Page 1

Installation Manual

MM102554V1

Rev. B, Dec- 04

®

MASTR

III

Conventional and P25

Base Stations

TABLE OF CONTENTS

Application and Assembly Diagrams........................MM102555V1

Antenna Systems.............................................................LBI-38983

Site Grounding and Lightning Protection ........AE/LZT 123 4618/1

Tower Requirements and Specifications.........................LBI-39185

Advanced Digital Capable

Page 2

MM102554V1 REV B

MANUAL REVISION HISTORY

REV DATE REASON FOR CHANGE

R1A August 2003 Initial Release.

B December 2004 Modified Regulatory Section.

NOTICE!

This manual covers M/A-COM, Inc. products manufactured and sold by M/A-COM, Inc.

This device made under license under one or more of the following US patents: 4,590,473; 4,636,791; 5,148,482;

5,185,796; 5,271,017; 5,377,229.

The voice coding technology embodied in this product is protected by intellectual property rights including patent rights,

copyrights, and trade secrets of Digital Voice Systems, Inc. The user of this technology is explicitly prohibited from

attempting to decompile, reverse engineer, or disassemble the Object Code, or in any way convert the Object Code into

human-readable form.

MASTR and Voice Guard are registered trademarks and Aegis is a trademark of is a registered trademark of M/A-COM,

Inc.

Microsoft, Windows, and WindowsNT are registered trademarks of Microsoft Corporation

Pentium is a registered trademark of Intel Corporation.

All other brand and product names are registered trademarks, trademarks, or service marks of their respective holders.

NOTICE!

Repairs to this equipment should be made only by an authorized service technician or facility designated by the supplier.

Any repairs, alterations or substitutions of recommended parts made by the user to this equipment not approved by the

manufacturer could void the user's authority to operate the equipment in addition to the manufacturer's warranty.

This manual is published by M/A-COM, Inc. , without any warranty. Improvem e nts and changes to this manual necessitated by typographical errors,

inaccuracies of current information, or improvements to programs and/or equipment, may be made by M/A-COM, Inc. , at any time and without notice.

Such changes will be incorporated into new editions of this manual. No part of this manual may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose, without the express written permission of M/A-COM, Inc.

Copyright© 2003 M/A-COM, Inc. All rights reserved.

2

Page 3

MM102554V1 REV B

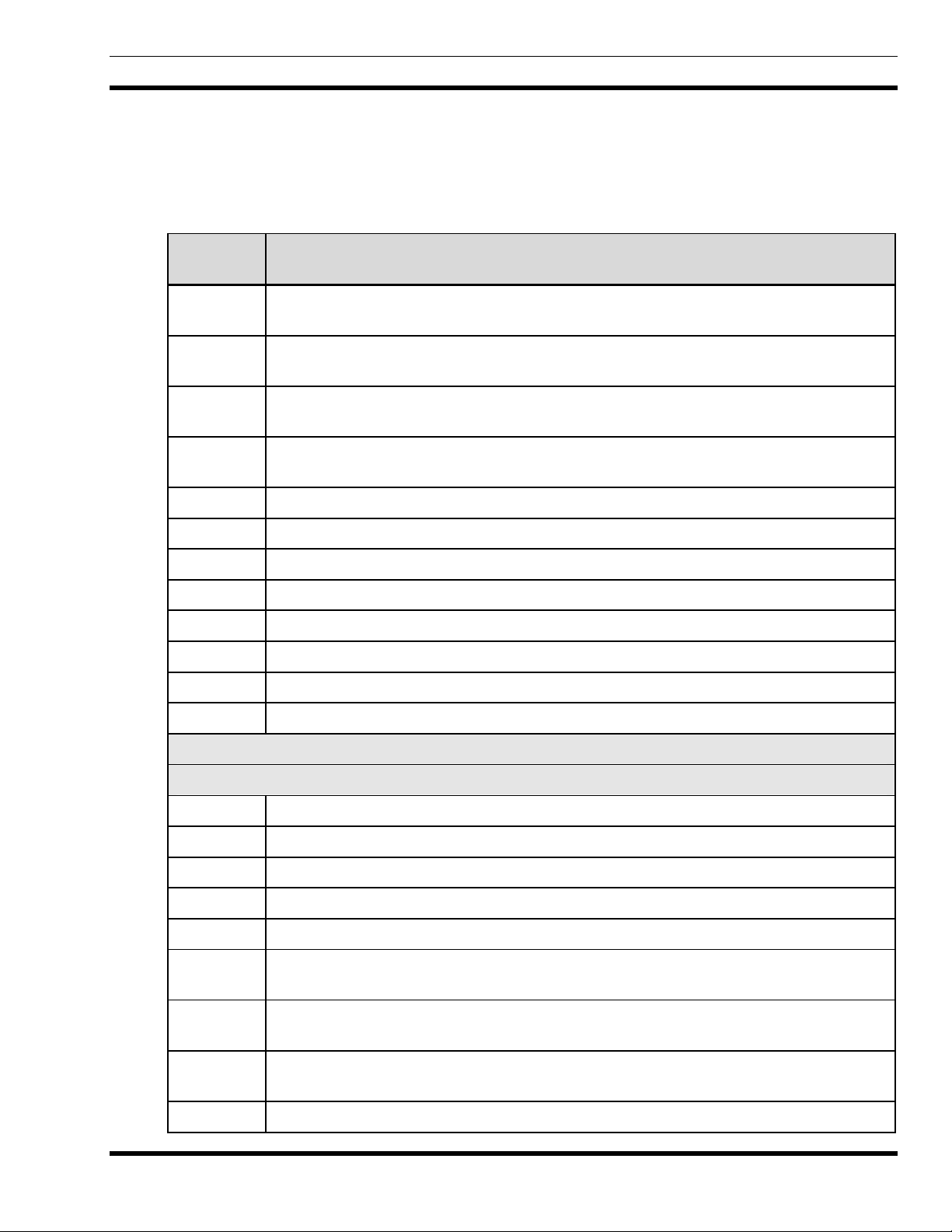

TABLE OF CONTENTS

Page

1. REGULATORY AND SAFETY INFORMATION............................................................................ 7

1.1 MAXIMUM PERMISSIBLE EXPOSURE LIMITS........................................................................ 7

1.2 DETERMINING MPE RADIUS......................................................................................................7

1.3 SAFETY TRAINING INFORMATION........................................................................................... 7

1.4 IMPORTANT SAFETY INFORMATION....................................................................................... 9

1.5 SAFETY SYMBOLS IN THIS DOCUMENT ............................................................................... 10

2. SPECIFICATIONS (GENERAL)...................................................................................................... 11

2.1 CABINET........................................................................................................................................ 11

2.2 STATION........................................................................................................................................ 11

2.3 INTERFACE................................................................................................................................... 12

3. INTRODUCTION ............................................................................................................................... 13

4. GENERAL INFORMATION.............................................................................................................15

4.1 REFERENCE MANUALS ............................................................................................................. 15

4.2 OPTIONS........................................................................................................................................ 17

5. SITE PREPARATION........................................................................................................................ 19

5.1 INTRODUCTION........................................................................................................................... 19

5.2 FACILITY PREPARATION.......................................................................................................... 19

5.2.1 Floor Plan........................................................................................................................... 19

5.2.2 Equipment Cabinet Placement........................................................................................... 19

5.2.3 Ceiling Requirements......................................................................................................... 20

5.2.4 Size and Weight Considerations ........................................................................................ 20

5.2.5 Operating Environment...................................................................................................... 20

5.3 POWER INSTALLATION............................................................................................................. 20

5.3.1 Existing Input Power.......................................................................................................... 20

5.3.2 AC Distribution.................................................................................................................. 21

5.3.3 Generator System............................................................................................................... 21

5.3.4 AC-DC Supply................................................................................................................... 21

5.3.5 Battery Backup................................................................................................................... 22

5.3.6 UPS System........................................................................................................................ 22

5.3.7 Electrical Power ................................................................................................................. 22

5.4 INTER-SITE COMMUNICATIONS ............................................................................................. 23

5.4.1 Hardwire Installation.......................................................................................................... 23

5.4.2 Leased Telephone Lines..................................................................................................... 24

5.4.3 T1 or E1 Links ................................................................................................................... 24

5.5 PROTECTIVE GROUNDING ....................................................................................................... 25

5.6 ANTENNA SYSTEM..................................................................................................................... 26

5.6.1 Antenna Mounting ............................................................................................................. 26

5.6.2 Transmission Lines ............................................................................................................ 27

5.7 QUALITY AUDIT.......................................................................................................................... 29

5.7.1 Antenna System ................................................................................................................. 29

3

Page 4

MM102554V1 REV B

TABLE OF CONTENTS

Page

5.7.2 Electrical System................................................................................................................30

6. EQUIPMENT INSTALLATION ....................................................................................................... 31

6.1 INTRODUCTION........................................................................................................................... 31

6.2 UNPACKING EQUIPMENT ......................................................................................................... 31

6.3 EQUIPMENT INSTALLATION.................................................................................................... 32

6.3.1 Mounting Vendor Supplied RF Equipment ....................................................................... 32

6.3.2 Mounting Base Station Cabinet (Typical) .......................................................................... 34

6.4 INTERIOR RF CABLING.............................................................................................................. 35

6.4.1 Cable Routing..................................................................................................................... 35

6.4.2 Install RF Cables................................................................................................................ 35

6.5 CONNECTING ELECTRICAL POWER....................................................................................... 37

6.5.1 AC Power Distribution....................................................................................................... 38

6.5.2 Generator Backup............................................................................................................... 38

6.5.3 AC-DC Supply................................................................................................................... 38

6.5.4 Battery Backup................................................................................................................... 38

6.5.5 UPS System........................................................................................................................ 39

6.6 POWER-UP SEQUENCE............................................................................................................... 39

7. DC AND TONE REMOTE CONTROL INSTALLATION ............................................................ 40

7.1 DC REMOTE INSTALLATION.................................................................................................... 40

7.1.1 Wiring Methods for DC Remote........................................................................................ 40

7.1.2 Installation Method 1 – Single Metallic Pair...................................................................... 43

7.1.3 Installation Method 2 – Single Metallic Pair with Earth Ground....................................... 43

7.1.4 Installation Method 3 - Metallic Control Pair, Audio Pair................................................. 43

7.1.5 Installation Method 4 - Full Duplex................................................................................... 45

7.2 E & M SIGNALING....................................................................................................................... 45

