Page 1

Installation and Product Safety Manual

MM-011712-001

Mar/07

CS-7200, SP-103, and TRCM-103

Control Station, Desk Set, and

Tone Remote Control Module

Page 2

MM-011712-001

MANUAL REVISION HISTORY

REV. DATE REASON FOR CHANGE

— Mar/07 Original release.

M/A-COM Technical Publications would particularly appreciate feedback on any errors found in this document and

suggestions on how the document could be improved. Submit your comments and suggestions to:

Wireless Systems Business Unit

M/A-COM, Inc. or fax your comments to: 1-434-455-6851

Technical Publications

221 Jefferson Ridge Parkway or e-mail us at: techpubs@tycoelectronics.com

Lynchburg, VA 24501

CREDITS

M/A-COM, Inc. and/or Tyco Electronics may have patents, patent applications, trademarks, copyrights, or other intellectual

property rights covering subject matter in this document. Except as expressly provided in any written license agreement from

M/A-COM, the furnishing of this document does not give you any license to these patents, trademarks, copyrights, or other

intellectual property.

The software contained in this device is copyrighted by M/A-COM, Inc. Unpublished rights are reserved under the copyright

laws of the United States.

This device made under license under one or more of the following U.S. Patents: 4,590,473; 4,636,791; 5,148,482;

5,185,796; 5,271,017; 5,377,229; 4,716,407; 4,972,460; 5,502,767; 5,146,497; 5,164,986; 5,185,795

The voice coding technology embodied in this product is protected by intellectual property rights including patent rights,

copyrights, and trade secrets of Digital Voice Systems, Inc. The user of this technology is explicitly prohibited from

attempting to decompile, reverse engineer, or disassemble the Object Code, or in any other way convert the Object Code into

human-readable form.

OpenSky

Microsoft

Inc., GAI-TRONICS

Corporation.

®

is a registered trademark of M/A-COM, Inc.

®

and Windows® are registered trademarks of Microsoft Corporation, Zetron® is a registered trademark of Zetron,

®

is a registered trademark of GAI-Tronics Corporation, and WAGO® is a registered trademark of Wago

NOTICE!

This manual covers M/A-COM products manufactured and sold by M/A-COM, Inc.

Repairs to this equipment should be made only by an authorized service technician or facility designated by the supplier. Any

repairs, alterations or substitution of recommended parts made by the user to this equipment not approved by the

manufacturer could void the user’s authority to operate the equipment in addition to the manufacturer’s warranty.

M/A-COM recommends the buyer use only a M/A-COM authorized representative to install and service this product.

The warranties provided to buyer under the terms of sale shall be null and void if this product is installed or serviced

improperly and M/A-COM shall have no further obligation to the buyer for any damage caused to the product or to any

person or personal property.

This product conforms to the European Union WEEE Directive 2002/96/EC. Do not dispose of this

product in a public landfill. Take it to a recycling center at the end of its life.

This manual is published by M/A-COM, Inc. without any warranty. Improvements and changes to this manual necessitated by typographical errors,

inaccuracies of current information, or improvements to programs and/or equipment, may be made by M/A-COM, Inc., at any time and without notice. Such

changes will be incorporated into new editions of this manual. No part of this manual may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying and recording, for any purpose, without the express written permission of M/A-COM, Inc.

Copyright© 2007, M/A-COM, Inc. All rights reserved.

2

Page 3

MM-011712-001

TABLE OF CONTENTS

Page

1 SAFETY INFORMATION ..........................................................................................................................5

1.1 SAFETY SYMBOLS........................................................................................................................ 5

1.2 IMPORTANT SAFETY INSTRUCTIONS...................................................................................... 5

1.3 FCC REGULATIONS ...................................................................................................................... 6

2 INTRODUCTION......................................................................................................................................... 8

2.1 CS-7200 CONTROL STATION.......................................................................................................8

2.1.1 Voice Operation..................................................................................................................8

2.1.2 Data Operation...................................................................................................................9

2.1.3 Intercom Operation............................................................................................................9

2.2 SP-103 DESK SET ...........................................................................................................................9

2.3 TRCM-103 TONE REMOTE CONTROL MODULE...................................................................... 9

2.4 RELATED DOCUMENTATION.....................................................................................................9

2.5 TECHNICAL ASSISTANCE........................................................................................................... 9

3 UNPACKING AND CHECKING EQUIPMENT.................................................................................... 10

3.1 MATERIALS..................................................................................................................................10

3.2 MATERIAL INSPECTION............................................................................................................ 10

4 INSTALLATION ........................................................................................................................................ 12

4.1 REQUIRED TOOLS AND CONFIGURATION EQUIPMENT....................................................12

4.1.1 Tools Required..................................................................................................................12

4.1.2 Equipment Required for CS-7200 Configuration.............................................................12

4.2 LOCATING COMPONENTS ........................................................................................................12

4.3 CS-7200 INSTALLATION ............................................................................................................13

4.3.1 Rack-Mount and Desktop Mounting.................................................................................13

4.3.2 AC Power Connection......................................................................................................14

4.3.3 Fuse Replacement.............................................................................................................14

4.4 ANTENNA INSTALLATION .......................................................................................................15

4.4.1 General Information.........................................................................................................15

4.4.2 Coaxial Cable...................................................................................................................15

4.5 GROUNDING AND LIGHTNING PROTECTION FOR THE CS-7200....................................... 16

4.6 SP-103 DESK SET CONNECTION............................................................................................... 17

4.7 CONNECTING TO A TONE REMOTE CONTROLLER (OPTIONAL)...................................... 18

4.7.1 DIP Switch and Jumper Settings ......................................................................................18

4.7.2 Installation Configurations...............................................................................................21

4.7.3 Installing the TRCM-103 into the CS-7200......................................................................23

4.7.4 Connecting to the TRC .....................................................................................................24

4.8 CONNECTING THE CAN CABLE ............................................................................................... 26

4.8.1 SP-103 CAN Connections.................................................................................................26

4.8.2 Connecting via the CAN Bus Extender (Fiber Optic Cable Installations) .......................30

4.8.3 TRCM-103 CAN Connections...........................................................................................30

5 POWER-UP PROCEDURE....................................................................................................................... 31

6 CHANGING OPERATING MODE.......................................................................................................... 32

6.1 SP-103 METHOD........................................................................................................................... 32

6.2 PC RUNNING A TERMINAL APPLICATION METHOD........................................................... 32

7 LINE-LEVEL ALIGNMENT FOR A TRCM-103 EQUIPPED STATION ..........................................34

7.1 TRCM-103 TO TONE REMOTE CONTROLLER ........................................................................34

7.2 TONE REMOTE CONTROLLER TO TRCM-103 ........................................................................ 35

8 PROGRAMMING TONE FUNCTIONS TO MATCH TRC BUTTONS (OPTIONAL).....................36

8.1 EMERGENCY START ..................................................................................................................37

3

Page 4

MM-011712-001

TABLE OF CONTENTS

8.2 EMERGENCY STOP .....................................................................................................................37

8.3 PRESET ..........................................................................................................................................38

8.4 SAVING NEW PROGRAMMING.................................................................................................38

9 ANTENNA PERFORMANCE TESTS......................................................................................................39

9.1 REQUIRED TEST EQUIPMENT ..................................................................................................40

9.2 TRANSMITTING INTO A DUMMY LOAD.................................................................................40

9.3 TRANSMITTING INTO THE ANTENNA....................................................................................41

9.4 TEST PERFORMANCE DATA FORM .........................................................................................43

10 COMPLETE THE INSTALLATION .......................................................................................................44

11 WARRANTY...............................................................................................................................................45

FIGURES

Figure 4-1: CS-7200 Front Panel.........................................................................................................13

Figure 4-2: CS-7200 Rear Panel..........................................................................................................14

Figure 4-3: CS-7200 Fuse Replacement (Rear Panel Views) .............................................................15

Figure 4-4: SP-103 Front and Rear Panels ..........................................................................................17

Figure 4-5: DIP Switch and Jumper Configuration Label (Located on Bottom of TRCM-103) ........19

Figure 4-6: TRCM-103 Jumper and Switch Settings ..........................................................................20

Figure 4-7: TRCM-103 Configured as an Endpoint and Interfaced to One TRC ...............................21

Figure 4-8: TRCM-103 Configured as an Endpoint and Interfaced to Multiple Paralleled TRCs......22

Figure 4-9: TRCM-103 in the Middle of a Chain and Interfaced to Multiple Paralleled TRCs..........22

Figure 4-10: TRCM-103 Installation into CS-7200 and its External Interfaces..................................23

Figure 4-11: Connecting CS-7200 to the SP-103 via In-Wall/Plenum CAN Cable Connections.......28

Figure 4-12: Dimensions for Stripping 3-Wire CAN Cables ..............................................................29

Figure 4-13: 3-Position Terminal Strip Connections...........................................................................30

Figure 7-1: TRCM-103 Line-Level Adjustments................................................................................34

Page

TABLES

Table 3-1: CS-7200 Accessories .........................................................................................................11

Table 4-1: TRCM-103 Audio Interface Pin-Out (RJ-11 Modular Jack Labeled “AUDIO”) ..............24

Table 4-2: TRCM-103 to Zetron Model 280 2-Wire Line Interface Connections .............................25

Table 4-3: TRCM-103 to Zetron Model 280 4-Wire Line Interface Connections .............................25

Table 4-4: TRCM-103 to GAI-TRONICS Model ITR2000A 2-Wire Line Interface

Connections.......................................................................................................................25

Table 4-5: TRCM-103 to GAI-TRONICS Model ITR2000A 4-Wire Line Interface

Connections.......................................................................................................................26

Table 6-1: HyperTerminal Settings Required for Changing Operating Mode ....................................33

Table 8-1: Function Tone Frequencies................................................................................................36

Table 9-1: Required Test Equipment...................................................................................................40

