Page 1

Broadcast

Console

8-input console: 99-1600-08

16-input console: 99-1600-16

24-input console: 99-1600-24

Operations

&

Technical

Manual

PRE75-54PRE75-54

PRE75-54

PRE75-54PRE75-54

Revision A • 6/06

Broadcast Communications Division

www.broadcast.harris.com

Page 2

HARRIS CORPORATION

ii

Revision A • 6/06

Page 3

Contents

CE Declaration of Conformity........................ iv

Safety Instructions ......................................... v

Hazard/Warning Label Identification............. v

1 - INTRODUCING NETWAVE

Product Overview ....................................... 1-1

Specifications .............................................. 1-8

Warranty................................................... 1-10

2 - INSTALLATION

Console Installation..................................... 2-2

Cabling and W iring ................................... 2-18

Mic Remote Control Logic Example.......... 2-27

Basic Peripheral Logic Example................ 2-28

Complex Peripheral Logic Example .......... 2-29

VistaMax Network Connections ................ 2-30

3 - USING NETWAVE

Console Overview .........................................3-1

Dual Fader Panel..........................................3-3

Dual Router Panel........................................ 3-4

Monitor Control Panel..................................3-5

Reflective Console Display............................3-9

NetW ave Applications................................3-10

Stand Alone Operation ..........................3-10

Telco/Codec Operation..........................3-11

5- SERVICING NETWAVE

Parts and Repair Services............................ 5-1

Spare and Replacement Parts...................... 5-2

Console T roubleshooting.............................. 5-3

Control Panel Service .................................. 5-3

Console Display Service............................... 5-5

48 V olt Supplies .......................................... 5-6

Product Description .................................... 5-7

6 - NETWAVE ACCESSORIES

Furniture and Cabinetry .............................. 6-1

Accessory Panels......................................... 6-1

Headphone Distribution Amp ..................... 6-3

ESE/SMPTE Master Clock ......................... 6-4

NetWave Upgrade Kits................................ 6-5

Mic Remote Panel Cables ............................ 6-6

INDEX

A - C ..................................................... Index-1

C - I.......................................................Index-2

I - P ...................................................... Index-3

P - W ....................................................Index-4

4 - LINKING NETWAVE

Linked NetWa ve Consoles............................4-1

Verifying Software Versions .....................4-1

Linked NetWave Features .......................4-2

Linked NetWave Setup.................................4-2

Signal Setup Details .....................................4-9

Macro Files ................................................ 4-10

iii

HARRIS CORPORATION

Revision A • 6/06

Page 4

Declaration of Conformity

HARRIS CORPORATION

iv

Revision A • 6/06

Page 5

Safety Instructions

RR

ead Aead A

ll Instrll Instr

ucuc

tionstions

1.

R

ead A

ll Instr

RR

ead Aead A

ll Instrll Instr

instructions before operating the product.

RR

etain Aetain A

ll Instrll Instr

2.

R

etain A

ll Instr

RR

etain Aetain A

ll Instrll Instr

instructions for future reference.

HH

eed Aeed A

ll ll

3.

4.

5.

6.

7.

8.

9.

WW

H

eed A

ll

W

HH

eed Aeed A

ll ll

WW

on the product and those listed in the operating

instructions.

olloollo

w Aw A

FF

F

ollo

w A

olloollo

w Aw A

FF

product usage instructions.

HH

eaea

tt

..

H

ea

t

. This product must be situated away from any

HH

eaea

tt

..

heat sources such as radiators, heat registers, stoves,

or other products (including power amplifiers) that

produce heat.

VV

enen

tilatila

tion.tion.

V

en

tila

ti on . Slots and openings in the product are

VV

enen

tilatila

tion.tion.

provided for ventilation. They ensure reliable operation

of the product and keep it from overheating. Do not

block or cover these openings during operation. Do

not place this product into a rack unless proper

ventilation is provided and the manufacturer’s

recommended installation procedures are followed.

WW

aa

tt

er and Mer and M

W

a

t

er and M

WW

aa

tt

er and Mer and M

water such as a bathtub, wash bowl, kitchen sink, or

laundry tub, in a wet basement, or near a swimming

pool or the like.

AA

ttachmenttachmen

A

ttachmen

AA

ttachmenttachmen

recommended by the product manufacturer as they

may cause hazards.

PP

oo

ww

er Ser S

ourour

P

o

w

er S

our

PP

oo

ww

er Ser S

ourour

the type of power source indicated on the marking

..

uc

tions

. Read all safety and operating

ucuc

tionstions

..

ucuc

tionstions

..

uc

tions

. Retain all safety and operating

ucuc

tionstions

..

arar

ningsnings

..

ar

nings

. You must adhere to all warnings

arar

ningsnings

..

ll Instrll Instr

ucuc

tionstions

ll Instr

ll Instrll Instr

cc

c

cc

..

uc

tions

. Follow all operating and

ucuc

tionstions

..

oistur

ee

..

oistur

oistur

e

. Do not use this product near

ee

..

oisturoistur

tsts

..

ts

. Do not use any attachments not

tsts

..

eses

..

es

. You must operate this product using

eses

..

label and in the installation instructions. If you are not

sure of the type of power supplied to your facility,

consult your local power company.

GG

rr

ounding and Pounding and P

10.

G

r

ounding and P

GG

rr

ounding and Pounding and P

equipped with a polarized AC plug with integral safety

ground pin. Do not defeat the safety ground in any

manner.

PP

oo

ww

er Cer C

oror

d Pd P

rr

11.

P

o

PP

oo

routed so that they are not likely to be walked on nor

pinched by items placed upon or against them. Pay

particular attention to the cords at AC wall plugs and

convenience receptacles, and at the point where the

cord plugs into the product.

LighLigh

12.

Ligh

LighLigh

unplug it from the AC wall outlet during a lightning

storm or when it is left unattended and unused for

long periods of time. This will prevent damage to the

product due to lightning and power line surges.

OO

vv

13.

O

v

OO

vv

extension cords, or integral convenience outlets as this

can result in a fire or electric shock hazard.

OO

bjecbjec

14.

O

bjec

OO

bjecbjec

kind into this product through openings as they may

touch dangerous voltage points or short out parts,

which could result in a fire or electric shock. Never spill

liquid of any kind on the product.

AA

cccc

15.

A

cc

AA

cccc

cart, stand, tripod, bracket, or table. The product may

fall, causing serious injury to a child or adult and serious

damage to the product. Any mounting of the pr oduct

must follow manufacturer’s installation instructions.

otot

w

er C

or

d P

r

ot

ww

er Cer C

oror

d Pd P

rr

otot

tningtning

..

tning

. For added protection for this product,

tningtning

..

..

erer

loadingloading

loading

. Do not overload AC wall outlets,

er

..

erer

loadingloading

t and Liquid Et and Liquid E

t and Liquid E

t and Liquid Et and Liquid E

essoressor

iesies

..

essor

ies

. Do not place this product on an unstable

essoressor

iesies

..

tion.tion.

olarolar

izaiza

tio n. This product is

olar

iza

tion.tion.

olarolar

izaiza

ecec

tion.tion.

ec

tion. Power supply cords must b e

ecec

tion.tion.

nn

trtr

yy

..

n

tr

y

. Never push objects of any

nn

trtr

yy

..

PP

rr

oo

ducduc

t and Ct and C

arar

t Ct C

ombinaombina

16.

P

r

o

duc

t and C

PP

rr

oo

with care. Quick stops, excessive force, and uneven

surfaces may cause the product and the cart

combination to overturn.

SS

erer

17.

S

er

SS

erer

personnel.

DD

amage Ramage R

18.

D

amage R

DD

amage Ramage R

from the wall AC outlet and refer servicing to qualified

service personnel under the following conditions:

a. When the AC cord or plug is damaged.

b. If liquid has been spilled or objects have fallen into

the product.

c. If the product has been exposed to rain or water.

d. If the product does not operate normally (following

operating instructions).

e. If the product has been dropped or damaged in any

way.

f. When the product exhibits a distinct change in

performance. This indicates a need for service.

RR

eplaceplac

19.

R

eplac

RR

eplaceplac

required, be sure the service technician has used

replacement parts specified by the manufacturer or

that have the same characteristics as the original parts.

Unauthorized substitutions may result in fire, electric

shock, or other hazards.

SS

afaf

20.

S

af

SS

afaf

product, ask the service technician to perform safety

checks to determine that the product is in proper

operating condition.

CC

leaningleaning

21.

C

leaning

CC

leaningleaning

only a damp cloth for cleaning.

ar

ducduc

t and Ct and C

arar

vicingvicing

..

vicing

. Refer all servicing to qualified ser vicing

vicingvicing

..

equirequir

equir

equirequir

emenemen

t Pt P

emen

t P

emenemen

t Pt P

etet

y Cy C

heck.heck.

et

y C

heck. Upon completion of any repairs to this

etet

y Cy C

heck.heck.

..

. Do not use liquid or aerosol cleaners. Use

..

tion.tion.

t C

ombina

tion. Move this product

t Ct C

ombinaombina

tion.tion.

ing Sing S

erer

vicvic

ee

..

ing S

er

vic

e

. Unplug this product

ing Sing S

erer

vicvic

ee

..

arar

tsts

..

ar

ts

. When replacemen t parts are

arar

tsts

..

Hazard/Warning Label Identification

EE

xx

clamaclama

tion Ption P

oinoin

t symbt symb

The

E

x

clama

tion P

tion Ption P

oin

oinoin

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

EE

xx

clamaclama

within an equilateral triangle, alerts the

user to the presence of important

operating and maintenance (servicing)

instructions in product literature and

instruction manuals.

WARNING: SHOCK HAZARD - DO NOT OPEN

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR

LighLigh

tning Ftning F

tning F

tning Ftning F

lash lash

lash

lash lash

olol

o l, within an

olol

The

Ligh

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK DO NOT

REMOVE ANY COVER OR PANEL. NO USER SERVICEABLE PARTS

INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

LighLigh

AA

rr

rr

oo

whead symbwhead symb

A

r

r

o

whead symb

AA

rr

rr

oo

whead symbwhead symb

equilateral triangle, alerts the user to

the presence of uninsulated

dangerous voltage within the

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THE POWER SUPPLY OR CONSOLE

TO RAIN OR MOISTURE.

WW

ARNINGARNING

W

ARNING—This e qu ip me nt generates, use s, and can radiate radio frequency ener gy. If no t installed and used in accordance with the instructions in this

WW

ARNINGARNING

manual it may cause interference to radio communications. It has been tested and found to comply with the limits for a Class A computing device

(pursuant to Subpart J of Part 15 FCC Rules), which ar e designed to pro vide reasonable prot ection against such interference when operated in a commercial environment. Operation of this equipment in a residential area is likely to cause interference, in which case the user, at his own expense, will be

required to take whatever measures may be required to correct the interference.

product’s enclosure that may be of

sufficient magnitude to constitute a

risk of electric shock.

t symb

t symbt symb

WW

ithith

W

ith

WW

ithith

olol

ol,

olol

v

HARRIS CORPORATION

Revision A • 6/06

Page 6

HARRIS CORPORATION

vi

Revision A • 6/06

Page 7

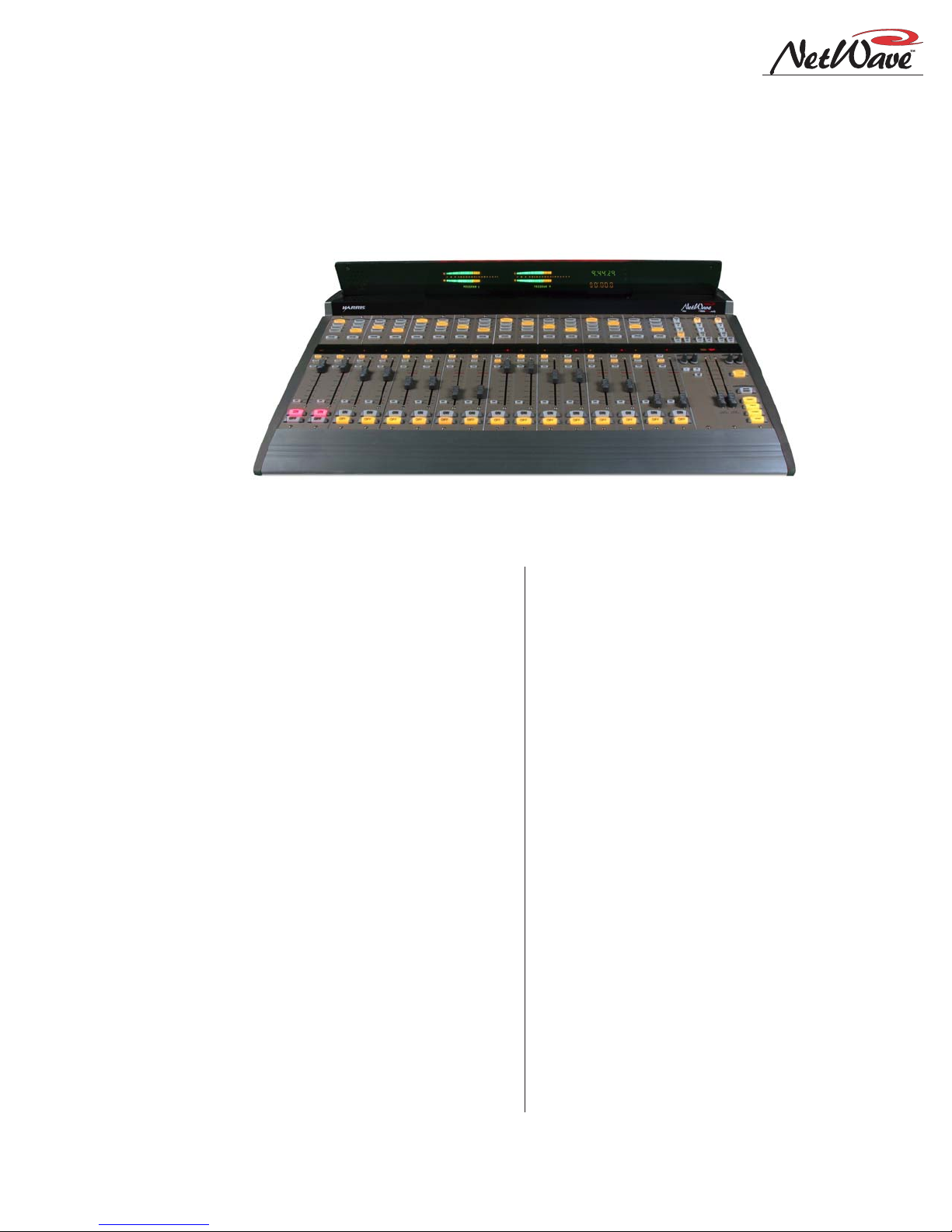

Introducing

NetWav e

NetWave-16 Console

Thanks for joining the growing ranks of

broadcasters employing Harris Corporation prod-

ucts designed by PR&E. Our mission: provide the

finest quality products, systems , documentation and

after-sale support.

