Page 1

DOCUMENT REV CN

780-0867

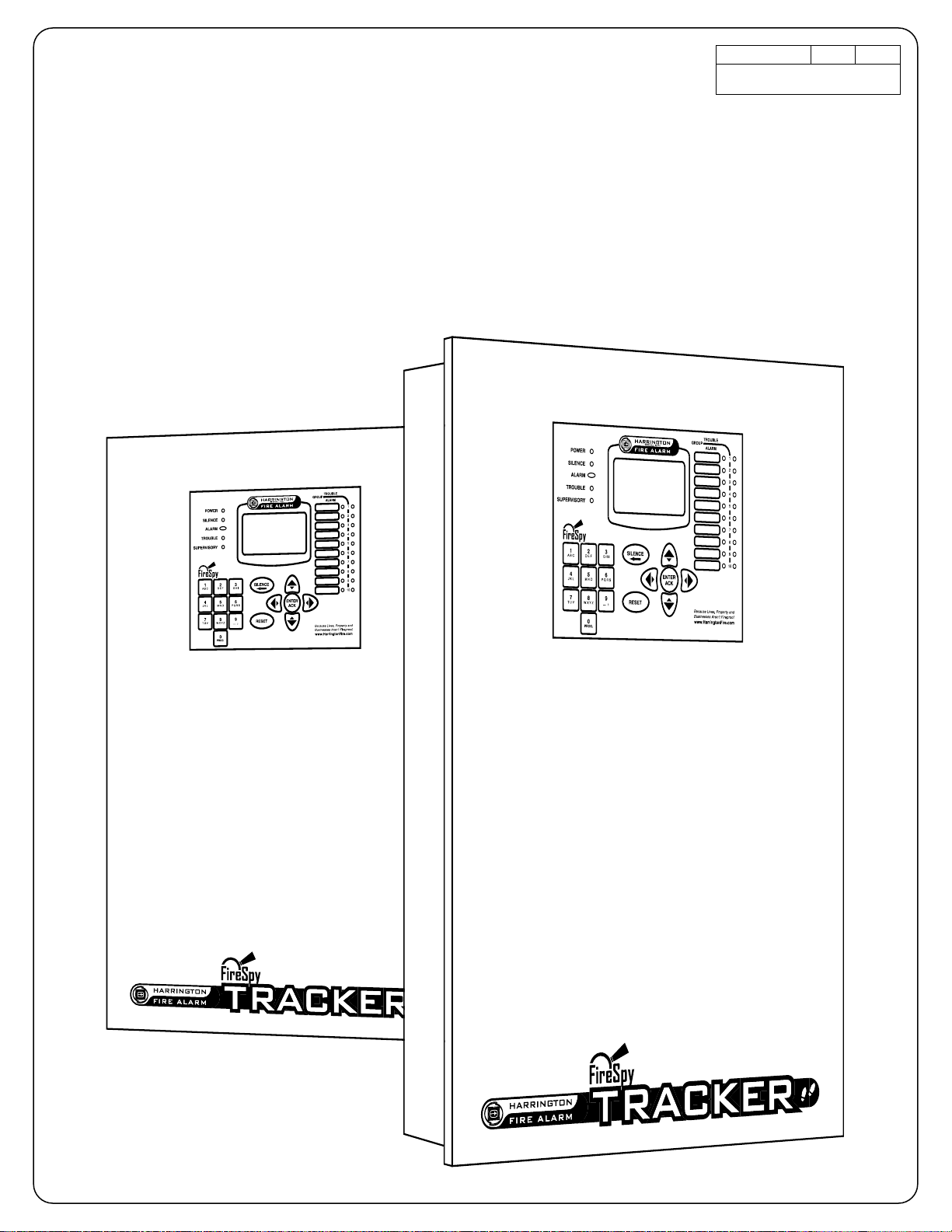

Installation Manual

FireSpy® Tracker T1000, T2000, T8000, T2000E

Fire Alarm Systems

C

1012

Page 2

Page 3

HSI #780-0867 FireSpy Tracker Installation Manual

Contents

1 Preliminary Information .........................................................1

Contents

1.1 Safety messages – Please read before proceeding..................................................................1

1.2 Warranty ........................................................................................................................................2

1.3 Support..........................................................................................................................................2

2 Overview..................................................................................3

2.1 General ..........................................................................................................................................3

2.2 System layout ...............................................................................................................................4

2.2.1 Standalone panel ....................................................................................................................4

2.2.2 Multiple panel network.............................................................................................................4

2.3 System components.....................................................................................................................5

2.3.1 Main circuit board assembly (T1-MB, T8000-MBC, T2000-MBCLC)......................................5

2.3.2 Display board (T-PDC)............................................................................................................8

2.3.3 Network Communications adapter (T8000-NCA)....................................................................8

2.3.4 LCD annunciator (T8000-RAN / -ANN)...................................................................................9

2.3.5 Graphic annunciator................................................................................................................9

2.3.6 Addressable Signaling Line Circuit (SLC) module (T8000-LCU)............................................9

2.3.7 Conventional zone module (T8000-CM) ...............................................................................10

2.3.8 Relay module (T8000-RC) ....................................................................................................11

2.3.9 Serial relay module (T8000-SRM).........................................................................................11

2.3.10 DACT communicator module (T-UDACT).............................................................................11

2.3.11 Audio evacuation modules ....................................................................................................12

2.3.12 City tie/reverse polarity communicator (UCT) .......................................................................12

2.3.13 Enclosures.............................................................................................................................13

2.4 Service use..................................................................................................................................14

2.5 Listings and approvals ..............................................................................................................14

1

2

3

A

B

C

3 Installation and Wiring.........................................................17

3.1 System planning.........................................................................................................................17

3.1.1 Battery calculation.................................................................................................................17

3.2 Control panel installation ..........................................................................................................17

3.2.1 Preparation............................................................................................................................17

3.2.2 Panel location........................................................................................................................17

3.2.3 Installation .............................................................................................................................18

3.3 Configuration and programming ..............................................................................................19

3.4 Check system operation ............................................................................................................19

Appendix A. Ordering and Parts Information.........................29

A.1 Component matrix......................................................................................................................29

A.1.1. Available panel configurations (factory pre-wired) ................................................................29

A.1.2. Board modules ......................................................................................................................29

A.1.3. Enclosures.............................................................................................................................30

A.1.4. Accessories...........................................................................................................................30

Appendix B. Compatible Devices............................................31

B.1 Startup delay for devices with alarm verification....................................................................31

i

D

Page 4

HSI #780-0867 FireSpy Tracker Installation Manual

B.2 Addressable SLC devices (for use with T8000-LCU, T2000-MBCLC, and T1-MB)...............31

B.2.1. System Sensor......................................................................................................................31

B.2.2. Harrington Signal...................................................................................................................32

B.2.3. Apollo.....................................................................................................................................34

B.2.4. Air Products...........................................................................................................................34

B.3 Conventional two-wire smoke detectors (for use with T8000-CM)........................................35

B.3.1. Harrington Signal...................................................................................................................35

Contents

B.3.2. Apollo.....................................................................................................................................35

B.3.3. ESL/Sentrol ...........................................................................................................................37

B.3.4. System Sensor......................................................................................................................37

B.4 Releasing devices (for use with a NAC on MB / MBC / MBCLC) ...........................................37

Appendix C. Wire Selection .....................................................39

C.1 General wiring guidelines..........................................................................................................39

C.2 Wire length calculations ............................................................................................................39

C.3 Wire selection tables..................................................................................................................40

Appendix D. Battery Capacity Calculation .............................45

ii

Page 5

HSI #780-0867 FireSpy Tracker Installation Manual

1 Preliminary Information

1.1 Safety messages – Please read before proceeding

People’s lives depend on your safe installation of our products. It is important to read, understand and

follow all instructions shipped with this product. The equipment described herein is listed by the NRTL

only when installed and configured in the manner described herein

It is possible to install equipment incorrectly or arrange system components and installation wiring in such

a manner that life safety functions are not properly performed and, as a result, lives may be lost. To

minimize this possibility, become familiar with the system layout and operation of the entire FireProtective Signaling System. Do not alter any mechanical or electrical features of the equipment supplied.

Become familiar with the Building Code and Fire Prevention Code or other authority having jurisdiction

requirements in the area of the installation.

The Facilities Engineer and the Safety Engineer should make selection of mounting location for this

equipment and routing of wiring. Listed below are some other important safety instructions and

precautions you should follow:

• This unit must be installed by a qualified electrician in accordance with NFPA 72, and national and

local electrical and fire codes, under the direction of the authority having jurisdiction.

• Only authorized and competent personnel must be allowed access to panel controls or panel power

source, to limit the possibility of malfunction or failure.

• Do not connect this unit to system wiring when circuits are energized. Check field wiring lines to

ensure that voltages are not present. Warranty is void if the equipment is damaged by improperly

connected untested wiring or if fused improperly.

• The equipment must be connected to a dedicated source of reliable AC power adequate for the rating

of the system as configured. The source must be secure and properly labeled "Fire Alarm Circuit

Control".

• A suitable battery set must be used to assure required operation in case of primary power loss. The

battery set must be replaced after 4 years, or earlier if capacity is excessively reduced. The batteries

should be checked at least twice per year, or more often if required by local codes.

• Wiring used in the system must be adequate for the service and installed in accordance with

applicable codes.

• Devices used in the system and connected to the control panel must be verified compatible with the

panel.

• All effective warning speakers produce loud sounds which, in certain circumstances, may cause

permanent hearing loss. Take appropriate precautions such as wearing hearing protection.

Recommendations in OSHA Sound Level Standard (29 CFR 1910) should not be exceeded.

• After installation and completion of initial system test, provide a copy of this instruction sheet to all

personnel responsible for operation, periodic testing and maintenance of this equipment.

• After installation, ensure that all bolts and threaded joints are tightened.