7.2.1 Standard (Type II) E & M Signaling.................................................................................. 45

7.2.2 Type 1 E & M Signaling.................................................................................................... 46

7.3 TONE REMOTE INSTALLATION............................................................................................... 46

7.3.1 Voting System Considerations........................................................................................... 48

7.3.2 Function Tones...................................................................................................................48

7.3.3 Wiring Methods for Tone Remote ..................................................................................... 49

7.3.4 Installation Method 1 – Two Wire Tone Remote............................................................... 50

7.3.5 Installation Method 2 - Four Wire Tone Remote............................................................... 50

7.4 T/R SHELF REMOTE CONTROL CONNECTIONS................................................................... 50

7.4.1 Interface Board Connections.............................................................................................. 50

7.5 SQUELCH OPERATED RELAY OPTION (SXSU3D)................................................................ 53

7.5.1 Installation.......................................................................................................................... 53

7.5.2 Operation............................................................................................................................ 53

7.6 SHARED REPEATER PANEL INSTALLATION........................................................................ 55

7.6.1 General............................................................................................................................... 55

7.6.2 Repeater Panel Interface..................................................................................................... 55

8. STATION TEST AND ALIGNMENT PROCEDURES .................................................................. 58

8.1 INTRODUCTION........................................................................................................................... 58

4

Page 5

MM102554V1 REV B

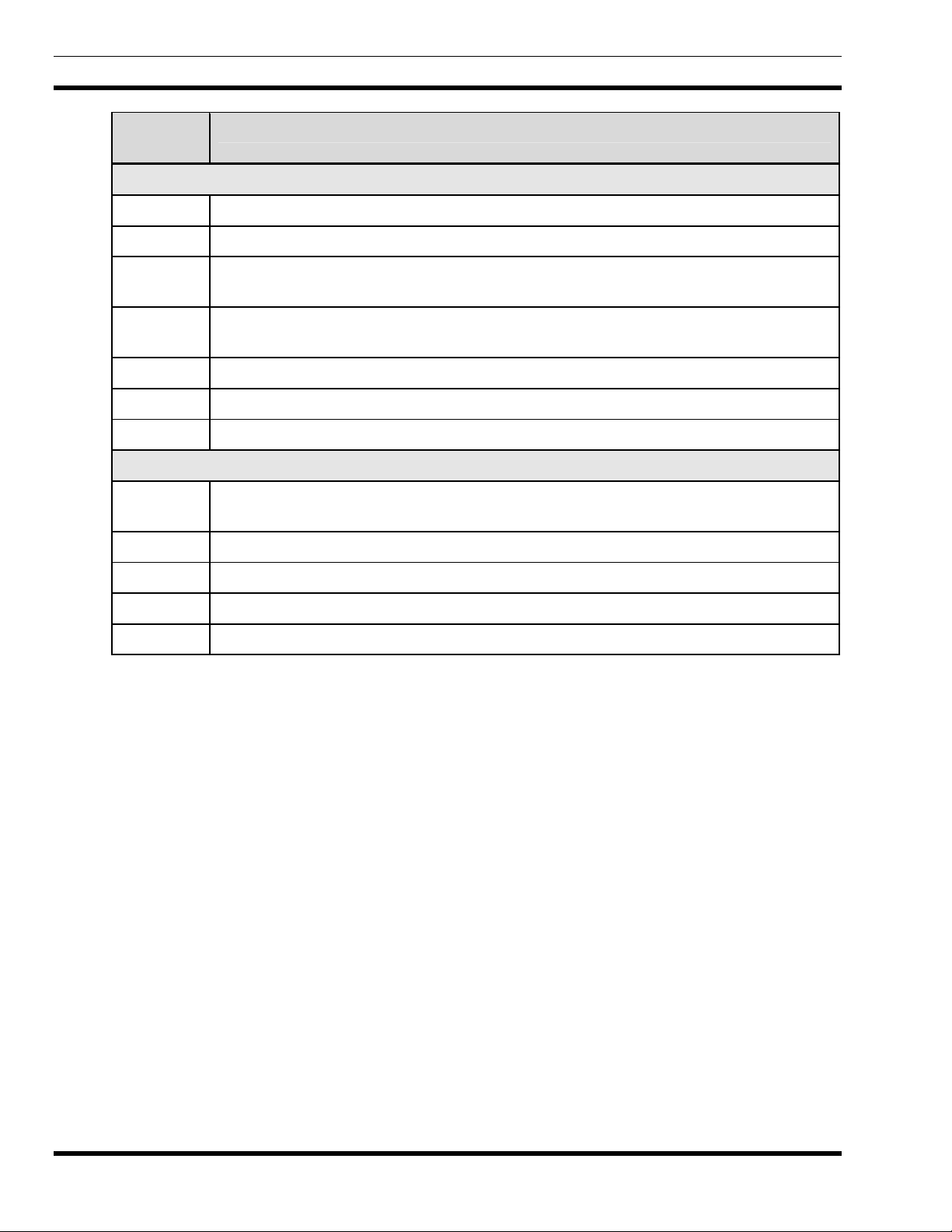

TABLE OF CONTENTS

Page

8.2 GENERAL...................................................................................................................................... 58

8.3 SUPPORT EQUIPMENT REQUIRED.......................................................................................... 58

8.3.1 Hardware............................................................................................................................ 58

8.3.2 Software ............................................................................................................................. 59

8.4 STATION CONFIGURATION...................................................................................................... 60

8.5 STATION ALIGNMENT............................................................................................................... 61

8.5.1 Preparation ......................................................................................................................... 63

8.5.2 Station Pot Defaults............................................................................................................ 64

8.5.3 Channel Guard (CG) Pot.................................................................................................... 64

8.5.4 Transmit Limiter (TX) Pot................................................................................................. 65

8.5.5 Repeater Gain (RG) Pot ..................................................................................................... 66

8.5.6 DSP Line Input (DLI) Pot.................................................................................................. 66

8.5.7 Compressor Gain (CP) Pot................................................................................................. 67

8.5.8 Compressor Threshold (CT) Pot........................................................................................ 68

8.5.9 DSP Line Cancellation (DC) Pot ....................................................................................... 68

8.5.10 Line Output (LO) Pot......................................................................................................... 69

8.5.11 P25 C4FM Deviation (DSP Module Adjustments)............................................................ 69

8.5.12 Enable the P25 Operation in the System Module............................................................... 69

8.5.13 Adjust P25 C4FM Deviation.............................................................................................. 70

8.5.14 SINAD Test........................................................................................................................ 71

8.5.15 Squelch Adjustment ........................................................................................................... 72

8.5.16 Transmitter Forward and Reverse Power........................................................................... 72

9. SYSTEM FUNCTIONAL TESTS...................................................................................................... 74

9.1 GENERAL...................................................................................................................................... 74

9.2 SETUP............................................................................................................................................. 74

9.3 CONVENTIONAL RADIO TEST ................................................................................................. 74

9.4 P25 RADIO TEST .......................................................................................................................... 74

9.4.1 P25 Individual Calls........................................................................................................... 74

9.4.2 P25 Group Calls................................................................................................................. 74

9.5 REMOTE STATION OPERATION............................................................................................... 75

10. MODULE TESTING AND ALIGNMENT ....................................................................................... 76

10.1 GENERAL...................................................................................................................................... 76

10.2 BENCH TESTING.......................................................................................................................... 77

10.2.1 Procedure............................................................................................................................ 78

10.3 IN-STATION TESTING................................................................................................................. 79

10.3.1 Procedure............................................................................................................................ 79

10.4 CHANGING THE BASE STATION FREQUENCY ..................................................................... 79

10.4.1 Vendor Equipment............................................................................................................. 80

10.4.2 800 MHz Stations............................................................................................................... 80

10.4.3 UHF Stations...................................................................................................................... 81

10.4.4 VHF Stations...................................................................................................................... 81

10.5 STATION ADJUSTMENTS FOR REMOTE CONTROL OPERATION..................................... 82

10.5.1 Line Out Level Adjustment................................................................................................ 82

10.5.2 Line In Level Adjustment .................................................................................................. 83

5

Page 6

MM102554V1 REV B

TABLE OF CONTENTS

Page

10.5.3 DSP Level Adjustments..................................................................................................... 83

11. PREVENTATIVE MAINTENANCE ................................................................................................ 84

11.1 GENERAL...................................................................................................................................... 84

11.2 BASE STATIONS ..........................................................................................................................84

11.2.1 Test Equipment .................................................................................................................. 84

11.2.2 Tests ................................................................................................................................... 84

11.3 RF SYSTEM................................................................................................................................... 85

11.3.1 Combiner............................................................................................................................ 85

11.3.2 Multicoupler....................................................................................................................... 85

11.3.3 Receive Filter ..................................................................................................................... 85

11.3.4 RF Cabling to Bulkhead..................................................................................................... 85

11.4 POWER SYSTEM.......................................................................................................................... 85

12. CHECKLISTS ..................................................................................................................................... 86

12.1 SITE DATA SHEET....................................................................................................................... 87

12.2 INSTALLER PROFILE DATA SHEET......................................................................................... 88

12.3 ANTENNA SYSTEM INSTALLATION CHECKLIST................................................................ 89

12.4 EQUIPMENT INSTALLATION CHECKLIST............................................................................. 90

12.5 POWER SYSTEM INSTALLATION CHECKLIST ..................................................................... 91

12.6 REPEATER TEST DATA.............................................................................................................. 92

12.7 PREVENTATIVE MAINTENANCE REPEATER TEST DATA................................................. 93

6

Page 7

MM102554V1 REV B

1. REGULATORY AND SAFETY INFORMATION

1.1 MAXIMUM PERMISSIBLE EXPOSURE LIMITS

DO NOT TRANSMIT with this base station and antenna when persons are within the MAXIMUM

PERMISSIBLE EXPOSURE (MPE) Radius of the antenna. The MPE Radius is the minimum distance

from the antenna axis that ALL persons should maintain in order to avoid RF exposure higher than the

allowable MPE level set by the FCC.

FAILURE TO OBSERVE THESE LIMITS MAY ALLOW ALL PERSONS WITHIN

THE MPE RADIUS TO EXPERIENCE RF RADIATION ABSORPTION, WHICH

EXCEEDS THE FCC MAXIMUM PERMISSIBLE EXPOSURE (MPE) LIMIT. IT IS

THE RESPONSIBILITY OF THE BASE STATION OPERATOR TO ENSURE THAT

THE MAXIMUM PERMISSIBLE EXPOSURE LIMITS ARE OBSERVED AT ALL

WARNING

TIMES DURING BASE STATION TRANSMISSION. THE BASE STATION

OPERATOR IS TO ENSURE THAT NO BYSTANDERS ARE WITHIN THE RADIUS

LIMITS.

