Page 1

HMX6803+

8-AES Audio Multiplexer

OP+HMX+

8-AES Audio Multiplexer with Fiber Output

Installation and Operation Manual

Edition B

175-100062-00

Page 2

Page 3

HMX6803+

8-AES Audio Multiplexer

OP+HMX+

8-AES Audio Multiplexer

With Fiber Output

Installation and Operation Manual

Edition B

June 2009

Page 4

Copyright Information

Copyright 2009 Harris Corporation, 1025 West NASA Boulevard, Melbourne,

Florida 32919-0001 U.S.A.

All rights reserved. This product and related documentation are protected by

copyright and are distributed under licenses restricting their use, copying,

distribution, and decompilation. No part of this product or related

documentation may be reproduced in any form by any means withou t prior

written authorization of Harris Corporation and its licensors, if any.

This publication could include technical inaccuracies or typographical errors.

Changes are periodically added to the information herein; these changes will be

incorporated into new editions of the publication. Harris Corporation may make

improvements and/or changes in the product(s) and/or the program(s) described

in this publication at any time.

All trademarks are property of their respective owners.

Warranty Information

The Limited Warranty Policy provides a complete description of your warranty

coverage, limitations, and exclusions, as well as procedures for obtaining

warranty service. To view the complete warranty, visit our website.

This publication is provided “as is” without warranty of any kind, either express

or implied, including, but not limited to, the implied warranties of

merchantability, fitness for a particular purpose, or non-infringement.

Page 5

Content s

Preface

Manual Information ...............................................................................................vii

Purpose ........................................................................................................... vii

Audience .........................................................................................................vii

Revision History .............................................................................................vii

Writing Conventions ..................................................................................... viii

Obtaining Documents ....................................................................................viii

Unpacking/Shipping Information ........................................................................... ix

Unpacking a Product .......................................................................................ix

Product Servicing ............................................................................................ix

Returning a Product .........................................................................................ix

References ............................................................................................................... x

Safety Standards and Compliances ........................................................................xi

Restriction on Hazardous Substances (RoHS) Compliance ............................ xi

Waste from Electrical and Electronic Equipment (WEEE) Compliance .......xii

Safety Terms and Symbols in this Manual ....................................................xiii

Chapter 1: Introduction

Product Description .................................................................................................1

Main Features ......................................... ..........................................................1

Optional Features .............................................................................................2

OP+HMX+ Module Types ...................................................... ........................3

Hardware Options .................................................................................. ..................3

Module Descriptions ...............................................................................................4

Front Module ....................................................................................................4

Back Connectors ..............................................................................................6

Breakout Cables ..................................................................................... ..........6

RS-422/232 Cable ..........................................................................................10

Signal Flow ................................................................................ ............................11

Chapter 2: Installation

Unpacking the Module ..........................................................................................13

Checking the Packing List ..............................................................................14

Choosing HMX6803+ and OP+HMX+ Upgrade Options ............................14

Selecting an External Balun ...........................................................................15

Setting Jumper CJ1 for Local or Remote Control .................................................16

Maximum 6800+ Frame Power Ratings ...............................................................17

Installing 6800+ Modules .....................................................................................18

HMX6803+ and OP+HMX+ Installation and Opera tion Manual iii

Copyright © 2009, Harris Corporation

Page 6

Contents

Required Frames and Back Connector Types ................................................18

Installing and Removing HMX6803+ Modules ............................................18

Installing OP+HMX+ Modules .....................................................................18

Inspecting and Cleaning Fiber Optic Connections .........................................21

Upgrading Module Firmware ................................................................................24

Chapter 3: Operation

Operating Notes .....................................................................................................25

Q-SEE Compliant Thumbnails .............................................................. .. ..............25

Activating HMX6803+ and OP+HMX+ Functions .............................................26

Adding a License Key ....................................................................................26

Audio Test Tones ...........................................................................................27

Audio Embedding Modes ...............................................................................27

Audio Embedding Errors ...............................................................................31

Mono Channel Audio Embedding ...................................... ............................32

Audio V-Fade .................................................................................................33

Input Audio Rate .......................................................................................... ..33

Audio Path ......................................................................................................34

Seamless Sound Function ...............................................................................34

Test Pattern Generator ....................................................................................36

Dolby-E Automatic Header Alignment ..........................................................36

Audio Delay Ranges .......................................................................................36

Maintaining Audio/Video Alignment ............................................................36

AFD/WSS/VI Detection and Insertion ........................................................... 37

Cross-Functional Parameter Changes ....................................................................38

Out Aspect Ratio .......................................................................................... ..38

ADS Clean Parameter ....................................................................................39

PCM/Non-PCM Settings ................................................................................39

Channel Word Length ....................................................................................40

Parameter Availability Based on Operating Mode ........................................40

Changing Parameter Settings ................................................................................42

Changing Parameter Settings Using Card-Edge Controls ..............................42

Changing Parameter Settings Using CCS Software .......................................43

Setting HMX6803+ Remote Control Parameters ..........................................44

LEDs and Alarms ..................................................................................................61

Monitoring LEDs ...........................................................................................61

Module Status LEDs ......................................................................................62

Alarms ............................................................................................................ 63

Chapter 4: Specifications

Overview ............................................................................................................... 65

Inputs ..................................................................................................................... 66

SDI Video Inputs ............................................................................................66

AES/DARS Inputs .........................................................................................67

Outputs ..................................................................................................................68

SDI Video Outputs .........................................................................................68

Laser Output (OP+HMX+ Only) ..........................................................................69

Optical Port (OP+HMX+ Only) ...........................................................................70

RS-232/RS-422 .....................................................................................................71

iv HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 7

Propagation Delay .................................................................................................71

Power Consumption ............................................... .................................... ...........72

Start-Up Time ........................................ .................................... ............................72

Operating Temperature ..........................................................................................72

Appendix A: Audio Bit Manipulation

Overview ............................................................................................................... 73

Manipulating Channel Status Bits (C-Bit) ............................................................74

Manipulating Validity and User Bits (V-Bit and U-Bit) ............................... ........77

Identifying Audio Characteristics

(Audio Sampling Frequency and Word Length) ...................................................78

Appendix B: Laser Safety Guidelines

Laser Safety ...........................................................................................................80

Precautions for Enclosed Systems ..................................................................80

Precautions for Unenclosed Systems ............................................................. 81

Labels ....................................................................................................................82

Appendix C: Communication and Control

Troubleshooting Tips

Overview ............................................................................................................... 83

Software Communication Problems ......................................................................84

Hardware Communication Problems ............................................................... .....87

Contents

Index

Keywords ...............................................................................................................89

HMX6803+ and OP+HMX+ Installation and Operatio n Ma nua l v

Copyright © 2009, Harris Corporation

Page 8

Contents

vi HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 9

Manual Information

Purpose

This manual details the features, installation, operation, maintenance, and

specifications for the HMX6803+ and OP+HMX+ auto-sensing SD/HD-SDI

8-AES audio demultiplexers.

Audience

This manual is written for engineers, technicians, and operators responsible for

installation, setup, maintenance, and/or operation of the HMX6803+ and

OP+HMX+

Revision History

Table P-1. Revision History of Manual

Edition Date Comments

Preface

auto-sensing SD/HD-SDI 8-AES audio demultiplexers.

A April 2009 Initial release

B June 200 9 Additional AFD feature set

HMX6803+ and OP+HMX+ Installation and Operation Manual vii

Copyright © 2009, Harris Corporation

Page 10

Preface

Note

Writing Conventions

To enhance your understanding, the authors of this manual have adhered to the

following text conventions:

Table P-2. Writing Conventions

Term or

Convention

Bold Indicates dialog boxes, property sheets, fields, buttons,

Italics Indicates E-mail addresses, the names of books or

CAPS Indicates a specific key on the keyboard, such as

Code Indicates variables or command-line entries, such as a

> Indicates the direction of navigation through a hierarchy

hyperlink Indicates a jump to another location within the

Internet address Indicates a jump to a website or URL

Description

check boxes, list boxes, combo boxes, menus,

submenus, windows, lists, and selection names

publications, and the first instances of new terms and

specialized words that need emphasis

ENTER, TAB, CTRL, ALT, or DELETE

DOS entry or something you type into a field

of menus and windows

electronic document or elsewhere

Indicates important information that helps to avoid and

troubleshoot problems

Obtaining Documents

Product support documents can be viewed or downloaded from our website.

Alternatively, contact your Customer Service representative to request a

document.

viii HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 11

Unpacking/Shipping Information

Unpacking a Product

This product was carefully inspected, tested, and calibrated before shipment to

ensure years of stable and trouble-free service.

1. Check equipment for any visible damage that may have occurred during

transit.

2. Confirm that you have received all items listed on the packing list.

3. Contact your dealer if any item on the packing list is missing.

4. Contact the carrier if any item is damaged.

5. Remove all packaging material from the product and its associated

components before you install the unit.

Keep at least one set of original packaging, in the event that you need to return a

product for servicing.

Product Servicing

Except for firmware upgrades, HMX6803+ and OP+HMX+ modules are not

designed for field servicing. All hardware upgrades, modifications, or repairs

require you to return the modules to the Customer Service center.

Preface

Returning a Product

In the unlikely event that your product fails to operate properly, please contact

Customer Service to obtain a Return Authorization (RA) number, and then send

the unit back for servicing.

Keep at least one set of original packaging in the event that a product needs to

be returned for service. If the original package is not available, you can supply

your own packaging as long as it meets the following criteria:

• The packaging must be able to withstand the product’s weight.

• The product must be held rigid within the packaging.

• There must be at least 2 in. (5 cm) of space between the product and the

• The corners of the product must be protected.

Ship products back to us for servicing prepaid and, if possible, in the original

packaging material. If the product is still within the warranty period, we will

return the product prepaid after servicing.

container.

HMX6803+ and OP+HMX+ Installation and Operation Manual ix

Copyright © 2009, Harris Corporation

Page 12

Preface

References

ANSI/SMPTE 259M-1997

10-Bit 4:2:2 Component and 4fsc NTSC Composite Digital Signals - Serial

Digital Interface

ITU-R BT.601-5

Studio Encoding Parameters of Digital Television for Standard 4:3 and

Wide-Screen 16:9 Aspect Ratios

SMPTE 292M-1999

Bit-Serial Digital Interface for High-Definition Television Systems

ITU-R BT.709-4

Parameter Values for the HDTV Standards for Production and International

Programme Exchange

SMPTE 291M-1998

Ancillary Data Packet and Space Formatting

SMPTE RP 184-1996

Specification of Jitter in Bit-Serial Digital Systems

ANSI/SMPTE 276M-1995

Transmission of AES/EBU Digital Audio Signal Over Coaxial Cable

AES3-2003

AES Recommended Practice for Digital Audio Engineering - Serial

Transmission Format for Two-Channel Linearly Represented Digital Audio

Data

TIA/EIA-232-E 1991

Interface Between Data Terminal Equipment and Data Circuit-Terminating

Equipment Employing Serial Binary Data Interchange

EIA/TIA-422-B 1994

Electrical Characteristics of Balanced Voltage Digital Interface Circuits

EIA RS-485 1983

Standard for Electrical Characteristics of Generators and Receivers for use in

Balanced Digital Multipoint Systems

SMPTE 346-M 2000

Time Division Multiplexing Video Signals and Generic Data over

High-Definition Interface

SMPTE 352-M 2002

Video Payload Identification for Digital Interfaces

SMPTE 424-M 2005 (Proposed)

3Gb/s Signal/Data Serial Interface

SMPTE 425-M 2005 (Proposed)

3Gb/s Signal/Data Serial Interface - Source Image Format Mapping

47 Code of Federal Regulations

Part 15 FCC rules—Radio Frequency Devices

EN55103-1

x HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 13

EMC emission requirements applies to professional audio, video, au dio-visual

and entertainment lighting control apparatus

EN55103-2

EMC immunity requirements applies to professional audio, video, audio-visual

and entertainment lighting control apparatus

IEC 61754-4

Specifications for the fiber optic connector type SC/PC

IEC 61754-2

Specifications for the fiber optic connector type ST/PC terminated to a type

BFOC/2,5

IEC 61754-13

Specifications for the fiber optic connector type FC/PC

Safety Standards and Compliances

See “Laser Safety” on page 80 to find the safety standards and compliances for

this OPT O+ series product. A 68 00+ series safety manual is shipped with every

6800+ Frame Installation and Operation Manual and can be downloaded from

our website. Alternatively, contact your Customer Service representative for a

copy of this safety manual.

