Harris BMXDIGITAL, 99-1200-1, 99-1200-2, 99-1200-3, 99-1200-8 Operation & Technical Manual

...Page 1

di

g

ital

Broadcast

Console

99-1200-0 (14-input mainframe)

99-1200-1 (22-input mainframe)

99-1200-2 (30-input mainframe)

99-1200-3 (38-input mainframe)

99-1200-8 (8-input mainframe)

Operations

&

Technical

Manual

PRE75-50PRE75-50

PRE75-50

PRE75-50PRE75-50

Revision D.1 • 12/10

Broadcast Communications Division

www.broadcast.harris.com

Page 2

ii

HARRIS CORPORATION

Revision D • 8/05

Page 3

Contents

CE Declaration of Conformity......................... iv

Safety Instructions .......................................... v

Hazard/Warning Label Identification..............v

Manual Revisions........................................... vi

1 - GENERAL INFORMATION

Product Overview ........................................1-1

Specifications ...............................................1-4

Warranty...................................................... 1-6

2 - INSTALLATION

Console Installation......................................2-2

Cabling and W iring ......................................2-7

Module Quick Guides

Mic Preamplifier ...................................2-16

Universal Input .....................................2-18

Telco/Codec ..........................................2-24

RLS ......................................................2-28

Session..................................................2-32

Control Room .......................................2-34

Studio ...................................................2-40

Outputs.................................................2-50

Mic Remote Control Logic Example........... 2-58

Basic Peripheral Logic Example.................2-60

Complex Peripheral Logic Example ...........2-62

Net Card .................................................... 2-64

3 - OPERATION

Module & Card Overview ............................. 3-1

Meter Panel Overview ..................................3-1

Microphone Preamplifier Module .................3-2

Universal Input Module................................3-3

Telco/Codec Module.....................................3-6

Telco/Codec Module Operation ....................3-8

Remote Line Selector (RLS) Module .......... 3-11

Session Module ..........................................3-12

Control Room Module................................ 3-14

Studio Module ...........................................3-16

Output Modules .........................................3-17

Meter Panel................................................3-18

Net Cardl ................................................... 3-20

4 - BMX

RMXd File Structure....................................4-1

RMXd Server Configuration .........................4-5

Session Files...............................................4-14

Session & Macro Files ................................4-16

Software Updates .......................................4-22

Settings Recovery .......................................4-22

digital

SERVER SETUP

5- SERVICE

Parts and Repair Services.............................5-1

Spare and Replacement Parts.......................5-2

Tool and Installation Kits.............................5-3

Module Servicing .........................................5-3

6 - ACCESSORIES

Furniture and Cabinetry ...............................6-1

Furniture Mounted Panels............................6-1

Peripheral Panels .........................................6-2

Headphone Distribution Amplifier ...............6-2

Logic Wiring Diagrams & Cables..................6-2

External Remote Line Selector (Ext. RLS) ...6-4

APPENDIX A: VMCC, SESSION &

MACRO FILES

VMCC File Maintenance............................. A-1

Community Monitor................................... A-1

VMCC Operations Errata ........................... A-3

Setup, Config, General File Info .................. A-6

Macro Files ................................................ A-7

INDEX

A - D..................................................... Index-1

E - M ....................................................Index-2

M - S..................................................... Index-3

S - W..................................................... Index-4

iii

HARRIS CORPORATION

Revision D • 8/05

Page 4

Declaration of Conformity

Application of Council Directive: 89/336/EEC

Standards To Which

Conformity Is Declared:

Manufacturer's Name:

Manufacturer's Shipping Address:

Manufacturer's Mailing Address:

Mason, Ohio USA 45040

Equipment Description:

Equipment Class:

Model Numbers:

4240 Irwin Simpson Road

Digital Broadcast Console

Professional Audio / Visual

BMX Digital Broadcast Console, Inclusive of

EN55103-1:1997

EN55103-2:1997

Harris Corporation BCD/Harris Pacific

Mason, Ohio USA 45040

513-459-3400

4393 Digital Way

513-459-3400

Legacy Digital Product Line

I the undersigned, hereby declare that the equipment specified above,

conforms to the above Directive(s) and Standard(s).

Harris Corporation – Mason, Ohio USA

Place:

Signature:

Douglas A. Bevington

Full Name:

Manager – Product/Technical Services Consoles

and Studio Products

Position:

iv

HARRIS CORPORATION

Revision D • 8/05

Page 5

Safety Instructions

RR

ead Aead A

ll Instrll Instr

ucuc

tionstions

1.

R

ead A

ll Instr

RR

ead Aead A

ll Instrll Instr

instructions before operating the product.

RR

etain Aetain A

2.

3.

4.

5.

6.

7.

8.

9.

ll Instrll Instr

R

etain A

ll Instr

RR

etain Aetain A

ll Instrll Instr

instructions for future reference.

HH

eed Aeed A

ll ll

WW

H

eed A

ll

W

HH

eed Aeed A

ll ll

WW

on the product and those listed in the operating

instructions.

olloollo

w Aw A

FF

F

ollo

w A

olloollo

w Aw A

FF

product usage instructions.

HH

eaea

tt

..

H

ea

t

. This product must be situated away from any

HH

eaea

tt

..

heat sources such as radiators, heat registers, stoves,

or other products (including power amplifiers) that

produce heat.

VV

enen

tilatila

tion.tion.

V

en

tila

ti on . Slots and openings in the product are

VV

enen

tilatila

tion.tion.

provided for ventilation. They ensure reliable operation

of the product and keep it from overheating. Do not

block or cover these openings during operation. Do

not place this product into a rack unless proper

ventilation is provided and the manufacturer’s

recommended installation procedures are followed.

WW

aa

tt

er and Mer and M

W

a

t

er and M

WW

aa

tt

er and Mer and M

water such as a bathtub, wash bowl, kitchen sink, or

laundry tub, in a wet basement, or near a swimming

pool or the like.

AA

ttachmenttachmen

A

ttachmen

AA

ttachmenttachmen

recommended by the product manufacturer as they

may cause hazards.

PP

oo

ww

er Ser S

ourour

P

o

w

er S

our

PP

oo

ww

er Ser S

ourour

the type of power source indicated on the marking

..

uc

tions

. Read all safety and operating

ucuc

tionstions

..

ucuc

tionstions

..

uc

tions

. Retain all safety and operating

ucuc

tionstions

..

arar

ningsnings

..

ar

nings

. You must adhere to all warnings

arar

ningsnings

..

ll Instrll Instr

ucuc

tionstions

ll Instr

ll Instrll Instr

cc

c

cc

..

uc

tions

. Follow all operating and

ucuc

tionstions

..

oistur

ee

..

oistur

oistur

e

. Do not use this product near

ee

..

oisturoistur

tsts

..

ts

. Do not use any attachments not

tsts

..

eses

..

es

. You must operate this product using

eses

..

label and in the installation instructions. If you are not

sure of the type of power supplied to your facility,

consult your local power company.

GG

rr

ounding and Pounding and P

10.

G

r

ounding and P

GG

rr

ounding and Pounding and P

equipped with a polarized AC plug with integral safety

ground pin. Do not defeat the safety ground in any

manner.

PP

oo

ww

er Cer C

oror

d Pd P

rr

11.

P

o

PP

oo

routed so that they are not likely to be walked on nor

pinched by items placed upon or against them. Pay

particular attention to the cords at AC wall plugs and

convenience receptacles, and at the point where the

cord plugs into the product.

LighLigh

12.

Ligh

LighLigh

unplug it from the AC wall outlet during a lightning

storm or when it is left unattended and unused for

long periods of time. This will prevent damage to the

product due to lightning and power line surges.

OO

vv

13.

O

v

OO

vv

extension cords, or integral convenience outlets as this

can result in a fire or electric shock hazard.

OO

bjecbjec

14.

O

bjec

OO

bjecbjec

kind into this product through openings as they may

touch dangerous voltage points or short out parts,

which could result in a fire or electric shock. Never spill

liquid of any kind on the product.

AA

cccc

15.

A

cc

AA

cccc

cart, stand, tripod, bracket, or table. The product may

fall, causing serious injury to a child or adult and serious

damage to the product. Any mounting of the pr oduct

must follow manufacturer’s installation instructions.

otot

w

er C

or

d P

r

ot

ww

er Cer C

oror

d Pd P

rr

otot

tningtning

..

tning

. For added protection for this product,

tningtning

..

..

erer

loadingloading

loading

. Do not overload AC wall outlets,

er

..

erer

loadingloading

t and Liquid Et and Liquid E

t and Liquid E

t and Liquid Et and Liquid E

essoressor

iesies

..

essor

ies

. Do not place this product on an unstable

essoressor

iesies

..

tion.tion.

olarolar

izaiza

tio n. This product is

olar

iza

tion.tion.

olarolar

izaiza

ecec

tion.tion.

ec

tion. Power supply cords must b e

ecec

tion.tion.

nn

trtr

yy

..

n

tr

y

. Never push objects of any

nn

trtr

yy

..

PP

rr

oo

ducduc

t and Ct and C

arar

t Ct C

ombinaombina

16.

P

r

o

duc

t and C

PP

rr

oo

with care. Quick stops, excessive force, and uneven

surfaces may cause the product and the cart

combination to overturn.

SS

erer

17.

S

er

SS

erer

personnel.

DD

amage Ramage R

18.

D

amage R

DD

amage Ramage R

from the wall AC outlet and refer servicing to qualified

service personnel under the following conditions:

a. When the AC cord or plug is damaged.

b. If liquid has been spilled or objects have fallen into

the product.

c. If the product has been exposed to rain or water.

d. If the product does not operate normally (following

operating instructions).

e. If the product has been dropped or damaged in any

way.

f. When the product exhibits a distinct change in

performance. This indicates a need for service.

RR

eplaceplac

19.

R

eplac

RR

eplaceplac

required, be sure the service technician has used

replacement parts specified by the manufacturer or

that have the same characteristics as the original parts.

Unauthorized substitutions may result in fire, electric

shock, or other hazards.

SS

afaf

20.

S

af

SS

afaf

product, ask the service technician to perform safety

checks to determine that the product is in proper

operating condition.

CC

leaningleaning

21.

C

leaning

CC

leaningleaning

only a damp cloth for cleaning.

ar

ducduc

t and Ct and C

arar

vicingvicing

..

vicing

. Refer all servicing to qualified ser vicing

vicingvicing

..

equirequir

equir

equirequir

emenemen

t Pt P

emen

t P

emenemen

t Pt P

etet

y Cy C

heck.heck.

et

y C

heck. Upon completion of any repairs to this

etet

y Cy C

heck.heck.

..

. Do not use liquid or aerosol cleaners. Use

..

tion.tion.

t C

ombina

tion. Move this product

t Ct C

ombinaombina

tion.tion.

ing Sing S

erer

vicvic

ee

..

ing S

er

vic

e

. Unplug this product

ing Sing S

erer

vicvic

ee

..

arar

tsts

..

ar

ts

. When replacemen t parts are

arar

tsts

..

Hazard/Warning Label Identification

EE

xx

clamaclama

tion Ption P

oinoin

t symbt symb

The

E

x

clama

tion P

tion Ption P

oin

oinoin

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

EE

xx

clamaclama

within an equilateral triangle, alerts the

user to the presence of important

operating and maintenance (servicing)

instructions in product literature and

instruction manuals.

WARNING: SHOCK HAZARD - DO NOT OPEN

AVIS: RISQUE DE CHOC ELECTRIQUE - NE PAS OUVRIR

LighLigh

tning Ftning F

tning F

tning Ftning F

lash lash

lash

lash lash

olol

o l, within an

olol

The

Ligh

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK DO NOT

REMOVE ANY COVER OR PANEL. NO USER SERVICEABLE PARTS

INSIDE. REFER SER VICING TO QUALIFIED SERVICE PERSONNEL.

LighLigh

AA

rr

rr

oo

whead symbwhead symb

A

r

r

o

whead symb

AA

rr

rr

oo

whead symbwhead symb

equilateral triangle, alerts the user to

the presence of uninsulated

dangerous voltage within the

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC

SHOCK, DO NOT EXPOSE THE POWER SUPPLY OR CONSOLE

TO RAIN OR MOISTURE.

WW

ARNINGARNING

W

ARNING—This equ ipme nt generates, u ses, and can radiate radio fr equency energy. If not installed and used in accordance with the instructions in this

WW

ARNINGARNING

manual it may cause interference to radio communications. I t has been tested and found to comply with the limits for a Class A computing device

(pursuant to Subpart J of Part 15 FCC Rules), which ar e designed to pro vide reasonable prot ection against such interference when operated in a commercial environment. Oper ation of this equipment in a residential area is likely to cause interference, in which case the user, at his own expense, will be

required to take whatever measures may be required to correct the interference.

product’s enclosure that may be of

sufficient magnitude to constitute a

risk of electric shock.

t symb

t symbt symb

WW

ithith

W

ith

WW

ithith

olol

ol,

olol

v

HARRIS CORPORATION

Revision D • 8/05

Page 6

Manual Revisions

This page provides a quick reference of the

current document pages and their revision level. If

you receive a revision to this document from Harris,

replace the old manual pages with the new ones and

discard the old pages. Replace this page with the

new Manual Revisions page.

Revision Affected pages Comments

A All pages 10/01 First Release

A.1 Contents, Ch 1, Index 12/01 corrected info

in Specifications.

B All pages 8/02 updated various

installation and

operation information.

Incorporated firmware

and hardware

updates.

B.1 Appendix B pages 3/03 add software

C All pages 1/04 Added info on the

D Contents,Ch. 4, 5, Added information on

Appendix A, index VMCC.

release 3.24 info.