• After installation and completion of initial system test, a program for periodic testing of this device

must be established. Proper periodic maintenance is required to assure operation through the life of

the system, and to determine that point at which useful life of the system or of any of its components

has been reached. Any malfunctioning units must be repaired or replaced immediately by competent,

authorized personnel. Refer to NFPA 72, local Fire Codes and the authority having jurisdiction.

• Instructions for proper response by building occupants must be developed and distributed in

accordance with the Building Code and Fire Prevention Code or other authority having jurisdiction.

• Unauthorized repair or servicing of equipment may result in degradation of performance and/or

property damage, serious injury, or death to you or others. If a malfunctioning unit is encountered, do

not attempt any field repair/retrofit of parts.

Failure to follow all safety precautions and instructions may result in property damage, serious injury, or

death to you and others.

1

2

3

A

B

C

D

1

Page 6

1

HSI #780-0867 FireSpy Tracker Installation Manual

The programming technician is ultimately responsible for conformance to the applicable codes and

purchase order.

This manual cannot cover all details or contingencies which could exist in a system application. Refer to

the authorized distributor if additional information is required.

Specifications are subject to change without notice.

Contents

1.2 Warranty

Harrington Signal products are covered by a limited warranty. See Harrington’s warranty statement for

more details (document #780-0762)

1.3 Support

If you have any questions or concerns about installation, operation, or programming of our equipment,

please contact us at:

Harrington Signal Inc.

2519 – 4th Ave

Moline, IL 61265

Toll Free: (800) 577-5758

Tel: (309) 762-0731

Fax: (309) 762-8215

Email: techservices@harringtonsignal.com

Web: www.harringtonfire.com

FireSpy is a registered trademark of Harrington Signal Inc.

This document is copyright © 2009 Harrington Signal Inc.. All rights reserved.

2

Page 7

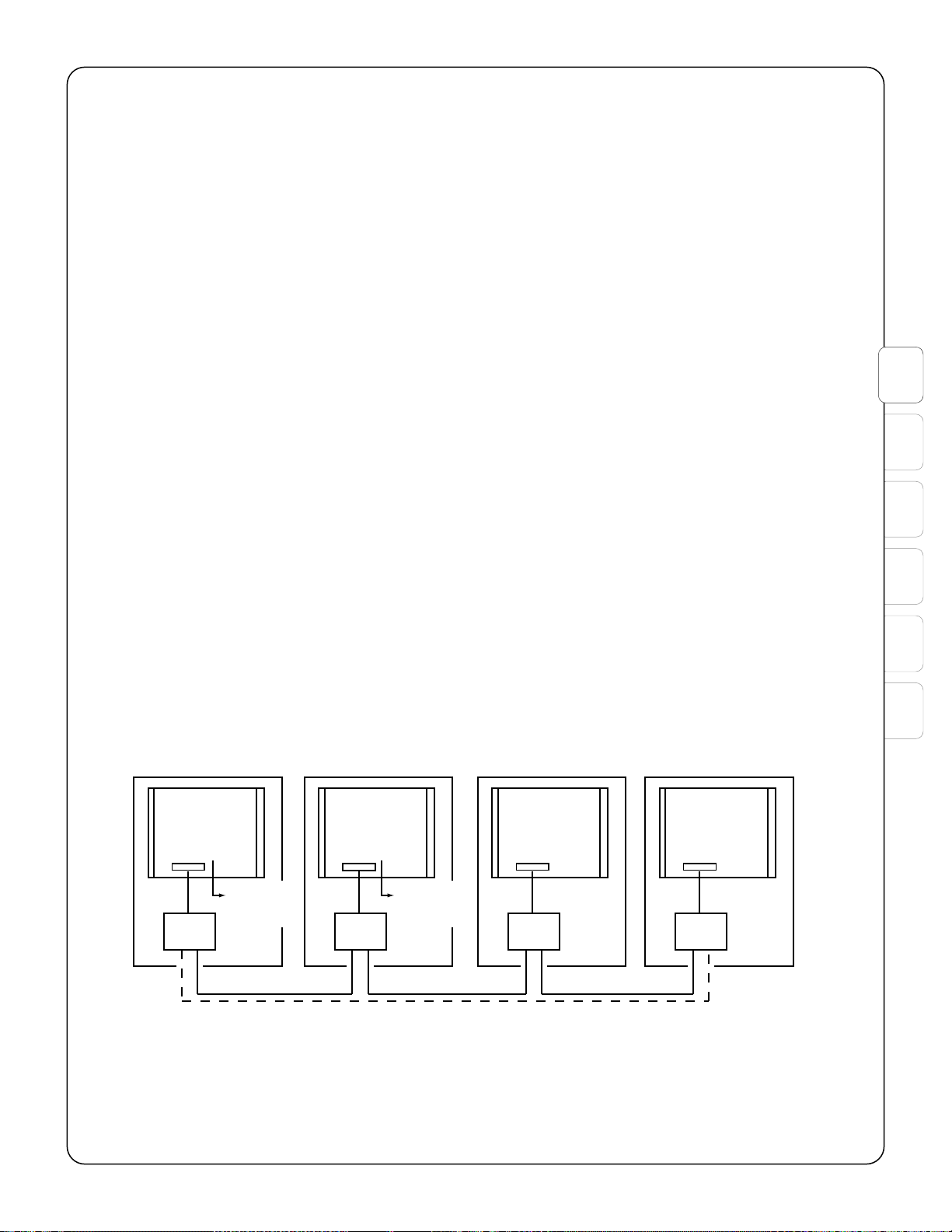

HSI #780-0867 FireSpy Tracker Installation Manual

290-0103

NETWORK WIRING (RS485)

LOW CAPACITANCE TWISTED PAIR OR FIBER

DAISY-CHAIN ONLY, DO NOT T-TAP

STYLE 4 (CLASS B): SOLID LINE

STYLE 7 (CLASS A): SOLID AND DOTTED LINES

MASTER PANEL

T8000*

MASTER PANEL LOCAL PANEL LOCAL PANEL

NCA

RS485

NCA

RS485

NCA

RS485

NCA

RS485

REPORTING

EQUIPMENT

(OPTIONAL)

REPORTING

EQUIPMENT

(OPTIONAL)

MB, MBC, or

MBCLC

MB, MBC, or

MBCLC

MB, MBC, or

MBCLC

MBC

* AT LEAST ONE T8000 MASTER PANEL IS REQUIRED.

TOTAL COMBINATION OF MASTER AND

LOCAL PANELS NOT TO EXCEED 254 PANELS.

2 Overview

2.1 General

The FireSpy Tracker series panels are sophisticated microprocessor-based fire alarm control systems

suited to the various needs of commercial, industrial and institutional applications. The Tracker panel can

connect to a Tracker network, a peer-to-peer network of up to 250 Tracker panels. Up to 254 points on

each Signal Line Circuit (SLC) and up to 60 conventional fire detector zones can be configured. The

distributed system architecture reduces the length of wiring needed because addressable SLC,

conventional IDC, and other modules can be located closer to where devices are installed.

The Tracker panel functions in accordance with the National Fire Protection Association (NFPA)

Standard 72 Fire Alarm Code. Activation of a compatible detector or normally open fire alarm initiating

device will sound audible appliances, notify a remote station, annunciate a fire or alarm condition, and

energize supplementary relays.

Automatic learning features can be used to quickly configure a system. Additional system configuration

can be done through the annunciator or with a PC.

The Tracker 8000 allows up to eight SLCs for a total of 2032 addressable points. The SLCs are provided

by the use of modular SLC boards, which may be mounted in the main enclosure or remotely.

The Tracker 2000 main board (MBCLC) has two SLCs for a total of 508 addressable points.

The Tracker 1000 main board (MB) has one SLC for a total of 254 addressable points.

The Tracker T2000E combines the Tracker 2000 fire alarm control panel and the HAVE audio voice

evacuation systems into one convenient package. In addition to the features of the T2000, it also provides

conventional audio with up to 8 Class B speaker circuits (or up to 4 Class A) with amplification for 25, 50

or 100 watts. Within this manual, references to the T2000 also apply to the fire alarm portion of the

T2000E (the MBCLC main board).

2

3

A

B

C

D

Figure 2-1: Peer-to-peer network layout

3

Page 8

1

T1000

SYSTEM

(TO NETWORK)

TO PC

290-0158

* MAY BE INDIVIDUALLY CONFIGURED AS NAC, AUX POWER, OR INPUT

** MAY BE CONFIGURED AS NAC (FOR CONNECTION TO NAC BOOSTER OR VOICE MODULE) OR INPUT

A SYSTEM MUST USE AT LEAST ONE INITIATING DEVICE

MAIN BOARD ASS'Y

MB

RS485

(3) NACs*

(1) SLC

RELAY CONTACTS

(8) PER SRM

PHONE LINES

TO CENTRAL

OR REMOTE

STATION

RELAY

CONTACTS

(2) PER RC

RELAY CONTACTS

(2) PER RC

ANN

(7) MAX

IDC

(5) CLASS A OR

(10) CLASS B

PER CM

RC

(5) MAX

PER CM

CM

(6) MAX

SRM

(6) MAX

250 OUTPUTS

PER LDV

(250 TOTAL

CONFIGURABLE)

LDV

(4) MAX

RC

(5) MAX

USB

RELAY CONTACTS:

(1) SYSTEM ALARM

(1) SYSTEM SUPV ALARM

(1) SYSTEM TROUBLE

NCA

ANNUNCIATOR

(MOUNTED ON

MAIN CABINET

DOOR)

