Page 1

Broadcast

Console

Operations

&

Technical

Manual

PRE75-53PRE75-53

PRE75-53

PRE75-53PRE75-53

Revision C.1 • 12/10

Broadcast Communications Division

www.broadcast.harris.com

Page 2

HARRIS CORPORATION

ii

Revision C • 10/07

Page 3

Contents

CE Declaration of Conformity ........................ iv

Safety Instructions ......................................... v

Hazard/Warning Label Identification............. v

Manual Revisions .......................................... vi

1 - GENERAL INFORMATION

Product Overview ....................................... 1-1

Specifications .............................................. 1-6

Warranty..................................................... 1-8

2 - HARDWARE INSTALLATION

Console Installation ..................................... 2-2

Cabling and Wiring ................................... 2-10

Installation Quick Guides

Frame & Console Display ..................... 2-20

KSU Card ............................................ 2-21

8-Input Expansion Card ....................... 2-25

VistaMax Connections ......................... 2-26

Mic Remote Control Logic Example .......... 2-27

Basic Peripheral Logic Example................ 2-28

Complex Peripheral Logic Example .......... 2-29

Buttoncap Lenses ...................................... 2-30

5- SERVICE

Parts and Repair Services............................ 5-1

Spare and Replacement Parts ...................... 5-2

Console Troubleshooting .............................. 5-3

Control Panel Servicing ............................... 5-5

Console Display Service ............................... 5-6

Backup Batteries ......................................... 5-7

48 Volt Power Supply .................................. 5-7

Frame Component Info ................................ 5-8

KSU Card Service Info ................................ 5-9

DSP Card Service Info ................................. 5-9

8-Input Expansion Card Service Info ........... 5-9

Motherboard Service Info .......................... 5-10

6 - ACCESSORIES

Furniture and Cabinetry .............................. 6-1

Accessory Panels ......................................... 6-1

Host Turret ................................................. 6-3

digital

RMX

Headphone Distribution Amp ..................... 6-3

ESE/SMPTE Master Clock Cable................ 6-3

Logic Wiring ............................................... 6-3

Divider Kit............................... 6-3

3 - CONSOLE OPERATION

Console Overview ......................................... 3-1

Panel Quick Guides

Universal Dual Fader Input Panel............3-2

Monitor Control Panel.............................3-4

Console Display ...................................... 3-8

digital

RMX

VistaMax Integration .............................. 3-9

Telco/Codec Operation .......................... 3-10

Applications ..............................3-9

4 - RMXDIGITAL SERVER

RMXd File Structure .................................... 4-1

RMXd Server Configuration .........................4-5

Session Files ............................................... 4-17

Session & Macro Files ................................ 4-20

Software Updates ....................................... 4-27

Settings Recovery .......................................4-27

HARRIS CORPORATION

APPENDIX A: VMCC, SESSIONS &

MACROS

VMCC File Maintenance ............................. A-1

Community Monitor ................................... A-1

VMCC Operations Errata ........................... A-3

Setup, Config, General File Info .................. A-7

Macro Files ................................................ A-8

Phantom Channels & Buses ..................... A-10

INDEX

A - C ..................................................... Index-1

C - L ..................................................... Index-2

L - R ..................................................... Index-3

S - W ..................................................... Index-4

iii

Revision C • 10/07

Page 4

Declaration of Conformity

Application of Council Directive: 89/336/EEC

Standards To Which

Conformity Is Declared:

Manufacturer’s Name:

Manufacturer’s Shipping Address:

Manufacturer’s Mailing Address:

Equipment Description:

EN55103-1 (Studio Environment)

EN55022 Class A

Magnetic Field Emissions

EN55103-2 (Studio Environment)

EN61000-4-2

EN61000-4-3

EN61000-4-4

EN61000-4-6

EN61000-4-8

Magnetic Field Immunity

Harris Corporation BCD

4240 Irwin Simpson Road

Mason, Ohio USA 45040

513.459.3400

4593 Digital Way

Mason, Ohio USA 45040

513.459.3400

Radio Mixing Console

Equipment Class:

Model Numbers:

Audio Equipment - Studio

RMXdigital Broadcast Console

I the undersigned, hereby declare that the equipment specified

above, conforms to the above Directive(s) and Standard(s).

Harris Corporation–Mason Ohio USA

Place

Signature

Ted Staros

Full Name

Director–Console Product Development

Position

HARRIS CORPORATION

iv

Revision C • 10/07

Page 5

Safety Instructions

RR

ead Aead A

ll Instrll Instr

ucuc

tionstions

1.

R

ead A

ll Instr

RR

ead Aead A

ll Instrll Instr

instructions before operating the product.

RR

etain Aetain A

ll Instrll Instr

2.

R

etain A

ll Instr

RR

etain Aetain A

ll Instrll Instr

instructions for future reference.

HH

eed Aeed A

ll ll

3.

4.

5.

6.

7.

8.

9.

WW

H

eed A

ll

W

HH

eed Aeed A

ll ll

WW

on the product and those listed in the operating

instructions.

olloollo

w Aw A

ll Instrll Instr

FF

F

ollo

w A

ll Instr

olloollo

w Aw A

ll Instrll Instr

FF

product usage instructions.

HH

eaea

tt

..

H

ea

t

. This product must be situated away from any

HH

eaea

tt

..

heat sources such as radiators, heat registers, stoves,

or other products (including power amplifiers) that

produce heat.

VV

enen

tilatila

tion.tion.

V

en

tila

tion. Slots and openings in the product are

VV

enen

tilatila

tion.tion.

provided for ventilation. They ensure reliable operation

of the product and keep it from overheating. Do not

block or cover these openings during operation. Do

not place this product into a rack unless proper

ventilation is provided and the manufacturer’s

recommended installation procedures are followed.

WW

aa

tt

er and Mer and M

W

a

t

er and M

WW

aa

tt

er and Mer and M

water such as a bathtub, wash bowl, kitchen sink, or

laundry tub, in a wet basement, or near a swimming

pool or the like.

AA

ttachmenttachmen

A

ttachmen

AA

ttachmenttachmen

recommended by the product manufacturer as they

may cause hazards.

PP

oo

ww

er Ser S

ourour

P

o

w

er S

our

PP

oo

ww

er Ser S

ourour

the type of power source indicated on the marking

..

uc

tions

. Read all safety and operating

ucuc

tionstions

..

ucuc

tionstions

..

uc

tions

. Retain all safety and operating

ucuc

tionstions

..

arar

ningsnings

..

ar

nings

. You must adhere to all warnings

arar

ningsnings

..

ucuc

tionstions

..

uc

tions

. Follow all operating and

ucuc

tionstions

..

oistur

oistur

ee

..

oistur

e

. Do not use this product near

oisturoistur

ee

..

tsts

..

ts

. Do not use any attachments not

tsts

..

cc

eses

..

c

es

. You must operate this product using

cc

eses

..

label and in the installation instructions. If you are not

sure of the type of power supplied to your facility,

consult your local power company.

GG

rr

ounding and Pounding and P

10.

G

r

ounding and P

GG

rr

ounding and Pounding and P

equipped with a polarized AC plug with integral safety

ground pin. Do not defeat the safety ground in any

manner.

PP

oo

ww

er Cer C

oror

d Pd P

rr

11.

P

o

PP

oo

routed so that they are not likely to be walked on nor

pinched by items placed upon or against them. Pay

particular attention to the cords at AC wall plugs and

convenience receptacles, and at the point where the

cord plugs into the product.

LighLigh

12.

Ligh

LighLigh

unplug it from the AC wall outlet during a lightning

storm or when it is left unattended and unused for

long periods of time. This will prevent damage to the

product due to lightning and power line surges.

OO

vv

13.

O

v

OO

vv

extensio n cords, or integral convenie nce outlets as this

can result in a fire or electric shock hazard.

OO

bjecbjec

14.

O

bjec

OO

bjecbjec

kind into this product through openings as they may

touch dangerous voltage points or short out parts,

which could result in a fire or electric shock. Never spill

liquid of any kind on the product.

AA

cccc

15.

A

cc

AA

cccc

cart, stand, tripod, bracket, or table. The product may

fall, causing serious injury to a child or adult and serious

damage to the product. Any mounting of the product

must follow manufacturer’s installation instructions.

otot

w

er C

or

d P

r

ot

ww

er Cer C

oror

d Pd P

rr

otot

tningtning

..

tning

. For added protection for this product,

tningtning

..

erer

loadingloading

..

er

loading

. Do not overload AC wall outlets,

erer

loadingloading

..

t and Liquid Et and Liquid E

t and Liquid E

t and Liquid Et and Liquid E

essoressor

iesies

..

essor

ies

. Do not place this product on an unstable

essoressor

iesies

..

tion.tion.

olarolar

izaiza

tio n. This product is

olar

iza

tion.tion.

olarolar

izaiza

ecec

tion.tion.

ec

tio n. Power supply cords must be

ecec

tion.tion.

nn

trtr

yy

..

n

tr

y

. Never push objects of any

nn

trtr

yy

..

PP

rr

oo

ducduc

t and Ct and C

arar

t Ct C

ombinaombina

16.

P

r

o

duc

t and C

PP

rr

oo

with care. Quick stops, excessive force, and uneven

surfaces may cause the product and the cart

combination to overturn.

SS

erer

17.

S

er

SS

erer

personnel.

DD

amage Ramage R

18.

D

amage R

DD

amage Ramage R

from the wall AC outlet and refer servicing to qualified

service personnel under the following conditions:

a. When the AC cord or plug is damaged.

b. If liquid has been spilled or objects have fallen into

the product.

c. If the product has been exposed to rain or water.

d. If the product does not operate normally (following

operating instructions).

e. If the product has been dropped or damaged in any

way.

f. When the product exhibits a distinct change in

performance. This indicates a need for service.

RR

eplaceplac

19.

R

eplac

RR

eplaceplac

required, be sure the service technician has used

replacement parts specified by the manufacturer or

that have the same characteristics as the original parts.

Unauthorized substitutions may result in fire, electric

shock, or other hazards.

SS

afaf

20.

S

af

SS

afaf

product, ask the service technician to perform safety

checks to determine that the product is in proper

operating condition.

CC

leaningleaning

21.

C

leaning

CC

leaningleaning

only a damp cloth for cleaning.

ar

ducduc

t and Ct and C

arar

vicingvicing

..

vicing

. Refer all servicing to qualified ser vicing

vicingvicing

..

equirequir

equir

equirequir

emenemen

t Pt P

emen

t P

emenemen

t Pt P

etet

y Cy C

heck.heck.

et

y C

he ck. Upon completion of any repairs to this

etet

y Cy C

heck.heck.

..

. Do not use liquid or aerosol cleaners. Use

..

tion.tion.

t C

ombina

ti on. Move this product

t Ct C

ombinaombina

tion.tion.

ing Sing S

erer

vicvic

ee

..

ing S

er

vic

e

. Unplug this product

ing Sing S

erer

vicvic

ee

..

arar

tsts

..

ar

ts

. When replacement parts are

arar

tsts

..

Hazard/Warning Label Identification

EE

xx

clamaclama

tion Ption P

oinoin

t symbt symb

The

E

x

clama

tion P

tion Ption P

oin

oinoin

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

EE

xx

clamaclama

within an equilateral triangle, alerts the

user to the presence of important

operating and maintenance (servicing)

instructions in product literature and

instruction manuals.

WARNING: SHOCK HAZARD - DO NOT OPEN

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR

LighLigh

tning Ftning F

tning F

tning Ftning F

lash lash

lash

lash lash

olol

ol, within an

olol

The

Ligh

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK DO NOT

REMOVE ANY COVER OR PANEL. NO USER SERVICEABLE PARTS

INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

LighLigh

AA

rr

rr

oo

whead symbwhead symb

A

r

r

o

whead symb

AA

rr

rr

oo

whead symbwhead symb

equilateral triangle, alerts the user to

the presence of uninsulated

dangerous voltage within the

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THE POWER SUPPLY OR CONSOLE

TO RAIN OR MOISTURE.

WW

ARNINGARNING

W

ARNING—This equipment generates, uses, and can radiate radio frequency energy. If not installed and used in accordance with the instructions in this

WW

ARNINGARNING

manual it may cause interference to radio communications. It has been tested and found to comply with the limits for a Class A computing device

(pursuant to Subpart J of Part 15 FCC Rules), which are designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area is likely to cause interference, in which case the user, at his own expense, will be

required to take whatever measures may be required to correct the interference.

product’s enclosure that may be of

sufficient magnitude to constitute a

risk of electric shock.

t symb

t symbt symb

WW

ithith

W

ith

WW

ithith

olol

ol,

olol

v

HARRIS CORPORATION

Revision C • 10/07

Page 6

Manual Revisions

This page provides a quick reference of the

current document pages and their revision level. If

you receive a revision to this document from Harris,

replace the old manual pages with the new ones and

discard the old pages. Replace this page with the

new Manual Revisions page.

Revision Affected pages Comments

A All pages 6/04 First Release

B All pages 8/05 VMCC info added

C All pages 10/07 reflective meter

& 500-series code

information added

HARRIS CORPORATION

vi

Revision C • 10/07

Page 7

General

Information

Thanks for joining the growing ranks of

broadcasters employing Harris Corporation prod-

ucts designed by PR&E. Our mission: provide the

finest quality products, systems, documentation and

after-sale support.

