 18

IGNITION

SENSE

18 PIN CONNECTOR

J100

PIN 13

(FEMALE)

DB-25 CONNEC TOR

DB-25 CONNEC TOR (MA LE)

TO BE SUPPLIED BY CUSTOMER

FUSE 1A (OPTIONAL)

VEHICLE FUSE BLOCK

Figure 15 – Ignition Sense Option

Microphone Hanger/Hook Switch Mounting – 344A4678P1

The microphone hanger or Hook Switch should be mounted in a location

convenient to the operator where it will not interfere with the safe operation

of the vehicle or be a hazard to the vehicle passengers. The hanger or hook

switch is designed to mount with the open e nd of the mounting button slot

pointed upward.

1. Use the hanger or Hook Switch as a template to mark and drill the

mounting holes. Mount the hanger or hook switch with the self-tapping

screws provided.

2. Connect microphone connector to connector on control unit and secure

with captive screw.

Do not torque microphone connector screw greater than 2 in-

NOTE

lb. Alternatively, finger tight plus 1/4 turn is acceptable.

Antenna

Installation instructions for the antenna are packaged with the antenna. The

antenna must be installed in accordance with good engineering practice for

optimum results.

30

Page 32

Typical Mobile Antenna Installation

A permanent mount-type antenna should be located in the center of the roof

or center of rear deck. Important Note: Rear deck mounting of an

antenna is only applicable when the installation provides at least 25

centimeters (10 inches) between the antenna and occupants of the vehicle.

This distance recommendation is made using a 50% duty cycle.

See “Safety Training Information” section at the

beginning of this manual for further information

regarding Specific Absorption Rate (SAR) limits of RF

WARNING

radiation absorption set by the FCC.

Try to route the cable away from locations where it will be exposed to heat,

sharp edges or mechanical damage, and where it will be out of the way of

the driver, passengers or vehicles mechanics. Wherever possible, existing

holes in the trunk wall, and the channels above or beneath doors and

window columns should be utilized.

Avoid routing the antenna cable near any electronic modules or along side

any vehicle wiring.

Connect the antenna cable to the TNC on the radio, being careful not to

twist the cable.

Typical Desktop Base Stat ion Antenna Installation

For desktop base station configurations, a typical building roof top/tower

installation may be used.

Noise Suppression Kit - Option KMPD1A (19A148539G1)

Refer to the noise suppression kit optio n i nstallatio n ma nual t hat i s inc luded

with this option.

31

Page 33

Com-Net Ericsson Critical Radio Systems, Inc.

P.O. Box 2000

Lynchburg, Virginia 24501

1-800-528-7711 (Outside USA, 804-239-3028)

www.com-netericsson.com Printed in U.S.A.

Loading...

Loading...