4

Page 5

1 SAFETY INFORMATION

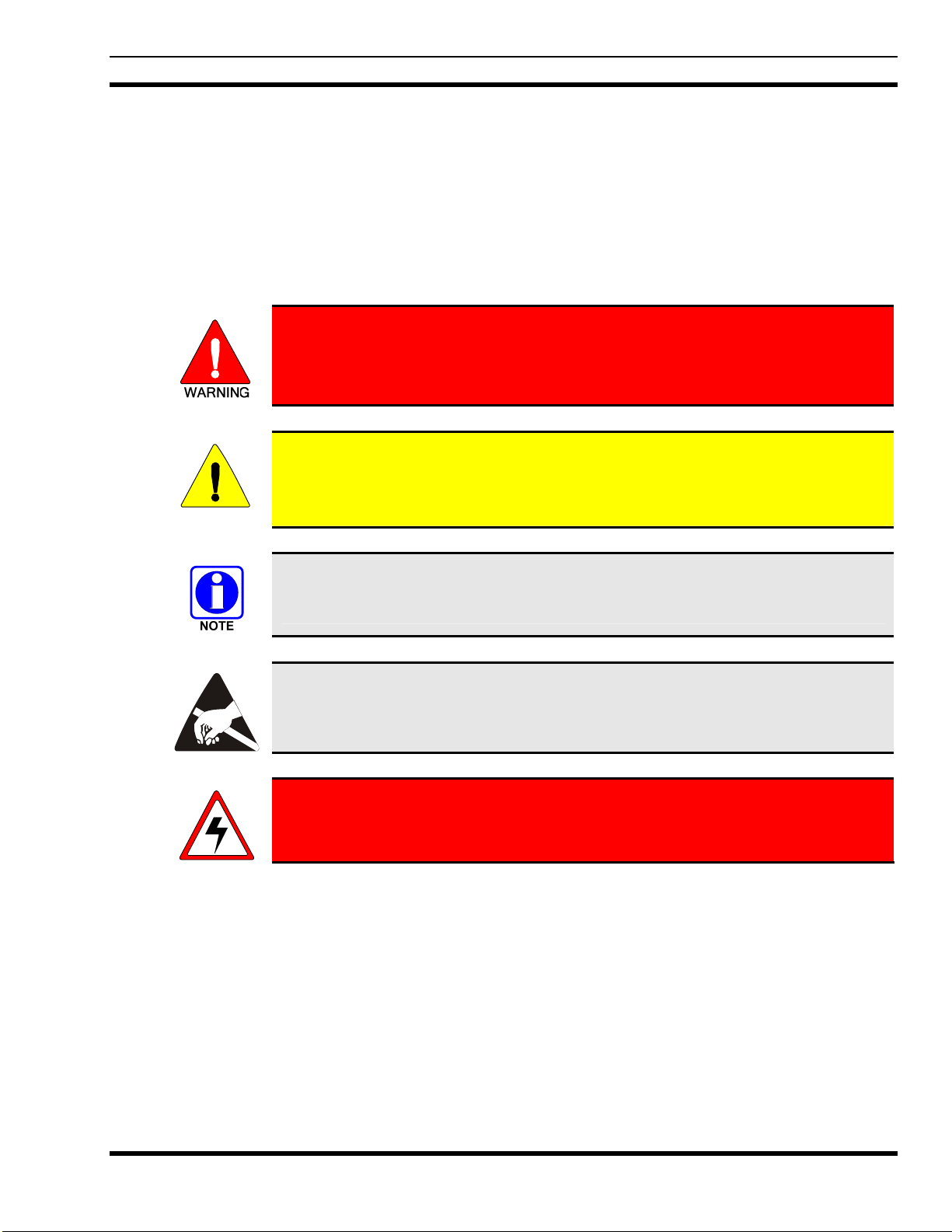

1.1 SAFETY SYMBOLS

The following conventions are used throughout this manual to alert the user to general safety precautions

that must be observed during all phases of operation, service, and repair of this product. Failure to comply

with these precautions or with specific warnings elsewhere violates safety standards of design,

manufacture, and intended use of the product. M/A-COM, Inc. assumes no liability for the customer's

failure to comply with these standards.

The WARNING symbol calls attention to a procedure, practice, or the like, which,

if not correctly performed or adhered to, could result in personal injury. Do not

proceed beyond a WARNING symbol until the conditions identified are fully

understood or met.

CAUTION

The CAUTION symbol calls attention to an operating procedure, practice, or the like,

which, if not performed correctly or adhered to, could result in damage to the

equipment or severely degrade equipment performance.

MM-011712-001

The NOTE symbol calls attention to supplemental information, which may improve

system performance or clarify a process or procedure.

The ESD symbol calls attention to procedures, practices, or the like, which could

expose equipment to the effects of Electro-Static Discharge. Proper precautions must be

taken to prevent ESD when handling circuit boards or modules.

The electrical hazard symbol is a WARNING indicating there may be an electrical

shock hazard present.

1.2 IMPORTANT SAFETY INSTRUCTIONS

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

5

Page 6

MM-011712-001

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including amplifiers) that produce heat.

9. Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has two

blades with one wider than the other. A grounding type plug has two blades and a third grounding

prong. The wide blade or the third prong is provided for your safety. If the provided plug does not fit

into your outlet, consult an electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched particularly at plugs, convenience

receptacles, and the point where they exit from the apparatus.

11. Only use attachments/accessories specified by the manufacturer.

12. Use only with the cart, stand, tripod, bracket, or table specified by the manufacturer, or sold with the

apparatus. When a cart is used, use caution when moving the cart/apparatus combination to avoid

injury from tip-over.

13. Unplug this apparatus during lightning storms or when unused for long periods of time.

14. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has been

damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled or

objects have fallen into the apparatus, the apparatus has been exposed to rain or moisture, does not

operate normally, or has been dropped.

15. Warning: The lightning bolt signifies an alert to the user of the presence of un-insulated “dangerous

voltage” within the product’s enclosure that may be of significant magnitude to constitute a risk of

electric shock to persons.

16. Warning: The exclamation point alerts the user to the presence of important operation and

maintenance (service) instructions in the literature accompanying the product.

17. Outdoor Use Warning: To reduce the risk of Fire or Electric Shock, Do Not Expose This Apparatus

to Rain or Moisture.

18. Wet Location Warning: Apparatus shall not be exposed to dripping or splashing and no objects

filled with liquids, such as vases, shall be placed on the apparatus.

1.3 FCC REGULATIONS

Use, installation and service of this equipment as summarized within this Manual will ensure the safe

performance of this equipment and will result in user exposure substantially below FCC recommended

limits for human exposure to Radio Frequency electromagnetic energy.

6

These devices comply with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) the device may not cause harmful interference; and (2) the device must accept any

interference received, including interference that may cause undesired operation.

Page 7

MM-011712-001

These devices are not required to comply with the FCC RF exposure limits for Uncontrolled Exposure

(General Population) and Occupational Exposure, because it is assumed that neither uncontrolled nor

occupational exposure is applicable in the general installation configuration. The CS-7200 must be

disabled before maintenance to the antenna is attempted.

The Federal Communications Commission (FCC) requires the user to obtain a station license for this

radio equipment before operation.

FCC regulations state that the frequency, deviation, and power of the radio transmitter must be

maintained within specific limits. It is recommended, therefore, that these three parameters be checked

prior to placing the station in service.

7

Page 8

MM-011712-001

2 INTRODUCTION

2.1 CS-7200 CONTROL STATION

The CS-7200 Control Station is a high-performance full-duplex dual-band digital radio control station. It

can operate on 700 MHz or 800 MHz OpenSky trunked radio networks using the OpenSky Trunking

Protocol (OTP). In the future, the station will also operate on 800 MHz Enhanced Digital Access

Communications System (EDACS) trunked radio networks, and 800 MHz APCO Project 25 phase I

compliant Common Air Interface (P25 CAI) trunked radio networks. Other future operating modes

include talk-around communications in accordance with the APCO Project 25 phase I standard, and

conventional FM repeater-based and FM talk-around voice communications in accordance with the

TIA/EIA-603 conventional land-mobile radio standard.

The CS-7200 is typically used for dispatch communications via a remotely-connected SP-103 Desk Set or

via a separately-supplied Tone Remote Controller (TRC). The CS-7200 is shown in Figure 4-1 and

Figure 4-2 on page 14, and the SP-103 is shown in Figure 4-4 on page 17. The CS-7200-to-SP-103

interconnection is performed via a Controller Area Network (CAN) link connections. The CAN link may

also employ an optional fiber optic-based CAN Bus Extender for increased distance separation between

the CS-7200 and the SP-103. CS-7200-to-TRC interconnection is performed via 2-wire or 4-wire line

audio connections.

The CS-7200 can operate as full-duplex radio frequency transceiver during data communications. Typical

full-duplex RF transmit output power is 10 watts. Typical half-duplex RF transmit output power is

15 watts.

700 MHz operating bands of the station include the two 3 MHz wide repeater output bands from 764 to

767 MHz and 773 to 776 MHz, and the two 3 MHz wide repeater input bands from 794 to 797 MHz and

803 to 806 MHz. The station can operate only on the narrowband channels within these bands. Transmit

output power is limited to 300 milliwatts on interoperability channels.

800 MHz operating bands of the station include the Specialized Mobile Radio (SMR) and the National

Public Safety Planning Advisory Committee (NPSPAC) radio frequency channels. This includes the 806

to 825 MHz repeater input band, and the 851 to 869 MHz band used for repeater output and talk-around

communications. These bands provide a total of over 830 possible channels spread over the

806 to 824 MHz mobile transmission and 851 to 869 MHz mobile reception bands.

The CS-7200 uses Time Division Multiple Access (TDMA) technology to allow multiple users to share a

single RF channel. In addition, a single 25 kHz RF channel can support simultaneous digital voice and

data communications.

The CS-7200 provides voice and data services in a dispatch operation. Voice operation is provided using

the SP-103 Desk Set or third-party Tone Remote Controllers (TRCs) interfaced via the TRCM-103. The

TRCM-103 is a field-installable option that is required when interconnecting the CS-7200 to one or more

TRCs. For data transfers, the CS-7200 and the SP-103 are equipped with an industry standard

TIA/EIA-232 serial interface port for connecting optional equipment such as a laptop PC or third-party

display or key-entry device. OpenSky works seamlessly with equipment from popular manufacturers and

off-the-shelf applications through standard User Datagram Protocol over Internet Protocol (UDP/IP) data

packet transfers, providing simple “plug and play” connectivity.

2.1.1 Voice Operation

8

The voice path operates like a traditional dispatch radio, with a microphone to transmit (push-to-talk) and

a speaker to receive. In OpenSky Trunked Protocol (OTP), there is no separate voice and data path—all

transmitted information is digital.

Page 9

2.1.2 Data Operation

Data operation requires the connection of a laptop PC or third-party display device. OpenSky works

through standard UDP/IP data packet transfers. The data path operates similarly to the voice path, with a

few differences. All external data information in and out of the radio uses the TIA/EIA-232 serial port

connection.

2.1.3 Intercom Operation

The optional intercom function allows communication between SP-103 Desk Set operators. Even when it

is activated, incoming network radio calls are still routed to the speaker in the SP-103 Desk Set. In other

words, radio calls are not muted when the Desk Set-to-Desk Set intercom function is active.