1.2 DETERMINING MPE RADIUS

THE MAXIMUM PERMISSIBLE EXPOSURE RADIUS is unique for each site and is determined at

during site licensing time based on the complete installation environment (i.e.. co-location, antenna type,

transmit power level, etc.). Determination of the MPE distance is the responsibility of the installation

licensee. Calculation of the MPE radius is required as part of the site licensing procedure with the FCC.

1.3 SAFETY TRAINING INFORMATION

YOUR M/A-COM MASTR III BASE STATION GENERATES RF

ELECTROMAGNETIC ENERGY DURING TRANSMIT MODE. THIS BASE

STATION IS DESIGNED FOR AND CLASSIFIED AS “OCCUPATIONAL USE ONLY”

MEANING IT MUST BE USED ONLY IN THE COURSE OF EMPLOYMENT BY

INDIVIDUALS AWARE OF THE HAZARDS OF RF ENERGY AND THE WAYS TO

MINIMIZE EXPOSURE. THIS BASE STATION IS NOT INTENDED FOR USE BY

THE “GENERAL POPULATION” IN AN UNCONTROLLED ENVIRONMENT. IT IS

WARNING

THE RESPONSIBILITY OF THE LISENSEE TO ENSURE THAT THE MAXIMUM

PERMISSIBLE EXPOSURE LIMITS ARE OBSERVED AT ALL TIMES DURING

TRANSMISSION. THE BASE STATION OPERATOR IS TO ENSURE THAT NO

BYSTANDERS COME WITHIN THE RADIUS OF THE LIMITS.

When licensed by the FCC, this base station complies with the FCC RF exposure limits when persons are

beyond the MPE radius of the antenna. In addition, your M/A-COM base station installation complies

with the following Standards and Guidelines with regard to RF energy and electromagnetic energy levels

and evaluation of such levels for exposure to humans:

7

Page 8

MM102554V1 REV B

FCC OET Bulletin 65 Edition 97-01 Supplement C, Evaluating Compliance with FCC Guidelines

for Human Exposure to Radio Frequency Electromagnetic Fields.

American National Standards Institute (C95.1 – 1992), IEEE Standard for Safety Levels with

Respect to Human Exposure to Radio Frequency Electromagnetic Fields, 3 kHz to 300 GHz.

American National Standards Institute (C95.3 – 1992), IEEE Recommended Practice for the

Measurement of Potentially Hazardous Electromagnetic Fields – RF and Microwave.

TO ENSURE THAT YOUR EXPOSURE TO RF ELECTROMAGNETIC ENERGY IS

WITHIN THE FCC ALLOWABLE LIMITS FOR OCCUPATIONAL USE, DO NOT

OPERATE THE BASE STATION IN A MANNER THAT WOULD CREATE AN MPE

CAUTION

DISTANCE IN EXCESS OF THAT ALLOWABLE BY THE FCC.

8

Page 9

1.4 IMPORTANT SAFETY INFORMATION

The following general safety precautions must be observed during all phases of operation, service, and

repair of this product. Failure to comply with these precautions or with specific warnings elsewhere in

this manual violates safety standards of design, manufacture, and intended use of the product. M/A-COM

Inc. assumes no liability for the customer's failure to comply with these standards.

SAVE THIS MANUAL - It contains important safety and operating instructions.

1. Before using this equipment, please follow and adhere to all warnings, safety and operating

instructions located on the product and in the manual.

2. DO NOT expose equipment to rain, snow or other type of moisture.

3. Care should be taken so objects do not fall onto or liquids do not spill into the equipment.

4. DO NOT expose equipment to extreme temperatures.

5. DO NOT connect auxiliary equipment to the MASTR III System that is not recommended or sold by

M/A-COM. To do so may result in the risk of fire, electric shock or injury to persons.

6. GROUND THE EQUIPMENT - To minimize shock hazard, the station equipment cabinet must be

connected to an electrical ground.

MM102554V1 REV B

If AC powered, the correct type of AC power cable and plug must be used. This cable and plug

assembly must conform to local standards and the installation of power cords must conform to local

standards and practices.

7. To reduce risk of damage to electrical cords, pull by plug rather than cord when disconnecting a unit.

8. Make sure all power cords are located so they will not be stepped on, tripped over, subjected to

damage or stress, or located such that they may be hazardous to health.

9. An extension cord should not be used unless absolutely necessary. Use of an improper extension

cord could result in a risk of fire or electric shock. If an extension cord must be used, ensure:

a) The extension conforms to local standards and practices,

b) The pins on the plug of the extension cord are the same number, size, and shape as those of the

plug on the power supply,

c) The extension cord is properly wired, in good condition, and

d) The wire size is capable of handling the AC ampere rating of unit/s being supplied.

10. DO NOT operate equipment with damaged power cords or plugs - replace them immediately.

11. DO NOT attempt to operate this product in an explosive atmosphere unless it has been specifically

certified for such operation.

12. To reduce risk of electric shock, isolate the unit and unplug from outlet before attempting any

maintenance or cleaning.

13. DO NOT attempt to operate this product with covers or panels removed. Refer all servicing to

qualified service personnel.

14. Use only fuses of the correct type, voltage rating and current rating as specified in the parts list.

Failure to do so can result in fire hazard.

GROUNDING AND AC POWER CORD CONNECTION - To reduce risk of electrical shock use

15.

only a properly grounded outlet. The system components are equipped with electric cords having

9

Page 10

MM102554V1 REV B

equipment grounding conductors and a grounding plug. Be sure all outlets are properly installed and

grounded in accordance with all local codes and ordinances.

16. DANGER - Never alter the AC cord or plug. Plug into an outlet properly wired by a qualified

electrician. Improper connection or loss of ground connection can result in risk of an electrical shock.

17. ELECTROSTATIC DISCHARGE SENSITIVE COMPONENTS - This station contains CMOS

and other circuit components that may be damaged by electrostatic discharge. Proper precaution must

be taken when handling circuit modules. As a minimum, grounded wrist straps should be used at all

times when handling circuit modules.

1.5 SAFETY SYMBOLS IN THIS DOCUMENT

The following conventions are used throughout this manual to alert the user to general safety precautions

that must be observed during all phases of operation, service, and repair of this product. Failure to comply

with these precautions or with specific warnings elsewhere in this manual violates safety standards of

design, manufacture, and intended use of the product. M/A-COM, Inc. assumes no liability for the

customer's failure to comply with these standards.

The WARNING symbol calls attention to a procedure, practice, or the like, which, if not

correctly performed or adhered to, could result in personal injury. Do not proceed beyond a

WARNING

WARNING symbol until the conditions identified are fully understood or met.

CAUTION

NOTE

The CAUTION symbol calls attention to an operating procedure, practice, or the like,

which, if not performed correctly or adhered to, could result in damage to the equipment or

severely degrade the equipment performance.

The NOTE symbol calls attention to supplemental information, which may improve system

performance or clarify a process or procedure.

The ESD symbol calls attention to procedures, practices, or the like, which could expose

equipment to the effects of Electro-Static Discharge. Proper precautions must be taken to

prevent ESD when handling circuit modules.

10

Page 11

2. SPECIFICATIONS (GENERAL)

2.1 CABINET

Cabinet Size (H x W x D): Total Rack Capacity

37-Inch Cabinet (37 x 21-1/2 x 18-1/4), (940 x 550 x 460 mm) 17

69-Inch Cabinet (69 x 23-3/16 x 21), (1750 x 590 x 533 mm) 33

83-Inch Cabinet (83 x 22-1/2 x 20-1/4), (2108 x 571 x 514 mm) 41

Weight (minimum) Continuous Duty Packed, Domestic Shipping

37-Inch Cabinet 150 lbs (68 kg) 165 lbs (75 kg)

69-Inch Cabinet (w/3 repeaters) 520 lbs (236 kg) 550 lbs (250 kg)

83-Inch Cabinet (w/3 repeaters) 550 lbs (250 kg) 580 lbs (263 kg)

MM102554V1 REV B

Options Required Rack Units

MASTR III Base Station & Power Supply 8

Auxiliary receivers (1 or 2 receivers) 4

Battery Shelf and Batteries (CH1R) 6

Duplexers (factory installed) (DU1J, DU1K, DU1M) 3

Receiver Voting Selector 4

TM

Aegis

Aegis Voice Guard Module and Shelf (VV1N, VW1J, VG3D, VV1S)

1 Rack Unit = 1.75-inches

/Voice Guard® Shelf (VG3E, VG3F) 1

2.2 STATION

Basic station occupies 8 RU

Service Speaker:

Service Microphone:

Duty Cycle (EIA) Continuous:

(includes T/R Shelf, PA, & Power. Supply)

1 watt at 8 ohms

Transistorized Dynamic

Transmit and Receive at 100%

Operating Temperature:

Humidity (EIA):

Input Power Source:

11

-22° to +140°F (-30°C to +60°C)

90% at 122°F (50°C)

5 Amps at 120 VAC (±20%) 60 Hz or

3 Amps at 230 VAC (±15%) 50 Hz

Page 12

MM102554V1 REV B

DC Input Power:

With 19D902797 Power Amplifier: 33 Amps at 13.8 VDC (transmit, full power)

25 Amps at 13.8 VDC (transmit, half power)

2.0 Amps at 13.8 VDC (receive only, standby)

With EA101292 Power Amplifier: 12 Amps at 26.4 VDC (transmit, full power)

8 Amps at 26.4VDC (transmit, half power)

0.5 Amps at 26.4 VDC (receive only, standby)

Antenna Connection:

Altitude:

Operating: Up to 15,000 ft (4,570 m)

Shippable: Up to 50,000 ft (15,250 m)

2.3 INTERFACE

Line Interface

Line Interface 2-wire or 4-wire (programmable)

Line Cancellation (2-wire) 20 dB amplitude only (programmable)

Audio (line to transmitter)

Type N

Line Terminating Impedance 600 ohms (2-wire or 4-wire)