To obtain the maximum benefit from the

console’s capabilities, read through the chapters

on

Installation, Operation

prior to actual product installation.

digital

An RMX

ing items:

• Mainframe, with 12, 20 or 28 input slots

• Universal Dual Fader Panels, installed, as

ordered

• Monitor Control Panel, 1 standard

• KSU Card, 1 standard

• DSP Card, one standard on the 12-input;

two standard on the 20-input; three stan-

dard on the 28-input)

• 8-Input Expansion Card, optional, total

number installed: up to the number of DSP

Cards installed in the mainframe

• Single or Dual Width Blank Panels, as re-

quired, to cover unpopulated input slots

• 48 VDC Power Supply, 1 standard

• Console Display, 1 low-profile display stan-

dard; original display, optional

• Installation Kit, 1 standard

• Tool Kit, 1 standard

• CD-ROM, 1 standard

console ships with the follow-

and the

RMXd Server

1-1

HARRIS CORPORATION

1

Product Overview

The RMX

trolled, routable audio console that sits in a coun-

tertop cutout. Framesizes with 12, 20 or 28 con-

trol strips are available. The console can operate

in a stand-alone capacity or, for maximum flex-

ibility and usability, be integrated with a VistaMax

Audio Management System.

A separate Console Display, with two stereo bar-

graph meters, an ESE/SMPTE-compatible Clock

and Event Timer, is included. The display sits on

the countertop near the mainframe and plugs into

the frame using a captive six-foot cable harness.

The console is designed for 24/7 operation. It

has two power connections, with integral coupler,

for a main and a redundant supply (PRE99-1205).

One supply is included with the mainframe.

All RMX

and power supply) are convection cooled for com-

pletely silent operation.

RMX

tained within an aluminum chassis for strength

and RFI immunity. All user connections are made

from the top surface. The connectors, and cable

access openings, are located below a hinged cue

speaker panel behind the main control surface.

Each RMX

mount RMX

Card that has these connections:

• Four program and one send output (each has a

dedicated analog and an AES digital output)

• Analog control room outputs (for a monitor amp,

and for operator and guest headphone amps) *

• Analog studio outputs (for a monitor amp, and

for host and guest headphone amps) *

digital

is a low profile, digitally-con-

digital

components (console, display,

digital

circuit board electronics are con-

digital

mainframe (and the rack-

d

8-HL) comes standard with a KSU

Revision C • 10/07

Page 8

1 General Information

• Cue speaker and Cue monitor output *

• Three talk audio outputs (Talk to: control room,

studio, and an external location) *

• Eight routable audio inputs (four analog and four

digital inputs, independently routable to any

channel strip) that are VistaMax sources

• Eight routable audio outputs (four analog and

four digital outputs, independently routed from

any console bus) that are VistaMax destinations

• Dedicated control room, studio and cue/talk/

external logic connectors, with three Assignable

Logic I/O connectors *

• VistaMax facet Link connectors (two copper RJ-

45, standard; two optical MT-RJ connectors, op-

tional) plus an Ethernet connection for commu-

nicating with a VistaMax LAN

• Serial Test Interface connection for diagnostic

and system software maintenance

* These connections are typically not used on the

d

-8HL

RMX

Additional audio inputs and logic I/O can be

added in a mainframe by installing the optional

8-Input Expansion Card onto a DSP card. Each

Expansion Card has eight audio inputs (individu-

ally switch set as an analog or a digital input) and

eight Assignable Logic I/O connectors to associ-

ate logic with the eight inputs. The audio inputs

are independently routed to channel strips through

session file settings or by manually selecting a

source using a channel strip source selector. Dur-

ing console setup, audio inputs can be “bound” to

logic I/O connectors for channel logic control to

and from peripheral devices and mic control pan-

els.

One 8-Input Expansion card can be added to a

12-input frame, up to two cards can be added to a

20-input frame and up to three cards can be in-

stalled in a 28-input frame.

VISTAMAX CONTROL CENTER

The RMX

configuration files that are maintained by the sup-

plied VistaMax Control Center (VMCC) software.

Monitor switch functions, channel button settings

and audio routing is “soft controlled” through setup

parameters—initially auto-loaded through a con-

trol file, called init.mac, and adjusted as re-

quired through session file settings.

The initial console settings can be changed, as

required by board operators, through manually

selecting different input signal sources and chang-

ing control surface button assignments, or by load-

ing a session file—a pre-saved file that reconfigures

the console for a different daypart or function.

digital

is set up for daily use through

SESSION FILES

Session files are initially created right on the

console by selecting input sources and setting de-

Save

sired switch conditions, then pressing

Monitor Control panel. This action creates a new

session file—which never affects previously saved

session files. The new session file can then be ed-

ited using a text-only editor on a Windows® com-

puter, if required, and then saved back to the con-

sole over the LAN connection. The session is then

“dialed up” by the operator using the Monitor Con-

trol panel session selector and

Take

For some facilities, a single customized session

file may be sufficient to set up a console for all

users but it is more likely that multiple session

files will be created to set the console for different

dayparts or different operations (e.g., one console

could serve split duty, being a newsroom feeding

live audio to air during the day, but then changing

to a production room at night).

Since session files can change any number of

console settings, dayparting the console is as easy

as selecting the desired session file and pressing

Take

—once the session files have been created,

edited and saved back to the console.

on the

button.

HARRIS CORPORATION

1-2

Revision C • 10/07

Page 9

1 General Information

For example, if the “morningzoo” session is cur-

rently loaded on a RMX

digital-12

console, and it

has configured the console inputs as: five mics

(each with the talent’s name shown in the channel

display), three Telco channels (two phone hybrid

caller inputs and an ISDN live remote input) and

four line inputs (three digital delivery inputs for

sound FX, music beds, commercials, etc., and a

traffic or weather service feed).

To switch the console for the midday daypart

(one board operator/jock who takes requests and

plays back all sources from a digital delivery sys-

tem), means there is some extensive switching that

must take place on a non-programmable console.

digital

On the RMX

, however, it is done simply

by dialing up and taking the “midday” session—

which immediately reconfigures the console, re-

sulting in Input 1 being the control room mic (with

the jock’s name shown in the channel display, if

desired); the next four inputs are routed from the

digital delivery system for music, liners and com-

mercials, while Input 6 remains the hybrid input

(for those call-in music requests). The remaining

Telco and input channels could be left alone or

they could be routed to silence, remaining avail-

able for the board operator to use as required.

To prevent on-air interruptions, any channels

that are On-Air when a session file is taken do not

immediately change settings. Instead, those chan-

nels only change to the new session file settings

when that channel is turned off in order to effect

seamless show transitions.

MAIN COMPONENT DESCRIPTIONS

An RMX

nents—as seen and used by the board operator:

Universal Dual Fader panels, a Monitor Control

panel and the Console Display.

Additional descriptions are presented in this

section for the power supply, KSU and DSP cards,

and for the optional 8-Input Expansion cards.

digital

console has only three compo-

Universal Dual Fader Panels

Each Dual Fader panel has two sets of channel

strip controls with these functions: channel on/

off; fader level control; cue on/off; momentary talk-

back control to remotes or callers (active when

the channel strip is set as a Telco channel); input

source selector and take button; input mode but-

tons with pan/balance pot; send bus on/off, mode

and level control; and assignment buttons for four

program and one offline bus.

A ten-character display on each channel strip

normally shows the input source name. Alternate

source names are shown when the yellow Next

LED is lit during source selection.

A channel strip control can be assigned to con-

trol any type of audio source: mic; line; router;

Telco, as required by a particular daypart.

The audio source for each fader is initially set

by loading a session file. The input’s source name

(or an alias name) is shown in the ten-character

display above each fader. If no signal is routed to

the fader, then

The capacity to change the source—via a source

selector and

channel strip since the physical audio source for

each channel is “virtual”—it can be any physical

console input (analog or digital) and, when the

console is tied into a VistaMax system, any input

source on any VistaMax device networked with

the RMX

available sources can be individually limited on a

channel strip through session file settings.

The input audio may also be linked with logic

from a peripheral or mic control panel to provide

fully independent parallel logic control functions

for remote control of the channel strip and/or

channel strip control of the source equipment.

Again, all of these parameters are set during con-

sole configuration so that the operator never has

to concern themselves about logic or signal rout-

ing when the session files are properly crafted.

SILENCE is displayed.

Take

button, is a standard part of each

digital

console. To simplify operation, the

1-3

HARRIS CORPORATION

Revision C • 10/07

Page 10

1 General Information

Monitor Control Panel

This standard panel is divided into three

functional sections: Session, Control Room, and

Studio, by graphic lines on the panel.

Session Section

The middle of the left section has the session

controls for selecting and saving session files

(rotary session selector, take and save buttons)

along with two ten-character displays for showing

the current session (in the top line) and a next

session (in the bottom line).

The Auxiliary Meter source selector buttons are

above the session controls. These allow one of

seven sources (defaults assignments are: Real Air,

the send bus, the Telco record bus, and the four

program buses) to feed the Auxiliary Meter located

on the Console Display. The selected source name

is shown below the Auxiliary Meter.

Just below the session controls are the Monitor

Mode buttons that are covered in the Control

Room Section that follows.

Five event timer control buttons are found at

the bottom of this section. Start, Stop, Hold, and

Reset manually control the event timer in the

Console Display. When the Auto Reset button is

lit, the timer can be reset automatically when a

channel is turned on. Which channels reset the

timer are set by session file commands.

Control Room Section

The center section of the Monitor Control panel

has monitor source selector buttons for the control

room monitor and operator headphone outputs.

A source can be selected from among the seven

buttons at the top of the center section (the defaults

are the same as for the Aux. Meter), or by using

the monitor source selector and take button to

select between an additional fifteen sources. The

selected source button lights to indicate its

selection, while blanking the selected name display.

When a source is selected using the source selector,

the name is shown in the ten-character display

and all source buttons are turned off.

Just above the monitor source display are two

level pots for setting the output levels of the cue

speaker and the control room talkback output.

Independent control room monitor and head-

phone fader level controls are at the bottom of

this section. The selected source is routed through

the monitor mode controls in the left-hand sec-

tion next to the top of the faders, which control

whether the monitor signal is stereo, left only, right

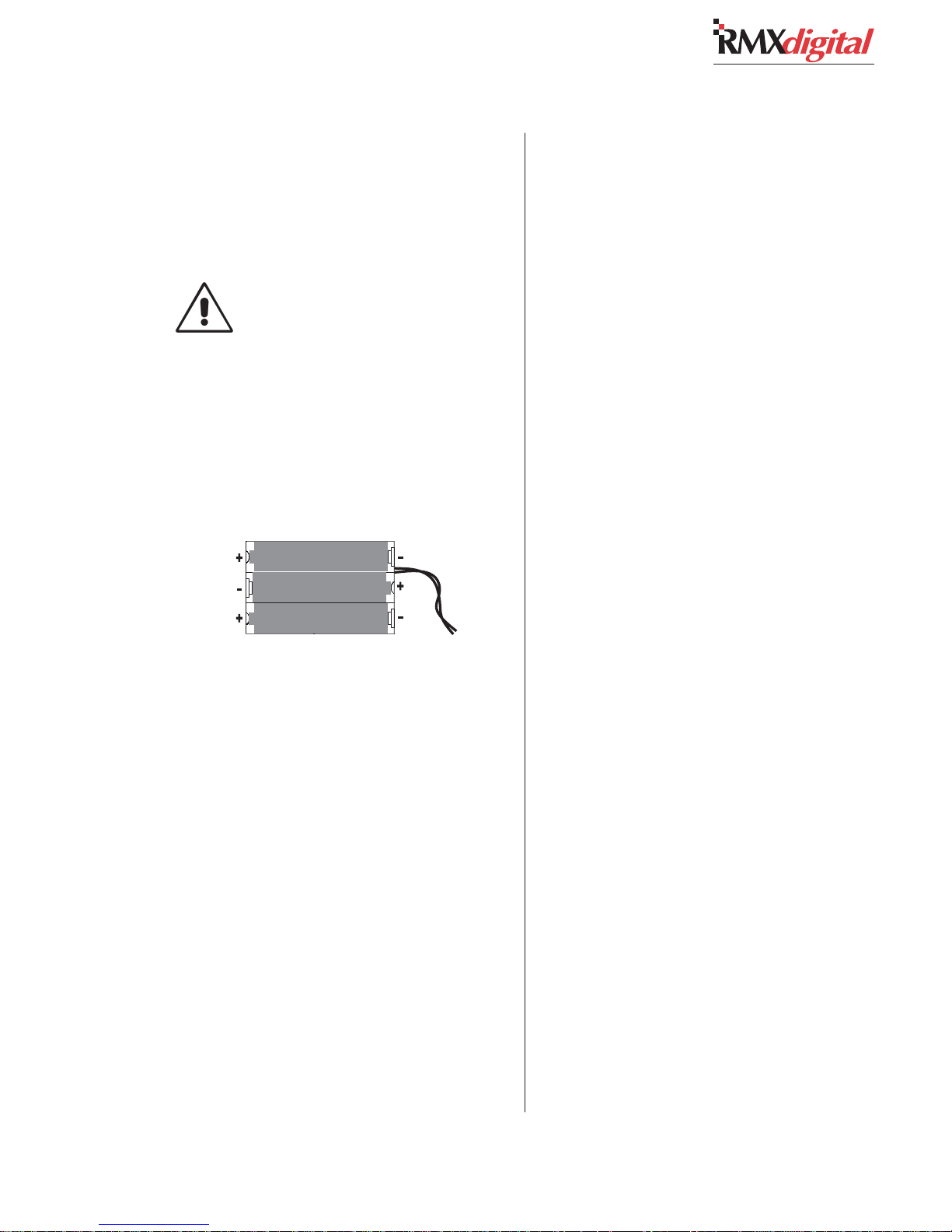

only, or mono (left and right summed together).