2.2 SP-103 DESK SET

The SP-103 Desk Set is part of the OpenSky suite of mobile radio products delivering high capacity endto-end digital communications. It provides remote access for voice, data, and control of the CS-7200

Control Station. See Figure 4-4 on page 17.

The SP-103 supports voice access to the radio via PTT (push-to-talk) microphones or headset

microphones/speaker devices. The SP-103 also provides an interface for a footswitch PTT in order to

support microphones/headsets that do not contain integral PTT switches.

MM-011712-001

The SP-103 has a 3 x 4 DTMF (Dual-Tone Multi-Frequency) keypad for log-on and selective calling

functions. The SP-103 contains an internal 10-Watt speaker and it is equipped with an external speaker

jack for connection of an external 10-Watt speaker. The serial port can be used for data operation.

2.3 TRCM-103 TONE REMOTE CONTROL MODULE

The TRCM-103 operates within the OpenSky network as part of a dispatch center in conjunction with the

CS-7200 Control Station and one or more third-party Tone Remote Controllers (TRCs). It provides

remote voice and control communication paths for the CS-7200. The TRCM-103 is a depot or fieldinstalled option. It mounts into a slot at the back of the CS-7200. It automatically detects one of five alert

tones and sixteen function tones with a 26 dB dynamic range. The audio interface utilizes a standard

RJ-11 port and is configurable for 2-wire half-duplex or 4-wire full-duplex operation. The audio

termination is selectable for either low impedance (600 ohms) or high impedance (6k ohms). These

features allow for easy integration with existing TRCs.

2.4 RELATED DOCUMENTATION

The following document contains additional information on the CS-7200, SP-103, and TRCM-103. This

document should be available for reference during the installation of this equipment.

• CS-7200, SP-103, and TRCM-103 Operator’s Manual MM-011709-001

2.5 TECHNICAL ASSISTANCE

Should the CS-7200, SP-103, or TRCM-103 require repair, or if you have questions or concerns about the

installation of this equipment, contact M/A-COM’s Technical Assistance Center (TAC) using the

following telephone numbers or email address:

• U.S. and Canada: 1-800-528-7711 (toll free)

• International: 1-434-385-2400

• Fax: 1-434-455-6712

• Email: tac@tycoelectronics.com

9

Page 10

MM-011712-001

3 UNPACKING AND CHECKING EQUIPMENT

3.1 MATERIALS

The CS-7200 Control Station, part number CT-011355-001, includes an AC Power Cord to connect it to

standard AC power (120 Vac, 60 Hz). No installation kit is available, as every installation is custom. The

CS-7200 is generally used in conjunction with the SP-103 Desk Set, both of which have accessories that

3.2 MATERIAL INSPECTION

can be installed. Table 3-1 lists available accessories.

The CS-7200 must not be powered up unless an antenna is installed and

connected. An antenna and its cabling must be purchased separately. Antennas

and coaxial cables are typically custom to the installation site. Have a site survey

performed to identify an appropriate antenna and antenna feedline requirements.

After removal from the carton, examine the components and installation items for

broken, damaged, loose or missing parts. If any are noted, contact M/A-COM’s

Technical Assistance Center (see page 9) immediately to discuss and arrange for the

return of the equipment to M/A-COM for replacement. Any unauthorized attempts to

CAUTION

repair or modify this equipment will void the warranty and could create a safety

hazard.

Upon removing items from the carton and verifying all equipment is accounted for, proceed with the

installation.

Mounting of the CS-7200, SP-103, TRCM-103 and/or antenna in ways other than

those described can adversely affect performance, violate FCC rules on RF exposure,

CAUTION

and even damage the unit, posing a potential safety hazard.

10

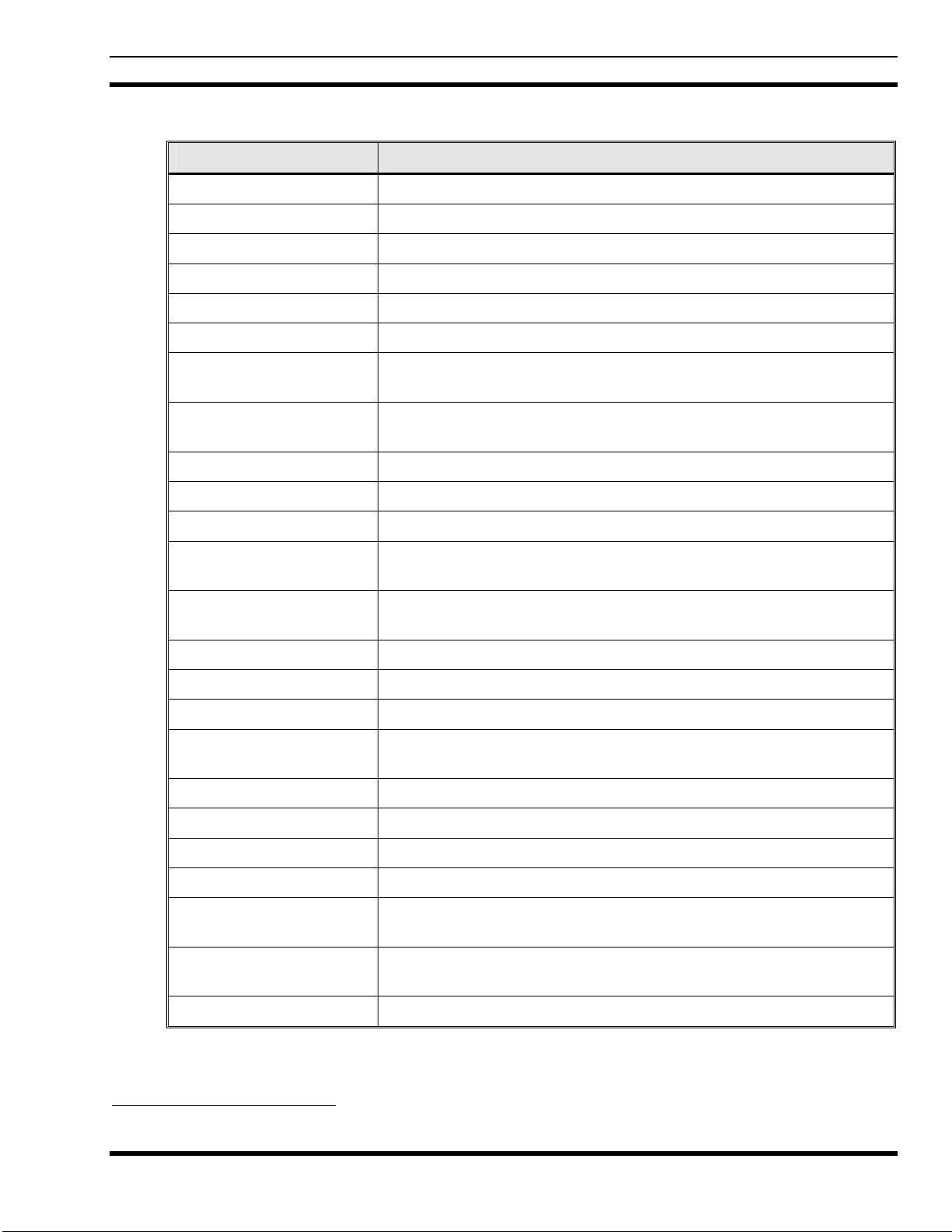

Page 11

MM-011712-001

Table 3-1: CS-7200 Accessories

PART NUMBER DESCRIPTION

MACDOS0007 TRCM-103 Tone Remote Control Module

MACDOS0008 SP-103 Desk Set

MACTOS0002 Controller, Tone Remote: M280, 115 Vac (Zetron)

MACTOS0003-FSDHA Controller, Tone Remote: TR10-16F-FD (CPI)

MACTOS0004 Controller, Tone Remote: ITR2000A (GAI-Tronics)

MACDOS0016 Cable Kit, Siren/PA Cables for SP-103

MC103334V20 Microphone, Noise-Canceling with Straight Connector; 14-pin

Alden type (See footnote

1

)

344A4678P1 Microphone Hanger Kit (Includes hanger and two #8 x ¾-inch

self-threading screws)

MAMROS0072 Microphone Head, Desktop with PTT button

MACDOS0013-SN004 Speaker, External Kit: for SP-103 with Straight Connector

MACDOS0013-SR004 Speaker, External Kit: for SP-103, with Right-Angle Connector

MAMROS0093 Antenna, 800 MHz 6-element Yagi with 8 dBd Gain (Includes

U-bolt mounting hardware.)

TBD2 Antenna, 700 MHz 6-element Yagi with 8 dBd Gain (Includes

U-bolt mounting hardware.)

MAMROS0094 Antenna Mounting Kit, Universal Mount for Yagi Antenna

MAMROS0095 Cable, Coax: Antenna Jumper Kit

IS-CT50HN-MA Lightning Protection Device, 800 to 900 MHz

CA-009562-0R6 Cable, CAN; 0.6 feet, Black, Right-Angle-to-Straight Connectors

(for TRCM-103 only)

CA-009562-006 Cable, CAN; 6 feet, Black, Right-Angle-to-Straight Connectors

CA-009562-030 Cable, CAN; 30 feet, Black, Right-Angle-to-Straight Connectors

CA-009562-090 Cable, CAN; 90 feet, Black, Right-Angle-to-Straight Connectors

CA-009562-250 Cable, CAN; 250 feet, Black, Right-Angle-to-Straight Connectors

CA-011344 CAN Y-Cable, Black, Right-Angle Connector-to-Two Straight

Connectors

MAA7-NSU5C Kit, CAN Bus Extender (Includes CAN Bus Extender MD-008577

and AC Wall Power Supply.)

MAMROS0055 TIA/EIA-232 Serial Data Cable, 6-foot

1

Microphone MC103334V20 replaced Microphone Head MAMROS0036 & Microphone Cable Assembly MAMROS0038.

11

Page 12

MM-011712-001

4 INSTALLATION

All equipment must be installed by an RF equipment installation professional.

Prior to installation, ensure that the CS-7200 has been configured for customer usage

such as channels and personality.

4.1 REQUIRED TOOLS AND CONFIGURATION EQUIPMENT

4.1.1 Tools Required

The following is a list of tools required to complete a standard installation:

• Non-insulated crimp tool with 0.128-inch and 0.429-inch dies;

• Phillips head screwdrivers, sizes #1 and #2;

• Flat head screwdrivers, sizes #1 and #2;

• Slip-jaw pliers;

• Various fasteners; and,

• Wire Strippers for 22-AWG and 14-AWG wire (required only for TRCM-103 installation).

