Page 1

Harris Broadcast is an independent company not affiliated with Harris Corporation.

HARDWARE MANUAL

Nexio G8

Edition 20131112

175-100489-00

TM

Page 2

Publication Information

© 2014 Harris Broadcast. Proprietary and Confidential.

Harris Broadcast is an independent company not affiliated with Harris Corporation.

This document and its contents are considered proprietary and confidential by Harris Broadcast. This

publication, or any part thereof, may not be reproduced in any form, by any method, for any purpose,

or in any language other than English without the written consent of Harris Broadcast. A reasonable

number of copies of this document may be made for internal use only. All others uses are illegal.

This publication is designed to assist in the use of the product as it exists on the date of publication of

this manual, and may not reflect the product at the current time or an unknown time in the future.

This publication does not in any way warrant description accuracy or guarantee the use for the

product to which it refers.

Harris Broadcast reserves the right, without notice to make such changes in equipment, design,

specifications, components, or documentation as progress may warrant to improve the performance

of the product.

Trademarks

[Product names and other appropriate trademarks, e.g. G8™, Invenio®, PowerSmart®, Versio™] are

trademarks of Harris Broadcast or its subsidiaries. Microsoft® and Windows® are registered

trademarks of Microsoft Corporation. All other trademarks and trade names are the property of their

respective companies.

Contact Information

Harris Broadcast Communications has office locations around the world. For domestic and

international location and contact information see: http://www.harrisbroadcast.com/contact-us/.

Support Contact Information

For domestic and international support contact information see:

•Support Contacts: http://www.harrisbroadcast.com/services/technical-support

•eCustomer Portal: http://support.harrisbroadcast.com

Page 3

Table of Contents

Preface

Manual Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Writing Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Obtaining Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unpacking/Shipping Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety Standards and Compliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Terms and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Restriction on Hazardous Substances (RoHS) Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Waste from Electrical and Electronic Equipment (WEEE) Directive . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electrical Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Electrical Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ESD Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chassis Components

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Inner Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Front LED Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Front Panel Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Front Panel LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SAS2/SATA LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

iTable of Contents

G8 Hardware Installation Manual

Page 4

Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Back Panel Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Motherboard I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

G411 Broadcast I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AES Ponytail Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

G411 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Power Supply Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installation and Setup

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chassis Components Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Important Safety Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Safety Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installation Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Install Hard Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Remove Hard Drive Trays from the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Install Hard Drive into a Drive Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Remove the Chassis Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

System Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Replace a System Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Replace the Onboard CR2032 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Change the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Install the Power Distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chassis Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Rack Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Prepare for Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Choosing a Setup Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Warnings and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Rack Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

General System Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Rack Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Ambient Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Reduced Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Mechanical Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Circuit Overloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Reliable Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Rack Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

ii Table of Contents

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 5

Identify the Sections of the Rack Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Lock Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Release the Inner Rail from the Outer Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Install the Inner Rails on the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Install the Outer Rails on the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Standard Chassis Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

BIOS Error Beep Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Non-Fatal and Fatal Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Setup and Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Disk Subsystems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Disk Subsystems Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Drive Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

GPI/AfterBurner 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Fanout Cable Pinouts (AB4 to RJ12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

AB4 Cabling Using Fanout Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Fanout Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pinout Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

AB4 RJ12 GPI PINOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Preview Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Preview Display Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Maintenance

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Hot Swap Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

To replace the failed power supply module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

System Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Create a Restore Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

System Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Prevent Damage and Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Anti-Virus Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Operating System Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Automatic Updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

G8 Hardware Installation Manual

iiiTable of Contents

Page 6

Specifications

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

System Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

G411 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

G411 HD/SDI Video Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

G411 AES Audio Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

G411 Genlock (Ref In) Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Power Supply Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

iv Table of Contents

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 7

Preface

Page 8

Manual Information

Purpose

Audience

Writing

Conventions

This manual details the features, installation, operation, maintenance, and

specifications of your Inscriber G8 system.

This manual is written for engineers, technicians, and operators responsible for

the system installation and setup.

This manual adheres to the following writing conventions.

Table ii-1. Writing Conventions

Term or Convention Description

CAPS Indicates a specific key on the keyboard, such

as ENTER, TAB, CTRL, ALT, DELETE

Code

>

hyperlink Indicates a jump to another location within the

Indicates variables or command-line entries,

such as a DOS entry or something you type

into a field.

Indicates the direction of navigation through a

hierarchy of menus and windows.

electronic document or elsewhere

Obtaining

Documents

6Preface

G8 Hardware Installation Manual

Internet address

Product documents can be viewed or downloaded from the Harris Broadcast

website at

customer service representative to request a document.

http://support.harrisbroadcast.com. Alternatively, contact your

Proprietary and Confidential

Indicates a jump to a website or URL

Copyright © 2014 Harris Broadcast

Page 9

Unpacking/Shipping Information

Your system has been carefully inspected, tested, and calibrated prior to shipment to ensure years of stable

and trouble free service.

Before you install and configure your Inscriber G8 system, follow these steps:

1 Check equipment for any visible damage that may have occurred during

transit.

2 Confirm that you have received all items listed on the packing list.

3 Contact your sales representative if any parts are missing.

4 Contact the carrier if any item is damaged.

5 Remove all packaging material from the product and its associated

components before you install the unit.

Keep at least one set of original packaging, in the event that you need to return

a product for servicing. If the original packaging is not available, you can

purchase replacement packaging at a modest cost or supply your own

packaging as long as it meets the following criteria:

• The packaging must be able to withstand the weight of the product.

• The product must be held rigid within the packaging.

• There must be at least two inches (5 cm) of space between the product and

the container.

• The corners of the product must be protected.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

7Preface

G8 Hardware Installation Manual

Page 10

Safety Standards and Compliances

Safety Terms and Symbols

This manual uses the following safety terms and symbols to identify certain

conditions or practices.

Table ii-2. Safety Terms and Symbols

WARNING: Identifies conditions or practices that can

result in personal injury or loss of life—high voltage is

present. Uninsulated dangerous voltage within the product’s

enclosure may be sufficient to constitute a risk of electric

shock to persons.

CAUTION: Identifies conditions or practices that can result

in damage to the equipment or other property. Important

operating and maintenance (servicing) instructions are

included in the literature accompanying the product.

Restriction on Hazardous Substances (RoHS) Directive

Directive 2002/95/EC – commonly known as the European Union (EU)

Restriction on Hazardous Substances (RoHS) – sets limits on the use of certain

substances found in electrical and electronic equipment. The Directive took

effect on July 1, 2006, and it refers to the following hazardous substances:

• Lead (Pb)

•Mercury (Hg)

•Cadmium (Cd)

• Hexavalent Chromium (Cr-V1)

• Polybrominated Biphenyls (PBB)

• Polybrominated Diphenyl Ethers (PBDE)

All relevant Harris Broadcast products either comply with the legislation or are

exempt. For example, spare parts supplied for the repair and upgrade of

equipment sold before July 1, 2006 are exempt from the legislation.

Figure ii-1. RoHS Compliant Symbol

8Preface

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 11

Waste from Electrical and Electronic Equipment (WEEE) Directive

The European Union (EU) Directive 2002/96/EC on Waste from Electrical and

Electronic Equipment (WEEE) deals with the collection, treatment, recovery,

and recycling of electrical and electronic waste products. The objective of the

WEEE Directive is to assign the responsibility for the disposal of associated

hazardous waste to either the producers or users of these products. Producers

or users are required to recycle electrical and electronic equipment at end of its

useful life, and must not dispose of the equipment in landfills or by using other

unapproved methods.

In accordance with this EU Directive, Harris Broadcast has affixed labels

indicating that such products must be properly recycled. Contact your local

Harris Broadcast sales representative for information on returning these

products for recycling. Harris Broadcast equipment that complies with the EU

directive will be marked with a WEEE-compliant symbol, as shown in Figure

ii-2.

Copyright © 2014 Harris Broadcast

Figure ii-2. WEEE Compliance Symbol

Proprietary and Confidential

G8 Hardware Installation Manual

9Preface

Page 12

Safety Guidelines

Warning

Warning

This unit is for use in restricted access only. Adhere to the following safety guidelines to avoid personal injury

or damage to your system.

Electrical Safety Guidelines

Power Cords

• Use the exact type of power cords as required.

• Be sure to use power cord(s) that came with safety certifications.

To avoid electrical shock, check

the power cords properly.

• The power cord(s) must be compliant with the AC voltage requirements in

your region.

• The power cord plug cap must have an electrical current rating that is at

least 125% of the electrical current rating of this product.

• The power cord plug cap that plugs into the AC receptacle on the power

supply must be an IEC 320, sheet C13, type female connector.

• Be sure to disconnect the power supply before accessing the G8 chassis or

its components.

