Page 1

TECHNICAL

MANUAL

HT EL2000LS/HS

994 9383 001 - HT EL2000LS

994 9384 001 - HT EL2000HS

TECHNICAL MANUAL

HT EL2000LS/HS

994 9383 001 - HT EL2000LS

994 9384 001 - HT EL2000HS

888-2457-001

I Installation

II Operation

III Theory of Operation

IV Maintenance & Alignments

V Troubleshooting

VI Parts List

Transmitter

PA Amplifier Modules

VII RF Amplifier Modules

T.M. No. 888-2457-001

© Copyright 1999, 2002, 2003

Harris Corporation

All rights reserved

Rev. B: 7-25-02

Rev. B1: 6-02-03

Page 2

Returns And Exchanges

Damaged or undamaged equipment should not be returned unless written approval and a

Return Authorization is r eceived from HARRIS CORPORATION, Broadcast Systems Division. Special shipping instructions and coding will be provided to as sure proper handling.

Complete details regarding circumstances and reasons for return are to be included in the

request for return. Custom equipment or special order equipment is not returnable. In those

instances where return or exchange of equipment is at the request of the customer, or

convenience o f the customer, a restocking fee will be charged. All returns will be sent

freight prepaid and properly insured by the customer. When communicating with HARRIS

CORPORATION, Broadcast Systems Division, specify the HARRIS Order N umber or Invoice Number.

Unpacking

Carefully unpack the equipment and preform a visual inspection to determine that no apparent damage was incurred during shipment. Retain the shipping materials until it has been

determined that all received equipment is not damaged. Locate and retain all PACKING

CHECK LISTs. Use the PACKING CHECK LIST to help locate and identify any components

or assemblies which are removed for shipping and must be reinstalled. Also remove any

shipping supports, straps, and packing materials prior to initial turn on.

Technical Assistance

HARRIS Technical and Troubleshooting assistance is available from HARRIS Field Service

during normal business hours (8:00 AM - 5:00 PM Central Time). Emergency service is

available 24 hours a day. Telephone 217/222-8200 to contact the Field Service Department

or address correspondence to Field Service Department, HARRIS CORPORATION, Broadcast Systems Division, P.O. Box 4290, Quincy, Illinois 62305-4290, USA. Technical Support

by e-mail: tsupport@harris.com. The HARRIS factory may also be contacted through a FAX

facility (217/221-7096).

Replaceable Parts Service

Replacement parts are available 24 hours a day, seven days a week from the HARRIS

Service Parts Department. Telephone 217/222-8200 to contact the service parts department

or address correspondence to Service Parts Department, HARRIS CORPORATION, Broadcast Systems Division, P.O. Box 4290, Quincy, Illinois 62305-4290, USA. The HARRIS factory may also be contacted through a FAX facility (217/221-7096).

NOTE

The # symbol used in the parts list means used with (e.g. #C001 = used with C001).

Page 3

MANUAL REVISION HISTORY

888-2457-001

Rev. Date ECN Pages Changed

001-B 7/25/02 48420 Replaced Title Page, iv, and 4-6

Added MRH-1/MRH-2

WARNING: Disconnect primary power prior to servicing.

888-2457-001 MRH-1/MRH-1

Page 4

This page left blank intentionally

Page 5

Guide to Using Harris Parts List Information

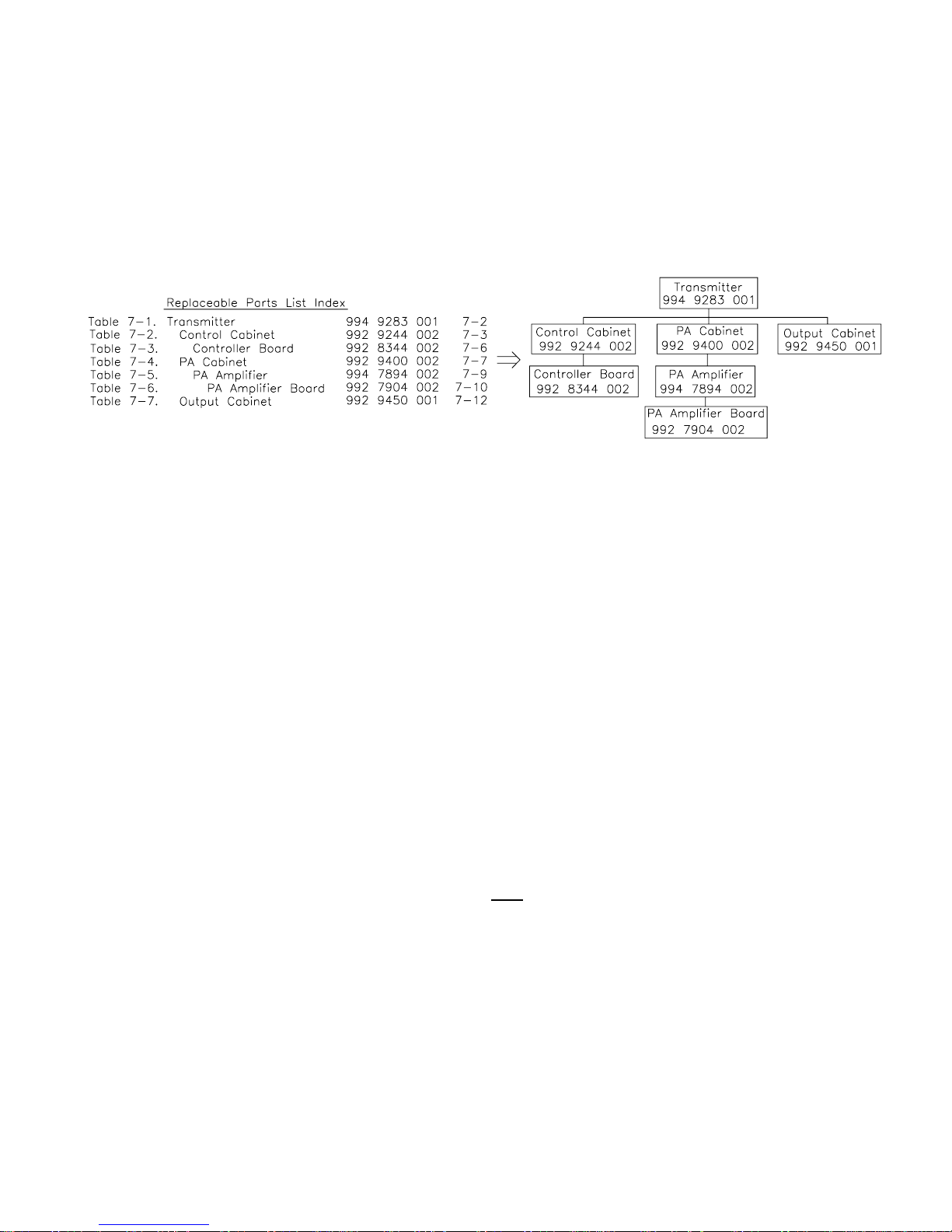

The Harris Replaceable Parts List Index portrays a tree structure with the major items being leftmost in the index.

The example below shows the Transmitter as the highest item in the tree structure. If you were to look at the bill of

materials table for the Transmitter you would find the Control Cabinet, the PA Cabinet, and the Output Cabinet. In

the Replaceable Parts List Index the Control Cabinet, PA Cabinet, and Output Ca binet show up one indentation level

below the Transmitter and implies that they are used in the Transmitter. The Controller Board is indented one level

below the Control Cabinet so it will show up in the bill of material for the Control Cabinet. The tree structure of this

same index is shown to the right of the table and shows indentation level versus tree structure level.

Example of Replaceable Parts List Index and equivalent tree structure:

The part number of the item is shown to the right of the description as is the page in the manual where the bill for

that part number starts.

Inside the actual tables, four main headings are used:

Table #-#. ITEM NAME - HARRIS PART NUMBER - this line gives the information that corresponds to the

Replaceable Parts List Index entry;

HARRIS P/N column gives the ten digit Harris part number (usually in ascending order);

DESCRIPTION column gives a 25 character or less description of the part number;

REF. SYMBOLS/EXPLANATIONS column 1) gives the reference designators for the item (i.e., C001, R102,

etc.) that corresponds to the number found in the schematics (C001 in a bill of material is equivalent to C1 on the

schematic) or 2) gives added information or further explanation (i.e., “Used for 208V operation only,” or “Used

for HT 10LS only,” etc.).

Inside the individual tables some standard conventions are used:

A # symbol in front of a component such as #C001 under the REF. SYMBOLS/EXPLANATIONS column means

that this item is used on or with C001 and is not the actual part number for C001.

In the ten digit part numbers, if the last three numbers are 000, the item is a part that Harris has purchased and

has not manufactured or modified. If the last three numbers are other than 000, the item is either manufactured by

Harris or is purchased from a vendor and modified for use in the Harris product.

The first three digits of the ten digit part number tell which family the part number belongs to - for example, all

electrolytic (can) capacitors will be in the same family

(524 xxxx 000). If an electrolytic (can) capacitor is found

to have a 9xx xxxx xxx part number (a number outside of the normal family of numbers), it has probably been

modified in some manner at the Harris factory and will therefore show up farther down into the individual parts

list (because each table is normally sorted in ascending order). Most Harris made or modified assemblies will

have 9xx xxxx xxx numbers associated with them.

The term “SEE HIGHER LEVEL BILL” in the description column implies that the reference designated part

number will show up in a bill that is higher in the tree structure. This is often the case for components that may

be frequency determinant or voltage determinant and are called out in a higher level bill structure that is more

customer dependent than the bill at a lower level.

2-02-93

Page 6

Page 7

WARNING

THE CURRENTS AND VOLTAGES IN THIS EQUIPMENT ARE DANGEROUS. PERSONNEL MUST AT ALL TIMES OBSERVE SAFETY WARNINGS, INSTRUCTIONS

AND REGULATIONS.

This manual is intended as a general guide for trained and qualified personnel who are aware of the dangers inherent in

handling potentially hazardous electrical/electronic circuits. It is not intended to contain a complete statement of all safety

precautions which should be observed by personnel in using this or other electronic equipment.

The installation, operation, maintenance and service of this equipment involves risks both to personnel and equipment, and

must be performed only by qualified personnel exercising due care. HARRIS CORPORATION shall not be responsible for

injury or damage resulting from improper procedures or from the use of improperly trained or inexperienced personnel

performing such tasks.

During installation and operation of this equipment, local building codes and fire protection standards must be observed.

The following National Fire Protection Association (NFPA) standards are recommended as reference:

- Automatic Fire Detectors, No. 72E

- Installation, Maintenance, and Use of Portable Fire Extinguishers, No. 10

- Halogenated Fire Extinguishing Agent Systems, No. 12A

WARNING

ALWAYS DISCONNECT POWER BEFORE OPENING COVERS, DOORS, ENCLOSURES, GATES, PANELS OR SHIELDS. ALWAYS USE GROUNDING STICKS AND

SHORT OUT HIGH VOLTAGE POINTS BEFORE SERVICING. NEVER MAKE INTERNAL ADJUSTMENTS, PERFORM MAINTENANCE OR SERVICE WHEN ALONE

OR WHEN FATIGUED.

Do not remove, short-circuit or tamper with interlock switches on access covers, doors, enclosures, gates, panels or shields.

Keep away from live circuits, know your equipment and don’t take chances.

WARNING

IN CASE OF EMERGENCY ENSURE THAT POWER HAS BEEN DISCONNECTED.