BMXd-8 & BMXd-14

frame sizes and the

VistaMax audio

management system.

vi

HARRIS CORPORATION

Revision D • 8/05

Page 7

General

digital

Information

Thanks for joining the growing ranks of

broadcasters employing Harris Corporation prod-

ucts designed by PR&E. Our mission: provide the

finest quality products, systems , documentation and

after -sale support.

The BMX

with an extensive range of features contained in a

compact design. To obtain maximum benefit from

the console’s capabilities, read the

Operation

Product Overview

Each BMX

ing installed into the mainframe assembly:

• Microphone Preamplifier Module

• Universal Input Modules (as ordered)

• Telco/Codec Modules (up to 6, as ordered)

• Remote Line Selector modules (as ordered)

• Session Module (1 standard)

• Control Room Module (1 standard)

• Studio Module (1 optional)

• Output Modules (3 standard)

• DSP Cards (1 to 5, depending on frame size)

• Net Card (1 optional)

• Blank Panels (as required)

The BMX

card area is surrounded by a sheet metal and ex-

digital

is a very sophisticated console

Installation

sections prior to product installation.

digital

console ships with the follow-

(1 Mic Preamp standard, 1 optional)

digital

’s motherboard and module/

HARRIS CORPORATION

and

1-1

1

truded aluminum chassis for strength and RFI immunity . The meter panel—hinged at the rear , closes

over the upper part of the modules, covering the

audio and logic connectors, the DIP switches and

DSP and Net Cards. Cable access to modules is

done from below the meter panel.

MODULE & CARD DESCRIPTIONS

Full-featured Input modules are described

throughout this manual. Limited-function versions

(minus the Send or Utility bus controls), Net-only

versions (no connectors) and Limited-function

Net-only versions (no connectors nor Send and

Utility bus controls) are also available.

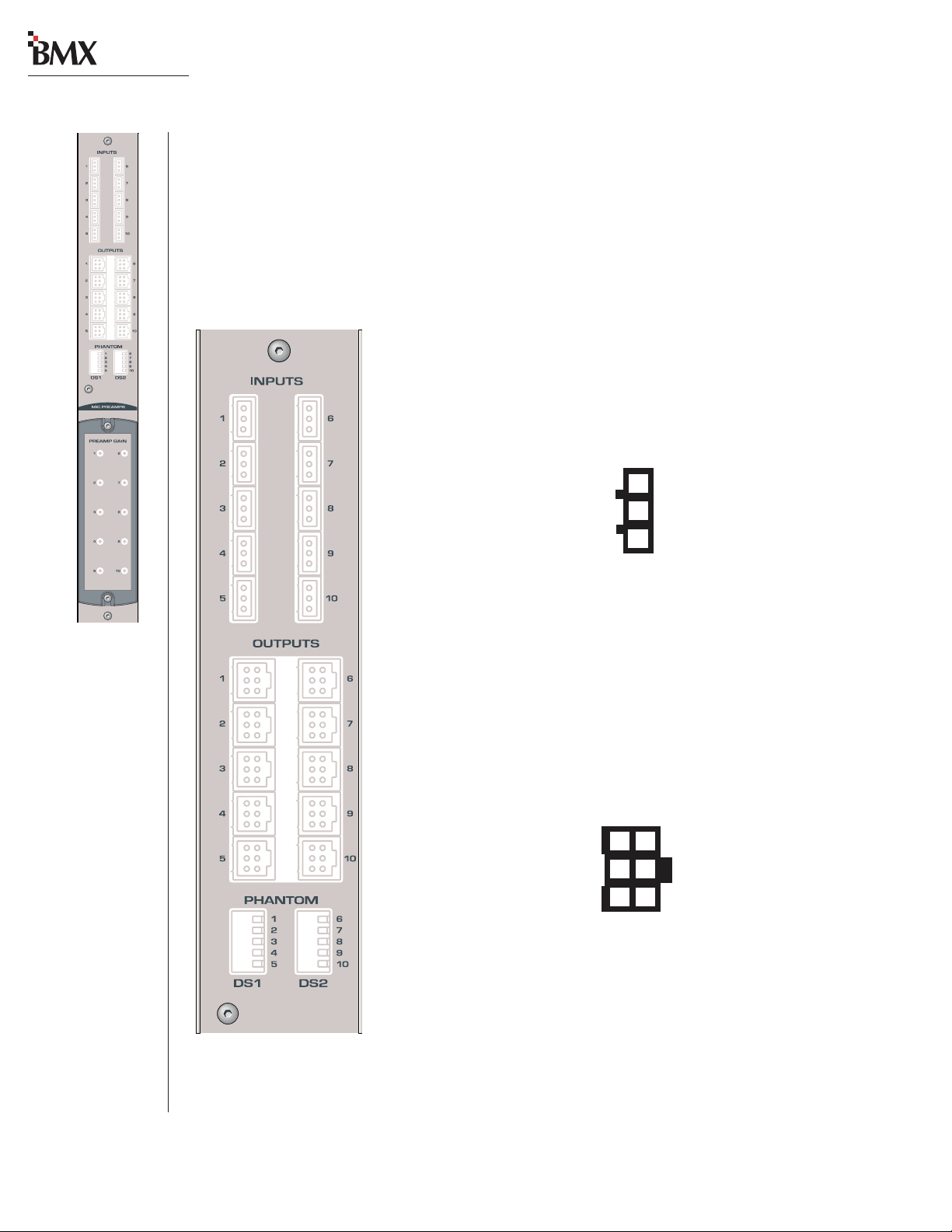

Microphone Preamplifier Module

Five mic preamps, each with a trim pot under a

security cover , come standard on the BMX

8 and -14. Ten preamps come standard on the

other frame sizes. A second five or ten input Mic

Preamp Module can be field installed.

Mic preamps take balanced input signals (from

-65 dBu to -30 dBu) and output balanced +4 dBu

outputs for direct connection to a Universal Input

module or to outboard processing equipment.

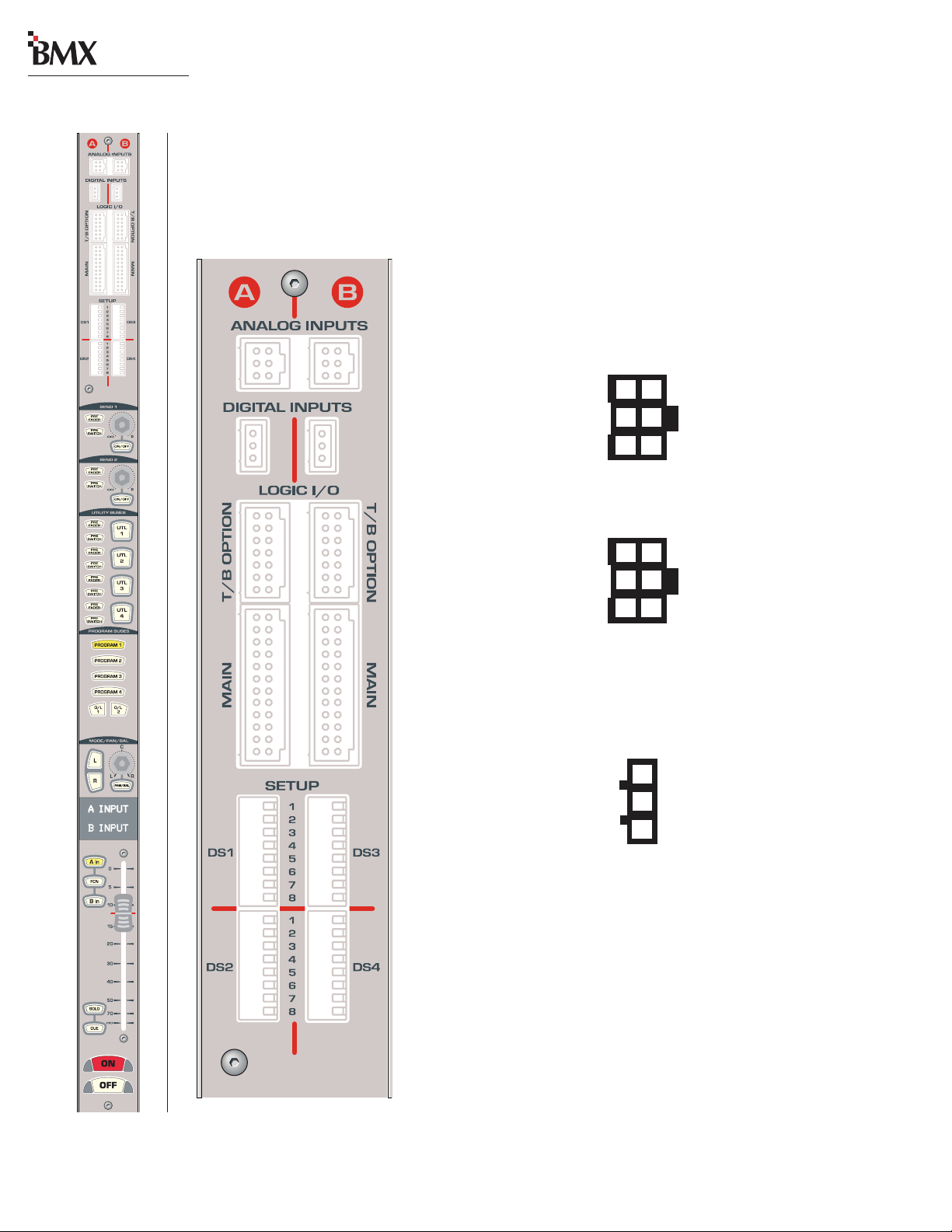

Universal Input

This module features two inputs (A and B), each

can come from an analog or a digital source

(source selection is set via a module DIP switch).

DIP switches also set the analog input level or the

digital attenuation. Each input has a fully independent parallel logic circuit for remote control

of the module and/or module control of the source

equipment. Each module has independent mic/

Module

digital

-

Revision C • 1/04

Page 8

digital

1 General Information

line logic functions for both inputs, also set using

the module’s Setup DIP switches.

The Universal Input module has controls for the

following functions: A/B input selection, input

mode selection, channel on/off, fader level, solo,

cue, pan/balance, two Send selectors and level

controls, and ten output bus selectors (four program, four utility, and two off-line buses). A twoline display shows the A and B input source names .

Two 24-pin connectors connect logic wiring to/

from external peripherals or control panels for the

A and B inputs. Two 14-pin connectors allow remote talkback (active when microphone logic is

selected) for the A and B inputs. Four 8-position

DIP switches set logic and module function options independently for the A and B inputs.

T elc o/C odec Input Module

An optional module that provides audio and

logic connections for a telephone hybrid or a codec

(satellite transceiver, ISDN interface, etc.). Up to

six Telco modules can be installed in the frame.

Telco modules have digital and analog inputs

(the active input is set via DIP switch) and the

same controls as a Universal Input—minus the

A/B input selector . Additional module controls include: telco monitor bus and telco record output

assignment buttons, a Talk to Codec function, a

Source Selector and a Take button (for source selection with a VistaMax, Ext. RLS or a router).

Each Telco module has an associated mixminus (Foldback) of an y combination of the program, utility or send buses and two off-line mix

buses. An Auto-Foldback function can automate

switching Foldback between an off-line mix and

the assigned bus with module off and on.

Remote Line Selector Input Module

An optional module that offers source selection

from a VistaMax system, an external remote line

selector or a router . Each module has a digital and

an analog input (active input set by module DIP

switch). Front panel controls are the same as the

Universal Input, minus the A/B selection. Instead,

there is a Source Selector and Take button.

Session

meter source selection, and event timer controls.

There are eleven Aux Meter selector buttons (for

viewing any External Input, Send, Utility bus, or

T elco Record output) and two Main Meter selectors

(PGM 1-4 and UTL 1-4) for viewing the Program

or the Utility buses on the four Main Meters (on

the BMX

the buses to show one at a time on the Main meter).

Selector and two buttons: Take and Save. A twoline display shows the session currently being used

and either the next session to be loaded, or when

the Session Selector is being turned, the various

sessions available in alphanumeric order.

controls: Start, Stop, Hold, and Reset, as well as

the Auto Reset control, which adds automatic

module on resetting of the event timer.

Module

This module provides session control, auxiliary

digital

-8, the two buttons cycle through

The session control section has a Session

The Timer Control section has the event timer

Control Room Module

This module has the monitor selection and control facilities for the console operator . It has parallel logic control for control room speaker dim and

mute, and to pro vide a control output for the Control Room warning lamp controller.

The Control Room module has independent

monitor and headphone source selectors and monitor and headphone fader level controls. The module also has input mode controls, Cue and talkback level controls and a solo clear button. Additional headphone controls include an Autocue selector and a button to force the headphones to

follow the monitor source selection.

1-2

HARRIS CORPORATION

Revision C • 1/04

Page 9

digital

1 General Information

Studio Module

This optional module has the monitoring and

talkback controls for two separate studios or voice

booths, plus talkback audio and control inputs

for a producer/call screener position and for an

external position.

The Producer and External audio inputs are

line level. The Mic Preamp module may be used

as needed for these inputs. A Producer Talkback /

IFB Panel (PRE99-1188) is also av ailable. It provides a mic and preamp for the Producer along

with T alk buttons for thirteen locations .

T he Studio module has two parallel logic connectors for the Studio 1 and 2 dim, mute, and Studio W arning Lamp interface controls .

The Studio module also has monitor and talkback selector controls, and monitor and talkback

level controls. All of the controls operate independently for each studio.

gram, Utility, and Send outputs. For digital outputs, sample rates of 48 kHz and 44.1 kHz are

supported. These modules feature output sample

rate selectors for the Program auxiliary outputs

and the Utility and Send outputs, as well as gain

trim controls for the Program, Utility, and Send

analog outputs.