If a Tone Remote Controller (TRC) will be connected to the CS-7200 via a TRCM-103 Tone Remote

Control Module, see the installation materials list on page 28.

4.1.2 Equipment Required for CS-7200 Configuration

The following is a list of additional equipment needed to configure the CS-7200:

• Personal Computer (PC) with an available serial communication port and running Microsoft

Windows operating system software and a terminal application software program such as Windows

HyperTerminal (see Table 6-1 on page 33 for settings);

• TIA/EIA-232 Serial Cable (MAMROS0055 or equivalent);

• For TRCM-103 option only: An SP-103 Desk Set (MACDOS0008) to set up function tones; and,

• See Table 9-1 on page 40 for a list of test equipment required to perform antenna tests procedures.

Additional equipment may be needed to install any tone remote controllers connected to the CS-7200 (via

a TRCM-103). Consult with the manufacturer’s recommendations as required.

4.2 LOCATING COMPONENTS

Plan the mounting locations of all components (CS-7200, antenna, and cables) and determine the routes

for all wiring and cables. Consider also the connection of the SP-103 and/or TRCM-103 for planning

purposes. Follow all manufacturer requirements and guidelines for the location of components.

12

Page 13

For installations with the SP-103 Desk Set which require connection through the CAN

(Controller Area Network) digital interface, pay particular attention to the routing of

CAN cable in the facility. It may be necessary to use plenum-rated cable for inbuilding installations. Refer to section 4.8 that begins on page 26 and/or consult with

TAC to identify the proper cabling.

All cables should be installed with a service loop at each end. During the installation,

do NOT bend any cable at a severe angle near a connector. When the installation is

complete, verify no cable is under any tension. Failure to do so may lead to damaged

CAUTION

cables, causing intermittent operation, or complete equipment failure.

Optimal performance is based upon proper mounting techniques. An improperly

installed unit may experience degradation in the quality of communication with the

OpenSky network.

4.3 CS-7200 INSTALLATION

Determine the customer’s preferences, if any, for location of components. Comply with these preferences

insofar as they are consistent with safety, manufacturer specifications, and generally accepted

professional practices.

MM-011712-001

4.3.1 Rack-Mount and Desktop Mounting

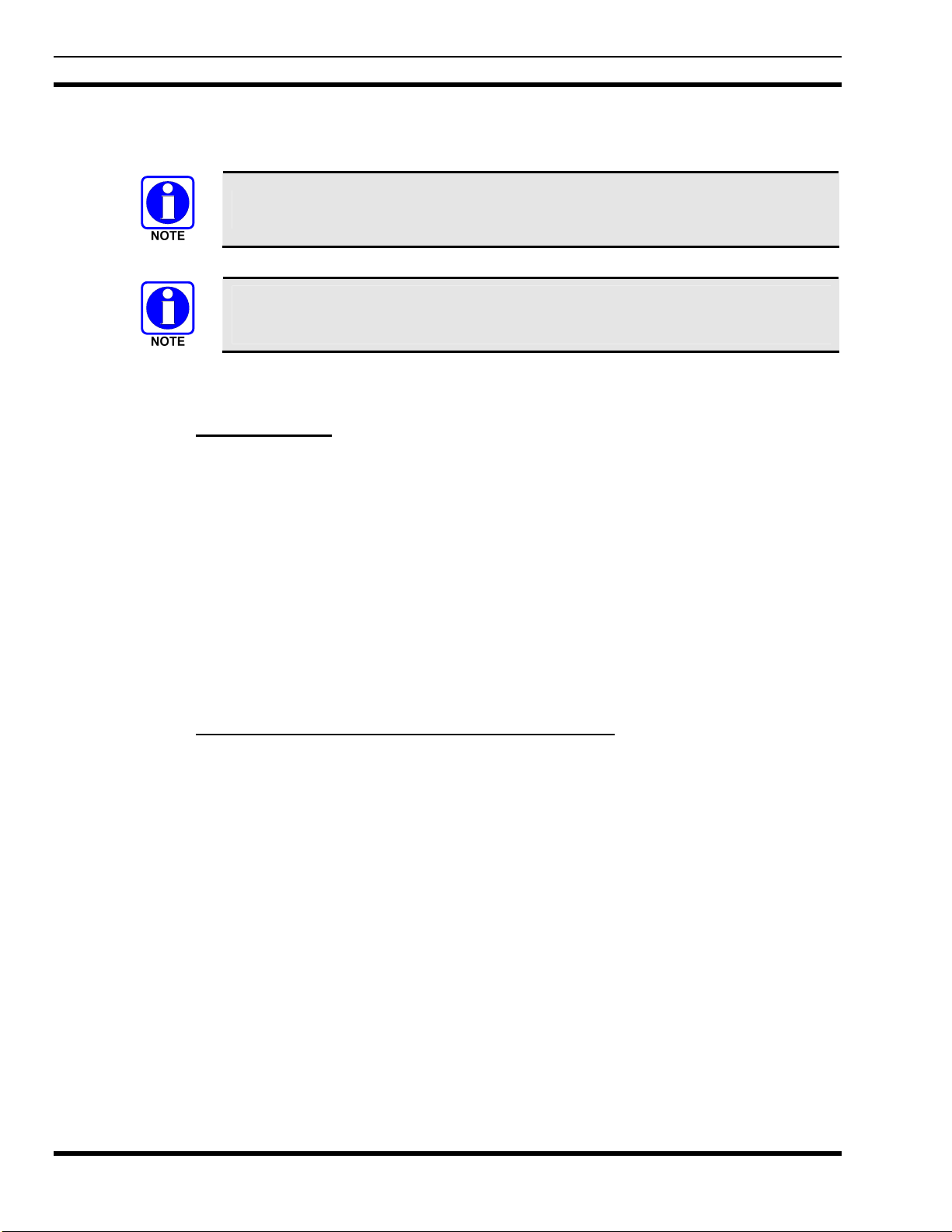

The CS-7200 is designed for mounting within a 19-inch rack-mount cabinet. Its height is three rack-units

(5.25 inches). Removable mounting brackets are attached to the side corners near the front panel of the

CS-7200 at the factory. Bracket-to-cabinet rail mounting screws are not

brackets are not shown in Figure 4-2.

However, the CS-7200 can be placed upon a desktop, tabletop, or another flat horizontal surface with an

adequate size and weight rating. The unit’s dimensions are 5.16 x 17 x 14.15 inches

(13.1 x 43.2 x 35.9 cm) and it weighs approximately 34 pounds (15.42 kilograms). Typically, the

mounting brackets are removed for installations of this type.

19-Inch Rack-Mount

Mounting Brackets

included. See Figure 4-1. The

Figure 4-1: CS-7200 Front Panel

13

Page 14

MM-011712-001

CAUTION

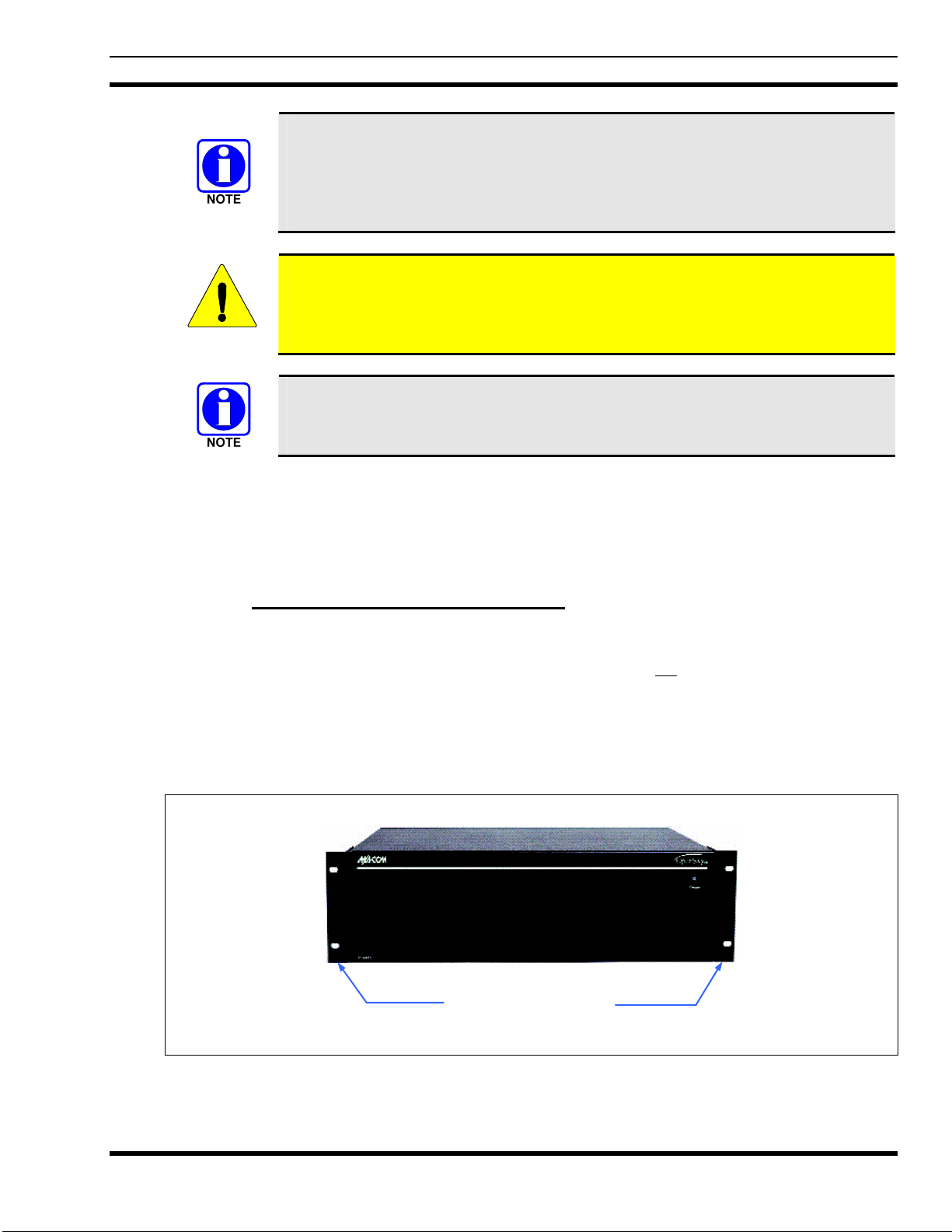

Figure 4-2: CS-7200 Rear Panel

Never place any other equipment directly on top of the CS-7200. The case is not

designed to handle the weight of other equipment.