To obtain the maximum benefit from the

NetWave’s capabilities, read through the chapters

on

Installation

product installation.

and

Operation

prior to the actual

1

NetWave consoles hav e these parts:

• Main Frame: with 8, 16 or 24 channel slots

• Monitor & Output Card: one per console

• DSP & I/O Card: one on 8-input frames; two

on 16-input frames; three on 24-input frames

• Monitor Panel: one per console

• Dual Fader Panel: four on 8-input frames; six

on 16-input frames; nine on 24-input frames

• Reflective Display: clock, timer and two meters

are standard, an additional two meters can be

added to the NetWave-16 and NetW a ve-24

• Dual Width Blank Panel: two standard on

NetW ave-16; three on NetWave-24 (cover the

unpopulated channel slots)

• 48-volt Supply: an in-line supply is standard

on the NetWave-8 and NetWave-16; a rackmount supply is standard on the NetW a ve-24

(optional on the other frame sizes)

• Installation Materials: installation kit; NetWave CD-ROM; NetWave Quick Guide

• Toolkit (optional): 76-1901 toolkit

• Printed Manual (optional): 75-54 NetWave

Installation & Operation manual

1-1

HARRIS CORPORATION

Revision A • 6/06

Page 8

1 Introducing NetWave

Product Overview

NetWave is a low-profile, digitally-controlled,

VistaMax-compatible audio console that sits on

the countertop. Three frame sizes are available,

with 8, 16 or 24 channel slots .

Each NetWave operates as a stand-alone console but, for maximum flexibility and usability,

can be tied into any VistaMax system (running

500-series code) by installing the optional Link

Activation Kit (99-1425). The kit activates the

built-in VistaMax Link which, via a single CAT-5e

cable, ties the console to a VistaMax or Envo y Hub

card to allow any system source (audio signals or

audio signals with logic) to be routed to any NetW a ve channel and to the External Monitor inputs.

The VistaMax Link also sends a number of NetWave signals to the VistaMax system including:

one input from each channel (either the local analog or digital input can be chosen); each program

bus output; both mix-minus outputs (which ha ve

both a clean feed and an IFB feed); the two channel Telco record output; and the stereo cue bus.

These signals can then be routed to an y VistaMax

system destination as required.

To further enhance a “Linked” console, an optional Dual F ader panel upgrade, the Dual Router

Kit (99-1424), is also available. This kit adds in

VistaMax source selection ability to both channels on any Dual Fader panel.

The Reflective Displa y , with two stereo bargraph

meters (PGM 1 and auxiliary), a clock which can

be slaved to an ESE or a SMPTE master clock

and an Event Timer, is integrated into the frame

behind the control panels. Quad meter displa y kits

are available for the NetWave-16 (99-1990-16Q)

and for the NetWave-24 (99-1990-24Q) to add

dedicated Program 2 and Program 3 meters.

Two 48-volt power supplies are used with NetWave consoles: a rack mount supply (99-1205),

which is the same one used with VistaMax and

Envoy card frames and RMXd and BMXd consoles, comes standard with the NetWave-24; while

an in-line supply (50-27) comes standard with the

NetW av e-8 and 16 frame sizes. A 99-1205 supply

can also be used on the smaller NetWave frames.

An optional 90-1995 Power Coupler is available to allow any NetWave console to be redundantly powered by coupling in a second matching

48-volt supply.

The NetWave has an all-aluminum chassis,

which fully contains all circuit board electronics,

for strength and RFI immunity. To ensure silent

operation, all NetWave parts (console frame, control panels, console display and power supplies)

are convection cooled—meaning no fans, and completely silent operation.

All user audio and logic connections are made

from the top rear of the frame. Connector access is

via a removable flip-open cover which hides the

cabling and connectors during normal operation.

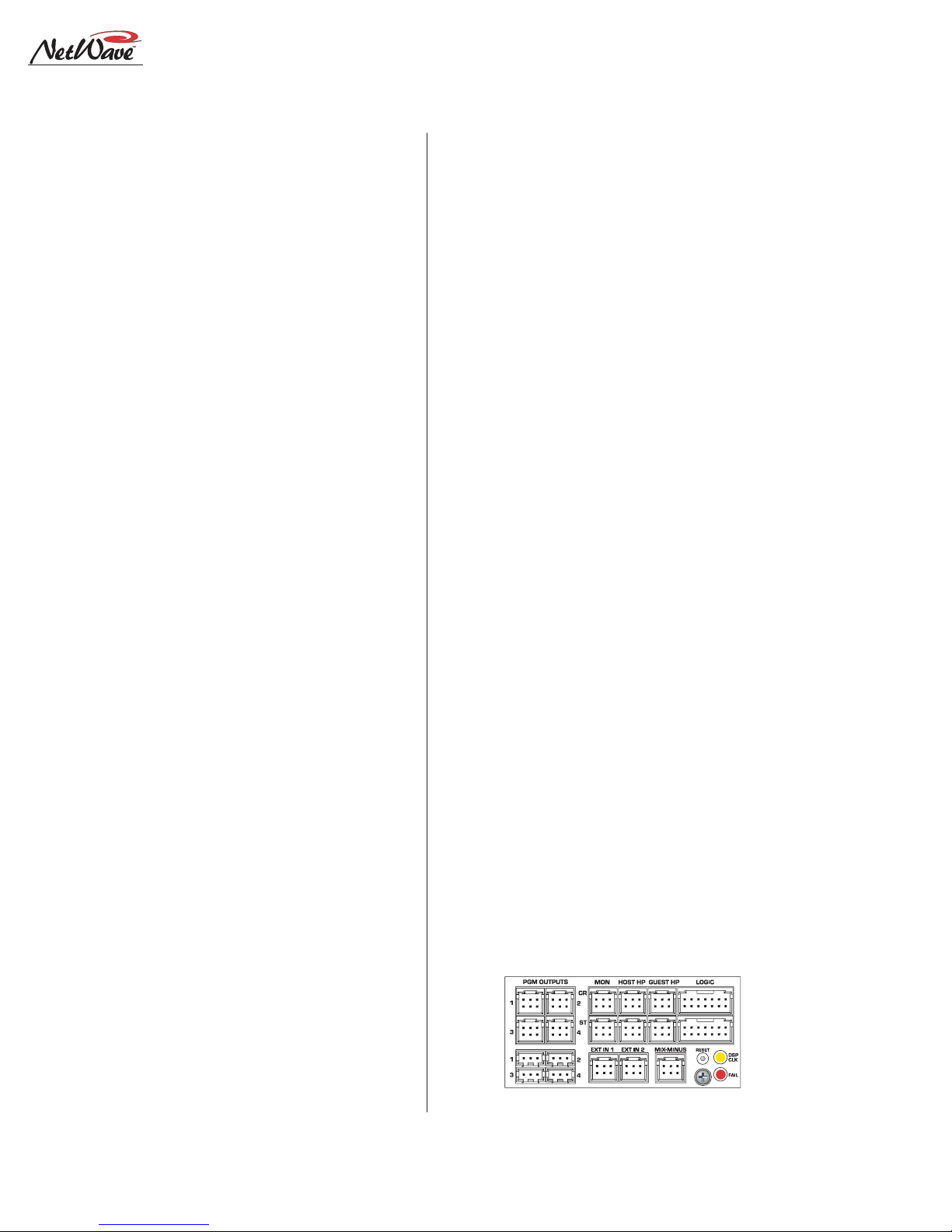

NETWAVE CONSOLE CONNECTIONS

•Monitor & Output Card:

» Four stereo Program bus outputs (each with

separate analog and AES digital outputs)

» Three stereo analog control room outputs (for

a room monitor amp and for separate host and

guest headphone amps)

» Three stereo analog studio outputs (for a stu-

dio monitor amp and for separate host and

guest headphone amps)

» Two stereo analog External Monitor inputs

» Two mono analog Mix-Minus outputs

Monitor and Output Card Connections

HARRIS CORPORATION

1-2

Revision A • 6/06

Page 9

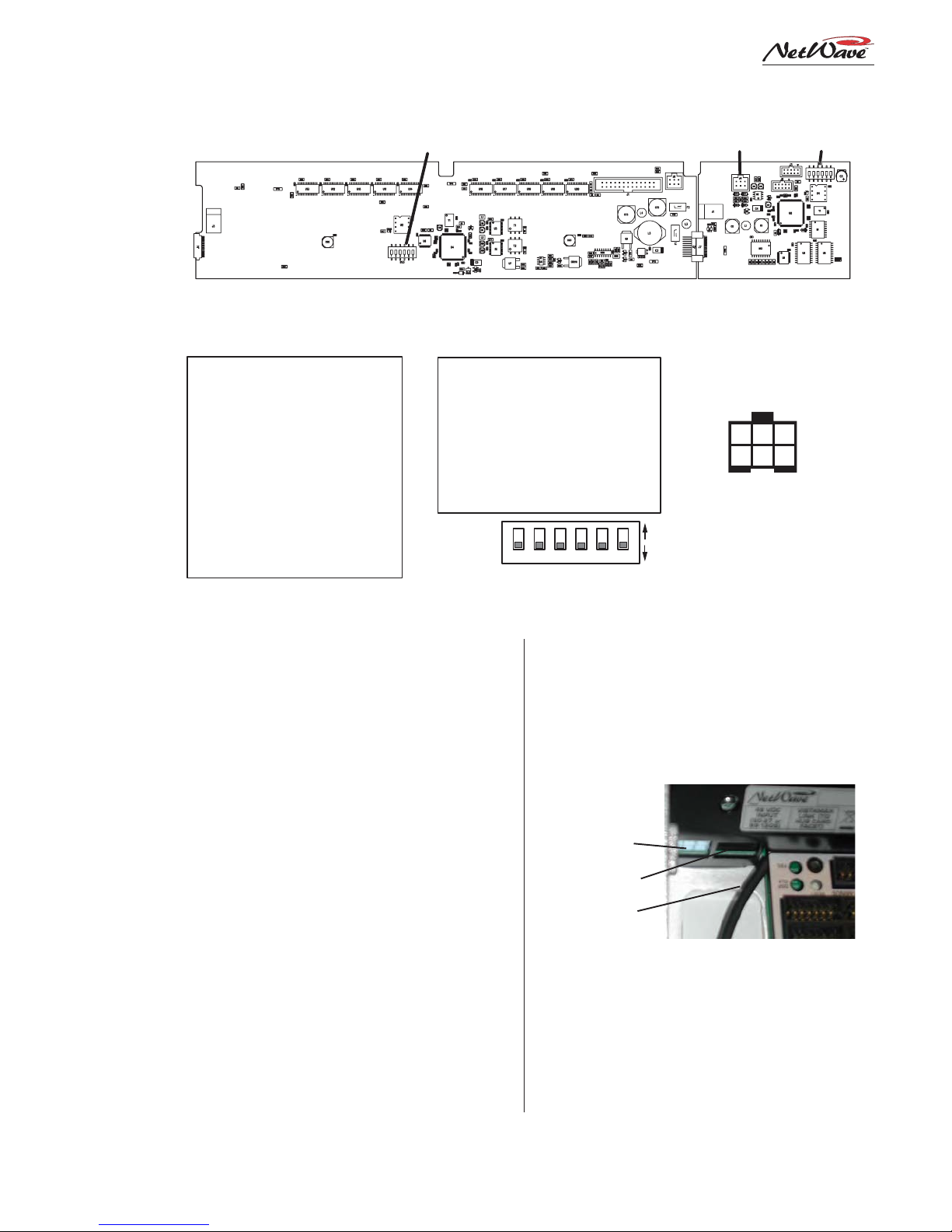

DSP and I/O Card Connectors and Channel Setup Controls

1 Introducing NetWave

» Separate control room and studio logic con-

nectors (warning interface output, logic I/O

for dim and mute control, talk logic output)

•DSP & I/O Cards:

» Sixteen stereo/dual mono audio inputs (eight

analog and eight digital), assignable as the A

or B source for the eight channel control strips

associated with that card

» Eight channel logic connectors, assignable to

either the A or B source for the eight channel

control strips associated with that card

•Other Connections:

» One 1/4" TRS jack for the board operator

headphones, left side panel

» One RJ-45 VistaMax Link connector for a

CAT-5e cable (requires the optional Link Activation Kit be installed)

» One keyed connector for the 48-volt power

supply supplied with the console

» Four , eight or twelve internal RJ-45 sockets to

supply power and signals to the Dual Fader

panels

» Four, eight or twelve internal and rear panel

LAN passthru RJ-45 sockets for standard

CAT-5 cabling to connect the optional Dual

Router Kits to the VistaMax LAN

» One ESE or SMPTE master clock input on

the clock-timer board

» One Timer Reset output, for a studio event

timer , on the clock-timer board

MAIN COMPONENT DESCRIPTIONS

NetWave board operators use three parts: the

Dual Fader panels; the Monitor panel; and the

Reflective Console Display . Each is cov ered in this

section along with descriptions for the other parts

making up the console: 48-volt power supplies,

the Monitor & Output card, the DSP & I/O card,

the VistaMax Link and the optional upgrade kits.