DSP Cards

The number of standard DSP (Digital Signal

Processor) cards installed is frame-size dependent

d

(BMX

and so on up to the BMX

the input modules, hidden below the meter panel

in normal use. Each card has a “heartbeat” LED

to indicate operation. An optional External Input

DSP (99-1355-1) adds an external AES-3 reference input for the first DSP Card position.

-8 has one DSP Card, BMXd-14 has two,

d

-38 with five cards).

DSP cards plug into the motherboard behind

Output Modules

There are three Output modules. The Output 1

module has the digital-to-analog converters and

mix matrices for creating mix-minus foldbacks to

support up to six Telco/Codec modules. It also contains individually mixed outputs for Telco monitoring and recording. Two monaural mix-minus

outputs for each Telco/Codec module, one with

talkback (IFB) and one with a clean feed, are on

this module.

Digital and analog outputs are provided for the

mix-minus and recorder feed outputs. For digital

outputs, sample rates of 48 kHz and 44.1 kHz

are supported. The mix-minus analog outputs are

fixed at +4 dBu. This module features output

sample rate selectors for digital outputs and gain

trim controls for the analog Telco record mix output and IFB level.

The Output 2 and Output 3 modules contain

the AES digital output drivers, digital-to-analog

converters, and analog line amplifiers for the Pro-

Net Card

This optional card allows the BMX

rectly interface to a VistaMax Audio Management

System. It plugs into the motherboard behind the

Output modules, hidden below the meter panel in

normal use. There are eight VistaMax inputs and

outputs on the card for connecting intercom, external monitors and other in-room equipment that

does not need to have local module control.

digital

to di-

POWER SUPPLY

The separate rack-mount power supply (99-

1205) supplies +48 VDC and a voltage monitor

signal to the console. One supply comes standard.

An optional second 99-1205 supply and a +48

VDC Coupler (99-1203) can be installed for redundant supply operation. Each power supply has

its own AC input, On/Off switch and LED power

good indicator. Each power supply is fully regulated and protected against excessive current by

internal fuses and electronic safeguards.

1-3

HARRIS CORPORATION

Revision C • 1/04

Page 10

digital

1 General Information

Specifications

The specifications for the BMX

nificantly more complete, and the related test conditions are more defined, than those usually shown

for consoles in this class. Be sure to follow the test

conditions and measure in the units as stated.

The specifications are for a fully loaded BMX-

digital

38-input mainframe.

Test Conditions:

Specifications are for the basic signal paths, per

channel, with >1 k ohm loads connected to the

analog main outputs.

0 dBu corresponds to an amplitude of 0.775

volts RMS regardless of the circuit impedance. This

is equivalent to 0 dBm measured into a 600 ohm

circuit for convenient level measurement with

meters calibrated for 600 ohm circuits. Noise specifications are based upon a 22 kHz measurement

bandwidth. The use of a meter with 30 kHz bandwidth will result in a noise measurement increase

of approximately 1.7 dB.

Total Harmonic Distortion (THD+N) is measured at a +18 dBu output level using a swept

signal with a 22 kHz low pass filter.

FSD = Full Scale Digital, +24 dBu

Microphone Preamplifiers

Source Impedance: 150 ohms

Input Impedance: 5 k ohms minimum, balanced

Input Level Range: Adjustable, -65 to -30 dBu

Input Headroom: >20 dB above nominal input

Output Level: +4 dBu, nominal

Analog Line Inputs

Input Impedance: >40 k ohms, balanced

Input Level Range: Selectable, -10 dBv, +4 dBu,

+6 dBu, +8 dBu

Input Headroom: 20 dB above nominal input

digital

are sig-

Analog Main Outputs

Output Source Impedance: <3 ohms balanced

Output Load Impedance: 1 k ohms minimum

Nominal Output Levels: Program, Utility, Send, Telco/

Codec Mix-Minus, Telco Record Mix Feed: +4

dBu, adjustable between +3 dBu and +9 dBu

Maximum Output Levels: Program, Utility, Send,

Telco/Codec Mix-Minus, Telco Record Mix Feed:

+24 dBu; +28 dBu with nominal output level

adjusted to +8 dBu

Digital Inputs and Outputs

Reference Level: +4 dBu (-20 dB FSD)

Digital I/O: Thru digital input and digital Program,

Utility, Send, Telco/Codec Mix-Minus outputs

Signal Format: AES-3, S/PDIF (input only)

AES-3 Input Compliance:

sion available, individually switch selectable

AES-3 Output Compliance:

Digital Reference:

ternal) at 48 kHz ±100 ppm

Internal Sample Rate:

Output Sample Rates: Program Main outputs are

48 kHz; Program A ux, Utility, Mix-Minus and

Telco Record Mix outputs, individually DIP

switch set for 48 kHz or 44.1 kHz

Processing Resolution:

precision accumulators

Conversions:

oversampling on all digital inputs; D/A 24-bit,

Delta-Sigma, 128x o versampling

Latency:

Monitor Outputs

Output Source Impedance: <3 ohms, balanced

Output Load Impedance: 1 k ohms minimum

Output Level: +4 dBu nominal, +24 dBu maximum

Frequency Response

Microphone or Line Input to Program, Utility, or Send

Output: +0 dB/-0.5 dB, 20 Hz to 20 kHz

A/D 24-bit, Delta-Sigma, 128x

<1.6 ms, mic in to monitor out

24-bit sample rate conver-

24-bit

Crystal (internal) or AES-3 (ex-

48 kHz

24-bit fixed with extended

1-4

HARRIS CORPORATION

Revision C • 1/04

Page 11

digital

1 General Information

Dynamic Range

Analog Input to Analog Output: 105 dB referenced to

FSD, 108 dB “A” weighted to FSD

Analog Input to Digital Output: 109 dB referenced to

FSD

Digital Input to Analog Output: 107 dB referenced to

FSD, 110 dB “A” weighted to FSD

Digital Input to Digital Output: 138 dB

Equi valent Input Noise

Microphone Preamp: -127 dBu, 150 ohm source

Total Ha rmonic Disto rtion + Noi se

Mic Pre Input to Mic Pre Output: <0.005%, 20 Hz to

20 kHz, -38 dBu input, +18 dBu output

Analog Input to Analog Output: <0.005%, 20 Hz to

20 kHz, +18 dBu input, +18 dBu output

Digital Input to Digital Output:

<0.00016%, 20 Hz to

20 kHz, -20 db FSD input, -20 db FSD output

Digital Input to Analog Output:

<0.005%, 20 Hz to

20 kHz, -6 db FSD input, +18 dBu output

Crosstalk Isolation

Program-to-Program or to-Utility or to-Send: >95 dB,

20 Hz to 20 kHz

A Input to B Input, B Input to A Input:

>110 dB, 20 Hz

to 20 kHz

Stereo Separation

Analog Program Outputs: >86 dB, 20 Hz to 20 kHz

Console Power Requirements

Fully configured BMXdigital 22: 250 watts at 115/

230 VAC, ±12%, 50/60 Hz

Fully configured BMXdigital 30: 285 watts at 115/

230 VAC, ±12%, 50/60 Hz

:

Fully configured BMXdigital 38

320 watts at 115/

230 VAC, ±12%, 50/60 Hz

Power Supply Voltage

Console power: +48 VDC at 6.25 Amps,

optional redundant supply can be added with

48 volt coupler

Powe r Sup p ly Gr o un d

Rack mounted power supply: grounded thru A C cord

Power Supply Connection

AC input: IEC power cord, one per plug-in power

supply

DC output: Keyed multi-pin connectors

Dimensions

BMXd-8: 9.8" [249] x 29.2" [742] x 33.4" [848]

BMXd-14: 9.8" [249] x 42.0" [1067] x 33.4" [848]

BMXd-22: 9.8" [249] x 54.8" [1392] x 33.4" [848]

BMXd-30: 9.8" [249] x 67.6" [1717] x 33.4" [848]

BMXd-38: 9.8" [249] x 80.4" [2042] x 33.4" [848]

48V Power Supply (Rack mount): 2 RU: 3.5" [89] x

19" [483] x 10" [254]

48V Coupler (Rack mount): 1 RU: 1.75" [45] x 19"

[483] x 10" [254]

All dimensions are Height, Width, Depth.

Harris Corporation reserves the right to change

specifications without notice or obligation.

1-5

HARRIS CORPORATION

Revision C • 1/04

Page 12

digital

1 General Information

WARRANTY

The BMX

a manufacturer’s warranty which is subject to the

following guidelines and limitations:

A) Except as expressly excluded herein, Harris

Corporation (“Seller”) warrants equipment of

its own manufacture against faulty workmanship or the use of defective materials for a period of one (1) year from date of shipment to

Buyer . The liability of the Seller under this War ranty is limited to replacing, repairing, or issuing credit (at the Seller’s discretion) for any

equipment, provided that Seller is promptly

notified in writing within five (5) days upon

discovery of such defects by Buyer, and Seller’ s

examination of such equipment shall disclose

to its satisfaction that such defects existed at

the time shipment was originally made by

Seller, and Buyer returns the defective equipment to Seller’s place of business in Mason,

Ohio, packaging and transportation prepaid,

with return packaging and transport guaranteed.

digital

console and power supply carry

E) This Warranty is void for equipment which

has been subject to abuse, improper installation, improper operation, improper or omitted maintenance, alteration, accident, negligence (in use, storage, transportation, or handling), operation not in accordance with

Seller’s operation and service instructions, or

operation outside of the environmental conditions specified by Seller.

F) This Warranty is the only warranty made by

Seller, and is in lieu of all other warranties,

including merchantability and fitness for a particular purpose, whether expressed or implied,

except as to title and to the expressed specifications contained in this manual. Seller ’ s sole

liability for any equipment failure or any

breach of this W arranty is as set forth in subparagraph A) above; Seller shall not be liable

or responsible for any business loss or interruption, or other consequential damages of any

nature whatsoever, resulting from any equipment failure or breach of this warranty.

B) Equipment furnished by Seller, but manufac-

tured by another, shall be warranted only to

the extent provided by the other manufacturer .

C) Thermal filament devices, such as fuses, are

expressly excluded from this warranty.

D) The warranty period on equipment or parts

repaired or replaced under warranty shall expire upon the expiration date of the original

warranty.

HARRIS CORPORATION

1-6

Revision C • 1/04

Page 13

digital

"

123456789012345678901234567890121234567

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

1

7

123456789012345678901234567890121234567

Installation

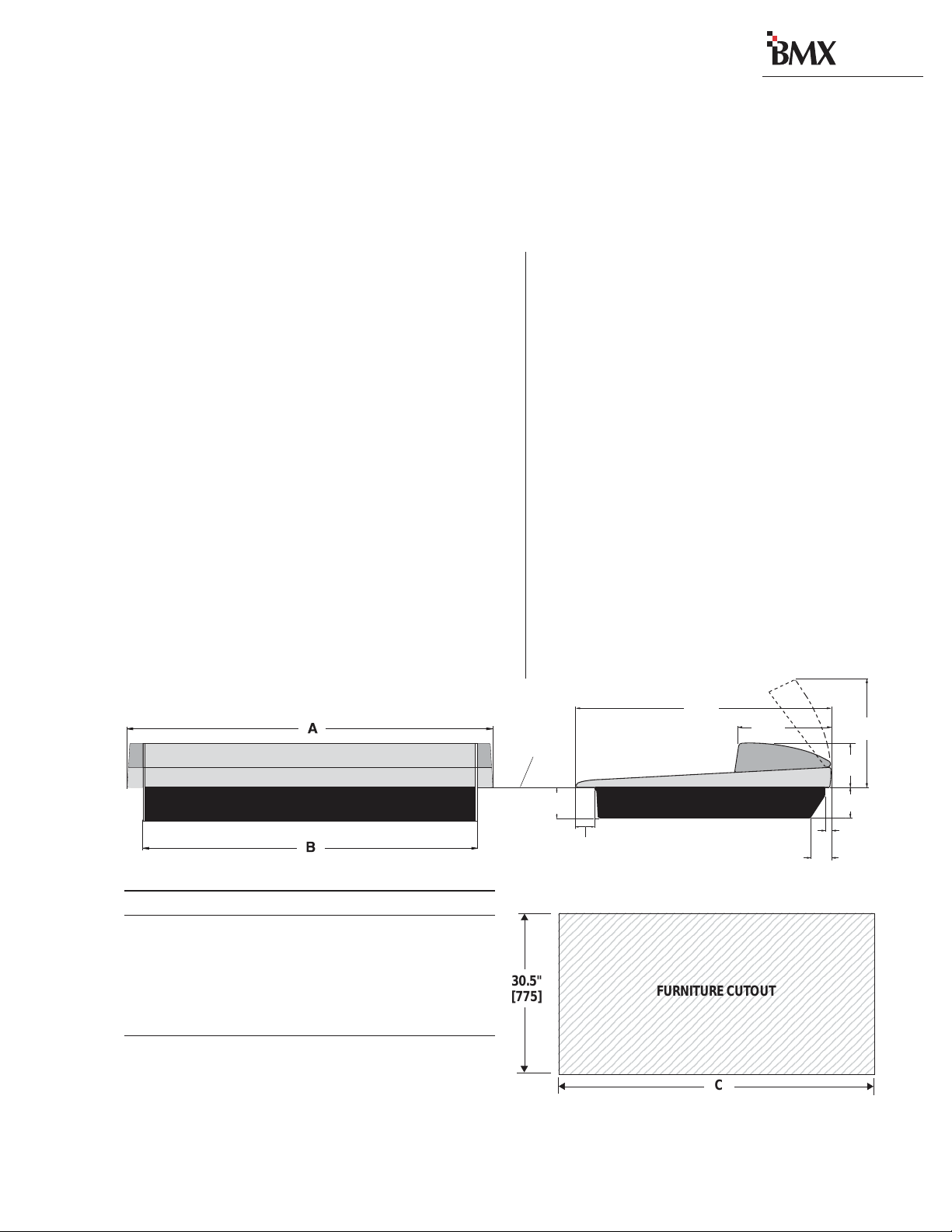

The BMX

a cutout (shown below) in the studio furniture

countertop. A minimum of 14 inches [356 mm] of

vertical clearance above the countertop is required

to fully open the meter panel. The rear 2.5 inches

[63.5 mm] of the mainframe bottom is open so

wiring can be easily dressed up through the main-

frame to the module connectors, which are hid-

den below the meter panel in normal use.

digital

mainframe “drops into”

2

The BMX

• The 8, 14, 22, 30 or 38 input frame with the

standard modules (Mic Preamp, Session, Control Room, three Outputs and DSP Cards) installed. Also installed are any optional items that

were also ordered (Universal Input, Telco/Codec and RLS modules, blank panels, Net Card).