The CS-7200 must be kept away from sources of heat. Adequate ventilation must

be provided to the air inlet at the rear of the unit where the fan is located and to

the ventilation holes on the side of the unit.

4.3.2 AC Power Connection

The CS-7200 only supports an AC power connection. Follow these general guidelines:

• Ensure familiarity with AC power input connection, including maintenance of the fuse; and,

• Make certain that cable routing will not damage or interfere with any existing wiring at the

installation location.

In order to accommodate both US and European standards, the CS-7200 can be used at voltages in the

range of 110 - 120 Vac (50/60 Hz) and 220 – 240 Vac (50/60 Hz). The power cord for US applications

(110 - 120 Vac) is included with the CS-7200 when it ships from the factory. For European applications,

the appropriate power cord must be purchased separately. The receptacle at the back of the CS-7200 is an

IEC-320 C14-type connector for accepting a cord with an IEC-320 C13-type plug.

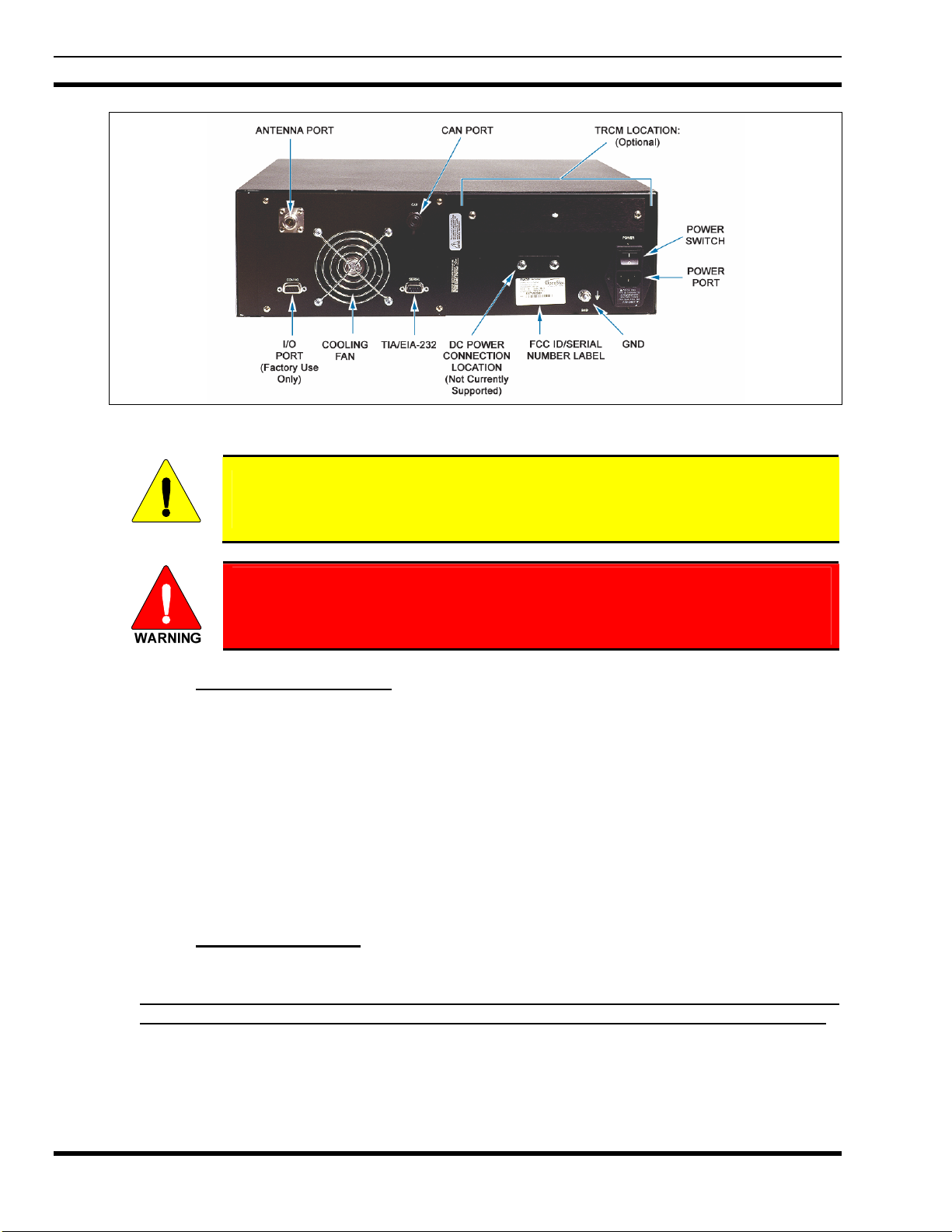

4.3.3 Fuse Replacement

In the event that a fuse blows in the CS-7200, follow this replacement procedure:

1. Disconnect AC power from the unit by unplugging the cord from the AC power source or by

unplugging the cord from the IEC-320-type AC power connector on the CS-7200’s rear panel!

14

2. As shown in Figure 4-3, slip the tip of a small flat-blade screwdriver into the pry slot of the AC

Power Module and pry open the fuse assembly door.

3. Remove the fuse holder and rotate it 180° in order to utilize the spare fuse included. Alternatively,

replace the blown fuse with a new 3-amp, 250-volt fuse.

Page 15

4. Re-insert and reseat the fuse assembly until the panel snaps back into place.

5. Reconnect AC power to the unit.

Figure 4-3: CS-7200 Fuse Replacement (Rear Panel Views)

4.4 ANTENNA INSTALLATION

4.4.1 General Information

MM-011712-001

The antenna must be installed by a qualified antenna professional before

completing the CS-7200 installation.

Improper installation of the antenna may lead not only to poor radio

performance, but also to harmful exposure to RF electromagnetic energy.

The CS-7200 is not required to comply with the FCC RF exposure limits for Uncontrolled Exposure

(General Population) and Occupational Exposure because it is assumed that neither uncontrolled nor

occupational exposure is applicable in the general installation configuration. Installation of the antenna

for the CS-7200 is to be performed so that no person is within the distance of maximum permissible

exposure limits specified in the FCC regulations. The CS-7200 must be disabled before maintenance to

the antenna is attempted.

Failure to follow these instructions will void the product warranty and may expose the end user and others

to excessive Radio Frequency hazard. All antennas should be installed outdoors and at distances from

personnel well beyond the minimum allowable distance.

The rooftop-mount Yagi antennas listed in Table 3-1 (on page 11) are recommended. Side-mounting onto

a building with other types of directional antennas is also acceptable as long as proper line-of-sight

alignment can be achieved.

For best performance, the antenna should be placed at least six feet (1.83 meters) from any other antenna

and high enough to clear the line-of-sight of major obstructions.

4.4.2 Coaxial Cable

Many different RF coaxial cable types can be used for the antenna connection as long as the utilized cable

meets the following minimum requirements. Link budget available to cable loss, length of cable, antenna

type used, etc., are issues to consider when selecting the type of cable needed. Minimum cable

requirements are:

• 50-ohm nominal impedance;

15

Page 16

MM-011712-001

• Required/utilized radio frequency range;

• 1.5:1 VSWR (typical);

• 5 dB/100 feet cable loss (maximum); and,

• Weatherproof construction.

Length of cable should be kept as short as possible to keep cable loss at a minimum. Therefore, the

CS-7200 should be installed within the building in a location as close to the location of the outside

antenna as reasonably possible. Consult with RF equipment installation professionals for more

information.

1. Install N-type RF connectors onto both ends of the cable. Follow the directions included with the

connectors.

2. At the antenna’s base, screw the cable’s N-type male connector to the N-type female connector at the

base of the antenna. Tighten firmly.

If routed through walls, plenums, or other channelling aids, the cable must be

protected from excessive handling, bending or rubbing.

3. Apply the weatherproofing recommended by the antenna manufacturer or supplied with the antenna.

4. At the CS-7200, screw the cable’s N-type male connector to the N-type female antenna port

connector on the rear of the control station. See Figure 4-2 on page 14. Hand-tighten firmly.

To prevent RF leakage and ensure peak performance, verify the RF coaxial

cable’s N-type connector is tight, but not so tight that damage occurs.

4.5 GROUNDING AND LIGHTNING PROTECTION FOR THE CS-7200

Proper grounding is necessary, not only for correct functionality and maximum performance, but also for

minimizing damage that may occur from lightning strikes.

Under the assumption the facility where the CS-7200 is installed is protected properly from lightning

strikes on the AC power line, the CS-7200 is still susceptible to damage from lightning through the RF

antenna port. The CS-7200 does not include an integrated lightning-protection device, so it is

recommended that one be installed. Lightning-protection devices are only effective if the connections are

made as the design intended. Follow the manufacturer’s mounting instructions to ensure a properly

grounded unit.

As shown in Figure 4-2 on page 14, a #10 grounding stud is located at the rear of the CS-7200. For safety

purposes, connect it to the cabinet’s mounting rack with a heavy-gauge wire or braid.

16

Page 17

4.6 SP-103 DESK SET CONNECTION

Figure 4-4 shows front and reviews of the SP-103 Desk Set. An SP-103 is interconnected to the CS-7200

via a CAN cable connection only, which may or may not employ the optional fiber-optic-based CAN Bus

Extender.

FRONT VIEW REAR VIEW

MM-011712-001

Figure 4-4: SP-103 Front and Rear Panels

The following procedure is recommended to connect the SP-103 to the CS-7200 when using only CAN

cable connections:

1. Place the SP-103 on a desk or tabletop, plug the AC power cord (included with the unit) into the rear

of the unit, and then plug the cord into an AC outlet.

The SP-103 and CS-7200 have the same type of AC power connector

(IEC-320 C14-type). However, the fuse in the SP-103 is different. The

instructions in section 4.3.3 can be used to replace the fuse in the SP-103, except

use a 1-amp fuse in the SP-103.

2. Connect the CAN cable to the CAN port on the rear of the CS-7200. When mating any CAN

connection (cables and terminators), visually align the ¾-moon-shaped keys of the connectors, and

then gently push and turn the outer locking ring of the plug (male) connector clockwise until it stops.

A mild click will be sensed to confirm proper mating.

See section 4.8 for additional CAN cable connection information, including

procedures for in-wall/plenum CAN cable installations, and information about the

CAN Bus Extender.

3. Route the CAN cable to the rear of the SP-103 and connect it to either one of the CAN ports. The

CAN cable carries digitized transmit and receive audio, and control data between the SP-103 and the

CS-7200.