WARNING

IF OIL FILLED OR ELECTROLYTIC CAPACITORS ARE UTILIZED IN YOUR

EQUIPMENT, AND IF A LEAK OR BULGE IS APPARENT ON THE CAPACITOR

CASE WHEN THE UNIT IS OPENED FOR SERVICE OR MAINTENANCE, ALLOW

THE UNIT TO COOL DOWN BEFORE ATTEMPTING TO REMOVE THE DEFECTIVE CAPACITOR. DO NOT ATTEMPT TO SERVICE A DEFECTIVE CAPACITOR

WHILE IT IS HOT DUE TO THE POSSIBILITY OF A CASE RUPTURE AND SUBSEQUENT INJURY.

i

Page 8

ii

Page 9

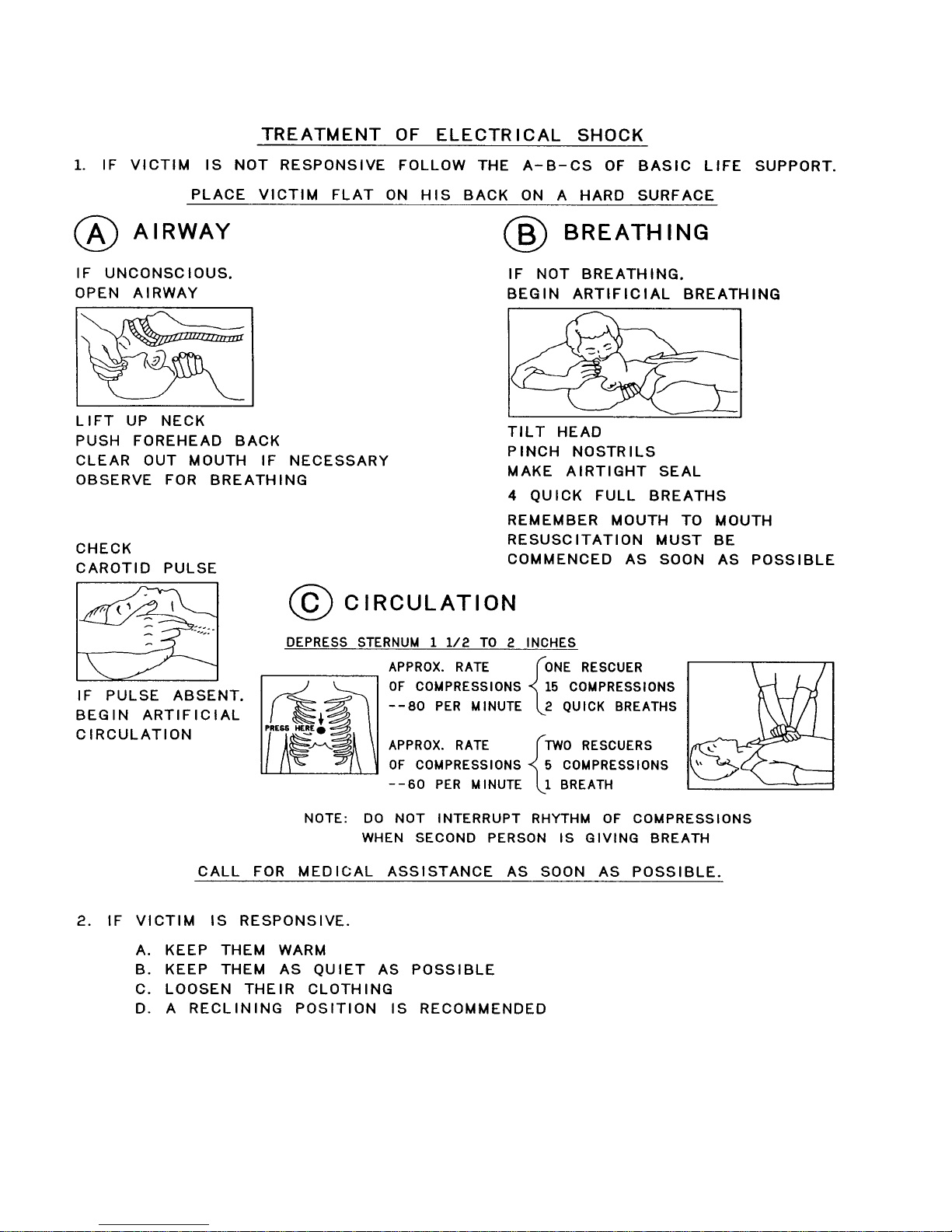

FIRST-AID

Personnel engaged in the installation, operation, maintenance or servicing of this equipment are urged to become familiar

with first-aid theory and practices. The following information is not intended to be complete first-aid procedures, it is a

brief and is only to be used as a reference. It is the duty of all personnel using the equipment to be prepared to give

adequate Emergency First Aid and thereby prevent avoidable loss of life.

Treatment of Electrical Burns

1. Extensive burned and broken skin

a. Cover area with clean sheet or cloth. (Cleanest available cloth article.)

b. Do not break blisters, remove tissue, remove adhered particles of clothing, or apply any salve or ointment.

c. Treat victim for shock as required.

d. Arrange transportation to a hospital as quickly as possible.

e. If arms or legs are affected keep them elevated.

NOTE

If medical help will not be available within an hour and the victim is

conscious and not vomiting, give him a weak solution of salt and soda:

1 level teaspoonful of salt and 1/2 level teaspoonful of baking soda to

each quart of water (neither hot or cold). Allow victim to sip slowly

about 4 ounces (a half of glass) over a period of 15 minutes. Discontinue fluid if vomiting occurs. (Do not give alcohol.)

REFERENCE:

2. Less severe burns - (1st & 2nd degree)

a. Apply cool (not ice cold) compresses using the cleanest available cloth article.

b. Do not break blisters, remove tissue, remove adhered particles of clothing, or apply salve or ointment.

c. Apply clean dry dressing if necessary.

d. Treat victim for shock as required.

e. Arrange transportation to a hospital as quickly as possible.

f. If arms or legs are affected keep them elevated.

ILLINOIS HEART ASSOCIATION

AMERICAN RED CROSS STANDARD FIRST AID AND PERSONAL SAFETY MANUAL (SECOND EDITION)

iii

Page 10

Table Of Contents

Section I

Introduction/Specifications

Introduction......................................1-1

GeneralDescription .............................1-1

ControlandMonitoring ............................1-1

Signal Flow Through the System..................... 1-1

RFAmplifierModules............................. 1-1

PowerSupplies...................................1-1

Cooling .........................................1-1

RFOutputSystem.................................1-1

OptionalEquipment ...............................1-1

BlockDiagram ...................................1-1

Specifications ....................................1-1

Section II

Installation

Introduction......................................2-1

TestEquipmentRequirementPlanning.............. 2-1

MechanicalInstallationPlanning.....................2-1

SpaceRequirements............................. 2-1

ApproximateShippingWeights....................2-1

RFSystemLayout ..............................2-1

AirSystem.....................................2-1

ElectricalInstallationPlanning.......................2-1

PowerRequirements.............................2-1

CircuitBreakerSelection.........................2-1

ACmainsDisconnectLocation....................2-2

UnloadingandUnpacking..........................2-2

EquipmentRequiredforUnloading.................2-2

Unpacking,EquipmentInventoryandInspection......2-2

FactoryTestDataSheets .........................2-3

CabinetPlacementandLeveling................... 2-3

ElectricalInstallation ..............................2-4

Grounding .....................................2-4

PrimaryWiring................................. 2-4

SettingTransformersTaps........................2-5

Input Signals ...................................2-5

SetupJumpers..................................2-5

BackupBattery.................................2-5

RFOutputCoaxConnections...................... 2-5

Interlocks......................................2-5

TransmitterCheckOut............................. 2-5

Pre-turnonchecks .............................. 2-5

InitialTurn-onSequence .........................2-5

Module Installation..............................2-5

ControlSystemCheckOut........................2-6

InitialApplicationofRFPower....................2-6

Visual.....................................2-6

Aural .........................................2-6

RemoteControlInputandOutput.................... 2-6

CommandIn1A12J21 ...........................2-6

1A12J22:StatusOutputs .........................2-6

StatusFunctions1A12J22 ........................2-7

AnalogOutputs1A12J23......................... 2-7

Section III

Operation

Introduction......................................3-1

ControlsAndIndicators............................ 3-1

LocalTurn-onandTurn-off ........................ 3-1

VideoControlledOperation ........................ 3-1

RemoteControl/ExtendedOperation................. 3-1

Section IV

Theory of Operation

Introduction ..................................... 4-1

SystemOverview................................. 4-1

Exciter,MeterandControlBoard.................... 4-1

A/D&Displays................................ 4-1

BarGraphDisplay.............................. 4-1

AnalogMultiplexers ............................ 4-1

MeterSelector................................. 4-1

LossOfVideoDelayDetector.................... 4-2

Override/NormalSelection....................... 4-2

ClockCircuits ................................. 4-2

BATTERY (BAT) SUPPLY VOLTAGE............ 4-2

VisualPowerControl ........................... 4-2

AuralPowerControl............................ 4-2

PowerUpReset................................ 4-2

JP2&JP3..................................... 4-2

FREQUNLOCK............................... 4-2

VIS_CLK_GATE U18 & AUR_CLK_GATE U19

FunctionalDescriptions......................... 4-3

METER_CLK_GATE U20 Functional De-

scriptions................................. 4-3

METER_SEL U17 Functional Descriptions.......... 4-3

VIS_UP/DWN_PWR_CTRLU26&U27....... 4-3

VisualDACU25............................... 4-3

VisualFoldbackControl......................... 4-3

AUR_UP/DWN_PWR_CTRLU29&U30.......... 4-3

InterfaceLogicModule............................ 4-4

PeakDetectors................................. 4-4

FoldbackCircuits............................... 4-4

HighVSWR................................... 4-5

Command Input Logic PAL U8 (917-2321-004)...... 4-5

XMTRCTRLPALU15 ..................... 4-5

Fault Encoder U19 (917-2321-008) ............ 4-5

50VOK .................................. 4-5

AirFault.................................. 4-6

ACBREAKERS ................................. 4-6

MAINBREAKER.............................. 4-6

ACCONTROLBREAKER...................... 4-6

LOGICSUPPLYBREAKER..................... 4-6

POWER MODULE 1A11 .......................... 4-6

POWER SUPPLY FAULT DISPLAY and INTER-

FACE1A11A6................................ 4-6

50VSUPPLIES1A11A1and1A11A5 ............. 4-7

LOGICSUPPLY1A11A3 ....................... 4-7

Section V

Maintenance and Alignments

Introduction ..................................... 5-1

StationRecords .................................. 5-1

Transmitter Logbook ............................ 5-1

MaintenanceLogbook........................... 5-1

SafetyPrecautions.............................. 5-1

PreventiveMaintenance ........................... 5-1

AirFilterMaintenance .......................... 5-1

iv 888-2457-001 Rev. B: 7/25/02

WARN9ING: Disconnect primary power prior to servicing.

Page 11

MOV’S....................................... 5-2

Semiconductors................................ 5-2

Capacitors................................. 5-2

FixedResistors............................. 5-2

Transformers .............................. 5-2

Relays.................................... 5-2

PerformanceChecks.............................. 5-2

Adjustments..................................... 5-2

RFPowerMeasurements .......................... 5-2

Through-LineMeters............................ 5-2

Visual Peak-sync to Average Power Conversion For-

mulas........................................ 5-3

TransmitterMeteringandControlCalibration.......... 5-3

Power Supply Meter Calibration................... 5-3

PSVOLTSCalibration:...................... 5-3

PSCURRENTCalibration ................... 5-3

ExciterRFOutputMeterCalibration............... 5-3

ExciterVisualPowerCalibration.............. 5-3

ExciterAuralPowerCalibration............... 5-3

TransmitterRFOutputMeterCalibration ........... 5-3

Transmitter Visual Forward Power Calibra-

tion...................................... 5-4

Transmitter Visual Reflected Power Calibra-

tion...................................... 5-4

TransmitterAuralForwardPowerCalibration.... 5-4

Transmitter Aural Reflected Power Calibra-

tion...................................... 5-4

VSWRFaultAndFoldbackAdjustments ........... 5-4

InitialSetupforAdjustment .................. 5-4

VisualHighVSWRAdjustment............... 5-4

VisualVSWRFoldbackAdjustment ........... 5-4

AURALHIGHVSWRAdjustment............ 5-4

AuralVSWRFoldbackAdjustment............ 5-4

TransmitterAGCAdjustment....................... 5-4

VisualAGC: .................................. 5-4

VisualPowerReduction......................... 5-5

AuralAGC.................................... 5-5

AuralPowerReduction.......................... 5-5

Component Replacement On Circuit Boards ........... 5-5

Section VI

Troubleshooting

Introduction..................................... 6-1

Troubleshooting Assistance......................... 6-1

Returns......................................... 6-1

Section VII

Parts List

Section VIII

Parts List

Appendix A

RF Amplifier M odules, Platinum Series

GeneralInformation .............................. A-1

Factory Module Repair .......................... A-1

LocalModuleRepair............................ A-1

RFAmplifierModulesTheoryofOperation........... A-1

Driver Module, Low Band........................A-2

Driver Module, High Band .......................A-2

PAModule....................................A-4

RF Quarter Modules.............................A-4

Low Band Quarter Module .......................A-4

HighBandQuarterModule.......................A-5

Quarter Module Bias ............................A-5

Protection,ControlandMonitorSubsystem..........A-5

Module Status LEDs ............................A-6

RedLEDFaultBlinkCodes ..................A-6

Module Troubleshooting ...........................A-6

Platinum™ TV Module Test Fixture (992-8556-002) . . A-7

Troubleshooting Based on Module Swapping ........A-7

Troubleshooting Based on Module Blink Codes ......A-7

IsolatingOtherFailures.........................A-10

LocatingFailedRFFETs........................A-11

DCResistanceTest.........................A-11

IdleCurrentTest...........................A-11

PartsReplacementProcedures......................A-12

SolderingPrecautions...........................A-12

Quarter Module Replacement ....................A-13

RFFETReplacement...........................A-13

TestingandReplacingIsolationResistors ..........A-14

PassFETReplacement..........................A-14

ChipCapReplacement .........................A-15

TestProcedureSolidStateTVModules..............A-15

Pre-operationalChecks .........................A-15

InitialPowerUp...........................A-15

IdleCurrentCheck.........................A-15

Over/UnderVoltageCheck..................A-15

RFTesting ...................................A-15

ApplicationofDrive........................A-15

GainCheck...............................A-15

Alternate method for measurement under

program conditions......................A-16

ISOVoltsCheck...........................A-16

OverdriveCheck...........................A-16

VSWRCheck.............................A-16

Appendix B

Air Conditioning Considerations

Air Conditioning ................................. B-1

HeatLoadEstimateGuide.......................... B-1

Appendix C

Surge and Lightning Protection and Grounding Consid-

erations

SurgeandLightningProtection...................... C-1

System Grounding ................................ C-1

Ground Wires .................................. C-1

ACGround....................................C-1

DCGround....................................C-2

Earth Ground ..................................C-2

RF Ground .................................... C-2

Rev. B: 7/25/02 888-2457-001 v

WARN9ING: Disconnect primary power prior to servicing.