Line Input Level (adjustable) -20 dBm to +7 dBm

Frequency Response ±3 dB @ 300 to 3000 Hz

Remote Tone Control

Function Tones (Hz): 1050, 1150, 1250, 1350, 1450, 1550, 1650, 1750, 1850,

Secur-it Tone and Transmit Tone 2175 Hz

Permissible Control Line loss @ 2175 Hz: 30 dB

Audio (receiver to line)

Output Impedance to Line 600 ohms (2-wire or 4-wire)

Output Level to Line (adjustable): Zero to +7 dBm (Reference at 1 kHz)

Frequency Response +1 and –3 dB @ 300 to 3000 Hz

Hum and Noise, Noise Squelch: -55 dBm (Reference 7 dBm)

Tone Squelch: -30 dBm (Reference 7 dBm)

DC Remote Control Currents:

Line Loop Resistance (maximum) 11K ohms (includes 3K ohm termination)

1950, & 2050

-2.5 mA, ±6.0 mA, ±11.0 mA

12

Page 13

3. INTRODUCTION

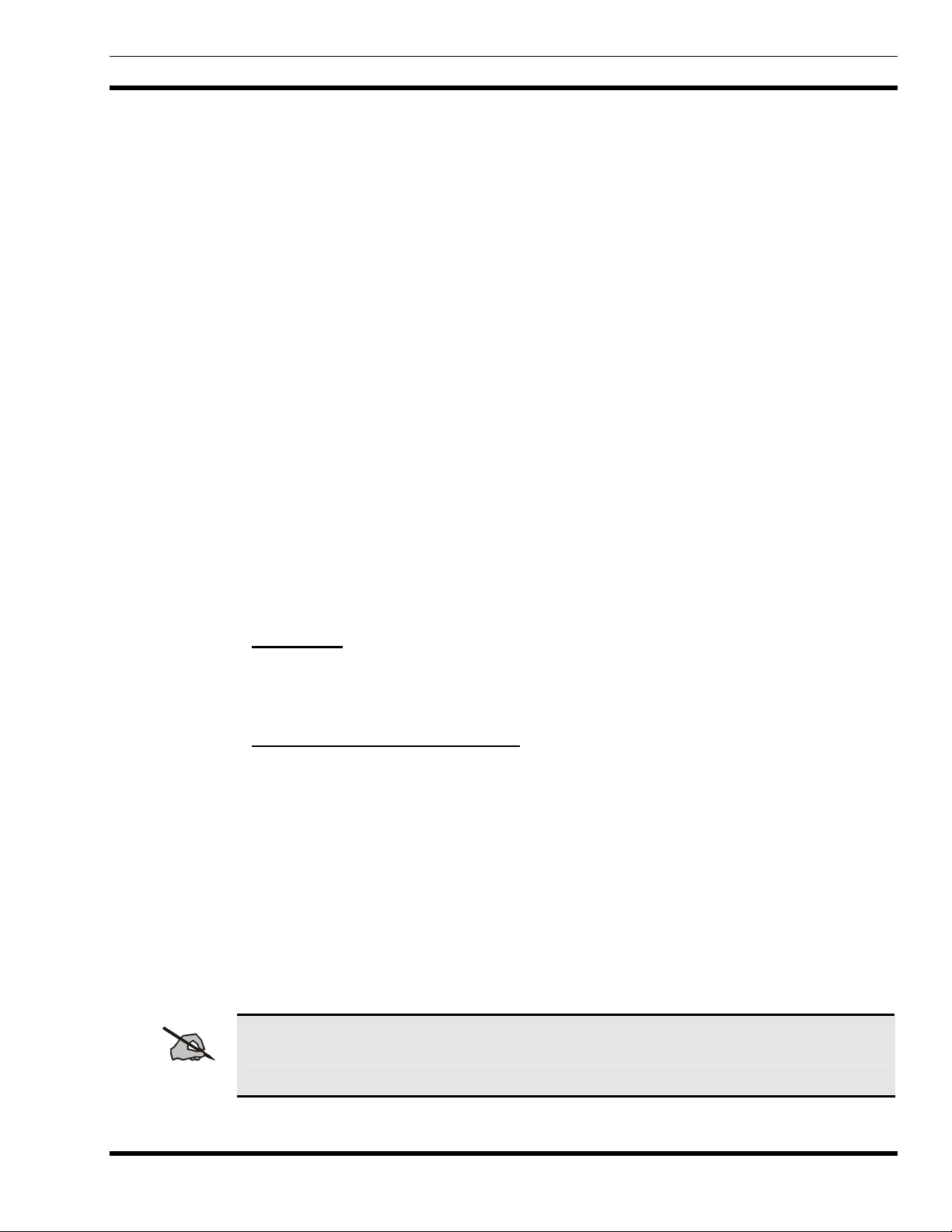

This manual describes how to install, setup, and test the MASTR® III Advanced Digital Capable (ADC)

Base Station configured for Conventional or P25 operation. Before attempting to install or checkout the

equipment, you should become familiar with the contents of this manual and observe all safety

precautions and warnings.

This manual is used with the MASTR III Conventional and P25 Application and Assembly Diagrams

Manual MM102555V1. The Application and Assembly Diagrams manual includes specific application

information, cable diagrams, and parts lists for the cabinet hardware. The installer should consult the

Application and Assembly Diagrams manual when installing and cabling the base station and for detailed

instructions for installing options and accessories.

MM102554V1 REV B

POWER

OFF

ON

16 RU

14 RU

12 RU

10 RU

8 RU

6 RU

4 RU

2 RU

0 RU

J802

POWER AMPLIFIER

J801

F801A/F801B

FRONT VIEW

REAR VIEW

Figure 3-1: Single Channel MASTR III ADC Conventional Base Station in 37" Cabinet

13

Page 14

MM102554V1 REV B

This manual is divided into the following chapters:

1. Regulatory and Safety Information – This chapter provides critical safety information governing

the installation and operation of the base station.

2. Specifications – This chapter provides the specifications for a typical conventional base station

installed in a 37" or 69" cabinet.

3. Introduction - This chapter provides a brief introduction on how this manual is structured.

4. General Information – This chapter lists many of the options and other technical manuals, which

may affect the installation of this base station.

5. Site Preparation - This chapter identifies site requirements and installation practices for the antenna

tower, transmission lines, and the equipment shelter.

6. Equipment Installation - This chapter provides instructions for unpacking and physically installing

the electronic equipment cabinets.

7. DC and Tone Remote Control Installation – This chapter provides information for configuring the

base station for operation with a DC or Tone Remote Control system.

8. Base Station Test and Alignment Procedures – This chapter provides detailed instructions for

testing and aligning each of the individual system components.

9. System Functional Tests - This chapter provides detailed instructions for verifying the overall

operation of the equipment as a system.

10. Module Testing and Alignment - This chapter provides details for bench testing or aligning

individual modules or testing and aligning the modules “in-station.” It also provides procedures for

changing the base station frequency.

11. Preventative Maintenance - This chapter defines those tests to be performed as part of Periodic

Preventative Maintenance.

12. Checklists – This chapter includes support features, such as Installation and Preventative

Maintenance Checklists.

14

Page 15

4. GENERAL INFORMATION

4.1 REFERENCE MANUALS

It may be necessary to consult one or more of the following manuals. These manuals will also provide

additional guidance if you encounter technical difficulties during the installation or testing process.

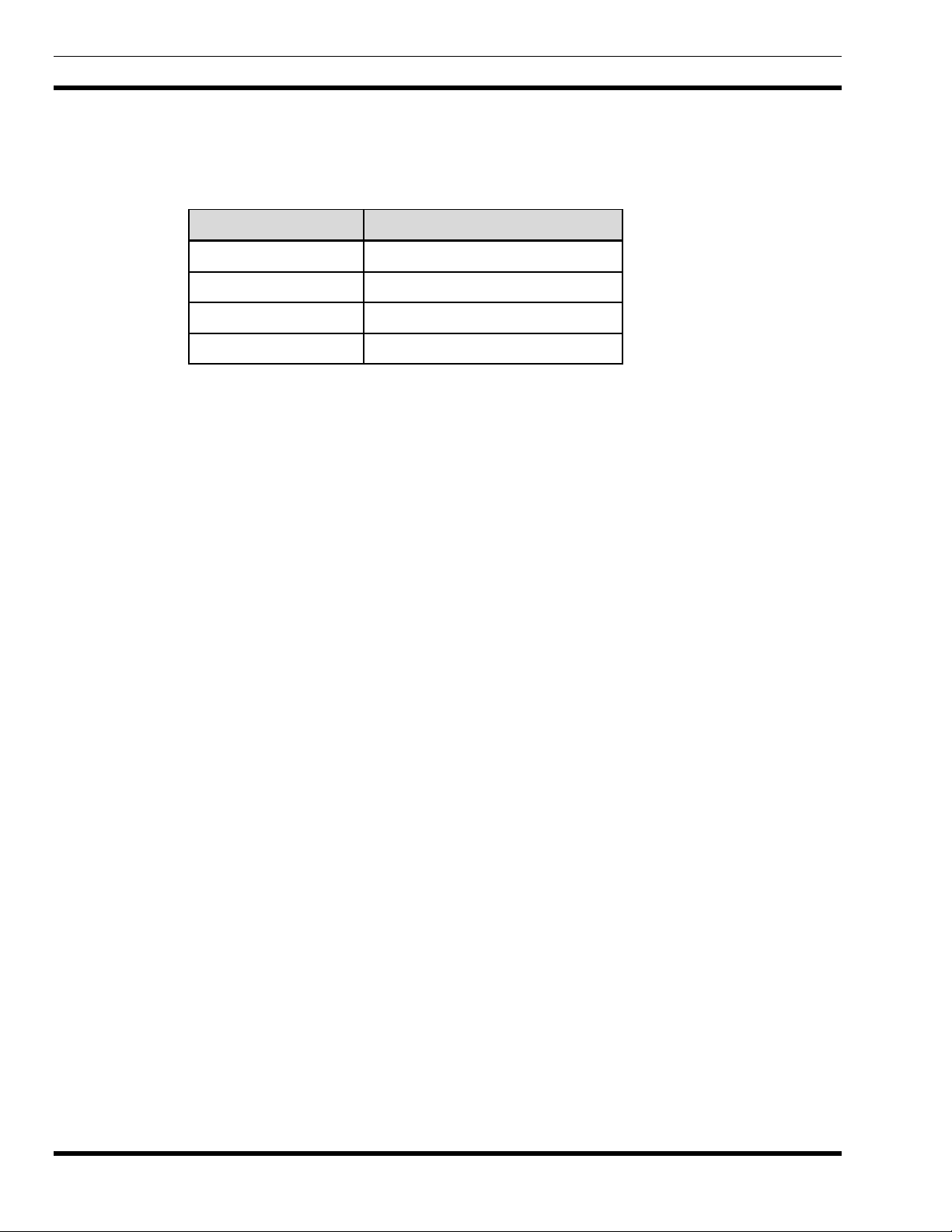

DESCRIPTION MANUAL NUMBER

MM102554V1 REV B

OVERVIEW MANUALS

MASTR III Conventional ADC Base Station MM102558V1

MASTR III P25Conventional ADC Base Station MM102559V1

MASTR III CONVENTIONAL & P25 INSTALLATION MANUAL

MASTR III Conventional & P25 Application and Assembly Diagrams MM102555V1

MASTR III ADC T/R SHELF

System Module (19D902590G6) LBI-39176

Power Module (19D902589G2) LBI-38752

DSP MODULE (EA101800V1)

