Page 1

TECHNICAL MANUAL

888-9058-001

Platinum-i Series Intelligent

Transmitter™

Platinum-i Series Intelligent Transmitter™

T.M. No. 888-9058-001

© Copyright Harris Corporation 2008, 2010 Rev B, 20 May, 2010

All rights reserved

Page 2

______________________________________________HARRIS

Returns And Exchanges

Damaged or undamaged equipment should not be returned unless written approval

and a Return Authorization is received from HARRIS Broadcast Communications

Division. Special shipping instructions and coding will be provided to assure proper

handling. Complete details regarding circumstances and reasons for return are to be

included in the request for return. Custom equipment or special order equipment is

not returnable. In those instances where return or exchange of equipment is at the

request of the customer, or convenience of the customer, a restocking fee will be

charged. All returns will be sent freight prepaid and properly insured by the

customer. When communicating with HARRIS Broadcast Communications

Division, specify the HARRIS Order Number or Invoice Number.

Unpacking

Carefully unpack the equipment and perform a visual inspection to determine that

no apparent damage was incurred during shipment. Retain the shipping materials

until it has been determined that all received equipment is not damaged. Locate and

retain all PACKING CHECK LISTS. Use the PACKING CHECK LIST to help

locate and identify any components or assemblies which are removed for shipping

and must be reinstalled. Also remove any shipping supports, straps, and packing

materials prior to initial turn on.

Technical Assistance

HARRIS Technical and Troubleshooting assistance is available from HARRIS

Field Service during normal business hours (8:00 AM - 5:00 PM Central Time).

Emergency service is available 24 hours a day. Telephone 217/222-8200 to contact

the Field Service Department or address correspondence to Field Service

Department, HARRIS Broadcast Communications Division, P.O. Box 4290,

Quincy, Illinois 62305-4290, USA. Technical Support by e-mail:

tsupport@harris.com. The HARRIS factory may also be contacted through a FAX

facility (217/221-7096).

Replaceable Parts Service

Replacement parts are available 24 hours a day, seven days a week from the

HARRIS Service Parts Department. Telephone 217/222-8200 to contact the service

parts department or address correspondence to Service Parts Department, HARRIS

CORPORATION, Broadcast Systems Division, P.O. Box 4290, Quincy, Illinois

62305-4290, USA. The HARRIS factory may also be contacted through a FAX

facility (217/221-7096).

NOTE:

The # symbol used in the parts list means used with (e.g. #C001 = used with C001).

2

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 3

______________________________________________HARRIS

Manual Revision History

Platinum-i Series Intelligent Transmitter™ Technical Manual

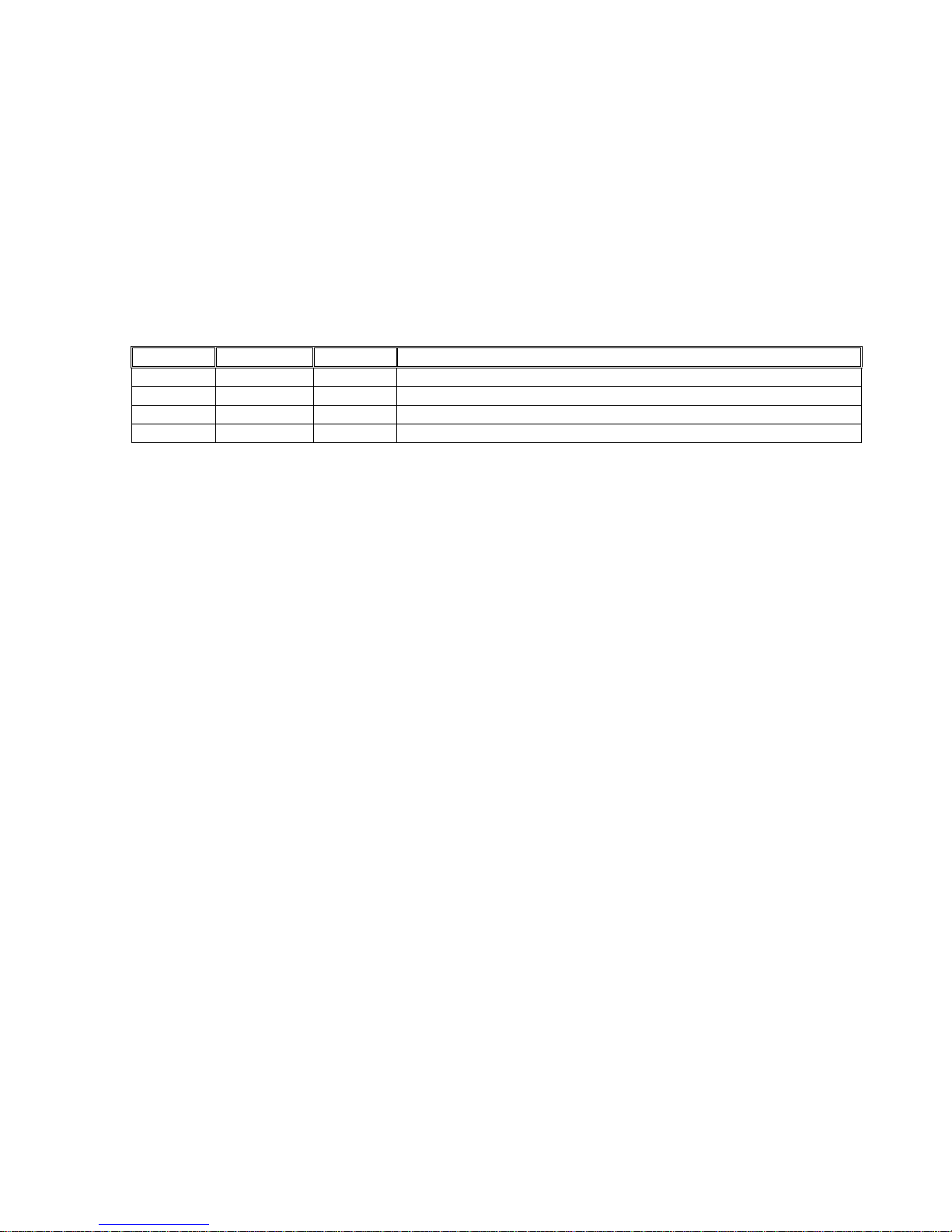

Rev Date ECN Description

A 22Apr2010 P43417 Released

B 20May2010 P47546 Revised Title Page, MRH, and Step-2 on Page-90

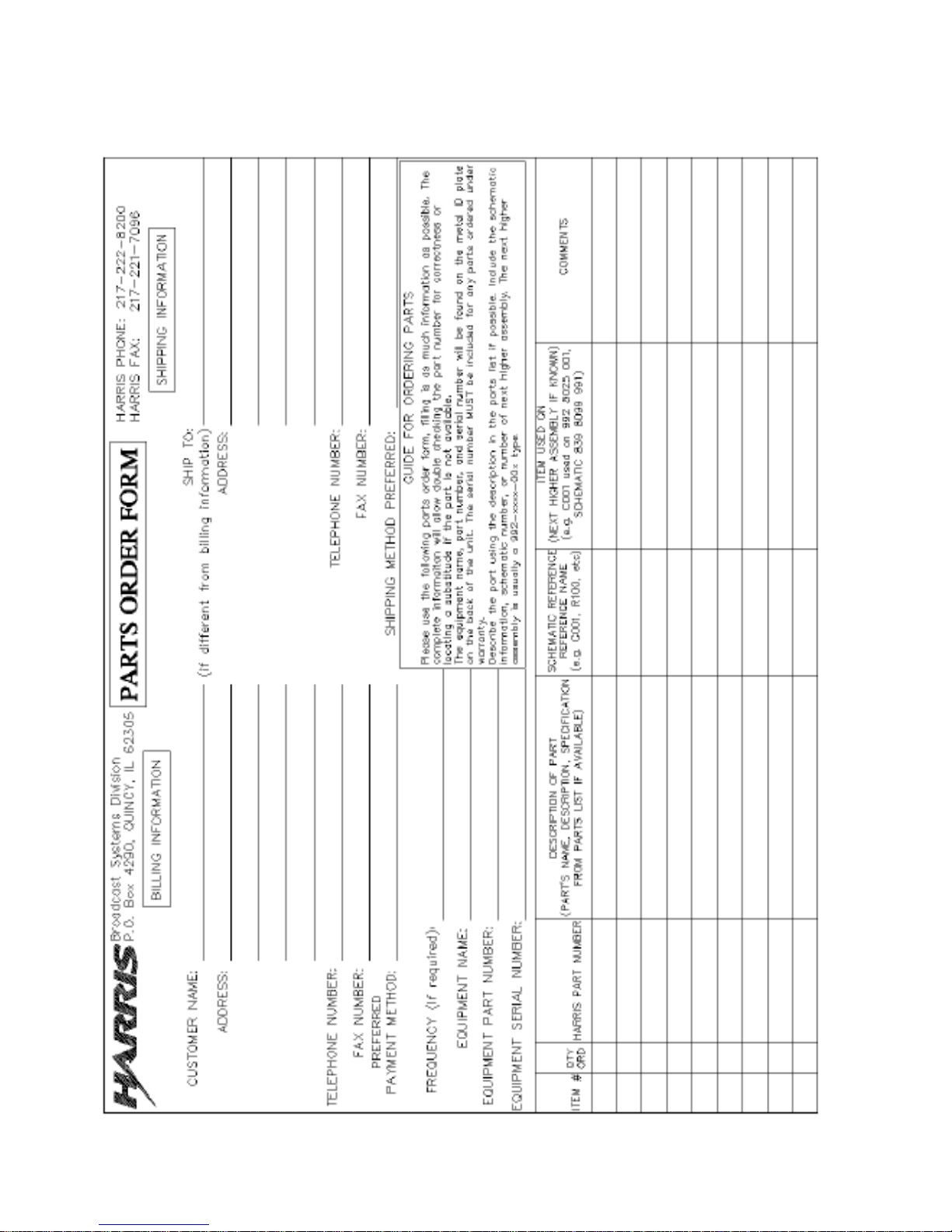

Guide to Using Harris Parts List Information

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

3

Page 4

______________________________________________HARRIS

The Harris Replaceable Parts List Index portrays a tree structure with the major items being leftmost in the index. The

example below shows the Transmitter as the highest item in the tree structure. If you were to look at the bill of materials table

for the Transmitter you would find the Control Cabinet, the PA Cabinet, and the Output Cabinet. In the Replaceable Parts

List Index the Control Cabinet, PA Cabinet, and Output Cabinet show up one indentation level below the Transmitter and

implies that they are used in the Transmitter. The Controller Board is indented one level below the Control Cabinet so it will

show up in the bill of material for the Control Cabinet. The tree structure of this same index is shown to the right of the table

and shows indentation level versus tree structure level.