AutoCue, another mode control, sets whether

cue feeds the headphone output. When unlit, cue

activity does not affect the headphone output.

When AutoCue is lit, the headphone output auto-

matically switches to listen to the cue bus while

cue is active.

The AutoCue function has two modes, as set

using the VMCC program. The default setting is

Split Cue where the monitor and cue audio are

separately summed to mono before going to the

headphones. Cue audio is sent to the left ear while

the monitor audio goes to the right ear. An alter-

native mode is Stereo Cue, where cue audio re-

placed the monitor audio with the Cue audio (in

stereo in the headphones).

Studio Section

The right-hand section of the Monitor Control

panel has controls for a separate talk or voice

studio. Monitor source selection is done in the same

manner as the control room: a source selector

button (at the top of this section) can be pressed,

or a source can be selected using the monitor

source selector and take button.

Level control of the dedicated studio monitor

and talkback outputs is done through the two

volume pots above the monitor source display.

HARRIS CORPORATION

1-4

Revision C • 10/07

Page 11

1 General Information

This section of the Monitor Control panel also

has two talkback buttons so the board operator

can talk to the studio and/or to an external

location using the board operator’s microphone.

Console Display

The separate Console Display sits or stands on

the countertop behind or to the side of the con-

sole control surface. The Main Meter shows the

PGM 1 output levels. The Aux Meter shows the

cue bus, when active, or a source selected using

the Aux Meter source controls on the monitor

panel.

An ESE and SMPTE-compatible time of day

clock and an event timer (controlled by Monitor

Control panel buttons and/or reset commands

from one or more channels) are also on the Con-

sole Display.

The display plugs into the console motherboard

using a six-foot captive cable harness.

KSU Card

Each RMX

has one KSU Card with eight assignable audio

inputs and eight assignable outputs; three Assign-

able Logic I/O connectors; dedicated logic con-

nectors for control room, studio, and cue/talk/

external logic; eighteen dedicated analog and digi-

tal program and monitor outputs; a VistaMax LAN

connector; a serial test connector; and two copper

(RJ-45) VistaMax Link connectors.

A KSU card with two MT-RJ optical VistaMax

Link connectors (PRE99-2672-2) is available for

interconnecting the console to a VistaMax system

when the distance between console and VistaMax

frame exceeds 100 meters (the maximum length

supported using CAT-5e or CAT-6 cables). The MT-

RJ optical connections support runs up to 2 km.

An optical Link RMX

also available.

digital

(including the RMXd8-HL)

d

8-HL (PRE99-1910-2) is

On the consoles, the KSU card plugs into the

motherboard behind the Monitor Control panel

and the two adjacent Dual Fader Input panels. In

normal use it’s hidden below the cue speaker panel.

The KSU consists of an SBC (Single Board Com-

puter), a VistaMax interface, and DSP for the eight

routed KSU inputs/outputs and the bus outputs.

DSP Card

The number of DSP (Digital Signal Processor)

cards installed is frame size dependent (RMX

d

12 has one DSP Card, RMX

d

-28 has three cards). DSP Cards plug into

RMX

-20 has two, and

d

the lower motherboard behind the Universal Dual

Fader Input panels, hidden below the cue speaker

panel in normal use. Each card handles routing

for eight stereo audio inputs and eight Assignable

Logic I/Os. Each card has DSP “heartbeat” and

automation LEDs to indicate operational status.

8-Input Expansion Card

This optional audio input and logic I/O card

(PRE99-2665) adds eight audio inputs and eight

Assignable Logic I/O connectors to any DSP Card,

in lieu of the blank panel between the DSP card

and the control surface. An 8-Input Expansion

card can be added to each DSP card.

Each audio input is physically set as an analog

or a digital input by a board-mounted DIP switch.

The input is assigned to a channel strip (or set as

a VistaMax input) by the session file. The Assign-

able logic connections can be “bound” to any one

of the audio inputs, and then jointly assigned to a

channel strip, or they can be used separately from

any of the audio inputs as determined by the cur-

rent session file settings.

Power Supply

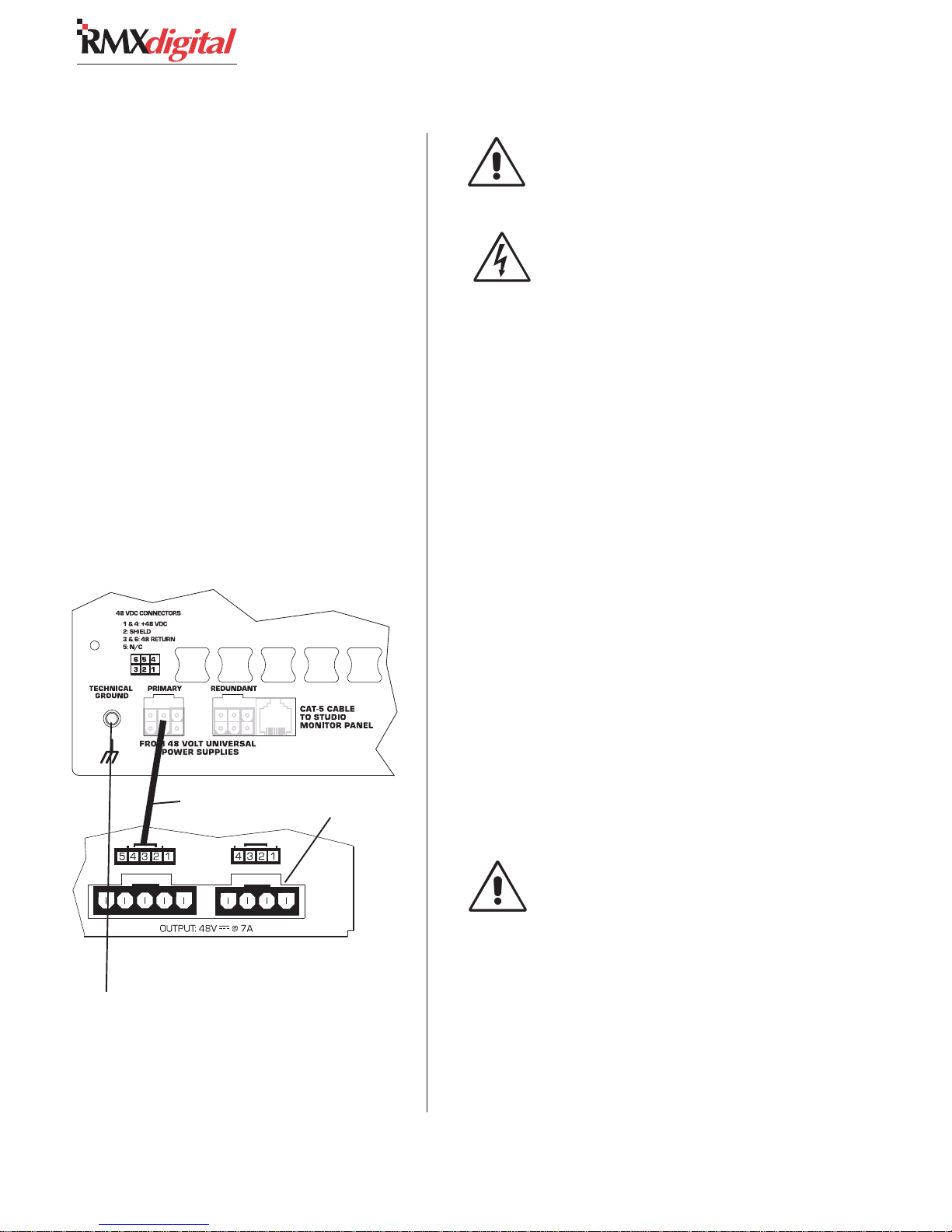

A separate rackmount power supply (PRE99-

1205) supplies +48 VDC to the console mainframe.

One supply comes standard with each mainframe.

-

1-5

HARRIS CORPORATION

Revision C • 10/07

Page 12

1 General Information

The RMX

are supplied with a 110 VAC IEC input cord.

Two keyed 48-volt power cables are supplied

with the console mainframe Installation Kit so that

a second PRE99-1205 supply (optional) can eas-

ily be added for redundant supply operation. The

mainframe and the RMX

gral power coupler so a second redundant supply

can be connected.

The power supply (and the RMX

recessed front panel On/Off switch along with a

green LED that indicates the +48 volt output is

good.

The power supply is designed for continuous

24/7 operation and is fully regulated and protected

against excessive current by internal fuses and elec-

tronic safeguards.

d

8-HL has a built-in 48-volt supply. All

d

8-HL include an inte-

d

8-HL) has a

Specifications

Specifications are for the basic signal paths, per

channel, with 600 ohm loads connected to the ana-

log program outputs in a fully loaded RMX

28-input slot mainframe.

0 dBu equals 0.775 volts RMS regardless of cir-

cuit impedance, which equals 0 dBm into a 600

ohm circuit. Noise specs based on 22 kHz mea-

surement bandwidth. A 30 kHz bandwidth mea-

surement increases noise by about 1.7 dB.

Total Harmonic Distortion (THD+N) is mea-

sured at a +18 dBu output, using a swept signal

and a 22 kHz low pass filter.

FSD = Full Scale Digital, +24 dBu

Analog Line Inputs

Input Impedance: >60 k ohms, balanced

Input Level Range: -10 dBv to +4 dBu (soft trim)

Input Headroom: 20 dB above nominal input

digital

Analog Outputs

Output Source Impedance: <3 ohms balanced

Output Load Impedance: 600 ohms minimum

Nominal Output Level: +4 dBu

Maximum Output Level: +24 dBu

Digital Inputs and Outputs

Reference Level: +4 dBu (-20 dB FSD)

Signal Format: AES-3, S/PDIF (input only)

AES-3 Input & Output Compliance:

24-bit sample rate

conversion

Digital Reference:

Crystal (internal) or VistaMax

slave (external) at 48 kHz ±100 ppm

Internal Sample Rate:

48 kHz

Output Sample Rate: 48 kHz (PGM 1, PGM 2 or

Send can be set for 44.1 kHz)

Processing Resolution:

24-bit fixed with extended

precision accumulators

Conversions:

A/D 24-bit, Delta-Sigma, 128x oversampling on all digital inputs; D/A 24-bit, DeltaSigma, 128x oversampling

Latency:

<1.6 ms, input to monitor out

HARRIS CORPORATION

1-6

Revision C • 10/07

Page 13

1 General Information

Monitor Outputs

Output Source Impedance: <3 ohms, balanced

Output Load Impedance: 1 k ohms minimum

Output Level: +4 dBu nominal, +24 dBu maximum

Frequency Response

Line Input to Program or Send Output: +0 dB/-0.5 dB,

20 Hz to 20 kHz

Dynamic Range

Analog Input to Analog Output: 104 dB referenced to

FSD, 107 dB “A” weighted to FSD

Analog Input to Digital Output: 105 dB referenced to

FSD, 108 dB “A” weighted to FSD

Digital Input to Analog Output: 110 dB referenced to

FSD, 113 dB “A” weighted to FSD

Digital Input to Digital Output: 125 dB

Total Harmonic Distortion + Noise

Analog Input to Analog Output: <0.003%, 20 Hz to

20 kHz, +18 dBu input, +18 dBu output

Digital Input to Digital Output:

<0.0005%, 20 Hz to

20 kHz, -6 dB FSD input, -6 dB FSD output

Digital Input to Analog Output:

<0.003%, 20 Hz to

20 kHz (<0.001%, typical at 1 kHz), -6 dB FSD

input, +18 dBu output

Power Supply Ground

Rack mounted power supply: grounded through AC

cord

Power Supply Connection

AC input: IEC power cord

DC output: Keyed multi-pin connector

Dimensions

For all RMXdigital frames: height above countertop

is 2.25" [57]. Depth below countertop is 9.85"

[250] at the rear of the frame. Front-to-back

depth is 22" [559]. See page 2-1 for a side view

with dimension details.

RMXd-12 is 27.4" [696] wide

RMXd-20 is 40.2" [1021] wide

RMXd-28 is 53.0" [1346] wide

RMXd8-HL (Rack mounted):

2 RU: 3.5" [89] x 19" [483] x 10" [254]

Console Display (sits/stands on countertop):

Original Tall Display: 11.13" [283] x 14.25"

[362] x 5.1" [130]

Low-Profile Display: 5" [127] x 17.25" [438] x

5.25" [133]

Crosstalk Isolation

Program-to-Program or Program-to-Send: >95 dB, 20

Hz to 20 kHz

Stereo Separation

Analog Program Outputs: >86 dB, 20 Hz to 20 kHz

Console Power Requirements

RMXd8-HL: 48 watts

RMXd-12: 99 watts

RMXd-20

RMXd-28

:

141 watts

:

186 watts

Measured at 115/230 VAC, ±12%, 50/60 Hz

Power Supply Voltage

Console power: +48 VDC at 6.25 Amps.