DATA MODULE (19D904558G1)

MASTR III RF PACKAGE: VHF (136 - 174 MHZ)

Transmit Synthesizer Module (19D902780G1) LBI-38640

Receive Synthesizer Module (19D902781G1) LBI-38641

Receiver Front End Module (19D902782G1) LBI-38642

Receiver IF Module (EA101401V1) MM101886V1

MM102554V1

MM102244V1

MM101943V1

LBI-38918

MM102557V1

Power Amplifier (EA101292V10, V11, & V12) MM101383V2

MASTR III RF PACKAGE: UHF (380 - 512 MHZ)

Transmit Synthesizer Module (19D902780G3, G6-G10) LBI-38671

Receive Synthesizer Module (19D902781G3) LBI-38672

Receiver Front End Module (19D902782G11) LBI-39129

Receiver IF Module (19D902783G11) LBI-39123

Power Amplifier (19D902797G11) LBI-38674

MASTR III RF PACKAGE: 800 MHz

Transmit Synthesizer Module (19D902780G5) LBI-39026

Receive Synthesizer Module (19D902781G5) LBI-39027

Receiver Front End Module (19D902782G5) LBI-39028

15

MM102557V2

LBI-39025

Page 16

MM102554V1 REV B

Receiver IF Module (19D902783G5) LBI-39029

Power Amplifier, 110 Watt (EA101292V1) MM101383V1

DESCRIPTION MANUAL NUMBER

OPTIONS AND ACCESSORIES

Electrostatic Discharge Protection LBI-38737

Antenna Systems Assembly Manual LBI-38983

Standard for Site Grounding and Protection LBI-39067

Duplexer Maintenance Manual LBI-38763

Base Station Power Supply Maintenance Manual (19D149978) LBI-38550

Base Station Power Supply Maintenance Manual (19D149979) LBI-38551

Emergency Power (Battery Charger) Maintenance Manual LBI-38625

AC Outlet Strip Maintenance Manual LBI-4841

Blower Kit Maintenance Manual LBI-4842

MASTR III Fuse Panel (12/24 Volt) Maintenance Manual LBI-30246

GETC Trunking Shelf Installation and Configuration Manual AE/LZB 119 2905/1

MASTR III Back-to-Back Repeater Configuration Manual LBI-39118

Conventional MASTR III Voice Guard Options Installation Manual AE/LZB 119 2905/2

Voice Guard System Manual LBI-31600

Voice Guard Interface Board Maintenance Manual LBI-38882

TEST AND DIAGNOSTICS

RF Module Test Fixture (TQ0650) - Model 344A4153P1

- Model TS101285V11

LBI 38805

MM101885V1

MASTR IIe Utility Handset Manual LBI-38599

MASTR III Programming Guide TQS3353 MM102518V1

MASTR III DSP Module Programming Guide TQS3413 MM102533V1

16

Page 17

4.2 OPTIONS

The MASTR III Conventional Base Station is available in the following frequencies and may be

combined with the options listed.

MM102554V1 REV B

MODEL

NUMBER

SXGPNX 136-150.8 MHZ, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC) P25,

110W

SXHPNX 150.8-174 MHZ, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC) P25,

110W

SXGMCX 136-150.8 MHZ, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC),

110W

SXHMCX 150.8-174 MHZ, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC),

110W

SXRMCX 403-425 MHZ, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC), 90W

SXPMCX 410-430 MHZ, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC), 90W

SXTMCX 425-450 MHZ, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC), 90W

SXUMCX 450-470 MHz, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC), 100W

SXVMCX 470-494 MHz, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC), 90W

SXWMCX 492-512 MHz, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC), 90W

SX8MCX 800 MHZ, CONVENTIONAL ADVANCED DIGITAL CAPABLE (ADC), 100W

DESCRIPTION

OTHER OPTIONS

CABINETS & FANS

SXCA1D 69" CABINET

SXCA1U 83" CABINET

SXCA1S 37" CABINET

SXMR1D 86" OPEN RACK

SXCA1X 45" OUTDOOR CABINET

SXFN1A 2-SPD FAN, 120 VAC. (Must be included when installing more than 1 repeater in a 69"

or 83" cabinet)

SXFA1L 2-SPD FAN, 230 VAC. (Must be included when installing more than 1 repeater in a 69"

or 83" cabinet)

SXFA1N 2-SPD FAN, 12 VDC. (Must be included when installing more than 1 repeater in a 69"

or 83" cabinet)

17

Page 18

MM102554V1 REV B

MODEL

NUMBER

POWER SUPPLIES

SXPS5G POWER SUPPLY, 120 VAC, 60 HZ, 12 VDC, 33A. For UHF applications.

SXPS5H POWER SUPPLY, 230 VAC, 50 HZ, 12 VDC, 33A. For UHF applications.

SXPS5S POWER SUPPLY, 120 VAC, 60 HZ, 12/24 VDC, 33A. For 800 MHz and VHF

applications

SXPS5Y POWER SUPPLY, 230 VAC, 50 HZ, 12/24 VDC, 33A. For 800 MHz and VHF

applications

SXCN1Z OUTLET STRIP. 120 VAC

SXCN3H OUTLET STRIP, 230 VAC

PROGRAMMING

TQS3353 MASTR IIE/MIII PROGRAMMING SOFTWARE, Provides capability of changing

radio's functions and features. Includes TQ0619 Utility Programming Software.

TQ0653 MASTR IIE/MASTR III MSEDIT SOFTWARE

SPK9024 UTILITY HANDSET

DESCRIPTION

TQS3413 DSP MODULE PROGRAMMING SOFTWARE

TQ3356 MASTR IIE/MIII PROGRAMMING CABLE

18

Page 19

5. SITE PREPARATION

5.1 INTRODUCTION

Before you install a MASTR III ADC Base Station, you need to prepare your site. Consider the

installation of the antenna system, space requirements, and weight. These issues are addressed in this

chapter.

This chapter is divided into the following sub-sections:

• Facility Preparation

• Power Installation

• Inter-Site Communication

• Protective Grounding

• Antenna System

• Power Up Sequence

MM102554V1 REV B

5.2 FACILITY PREPARATION

This section provides information for preparing the facility prior to receiving or installing the MASTR III

ADC Base Station equipment.

5.2.1 Floor Plan

When creating the floor plan for cabinet placement, ensure consideration is given to safety, lighting, fire

suppression systems, access to other equipment and storage facilities in the room, etc.

5.2.2 Equipment Cabinet Placement

Direct access (for antenna cables and personnel) between the tower and the equipment room is necessary

for installation purposes).

The equipment cabinet you plan to install should be in an area that is:

• A dedicated equipment room or closet, wired in accordance with local electrical codes

• Large enough to allow easy access for service and maintenance

• Free of dust, smoke, and electrostatic discharge

• Properly ventilated

• Well lighted

The recommended aisle spacing is 29.5 in. (750 mm).

NOTE

19

Page 20

MM102554V1 REV B

5.2.3 Ceiling Requirements

Consider the following ceiling requirements before you install the equipment cabinet:

• The ceiling should be clear of obstructions such as beams, heating and air conditioning ducts, water

pipes, and lights.

• The ceiling should not have sprinklers; however, appropriate fire protection devices should be

available.

5.2.4 Size and Weight Considerations

Before you install the equipment at your site, make sure that the equipment room can accommodate the

size and weight of the cabinet and the MASTR III ADC Base Station. To determine the total weight, add

the weight of the radio system (about 150 lbs, 68 kg for each radio system), and the weight of the rack.

Typical equipment size and weight is listed in the Specifications section. For the specific weight of

individual units or optional equipment, you should refer to the applicable maintenance manuals or product

Data Sheets.

5.2.5 Operating Environment

The equipment room or area where the MASTR III ADC Base Station is installed must meet the

environmental conditions listed in the Station Specifications section of this manual. In addition, the site

grounding must conform to the requirements of the Standards for Site Grounding and Protection manual

AE/LZT 123 4618/1.

Although the temperature requirements for individual components may be broader, when several units are

assembled together in a cabinet more heat is generated. Because of this condition, the ambient room

temperature outside the cabinet must be lowered to ensure the temperature inside the cabinet does not

exceed the limits for the equipment.

5.3 POWER INSTALLATION

In all cases where the customer provides a single AC supply input to a site, for AC or DC systems, the

input must be protected with a Joselyn AC protector, or equivalent. The AC Protector is installed after

the disconnect switch and must be connected to the external ground system.

If the AC supply is provided from wall outlets, the fuse panel breaker for the room must be sized for the

load of the proposed equipment that is to be installed in the site.

5.3.1 Existing Input Power

If the site already has an existing input power source, then the installers and a certified electrician should

ensure the power meets site requirements and is equipped with the necessary breakers to conform to both

design and local regulatory standards.

If the site input power source does not meet the site requirements or is not equipped with the necessary

breakers to conform to both design and local regulatory standards, refer the matter to the Site Manager.

20

Page 21

MM102554V1 REV B

5.3.2 AC Distribution

If the site requires an AC distribution system to be installed, ensure it installed by qualified installers in

agreement with the customer. The Applications Engineer will provide the Site Manager with drawings

containing the installation requirements.

Ensure the input supply is isolated and power is not applied until the installation is complete.

5.3.3 Generator System

If the system already has a backup generator system providing backup supply to the site, inspect and test

the generator as defined in the equipment manuals.