4. Connect a CAN Terminator (part number MACDOS0010) to the other CAN port on the rear of the

SP-103.

5. An optional microphone can be connected to the 14-pin mic connector on the front of the SP-103 as

follows: Align the white arrows on the mating connectors then push the mic cable’s connector into

17

Page 18

MM-011712-001

the mate—the outer ring of the connector will rotate during the insertion. The outer ring will lock into

place (arrows aligned) when full connection is made and a click will be sensed.

6. An optional external PTT (push-to-talk) footswitch can be used with the SP-103 by plugging it to the

3.5-millimeter jack on the rear panel of the SP-103.

7. The SP-103 has a built-in speaker. If an external speaker is utilized, connect it to the ¼-inch jack on

the rear panel of the SP-103. Connecting an external speaker will disable (silence) the internal

speaker.

Only connect a M/A-COM-approved external speaker to the SP-103. Use of

improperly configured or grounded speaker connection may damage the audio

CAUTION

amplifier circuitry in the SP-103.

8. For data applications, the 9-pin D-subminiature connector on the rear panel of the SP-103 can be

connected to a personal computer’s 9-pin serial communication port. Use TIA/EIA-232 data cable

part number MAMROS0055 (or equivalent). Cable MAMROS0055 is six feet (1.83 meters) long.

4.7 CONNECTING TO A TONE REMOTE CONTROLLER (OPTIONAL)

If the CS-7200 will be connected to and controlled by one or more Tone Remote Controllers (TRCs), the

TRCM-103 Tone Remote Control Module must be installed into the CS-7200, and the CS-7200 and the

TRCM-103 must be properly configured as described in this section. Figure 4-10 shows this installation

and the TRCM-103’s external interfaces.

When not installed in the CS-7200, the TRCM-103 is an exposed printed circuit board

assembly. Therefore, observe precautions for damage due to Electro-Static Discharge

(ESD). Use proper grounding techniques such as a wrist strap connected to a grounded

surface and other approved handling methods in order to minimize the chance of

damage from ESD.

4.7.1 DIP Switch and Jumper Settings

The TRCM-103 is shipped from the factory with default DIP switch and jumper settings. Prior to

installing the TRCM-103 into the CS-7200, verify the switches and jumpers are set appropriately. For

reference in the field, these settings are listed on a label located on the bottom of the TRCM-103. This

label is shown in Figure 4-5.

TRCM-103 DIP switch locations are shown in Figure 4-6 on page 20. Switch positions of SW1 and

SW2 are factory-set and must not

as presented in the step 3 of this procedure:

1. Referring to Figure 4-6 for switch locations, verify all DIP switch positions are at the factory-default

settings as shown in the “NORMAL OPERATION” part of Figure 4-5. (All positions of SW1 must

be DOWN, SW2 position 1 must be DOWN, SW2 positions 2 through 4 must be UP, and positions 1,

3 and 4 of SW4 must be UP.)

2. The default configuration for jumper J8 on the TRCM-103 is ON (installed). This sets the

TRCM-103’s audio line termination to the low impedance (600-ohm) state so it can be utilized as an

endpoint in the CS-7200-to-TRC(s) 2 or 4-wire audio “chain.” Refer to Figure 4-6 for the location of

jumper J8. If the TRCM-103 is to be configured in the middle of the chain when paralleled TRCs are

employed, see section 4.7.2.3 on page 22 for additional information.

be changed. Changes may be required to SW4 position 2 (“SW4-2”)

18

Page 19

MM-011712-001

3. Factory default TRCM-103 settings configure it for a 4-wire line interface to the TRC(s). This is

determined by jumper J9 being ON (installed) and SW4 position 2 being DOWN. If a 2-wire line

interface connects the TRC to the TRCM-103, move the jumper on J9 to J7 and set SW4 position 2

UP. Refer to Figure 4-6 on page 20 as necessary.

A jumper must be on either J9 or J7 and SW4-2 must be in the appropriate setting in

order for the TRCM-103 to work properly.

Figure 4-5: DIP Switch and Jumper Configuration Label (Located on Bottom of TRCM-103)

The TRC operator/dispatcher cannot pre-empt radio-originated calls when 2-Wire

connections are employed between the TRC and the CS-7200. Therefore, 4-wire

connections are recommended when a CS-7200 is interfaced to a TRC.

19

Page 20

MM-011712-001

1 2 3 4

Detail of SW2 Settings

(Viewed From Opposite

1 2 3 4

SW2

Side):

SW1

J7

J8

J9

Tune LED

SW4

Tuning Panel

Figure 4-6: TRCM-103 Jumper and Switch Settings

20

Page 21

MM-011712-001

4.7.2 Installation Configurations

The following subsections describe various TRC configurations supported by a TRCM-103 equipped

CS-7200. If more than one TRC is connected to via a TRCM-103, line connections are in parallel and the

TRCM-103 can be configured to operate at either the end or in the middle of the “chain” of paralleled

TRCs. For specific TRC configuration information, refer to the respective TRC’s installation manual

provided by the manufacturer.

4.7.2.1 TRCM-103 as an Endpoint and Interfaced to a Single TRC

If only one TRC is connected, the TRCM-103 and the TRC are both considered line terminating

endpoints. Both devices must have their line impedance set to the low impedance (600-ohm) state for

proper termination. This line interface configuration is illustrated in the following figure:

Tone Remote

Controller

Line Interface = LOW

impedance

CS-7200 Control Station

TRCM-103

Line Interface = LOW

impedance (600 ohms)

2 or 4-wire line interface

Figure 4-7: TRCM-103 Configured as an Endpoint and Interfaced to One TRC

If using this configuration, no change of jumper J8 is needed from the factory default setting as described

in section 4.7.1 because the factory default setting is low impedance line termination. However, if the line

interface is a 2-wire line connection, the factory default setting of 4-wire line must be changed to 2-wire

line by moving jumper J9 to J7, and setting SW4 position 2 UP as described in section 4.7.1.

21

Page 22

MM-011712-001

)

4.7.2.2 TRCM-103 as an Endpoint and Interfaced to Multiple TRCs

The following figure illustrates the TRCM-103 at the end of a “chain” of paralleled TRCs. In this

configuration, the TRCM-103 and the TRC that is furthest away from the TRCM-103 in physical cable

distance must have their line impedance set to the low impedance (600-ohm) state for proper termination.

All other TRCs must be set to the high impedance state.

Tone Remote

Controller 1

Line Interface = HIGH

impedance

Tone Remote

Controller 2

Line Interface = HIGH

impedance

Tone Remote

Controller N

Line Interface = LOW

impedance

CS-7200 Control Station

• • • • • • •

TRCM-103

Line Interface = LOW

impedance (600 ohms)

2 or 4-wire line interface

Note: Tone Remote

Controller N is furthest

Splitters or Terminal Distribution

away in p hysical distance.

Figure 4-8: TRCM-103 Configured as an Endpoint and Interfaced to Multiple Paralleled TRCs

As with the previous configuration, no change of jumper J8 is needed from the factory default setting as

described in section 4.7.1 because the factory default setting is low impedance line termination. If the line

interface is a 2-wire line connection, the factory default setting of 4-wire line must be changed to 2-wire

line by moving jumper J9 to J7, and setting SW4 position 2 UP as described in section 4.7.1.

4.7.2.3 TRCM-103 in the Middle and Interfaced to Multiple TRCs

The following figure illustrates the TRCM-103 in the middle of a “chain” of TRCs. In this configuration,

the two TRCs furthest away from each other in physical cable distance must have their line impedance set

to the low impedance (600-ohm) state for proper termination. The TRCM-103 and all other paralleled

TRCs must be set to the high impedance state.

22

Tone Remote

Controller 1

Line Interface = LOW

impedance

• • • • • • •

Tone Remote

Controller X

Line Interface = HIGH

impedance

CS-7200 Control Station

TRCM-103

Line Interface = HIGH

impedance

Splitters or

Terminal

Distribution

2 or 4-wire line interface

Tone Remote

Controller Y

Line Interface = HIGH

impedance

Note: Tone Remote Controller 1

and Z are furthest away in

physical distance. (i.e., “at the

ends of the chain”

• • • • • • •

Figure 4-9: TRCM-103 in the Middle of a Chain and Interfaced to Multiple Paralleled TRCs

Tone Remote

Controller Z

Line Interface = LOW

impedance

Page 23

MM-011712-001

To set the TRCM-103 to the high impedance state, remove jumper J8. If the line interface is a 2-wire line

connection, the factory default setting of 4-wire line must be changed to 2-wire line by moving jumper J9

to J7, and setting SW4 position 2 UP as described in section 4.7.1.

4.7.3 Installing the TRCM-103 into the CS-7200

1. If not already, disconnect AC power from the unit by unplugging the cord from the AC power

source or by unplugging the cord from the IEC-320-type AC power connector on the CS-7200’s

rear panel!

2. At the CS-7200 rear panel, loosen and remove the two (2) Phillips-head screws that secure the blank

panel that covers the slot for the TRCM-103. See Figure 4-2 on page 14.

3. Remove the DC power cable (red and black wire) from the back of the blank panel by untwisting the

twist-lock. The blank panel can be discarded.

4. Connect the DC power cable’s connector to the power connector on the edge of the TRCM-103’s

printed circuit board. See Figure 4-10.

5. With the TRCM-103 facing up (board horizontal and large components up), gently slide it into the

slot and align the captive screws with the screw holes on the CS-7200 chassis.

6. Tighten the TRCM-103 the captive screws firmly, but do not over-tighten.

7. Another connection to the CS-7200 is made with a CAN cable. See Section 4.8.3 for more

information.

The required TRCM-103-to-TRC line-level alignment procedure is presented on page

34 of this manual.

TOP VIEW REAR VIEW

Figure 4-10: TRCM-103 Installation into CS-7200 and its External Interfaces

23

Page 24

MM-011712-001

4.7.4 Connecting to the TRC

A variety of Tone Remote Controllers (TRCs) can be interfaced to the CS-7200 via the TRCM-103. Two

models supported by M/A-COM are Zetron

®

Model 280, and GAI-TRONICS® Model ITR2000A. The

information presented in the following subsections describes how hardware connections are made to these

units, although the manufacturer’s instructions included with the unit provide the ultimate guidelines.

Other TRCs typically follow these installation approaches.

In all TRC installation cases, connect TRCM-103 Rx audio lines to TRC Tx audio

lines, and connect TRCM-103 Tx audio lines to TRC Rx audio lines. Line

misconnections will cause link failure and may damage the TRC.