(The console includes an integral power coupler for a primary and a redundant supply. One

supply is included with the mainframe, along

with two DC power cables.)

HARRIS CORPORATION

48 Volt Power Supply (Rack mounted):

2 RU: 3.5" [89] x 19" [483] x 10" [254]

All dimensions: Height x Width x Depth.

Harris Corporation reserves the right to change

specifications without notice or obligation.

1-7

Revision C • 10/07

Page 14

1 General Information

Warranty

Each RMX

digital

console, RMXd-8HL and 48-

volt power supply carry a standard manufacturer’s

warranty of 15 months from the DATE OF SHIP-

MENT from Harris.

A copy of the domestic (USA) product warranty

policy, dated July 1, 2007, is presented on the fol-

lowing two pages.

To view or download the current Harris Broad-

cast Communications Standard Warranty Policy

Statement for either domestic or international lo-

cations, visit this Harris corporate website page:

http://www.broadcast.harris.com/

support/warranties.asp

HARRIS CORPORATION

1-8

Revision C • 10/07

Page 15

PRODUCT WARRANTY (USA)

TECHNICAL SUPPORT

For information about products or support services:

Call: +1 888 534 8246

Website: www.broadcast.harris.com

To register products or update company information visit:

https://premier.harris.com/broadcast/warranty_registration.asp

PROFESSIONAL SERVICES COMMITMENT

We are serious about our professional services business. We strive to

provide the highest level of support in the industry and offer a

complete set of integrated support solutions designed to help our

customers across every phase of their business. Harris works with you

to provide the type of coverage you need. We are committed to

service excellence.

Standard Warranty Services

Technical support 9 hours a day, 5 days a week

After-hours emergency “Down or Off-air” phone support

5-day advance exchange of parts

Software updates and bug fixes

Access to technical knowledge bank

Optional Gold ServicePAK

Technical phone support 24 hours a day, 7 days a week

Next-day advance exchange of parts

HARRIS BROADCAST COMMUNICATIONS

STANDARD WARRANTY POLICY STATEMENT

Effective July 1, 2007

STANDARD EQUIPMENT WARRANTY

Harris Corporation (“Harris”) warrants that all Harris Broadcast Communications-manufactured equipment will be free of any defect in materials or

workmanship for the period of time specified in the table below (or such other time period as agreed in writing by the parties). Warranty begins from

the date of shipment from a Harris facility. The warranty is ex-tended to customers and applies to all Harris Broadcast Communications-manufactured

equipment purchased, installed, and used for the pu rpose for which such equipment was originally designed.

Product Family Standard Equipment Warranty Period

Transmitters (except Platinum VHF transmitters), Storage,

Servers, Automation, Graphics, Post Production, C onso les

and Audio Management Equipment

Test & Measurement, Routing & Distribution Equipment 27 months from shipment

Digital Exciters (Radio) 39 months from shipment

Platinum VHF Transmitters 63 months from shipment

B-Stock Equipment Same as applicable product warranty

Replacement Parts – within Standard Warranty Period Longer of (i) applicable product warranty or (ii) 90 days from shipment

Replacement Parts – post Standard Warranty Period 90 days from shipment

WARRANTY CLAIMS AND PROCEDURES

1. During the applicable Standard Equipment Warranty Period outlined above, customer’s sole and exclusive remedy for any breach of the Standard

Equipment Warranty will be, at Harris’ sole discretion and option, repair or replacement of the defective product. Components that customer claims to

be defective must be available to Harris for inspection and evaluat ion. Unless otherwise agreed in writing by Harris, customs clearance for all

replacement parts under the warranty or otherwise will be customer’s sole r esponsibility. To be entitled to rights under the Standard Equipment

Warranty, the customer must notify Harris in writing within thirty (30) days after discovering a suspected defect in any product, but in any event prior

to the expiration of the applicable Standard Equipment Warranty Period. Notice to a Harris dealer, systems integrator, sales represen tative or other

third party is not notice to Harris. Following its receipt of any such customer notice, Harris will determine whether the reported problem is covered by

this Standard Equipment Warranty. If Harris determines that the problem is covered, Harris will authorize repair or replacement of the defective

product, as deemed appropriate by Harris in its s ole discretion. For clarificatio n purposes, any technical support provided by Ha r r is w i ll be fo r the s o l e

purpose of fulfilling Harris’ warranty obligations. If Harris determines that customer is using technical support as a substitute for training of customer’s

personnel, then such technical support will be subject to additional charges at Harris’ then prevailing unit rate for such services.

2. Before shipping any product to Harris, the customer must obtain a written return authorization from Harris, and provide any proof of warranty

eligibility requested by Harris. Any product received by Harris without a return authorization may, at Harris’ option, be returned to the customer co llect.

Once a return aut horization is obtained, the custom er is responsible for packing and shipping the product to which its warranty claim relates to a service

facility designated by Harris, with all shipping charges prepaid by Harris, within thirt y (30) days after receipt of the return authorization. Harris will pay

for return of the repaired or replacement product to the customer if the repaired or replacement product is shipped to a designated Harris service

facility. In the event that the foregoing procedure is not followed by customer, Customer shall pay for return shipping of the d efective equipment (or

part thereof) to Harris and Harris shall only pay delivery charges of the replacement equipment (or part thereof) to customer. Harris will use

commercially reasonable efforts to supply equipment (or part thereof) from the geographical region of customer’s site, so as to minimize freight and

duty. Harris bears the risk of loss or damage while the equipment (or part thereof) is in transit to customer from the Harris serv ice ce nter, and

customer bears the risk of loss or damage while the equipment (or part thereof) is in transit back to the Harris service center.

3. Upon receipt of replacement equipment (or part thereof), customer has thirty (30) days to tender the defective equipment (or part thereof) to the

return carrier for shipment to the service center designated by Harris. If customer does not timely return the defective equipment (or part thereof),

Harris shall invoice customer for the list price of such equipment (or part thereof), plus applicable shipping. Such failure to return the equipment (or

part thereof) may, in Harris’ discretion, be grounds for termination of the warranty and/or suspension of any future advance exchang e privileg es until

such outstanding defective equipment has been returned. Under the Standard Equipment Warranty Harris will provide customer with new, rebuilt,

refurbished or alternate equipment (or part thereof) of equal or improved quality, as exchange equipment (or part thereof) to replace eligibl e defective

equipment (or part thereof). Any alternate equipment (or part thereof) will meet or exceed the specifications of the replaced equipment (or part

thereof). Rebuilt or refurbished equipment may bear cosmetic blemishes that do not affect perform ance. Unless otherwise specified by Harris in

writing, repaired or replaced equipment (or parts thereof) are covered only for the remainder of the term of the applicable Standard Equipment

Warranty. All defective equipment (or parts thereof) replaced by Harris become the property of Harris. Harris has no obligation to (i) service, exchange

or otherwise replace any equipment (or part thereof) that has been damaged, modified, abused, misused or over-used as determined by Harris or has

been used with non-Harris supplies or products that have caused damage or malfunction; (ii) paint, refinish, refurbish, restore or exchange any

equipment (or part thereof) with cosmetic blemishes; (iii) service, exchange or otherwise rep lac e any equipment (or part thereof) if the same would

interfere with, impede or be redundant with normal or scheduled maintenance of such equipment (or part thereof); (iv) service, exchange or otherwise

replace any equipment (or part thereof) that is within sixty (60) days of the end of its production life; or (v) provide any application sof tware support or

service involving application h ardware or replace any accessories. If Harris elects to perform any such services at customer’s request, then such

services will be deemed a service call and all labor, parts and materials used for the service call will be charged at Harris’ then-prevailing rates.

15 months from shipment

Broadcast Communications Division 4393 Digital Way, Mason, OH USA 45040, Tel: 1 (513) 459 3400 Part Number: 158-000026-01

www.broadcast.harris.com ©2007 Harris Corporation

Page 16

EQUIPMENT WARRANTY EXCLUSIONS

Harris does not warrant or guarantee, and is not responsible for:

1. Defects, failures, damages or performance limitations caused in whole or in part by (A) power failures, surges, fires, floods, snow, ice, lightn ing,

excessive heat or cold, highly corrosive environments, accidents, actions of third parties, or other events outside of Harris’ control, or (B) customer’s

abuse, mishandling, misuse, negligence, improper storage, servicing or operation, or unauthorized attempts to repair or alter the equipment in any

way. Customer mus t provide qualified technical personnel to maintain and repair t he equipment.

2. Equipment built to customer’s specifications that are later found not to meet customer’s needs or expectations.

3. The performance of the equipment when used in combination with equipment not purchased, specified, or approved by Harris.

4. Signal coverage delivered by antenna equipment whether or not supplied by Harris.

5. Batteries and other consumable goods.

ADDITIONAL WARRANTY NOTES

1. OEM or third-party equipment that is incorporated into Harris equipment is covered under the applicable Harris Standard Equipment Warranty

unless the OEM or Third-Party equipment carries its own limited warranty, in which event the OEM or third-party warranty will apply to such equipment

incorporated into Harris equipment. For example and not limitation, CRTs, LCDs, FSMs and Optical Test products are OEM products that have a limited

1 year manufacturer’s warranty.

2. Items Sold As Resale

independently of Harris manufactured equipment (such as tubes, printers and antenna transmission lines) and shall be covered only by the specific

warranty terms of the supplier or original equipment manufacturer of those items. IF AN ORDER COVERS EQUIPMENT NOT OWNED BY HARRIS, IT IS

SOLD SUBJECT TO HARRIS’ ACQUISITION OF POSSESSION.

3. B-Stock Equipment

three (3) years old. B-Stock equipment related to transmitters is defined as equipment repurchased by Harris that is reconditioned or refurbished for

sale to a second generation owner by Harris or its reseller.

4. Used Equipment

PARTIES, IT IS SOLD “AS IS” AND WITH NO WARRANTY.

SERVICES WARRANTY

Harris warrants that the services will be performed in a professional manner (the “Services Warranty”). Notice of a breach of the Services Warranty

must (i) specify in reasonable detail, the nature of the claim, and (ii) be received within ninety (90) days from the last day of performance of the

services. Upon notice of a breach of the services warranty and Harris’ determination of the validity of such breach of the Services Warranty, Harris will

re-perform the applicable services at Harris’ expense. If after reasonable opportunity Harris is unable to re-perform such services to the reasonable

satisfaction of customer, customer may, as its exclusive remedy, obtain a refund of the fees paid to Harris under the applicable order for such services.

SOFTWARE WARRANTY

1. Physical Media

traffic translators (“Licensed Programs”), to be free of defects in material or workmanship for a period of ninety (90) days from the date of completed

installation, or if customer should assume responsibility for installation of the software, for a period of ninety (90) days from the date of shipment of the

Licensed Programs by Harris (the “Software Warranty Period”). This limited warranty extends only to customer as the original licensee. Customer’s

sole and exclusive remedy under this limited warranty will be, at Ha rris’ option, repair or replacement of the software media.

2. Licensed Programs

Licensed Programs shall operate substantially in compliance with Harris’ specifications for the Licensed Programs (the “Software Warranty”). Th e entire

liability of Harris under this limited warranty is to provide, free of charge, a corrected copy of any portion of the Licensed Programs which is found by

Harris inspection not to be in substantial compliance with its specifications. If Harris is unable to provide a c orrected copy of the Licensed Programs

within a reasonable time, as customer’s sole and exclusive remedy, Harris will replace the same with a functionally similar program or refund to

customer the amounts customer paid Harris to purchase or license such Licensed Programs. Harris does not warrant that such programs are error free

or that customer will be able to operate such programs without problems or interruptions. Corrections to the Licensed Programs beyond the Software

Warranty Period will only be made by Harris pursuant to a separate software maintenance agreement.

3. Cost of Corrections

Programs at no charge to customer. Software corrections will be sent via e-mail. In the rare event customer requires a Harris customer support

engineer to visit the site, related reasonable pre-approved on-site time and travel expenses will be billed at the prevailing daily rates, unless otherwise

agreed to in writing prior to the visit. A ONE-DAY MINIMU M CHARGE APPLIES TO ALL ON-SITE VISITS.

4. Software Warranty Exclusions. The Software Warranty does not apply to any software media or Licensed Program that (A) has been altered or

modified, except by Harris; (B) has not been installed, operated, repaired, or maintained in accordance with instructions supplied by Harris; (C) has

been subjected to abnormal physical or electrical stress, misuse, negligence, or accident; or (D) is used in ultra-hazardous activities.

DISCLAIMER OF WARRANTY

EXCEPT AS EXPRESSLY PROVIDED IN THIS STANDARD WARRANTY POLI CY STATEMENT, HARRIS HEREBY EXPRESSLY DISCLAIMS ALL

REPRESENTATIONS, CONDITIONS AND WARRANTIES, WHETHER EXPRESS OR IMPLIED, INCLUDING BY WAY OF EXAMPLE AND NOT LIMITATION, THE

IMPLIED WARRANTIES OF TITLE, MERCHANTABILITY, NONINFRINGEMENT AND FITNESS FOR A PARTICULAR PURPOSE.