Adhere to the following

Electrical Safety Guidelines to

avoid possible damages to the

system or injury to yourself.

• Plug the Power cord(s) into a socket that is properly grounded before

turning on the power.

General Electrical Safety Guidelines

• Be aware of the locations of the power switches on the chassis and in the

room, so you can disconnect the power supply if an accident occurs.

• Take extra precautionary measures when working with high voltage

components. It is not recommended to work alone.

• Before removing or installing main system components, be sure to

disconnect the power first. Turn off the system before you disconnect the

power supply.

• Use only one hand when working with powered-on electrical equipment to

avoid possible electrical shock.

• Use rubber mats specifically designed as electrical insulators when working

with computer systems.

• The power supply or power cord must include a grounding plug and must

be plugged into grounded outlets.

10 Preface

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 13

• Motherboard Battery: CAUTION – To avoid possible explosion, make sure

Warning

Caution

you do not install the onboard battery upside down. The positive side must

face up on the motherboard. This battery must be replaced only with the

same or an equivalent type.

• CD-ROM Laser: CAUTION – Do not open the enclosures of power

supplies or CD ROM to avoid injury.

General Safety Guidelines

• Keep the area around the G8 chassis clean and free of clutter.

• To avoid injuries to your back, be sure to use your leg muscles, keep your

Adhere to the following General

Safety Guidelines to ensure

your personal safety.

back straight, and bend your knees when lifting the system.

• Avoid wearing loose clothing to prevent it from coming into contact with

power circuits.

• After removing the components or chassis covers from the system, place

them on a table for safeguard.

• Be sure to remove any jewelry or metal objects before working on the

chassis to avoid short circuits should these objects come into contact with

power circuits.

• After accessing the interior of the chassis, be sure to close the chassis with

ESD Safety Guidelines

The following measures are generally sufficient to protect against Electric

Statics Discharge (ESD).

Electric Static Discharge (ESD)

can damage electronic

components. To prevent

damage to your system board, it

is important to handle it very

carefully.

• Do not use mats designed to decrease electrostatic discharge as protection

• Use a grounded wrist strap designed to prevent static discharge.

• Keep all components and printed circuit boards (PCBs) in their anti-static

• Touch a grounded metal object before removing the board from the

• Do not let components or PCBs come into contact with your clothing,

chassis covers and secure the chassis to the racks with screws.

from electrical shock. Instead, use rubber mats that have been specifically

designed as electrical insulators.

bags until ready for use.

anti-static bag.

which may retain a charge even if you are wearing a wrist strap.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

11Preface

G8 Hardware Installation Manual

Page 14

• Handle a board by its edges only; do not touch its components, peripheral

Warning

Caution

chips, memory modules, or contacts.

• When handling chips or modules, avoid touching their pins.

• Put the motherboard and peripherals back into their anti-static bags when

not in use.

• For grounding purposes, make sure your computer chassis provides

excellent conductivity between the power supply, the case, the mounting

fasteners, and the motherboard.

Operation Safety Guidelines

Before accessing the G8 chassis:

1 Turn off all peripheral devices connected to the G8 chassis.

2 Press the power button to power off the system.

To avoid personal injury and

property damage, please

carefully follow all the

Operation Safety Guidelines

precisely.

3 Unplug all power cords from the system or the wall outlets.

4 Disconnect all the cables and label the cables for easy identification.

5 Use a grounded wrist strap designed to prevent static discharge when

handling components.

For proper cooling, make sure

to chassis covers are properly

installed before turning on the

system. If this rule is not strictly

followed, warranty may become

void. Do not open the casing of

a power supply. Power supplies

can only be accessed and

serviced by a qualified

technician of the manufacturer.

Removing the chassis covers:

After completing the above steps, you can remove the covers and install

components/peripheral devices into the G8 chassis. See ”Chassis Components

Installation” on page 27 for details.

1 Unlock and remove the screws and fasteners to remove the cover or

components.

2 Save all the screws and fasteners for later use. (If necessary, label these

screws or fasteners for easy identification.)

3 Follow the instructions in ”Remove the Chassis Cover” on page 31 to

remove the chassis cover.

Reinstalling the chassis covers:

To maintain proper system cooling and airflow, do not operate the system

without installing all chassis covers back onto the chassis. To reinstall the

chassis covers, please follow the steps listed below:

1 Make sure that all components and devices are securely fastened on the

chassis and that there are no loose parts/screws inside the chassis.

12 Preface

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 15

2 Make sure that all cables are properly connected to the connectors and

ports.

3 Use the original screws or fasteners to install the covers to the chassis.

4 Be sure to lock to the chassis or the system to prevent unauthorized

access.

5 For proper cooling, enclose the chassis with covers before operating the

system.

Before installing the chassis into a rack:

1 Make sure that the rack is securely anchored onto an unmovable surface or

structure.

2 Unplug the power cord(s) of the rack before installing the chassis.

3 Make sure that the system is adequately supported and that all components

are securely fastened to the chassis to prevent them from falling off the

chassis.

4 Be sure to install an AC Power Disconnect for the entire rack assembly.

Clearly mark the Power Disconnect.

5 The rack assembly must be properly grounded to avoid electric shock.

6 The rack assembly must provide sufficient airflow to the chassis for proper

cooling.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

13Preface

G8 Hardware Installation Manual

Page 16

14 Preface

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 17

Chapter 1

Chassis Components

Page 18

Overview

This chapter provides an introduction to your G8 System, and includes the

following topics:

• “Front Panel” on page 17

• “Back Panel” on page 21

16 Chapter 1 | Chassis Components

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 19

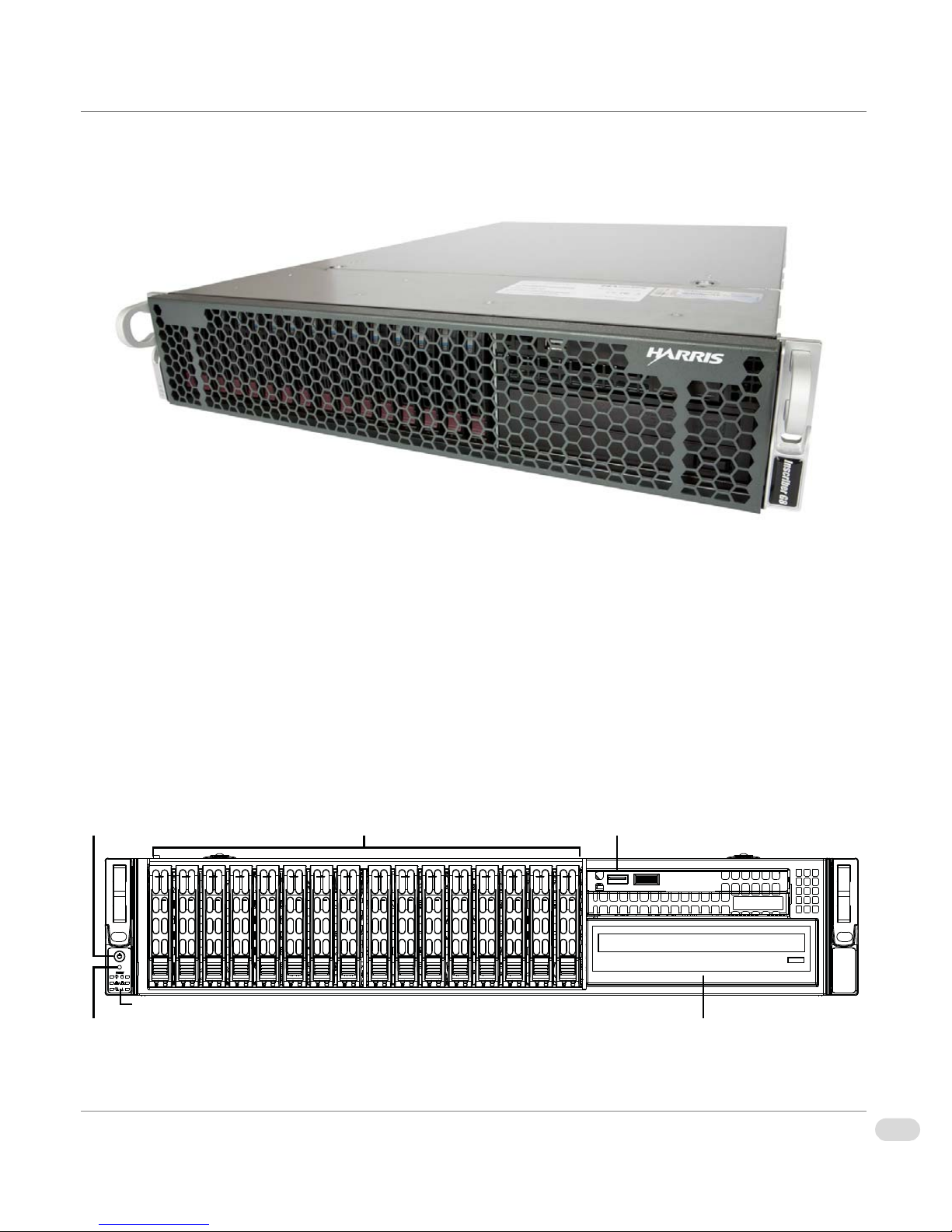

Front Panel

Power button USBRemoveable Drive Trays

CD/DVD-RWReset button

LED Panel

The following information describes the front panel components for G8 systems.