Example of Replaceable Parts List Index and equivalent tree structure:

Replaceable Parts List Index Part Number Page

Table 7-1. Transmitter 994 9283 001 7-2

Table 7-2. Control Cabinet 992 9244 002 7-3

Table 7-3. Controller Board 992 8344 002 7-6

Table 7-4. PA Cabinet 992 9400 002 7-7

Table 7-5. PA Amplifier 994 7894 002 7-9

Table 7-6. PA Amplifier Board 992 7904 002 7-10

Table 7-7. Output Cabinet 992 9450 001 7-12

The part number of the item is shown to the right of the description as is the page in the manual where the bill for that

part number starts. Inside the actual tables, four main headings are used:

• Table #-#. ITEM NAME - HARRIS PART NUMBER - this line gives the information that corresponds

Replaceable Parts List Index entry;

to the

• HARRIS P/N column gives the ten DIGIT Harris part number (usually in ascending order);

• DESCRIPTION column gives a 25 character or less description of the part number;

• REF. SYMBOLS/EXPLANATIONS column 1) gives the reference designators for the item (i.e., C001,

R102,etc.) that corresponds to the number found in the schematics (C001 in a bill of material is equivalent

to C1 on the schematic) or 2) gives added information or further explanation (i.e., “Used for 208V

operation only,” or “Used for HT 10LS only,” etc.).

Inside the individual tables some standard conventions are used:

• A # symbol in front of a component such as #C001 under the REF. SYMBOLS/EXPLANATIONS

column means that this item is used on or with C001 and is not the actual part number for C001.

• In the ten digit part numbers, if the last three numbers are 000, the item is a part that Harris has

purchased and has not manufactured or modified. If the last three numbers are other than 000, the item is

either manufactured by Harris or is purchased from a vendor and modified for use in the Harris product.

• The first three digits of the ten DIGIT part number tell which family the part number belongs to - for

example, all electrolytic (can) capacitors will be in the same family (524 xxxx 000). If an electrolytic (can)

capacitor is found to have a 9xx xxxx xxx part number (a number outside of the normal family of

numbers), it has probably been modified in some manner at the Harris factory and will therefore show up

farther down into the individual parts

4

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 5

______________________________________________HARRIS

list (because each table is normally sorted in ascending order). Most Harris made or modified assemblies

will have 9xx xxxx xxx numbers associated with them.

The term “SEE HIGHER LEVEL BILL” in the description column implies that the reference designated

part number will show up in a bill that is higher in the tree structure. This is often the case for components

that may be frequency determinant or voltage determinant and are called out in a higher level bill structure

that is more customer dependent than the bill at a lower level.

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

5

Page 6

______________________________________________HARRIS

6

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 7

______________________________________________HARRIS

WARNING:

THE CURRENTS AND VOLTAGES IN THIS EQUIPMENT ARE DANGEROUS.

PERSONNEL MUST AT ALL TIMES OBSERVE SAFETY WARNINGS, INSTRUCTIONS

AND REGULATIONS.

This manual is intended as a general guide for trained and qualified personnel who are

aware of the dangers inherent in handling potentially hazardous electrical/electronic

circuits. It is not intended to contain a complete statement of all safety precautions which

should be observed by personnel in using this or other electronic equipment.

The installation, operation, maintenance and service of this equipment involves risks both

to personnel and equipment, and must be performed only by qualified personnel

exercising due care.

HARRIS CORPORATION shall not be responsible for injury or damage resulting from

improper procedures or from the use of improperly trained or inexperienced personnel

performing such tasks. During installation and operation of this equipment, local building

codes and fire protection standards must be observed.

The following National Fire Protection Association (NFPA) standards are recommended

as reference:

- Automatic Fire Detectors, No. 72E

- Installation, Maintenance, and Use of Portable Fire Extinguishers, No. 10

- Halogenated Fire Extinguishing Agent Systems, No. 12A

WARNING:

ALWAYS DISCONNECT POWER BEFORE OPENING COVERS, DOORS,

ENCLOSURES, GATES, PANELS OR SHIELDS. ALWAYS USE GROUNDING STICKS

AND SHORT OUT HIGH VOLTAGE POINTS BEFORE SERVICING. NEVER MAKE

INTERNAL ADJUSTMENTS, PERFORM MAINTENANCE OR SERVICE WHEN ALONE

OR WHEN FATIGUED.

Do not remove, short-circuit or tamper with interlock switches on access covers, doors,

enclosures, gates, panels or shields. Keep away from live circuits, know your equipment

and don’t take chances.

WARNING:

IN CASE OF EMERGENCY ENSURE THAT POWER HAS BEEN DISCONNECTED.

WARNING:

IF OIL FILLED OR ELECTROLYTIC CAPACITORS ARE UTILIZED IN YOUR

EQUIPMENT, AND IF A LEAK OR BULGE IS APPARENT ON THE CAPACITOR CASE

WHEN THE UNIT IS OPENED FOR SERVICE OR MAINTENANCE, ALLOW THE UNIT

TO COOL DOWN BEFORE ATTEMPTING TO REMOVE THE DEFECTIVE

CAPACITOR. DO NOT ATTEMPT TO SERVICE A DEFECTIVE CAPACITOR WHILE IT

IS HOT DUE TO THE POSSIBILITY OF A CASE RUPTURE AND SUBSEQUENT

INJURY.

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

7

Page 8

______________________________________________HARRIS

Table of Contents

Platinum-i Series Analog

Transmitter

Section 1

Introduction

Introduction....................13

Transmitter Configurations......13

Organization of Transmitter Doc.14

GeneralDescription..............15

AC Power Distribution...........16

Transmitter Control System......17

Main Controller.................17

PA Cabinet Slave Controllers....17

Control Cabinet.................18

Control System Block Diagram....19

50 Volt Power Supply............20

RF Amplifier Modules............20

Power Amplifier Modules.........20

Driver Modules..................20

Visual Signal Flow Path.........20

Exciter.........................20

Transmitter AGC Module..........21

Phase and Gain Module...........21

Visual RF Chains................21

Aural Signal Path...............23

Exciter.........................23

Dual Carrier Systems............23

AGC Module......................23

Phase and Gain..................24

Aural RF Amplifier Chains.......24

Transmitter Output Networks.....25

Transmitter System Theory.......25

Control System..................25

Main Controller Board...........26

PA Cabinet Slave Controller ....26

Module Controller...............26

Control Cabinet.................26

Exciter Switcher................26

Transmitter AGC Module..........26

Phase and Gain..................26

Signal Interface................27

RF PA Cabinets..................27

50 Volt Power Supply............27

RF Output Systems...............27

Platinum RF Combining para......28

Percent of Cabinet Power 3 Cab..28

Percent of Cabinet Power 4 Cab..29

Specifications..................30

Section 2

Installation

Introduction....................33

Installation Planning...........33

Space Requirements..............35

Weights.........................35

RF System Layout................35

Air System......................36

Outside Air Cooling.............36

Air Conditioning................37

Electrical Power................37

Circuit Breaker Selection.......37

Isolation Transformer...........38

Unpacking and EquipmentInvent...38

Equipment Required for Unload...38

Inventory and Inspection........39

Packing Check List..............39

Factory Test Data Sheets........39

Cabinet Placement and Leveling..40

Grounding.......................40

Tap Transformers................41

Installation of 50 Volt Supp....41

RF Output Coax..................41

AC Primary Wiring...............42

UPS Installation................42

Inter-cabinet Wiring............42

Input Signal Wiring.............43

Interlocks and Interfaces.......43

External Interlock: TB1-1, 2....43

Fail-safe Interlock: TB1-3, 4...43

Individual PA Cab External Int..44

External Blower Control.........44

RF Samples......................44

Remote Control I/O..............45

Command In......................45

J31 COMMAND INPUTS..............45

Command Functions...............46

J32: Status Outputs.............46

Status Functions................47

J33: Analog Outputs.............48

J33 Calibrated Outputs Range....48

Optional Remote Status..........48

8

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 9

______________________________________________HARRIS

Table of Contents (continued)