Page 12

This page left blank intentionally

Page 13

Section I

Introduction/Specifications

1.1 Introduction

1.1.1 General Description

Platinum™ Series The HT EL 2000 watt television transmitter

is an externally diplexed transmitter available in CCIR systems

forM,D/K,B,I,andK.

The transmitter consistsof5 RFamplifier modules, coolingfans,

50 volt power supplies,controlinterface tray,logicpower supply

and an exciter. The exciter includes thetransmitter controlpanel.

Transmitters operate on a 208-240 volt single phase 50 or 60

Hertz. The transmitter assemblies all are mounted in a single

cabinet 183 cm (72 inches) high.

1.2 Control and Monitoring

Transmitters are designed for local, video present control, or

remote/extended operation. VSWR foldback is used to protect

the transmitter RF system. Over temperature protection of RF

modules and module power supplies is standard.

1.3 Signal Flow Through the System

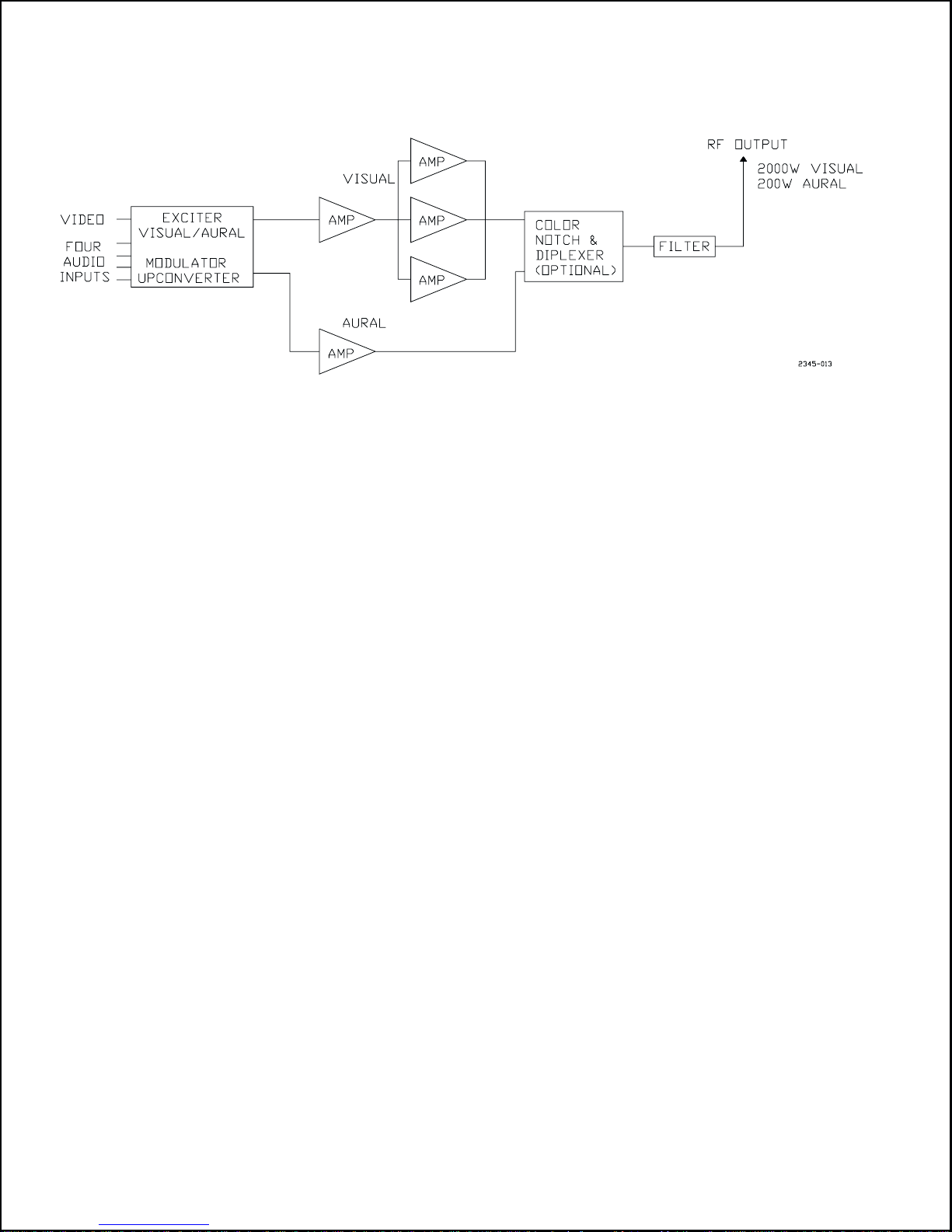

Refer to transmitter block diagram Figure 1-1.

The visual exciter uses IF modulation with pre-correction at

video and IF. The visual signal is amplified by a driverand three

PA modules.

The aural exciter modulates audio baseband and subcarrier inputs at aural IF carrier . Optional IF group delay correction is

available for a Notch Diplexer and aural linearization for dual

carrier systems. The aural signal is amplified by a RF driver

amplifier module.

1.6 Cooling

The main coolingair intake isthrough the reardoor and exhausts

out the top and right side. There are fivesupply and five exhaust

fans for module cooling. T wo other fans are used for heat pipe

cooling.

Removing one module will not affect air flow to other modules.

Each power supply has a fan to draw air from the front of the

transmitter.

1.7 RF Output System

Various diplexing systems are used as the system requires. Harmonic and imagefrequency color subcarrierfiltersare part ofthe

system.

1.8 Optional Equipment

Single or dual cavity Notch Diplexer

Multichannelsound:NICAM, IRTDual Carrierand BTSC

Precision Offset

Combined transmitters

Main/alternate transmitters

Second exciter with automatic exciter switcher

Power measurement wattmeter

RF module test fixture

Spare parts, semiconductors and board assemblies

Spare RF modules

Transmitter Remote Control System

1.9 Block Diagram

Figure 1-1 is a block diagram of the HT EL2000LS/HS.

1.4 RF Amplifier Modules

Like aural and visual modules are interchangeable and have

overdrive, over/undervoltage, power unbalance, VSWR, and

overtemperature protection. The modules may be repaired in the

field at the quarter module or component level.

1.5 Power Supplies

The exciter and interface logic utilize linear regulator supplies.

The RF module power comes from power factor corrected

switching supplies in the power module assembly.

WARNING: Disconnect primary power prior to servicing.

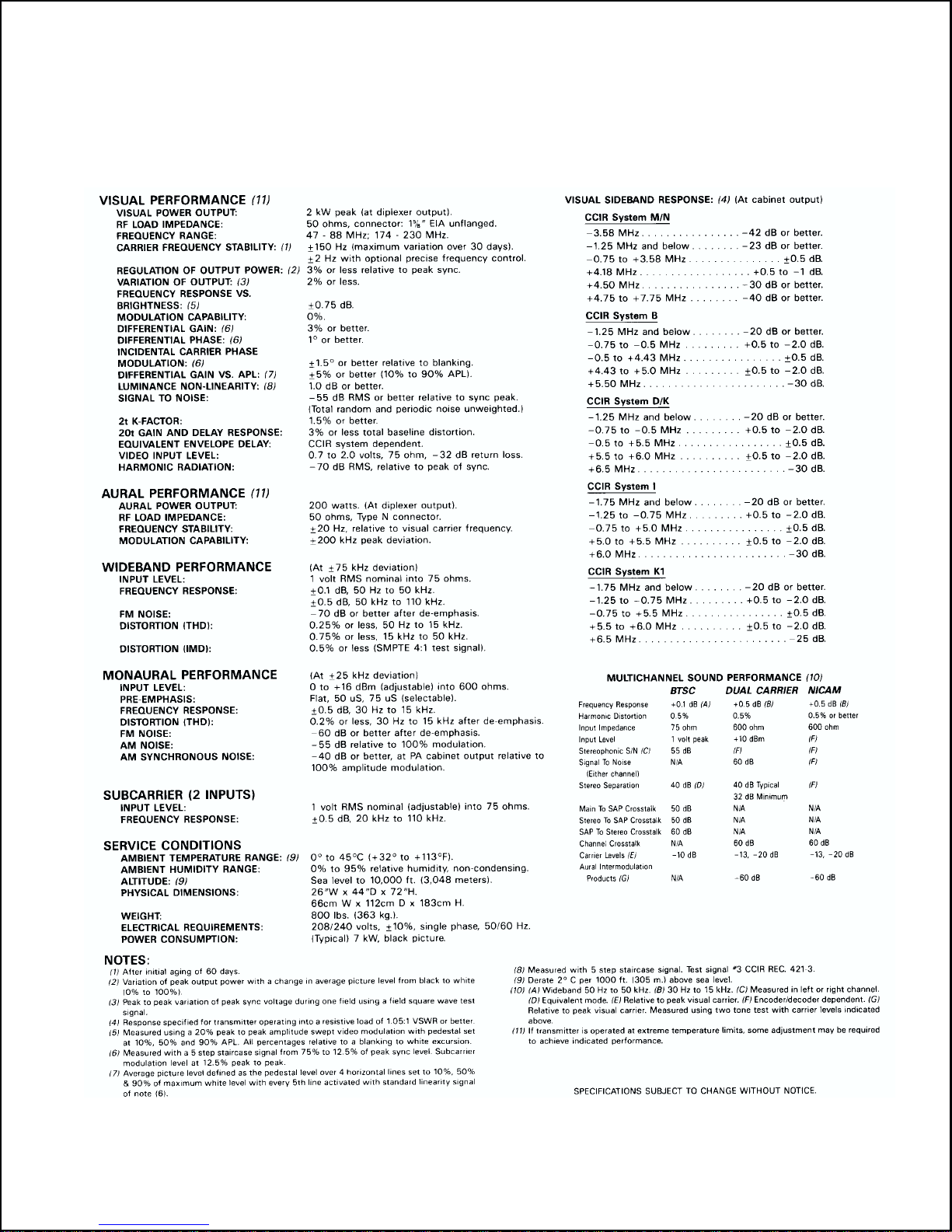

1.10 Specifications

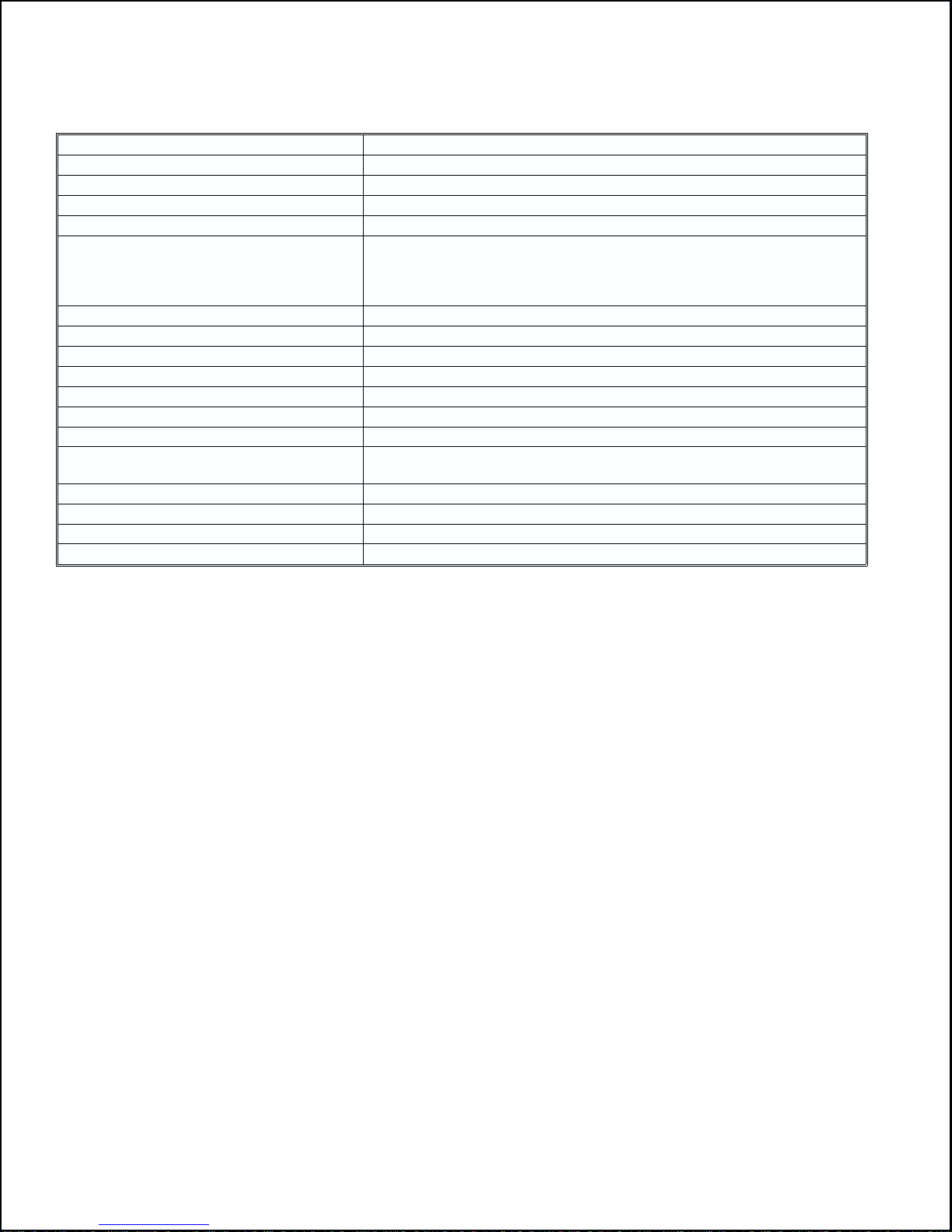

Table 1-1 lists the specificaitons for the HT EL2000LS/HS.