(1) AUX I/O**

1

2

3

4

5

6

7

8

9

10

SILENCE

POWER

ALARM

TROUBLE

SUPERVISORY

1

2

3

4

5

6

7

8

9

10

SILENCE

POWER

ALARM

TROUBLE

SUPERVISORY

2

HSI #780-0867 FireSpy Tracker Installation Manual

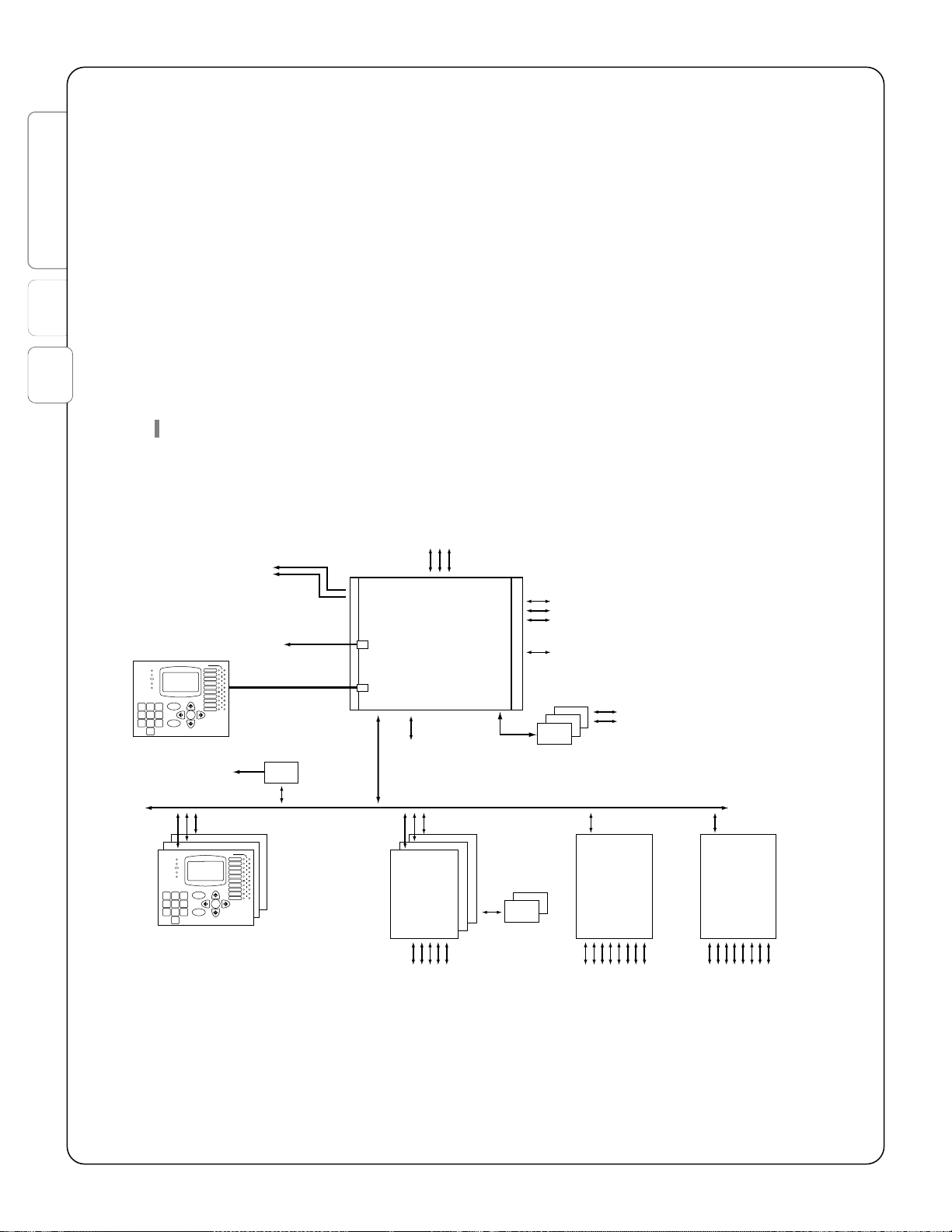

2.2 System layout

2.2.1 Standalone panel

A Tracker panel consists of the main board (MB for T1000, MBC for T8000 or MBCLC for T2000) in the

main enclosure and various devices that connect to the main board (see Figure 2-2). System

programming can be done from a PC or laptop through the serial port of the panel’s communications

Contents

adapter.

2.2.2 Multiple panel network

A Tracker network consists of multiple Tracker panels with each panel connected to the network through

a communications adapter (see 2.3.3 Network Communications adapter (T8000-NCA)). Local network

devices (annunciators, etc.) connect to the RS485 outputs of each panel, as they would in a standalone

panel. Each panel provides the same capabilities as it would as a standalone panel, with the addition of

the network connection. System programming can be done from a PC or laptop through the serial port of

the panel’s communications adapter.

NOTE: A Tracker network must include at least one T8000 panel, set up as master.

Figure 2-2: System layout (T1000)

4

Page 9

HSI #780-0867 FireSpy Tracker Installation Manual

T2000

,

T8000

SYSTEM

* MAY BE INDIVIDUALLY CONFIGURED AS NAC, AUX POWER, OR INPUT

A SYSTEM MUST USE AT LEAST ONE INITIATING DEVICE

(TO NETWORK)

TO ONE OF:

- PRINTER (straight cable)

- MODEM (straight cable)

TO PC

290-0104

(2) SLCs

T2000 ONLY

MAIN BOARD ASS'Y

MBC (T8000) OR

MBCLC (T2000)

RS485

(4) NACs*

RELAY CONTACTS

(8) PER SRM

PHONE LINES

TO CENTRAL

OR REMOTE

STATION

RELAY

CONTACTS

(2) PER RC

RELAY CONTACTS

(2) PER RC

SLC

(2) PER LCU

ANN

(15) MAX (T8000)

(7) MAX (T2000)

IDC

(5) CLASS A OR

(10) CLASS B

PER CM

RC

(5) MAX

PER CM

CM

(6) MAX

SRM

(6) MAX

UDACT

250 OUTPUTS

PER LDV

(250 TOTAL

CONFIGURABLE)

LDV

(4) MAX

RC

(5) MAX

LCU

(4) MAX

RS232

USB

RELAY CONTACTS:

(1) SYSTEM ALARM

(1) SYSTEM SUPV ALARM

(1) SYSTEM TROUBLE

NCA

T8000 ONLY

1

2

3

4

5

6

7

8

9

10

SILENCE

POWER

ALARM

TROUBLE

SUPERVISORY

1

2

3

4

5

6

7

8

9

10

SILENCE

POWER

ALARM

TROUBLE

SUPERVISORY

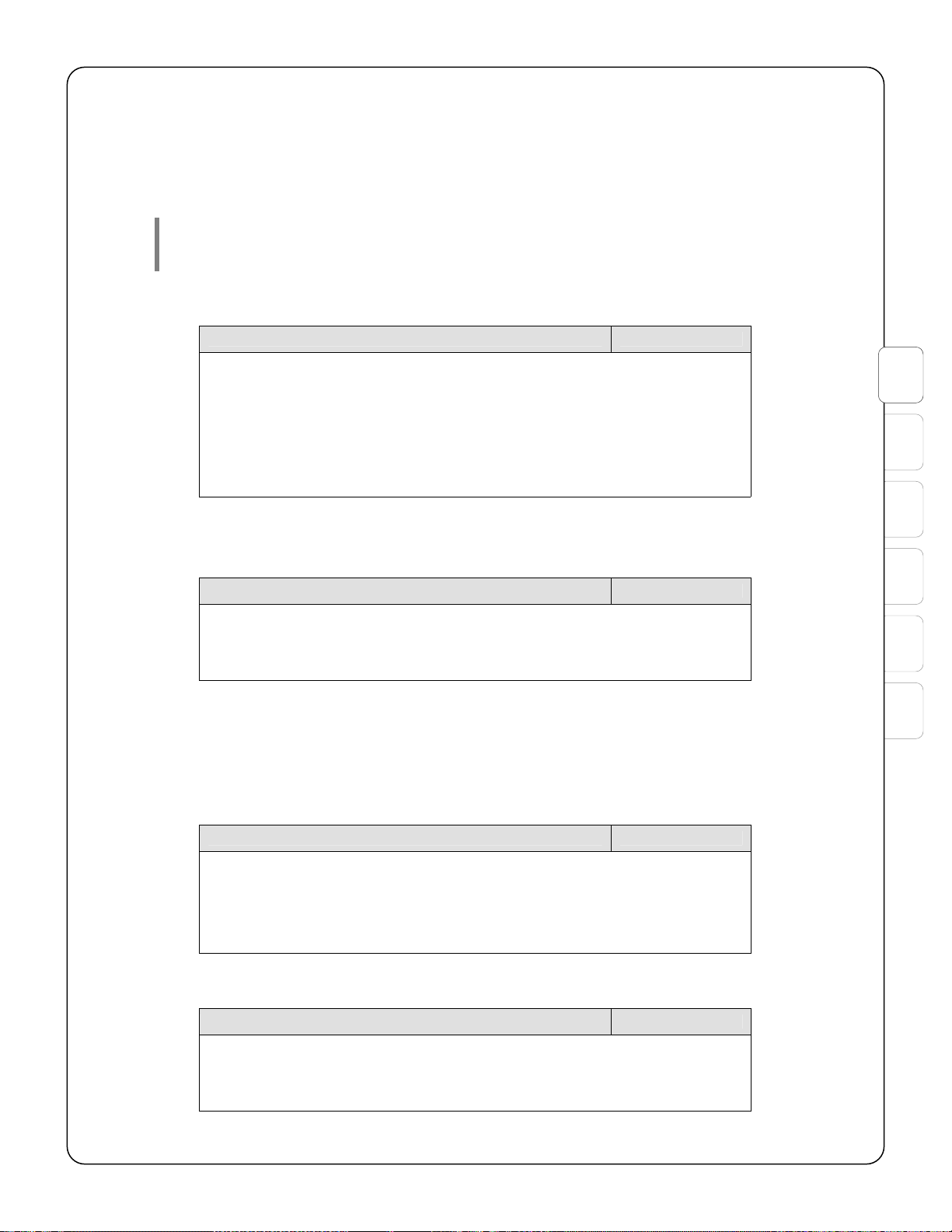

2.3 System components

The Tracker is a modular system. Each module may be purchased and installed separately. Some

common system configurations are also available pre-assembled at the factory.

