Page 1

Platinum Z2 CD™

FM Transmitter Manual

Platinum Z2CD™

FM Transmitter Manual

888-2406-002

June 9, 2003

Rev. C

T.M. No. 888-2406-002

© Copyright Harris Corporation 2000, 2001

All rights reserved

Page 2

888-2406-002

WARNING: Disconnect primary power prior to servicing.

Returns And Exchanges

Damaged or undamaged equipment should not be returned unless written approval and a

Return Authorization is received from HARRIS CORPORATION, Broadcast Systems

Division. Special shi pping instructions an d coding will be provided to assure proper

handling. Complete details regarding circumstances and reasons for return are to be

included in the request for ret urn. Custom equipment or specia l order equipment is not

returnable. In those instances where return or exchange of equipment is at the request of the

customer, or convenience of the customer, a restocking fee will be charged. All returns will

be sent freight prepaid and properly insured by the customer. When communicating with

HARRIS CORPORATION, Broadcast Division, specify the HARRIS Order Number or

Invoice Number.

Unpacking

Carefully unpack the equipment and preform a visual inspection to determine that no

apparent damage was incurred during shipment. Retain the shipping materials un til it has

been determined that all received equipment is not damaged. Locate and retain all

PACKING CHECK LISTs. Use the PACKING CHECK LIST to help locate and identify

any components or assemblies which are removed for shipping and must be reinstalled.

Also remove any shipping supports, straps, and packing materials prior to initial turn on.

Technical Assistance

HARRIS Tech nical and Trouble shooting assist ance is availabl e from HARRIS Fiel d

Service during norm al business hours (8 :00 AM - 5:00 PM Centra l Time). Emergency

service is available 24 hours a day. Telephone 217/222-8200 to contact the Field Service

Department or address correspondence to Field Service Department, HARRIS CORPORATION, Broadcast Systems Division, P.O. Box 4290, Quincy, Illinois 62305-4290,

USA. The HARRIS factory may also be contacted through a FAX facility (217/222-7041)

or a TELEX service (650/372-2976).

Replaceable Parts Service

Replacement parts are available 24 hours a day, seven days a week from the HARRIS

Service Parts Department. Telep hone 217/222-82 00 to contact the service part s department

or address correspondence to Service Parts Department, HARRIS CORPORATION,

Broadcast Systems Division, P.O. Box 4290, Quincy, Illinois 62305-4290, USA. The

HARRIS factory may also be contacted through a FAX facility (217/222-7041) or a

TELEX service (650/372-2976).

NOTE

The # symbol used in the parts list means used with (e.g. #C001 =

used with C001)

Page 3

2406ti.fm

888-2406-002

WARNING: Disconnect primary power prior to servicing.

MANUAL REVISION HISTORY

Platinum Z2 CD™

888-2406-002

Rev. Date ECN Pages Affected

B 12-17-01 47926 Title page, added MRH1/MRH2, sections 2 and 4.

C 06-09-03 TBD Title page, MRH1/MRH2 and page 2-30.

Page 4

888-2406-002

WARNING: Disconnect primary power prior to servicing.

Page 5

2406ti.fm

888-2406-002

WARNING: Disconnect primary power prior to servicing.

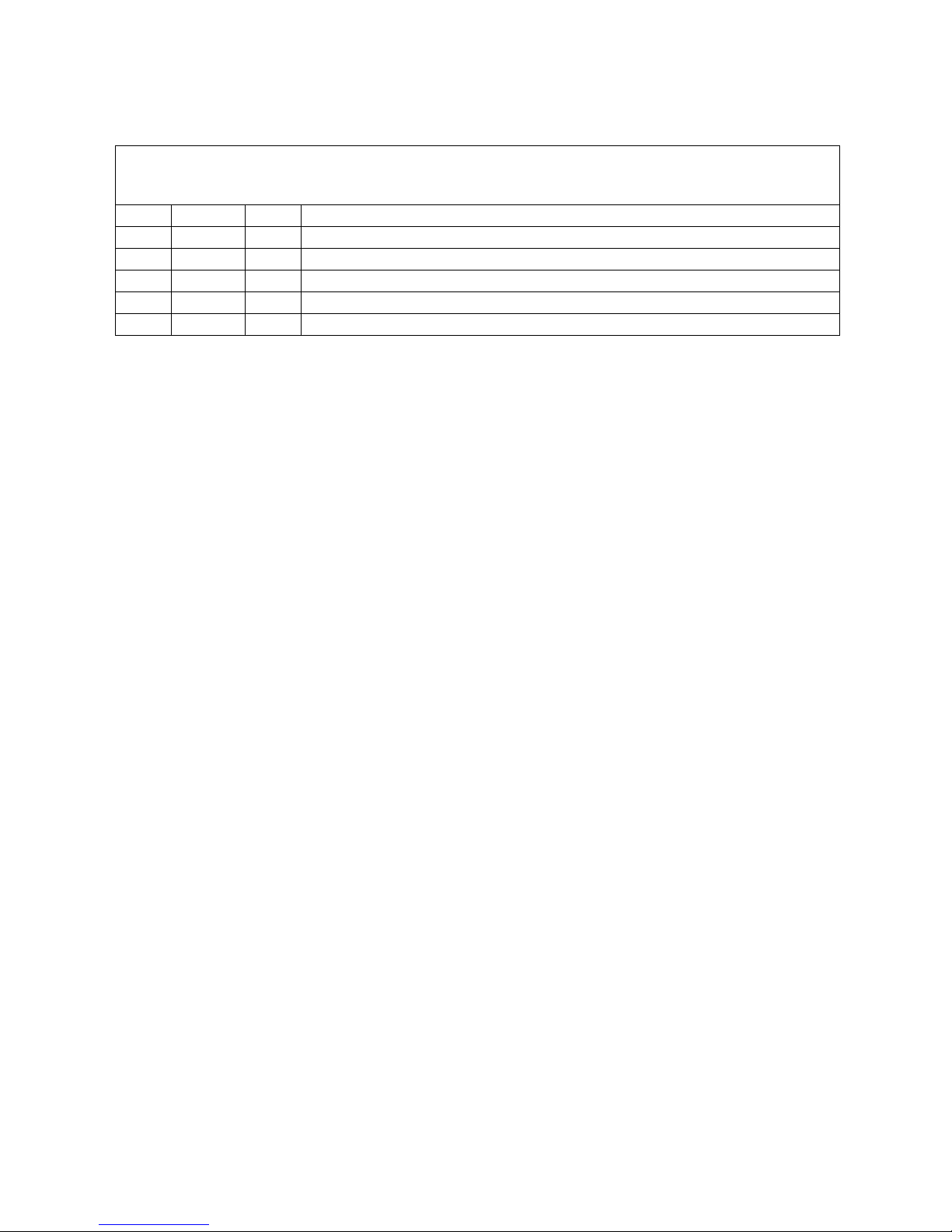

Guide to Using Harris Parts List Information

The Harris Replaceable Parts List Index portrays a tree structure with the major items being leftmost in the index.

The example below shows the Transmitter as the highest item in the tree structure. If you were to look at the bill of

materials table for the Transmitter you would find the Control Cabinet, the PA Cabinet, and the Output Cabinet. In

the Replaceable Parts List Index the Control Cabinet, PA Cabinet, and Output Cabinet show up one indentation level

below the Transmitter and implies that they are used in the Transmitter. The Controller Board is indented one level

below the Control Cabinet so it will show up in the bill of material for the Control Cabinet. The tree structure of this

same index is shown to the right of the table and shows indentation level versus tree structure level.

Example of Replaceable Parts List Index and equivalent tree structure:

The part number of the item is shown to the right of the description as is the page in the manual where the bill for

that part number starts.

Inside the actual tables, four main headings are used:

Table #-#. ITEM NAME - HARRIS PART NUMBER - this line gives the information that corresponds to the

Replaceable Parts List Index entry;

HARRIS P/N column gives the ten digit Harris part number (usually in ascending order);

DESCRIPTION column gives a 25 character or less description of the part number;

REF. SYMBOLS/EXPLANATIONS column 1) gives the reference designators for the item (i.e., C001, R102,

etc.) that corresponds to the number found in the schematics (C001 in a bill of material is equivalent to C1 on the

schematic) or 2) gives added information or further explanation (i.e., “Used for 208V operation only,” or “Used

for HT 10LS only,” etc.).

Inside the individual tables some standard conventions are used:

A # symbol in front of a component such as #C001 under the REF. SYMBOLS/EXPLANATIONS column means

that this item is used on or with C001 and is not the actual part number for C001.

In the ten digit part numbers, if the last three numbers are 000, the item is a part that Harris has purchased and

has not manufactured or modified. If the last three numbers are other than 000, the item is either manufactured by

Harris or is purchased from a vendor and modified for use in the Harris product.

The first three digits of the ten digit part number tell which family the part number belongs to - for example, all

electrolytic (can) capacitors will be in the same family

(524 xxxx 000). If an electrolytic (can) capacitor is found

to have a 9xx xxxx xxx part number (a number outside of the normal family of numbers), it has probably been

modified in some manner at the Harris factory and will therefore show up farther down into the individual parts

list (because each table is normally sorted in ascending order). Most Harris made or modified assemblies will

have 9xx xxxx xxx numbers associated with them.

The term “SEE HIGHER LEVEL BILL” in the description column implies that the reference designated part

number will show up in a bill that is higher in the tree structure. This is often the case for components that may

be frequency determinant or voltage determinant and are called out in a higher level bill structure that is more

customer dependent than the bill at a lower level.

Page 6

888-2406-002

WARNING: Disconnect primary power prior to servicing.

Page 7

2406ti.fm

888-2406-002

WARNING: Disconnect primary power prior to servicing.

WARNING

The currents and voltages in this equipment are dangerous. Personnel must at all times observe safety warn ings, in struct ions and regu lations.

This manual is intended as a general guide for trained and qualified per sonnel who are

aware of the dangers inherent in handling potentially hazardous electrical/electronic

circuits. It is not intended to contain a complete statement of all safety precautions which

should be observed by personnel in using this or other electronic equipment.

The installation, operation, maintenance and service of this equipment involves risks both

to personnel and equipment, an d must be pe rformed only by qualified pe rsonnel exercis ing

due care. HARRIS CORPORATION shall not be responsible for injury or damage

resulting from improper procedures or from the use of improperly trained or inexperienced

personnel performing such tasks.

During installation and operation of this equipment, local building codes and fire protection standards must be observed. The following National Fire Prote ction Association

(NFPA) standards are recommended as reference:

• Automatic Fire Detectors, No. 72E

• Installation, Maintenance, and Use of Portable Fire Extinguishers, No. 10

• Halogenated Fire Extinguishing Agent Systems, No. 12A

WARNING

Always disconnect power before opening covers, doors, enclosures,

gates, panels or shields. Always use grounding sticks and short out

high volta ge points before servi cing. Never make int ernal adjustments, perform maintenance or service when alone or when fatigued.