J34 Optional Status...............49

Transmitter Check Out.............49

Control Cabinet Pre-Operational...49

3 Phase AC and Logic SupplyCheck..49

GUI Setup.........................50

PA Cabinet Checkout...............51

Module Installation...............53

Control System Check Out..........53

Initial Applctn RF Visual Power...54

InitialApplctn RF Aural Power.....55

Power Calibration.................57

Basics of Power Calibration.......57

Visual Power Calibration..........57

PA Cabinet Power Calibration......58

Two Cabinet Reject Load...........58

Three and Four Cabinet Calibra....58

Aural Power Calibration...........59

System Forward Power..............59

Reflected Power...................59

PA Cabinet Power Calibration......59

Two Cabinet Reject Load...........59

Three and Four Cabinet Calibra....60

Visual VSWR Calibration...........60

Aural VSWR Calibration............61

Power Limit.......................62

Section 3

Software Installation/Setup

Re Introduction...................63

eCDi™ and the Platinum-i™Trans....63

Hardware..........................64

Features..........................64

Web GUI...........................65

SNMP Agent........................66

Level 1/Level 2 Functionality.....66

Security..........................67

Downloading the Manual............67

Setup.............................68

Detailed Installation Procedures..69

CD-1A Exciter Serial Number Reset.69

eCDi™ Configuration...............70

Troubleshooting Tips..............72

Apply Changes.....................86

Backing Up the Configuration......87

Restoring a Configuration File....87

Reset Computer IP Address.........87

eCDi Software Updates.............88

Updating the eCDi™.............88

Before Starting................88

Main Controller SerialProgram..91

Exciter Switcher...............92

AGC Module.....................93

PA Cabinets....................95

Slave Controller Indicators....95

RF PA Module LED Display.......97

Operation......................98

Turn ON Sequence...............98

Turn OFF Sequence..............98

Power Raise/Lower..............99

AGC Setup......................99

Section 4

Operation

Introduction..................101

Graphical User Interface......101

376 Micro Controller CPLD.....102

Front Control Panel...........103

CONTROL Pushbuttons...........103

STATUS Indicators/Pushbuttons.103

Auxiliary Control Panel.......104

GUI and eCDi Control..........105

A Short Tutorialusing the GUI.107

GUI Display Screen............109

Fault & Event Screen..........109

Fault Alarm Listing...........110

Control Section...............111

Status and Metering Screens...111

Drive Tab.....................111

PA Cabinet Tab................115

Output Tab....................118

P.S. Power Supply Tab.........122

System Tab....................125

GUI Screen Faults Sum List....127

Section 5

Control System Theory

ControlSystemOverall Descrip..129

Transmitter Control System....129

Micro Module..................131

Features of the 376 module....132

CPLD, Complex Prog Logic Dev..132

I/O Expansion.................132

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

9

Page 10

______________________________________________HARRIS

Table of Contents (continued)

Life Support Backup..............133

Controller Area Network(CAN)Bus..133

Main Controller..................135

Transmitter Control..............135

Graphical User Interface (GUI)...135

Remote Controls..................135

Control Panel & Indicator Dis....135

Introduction.....................137

Modes of Operation...............137

Button Press.....................137

Button / Indicator Lighting......138

Button States....................139

Messages in the LED Display......140

FP Error.........................140

Com Error, Main Controller.......140

Other Indicators.................140

LIfe Support Functionality.......141

Status Indicators................141

Switches.........................141

Test Points......................141

Module Logic.....................142

Main Controller..................142

Platinum-i TV Controller.........142

Micromodule Interface (Sheet 2)..143

Micro Module (Sheet 3)...........143

Development Hrdwr & Bd (Sheet 3).143

RS232, Watch Dog & Fr Pnl(Sht4)..144

Controller Analog Sense (Sht 5)..144

CPLD (Sheet 6)...................144

Cabinet Bus Controller (Sht 7)...145

Transmitter ON/OFF Cntrl (Sht 8).145

Foldback Voltage D /A (Sheet 9)..145

Controller/Exc Swtchr (Sht 10)...145

Line Voltage & AGC Mon(Sht 11)...145

Interlocks (Sheet 12)............146

Peak Detectors (Shts 13 and 14)..146

Fault Detection (Sheet 15).......146

Dual Tran Interface (Sheet 16)...147

Remote Commands Input (Sht 17)...147

Remote Status Out (Shts 18-19)...147

Optional Remote Status (Sht 20)..147

Remote Analog Outputs (Sheet 21).147

DC Distribution..................148

The Slave Controller Descrip.....148

Slave Controller...............148

Sheet 1........................148

Sheet 2........................149

Sheets 3 and 4.................149

Sheet 5........................149

Sheet 6........................150

Sheet 7........................150

Sheet 8........................150

Sheet 9........................150

Graphical User Interface.......150

Section 6

Control Cabinet

Introduction...................151

Control Cabinet Common.........151

Control Interconnects..........152

AC Power Distribution..........152

DC Power Supplies..............152

Diode Oring....................153

Wiring Diagram, Cntrl Cab Dig..153

RF Flow Path...................153

Main Controller................153

Front Panel Switch Unit........153

Display Unit...................154

Accessory Tray.................154

Exciter Switcher (843-5275-211)154

Logic Crd Detailed Ckt Descrip.155

Exciter Switcher Relay Bd Pnl..155

Operational Setup and Adj......155

Troubleshooting................157

AGC............................157

Detailed Circuit Description...157

Operational Setup and Adj......158

Troubleshooting................158

Phase and Gain.................159

Detailed Circuit Description...159

Operational Setup and Adj......161

Troubleshooting................162

UPS Battery Testing............162

10

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 11

______________________________________________HARRIS

Table of Contents (continued)

Section 7

PA Cabinet

Introduction.....................163

Theory of Operation..............163

AC Power Flow....................163

Fan and air flow monitoring......163

Interlock Circuits...............163

SCR crowbar......................164

Mechanical Shorting Switch.......164

PA Cabinet Control Logic.........164

Analog PA Cabinet RF Config......164

15KW Vision only PA Cabinet......164

Vision Driver & Sound PA Cabinet.165

Comb Sound & Vision 10KW PA Cab..165

Power Divider....................165

PA Output Combiner Network.......166

Gysel Combiner Theory............166

Maintenance and Troubleshooting..168

Cooling System...................168

Air Filter Replacement...........168

Air Switch Adjustment............168

Back Door Fan....................170

Check for Loose Connections......170

Check MOV Boards.................171

Checking Multi PA Cab Intrlcks...171

Cleaning.........................171

RF Trouble Shooting Divider Comb.172

Section 8

RF Amplifier Modules

General Information..............173

Factory Module Repair............173

Local Module Repair..............174

Module Part Numbers..............174

RF Amplifier Modules Theory......175

Driver Module, Lo Band (Band I)..176

Driver Module, Hi Band (Band II).177

PA Module........................178

RF Quarter Modules...............180

Low Band Quarter Module..........180

High Band Quarter Module.........181

Quarter Module Bias..............182

Protection, Cntrl & Monitor......183

Module Status LEDs...............184

Red LED Fault Blink Codes........185

Module Troubleshooting.........186

Platinum Module Test Fix......187

Troubleshooting-Module Swap....189

Troubleshooting Blink Codes....189

Isolating Other Failures.......194

Locating Failed RF FETs........196

DC Resistance Test.............196

Idle Current Test..............196

Parts Replacement Proced.......197

Soldering Precautions..........197

Quarter Module Replacemnt......199

RF FET Replacement.............200

Testing and Replacing Iso Res..204

Pass FET Replacement...........204

Chip Cap Replacement...........205

Test Procedure TV Modules......205

Pre-operational Checks.........205

Initial Power Up...............205

Idle Current Check.............205

Over/Under Voltage Check.......206

RF Testing.....................206

Application of Drive...........207

Gain Check.....................207

ISO Volts Check................208

Overdrive Check................208

VSWR Protection Check..........210

Section 9

50 Volt Supply

Introduction...................213

Theory of Operation............213

Transformer Primary............213

Six Phase SCR Rectification....214

DC Supply Filtering............214

Control Board..................214

Controller Power Supply........215

50 V Supply Regulation Ckt.....215

Fault Protection Circuits......216

GO / NOGO Circuit..............216

Troubleshooting and Maint......217

Over-temp Fault................218

Over-voltage...................219

Over-current...................219

Breaker Trips..................219

Slave Cntrlr PS Fault Indicat..219

Delay Angle Balance Adjust.....220

Vendor Repair..................229

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

11

Page 12

______________________________________________HARRIS

NOTES:

12

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 13

______________________________________________HARRIS

Section 1 1

Platinum-i Series Analog

Transmitter Introduction

______________________________________________________________________

1.1 Introduction

This manual is desrcibes the Harris Analog Platinum-i

transmitters which include the following models with their peak sync power ratings.

Larger models are available by request. Each model is rated for 10% aural.

MODEL POWER MODEL POWER

HT15HS/LS 15 KW HT10HSP 10 KW

HT11LSP 11 KW

HT30HS/LS 30 KW HT20HSP 20 KW

HT22LSP 22 KW

HT45HS/LS 45 KW HT30HSP 30 KW

HT33LSP 33 KW

HT60HS/LS 60 KW HT40HSP 40 KW

HT44LSP 44 KW

TM

series of solid state VHF

1.1.1 Transmitter Configurations

The Platinum-i series contains a separate intelligent control cabinet that can be used in

multiple Platinum Analog transmitter configurations.

There are 2 basic PA cabinet configurations: Standard and Parallel Path. In Standard

configuration; a separate PA cabinet houses vision Driver(s), vision Driver PAs, sound

Driver(s), and the sound PAs. This cabinet is often referred to as the Aural/Driver

Cabinet or Sound/Driver Cabinet. In addition to the Aural/Driver Cabinet are 15kW

vision PA building block cabinets. A 30kW system would include 1 Aural/Driver Cabinet

plus two 15kW vision PA cabinets. In Parallel Path configuration there is no separate

Aural/Driver cabinet. Instead, each PA Cabinet contains vision and sound Drivers, vision

Driver PAs plus sound PAs resulting in 10kW building block cabinets. Thus a 20kW

system would have 2 PA cabinets plus the Control Cabinet.

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

13

Page 14

______________________________________________HARRIS

NOTE:

The HT60HS/LS Standard configuration system uses 2 Aural/Driver cabinets.

1.1.2 Organization of Transmitter Documentation

• The documentation consists of:

a. Platinum-i Analog Technical Manual (this manual)

b. Platinum-i Analog Drawing Package for High Band or for Low Band

c. HX1V Exciter Manual (a separate manual and drawing package).

• Organization of the Technical Manuals

The text part of the manual is divided into the following sections.