NOTE

Specifications subject to change without notice.

888-2457-001 1-1

Page 14

Platinum™ Series

Figure 1-1. HT EL2000 LS/HS Block Diagram

1-2 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Page 15

Table 1-1. Specifications

Section I - Introduction/Specifications

WARNING: Disconnect primary power prior to servicing.

888-2457-001 1-3

Page 16

Platinum™ Series

Table 1-1. Specifications

Electrical Specifications HT EL2000LS/HS

V isual Specifications:

Power Output 2 kW Peak of sync

Measured at output of optional diplexer

Frequency Range HT EL2000LS, 47-88 MHz

HT EL2000HS, 170-230 MHz

Systems CCIR-M,N,B,D/K,K1,I

Color Formats NTSC, PAL, SECAM

RF Output:

Impedance 50 ohms.

Connector 1 5/8" EIA unflanged

Video Input:

Impedance 75 Ohm, 32 dB return loss up to 5.0 MHz

Level 0.5 - 2.0 Volts, peak to peak

Visual Modulation Capability 0%

Measured using synchronous detector.

Frequency Response vs. Brightness 0.75 dB or better

Measured using a 20% amplitude swept video modulation with pedestal set at

10%, 50% and 90% APL. All percentages relative to a blanking to white

excursion.

Differential Gain 3% or better

Measured with a 5-step staircase signal 0 to 100 IRE units and color subcarrier

of 20 IRE units peak to peak.

Differential Phase 1 or better

Measured with 5-step staircase signal as in Differential Gain.

Incidental Carrier Phase Modulation 1.5 or better

Carrier phase variation from reference white to sync tip relative to blanking.

Luminance Non-linearity 1.0 dB or better

Measured with a 5-step staircase signal. Test Signal #3 CCIR Rec. 421-3.

Equivalent Envelope Delay Compliant with CCIR system

2T Pulse K-Factor 1.5% Maximum

20T Pulse 3% Maximum baseline disturbance

Signal-to-Noise -55 dB RMS or better

Total random and periodic noise unweighted, relative to peak sync.

Variation of Output 2% or less

Total peak-to-peak variation of peak sync voltage during one field, using a field

square wave test signal.

Regulation of Output Power 3% or less

Variation of peak output power with a change in average picture level from

black to white (0% to 100%).

Carrier Frequency Stability 150 Hz per month

After 60 day initial aging.

(2 Hz, with optional precise frequency control)

Harmonic Radiation -70 dB RMS, relative to peak vision power.

Aural Specifications:

1-4 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Page 17

Table 1-1. Specifications

Continued

Power Output 200 W

Measured at output of optional notch diplexer.

RF Output:

Impedance 50 Ohms

Connector Type N, Female

Audio Inputs:

1. Monaural

Level 0 to +16 dBm, 25 kHz deviation

Impedance 600 Ohms balanced

Response 0.5 dB, 30 Hz-15 kHz

Pre-emphasis Flat / 50uS / 75uS, selectable

2. Subcarrier (2 inputs)

Level 1 volt RMS, adjustable.

Impedance 75 Ohms, unbalanced

Response 0.5 dB, 20 kHz-110 kHz.

3. Wideband(composite)

Level 1 volt RMS nominal for 75 kHz deviation

Impedance 75 Ohms, unbalanced

Response 0.1 dB, 50 Hz to 50 kHz

0.5 dB, 50 kHz to 110 kHz

Monaural Performance:

Frequency Response 0.5 dB, 30 Hz to 15 kHz

Relative to standard 75S or 50S pre-emphasis curve.

Harmonic Distortion 0.2% or less

Measured at 25 kHz deviation, 30 Hz to 15 kHz after de-emphasis.

FM Signal-to-Noise 60 dB RMS or better

Relative to 25 kHz deviation.

AM Signal-to-Noise 55 dB RMS or better

Relative to 100% amplitude modulation.

AM Synchronous Noise 40 dB RMS or better

Relative to 100% amplitude modulation, measured before optional diplexer.

Wideband Composite Performance: (At 75kHz deviation)

Harmonic Distortion 0.25% or less, 50 Hz to 15 kHz

0.75% or less, 15 kHz to 50 kHz

Distortion (IMD) 0.5% or less

SMPTE 4:1 test signal.

FM Signal-to-Noise 70 dB RMS or better

Measured after de-emphasis.

AM Signal-to-Noise 55 dB RMS or better

Relative to 100% amplitude modulation.

AM Synchronous Noise 40 dB RMS or better

Relative to 100% amplitude modulation.

Stereo Separation 45 dB or better ,50 Hz to 15 kHz

Equivalent mode (uncompanded).

Crosstalk 50 dB or better

Stereo or Main channel into SAP.

Mechanical, Environment, Power

Physical Dimensions:

Section I - Introduction/Specifications

WARNING: Disconnect primary power prior to servicing.

888-2457-001 1-5

Page 18

Platinum™ Series

Table 1-1. Specifications

Continued

Width 26" (66 cm)

Height 72" (183 cm)

Depth 35" (89 cm)

Weight 800 lbs (363 kg)

Environmental Requirements:

Operating Temp. Range 0 to +45 degrees C

(+32 to +113 degrees F)

Maximum temperature rating decreases 2 degrees C per 1,000 foot altitude

above mean sea level.

Humidity Range 0 to 95% Relative Humidity

Maximum Altitude 10,000 feet (2,286 meters)

Power Requirements:

Input 208/240 volts 11 volts, single phase, 50/60 Hz

Regulation 10%

Air System Requirements:

Inlet Air Openings Rear door and front power module, with filters

Exhaust Air Openings Amplifier cabinet top, 30" x 8" and amplifier cabinet right rear side (two areas),

6" x 18" and 9" x 11".

Exhaust Temperature 10 degrees C temperature rise above inlet

Allowable Back Pressure 0.05" of water at each cabinet exhaust stack

Acoustic Noise 65dB, @ 3 feet in front of center of transmitter (“A” weighting scale)

Inlet/Exhaust Air Flow 1225 cfm

1-6 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Page 19

2.1 Introduction

This section contains information necessary for installation

planning, installation, and initial checkout procedures on Plati-

num™ Series HT EL2000LS/HS television transmitters. The

informationinthissectionisintendedtobeusedonlyasa

general guideline in planning the installation. Since all installations differ in some respects, and in order to conform to local

building and electrical codes,the informationcontained mustbe

adapted for each installation.

2.1.1

Test Equipment Requirement Planning

See Table 2-1 for a list of recommended test equipment.

2.2 Mechanical Installation Planning

2.2.1 Space Requirements

(Refer to Transmitter Outline drawing: 843-5285-110)

Planning for the transmitter room should allow space for pro-

gram input, monitoring, remote control, and test equipment as

well as the transmitter. Additional area may also be required for

tower lighting, HVAC (heating, ventilation and air-conditioning) equipment, storage, and a workbench. To allow for servicing the transmitter, a minimum clearance of 3 feet (92 cm) in

front of and 20 inches (51 cm.) behind the cabinet is recommended.

The Transmitter Outline drawing, shows the air exhaust hole

pattern locations, do notobstruct these exhaustareas.Leaveside

exhaust areas unobstructed for at least 8 inches (20 cm.).

2.2.2

Approximate Shipping Weights

(lb) (kg)

Cabinet 435 198

Exciter 55 25

RF modules each 26 12

Power module 125 57

Be sure to include this information in your planning for the

building and verify that the structure is capable of safely supporting the total weight of the transmitter and peripheral equipment.