Do not remove, short-circuit or tamper with interlock switche s on access covers, doors,

enclosures, gates, panels or shields. Keep away from live circuits, know your equipment

and don’t take chances.

WARNING

In case of emergency ensure that power has been disconnected.

If oil filled or electrolytic capacitors are utilized in your equipment, an d if a leak or b ulge

is apparent on the capacitor case when the unit is opened for service or mainten ance, allow

the unit to cool down before attempting to remove the defective capacitor. Do not attempt

to service a defective capacitor while it is hot due to the po ssibility of a case rup ture and

subsequent injury.

Page 8

888-2406-002

WARNING: Disconnect primary power prior to servicing.

Page 9

2406ti.fm

888-2406-002

WARNING: Disconnect primary power prior to servicing.

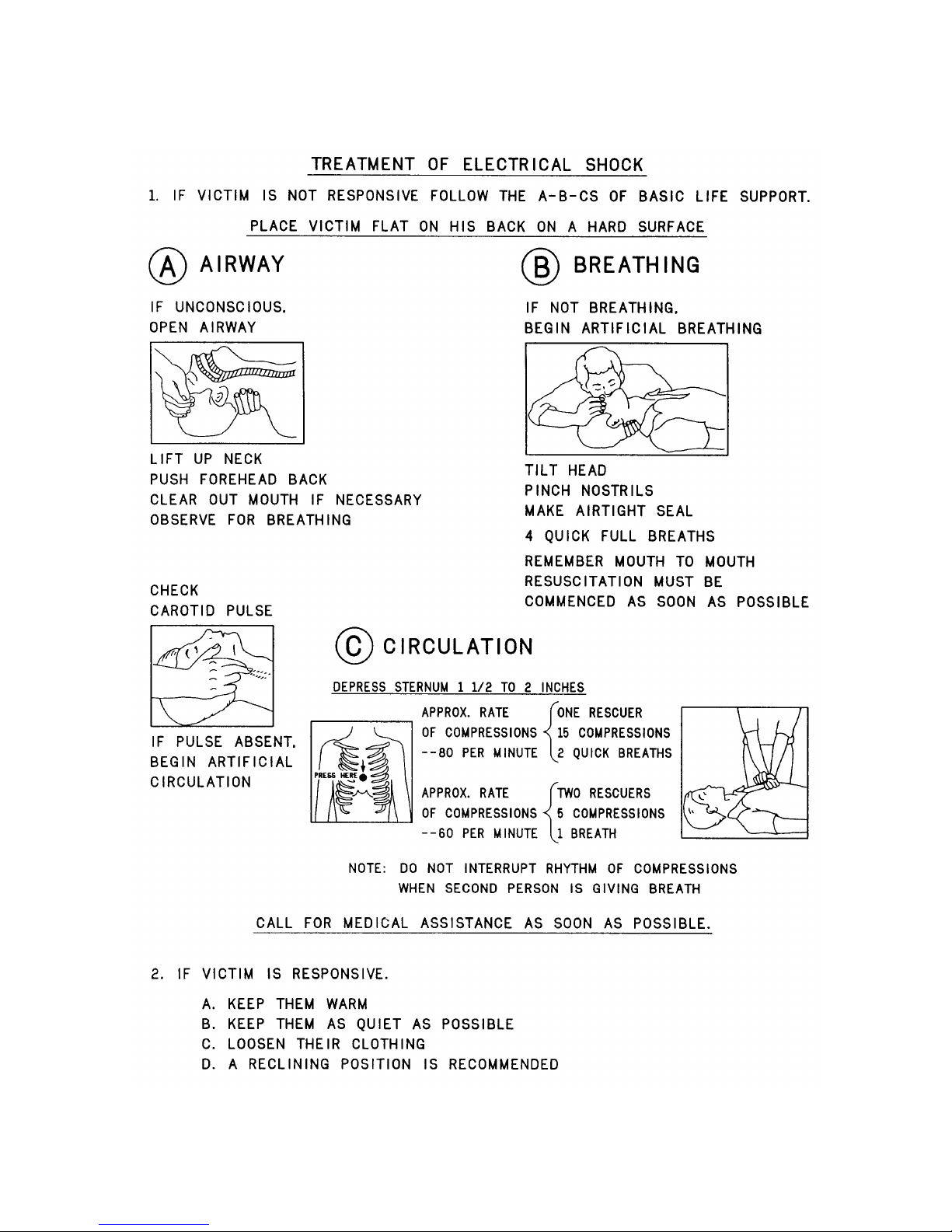

FIRST -AID

Personnel engaged in the installation, operation, maintenance or servicing of this

equipment are urged to become familiar with first-aid theory and practices. The following

information is not intended to be complete first-aid procedures, it is a brief and is only to

be used as a reference. It is the duty of all personnel using the equipment to be prepared to

give adequate Emergency First Aid and thereby prevent avoidable loss of life.

Treatment of Electrical Burns

1. Extensive burned and broken skin

A. Cover area with clean sheet or cloth. (Cleanest available cloth article.)

B. Do not break blisters, remove tissue, remove adhered particles of clothing, or

apply any salve or ointment.

C. Treat victim for shock as required.

D. Arrange transportation to a hospital as quickly as possible.

E. If arms or legs are affected keep them elevated.

NOTE

If medical help will not be available within an hour and the victim

is conscious and not vomiting, give him a weak solution of salt and

soda: 1 level teaspoonful of s al t and 1/ 2 le vel teas po onf ul of bak ing

soda to each quart of water (neither hot or co ld). Allow victim to si p

slowly about 4 ounces (a half of glass) over a period of 15 minutes.

Discontinue fluid if vomiting occurs. (Do not give alcohol.)

2. Less severe burns - (1st & 2nd degree)

A. Apply cool (not ice cold) compresses using the cleanest available cloth arti-

cle.

B. Do not break blisters, remove tissue, remove adhered particles of clothing, or

apply salve or ointment.

C. Apply clean dry dressing if necessary.

D. Treat victim for shock as required.

E. Arrange transportation to a hospital as quickly as possible.

F. If arms or legs are affected keep them elevated.

REFERENCE

ILLINOIS HEART ASSOCIATION

AMERICAN RED CROSS STANDARD FIRST AID AND PERSONAL SAFETY

MANUAL (SECOND EDITION)

Page 10

888-2406-002

WARNING: Disconnect primary power prior to servicing.

Page 11

888-2406-002 1

WARNING: Disconnect primary power prior to servicing.

Table of Contents

1 Introduction/Specifications

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Features/Benefits. . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Harris DIGIT Digital FM Exciter. . . . . . . . . . . . . . .1-3

Harris SuperCiter Analog Exciter. . . . . . . . . . . . . . .1-3

Redundant Exciters. . . . . . . . . . . . . . . . . . . . . . . . . .1-3

PA/IPA Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

RF Combining. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

Directional RF Sample Port . . . . . . . . . . . . . . . . . . .1-5

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Air System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 -5

Performance Specifications. . . . . . . . . . . . . . . . . . . . .1-5

2 Installation & Initial Turn-On

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Returns and Exchanges . . . . . . . . . . . . . . . . . . . . . . . .2-1

Air Cooling Requirements. . . . . . . . . . . . . . . . . . . . . .2-2

Z2 Transmitter Installation . . . . . . . . . . . . . . . . . . . . .2-2

Transmitter Placement . . . . . . . . . . . . . . . . . . . . . . .2-3

Removal of Pallet Bolts . . . . . . . . . . . . . . . . . . . . .2-3

Visual Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Exciter Installation . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

3-Phase Power Supply Installation . . . . . . . . . . . . . .2-5

Power Transformer Tapping. . . . . . . . . . . . . . . . . .2-5

Power Supply Connections . . . . . . . . . . . . . . . . . .2-5

Dual Power Supply Option. . . . . . . . . . . . . . . . . . .2-8

Single Phase Power Supply Installation . . . . . . . . . .2-9

Power Transformer Tapping. . . . . . . . . . . . . . . . . .2-9

Power Supply Connections . . . . . . . . . . . . . . . . . .2-9

Dual Power Supply Option. . . . . . . . . . . . . . . . . .2-12

Transmitter AC Connections. . . . . . . . . . . . . . . . . .2-13

Information concerning some 360 to 416

volt systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

Three Phase AC Connection . . . . . . . . . . . . . . . .2-14

Single Phase AC Connection . . . . . . . . . . . . . . . .2-15

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

Low Voltage Power Supply and Blower . . . . . . .2-16

Exciter AC Voltage Selection. . . . . . . . . . . . . . . .2-16

RF Output Connection . . . . . . . . . . . . . . . . . . . . . .2-16

Audio Input Connections . . . . . . . . . . . . . . . . . . . .2-16

External and Failsafe Interlock Connections . . . . . 2-17

External Interlock Connection . . . . . . . . . . . . . . .2-17

Failsafe Interlock Connection . . . . . . . . . . . . . . . 2-17

Initial Turn-on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Remote Control Connections . . . . . . . . . . . . . . . . . . 2-23

Remote/Extended Control and Status Connections 2-24

Typical remote/extended control and status connec-

tions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Extended Metering. . . . . . . . . . . . . . . . . . . . . . . . 2-26

UPS IN/Remote Exciter S elect,

Configurable Input TB1-9. . . . . . . . . . . . . . . . . . . 2-26

Using an Uninterruptable Power Supply or UPS . . . 2-27

Setting the UPS Power Level. . . . . . . . . . . . . . . . 2-27

Optimizing Efficiency. . . . . . . . . . . . . . . . . . . . . . . . 2-28

Setting the Low Power Alarm. . . . . . . . . . . . . . . . . . 2-29

Jumper Settings for In stallation of a Harris Exciter . 2-29

Power Distribution for Optimum Transmitter

Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Overheating from Line Unbalance. . . . . . . . . . . . . 2-33

Transmitter Noise Performance . . . . . . . . . . . . . . . 2-33

The Causes of Line Unbalance. . . . . . . . . . . . . . . . 2-34

Three Phase Delta Distribution Transformers . . . . 2-34

Three Phase Wye Distribution Transformers . . . . . 2-35

3 Operator Guide

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Transmitter Controls . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Transmitter Metering. . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Forward Power (FWD PWR) Units of Measure . . . 3-3

Reflected Power (RFL PWR) Units of Measure . . . 3-3

Using the Diagnostic Display . . . . . . . . . . . . . . . . . . . 3-4

HOME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

BACK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

MORE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Asterisk and Pound Signs(*, #) . . . . . . . . . . . . . . . . 3-8

Fault Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Emergency Operating Procedures. . . . . . . . . . . . . . . 3-10

Multiple PA Failures in a Foursome. . . . . . . . . . . . 3-10

Manual Exciter Switching. . . . . . . . . . . . . . . . . . . . . 3-11

Manual IPA Switching . . . . . . . . . . . . . . . . . . . . . . . 3-11

Optimizing Efficiency. . . . . . . . . . . . . . . . . . . . . . . . 3-12

Fan Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

4 Overall System Theory

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Page 12

2 888-2406-002

WARNING: Disconn ect primary power pri or to servicing.