• A 2RU rack-mount 48 volt power supply with

interconnecting cable.

• A BMX

MOD IV crimp tool and contact removal tool,

hex driver, and module removal tool).

• Audio and logic connector kit. T he kit contains

all the AMP MOD IV connector housings and

receptacle contacts typically needed for installation.

digital

console shipment consists of:

digital

Tool kit (3 AA batteries, AMP

Console, back view

Dimension T able

Mainframe A B C

BMXdigital-8 29.2" [742] 26.1" [663] 26.4" [671]

BMXdigital-14 42.0" [1067] 38.9" [988] 39.2" [996]

BMXdigital-22 54.8" [1392] 51.7" [1313] 52.0" [1321]

BMXdigital-30 67.6" [1717] 64.5" [1638] 64.8" [1646]

BMXdigital-38 80.4" [2042] 77.3" [1963] 77.6" [1971]

Millimeter dimensions in brackets. All dimensional tolerances are: +¼"

[6.4], -0" [0.0]. Typical setback from countertop edge to the front of the

console is 12" [305]. There must be 14" [356] of clearance above the

countertop to open up the meter panel.

33.4"

COUNTERTOP

4.00"

[102]

2.50"

[63.5]

[848]

11.8"

[300]

Console, side view, with dimensions

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

30.5"

[775]

HARRIS CORPORATION

2-1

Revision C • 1/04

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

2345678901234567890123456789012123456

FURNITURE CUTOUT

C

5.75"

[146]

4.00"

[102]

0.75"

[19]

2.50"

[63.5]

14.00

[356]

Page 14

digital

2 Installation

Console Installation

To simplify console installation, logic cable wir ing diagrams for specific peripheral equipment are

available from Harris Technical Support. Refer to

page 5-1 for contact information.

INST ALLATION NOTE: Do not locate the con-

sole near intense electromagnetic hum fields, such

as those produced by large power transformers

and by audio amplifiers that use inexpensive power

transformers operating in or near saturation.

Strong electromagnetic fields may impair the per -

digital

formance of the BMX

equipment. Route audio cables to achieve maximum practical distance from all AC power mains

wiring.

and neighboring

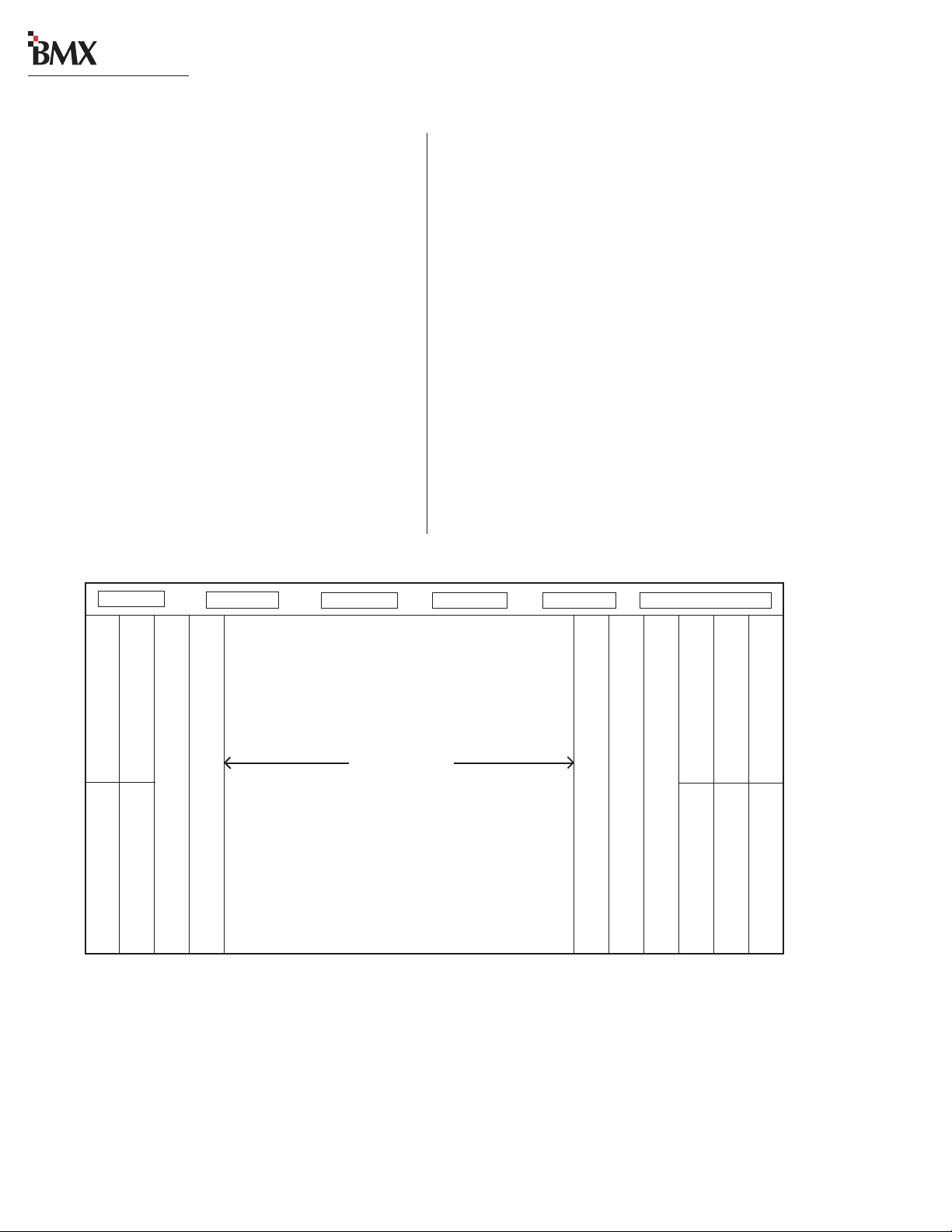

BMXdigital Mainframe, Module Configuration

MAINFRAME CONFIGURATION

The BMX

ules in the physical center of the mainframe. This

gives the operator equal reach to peripheral equipment located to either side of the console.

Module Placement

The 8, 14, 22, 30 or 38 input module positions

can have any combination or order of the following modules installed: Universal Input, Telco/

Codec (six maximum), and Remote Line Selector

(RLS). The remaining console positions are fixed.

The Microphone Preamp module(s), Session module, Control Room module, optional Studio module, and Output modules must be positioned as

shown below.

digital

design positions the input mod-

DSP Card 1 DSP Card 2* DSP Card 3* DSP Card 4* DSP Card 5* Net Card **

* The number of DSP Cards used is set by the frame size.

** The optional Net Card is used with the VistaMax Audio Management System.

*** These two slots are input module positions 1 and 2 on the BMXdigital-8 frame.

Output 1 (standard)

Output 2 (standard)

Mic Preamp (standard)

Mic Preamp 2 (optional)

12.5” blank panel (standard)

The input module positions are filled

with any combination or number of

Universal Input and Remote Line

Selector modules, and up to six Telco/

Codec modules. Unused positions are

Reserved position (covered by a 25" Blank panel) ***

Reserved position (covered by a 25" Blank panel) ***

12.25" Blank Panel (standard)

12.25" Blank Panel (standard)

NOTE:NOTE:

NOTE: The number of input module positions matches the console model number (e.g., BMXdigital-22 has 22 input positions). There is

NOTE:NOTE:

one DSP card in the BMXd-8, two DSP cards in the BMXd-14, three in the BMXd-22, four in the BMXd-30, and five in the BMXd-38.

The areas covered by the five 12.25" Blank Panels can be used for mounting Harris BMXdigital Accessory Panels or custom remote

control panels. Since the Harris BMXdigital Accessory Panels are 6" long, a PRE99-1100 Divider Kit (for mounting up to four Accessory

Panels in place of two 12.25" Blank Panels), or a PRE99-1101 Divider Kit (for mounting up to six Accessory Panels in place of three

12.25" Blank Panels) is required. Typically, the PRE99-1100 Divider Kit is installed in place of the Blank Panels on the left end of the

console and the PRE99-1101 is installed in place of the Blank Panels on the right end of the console. 6" Blank Panels (PRE99-1714-3)

cover unused Accessory Panel positions.

Input modules

Session (standard)

Control Room (standard)

covered with 25" Blank Panels.

Studio (optional) 25” blank panel (standard)

12.25" Blank Panel (standard)

Output 3 (standard)

12.25" Blank Panel (standard)

12.25" Blank Panel (standard)

2-2

HARRIS CORPORATION

Revision C • 1/04

Page 15

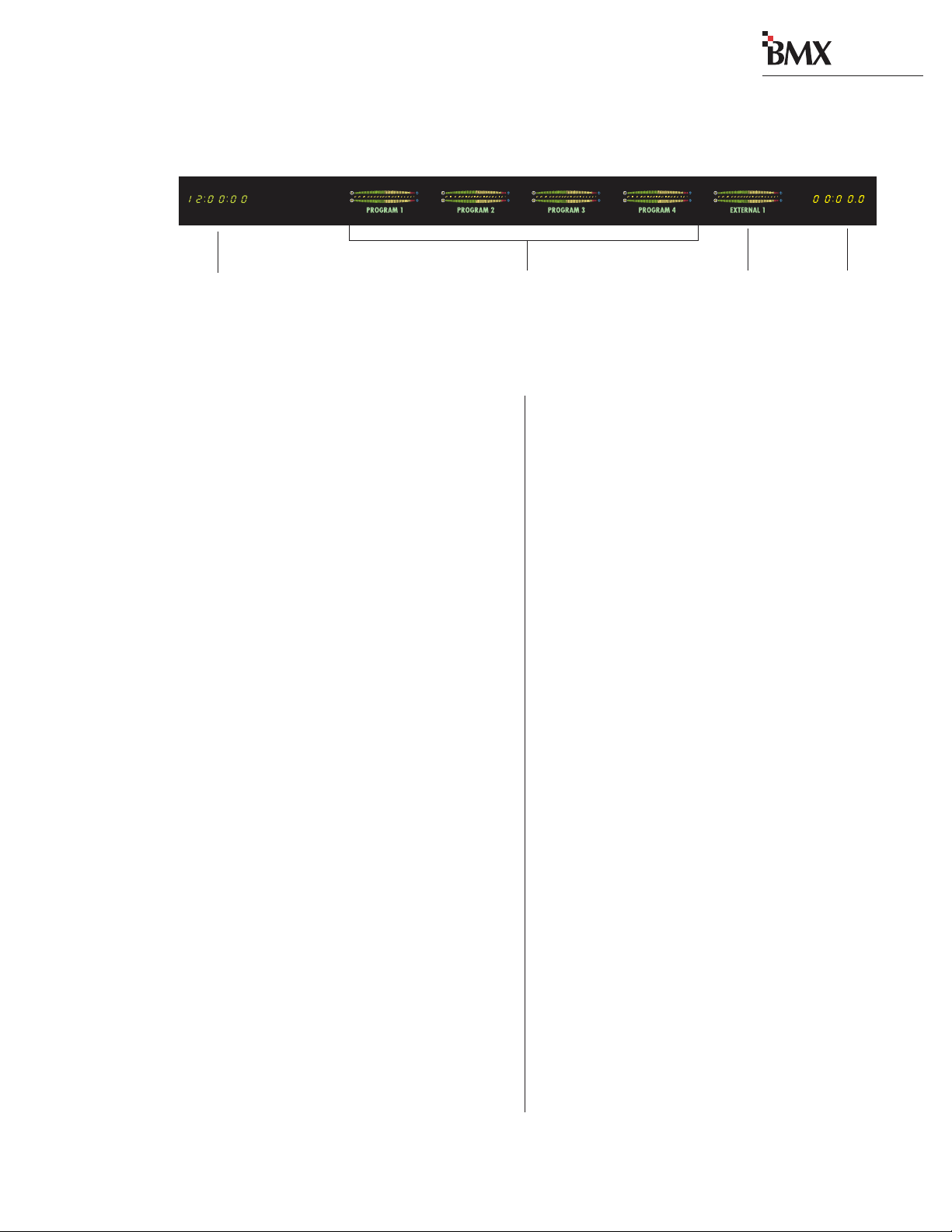

BMXdigital Meter Panel

digital

2 Installation

Clock

(not available on

the BMXdigital-14)

(BMXdigital-8 only has one meter)

Two Session module switches select

whether the Program or the Utility

Meter Panel

The meter panel has five horizontal Stereo Bar graph Meters, except for the BMX

has two meters. An alphanumeric display below

each meter identifies the current signal source

(PROGRAM 1, UTILITY 1, etc.).

Four of the meters provide simultaneous level

monitoring of the four Program or the four Utility

bus outputs, as selected by two Session module

buttons. On the BMX

module buttons cycle through the four Program

and the four Utility buses to select which bus to

display on the single main meter.