2.3.1 Main circuit board assembly (T1-MB, T8000-MBC, T2000-MBCLC)

The main circuit board assembly (T1-MB, T8000-MBC or T2000-MBCLC) is the core of the Tracker panel.

It contains the main board and power supply mounted on a metal chassis. The MB / MBC / MBCLC

mounts in the main panel enclosure.

The T1-MB, T8000-MBC and T2000-MBCLC are respectively referred to as MB, MBC and MBCLC in this

manual.

2

3

A

Figure 2-3: System layout (T2000, T8000)

5

B

C

D

Page 10

1

2

HSI #780-0867 FireSpy Tracker Installation Manual

Table 2-1: Power supply specifications (MBC/MBCLC).

Parameter Rating

Input voltage (AC supply) 120VAC @ 50/60Hz

Input current draw (AC supply) 1.8A @ 120VAC

Contents

24VDC power available (total system current) and max battery load 7A

Battery charge voltage, max 27.6V

Battery charge current, max 1.6A

Battery capacity

Min

Max

Use two UL864 listed 12V batteries connected in series.

Table 2-2: Power supply specifications (MB).

Parameter Rating

Input voltage (AC supply) 120VAC @ 50/60Hz

Input current draw (AC supply) 1.8A @ 120VAC

24VDC power available (total system current) and max battery load 4A

Battery charge voltage, max 27.6V

Battery charge current, max 1.6A

Battery capacity

Min

Max

Use two UL864 listed 12V batteries connected in series.

230VAC @ 50/60Hz

0.4A @ 230VAC

8Ah

40Ah

240VAC @ 50/60Hz

2.15A @ 240VAC

7Ah

40Ah

Table 2-3: Environmental specifications (MB / MBC / MBCLC).

Parameter Rating

Environment

UL864 location

Temperature range

Maximum relative humidity

Indoor, dry

32 to 120° F

93%

Table 2-4: RS-485 specifications (MB / MBC / MBCLC).

Parameter Rating

Output voltage (MBC / MBCLC) 24VDC

Max output current (MBC / MBCLC) 2.5A

Max impedance, RS-485 wiring* 100 ohms

Max capacitance, RS-485 wiring* .3uF

Max impedance, power wiring, total (3V drop each wire @ 80mA)*

(MBC / MBCLC)

* See Appendix C Wire Selection for suggested wiring distances.

75 ohms

6

Page 11

HSI #780-0867 FireSpy Tracker Installation Manual

The main circuit board contains 4 circuits (3 for MB) that can be individually programmed to operate in the

following modes:

• NAC (steady, temporal coding, or march time coding, Gentex 1 synchronization for Commander 3

and 4, Gentex 2 synchronization for Commander 1)

• Auxiliary power supply (resettable or continuous)

• Auxiliary input

NOTE: UL864 requires audible alarm notification devices to be synchronized on a

circuit or a system basis. If using notification appliances other than Gentex

Commander 1, 3, or 4, synchronization modules must be used.

Table 2-5: NAC specifications (output modes) (MB / MBC / MBCLC)

Parameter Rating

Output voltage 24VDC

Output current, max

MBC / MBCLC

MB

Wiring styles (NAC mode) Style Y (Class B)

End-of-line resistance (NAC mode, Class B) 10k ohm

* See Appendix C Wire Selection for suggested wiring distances.

3A

1.8A

Style Z (Class A)

2

3

A

Table 2-6: NAC specifications (input mode) (MB / MBC / MBCLC)

Parameter Rating

Input voltage (input mode) 24VDC

Input current draw, max (input mode), inherently power limited 5mA

End of line resistance (input mode) 10k

The MB contains an auxiliary input/output circuit that can be used in a NAC mode or as an input. The

NAC mode can be used to activate an external NAC-driven device, such as a NAC power supply or

HAVE voice evacuation system. The AUX IO port provides alarm activation, silencing and resound

operation.

Table 2-7: AUX IO specifications (output mode) (MB)

Parameter Rating

Output voltage 24VDC

Output current, max 0.02A

Wiring styles Style Y (Class B)

End-of-line resistance 10k ohm

Table 2-8: AUX IO NAC specifications (input mode) (MB)

B

C

D

Parameter Rating

Input voltage (input mode) 24VDC

Input current draw, max (input mode), inherently power limited 5mA

End of line resistance (input mode) 10k

7

Page 12

1

HSI #780-0867 FireSpy Tracker Installation Manual

The main board contains (1) common alarm relay output, (1) common supervisory alarm relay output, and

(1) common trouble relay output, as well as a connection for up to (5) relay modules (T8000-RC).

Table 2-9: Output relay specifications (MB / MBC / MBCLC)

Parameter Rating

Type Form C (SPDT)

Contents

Contact rating

MBC / MBCLC resistive load, PF=1.0

inductive load, PF=0.4

MB resistive load, PF=1.0

* Limited to 50VDC due to spacing

10A @ 30VDC

10A @ 240VAC*

3A @ 240VAC*

2A @ 30VDC

2

Table 2-10: SLC specifications (MB / MBCLC)

Parameter Rating

Loop output voltage 32V @ 10kHz

Max loop output current 400mA max

Max loop capacitance 0.5uF

Max loop impedance (total per loop) 40 ohms

Environment

UL864 location

Temperature range

Maximum relative humidity

* See Appendix C Wire Selection for suggested wiring distances.

Indoor, dry

32 to 120° F

93%

2.3.2 Display board (T-PDC)

The display board may mount either inside the enclosure door so its buttons are accessible with the door

closed or on the chassis assembly (MBC or MBCLC only) so it is accessible after unlocking and opening

the enclosure. When the PDC is mounted on the door and connected to the keyswitch, the keyswitch

must be activated to enable keypad access to the system’s security-sensitive control functions.

2.3.3 Network Communications adapter (T8000-NCA)

The network communications adapter is used with each panel in a networked system. It allows the

connected panel to communicate with other panels on the panel network.

Table 2-11: Communications adapter (T8000-NCA) specifications.

Parameter Rating

Input voltage Regulated 24 DC

Input current draw 60 mA

Max impedance, RS485 communication wiring, total 40 ohms*

Max capacitance, RS485 communication wiring 0.3 uF*

Environment

UL864 location

Temperature range

Maximum relative humidity

* See Appendix C Wire Selection for suggested wiring distances.

Indoor, dry

32 to 120° F

93%

8

Page 13

HSI #780-0867 FireSpy Tracker Installation Manual

2.3.4 LCD annunciator (T8000-RAN / -ANN)

The Tracker 8000 allows up to 15 remote display annunciators (Model T8000-ANN or T8000-RAN). The

T2000 and T1000 allow up to 7 remote annunciators. The T8000-ANN remote annunciator is intended for

surface or flush mounting and is comprised of the T8000-RAN module within the T8000-A-CAB cabinet.

Table 2-12: Remote annunciator (T8000-RAN/T8000-ANN) specifications.

Parameter Rating

Dimensions (backbox of T8000-ANN) 8.5H x 10W x 2D

Input voltage 24VDC

Input current draw

Standby

Alarm, without backlight

Alarm, with backlight (10 seconds after key press)

Max impedance, power wiring, total (3V drop each wire @ 80mA)* 75 ohms

Environment

UL864 location

Temperature range

Maximum relative humidity

* See Appendix C Wire Selection for suggested wiring distances.

(inches)

19mA

25mA

80mA

Indoor, dry

32 to 120° F

93%

2

3

A

2.3.5 Graphic annunciator

A graphic annunciator module (T8000-LDV) is for use in appropriately UL864 Listed custom enclosures to

provide graphic annunciator capabilities. The module may be configured to use either LED or

incandescent lamps; either type of output is supervised. Up to 4 lamp annunciator modules may be used

for a total of 250 programmable outputs per Tracker panel. Additionally, each module has outputs for

power on, common alarm and common trouble visual indicators and a sounder.

Table 2-13: Lamp annunciator module (T8000-LDV) specifications.

Parameter Rating

Input voltage 24VDC

Input current draw

Standby (no devices)

Alarm (full load)

Max impedance, RS-485 wiring* 100 ohms

Max impedance, power wiring, total (3V drop each wire @ ?? mA)* ?? ohms

Environment

UL864 location

Temperature range

Maximum relative humidity

* See Appendix C Wire Selection for suggested wiring distances.

TBD

Indoor, dry

32 to 120° F

93%

B

C

D

2.3.6 Addressable Signaling Line Circuit (SLC) module (T8000-LCU)

The Tracker panel monitors addressable fire detection devices that are connected to up to (4) loop

modules (T8000-LCU).

Each loop module provides the following:

• Two Signaling Line Circuits (SLCs).

• Up to 254 addressable analog devices can be installed on any loop (limited by device protocol).

9

Page 14

HSI #780-0867 FireSpy Tracker Installation Manual

• Compatible with System Sensor, Apollo, Harrington and Air Productsdevices (see Appendix B for

details).

• Mounts in the main enclosure or remotely (see Table 2-20)

Table 2-14: Addressable SLC module (T8000-LCU) specifications.

1

2

Contents

Parameter Rating

Input voltage 24V

Input current draw

Standby (no devices)

Alarm (full load)

Max impedance on 24VDC input wiring (per side) 2 ohms

Loop output voltage 25V

Max loop output current 400mA max

Max loop capacitance 0.5uF

Max loop impedance (total per loop) 100 ohms

Environment

UL864 location

Temperature range

Maximum relative humidity

* See Appendix C Wire Selection for suggested wiring distances.

2.3.7 Conventional zone module (T8000-CM)

The Tracker panel monitors conventional fire detection devices that are connected to conventional zone

modules (T8000-CM). Each zone module provides 5 Class A zones or 10 Class B zones for FireSpy

conventional devices. Zone modules may be mounted in the main enclosure or in remote enclosures.