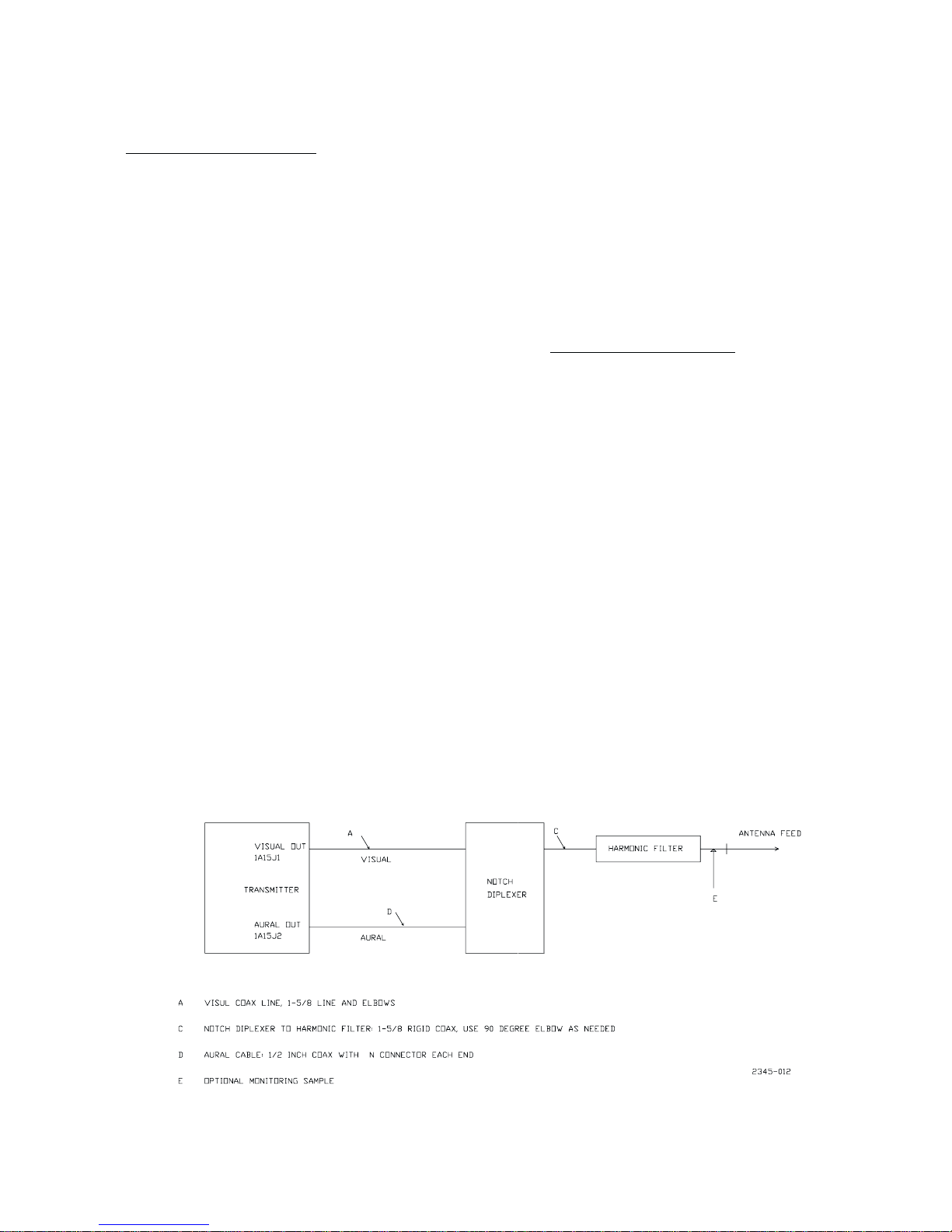

2.2.3

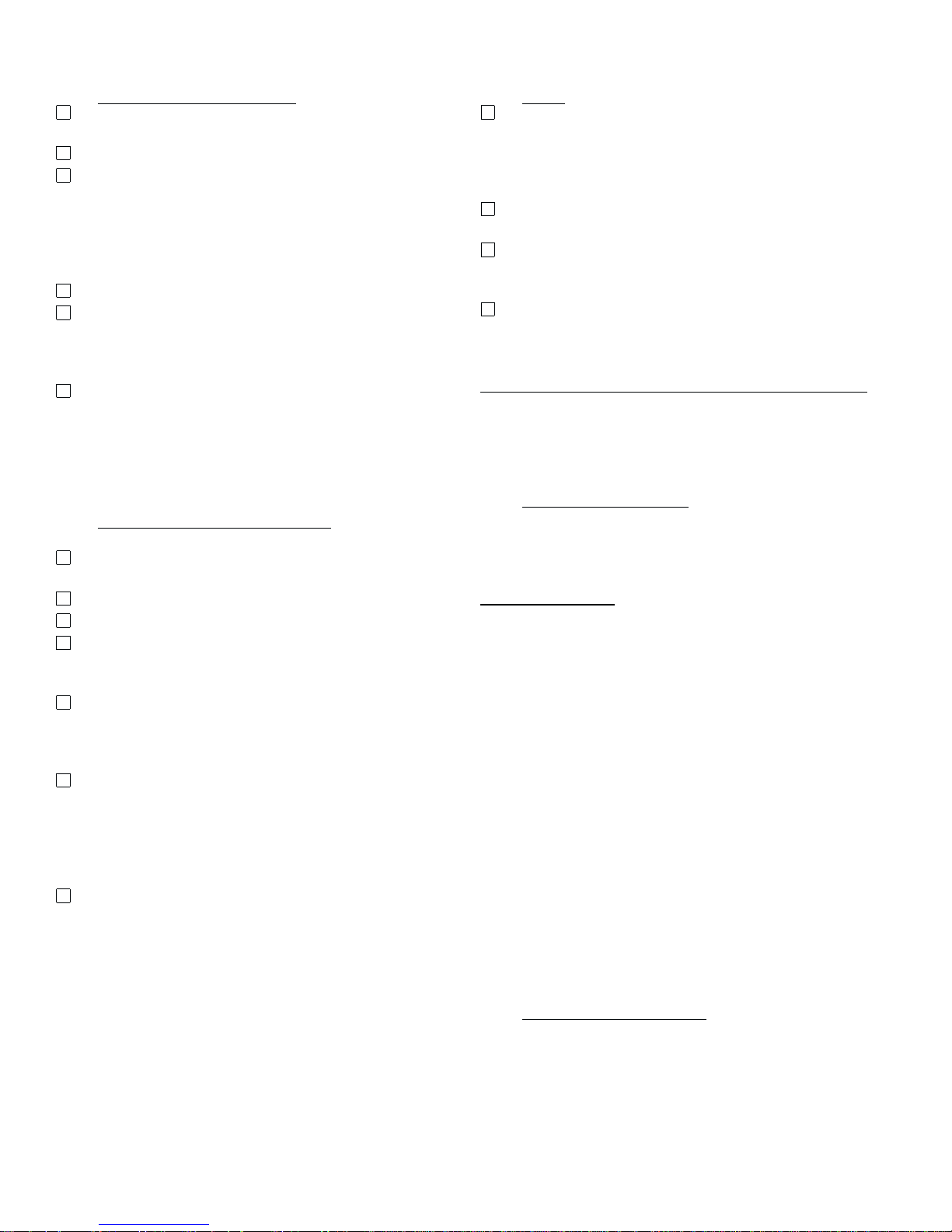

RF System Layout

The 1 5/8 EIA unflanged visual RF output and the N connector

aural output areon the top of thecabinet. Adapters arefurnished

where needed to connect RF coax cables to 1 5/8 EIA components. The outline drawings of typical RF notch diplexers and

harmonic filters are included. Use the block diagrams and

component outline drawings (Fig 2-2 through 2-11) to plan the

installation for the site requirements. Locate the transmitter

close to thediplexerto minimize theinterconnectionline losses.

A support system should beinstalled sothat the RF components

are completely supported,to minimizethe weight carried by the

Section II

Installation

output connectors. This will prevent possible damage to components and connectors. Notch diplexersare generally supplied

in a frame which rests on or is bolted to the floor.

Directional couplers for metering are in the transmitter cabinet.

Optional directional couplers for monitoring are on the block

diagram and should be ordered with the transmitter. Be sure all

components necessary for installation are available on site.

2.2.4

Air System

Minimum transmitter air cooling requirements are 1200 cubic

feet per minute (34 cubic meters per minute). Additional flushing air is recommended for the removal of heat from any

equipment surrounding the transmitter. A good guideline is to

keepinputair no greater than 5°C above ambient. The maximum

transmitter operating temperature is 45°Catsealevel(derate

2°C for each 1000 feet (300 meters) above sea level. Hot air

rises, one approach would be to use exhaust duct(s) or louvers

at the highest point of the room and use a supply fan and filter

frame to keep the room at a positive pressure.

Appendix B contains information useful to those intending to

use air conditioning equipment to control transmitter building

temperature.

2.3 Electrical Installation Planning

Each country establishes standards for AC power systems. The

national and localapplicable standard for the installationshould

be followed.

See Appendix C for information about lightning and surge

protection.

2.3.1

Power Requirements

The transmitter is designed to operate from 208 to 240 volts,50

or 60 Hz, single phase. If voltage variations in excess of

areanticipated, it isrecommended that thetransmitter ACmains

be equipped with automatic voltage regulators capable of correcting the primary voltage.

All control wiring and signal inputs are located at the I/O panel

in the cabinet. Additional access is provided in the cabinet floor

for AC wiring only. AC power to the transmitter should be run

in metallic conduit, connected to earth ground for safety and to

provide shielding against interference. The power wiring must

be terminated in a power distribution panel,this panelmust also

beconnected to earth ground.Atransmitter cabinet ground strap

connection is located at the lower rear edge.

2.3.2

Circuit Breaker Selection

The transmitter requires a relatively stable source of input

power. For this reason, the primary power for the transmitter

should originate at the main power distribution system and

remain isolated from other electrical distributions.

+10%

WARNING: Disconnect primary power prior to servicing.

888-2457-001 2-1

Page 20

Platinum™ Series

Table 2-1. Recommended Test Equipment

Ve stigial Sideband Demodulator Tektronix 1450/1350 or

Equivalent

Option 1 37 MHz IF, NTSC CCIR-M (USA and others)

Option 2 38.9 MHz IF, CCIR-G, PAL

Tektronix Sideband Analyzer

Consisting of:

1405 Sideband Adaptor

2710, 490, or 2750 Spectrum Analyzer

Tektronix 1910 Signal Generator or equivalent

Tektronix 1780 Video Measurement Set

Aural Stereo Generator, Orban 8182A or equivalent

Aural Demodulator Tektronix 751, TFT-850,or equivalent for

stereo

Time & Frequency Technology 701, 702, or equivalent for

monaural

A method of measuring transmitter frequency with two

sources. (Frequency Counter, Frequency Counter on Demodulator, Outside Frequency Measuring Service.)

Audio Oscillatorand Distortion Analyzer (Sound Technology

1710A or equivalent).

Asaca 201-1 Envelope Delay Measuring Set

Scope Camera

RF Bridge, Ealge RLB-150, or precision directional coupler

700-1289-000

UHF RF Notch Filter, Eagle Model TNF-1 484-0300-000

Various RF Adaptors and Connectors

3-1/8 inch to type “N” adapter - 620-0008-000

Type N to BNC male to female - 620-0128-000

Type N to BNC female to male - 620-0547-000

Type BNC plug to Subminiax Plug

Type BNC plug to Subminiax Jack

Type BNC barrel - 620-0604-000

Type BNC to SMB (push-on) - 620-0628-000

TNC-BNC - 620-2821-000

Bird Model 43 Wattmeter with elements from 1W to 1000W

Adaptor 1 5/8" coax to N connector

Manometer Dwyer model40-1 (range 0.1-0-1.0"WC)or equal

Tee kit Dwyer A-604T or equal

Fluke Multimeter and Style C Current Probe

A short-duration surge, due to transformer inrush current, will

occur at turn-on or during a short AC power loss.This surgecan

be as high as 400 amps. During this surge,the linevoltage at the

cabinetmustnotdropbelow80%of the rated line voltage. Select

a 40 amp breaker or fuse for the transmitter using the above

inrush current information.

AC mains Disconnect Location

2.3.3

The circuit breaker panel should be located near the transmitter

in a well lighted area. As a safety precaution, controls for

disconnecting the main power service supplying the transmitter

must be convenient to the operator and maintenance personnel.

Breakers must be clearly labeled. Provisions for emergency

lighting should be made.

2.4 Unloading and Unpacking

2.4.1 Equipment Required for Unloading

Examine the weights listed on the Transmitter Outline drawing

for guidance on the equipment needed. Note: The notch

diplexer, if used, will be the heaviest.

Unpacking, Equipment Inventory and Inspection

2.4.2

A“check-off”boxis availableto help the installertrackthe steps

that have been completed.

Whenthetransmitteris deliveredtothesite, the shipment should

be inspected and inventoried before installation is begun. This

section provides information to assist unpacking and inventory.

Locate the packing check list when the shipment arrives.

Each transmitter shipment will be accompanied by a packing

check list identifying which equipment is packed in the various

crates and boxes.

LOCATED PACKING CHECK LIST

The contents of the shipment should be inventoried with the

packing list. Carefully unpack the unit and perform a visual

inspection to determine if any apparent damage has been incurred during shipment. Retain all shipping materials until ithas

been determined that all items on the list are on site and no

damageoccurred during shipment.It maybenecessaryto search

packing material for parts initially missed during unpacking.

The carrier may also wish to examine the packing material.

If the contents are incomplete, or if the unit is damaged electrically or mechanically, notify the Harris Customer Service Department by phone at 217-222-8200, FAX at 217-222-9443 or

at the following address:

Harris Corporation,

Broadcast Division

P.O. Box 4290

Quincy, Il 62305

Attn. Customer Service Department

INVENTORY OF EQUIPMENT COMPLETED

The equipment becomesthe propertyof the customer when the

unit is delivered to the carrier. Claims for damaged equipment

2-2 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Page 21

Section II - Installation

must be filed promptly; otherwise, the carrier may not accept

the claim.

2.4.3

Factory Test Data Sheets

Factory test data is supplied with each transmitter. It lists parameters for operation of the transmitter. These readings were

recorded during factory testing. Locate the test data and place it

in the manual at the end of the maintenance section.

Record the same readings periodically to establish and maintain

an information base from which to work in the event of future

changes or problems.

FACTORY TEST DATA LOCATED

Cabinet Placement and Leveling

2.4.4

Four bolts hold the cabinet to its skid. They are located two per

side, front and rear. When the cabinetis inits final position, you

may need to level the cabinet. The HT EL cabinet has leveling

jacks in the corners to aid in leveling the cabinet on un-even

floors.The four 0.5inch hold-downs in thebottomofthe cabinet

used to bolt the cabinet to the shipping skid that may be used to

bolt the unit to thefloor.Levelthecabinet using shimsunder the

bottom, this is important to avoid deforming the cabinet when

bolting it to the floor.

Install the power module assembly in the bottom of the rack. It

will slide intomating electrical connectors.Install the Exciter(s)

and connect power and signal cables to exciter(s).

NOTE

DO NOT INSTALL RF MODULES AT THIS TIME

WARNING: Disconnect primary power prior to servicing.