Table of Contents

RF Flow Block Diagram Description . . . . . . . . . . . . .4-1

Exciters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

IPAs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Z-Plane Divider Board . . . . . . . . . . . . . . . . . . . . . .4-3

Z-Plane Combiner Board . . . . . . . . . . . . . . . . . . . .4-4

RF output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Detailed RF Theory of Operation . . . . . . . . . . . . . . . .4-5

Exciter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

Automatic Exciter Switching . . . . . . . . . . . . . . . . .4-5

Manual Exciter Switching . . . . . . . . . . . . . . . . . . .4-5

IPA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

IPA Power Output. . . . . . . . . . . . . . . . . . . . . . . . . .4-6

IPA Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . .4-6

IPA Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Main/Alternate Exciter Switching . . . . . . . . . . . . .4-7

Main/Alternate IPA Switching . . . . . . . . . . . . . . . .4-7

IPA Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Air flow sensing.. . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

IPA_1 and IPA_2 interlocking.. . . . . . . . . . . . . . . .4-8

IPA Power Divider (3dB Hybrid). . . . . . . . . . . . . .4-9

Z-Plane Combiner/Divider Boards . . . . . . . . . . . . . .4-9

8-Way Divider . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

8-Way Combiner. . . . . . . . . . . . . . . . . . . . . . . . . .4-10

PA Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Power Amplifier (PA). . . . . . . . . . . . . . . . . . . . . .4-12

Harmonic Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 -14

Directional Coupler Assembly . . . . . . . . . . . . . . . .4-14

Power Supply Block Diagram Description . . . . . . . .4-15

PA Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . .4-15

3-Phase Power Supply . . . . . . . . . . . . . . . . . . . . .4-15

3-Phase Power Supply . . . . . . . . . . . . . . . . . . . . .4-16

Single Phase Power Supply . . . . . . . . . . . . . . . . .4-18

Low Voltage Power Supply. . . . . . . . . . . . . . . . . . .4-20

Detailed Power Supply Descriptions. . . . . . . . . . . . .4-21

3-Phase PA Power Supply. . . . . . . . . . . . . . . . . . . .4-21

Rectifier Board . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Rectifier Board Circuit Description . . . . . . . . . . .4-23

Single Phase PA Power Supply. . . . . . . . . . . . . . . .4-25

Rectifier Board . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

Rectifier Board Circuit Description . . . . . . . . . . .4-26

Power Supply ID Jumpers. . . . . . . . . . . . . . . . . . . .4-28

Low Voltage Power Supply Board . . . . . . . . . . . . .4-29

Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-29

Cooling System Description . . . . . . . . . . . . . . . . . . .4-30

Control System Description. . . . . . . . . . . . . . . . . . . .4-30

Master Controller . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

EEPROM U39 . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

APC, Automatic Power Control . . . . . . . . . . . . . 4-32

Calibration Factors and A/D Values. . . . . . . . . . . . 4-34

DAC_APC_REF . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Forward Factor and A/D_FWD_PWR . . . . . . . . 4-36

APC Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-37

MAX HIGH, MAX LOW and UPS Power Levels4-38

EXC Factor and IPA Factor . . . . . . . . . . . . . . . . . 4-39

Reflect Factor and A/D_RFL_PWR . . . . . . . . . . 4-39

VSWR Foldback. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-40

Master Controller Faults . . . . . . . . . . . . . . . . . . . 4-41

PA Controller Board. . . . . . . . . . . . . . . . . . . . . . . . 4-42

PA Turn On/Turn Off. . . . . . . . . . . . . . . . . . . . . . 4-42

Metering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

Crossover (XOVER) Protection (Z2R only) . . . . 4-43

PA Controller Faults . . . . . . . . . . . . . . . . . . . . . . 4-44

Power Supply Controller . . . . . . . . . . . . . . . . . . . . 4-44

Power Supply Turn On . . . . . . . . . . . . . . . . . . . . 4-44

PA Power Supply Discharge . . . . . . . . . . . . . . . . 4-45

Power Supply Standby Mode . . . . . . . . . . . . . . . 4-45

Discharge Protection Circuit . . . . . . . . . . . . . . . . 4-45

RESET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Watchdog Timer. . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

PS Controller Faults. . . . . . . . . . . . . . . . . . . . . . . 4-47

Life Support Board. . . . . . . . . . . . . . . . . . . . . . . . . 4-47

Normal Operational Mode. . . . . . . . . . . . . . . . . . 4-47

Life Support Mode. . . . . . . . . . . . . . . . . . . . . . . . 4-54

5 Maintenance and Alignment

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Routine Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Record Keeping . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Recommended Log Readings . . . . . . . . . . . . . . . . 5-1

Transmitter Logbook. . . . . . . . . . . . . . . . . . . . . . . 5-2

Maintenance Logbook. . . . . . . . . . . . . . . . . . . . . . 5-2

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Module cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Cleaning the Air Filter. . . . . . . . . . . . . . . . . . . . . . 5-3

Cleaning the Power Supply . . . . . . . . . . . . . . . . . . 5-3

Blower Motor Maintenance . . . . . . . . . . . . . . . . . . . . 5-3

System Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Isolation Board Maintenance . . . . . . . . . . . . . . . . . . . 5-4

Isolation Board Removal . . . . . . . . . . . . . . . . . . . . . 5-5

Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Installation of Isolation Assembly. . . . . . . . . . . . . 5-6

Page 13

888-2406-002 3

WARNING: Disconnect primary power prior to servicing.

Table of Contents

PA Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Directional Coupler Removal and Replacement. . . . .5-7

Typical Coupling Ratios . . . . . . . . . . . . . . . . . . . . . .5-7

Setting Maximum Power Limits . . . . . . . . . . . . . . . . .5-8

Setting FWD PWR to Display 100% . . . . . . . . . . . . .5-9

Setting Life Support Power Level . . . . . . . . . . . . . . . .5-9

Forward Power Calibration . . . . . . . . . . . . . . . . . . . .5-10

Reflected Power Calibration . . . . . . . . . . . . . . . . . . .5-13

PC Board Replacement Procedures. . . . . . . . . . . . . .5-15

Replacement of the Life Support Board . . . . . . . . . 5-15

Replacing the Power Supply Controller Board. . . .5-17

Replacing a PA Controller Board . . . . . . . . . . . . . .5-17

Replacing the Master Controller Board . . . . . . . . . 5-18

Replacement Using EEPROM U39 From

Old Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

Replacing EEPROM U39. . . . . . . . . . . . . . . . . . . .5-19

System Configuration and Calibration . . . . . . . . . . .5-21

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-21

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-23

Removing and Replacing Firmware ICs . . . . . . . . . .5-23

6 Troubleshooting

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Power Amplifier Repair. . . . . . . . . . . . . . . . . . . . . . . .6-2

Transmitter Power vs. Module Failures . . . . . . . . . .6-2

Multiple PA Failures in a Foursome. . . . . . . . . . . . 6-3

Software Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

System Reset - TX_RESTART . . . . . . . . . . . . . . . . . .6-4

3 Strike Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-5

Diagnostics Display Menu Tree . . . . . . . . . . . . . . . . .6-6

Fault Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Front Panel Fault LED . . . . . . . . . . . . . . . . . . . . . . .6-7

Fault Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-7

Abbreviations Used In Fault Reporting . . . . . . . . . .6-7

Fault Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

Self Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-8

System Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

PA Muting Test. . . . . . . . . . . . . . . . . . . . . . . . . . .6-10

PA_ISO Resistor and Thermistor Test . . . . . . . . .6-10

PA RF Switch Te st . . . . . . . . . . . . . . . . . . . . . . . .6-11

Hardware Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-11

General Troubleshooting Tips . . . . . . . . . . . . . . . . . .6-12

Foldback Conditions. . . . . . . . . . . . . . . . . . . . . . . .6-12

Turning the Transmitter O N with No Pow er

Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

Asterisk and Pound Signs(*, #) . . . . . . . . . . . . . . . 6-12

Master Controller Faults. . . . . . . . . . . . . . . . . . . . . . 6-13

THERMISTOR, Fault . . . . . . . . . . . . . . . . . . . . . . 6-13

EEPROM_DEF, EEPROM U39 Default Load . . . 6-13

REF_WARNING, +5V Reference Warning. . . . . . 6-14

MSTR_REF, +5V Reference Fault. . . . . . . . . . . . . 6-14

RFL_PWR, Reflected Power Fault . . . . . . . . . . . . 6-14

INTLK, External Interlock Fault . . . . . . . . . . . . . . 6-15

FAILSAFE, Interlock Fault . . . . . . . . . . . . . . . . . . 6-15

POWER_FAIL, Fault. . . . . . . . . . . . . . . . . . . . . . . 6-15

LOW_AIR, Fault . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

UPS, Uninterruptable Power Supply Fault. . . . . . . 6-16

CPLR_NC, Forward Directional Coupler Cable Not

Connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

IPA_#_MUTE, Fault . . . . . . . . . . . . . . . . . . . . . . . 6-16

IPA_#_LOW, Fault. . . . . . . . . . . . . . . . . . . . . . . . . 6-16

IPA_#_OC, Fault . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16

IPA_TW, IPA Temperature Warning . . . . . . . . . . . 6-17

IPA_OT, Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

IPA_#_OUT, Fault . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

IPA_LOAD, Fault. . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

PSC#_COMM, Fault . . . . . . . . . . . . . . . . . . . . . . . 6-17

PAC#_COMM, Fault . . . . . . . . . . . . . . . . . . . . . . . 6-17

AMB_WARNING, Ambient Temperature Warning6-18

AMB_TEMP, Ambient Temperature Fault . . . . . . 6-18

ISO_BZ, Over-Temperature. . . . . . . . . . . . . . . . . . 6-18

System ISO Foldback . . . . . . . . . . . . . . . . . . . . . 6-18

System ISO Overload (Fault) . . . . . . . . . . . . . . . 6-19

EXC#_FAULT, Fault . . . . . . . . . . . . . . . . . . . . . . . 6-19

EXC#_LOW, Fault. . . . . . . . . . . . . . . . . . . . . . . . . 6-19

EXC#_AFC Fault. . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

PA Signal Tracing . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

PA Controller Faults . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

General PA Troubleshooting . . . . . . . . . . . . . . . . . 6-21

PA#_OC, PA Over-Current Fault . . . . . . . . . . . . . . 6-21

PA Current Foldback . . . . . . . . . . . . . . . . . . . . . . . 6-21

PA#_UC, PA Under-Current Fault . . . . . . . . . . . . . 6-22

PA#_MUTE_FLT, PA Mute Fault . . . . . . . . . . . . . 6-22

PA#_OT, PA Over-Temperature Fault . . . . . . . . . . 6-22

PA#_OUT, PA Out Fault . . . . . . . . . . . . . . . . . . . . 6-22

PA#_ISO, PA ISO Over-Temperature Fault. . . . . . 6-22

PA_ISO_OT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23

PA_ISO_LOW, Fault . . . . . . . . . . . . . . . . . . . . . . . 6-23

PA_ISO_SW, Fault. . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Combiner ISO Faults . . . . . . . . . . . . . . . . . . . . . . . 6-24

PAC#_REF, +5V Reference Fault . . . . . . . . . . . . . 6-24

PAC#_VOLTS, Power Supply Fault . . . . . . . . . . . 6-24

PAC#_-15V, PA Controller PS Fault . . . . . . . . . . . 6-24

Page 14

4 888-2406-002

WARNING: Disconn ect primary power pri or to servicing.