107mA

Indoor, dry

32 to 120° F

93%

Table 2-15: Conventional IDC module (T8000-CM) specifications.

Parameter Rating

Input voltage 24V

Input current draw

Standby (no detectors)

Alarm, base module current

Alarm, each additional zone in alarm*

Max impedance, power wiring, total (3V drop each wire) 6V divided by total

Max impedance, RS-485 wiring* 100 ohms

Zone output voltage (normal standby) 26.5V

Zone output current

Supervision

Short circuit

Zone impedance (total per loop), max 100 ohms

Zone end-of-line resistor 4.7k ohms

Environment

UL864 location

Temperature range

Maximum relative humidity

* For total alarm current, add 14mA plus 40mA for each additional zone used

** See Appendix C Wire Selection for suggested wiring distances.

11mA

14mA

40mA

alarm current*

5mA

40mA

Indoor, dry

32 to 120° F

93%

10

Page 15

HSI #780-0867 FireSpy Tracker Installation Manual

2.3.8 Relay module (T8000-RC)

The T8000-RC relay module has (2) form C (SPDT) relays, providing individually programmable dry

contact outputs. Up to (5) relay modules may be daisy-chained, with the first one connected to a

conventional zone module (T8000-CM) or the main board (MB, MBC, MBCLC) via the relay output

connector. Relay modules may be mounted in the main enclosure or remotely (see Table 2-20).

Table 2-16: Relay module (T8000-RC) specifications.

Parameter Rating

Input current draw

Standby

Alarm

Relay type Form C (SPDT)

Contact rating

resistive load, PF=1.0

inductive load, PF=0.4

UL864 location Indoor, dry

Temperature range 32 to 120° F

Maximum relative humidity 93%

2mA

25mA

10A @ 30VDC

10A @ 240VAC

3A @ 240VAC

2.3.9 Serial relay module (T8000-SRM)

The T8000-SRM module provides (8) programmable relays. It may be mounted in the main enclosure or

remotely (see Table 2-20).

2

3

A

B

Table 2-17: Relay module (T8000-SRM) specifications.

Parameter Rating

Input current draw

Standby

Alarm

Max impedance, power wiring, total (3V drop each wire)* 26 ohms

Max impedance, RS-485 wiring* 100 ohms

Relay type Form C (SPDT)

Contact rating

resistive load, PF=1.0

inductive load, PF=0.4

Environment

UL864 location

Temperature range

Maximum relative humidity

30mA*

230mA*

10A @ 30VDC

10A @ 240VAC

3A @ 240VAC

Indoor, dry

32 to 120° F

93%

2.3.10 DACT communicator module (T-UDACT)

The T-UDACT is used for off-premises monitoring of the Tracker system. The T1000 has the DACT builtin. For the T2000 or T8000, the DACT mounts in the main cabinet or in a separate UL864 listed

enclosure. Programming is done through the Tracker user interface or a PC with the Tracker PC

Programmer software.

Signals are sent to a Digital Alarm Communicator Receiver (DACR) using either a primary or secondary

telephone line. A test call is transmitted to the DACR every 24 hours.

C

D

11

Page 16

1

2

HSI #780-0867 FireSpy Tracker Installation Manual

The DACT flashes the Fault LED when it recognizes a fault condition on itself. The following are the

possible fault conditions.

• Loss of communication with the fire panel. The DACT will attempt to communicate a trouble condition

to the central station

• Low or missing phone line voltage

Contents

Table 2-18: T-UDACT module specifications (T2000 / T8000).

Parameter Rating

Input current draw

Standby

Alarm

Environment

UL864 location

Temperature range

Maximum relative humidity

* Refer to T-UDACT installation instructions for other specifications.

30mA

32mA

Indoor, dry

32 to 120° F

93%

2.3.11 Audio evacuation modules

These are the core of the audio system. The T2000E provides space for one of the following amplifier

modules: 25HAVE, 50HAVE, or 100HAVE. Amplifier modules contain an amplifier, tone generator, digital

message repeater, and supervisory interface. The amplifier provides a total of 25, 50, or 100 watts to the

speaker outputs at 25 or 70 VRMS. The number in the model number indicates the number of watts

available. The speaker outputs can be configured as a Class A (Style Z) or Class B (Style Y) speaker

zone. The T2000E enclosure has space to connect up to two zone splitter modules:

* ZSC-2A: Splits a zone into two Class A (Style Z) speaker zones

* ZSC-4B: Splits a zone into four Class B (Style Y) speaker zones

2.3.12 City tie/reverse polarity communicator (UCT)

The model UCT interfaces between the Tracker and a local energy city box or remote station (reversepolarity). The UCT provides a form C system trouble contact and a form C general alarm contact. The

interface from the control panel is via 24VDC inputs for alarm, supervisory alarm, and trouble. A

disconnect switch is provided to prevent false alarms while the system is being tested or serviced.

When configured for remote station, this module is intended for connection to a polarity reversal circuit of

a remote station receiving unit having compatible ratings. This module is not suitable for Remote Station

Protected Premises service where separate transmission circuits are required for fire, supervisory, and

trouble signals. When configured for local energy, this module is intended for connection to a local energy

city tie box having compatible ratings.

12

Page 17

HSI #780-0867 FireSpy Tracker Installation Manual

Table 2-19: City tie/reverse polarity communicator (UCT) specifications.

Parameter Rating

Supply voltage 24V*

Input current draw 350mA max

Relay contacts

Trouble contacts

Alarm contacts

Remote station transmitter circuit outputs (power limited)**

Voltage

Current

Local energy city tie outputs (not power limited)

Standby voltage

Standby current

Alarm voltage

Alarm current

Ripple voltage (alarm)

Intended trip coil

* The same power source must be used for powering the UCT and relay contact wiring.

** These circuits are to be supervised by the remote station.

1A @ 28VDC, form C

5A @ 28VDC, form C

16.5 – 24.6VDC

14mA max

18-40mVDC

1.5mA max

16-28VDC

270mA max (momentary load)

1.2V max

14.5 ohm

2.3.13 Enclosures

2

3

A

Table 2-20: Enclosure dimensions and module mounting provisions.

T1-CAB

Size (inches)

Overall

Backbox

Knockouts

(1-1/8 dia)

Module Quantity of modules that may be mounted

T1-MB 1

T8000-MBC or

T2000-MBCLC or

T8000-LCU 2* 2*

T8000-CM 2* 2*

T8000-SRM 1* 1*

T8000-RC 2

T-UDACT 1

T8000-NCA 1

25HAVE, 50HAVE,

or 100HAVE

ZSC-2A or ZSC-4B 2*

Batteries (2) 12V, up to 12Ah** (2) 12V, up to 12Ah** (4) 12V, up to 18Ah†

* A total of two mounting locations are provided for a combination of these modules.

** Larger batteries may be mounted in an auxiliary UL864 Listed enclosure.

† Two batteries are for the fire system and two batteries are for the audio system. 100HAVE may use up to 24Ah batteries.

W x H x D

15.88 x 25.19 x 4.8

14.5 x 23.5 x 4

4 top

3 each side

1 1

1

T8000-CAB

T2000-CAB

W x H x D

15.88 x 25.19 x 4.8

14.5 x 23.5 x 4

4 top

3 each side

T2000E-CAB T8000-EXP

W x H x D

19.25 x 33.25 x 4.5

18 x 32 x 4

3 top, 2 bottom,

4 each side

W x H x D

11.37 x 15.44 x 3.8

10 x 14 x 3

3 top

3 bottom

B

C

D

13

Page 18

1

2

HSI #780-0867 FireSpy Tracker Installation Manual

T8000-A-CAB T8000-EXP5 T8000-EXP5N

Size (inches)

Overall

Backbox

Knockouts

(1-1/8 dia)

Contents

Module Quantity of modules that may be mounted

T8000-CM 1

T8000-RC 5 5

T8000-RAN 1

W x H x D

11.37 x 9.94 x 2.8

10 x 8.5 x 2

3 top

3 bottom

W x H x D

15.88 x 19.44 x 3.8

14.5 x 18 x 3

4 top

4 bottom

W x H x D

7.38 x 19.5 x 2.88

6 x 18.13 x 3.13

2 top

2 bottom

4 each side

2.4 Service use

The Tracker is suitable for the following NFPA72 service uses:

Table 2-21: Service uses.

Type Service Signaling Required Equipment

Local (PPU) A, M, SS, WF, R Non-coded, march time

Proprietary (PPU) A, M, SS, WF, R Multiplex

Remote Station (PPU) A, M, SS, WF, R DACT

Reverse polarity

Central Station (PPU) A, M, SS, WF, R DACT T-UDACT*

Auxiliary (PPU) A, M, WF, R N/A UCT

Abbreviations for services:

A = Automatic fire alarm

M = Manual fire alarm

SS = Sprinkler supervisory service

WF = Waterflow alarm

R = Releasing device service

* The T-UDACT is required equipment for these uses on the MBC and MBCLC. It is not required for these uses on the MB

because the MB has a built-in DACT.

T-UDACT*

UCT

2.5 Listings and approvals

ETL Listed: Standard UL864

CSFM Listed 7165-0476:172 (T2000, T8000)

MEA/BSA MEA 43-05-E, 43-05-E Vol 2 (T2000, T8000)

14

Page 19

HSI #780-0867 FireSpy Tracker Installation Manual

3 Installation and Wiring

Installation of the panel and system accessories requires qualified, trained, and equipped personnel who

are familiar with both the fire alarm codes and installation methods for this specific equipment. Final

programming requires special familiarity with the applicable local codes. The versatility of this system

implies sensitivity to mishandling and misprogramming beyond that of less capable equipment.

3.1 System planning

3.1.1 Battery calculation

The battery provides a secondary source of power if loss of primary power occurs. The batteries need to

have enough capacity to provide power for the control panel and attached devices for a minimum standby

period followed by an alarm period. Follow the directions below to fill in the calculation template in the

appendix.

The first section calculates the current draw loads for standby and alarm conditions.