Preface

Restriction on Hazardous Substances (RoHS) Compliance

Directive 2002/95/EC—commonly known as the European Union (EU)

Restriction on Hazardous Substances (RoHS)—sets limits on the use of certain

substances found in electrical and electronic equipment. The intent of this

legislation is to reduce the amount of hazardous chemicals that may leach out of

landfill sites or otherwise contaminate the environment during end-of-life

recycling. The Directive, which took effect on July 1, 2006, refers to the

following hazardous substances:

HMX6803+ and OP+HMX+ Installation and Operation Manual xi

Copyright © 2009, Harris Corporation

Page 14

Preface

• Lead (Pb)

• Mercury (Hg)

• Cadmium (Cd)

• Hexavalent Chromium (Cr-V1)

• Polybrominated Biphenyls (PBB)

• Polybrominated Diphenyl Ethers (PBDE)

According to this EU Directive, all products sold in the European Union will be

fully RoHS-compliant and “lead-free.” (See our website for more information

on dates and deadlines for compliance.) Spare parts supplied for the repair and

upgrade of equipment sold before July

Equipment that complies with the EU directive will be marked with a

RoHS-compliant emblem, as shown in

Figure P-1. RoHS Compliance Emblem

1, 2006 are exempt from the legislation.

Figure P-1.

Waste from Electrical and Electronic Equipment (WEEE) Compliance

The European Union (EU) Directive 2002/96/EC on Waste from Electrical and

Electronic Equipment (WEEE) deals with the collection, treatment, recovery,

and recycling of electrical and electronic waste products. The objective of the

WEEE Directive is to assign the responsibility for the disposal of associated

hazardous waste to either the producers or users of these products. As of August

13, 2005, the producers or users of these products were required to recycle

electrical and electronic equipment at end of its useful life, and may not dispose

of the equipment in landfills or by using other unapproved methods. (Some EU

member states may have different deadlines.)

xii HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 15

Preface

In accordance with this EU Directive, companies selling electric or electronic

devices in the EU will affix labels indicating that such products must be

properly recycled. (See our website for more information on dates and deadlines

for compliance.) Contact your local Sales representative for information on

returning these products for recycling. Equipment that complies with the EU

directive will be marked with a WEEE-compliant emblem, as shown in

Figure

P-2.

Figure P-2. WEEE Compliance Emblem

Safety Terms and Symbols in this Manual

This product manual uses the following safety terms and symbols to identify

certain conditions or practices. See

Safety Instructions and Standards Manual for more information.

WARNING

Statements identifying conditions or practices that may

result in personal injury or loss of life. High voltage is

present.

CAUTION

Statements identifying conditions or practices that can

result in damage to the equipment or other property.

“Laser Safety” on page 80 and the FR6802+

HMX6803+ and OP+HMX+ Installation and Operation Manual xiii

Copyright © 2009, Harris Corporation

Page 16

Preface

xiv HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 17

Product Description

The HMX6803+ is an auto-sensing SD/HD-SDI 4-AES audio multiplexer and

processing amplifier with one digital video input and one DARS reference

input, and has four processed SD/HD-SDI outputs. The OP+HMX+ module has

the same features, and an additional optical transmitter. The modules support

embedding and passing of Dolby E™ metadata , and picture and sound control

through integrated processing amplifiers. The basic HMX6803+ and

OP+HMX+ provide SD and HD-SDI audio embedding, and there is an optional

upgrade to 3G HD-SDI. Another optional upgrade adds four AES inputs, for a

total of eight.

Each HMX6803+ or OP+HMX+ package includes a module-specific breakout

cable with unbalanced (coaxial) audio connectors that expands the number of

available connections beyond what would fit on a standard two-slot back

connector. Balanced AES inputs are supported with external baluns. The

breakout cable includes an RS-232/RS-422 serial connector to embed metadata.

Chapter 1

Introduction

HMX6803+ and OP+HMX+ can be operated locally (using card-edge

controls); or operated and monitored remotely with control software

applications such as CCS

SNMP-based control applications, or CCS-compliant remote control panels

such as NUCLEUS. The modules are QSEE™-compliant, so you can monitor a

thumbnail when it is installed in an Ethernet-equipped FR6802+QXF or

FR6822+ frame.

The HMX6803+ and OP+HMX+ back connector requires two frame slots

within an FR6802+XF, FR6822+, or FR6802+QXF frame. There is no

backward compatibility provided for use with 6800/7000 series frames or

FR6802+DM frames. HMX6803+ and OP+HMX+ must be installed in a frame

with fans.

Navigator™, HTTP web browser, third-party

Main Features

All versions of HMX6803+ and OP+HMX+ include the following features:

• Inputs

• One serial digital SMPTE 292M/SMPTE 259M SDI input

• Metadata

HMX6803+ and OP+HMX+ Installation and Operation Manual 1

Copyright © 2009, Harris Corporation

Page 18

Chapter 1: Introduction

• Four AES audio

• DARS input (unbalanced, balanced compatible with external balun)

•Outputs

• Four serial digital SMPTE 292M/259M SDI processed outputs

• One RS-232/RS-422 serial connector to embed metadata

• 10-bit video processing in the following standards and frame rates:

• Standard definition 525/625

• 1080psf (progressive segmented frame), 23.98/24 Hz

• 1080i (interlaced), 25/29.97/30 Hz

• 1080p (progressive), 23.98/24/25/29.97/30 Hz

• 720p (progressive), 50/59.94/60 Hz

• Up to 50 frames of SD video delay, up to 11 frames of HD video delay

• Auto-detect or user-forced input video standard with HD/SD-SDI auto

sensing

• AFD/WSS/VI detector and inserter

• Seamless sound functionality

• V-fading of the output audio on so urce audio change

• Automatic cable equalization

Optional Features

• Embed on black or grey on loss of video mode

• Video processing amplifier with luminance gain/offset and chrominance

gain/offset controls

• 16-, 20-, or 24-bit audio processing

• Shadowed/restored parameter settings when switching video standards

• Card-edge control and monitoring

• Serial and Ethernet remote control and monitoring

• Video and audio test signal generators

OP+HMX+ has an optional fiber transmitter.

HMX68OPT+AES8 adds four balanced or unbalanced AES inputs, for a total

of eight.

The HMX68OPT+3G upgrade option adds 10-bit video processing with 1080p

(progressive) video standard at 50/59.94/60 Hz frame rates as per SMPTE

424M.

2 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 19

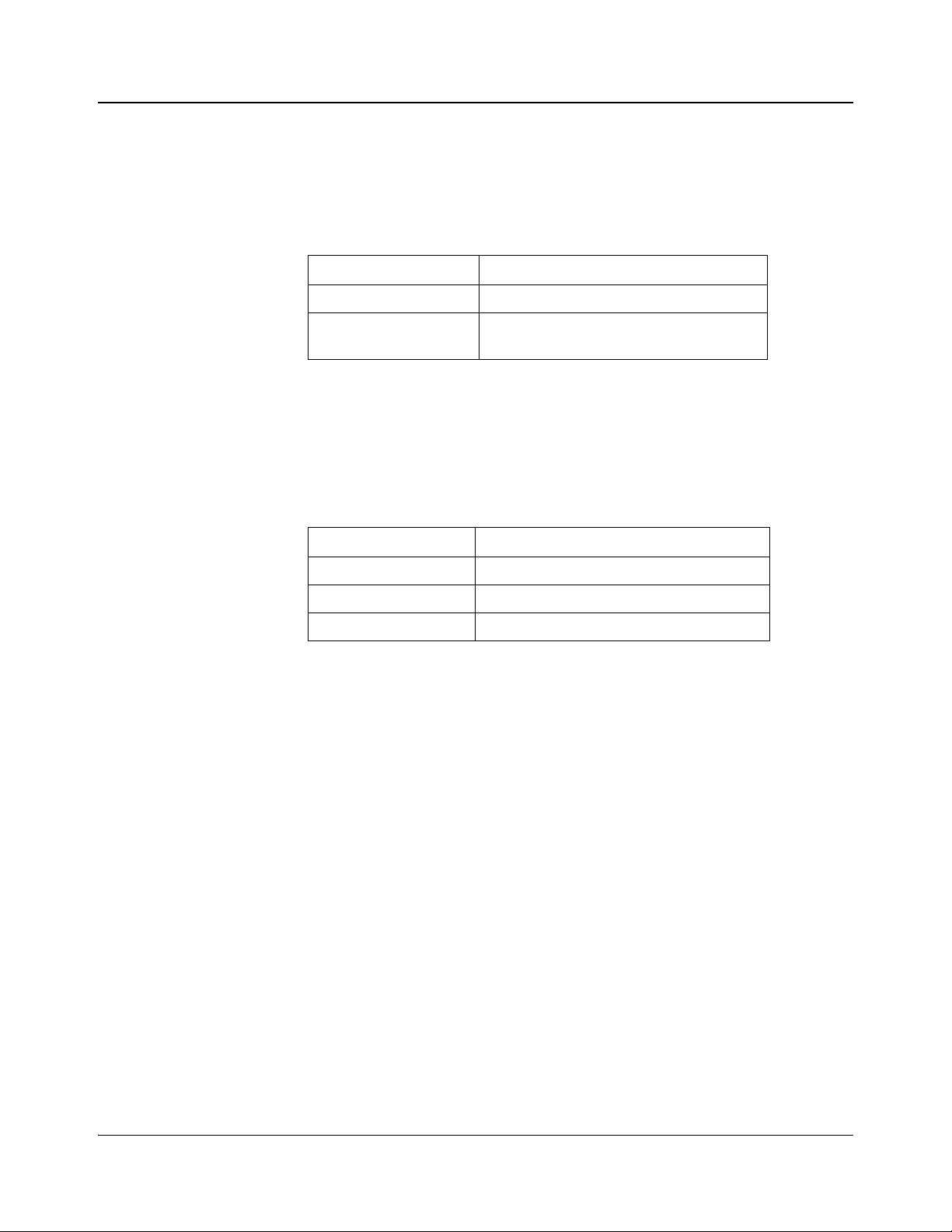

OP+HMX+ Module Types

Table 1-1 describes the different versions of the OP+HMX+ product. The basic

module outputs through an SC/PC connector. Hardware upgrade options are

listed in

Table 1-2.

Table 1-1. OP+HMX+ Modules

Module Name Description

OP+HMX+13D Fiber transmitter set at 1310 nm

OP+HMX+CxxD Fiber transmitter set at CWDM wavelength

Hardware Options

All OP+HMX+ modules are shipped with standard SC/PC fiber connectors.

Other connectors are available (see

Table 1-2. Available Connectors

Chapter 1: Introduction

of 1xx0 nm

Table 1-2).