LIMITATION ON LIABILITY

NOTWITHSTANDING ANYTHING HEREIN TO THE CONTRARY, IN NO EVENT WILL HARRIS BE LIABLE FOR ANY SPECIAL, INCIDENTAL, PUNITIVE OR

CONSEQUENTIAL DAMAGES WHATSOEVER, INCLUD ING LOSS OF PROFITS, WHETHER ARISING IN CONTRACT, TORT, WARRANTY OR OTHERWISE,

EVEN IF IT HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. THE LIMITATIONS S ET FORTH HERE WILL APPLY EVEN IF THE REMEDIES OF

ERROR CORRECTION, REPAIR OR REPLACEMENT, REPERFORMANCE OF SERVICES AND REFUND OF PAYMENTS COMPLETELY FAIL OF THEIR ESSENTIAL

PURPOSE. NOTWITHSTANDING ANYTHING HEREIN TO THE CONTRARY, THE LIMIT OF HARRIS’ LIABILITY (WHETHER IN CONTRACT, TORT,

NEGLIGENCE, STRICT LIABILITY, BY STATUTE OR OTHERWISE) TO CUSTOMER OR TO ANY THIRD PARTY CONCERNING THE HARRIS EQUIPMENT OR

SOFTWARE LICENSES SOLD TO CUSTOMER AND WARRANTED HEREUNDER, HARRIS’ PERFORMANCE OR NONPERFORMANCE, OR IN ANY MANNER

RELATED TO THIS STANDARD WARRANTY POLICY STATEMENT, FOR ANY AND ALL CLAIM S WILL NOT IN THE AGGREGATE EXCEED THE ACTUAL

AMOUNTS RECEIVED BY HARRIS FOR THE SPECIFIC PRODUCT WITH RESPECT TO WHICH SUCH CLAIM IS MADE.

GOVERNING LAW AND JURISDICTION

1. Applicable Law, Venue and Jurisdiction

interpreted in accordance with the laws of the state of Florida, US A, regardless of any law principles requiring the application of any other law. The

parties agree that the exclusive venue for any action related to the dispute or interpretation of this Standard Warranty Policy Sta tement shall be in the

courts with the appropriate jurisdiction located in Orlando, Florida, and each party irrevocably submits to the jurisdiction of each such court in any such

action and waives any objection it may now or hereafter have to venue or personal jurisdiction in each such court. The prevailing party in any action

related to the dispute or interpretation of this Standard Warranty Policy Statement shall be entitled to recover its reasonable attorneys fees incurred in

pursuing the action, including those fees incurred througho ut all bankruptcy and appellate proceedings.

2. Jury Waiver

RELATING TO THE DISPUTE OR INTERPRETATION OF THIS STANDARD WARRANTY POLICY STATEMENT, WHETHER SOUNDING IN CONTRACT, TORT, OR

OTHERWISE. THE PARTIES SPECIFICALLY ACKNOWLEDGE THAT THIS WAIVER IS MADE KNOWINGLY AND VOLUNTARILY AFTER AN ADEQUATE

OPPORTUNITY TO NEGOTIATE ITS TERMS.

. THE PARTIES FURTHER AGREE, TO THE EXTENT PERMITTED BY LAW, TO WAIVE ALL RIGHTS TO A TRIAL BY JURY OF ANY ACTION

. Items sold as resale are such items that are not manufactured by Harris but may be utilized in conjunction with or

. B-Stock equipment for non-transmitter related equipment is defined as any non- out-of-production product that is less than

. IF THE EQUIPMENT SPECIFIED IN AN ORDER IS DESCRIBED AS USED, UNLESS OTHERWISE AGREED IN WRITING BY THE

. Harris warrants all physical media (“software media”) for the licensed programs, including without limit custom software and

. Harris warrants that during the Software Warranty Period (or such other time period as agreed in writing by the parties) the

. During the Software Warranty Period, Harris will bear the material cost and shipment of corrected or replacement Licensed

. This Standard Warranty Policy Statement, and any disputes related hereto, shall be governed by and

Page 17

Installation

123456789012345678901234567890121234567

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

123456789012345678901234567890121234567

2

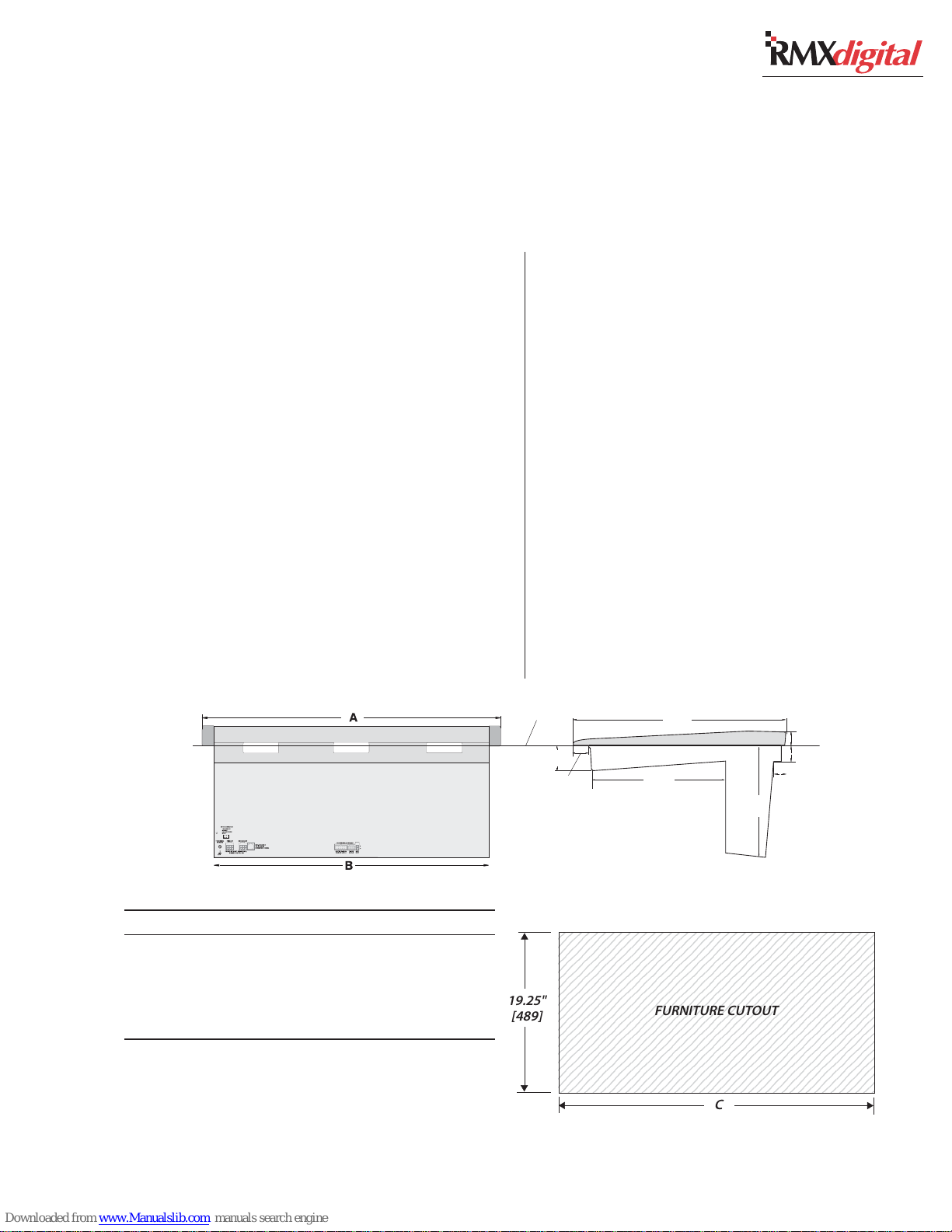

The RMX

digital

mainframe “drops into”

a cutout (as shown below) in the furniture coun-

tertop.

The console card cage, which extends below the

console, can be positioned to fall within the cabi-

net or above a cable tray.

The low-profile Reflective Display (footprint:

17.25" x 5.25") is only 5” tall. It can set behind

the frame or on top of the rear cover. If the op-

tional Tall Console Display is used, it stands on

the countertop behind the frame (its footprint: 14"

x 6", and it stands 11” tall).

Locate a 3" cable grommet near the display to

route the 6-foot cable harness thru the countertop

in order to plug into the back of the frame.

Console, back view

COUNTERTOP

2.50"

[64]

The RMX

digital

console shipment contains:

• The 12, 20 or 28 input mainframe with a Moni-

tor Control panel, a KSU card, and the DSP

cards installed with the optional items ordered

(Universal Dual Fader Panels, Blank Panels,

8-Input Expansion Cards)

• 2 RU rackmount 48-volt power supply

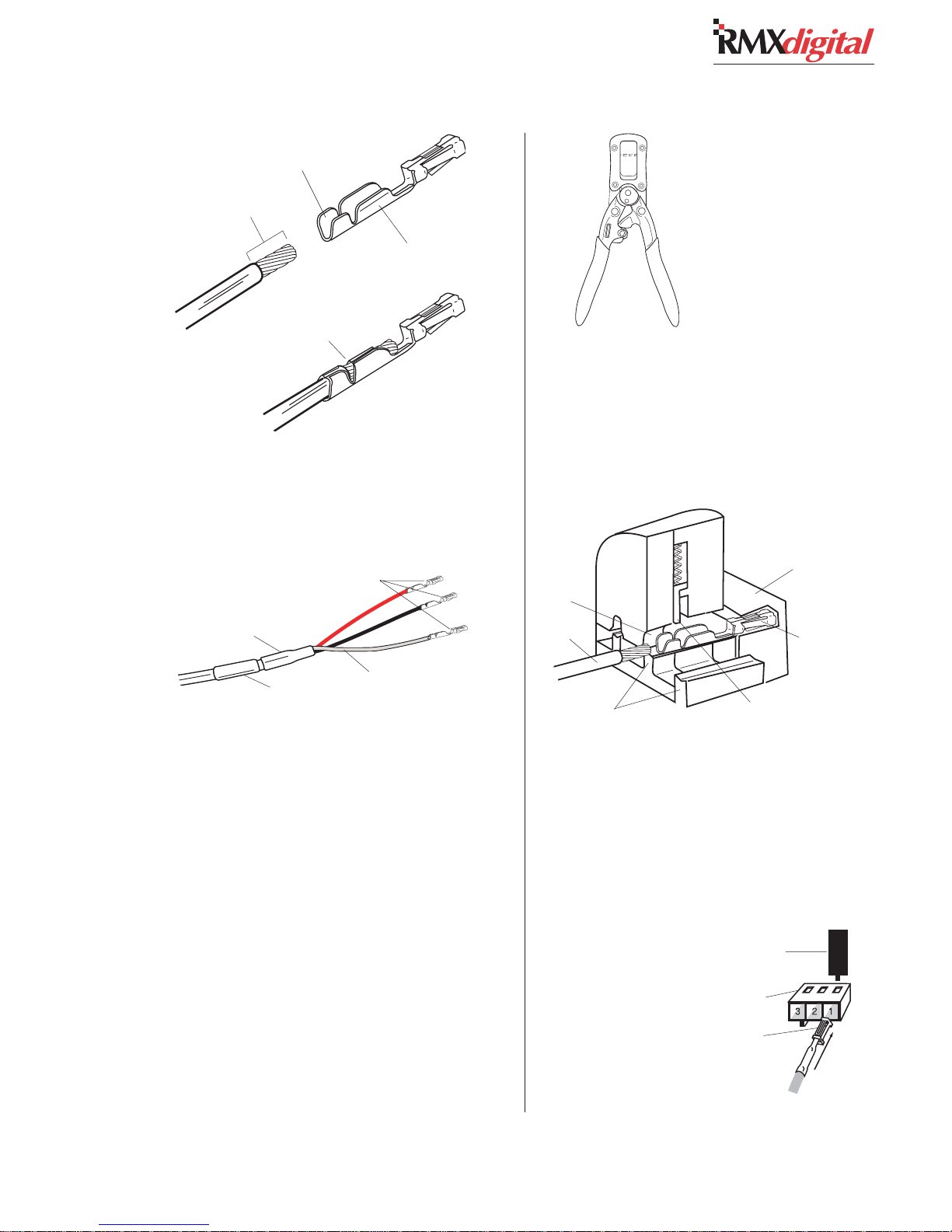

• Installation and tool kits (AMP MOD IV con-

nector housings and receptacle contacts, crimp

and contact removal tools, hex driver, backup

batteries, removable clear lenses and clear in-

sert sheet), two 48 VDC power cables, and CD-

ROM

• Stand alone Console Display with integral cable

and power supply

22"

2.75"

[70]

12.5"

[317.5]

[559]

9.75"

[248]

1.5"

[38]

1.5"

[38]

1.75"

[44]