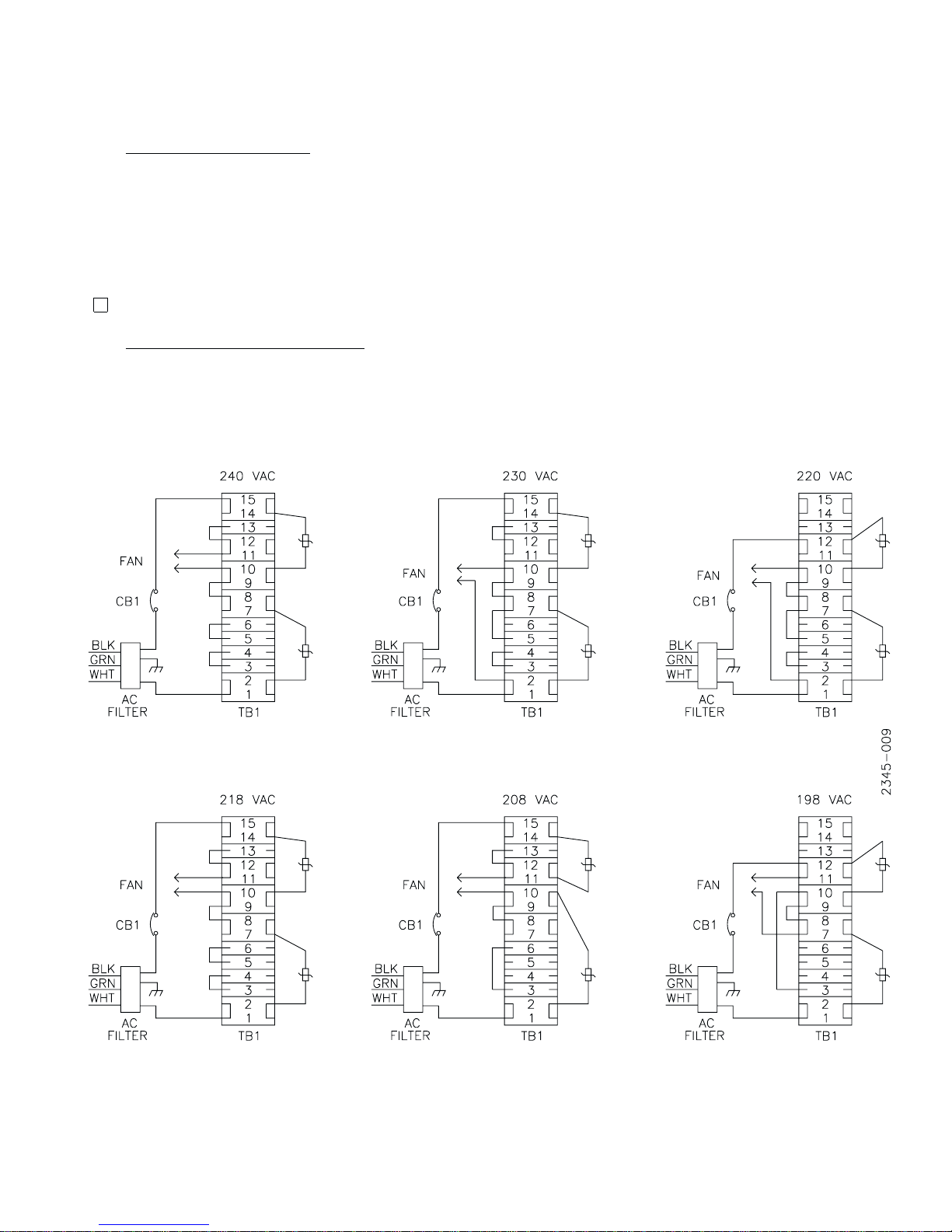

Figure 2-1. Transformer Taps

888-2457-001 2-3

Page 22

Platinum™ Series

2.5.2

2.5 Electrical Installation

2.5.1 Grounding

Located in the lower left rear corner of the cabinet is a ground

strap. Connect thestation groundto this strap with 2 inch(5 cm)

copper strap. For additional information on station grounding

requirements refer to Appendix C.

GROUND STRAP CONNECTED

Table 2-2. Input Signals & Remote Conrol I/O

SYMBOL FUNCTION CONNECTOR LABEL CONNECTOR TYPE

Exciter A Exciter B

J1 J11 Video Input VIDEO IN BNC

J2 J12 Aural Composite input COMP AUR BNC

J3 J13 Aural Subcarrier 1 AUR SCA 1 BNC

J4 J14 Aural Subcarrier 2 AUR SCA 2 BNC

J5 J15 Precise Frequency Control Input PFC IN BNC

J6 J16 Monaural Aural Input/Dual Sound Audio 1 MONO AUR 1 XLR

J7 J17 Monaural Aural Input/Dual Sound Audio 2 MONO AUR 2 XLR

J8 J18 NICAM Reference BNC

J9 J19 NICAM IF In BNC

J10 J20 Option Access BNC

J21 Remote Command Input 37 Pin D

J22 Remote Status Output 37 Pin D

J23 Remote Analog Output 37 Pin D

Primary Wiring

(Refer to drawing 839-7994-179.)

AC power is connected to terminal block 1A14TB1 located on

the right wall inside the rear door. Use #8 A WG wire at a

minimum or larger if required by Wiring Codes. Connect the

“hot” side of the ac line to 1A14TB1-1, the neutral side to

1A14TB1-2 and connect 1A14TB1-3 tothe safety or protective

ground wire.

PRIMARY WIRING CONNECTED

Table 2-3. Setup Jumpers - Normal Positions

1A2 Exciter Meter/Control Board

JP # POSITION FUNCTION (AS SHIPPED)

JP1 1-2 Loss of video enabled

JP2 1-2 Remote control of aural group delay

JP3 1-2 Remote control of notch diplexor

1A3 Interface Logic

JP# POSITION NORMAL FUNCTION

JP1 1-2 Visual foldback enabled

JP2 1-2 Aural foldback enabled

JP3 1-2 Aural AGC enabled

JP4 1-2 Source/Sink for Remote Status

JP5 1-2 Source/Sink for Remote Command

JP6 Factory Select Aural AGC 2dB pad select

JP7 1-2 Exciter A fault select DIGITAL

JP8 1-2 Exciter B fault select DIGITAL

JP9 1-2 Power supply 3 not present

JP10 1-2 Video control enabled

JP11 Factory Select Aural AGC 3dB pad select

JP12 1-2 Aural AGC enabled

JP13 Factory Select Visual AGC 3dB pad select

JP14 Factory Select Visual AGC 2dB pad select

JP15 1-2 NO 5 sec restart, AC FAIL

JP16 1-2 High VSWR shutdown enabled

2-4 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Page 23

Section II - Installation

2.5.3 Setting Transformers Taps

Check taps on the power supply in the exciter. Refer to figure

2-1, or drawing 839-7900-504. The logic supply 1A11PS1

located in the rear of the power module behind the 1A12 I/O

panel is tapped as shown in chart below

PRIMARY VOLTAGE

208-220 230-240

JUMPER CONNECTION 2 AND 3 2 AND 3

AC CONNECTION 1 AND 5 1 AND 4

TRANSFORMER PRIMARY TAPS CHECKED

Input Signals

2.5.4

The input signals and remote control I/O are located on 1A12.

See Table 2-2.

NOTE: The coax wiring for the External Precise Frequency

Control (PFC) option is installed in the cabinet. If the PFC

option is purchased the wiring will be added to the exciter.

INPUT SIGNALS CONNECTED

Setup Jumpers

2.5.5

Check the set-up jumpers, located in the exciter 1A2 and Interface Logic 1A3. Jumpersare normally shipped from the factory

in the positions shown in Table 2-2. They may be changed if

needed.

JUMPERS SET FOR CORRECT CONFIGURATION

Backup Battery

2.5.6

CAUTION

DO NOTUSE RECHARGEABLE BATTERIES

The battery holder will accept three size AA (NEDA 15A) 1.5

Volt batteries. These batteries furnish power to hold the transmitter status in the control system and control the return to

operation when AC power returns. The batteries should be

replaced as part of a regular mantenance schedule.

2.5.7

RF Output Coax Connections

(Refer to 843-5285-110)

The RF output connections, 1A15J1 for visual and 1A15J2 for

aural are located on the top of the cabinet. Make any desired

VSWR measurements of the RF plant before making final

connections to the cabinets.

2.5.8

Interlocks

External interlocks are connected to REMOTE COMMAND

1A12J21-7. A contact closure to ground mustbe present to turn

on the transmitter. If this interlock is not used, 1A12J21-7 must

be jumpered to ground.

The external contact closure or other device must sink 50

microamps to less than 0.5 volts. Open circuit voltage is +5V.

INTERLOCK WIRING INSTALLED

2.6 Transmitter Check Out

2.6.1 Pre-turn on checks

CAUTION

BEFORE PROCEEDING WITH CHECK OUT, INSPECT THE

TRANSMITTER FOR AC POWER SHORTS, LOOSE HARDWARE,

WIRINGERRORS,UNCONNECTEDWIRES, MISSING PARTS,AND

DEBRIS.

2.6.2 Initial Turn-on Sequence

The following procedures arethe sequential stepsto safely turn

on the transmitter, and must be performed in the order listed. It

is recommended that the installation personnel read the general

description in section one, the controls and operation material

in section three, and these procedures before starting.

a.

MODULESMUST NOTBEINSTALLEDAT THIS TIME

b.

Apply 1 volt p-p video to exciter video input.

c.

Theloss of video indicatorshould extinguish immediately

or after the loss of video times out depending on option

that is jumper selected.

d.

Press transmitter ON pushbutton.

e.

Openthe externalinterlock. The external interlock lampshould

be illuminated and the transmitter should shut off. Press ON

button.The transmitter shouldnot come on.Closethe interlock

circuit. The external interlock lamp should extinguish.

f.

Verify operation of RAISE and LOWER switches.

g.

If the system has a remote control, place transmitter in the

REMOTE mode and check for operation of transmitter

ON/OFF and RAISE/LOWER from the remote.

h.

Verify that LOCAL mode inhibits remote commands.

i.

Return exciter to minimum power by depressing and

holding LOWER commands for about 15 seconds.

j.

Measure the 50 voltsupply by usingthe multimeter onthe

front of the exciter. It should measure 50 volts.

k.

Press transmitter OFF pushbutton.

2.6.3

Module Installation

The modules may now be installed. Refer to factory test data for

placement ofmodules byserial number and slotnumber.There are

threetypesofmodules,DRIVERS, HIGHPOWERDRIVERS and

PA’s. The DRIVERS are keyed to be eitherstandard or high power

drivers and will not fit into a P Aslot. Use of a P Ain a driv eslot is

for emergency only. Although each type is interchangeable from

aural to visual and will work in any like socket, when starting out

it is best to reassemble them in the same locations as tested. Keep

a record of any changes for future reference.

Make sure each module is completely seated.

CAUTION

DO NOT USE EXCESSIVE FORCE INSTALLING MODULES INTO

THE SLOTS.

WARNING: Disconnect primary power prior to servicing.

888-2457-001 2-5

Page 24

Platinum™ Series

2.6.4 Control System Check Out

a.

Depress andhold powerLOWER controls for 15 seconds

each to ensure that exciters are turned all the way down.

b.

Press transmitter ON pushbutton.

c.

Check that all modules are enabled. Drivers will show a

full green LED. PA modules will illuminate half of the

green LED. It is normal for the red module LEDs to come

on momentarily as the transmitter 50 volt supplies come

up to voltage at turn on. They also will come on at

shut-down,gradually fading outas the suppliesdischarge.

d.

Open back door and verify that all fans are functioning.

e.

Check MODULE FAULT status for each module. Check

to see that all modules are enabled (green LED on); press

transmitter ON to enable any modules that are not already

on.

f.

Squeeze the disable switch in the handle of the first

module. The module LEDsshould go out. You should see

the MODULE FAULT lamp on at the control panel. Reenable the module by pressing transmitter ON at the

control panel. The MODULE FAULT lamp on the control

panel should go out. Repeat procedure for each module.

2.6.5

Initial Application of RF Power

2.6.5.1 Visual

a.

LOWER the exciter to minimum drive and apply a ramp

or staircase test signal.

b.

Press transmitter ON pushbutton.

c.

Check to see that all RF amplifier modules are enabled.

d.

Slowly raise visual power while observing VSWR and

FORWARD POWER. Stop at approximately 25% forward power .

e.

Switch video to black picture with no setup for power

calibration. Sync peak power multiplied by a system

dependantconstantequalsaveragepower.Some constants

are 0.568 (CCIR B) and 0.595 (CCIR M)

f.

Using an external power meter to confirm power output,

slowly increase visual power to 100% on external power

meter.

If external power meter and panel readings do not reasonably agree, refer to the power calibration procedures

in Section 5.

g.

Atfulloperatingpowermeasurethebelowparametersand

adjust if needed. See Section 5 for alignment procedures.

Depth of modulation

Differential gain

Incidental phase (ICPM)

Differential phase

Amplitude response and group delay compensation

(Exciter Group Delay Compensator and Notch Diplexer

Equalizer adjustments)

Power limit

Frequency

2.6.6

Aural

a.

Slowly apply aural exciter drive while watching VSWR

and FORWARD power. If a notch diplexer or hybrid

output combiner is used, check its reject load power as

well. Stop at about 50% and use external power metering

to confirm power.

b.

Check the AURAL FWD readings against the external

meter. Refer to power calibration in Section 5 if needed.

c.

Apply aural baseband signals to the appropriate exciter

input(s). Adjust the input level(s) using Section 5 as a

guide for correct deviation.

d.

CompareDC INPUTPOWERand50 voltsupplycurrentto

factory test data at no signal and black picture conditions.

2.7 Remote Control Input and Output

Command In 1A12J21

Status Out 1A12J22

Analog Out 1A12J23

2.7.1

Command In 1A12J21

The Command inputs are optocoupled and mustbe asserted low

to turn on the function. The optocoupler is supplied by the +12

volt supply and require a current sink of 5 ma to activate the

input.