1. Fill in the quantity and calculate standby and alarm current draw totals for each system

component.

2. Fill in the quantity and calculate standby current draw totals for each detector, base, and module.

3. Use rows A, B, C and D to estimate the total alarm current for detector and module LEDs. Row B

assumes that 5% of the LEDs of these devices will be turned on.

4. Fill in the quantity and calculate total alarm current for each NAC circuit.

5. Calculate the sum columns E and F. Verify that these values are within the limits of the power

supply (see table at the bottom).

6. Verify that the current draw on each circuit is within the current limit of the circuit.

The second section calculates the battery size needed to sustain the loads for the minimum time

durations.

1. Enter the standby and alarm time according to the type of system (see table at the bottom).

2. Fill in and calculate the remaining rows above row h and calculate row i.

3. Row i shows the battery size that is needed. Select a battery that is the next available size bigger

than this value.

3

A

B

C

D

3.2 Control panel installation

3.2.1 Preparation

Verify that all installation materials are on-hand. Read all instructions before beginning installation.

To avoid degradation of the operating circuitry, it is recommended that the printed circuit boards be

removed during cabinet mounting, wire installation, and any other procedures that may introduce dust,

metal shavings, grease or any other foreign matter into the area of the electronic circuitry.

WARNING: In an extended system, there may be several sources of power on devices

connected into the control unit. All power must be disconnected during

installation or wiring of system components and not introduced until

installation is complete and checked out.

3.2.2 Panel location

The control unit should be located on the ground floor and easily accessible to authorized personnel. The

area should be reasonably free of dust, vibration, and moisture and a dedicated source of power must be

available. The mounted enclosure should be at a convenient height to facilitate servicing.

15

Page 20

1

2

3

HSI #780-0867 FireSpy Tracker Installation Manual

Annunciators should be mounted at convenient locations, at approximately eye-level.

3.2.3 Installation

Mount the enclosure

Remove circuit boards from the enclosure before mounting to avoid damage. Refer to enclosure

Contents

documentation for detailed installation instructions.

If an auxiliary power supply or battery enclosure is being used at the panel, it may be mounted directly

below the main panel enclosure, close-nippled, with a minimum of 1 inch between enclosures for door

clearance. Wiring to these devices should be as short as possible to minimize voltage drop

Prepare for wiring

Break out the required entry points and attach any required conduit. Run the system wires and label each

adequately for future reference. The enclosure door may be temporarily removed for easier access by

removing the screw at the bottom hinge and detaching the ground wire at one end.

Note that the code requirements for power-limited wiring apply to most external runs, and the

requirements for non-power-limited wiring apply to the mains power inputs.

Install main circuit board and chassis set

For T1000, mount the main circuit board assembly (MB) onto the enclosure studs with the board oriented

as shown in Figure 3-4. Secure with #8 nuts.

For T2000 or T8000, mount the main circuit board assembly (MBC or MBCLC) onto the enclosure studs

with the board oriented as shown in Figure 3-6. Secure with #10 nuts.

For T2000E, mount the main circuit board assembly (MBCLC) onto the enclosure studs with the board

oriented as shown in Figure 3-8. (T2000E). Secure with #10 nuts.

Install optional accessories

To install accessory assemblies, follow the installation instructions provided with the accessories (see

Appendix A).

Connect AC power circuits

Wire the dedicated AC supply line to the terminals on the main circuit board as shown. The supply should

have a separate fuse or breaker at the main distribution panel so that no other electrical devices can

initiate power loss in the circuit. The grounding conductor must be at least 14AWG and 15A protection is

required. Be sure that the ground terminal is wired directly to the electrical panel ground bonding point or

another acceptable earth ground. The neutral wire must connect to the electrical panel neutral distribution

bar and not directly to ground.

WARNING Dangerous voltages appear on these terminals and associated circuitry when

the AC supply is turned on. Be sure the circuit is protected from inadvertent

energization during the assembly process.

Connect external circuits

When all remote devices have been connected to their circuits, connect these circuits to the panel (see

Figure 3-1, Figure 3-2 and Figure 3-3).

CAUTION: To maintain proper operation and supervision of detectors, indicators, and

modules, it is necessary that wiring instructions with the devices be followed

exactly, particularly with regard to in and out connections to the devices. It is

also necessary that each addressable device be properly programmed with

address and status (if applicable), and in conformance with the building

system layout. Misaddressed or miswired devices may cause severe

malfunctions and be difficult to locate.

16

Page 21

HSI #780-0867 FireSpy Tracker Installation Manual

Mount the door

If the door was removed, remount it by installing the screw at the bottom hinge and reattaching the

ground wire.

For T1000, connect the cable from the annunciator on the door to the main board.

Frame and mount a copy of the operating instructions found in the appendix to the wall near the panel.

Install batteries

WARNING: Improperly connecting or shorting the battery terminals may cause severe

damage to the panel and/or batteries and might result in personal injury.

Place the required batteries in the space provided at the bottom of the control panel enclosure. If a

battery set larger than 12Ah is required, an additional battery enclosure is required.

The 24V battery set required by the panel consists of two 12V sealed lead-acid batteries connected in

series.

Attach the red wire to the red or + terminal of one battery. Attach the black wire to the black or – terminal

of the other battery. Connect a jumper wire between the remaining two battery terminals.

Apply system power

Energize the AC power lines to the panel. The AC Power LED at the annunciator should be illuminated.

3

A

3.3 Configuration and programming

Initial configuration by scanning the network and loops will give all devices their initial default parameters

and assign input and control devices to the default group. Performing the scan is recommended to assure

that all accessories are as selected and at the assigned addresses. However, most systems also require

specific programming. Refer to the programming manual for more instructions.

3.4 Check system operation

Initial acceptance testing is required before normal operation of the system. Inspection, testing, and

maintenance may be performed by the owner, if qualified, or by a qualified contractor. Service personnel

must be qualified and experienced in inspection, testing, and maintenance of fire alarm systems,

including certification by the manufacturer or a recognized authority.

Any individuals or facilities receiving transmitted alarm, supervisory, or trouble signals, and all building

occupants, must be notified before commencement and on completion of any test operations, to prevent

unnecessary response.

Initial acceptance testing includes complete visual inspection and verifying the items below. NFPA 72 or

the authority having jurisdiction may include additional requirements that must be followed.

• Correct function of the control panel in receipt of all functional inputs and operation of all signals and

auxiliary functions, and supervision of shorts, opens, grounds, power supply faults and battery faults.

• Instrument measurement of the integrity and isolation of all applicable conductors (unpowered).

o No improper shorts or opens.

o No stray voltages between installation conductors and other conductors or ground. The maximum

stray voltage must not exceed 1 volt ac/dc.

o All conductors not intentionally grounded must be isolated from ground by at least 500k ohms

(2.2M ohms for T1000). An isolation of 10k or less will cause a ground fault. An isolation of

between 10k and 500k (10k and 2.2M for T1000) might or might not cause a ground fault, or will

cause intermittent ground faults.

B

C

D

17

Page 22

1

2

3

HSI #780-0867 FireSpy Tracker Installation Manual

o All conductors not intentionally connected together must be isolated from each other and from

ground.

• Loop resistance of each initiating and indicating circuit conductor loop must be recorded and must not

exceed the resistance of the equivalent of maximum wire length and end-of-line device.

• Operation of lamps, LEDs, and displays

• Rated power supply load, and charging capability and parameters.

Contents

o Power supply must be tested under worst-case maximum load with the battery disconnected.

o With the batteries charged and on trickle charge from the power supply, the terminal voltage shall

be approximately 27.6v.

• Visual inspection of the batteries and system connections must verify sound condition before

conducting back-up power tests.

• Operation of back-up supply (battery), including standby and alarm load capability.

o With the AC supply to the panel disconnected, the power loss trouble must be indicated, and the

standby and alarm current demand measured. General alarm systems must be operated for at

least 5 minutes to demonstrate the capability of operating standby and alarm on battery power.

• Proper operation of all audible and visual trouble signals, including ground-fault indication when any

conductor is grounded.

• Proper operation of annunciators shall be verified, including fault conditions.

• Function of all detection devices.

o Smoke and thermal fire detectors must be tested per manufacturer's instructions.

o Manual fire alarm boxes and other input devices must initiate alarm.

• Function of all other sensing or initiating devices must be tested under defined operating conditions

according to manufacturer's specifications.

• Function of all supervisory devices must be tested under operating conditions as specified by the

manufacturer.

• Function of all notification devices, including visible indicators verified against approved plans and

audible output levels measured with a sound level meter.

• Alarm verification time delay and alarm response must be verified for circuits so programmed.

• Circuit supervision must be verified by creating open circuits.

• Normal and trouble operation of the DACT, if used, and connection to two separate telephone lines

must be verified.

Any change in system hardware or software must be followed by complete test of the items involved and

10% of the unchanged items up to 50 devices. Full change records must be kept, as well as the system

test records. Changes to the control panel require retest of all critical functions.

18

Page 23

HSI #780-0867 FireSpy Tracker Installation Manual

290-0159

NOTES:

1) Use only smoke detectors that are in the compatibility list in the

owner's manual.

2) Leave end-of-line resistors on unused circuits.

3) Combined load of all devices, including indicating appliances, is not to

exceed 4A.