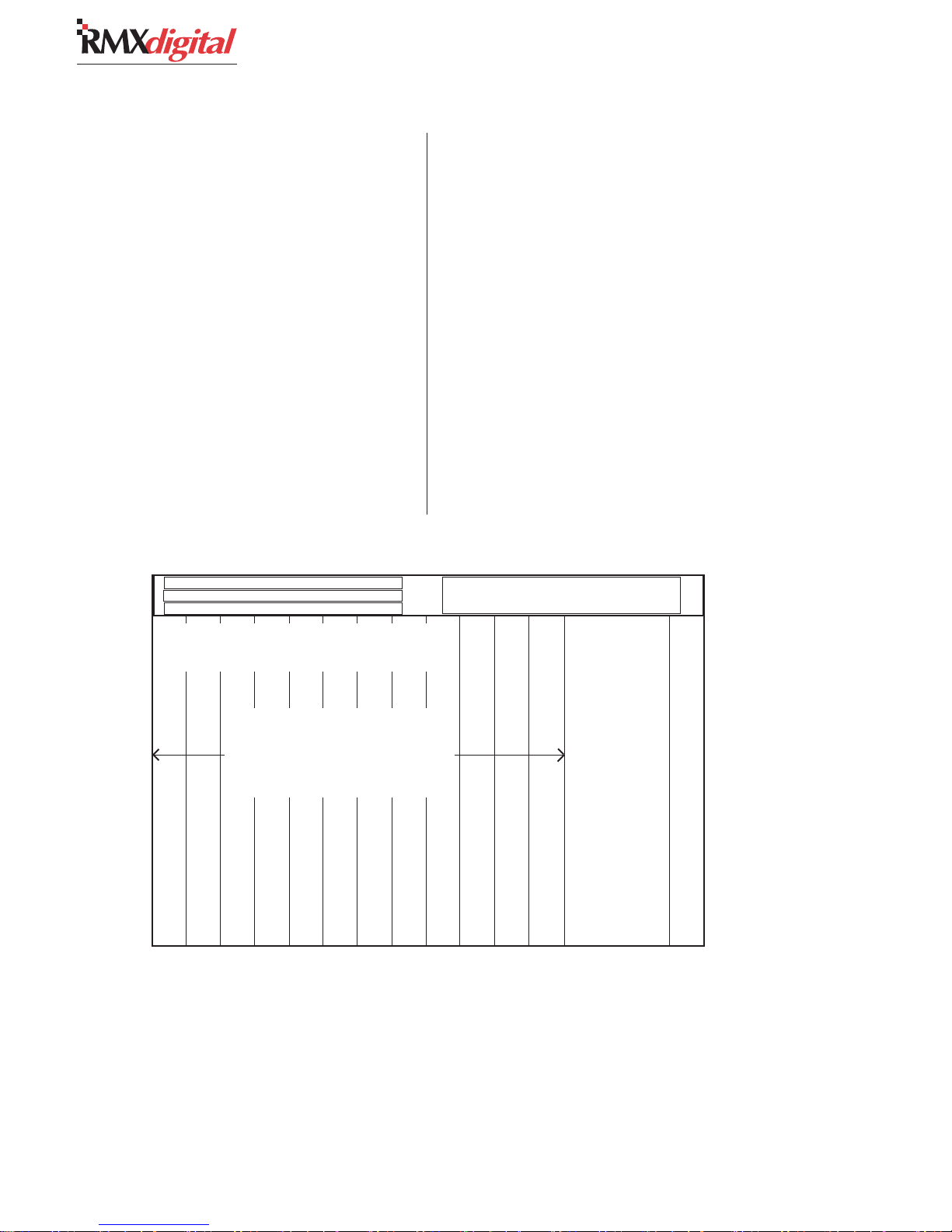

Dimension Table

Mainframe A B C

RMXdigital-4 14.6" [371] 13.3" [337] 13.5" [343]

RMXdigital-12 27.4" [696] 26.1" [662] 26.25" [668]

RMXdigital-20 40.2" [1021] 38.9" [987] 39.25" [993]

RMXdigital-28 53.0" [1346] 51.7" [1312] 52.0" [1320]

Millimeter dimensions in brackets. All dimensional tolerances are: +¼"

[6.4], -0" [0.0]. Typical setback from countertop edge to the front of

the console: 6" [152] to 12" [305].

Console, side view, with dimensions

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

19.25"

[489]

HARRIS CORPORATION

2-1

Revision C • 10/07

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

FURNITURE CUTOUT

C

Page 18

2 Installation

Console Installation

To simplify console installation, logic cable wir-

ing diagrams for specific peripheral equipment are

available from Harris Technical Support. Refer to

page 5-1 for contact information.

INSTALLATION NOTE: Do not position the con-

sole near intense electromagnetic hum fields such

as those created by audio amplifiers that use in-

expensive power transformers operating in or near

saturation. Strong electromagnetic fields may im-

pair the performance of the RMX

boring equipment. Route audio cables to achieve

maximum practical distance from all AC power

mains wiring.

99-2667 DSP Card *

99-2665 8-Input Expansion Card (optional) 99-2672-1 or 99-2672-2 KSU Card **

80-1846 Blank Panel

The DSP, KSU and 8-Input Exp. cards are hidden below a card access cover.

* The number of DSP Cards installed is determined by the frame size.

** The 99-2672-1 KSU Card comes standard in all frame sizes.

digital

RMX

and neigh-

digital-12,

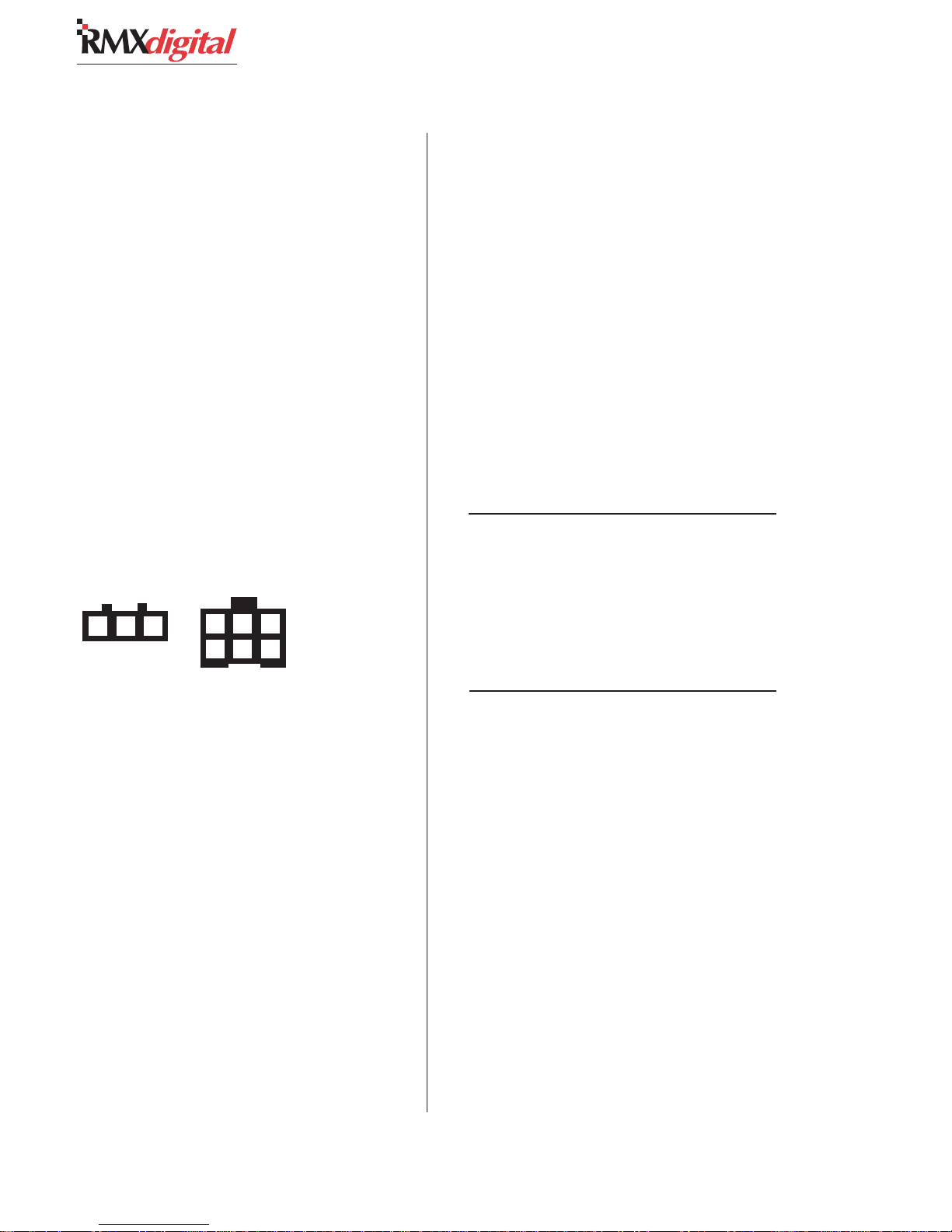

FRAME CONFIGURATION

Two panels are available for the RMX

the Universal Dual Fader Input and the Monitor

Control, which is standard on the mainframe. The

Dual Fader panel is two input slots wide, while

the Monitor Control panel is three slots wide. Typi-

cal panel positions are shown below, but panels

can be positioned up to two slots from their stan-

dard slot designations since each panel connects

to the mainframe using a single red CAT-5 cable.

Input slots can have any combination of Dual

Fader panels, single or dual width blank panels,

single or dual width divider kits, or custom switch/

control panels installed.

Contact a Harris sales representative for more

details on available RMX

Frame Configuration

digital

options.

digital

:

99-1407 Universal Dual Fader panels

take up two input slots, so there can be

up to six in a 12-input slot mainframe.

Remaining input slots are covered with

99-1410 Dual Width Blank Panels.

Input Slot 1

Input Slot 2

Input Slot 3

Input Slot 4

Input Slot 5

Input Slot 6

Input Slot 7

NONO

TE:TE:

NO

TE:

The number of available input slots equals the console

NONO

TE:TE:

model number (e.g., RMXd-20 has 20 input slots). All RMXdigital

frames have one KSU card with DSP for the buses, four input

channels and four special purpose phantom channels. Each DSP

card adds the DSP for another eight input channels (e.g., RMXd4 has no DSP card, RMXd-12 has one DSP card, RMXd-20 has

two DSP cards, and RMXd-28 has three DSP cards).

The RMXd Divider Kit allows standard Harris/PR&E Turret

Accessory Panels to be installed in a frame. There are two kits

HARRIS CORPORATION

Input Slots:

with Session, Control Room

and Studio Monitor Controls

99-1406 Monitor Control Panel (one standard)

Input Slot 8

Input Slot 9

Input Slot 10

Input Slot 11

Input Slot 12

available: 99-1411-1 is one input slot wide and holds one or

two single width turret panels; 99-1411-2 is two input slots wide

and holds two dual width panels, four single width panels, or a

combination thereof. A kit can be installed into any input slot

location. Dual Fader panels or the Monitor Control panel can be

moved left or right one or two slots to accommodate a divider kit.

Blank turret panels 99-1714-3 (1.6" x 6") or 99-1740-3 (3.2"

x 6") cover unused accessory panel openings when using the

divider kit.

2-2

99-1409 Single Width Blank Panel (standard)

Revision C • 10/07

Page 19

2 Installation

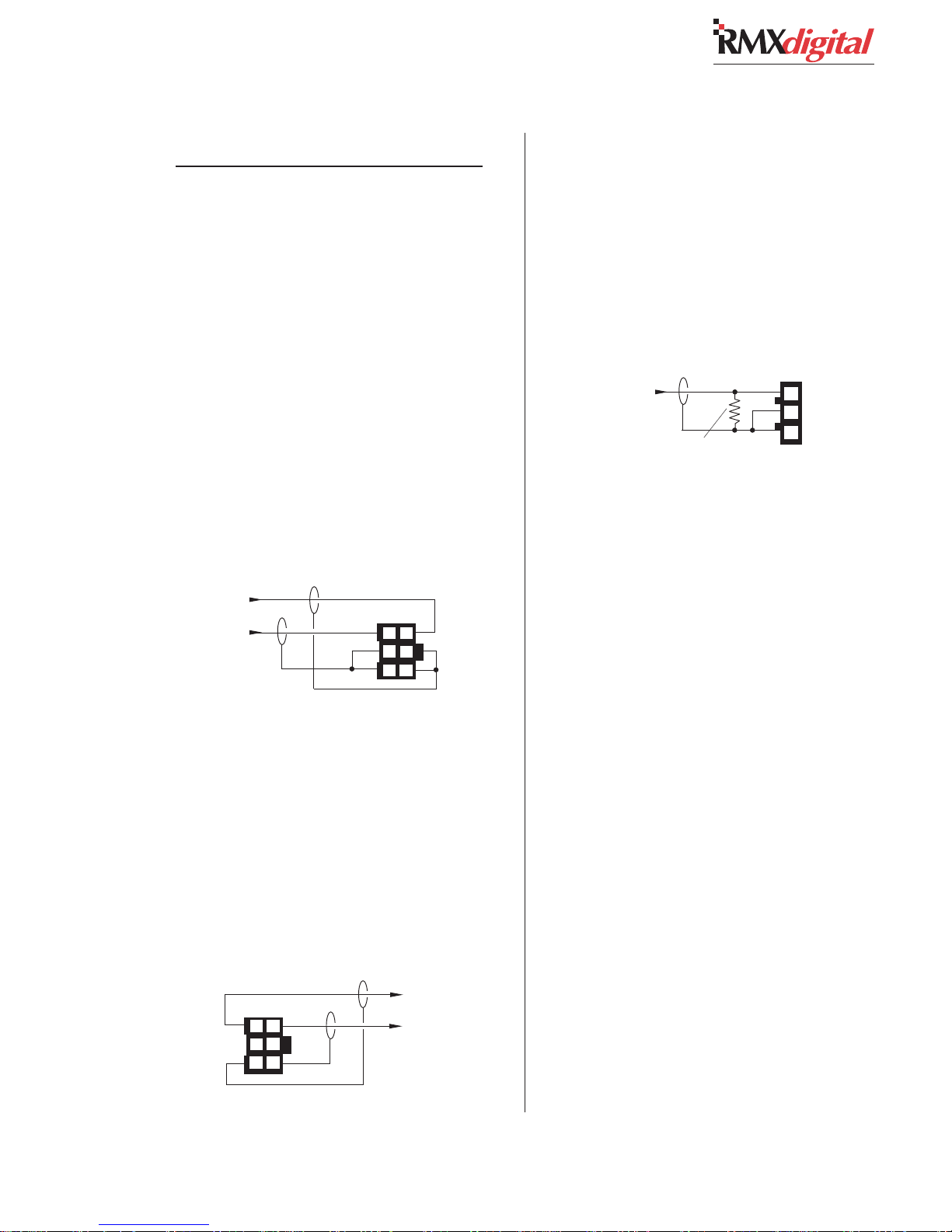

CHANNEL CONFIGURATION

Each Dual Fader panel’s specific operations and

functions are established through the settings in

the init.mac file and the current session file.