Command Functions:

PIN FUNCTION

1 Transmitter ON

2 Transmitter OFF

3 Visual raise power

4 Visual lower power

5 Aural raise power

6 Aural lower power

7 External interlock

8Spare

9 Loss of video over-ride

10 Exciter comp/mono select

11 Aural group delay select

12 Notch diplexer select

13 Exciter switcher auto select (option)

14 Exciter switcher manual select (option)

15 Exciter switcher a exciter select (option)

16 Exciter switcher b exciter select (option)

17-19 Not used

20 Common (+12V or gnd JP-4 & 5 option)

36-37 Not used

2.7.2

1A12J22: Status Outputs

The Status outputs are open-collector drivers with a 100 Ohm

resistor in series and a 24 volt zener (avalanche)diode clamp to

ground. An internal voltage source of +12 volts can be made

available to the outputs by placing main controller optional

status jumper J21 in the 1-2 position. When in the 2-3 position,

an external voltage source must be supplied. Theopen collector

2-6 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Page 25

Section II - Installation

is30 volts DCmaximum, and maximumcurrentmust be limited

to 48 Ma. Each output is asserted low for status true condition.

2.7.3

Status Functions 1A12J22

PIN FUNCTION

1-16 Common (+12V or gnd JP-4 & 5 opt)

17-19 Not used

20 Transmitter ON status

21 Local status

22 Loss of video status

23 Frequency unlock status

24 Corrector bypass status

25 RF muted status

26 Air fault status

27 High vswr status

28 Foldback active status

29 Module fault status

30 50 volt power supply fault status

31 External interlock status

32 Exciter switcher auto selected (option)

33 Exciter switcher manual selected (option)

34 Exciter switcher A selected (option)

35 Exciter switcher B selected (option)

36 No connection

37 No connection

LOCAL: Indicates the transmitter will not accept remote command inputs. This line will be asserted low when the transmitter

is in the LOCAL mode.

VSWR FOLDBACK ACTIVE: Indicates antenna VSWR has

caused the transmitter to reduce its output power. It will be

asserted low while the foldback is active.

HIGH VSWR(VSWR FAULT): Indicates the modules have not

come up to power at the end of three seconds after a VSWR

overloadset point has beenexceeded. Note thatactivefold-back

will inhibit VSWR overload detection. Upon detection of an

overload, this line will be asserted low.

EXTERNAL INTERLOCK: Indicates the status of the external

interlock. If the interlock is open, a low will be asserted.

RF MUTE: Exciter mute: Indicates that some function has

muted the exciter. Asserted low for mute.

EXCITER FAULT: Indicates exciter fault directly in single

exciter configuration. Asserted low for fault.

SUPPLY FAULT:Indicates the 50 volt powersupply has failed.

Asserted low upon fault.

MODULE FAULT: Indicates one or more of the cabinet RF

modules has faulted off. Asserted low upon fault.

AIR LOSS: Indicates a loss of air flow. Asserted low upon loss

of air flow.

SPARE FAULT: Not used at this time.

2.7.4

Analog Outputs 1A12J23

The analog outputs on the I/O panel provide bothcalibrated and

un-calibrated readings for some functions. The calibrated outputs are a function of the monitoring system. The raw outputs

come directly from the RF peak detectors. Each output is buffered by avoltage follower,with a1 k Ohm resistor inseries with

the signal, before leaving the main controller board.

PIN FUNCTION

1 Visual forward power

2 Visual reflected power

3 Aural forward power

4 Aural reflected power

5 50 volt power supply voltage sample

6 50 volt power supply current sample

7 +5 volt logic supply voltage sample

8 +12 volt logic supply voltage sample

9 -12 volt logic supply voltage sample

10 Inlet temperature

11-14 Not used

15 Exciter status: A Failed

16 Exciter Status: B Failed

17-19 No connection

20-35 COMMON

36-37 No connection

WARNING: Disconnect primary power prior to servicing.

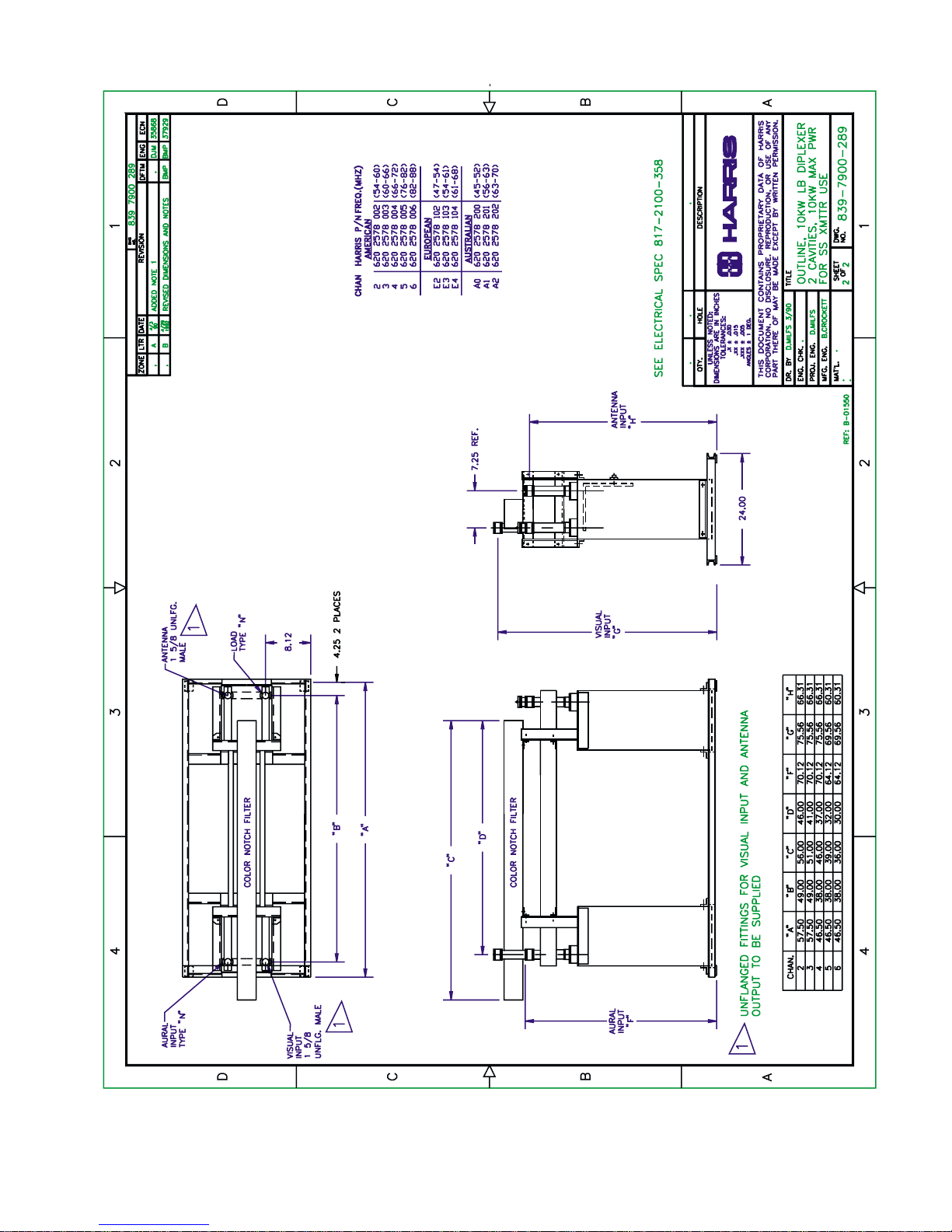

Figure 2-2.

888-2457-001 2-7

Page 26

Platinum™ Series

2-8 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Figure 2-3.

Page 27

Section II - Installation

WARNING: Disconnect primary power prior to servicing.

Figure 2-4.

888-2457-001 2-9

Page 28

Platinum™ Series

2-10 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Figure 2-5.

Page 29

Section II - Installation

WARNING: Disconnect primary power prior to servicing.

Figure 2-6.

888-2457-001 2-11

Page 30

Platinum™ Series

2-12 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Figure 2-7.

Page 31

Section II - Installation

WARNING: Disconnect primary power prior to servicing.

Figure 2-8.

888-2457-001 2-13

Page 32

Platinum™ Series

2-14 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Figure 2-9.

Page 33

Section II - Installation

WARNING: Disconnect primary power prior to servicing.

Figure 2-10.

888-2457-001 2-15

Page 34

Platinum™ Series

2-16 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Figure 2-11.

Page 35

3.1 Introduction

This section identifiesall controlsand indicatorsassociated with

the Platinum™ Series HT EL Transmitter. The exciter control

panel contains the operator controls, indicators and metering for

the transmitter. The Interface Logic Module has additional indicators for power supply status and reflected RF power foldback.

3.2 Controls And Indicators

Refer to Figure3-1 for the location of all controls and indicators

associated with day-to-day standard operation of the transmitter.

The function of each control and indicator is listed in Table 3-1.

Interface Logic Module 1A3 LED indicators

INDICATOR FUNCTION

+5 VOLT Indicates the 5 volt logic supply is on

+12 VOLT Indicates the +12 volt supply is on

-12 VOLT Indicates the -12 volt supply is on

+50 VOLT Indicates the 50 volt supply is on

VIS F/B ACT Indicates reflected visual RF power is

causing the visual power to foldback

AUR F/B ACT Indicates reflected aural RF power is

causing the aural power to foldback

Section III

Operation

Next select visual output power (VIS FWD) on the multimeter

and press visual raise “up arrow” or visual lower “down arrow”

button to set the visual poweroutput level.

Next select aural output power (AUR FWD) on the multimeter

and press aural raise “up arrow” or lower “down arrow” to set

the power output level. If the transmitter is to be operated by

remote control press REMOTE button to enable the command

remote control inputs.

To turn transmitter off, push the OFF button.

3.4 Video Controlled Operation

If the loss of video jumper 1A3JP1 is in the 1-2 position and the

over-ridejumper on 1A2JP1 is in NORMAL position the loss of

video detector is enabled. This provides two user adjustable

delaysone for videopresentand the other videolossdelay.When

video is applied, the video present delay timer will holdoff turn

on of the transmitter until the present delay times out. On loss of

video,the transmitterwill change to a predetermined (adjustable)

cw power level until the loss timer has timed out, then automatically turn transmitter off.

3.3 Local Turn-on and Turn-off

The control panel on the front of the exciter contains all the

operator controls and fault indicators. To turn the transmitter on

first apply a video signal to the video input. After the VIDEO

LOSS indicator turnsoff,pressing the transmitterON button will

place the transmitter on air.

3.5 Remote Control/Extended Operation

Verify that the HT EL is not in local operation mode. The

transmitter can the be operated by following the instructions for

the control system in use.

If the transmitter fails to operate begin analyses by checking the

status of the indicator LED’s on the control panel. Refer troubleshooting and repair to qualified technical personnel. Theory

of operationand othertroubleshooting informationare inappropriate sections of the manual.

WARNING: Disconnect primary power prior to servicing.

888-2457-001 3-1

Page 36

Platinum™ Series

Figure 3-1. Transmitter Controls and Indicators

3-2 888-2457-001

WARNING: Disconnect primary power prior to servicing.

Page 37

Section III - Operation

Table 3-2. Transmitter Controls and Indicators

Ref. Item Function

1 Multimeter VisualForward Power in Watts

VisualReflected Power in Watts

Sound Forward Power in Watts

Sound 2 Forward Power in Watts

Sound Reflected Power in Watts

Module Power Supply in Volts

Module Current in Amps

Exciter Visual Power in Watts

Exciter Video Input Level in mV

Exciter Sync Input Level in mV

Exciter Sound 1 Power in mW

Exciter Sound 2 Power in mW

Exciter Sound Deviation in kHz

Exciter Audio Input Levelin mV

2 Selection Indicates Multimeter reading selection

3 Bar Graph Indicates Multimeter 0000 to 1000

4

5

↑

↓

Multimeter selector button roll-down

Multimeter selector button roll-up

6 Xmtr ON Turn TransmitterON

7 ON Indicator Lights when Transmitter is ON

8 Xmtr OFF Turn Transmitter OFF

9 LOCAL Inhibit Transmitter remote control inputs

10 LOCAL Indicator Lights when in LOCAL only mode

11 REMOTE Enable Transmitter remote control inputs

12 Remote Indicator Lights when in REMOTE mode

13

14

15

16

↑

↓

↑

↓

Raise Visual Power of Transmitter

Lower Visual Power of Transmitter

Raise Aural Power of Transmitter

LowerAuralPowerofTransmitter

17 POWER When ON, indicates A Cpower to Exciter

18 EXTERNAL INTERLOCK When ON, indicates external interlock OPEN

19 50V SUPPLY FAULT When ON, indicates power supply fault condition

20 MODULE FAULT When ON, indicates one or more of the modules has a fault condition

21 AIR FAULT When ON, indicates loss of air

22 HIGH VSWR When ON, indicates a high VSWR condition

24 RF MUTED When ON, indicates RF Output of Exciter is muted

25 CORRECTOR BYPASS When ON, indicates one or more corrector boards in the BYPASS mode

26 FREQUENCY UNLOCK When ON, indicates one or more of the phase lock loops are unlocked

27 VIDEO LOSS When ON, indicates a loss of input video or video preset delay

28 VISUAL F/B ACT Indicates a VSWR is causing the visual & aural power to foldback

29 AUTAL F/B ACT Indicates a VSWR is causing the aural power to foldback

30 50 VOLT POWER Indicates the 50 volt supply is on

31 5 VOLT POWER Indicates the 5 volt logic supply is on

32 +12 VOLT POWER Indicates the +12 volt supply is on

33 -12 VOLT POWER Indicates the -12 volt supply is on

34 PRE-CORRECTED VISION IF Corrector output

35 VISION IF MODULATOR IF Modulator Output

36 PRE-CORRECTED VIDEO Modulator Input Video

WARNING: Disconnect primary power prior to servicing.