Figure 1-1. G8 Outer Front Panel

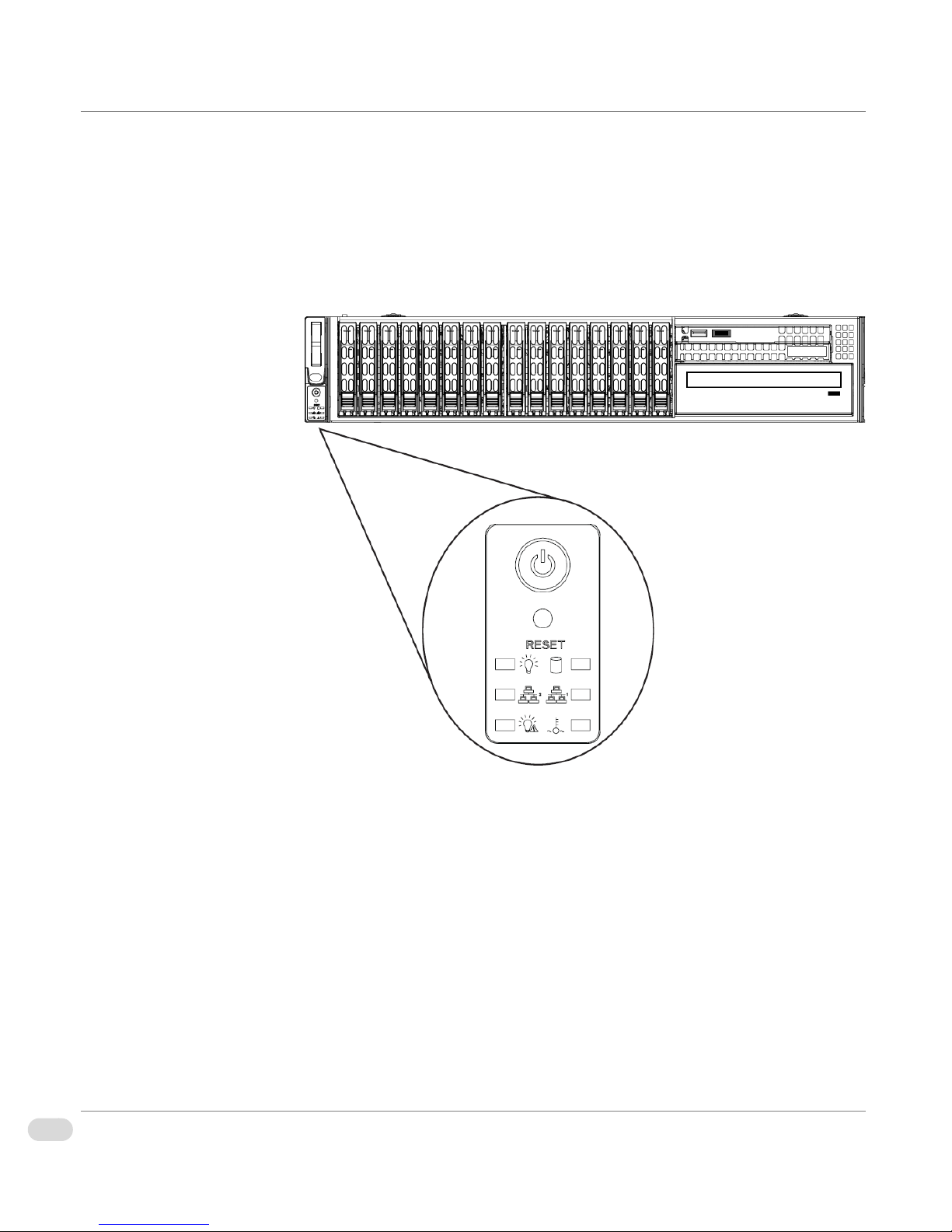

Inner Front Panel

The G8 inner front panel includes the following:

• System Power (on/off) button

• System Reset (restart) button

• LED indicators

• Hot-swappable hard disk drives

•One USB port

• CD/DVD-RW

Copyright © 2014 Harris Broadcast

Figure 1-2: G8 Inner Front Panel

Proprietary and Confidential

17Chapter 1 | Chassis Components

G8 Hardware Installation Manual

Page 20

Front LED Panel

There are several LEDs on the LED panel as well as other LEDs on the drive

carriers to keep you constantly informed of the overall status of the system, as

well as the activity and health of specific components.

This section explains the meaning of the LED indicators and the appropriate

response you may need to take.

18 Chapter 1 | Chassis Components

G8 Hardware Installation Manual

Figure 1-3. Front Panel Interface

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 21

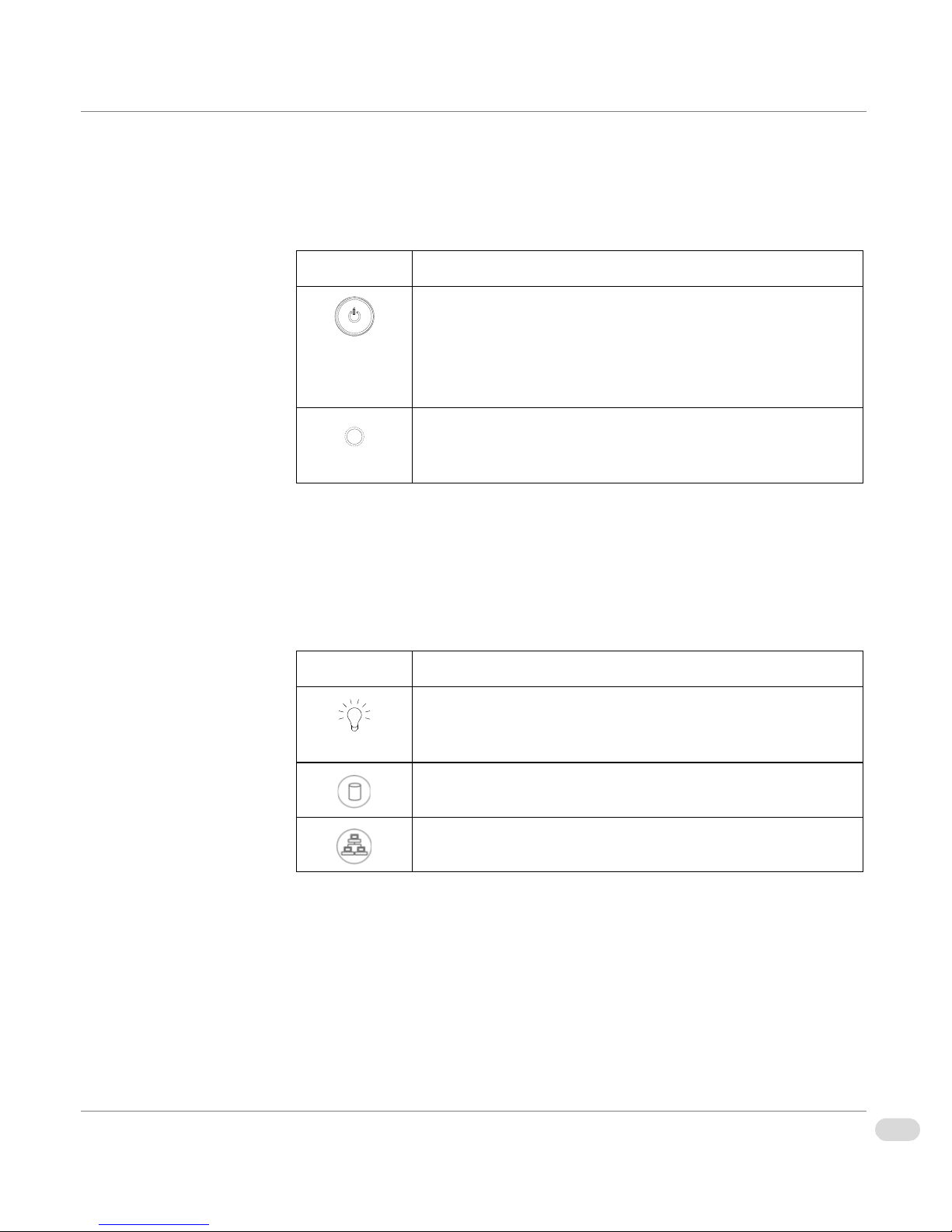

Front Panel Buttons

There are two push-buttons located on the front of the chassis. These are the

power on/off button and the reset button.