Table 4-1 describes pins of the TRCM-103’s RJ-11 modular jack utilized for 2-wire and 4-wire line

connections. If both 2- and 4-wire connections are available at the TRC, the customer is free to choose

either connection. As the TRCM-103 is factory set for 4-wire operation, 4-wire is recommended, though

not required.

Table 4-1: TRCM-103 Audio Interface Pin-Out

(RJ-11 Modular Jack Labeled “AUDIO”)

RJ-11 PIN SIGNAL

1 (No Connection)

2 4-Wire +RX IN

3 2-Wire +TX OUT/RX IN

4 2-Wire -TX OUT/RX IN

5 4-Wire -RX IN

6 (No Connection)

4.7.4.1 Connecting the Zetron Model 280

The Zetron® Model 280 TRC supports up to four (4) separate control stations and can be configured for

either a 2-wire or a 4-wire audio interface. Installation requires opening the unit to make connections to a

terminal block inside the unit. This terminal block is identified TB1.

For multiple (paralleled) TRCs in which the line impedances must be changed at one or more units, the

Model 280 supports this via configuration jumpers inside the unit. See the Model 280 Installation Manual

for additional information.

A standard one-to-one modular telephone cable can be run directly from the RJ-11 modular jack on the

TRCM-103 to the TRC. However, because the connections at the Model 280 TRC need to be made at

terminal block TB1 inside the unit, either the modular plug at the Model 280 end of the cable needs to be

cut off and the cable’s wires stripped, or a mating jack adapter with “flying” leads must be utilized to

make the connections at the terminal block.

Table 4-2 shows pin-out interconnection details for a 2-wire interface and Table 4-3 shows the same for a

4-wire interface.

24

Page 25

MM-011712-001

Table 4-2: TRCM-103 to Zetron Model 280 2-Wire Line Interface Connections

TRCM-103 RJ-11 “AUDIO” JACK MODEL 280 TERMINAL BLOCK TB1

Pin Signal Terminal Signal

3 2-Wire +TX OUT/RX IN 8 2W+1

4 2-Wire –TX OUT/RX IN 9 2W–1

Table 4-3: TRCM-103 to Zetron Model 280 4-Wire Line Interface Connections

TRCM-103 RJ-11 “AUDIO” JACK MODEL 280 TERMINAL BLOCK TB1

Pin Signal Terminal Signal

2 4-Wire +RX IN 8 2W+1 (+TX)

3 2-Wire +TX OUT/RX IN 7 4-Wire+1 (+RX)

4 2-Wire –TX OUT/RX IN 10 4-Wire-1 (-RX)

5 4-Wire –RX IN 9 2W–1 (-TX)

4.7.4.2 Connecting the GAI-TRONICS Model ITR2000A

The GAI-TRONICS® Model ITR2000A TRC supports only one control station, but it can be configured

for either a 2-wire or a 4-wire audio interface. Installation does not require the unit to be opened to make

connections, as connections are performed directly at the RJ-11 modular jack labelled “LINE” at the rear

of the unit.

For multiple (paralleled) TRCs, the ITR2000A supports low and high line impedance configuration

changes via its programming configuration. See the ITR2000A’s User and Installation Manual for

additional information.

For a 2-wire line interface connection, a standard one-to-one modular telephone cable can be connected

directly between the TRCM-103’s RJ-11 modular jack and the ITR2000A. The following table lists the

required connections:

Table 4-4: TRCM-103 to GAI-TRONICS Model ITR2000A 2-Wire Line Interface Connections

TRCM-103 RJ-11 “AUDIO” JACK MODEL ITR2000A “LINE” JACK

Pin Signal Pin Signal

3 2-Wire +TX OUT/RX IN 3 2-Wire TX +OUT/RX IN

4 2-Wire –TX OUT/RX IN 4 2-Wire TX -OUT/RX IN

25

Page 26

MM-011712-001

For 4-wire line interface connections, a crossover (null modem) connection between the TRCM-103 and

the ITR2000A is required to mate the RX to TX and TX to RX connections. A Standard one-to-one

modular cable can be utilized at the ITR2000A’s “LINE” jack, with the crossover made at the

TRCM-103. This will ease wiring when paralleled TRCs are employed, or added at a later date. Up to

ten (10) ITR2000A TRCs can be paralleled together to control a single CS-7200.

Table 4-5: TRCM-103 to GAI-TRONICS Model ITR2000A 4-Wire Line Interface Connections

TRCM-103 RJ-11 “AUDIO” JACK MODEL ITR2000A “LINE” JACK

Pin Signal Pin Signal

2 4-Wire +RX IN 3 2-Wire TX +OUT/RX IN

3 2-Wire +TX OUT/RX IN 2 4-Wire RX +IN

4 2-Wire –TX OUT/RX IN 5 4-Wire RX -IN

5 4-Wire –RX IN 4 2-Wire TX -OUT/RX IN

The required TRCM-103-to-TRC line-level alignment procedure is presented on page

34 of this manual.

4.8 CONNECTING THE CAN CABLE

The CS-7200’s CAN port needs to be connected to provide the user interface for the CS-7200. As shown

in Figure 4-2, the CAN port is located at the rear of the CS-7200. This is where the SP-103 or TRCM-103

CAN cable is connected. To make CAN connections, visually align the 3-pin male connectors of the cable

to the 3-pin female connectors on each unit. Connect by pushing and twisting the outer housing of the

cable connector until a click is sensed. Do not use excessive force when twisting.

The CAN digital interface must be terminated properly at both ends in order to work

correctly. The CS-7200 has an internal terminator that provides the termination for its

end.

4.8.1 SP-103 CAN Connections

The SP-103 Desk Set has two CAN ports on its rear panel to support “daisy-chaining” of multiple

SP-103s or other CAN devices. When an SP-103 is in the middle of a chain (e.g., Control Station on one

end and a different SP-103 on the other), two separate CAN cables connect to the two ports. When the

SP-103 is at the end of a chain of devices, one CAN port connects to the previous CAN device and the

other port must be terminated with a CAN Terminator (part number MACDOS0010).

Currently, in a multiple CAN device (i.e., SP-103) configuration, all daisy chaining

must be performed such that the CS-7200 is an end point, because the CS-7200 is

internally terminated. Do not use a CAN Y-Cable to split the CAN port of the

CS-7200 to two separate devices.

26

4.8.1.1 Collocated Installations

For installations in which the SP-103 is in the same location as the CS-7200 and no routing of cables into

walls or through plenums is required, the standard CAN cable can be used. For cables whose connectors

Page 27

MM-011712-001

can be routed without the fear of being damaged in routing (e.g., cables do not need to be snaked through

holes), the molded CAN cables are preferred, part number CA-009562-xxx. See Table 3-1 on page 11 for

specific cable part numbers. The “xxx” suffix specifies cable length in feet.

If connectors might get snagged or damaged during routing, CAN cable part number 9451-BLK-1000 is

available by the spool (1000 feet of cable). However, a CA-009562-xxx CAN cable must also be

purchased, as its molded connectors must be splice to both ends of the 9451-BLK-1000 spooled cable.

Splicing instructions are presented on page 28.

4.8.1.2 In-Wall/Plenum CAN Cable Installations for Remote SP-103

4.8.1.2.1 Cable Requirements and Routing

As described in the previous section, various lengths of molded CAN cables are available for the SP-103.

The standard molded CAN cable, part number CA-009562-030, is primarily for general use. However, for

in-building applications, this cable does not meet certain safety agency codes for routing through walls

and plenums. For this reason, a plenum-rated cable, Belden part number 87761-RED-1000, can be

purchased by the spool. This cable is recommended for in-wall/plenum CAN cable installations because

of its properties of impedance, shielding, and flexibility. In-wall/plenum routing faces the rigors of

“snaking” and pulling of the cable. These actions can damage installed connectors. Therefore, a procedure

for routing raw cable through the walls and mating connections reliably is necessary.

Figure 4-11 illustrates the general concept for connecting the CS-7200 to the SP-103 via in-wall/plenum

CAN cabling. Follow these requirements:

• Materials (e.g., junction boxes, cabling, etc) must meet all building codes.

• The in-wall/plenum cable must be a plenum-rated, shielded, twisted-wire pair of 22-AWG. Belden

87761 cable is recommended. If the utilized cable does not meet building codes, it must be dressed or

placed inside a conduit (not provided), or some other installation method must be employed so that it

does meet building codes.

• Total length of the CAN cable must not

cable daisy-chained through multiple CAN devices (e.g., the SP-103).

The standard (non-plenum) CAN cable (e.g., CA-009562-030) is spliced to the plenum cable using

3-position terminal blocks placed inside junction boxes. Plenum-rated cable is needed for in-wall/plenum

routing, but the standard cable, as long as it isn’t routed through a wall or concealed ducting, is acceptable

for connections to the wall. The standard cable is needed because its solder-type molded connectors do

not accommodate customary in-field installation.

exceed 250 feet (76.2 meters), including any amount of

27

Page 28

MM-011712-001

MACDOS0006-NR030

(Cut to required length)

One Half of

CAN Cable Routing

Throughout Building

Other Half of

MACDOS0006-NR030

(Cut to required length)

CS-7200

Control

Station

In-Wall Junction Box

3-Pole Terminal Block

(Wago #

261-423/341-000)

CAN

Port

CAN

Belden 87761 Plenum Rated Cable (Maximum

length = 220 feet + the

length cut from the

MACDOS0006-NR030

cable)

3-Pole Terminal Block

(Wago #

Port

In-Wall Junction Box

261-423/341-000)

SP-103

Desk Set

Figure 4-11: Connecting CS-7200 to the SP-103 via In-Wall/Plenum CAN Cable Connections

4.8.1.2.2 Installation Materials

The following materials are required:

®

• 3-Pole 2-Conductor Terminal Blocks, WAGO

part number 261-423/341-000 (2 required)

• Junction boxes (2 required)

• Assorted tools for routing cable through walls/plenums and mounting junction boxes

4.8.1.2.3 Splicing CAN Cable

The following procedure is recommended for splicing plenum-rated cable to the standard CAN cable:

1. Cut the standard CAN cable (part number CA-009562-030) approximately in half.

2. If not already, power-off both the CS-7200 and the SP-103. Both units should remain off until after

the cable installation is complete.

3. Connect each end of the cut CAN cable to the CS-7200 and SP-103 CAN ports.

4. Using the cut ends of the cable, determine acceptable locations for wall junction boxes and mount the

two junction boxes using an approved method.