Sites equipped with generator systems will use a manual or an automatic transfer switch system. Inspect

the customer system to ensure that it is fitted with the appropriate transfer switch system. This is to be

inspected and tested as defined in the equipment manuals.

If a new generator system is being installed, ensure it is installed by qualified generator installers in

agreement with the customer. When installing generator system remote controls, ensure that the installer

thoroughly understands the application and necessary generator connections. The Applications Engineer

will provide the Site Manager with drawings containing the installation requirements.

5.3.3.1 Manual Transfer Switch

If a Manual Transfer Switch is to be installed, the same team who installed the generator should install the

transfer switch. If this is an additional or new feature, the system is to be modified by qualified engineers

in agreement with the customer. The Applications Engineer will provide the Site Manager with drawings

containing the installation requirements.

5.3.3.2 Automatic Transfer Switch

If an Automatic Transfer Switch is to be installed, the same team who installed the generator should

install the transfer switch. If this is an additional or new feature, the system is to be modified by qualified

engineers in agreement with the customer. The Applications Engineer will provide the Site Manager with

drawings containing the installation requirements.

5.3.4 AC-DC Supply

If the system already has an AC-DC conversion system that meets the system requirements, then inspect

and test the system as defined in the equipment manuals.

If the site requires an AC-DC conversion system to be installed, this is to be performed by qualified

installers in agreement with the customer. The Applications Engineer will provide the Site Manager with

drawings containing the installation requirements.

The system will normally include input circuit breakers, a rectifier stage, converters and individual output

circuit breakers. These components will have their voltage and/or current specified on the site design

drawings. Ensure that input supply is isolated and not re-apply power until installation is complete.

21

Page 22

MM102554V1 REV B

5.3.5 Battery Backup

A Battery backup system is normally installed to ensure smooth supply voltages during normal operation

or in the event of an input power failure.

If the site already has a battery backup system that meets the system’s requirements, then inspect and test

as defined in the equipment manuals.

The battery backup system will normally be a battery cell system. The backup battery system capacity

should be sufficient to provide the radio system with the desired voltage for a specified time. This should

also include power needed for the inverter equipment, input and output breakers, and either manual or

automatic switches to switch the system into circuit. The installation requirements will be in the site

design drawings agreed to by the customer and Application Engineer.

5.3.6 UPS

An Uninterruptible Power Supply (UPS) system may be an alternative to other backup supply options. It

may comprise some or all of the following components:

• Input supply and protection

• Various DC outputs (additional equipment that is required)

• Output protection

• Battery backup

• Bypass switch

• Automatic switch-over to generator

If the site already has an UPS system that meets the system requirements, then inspect and test the UPS as

defined in the equipment manuals.

If the site requires an UPS system to be installed, ensure the installation is made by a qualified installer in

agreement with the customer. The Applications Engineer will provide the Site Manager with drawings

containing the installation requirements.

5.3.7 Electrical Power

5.3.7.1 AC Power

Each MASTR III cabinet is equipped with its own AC power cord. Each of these power cords should be

connected to a separate circuit breaker. The following circuit breakers are recommended.

• 115 VAC (60 Hz) - a 20-amp circuit breaker for each power cord.

• 230 VAC (50 Hz) - a 15-amp circuit breaker for each power cord.

Receptacles must be installed within reach of the power cords and should be individually fused. They

may be installed on the wall behind the cabinets, in the floor under the cabinets, on the cable ladder above

the cabinets, or in the cabinet top cable ducts. The power cords must not be installed such that they cause

a hazard to persons in the site.

AC Power Installation must conform to local Installation Regulations.

22

Page 23

MM102554V1 REV B

5.3.7.2 DC Power

When required, DC power options are available, but will be customized for the particular system. The

power supplies will be omitted from the cabinets and replaced by a fused DC panel. In this case, power

must be supplied to the repeaters from an external 13.8 or 24 VDC power source through a separate 30amp circuit breaker for each repeater.

The supply system will normally consist of an AC to DC converter, a Circuit Breaker Panel and various

DC-DC Converters sized for the equipment. DC feeds to the equipment that will be direct from the circuit

breaker panel.

5.3.7.3 Generators

Some systems, predominately remote sites, will require emergency generators with automatic switchover

systems. The generators must be connected to the external site grounding system and should be located

external to the equipment room.

Automatic switchover systems must be disabled during installation.

5.3.7.4 Battery Backup

Some systems will require a battery backup connected to the supply system in case of input power failure.

The battery bank should be located either separate from the equipment room or within the room but at a

point furthest from the entrance. It should have a separate fume extraction system or should be located

below the air extraction system for the site.

5.4 INTER-SITE COMMUNICATIONS

There are various types of Inter-Site Communication Systems, which require interfaces to be pre-installed

within the site. These interfaces will be the agreed demarcation points to which the Customer, SubContractor and system installer will make connections.

There are three types of inter-site connections:

• Hardwire Installation

¾ Direct Connection

• Leased Line

¾ Leased or Dedicated Telephone Line

• T1 or E1

¾ Leased T1 or E1

¾ Microwave

¾ Fiber Optic Cable

5.4.1 Hardwire Installation

When the media specified is to be Hardwire, that is point-to-point wiring on-site, the following

specifications apply:

23

Page 24

MM102554V1 REV B

• Audio: 2-wire or 4-wire shielded cable; screen connected to site ground system and cable core is to be

solid in order that it may be punched-down.

• Data: Shielded twisted pair, shield connected to site ground system and cable core is to be solid in

order that it may be punched-down.

5.4.2 Leased Telephone Lines

When the media specified is to be Leased-Line via the local telephone company, request a 4-Wire 43202

Type 5 Data-Grade line from the local or regional telephone carrier. If using an equivalent line (old

specification is 3002 Data Grade), it must meet the following specifications:

• Frequency response:

1000 Hz Reference

500 - 2400 Hz -1 to +3 dB

300 - 2700 Hz -2 to +6 dB

• Max Frequency Error = ±5 Hz

• Max Net Loss = 16 dB

• Max Group Delay (800-2400Hz) = 2000µS

• Min S/N Ratio = 24 dB

The Telephone Company or customer will provide a point of interface for the telephone system within the

site known as the Demarcation Point. The installer will make necessary connections between the

Demarcation Point and the equipment

5.4.3 T1 or E1 Links

A T1 or E1 link may be leased from the Local or Regional Telephone Carrier. The physical link may be

via a Microwave System or via Fiber Optic cable. The Microwave or Fiber Optic system may also be

provided by the customer or sub-contracted from an alternate provider.

5.4.3.1 Leased T1/E1

If the link is Leased-Line T1 or E1, the carrier may provide the Multiplex (Mux) equipment and Channel

Service Unit (CSU). If so, they will connect to an agreed Demarcation Point (Punchblock) and collect the

data and modem audio as appropriate. If they do not provide the Mux or CSU, a Mux and CSU will be

provided and the demarcation point will be the appropriate T1/E1 interface on the Mux or CSU.

5.4.3.2 Microwave

The Microwave system may be provided by the Customer, M/A-COM, or a Sub-Contractor. Whichever

is the case, the Inter-Site Communications System should be in place prior to equipment installation and

the system provided will have a Demarcation Point to which the installer will connect the Inter-Site

Communications. This may be Punchblocks or the input connection to the multiplexer and the length of

the cross-connect cabling must be calculated to allow for the agreed location of the interface.

It is normal for the microwave radio to be close to its antenna and, in some installations, this may mean

some distance between radio and multiplexer. If the distance between radio and multiplex equipment is

excessive, consideration must be given to type of cable used for the connection, cable shield/ground,

24

Page 25

grounding through in-building cable routes, etc. This subject is to be discussed with microwave provider

and must conform to local installation regulations.

5.4.3.3 Fiber Optic

It is a requirement that the demarcation point for fiber optic cable is the fiber optic interface on the

multiplexer. If the multiplexer is not equipped with such an interface, a fiber optic line driver will be

provided and will be the point to which the cable is to be connected.

All other considerations are as for Microwave.

5.5 PROTECTIVE GROUNDING

For information on protective grounding outside the equipment room and general information for internal

grounding refer to the Site Grounding and Lightning Protection Standard manual AE/LZT123 4618/1.

However, a general rule for the external grounding system is that the resistance to ground should be five

(5) ohms or less, as measured with a Biddle DET2/2 Megger or equivalent, per IEEE STD 81-1983 or

local equivalent.

All equipment that is within the site must be connected to an internal halo ground of No. 2 AWG copper

wire six (6) inches below the ceiling. This interior halo ground must be connected to the external ground

system at each corner, using separate No. 2 AWG copper wires. The halo may be mounted on the cable

ladder, in the ducting or beneath the false floor.

MM102554V1 REV B

All metal (electrically conductive) objects within the equipment room must be grounded. These objects

are divided into the following three (3) groups.

• Room Fixtures

• Power Supply

• RF equipment

All metallic fixtures and room parts, such as doorframes, sheet metal, ventilation louvers, air conditioning

units, light fixtures, etc., should be connected to the internal halo ground.

In addition to all other AC power protection, the AC power must be equipped with a Jocelyn AC

protector, or equivalent, placed immediately after the main disconnect switch. This protector must be

connected to the external ground system using a separate No. 2 AWG copper wire.

All equipment cabinets, cable trays, and protectors for cables connecting to this equipment must be

connected to a single grounding plate or bulkhead panel mounted on the wall where the antenna cables

enter the equipment room. This grounding plate must be connected to the external ground system using

two (2), two-inch wide copper strapping, or equivalent. A separate No. 6 AWG copper wire must be used

for each cabinet, each cable tray/ladder, and each group of cable protectors.

A few general rules of thumb are as follows:

• Make ground wires as short as possible and direct as possible - avoid bends if possible - absolutely no

bends with a radius of less than eight (8) inches.

• Surface area of ground wires is more important than cross sectional area.

• All connections must be clean, free of non-conductive coatings, and be coated with an anti-oxidant.

25

Page 26

MM102554V1 REV B

5.6 ANTENNA SYSTEM

This section covers installing the antenna system, including RF cables from the antenna to the equipment

room wall feed through connector.

Refer to LBI-39185 for Tower Requirements and General Specifications.

NOTE

Crews trained and equipped for working on antenna towers generally install antenna systems. As a result,

this manual assumes crews with the specialized equipment and skills required for working on towers and

installing the antenna cables will install the Antenna Systems. However, it may be necessary for the

system installer to provide information and directions to the crew installing the antenna system and to

verify proper installation.