Button Description

Power: The main power button is used to apply or remove

power from the power supply to the system. Turning off

system power with this button removes the main power but

keeps standby power supplied to the system. Therefore, you

must unplug system before servicing.

Reset: The reset button is used to reboot the system. A pen

or other small device is required to activate this button and

reset the system.

Front Panel LEDs

The control panel located on the front of the chassis has six LEDs. These LEDs

provide you with critical information related to different parts of the system.

The following table explains what each LED indicates when illuminated and any

corrective action you may need to take.

LED Description

Power: Indicates power is being supplied to the system's

power supply units. This LED should normally be illuminated

when the system is operating.

HDD: Indicates IDE channel activity and SAS2/SATA drive

activity when flashing.

NIC 1: Indicates network activity on GLAN1 when flashing.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

19Chapter 1 | Chassis Components

G8 Hardware Installation Manual

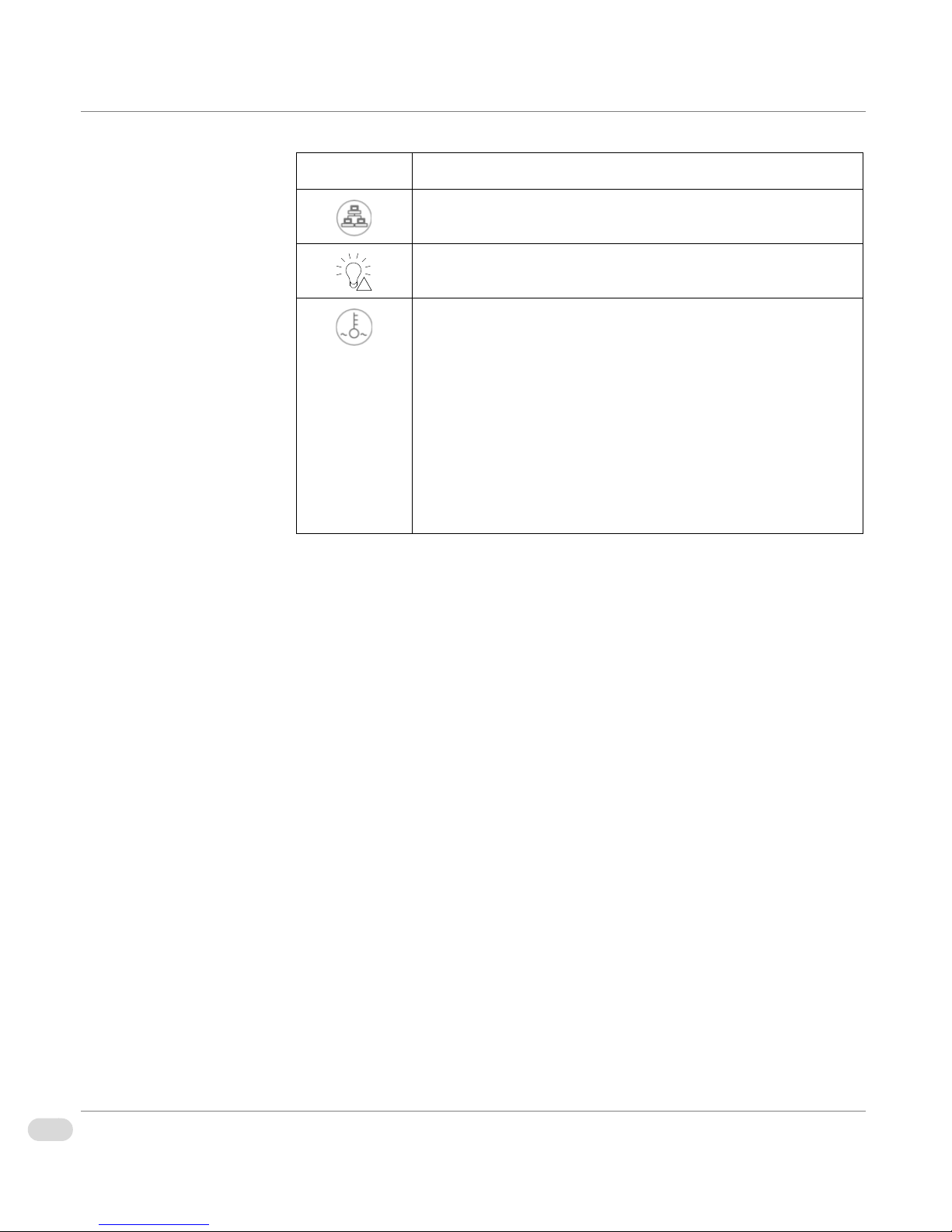

Page 22

LED Description

!

NIC 2: Indicates network activity on GLAN2 when flashing.

Power Failure: When this LED flashes, it indicates a power

failure in the power supply.

Overheat/Fan Fail: When this LED flashes it indicates a fan

failure. When continuously on (but not flashing) it indicates

an overheat condition, which may be caused by cables

obstructing the airflow in the system or the ambient room

temperature being too warm. Check the routing of the cables

and make sure all fans are present and operating normally.

You should also check to make sure that the chassis covers

are installed properly. Finally, verify that the heatsinks are

also installed properly. This LED will remain flashing or on

as long as the overheat condition exists.

SAS2/SATA LEDs

Each SAS2/SATA drive carrier has two LEDs.

•

Green or Blue: Each hard disk drive carrier has either a green or a blue

LED, depending on the hard disk drives and backplane used. When

illuminated, this LED indicates drive activity. A connection to the SATA

backplane enables this LED to blink on and off when that particular drive is

being accessed.

•

Red: The red LED indicates a SAS2/SATA drive failure. If one of the SAS2/

SATA drives fail, you should be notified by your system management

software.