Section 1: Introduction

Section 2: Hardware Installation

Section 3: Software Installation and Setup

Section 4: Operation

Section 5: Control System Theory of Operation

Section 6: Control Cabinet

Section 7: PA Cabinet

Section 8: RF Modules

Section 9: 50 Volt Power Supply

Section 10: Parts Listing

There are different drawing packages for low band and high band systems: the drive

chains and modules are different. The drawing packages are organized in sections with

tab separators as follows:

10K SYSTEM or 15K SYSTEM COMMON SUBSYSTEMS

100 HT10H/11LSP i HT15H/LS i 600 Control System

200 HT20H/22LSP i HT30H/LS i 700 Control Cabinet

300 HT30H/33LSP i HT45H/LS i 800 PA Cabinet

400 HT40H/LSP i HT60H/LS i 900 50 Volt Power Supply

500 NOT USED 1000 High Power RF Modules

14

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 15

______________________________________________HARRIS

1.2 General Description

The Analog Platinum-i

cabinets (PA). and RF output system. The RF system includes a color notch filter,

harmonic filter and a vision plus sound RF combiner feeding the antenna.

The eCDi version of the control cabinet will be used with new Platinum-i cabinets and

as a retrofit to older PA cabinets. The different versions of the PA cabinet will use

various drive configuration and different modules types.

TM

WARNING: Disconnect and lockout AC primary power prior to servicing

Figure 1- HT10HSi/LSi

consists of a control cabinet, one or more power amplifier

888-9058-001

15

Page 16

______________________________________________HARRIS

Another use will be to retrofit existing analog transmitters to digital service. These

PAs will continue to use the 12 or 17 visual PA module configuration as the digital

power amplifier.

Platinum Series transmitters employ rugged field effect transistors (FETs), parallel

amplifier modules, multiple power supplies, and a high-resolution flat display screen for

monitoring.

The control and monitor system includes storage of fault events with time, date, and

description. VSWR foldback automatically reduces power during high VSWR operation,

such as that encountered with antenna icing.

Available options include dual exciters, an automatic exciter switcher, and redundant

control power supplies.

Each transmitter consists of a control cabinet and one or more amplifier cabinets.

Transmitters from 1-10 kW have a single amplifier cabinet containing the aural path, the

visual drive chain, and the visual final. 20 kW transmitters have two amplifier cabinets like

those used in the 10 kW transmitter.

15 kW transmitters have two amplifier cabinets: one for the aural path and visual drive

chain, and one for the visual final. 30 kW transmitters have one cabinet for aural path and

visual drive chain, and two 15 kW visual final cabinets. 45kWunits have two aural

path/visual drive chain cabinets and three 15 kW visual finals. Finally, 60 kW transmitters

have six cabinets, doubling the 30 kW architecture.

In transmitters with multiple visual amplifier cabinets, outboard hybrids are used to

combine the outputs of the visual finals. Optional notch or hybrid diplexers are available

for all models to combine aural and visual signals to permit using a common antenna

system.

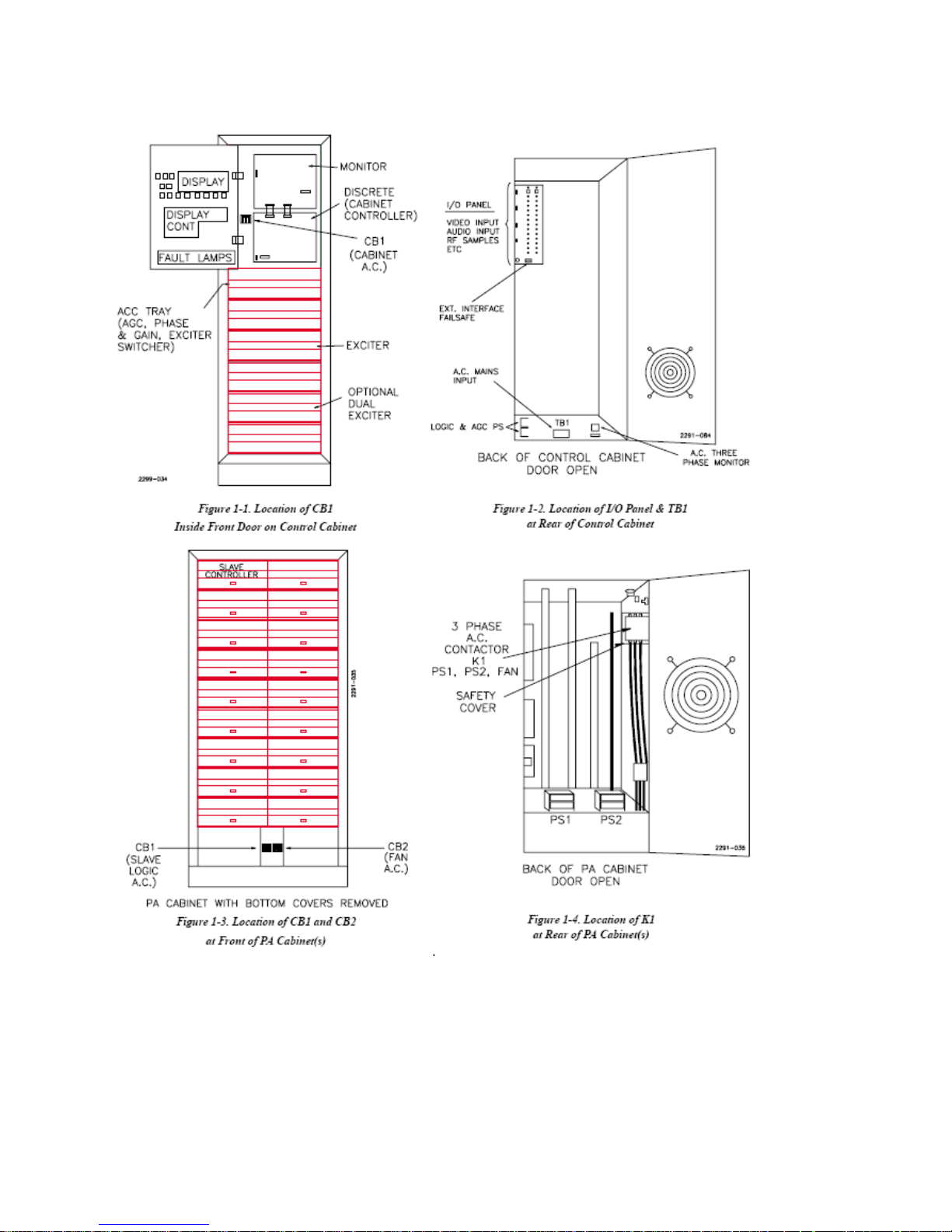

1.2.1 AC Power Distribution

Refer to AC Power Distribution drawing for the following discussion. Each cabinet has its

own AC power source. Control cabinet breaker CB-1, located behind the control panel left

of the controller boards, protects the wiring in the control cabinet (see Figure 1-1). A phase

monitor guards against low voltage, loss of one phase, and reversal of the phase

sequencing. Line voltage samples are provided for the system monitor. All logic supplies,

exciter power and fan in the control cabinet are controlled by CB-1.

Each amplifier cabinet’s AC power is fed through CB-1 to the logic supply (see Figure 1-

3). AC Contactor K-1 feeds the 50 volt supplies and fan breaker CB-2 (see Figure 1- 4).

Aux relay K-2 activates the AC contactor through commands from the slave controller.

16

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 17

______________________________________________HARRIS

1.2.2 Transmitter Control System

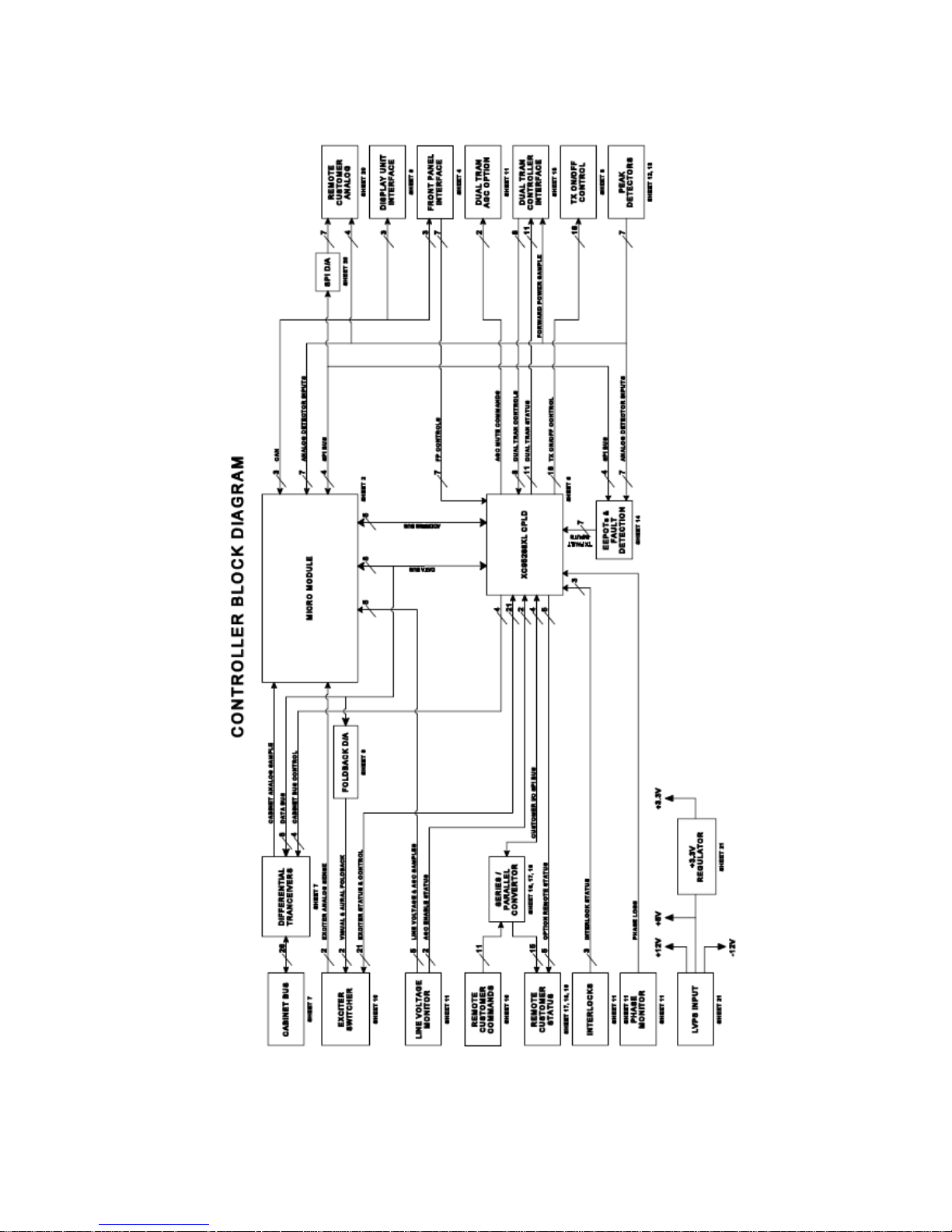

See Figure 1-5. The control system for the transmitter consists of a main controller