TYPICAL

STYLE Y

(CLASS B)

WIRING

USB

PORT

10K

LINE

NEU/LINE

EARTH

14 AWG MIN.

RJ31X

RJ31X

LINE INPUT

120VAC - 50/60Hz

240VAC - 50/60Hz

TO EXTERNAL

SERIAL MODULES

TYPICAL STYLE Z

(CLASS A)

WIRING

(end-of-line resistor

not needed)

CONTACTS RATED

2A @ 30VDC

1.0 POWER FACTOR

USE ONLY POLARIZED

DEVICES ON NACs

Polarity shown is alarm condition

ALL NACs ARE REGULATED 24 DC

+- - +

RS485 RS485

B+A+ A-B- B+A+ A-B-

NAC2 NAC3 /

AUX PWR

B+

A+ A-B-

NC

COM

NO

NC

COM

NO

NC

COM

NO

-

+

+

-

RC

RELAYS

NAC1

RELAY1RELAY2AUX I/O

BATT

TROUBLE

TO INTERNAL

SERIAL MODULES

A+A- B- B+

SLC

+

+

+

+

10K

USB

SECNDRY

PHONE

PRIMARY

PHONE

PDC

MB

J4

SW1

LEDs

FH1 FUSE: 7.5A MAX

CAUTION: For continued protection against risk of fire,

replace only with same type and rating of fuse.

FH1

24VDC, .02A

10K

Marks non-supervised circuits

Marks non-power-limited circuits

All others are supervised and power limited.

Segregate power-limited wiring from

non-power-limited wiring by at least 1/4 inch.

SUPERVISED AND POWER LIMITED

S

P

S

P

P

P

P

P

P

TO RC

TO ANNUNCIATOR

ON CABINET DOOR

J4 jumpers present

TYPICAL STYLE 4 (CLASS B) WIRING

SLC B-

SLC B+

Example SLC wiring Example RJ31X wiring

Isolators (optional) separate each zone

TYPICAL STYLE 6 (CLASS A) WIRING

ZONE 1

SLC A-

SLC A+

SLC B-

SLC B+

SLC A-

SLC A+

SLC B-

SLC B+

ZONE 2

Isolators separate each detector

Remove J4 jumpers

Remove J4 jumpers

TYPICAL STYLE 7 (CLASS A) WIRING

TIP

HOUSE

RING

TIP

TELCO

RING

GRAY

BROWN

GREEN

RED

3

A

B

C

D

Figure 3-1: Wiring on MB

19

Page 24

HSI #780-0867 FireSpy Tracker Installation Manual

290-0127

NOTES:

1) Use only smoke detectors that are listed in compatibility listing in

owner's manual.

2) Leave end-of-line resistors on unused circuits.

3) All terminals are rated for 14-22 AWG wire unless otherwise noted.

4) Combined load of all devices, including indicating appliances, is not to

exceed 7A.

TYPICAL

STYLE B (CLASS B)

WIRING

4.7k

4.7k

A+

A- B+B-

ZONE

TYPICAL

STYLE D (CLASS A)

WIRING

TYPICAL

STYLE Y

(CLASS B)

WIRING

USB

PORT

ETHERNET

PORT

(OPTIONAL)

SERIAL

PORT

10K

LINE

NEU/LINE

EARTH

LINE INPUT

120VAC - 50/60Hz

230VAC - 50/60Hz

RS485

TO SERIAL

MODULES

TYPICAL STYLE Z

(CLASS A)

WIRING

(end-of-line resistor

not needed)

CONTACTS RATED

10A @ 30VDC

10A @ 250VAC

1.0 POWER FACTOR

USE ONLY POLARIZED

DEVICES ON NACs

Polarity shown is alarm condition

ALL NACs ARE REGULATED 24 DC

+- - +

24VDCP1RS485

B+A+ A-B- B+A+ A-B-

P7 NAC

B+

A+ A-B-

P8 NAC

B+

A+ A-B-

NC

COM

NO

NC

COM

NO

NC

COM

NO

P9 NACP6

J3

J4

J2

P3

P4

P5

NAC

SUPV ALARMTROUBLE ALARM

24VDC

TO SERIAL

MODULES

BATTERY

CABLE

(TO P2)

RS485

TO SERIAL

MODULES

+- - +

24VDCP2RS485

24VDC

TO SERIAL

MODULES

+

+

+

+

10K10K

P10

(U20)

MBC

J6

TO NETWORK

COMMUNICATOR

A+A- B+B-

ZONE

Marks non-supervised circuits

Marks non-power-limited circuits

All others are supervised and power limited.

Segregate power-limited wiring from

non-power-limited wiring by at least 1/4 inch.

SUPERVISED AND POWER LIMITED

S

P

4.7k

4.7k

Example zone wiring on CM

S

P

P

P

TO RC

J1 jumpers present

TYPICAL STYLE 4 (CLASS B) WIRING

SLC B-

SLC B+

Example SLC wiring on LCU

Isolators (optional) separate each zone

TYPICAL STYLE 6 (CLASS A) WIRING

ZONE 1

SLC A-

SLC A+

SLC B-

SLC B+

SLC A-

SLC A+

SLC B-

SLC B+

ZONE 2

Isolators separate each detector

Remove J1 jumpers

Remove J1 jumpers

TYPICAL STYLE 7 (CLASS A) WIRING

SW2

1

8

(RESERVED)

SW1

1

8

ON/OFF

Contents

1

2

3

Figure 3-2: Wiring on MBC

20

Page 25

HSI #780-0867 FireSpy Tracker Installation Manual

LINE INPUT

120VAC - 50/60Hz

230VAC - 50/60Hz

RS485

TO SERIAL

MODULES

A+A- B+B-+- - +

24VDCP8RS485

B+A+ A-B- B+A+ A-B-

P7 NAC

B+

A+ A-B-

P8 NAC

NC

COM

NO

NC

COM

NO

NC

COM

NO

P9 NACP6

J3

P3

P4

P5

NAC

SUPV ALARMTROUBLE ALARM

A+A- B+B-

P9

SLC2SLC1

MBC-LC

TYPICAL

STYLE Y

(CLASS B)

WIRING

10K

LINE

NEU/LINE

EARTH

TYPICAL STYLE Z

(CLASS A)

WIRING

(end-of-line resistor

not needed)

CONTACTS RATED

10A @ 30VDC

10A @ 250VAC

1.0 POWER FACTOR

USE ONLY POLARIZED

DEVICES ON NACs

Polarity shown is alarm condition

ALL NACs ARE REGULATED 24 DC

SERIAL

PORT

24VDC

TO SERIAL

MODULES

BATTERY

CABLE

(TO P2)

+

+

+

+

10K10K

B+A+ A-B-

J6

TO NETWORK

COMMUNICATOR

USB

PORT

ETHERNET

PORT

(OPTIONAL)

290-0119

TYPICAL

STYLE B (CLASS B)

WIRING

4.7k 4.7k

A+A- B+B-

ZONE

TYPICAL

STYLE D (CLASS A)

WIRING

A+A- B+B-

P10

ALL NACs ARE REGULATED 24 DC

NOTES:

1) Use only smoke detectors that are listed in compatibility listing in

owner's manual.

2) Leave end-of-line resistors on unused circuits.

3) All terminals are rated for 14-22 AWG wire unless otherwise noted.

4) Combined load of all devices, including indicating appliances, is not to

exceed 7A.

J1 jumpers present

TYPICAL STYLE 4 (CLASS B) WIRING

SLC B-

SLC B+

Example SLC wiring on MBC-LC

Isolators (optional) separate each zone

TYPICAL STYLE 6 (CLASS A) WIRING

ZONE 1

SLC A-

SLC A+

SLC B-

SLC B+

SLC A-

SLC A+

SLC B-

SLC B+

ZONE 2

Isolators separate each detector

Remove J1 jumpers

Remove J1 jumpers

TYPICAL STYLE 7 (CLASS A) WIRING

A+A- B+B-

ZONE

S

P

P

P

TO RC

Marks non-supervised circuits

Marks non-power-limited circuits

All others are supervised and power limited.

Segregate power-limited wiring from

non-power-limited wiring by at least 1/4 inch.

SUPERVISED AND POWER LIMITED

S

P

4.7k

4.7k

Example zone wiring on CM

J1

SW2

8

1

(RESERVED)

SW1

8

1

(RESERVED)

SW4

8

1

(RESERVED)

SW3

8

1

ON/OFF

3

A

B

C

D

Figure 3-3: Wiring on MBC-LC

21

Page 26

1

AC power

input

Battery cable

Non-power-limited areas are gray.

Segregate power-limited wiring from

non-power-limited wiring by at least

1/4 inch.

CAB

MB

BATTERY BATTERY

USB

PDC

SECNDRY

PHONE

PRIMARY

PHONE

B+A+ A-B- B+A+ A-B-

NAC2

B+

A+ A-B-

NAC3NAC1

+- - +

RS485 RS485

A+

A- B+B-

SLC

NC

COM

NO

NC

COM

NO

NC

COM

NO

-

+

+

-

RELAYS

RELAY1RELAY2AUX I/O

BATT

TROUBLE

RC

290-0160

2

3

HSI #780-0867 FireSpy Tracker Installation Manual

Contents

Figure 3-4: Wire routing on T1000

22

Page 27

HSI #780-0867 FireSpy Tracker Installation Manual

290-0058

AC power input

Max 50VDC

per circuit

Con10M

J2

TB3

J1

TB4

SLC1

J3

J1

SLC2

TB3 TB4

SLC1 SLC2

LCU

LCU

CAB

MBC

Includes: chassis, MCC,

keypad, and power supply

modules

BATTERY 1 BATTERY 2

SUPV ALARMTROUBLE ALARM

J1

J2

J2

J1

B+A+ A-B- B+A+ A-B-

P5 NAC

B+

A+ A-B-

P6 NAC

B+

A+ A-B-

P7 NACP4 NAC

NC

COM

NO

NC

COM

NO

NC

COM

NO

P3

P4

P5

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

+A-A +B-B

+A-A +B-B +A-A +B-B

+A-A +B-B

-+ + -

RS485

TO LOWER MODULE

TB2

24VDC

+- - +

RS485P124VDC

+- - +

RS485P224VDC

-+ + -

RS485

TB1

24VDC

Non-power-limited areas are gray.

Segregate power-limited wiring from

non-power-limited wiring by at least

1/4 inch.