20 Chapter 1 | Chassis Components

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 23

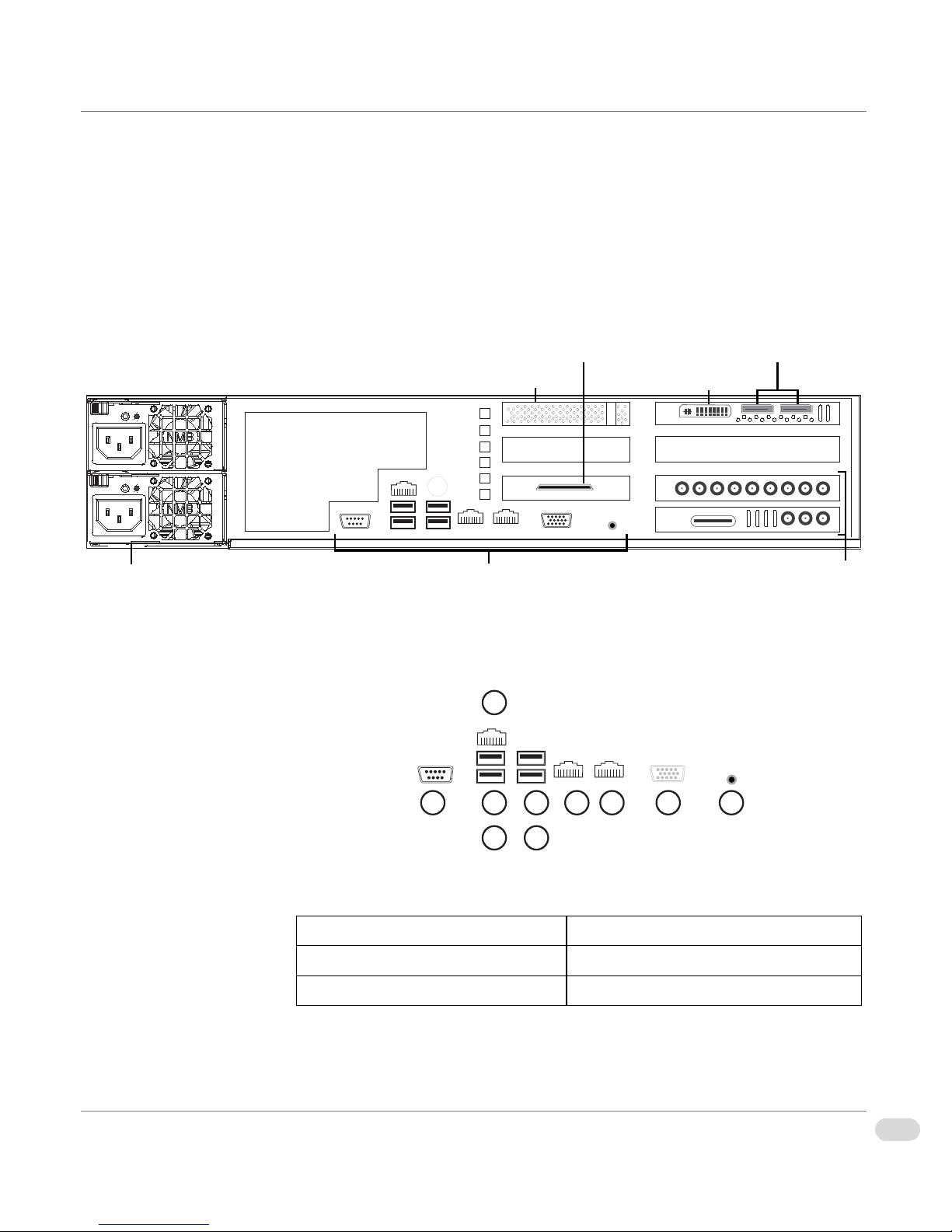

Back Panel

Motherboard I/OPower Supply Modules 1 & 2

GPI/O AB4 (AfterBurner4)

Media Disk Subsystem RAID Controller

GPU/DVI Port

Display Ports 1 & 2

Broadcast I/O

6

109875

4

1 3

2

The following information details the back panel components of the G8 system.

Back Panel

Components

Motherboard I/O

The following image shows the back panel components of the G8 system. Note

that the exact device placement on your system may vary slightly from the

graphic.

Figure 1-4: G8 Back Panel

The following details the motherboard connectors and I/O.

1: COM port 7-8: Gigabit LAN 1 & 2

2: IPMI_LAN * 9: VGA (INACTIVE)

3-6: USB ports 10: UID switch

Copyright © 2014 Harris Broadcast

Figure 1-5. Motherboard I/O

Proprietary and Confidential

21Chapter 1 | Chassis Components

G8 Hardware Installation Manual

Page 24

* For further details on the IPMI functions, see the “IPMI Manual (SMT).pdf”

that is accessible from the following Supermicro web page:

http://www.supermicro.com/support/manuals/

.

G411 Broadcast I/O

The following details the G411 broadcast I/O:

9 8 7 6 5 4

13 12 11 10

Figure 1-6. G411 Broadcast I/O

G411 Video I/O (right to left)

1

: SDI output 1 6: SDI input 3

2: SDI input 1 7: SDI output 4

3: SDI output 2 8: SDI input 4

4: SDI input 2 9: analog reference input

5: SDI output 3

3 2 1

HD BNCs (right to left)

10: SD preview output (UNSUPPORTED)

11: SD preview output (UNSUPPORTED)

12: LTC Timecode input

13: AES audio ponytail cable connector

22 Chapter 1 | Chassis Components

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 25

AES Ponytail Cable

The following details the BNC connectors for the AES ponytail cable.

Figure 1-7. AES Ponytail Cable

G411

Specifications

Power Supply

Modules

For G411 technical specifications see:

• “G411 General Specifications” on page 68

• “G411 HD/SDI Video Specifications” on page 69

• “G411 Genlock (Ref In) Specifications” on page 71

There are two power supply modules connected to your system. If there is a

failure with one of the modules, an alarm sounds. It is essential that both power

supply modules be connected at all times, therefore it is recommended that the

failed module be replaced immediately to avoid possible damage to your

system due to loss of power.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

23Chapter 1 | Chassis Components

G8 Hardware Installation Manual

Page 26

If you need to replace a failed power supply, see “Change the Power Supply” on

page 34 for replacement the procedure.

Table 1-1. Power Supply LED Descriptions

Component Color Condition Description

Power Supply

Modules LED

Green Power Supply DC On

Amber Power Supply Standby

Off No AC Power to the System

Note: For extra insurance against power loss, you may wish to connect the two

power supply modules to AC outlets on different circuit breakers or

connect the system to an Uninterruptible Power Supply (UPS).

24 Chapter 1 | Chassis Components

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 27

Chapter 2

Installation and Setup

Page 28

Overview

This chapter provides information about installing your Inscriber G8 system,

and includes the following topics:

• “Chassis Components Installation” on page 27

• “Chassis Rack Installation” on page 36

26 Chapter 2 | Installation and Setu p

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 29

Chassis Components Installation

Warning

This section describes important safety guidelines, tools needed for installation, and how to access and

install chassis components.

Important Safety

Guidelines

This product should only be

accessed and serviced by

technically qualified personnel

or technicians.

To avoid personal injury and property damage, please read all the information

provided in “Safety Guidelines” on page 10, and carefully follow all the safety

steps listed in this chapter before accessing or servicing your system or its

components.

Safety Steps

Before accessing the chassis

1 Turn off all peripheral devices and the power supply connected to the

system.

2 Unplug all power cords from the system or wall outlets.

3 Disconnect all the cables and label the cables for easy identification.

4 Use a grounded wrist strap designed to prevent static discharge when

handling components.

Removing the chassis covers

After completing the above steps, you can remove the chassis covers and install

components and devices into the chassis as described in this chapter.

1 Unlock and remove the screws and fasteners to remove the covers or

components.

2 Save all the screws and fasteners for later use. (If necessary, label the

3 Follow the instructions provided in this chapter to remove the chassis

Installation Tools

You will need the following tools for the safe and proper installation of your

system.

• Phillips screw driver

• Anti-static strap

Copyright © 2014 Harris Broadcast

screws and fasteners for easy identification.)

covers.

Proprietary and Confidential

G8 Hardware Installation Manual

27Chapter 2 | Installation and Setup

Page 30

Install Hard Drives

7

The G8 comes equipped with sixteen hot-swappable hard drives. Only SAS2 or

enterprise SATA HDDs are recommended for use in the G8 chassis.

Remove Hard Drive Trays from the Chassis

1 Press the release button on the drive carrier. This extends the drive carrier

handle.

2 Hold the handle to pull the tray out of the chassis.

7

Release button is located on

the bottom of the drive carrier.

Figure 2-1. Tray Removed from Chassis

Install Hard Drive into a Drive Carrier

1 Insert a drive into the carrier with the PCB side facing down and the

connector end toward the rear of the carrier.

2 Align the drive in the carrier so that the mounting holes of both are

aligned. Note that there are holes in the carrier marked "SAS" or “SATA”

to aid in correct installation.

28 Chapter 2 | Installation and Setu p

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 31

3 Secure the drive to the carrier with four screws as illustrated. Use the four

M3 flat-head screws included in the HDD bag of your accessory box. Note

that the screws used to secure the dummy drive to the tray cannot be used

to secure the hard drive.

4 Insert the hard drive and drive carrier into its bay vertically, keeping the

carrier oriented so that the release button is on the bottom. When the

carrier reaches the rear of the bay, the release handle will retract.

Copyright © 2014 Harris Broadcast

Figure 2-2. Chassis Drive Tray

Proprietary and Confidential

29Chapter 2 | Installation and Setup

G8 Hardware Installation Manual

Page 32

5 Using the thumb, push against the upper part of the hard drive handle.

Push the hard drive into the hard drive bay as illustrated until the hard

drive clicks into the locked position.

Figure 2-3. Proper Installation of the Hard Drive into the Har d Driv e Bay

30 Chapter 2 | Installation and Setu p

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 33

Remove the

Warning

1

1

2

3

Chassis Cover

Except for short periods of

time, do NOT operate the

server without the cover in

place. The chassis cover must

be in place to allow proper

airflow and prevent

overheating.

Before installing any components, replacing chassis fans, or accessing the

motherboard, you first need to remove the top cover.

1 Press both release tabs at the same time to release the cover from the

locked position.

2 Once the top cover has been released, slide the cover backwards, toward

the rear of the chassis.

3 Lift the cover up and off the chassis.

Copyright © 2014 Harris Broadcast

Figure 2-4. Remove Chassis Cover

Proprietary and Confidential

G8 Hardware Installation Manual

31Chapter 2 | Installation and Setup

Page 34

System Fans

Release Tab

There are three fans that provide cooling for the chassis. These fans circulate

air through the chassis as a means of lowering the chassis internal temperature.

The fans are hot-swappable and can be replaced without powering-down the

system.