Item Description

OP+OPT+SC SC/PC fiber optic connectors (standard)

OP+OPT+ST ST/PC fiber optic connectors (optional)

OP+OPT+FC FC/PC fiber optic connectors (optional)

HMX6803+ and OP+HMX+ Installation and Operation Manual 3

Copyright © 2009, Harris Corporation

Page 20

Chapter 1: Introduction

Module

status

LEDs

Mode select

rotary

switch

Navigation

toggle

switch

Monitoring

LEDs

Remote/local

control

jumper

Extractor

handle

Control

LEDs

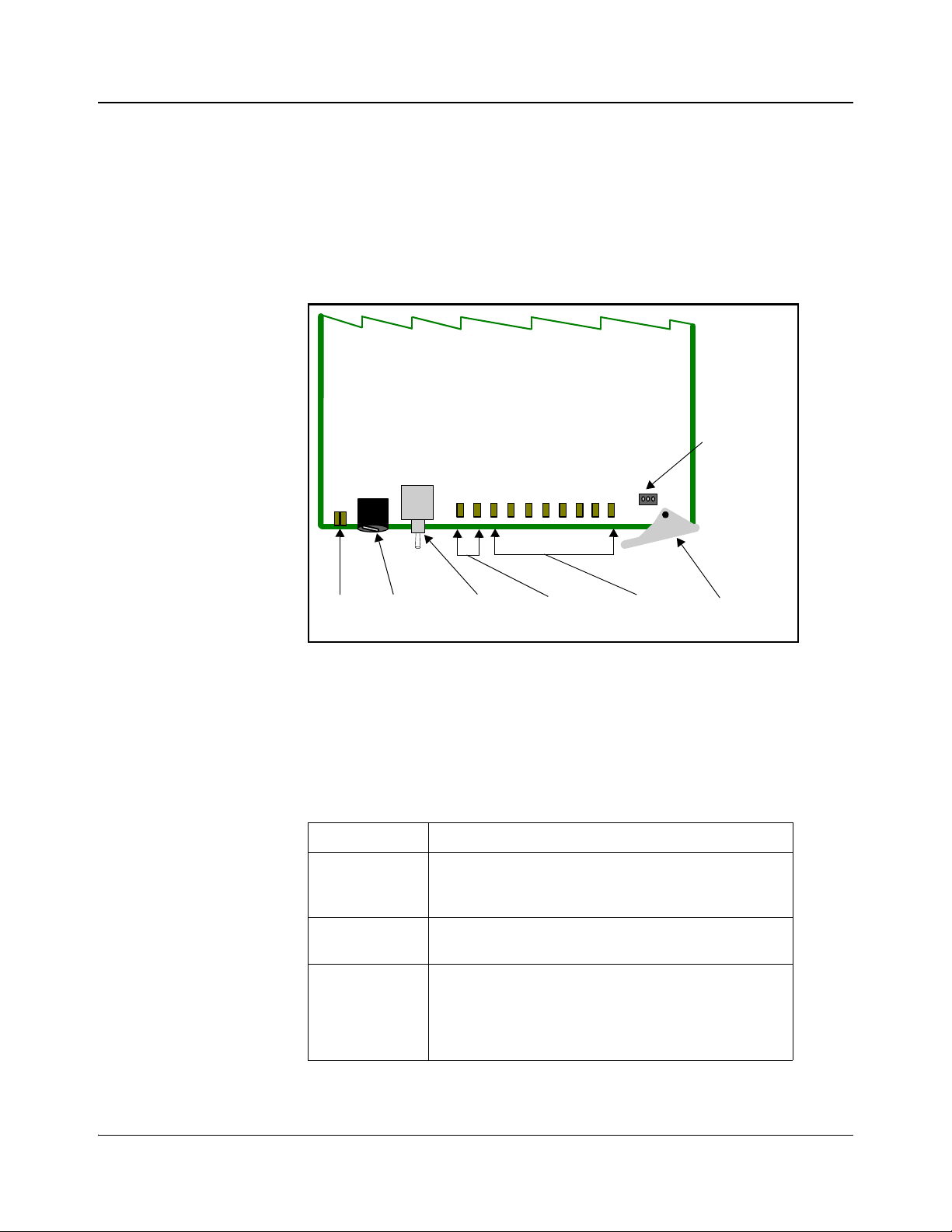

Module Descriptions

Front Module

Figure 1-1 is a generic top-front view of a typical 6800+ module and shows the

general location of standard LEDs, controls, and jumpers. The number of

control and monitoring LEDs on 6800+ modules varies.

Figure 1-1. Typical 6800+ Module

Table 1-3 on page 4 briefly describes generic 6800+ LEDs, switches, and

jumpers. See “Chapter 3: Operation” for more information on specific

HMX6803+ and OP+HMX+ module controls, LEDs, and jumpers.

Table 1-3. Generic 6800+ Module Features

Feature Description

Module status

LEDs

Mode select

rotary switch

Navigation

toggle switch

Various color and lighting combinations of these LEDs

indicate the module state. See

page 61 for more information.

This switch selects between various control and

feedback parameters.

This switch navigates up and down through the available

control parameters:

• Down: Moves down through the parameters

• Up: Moves up through the parameters

“Monitoring LEDs” on

4 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 21

Chapter 1: Introduction

Table 1-3. Generic 6800+ Module Features(Continued)

Feature Description

Control LEDs Various lighting combinations of these control LEDs

(sometimes referred to as “Bank Select LEDs”) indicate

which bank is currently selected. See

Indicated by Control LEDs” on page 42 for more

information.

“Selected Bank as

Monitoring

LEDs

Local/remote

control jumper

Each 6800+ module has a number of LEDs assigned to

indicate varying states/functions. See

“Monitoring

LEDs” on page 61 for a description of these LEDs.

• Local: This jumper setting locks out external control

panels and allows card-edge control only; limits the

functionality of remote software applications to

monitoring

• Remote: This jumper setting allows remote or local

(card-edge) configuration, operation, and monitoring

of the HMX6803+ and OP+HMX+ (this is the

default setting)

HMX6803+ and OP+HMX+ Installation and Operation Manual 5

Copyright © 2009, Harris Corporation

Page 22

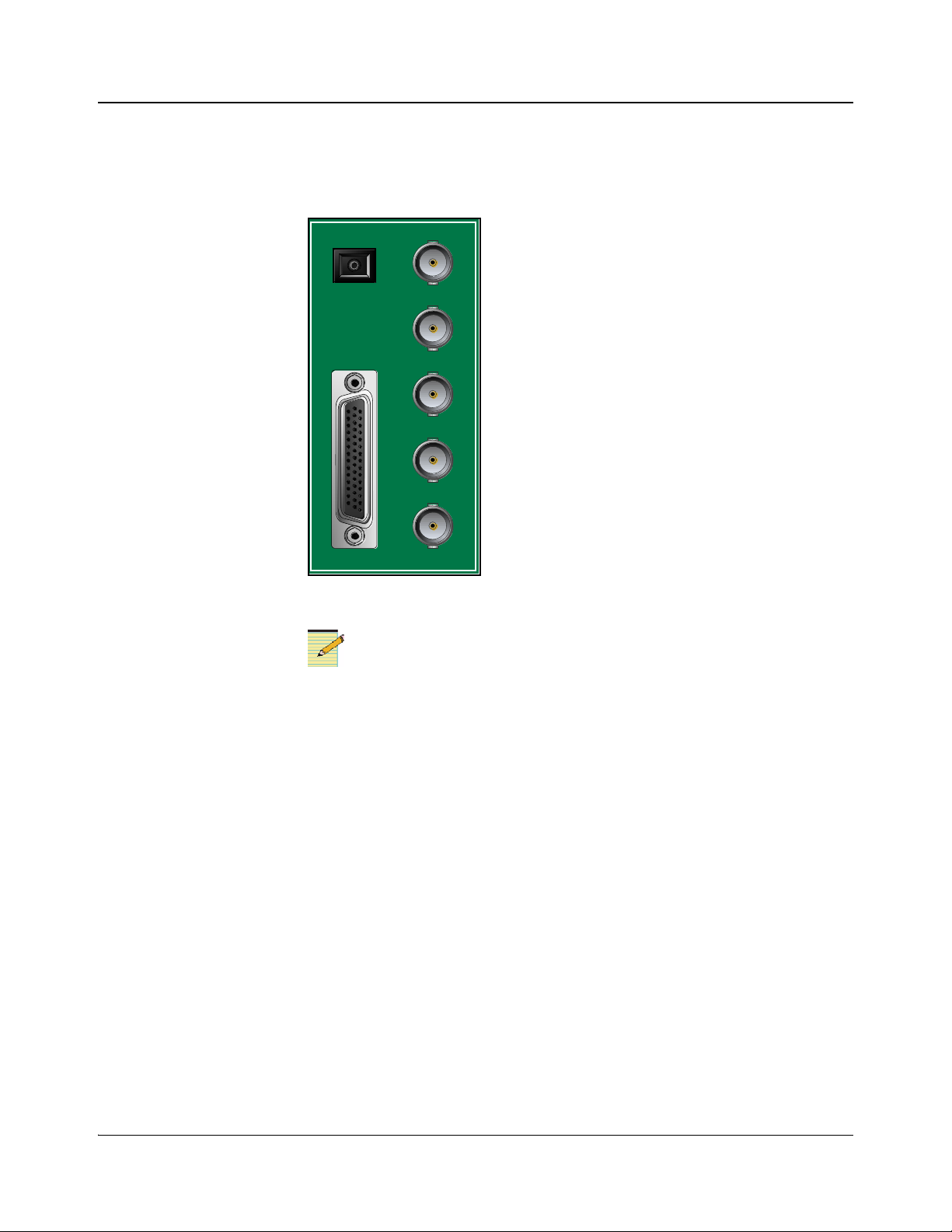

Chapter 1: Introduction

Note

SDI I N 1

SDI OUT 1

SDI OUT 2

SDI OUT 3

SDI OUT 4

BREAKOUT

Fiber

Back Connectors

Figure 1-2 shows the double-slot back connector used by HMX6803+ and

OP+HMX+ modules.

Breakout Cables

Figure 1-2. HMX6803+ and OP+HMX+ Back Connector

To maintain optimal output video signal integrity, terminate unused output

video BNCs with 75Ω terminators.