mounted in the control cabinet, plus individual slave controllers mounted in each amplifier

cabinet. Data from the system is interfaced through the monitor board to the display

controller, and shown on the front panel flat display screen as bar graphs and numerical

readings. Transmitter ON/OFF, LOCAL/REMOTE, and power RAISE/LOWER switches

are located on the control cabinet, to the right of the display panel.

1.2.3 Display Panel

The main control system samples each cabinet and gathers all of the status and analog data

for the display. The touch screen display is part of a monitoring computer and the main

controller will continue operation of the transmitter when this computer has a fault. The

control panel indicators back up the touch screen and operation button back up the touch

screen button functions.

1.2.4 Main Controller

The transmitter main control unit provides a central point for control and monitoring the

entire system. The main controller interfaces with the slave controller(s) for the amplifier

cabinets’ ON/OFF commands, and with the exciter for power RAISE/LOWER commands.

Peak detectors collect aural and visual RF samples and send them to the main controller for

power metering. The main controller also directs VSWR foldback action.

The main controller has a battery backup to restore the transmitter to its previous operating

condition after a temporary AC power failure. A power down timer will automatically turn

the transmitter off if the power is not restored within approximately two hours. Remote

status and analog outputs are provided by the main controller to a series of D connectors in

the rear of the control cabinet.

1.2.5 Slave Controllers

The slave controllers are mounted in the upper left-hand slot of each amplifier cabinet.

Each is responsible for controlling and monitoring its PA cabinet. The controllers interface

the cabinet to the main controller and monitor in the control cabinet.

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

17

Page 18

______________________________________________HARRIS

18

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 19

______________________________________________HARRIS

WARNING: Disconnect and lockout AC primary power prior to servicing

Figure 1-5, Control System Block Diagram

888-9058-001

19

Page 20

______________________________________________HARRIS

Each slave controller controls a cabinet’s fan motor, 50 volt DC supplies, and RF amplifier

modules. Slave controllers also report cabinet door interlock status, air interlock status,

module faults, and power supply faults to the main controller.

Cabinet input drive and RF power output samples, detected by RF peak detectors, are

relayed to the main controller through the slave controllers as well.

In the event of loss of the main controller, each slave may be used to operate its amplifier

cabinet for emergency service.

1.2.7 50 Volt Power Supplies

Each PA cabinet has one or two 50 volt supplies, depending on system configuration.

These supplies convert the AC power to 50 volts DC for the RF amplifier modules. Each is

rated at 300 amps, and regulated to hold the transmitter power stable despite power line

voltage changes. Internal fault protection is interfaced to the slave controller.

1.2.8 RF Amplifier Modules

Only two types of RF amplifier modules are used in the aural and visual chains of any

given Platinum transmitter system:

1.2.8.1 Power Amplifiers (PAs)

PAs are used primarily as final amplifiers. Each is capable of supplying 1,050 watts RF

output, either aural CW or visual peak sync. PAs are also used as inter-stage amplifiers in

larger visual cabinets, to drive several subsequent parallel PA modules. PAs are singlestage amplifiers, consisting of paralleled class AB amplifiers.

1.2.8.2 Driver Modules

Driver modules provide high gain. Primarily used in preamp applications to drive PAs, they

are also used as aural final amplifiers in low power applications. Driver modules are keyed

so that they cannot be plugged into a PA slot.

Low band drivers contain two cascaded class A stages. High band drivers contain two class

A stages and one class AB stage. In both cases, the final stage in a driver consists of two

paralleled amplifier blocks.

1.2.9 Visual Signal Flow Path

A basic visual signal flow topology is common to all Platinum Series transmitters. For the

following discussion, refer to the transmitter block diagram in the drawing package.

1.2.9.1 Exciter

Video is applied to the exciter where it is clamped, pre-corrected for differential gain and

differential phase, and modulated onto the IF carrier (37 MHz for system M/NTSC,

38.9MHz for B/PAL). Next, frequency response and group delay are corrected. Vestigial

sideband filtering follows. The IF signal then passes through an AGC amplifier to

correctors for linearity and ICPM. A local oscillator and mixer in the exciter upconvert the

20

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 21

______________________________________________HARRIS

IF signal to the transmit frequency, and the resulting signal is bandpass filtered and

amplified. The exciter’s final amplifier is capable of supplying up to 1 watt peak sync to

subsequent stages, and a sample of its output is routed to the exciter’s AGC circuit to hold

the exciter’s power output constant.

If optional dual exciters and an exciter switcher are used, both exciters are fed a video

signal, and each exciter’s visual output feeds the switcher.

1.2.9.2 Transmitter AGC Module

The exciter switcher output (or single exciter output) then passes to the transmitter AGC

module whose job is to maintain a constant gain loop by monitoring a sample of transmitter

visual output and correspondingly controlling exciter drive.

1.2.9.3 Phase and Gain Module

In transmitters with multiple visual PA cabinets, the AGC module passes the RF signal to

one or more phase and gain modules. Each phase and gain module splits the drive into two

parts whose relative amplitude and phase are adjustable. This allows trimming to

compensate for small gain and phase differences between cabinets, to insure the cabinet

outputs maintain the proper phase and amplitude relationships when passed to the final

hybrid Combiner(s).

The number of phase and gain modules used depends on the number of visual PA cabinets.

In transmitters with a single visual PA cabinet (15 kW and below), no phase and gain

modules are

necessary. The output of the AGC module passes directly to the RF chain.

Since phase and gain modules introduce loss into the system, additional preamps are

sometimes necessary. The locations of phase and gain modules and preamps, vary by

configuration. For details, see the descriptions in the following section on visual the

RF chain configurations.

1.2.9.4 Visual RF Amplifier Chains

The Visual RF amplifier chains in the various models vary in complexity from as few as

two amplifier modules to over sixty. Following are synopses of the various combinations:

10 kW HT10HSP and the HT11LSP which is 11kW, Parallel Path,

The AGC output feeds a driver module, whose output passes through a PA module. In

a 10 kW and 11kW transmitters, a 12-way divider feeds 12 PA modules.

The PA outputs are recombined in a six-way (5 kW) or twelve-way (10 kW)

combiner, whose output becomes the cabinet’s visual output.

In a 20 kW system (also 22kW Low band), the AGC module feeds a phase and gain

module, whose outputs feed two 10 kW (11kW) visual cabinets like those described

above. A 3 dB quadrature hybrid then combines the two cabinet outputs.

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

21

Page 22

______________________________________________HARRIS

15 kW (Standard)

In a 15 kW system, the AGC module’s output feeds a driver module, which drives a

PA module. In a low band transmitter, the PA’s output is split in a 16-way divider,

whose outputs feed 16 PA modules. The outputs are recombined in a 16-way

combiner, whose output becomes the cabinet’s visual output.

In high band transmitters, the same principle applies, except that 17 PA modules and

17-way dividers and combiners are used.

The 30, 45, and 60 kW transmitter visual chains are multiples of this basic 15 kW

architecture.

30 kW (Standard)

In a 30 kW transmitter, the AGC output passes through a phase and gain module. In

high band systems, the two outputs are sent to two preamps. In low band systems, the

preamps are not necessary.

The resulting outputs are sent to two 15 kW visual cabinets (see 15 kW system,

above). The cabinet outputs are combined with a 3 dB quadrature hybrid combiner.

45 kW (Standard)

In a 45 kW system, one phase and gain module feeds one visual cabinet and a

preamp, whose output feeds a second phase and gain module. Three outputs are thus

obtained. In high band systems, a preamp is inserted in each path at this point, and

the three outputs pass to the aural PA and visual driver cabinet. In low band systems,

these three preamps are omitted.

The three outputs are each fed to driver modules. In low band systems, the driver

outputs are each passed to one of three PA modules, whose outputs each drive a 15

kW visual PA cabinet (see 15 kW system, above).

In high band systems, each of the three drivers supplies input to a pair of PA

modules. The PAs are paralleled into pairs using two-way power dividers and

combiners. The three outputs then pass to three 15 kW visual cabinets (see 15 kW

system, above).

At the outputs of the three visual PA cabinets, a 3 dB hybrid combines the first two

visual cabinet outputs, which combine with the third in a 4.77/1.76 dB asymmetrical

hybrid combiner. The combined output passes through a harmonic and color notch

filter on its way to the optional diplexer.

60 kW (Standard)

The AGC module output feeds a phase and gain module, whose outputs feed two

more phase and gain modules.

22

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 23

______________________________________________HARRIS

In low band systems, the four outputs are sent to four driver modules, which in turn

are used to drive four PA modules. These four outputs drive four 15 kW visual PA

cabinets (see 15 kW system, above).