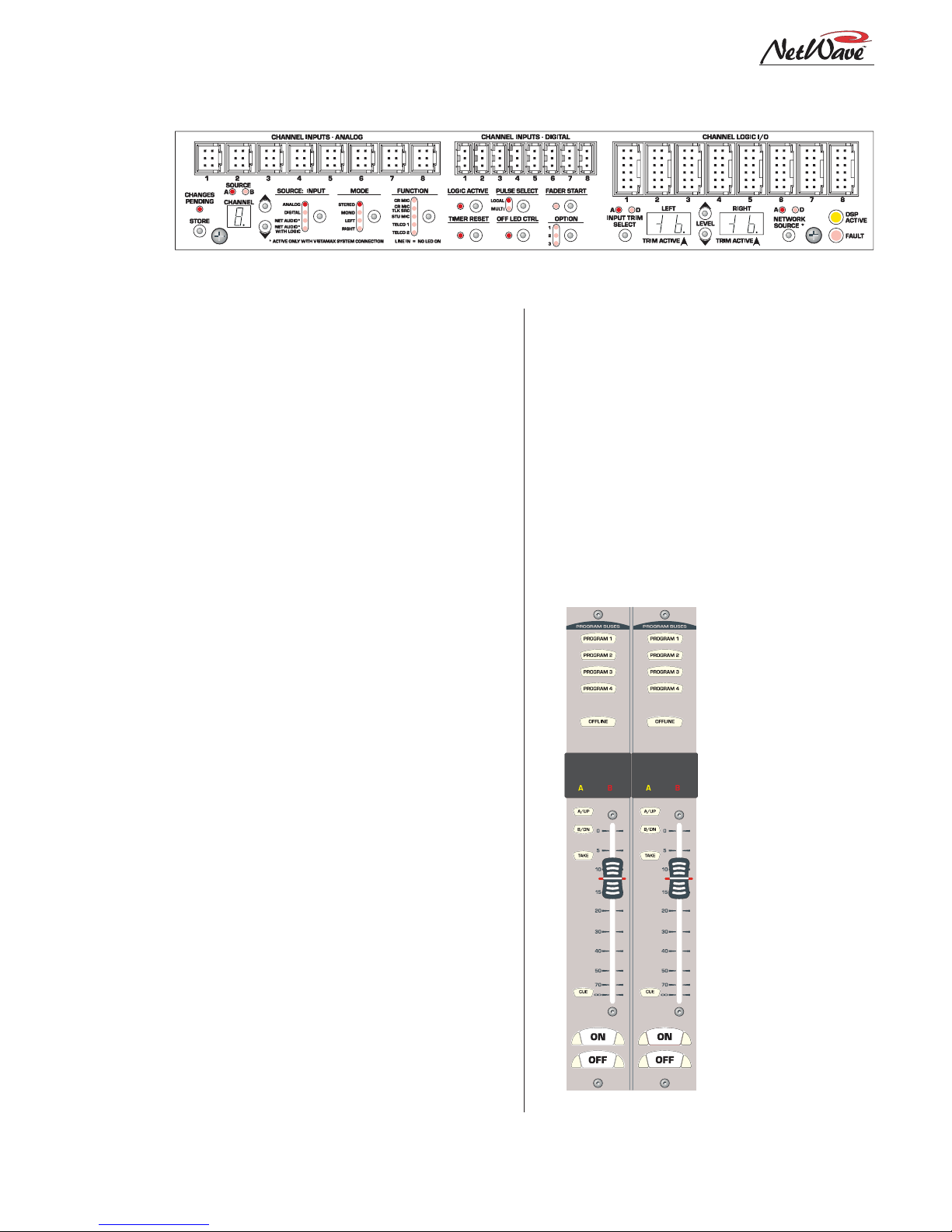

NetWa ve Dual Fader Panels

Each Dual Fader panel has two channel control

strips. Each strip has the following features: sepa-

rate channel on and off

buttons; a 100mm fader

for channel level control;

cue on/off button; A and

B source selector buttons

with a Take button; active

source illuminated label;

and five bus assignment

buttons (four Program

and one Offline).

Channel control is digital, so no audio ev er travels through the Dual

Fader panel. In fact, a

Dual Fader panel can be

swapped “hot” without affecting either channel’s

audio performance.

Each Dual F ader panel

plugs into a DSP & I/O

card using a single red

Dual Fader Panel

1-3

HARRIS CORPORATION

Revision A • 6/06

Page 10

1 Introducing NetWave

CAT-5 cable. Since each DSP & I/O card carries

eight audio channels, up to four Dual Fader panels are plugged into each DSP & I/O card.

Each Dual F ader channel control strip has two

audio inputs and one logic I/O connector associated with it on the DSP & I/O card. Since each

channel strip has two possible sources (A and B),

which audio input is used for each source is assigned during console setup . In the standard, nonlinked, NetWave console the two possible inputs

are the local analog input or the local digital input assigned to that channel on the DSP & I/O

card. When the NetWave is linked to a VistaMax

system, there are three selections per source: the

local analog input, the local digital input, or a

routed VistaMax source.

The operating parameters for each source, on

each channel, are independently set during console setup through a common group of setup buttons and LEDs on each DSP & I/O card (shown

in the illustration on the previous page). These

controls set the parameters used when the A and

the B source is selected. The parameters include:

input type (is the input a control room mic, a studio mic, a line input or a Telco input?); whether

logic is be associated with that input; whether the

event timer is reset at channel on; whether fader

start is active; etc. The parameter settings are

stored in nonvolatile RAM.

The channel strip’s A and B select buttons are

used along with the Take button to choose the

active source for that channel. W hen the A source

is active, yellow LEDs backlight the A source label under a smoked polycarbonate window above

the A button, and the A button is lit. When the B

source is active, red LEDs backlight the B source

label above the fader and the B button is lit.

Setting a channel source to use the logic I/O

means the channel can remotely control a peripheral device (mic control panel, CD player, computer playback system, etc.) and that peripheral

can also control the channel. The logic I/O provides fully independent parallel logic functions

that: outputs start and stop pulses to line devices

(on and off tallies to mic panels); receives channel

on, off, cue and reset/ready commands from line

devices (on, off, cough and talkback commands

from mic panels).

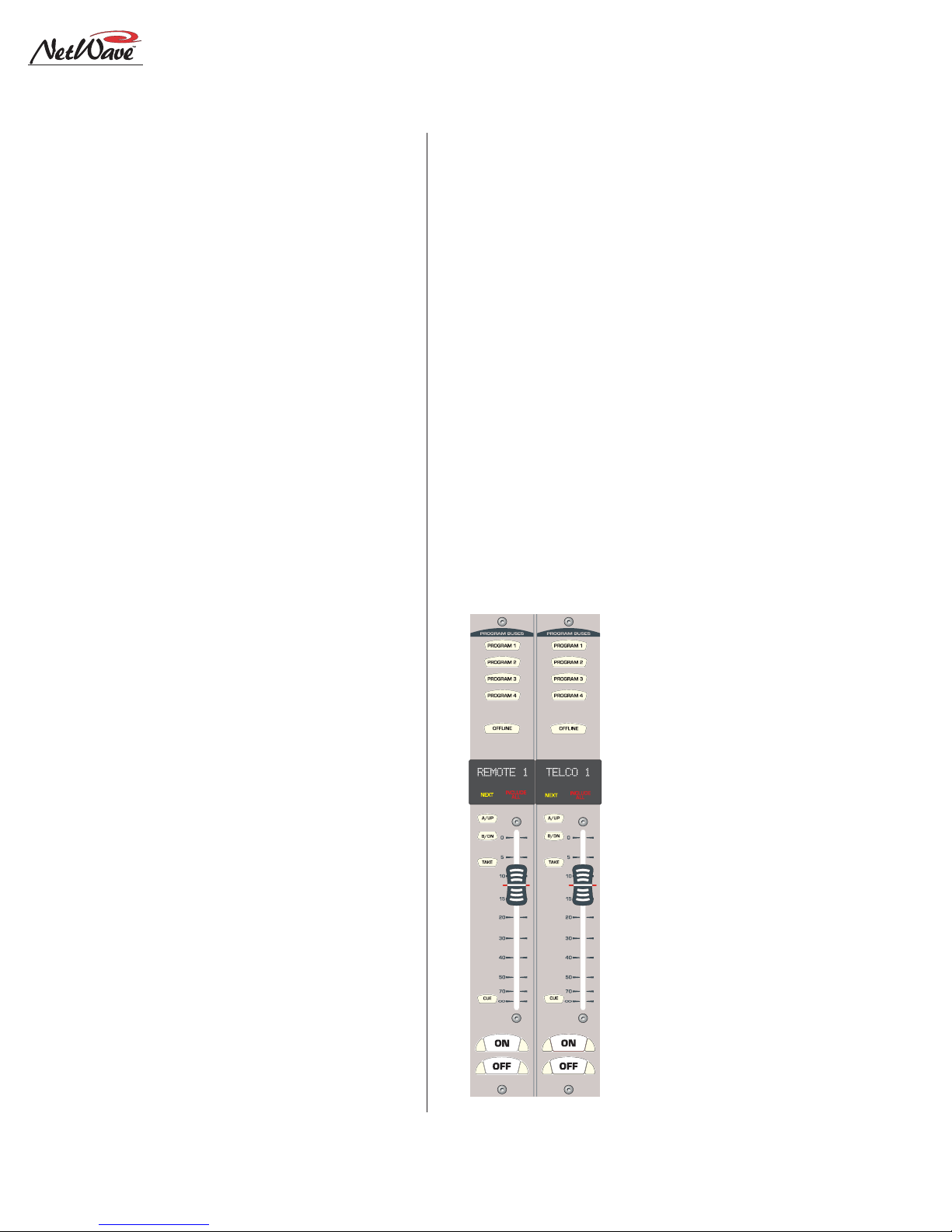

Dual Router Channels

The optional Dual Router Kit changes the A/B

selector buttons on both channels of any Dual

Fader panel into VistaMax source selector Up/

Down buttons. To use this functionality, the

console’s VistaMax Link must be active.

Dual Fader panels that have the Dual Router

Kit installed are easily identified by the two 10character signal name displays under the top half

of the smoked polycarbonate lens above the fader .

The display normally shows the name of the cur-

rent VistaMax source

feeding that channel.

But, when finding the

next source by pressing

an Up or Down button,

the displayed name

switches to show a potential Next Source for

that channel. The yellow

Next label above the Up

button lights while the

Next Source name is displayed. Holding down, or

repeatedly tapping the

Up or Down button,

steps alphanumerically

through the list of potential Next Source names

available on that channel.

Once the desired

Dual Router Panel

source name is shown,

HARRIS CORPORATION

1-4

Revision A • 6/06

Page 11

1 Introducing NetWave

pressing the Take button selects that source—when

the channel is off. New routed sources cannot be

taken when the channel is on (the On button

flashes three times to indicate the next source cannot be taken while the channel is on). But, a next

source can be pre-selected and then taken once

the channel is turned off.

Which sources are seen when the Up and Down

buttons are pressed on the router channel is set

using the VistaMax Control Center (VMCC) software, vers 1.1 or later. Each channel could be assigned anywhere from one source up to every av ailable source in the VistaMax system in its selection

list. In regular use, the signal list is kept short to

make it easy for board operators to easily find

desired sources. If a board operator needs to selected a source that is not shown, pressing both

the Up and Down buttons together turns on the

Include All function, lighting up the red Include

All label. Every source available to the console’s

parent device is now displayed. Pressing both Up

and Down buttons together again turns off the Include All function.

The VMCC 1.1 software is included on the NetWave CD-ROM (99-5001) that comes with the

console.