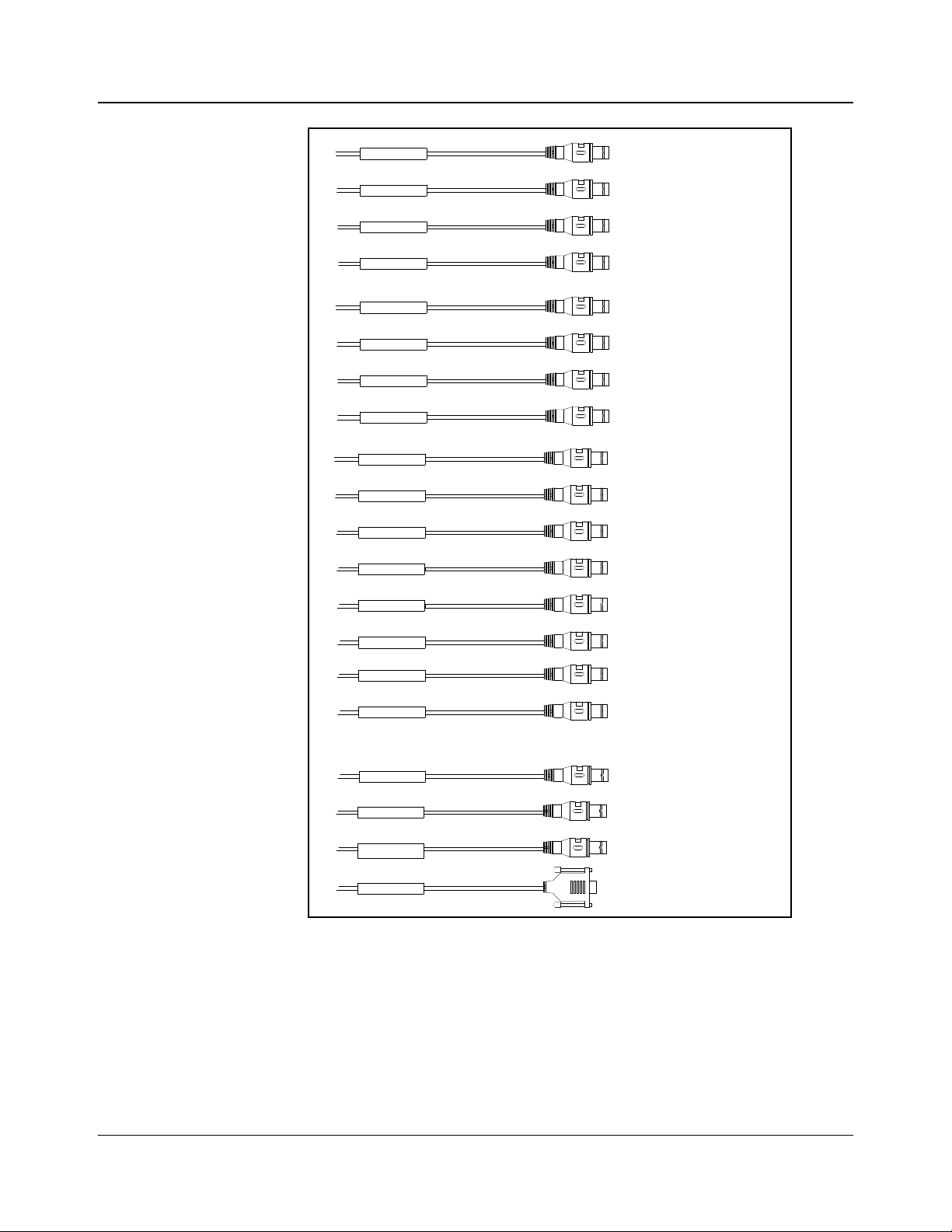

The standard HMX6803+ and OP+HMX+ ship with an unbalanced breakout

cable, pictured in

Figure 1-3. For information on ordering cables, see Table 2-1

on page 14.

If you need to make your own breakout cable, pinouts are listed in Table 1-4,

and pin numbers for the 44-pin connector are listed in Figure 1-4 on page 8.

6 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 23

Chapter 1: Introduction

AES 1 In

AES 2 In

AES 3 In

AES 4 In

AES 5 In

AES 6 In

AES 7 In

AES 8 In

AES 1 Ou t

AES 2 Ou t

AES 3 Ou t

AES 4 Ou t

AES 5 Ou t

AES 6 Ou t

AES 7 Ou t

AES 8 Ou t

DARS In

Data I/O

Genlock

Serial

AES1 IN

AES2 IN

AES3 IN

AES4 IN

AES5 IN

AES6 IN

AES7 IN

AES8 IN

AES1 OUT

DARS IN

DATA I/O

GENLOCK

SERIAL

AES2 OUT

AES3 OUT

AES4 OUT

AES5 OUT

AES6 OUT

AES7 OUT

AES8 OUT

Figure 1-3. HMX6803+ and OP+HMX+ Breakout Cable

HMX6803+ and OP+HMX+ Installation and Operation Manual 7

Copyright © 2009, Harris Corporation

Page 24

Chapter 1: Introduction

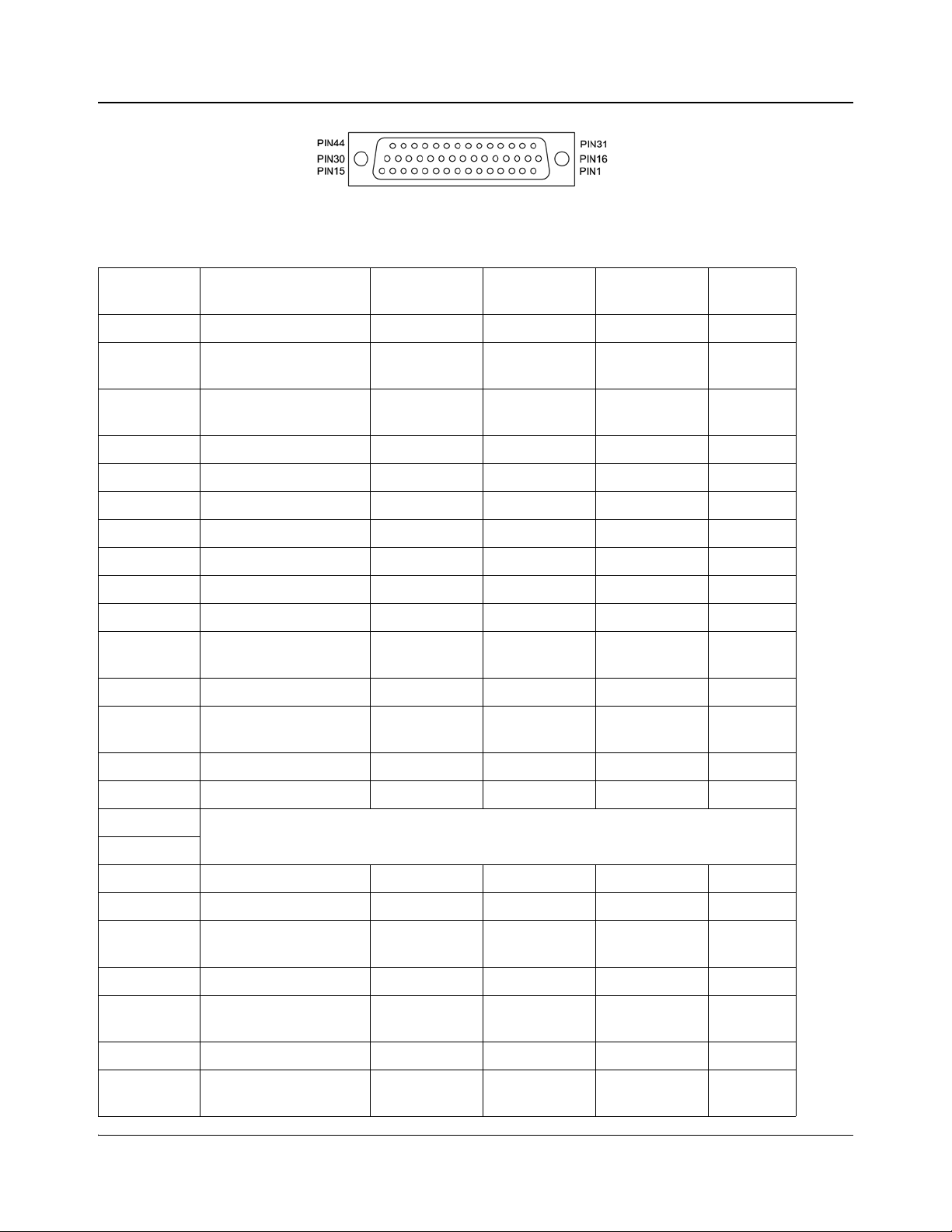

Figure 1-4. Pin Numbers for 44-Pin Connector

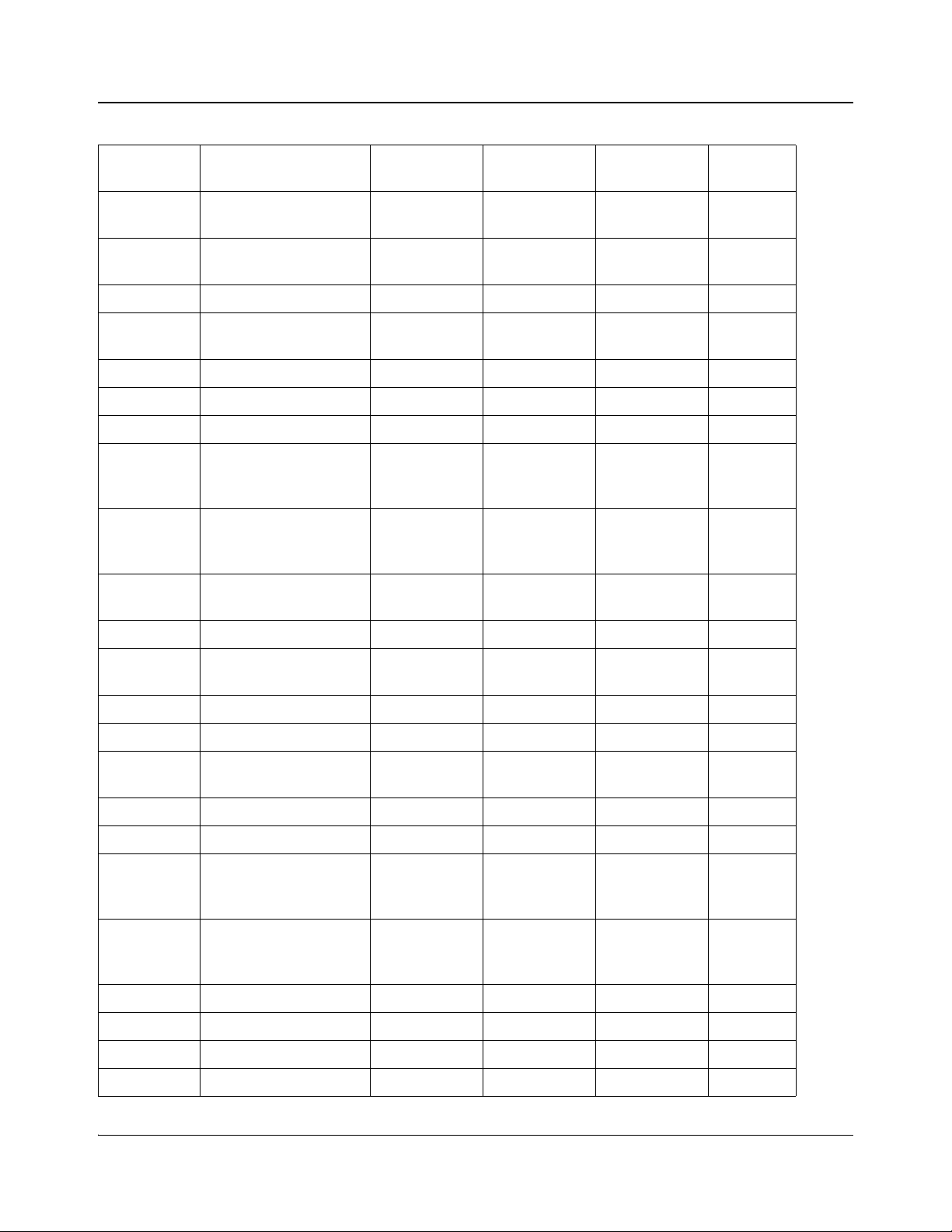

Table 1-4. Pinouts for 44-Pin Connector

Pin No. on

DB-44M

1 BNC GENLOCK GENLOCK Black Black

2 BNC GND GENLOCK

3 BNC GND AES OUT 7

4 BNC AES IN 4 AES IN 4 White White

5 BNC GND AES IN 4 GND AES IN 4 White White

6 BNC AES IN 3 AES IN 3 White White

7 BNC GND AES IN 3 GND AES IN 3 White White

8 BNC DATA IO DATA IO Yellow Yellow

9 BNC GND DATA IO GND DATA IO Yellow Yellow

10 BNC AES OUT 2 AES OUT 2 Blue Blue

11 BNC GND AES OUT 2

12 BNC AES OUT 1 AES OUT 1 Blue Blue

13 BNC GND AES OUT 1

Connection Type Description Wire Label

GENLOCK Black Black

GND

AES OUT 7 Blue Blue

GND

AES OUT 2 Blue Blue

GND

AES OUT 1 Blue Blue

GND

External

Cable Color

BNC

Color

14 BNC GND AES IN 7 GND AES IN 7 White White

15 BNC AES IN 7 AES IN 7 White White

16

17

18 BNC AES OUT 7 AES OUT 7 Blue Blue

19 BNC DARS IN 1 DARS IN 1 Yellow Black

20 BNC GND DARS IN 1

GND

21 BNC AES IN 2 AES IN 2 White White

22 BNC GND AES OUT 3

GND

23 BNC AES OUT 3 AES OUT 3 Blue Blue

24 BNC GND AES OUT 6

GND

8 HMX6803+ and OP+HMX+ Installation and Operation Manual

Not Connected

DARS IN 1 Yellow Black

AES OUT 3 Blue Blue

AES OUT 6 Blue Blue

Copyright © 2009, Harris Corporation

Page 25

Table 1-4. Pinouts for 44-Pin Connector (Continued)