In high band transmitters, the four phase and gain module outputs to four driver

modules. Each driver module output is split using a two-way divider, whose outputs

each drive a PA module. The PA module outputs are recombined using four two-way

combiners, before passing to the four 15 kW PA cabinets (see 15 kW system, above).

The visual cabinet outputs are recombined in pairs, using two 3 dB quadrature

hybrids. Finally, the pairs are recombined with a final 3 dB hybrid.

1.2.10 Aural Signal Path

Again, the basic topologies of the aural paths in the various models are similar. As in the

visual path, the exciter aural output passes to an AGC module which monitors a sample of

the aural System output. The AGC module output then drives the aural RF chain. (Refer to

the transmitter block diagram in the drawing package for this discussion.)

1.2.10.1 Exciter

Either monaural audio and SCA, or externally generated composite stereo, is fed to the

exciter and modulated onto an IF frequency, which is lower than that of the visual IF by an

amount equal to the difference between the desired aural and visual carriers. The modulator

is a voltage-controlled oscillator whose center frequency is held constant by a phase-locked

loop (PLL).

IF group delay correction (optional) can be used at this point to improve stereo separation

in systems where notch diplexers are used. The IF signal is converted up to channel using a

mixer and the same LO as in the visual chain. The resulting signal is bandpass filtered and

amplified, becoming the exciter’s aural output. As in the visual path, if dual exciters

(optional) are used, each exciter’s aural output is routed to the exciter switcher.

1.2.10.2 Dual-Carrier Systems

In systems where dual aural carriers are generated, the exciter path takes a different form.

The two signals are modulated onto two different IF carriers, and the modulated carriers are

added together. Linearity pre-correction is added to prevent intermodulation of the two

carriers. The resulting signal is mixed up to channel with the same LO as used in the visual

chain, and is bandpass filtered and amplified, becoming the exciter output.

1.2.10.3 AGC Module

As in the visual path, the exciter switcher output or single exciter feeds an AGC module,

which holds the aural transmitter gain constant by controlling aural RF drive based on

samples of exciter drive and transmitter aural output.

1.2.10.4 Phase and Gain Module

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

23

Page 24

______________________________________________HARRIS

As in the visual signal path, in higher-powered systems, it may become necessary to feed

parallel signal paths through one or more phase and gain modules. These modules allow the

gain and phase of each path to be trimmed, so that the proper phase and amplitude

relationships are obtained at the final combiner input.

1.2.10.5 Aural RF Amplifier Chains

The aural RF amplifier chains vary in complexity depending on visual peak power output,

10% or 20% aural power, and single or parallel paths. The following configurations are

used in the various transmitter models:

10 kW and 15 kW Systems, 10% Aural (normal sound power)

In these systems, the aural AGC output feeds a driver module, whose output is split in

a two-way splitter and sent to two PA modules. The PA module outputs are

recombined in a two-way combiner, whose output passes through a harmonic filter

before reaching the optional notch or hybrid diplexer.

The drive signal is then split four ways in a four-way splitter, whose outputs drive

four parallel PA modules. The outputs are recombined in a four-way combiner and

passed through a harmonic filter before being sent to the optional diplexer.

20 kW Systems, 10% Aural (normal)

The aural AGC module output passes through a phase and gain module. Each of the

two outputs passes to an aural chain in one of the PA cabinets.

Once inside the PA cabinets, the two signals are sent to driver modules. Their outputs

are split using two-way dividers, and the resulting outputs feed an array of four PA

modules. The two PAs in each cabinet feed two-way combiners, and the combiner

outputs feed a 3 dB hybrid used as a final two-way combiner. The resulting signal

passes through a harmonic filter before being sent to the optional diplexer.

30 kW Systems, 10% Aural (normal)

In a high band system, the AGC module output first passes through a preamp. In lowband systems, the preamp is not necessary.

The resulting output drives a driver module. The driver output is divided in a fourway divider, and fed to four parallel PA modules. The outputs are recombined in a

four-way combiner, whose output passes through a harmonic filter on its way to the

optional diplexer.

45 kW Systems, 10% Aural (normal)

In a 45 kW low band system, the AGC module output drives a phase and gain

module, whose outputs drive two driver modules. In high band systems, the two

signals each pass through three-way power dividers, whose outputs feed a total of six

aural PA modules. The PA module outputs are recombined using three-way

combiners and a 3 dB quadrature hybrid, whose output passes through a harmonic

filter to the optional diplexer.

24

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 25

______________________________________________HARRIS

60 kW Systems, 10% Aural (standard)

The AGC module output feeds a phase and gain module. In high band systems, the

two outputs are then fed to two preamps. In low band transmitters, the preamps are

not necessary.

Each of the two outputs feeds a driver module. The driver outputs are each split in

four-way dividers, for a total of eight outputs, and the outputs drive an array of eight

PA modules. The PA outputs pass to four-way power combiners, whose outputs are

combined in a 3 dB quadrature hybrid used as a two-way combiner. The combined

output passes through a harmonic filter before being sent to the optional diplexer.

1.2.11 Transmitter Output Networks

The transmitter output network performs three functions: filtering harmonics from the

outputs, removing color subcarrier remnants from the vestigial sideband, and combining

the aural and visual outputs into a common antenna feed for transmission. Two common

configurations exist:

10 kW Systems

A combination color notch filter/notch diplexer (optional) receives the aural and

visual outputs and combines them. The output then passes through a harmonic filter

to the antenna system.

15-60 kW Systems

Two harmonic filters are used: one in the visual path, and one in the aural path. The

output of the visual harmonic filter feeds a color notch filter. The outputs of the aural

harmonic and visual color notch filters feed a notch diplexer (optional),whose output

passes to the antenna system.

1.3 Transmitter System Theory of Operation

1.3.1 Control System

The transmitter uses a distributed architecture control system . This means that some

transmitter sub-systems include self monitoring and protection and report to the Main

Controller for display on the GUI (Graphical User Interface) and to a remote interface.

The heart of the system is the 376 Micro Module and the XC95288XL CPLD which is

used for control and monitoring interface.

1.3.1.1 Main Controller Board

This board is responsible for transmitter control and monitoring. The Main Controller is

responsible for system level control (multiple sub-systems) since it is the only part of the

control system which can monitor the entire transmitter. This printed wiring board is

mounted just below the top of the cabinet and also serves as the customer and system Input

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

25

Page 26

______________________________________________HARRIS

and Output, I/O. It gathers status and fault data from the individual sub-systems and reports

that information to the operator locally and by remote control.

1.3.1.2 PA Cabinet Slave Controller

This board interfaces with the module and power supply controller boards to transfer

information to the main controller. It also has control functions related to that PA

cabinet. Refer to paragraph 1.2.6.

1.3.1.3 RF Module Controller

A logic and control board responsible for protection and control of the one RF Driver or

PA Module that it is part of.

1.3.1.4 50 RF Module Power Supply Controller Board

Responsible for control and monitoring of the 50V RF amplifier power supplies.

1.3.2 Control Cabinet.

The control cabinet contains a digital exciter, and an optional second Exciter. The RF

signal path includes an optional exciter switcher, automatic gain control module and phase

and gain modules when more than one PA cabinet is used. The main controller and the GUI

are part of the control cabinet. The RF drive levels to the PA cabinet input(s) are in the 25

to 100mW range.

1.3.2.1 Exciter Switcher

If optional dual exciters and an Exciter switcher are used, both exciters are fed video and

the appropriate sound signals. Each Exciter's RF output feeds a logic controlled coax

switch. The selected Exciter signal in a single PA cabinet system then goes to the AGC.

When more than one

PA cabinet is used the AGC output is connected to one or more Phase and Gain units.

1.3.2.2 Transmitter AGC Module

The single Exciter output/exciter switcher output to the transmitter AGC module, whose

job is to maintain a constant drive level by monitoring a sample of transmitter output, and

correspondingly controlling PA cabinet input drive.

1.3.2.3 Phase and Gain

In transmitters with multiple PA cabinets, the AGC module is followed by one or more

phase and gain modules. Each phase and gain module splits the drive into two signals

whose relative amplitude and phase are adjustable. This allows trimming to compensate for

small gain and phase differences between cabinets, so that the PA cabinet outputs maintain

the proper phase and amplitude relationships when combined in the following 3 dB or 4.77

dB hybrid combiner(s). Phase and Gain units are adjusted for minimum hybrid reject load

power.

26

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 27

______________________________________________HARRIS

1.3.3 Signal Interface

Signal interface for signal input and monitoring by remote control is located on top of

the control cabinet. The PA cabinet top is used for the control and monitoring cable

interconnect with the PA cabinet(s) and the monitor sample cables.

1.3.4 RF PA Cabinets

The PA cabinets have independent:

• AC power feed from a circuit breaker.

• Cabinet level control system

• Cooling system, fan and interlock pressure switch

• Logic power supply

• 50 Volt RF module supplies with control logic

• Rear Door interlock

• Cabinet external interlock to protect combining hybrid reject loads. Maintenance can be

performed on one PA cabinet while the others are operating. A block diagram documents

each transmitter configuration in the appropriate drawing package system, sections

through 5.

Refer to paragraph 1.2.9.4 for individual cabinet configurations.

1.3.5 50 Volt Power Supply

These regulated supplies convert the AC power to 50 volts DC for the RF amplifier

modules. Each is rated at 300 amps, and designed to accommodate -10% to +20%

power line voltage changes. Internal supply fault protection is interfaced to the slave

controller.

The PTCD5P1i has one supply. Larger PA cabinets have two 50 volt power supplies.

The supply uses SCRs for voltage regulation. When two power supplies are used, one

supply will be connected as a delta load, the other as a wye load to reduce supply

induced AC mains harmonics. Each supply also has a tuned power line harmonic filter.

This is tuned near the 5 harmonic to reduce a possible motor damaging harmonic.

Single cabinet PAs may have optional internal diode ORing to power driver modules

from either supply.