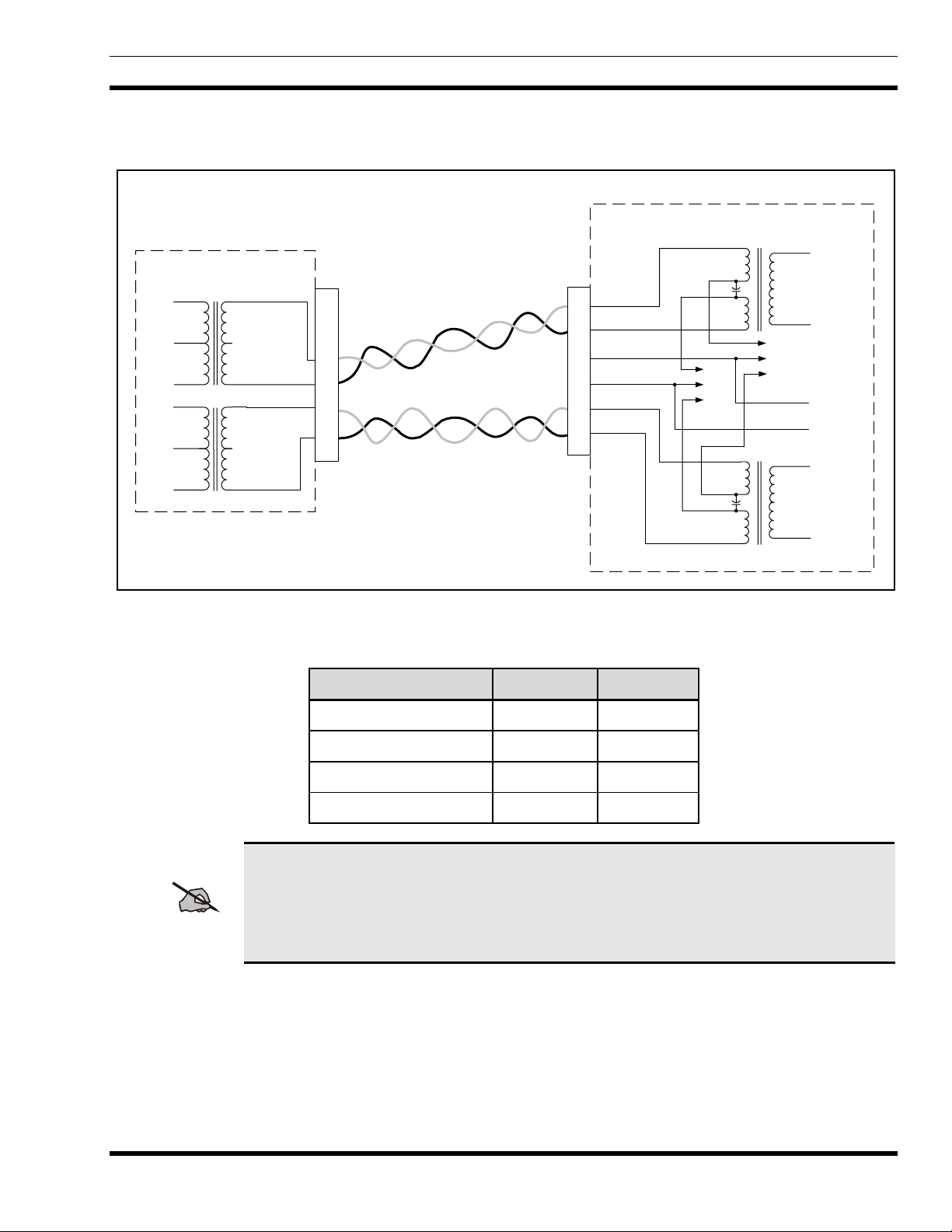

5.6.1 Antenna Mounting

The antennas must be installed on the tower in such a way as to ensure that there is at least 25 dB of

separation between the TX and RX antennas. This is necessary to avoid interference in the receivers

caused by the transmitters. An isolation of greater than 25 dB is easily obtained by placing one antenna

directly above the other on the tower (minimum 10-foot separation).

26

Page 27

MM102554V1 REV B

Figure 5-1: Antenna System Requirements

5.6.2 Transmission Lines

When installing the transmissions lines, refer to the block diagram for UHF and 800 MHz Antenna

Systems contained in LBI- 38983.

5.6.2.1 Length

The length of the main coaxial cable for each antenna should be planned as a continuous run with no

connectors or splices between the antenna and the equipment room. Each cable includes a 50-foot

allowance for the distance from the bottom of the tower to the equipment room. Smaller diameter, more

flexible coaxial cables are used at both ends of the main coaxial cable to facilitate installation.

27

Page 28

MM102554V1 REV B

5.6.2.2 Minimum Bending Radius

Always adhere to the minimum bending requirements provided by the manufacturer. For Andrew

Products, the values are:

CABLE SIZE BENDING RADIUS

1/4-inch 1-inch (25 mm)

1/2-inch 1.25-inch (32 mm)

7/8-inch 10-inches (250 mm)

1 5/8-inch 20-inches (510 mm)

5.6.2.3 Hoisting Grips

Hoisting grips provide the means to attach a lifting mechanism to the coaxial cable without damaging the

cable. Each hoisting grip is capable of safely lifting 200 feet of cable without causing damage.

Therefore, one hoisting grip is required for every 200-foot section of cable. The grips may be left

attached to the cable after the cable installation is completed.

Some situations may require more hoisting grips, such as:

• When installing cables on a tower mounted on top of another structure.

• When installing a cable whose length is greater than the height of the tower.

In these situations, additional hoisting grips should be ordered.

5.6.2.4 Hangers and Adapters

Coaxial cables on the tower should be secured at intervals of 3-5 feet (maximum).

Securing 7/8-inch and 1-5/8-inch diameter coaxial cables is accomplished by using either hangers or

hanger-adapter combinations. The hangers secure the cables to the tower structure by using prepunched

holes or attachment adapters.

• When the tower structure is prepunched with 3/4-inch holes, snap-in hangers are used (preferred

method).

• When the tower is prepunched with 3/8-inch holes, the hanger is secured by a 3/8-inch bolt.

For towers without prepunched holes, the hangers are attached with adapters. The type of adapter

depends on the type of tower structure. Adapters are available for either angle tower members or round

tower members.

Adapters for each antenna system are selected when ordering the system. If the coaxial cable must be

attached to a structure that is not compatible with any of the above hangers or adapters, then additional

materials or other special considerations may be required

To secure 1/4-inch or 1/2-inch vertical or horizontal coaxial cables of any size, use nylon cable ties.

28

Page 29

5.6.2.5 Weatherproofing

A kit of weatherproof tape is provided to protect coaxial connectors from the outside elements. One roll

of tape is sufficient to weatherproof four exposed outside connector joints.

5.7 QUALITY AUDIT

5.7.1 Antenna System

After the Antenna System is installed, it should be inspected before the installers leave. A checklist of

tasks performed on the antenna system is provided in section 12.3. Be sure to complete this visual

inspection before

Using field glasses, if necessary, view the Antenna System from various positions on the ground. Using

copies of the Antenna System Installation Checklist 12.3, fill out a checklist for each antenna as you go

through the following inspection procedure. This will provide a record of the inspection, and of some

antenna information for future reference.

• Record the make of antenna.

• Record the type of antenna (omni or directional).

the installers leave, so any obvious errors can be corrected.

MM102554V1 REV B

• Record the design gain of the antenna.

• If the antenna is directional, record the bearing of the main lobe. If it is omni, write "Omni" in the

data entry line.

• Record the height of the antenna above ground.

• Confirm that cable-hoisting grips were installed as required to prevent damage to the coaxial cable.

Hoisting grips should have been installed at the antenna end of the cable plus one for each 200 feet of

cable length.

• Confirm the cable is secured to the tower at intervals, which do not exceed 3 feet.

• Confirm the cable is grounded at the top of the tower.

• Confirm the cable is grounded at the point where it leaves the tower.

• Confirm the cable is grounded at the point where it enters the building.

• Confirm the coaxial cable run looks OK. The cable must be tight (nothing to flap in the breeze), have

no kinks, is one continuous run (no connectors or splices), and not exceed the minimum-bending

radius on any bend.

• Confirm the cable feed through is properly installed where the cable enters the building.

• Confirm the coaxial connectors have been properly weather sealed with tape.

• Confirm the cable entrance to the building has been properly weather sealed.

29

Page 30

MM102554V1 REV B

5.7.2 Electrical System

If the electrical supply system has been installed by other than the company, it must be inspected to

ensure that it is safe and complies with both local regulations and the requirements of the site. Complete

the Power System Installation Checklist found in section 12.5, as required.

• Confirm that the supply system is rated to handle the full operating load of the equipment.

• Confirm that all outputs to which the site equipment will be connected have suitably rated breakers

installed.

• Confirm that electrical cabling to the equipment is correctly rated, installed and meets local

regulations.

• Confirm that the system is correctly grounded.

• Confirm that cables, bus bars and associated equipment are not a hazard to installers or maintenance

teams.

• Confirm that manuals for the supply system have been provided at the site.

30

Page 31

6. EQUIPMENT INSTALLATION

6.1 INTRODUCTION

AC power adequate to meet system requirements, environmental control, civil works and

site preparation, and digital or voice grade phone lines must be available at the site prior

NOTE

WARNING

to installation.

DO NOT apply power at this time!

During installation, all circuit breakers must be left in the OPEN position. Make sure all

equipment circuit breakers are in the OPEN position.

To prevent damage to equipment, ensure power is not accidentally applied at this time.

MM102554V1 REV B

This chapter is divided into the following sub-sections:

• Unpacking the Equipment

• Equipment Installation

• Interior RF Cabling

• Connecting Electrical Power

• Quality Audit

6.2 UNPACKING EQUIPMENT

Station equipment is generally packed in one of the following ways:

• Bolted vertically to a mini pallet approximately 36” deep x 32” wide, with a corrugated cardboard

cover held down with two plastic straps. This technique is generally used for domestic shipments.

The mini pallet adds approximately three inches to the overall cabinet height. The weight varies

according to the content, but generally runs from 300 pounds to 600 pounds.

• Crated vertically or horizontally. This technique is generally used for open-racked equipment and

overseas shipments of 69-inch and 83-inch cabinets. Crates may contain one or several cabinets or

racks, and the dimensions and weight will vary accordingly. If size and weight limits are required,

contact the factory for special packing instructions.