Chapter 1: Introduction

Pin No. on

DB-44M

25 162A10019X (DB9.5) RS232_GND

25 BNC GND AES OUT 4

26 BNC AES OUT 4 AES OUT 4 Blue Blue

27 BNC GND AES OUT 5

28 BNC AES IN 8 AES IN 8 White White

29 BNC GND AES IN 8 GND AES IN 8 White White

30 BNC GND AES IN 5 GND AES IN 5 White White

31 162A10019X (DB9.3) BALANCED

32 162A10019X (DB9.8) BALANCED

33 BNC GND AES OUT 8

Connection Type Description Wire Label

SERIAL Black N/A

(DB9)

AES OUT 4 Blue Blue

GND

AES OUT 5 Blue Blue

GND

SERIAL Red N/A

SERIAL IN(DB9)

SERIAL Yellow N/A

SERIAL IN+

(DB9)

AES OUT 8 Blue Blue

GND

External

Cable Color

BNC

Color

34 BNC AES OUT 8 AES OUT 8 Blue Blue

35 162A10019X (DB9.1) RS422_FR_GN

D (DB9)

35 BNC GND AES IN 2 GND AES IN 2 White White

36 BNC AES IN 1 AES IN 1 White White

37 162A10019X (DB9.9) RS422_FR_GN

D (DB9)

37 BNC GND AES IN 1 GND AES IN 1 White White

38 BNC AES OUT 6 AES OUT 6 Blue Blue

39 162A10019X (DB9.7) BALANCED

SERIAL OUT(DB9)

40 162A10019X (DB9.2) BALANCED

SERIAL OUT+

(DB9)

41 BNC AES OUT 5 AES OUT 5 Blue Blue

42 BNC GND AES IN 6 GND AES IN 6 White White

43 BNC AES IN 6 AES IN 6 White White

44 BNC AES IN 5 AES IN 5 White White

SERIAL Black N/A

SERIAL Black N/A

SERIAL Blue N/A

SERIAL Green N/A

HMX6803+ and OP+HMX+ Installation and Operation Manual 9

Copyright © 2009, Harris Corporation

Page 26

Chapter 1: Introduction

RS-422/232 Cable

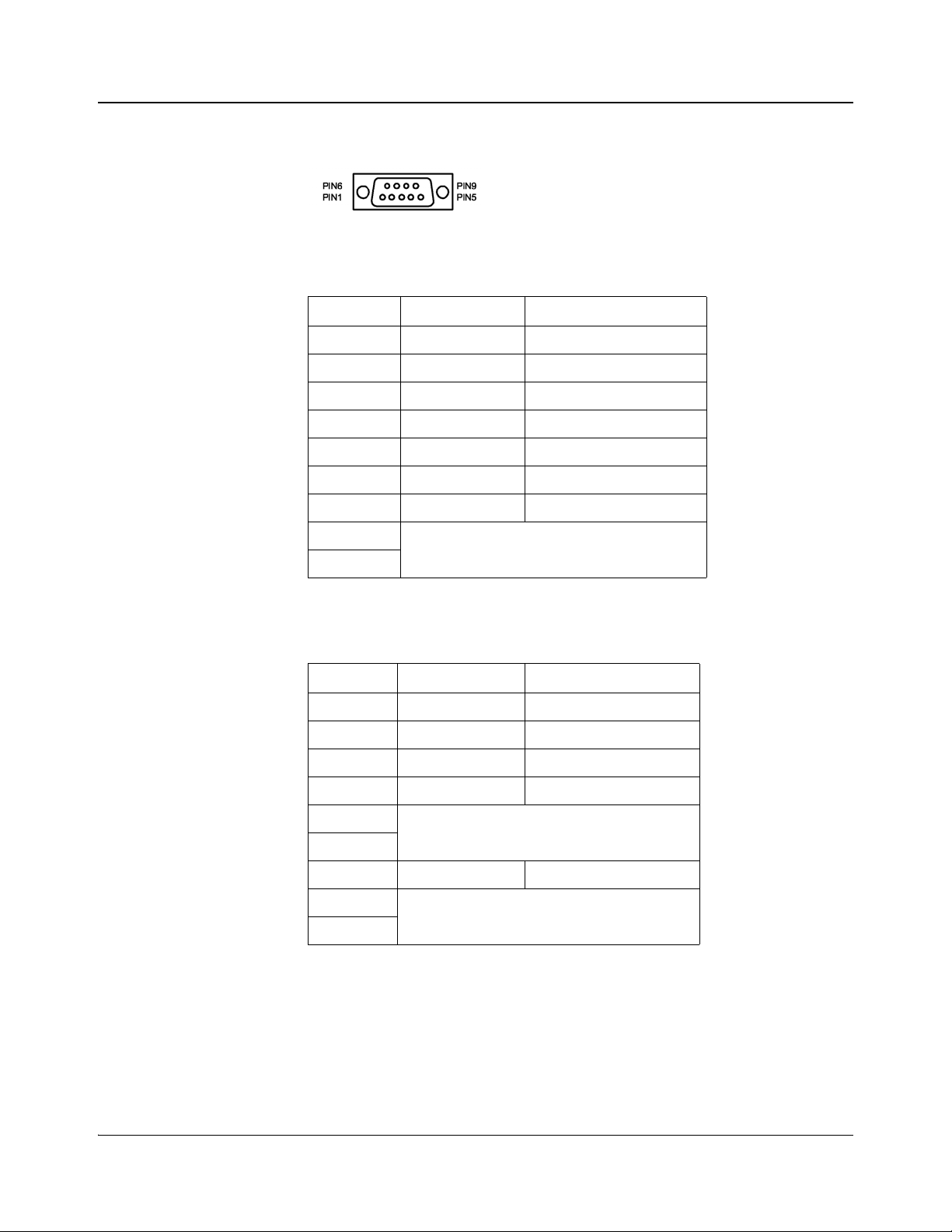

Figure 1-5. Pin Numbers for RS-422/232 Female Connector

Table 1-5. Pin Assignment of DB-9 Connector (Female) in RS-422

Format

Pin No. Signal Comments

1 FG Frame Ground

9 FG Frame Ground

5 FG Frame Ground

2 TA (Tx-) Transmitted Data 7 TB (Tx+) Transmitted Data +

8 RA (Rx-) Received Data 3 RB (Rx+) Received Data +

4

6

Not connected

Table 1-6. Pin Assignment of DB-9 Connector (Female) in RS-232

Format

Pin No. Signal Comments

1 FG Frame Ground

9 FG Frame Ground

5 FG Frame Ground

2 Tx Transmitted Data

7

8

3 Rx Received Data

4

6

Not connected

Not connected

10 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 27

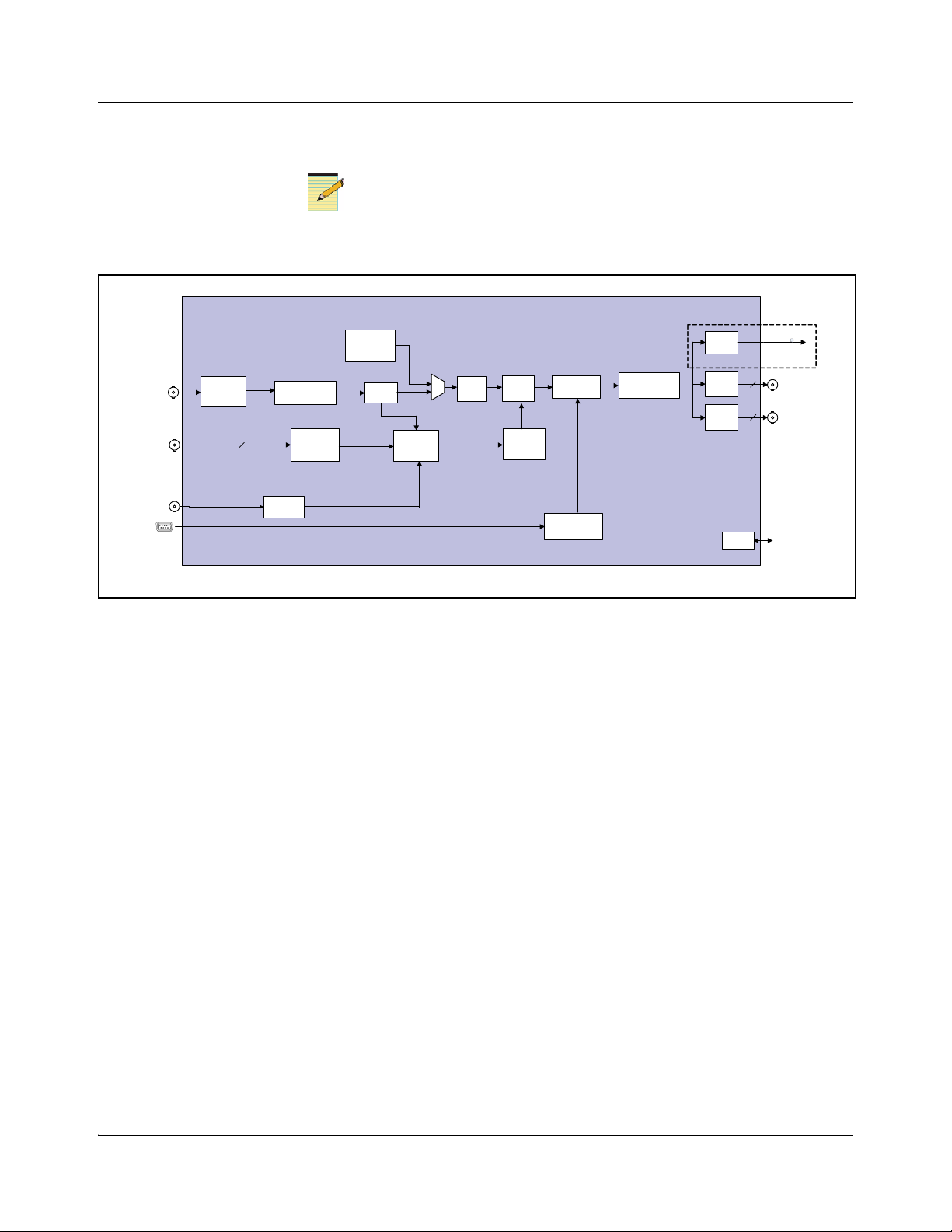

Signal Flow

Note

1

Available via breakout cable ( included).