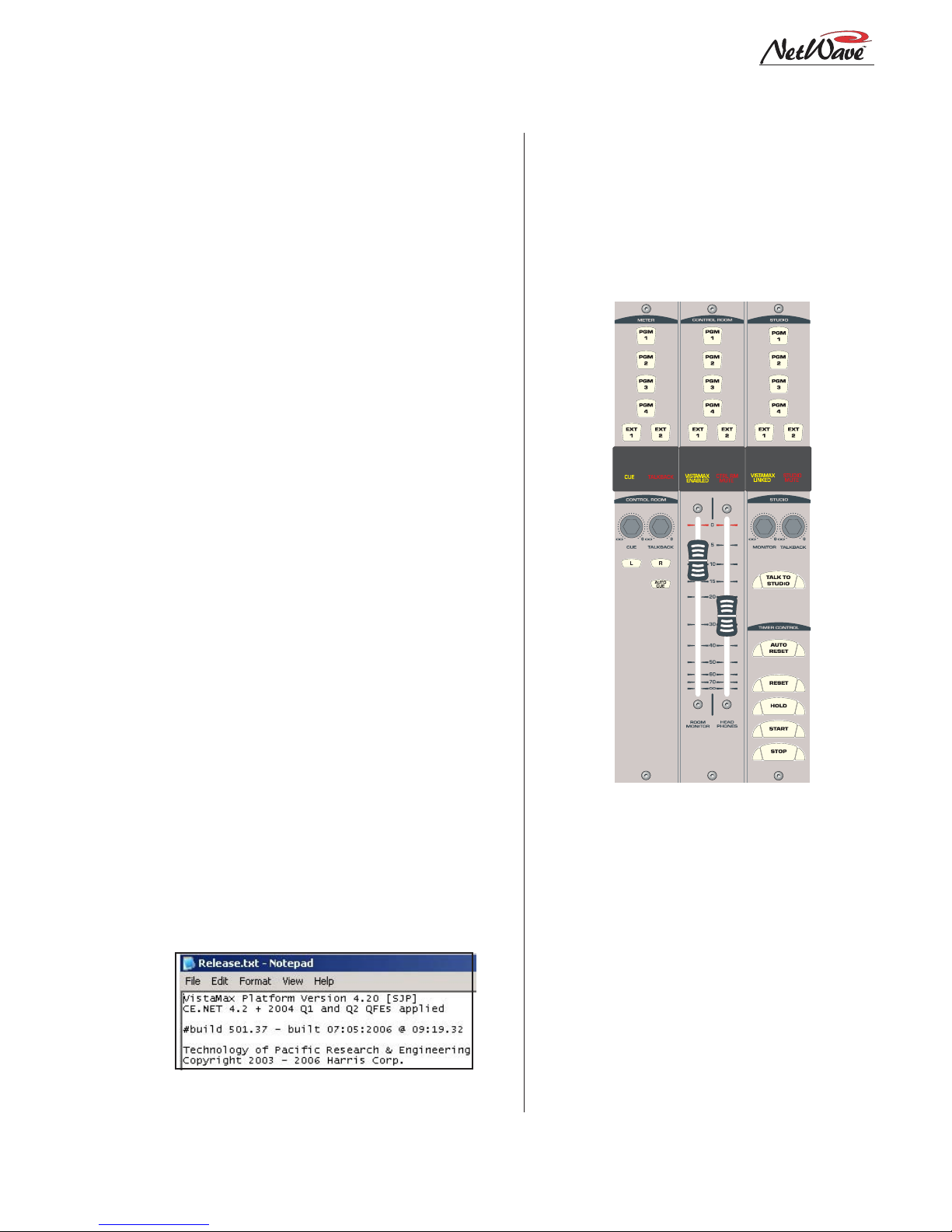

To integrate the NetWave with a VistaMax or

Envoy card frame, the VistaMax devices must be

running 500-series code. The current operating

system code build can be viewed by opening the

release.txt file on the parent card frame or

by using Community Monitor, another program

included on the NetWave CD-ROM.

Operating System Code build,

as shown in the release.txt file

Monitor Panel

This standard panel is divided into three sections

separated by double graphic lines. From left to

right the sections, divided by main function, are:

Aux Meter control; Control Room control; and

Studio control.

Monitor Control Panel

Aux Meter Section

The top of all three sections have exclusiv e action

source selector buttons to select one monitor signal

from the PGM 1 thru 4 buses and the two External

Monitor inputs. In the Aux Meter section, the

buttons select which signal feeds the right-most

meter in the Reflective Display, with the selected

source name shown below the Aux Meter.

Note that the Aux Meter is normally set to

alternately display the cue levels while cue is active

(when the cue label is lit, Cue is displayed below

the meter and the cue level is shown).

1-5

HARRIS CORPORATION

Revision A • 6/06

Page 12

1 Introducing NetWave

Several Control Room controls are located below

the meter selector buttons in this section of the

panel. They are covered in the Control Room

Section that follows.

Control Room Section

The middle of the panel has the control room

monitor source selector buttons and the two faders

to control the room monitor speaker level and the

operator headphone output level.

Any one source can be selected to feed all control

room monitor outputs. The active source button

lights to indicate its selection.

A cue speaker, at the left end of the console

display, is level controlled by the cue pot in the

middle of the left-hand section. A cue indicator

(yellow) lights while cue is active.

A talkback pot controls the level of incoming

talkback that feeds the cue speaker independently

of the cue volume pot. A Talk to Control Room

indicator (red) lights while a studio microphone

is talking to the control room.

A control room monitor output fader and the

operator headphone output fader are at the bottom of the center section.

The signal mode for both the control room and

studio outputs is set by the Monitor Mode buttons in the left-hand section (below the cue and

talkback pots). The L and R buttons control

whether the monitor signal for all outputs is stereo (when neither button is lit), left only (when L

is lit), right only (when R is lit) or a mono sum

signal (when L and R are both lit) where the left

and right signals are summed together to feed all

monitor outputs.

Just below the R mode button is the AutoCue

button. When lit, the operator’s headphone output automatically switches to feed the cue bus into

the operator’s headphones while cue is active.

When unlit, cue activity does not affect the board

operator’s headphone audio. AutoCue has two

modes of operation (set by switch DS1-3 on the

Monitor & Output card). The default setting is Split

Cue, where the monitor and cue audio are separately summed to mono before feeding the operator headphones. Cue audio is sent to the one ear

while the monitor audio goes to the other ear . T his

is typically used when the console is in an on-air

studio.

The second AutoCue mode is Stereo Cue, where

stereo cue audio replaces the monitor audio source

in the headphones. This setting may be desirable

for production rooms and other off-air applications.

Studio Section

The right-hand section of the Monitor panel has

the monitor source selection buttons and level

controls for a separate talk or voice studio. One

source can be selected from among the six buttons

at the top of the center section. The selected source

button lights to indicate its selection.

The two pots in this section control the output

level of a dedicated studio monitor output

(Monitor) and the amount of talk to studio audio

(Talkback) that is fed to the monitor output.

This section of the Monitor Control panel also

has a Talk to Studio button to allow the board

operator to talk to the studio using the board

operator mic. If desired, multiple control room

mics can be assigned as talk sources to enable both

a board op and a producer to talk to the studio

without having to add a mic control panel.

Five event timer control buttons are at the

bottom of this section. Start, Stop, Hold and Reset

manually control the event timer in the Console

Display. When the Auto Reset button is lit, the

timer can be reset automatically when a channel

is turned on. Which channel sources reset the timer

are set during installation using the DSP & I/O

card setup controls.

HARRIS CORPORATION

1-6

Revision A • 6/06

Page 13

1 Introducing NetWave

Reflective Console Display

The integrated Reflective Console Display is located just behind the Dual Fader and Monitor

panels. The standard display has two stereo bargraph meters with the left one showing the PGM

1 output levels. The right-hand, or Aux Meter,

shows a source selected using the Meter source

controls on the Monitor panel. Two more stereo

bargraph meters (for Program 2 and Program 3)

can be added to the larger frame sizes by installing the optional Quad Meter kit.

A time of day clock and an event timer are also

in the Console Display . The default operating mode

for the clock is autonomous, meaning the clock

runs independently and must be set by hand. The

clock time remains current for about three days

with the power off. After that, the time must again

be set. The clock can alternately be slaved to a

SMPTE, ESE TC-89 or ESE TC-90 master clock.

In this mode, the time set buttons are not active.

The event timer is controlled by Monitor panel

buttons, as well as reset commands from one or

more channels when the Auto button is lit.

Monitor & Output Card

Each NetW a ve console has one Monitor & Output card with the user connections listed on page

1-2. The Monitor panel plugs into the Monitor &

Output card, receiving power and control signals.

The card also supplies power and clock signals,

and sends and receives bused audio signals, to the

DSP & I/O cards via a short flat cable jumper.

There are two LEDs, to indicate operational status (DSP clock and F ail), and a console reset button located on the Monitor & Output card.

The Monitor & Output card is located below

and behind the Monitor panel and Reflective Console Display. In normal operation the card connections are hidden by a cosmetic flip-open rear

cover.

DSP & I/O Cards

Each DSP & I/O card (Digital Signal Processor

plus Inputs and Outputs) has the setup controls,

audio inputs and logic I/O connectors for eight

console channels. The channels are on the four

Dual F ader panels that mount directly in front of

each card. A DSP Active and a Fault LED indicate operational status on each card.

There is one DSP & I/O card on NetWave-8

consoles, two on NetWave-16 consoles and three

on NetWave-24 consoles. In normal operation, the

DSP & I/O cards are completely hidden from the

operator by a cosmetic flip-up cover.

Each DSP & I/O card has twelve RJ-45 connectors. Eight are internal connectors for four Dual

F ader panels (using red CA T-5 cables supplied with

the frame); the other four RJ-45 connectors are

for optional Dual Router Kits (which plug in using a supplied blue CAT-5 cable). Customer-supplied CAT-5 cables then connect the Dual Router

kits to the VistaMax LAN using the four rear panel

RJ-45 passthru connectors.

Each DSP & I/O card has a common set of assignment buttons and indicator LEDs to assign

the parameter settings for each A and B source on

the eight channels associated with that DSP &

I/O card. The setup parameters include: input selection (analog, digital or network); mode selection (stereo, L, R or mono); signal function (mic,

line, Telco); whether the logic I/O is active; input

left and right gain trims for both analog and digital inputs; network source assignment; and other

logic settings.

Pow er Supply

Two different power supplies are used with NetWave consoles. Each has a single 48-volt output

on a keyed DC connector and each is supplied

with a detachable IEC AC cord.

An in-line supply (50-27) is standard on the NetWave-8 and -16 consoles. It has a captive six foot

1-7

HARRIS CORPORATION

Revision A • 6/06

Page 14

1 Introducing NetWave

DC cable which allows the supply to sit below the

console within the cabinetry. This supply is not

recommended for use with a NetWave-24 console.

NetW av e-24 consoles ship with a Universal 48volt Supply (99-1205), which is also used by

VistaMax card frames and RMX

soles. A fifteen foot detachable DC cable (90-1858-

1) connects that supply to the console.

One supply, either the 50-27 or the 99-1205,

comes standard with each console. A second

matching redundant supply can be connected to

any NetWave console by using the optional 901995 Power Coupler.

NOTE: When adding a 99-1205 supply for redundant powering, order a 99-1205-1 supply (it includes a 90-1858-1 fifteen-foot DC cable).

The 99-1205 supply has a recessed front panel

on/off switch and a green LED to indicate the 48volt output is good. The 50-27 supply has a green

LED on the top of its case to indicate its 48-volt

output is good but it does not have a power switch.

Each supply is designed for continuous 24/7

operation and is fully regulated and protected

against excessive current by internal fuses and electronic safeguards.

d

and BMXd con-

VistaMax Link

The RJ-45 VistaMax Link connector is located

next to the DC input connector on the rear panel.

This connector links the NetWave console to a VistaMax or Envoy Hub card in order to network

the console with a VistaMax system. The optional

Link Activation Kit must be installed to use the

Link connection.

Once activated, the Link sends up to 32 stereo

signals (the four program buses, cue bus, Telco

record output, two dual channel mix-minus signals and one input from each channel) to a

VistaMax network as source signals. Up to 26 ste-

reo destinations (two routed External Monitor inputs and one input for each channel) are routed

from the VistaMax system to the console.

Specifications

Listed for the basic signal paths, per channel,

with 100k ohm loads connected to the analog program outputs in a full NetWave-24 frame.

0 dBu=0.775 volts RMS, regardless of circuit

impedance (equal to 0 dBm into 600 ohms). Noise

measurements done using a 20 kHz bandwidth

(add 1.7 dB for a 30 kHz bandwidth).

Total Harmonic Distortion (THD+N) is measured using a +18 dBu output with a swept signal

and a 20 kHz low pass filter.

FSD (Full Scale Digital) = +24 dBu

Analog Line Inputs

Input Impedance: >60 k ohms, balanced

Nominal Input Level: +4 dBu (each input can be

independently trimmed by +/-15dB)

Input Headroom: 20 dB above nominal input

Analog Outputs

Output Source Impedance: <3 ohms, active balanced

Output Load Impedance: 1k ohms min.

Nominal Output Level: +4 dBu

Maximum Output Level: +24 dBu

Digital Inputs and Outputs

Reference Level: 20 dB below FSD

Input Level: each input can be independently

trimmed by +/-15 dB

Signal Format: AES-3, S/PDIF (input only)

AES-3 Input & Output Compliance:

conversion

Digital Reference:

slave (external) at 48 kHz ±100 ppm

Internal Sample Rate:

Output Sample Rate: 48 kHz nominal (each can be

set for 44.1 kHz)

Crystal (internal) or VistaMax

48 kHz

24-bit sample rate

HARRIS CORPORATION

1-8

Revision A • 6/06

Page 15

1 Introducing NetWave

Digital Inputs and Outputs (cont.)