The right-hand meter (Auxiliary) shows the Cue

or Solo bus levels. When neither function is active, the meter shows a source selected on the Session module (from between the four external inputs, the two Sends, the four Utility buses or the

Telco Record output).

The meter display mode (peak hold or non-peak

hold) and the level where the peak indicators turn

on are set for each meter via DIP switches on each

meter display board.

On the left end of the meter panel is an ESEslaveable 12/24-hour digital clock (on all sizes

except for the BMX

there is an event timer that can be controlled

manually, through buttons on the Session module, or automatically, through module On reset

commands.

digital

digital

digital

-8, which

-8, these two Session

-14). On the right end

Main Meters

Buses are displayed

CONNECTOR ACCESS

panel, which is hinged on the rear of the mainframe. To access the connectors, open up the meter

panel by lifting up on the middle of the meter panel

while allowing it to pivot rearward to fully extend

the two gas springs.

way so that it does not accidentally fall shut.

be entirely removed from the mainframe:

of the hinges, then release the pins out of their

unlocked positions.

inserting a screw through the gas spring and the

bushing.

Auxiliary Meter

(Cue, Solo, or Session

module-switched source)

Module connectors are hidden below the meter

Event

Timer

Caution: Make sure the panel is open all the

To facilitate initial wiring, the meter panel can

1 Open up the meter panel fully and unplug

the meter power cable (attached to the rear

panel) and the three signal cables plugged into

the Session module.

2 With another person assisting to hold the

meter panel, remove the screw and bushing

that attach each gas spring to the meter panel.

Lay the gas springs on the mainframe while

working.

3 Unlatch the hinges by moving the release pins

to their unlocked positions and lift the meter

panel up and off the mainframe.

To reinstall the meter panel, align the two halves

Reattach each gas spring to the meter panel by

2-3

HARRIS CORPORATION

Revision C • 1/04

Page 16

digital

2 Installation

POWER SUPPLY

The 99-1205 power supply requires 2 RU of

rack space within the console cabinetry , below and

to the left or right of the supporting countertop.

The 48 Volt Power Supply must be installed so

that the 30 foot power supply cable (90-1709) is

not under any tension when routed through the

cabinet and connected to the mainframe’s rear

panel connectors.

Connecting the Power Supply

The power supply cable has two connectors:

• A 5-pin connector to supply 48 volt DC

power to the console.

• A 4-pin connector to supply power status

information (Imminent Power Loss) to the

console.

Both connectors must be attached to the back

digital

of the BMX

and to the power supply.

GROUNDING AND SHIELDING

The broadcast facility’ s technical ground can be

connected to the mainframe chassis using the

threaded insert on the rear of the console (shown

in the Power Connections drawing on this page).

Use a 10-32 screw and crimp lug to terminate the

facility’s technical ground wire.

Connect the cable shields at both the console

and the peripheral end when all system components share a common ground potential and are

using isolated ground A C outlets tied individually

back to the main technical ground.

If isolated ground A C outlets are not available,

connect the cable shields at the console end only.

The shields should be floated (left unconnected)

at the peripheral device end. Ensure the peripheral devices connect to a clean ground through

their power cords, or through separate ground

wires to the facility’s technical ground.

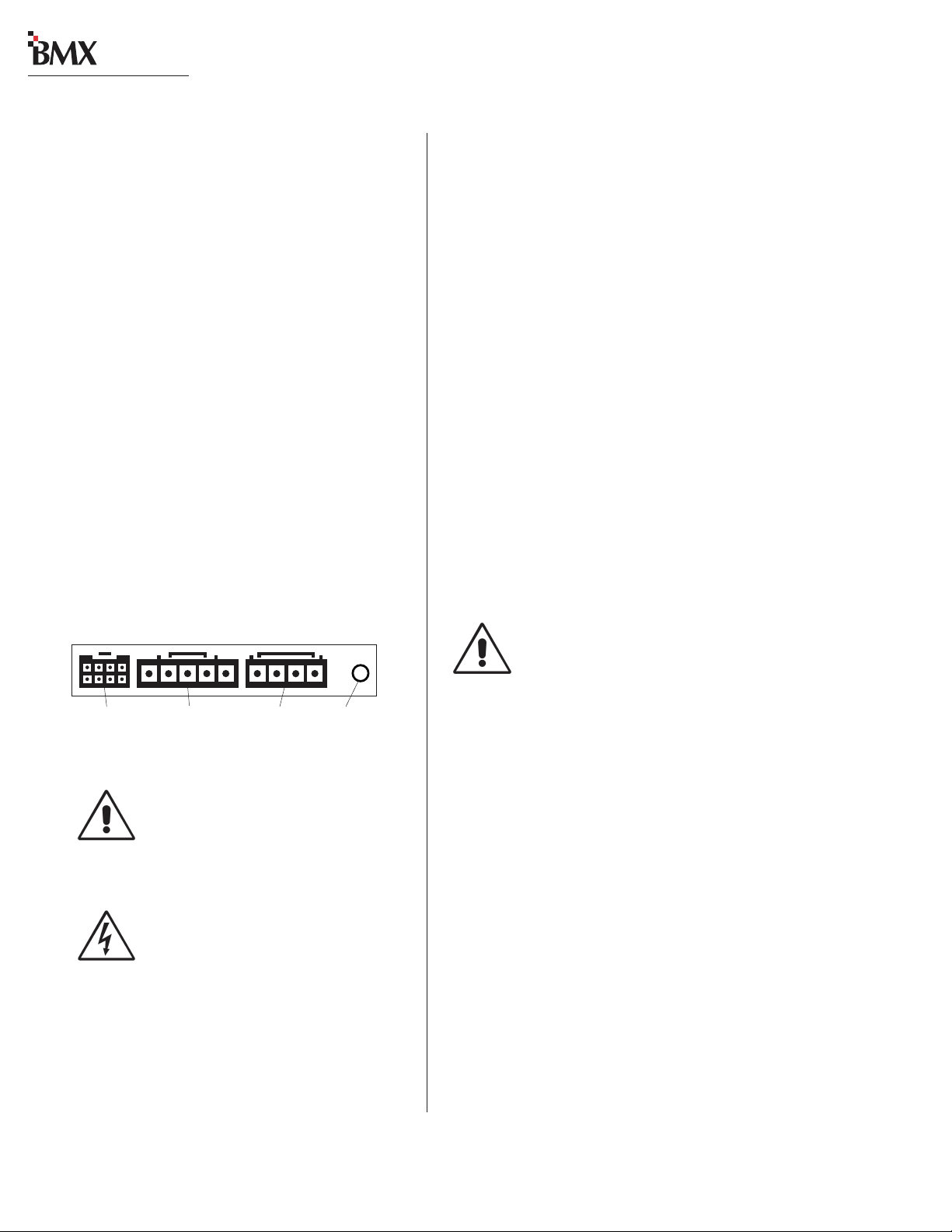

Power Connections —

Console Mainframe, Rear Panel

Meter Panel

Power

48 VDC

Power

Power Supply

Status

DC GROUNDING NOTE:

connect

ground wiring to the chassis of the

power supply .

the audio or logic supply

AC GROUNDING NOTE: Do not

defeat the safety ground in any way.

Doing so may provide a potentially

dangerous condition to the operator.

Threaded

Insert for

10-32 screw

Do not

Redundant Power Supply

To provide redundant console power, two

99-1205 power supplies can be connected to the

console through a 99-1203 48 Volt Coupler.

POWER SUPPLY GROUNDING NOTE:

The P ower Supply chassis connects to the

AC mains safety or “U” ground wire.

AUDIO GROUND NOISES: Buzz pickup is gener -

ally electrostatic—such as capacitive coupling

between an audio line and a power line. To avoid

audio ground noises, do not route audio lines in

the same wireway as an AC power line.

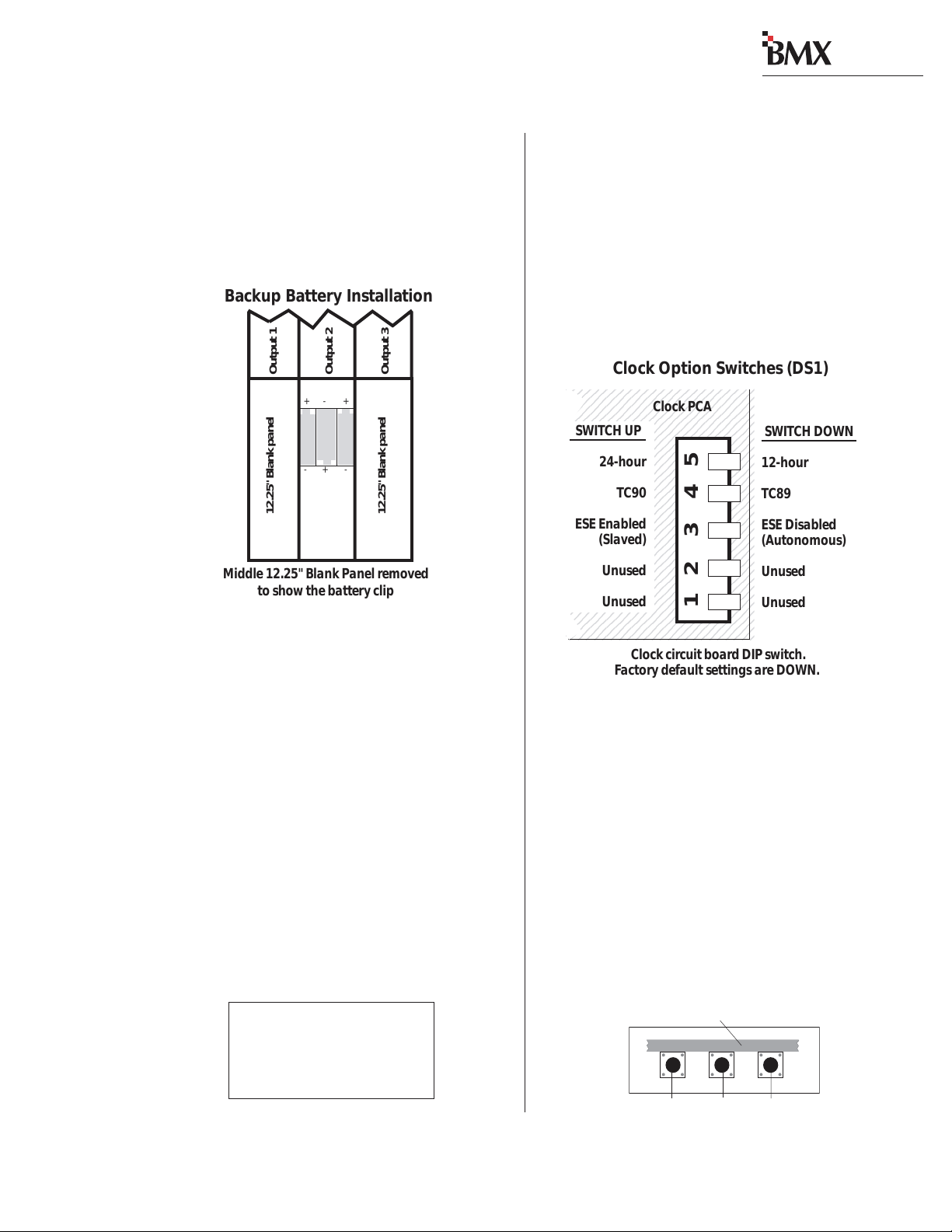

INSTALLING BACKUP BATTERIES

Three AA rechargeable NiCad batteries are supplied in the 76-2001 Tool Kit. They should NOT

be installed until the console is completely installed

and is ready for everyday use.

The batteries supply a “K eep Alive” voltage that

holds each module’s logic state during momentary power outages. They mount in a battery clip

located below the three 12.25" blank panels on

the right end of the console.

2-4

HARRIS CORPORATION

Revision D.1 • 12/10

Page 17

digital

2 Installation

To install the backup batteries:

1 Remove the blank panels in front of the Out-

put modules using the supplied hex driver.

2 Install the batteries into the battery clip,

observing the correct polarity as marked on

the battery clip and shown below.

Backup Battery Installation

Output 1

12.25" Blank panel

Middle 12.25" Blank Panel removed

to show the battery clip

Note: Replace the batteries yearly to ensure con-

tinuous backup protection. Use only P anasonic P50AAH or equivalent batteries designed for continuous slow charge operation. To prolong battery

life, remov e the batteries when the console is powered down for an extended period.

Output 2

+- +

-+-

Output 3

12.25" Blank panel

SETTING THE CL OCK

The digital time-of-day clock (not available on

digital

the BMX

or slave modes. W hen used autonomously (the factory preset), a temperature-controlled quartz crystal oscillator controls the clock timing. In slave

mode, clock timing comes from a TC89- or TC90compatible ESE master clock reference signal.

-14) can operate in autonomous

Master clocks are available from:

ESE

142 Sierra St.

El Segundo, CA 90245.

Telephone: 310.322.2136

www.ese-web.com

The operating mode (autonomous or ESE sla ve),

the type of ESE signal (TC89 or TC90), and the

type of clock time desired (12-hour or 24-hour

format) are set using DIP switch DS1 on the clock

PCA. DS1 is on the right rear edge of the circuit

board.

To access the clock PCA, open the meter panel.

The clock PCA is mounted behind the clock display on the meter panel.