The 50 Volt supply is covered in detail in this manual section 9.

1.3.6 RF Output Systems

The transmitter output network has several functions, depending on the system, including

combining RF amplifiers, removing out-of-band signals, and filtering harmonics from the

outputs. The sharp tuned (Cool Fuel) filter together with the Apex exciter allow higher

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

27

Page 28

______________________________________________HARRIS

average power levels while maintaining out of band emission specifications by filtering

IMD product near the mask filter shoulder. Some RF systems contain channel combiners,

allowing two or more channels to share the same transmission line and antenna.

Directional coupler units develop RF samples for metering RF power levels and are used as

feedback samples for the exciter real time correction circuits. The IPA sample inputs on the

Apex exciter are not used, therefore the Apex exciter IPA mode should be set to bypass.

The Platinum transmitter system interconnect drawings detail these RF sample connections.

The combining of transmitters on different frequencies often require special attention to

the sample lines for exciter correction and VSWR monitoring. The sample lines may

require filtering and phasing networks to remove unwanted frequencies in the RF samples.

This is critical for RTAC samples.

1.4 Platinum RF Combining Parameters

1.4.1.01 Two PA Cabinets

The parameters for the two cabinet system are easy to determine by applying the hybrid

rules for division and combining to determine how to calibrate the cabinet power levels

and the reject load wattage. When one cabinet does not put out power, the other cabinet

will deliver half of its output power to the antenna, the other half to the reject load. The

cabinet output power is calibrated in watts and the reject power in percentage of the

loads rating.

Example:

Total power out (TPO) is 7.4 KW, each cabinets output is 3.7 KW (ignoring losses) and

cabinet half power would be 1.85 KW. The reject load is rated at 2.5 KW, the power

calibration in this case would be 1.85 / 2.5 or 74 percent.

1.4.0.2 Percent of Cabinet Power With Three PA Cabinets

CABINET CABINET CABINET A/B AB/C COMBINED

A B C REJECT REJECT OUTPUT

100 0 0 50 16.6 33.3

0 100 0 50 16.6 33.3

0 0 100 0 66.6 33.3

100 100 0 0 66.6 133.3

100 0 100 50 16.6 133.3

100 100 100 0 0 300

28

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 29

______________________________________________HARRIS

1.4.0.3 Percent of Power With Four PA Cabinets

CABINETS A/B CABINETS C/D AB/CD COMBINED

A & B REJECT C & D REJECT REJECT OUTPUT

ONE 50 BOTH 0 25 225

BOTH 0 ONE 50 25 225

BOTH 0 NONE 0 100 100

ONE 50 ONE 50 0 100

BOTH 0 BOTH 0 0 400

This information can be used to calibrate the power metering for the cabinet and reject

loads. This is assuming the phase and gain controls have minimized the amount of

reject power and the cabinets output powers are about the same.

1.4.0.4 Drive Power Meter Calibration

The drive levels can be calibrated using the drive directional coupler element. The

Agilent power meter has a offset feature, enter the coupling ratio from the element as

the offset. The power meter now reads the power direct. This procedure can also be

used as an alternative to calibrate the cabinet power out and reject load power.

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

29

Page 30

______________________________________________HARRIS

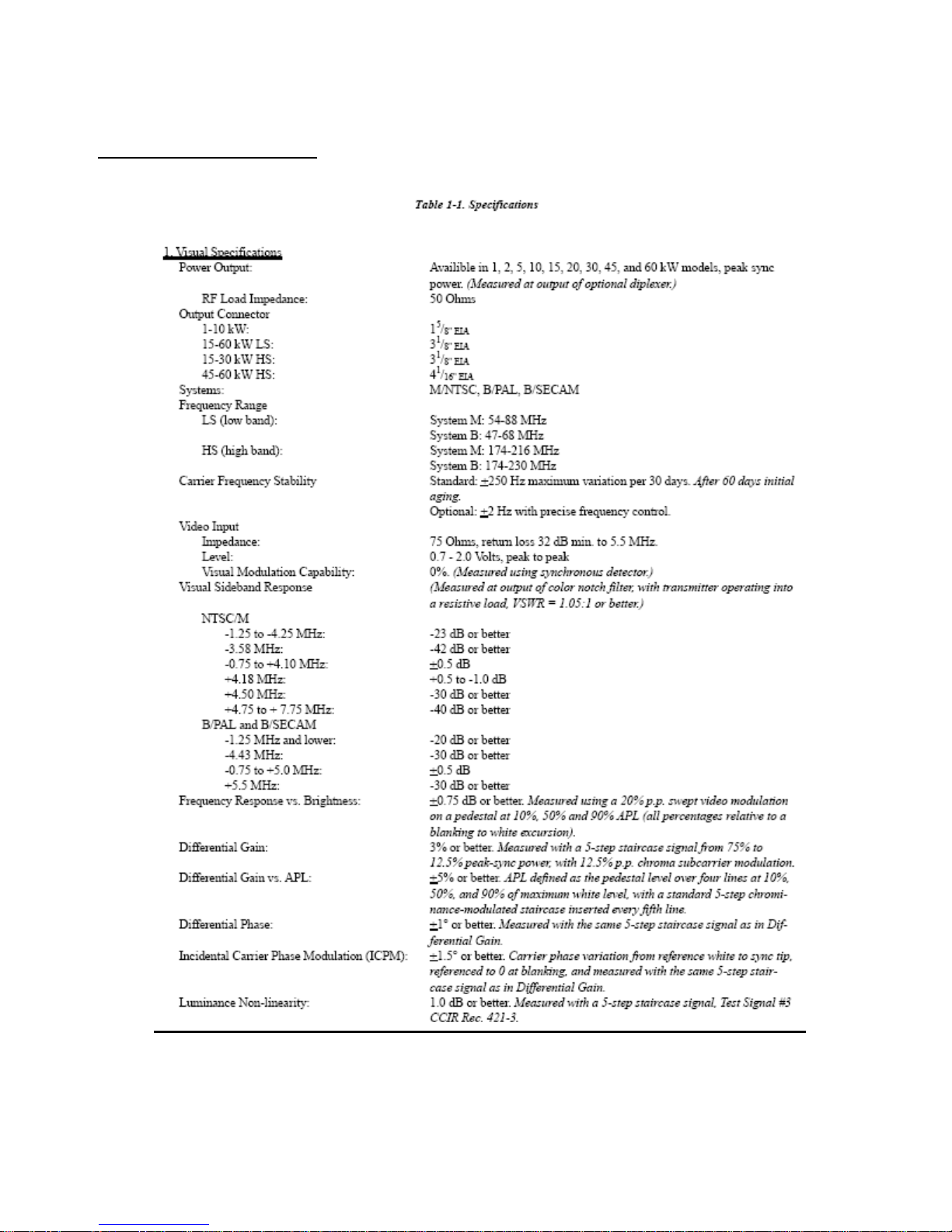

1.3 Specifications

30

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 31

______________________________________________HARRIS

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

31

Page 32

______________________________________________HARRIS

32

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 33

______________________________________________HARRIS

Section 2 2

Platinum-i Series Analog

Transmitter Installation

____________________________________________________________________________

2.1 Introduction

This section contains information necessary to install and to perform initial checkout

procedures on Platinum-i Series television transmitters. The drawing package will

contain drawings referred to in section 2, use the first page Cover Sheet to locate the

drawings.

2.2 Installation Planning

The information in this section is intended to be used only as a general guideline in

planning installation. Since all installations differ in some respects, and in order to

conform to local building and electrical codes, the information contained herein must

be adapted for each particular installation.

Planning and preparation are the most important factors in a successful, efficient, and

safe installation phase of a new transmitter. Study equipment manuals beforehand and

become thoroughly familiar with the installation requirements for each piece of

equipment.

The transmitter equipment installation phases should be planned carefully before the

equipment arrives and a detailed plan worked out and written down. Know what

installation equipment and materials Harris is supplying with the transmitter and what

equipment and materials the station must supply. In general, a transmitter installation

requires that the following areas be addressed:

a. Have a clear plan for transmitter system monitoring and make provision for any

needed RF monitoring samples. Make sure the monitoring equipment will be

suitably located for convenient operation and monitoring. STL and remote control

equipment should also be planned early. While not part of the transmitter,

monitoring and control equipment (and the STL) must be available when installation

is completed to test the transmitter and to put it into service.

b. Plan a star point grounding system for the building and equipment cabinets. This

grounding system should incorporate the grounding system for the AC service

entrance and the grounding system for the tower.

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

33

Page 34

______________________________________________HARRIS

c. When considering the sequence of events during an installation, it is important to

approach the transmitter, its peripherals, and the building as a system . “typical”

drawings are used as references. It must be assumed special requirements will

cause deviations from the published installation drawings in order to accommodate

a particular configuration or building requirement.

d. In a new installation, interior walls should be in place, ceiling work should be

complete, concrete floors should be aged and well sealed, and all painting be

completed before arrival of the equipment or the transmitter is placed in the

room. Transmitters and other electronic equipment can be damaged or made

inoperable by dust and dirt entering the equipment. Even a plastic covering

placed over the transmitter rarely keeps out concrete dust and plaster dust created

from drywall installation.

e. In a new installation, will electrical power be available when needed? Often

transmitter installation and checkout is held up because primary power is not

available.

f. In an existing facility, must an existing transmitter remain on the air during

installation of the new equipment? Plan how this is to be done to minimize off-air time.

g. A staging area should be chosen and set aside to place the boxes and crates that

contain all the smaller parts and assemblies not shipped attached to the transmitter.

A separate area should be used to stage all installation materials (plumbing

materials, wire, conduit and accessories, loose hardware, etc.)

h. Each piece of equipment should be inspected for shipping damage. Inventory all

equipment and the contents of each box and compare to the packing check list

that comes with the equipment.

i. Think about how the equipment will be unloaded. Will the proper lifting and

moving equipment be there when the truck containing the transmitter arrives?