Replace a System Fan

1 If necessary, open the chassis while the power is running to determine

which fan requires changing.

Note that you should never run the system for an extended period of time

with the chassis open.

2 Press the fan release tab to lift the failed fan from the chassis and pull it

completely out of the chassis.

Figure 2-5. System Fan

3 Place the new fan into the vacant space in the housing while making sure

the arrows on the top of the fan (indicating air direction) point in the same

direction as the arrows on the other fans.

The fan will automatically begin running at the correct speed.

Figure 2-6. Placing the Low Profile System Fan

32 Chapter 2 | Installation and Setu p

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 35

Figure 2-7. Placing the UIO System Fan

Replace the

Onboard CR2032

Battery

Power Supply

If you are replacing the onboard battery make sure to handle the used battery

carefully. Do not damage the battery in any way; a damaged battery may release

hazardous materials into the environment. Do not discard a used battery in the

garbage or a public landfill. Please comply with the regulations set up by your

local hazardous waste management agency to dispose of your used battery

properly.

Lithium Battery

Battery Holder

The G8 system has two redundant 720 or 900 Watt power supplies. The power

modules are hot-swappable, enabling the power supplies to be changed without

powering down the system. These power supplies are auto-switching capable.

This enables the power supply to automatically sense and operate at a 100v to

240v input voltage. An amber light will be illuminated on the power supply

when the power is off. An illuminated green light indicates that the power

supply is operating.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

33Chapter 2 | Installation and Setup

G8 Hardware Installation Manual

Page 36

Warning

Unplug the power cord

Release Tab

before removing the power

supply.

Change the Power Supply

1 Determine which power supply needs to be replaced and unplug the power

cord to that module.

2 Push the release tab (on the back of the power supply) to release the power

module from the chassis.

Figure 2-8. Power Supply Removed

3 Hold down the release tab and pull the power supply out using the handle

provided on the power module.

4 Replace the failed power module with the same model power supply.

5 Push the new power supply module into the power bay until the tab clicks

into the locked position.

6 Plug the AC power cord back into the module and the replacement power

module will automatically power-up.

Install the Power Distributor

The power distributor provides failover and power supply redundancy and is

pre-installed in the chassis. In the rare event that you have to replace the power

distributor, use the following steps.

1 Power-down the system and unplug the power cord from the power

module.

2 Remove all cable connections to the power supply from the motherboard,

backplane, and other components.

3 Remove both power supply modules.

4 Remove the screws securing the power distributor.

5 Gently pull the power distributor from the chassis. Gently guide all the

cables through the power distributor housing.

34 Chapter 2 | Installation and Setu p

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 37

6 Slide the new power distributor module into the power distributor housing.

Make sure that you slide the cables through the bottom of the housing.

Figure 2-9. Installing the Power Distributor

7 Reconnect all the power cables, replace the power supply, and insert the

plug into the wall.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

35Chapter 2 | Installation and Setup

G8 Hardware Installation Manual

Page 38

Chassis Rack Installation

This section provides steps for installing the chassis into the rack unit you are using.

Rack Location

Prepare for Setup

Decide on a suitable location for the rack unit that will hold your chassis. It

should be situated in a clean, dust-free area that is well ventilated. Avoid areas

where heat, electrical noise and electromagnetic fields are generated. The

system needs to be placed near a grounded power outlet. Be sure to read the

precautions in the next section.

The box your chassis was shipped in should include two sets of rail assemblies

and the mounting screws needed for installing the system into the rack. Also

included is an optional square hole to round hole converter bracket, for use in

racks with round mounting holes. Please read this section in its entirety before

you begin the installation procedure outlined in the sections that follow.

Choosing a Setup Location

• Leave enough clearance in front of the rack to enable you to open the front

door completely (~25 inches).

• Leave approximately 30 inches of clearance in the back of the rack to allow

for sufficient airflow and ease in servicing.

• This product is for installation only in a Restricted Access Location

(dedicated equipment rooms, service closets and the like).

Warnings and

Precautions

36 Chapter 2 | Installation and Setu p

G8 Hardware Installation Manual

Rack Precautions

• Ensure that the leveling jacks on the bottom of the rack are fully extended

• In single rack installations, stabilizers should be attached to the rack.

• In multiple rack installations, the racks should be coupled together.

• Always make sure that the rack is stable before extending a component

• You should extend only one component at a time. Extending two or more

General System Precautions

• Review the electrical and general safety precautions that came with the

to the floor with the full weight of the rack resting on them.

from the rack.

simultaneously may cause the rack to become unstable.

components you are adding to your chassis.

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 39

• Determine the placement of each component in the rack before you install

the rails.

• Install the heaviest system components on the bottom of the rack first, and

then work upwards.

• Use a regulating uninterruptible power supply (UPS) to protect the system

from power surges, voltage spikes and to keep your system operating in

case of a power failure.

• Allow the hot plug hard drives and power supply modules to cool before

touching them.

• Always keep the rack's front door and all panels and components on the

system closed when not servicing them to maintain proper cooling.

Rack Mounting

Considerations

Ambient Operating Temperature

If installed in a closed or multi-unit rack assembly, the ambient operating

temperature of the rack environment may be greater than the ambient

temperature of the room. Therefore, consideration should be given to installing

the equipment in an environment compatible with the manufacturer’s maximum

rated ambient temperature (TMRA).

Reduced Airflow

Equipment should be mounted into a rack so that the amount of airflow

required for safe operation is not compromised.

Mechanical Loading

Equipment should be mounted into a rack so that a hazardous condition does

not arise due to uneven mechanical loading.

Circuit Overloading

Consideration should be given to the connection of the equipment to the power

supply circuitry and the effect that any possible overloading of circuits might

have on overcurrent protection and power supply wiring. Appropriate

consideration of equipment nameplate ratings should be used when addressing

this concern.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

37Chapter 2 | Installation and Setup

G8 Hardware Installation Manual

Page 40

Reliable Ground

Rail Assembly

(with rails extended)

Rail Assembly

(with rails retracted)

outer rail

middle rail

inner rail

This side

faces outward.

locking tab

A reliable ground must be maintained at all times. To ensure this, the rack itself

should be grounded. Particular attention should be given to power supply

connections other than the direct connections to the branch circuit (i.e. the use

of power strips, etc.).

Rack Mounting

This section provides information on installing the chassis into a rack unit with

the rails provided. There are a variety of rack units on the market, which means

that the assembly procedure might differ slightly from the instructions

provided. You should also refer to the installation instructions that came with

the rack unit you are using.

Note: This rail will fit a rack between 26.5" and 36.4" deep.

Identify the Sections of the Rack Rails

The chassis package includes two rail assemblies in the rack mounting kit. Each

assembly consists of three sections: an inner chassis rail which secures directly

to the chassis, an outer rail that secures to the rack, and a middle rail which

extends from the outer rail. These assemblies are specifically designed for the

left and right side of the chassis.

Lock Tabs

Each inner rail has a locking tab. This tab locks the chassis into place when

installed and pushed fully into the rack. These tabs also lock the chassis in

place when fully extended from the rack. This prevents the system from coming

38 Chapter 2 | Installation and Setu p

G8 Hardware Installation Manual

completely out of the rack when the chassis is pulled out for servicing.

Figure 2-10. Left Rail Assembly

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 41

Release the Inner Rail from the Outer Rails

Press locking tab down.

inner rail released

1 Identify the left and right outer rail assemblies.

2 Pull the inner rail out of the outer rail until it is fully extended.

3 Press the locking tab down to release the inner rail.

Figure 2-11. Release Inner Rail

4 Repeat steps 1-3 for the second outer rail.

Install the Inner Rails on the Chassis

1 Confirm that the left and right inner rails have been correctly identified.

2 Place the inner rail firmly against the side of the chassis, aligning the hooks

on the side of the chassis with the holes in the inner rail.

3 Slide the inner rail forward toward the front of the chassis until the rail

clicks into the locked position, which secures the inner rail to the chassis.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

39Chapter 2 | Installation and Setup

G8 Hardware Installation Manual

Page 42

4 Secure the inner rail to the chassis with the screws provided.

inner rails

Figure 2-12. Secure Inner Rails to Chassis

5 Repeat steps 2 - 4 for the second inner rail.

40 Chapter 2 | Installation and Setu p

G8 Hardware Installation Manual

Figure 2-13. Inner Rails Installed

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 43

Install the Outer Rails on the Rack

1 Press upward on the locking tab at the rear end of the middle rail.

Figure 2-14. Locking Tab

2 Push the middle rail back into the outer rail.

3 Hang the hooks of the front of the outer rail onto the slots on the front of

the rack. If necessary, use screws to secure the outer rails to the rack.