3G/HD/SD-SDI

Metadata

Video

Delay

Test

pattern

generator

Video

proc

Audio

embed

Data

embed

Sample

rate

converter

Audio

delay

Metadata

router

CCS &QSEE

monitor ing

&

control

Laser

Driver

Audio

proc amp

OP+SFS+(C)xxD

Equalizer

AES In

8

3G/HD/SD-SDI

2

3G/HD/SD-SDI

2

Driver

Driver

CCS & SNMP

control

DARS DARS

AFD/WSS/VI

Detector

AFD/WSS/VI

Inserter

Chapter 1: Introduction

3G HD-SDI in and out are only available if your module has the optional

HMX68OPT

+3G license key.

Figure 1-6. HMX6803+ and OP+HMX+ Signal Flow Diagram

HMX6803+ and OP+HMX+ Installation and Operation Manual 11

Copyright © 2009, Harris Corporation

Page 28

Chapter 1: Introduction

12 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 29

Unpacking the Module

Before you install modules, perform the following:

• Check the equipment for any visible damage that may have occurred during

transit.

• Confirm receipt of all items on the packing list. See “Checking the Packing

List” for more information.

Contact your Customer Service representative if parts are missing or

damaged.

• Remove the anti-static shipping pouch, if present, and all other packaging

material.

• Retain the original packaging materials for possible re-use.

See “Unpacking/Shipping Information” on page ix for information about

returning a product for servicing.

Chapter 2

Installation

HMX6803+ and OP+HMX+ Installation and Operation Manual 13

Copyright © 2009, Harris Corporation

Page 30

Chapter 2: Installation

Checking the Packing List

\

Table 2-1. Available Product Packages

Ordered Product Content Description

HMX6803+D

OP+HMX+D

6800+OPT+16CAPM One breakout cable with unbalanced audio

• One HMX6803+ front module

• One double-slot back connector

• One 6800+OPT+16CAPM breakout cable

with unbalanced audio connectors

• One HMX6803+ and OP+HMX+ Installation

and Operation Manual

•One OP+HMX+ front module

• One double-slot back connector

• One 6800+OPT+16CAPM breakout cable

with unbalanced audio connectors

• One HMX6803+ and OP+HMX+ Installation

and Operation Manual

connectors

Choosing HMX6803+ and OP+HMX+ Upgrade Options

Basic HMX6803+ and OP+HMX+ modules have one SD-SDI input and four

SD-SDI outputs with embedded audio. The following firmware upgrades are

available:

Table 2-2. Available License Key Upgrades

Ordered Product Content Description

HMX68OPT-AES8 Adds four discrete AES inputs, for a total of eight

HMX68OPT-3G Adds 3G HD-SDI functionality to an 1.5G

HD-SDI and SD-SDI module

To purchase additional licen se keys, contact your Sales representative. To

activate a license key, see

“Adding a License Key” on page 26.

14 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 31

Selecting an External Balun

The following baluns from Neutrik® or equivalent are recommended for the

unbalanced to balanced AES conversion:

• NADITBNC-F: Female chassis XLR 110Ω input - female BNC 75Ω

output.

http://www.neutrik.com/fl/en/audio/210_309314683/NADITBNC-F_detail.

aspx

• NADITBNC-M: Female BNC 75Ω input - male chassis XLR 110Ω output.

http://www.neutrik.com/fl/en/audio/210_2044239418/NADITBNC-M_det

ail.aspx

• NADITBNC-FX: Female cable end XLR 110Ω input - female BNC 75Ω

output.

http://www.neutrik.com/fl/en/audio/210_1576769505/NADITBNC-FX_det

ail.aspx

• NADITBNC-MX: Female BNC 75Ω input - male cable end XLR 110Ω

output.

http://www.neutrik.com/fl/en/audio/210_1923043515/NADITBNC-MX_d

etail.aspx

Chapter 2: Installation

HMX6803+ and OP+HMX+ Installation and Operation Manual 15

Copyright © 2009, Harris Corporation

Page 32

Chapter 2: Installation

Note

Note

CJ1 jumper

Remote control

setting

Local control

setting

3 2 1 3 2 1

Setting Jumper CJ1 for Local or Remote Control

The HMX6803+ and OP+HMX+ module has one jumper, CJ1, which sets the

module for local or remote control.

You need to configure modules for local or remote operation prior to

power-up. To change the configuration, first remove power from the module,

reset the jumper, and then reapply power.

Figure 2-1. Jumper Location

1. Locate jumper CJ1 on the module (behind the mode select rotary switch).

Figure 2-1 shows the location of the CJ1 jumper.

2. Place a jumper on pins 1 and 2 to set the module for Remote control, or pins

2 and 3 to set the module for Local control. See Figure 2-2.

Figure 2-2. CJ1 Settings for Local and Remote Control

The white triangle near the jumper pins on the module

indicates pin 1.

16 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 33

Maximum 6800+ Frame Power Ratings

Caution

Note

See the FR6802+ Frame Installation and Operation Manual for information

about installing and operating an FR6822+, FR6802+QXF or FR6802+ frame

and its components.

Before installing this product, read the 6800+ Series Safety

Instructions and Standards Manual shipped with every 6800+ Frame

Installation and Operation Manual or downloadable from our website.

This safety manual contains important information about the safe

installation and operation of 6800+ series products.

The power consumption for the HMX6803+ and OP+HMX+ modules is 12 W.

Table 2-3 describes the maximum allowable power ratings for 6800+ frames.

Note the given maximums before installing any 6800+ modules in your frame.

HMX6803+ and OP+HMX+ modules operate only in fan-cooled FR6802+ and

FR6822+ frames, subject to the limitations shown in

cannot be installed in 6800/7000 series frames.

Chapter 2: Installation

Table 2-3. These modules

To maintain proper temperatures, ensure that the front panel is closed at all

times and that the fan module is fully operational.

Table 2-3. Maximum Power Ratings for 6800+ Frames

Max. Frame

6800+ Frame Type

Power

Dissipation

FR6802+XF

(frame with AC power supply)

FR6802+XF48

(frame with DC power supply)

FR6802+QXF frame

(with AC or DC power supply)

FR6822+ frame (with AC or DC power supply) 120W 20 6 W

120 W 20 6 W

105 W 20 5.25 W

120W 20 6 W

Number of

Usable

Slots

Max. Power

Dissipation

Per Slot

HMX6803+ and OP+HMX+ Installation and Operation Manual 17

Copyright © 2009, Harris Corporation

Page 34

Chapter 2: Installation

Installing 6800+ Modules

Required Frames and Back Connector Types

HMX6803+ and OP+HMX+ modules have double-width back connectors that

can be installed in an FR6802+XF, FR6822+, or FR6802+QXF frame.

HMX6803+ and OP+HMX+ modules cannot be installed in an FR6802+DM

frame, a FR6800/7000 frame, or a frame without fans.

See your 6800+ Frame Installation and Operation Manual for details on

installing back connectors in an FR6802+ or FR6822+ frame.

A FR6802+RM (Rear Support Extension Rails for 6800+ series frames) option

is recommended for the HMX6803+ and OP+HMX+ modules. See your 6800+

Frame Installation and Operation Manual for installation instructions.

Installing and Removing HMX6803+ Modules

These modules require no specialized installation or removal procedures.

However, if installing both front and rear modules, ensure that the back module

is installed first before plugging in the front module.

When removing both the front and rear modules, ensure that the front module is

unplugged from the frame first, before removing the rear module.

• See the 6800+ Frame Installation and Operation Manual for information

about installing and operating a frame and its components.

• See the 6800+ Safety Instructions and Standards Manual for important

information about safely installing your module.

Once you have installed your HMX6803+ and OP+HMX+ modules, you can

connect them to the appropriate input and outputs.

Installing OP+HMX+ Modules

Front and back modules in the OPTO+ series have plastic caps that protect the

fragile laser connections from damage. You must remove these protective

covers before you install the back and front modules (see

18 HMX6803+ and OP+HMX+ Installation and Operation Manual

Figure 2-3).

Copyright © 2009, Harris Corporation

Page 35

Chapter 2: Installation

Caution

Caution

Remove these

protective covers

Remove this

protective cover

In addition, all fiber optic connections must be inspected and cleaned before

they are assembled. Carefully follow the inspection and cleaning steps

described in the next pages. Additional safety information appears in

“Laser

Safety Guidelines” on page 79.

Ensure that you remove the fiber optic protective covers from the front and

back modules before installation. Take care to avoid touching the fiber optic

connections. Thoroughly clean the connections before installa tion. Remove

power from the frame before installing or removing back modules.

Back Module Installation

Figure 2-3. Protective Covers for Laser Connectors

Follow these steps to install the back module into an FR6802+XF,

FR6802+XF48, FR6822+, or FR6802+QXF frame:

1. Remove a blank back plate from the frame.

Do not discard the blank back plates. They may be needed for future

configurations.

2. On the side of the back module that inserts into the front module, remove

the inner protective cap from the fiber connection (see Figure 2-3 on

page 19).

Microscopic dust or other contaminants can seriously impair or disable a

fiber optic network. Observe strict cleaning procedures. Do not touch the

end of the fiber.

3. Follow the inspection and cleaning procedure that begins on page 21.

HMX6803+ and OP+HMX+ Installation and Operation Manual 19

Copyright © 2009, Harris Corporation

Page 36

Chapter 2: Installation

Caution

Note

Front Module Installation

4. If it is already installed, remove the front module from the slot.

5. Install the new back module by inserting the bottom lip into the required

frame slot, and then screwing it into place.

Ensure that the EMI gaskets on the right side of the back module remains in

place during the installation. The EMI gaskets fit tightly.

6. Apply the adhesive label to the back module if it is supplied separately.

Follow these steps to install the front module:

1. Pull out the finger-release screws on the right and left side of the front panel

of the frame, and then open it.

2. Locate the front module slot that corresponds with the matching back

module.

3. Gently remove the outer and inner protective caps from the laser

connections. (see Figure 2-3 on page 19).

Microscopic dust or other contaminants can seriously impair or disable a

fiber optic network. Observe strict cleaning procedures. Do not touch the

end of the fiber.

4. Follow the fiber cleaning instructions that begin on page 21.

5. Ensure that your front module matches with a corresponding back module

6. Slide the module into the guides in the frame.

7. When the module edge is flush with the guide, close the extractor handle.

8. Close the front panel to ensure proper frame ventilation.

Removing OP+HMX+ Modules

Front Module

Follow these steps to remove a front module from a frame:

1. Pull out the finger-release screws on the right and left side of the front panel

of the same name.

The module is properly seated when its edge is flush with the guide edge

and the extractor handle closes.

To prevent overheating, keep the front panel closed and all back module

plate slots covered during operation.

The removal steps provided here are simila r to those outlined in your 6800+

Frame Installation and Operation Manual. Refer to that manual for detailed

information about installing and operating a frame and its components.

of the frame, and then open the front panel.

20 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 37

2. Grasp the extractor handle on the installed module, and then pull the

module out of its slot. Use the handle as a lever.

3. Close the front panel to ensure proper frame ventilation.

Back Module

Follow these steps to remove a back module from a frame:

1. Remove the front module, as described above.

2. Unscrew the top of the corresponding back module, and then tip it towards

you.

3. Pull the bottom lip of the back module from its slot.

4. Reinstall a new or blank back plate in the empty slot to ensure proper frame

ventilation.

5. Reinstall the front module.

Inspecting and Cleaning Fiber Optic Connections

Small amounts of microscopic dust or other contaminants can seriously impair

or disable a fiber optic network. To ensure that your network operates reliably,

you must carefully inspect and clean each connection when installing OPTO+

products.