In general, Dual Fader channels are divided into

two types: VistaMax control channels and Telco

channels—which can also function as VistaMax

router control channels, but which have a special

IFB or mix-minus output assigned to each Telco

channel. Each channel in a frame comes standard

as a VistaMax control channel, but only up to six

channels can be uniquely identified as Telco chan-

nels. The Telco channels are readily apparent by

their lighted Talkback buttons.

Each channel’s functions are also configured by

the selected source signal. When a mic input is

the source, the channel strip becomes a mic chan-

nel (which means it may be controlled by a mic

remote panel, it may mute outputs and trigger a

warning lamp output when On). When a periph-

eral device is the source, the channel becomes a

line input channel (which means it may control,

and be controlled by, the peripheral device).

The six mix-minus outputs in a console can be

assigned to any six channels in the frame through

rotary switch settings on each Dual Fader panel.

NOTE: Either or both channel strips on a Dual

Fader panel can be set as a Telco input channel,

but only six total channels can be set as the six

unique Telco channels on the console.

The remaining channels in the mainframe must

have their rotary switches set to either 0 or 7. The

0 setting (the default setting for each channel) iden-

tifies it as a VistaMax control channel. The 7 set-

ting identifies that channel as being available to

be a source for control room talkback audio.

The talkback function only becomes active when

a control room mic is set as the channel’s source

and that channel’s rotary switch is set to 7.

Setting Dual Fader Panel Rotary Switches

Determine which channels will be designated

as Telco channels (up to six can be assigned) and

which channel(s) should be assigned as the con-

trol room talkback source(s).

Typically, the Telco channels are grouped to-

gether but they do not have to be. For ease of con-

figuration and system troubleshooting, however,

it is best to number the Telco channels in order

from left to right in the frame (e.g. set Telco 1 as

the left-most Telco channel, then set Telco 2 as the

next one to the right, and so on).

Determine which channels will typically have

the control room mics routed to them that may

need to talk to the Telco mix-minus outputs, to

the studio and to an external location. This is typi-

cally the board operator’s mic and a producer mic,

but any number of mics could be assigned. If the

CR mics are dedicated to certain channels, than

only those channels would need to be set to 7. If

complete flexibility is required, every channel—

except for the Telco channels, could be set to 7.

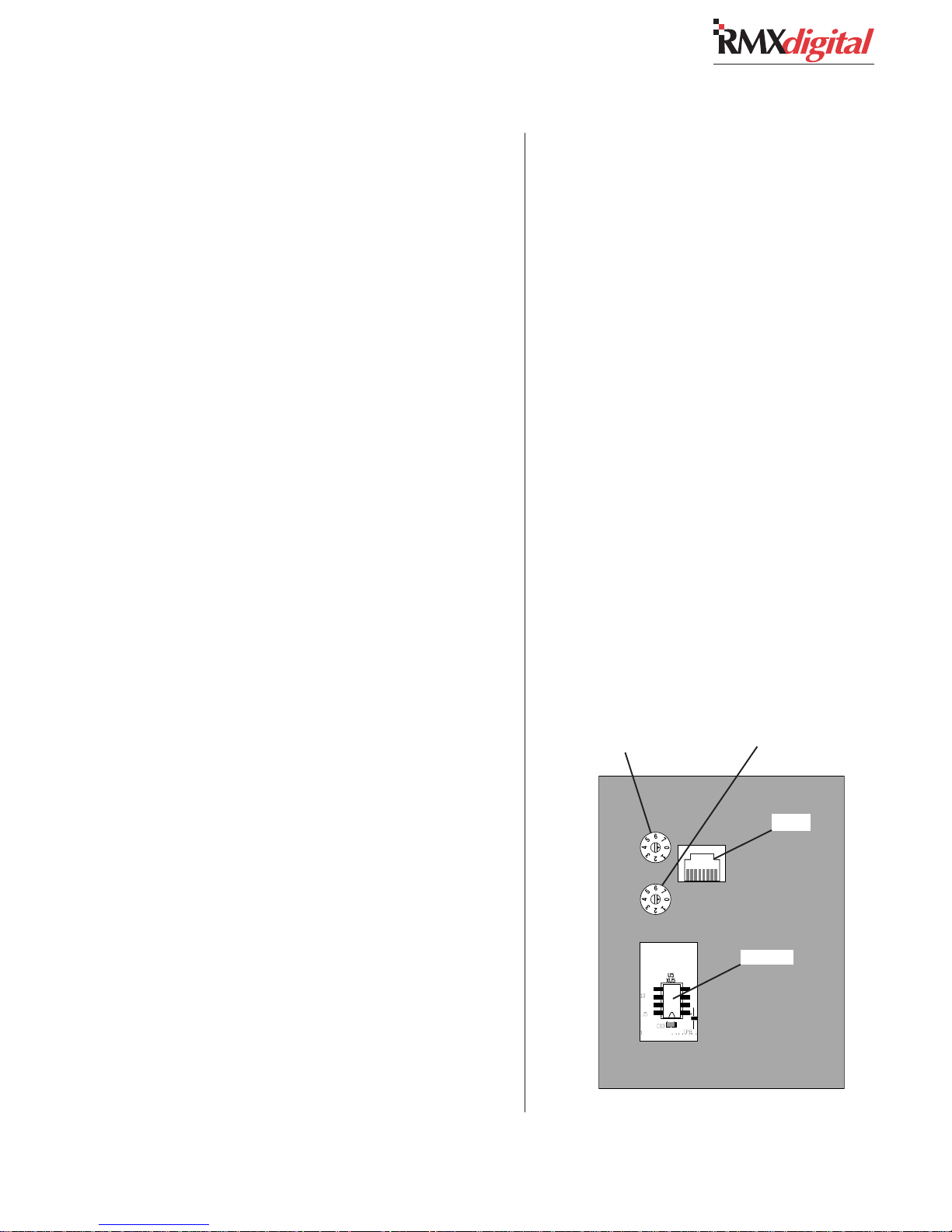

Telco Channel

Number and Talk

Channel Select

Switch for the left

channel strip

Telco Channel

Number and Talk

Channel Select

Switch for the right

channel strip

RJ-45

PROM

Dual Fader Panel, bottom view

2-3

HARRIS CORPORATION

Revision C • 10/07

Page 20

2 Installation

Remove the Dual Fader panels that need to have

their rotary switches changed (from the default 0

settings) from the mainframe (see page 5-3 for

panel removal instructions). The console power can

be left on while unplugging and reconnecting the

Dual Fader panels.

Unplug the red CAT-5 cable from the panel and

turn the panel over. Several openings—for the RJ-

45 jack, two rotary switches and the PROM, are

on the back cover (shown on the previous page).

The two rotary switches are labeled 0 - 7 with

an arrow indicating the currently selected num-

ber. The upper switch sets the Telco number or

CR mic setting for the left channel strip. The lower

switch sets the Telco number or CR mic setting for

the right channel strip. If a channel strip is not a

Telco channel or a possible CR talk source, set the

switch to 0.

Change the rotary switch to position 1 to set

that channel strip as Telco 1; to position 2 to set

that channel strip as Telco 2; and so on up to po-

sition 6 which sets that channel strip as Telco 6.

Change the rotary switch to position 7 for those

channels that will have the control room talkback

mic as a source.

Once the Dual Fader panel’s rotary switches are

set, plug the red CAT-5 cable back into the RJ-45

connector and refasten each panel to the main-

frame. Verify that all channels set as Telco chan-

nels have lighted Talkback buttons. If desired, the

Talkback button cover can be replaced by a clear

cover and a label to identify each Telco channel.

There are no other adjustments or settings re-

quired on the Dual Fader panels.

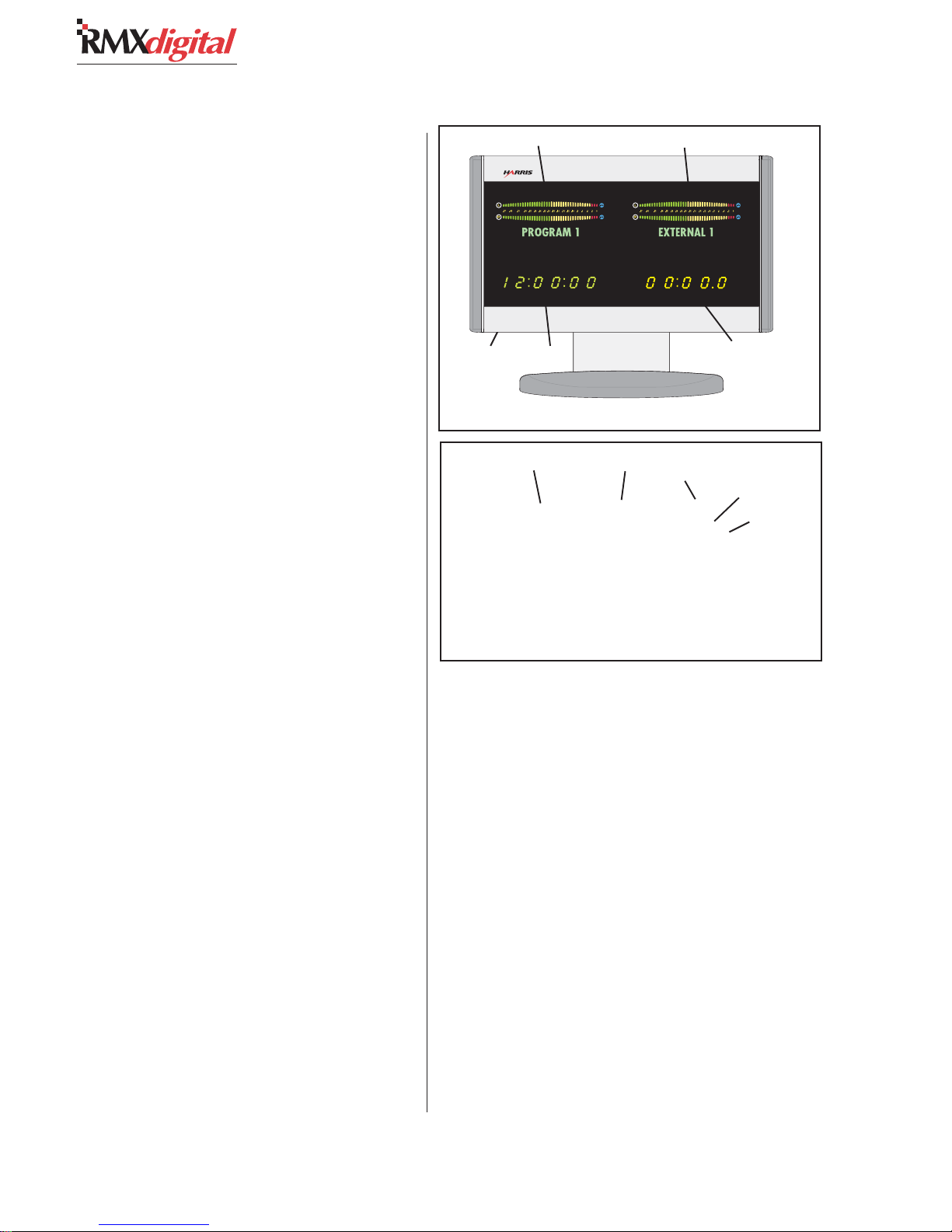

CONSOLE DISPLAY

Two console displays are available: the original

tall direct-view display (90-1950) and the low-

profile reflective display (99-1975-1). Each is po-

sitioned on the countertop behind the back of the

mainframe. The 99-1975-1 is supplied standard

Program 1 Meter Auxiliary Meter

Clock set

switches

(on bottom)

Clock

Original RMXd Console Display

Program 1 Meter Auxiliary Meter

Clock

Low-Profile Reflective Display

and the original display (90-1950) is available as

a special order. The 90-1950 is powered by a sepa-

rate 5-volt wall-wart supply (included) that plugs

into the back of the display. The low-profile dis-

play uses 48 VDC from the console. Each display

has a captive six-foot umbilical cable to carry the

meter signals, meter name display data and timer

control wires. These cables plug into keyed con-

nectors on the back of the mainframe.

Two horizontal stereo bargraph meters, with al-

phanumeric displays (PROGRAM 1, CUE, etc.)

to identify the signals, a slaveable clock, and an

event timer, are provided on each display.