Table of Contents

PAC#_J#, Cable Fault. . . . . . . . . . . . . . . . . . . . . . .6-24

Power Supply Controller Faults. . . . . . . . . . . . . . . . . 6-26

General Power Supply Troubleshooting. . . . . . . . .6-26

Critical Power Supply Faults. . . . . . . . . . . . . . . . . .6-26

Soft Start Circuit Fault . . . . . . . . . . . . . . . . . . . . .6-27

PS1_HS_TEMP, Fault . . . . . . . . . . . . . . . . . . . . .6-27

PS_DSCHG, Discharge circuit fault. . . . . . . . . . .6-27

PS_PHS_LS, Phase Loss (100-120 Hz ripple). . .6-27

PSC#+20V, Fault . . . . . . . . . . . . . . . . . . . . . . . . .6-28

PS#_CONFIG, Configuration Fault. . . . . . . . . . .6-28

PS1_JUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

Non Critical Power Supply Faults. . . . . . . . . . . . . .6-29

PS#_TAP#, Power Supply Tap Fault . . . . . . . . . .6-29

7 Parts List

Parts List Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

Page 15

888-2406-002 1-1

WARNING: Disconnect primary power prior to servicing.

Introduction/

Specifications

1.1 Introduction

This technical manual describes the Harris Platinum Z2 solid-state FM radio

transmitter. This manual contains all the information needed to install, operate and

service these transmitters.

This manual contains the following sections:

• Section 1: Introduction/Specifications, identifies the versions of the product

available and the possible options, and provides specifications.

• Section 2: Installation/Initial Turn-on, details the procedures to receive, install

and prepare the transmitter for use, up through the initial turn-on of the equipment.

• Section 3: Operators Guide, describes operation of the equipment and is intended

to be the primary section referenced by operating personnel.

• Section 4: Overall System Theory, is included to help service personnel to under-

stand the inner workings of the transmitter.

• Section 5: Maintenance/Alignments-Adjustments, lists and explains alignments

and adjustments which might be required once the transmitter leaves the Harris

Broadcast factory.

• Section 6: Troubleshooting, is included as a servicing aid, to be used along with

Sections 4 and 5 by qualified service personnel to identify and correct any equipment problem which might develop.

• Section 7: Parts List, a comprehensive listing any of the equipment’s component s

which might ever be needed.

Page 16

1-2 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Introduction/Specifications

1.2 Features/Benefits

• Includes the field-proven Harris DIGIT Digital FM Exciter with built in DSP ste-

reo generator. As the world’s first all-digital FM e xciter the Harris DIGIT accepts

AES/EBU digital audio and generates the fully modulated RF carrier totally in

the digital domain for the lowest noise and distortion available in any FM transmitter (16 bit digital audio quality).

• Power output range: 500W - 2.5kW for Z2CD; up to 2.75kW into a 1.1 or less

VSWR.

• Redundant, autoswitching, IPA amplifiers to eliminate a single point of failure.

• Microprocessor based controller for advanced control, diagnostics and display

capability. Includes built-in logic and commands for switching between main/

alternate DIGIT exciters and IPAs.

• Redundant RF amplifier modules that allow maintenance while the transmitter

remains on the air at reduced power (“Hot-Pluggable” modules).

• Broadband design to eliminate tuning adjustments from 87 through 108MHz

(N+1 capable). Frequency change can be done manually in less than five minutes

using simple switch settings, and in less than 0.5 seconds using an optional,

external controller.

• Quick start design provides full output power meeting all specifications within

five seconds of an “On” Command.

• Versatile air cooling design uses either an internal blower or an external air sys-

tem.

• Dual output power settings, standard, along with a third available power setting

for use with UPS or generator backup systems.

• Directional RF sample port provided for customer use.

• Available for single or three phase mains power, 50/60Hz.

• Optional Redundancy Package (See Appendix A).

1.3 General Description

The Harris Platinum Z is a series of highly-functional, cost-effective FM radio

transmitters designed using a concept called Z-Axis 3-dimensional electronic

design. The Z2CD and Z2FM are 2kW versions of the Platinum Z FM transmitter.

The Z2CD (Clearly Digital) utilizes the Harris DigitCD, Digital FM exciter, while

the Z2FM would designate an analog exciter such as the Harris SuperCiter is being

used.

Page 17

888-2406-002 1-3

WARNING: Discon nect primar y power prior t o servicing .

Introduction/Specifications

The Z-axis approach arranges the system RF components such as dividers,

combiners and amplifiers in three dimensions, to permit the most efficient possible

signal paths between them. The method allows the transmitter amplifying group to

be broken down economically into the smallest possible blocks for removal,

servicing and replacement. See Figure 4-1 (in Section IV) for overall block

diagram.

1.3.1 Harris DIGIT Digital FM Exciter

The Harris DIGIT FM exciter is supplied as standard equipment with all Platinum Z

transmitters. The DIGIT, with its digital input module, generates the complete

stereo FM waveform in the digital domain, using a digital signal processor (DSP) as

a stereo generator and composite limiter, and a 32-bit numerically controlled

oscillator (NCO) as a digital modulator. Digital techniques allow direct connection

of standard AES/EBU stereo audio data to the FM exciter to eliminate the distortion

and alignment problems of analog signal paths and analog FM exciters. DIGIT is

also available with an analog interface module for stations with analog program

paths, easily interchangeable with the digital module.

1.3.2 Harris SuperCiter Analog Exciter

The optional Harris SuperCiter is a 55 watt, high quality, analog exciter designed

for broadcasters needing state-of-the-art analog performance at a value price. The

SuperCiter combines time-proven PLL technology with modern RF amplifier

circuits to provide driving power of very high quality to any FM transmitter.

1.3.3 Redundant Exciters

Each transmitter includes one exciter in a basic version but allows space for a

second optional exciter with the needed exciter exchange autoswitching hardware

and control within the cabinet.

1.3.4 PA/IPA Modules

Each PA module contains a single RF PA on one side of the heatsink with the

opposite side empty. Each PA has two MOSFET devices mounted on a compact

heat spreading assembly, and is capable of providing up to 425 watts. The RF

modules plug directly into an isolated combiner without using channel sens itive RF

cables. PA modules are “hot-pluggable” and can be removed and inserted into an

operating transmitter without removing plugs and cables. Each PA module is

conservatively rated to produce over 375 watts of output power into a system

VSWR of 1.5:1 at up to 50oC ambient temperature at sea level.

Page 18

1-4 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Introduction/Specifications

The IPA consists of a standard PA Module with one PA on each side of t he heatsink.

Only one half of the IPA module is active at a time to provide the required drive to

the PA. The transmitter contains sensing, logic and switching circuitry which will

automatically switch from a failed IPA to the remaining one. For even further

redundancy, any PA module can also be used as an IPA module, without

modification.

1.3.5 RF Combining

All 8 PAs are combined in a compact, “Z plane” isolated combiner. True isolation

means that each module will continue to work into a nominal 50 ohm load

regardless of the number of active amplifiers, for almost zero stress to the amplifiers

during fault conditions. The output of the 8 way combiner is then filtered by the

transmission line filter before leaving the transmitter. Directional couplers and a

customer RF demodulator sample are provided.

1.3.6 Control System

A microprocessor based controller monitors over 100 operating functions of the

transmitter and makes intelligent operating decisions based on operating conditions.

Detailed system information is available using the front panel diagnostic display.

The controller is designed for direct connection to standard parallel remote control

systems.

The Controller also includes built-in logic and controls for automatically switching

to the reserve IPA section, and a backup exciter if installed. The main controller

provides automatic power control, VSWR overload protection, automatic VSWR

foldback, RF power soft start, AC restart and diagnostics. Basic control functions

available even without the main controller are VSWR protection, IPA protection,

transmitter on/off, failsafe and interlock.

The control system for the transmitter is modular and is centered on the backplane

which is also the control panel for the transmitter. Various control printed circuit

boards are plugged into the backplane to fit the transmitter for the configuration

being supplied.

The control system front panel includes an output metering LCD display which can

be used to view power output, VSWR, PA voltage and PA current. A second LCD

window, the Diagnostics Display, permits extensive viewing of internal voltages,

temperatures and a detailed Fault Log to easily pin-point problems. Long-life LED

fault and status indicators and reliable membrane switches provide all needed local

control and selection for the transmitter.

Page 19

888-2406-002 1-5

WARNING: Discon nect primar y power prior t o servicing .

Introduction/Specifications

1.3.7 Directional RF Sample Port

Platinum Z FM transmitters provide an RF sample port with 30dB nominal

directivity. A directional RF sample provides more accurate performance

measurements by supplying a nearly reflection free RF sample source for external

monitoring equipment.

1.3.8 Power Supplies

The Z2 can be configured with a 3-Phase or Single Phase power supply. The

supplies are regulated by reliable tap-switching techniques (non-switching design).

This approach provides high conversion efficiency and excellent power factor with

very low line harmonics, in an easy to service design. The power supply is mounted

on a roll-out mounting plate for complete accessibility.

The Z2 can be configured with an optional second supply as part of the Z2

Redundancy package. The package includes a second PS Controller, a second PA

Controller and the second supply. For more information refer to Appendix A, Z2

Redundancy Package Option.

1.3.9 Air System

The Platinum Z uses a 2 speed fan to pull air in the back of the transmitter and

exhausts it out the top. There are air channels up through the PA assembly for

cooling. Upon startup, the transmitter will run at high speed for 1 minute, then will

drop to a lower speed provided there are no active faults. If a fault does occur during

normal operation the fan will automatically switch to high speed. For detailed

airflow information, refer to the Cabinet Outline Drawing in the Schematic

package.