Processing Resolution: 24-bit fixed with extended

precision accumulators

Conversions:

sampling on all digital inputs; D/A: 24-bit,

Delta-Sigma, 128x ov ersampling

Latency:

A/D: 24-bit, Delta-Sigma, 128x over -

<600µs, an y input to monitor output

Monitor Outputs

Output Source Impedance: <3 ohms, activ e balanced

Output Load Impedance: 1 k ohms min.

Output Level: +4 dBu nominal, +24 dBu max.

Frequency Response

Input to Program Output: +0.3 dB/-0.1 dB, from

20 Hz to 20 kHz

Dynamic Range

Analog Input to Analog Output: 106 dB referenced to

FSD, 108 dB “A” weighted to FSD

Analog Input to Digital Output: 108 dB referenced to

FSD, 110 dB “A” weighted to FSD

Digital Input to Analog Output: 108 dB referenced to

FSD, 111 dB “A” weighted to FSD

Digital Input to Digital Output: 115 dB

Total Harmonic Distortion + Noise

Analog Input to Analog Output: <0.003%, 20 Hz to

20 kHz (<0.002% typical at 1k), +18 dBu input, +18 dBu output

Analog Input to Digital Output:

20 kHz,+18 dBu input, -6 dB FSD output

Digital Input to Analog Output:

20 kHz (<0.002%, typical at 1 kHz), -6 dB FSD

input, +18 dBu output

Digital Input to Digital Output:

20 kHz, -6 dB FSD input, -6 dB FSD output

<0.0009%, 20 Hz to

<0.003%, 20 Hz to

<0.0005%, 20 Hz to

Crosstalk Isolation

Program-to-Program: -85 dB, 20 Hz to 20 kHz

Console Power Requirements

Measured at 120 V AC/60 Hz.

NetWave-8: 54 watts

NetWave-16: 99 watts

NetWave-24

:

141 watts

Required Supply Voltage

NetWave-8: +48 VDC @ 1.2 amps

NetWave-16: +48 VDC @ 2 amps

NetWave-24

One power supply included. The NetW a ve-8 and

NetW av e-16 use a 50-27 supply . The NetWave24 uses a 99-1205 supply.

An optional Power Coupler (90-1995) is avail-

able for adding a matching redundant supply

for on-air consoles.

:

+48 VDC @ 3 amps

Power Supply Ground

Rack mount or in-line power supply: grounded through

the AC input cord ground pin

Power Supplies

AC input voltage & frequency: 90-240 V AC, 50/60 Hz

AC input: detachable IEC power cord

DC output: Uses a keyed, latching connector on a

captive cable on the 50-27 supply or a detachable cable (90-1858-1) on the 99-1205 supply

Dimensions

All NetWave consoles: 3" [76] max height abov e coun-

tertop, except for console reflector, 6" [152].

Front-to-back depth is 21" [533].

NetWave-8 is 20" [508] wide

NetWave-16 is 32.4" [823] wide

NetWave-24 is 45.2" [1148] wide

50-27 (in-line supply for NetWave-8 and NetWave-16):

2" [51] x 3.8" [97] x 9.5" [241]

99-1205 (rack mount supply for NetWave-24):

2 RU: 3.5" [89] x 19" [483] x 10" [254]

All dimensions: Height x Width x Depth.

Stereo Separation

Analog Program Outputs: >90 dB, 20 Hz to 20 kHz

Harris Corporation reserves the right to change

specifications without notice or obligation

1-9

HARRIS CORPORATION

Revision A • 6/06

Page 16

1 Introducing NetWave

Warranty

NetWave consoles carry a manufacturer’s warranty which is subject to the following guidelines

and limitations:

A) Except as expressly excluded herein, Harris

Corporation (“Seller”) warrants equipment of

its own manufacture against faulty workmanship or the use of defective materials for a period of one (1) year from the date of shipment

to Buyer. The liability of the Seller under this

Warranty is limited to replacing, repairing or

issuing credit (at the Seller’s discretion) for an y

equipment, provided that Seller is promptly

notified in writing within five (5) days upon

discovery of such defects b y Buyer , and Seller’ s

examination of such equipment shall disclose

to its satisfaction that such defects existed at

the time shipment was originally made by

Seller, and Buyer returns the defective equipment to Seller’s place of business per the

Seller’s RA procedures and directions, packaging and transportation prepaid, with return

packaging and transport guaranteed.

E) This Warranty is void for equipment which has

been subject to abuse, improper installation,

improper operation, improper or omitted

maintenance, alteration, accident, negligence

(in use, storage, transportation or handling),

operation not in accordance with Seller’s operation and service instructions, or operation

outside of the environmental conditions specified by Seller.

F) This Warranty is the only warranty made by

Seller, and is in lieu of all other warranties,

including merchantability and fitness for a particular purpose, whether expressed or implied,

except as to title and to the expressed specifications contained in this manual. Seller ’s sole

liability for any equipment failure or any

breach of this Warranty is as set forth in subparagraph A) above; Seller shall not be liable

or responsible for any business loss or interruption, or other consequential damages of an y

nature whatsoever, resulting from any equipment failure or breach of this warranty.

B) Equipment furnished by the Seller, but manu-

factured by another, shall be warranted only

to the extent provided by the other manufacturer.

C) Thermal filament devices, such as fuses or

lamps, are expressly excluded from this warranty.

D) The warranty period on equipment or parts

repaired or replaced under warranty shall expire upon the expiration date of the original

warranty.

HARRIS CORPORATION

1-10

Revision A • 6/06

Page 17

Installation

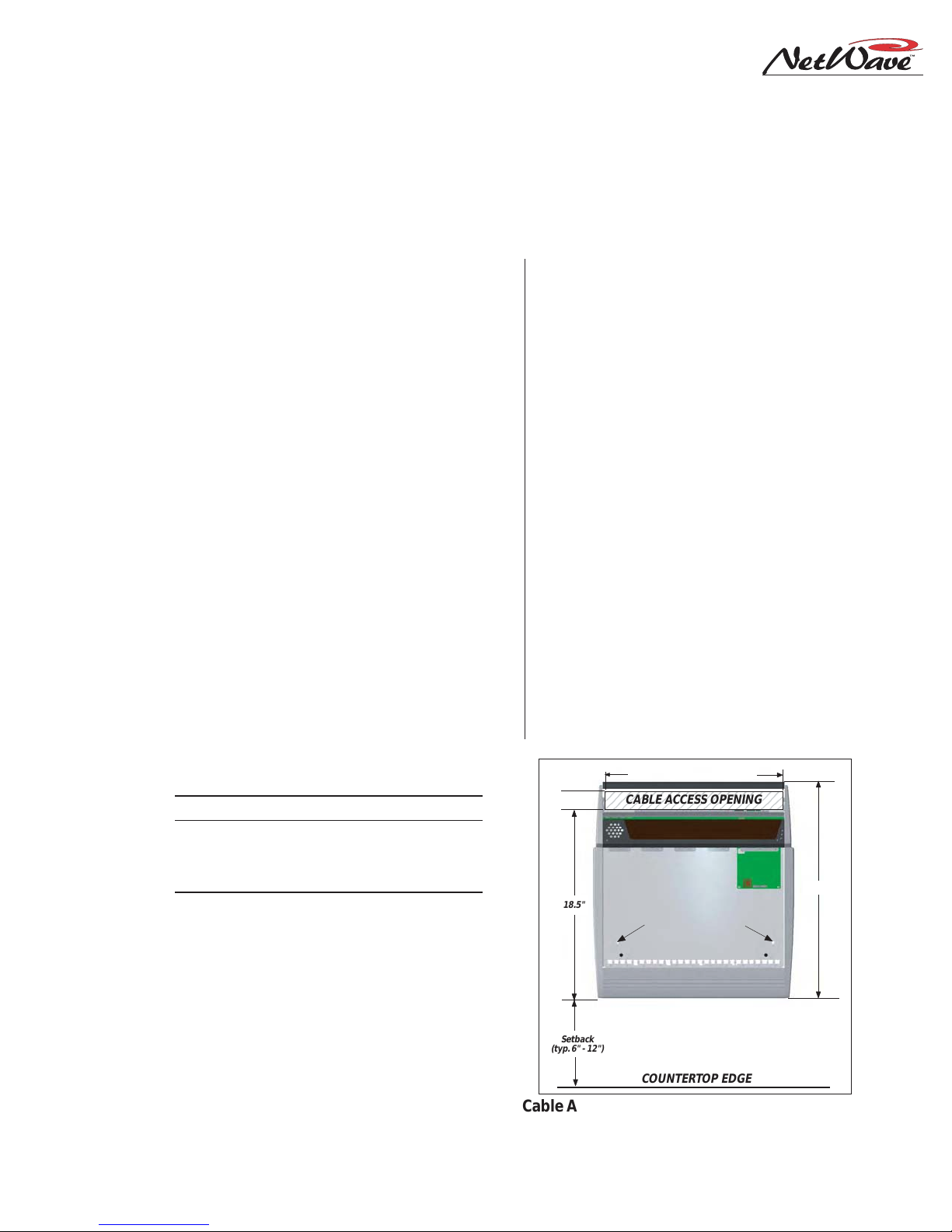

3

The NetW ave console sits on the countertop

on four rubber feet. One cable access cutout is re-

quired under the frame for cabinet wiring to cleanly

connect to the console connectors. These are hid-

den under a cosmetic cover after installation. For

security and stability , the console should be fastened

2

The NetWave console shipment contains:

• NetWave main frame, loaded with DSP & I/O

and Monitor & Output cards; a Monitor panel;

Dual Fader panels (NetWave-8 has four; NetW ave-16 has six plus two dual blanks; NetW av e24 has nine plus three dual blanks); optional

items ordered (additional Dual Fader panels, VistaMax Link Activation Kit, Dual Router Kits,

Quad Meter Package)

• 48-volt DC power supply (50-27 in-line supply

or a 99-1205 rackmount supply and DC cable)

to the countertop using two #8 or #10 screws or

bolts (not supplied). Two .256" chassis holes be-

hind the front two feet are provided for this. F rame

sizes and cutout dimensions are listed below .

Dimension Table

Frame Size Width Cable Access Dims.

NetWave-8 20" [508] 2" x 17" [51 x 432]

"

NetWave-16 32.8" [833] 2

NetWave-24 45.6" [1158] 2" x 43" [51 x 1092]

NetWave consoles are 21" [534] deep (from the front of the palm rest

to the back tips of the side panels). Add .5" [13] additional clearance behind the console in order to fully open the connector cover

when the console’s rear is against a wall.

The console height above the countertop is 3" [76], except for the console display reflector, which is 8" [203] above the countertop.

Typical console setback from the countertop edge to the palm rest is between 6" [152] and 12" [305].

Millimeter dimensions listed in brackets. All dimensional tolerances are:

±¼" [6.4].

x 30" [51 x 762]

• Installation kit (MOD IV housings and receptacle contacts, blank source name labels)

• Channel Setup Stylus Tool

• Reflector for the Console Display

• NetWa ve Quick Guide

• NetWave CD-ROM

See Dimension Table for Width

234567890123456789012

2"

18.5"

Setback

(typ. 6" - 12")

CABLE ACCESS OPENING

.256" holes to fasten

console to countertop

NetWave-8 console with Dual Fader and

Monitor Control panels removed

COUNT ERTOP EDGE

21"

Cable Access Cutout & Console Mounting holes

2-1

HARRIS CORPORATION

Revision A • 6/06

Page 18

2 Installation

Console Installation

The 99-5001 NetWave CD-ROM has

several video files on console installation; on installing optional items; on

setting up the console channels; and

on typical console operations.

GENERAL WIRING INFO

To facilitate console installation, create a wire

list of all console interconnections to and from peripheral devices. Identify and create tags for each

audio and logic cable. List these connections in a

master facility wiring logbook to ease installation,

future system wiring or equipment changes and

system troubleshooting.

Pages 2-18 to 2-22 cov er wire preparation and

connector installation. Page 2-23 has block diagrams for the various NetWave logic connectors.

Pages 2-27 to 2-30 show typical peripheral connections for a mic, a CD player, a computer playback system and linking to a VistaMax system.

Audio cables to/from the console should always

be run with the maximum practical distance from

all AC power mains wiring within the cabinetry.

The console’ s 48-volt power cable carries only DC

voltage so audio wiring can run parallel or be tie

wrapped to this cable without problem.

The channel audio and logic wiring connects

sequentially along the back of the console in eight

channel groups. The chassis metal is cutaw ay between the DSP & I/O cards to facilitate getting

the connectors and wiring up through the countertop.

To ease installation, break out each group of

cables, using the dimensions shown below as measured from the right end of the cutout. Cabling is

normally broken out and tie wrapped to the bottom of the countertop just behind the cable cutout. Lea ve a six to eight inch service loop on each

cable to ease installation and future wiring

changes. This extra cabling hangs down into the

cabinet (or the cable tray) after being connected.

The monitor and program outputs connect at

the right corner of the console along with the 48volt supply, the optional Link cable and the technical ground wire. The chassis is also cutout in

this area to ease installation.

Plug in all audio and logic cables first. Then

route the excess cabling (i.e., service loops) into

the cabinet by folding the audio and logic wires

over their connectors and arranging the cables to

go into the gap between the connectors and the

flip-up connector cover such that the cover sits

down onto the chassis behind the console display .

The technical ground wire, DC cable and any

Link and LAN cables can now be connected.