5. Route the cables into the junction boxes and anchor according to building codes.

6. Cut off any excess cable length, allowing at least one foot (0.3 meters) for splicing and servicing. The

total amount of cable removed from both halves is an amount that can be added to the 220 feet of

plenum cable, if needed. For example, if 10 feet of excess length is cut from the standard 30-foot

CAN cable, the plenum cable is allowed to be as long as 230 feet. In any case, do not exceed 250 feet

(76.2 meters) of total CAN cable length.

7. Measure out an amount of spooled plenum cable needed to reach the two junction box splice points

and route it through the building walls, plenums, etc. using approved methods.

8. Route the cable’s ends into the junction boxes and anchor according to building codes.

9. Cut off any excess cable length, allowing a foot or so of length for splicing.

28

Page 29

MM-011712-001

(

)

10. With a 14-AWG wire stripper, strip off 3/4-inch of the cable’s outer jacket and remove any shield

foil. This dimension is critical, as too much unexposed lead length can have adverse effect on

performance. Ensure no damage was done to the individual wires.

11. With a 22-AWG wire stripper, strip off 5/16-inch of insulation from each individual wire in the

shielded pair. The third wire in the cable is the shield ground wire—do not cut it. See Figure 4-12.

Shield Wire

3/4”

5/16”

Cable’s Outer Jacket

Stripped Wires

1 Pair

Figure 4-12: Dimensions for Stripping 3-Wire CAN Cables

12. At both ends of the spooled plenum cable, simultaneously insert the red and black wires into two

poles of the terminal block by simultaneously pushing two adjacent buttons down with a large #2

flathead screwdriver, and guiding the bare end of the wire into the side openings of the terminal

block. Next, release pressure on the buttons while ensuring the bare wires are visible entering the

block’s clamping mechanisms. See Figure 4-13. The order of wires in the terminal block housing

does not matter, but the red and black wires must be next to each other. Consistency between the two

blocks is recommended.

13. Insert the bare shield wire into the third pole of the terminals block by pushing the button down with

the screwdriver, guiding the wire into the opening, and releasing pressure on the button.

14. Strip and connect the CS-7200 and the SP-103’s standard CAN cable wires to the terminal blocks so

matching wire colors on each half of the standard CAN cable will be electrically connected.

15. Finish the installation by pushing the terminal block into the junction boxes and covering the boxes

appropriately. Alternatively, the terminal blocks may be secured with small screws (not supplied) at

the mounting flanges.

29

Page 30

MM-011712-001

Push Buttons

Screwdriver

Mounting Flange

WAGO Terminal

Block Openings

Cable’s Outer Jacket

Figure 4-13: 3-Position Terminal Strip Connections

4.8.2 Connecting via the CAN Bus Extender (Fiber Optic Cable Installations)

When using the CAN Bus Extender to connect an SP-103 to the CS-7200, the extender should be colocated with and connected directly to the CS-7200. For installation-related information, refer to manual

publication number MM-009088-001.

4.8.3 TRCM-103 CAN Connections

A 0.6-foot CAN cable is included with TRCM-103 when it ships from the factory. Standard TRCM-103

installations require connecting this cable directly between the CS-7200’s CAN port and the TRCM-103’s

CAN port.

If both the SP-103 and the TRCM-103 are connected to a common CS-7200, CAN Y-cable part number

CA-011344, is needed at the TRCM-103’s CAN port to split the CAN connection. In this case, connect

the male connector of the Y-cable to the TRCM-103’s CAN port, one of the female legs to the short

0.6-foot cable from the CS-7200’s CAN port, and the other female leg to the CAN cable from the SP-103.

The CS-7200 can support up to five SP-103s, whether or not a TRCM-103 is installed

in the CS-7200.

The total physical length of CAN cable, including the amount that is “daisy-chained”

between multiple SP-103 Desk Sets, cannot exceed a length of 250 feet (76.2 meters).

CAUTION

Lengths beyond this will cause failure in the communications link between units.

30

Page 31

MM-011712-001

5 POWER-UP PROCEDURE

Unlike many radios, the OpenSky family of radio products power up to the state of last

control. However, the CS-7200 will not be operational unless a CAN device is

connected through the CAN port and this device is itself powered up.

1. Connect AC power to the CS-7200. See section 4.3.2 on page 14 for details.

2. Turn on the CS-7200 via the power switch on its rear panel.

3. Verify power is applied to the CS-7200 by checking for a lit green LED on the front of the CS-7200.

4. If the CAN Bus Extender is employed, connect its “wall cube” power supply to an appropriate AC

power source and then connect the supply’s 24-volt DC cable to the extender’s DC power input jack.

5. If using an SP-103, connect AC power to it and turn it on via the power switch on its rear panel.

Verify the SP-103 display is illuminated and not reporting any errors.

The SP-103 will go through a short boot sequence, then attempt to logon to the

OpenSky network. If the CAN cable is not connected (see section 4.8) to the CS-7200

or if power to the CS-7200 is not applied, the display will indicate an error.

If using a third-party Tone Remote Controller (TRC), follow manufacturer’s

instructions regarding TRC power up.

31

Page 32

MM-011712-001

6 CHANGING OPERATING MODE

If for some reason the CS-7200 is not set to the proper OpenSky Trunking Protocol (OTP) operating

mode, or if verification that the unit is in OTP mode is sought, this can be accomplished either via an

SP-103 or by a PC running a terminal application such as Microsoft Windows HyperTerminal. Both

methods are described in the following subsections.

6.1 SP-103 METHOD

1. Verify both the CS-7200 and the SP-103 are powered-up and no errors are reported by the SP-103.

2. Using the SP-103 menu selection buttons, press ▲ (up arrow) repeatedly until “MODE” appears in

the display.

3. Press

4. Press ► (right arrow) repeatedly until “OTP” appears in the display.

5. Press

6. Press ► again and then

7. The CS-7200 will go through a short reboot sequence during which time the OTP operating mode and

version number will be reported in the display.

.

.

again to confirm the selection.

6.2 PC RUNNING A TERMINAL APPLICATION METHOD

If a TRCM-103 is installed in a CS-7200 but an SP-103 is not available, a PC running a terminal

application can be used to set OTP operating mode. Settings shown in the Table 6-1 are required and

correspond to the Microsoft Windows HyperTerminal program. Consult with the user’s manual of other

terminal applications as necessary.

1. Ensure the CS-7200 is powered off.

2. Using a standard modem-type TIA/EIA-232 serial cable (MAMROS0055 or equivalent), connect the

CS-7200 to the PC by connecting the PC’s serial (COM) port to the 9-pin D-subminiature (DB-9)

connector on the rear of the CS-7200 labelled “SERIAL”.

3. Run the terminal application.

4. Follow the POWER-UP PROCEDURE presented in Section 5 to power up the CS-7200.

32

5. The operating mode will be displayed within the PC’s terminal program.

6. If the mode is not OTP (followed by its version), type atz9 (case sensitive) and then press <Enter> at

the PC’s keyboard. The CS-7200 will go through a rebooting sequence and the mode will change to

OTP.

Page 33

MM-011712-001

Table 6-1: HyperTerminal Settings Required for Changing Operating Mode

“General” or “Connect To” Tab:

Connect Using COM 1

Configure (Button)

Bits per Second 19200

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

“Settings” Tab:

Terminal Keys (Selected)

Emulation VT100

Backscroll buffer Line 500

ASCII Setup (Button) (Everything should be unselected

Line Delay and Character set to 0)

Terminal Settings (Button)

Check Off 132 Column Mode

Character Set ASCII

33

Page 34

MM-011712-001

7 LINE-LEVEL ALIGNMENT FOR A TRCM-103

EQUIPPED STATION

Proper line-level alignment is required when using the TRCM-103 to interface the CS-7200 to a Tone

Remote Controller (TRC). Complete the following two procedures to ensure proper line level alignment:

7.1 TRCM-103 TO TONE REMOTE CONTROLLER

1. If installed, temporarily disconnect the short CAN cable between the TRCM-103’s CAN port and the

CS-7200’s CAN port.

2. If not already, connect either a 2-wire or a 4-wire line interface cable between the RJ-11 jack at the

TRCM-103 (jack labelled “AUDIO”) and the TRC. See Figure 7-1 on page 34, Section 4.7.4 on page

24, and follow all manufacturer’s instructions for connecting to and setting up the TRC.

3. Using a Phillips head screwdriver, remove the two (2) screws securing the TRCM-103 tuning panel to

the rear of the TRCM-103. See Figure 7-1.

4. Temporarily set SW4 position 1 to the DOWN position. This causes the TRCM-103 to output a 1 kHz

tone onto the line interface.

5. Monitor the line interface output level at the TRCM-103 using a true-RMS reading multimeter.

6. Using a small Phillips head screwdriver, adjust the TRCM-103’s Output Trim Pot until a reading of

0 dBm (770 mV rms @ 600-ohm impedance) at 1 kHz is obtained at the TRCM-103’s line interface

output.

7. Follow the alignment procedure defined by the manufacturer of the TRC to align its line interface

input level as required. Repeat at each paralleled TRC connected to the CS-7200.

8. At the TRCM-103, set SW4 position 1 back to the UP position to resume normal operation.

9. Continue with the procedure presented in the next section.

34

TO/FROM TONE

REMOTE

CONTROLLER

Figure 7-1: TRCM-103 Line-Level Adjustments

Page 35

7.2 TONE REMOTE CONTROLLER TO TRCM-103

1. Follow the alignment procedure defined by the manufacturer of the TRC to align its line interface

output level to provide a 0 dBm 1 kHz tone signal at its line output.

2. Adjust the TRCM-103’s Input Trim Pot until the tune LED’s color turns to amber, then turn the pot in

the opposite direction to the point where the LED just changes to green.

3. If paralleled TRCs are employed, repeat steps 1 and 2 until an acceptable balance can be achieved

between the TRC with the most line loss and the TRC with the least line loss. Also refer to the

following NOTE.

4. Re-install the tuning panel so the LED protrudes through the access hole in the panel. Do not over-

tighten the screws.

5. Reconnect the short CAN cable between the TRCM-103’s CAN port and CS-7200’s CAN port.

If paralleled TRCs are employed and a major line level difference exists between two

or more TRCs, good signal level balance can normally be achieved as follows:

1. Initially align the TRCM-103 Input Trim Pot using the TRC with the most line loss

(i.e., the lowest 1 kHz signal at the TRCM-103).

2. At each of the other paralleled TRCs in the system, lower the TRC line interface

output level until the tune LED at the TRCM-103 just turns green. Do not adjust

the TRCM-103’s Input Trim Pot.

While this method will improve overall system performance, too high or too low of

TRC intercom levels may result. If so, improve (decrease) line loss differences

between the TRCs and the CS-7200 and/or perform individual intercom level