Clock Option Switches (DS1)

12345678901234567890123

2345678901234567890123

1

1

2345678901234567890123

2345678901234567890123

1

1

2345678901234567890123

2345678901234567890123

1

2345678901234567890123

1

SWITCH UP

1

2345678901234567890123

12345678901234567890123

12345678901234567890123

24-hour

12345678901234567890123

2345678901234567890123

1

1

2345678901234567890123

12345678901234567890123

2345678901234567890123

1

12345678901234567890123

2345678901234567890123

1

1

2345678901234567890123

ESE Enabled

12345678901234567890123

12345678901234567890123

(Slaved)

12345678901234567890123

12345678901234567890123

2345678901234567890123

1

12345678901234567890123

Unused

12345678901234567890123

12345678901234567890123

12345678901234567890123

Unused

12345678901234567890123

12345678901234567890123

12345678901234567890123

12345678901234567890123

TC90

Clock PCA

12345

SWITCH DOWN

12-hour

TC89

ESE Disabled

(Autonomous)

Unused

Unused

Clock circuit board DIP switch.

Factory default settings are DOWN.

With the clock set to autonomous mode, it must

be set after power-up. There are three clock set

buttons on the bottom left front of the clock PCA.

• Use the right button (F ast) to scroll by minutes at a time.

• Use the middle button (Slow) to scroll by

seconds at a time.

• Use the left button (Hold) to synchronize

the console clock to an external time refer ence by setting the clock ahead of the external time reference, then press and hold

Setting the Clock

Clock Circuit Board, lower left front edge

Hold Slow Fast

2-5

HARRIS CORPORATION

Revision D.1 • 12/10

Page 18

digital

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

1234567890123456789012345678901212345678901234567

1234567890123456789012345678901212345678901234567

2 Installation

the HOLD button to freeze the time. When

the external time reference reaches the time

digital

on the BMX

clock, release the HOLD

button to start the clock.

When an ESE time-code signal is connected to

the BNC connector on the clock circuit board, and

slave mode is selected (DS1-3 is set UP), the clock

does not require setting. If the ESE time-code signal fails, the clock automatically defaults to its internal crystal reference oscillator , flashing the display colons to indicate the loss of time-code.

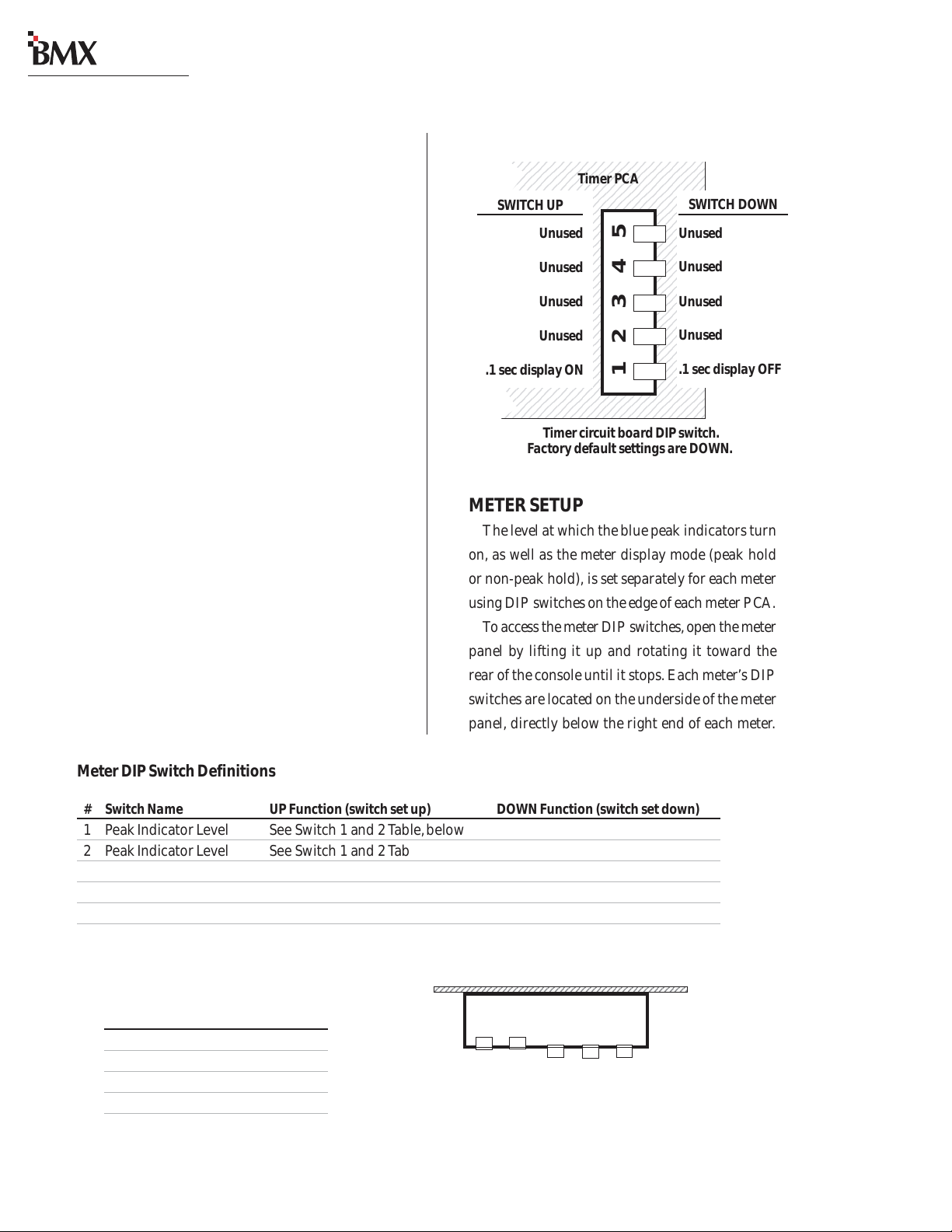

EVENT TIMER

The event timer displays time in minutes, seconds and tenths of seconds. The only timer option

setting is whether to display the tenths of seconds

digit as the timer runs. DS1-1 (a DIP switch on

the timer circuit board, located behind the timer

display), sets whether the tenths are shown or not.

In the UP position, the tenths of seconds are displayed. In the DOWN position, the factory default,

the tenths do not display while the timer runs.

Note that the tenths of seconds are always shown

when the timer is in the Stop or Hold mode.

Event Timer Option Switches (DS1)

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

SWITCH UP

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

.1 sec display ON

234567890123456789012345

234567890123456789012345

234567890123456789012345

234567890123456789012345

Unused

Unused

Unused

Unused

Timer PCA

12345

SWITCH DOWN

Unused

Unused

Unused

Unused

.1 sec display OFF

Timer circuit board DIP switch.

Factory default settings are DOWN.

METER SETUP

The level at which the blue peak indicators turn

on, as well as the meter display mode (peak hold

or non-peak hold), is set separately for each meter

using DIP switches on the edge of each meter PCA.

To access the meter DIP switches, open the meter

panel by lifting it up and rotating it toward the

rear of the console until it stops. Each meter ’s DIP

switches are located on the underside of the meter

panel, directly below the right end of each meter.

Meter DIP Switch Definitions

# Switch Name UP Function (switch set up) DOWN Function (switch set down)

1 Peak Indicator Level See Switch 1 and 2 Table, below

2 Peak Indicator Level See Switch 1 and 2 Table, below

3 Meter Display Mode * Non-peak hold Peak hold

4 Spare Switch

5 Termination Switch Set UP for Me ter 1 Set DOWN for Meters 2 - 5

* Active only when meters are set to display Average and Peak (Session module DIP switch 1 set to Off)

Switch 1 and 2 Table

Use these switches to set the level

where the Blue peak indicators light.

#1 # 2 Peak Level

DOWN DOWN 0 dB

UP DO W N -2 dB

DOWN UP -4 dB

UP UP -6 dB

Meter Option Switches (DSW2)

Switches 1, 2, 3 shown down,

switches 4 and 5 shown up.

2-6

HARRIS CORPORATION

Revision C • 1/04

123 45

Meter PCA

Page 19

digital

2 Installation

Cabling and Wiring

Before installing the console, dra w up a facility

wiring plan that lists the console interconnections

with all peripheral devices. Identify and create tags

for all audio and logic cabling. List each connection in a master facility wiring logbook to facilitate wiring installation, future system wiring

changes, equipment updates , and system troubleshooting.

Refer to the module Quick Connection Guides,

on pages 2-16 to 2-57, for information on each

audio and logic connection (including block diagrams for each logic interface connector) and on

each module’s setup DIP switches.

REQUIRED CABLES AND WIRE

The BMX

cables and wires:

digital

uses the following types of

WIRE PREPARATION

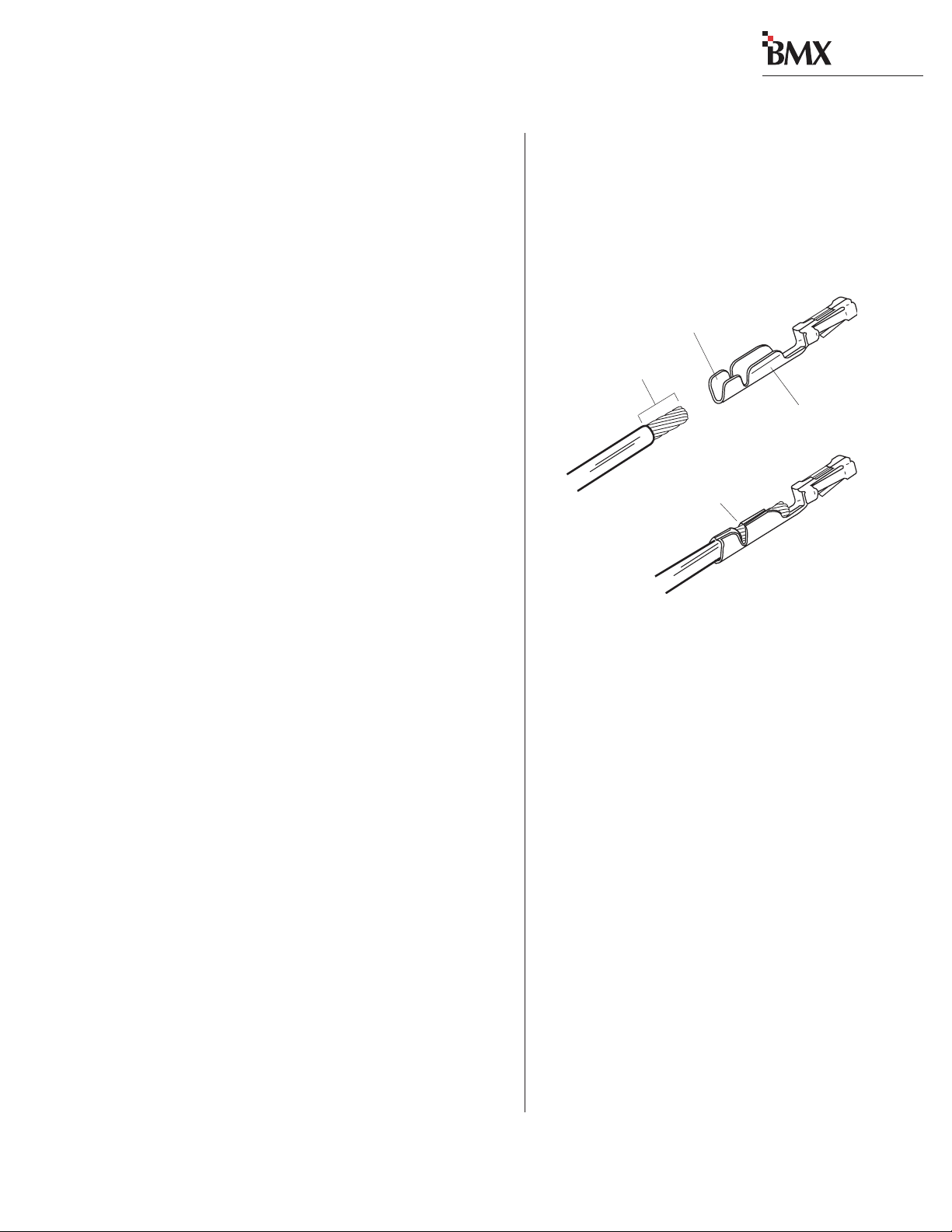

All BMX

nates in AMP MOD IV receptacle contacts at the

console. Stranded wire of 22 to 26 AWG, with insulation diameters of .040 to .060 inch, can be

used with the AMP MOD IV receptacle contacts.

9/64” [3.57 mm]

digital

audio and logic wiring termi-

Insulation Barrel

Properly

Crimped Contact

Wire Barrel

• Analog audio connections require twoconductor, stranded, insulated, foil-shield

cable using a separate shield drain wire

(equivalent to Belden 8451, 9451 or 8761).

• AES/EBU connections require 110 ohm

two-conductor, stranded, insulated, foilshield cable containing a separate shield

drain wire (equivalent to Belden 1800A).

• Logic control cables require stranded, 22

AWG, multiple-conductor, non-shielded,

jacketed cable (equivalent to Belden 9423,

8457 or 9421). The number of conductors

used is determined by the application. Typically cables with five and eight wires are

most often used for constructing logic

cables. Ev en though there are eighteen distinct signals on the Logic Interface connector, only a handful are typically used for

any given application.

AMP MOD IV Receptacle Contacts

Follow these steps for audio wire preparation:

1 Strip the cable insulation jacket and foil shield

back 1½" [38.10 mm].

2 Remove the foil shield and sleeve the drain

wire with 20 AWG Teflon sleeving. Leave

9/64" [3.57 mm] of the drain wire exposed.

3 Cover the cut end of the jacket with 3/4"

[19.05 mm] of heat-shrink tubing. Shrink this

tubing, centered on the jacket cut end, to hold

the drain wire sleeving in place.

4 Strip the signal wire insulation back 9/64"

[3.57 mm].

5 Crimp the receptacle contact onto the wire

and insulation.