Table 2-4 lists some typical contaminants of a fiber optic connection. The

inspection and cleaning procedure begins on page 22.

Chapter 2: Installation

Important Points

Table 2-4. Typical Contaminants

Contaminant Comments

Dust particle, 1 micron Can block up to 1% of th e light transmission,

creating a loss of 0.05 dB

Dust particle, 9 microns Although microscopic, the particle can completely

block the fiber core

Human hair Typically 50 to 75 microns in diameter

Oil Frequently caused by touching

Film residues Can accumulate from vapors or smoke

Powdery coatings Can be left behind after water or other solvents

evaporate

• Before you begin cleaning, always inspect the fiber connections.

• Inspect and clean both fiber ends every time you make a connection.

• Keep a protective cap on unplugged fiber connectors .

• Do not touch the end of a fiber.

• Store unused protective caps in a clean resealable container, located nearby

for easy access.

HMX6803+ and OP+HMX+ Installation and Operation Manual 21

Copyright © 2009, Harris Corporation

Page 38

Chapter 2: Installation

Warning

Zone 2

(20 t o 50 micr on d iam et er)

Maximum of 3 scratches <1.0 mi cron width is acceptable;

Maximum 1.0 micron light dig is acceptable

Zone 1

(0 to 20 micron diam eter)

No scratches or digs are allowed

Zone 3

(50 to 126 micron diameter)

Maximum 25 micron dig is acceptable;

Maximum scrat ch size of 1.0 micron is acceptable

Maximum 25 micron diameter dig is acceptable

Scratches and dust

• Do not reuse cleaning tissues or swabs.

• Do not allow alcohol or another wet cleaning agent to dry on a fiber end.

• Never touch the dispenser tip of an alcohol bottle or any clean portion of a

tissue or swab.

• Use care when handling the fiber; do not twist or pull.

• Keep your cleaning fluids away from open flame or spark.

Figure 2-4 describes the acceptable limits of defects in a fiber connection.

Figure 2-4. Fiber Optic Cross Section

Inspection and Cleaning Procedure

22 HMX6803+ and OP+HMX+ Installation and Operation Manual

Inspection

Eye damage may occur if an optical instrument such as a microscope,

magnifying glass, or eye loupe is used to stare at an energized fiber end.

To inspect and clean the fibers, follow these steps:

1. Ensure the fiber is not “live.”

2. Inspect the fiber endface with a fiberscope.

3. If the fiber endface is clean, return to the installation instructions on page 19

for back modules or page 20 for front modules.

If the connector is dirty, proceed to the dry cleaning instructions below.

Copyright © 2009, Harris Corporation

Page 39

Chapter 2: Installation

Caution

Caution

Dry Cleaning

If you are using cartridge or pocket-style dry cleaning tools, follow the

manufacturer’s directions. If you are using lint-free wipes, follow these steps:

1. Fold the lint-free wipe four to eight times into a square, taking care to avoid

touching the cleaning surface of the wipe.

2. Lightly wipe the fiber tip in the central portion of the lint-free wipe.

Do not scrub the fiber. Excessive rubbing will leave scratches.

3. Repeat the wiping action on another clean section of the wipe or a new

wipe.

4. Inspect the connector again with the fiberscope.

5. If the connection is clean, return to the installation steps on page 19 for back

modules, or page 20 for front modules.

If the connector is still dirty, proceed to the wet cleaning instructions.

Wet Cleaning

Using 99% isopropyl alcohol and lint-free wipes, follow these steps to wet clean

the fiber:

1. Fold the wipe into a square, about four to eight layers thick.

2. Moisten one section of the lint-free wipe with one drop of 99% alcohol,

ensuring that a portion of the wipe remains dry.

3. Lightly wipe the fiber end in the alcohol-moistened portion of the lint-free

wipe.

4. Immediately repeat the wiping action on the dry section of the wipe,

removing any residual alcohol.

5. Inspect the fiber endface again, and if necessary, repeat the wet cleaning

with another clean section of the lint-free wipe.

Do not scrub the fiber. Excessive rubbing will leave scratches.

6. Dry clean any remaining residue, and then inspect the connector again.

7. If the contamination persists, repeat the dry and wet cleaning procedure

until the endface is clean.

If the fiber end still remains dirty after repeated cleaning attempts, call

Customer Service for further instructions.

If the fiber end is clean, return to the installation instructions on page 19 for

back modules, or page 20 for front modules.

HMX6803+ and OP+HMX+ Installation and Operation Manual 23

Copyright © 2009, Harris Corporation

Page 40

Chapter 2: Installation

Upgrading Module Firmware

This module’s firmware can be updated using CCS Pilot, CoPilot, or Navigator

version 3.1.1 or higher, or the HTTP software upgrade tool. In order to perform

these upgrades, your frame must be equipped with a 6800+ETH module. See

your frame manual for more information.

24 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 41

Operating Notes

Note

When you set the control parameters on the HMX6803+ and OP+HMX+,

observe the following:

• If you make changes to certain parameters, other related parameters may

also be affected. See “Cross-Functional Parameter Changes” on page 38 for

more information.

• When you change a parameter, the effect is immediate. However, the

module requires up to 30 seconds to save the latest change. After 30

seconds, the new settings are saved and will be restored if the module loses

power and must be restarted.

Q-SEE Compliant Thumbnails

When installed in an FR6802+QXF or FR6822+ frame that also contains a

6800+ETH resource module, HMX6803+ and OP+HMX+ module control

windows have an extra Streaming tab in CCS Pilot and Navigator (version

3.2.1 or later). There you can view output video from the module.

In addition, video from the HMX6803+ and OP+HMX+, displayed at up to

three frames per second, can be displayed on the 6800+ETH’s control page, and

(for CCS Navigator only) on Graphical Navigation pages.

Chapter 3

Operation

HMX6803+ and OP+HMX+ modules all show a HMX6803+ label in

Navigator.

Thumbnail streaming is not supported for the following video standards:

• 1080i 60

• 720p 60

• 1080p 24/25/29.97/30

• 1080psF 23.98/24

• 1080p 50/59.94/60

HMX6803+ and OP+HMX+ Installation and Operation Manual 25

Copyright © 2009, Harris Corporation

Page 42

Chapter 3: Operation

Note

Activating HMX6803+ and OP+HMX+ Functions

The following sections provide information about the HMX6803+ and

OP+HMX+ special functions:

• “Adding a License Key” on page 26

• “Audio Test Tones” on page 27

• “Audio Embedding Modes” on page 27

• “Audio Embedding Errors” on page 31

• “Input Audio Rate” on page 33

• “Audio Path” on page 34

• “Seamless Sound Function” on page 34

• “Test Pattern Generator” on page 36

• “Dolby-E Automatic Header Alignment” on page 36

• “Audio Delay Ranges” on page 36

• “Maintaining Audio/Video Alignment” on page 36

Adding a License Key

For assistance with a license key, or to purchase a license key, please

contact your Sales representative.

To enter a license key to activate AES audio and/or 3G HD video, your CCS

software must be in Control mode.

1. Select the HMX6803+ module in the Navigation pane, right click, and then

select Control to open the module’s Control window.

2. Select the Parameters tab.

3. Select General in the tree view, and then type your license key in the

License Key field.

HMX6803+ and OP+HMX+ modules appear as HMX6803+ modules in

Navigator.

If your license key is valid, the Installed Options field displays the features

that are activated on the module, which in this case is 3G and/or AES.

26 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 43

Audio Test Tones

Table 3-1 describes the frequency and levels of each audio output test tone,

available as a selection from each of the Output Ch (1–16) Source Select and

Audio Procamp AES (1A-8B) Out Source parameters (see

Table 3-1. Audio Test Tones

Test Tone Frequency Level

Test Tone 1 400 Hz -18 dBFS

Test Tone 2 1 kHz -18 dBFS

Test Tone 3 2 kHz -18 dBFS

Test Tone 4 4 kHz -18 dBFS

EBU R68 1 kHz -18.06 dBFS

SMPTE RP155 1 kHz -20 dBFS

Audio Embedding Modes

The audio embedder component in the HMX6803+ and OP+HMX+ is

composed of several smaller subcomponent blocks:

Chapter 3: Operation

page 57).

• One ancillary data stripper (ADS)

• Four audio embedding subcomponents

The first subcomponent is an ancillary data stripper ( ADS). This block removes

all ancillary data packets in the input SDI stream, prior to embedding.

Following the ADS block are four separate audio-embedding subcomponents.

Each subcomponent has the ability to operate on only one audio group, either

appending or overwriting a predetermined group onto the SDI stream.

The audio embedding modes are Audio Group (1–4) Embedding Mode

parameters (see

page 51). Table 3-2 briefly describes the Off, Append,

OverWrt, and Auto options available from each of the embedding modes.

Table 3-2. Embedding Mode Options

Options Description

Off Deactivates embedding of the selected audio group

Append Attempts to insert the audio dat a and co ntrol packets

immediately following the last existing audio data/control

packet in the horizontal ancillary region (see

Embedding” on page 28)

OverWrt Attempts to overwrite existing audio data and control

packets of the same group number with the new audio data

(see

“Overwrite Embedding” on page 30)

“Append

HMX6803+ and OP+HMX+ Installation and Operation Manual 27

Copyright © 2009, Harris Corporation

Page 44

Chapter 3: Operation

EAV

ADS before em bedding

EAV

ADS afte r e m bedding group 1

Group 1

ADS before em bedding

Other

auxilliary dat a

A

EAV

Other

auxilliary dat a

B

ADS afte r e m bedding group 1

Group 1

EAV

Other

auxilliary dat a

A

Other

auxilliary dat a

B

Append Embedding

Table 3-2. Embedding Mode Options (Continued)

Options Description

Auto Attempts first to overwrite existing audio data and control

packets of the same audio group number; failing that, it

appends the new audio data and control packets

immediately following the last existing audio data/control

packet (refer to the Audio Group (1–4) Exists parameters

on

page 51 to determine what audio groups are already

present in the incoming SDI signal)

When you select Append embedding, the HMX6803+ and OP +HMX+

attempts to insert the audio data and control packets immediately following the

last existing data/control packet in the horizontal ancillary data space (ADS).

Append embedding is only valid if the audio group to be embe dded does not

already exist.

Figure 3-1 shows how append embedding will appear in the ancillary data space

when there is no previous audio or other data.

Figure 3-1. In Append Embedding Mode, Adding Group 1 When No Other Data is Present

Figure 3-2. In Append Embedding Mode, Adding Group 1 When Auxiliary Data is Present

28 HMX6803+ and OP+HMX+ Installation and Operation Manual

When auxiliary data exists in the ancillary data space, appended audio appears

following that data, as shown in

Figure 3-2.

Copyright © 2009, Harris Corporation

Page 45

Chapter 3: Operation

ADS afte r attem pt ing to em bed gr oup 1

ADS before em bedding

Pre-existing

Group 1

EAV

EAV

Pre-existing

Group 1

R esu l t : Error i s returne d

ADS afte r em be ddi ng group 2

EAV Group 1

Group 2

EAV

ADS before e m bedding

Group 1

ADS before em be ddi ng

EAV

Group 2

ADS aft er embedding gr oup 1

Group 1

EAV

Group 2

If you attempt to insert audio into Group 1 when Group 1 audio data already

exists in the ancillary data space, an error will be returned, as shown in

Figure 3-3.

Figure 3-3. Append Embedding Mode When Adding Group 1 and a Group 1 Already Exists

If you insert Group 2 audio when there is pre-existing Group 1 audio in the

ancillary data space and no Group 2 audio, the Group 2 audio will be inserted

following the Group 1 audio, as shown in

Figure 3-4.