POWER SUPPLY PLACEMENT

Two types of power supplies are used with NetWave consoles. Each has a single 48-volt DC output using a keyed and locking connector. Each

uses an IEC AC input cable which is shipped with

a USA-type plug. The AC connector, or the IEC

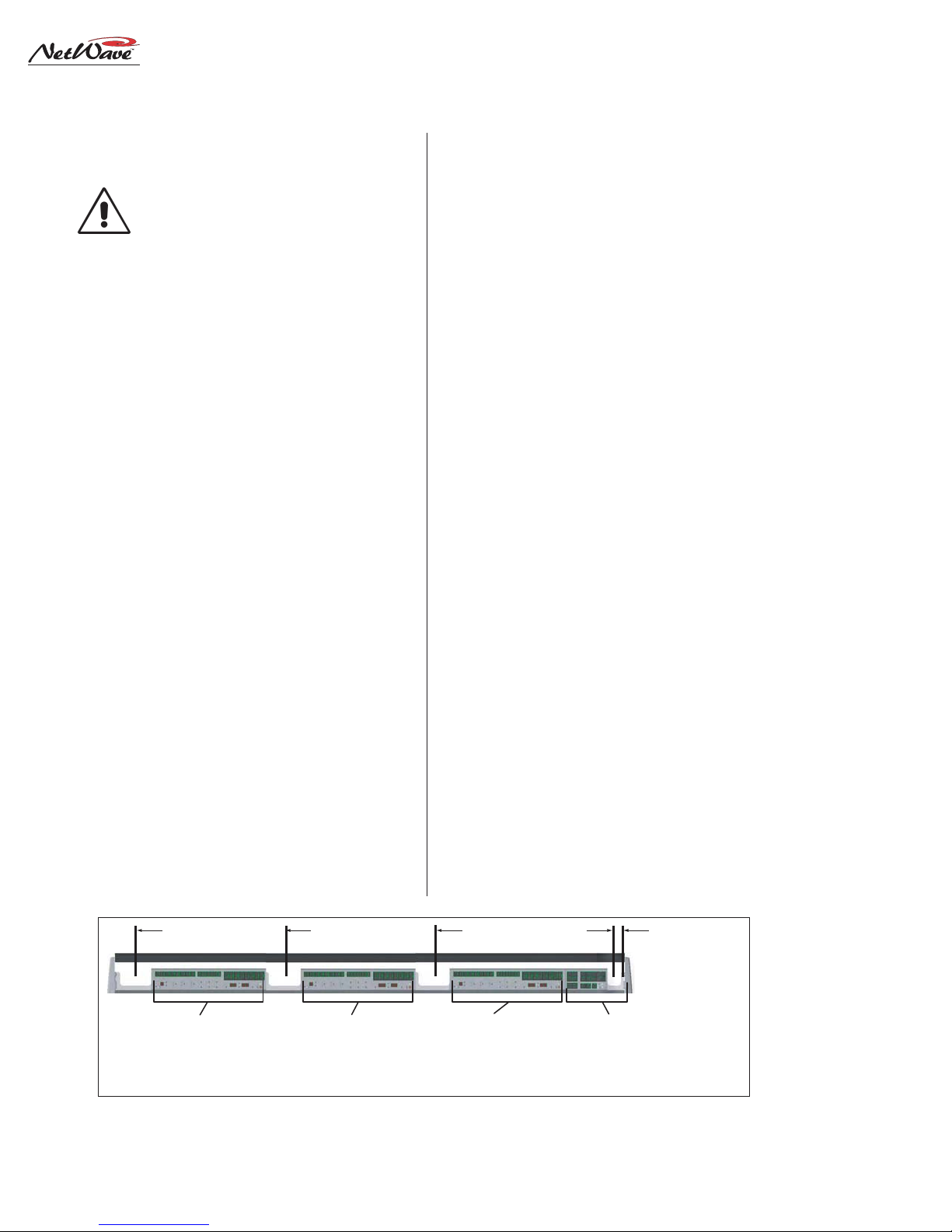

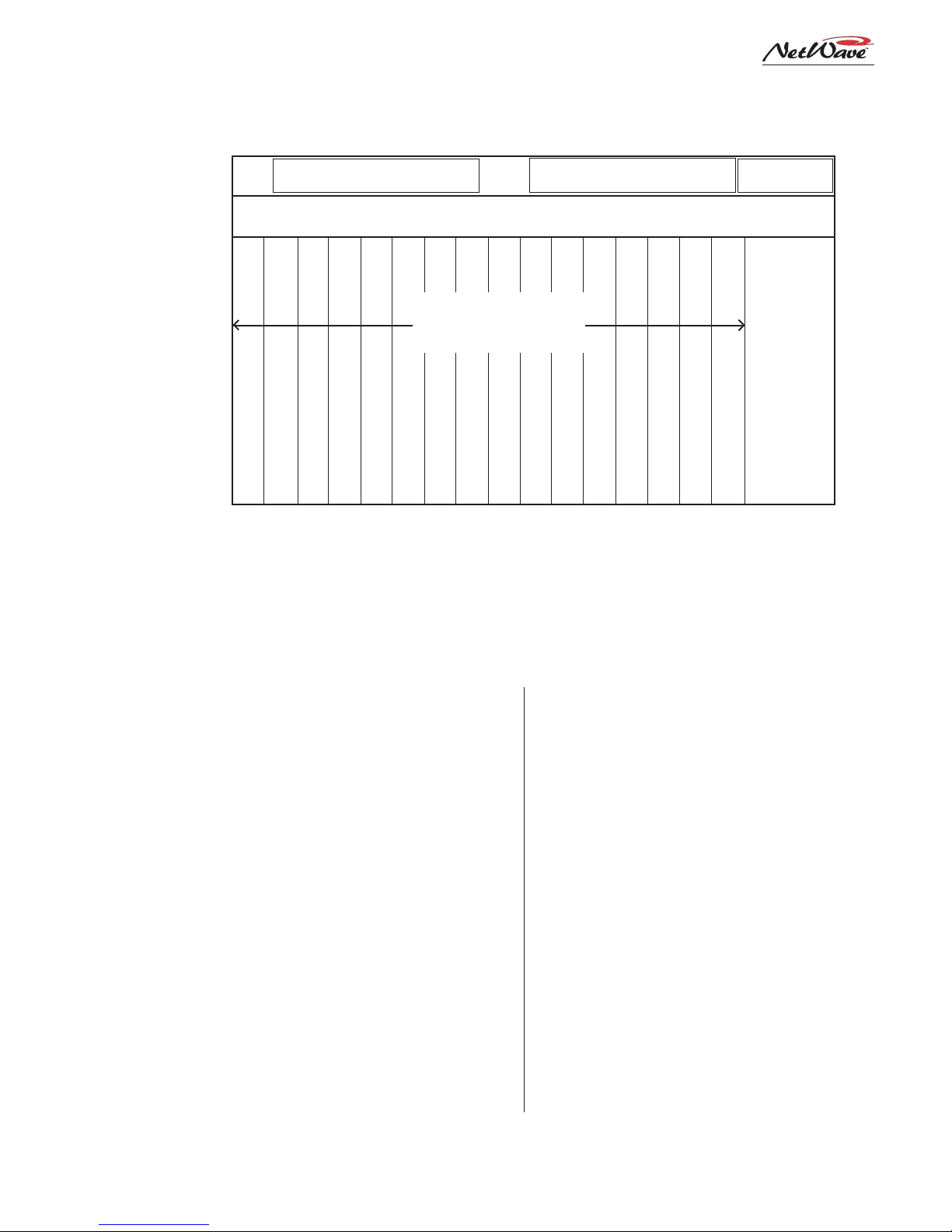

41" 28" 16" 1" 0"

AUDIO INPUTS & LOGIC I/O

CH 1-8 (NETWAVE-24)

AUDIO INPUTS & LOGIC I/O

CH 9-16 (NETWAVE-24)

CH 1-8 (NETWAVE-16)

Console Connections with Access Points (measured from the right end of the cable cutout)

HARRIS CORPORATION

AUDIO INPUTS & LOGIC I/O

CH 17-24 (NETWAVE-24)

CH 9-16 (NETWAVE-16)

CH 1-8 (NETWAVE-8)

2-2

Revision A • 6/06

CR AND STUDIO AUDIO & LOGIC OUTPUTS,

PGM BUSES & MIX-MINUS OUTPUTS,

EXT MON INPUTS,

TECHNICAL GROUND POINT,

48VDC SUPPLY INPUT,

LINK CONNECTOR

Page 19

2 Installation

cord, will have to be changed for overseas operation. Both supplies operate from 90 to 240 VAC

on 50 or 60 Hz power .

The 50-27 in-line supply comes standard on the

NetWave-8 and NetWave-16 consoles. It has a

captive six-foot DC cable, so it must be located

near the right rear corner of the console. It is typically set on the wire tray or within the cabinet (it

can be tie wrapped to a vertical wall to save space).

This supply will get warm under normal use as it

uses free air space for ventilation, so it must never

be covered or enclosed.

The 99-1205 Universal 48-volt Supply comes

standard on the NetWave-24. It requires 2 RU of

rack space within the console cabinetry, typically

located below and to the left or right of the console. It is the same supply used with VistaMax card

frames and consoles. A detachable 15-foot DC

cable (90-1858-1) connects this supply to the

NetWave console.

Either supply must be installed such that the

keyed 48-volt supply cable is not under any tension when routed through the cabinet. The 48volt cable locks into a keyed power connector on

the right rear corner of the NetWave chassis.

A 90-1995 Power Coupler (optional) is available to add a redundant power supply for on-air

consoles. T he main and redundant power supplies

plug into its special Y-cable, which then plugs into

the console. It hangs below the countertop.

AC GROUNDING NOTE: Do not

defeat the IEC power cord “U” safety

ground in any way, as this may create

a potentially dangerous condition to

the operator .

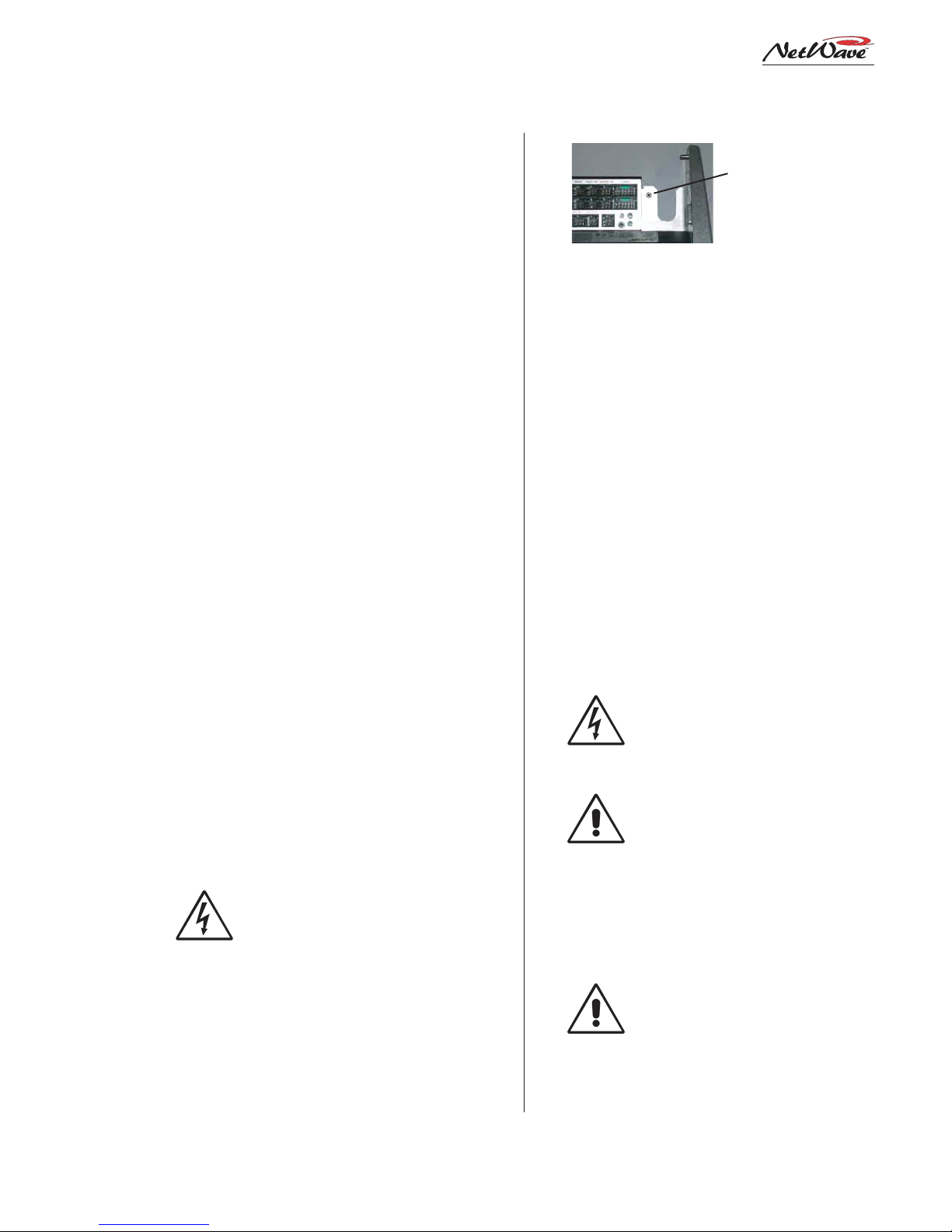

GROUNDING AND SHIELDING

Terminate the facility’s technical ground wire

for the console into a crimped ring tongue terminal suitable for a #8 stud. Fasten the ground wire

Tie a 14-16 AWG

ground wire to this

screw using a ring

tongue fastener

Technical Ground Connection Point,

NetWave Chassis, r ight rear view

to the NetWave chassis using the #8 chassis screw

behind the Link connector.