AA

udio Cudio C

able Sable S

A

udio C

AA

udio Cudio C

mended grounding procedures, the drain wires

must be sleeved with Teflon sleeving and heat

shrink tubing must cover all cable jacket cut ends

to insulate the shield wiring.

able S

able Sable S

hielding Nhielding N

hielding N

hielding Nhielding N

otot

e:e:

ot

e: T o follow recom-

otot

e:e:

2-7

HARRIS CORPORATION

Revision C • 1/04

Page 20

digital

2 Installation

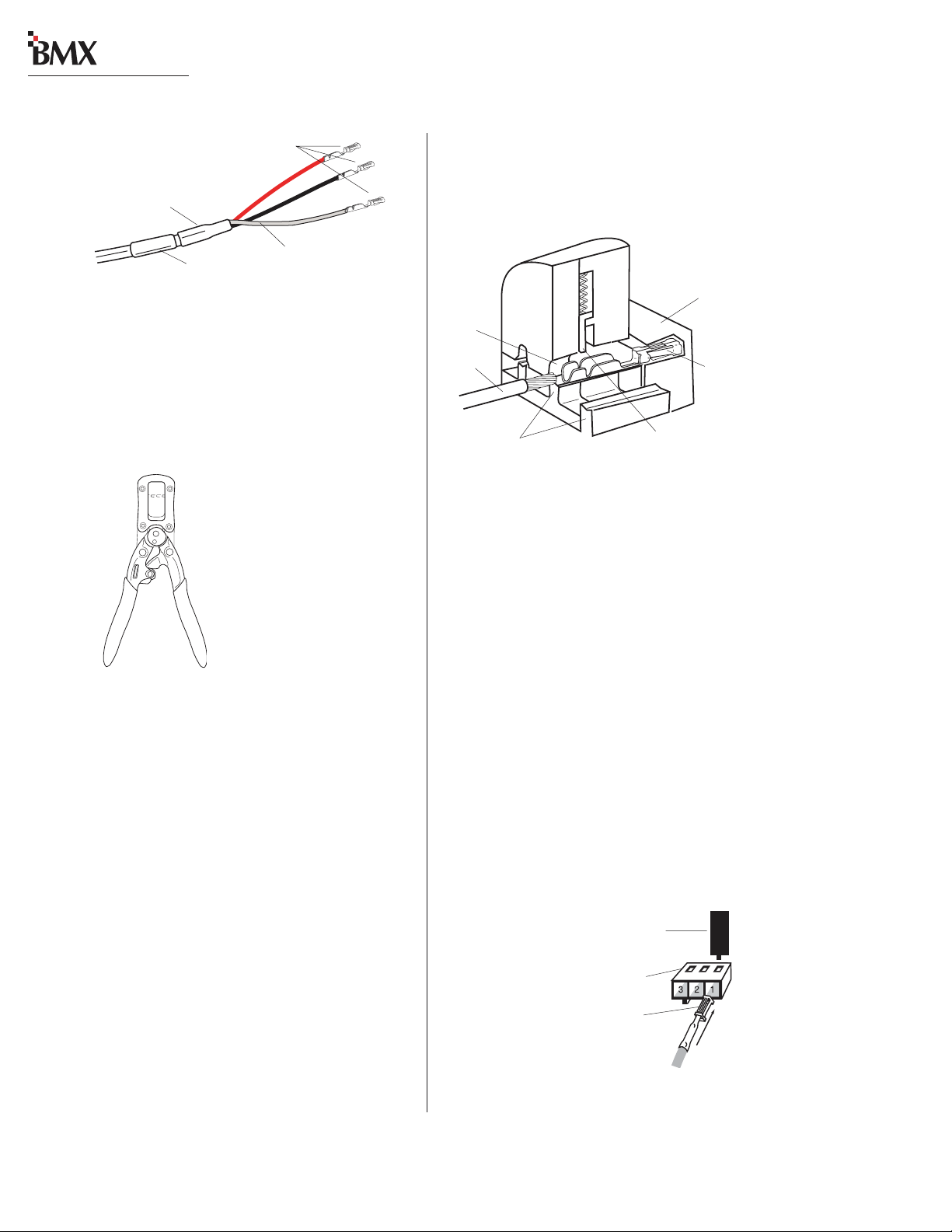

AMP MOD IV

Receptacle Contacts

3/4” [19.05 mm]

Shrink Tubing

Teflon Sleeving

Cable ID Tag

over drain w ire

Audio Wire, ready for insertion into an

AMP MOD IV connector housing

Logic control cables are fabricated in a similar

manner to the audio wiring. Strip the jacket insulation back 1½" [38.10 mm], sleeve the cut end

with 3/4" [19.05 mm] of shrink tubing and strip

the insulation from each wire 9/64" [3.57 mm].

AMP MOD IV

Contact

Crimp T ool

CRIMP TOOL OPERA TION

A ratcheting AMP crimp tool with contact holder

is included. The tool crimps both the insulation and

wire barrels on the AMP MOD IV receptacle contact in one crimp. To use the ratcheting crimp tool:

1 Insert the contact into the contact holder with

the barrel openings up. Typically the middle

holder is used (for 20 - 24 AWG wire). Flip

the holder up so it magnetically latches against

the crimp tool. The end of the insulation barrel will be about 2 mm from the end of the

die. Close the tool one click (only until the

anvil holds the contact in place, as shown in

the cutaway view, above.)

2 Insert the prepped wire into the contact until

the insulation hits the tool’s wire stop. Hold

the wire in place while squeezing the tool

handles to crimp the contact onto the wire.

The tool handles automatically release and

spring open after the crimp cycle is complete.

Contact Holder,

snapped against

Crimp Tool

AMP MOD IV

Receptacle

Contact

Die

Wire

Printed

Anvils

Side of

Crimp

Tool

Insulation Stop

Crimp Tool — Cutaway View

Once the contact has been crimped, insert and

lock the contact receptacle into the appropriate

connector housing following the pinout diagrams

found in the Quick Connection Guides on pages

2-16 to 2-57.

A receptacle contact is inserted into the housing with its locking tab side toward the locking

tab slots on the side of the connector housing. A

slight click can be heard when the contact’s locking tab springs up into the locking tab slot.

To remove a contact from a housing , the PRE70129 Contact Removal Tool (included in the

PRE76-2001 tool kit) is required. Insert the tool's

tip into the locking tab slot and press the locking

tab down while lightly pulling on the wire to remove the contact from the housing.

Contact Removal Tool

Locking Tab Slots

Locking Tab

Receptacle Contact,

Insertion & Removal Detail

2-8

HARRIS CORPORATION

Revision C • 1/04

Page 21

digital

2 Installation

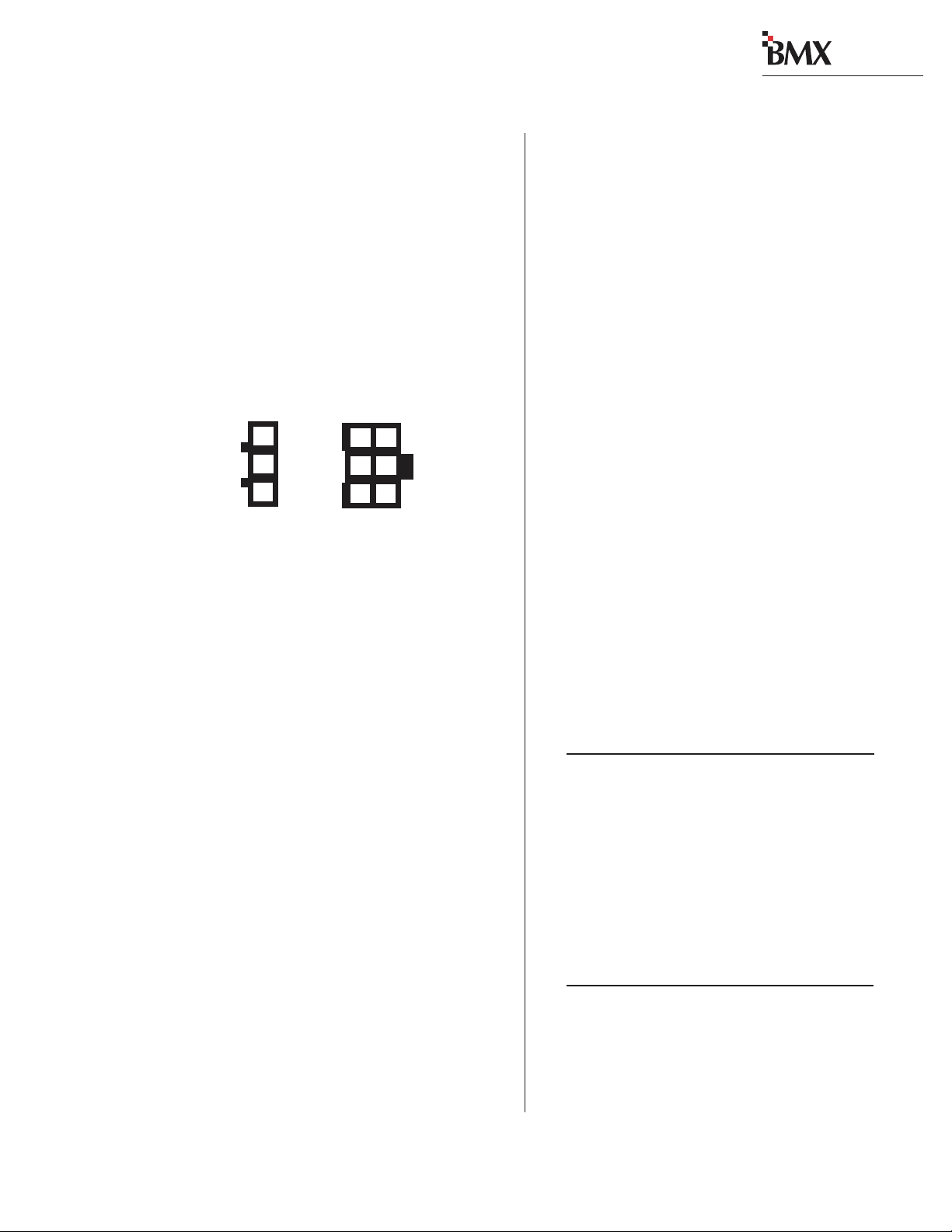

AUDIO CONNECTIONS

Audio connections take advantage of the threepins per row design of the three- and six-pin AMP

MOD IV housings. Three-pin housings are used

for balanced digital connections while six-pin

housings are used for balanced analog connections.

One important exception is the Mic Preamp module, which uses three-pin connectors for balanced

analog microphone inputs.

Pin Numbers for Analog &

Digital Audio Connectors,

3

2

1

3-pin

connector

Pin numbering shown from the wire insertion end,

oriented from the board operator’s perspective.

All audio wiring, when plugged into a module

connector, has this orientation:

• The audio shields are on pins 1 and 4 (the

pins closest to the board operator).

• The audio low wires (typically the black

wires) are on pins 2 and 5 (the middle pins).

• The audio high wires (typically the red

wires) are on pins 3 and 6 (the back pins).

For stereo applications, the left channel wires

plug into the left column of pins and the right channel wires plug into the right column of pins (from

the board operator’s perspective).

When a six-pin input comes from a mono source

(such as an external microphone preamp output),

the left and right inputs should be paralleled together (pins 1 and 4 tied together, pins 2 and 5

tied together and pins 3 and 6 tied together). If

this is not done, then the module’s mode buttons

will have to be set for mono operation (see page 35 for L/R Mode information on the Universal Input Module).

3

6

2

5

1

4

6-pin

connector

Analog Connections

There are no analog interstage patch points

within the BMX

digital

input or output modules.

To use the console with a patch bay, connect the

line level outputs from the peripheral devices directly to the patch bay. Normal these signals to

the appropriate analog input modules.

digital

Likewise, the BMX

’s analog outputs may

be routed through a patch bay normalled to standard peripherals such as analog on-air processing

gear , recorders, telephone hybrids, etc.

The Mic Preamp module’ s line-level outputs (+4

dBu, nominal, balanced, mono outputs) can also

be routed through a patch bay normalled to an

input module, or to external mic processing .

When a mic processor with only a microphone

level input is used, the microphone is connected

directly to the mic processor , with the processor ’s

line-level output either directly connected to an

input module (using the mono wiring pinout

shown below) or through a patch bay normalled

to an input module.

Two-Channel (Ster e o)

Line Input or Output — 6-Pin Housing

Pin Signal Description

1 Shield for the left channel, or signal 1

2 Low (- input or output), left channel, or signal 1

3 High (+ input or output), left channel, or signal 1

4 Shield for the right channel, or signal 2

5 Low (- input or output), right channel, or signal 2

6 High (+ input or output), right channel, or signal 2

Single Channel (Mono)

Line Input — 6-Pin Connector

Pin Signal Description

1 Shield (connects directly to the chassis)

2 Low (- input) tied to pin 5

3 High (+ input) tied to pin 6

4 Shield (connects directly to the chassis)

5 Low (- input) from pin 2

6 High (+ input) from pin 3

2-9

HARRIS CORPORATION

Revision C • 1/04

Page 22

digital

2 Installation

Microphone Input — 3-Pin Connector

Pin Signal Description

1 Shield (connects directly to the chassis)

2 Low (- input)

3 High (+ input)

Digital Connections

Digital inputs and outputs are wired like the

Microphone Input shown above.

The Universal Input, RLS and Telco/Codec modules have digital inputs. The three-pin digital inputs accept AES-3 (AES/EBU) compatible signals,

and as mentioned in the Unbalanced Connections

section that follows, can also accept

S/PDIF signals in most cases.

Each Output module has multiple digital outputs. Each outputs an AES-3 compatible signal.

Note: The digital outputs cannot connect directly to an S/PDIF input. A signal translation

interface is required.