Figure 2-15. Secure Outer Rails

4 Pull out the rear of the outer rail, adjusting the length until it fits within the

posts of the rack.

5 Hang the hooks of the rear portion of the outer rail onto the slots on the

rear of the rack. If necessary, use screws to secure the rear of the outer rail

to the rear of the rack.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

41Chapter 2 | Installation and Setup

G8 Hardware Installation Manual

Page 44

6 Repeat steps 1 - 5 for the second outer rail.

ball-bearing shuttle

Figure 2-16. Outer Rail Installed

St andard Chassis

Installation

1 Confirm that the inner rails are properly installed on the chassis.

2 Confirm that the outer rails are correctly installed on the rack.

3 Pull the middle rail out from the front of the outer rail and make sure that

the ball-bearing shuttle is at the front locking position of the middle rail.

4 Align the chassis inner rails with the front of the middle rails.

42 Chapter 2 | Installation and Setu p

G8 Hardware Installation Manual

Figure 2-17. Align Chassis Inner Rails to Middle Rails

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 45

5 Slide the inner rails on the chassis into the middle rails, keeping the

pressure even on both sides, until the locking tab of the inner rail clicks

into the front of the middle rail, locking the chassis into the fully extended

position.

6 Depress the locking tabs of both sides at the same time and push the

chassis all the way into the rear of the rack.

7 If necessary for security purposes, use screws to secure the chassis handles

to the front of the rack.

Copyright © 2014 Harris Broadcast

Figure 2-18. Chassis Installed in Rack

Proprietary and Confidential

G8 Hardware Installation Manual

43Chapter 2 | Installation and Setup

Page 46

BIOS Error Beep Codes

During the POST (Power-On Self-Test) routines, which are performed each time the system is powered on,

errors may occur.

Non-Fatal and

Fatal Errors

Non-fatal errors are those which, in most cases, allow the system to continue

the boot-up process. The error messages normally appear on the screen.

Fatal errors are those which will not allow the system to continue the boot-up

procedure. If a fatal error occurs, you should consult with your system

manufacturer for possible repairs.

These fatal errors are usually communicated through a series of audible beeps.

The numbers on the fatal error list correspond to the number of beeps for the

corresponding error. All errors listed, with the exception of Beep Code 8, are

fatal errors.

Table 2-1. BIOS Error Beep Codes

Beep Code Error Message Description

1 beep Refresh Circuits have been reset (Ready to

power up)

5 short beeps and

Memory error No memory detected in the system

1 long beep

5 beeps No Con-In or

Conout devices

Con-In includes USB or PS/2

keyboard, PCi or Serial console

redirection, IPMI KVM or SOL.

Con-Out includes video controller,

PCI or Serial console redirection or

IPMI SOL.

1 Continuous

beep

44 Chapter 2 | Installation and Setu p

G8 Hardware Installation Manual

System OH System Overheat

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 47

Chapter 3

Setup and Configuration

Page 48

Overview

This chapter provides information about configuring your G8 system, and

includes the following topics:

• “Disk Subsystems” on page 47

• “GPI/AfterBurner 4” on page 49

• “Preview Display” on page 53

46 Chapter 3 | Setup and Configuration

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 49

Disk Subsystems

This section details the G8 disk subsystems.

Disk Subsystems

Organization

Operating drives 0 and 1 are set up in a RAID 1 mirror configuration. This

configuration consists of 2 x 250 GB SATA II drives with the addition of eight

250 GB SATA media drives in RAID 5 linked together for a total drive capacity

of approximately 1.7 TB.

The G8 disk subsystems features:

• RAID 1 for system boot drive

• RAID 5 for media storage

• 100 MB data rate for system drive

• 400 MB data rate for media drive

• System and media storage on separate spindles

• 2 x 250 GB SATA system drives

• 8 x 250 GB SATA media drives

• 1.7 TB approximate total media drive capacity

Spare Drive Bays

Drives:

Media Disk Subsystem: RAID 5

8 9 10 11 12 13 14 150 1 2 3 4 5 6 7

Drive

Configuration

Copyright © 2014 Harris Broadcast

The G8 system uses mirror (RAID 1) drives. If one drive fails, the other drive

can continue operations while you replace the failed drive. For details on

Empty Drive Bays (potential drive storage)

System Drives: RAID 1 (Mirror)

Figure 3-1. Front Panel: Disk Subsystems

Proprietary and Confidential

G8 Hardware Installation Manual

47Chapter 3 | Setup and Configuration

Page 50

replacing a hard drive see “Install Hard Drives” on page 28.

3

2

7

6

5

4

15149810 1312111010

RAID 1

250 GB

RAID 5

1.7 TB

250 GB x 8250 GB x 2

Disks 8 -15

D:\

Disks 0,1

C:\

1.7 TB250 GB

Figure 3-2. Drive Configuration

48 Chapter 3 | Setup and Configuration

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 51

GPI/AfterBurner 4

VHDCI

Pin

Port

Signal

RJ

Pin

RJ-11

#

(Label)

RJ

Pin

VHDCI

Pin

Port

Signal

1 GND

NC

NC

35 GND

2 1 TX+ → 1

1

(A)

2 ← 36 1 TX-

3 1 RX+ ← 4

3 → 37 1 RX-

4 2 TX+ → 1

2

(B)

2 ← 38 2 TX-

5 2 RX+ ← 4

3 → 39 2 RX- 6 3

TX+ → 1

3

(C)

2 ← 40 3 TX-

7 3 RX+ ← 4

3 → 41 3 RX-

8 4 TX+ → 1

4

(D)

2 ← 42 4 TX-

9 4 RX+ ← 4

3 → 43 4 RX-

10 5 TX+ → 1

5

(E)

2 ← 44 5 TX-

11 5 RX+ ← 4

3 → 45 5 RX-

12 6 TX+ → 1

6

(F)

2 ← 46 6 TX-

13 6 RX+ ← 4

3 → 47 6 RX-

14 7 TX+ → 1

7

(G)

2 ← 48 7 TX-

15 7 RX+ ← 4

3 → 49 7 RX-

16 8 TX+ → 1

8

(H)

2 ← 50 8 TX-

17 8 RX+ ← 4

3 → 51 8 RX-

18 9 GPO1

→

1

9

(J)

2 ← 52 9 GPO1

19 9 GPI1

←

4

3 → 53 9 GND

20

10

GPO2

→

1

10

(K)

2 ← 54

10

GP02

21

10

GPI2

←

4

3 → 55

10

GND

22

11

GPO3

→

1

11

(L)

2 ← 56

11

GPO3

23

11

GPI3

←

4

3 → 57

11

GND

24

12

GPO4

→

1

12

(M)

2 ← 58

12

GPO4

25

12

GPI4

←

4

3 → 59

12

GND

26

13

GPO5

→

1

13

(N)

2 ← 60

13

GPO5

27

13

GPI5

←

4

3 → 61

13

GND

28

14

GPO6

→

1

14

(P)

2 ← 62

14

GPO6

29

14

GPI6

←

4

3 → 63

14

GND

30

15

GPO7

→

1

15

(Q)

2 ← 64

15

GPO7

31

15

GPI7

←

4

3 → 65

15

GND

32

16

GPO8

→

1

16

(R)

2 ← 66

16

GPO8

33

16

GPI8

←

4

3 → 67

16

GND

34 GND

NC NC

68 GND

G8 systems currently support eight GPIO on the AfterBurner4 (AB4) via the orderable fanout cable (Harris

Broadcast part number:

INSG8AB7 or INSG8AB16).

Fanout Cable

Pinouts (AB4 to

RJ12)

Note that the RS422 ports (labels A - H) are not currently supported and are

reserved for future expansion.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

49Chapter 3 | Setup and Configuration

G8 Hardware Installation Manual

Page 52

AB4 Cabling

Currently not supported.

Reserved for future expansion.

Using Fanout

Cables

Instead of the individual RJ cables for each port, a single "fanout" cable is

available for each serial 16 card. This cable allows a single VHDCI connection

to the board, while providing 16 individual RJ connections. Eight connections

are currently supported (labeled J - N and P - R) while eight connections are

reserved for future expansion (labeled A - H).

The design of the cables allows this single VHDCI connection to the board to

be accomplished without splices within the length of the cable. This approach

greatly reduces the number of cables, simplifies the installation, connection,

labeling, and dressing of cables, and improves the overall cabling to the

chassis.