When all system components share a common

ground potential (by using isolated ground AC outlets tied individually back to the main technical

ground), the audio cable shields can be connected

at both the console and the peripheral ends.

If isolated ground AC outlets are not used, connect the cable shields at the console end only. Do

not connect the shields on the peripheral device

end. Ensure the peripheral devices connect to a

clean ground through their power cords or through

separate ground wires to the facility’s technical

ground.

GROUNDING NOTE: The Power Sup-

ply chassis connects to the AC mains

safety or “U” ground wire.

AUDIO GROUND NOISES: Buzz

pickup is generally electrostatic—such

as capacitive coupling between an audio line and an A C power line. To avoid

audio ground noises, do not route audio wires in the same wireway as an

AC power line.

NOTE: Strong electromagnetic fields

from peripheral equipment using

switching power supplies may impair

NetWave performance, so keep these

products as far away as practical from

the console’s location.

2-3

HARRIS CORPORATION

Revision A • 6/06

Page 20

2 Installation

COUNTERTOP PREPARATION

Follow the dimensions listed on page 2-1 to

mark and router the cable access opening through

the countertop and substrate. Always radius the

corners to prevent laminate cracks.

NOTE: If the console will be set against a wall,

leave a .5" [13] gap between the side panels and

the wall in order to flip-up the connector cover.

Center the console over the cable access cutout

so that the rear connector cover , when closed, covers the cutout.

For security or stability the console can be fastened to the countertop. To do this, the leftmost

Dual Fader panel and the Monitor Panel must be

removed to access the two chassis holes (see page

2-1 for hole locations).

pilot holes for screws or clear holes for bolts. On

laminate countertops it is important that the hole

through the laminate is larger than the screw or

bolt threads to prevent future laminate cracks.

Use #8 or #10 screws or bolts to fasten the console to the countertop substrate. Do not deform

the chassis, or unbalance the rubber feet, by applying excessive torque on the screws or bolts.

NOTE: Install the optional Link Acti-

vation kit at this time while the Monitor panel is already out of the chassis.

The install instructions are on the next

page. Also, if changes are needed on

the Monitor & Output card setup

switches, they should be done at this

time as well. Switch setting information is on page 2-10.

Removing Control Panels

Control panels are fastened to the frame using

3mm silver hex screws. The panels connect to

frame cards using short red CAT-5 cables.

To remove a control panel:

1. Remove the 3mm hex screws that fasten the

panel to the frame (a hex driver is in the optional 76-1901 NetW a ve/SMXdigital toolkit).

2. Move that panel’s faders to full off and use the

two fader knobs to lift up the panel enough to

remove the panel by its metal extrusion.

WARNING: The red CAT-5 cable connecting

the panel is short, so lift the panel up just

enough to clear the console surface.

3. Unplug the CAT -5 cable from the panel. If the

panel is a Dual Router panel, there will be a

two labeled CAT-5 cables.

Before marking the holes to fasten the console

to the countertop , make sure the console is set par allel to the countertop edge and is covering the

cable cutout. Mark, then move the console, to drill

Reinstall the panels into the frame, using the

reverse order to their removal. T he red CA T-5 cable

plugs into J5 on the Dual Fader panels.

INSTALLING CONSOLE OPTIONS

All NetW a ve consoles ship from the factory in a

standard configuration. Any console options (Link

Activation kit, Dual Router kit, Quad Meter package, additional Dual Fader panels) will be separately packaged and must be installed into the

console. Optional items can be installed during

console installation or at any future time.

Installing the Link Activation kit or a Quad

Meter package requires that the console be

unpowered during the installation. The other kits

can be installed while the console is powered.

Link Activation Kit

The Link Activation kit turns any NetWave from

a non-networked, stand-alone console into a networked or Linked console that is ready to connect into a VistaMax audio management system.

HARRIS CORPORATION

2-4

Revision A • 6/06

Page 21

2 Installation

The NetWave’s RJ-45 Link connector, next to

the keyed DC power connector , ties the console to

an available VistaMax Hub card facet using a CA T5e or CAT-6 crossover cable. Cable runs of up to

300 feet [100 meters] are allowed.

Link activation adds the following capabilities

to any NetWave console:

• A network signal can be set as any channel’s

input for either the A or B source. The signal

is selected using a VistaMax source selector,

by a session or macro file entry or by installing a Dual Router kit in a Dual Fader panel.

• A network signal can also be used for either

External Monitor input. The signal is set by a

VistaMax source selector or by a session or

macro file entry.

• The console’ s buses (four programs, two mix-

minuses and cue) and one local input (analog

or digital) from each channel become network

sources, a vailable for routing to any VistaMax

destination.

To install this kit, the Monitor panel must be

removed. An installation video and a PDF file of

the installation sheet are included on the 99-5001

CD-ROM.

NOTE: Discharge possible static

charges into the console frame before

following this procedure and before

handling the PROMs.

Link Activation Kit Installation

1. Turn off the console’s power supply.

2. Remove the Monitor panel, per the instruc-

tions on page 2-4.

3. Use the 70-134 PLCC removal tool (included

in the Link Activation kit) to remove PROM

U64 from the Monitor & Output card.

Place the two tool tips into the two open

corners of the 21-352-3 PROM and then

squeeze the tool handles to “pop” the PROM

out of the socket.

4. Place the 21-352-4 PROM into the U64 socket

with its pin 1 mark aligned with the pin 1

mark on the board. Firmly press down on the

PROM to fully seat it in the socket.

5. Replace the Monitor panel (plug in the CA T-5

cable and fasten the panel to the frame).

6. Power up the console and verify that the

taMax Enabled

label is now lit on the Moni-

Vis-

tor panel.

Dual Router Kit

A Dual Router kit adds VistaMax source selection capability to both channels on a Dual Fader

panel. The Link Activation kit must be installed

in order to use a Dual Router kit.

Any Dual Fader panel can have a Dual Router

kit installed but, for most applications, between

one and three Dual Fader panels will have kits

installed. This results in two, four or six channels

that can select their own VistaMax source. The remaining channels can have a VistaMax source set

as their A or B input, but they cannot locally

change their VistaMax source.

A Dual Router kit consists of two 10-character

displays for source name display; two

Include All

labels; a plug-in TINI card; two color -

Next/

coded flat CAT-5 cables; and an installation instruction sheet.

Dual Router Kit Installation

1. Remove the Dual Fader panel following the

panel removal instructions on page 2-4.

2. Unplug the CA T-5 cable from the Fader P anel

connector on the chassis. The cable will not

be reused, but keep it as a spare part.

3. Remove the two display lenses from the front

of the Dual Fader panel by unsnapping each

lens starting from the side of the Dual Fader

panel.

2-5

HARRIS CORPORATION

Revision A • 6/06

Page 22

2 Installation

4. Remove the two A/B labels from their rubber

silos and replace them with the two Next/Include All labels. The A/B labels should be kept

as spare parts.

5. Plug the two 10-character displays into the

two DIP sockets. Orient the displays with their

bottom row of connections toward the Next/

Include All labels.

Display

Connections

10-Character Display Orientation

6. Snap the display lenses back onto the panel.

7. Discharge static electricity before removing the

TINI card. Firmly insert the TINI into its connector at a 45 degree angle, then press it down

to lock it in place. The TINI’s bag has a label

with its MAC address. Write the console name

and the two channels this TINI controls in the

space provided on the label as this will be

needed during software configuration.

8. Plug in the two CA T-5 cables from the kit. T he

red

cable plugs into J5. The

blue

cable plugs

into J3.

9. Hold the panel above its slot and plug the

cable into the F ader P anel jack. Plug the

red

blue

cable into the LAN Passthru jack, noting the

jack’s letter (the corresponding lettered jack

on the rear panel will then connect the Dual

Router panel to the VistaMax LAN).

10.Set the panel onto the frame, making sure that

the CA T-5 cables are not pinched by the metal

extrusion while it is fastened to the frame.

11.Connect a straight-thru CAT-5 cable from the

matching rear panel LAN Passthru jack (the

same letter jack as used in step 9) to the VistaMax LAN switch.

12.Use VMCC to set up the new Dual Router

panel. The information written on the TINI’s

antistatic bag label is used during this step.

Quad Meter Package

This option replaces the standard console display with a four meter display . Kits are only available for NetWave-16 and NetW a ve-24 consoles.

The Quad Meter Package includes a new console display housing and another meter board. The

console’s original meter and clock-timer boards

are moved to the new housing, which then replaces

the original dual meter console display.

The Quad Meter P ackage has dedicated displays

for PGM 1, PGM 2 and PGM 3, with the fourth

meter (AUX) being used to display PGM 4 or an

external monitor input.

Because the Quad Meter Package requires extensive frame disassembly , the console power must

be turned off during installation. For installation

instructions, refer to the installation guide that

comes with the package.

REFLECTIVE CONSOLE DISPLAY

The reflector can be inserted into its slot behind the console display at this time—if the best

access to the console connectors is from the rear

of the console. If the best access is from the front,

wait until the wiring is completed before installing the reflector .

The reflector is shipped with protective paper

stuck to both sides. This paper must be removed

before installing the reflector.

NOTE: Handle the reflector by its edges

to prevent scratches and fingerprints.

When the reflector is removed, place it

on a lint-free cloth to prevent scratching the reflective surface. Use a lint-free

cloth dampened with either diluted

dish soap or alcohol, or a damp chamois, to clean the surface.

Two 4-40 screws, on the rear of the display assembly , firmly hold the reflector in place after it is

HARRIS CORPORATION

2-6

Revision A • 6/06

Page 23

2 Installation

Reflector Slot

Reflector Notch

Reflector

Installing the Reflector into the Console Display Slot

Detail: Two rear

panel screws hold

reflector in place

installed into its slot. These screws are shipped

installed and must be removed before the reflector can be inserted into its slot.

Insert the reflector, with its notched edge behind the clock and timer , into the slot. The reflector is designed to sit at a 22° angle toward the

board op. This is assured by the two mounting

screws. They should be installed once all console

connections are finished and the console is ready

for daily use. Before this time the reflector can sit

in the slot without the screws for easy removal.

The standard Console Display has two horizontal stereo bargraph meters. Alphanumeric displays

below each meter identify the signal displayed

(PROGRAM 1, PROGRAM 2, etc.). T he standard

meters provide simultaneous level monitoring of

the Program 1 bus on the left-hand meter and

another bus or system signal on the right-hand

Auxiliary Meter , as selected by the Aux Meter buttons on the Monitor panel.

An upgrade option (Quad Meter Package) adds

two more meters so that all four Program buses

can be displayed simultaneously. T his Quad Meter

package upgrade displays Program buses 1, 2 and

3, plus the Auxiliary Meter selection. The Aux

meter functions the same as in the standard meter

configuration.

Various meter, clock and timer parameters are

set using switches on the meter (DS3) and clocktimer circuit boards (DS1). The procedure to

change the switch settings is detailed in the following sections. In summary, here are the various

display parameters that can be changed, with their

factory default setting listed first:

• Meter Display Mode (average plus peak dis-

play or average-only display)

• Blue Over LED turn-on level (-6 dBFS, -4

dBFS, -2 dBFS, 0 dBFS)

• Peak Signal Hold (active or not active)

• Clock Mode (autonomous or slaved to a mas-

ter clock input signal)

• Autonomous Time Display (12-hour or 24-

hour)

• Master Clock Type (ESE or SMPTE)

• Event T imer (display .1 sec or no .1 secs while

running)