888-2457-001 3-3

Page 38

This page left blank intentionally

Page 39

Section IV

Theory of Operation

4.1 Introduction

This section provides theory of operation for the HT EL 2000

TV Transmitter. For purposes of discussion, the circuitry is

dividedintofunctionalsubassembliesinthefollowingtext.Refer

to the separately packaged diagrams as required.

4.2 System Overview

The transmitter is composed of subassemblies mounted in a

common cabinet. The 1 watt visual and aural signals are generated in a exciter chassis with exciter powermetering andcontrol.

The exciter front panel and the Interface Logic Module implement transmitter metering and transmitter control.

Modulated visual RF signal is amplified in a DriverModule and

divided four ways. Three outputs drive visual Power Amplifiers

(PA’s), the other is terminated in a load. The three PA’sare

combined in a three way Gysel combiner. The Gysel combiner

features a constant 50 ohm input and a high degree of isolation

between modules. This allows removal of one module without

impacting the others. The output forward and reflected power is

sampled bythe transmitter for meter reading andVSWR protection.

Auraldrivefrom the exciter isamplifiedbya drivermodule. This

aural RF signal is also sampled for metering and VSWR protection.

Thepowersupplies consist oftwohigh power switching supplies

connected in parallel for the RF modules and a small supply for

the interface logic.

The optional Exciter Switcher contain level sensing circuitry,

logic and transfer relays for automatic exciter switching.

4.3 Exciter, Meter and Control Board

The meter board is mounted to the back side of the exciter front

panel and provides the metering, control and status indications

for the transmitter.

4.3.1

A/D & Displays

Schematic drawing 839-7994-125 shows the meter board for the

transmitterwith sheetone being the analogmeteringsection.The

meter is a digital 4-1/2 digit A/D convertor with multiplexed

binary coded decimal(BCD) outputs. Thisis followed bya BCD

to seven segment display decoder and LED displays.

TheA/D U1 can display0000to 9999 on thedigital displaysDS1

and DS2 and is updated about 5 times a second. The display is

normally calibrated for 2000 when the Bar Graph is at full scale

or 1.25 volts at pin 5 of U2 and U3 Bar Graph display ICs.

The A/D referenceadjust isset for 1.000 volts between pin2 and

ground. Each metering input has a calibration control.

4.3.2

Bar Graph Display

The Bar Graph displays consisting of U2 and U3 are designed

using LM3914s cascaded to make a 20 bar magnitude display

which lights all 20 bars with 1.25 volts applied to pin 5. Each

meter position also has a corresponding calibration adjustment

for the analog bar display.

4.3.3

Analog Multiplexers

The analog multiplexer consisting of U4 and U6 provides the

analog selection switches to apply the various voltage monitor

points the A/D and Bar Graph displays. IC U4 is an 8 channel

multiplexerandisused to route thepowersamplepointsto buffer

U7 and on to U5 an analog squaring circuit. The squared sample

is then passed through U6-1 to 2 and on to the display circuits.

The two linear voltage samples, 50V and supply current, are

routed through U6-4 to 3 or U6-8 to 9 to the displays.

ENABLE

ADR U4 U6 DESCRIPTION

0 4-8 1-2 VISUAL FORWARD POWER

1 5-8 1-2 AURAL FORWARD POWER

2 6-8 1-2 VISUAL REFLECTED POWER

3 7-8 1-2 AURAL REFLECTED POWER

4 12-8 1-2 EXCITER VISUAL OUTPUT POWER

5 1-8 1-2 EXCITER AURAL OUTPUT POWER

6 x 4-3 50 VOLTS SUPPLY

7 x 8-9 MODULE CURRENTS

Rev. B: 7/15/02 888-2457-001 4-1

WARNING: Disconnect primary power prior to servicing.

4.3.4

Meter Selector

The multiplexers are controlled from the meter selection PAL

U17 on sheet 4 of the schematic. This PAL contains a three bit

up/down counter plusdecoders to enablethe multiplexersfor the

Table 4-1. Meter Counter/Display Function

Page 40

Platinum™ Series

sample selected and the decimal point selection for the digital

display. The enable line (EN_SQ, EN_VOLT, EN_CUR) to the

multiplexersis assertedHI andthe decimal points (DP1*, DP2*,

DP3*) are asserted low to turn on the display decimal point.

NOTE: The (*) character is used to denote a signal is asserted

LOW when true.

Table 4-1 shows the address of A0, A1, & A3 (ADR) the three

bit meter selection counter coupled to the functions displayed.

Loss Of Video Delay Detector

4.3.5

The Loss of Video Delay Detector, page two, is made up of U8

through U14 to form a function “on” video present delay of 3.5

to9.2secondsandonvideolossadelayof1to2.7minutes.The

function can be inhibited by placing JP1 in the 2-3 position or

enabled in the 1-2 position.

With JP1 in the NORMAL (1-2) position and video present the

reset to U11-6 is asserted low allowing the oscillator in U11 to

run startinga terminalcount of 32768. This will assert U11-8 Hi

which clocksU13-3 (D latch) Hi causing U13-5 to change to the

state of the D input which is Hi. This will assert U13-6 low

causing U14-1 to assert Hi signaling the delayed presence of

video and un-mute the rf mute circuit.

On the loss of video U11-6 is asserted Hi resetting the video

present counter and U12-6 is asserted low allowing U12 to start

counting. At the time between loss of video and the terminal

count of U12 the visual rf level is reduced by asserting U16-18

low which inserts R41 CW LEVEL SET pot in the visual power

control circuit. At the terminal count of 32768 U12-8 will assert

Hi causing U14-10 to assert low causing U13-1 to reset the D

latch asserting U13-6 Hi causing U14-1 low signaling the delayed loss of video which will rf mute exciter output.

Oscillator U22 is running about 77.6kHz and is programmedfor

a divide by 256 to produce the 300Hz output frequency.

BATTERY (BAT) SUPPLY VOLTAGE

4.3.8

All the PALs operate from the BAT Vcc supply line which

maintains voltage on the counters in the event of a power failure.

At some point after that all counters will be reset to 0 on power

return if BAT drops to a low enough voltage. BAT is supplied by

three AA size batteries mounted on the rear of the exciter.

Visual Power Control

4.3.9

The visual power control is shown on sheet 5 of the schematic

and controls the rf output of the visual channel. The 12 bit

up/down counter consists of U26& U27which supplies a binary

code to the DAC U25 which controls the gain of U24-1

VIS_DAC_BUF. Thesignal is passed through the rf muteswitch

U23-1to2andontoU23-3to4CWLEVELSETswitchandon

to U24-5 VIS_CTRL_BUF subtractor circuit where the visual

reflected power foldback input reducesthe output when applied.

VIS_PWR_CTRL J1-23 will normally swing between 0 and 4

volts for a 0 to 1 watt output level but can vary somewhat and

will depend on where R48 VIS_PWR_LIMIT is set.

4.3.10

Theaural power control shownon sheet6of the schematic works

the same as the visual except there is no CW_LEVEL_SET

switch in the aural path.

4.3.11

The power up resetcircuit is U31 which forms a voltage comparator referenced to the 1.23 volts of CR11, normal power fail

detection point is about 4.6 volts. When the voltage of U31-3 is

morethan U31-2 thenU31-1 will assertaHi removing the power

up reset signal.

Aural Power Control

Power Up Reset

4.3.6

Override/Normal Selection

Located in the upper right hand corner of the meter board is JP1

NORMAL/OVERRIDE jumper selection. In the NORMAL position the delay timers operate as outlined above. In the OVERRIDE position both delay timers are inhibited and the loss of

video signal is passed through U14 to rf mute circuit of the

exciter.

Clock Circuits

4.3.7

Sheet 4 of the schematic shows the clock PALs for the up/down

counters for VISUAL RAISE/LOWER U18, AURAL

RAISE/LOWER U19, METER CLOCK U20, and METER SELECT U17. U18 and U19 are clocked by the 300Hz oscillator

U22 to generate the VIS_PWR_CLK and the AUR_PWR_CLK

signals to drive the visual and aural up/down 12 bit counters.

Upon pressing an UP or DOWN button, U18 or U19 pin 23

PWR_CLK willissue onepulse thenwait for2 seconds and start

issuing a 300Hz clock rate if the button is still pressed.

IC U18 also generates a 9.5Hz clock used by the METER

CLOCK GATE U20 which operates similar to U18 & U19 but

at a slower one pulse per 1.17 second rate to clock U17 METER

SELECT 4 bit counter.

4-2 888-2457-001 Rev. B: 7/15/02

WARNING: Disconnect primary power prior to servicing.

4.3.12

These two jumpers extend AUR_GROUP_DELAY and

NOTCH_DIP_ENABLEsignals to the remote control interface.

4.3.13

The unlocked status of the three phased locked oscillator is

displayed by DS27, DS28, & DS29 and passed to PAL U17

where they are combined to produce the signal FREQ_LOCK*

on U17-23. FREQ_LOCK* drives the FREQ UNLOCK status

indicator and the U27-11 where it is combined with

VIDEO_LOSS_DELAY* to generate RF_MUTE U27-22. Also

ifanyFREQUNLOCKorVIDEOLOSSDELAYisassertedlow

the exciter will mute the rf output.

JP2 & JP3

FREQ UNLOCK

Page 41

Section IV - Theory of Operation

4.3.14 VIS_CLK_GATE U18 & AUR_CLK_GATE

U19 Functional Descriptions

IC

PIN TYPE FUNCTION

1 IN CLOCK TO ALL REGISTERED OUTPUTS

2 IN VISUAL POWER UP COMMAND

3 IN VISUAL POWER DOWN COMMAND

4-13 IN NOT USED

14 OUT DIVIDE BY 16 OF CLOCK PIN 1

15 OUT U/D DELAY COUNTER BIT 1

16 OUT U/D DELAY COUNTER BIT 4

17 OUT U/D DELAY COUNTER BIT 0

18 OUT DIVIDE BY 32 OF CLOCK PIN 1

19 OUT U/D DELAY COUNT BIT 3

20 OUT DIVIDE BY 8 OF CLOCK PIN 1

21 OUT DIVIDE BY 4 OF CLOCK PIN 1

22 OUT DIVIDE BY 2 OF CLOCK PIN 1

23 OUT CLOCK TO UP/DOWN POWER CONTROL

PALs U18 & U19 contain a divide by 32 free running counter

plus a gated one-shot delay repeat clock rate counter called U/D

DELAY COUNTER.

The U/D DELAY COUNTER BITS only change state when the

UP or DOWNbutton is pressed otherwise the U/D counter rests

at state 0 count. The U/D counter is clocked once each time pin

18 changes (divide by 32 of pin 1) state. Once the U/D counter

reachesthe count of0Dhit stays thereuntilthe button is released.

Pin 23 POWER CONTROL clocks the 12 bit UP/DOWN

POWER CONTROL counters when the RAISE or LOWER

buttonis pressed. Thefirstone-shot pulse isissuedwhen the U/D

counter is at the count of 04h and then repeats the pin 1 clock

rate after U/D counter reaches the count of 0Dh.

4.3.14.1 METER_CLK_GATE U20 Functional Descriptions

IC

PIN TYPE FUNCTION

1 IN 9.5HZ CLOCK TO ALL REGISTERS

2 IN METER UP COMMAND

3 IN METER DOWN COMMAND

4 IN VISUAL RAISE POWER COMMAND

5 IN VISUAL LOWER POWER COMMAND

6 IN AURAL RAISE POWER COMMAND

7 IN AURAL LOWER POWER COMMAND

8-13 IN NOT USED

14 OUT VISUAL STAY

15 OUT AURAL POWER DOWN

16 OUT VISUAL POWER DOWN

17 OUT VISUAL POWER UP