Cabinets packed on mini pallets can be moved with a hand-truck, crates may need a forklift or pallet jack,

depending on the size. Wrenches will be needed to unbolt the cabinets from the mini pallets, and a

crowbar and hammer will be useful in opening the crates. Do not leave packed or unpacked equipment

exposed to the weather.

Upon receipt of the station equipment, carefully examine each carton. If any packaging damage is

detected, note the damage on the Bill of Lading.

31

Page 32

MM102554V1 REV B

Move the cartons as close as possible to their mounting location.

Carefully unpack the equipment and examine each item. If there is any damage to the equipment, contact

the carrier immediately and have their representative verify the damage. If you fail to report the shipping

damage immediately, you may forfeit any claim against the carrier.

When unpacking the equipment, check the contents against the packing list. Contact your M/A-COM

representative and the carrier if any discrepancies are noted.

Carefully open each cabinet and inspect the contents to ensure that enclosed equipment has not been

damaged during delivery. If damage has occurred, note details of the damage and, if necessary, contact

the carrier immediately and have their representative verify the damage. Contact your M/A-COM

representative if the damage is such that installation cannot proceed.

6.3 EQUIPMENT INSTALLATION

Refer to AE/LZT 123 4618/1 for Site Grounding and Protection Standards.

NOTE

These procedures are for M/A-COM standard installations. If the system is nonstandard, installation procedures may differ. In this event, installers should consult with

NOTE

M/A-COM.

• This section provides instructions for installing the RF Equipment and for running the necessary RF

cables to the equipment room wall TX and RX feed through connectors.

6.3.1 Mounting Vendor Supplied RF Equipment

RF Equipment used for interfacing the Antenna System to the Repeaters may be pre-racked by M/ACOM or dropped shipped from the individual vendors directly to the customer. If the RF equipment is

supplied directly from the vendor, it will be necessary to install the equipment into the RF Equipment

Cabinet.

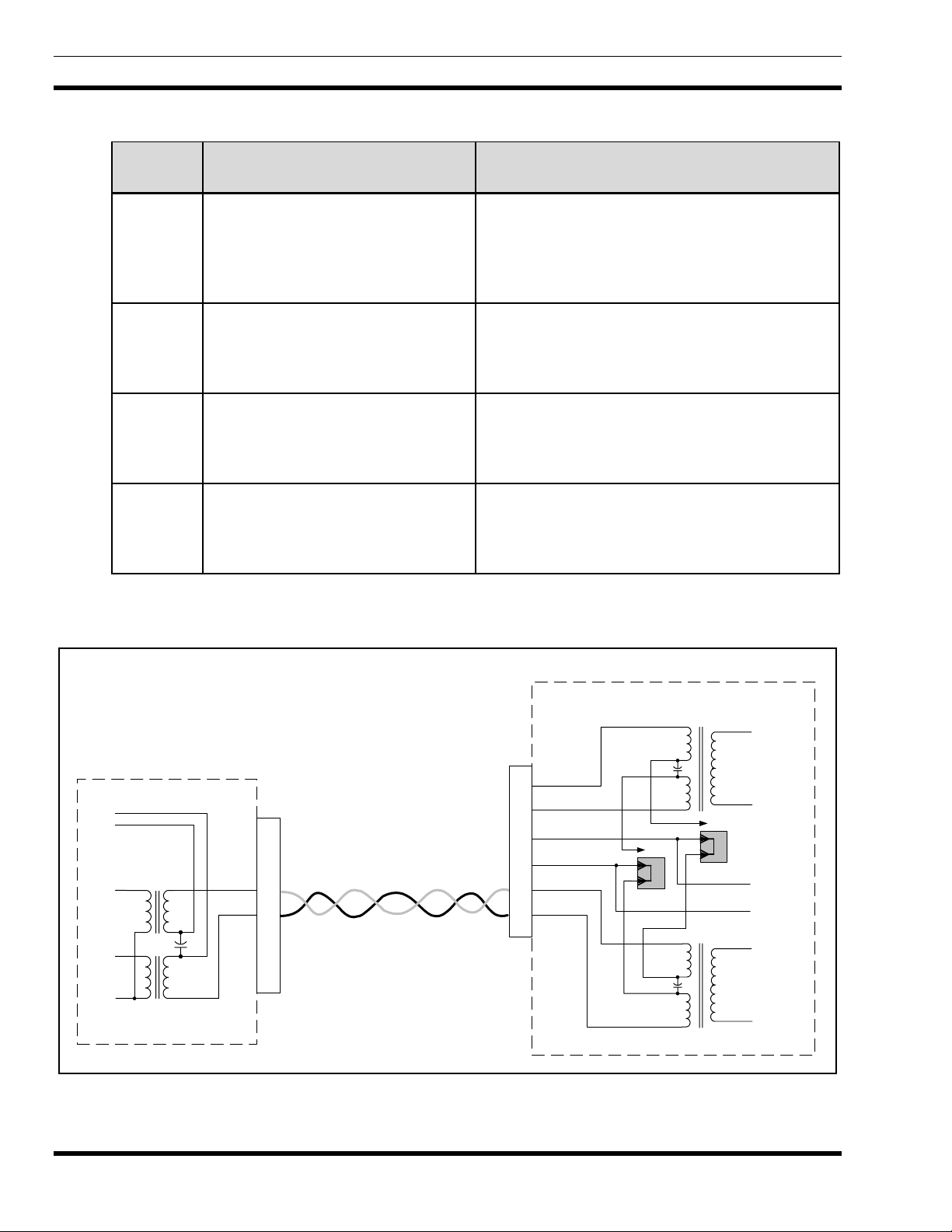

The system is designed to use either a Tower Top Amplifier or a Receiver Filter. When a

NOTE

Tower Top Amplifier is used, the Receiver Filter is not required.

32

Page 33

MM102554V1 REV B

RX SURGE PROTECTOR IS-DC50LNZ-MA

Suffix: -MA for male connector bulkhead port (not

threaded like female shown)

Figure 6-1: Surge Protectors

WALL

FEEDTHRU

RF CABLE

TO ANTENNA

WALL

1/2" SUPERFLEX

JUMPER

TX SURGE PROTECTOR IS-CT50HN-MA

Suffix: -MA for male antenna port (not threaded like female

shown)

GROUNDED

BULKHEAD PANEL

RF CABLE

FROM

EQUIPMENT

CABINET

SURGE PROTECTOR

IS-DC50LNZ

Figure 6-2: Typical Mounting of the RX Surge Protectors

1. Install the vendor supplied RF equipment into the RF Equipment cabinet.

2. Secure each component to the cabinet using standard mounting screws and clips that come as part of

the cabinet hardware kit.

3. Mount the Receive Surge Protector (IS-DC50LNZ-MA), if not previously installed, to the grounded

bulkhead panel, located at the wall feed through where the antenna system enters the building. Other

installers (refer to Surge Protector Diagrams in Figure 6-1 and Figure 6-2) should have already

installed this panel.

33

Page 34

MM102554V1 REV B

4. Mount the transmit surge protector (IS-CT50LNZ-MA) to the grounded bulkhead panel, located at

the wall feed through where the antenna system enters the building. Installers should have already

installed this panel. (Refer to Surge Protector Diagrams in Figure 6-1 and Figure 6-2)

5. Install Top Cover (if cabinet).

6.3.2 Mounting Base Station Cabinet (Typical)

The following tools and materials are typically needed to fasten the cabinets to concrete floor (if installing

on wood flooring - do not use lead anchors):

• ½" x 2" Lag screws (4 per rack)

• 1/2" Flat washers (4 per cabinet/rack)

• Lead anchor for 1/2" lag screws (4 per rack)

• Measuring tape

• Heavy-duty marker (suitable for marking coarse concrete)

• Eye protection

• Ear protection

• Drill with masonry bit (see size marked on anchor)

• 1/4" x 24" Flexible plastic tubing (blow debris out of hole)

• Hammer (seat anchor in hole)

• Wrench (screw lag screw into anchor)

The following additional hardware is supplied with each optional open-rack. The hardware enables the

installer to fasten adjacent side rails together at the top and bottom:

• 3/8" x 1 1/2" Hex machine screws (2 per open-rack)

• 3/8" Hex nut (2 per open-rack)

• 3/8" Flat washers (4 per open-rack)

• 3/8" Lock washer (2 per open-rack)

The RF Equipment cabinet(s) should be located at a point nearest the RF Bulkhead, where the antenna

cables enter the building. This allows the antenna cable lengths to be minimized.

Position the cabinet(s) on the floor exactly where they are to be mounted. Allow one (1) meter (3 feet) of

free space in front of and behind each cabinet, to allow the cabinet doors to swing completely open. Also

allow one (1) meter (3 feet) of free space around at least one end of each row of cabinets, to get to the

back of the cabinets.

Mark the position of the mounting bolt holes on the floor using the four holes in the bottom of each

cabinet as a template. Move the cabinets, drill the holes in the floor for the screw anchors, seat the

anchors in the holes, reposition the cabinets, and fasten the cabinets down with lag screws (use a flat

washer under each lag screw head, to prevent damage to the cabinet).

34

Page 35

6.4 INTERIOR RF CABLING

Some RF coaxial cables may be pre-made and included with the system. However, most cables must be

custom made, on site, to the required length. Table 6-1 lists the cables and associated connectors, which

are typically fabricated at the site.

The coaxial cable and connectors are supplied in bulk. To cut the cable properly for easy connector

attachment, use an Andrew's "EASIAX" coaxial cable cutting tool (or equivalent).

When installing the RF or power cables, refer to the Antenna System Block Diagrams in LBI38983 and the Application Assembly Diagrams in technical manual MM102556V1 for in

NOTE

installation instructions.

6.4.1 Cable Routing

If cabinet-top cable ducts are supplied, install per LBI-38875 using the hardware provided. However,

leave the duct covers off until the site wiring is complete. These cable ducts are not available for opentype equipment racks.

MM102554V1 REV B

Larger systems should make use of cable ladders for ease of installation and maintenance. It is preferable

that dual ladders be used for large systems such that audio and data may occupy one level of the ladder

and RF and power occupy the other. If dual systems are not available, ensure maximum separation

between Audio/Data runs and RF/Power runs.

Install as shown on the site plans and install all grounding leads across ladder section connections.

6.4.2 Install RF Cables

Assemble and install the RF coaxial cables. Be careful not to exceed minimum bend radius (refer to Site