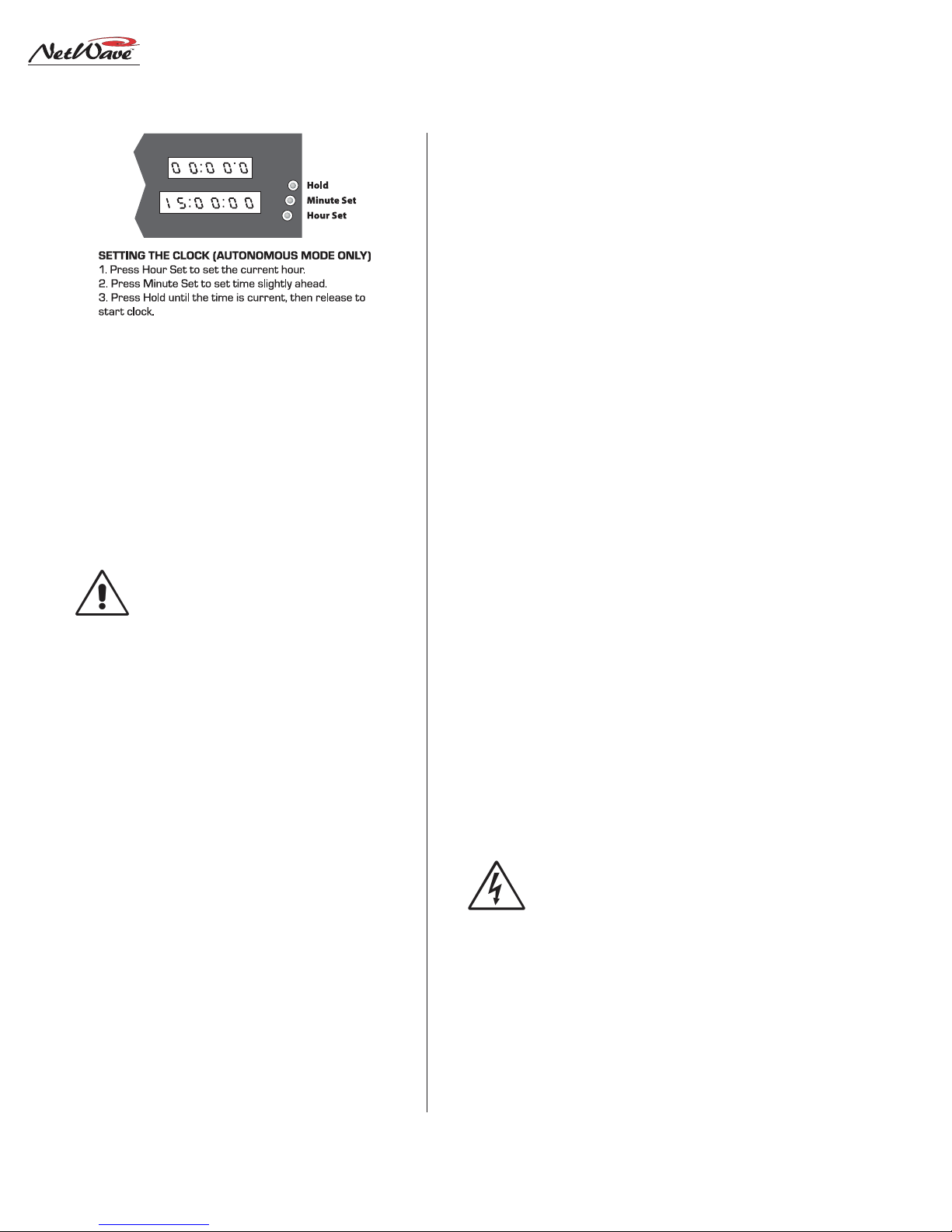

Setting The Clock

When used autonomously (the factory default

setting), a quartz crystal oscillator controls clock

timing. After applying power to the console, the

clock must be manually set to the current time

using the three recessed buttons adjacent to the

clock display (shown on the next page). Use a

blunt-tipped nonconductive object (wooden swab ,

toothpick, etc.) to press the recessed buttons.

PGM 1 Meter Aux Meter

Standard Reflective Display, with

two meters, clock and timer

2-7

HARRIS CORPORATION

Revision A • 6/06

Clock

Event Timer

Page 24

2 Installation

• The Hour Set button (the closest to the board

• The Minute Set button (middle) adjusts the

• The Hold button freezes the clock so it can be

The clock will keep time for about three days

with the console powered off. Beyond this point

the time will have to be reset again when autonomous mode is used.

Removing the Console Display

The console display must be removed from the

frame to change display settings, to connect a master clock or remote timer reset cable or to install

the Quad Meter P ackage.

Each of these activities require accessing the

meter and clock-timer printed circuit assemblies

(PCAs) on the bottom of the console display. The

console should be powered off when removing and

reinstalling the display assembly . Two padded sur-

operator) adjusts the hour display

minute display

manually synchronized to a local time reference. Set the time slightly ahead of the reference time then press Hold. Release Hold when

the time display matches the reference time.

NOTE: When one of the master modes

is selected (see Clock Settings) and the

selected format signal (ESE or SMPTE)

is not present, the clock runs off its internal oscillator. Both display colons

blink to indicate the ESE or SMPTE

timecode is not present or valid.

faces are required for this procedure. To remove

the console display:

1. Flip-up the rear connector cover to access the

two rear corner 4-40 screws that hold the reflector in place. Remove these screws.

2. Lift the reflector out of its slot. Place it on a

padded surface to protect its mirrored surface.

3. Remove the console display cosmetic cover

screws (two or four 4-40 Phillips screws). Remove the cover by lifting it straight up.

4. Set the smoked display window (which was

sandwiched between the display cover and the

main display subassembly) off to the side.

5. Remove the display subassembly mounting

screws (4-40 Phillips) along the front of the

subassembly just above the control panels .

6. To protect the control panels and display sub-

assembly , lay padded material over the top half

of the control panels. Lift the display subassembly up just enough to clear the frame, flip

it forward and lay it facedown onto the padded material. The display subassembly connects to the Monitor & Output board using

two cables. Do not strain these cables while

removing the subassembly and placing it onto

the control panels.

7. Use the illustration on the next page to iden-

tify the switches and connectors on the clocktimer and meter PCAs.

SAFETY NOTE: Touch the metal chas-

sis to dissipate static before adjusting

the switches or plugging in an ESE,

SMPTE or remote timer cable. Do not

touch any components on the PCAs

other than the switches or connectors.

Reinstall the console display in reverse order . Use

care to not pinch any cables between metal parts.

Align the smoked display window holes with the

clock set holes. T he cosmetic co ver holds it in place.

HARRIS CORPORATION

2-8

Revision A • 6/06

Page 25

2 Installation

DS3 J4 DS1

METER PCA CLOCK-TIMER PCA

Meter Boards

DS3 Switch Settings

Switch Function: Off / On

1 - Av & peak / average only

2 - 2s peak hold / no hold

3 - Blue LEDs turn on level*

4 - Blue LEDs turn on level*

5 - NetWave / RMXdigital

6 - NetWave / non-mirrored

* Blue Peak LEDs turn on at:

-6 dBFS, 3 and 4 are off

-4 dBFS, 3 is on and 4 is off

-2 dBFS, 3 is off and 4 is on

0 dBFS, 3 and 4 are on

Console Display PCA Setup Switches and Connections

(orientation shown while set onto the control panels)

DS1 / DS3:

Default

settings

are all off

Clock-Timer Board

DS1 Switch Settings

Switch Function: Off / On

1 - .1s displays / .1 off (Timer)

2 - no ESE / ESE master

3 - unused

4 - 12-hour / 24-hour **

5 - no SMPTE / SMPTE master

6 - NetWave / non-mirrored

* active only when 2 and 5

are both set to off

Clock Settings

Clock parameters are set using multi-switch

DS1, located near the upper right corner of the

clock-timer PCA. The default settings are all

switches set to off.

When used autonomously, the clock time can

display 12-hour or 24-hour time. Set DS1-4 to on

to display 24-hour time. This setting is ignored

when a master clock signal is used.

When an ESE TC-89 or TC-90 master clock is

used, set DS1-2 to on. T he ESE signal type is autodetected. When a SMPTE master clock is used,

set DS1-5 to on. If both DS1-2 and DS1-5 are set

on, only SMPTE is valid. An ESE signal will be

ignored.

ESE, SMPTE & Remote Timer Reset

An ESE or SMPTE master clock signal connects to J4, pins 5 and 6. The signal is polarity

sensitive, but can be balanced or unbalanced. Con-

1 2 3 4 5 6

nect the high (center conductor) or + signal to pin

5 and the low (shield) or - signal to pin 6.

J4, pins 3 and 4 are used to connect a cable

that can reset a studio event timer. Pin 3 is the

timer reset output (pulse low on timer reset) and

pin 4 is ground.

DC Input

RJ-45 Link

Cable to J4

J4 (ESE/SMPTE, studio event timer reset) Cable

NOTE: T he wiring to J4 must be routed through a

small chassis opening (next to the RJ-45 Link

connector) before being terminated into the 6-pin

MOD IV housing. Leave sufficient wire length to

plug in J4 while the display is face down over the

control panels.

Clock-Timer J4

(ESE / SMPTE

MASTER CLOCK &

REMOTE TIMER )

6 5 4

3 2 1

1 - TIMER RESET LOGIC, IN

2 - GROUND

3 - TIMER RESET LOGIC, OUT

ON

4 - GROUND

OFF

5 - ESE or SMPTE INPUT +

6 - ESE or SMPTE INPUT -

2-9

HARRIS CORPORATION

Revision A • 6/06

Page 26

2 Installation

Event Timer Settings

The event timer displays time in minutes, seconds and tenths of seconds. T he only timer setting

(DS1-1) sets whether the tenths of seconds digit is

displayed while the event timer is running .

When set off (the factory default) the tenths are

always displayed. When DS1-1 is set on, the tenths

of seconds are not displayed while the timer is

running, but are displayed while the timer is

stopped or is being held.

Exposed portion of

the Monitor & Output

board, below the

Monitor panel

DS1 DS2

Monitor & Output Board, Multi-Switch Settings

Meter Settings

The PGM 1 and Aux meter parameters are set

using multi-switch DS3 (shown on page 2-9). The

Quad Meter Package adds a second meter board.

The left-hand board’ s DS3 settings affect the first

pair of meters (PGM 1 and PGM 2) and the righthand meter board’s DS3 settings affect the PGM

3 and Aux meters. Typically the two meter boards

would be set to the same settings. The DS3 factory settings are all switches set to off.

To turn off the peak displays and to show only

the average meter lev els, set DS3-1 to on.

To have the Peak indicators decay immediately,

switch DS3-2 to on.

To change the level where the Blue LEDs turn

on: set DS3-3 and DS3-4 to off to turn on the Blue

LEDs at -6 dBFS; set DS3-3 on and DS3-4 off to

turn on the Blue LEDs at -4 dBFS; set DS3-3 off

and DS3-4 to turn on the Blue LEDs at -2 dBFS.

DS3-5 and DS3-6 must be left set to off for NetWave consoles.

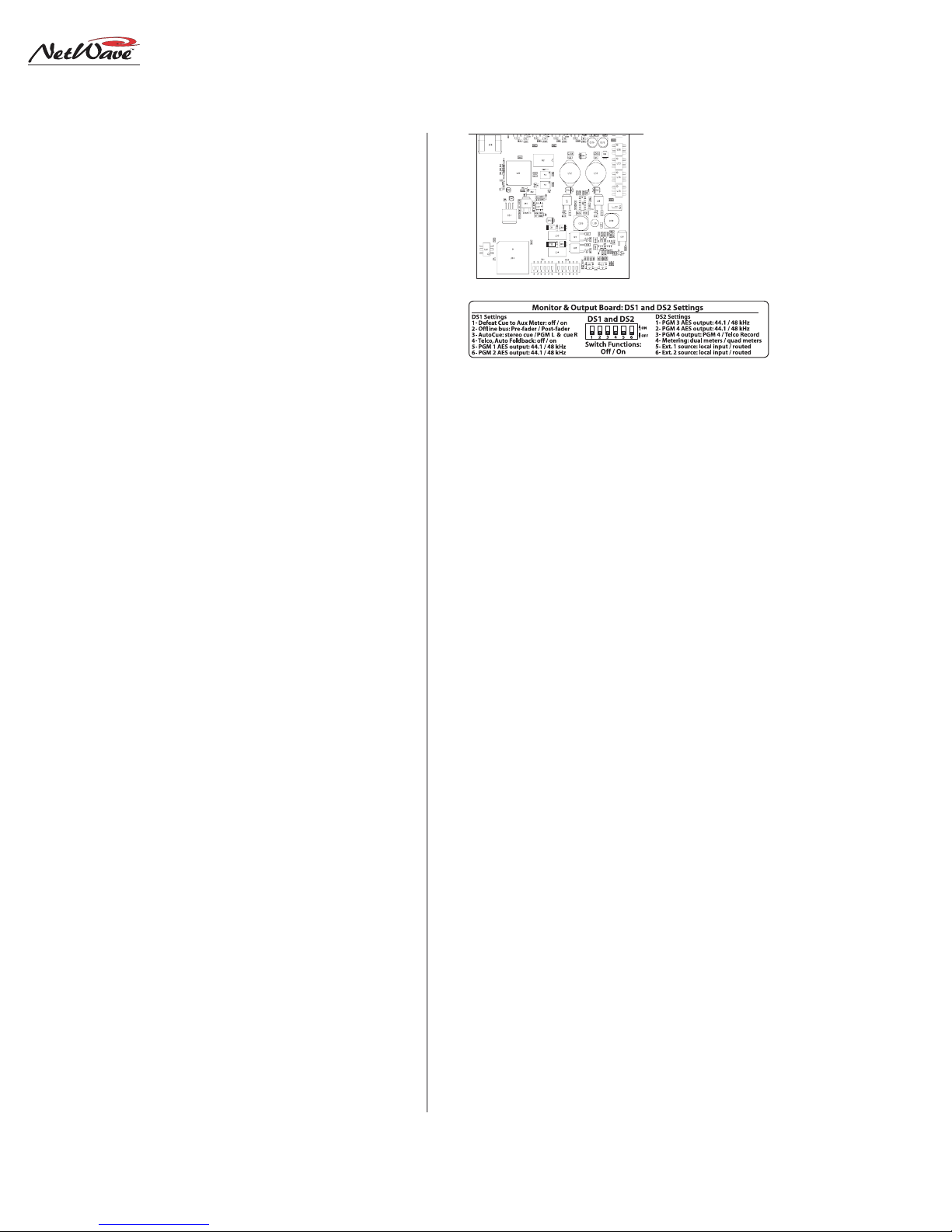

MONITOR & OUTPUT BOARD SETTINGS

The Monitor & Output board has two multiswitches to assign various parameters to the Monitor & Output board outputs. The factory default

setting for all switches is off.

To access the switches, the Monitor panel must

be removed from the frame. Follow the directions

on page 2-4 to remove the panel.

DS1 and DS2 Settings