1.4 Performance Specifications

See Sales Brochure at the end of this manual for a listing of the Performance

Specifications for the Platinum Z FM Transmitter.

NOTE:

Specifications subject to change without notice.

Page 20

1-6 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Introduction/Specifications

Page 21

888-2406-002 2-1

WARNING: Disconnect primary power prior to servicing.

Installation &

Initial Turn-On

2.1 Introduction

This section contains information for the installation of the Platinum Z2 solid state

FM Broadcast Transmitter and for performing the pre-operational checks.

NOTE:

For Dual transmitter configurations refer to the Systems Manual before proceeding with this installation procedure.

2.2 Unpacking

Carefully unpack the transmitter and perform a visual inspection to ensure that no

apparent damage was incurred during shipment. Retain the shipping materials until

it has been determined that the unit is not damaged. The contents of the shipment

should be as indicated on the packing list. If the contents are incomplete or if the

unit is damaged electrically or mechanically, notify the carrier and HARRIS

CORPORATION, Broadcast Systems.

2.3 Returns and Exchanges

Damaged or undamaged equipment should not be returned unless written approval

and a Return Authorization is received from HARRIS CORPORATION, Broadcast

Systems. Special shipping instructions and coding will be provided to assure proper

handling. Complete details regarding circumstances and reasons for return are to be

included in the request for return. Custom equipment or special order equipment is

not returnable. In those instances where return or exchange of equipment is at the

request of the customer, or convenience of the customer, a restocking fee will be

charged. All returns will be sent freight prepaid and properly insured by the

customer. When communicating with HARRIS CORPORATION, Broadcast

Systems, specify the HARRIS Order Number or Invoice Number.

Page 22

2-2 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Installation & Initial Turn-On

2.4 Air Cooling Requirements

Harris transmitters are designed to operate in a free, unobstructed environment with

a maximum inlet air tem perature of 50°C. This means that the t ransmitter air system

is designed to supply sufficient air at the required static pressure to cool the

transmitter only. Any additional pressure losses introduced by air exhaust systems

& air supply systems must be satisfied by means other than the transmitt er blo wers.

These inlet & exhaust systems generally need to be fan driven. Refer to the Outline

Drawing in the schematic package for information on intake and exhaust air flows.

NOTE:

“Clean” air is required. No salt air, polluted air, or sulphur air can be tolerated. A closed air system is recommended in these environments; that is, an

air conditioned room that recirculates, and properly filters, the room air. No

outside air is brought into the transmitter room.

2.5 Z2 Transmitter Installation

Prior to installation, this Technical Manual and the appropriate FM Exciter

T echnical Manual should be carefully studied to obtain a thorough understanding of

the principles of operation, circuitry and nomenclature. This will facilitate proper

installation and initial checkout.

!

CAUTION:

ALL CONNECTIONS REFERRE D TO IN THIS INS TALLATION PROCEDURE

SHOULD BE VERIFIED USING THE SCHEMATICS SUPPLIED WITH THE

TRANSMITTER. THE SCHEMATICS SHOULD BE CONSIDERED THE MOST

ACCURATE IN CASE OF A DISCREPANCY.

The FM Transmitter installation is accomplished in the following order:

1. Transmitter placement

2. Visual Inspection

3. Exciter Installation

4. Power Supply Installation

5. Transmitter wiring

6. Initial checkout.

7. Remote Control Connections

Page 23

888-2406-002 2-3

WARNING: Discon nect primar y power prior t o servicing .

Installation & Initial Turn-On

2.5.1 Transmitter Placement

Set the transmitter in place on a level surface near power and signal cables. Either or

both sides of the FM Transmitter may be placed against a wall or other equipment.

Complete access is through the front and rear of the transmitter. The floor must be

capable of supporting a load of 250 pounds per-square-foot (1221 kg per-squaremeter) (refer to Cabinet Outline drawing). Also be aware that the power supplies are

very heavy and roll out the front of the tran smitt er for mainte nance . Be sure to have

a smooth flat surface in front of the transmitter of at least 36 inches for power

supply maintenance.

2.5.1.1 Removal of Pallet Bolts

There are 4 bolts which must be removed in order to take the transmitter off the

wooden pallet, 2 toward the front of the cabinet and 2 toward the rear. Location of

these bolts can be verified by looking for the bolt heads underneath the pallet. If the

transmitter was shipped with the power supply removed, simply remove the power

supply cover from the bottom front of the transmitter cabinet to access the pallet

bolts. However, if the transmitter was shipped with the power supply installed, the

power supply tray is covering the bolts, so the fan assembly on the rear of the

transmitter will also have to be removed to access the rear pallet bolts (the power

supply itself does not have to be removed). Open and remove the rear door by lifting

it off its hinges. Remove the fan assembly by removing six screws and two nuts

located around the outside edge of the fan assembly. Slowly move the assembly to

the righthand side and disconnect the blower wire connector. The fan assembly can

now be set aside while removing the transmitter from the pallet. The rear pallet bolts

can now be accessed under the rear of the power supply tray.

After the transmitter is off the pallet, it is also a good idea to remove the shipping

screws holding the rear of the power supply tray. This will allow the power supply

to be rolled out the front of the transmitter at a later date without having to take off

the fan assembly.

2.5.2 Visual Inspection

Be sure to check the connection of all cables and wires in the transmitter. Areas to

check would include:

a. Power Supply Connections

1. Check for loose cables and connections and loose hardware on the floor

of the cabinet.

2. Make sure the Rectifier Boards are properly seated in the connectors on

top of the transformers (3-phase version).

3. Check the power supply and control connections to the Rectifier

Boards.

Page 24

2-4 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Installation & Initial Turn-On

b. Controller Connections

1. Check the Ribbon cables connected to the back of the controller boards

and to the exciter(s).

2. Make sure that all of the boards in the controller are properly seated in

the backplane (motherboard) connector.

2.5.3 Exciter Installation

The exciter may or may not be removed from the transmitter depending on the

shipping considerations. If the exciter was not removed for shipping, then all

transmitter connections will already be hooked up. The audio input connections and

level adjustments can be found in the exciter manual accompanying the transmitter.

The exciter input cables should be installed in a metal conduit which is separate

from the AC supply.If the exciter was removed for shipping, there are three cables

which will need to be hooked up (not counting the audio inputs).

a. A ribbon cable which will hook to the remote control connector on the back

of the exciter. This is A10-J2 on the SuperCiter and J2 on the ‘DIGIT.

b. A coaxial cable with a male BNC connector which connects to the exciter RF

output. This is A10-J11 on the SuperCiter and J1 on the DIGIT.

c. AC Power Cable. Verify that the exciter is set for the correct operating volt-

age. For more information refer to the Excite r Manual, Section II, Insta llation.

NOTE:

For Digit Exciters, the VCO shipping screws must be removed as outlined in

the exciter manual in Section II.

Page 25

888-2406-002 2-5

WARNING: Discon nect primar y power prior t o servicing .

Installation & Initial Turn-On

2.5.4 3-Phase Power Supply Installation

The Z2 transmitter can be configured with either a 3-Phase or Single Phase power

supply. Operation of the supplies is basically the same with both using the dynamic

tap switching for efficiency. However, their physical make-up is different and

requires separate installation procedures. The 3-phase will be discussed first, then

the Single Phase will follow. Note that some transmitters may be shipped with the

power supply installed, depending on where and how it is shipped. If the power

supply was shipped installed in the transmitter, skip to "2.5.6 Transmitter AC

Connections" on page 2-13. Before installing the power supply check the primary

AC tapping on the power transformers as outlined below.

!

WARNING:

DISCONNECT AND LOCKOUT STATION PRIMARY POWER AT THE WALL

BREAKER BEFORE MAKING ANY CONNECTIONS.

2.5.4.1 Power Transformer Tapping

The power transformers are tapped at the factory for the primary AC voltage

specified by the customer. This voltage should be documented in the factory test

data accompanying the transmitter and tagged at the main contactor in the rear of

the transmitter. However, the voltage at the site and the transformer tapping should

be verified by the installation personnel. The input voltage and strapping chart is

shown on the Overall System Block Diagram along with the transformer schematic.

Verification and/or re-tapping will require opening the power supply access panel

on the front of the transmitter and rolling out the power supply (this is only if the

transmitter was shipped with the power supply installed). To remove the power

supply refer to Section V, under the heading “Power Supply Removal.”

2.5.4.2 Power Supply Connections

First, remove the front cover panel from the power supply compartment at the

bottom of the transmitter. The power supply connection cables are either tied up in

the power supply compartment (in the bottom of the transmitter) or tied up with the

power transformers. The power supply should be rolled into position in front of the

transmitter, then carefully rolled into the transmitter making sure that none of the

interconnect cables get caught on the power supply tray.

The following cables will need to be connected:

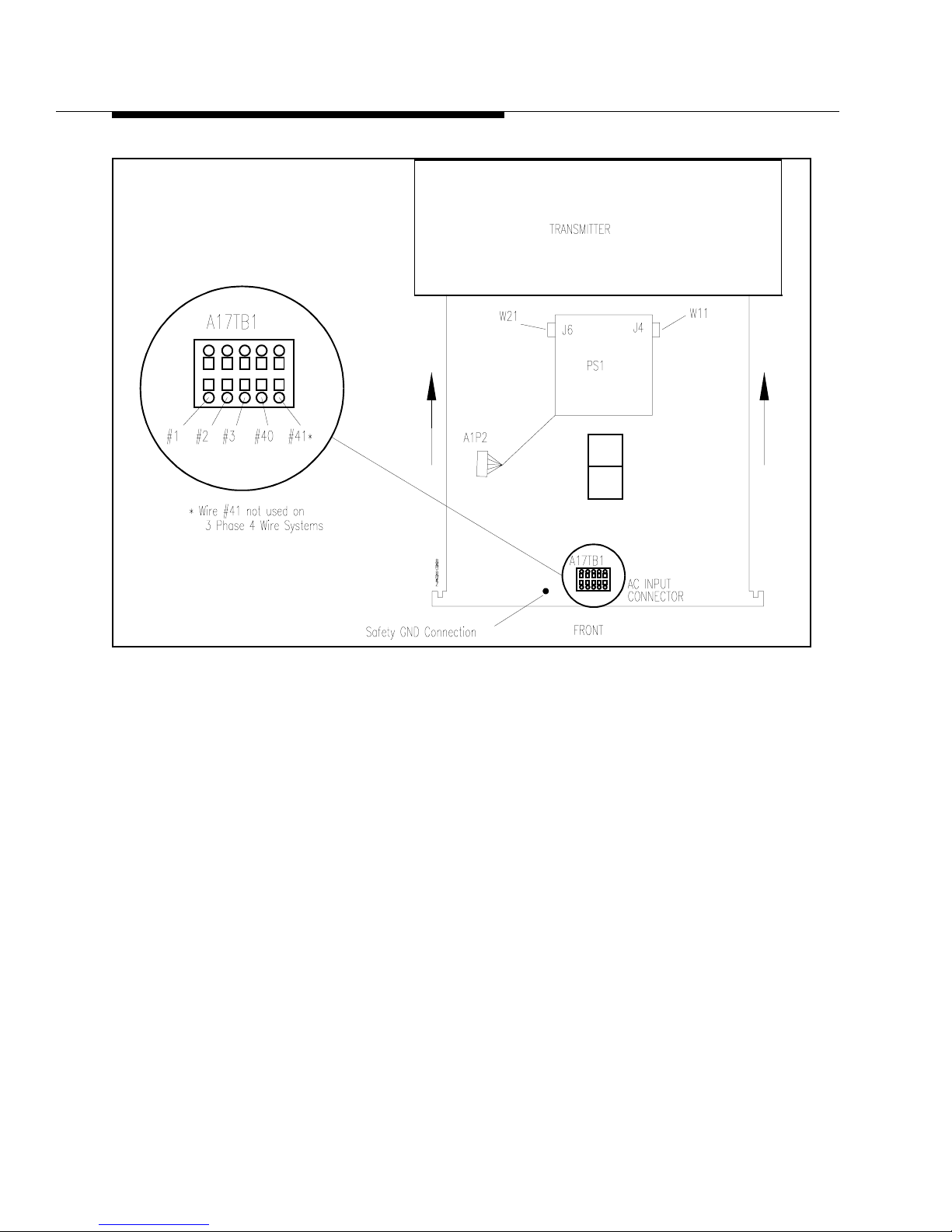

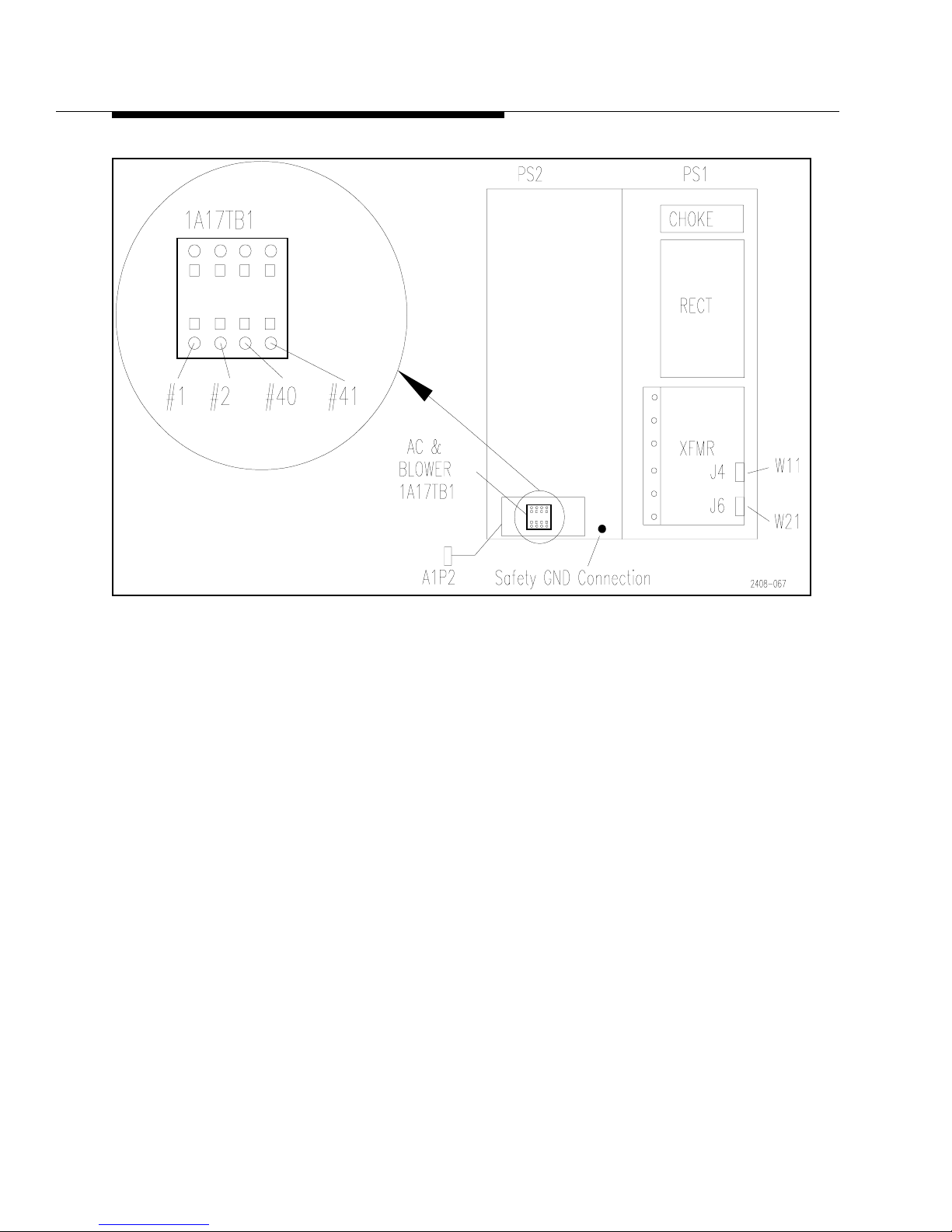

a. There is one ribbon cable W11 (blue) and one control voltage cable W21

(gray with orange connector) hanging on the right side of the power supply

compartment. Connect W11 to J4 on the Rectifier Board (on the Left side of

the supply). Connect W21 (flat gray cable with orange connector) to J6 on the

PS1 Rectifier Board (on the right side of the supply). See Figure 2-1.

Page 26

2-6 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Installation & Initial Turn-On

Figure 2-1 3-Phase Power Supply Top View

b. The cable labelled A1P2 (multi-conductor cable with gray connector) plugs

into its mating connector on the left wall of the power supply compartment,

see Figure 2-1.

c. Wires #1, #2, and #3 (orange cables tied up on the left side of the power sup-

ply compartment) and two smaller gray wires #40 and *#41 plug into the gray

Wago block connector, A17TB1 on the front of the power supply tray (A17

designates a component on the power supply tray). See Figure 2-1. The wago

block has 5 terminals labelled terminal #1 on the left and #5 on the right. The

connections are as follows:

1. Wire #1 connects to terminal #1

2. Wire #2 connects to terminal #2

3. Wire #3 connects to terminal #3

4. Wire #40 connects to terminal #4

5. Wire *#41 connects to terminal #5

(*Wire #41 is not used on 3 phase 4-wire system)

Page 27

888-2406-002 2-7

WARNING: Discon nect primar y power prior t o servicing .

Installation & Initial Turn-On

To insert the wires into the Wago block, insert a screwdriver into the rectangular slot

above the wire hole and then carefully lift up. This will open the contact inside the Wago

block and the wire can be inserted. Be very careful not to let the wire ends fray as the connectors are very close together and could cause a short. The wire insulation should actually extend just inside the Wago block hole.

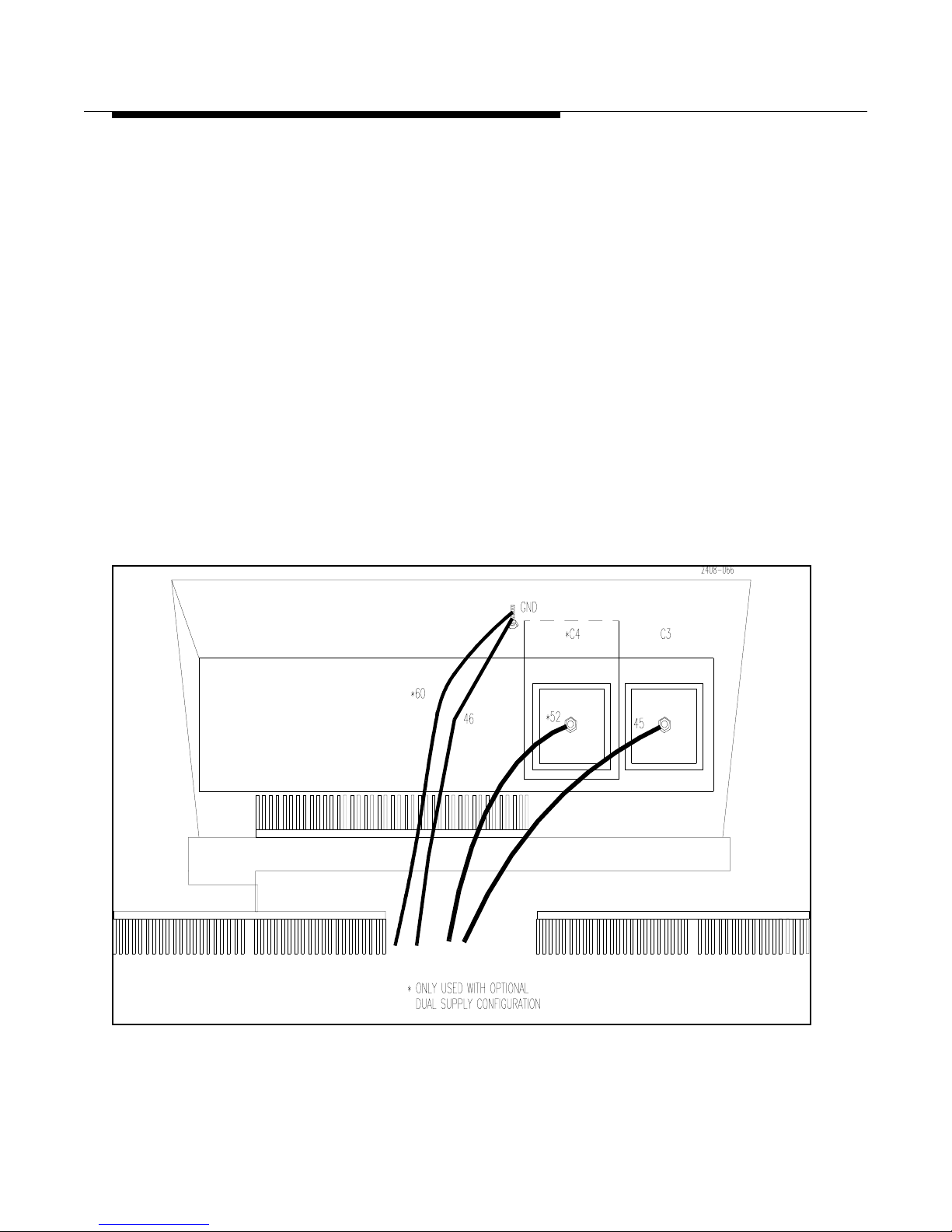

d. Wire 45 (large orange cable tied up with the transformer) connects to the

feed-thru terminal C3 at the top of the power supply compartment. This is the

52Vdc output from the supply. See Figure 2-2.

e. The large orange ground wire #46, coming from the top of the rectifier assem-

bly attaches to a ground stud at the top-front edge of the power supply compartment. It is located under the shelf which separates the power supply from

the PA compartment just above C3. See Figure 2-2.

f. Connect the safety ground wire to the stud on the front of the power supply

tray, next to A17TB1, see Figure 2-1.

g. Tighten the two hold down nuts located on the bottom front corners of the

power supply compartment. Re-install the front cover panel for the power

supply compartment.