Will there be enough workers there to help?

j. Equipment placement must be worked out carefully. Use a station layout drawing

to determine equipment placement and the order in which the equipment should

be set in place. If possible, lay out equipment location with lines marked on the

floor.

k. When planning placement of the output RF system, make certain the ceiling or

overhead framing will support the weight of the RF components. If not, structure

modification or floor-mounted components may be required.

34

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 35

______________________________________________HARRIS

l. The electrical and RF plumbing work should begin at the start of the installation

in order not to delay completion, however the transmitter, RF output system and

cooling system plumbing should be installed prior to running electrical conduits

or air handling ducts in the transmitter space. This will prevent interference issues

between RF lines and electrical conduit and cooling ductwork.

m. Hanging hardware must be on-hand to avoid delays. Ensure that all pipe hangers,

conduit hangers, threaded rod, beam clamps, Unistrut and Unistrut hardware are

on site.

Ensure that all necessary tools are on site and in good shape when needed. Check

transmitter and other equipment technical manuals to see if any specialized tools are

required. Make arrangements to obtain them if necessary.

2.2.0.1 Space Requirements

(Refer to Transmitter Outline drawings.)

To allow for servicing the transmitter, a minimum clearance of 4 feet in front of and 5

feet behind the cabinets is recommended. Minimum clearances are shown in the

drawings.

Planning for the transmitter room should allow space for program input, monitoring,

remote control, and test equipment as well as the transmitter. Additional area may also

be required for tower lighting, HVAC equipment, storage, and a workbench.

2.2.1 Weights

Weights are listed below each cabinet on the Transmitter Outline drawing. Be sure to

include this information in your planning for the building and verify that the structure is

capable of safely supporting the total weight of the transmitter and its peripheral

equipment. The 50 Volt power supplies are furnished with two metal wheels for easy

movement and installation in the transmitter.

Consider the type of floor on which the power supply will rest. The weight is carried on

two wheels, which will possibly mar the floor. Long term weight may damage the floor,

making power supply removal for maintenance very difficult. Protection of tiled floors

should be considered.

2.2.2 RF System Layout

Refer to the RF Layout drawing for the transmitter and RF system floor plan. A system

of overhead supports and hangers is needed to support the coaxial lines, filters, and

other RF components. The support system should be installed so that the RF

components are completely supported by the hangers, to minimize the weight carried

by the output connectors at the top of the cabinets.

888-9058-001

WARNING: Disconnect and lockout AC primary power prior to servicing

35

Page 36

______________________________________________HARRIS

n. An overhead grid of Unistrut™ or angle iron and 3/8 inch threaded rod is most

commonly used. Pipe hangers for steam pipe may be used to hold the coax, combiners,

etc. Pay special attention to the different types of materials being used. For example, if

galvanized parts are used to support copper RF plumbing, the two must be separated

using adhesive-backed rubber strips or tape to prevent galvanic corrosion.

o. The basic transmitter generally includes filters and directional couplers for metering

and AGC samples. One or more hybrid combiners are present in multiple cabinet

systems. Line is included for a typical installation up to the filter output. Any

other RF line components are purchased separately. Be sure to obtain all components

necessary for your installation.

2.2.3 Air System

2.2.3.1 Outside Air Cooling

The Transmitter Outline drawing shows a typical exhaust duct and blower system, and

the total transmitter requirement for cooling air. Do not include control cabinet in an

overhead hood system, hood turbulent air flow can compromise control cabinet air

flow.

The minimum ceiling height to properly handle exhaust air as shown is 12 feet.

The outline drawing also shows a typical air intake and pre-filter system. Minimum air

flow requirements are 3,500 CFM per PA cabinet.

The intake blower should be sized to provide slight positive room pressure. A

manometer installed to sense pressure drop across the filters can be used to indicate

when pre-filter replacement is due.

If the existing space on site will not permit construction of the recommended air

system,

then care must be taken to modify the design to fit the available space and still properly

cool the transmitter.

Keep in mind that the recommended system is sized only for cooling the transmitter.

Any additional cooling load in the building must be considered when selecting the air

system components.

The transmitter exhaust should not be the only exhaust in the room, as heat from the

peripheral equipment would then be drawn through the transmitter. Additional flushing

air is recommended for the removal of heat from any equipment surrounding the

transmitter. A good guideline is to keep input air no greater than 5 C degrees above

ambient. The maximum transmitter operating temperature is 50 degrees C at sea level

(de-rate 2 C degrees for each 1000 feet above sea level). A high altitude fan blade is

available if this rating is exceeded. Contact Harris field service for information and

application assistance when high altitude operation is required.

36

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 37

______________________________________________HARRIS

2.2.3.2 Air Conditioning

The heat load for planning air conditioning is 6,600 BTU for each PA, the control

cabinet heat load is 500 BTU. The best approach is to keep the room cool with a N+1

system and to minimize the air ducts used. The use of supply ducts is preferred over

ducting of return air.

2.2.4 Electrical Power

Two standards are commonly used as a source of data for AC power systems: the

National Electrical Code published by the National Fire Protection Association in the

United States, and the Canadian Electrical Code published by the Canadian Standards

Association. These standards should be followed since they are referenced in most state

and local codes.

The transmitter is designed to operate from 208, 220/240 or 480 volts, 60 Hz or 80/415

volts, 50 Hz. If voltage variations in excess of +/-10% are anticipated, the transmitter

power input must be equipped with automatic voltage regulators (optional) capable of

correcting the primary AC mains voltage.

The transmitter requires a relatively stable source of input power. For this reason, the

primary power for the transmitter should originate at the main power distribution

system and remain isolated from other electrical distributions.

All wiring and signal inputs are at the top of the cabinets. Overhead cabling is used. No

access is provided in the cabinet floors for under-floor or trench wiring.

AC power to the transmitter should be run in metallic conduit, connected to earth

ground for safety and to provide shielding against interference. All phases should be

run within the same conduit to cancel induced magnetic fields. The power run must be

terminated in a power distribution panel, whose enclosure must also be connected to

earth ground.

2.2.4.1 Circuit Breaker Selection

Refer to AC Distribution Diagram for the connection and breaker sizing information. It

is important that the circuit breakers withstand the listed inrush current. Each cabinet is

fed from the distribution panel through a separate circuit breaker. If fuses are used,

contact Harris Field Service for guidance on fuse sizing and phase loss protection.

NOTE: Starting Surge Requirement

A short-duration starting surge, due to transformer inrush current, will last for a

portion of the first few cycles after power is turned on. During this surge, the

line voltage at the cabinets must not drop below 80% of the rated line voltage.

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

37

Page 38

______________________________________________HARRIS

NOTE: Disconnect Location

The circuit breaker panel should be located near the transmitter in a well lighted

area. As a safety precaution, controls for disconnecting the main power service

supplying the transmitter must be convenient to the operator and maintenance

personnel. Emergency lighting should be provided.

2.2.4.2 Isolation Transformer

If a separate isolation transformer is used, it should be connected to the highest

potential primary source available to minimize voltage fluctuations on the secondary.

The isolation transformer must have both primary and secondary taps so that power

input variations and changes in loads can be compensated. The isolation transformer

must maintain the rated output during the transmitter starting surge. The transformer

should be located as closely as possible to the transmitter.

No load other than the transmitter should be connected to the transformer secondary.

NOTE: Isolation Transformer Loading

Any other loads connected to the isolation transformer, especially from line to

neutral may not tolerate the sine wave distortion inherent in an isolation

transformer.

The feed line to the transformer must be protected by a main line circuit breaker to

protect against a transformer short. Individual cabinets are protected by branch

breakers.

2.3 Unpacking and Equipment Inventory

2.3.1 Shipping Weights & Equipment Needs for Unloading

Before the truck arrives with the new transmitter, have ready on site a fork lift truck or

a suitable unloading dock, a pallet jack, heavy duty two wheel cart, and any other

equipment necessary to unload up to 1100 pounds (500 kg) at the site in question. The

cabinets and power supplies are too heavy to be safely unloaded by hand. An area large

enough to store the boxes should be prepared in advance to help the unloading process.

Remove the cabinets from the truck and set in a location where they cannot be

damaged. If any modules are shipped in individual boxes, save these to ship modules

back for repair.

IMPORTANT:

DO NOT USE THE ROUNDED EDGES OF THE CABINETS FOR

PUSHING, PULLING OR LIFTING!

The Control cabinet and skid together weigh approximately 470 pounds (215

kg). The skid itself weighs 30 pounds (14 kg).

38

WARNING: Disconnect and lockout AC primary power prior to servicing

888-9058-001

Page 39

______________________________________________HARRIS

PA cabinet with skid weighs approximately 990 pounds (450 kg). The amplifier cabinet

skids weigh 65 pounds (30 kg) each.

Weights are generally marked on each box. Check the markings on each container

before lifting.

IMPORTANT:

As each piece is unloaded, inspect for visible damage to unit or packing container.

If any damage is observed unpack and inspect for damage show delivery damage

and note damage on bill of lading. Claims for damage must be filed promptly (48

hours) or claim may be denied. Retain shipping materials until all parts have been

located or as proof of shipping damage.

When the transmitter is delivered to the site, the shipment should be inspected and

inventoried before installation is begun. This section provides information to assist

unpacking and inventory.

2.3.2 Inventory and Inspection

2.3.2.1 Packing Check List

Each transmitter shipment will be accompanied by a packing check list identifying

which equipment is packed in the various crates and boxes. Be sure to locate this

document when the shipment arrives.

The contents of the shipment should be as indicated on the packing lists. If the contents

are incomplete, or if any part is damaged electrically or mechanically, notify the Harris

TV Customer Service Department:

Phone at 217-222-8200

FAX at 217-221-7086

2.3.2.2 Factory Test Data Sheets

A set of factory test data is supplied with each transmitter. It lists parameters for operation

of the transmitter at your power level and channel. These readings were recorded during