50 Chapter 3 | Setup and Configuration

G8 Hardware Installation Manual

Figure 3-3. Fanout Cable

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 53

Fanout Cable Lengths

The standard cable is 7 ft (210 cm) in total length, with a 3 ft (90 cm) portion,

a single cable from the VHDCI connector carrying all 16 ports, and the

remaining 4 ft (120 cm) individual cables for each port (Harris Broadcast part

number:

part number:

INSG8AB7). A 16 ft (485 cm) cable is also available (Harris Broadcast

INSG8AB16).

INSG8AB16INSG8AB7

Copyright © 2014 Harris Broadcast

Figure 3-4. Available Fanout Cable Lengths

Proprietary and Confidential

G8 Hardware Installation Manual

51Chapter 3 | Setup and Configuration

Page 54

Pinout Reference

2

1

3

4

NO

GPI - OUTPUT CIRCUIT

OMRON G3VM-21LR1

GPI - INPUT CIRCUIT

MOCD207/SO

4

3

2

1

5

6

7

8

5V

51OR

51OR

AB4 RJ12 GPI PINOUT

RJ12

1GPI-O

2GPI-I

3GPI-IGND

4GPI-O

5nc

6nc

52 Chapter 3 | Setup and Configuration

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 55

Preview Display

Before you start using the G-Scribe software application, you should set up your preview display. The

available preview options depend on your system setup.

Preview Display

Setup

1 With the G8 system shut down, connect the second monitor to the DVI

port on the back of the system.

2 Reboot the system.

3 When the system has restarted, right-click on the Windows desktop.

4 Select NVIDIA Control Panel from the right-click menu.

Figure 3-5. Select NVIDIA Control Panel

5 In the NVIDIA Control Panel, click the “Set up multiple displays” link

included with the Display options on the left. The options for multiple

displays appear on the right.

6 In the first step, select the “Configured independently from each other

Copyright © 2014 Harris Broadcast

Figure 3-6. NVIDIA Control Panel - Multiple Display Options

(Dual View)” option.

Proprietary and Confidential

G8 Hardware Installation Manual

53Chapter 3 | Setup and Configuration

Page 56

7 In the second step, confirm your display monitors are selected from the

drop-down list.

8 In the third step, confirm the display you are using for G8 operations is

selected from the drop-down list. The second display is then used for the

VGA preview.

9 Click Apply to apply the preview settings.

54 Chapter 3 | Setup and Configuration

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 57

Chapter 4

Maintenance

Page 58

Overview

This chapter provides information about maintaining your G8 system, and

includes the following topics:

• “Hot Swap Power Supplies” on page 57

• “System Restore” on page 58

• “Prevent Damage and Malfunction” on page 63

56 Chapter 4 | Maintenance

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 59

Hot Swap Power Supplies

Your system uses a dual-redundant hot-swappable power supply. You can

replace a failed power supply module without turning the system off.

Make sure you have a replacement power supply before starting this procedure.

Keep a replacement power supply module on hand, and replace failed modules

promptly. Running on one power supply module for any length of time can

compromise the uninterrupted operation of your system.

Three signals indicate that a power supply module has failed.

• The warning alarm sounds.

• The green LED on the failed power supply module is off.

• The PS FAIL LED on the front of the unit is red.

To stop the alarm from sounding, unplug the power supply module from the

system.

Note: For redundant operation your system requires two working modules. If

one module fails, replace the failed module immediately.

To replace the

failed power

supply module

1 Put on protective gloves before removing the failed power supply module.

The power supply module is very hot.

2 Pull out the failed power supply module, and put it somewhere where it

will not be touched until it cools down.

3 Insert a replacement power supply module.

4 Confirm that the power supply module LED is green.

5 Confirm that the PS FAIL LED on the front of the unit is off.

6 Snap the power supply module in place.

See “Change the Power Supply” on page 34 for details on replacing a power

supply module.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

57Chapter 4 | Maintenance

G8 Hardware Installation Manual

Page 60

System Restore

Create a Restore

Point

A factory system restore image is available on your system’s D:\Recovery

folder. This folder is protected from accidental deletion. Do not attempt to

change the protection settings of the folder or attempt to delete it.

To perform system recovery or custom image creation tasks, use the System

Restore flash drive that was shipped in your accessory box with the system. You

may wish to create an additional “production” system restore image after you

have fully configured/administered your system.

1 Follow these steps to change the system’s Hard Disk Drive and Boot

Device Priority so that the System Restore flash drive is the first device.

a Unplug all USB devices from the system.

b Attach the System Restore flash drive to one of the USB ports on the

system.

You may use a different flash drive to store your restore point if you

wish. This might be necessary if your restore point is too large to fit on

the System Restore flash drive.

c Power on the system.

d As the system boots, during the POST cycle, press

F11 to access the

BBS (Boot Block Selection) menu.

58 Chapter 4 | Maintenance

G8 Hardware Installation Manual

e Move the cursor down to the

USB Disk option and hit Enter.

2 Windows loads, followed by the Windows Preinstallation Environment.

This process may take several minutes.

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 61

3 The Harris Broadcast System Recovery screen appears.

Figure 4-1. Harris Broadcast System Recovery Screen

System Restore

4 Click the Advanced Options button. The Advanced Options menu appears.

5 Click the Manual Recovery button to allow manual image creation and

recovery.

6 Ghost launches. Use the Ghost application to choose a source and a target

for your restore point.

Note: Loss of data is possible if you incorrectly specify your target. Be

sure of your settings before you continue.

7 Within Ghost, create the image.

8 After the image creation is complete, shut down your system so the power

is off.

9 Remove the flash drive which contains your new restore point and store it

in a safe place.

10 Reattach any USB devices that you removed before starting this procedure.

11 Power on your system.

1 Follow these steps to change the system’s Hard Disk Drive and Boot

Device Priority so that the System Restore flash drive is the first device.

a Unplug all USB devices from the system.

Copyright © 2014 Harris Broadcast

Proprietary and Confidential

59Chapter 4 | Maintenance

G8 Hardware Installation Manual

Page 62

b Attach the System Restore flash drive to one of the USB ports on the

system.

c Power on the system.

d As the system boots, during the POST cycle, press

F11 to access the

BBS (Boot Block Selection) menu.

e Move the cursor down to the

USB Disk option and hit Enter.

2 Windows loads, followed by the Windows Preinstallation Environment.

This process may take several minutes.

3 The Harris Broadcast System Recovery screen appears.

60 Chapter 4 | Maintenance

G8 Hardware Installation Manual

Figure 4-2. Harris Broadcast System Recovery Screen

•

Follow these steps to restore your system to a restore point that you

have created previously.

a Click the Advanced Options button. The Advanced Options menu

appears.

b Click the Manual Recovery button to allow manual image creation

and recovery.

c The Ghost application launches. Select the recovery source you

wish to use and the target of the recovery.

Note: Loss of data is possible if you incorrectly specify your

target. Be sure of your settings before you continue.

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 63

d Wait for the recovery process to finish.

• Follow these steps to automatically restore your system to its factory

settings.

a Click the Recover System button.

b When the factory recovery data is found, you are prompted to

continue.

Figure 4-3. System Recovery Prompt

c If you are certain that you want to recover your system, click the

OK button.

d The Ghost application launches and the restore procedure begins.

4 After the restore is complete, click the Reboot Now button to restart your

Copyright © 2014 Harris Broadcast

system.

Figure 4-4. Restore Progress Indicator

Proprietary and Confidential

G8 Hardware Installation Manual

61Chapter 4 | Maintenance

Page 64

5 If you are prompted to reactivate Windows, use your Windows License key

to reactivate the operating system. Refer to the Harris Broadcast System

Note for details on your Windows license.

6 Reattach any USB devices that you removed before starting this procedure.

7 Install any product updates you have received for products that are newer

than your restore point. You can download updates at

http://harrisbroadcast.com/support.

If the system is not fully operational when the restore is complete, verify that

you did not make any incompatible hardware changes.

62 Chapter 4 | Maintenance

G8 Hardware Installation Manual

Proprietary and Confidential

Copyright © 2014 Harris Broadcast

Page 65

Prevent Damage and Malfunction

Read and observe all instructions in this section to keep your system working safely and effectively.

Hardware

Anti-Virus

Software

Do NOT modify the hardware. Your system is delivered with all the necessary

hardware and software already installed. You should not have to open the

system case. However, if the system case is damaged, refer to “Chassis

Components Installation” on page 27 for proper instructions on accessing the

chassis components. Installing additional hardware or modifying the hardware

in any way can compromise the operation of your system.

Harris Broadcast does not condone the operation of anti-virus software on

Graphics systems during operation of the software.

Harris Broadcast supports regular manual or scheduled scans on Graphics

systems, using licensed professional third party applications, during known

off-line time periods when the software is not on-air or actively in use. Under