Figure 3-4. Append Embedding Mode, Adding Group 2 Following Group 1

If you insert Group 1 audio when there is pre-existing Group 2 audio in the

ancillary data space and no Group 1 audio, the Group 1 audio will be inserted

following the Group 2 audio, as shown in

Figure 3-5. Append Embedding Mode, Adding Group 2 Following Group 1

HMX6803+ and OP+HMX+ Installation and Operation Manual 29

Copyright © 2009, Harris Corporation

Figure 3-5.

Page 46

Chapter 3: Operation

Note

ADS before em be ddi ng

EAV

Other

auxillary

data

Other

auxillar y

data

Other

auxillar y

data

ADS after att em pting t o em be d gr oup 1

EAV

R esu l t : Error i s re t u rned

Other

auxillary

data

Other

auxillar y

data

Other

auxillar y

data

ADS before e m bedding

EAV

EAV

ADS after attempting to embed group 1

R esu l t : Error i s re t u rned

An audio group cannot be divided. In Append embeddin g, the audio group is

always added following the last block in the ADS. If there is not enough room

to append the audio group following the last block of auxiliary data or audio in

the ADS, the attempt will result in an error, as shown in

Figure 3-6.

Figure 3-6. Append Embedding Mode Returns Error When Auxiliary Data Exists in all Audio Groups

Overwrite Embedding

When you select Overwrite embedding, the module attempts to overwrite any

existing audio data and control packets of the same group number with the new

audio data. This setting is valid only if the audio group to be embedded already

exists. If the new sample distribution does not exactly match the existing audio

data packet sample distribution, the embedder will mark some audio data

packets for deletion (DID word will be set to 180h).

Figure 3-7. Overwrite Embedding Mode When There is No Pre-Existing Audio

To avoid sample distribution issues, activate the ADS Clean feature (see

“ADS Clean Parameter” on page 39).

When you attempt Overwrite embedding and there is no previous audio (as in

Figure 3-7), it will return an error because there is nothing to overwrite.

30 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 47

Figure 3-8 shows how overwrite embedding will appear in the ancillary data

EAV

ADS before e m bedding

other

auxilliary data

A

other

auxilliary data

B

ADS after attempting to embed group 1

EAV

other

auxilliary data

A

other

auxilliary data

B

R esu l t : Error i s re t urn ed

ADS after embeddi ng gr oup 1

( with overw ri t e group spec i f i ed as G roup 1 )

G roup 1

EAV

ADS before em be ddi ng

Pre-existing Group 1

EAV

space when there is auxiliary data where Group 1 should be inserted.

Figure 3-8. Overwrite Embedding Mode When There is Auxiliary Data on Group 1

Figure 3-9 shows how overwrite embedding will appear in the ancillary data

space when there is pre-existing Group 1 audio. This operation is successful.

Chapter 3: Operation

Figure 3-9. Overwrite Embedding Mode When There is Group 1 Audio in the Group 1 Space

Audio Embedding Errors

Table 3-3 describes Group (1–4) Append Embedding Error and Group (1–4)

Overwrite Embed Error audio embedding errors (also see page 51).

Table 3-3. Audio Embedding Error Descriptions

Error Description

Group (1–4)

Append

Embedding

Error

Group (1–4)

Overwrite

Embed Error

HMX6803+ and OP+HMX+ Installation and Operation Manual 31

Copyright © 2009, Harris Corporation

To avoid embedding errors, follow these guidelines:

This error occurs if the embedder is set to Append mode

for a particular audio group, but that audio group already

exists in the incoming SDI signal.

In this case, the embedder does not embed another audio

data and control packet of the same audio group, as this

will result in incorrect audio sample distribution.

This error occurs if the embedder is set to Overwrite

mode for a particular audio group, but that audio group

does not exist in the incoming SDI signal

Page 48

Chapter 3: Operation

• Set the embedding mode to Auto. If the group is present, it will be

overwritten; if it is not present, it will be appended. The overwrite and

append errors are actually warnings that the operation is not being

performed.

• In SD-SDI mode do not overwrite embedded groups of 20-bit audio

samples with groups of 24-bit audio samples. The required extended data

packet information appended to that group may over write a pre-existing

audio group. For 24-bit audio embedding, use the ADS Clean feature

provided.

Mono Channel Audio Embedding

To embed audio on a channel-by-channel (mono) basis, preserving some

embedded audio channels while replacing others from external AES sources,

follow these steps:

1. Configure the input audio routing path (Input > Audio > Routing) by

selecting audio pair sources to the individual audio sample rate converters.

By default, SRCs 1-8 are assigned to the 8 deembedded audio sources

(DMX Grp1 Ch1/2, DMX Grp1 Ch3/4, DMX Grp2 Ch1/2, etc.) and SRCs

9-16 are assigned to the external AES audio sources (AES1a/1b, AES2a/2b,

etc.).

2. Configure the output audio routing path (Output > Audio Source Select >

Embedded Audio) by selecting sources to each mono embedded audio

output channel.

Each SRC (SRC1a, SRC1b, SRC2a, etc.) can be selected to any output

embedded audio channel, allowing for any input-to-output au dio

configuration.

3. Remove or preserve existing embedded audio with the ADS Clean

parameter (Processing > Audio).

4. Use the Audio Group (1-4) Embedding Mode parameters (Processing >

Audio > Embedding) to select the desired audio group embedding mode for

each audio group.

•In Auto mode, non-existing audio groups are appended and existing

audio groups are overwritten.

•In Overwrite mode, the original audio is preserved using the settings in

step 2.

•In Off mode, audio groups are untouched unless the ADS Clean

parameter is enabled.

Example: Replacing Audio Channel 1 in Group 1 Only

To replace only embedded audio channel 1 in group 1 with audio from external

AES 1A source, follow these steps:

1. Leave the input audio routing path at the default configuration (SRCs 1-8

from deembedded audio, SRCs 9-16 from external AES audio).

32 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 49

Chapter 3: Operation

Note

2. Route the output audio sources as follows (Output > Audio Source Select >

Embedded Audio):

Output Emb Ch 1 Source Select: SRC9a

Output Emb Ch 2 Source Select: SRC1b

Output Emb Ch 3 Source Select: SRC2a

Output Emb Ch 4 Source Select: SRC2b

3. Preserve existing embedded audio by setting the ADS Clean parameter

(Processing > Audio) to No.

4. Set the audio group embedding mode (Processing > Audio > Embedding):

Audio Group 1 Embedding Mode: Auto

Audio Group 2 Embedding Mode: Off

(incoming audio group 2 will be preserved)

Audio Group 3 Embedding Mode: Off

(incoming audio group 3 will be preserved)

Audio Group 4 Embedding Mode: Off

(incoming audio group 4 will be preserved)

Audio V-Fade

Input Audio Rate

To enable a smooth deembedded audio V-fade transition when switching video

sources, set the

Audio V-Fade parameter to Enable, and the Audio LOV Output

Mode parameter to Mute.

AES outputs in this mode are not AES11 alignment compliant and are not

aligned with video.

For proper operation in this mode, set the user delay parameters for all

audio channels (Processing > Audio > Delay) to the same value.

When embedding audio in PCM mode (Audio Ch [1–16] Format = PCM or

Audio Ch [1–16] Format

=

PCM), the input audio sample rate may be from 32 kHz to 108 kHz. This

= Auto and Audio Ch [1–16] Format Feedback

input audio will be sample rate converted to 48 kHz prior to embedding in the

video signal; as well, the embedder will indicate 48 kHz in the “Rate” word of

the audio control packet for each embedded audio group.

When embedding audio in Non-PCM mode (Audio Ch [1–16]

Format

[1–16] Format Feedback

= Non-PCM or Audio Ch [1–16] Format = Auto and Audio Ch

= Non-PCM), the input audio sample rate must be

48 kHz, and it must be frequency locked to the source video. In this scenario,

the sample rate conversion function is bypassed and the embedder will indicate

48 kHz in the “Rate” word of the audio control packet for each embedded audio

group.

(The parameters are listed on page 45.)

HMX6803+ and OP+HMX+ Installation and Operation Manual 33

Copyright © 2009, Harris Corporation

Page 50

Chapter 3: Operation

Note

Audio Path

The output audio source selection consists of two sets of controls.

• Input Sample Rate Conversion (SRC) routing source selections

Each SRC source can be assigned to one of the following sources:

• AES In (1A/1B to 8A/8B) (with AES8 option)

• Demuxed audio (Group 1 channels 1/2 to Group 4 channels 3/4)

• Output Audio Source Selection for the embedded audio

Each output embedded Audio channel can be assigned to one of the

following sources:

• SRC (1a to 16b)

• In Pair (SRC1a+1b to SRC16a+16b) Sum

• TstTone 400 Hz

• TstTone 1 kHz

• TstTone 2 kHz

• TstTone 4 kHz

• EBU R68

• SMPTE RP155

• SRC1a+2a

• SRC1b+2b

• SRC2b+3b

• SRC2a+4a

• SRC2b+4b

(The parameters are listed on page 45.)

Seamless Sound Function

When used in conjunction with HDX6803+ or SFS6803+ in a de-embedding

mode, the HMX6803+ can provide an uninterrupted (“popless”) embedding and

de-embedding path for the discrete audio channels regardless of the presence or

input switching of the video, as long as a constant video standard is maintained.

HMX6803+/OP+HMX+ connected to HDX6803+/OP+HDX+

HMX6803+/OP+HMX+ parameter settings (embedding module):

Set the Seamless Sound Enable parameter (Processing > Audio) to Enable.

Set the Audio LOV Output Mode to Pass.

If an audio group already exists and you want to replace it, set the ADS Clean

parameter to Yes (Processing > Audio > Embedding).

The ADS Clean parameter removes all audio groups from the vid eo stream.

34 HMX6803+ and OP+HMX+ Installation and Operation Manual

Copyright © 2009, Harris Corporation

Page 51

Chapter 3: Operation

Note

If the audio group already exists and you do not want to replace it, or if the

audio group to be embedded does not exist, set the ADS Clean parameter to No

(Processing > Audio > Embedding).

To set an audio group to be embedded to the Append mode, set the Audio

Group 1-4 Embedding Mode parameter to Append (Processing > Audio >

Embedding).

For optional minimum propagation delay, set the Video Delay Bypass

parameter to Yes (Processing > Video > Delay).

HDX6803+/OP+HDX+ parameter settings (de-embedding module):

Set the Seamless Sound Enable parameter (Processing > Audio) to Enable.

Set the Audio LOV Output Mode to Pass.

To set the AES output(s) to be sourced directly fro m the audio deembedder by

using the appropriate Demux Ch source, set the Output AES 1-8 Source Select

parameter to Demux Ch 1/2, Demux Ch 3/4, etc. (Output > Audio Source

Select > AES Audio).

For optional minimum propagation delay, set the Video Delay Bypass

parameter to Yes (Processing > Video > Delay).

HMX6803+/OP+HMX+ connected to SFS6803+/OP+SFS+

HMX6803+/OP+HMX+ parameter settings (embedding module):

Set the Seamless Sound Enable parameter (Processing > Audio) to Enable.

Set the Audio LOV Output Mode to Pass.

If an audio group already exists and you want to replace it, set the ADS Clean

parameter to Yes (Processing > Audio > Embedding).

The ADS Clean parameter removes all audio groups from the vid eo stream.

If an audio group already exists and you do not want to replace it, or if the audio

group to be embedded does not exist, set the ADS Clean parameter to No

(Processing > Audio > Embedding).

To embed an audio group in Append mode, set the Audio Group 1-4

Embedding Mode para meter to Append (Processing > Audio > Embedding).

For optional minimum propagation delay, set the Video Delay Bypass