Figure 2-2 3-Phase DC Power Supply Connections

Page 28

2-8 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Installation & Initial Turn-On

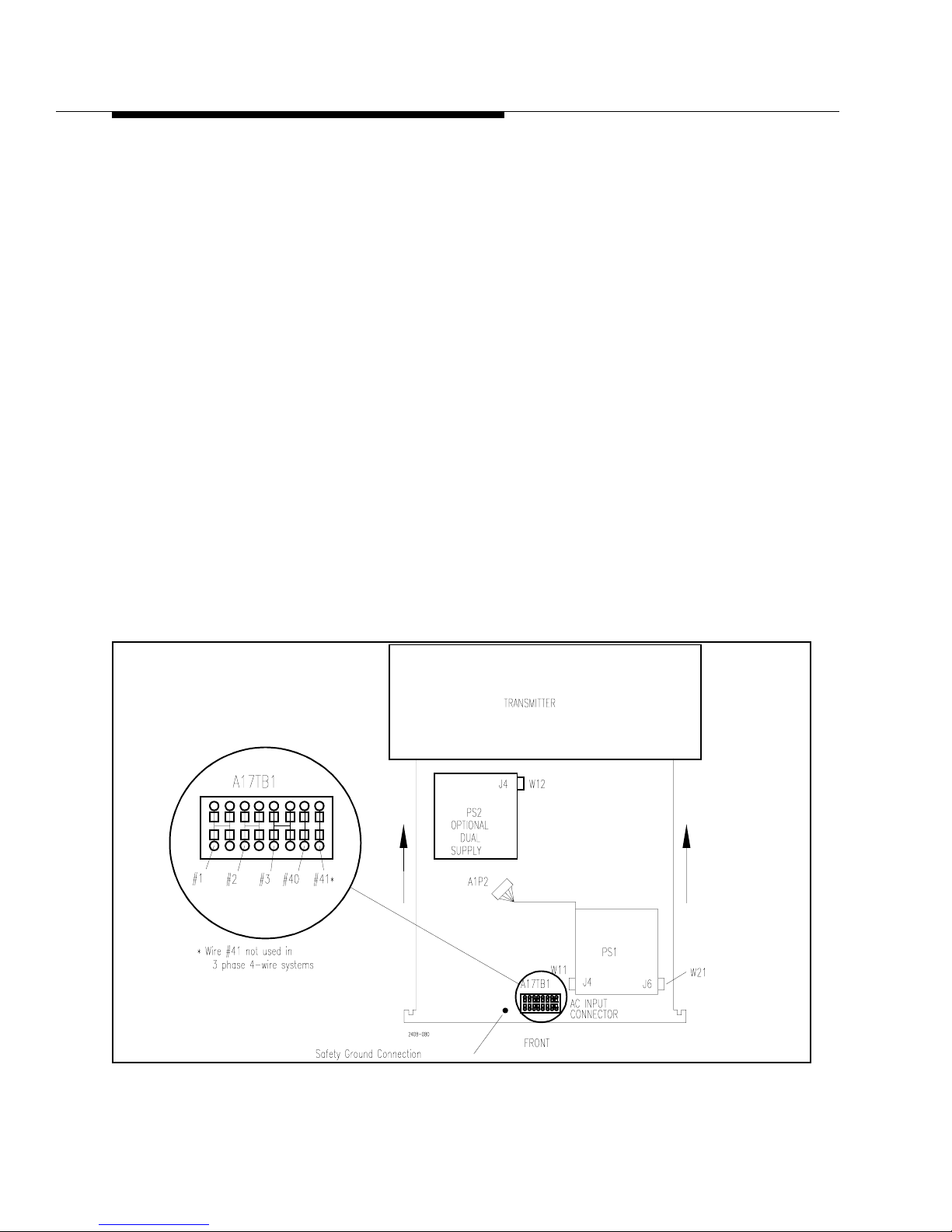

2.5.4.3 Dual Power Supply Option

T o add redundancy the Z2 can be configured with an optional second power supply.

The installation procedure only changes slightly for this configuration. The

following lists only the additions to the above procedure.

h. Before rolling the power supply all of the way into the cabinet, connect the

blue ribbon cable labelled W12 to J4 on the power supply which will be closest to the rear of the transmitter . The suppl y may now be rolled all of the way

into the cabinet.

i. The Wago block on the front of the power supply tray, A17TB1, has 8 con-

nections compared to the 6 connections for the single supply configuration.

The connections are shown in Figure 2-3 and are as follows:

1. Wire #1 connects to terminal #1

2. Wire #2 connects to terminal #3

3. Wire #3 connects to terminal #5

4. Wire #40 connects to terminal #7

5. Wire *#41 connects to terminal #8

(*Wire #41 is not used on 3 phase 4-wire system)

Figure 2-3 3-Phase Dual Power Supply Top View

Page 29

888-2406-002 2-9

WARNING: Discon nect primar y power prior t o servicing .

Installation & Initial Turn-On

NOTE:

T erminals 1 and 2 are connected inside the Wago block as are terminals 3 and

4 and terminals 5 and 6. This allows for connections to the second supply on

the output side of the Wago block.

j. The +52Vdc output and ground from the second supply must also be con-

nected. Wire #52 connects to feedthru C4. Ground wire #60 connects to the

ground stud at the top front of the power supply compartment (above C3 and

C4). See Figure 2-2.

2.5.5 Single Phase Power Supply Installation

Before installing the power supply check the primary AC tapping on the power

transformers as outlined below. Even if the transmitter was shipped with the power

supply installed, it would be a good idea to check the power supply tapping if

possible.

2.5.5.1 Power Transformer Tapping

The power transformers are tapped at the factory for the primary AC voltage

specified by the customer. This voltage should be documented in the factory test

data accompanying the transmitter and tagged at the AC contactor. However, the

voltage at the site and the transformer tapping should be verified by the installation

personnel. The input voltage and strapping chart is shown on the Overall System

Block Diagram along with the transformer schematic. V erification and/or re-tapping

will require opening the power supply access panel on the front of the transmitter

and rolling out the power supply if the transmitter was shipped with the power

supply already installed (this depends on where and how it is shipped).

2.5.5.2 Power Supply Connections

First, remove the front cover panel from the power supply compartment at the

bottom of the transmitter. The power supply connection cables are either tied up in

the power supply compartment (in the bottom of the transmitter) or tied up with the

power transformers. The power supply should be rolled into position in front of the

transmitter, then carefully rolled into the transmitter making sure that none of the

interconnect cables get caught on the power supply tray.

The following cables will need to be connected:

a. There is one ribbon cable and one power connector hanging on the right side

of the power supply compartment inside the transmitter. The ribbon cable

connects to J4 on the Rectifier Board. Be sure to route this cable so it does not

touch the resistor located on top of the Rectifier board. The power cable (the

gray cable with the orange connector) connects to J6, on the Rectifier Board

near the front of the transmitter. See Figure 2-4.

Page 30

2-10 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Installation & Initial Turn-On

Figure 2-4 Single Phase Power Supply Top View

b. The cable labelled A1P2 (gray and yellow multi-conductor cable with gray

connector) plugs into its mating connector on the left wall of the power supply compartment, see Figure 2-4.

c. Wires #1 and #2 (orange cables tied up on the left side of the power supply

compartment) and wires #40 and #41 plug into the gray Wago block connector on the front of the power supply tray. See Figure 2-4.

d. The wago block has 4 terminals labelled terminal #1 on the left and #4 on the

right. The connections are as follows:

1. Wire #1 connects to terminal #1

2. Wire #2 connects to terminal #2

3. Wire #40 connects to terminal #3

4. Wire #41 connects to terminal #4

To insert the wires into the wago block,insert a screwdriver into the rectangular slot

behind the wire hole and then carefully push toward the rear of the transmitter. This will

open the contact inside the wago block and the wire can be inserted. Be very careful not to

let the wire ends fray as the connectors are very close together and could cause a short.

The wire insulation should actually extend just inside the Wago block hole.

Page 31

888-2406-002 2-11

WARNING: Discon nect primar y power prior t o servicing .

Installation & Initial Turn-On

e. Wire 80 (large orange cable tied up with the transformers) connects to the

feed-thru terminal C3 at the top of the power supply compartment. See Figure

2-5.

f. The large orange ground wire #52, coming from the power supply attaches to

the ground stud at the top-front edge of the power supply compartment. It is

located under the shelf which separates the power supply from the PA compartment.

g. Connect the safety ground wire to the stud on the front of the power supply

tray, next to A17TB1, see Figure 2-4.

h. Tighten the two hold down nuts located on the bottom front corners of the

power supply compartment.

Re-install the front cover panel for the power supply compartment.

Figure 2-5 Single Phase DC Power Supply Connections

Page 32

2-12 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Installation & Initial Turn-On

2.5.5.3 Dual Power Supply Option

T o add redundancy the Z2 can be configured with an optional second power supply.

The installation procedure only changes slightly for this configuration. The

following lists only the additions to the above procedure.

a. Before rolling the power supply all of the way into the cabinet, connect the

blue ribbon cable labelled W12 to J4 on the power supply on the left side of

the tray (PS2). The supply may now be rolled all of the way into the cabinet.

b. The wago block connection on the front of the power supply tray, 1A17TB1,

has 6 connections whereas the single supply version has only 4. The connections are shown in Figure 2-6 and are as follows:

1. Wire #1 connects to terminal #1

2. Wire #2 connects to terminal #3

3. Wire #40 connects to terminal #5

4. Wire #41 connects to terminal #6

NOTE:

T erminals 1 and 2 are connected inside the Wago block as are terminals 3 and 4.

c. The +52Vdc output and ground from the second supply must also be con-

nected. Wire #81 connects to feedthru C4. Ground wire #152 connects to the

ground stud at the top front of the power supply compartment (above C3 and

C4). See Figure 2-5.

Figure 2-6 Dual Single Phase Power Supply Top View

Page 33

888-2406-002 2-13

WARNING: Discon nect primar y power prior t o servicing .