The meters provide simultaneous level moni-

toring of the Program 1 bus on the left-hand meter

and another bus or system signal on the right-

hand Auxiliary Meter. The Aux Meter buttons on

the Monitor Control panel select the source for

Event

Timer

Event

Timer

Clock set

switches

(recessed)

HARRIS CORPORATION

2-4

Revision C • 10/07

Page 21

2 Installation

the right-hand meter, which switches to display

the cue bus level while Cue is active.

The meter display mode (average only or aver-

age and peak) is set by an init.mac file setting

(which is edited using the VMCC program). The

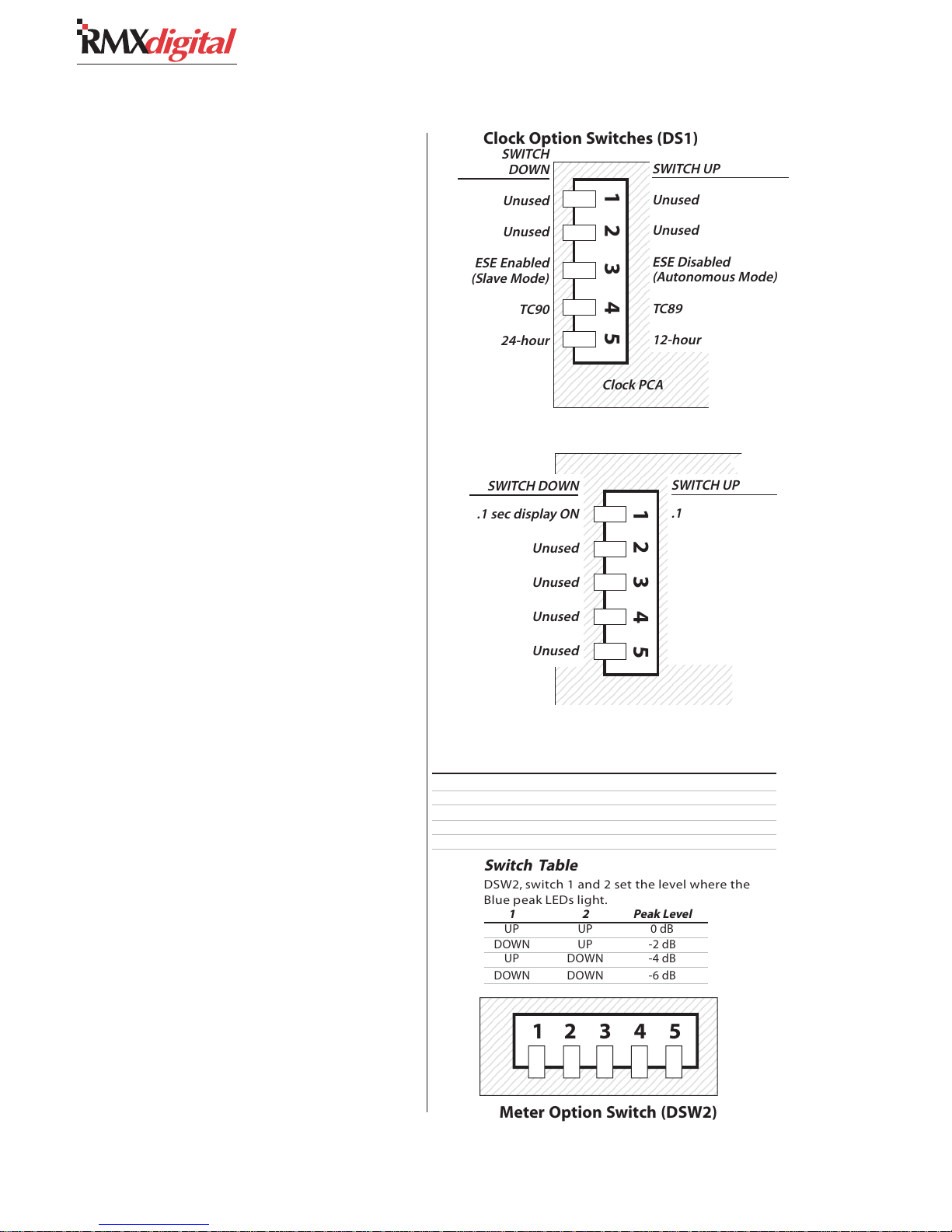

level where the blue peak indicators turn on is set

via internal DIP switches on the meter display

boards. To change these settings, the rear/bottom

cover of the Console Display must be removed.

The 12/24-hour digital clock can be slaved to

an ESE (or SMPTE in the low profile display)

master clock. An extender cable is provided in the

display umbilical cabling for the original display

so that an ESE cable can be connected at the back

of the frame. On the reflective display, an ESE or

SMPTE cable plugs into a clock board connector.

See page 6-3 for details on master clock cabling.

The event timer is controlled manually, through

buttons on the Monitor Control panel, or auto-

matically, through channel On timer reset com-

mands.

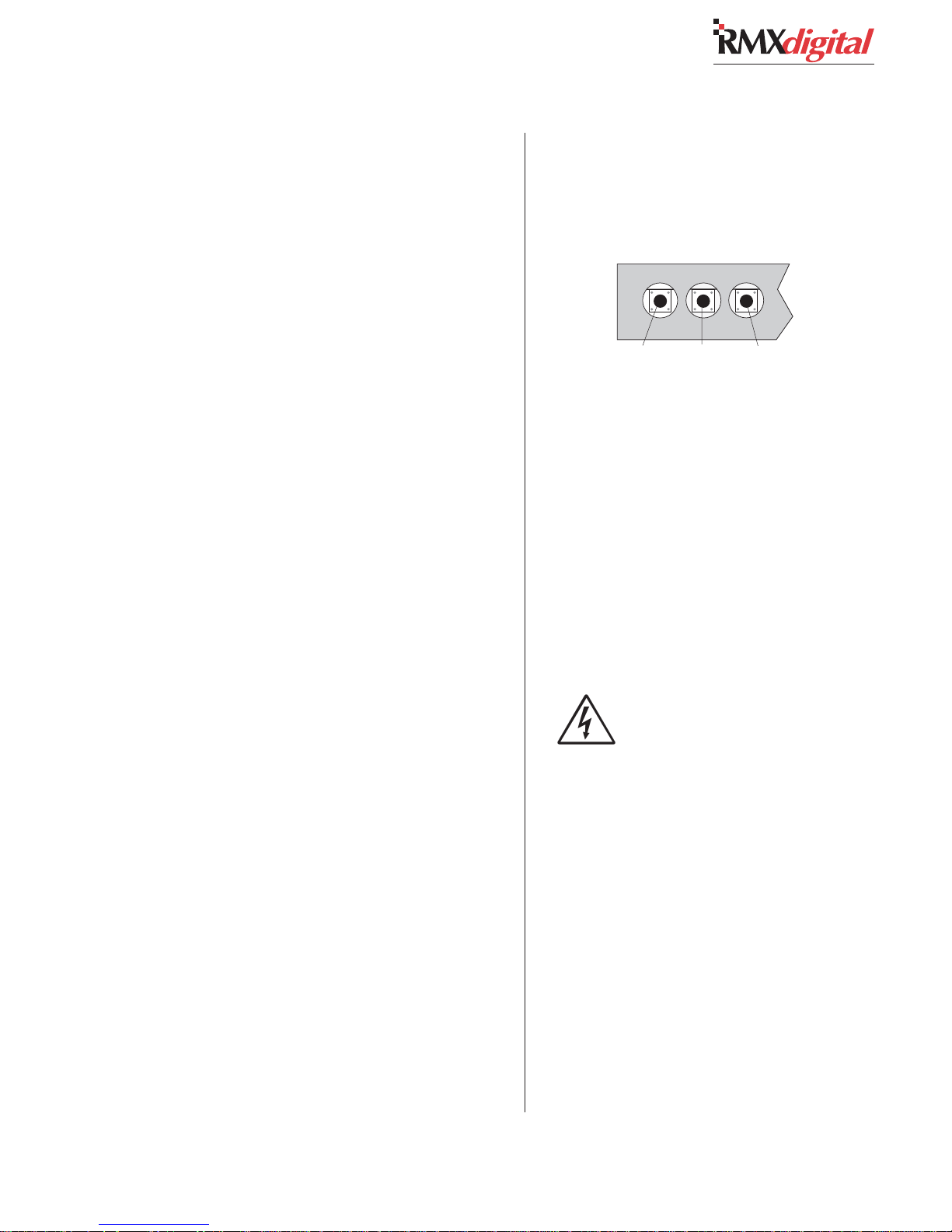

Setting The Clock

The clock can operate in autonomous or slave

mode. When used autonomously (the factory pre-

set), a quartz crystal oscillator controls clock tim-

ing. After power is applied, set the clock manually

to the current time using a nonconductive tool

(wooden swab, toothpick, etc.) to press the recessed

time-set switches (bottom left of the original dis-

play, top right on the reflective display).

• Press Fast to increment time by minutes at

a time.

• Press Slow to increment time by seconds

at a time.

• Press and hold Hold to freeze the clock to

synch it to a time reference. Set the time

slightly ahead of the reference time. Release

Hold to start the clock.

NOTE: When slave mode is selected (see Clock

Settings), if the clock is not properly connected to

an ESE or SMPTE master clock, the clock runs

off its internal oscillator. Both display colons flash

to indicate ESE timecode is not detected.

Manually Setting the Clock

(Original Display, bottom, left side)

Hold Slow Fast

(Reflective Display, top, right side)

Hold

Slow

Fas t

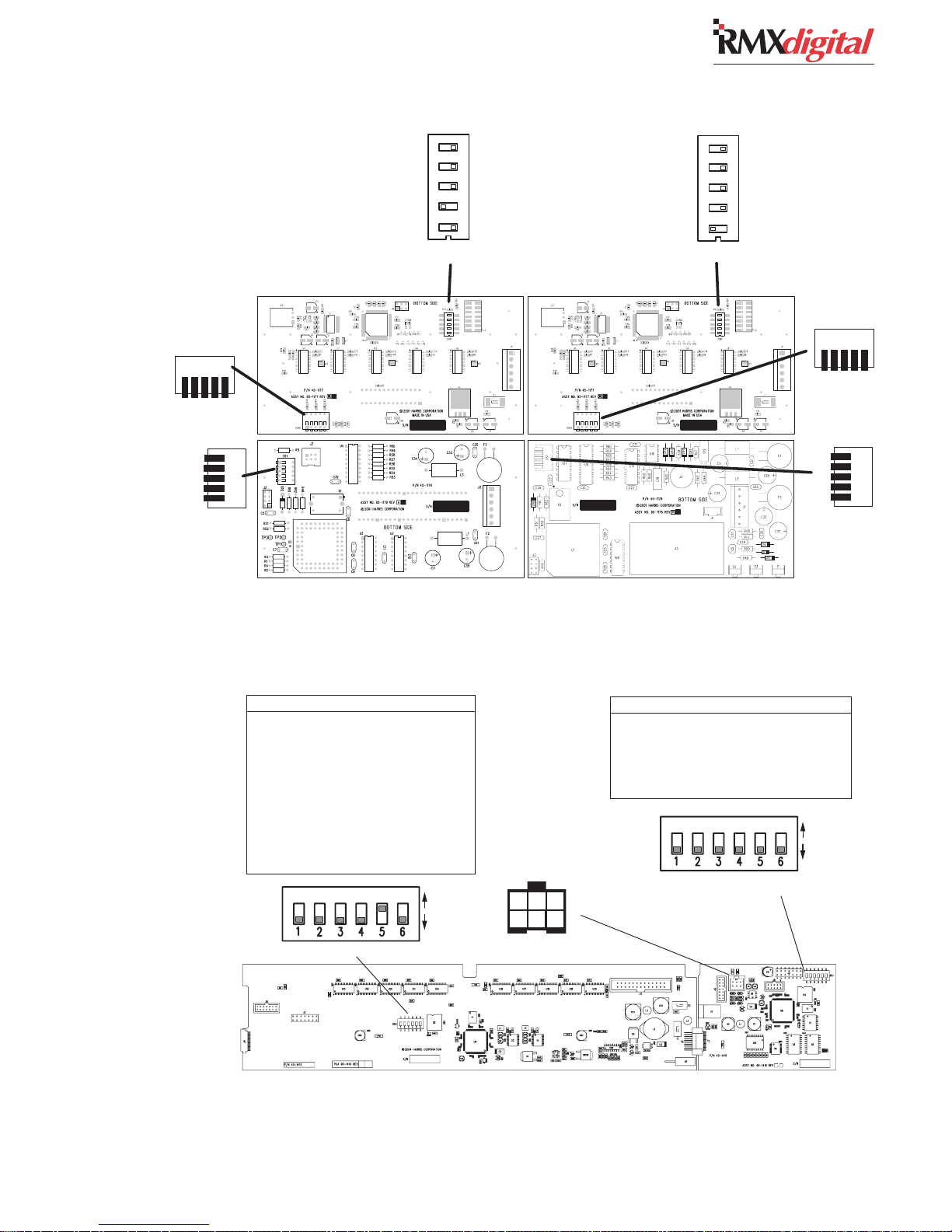

Setting Console Display DIP Switches

To change DIP switch settings on the meters,

timer or clock requires that the rear or bottom