AES/EBU Digital Inputs and

External Clock Reference Input

Pin Signal Description

1 Shield (connects directly to the chassis)

2 Low (- input)

3 High (+ input)

AES/EBU Digital Outputs

Pin Signal Description

1 Shield for AES/EBU signal

2 Low (- output)

3 High (+ output)

If a match box is not available, connect an un-

digital

balanced device to a BMX

input using the

following illustration.

Connecting an Unbalanced Device

to a BMXdigital Analog Input

From the

Unbalanced

Device

R

L

Shields

Console

Balanced

Input

6

3

5

2

4

1

When an unbalanced device must be connected

digital

to a BMX

balanced analog output, and an

IHF-PRO match box is not available, do not tie

the low (-) and shield pins together to “unbalance”

the signal. The low output pin must always be left

digital

“floating” when unbalancing a BMX

out-

put, as shown in the following illustration.

Connecting an Unbalanced Device

to a BMXdigital Analog Output

(Nominal Output is -2 dBu)

Console

Balanced

Output

3

6

2

5

1

4

(Make no connections to pins 2 & 5)

To the

Unbalanced

Device

L

R

Shields

UNBALANCED CONNECTIONS

Although all analog inputs and outputs are

active and balanced, unbalanced consumer or

“semipro” equipment can be connected to the console. For best results, connect an unbalanced device through an IHF-PRO match box and keep

the unbalanced cable lengths as short as possible.

HARRIS CORPORATION

2-10

Revision C • 1/04

S/PDIF Signals

Digital devices with only an S/PDIF digital output can connect to a BMX

when a 249 ohm resistor is used to load the 75

ohm S/PDIF cable. Install the resistor at the AMP

MOD IV housing per the illustration on the next

page.

digital

input, but only

Page 23

digital

2 Installation

Connecting an S/PDIF Device to

a BMXdigital AES/EBU Input

From

S/PDIF

Device

Signal

Shield

249 ohm resistor

Console

AES/EBU

Input

3

2

1

An unbalanced-to-balanced line transformer can

also be used to interface an S/PDIF signal.

Note 1: A signal conversion interface must be

used to connect an AES/EBU output to a S/PDIF

input.

Note 2: Some S/PDIF signals may not work with

digital

the BMX

’s inputs, even with the additional

load resistor or a transformer , because of nonstandard levels or protocols in the S/PDIF product.

DIGITAL CLOCK REFERENCE

The BMX

rate timing, with sample rate converters on each

input to synchronize/convert external digital signals to the console’s internal 48 kHz sample rate.

The console can synchronize to an external AES3 digital reference signal (of 48 kHz, ±100 ppm

only) when using the optional Ext. Input DSP card

(99-1356-1). A 3-pin connector on the card has a

green LED next to it to indicate whether the internal or external reference is active. When a valid

external reference signal is present, the LED is

off. If the LED is still lit with an external signal

connected, it indicates the reference signal is not

present or is out of range.

Heartbeat LED —

Flashes to indicate the

DSP is good.

digital

has an internal clock for sample

DSP Card Features

External Input and LED —When

unlit, indicates the console is

using the External reference.

(optional connection)

Thumbscrews

LOGIC CONNECTIONS

BMX

digital

modules have built-in logic I/O interfaces that can control, or be controlled by,

peripheral devices connected to the console. For

example, a CD player connected to a module can

be automatically started when the module is

turned on. Then, at the end of the cut, the CD

Player logic can turn the module audio off and

control the off button illumination to indicate that

the cut has been played.

When a mic remote control panel is connected,

its On, Off, Cough and Talkback buttons control

the module while tally outputs from the module

control the button tallies on the mic panel.

digital

BMX

connectors:

• Universal Input modules have two MAIN

connectors for the devices connected to the

A and the B inputs and two T/B OPTION

connectors for separate talkback control for

the A and B mic inputs.

• Telco/Codec and RLS modules have a

single LOGIC I/O connector for the device

connected to the module.

• The Session module has three EXT TIMER

connectors for resetting studio or producer

timers, a D AT A (RJ-45) connector for connecting the console to a local LAN and the

connectors for the factory-installed wiring

that ties the mainframe to the meter panel.

• The Control Room module has a LOGIC

connector for the warning light, mute, dim,

and talkback. A CUE CNTL connector allows external cue input control.

• The optional Studio module has two

LOGIC connectors for dim, mute, and warning indications and two talkback connectors (PRODUCER and EXTERNAL).

• The Output 1 module has a PRODUCER

IFB LOGIC connector.

modules have the following logic

2-11

HARRIS CORPORATION

Revision C • 1/04

Page 24

digital

2 Installation

MODULE QUICK GUIDES

Pages 2-16 to 2-57 have Quick Guides to configuring logic connections and DIP switch settings.

Each guide covers the audio and logic connector

pinouts and signal descriptions, DIP switch setting definitions, and, for some modules, logic block

diagrams. The Module Quick Guides:

• Mic Preamp: pages 2-16 & 2-17

• Universal Input: pages 2-18 to 2-23

• Telco/Codec: pages 2-24 to 2-27

• RLS: pages 2-28 to 2-31

• Session: pages 2-32 & 2-33

• Control Room: pages 2-34 to 2-38

• Studio: pages 2-40 to 2-49

• Output 1: pages 2-50 to 2-53

• Output 2: pages 2-54 & 2-55

• Output 3: pages 2-56 & 2-57

Note: T here are four versions of each Input module: full-featured (shown in the Quick Guides); limited-function modules (without the Utility or Send

bus controls); and full-featured or limited-featured

Net-only modules (which have no input and logic

connectors).

Pages 2-58 to 2-63 show examples of typical

logic connections to the Universal Input module

from a mic remote control panel, a CD pla yer and

a digital delivery system. Pages 2-64 thru 2-66

cover the Net Card and Net-Only modules.

Note: F or complete isolation of the console and

a peripheral device, use only the opto-isolated control connections. Both logic ground and +5 VDC

are referenced to the console’s power supply and

ground and should only be connected to isolated

devices like mic control panels or other Harris Accessory Panels. Connecting logic ground to a nonisolated device may result in a ground loop between the console and the peripheral device.

HARRIS CORPORATION

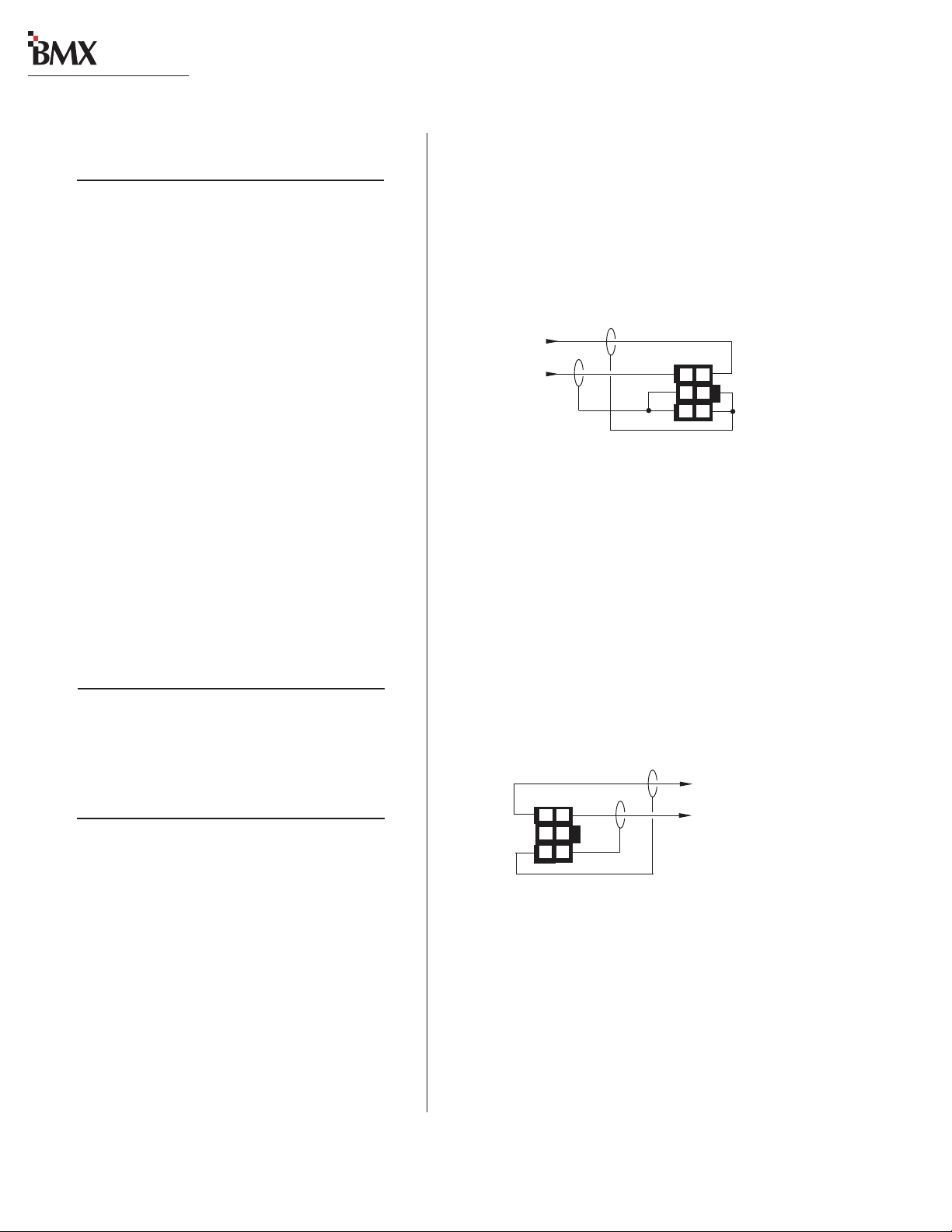

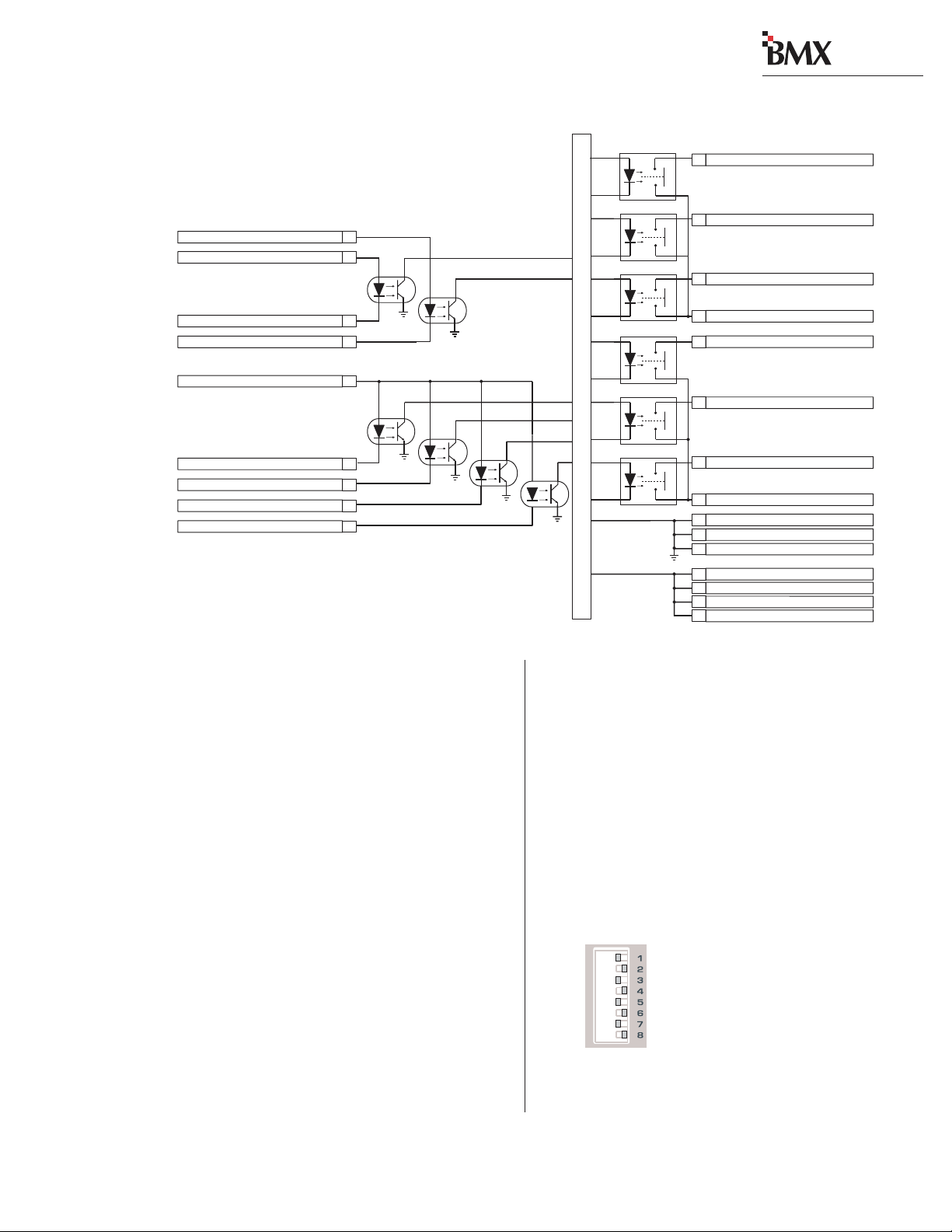

UNIVERSAL LOGIC INTERFACE

A block diagram of the Universal Input module

logic interface is shown on page 2-13. Logic outputs (shown on the right side of the illustration)

are isolated from the peripheral device by six solidstate “relays. ” T he “relay contacts” can switch logic

voltages of up to 60 volts at 350 mA.

Pressing the On button generates a 220 ms contact closure from pin 5 (Start Command Pulse). A

sustained contact closure while On is available on

pin 23 (Start Command Sustained). It stays closed