Installation & Initial Turn-On

2.5.6 Transmitter AC Connections

The AC input for the transmitter should be low impedance, 50/60 Hz, single or three

phase depending on transmitter phase supply with sufficient capacity to supply the

transmitter. Refer to the “Z2 Outline Drawing” in the drawing package for current

ratings, nominal fuse sizes and wire gauge for the 3 phase delta, 4 wire wye, and

single phase input voltage combinations. For more information on AC mains

requirements see “Power Distribution for Optimum Transmitter Performance”

at the end of this section.

The recommended fuse type is class RK5, a dual element time delay fuse. Examples

are the Bussmann FRN-R (250V), FRS-R (600V), Littelfuse FLNR (250V), FLSR

(600V), and Ferraz gG fuses. If you prefer to use a circuit breaker in your

installation, select one with a motor-starting trip curve, similar to the RK5 curve for

fuses. This type of delayed response is needed in order to accommodate the

momentary in-rush current. This can be 300 to 600 amps, depending on the

transmitter model and AC configuration.

!

WARNING:

DISCONNECT AND LOCK OUT STATION PRIMARY POWER TO TRANSMITTER

BEFORE ATTEMPTING ANY CONNECTIONS.

NOTE:

Proper wire size information is available on the Cabinet Outline Drawing in

the drawing package. Observe maximum specified ratings for safe operation.

A customer supplied AC primary power disconnect or means to completely deenergize the transmitter primary circuit for servicing is necessary.

2.5.6.1 Information concerning some 360 to 416 volt systems

This transmitter is equipped with MOVs (metallic oxide varistors) which provide a

measure of protection against incoming overvoltage transients. However, the

selection of some of the MOVs relies upon knowing the approximate voltage from

each AC phase to ground. Unfortunately a few AC power systems around the world

do not have a direct connection to earth ground, thereby making it impossible to

predict the phase-to-earth ground voltage.

In a typical 380 volt system that has a connection to earth ground, each AC phase

will measure about 220 volts to ground. The phase-to-phase, and phase-to-ground

voltages should be balanced within a few percent.

However, in a system which has no direct connection to earth ground, each AC

phase will measure a voltage which follows no particular pattern. In such a case, the

Page 34

2-14 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Installation & Initial Turn-On

MOV protection may need to be modified. Please consult with an electrician if this

applies to your installation. If applicable, the phase-to-earth 275 volt MOVs in the

RV7 through RV13 and RV20 positions may be replaced with 510 volt MOVs

(Harris part number 5600042000, quantity 8).

For safety reasons, you also must install a 4 pole disconnect device if your neutral

line is not connected to earth ground.

NOTE:

Install the exciter input cables in a metal conduit which is separate from the

AC supply . Remote control cabling may be included in the same conduit with

the exciter cabling. AC power wiring and small signal lines should never be

put in the same conduit.

2.5.6.2 Three Phase AC Connection

AC connections are made to the top of the AC

mains contactor K1. K1 is on the top right side in

the rear of the cabinet. There is also a large

standoff located near the main contactor for the

NEUTRAL connection in 380VAC (342432Vac) 4-wire WYE systems. Bring the AC

wires through the holes in the top of the

transmitter and connect to the top terminals on

contactor K1.

!

CAUTION:

THE NEUTRAL CONNECTION IS EXTREMELY IMPORTANT IN 380VAC 4WIRE WYE APPLICATIONS. BY VIRTUE OF THE SINGLE PHASE LOADS

WITHIN THE TRANSMITTER, THE SYSTEM IS NOT ENTIRELY

BALANCED, REQUIRING NEUTRAL CURRE NT TO MAINTAIN PROPER

PHASE TO NEUTRAL VOLTAGES. A POOR NEUTRAL CONNECTI ON

COULD CAUSE DAMAGE TO THE SINGLE PHASE ELEMENTS IN THE

TRANSMITTER.

NOTE:

The NEUTRAL connection is NOT required for 208/220VAC 4-wire

WYE source voltage and shou ld not be run to the trans mitter. There is no

connection in the transmitter for the neutral connection (for this application)

and it should not be connected to chassis ground. The power supply transformers in the transmitter will be configured as delta for this application.

Page 35

888-2406-002 2-15

WARNING: Discon nect primar y power prior t o servicing .

Installation & Initial Turn-On

2.5.6.3 Single Phase AC Connection

The single phase connects to the top of the AC mains contactors K1. The two wires

should be connected to the terminals closest to the front of the transmitter. The last

terminal (toward the rear) is not connected.

2.5.6.4 Grounding

The importance of a good grounding system and lightning protection can hardly be

overemphasized for reasons of personnel safety, protection of the equipment, and

equipment performance. The following is only a brief overview.

Lightning and transient energy via the power line or tower connections can impose

serious threats to your personal safety as well as damage the equipment. For these

reasons you should have a good protective earthing system to divert these forms of

energy to earth ground. Proper grounding of the equipment also guards against

electrical shock hazards that would exist if the equipment failed in a way which put

a hazardous voltage on the chassis.

A good grounding system should include substantial grounding at the tower base

using copper ground rods and/or a buried copper ground screen, with copper strap

used to connect the tower base to earth ground. A low impedance will help carry

lightning current directly into the ground instead of into your building. Additionally,

coax shield(s) should be electrically connected to and exit the tower as near to the

bottom as practical to minimize the lightning voltage potential carried by the coax

into your building.

For coaxes, a single point of entry into the building is best, with all connected to a

common grounding plate (or bulkhead panel) having a low impedance connection

to the building perimeter ground. Wide copper straps should be used for making the

connection from the common grounding plate to earth ground.

A common grounding plate is also the best location for coaxial surge protectors for

sensitive equipment such as an STL receiver. Ideally, this plate should also be the

entry point for all signal lines, and serve as a single point ground for AC power

surge protection.

A good ground system should include perimeter grounding of the transmitter

building using copper ground rods and copper strap. There should also be a copper

strap running from tower ground to the building perimeter ground.

Good grounding and shielding will help keep stray RF current to a minimum. RF

interference usually shows up in one of several ways, intermittent problems with

digital or remote control circuits, audio feedback or high pitched noise. Even a

small amount of non-shielded wire makes a very efficient antenna for RF and

transient energy. If RF is allowed into the audio equipment, it can be rectified and

Page 36

2-16 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Installation & Initial Turn-On

may show up as noise or feedback. Wire and cable shields should normally be

connected at both ends to the equipment chassis.

A ground strap attachment point is located on the top, right rear, of the cabinet (use

four 1/4-20 brass screws with brass washers). Use this connection when utilizing a

single point grounding system, attaching your ground strap to the common

grounding plate. An alternate ground connection is a short copper strap on the back

of the Platinum Z transmitter, on the bottom right side. Unfold this strap and

securely bolt or silver solder it to the building ground. This strap can be removed

from the bottom and used at the top.

A grounding stud is also provided near the AC input connections in the upper

portion of the Platinum Z transmitter . Use this connection for the power line ground.

It is located above the low voltage power supply board.

2.5.6.5 Low Voltage Power Supply and Blower

The Low Voltage Power Supply and the blower motor operate from any voltage

within the specified range of the tapping chart without re-tapping.

2.5.6.6 Exciter AC Voltage Selection

Once the site voltage has been checked, verify that the exciter(s) are set for the

proper input AC voltage. For verification, the selected voltage should be visible

next to the AC power cord connection on the rear of the exciter. The voltage at the

exciter AC input can be found by measuring between any two phases of a 3 phase 3

wire system or any phase to Neutral in a 3 phase 4 wire system. If single phase

power is used the exciter should be set to the same as the AC line voltage. For more

information on setting the exciter voltage, refer to the exciter technical manual.

2.5.7 RF Output Connection

The station transmission line may now be connected at the 1 5/8" EIA flange

located on top of the transmitter. Be sure the bullet seats correctly and all flange

bolts are tight. Make sure the clamp at the top of the harmonic filter is tightened.

2.5.8 Audio Input Connections

All audio signals connect directly to the back of the exciter(s) by routing the cables

through the top or bottom of the transmitter. The exciter technical manual has all of

the information pertaining to audio connections, input levels and adjustments. Be

sure to leave enough cable slack to allow the exciter to be pulled all of the way out

on the rack slides.

Page 37

888-2406-002 2-17

WARNING: Discon nect primar y power prior t o servicing .

Installation & Initial Turn-On

2.5.9 External and Failsafe Interlock Connections

The transmitter is shipped with two jumpers installed on TB1, the Remote Control

Interface terminal strip: TB1-7 to TB1-6(GND) is for External Interlock and TB1-8

to TB1-10(GND) is for Failsafe.

2.5.9.1 External Interlock Connection

To use the External Interlock connection, remove the jumper between terminals

TB1-7 to TB1-6(GND), then connect external interlock wires. A contact closure

allows the transmitter to operate. When the external interlock connection is opened

the P A power supplies, blower and exciter turn off, the status of the transmitter is set

to off. The external interlock wires can also be connected directly to the Life

Support Board at J4-7 and J4-10 if it is desired to have the interlock completely

separate from the remote control interface. The TB1 and J4 connections are in

parallel. Only one or the other is to be used. NOTE: The transmitter will require an

ON command after the external interlock connection is restored.

!

CAUTION:

TO CONNECT TO THE WAGO BLOCK, J4 ON THE LIFE SUPPORT BOARD

REQUIRES PRESSING A SCREWDRIVER INTO THE RECTANGULAR

SLOT ON THE FRONT SIDE OF THE BLOCK SO THE WIRE CAN BE

INSERTED FROM THE REAR. BE SURE TO PROPERLY SUPPORT THE

BOARD SO THAT IT IS NOT BENT OR STRESSED IN ANY WAY WHILE

INSERTING THE WIRES.

2.5.9.2 Failsafe Interlock Connection

To use the failsafe interlock connection, remove the jumper between TB1-8 to TB110(GND), then connect failsafe interlock wires. A contact closure allows the

transmitter to operate. The Failsafe connection can be used for any application

which requires muting the transmitter RF output. When the failsafe interlock

connection is open the fan is set to high, the IPA and exciter are muted. The failsafe

interlock wires can also be connected directly to the Life Support Board at J4-7 and

J4-8 if it is desired to have the failsafe interlock completely separate from the

remote control interface. The TB1 and J4 connections are in parallel. Only one or

the other is to be used. NOTE: The transmitter will transmit when the failsafe

interlock connection is restored (if it was transmitting when the failsafe connection

was opened).

Page 38

2-18 888-2406-002

WARNING: Discon nect primar y power prior to servicing.

Installation & Initial Turn-On

2.6 Initial Turn-on

Each transmitter is thoroughly checked out during factory final test but adjustment

may be required during installation due to shipping, variations in primary power,