RC

RC

MBC

3

A

B

C

D

Figure 3-5: Wire routing on T8000 with LCU modules

23

Page 28

1

Max 50VDC

per circuit

Max 50VDC

per circuit

LCU

+A-A +B-B +A-A +B-B

-B

+B

-A

+A

-B

+B

-A

+A

-B

+B

-A

+A

-+ + -SHD

RS485P124VDC

-+ + -SHD

RS485

TO LOWER

MODULE

P2

24VDC

Con10M

P7

P6

P5

+A

-A

+B

-B

+A

-A

+B

-B

P3

P4

TB3 TB4

SLC1 SLC2

CM

-B

+B

-A

+A

-B

+B

-A

+A

-B

+B

-A

+A

-+ + -SHD

RS485P124VDC

-+ + -SHD

RS485

TO LOWER

MODULE

P2

24VDC

Con10M

P7

P6

P5

+A

-A

+B

-B

+A

-A

+B

-B

P3

P4

CM

Con10M

Con10M

J1

J2

J2

J1

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

RC

RC

Con10M

Con10M

J1

J2

J2

J1

NC

COM

NO

NC

COM

NO

NC

COM

NO

NC

COM

NO

RC

RC

BATTERY 1BATTERY 1 BATTERY 2

J2

J1

SUPV ALARMTROUBLE ALARM

SUPV ALARMTROUBLE ALARM

BATTERY BATTERY

B+A+ A-B- B+A+ A-B-

P5 NAC

B+

A+ A-BP6 NAC

B+

A+ A-B-

P7 NACP4 NAC

NC

COM

NO

NC

COM

NO

NC

COM

NO

P3

P4

P5

-+ + -SHD

RS485P124VDC

-+ + -SHD

RS485P224VDC

B+A+ A-B- B+A+ A-B-

P5 NAC

B+

A+ A-B-

P6 NAC

B+

A+ A-B-

P7 NACP4 NAC

NC

COM

NO

NC

COM

NO

NC

COM

NO

P3

P4

P5

A+A- B+B-

P10

+- - +SHD

24VDCP8RS485

A+A- B+B-

P9

Non-power-limited areas are gray.

Segregate power-limited wiring from

non-power-limited wiring by at least

1/4 inch.

MBC MBCLC

290-0154

2

3

HSI #780-0867 FireSpy Tracker Installation Manual

Contents

T8000 SYSTEM T2000 SYSTEM

Figure 3-6: Wire routing with LCU and CM / CM

24

Page 29

HSI #780-0867 FireSpy Tracker Installation Manual

290-0130

AC power input

Max 50VDC

per circuit

Max 50VDC

per circuit

AC power input

Battery cable

BATTERY 1 BATTERY 2

J2

J3

J1

SUPV ALARMTROUBLE ALARM

TB3 TB4

SLC1 SLC2

TB3 TB4

SLC1 SLC2

LCU

LCU

J3

SUPV ALARMTROUBLE ALARM

BATTERY BATTERY

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8

B+A+ A-B- B+A+ A-B-

P5 NAC

B+

A+ A-B-

P6 NAC

B+

A+ A-BP7 NACP4 NAC

NC

COM

NO

NC

COM

NO

NC

COM

NO

P3

P4

P5

+

- - +

RS485P124VDC

+

- - +

RS485P224VDC

-+ + -

RS485

TB1

24VDC

+A-A +B-B

+A-A +B-B +A-A +B-B

+A-A +B-B

-+ + -

RS485

TO LOWER MODULE

TB2

24VDC

-

+ + -

RS485

TB1

24VDC

B+A+ A-B- B+A+ A-B-

P5 NAC

B+

A+ A-B-

P6 NAC

B+

A+ A-B-

P7 NACP4 NAC

NC

COM

NO

NC

COM

NO

NC

COM

NO

P3

P4

P5

A+A- B+B-

P10

+- - +

24VDCP8RS485

A+

A- B+B-

P9

-+ + -

RS485

TB1

24VDC

UDACT UDACT

Non-power-limited areas are gray.

Segregate power-limited wiring from

non-power-limited wiring by at least

1/4 inch.

MBC MBCLC

3

T8000 SYSTEM T2000 SYSTEM

A

B

C

D

Figure 3-7: Wire routing for UDACT

25

Page 30

1

290-0148

Non-power limited

areas are shaded

Non-power limited

areas must be

segregated from

power limited areas

by at least 1/4 inch

-+ + -SHD

RS485

P1

24VDC

-+ + -

RS485P824VDC

A+

A- B+B-

P9

A+A- B+B-

P10

DB9M

J2

B+A+ A-B- B+A+ A-B-

P7 NAC

B+

A+ A-B-

P8 NAC

B+

A+ A-B-

NC

COM

NO

NC

COM

NO

NC

COM

NO

P9 NACP6

J3

P3

J1

P4

P5

NAC

SERIAL

SUPV ALARMTROUBLE ALARM

NEU

HOT

EARTH

TB1

12345678

12345678

1234567

TB3

87654321

TB2

12345678

1234567

1 11

S1

SN2 SN1

1 11

1 11

10K

10K

HOT

EARTH

NEU

MBC-LC

XFMR

25HAVE,

50HAVE,

or

100HAVE

UDACT

or

NCA

ZSC-2A

OR

ZSC-4B

ZSC-2A

or

ZSC-4B

T2000E-CAB

To HAVE NAC input

From NAC output

From

MCC-LC

P8

To UDACT / NCA

Speaker zones

LINE INPUT

120 VAC

50-60 Hz

Batteries:

24VDC

18Ah max

Max 50VDC

per circuit

This area is non-power

limited for phone line

connections (if using

UDACT)

Batteries:

24VDC

18Ah max

HSI #780-0867 FireSpy Tracker Installation Manual

Contents

2

3

Figure 3-8: Wire routing on T2000E

26

Page 31

HSI #780-0867 FireSpy Tracker Installation Manual

Appendix A. Ordering and Parts Information

A.1 Component matrix

A.1.1. Available panel configurations (factory pre-wired)

Part Number

T1-P 1 1 1

T8-P-U 1 1 1 1

T8-P-UD 1 1 1 1 1

T8-P-2U 1 1 2 1

T8-P-2UD 1 1 2 1 1

T8-P-C 1 1 1 1

T8-P-CD 1 1 1 1 1

T2-P 1 1 1

T2-P-D 1 1 1 1

T8-EXP5-R 1 1

T8-EXP-U 1 1

T8-EXP-2U 2 1

T1-MB

T8000-MBC

T2000-MBCLC

T-PDC

T8000-LCU

T8000-CM

T8000-RC

T1-CAB

T8000-CAB or

T2000-CAB

T8000-EXP

T8000-EXP5

A.1.2. Board modules

Model Description Reference Document

T1-MB Main board set 780-0935

T8000-MBC Main board set 780-0862

T2000-MBCLC Main board set 780-0929

T-PDC Main display board 780-0936

T8000-ANN Annunciator with T8000-RAN module in T8000-A-CAB enclosure 780-0856

T8000-RAN Annunciator module 780-0856

T8000-LCU Addressable SLC module 780-0921

T8000-CM Conventional zone module 780-0859

T8000-RC Relay module 780-0861

T8000-SRM Serial relay module 780-0879

T8000-NCA Communications adapter 780-0922

T-UDACT Point DACT communicator 780-0914

T-UDACT

A

B

C

D

27

Page 32

HSI #780-0867 FireSpy Tracker Installation Manual

Model Description Reference Document

UCT City tie/reverse polarity communicator 780-0773

A.1.3. Enclosures

1

2

3

A

Contents

Model Description Reference Document

T1-CAB Main cabinet (T1000) 780-0858

T8000-CAB Main cabinet (T8000) 780-0858

T2000-CAB Main cabinet (T2000) 780-0858

T2000E-CAB Main cabinet (T2000E) 780-0858

T8000-EXP Small expansion cabinet 780-0858

T8000-EXPD Small expansion cabinet for UDACT 780-0858

T8000-EXP5 Large expansion cabinet 780-0858

T8000-EXP5N Narrow expansion cabinet 780-0858

T8000-A-CAB Annunciator cabinet 780-0858

327-0089 UCT enclosure 780-0773

HS-SBC Small battery box 780-0855

HS-LBC Large battery box 780-0855

A.1.4. Accessories

Part Description

TG-CBL-RC Cable for T8000-RC

T-4.7K 4.7k ohm end-of-line resistor

T-10K 10k ohm end-of-line resistor

28

Page 33

HSI #780-0867 FireSpy Tracker Installation Manual

Appendix B. Compatible Devices

B.1 Startup delay for devices with alarm verification

The Tracker system includes an alarm verification feature that will result in a delay of the system alarm

signal from the indicated circuits.

The following statement applies to installations intended to meet UL864 requirements: The total delay

(control unit plus smoke detector) shall not exceed 60 seconds. No other smoke detector shall be

connected to these circuits unless approved by the local authority having jurisdiction.

The following statement applies to installations intended to meet California State Fire Marshal

requirements: For fire alarm verification feature (delay of fire alarm), the maximum retard/reset/restart

period (control unit plus detector) must be adjusted to 30 seconds or less.

For the devices below, the delay start-up time marked on the installation wiring diagram of the smoke

detector or on the installed smoke detector is to be used.

Circuits Compatible smoke detectors with alarm verification

LCU and MCCLC, Class A and B Apollo 55000-550, -650, -886

Harrington TS8-DP, TS8-DH, TS8-DM

B.2 Addressable SLC devices (for use with T8000-LCU, T2000-MBCLC, and

T1-MB)

Each SLC circuit must use devices from a single series of compatible devices. Do not mix and match

unless otherwise noted. For example, do not use System Sensor and Apollo devices on the same circuit.

The following devices below may be used together on the same SLC circuit:

• Harrington ISpy, TSpy, HSPS

• Apollo XP95, Discovery

• Air Products

B.2.1. System Sensor

Harrington

Part No.

Detectors

349-0508 1551 Ion smoke detector

349-0494 2551 Photo smoke detector

349-0495 5551 Heat detector, fixed temperature

349-0646 5551R Heat detector, rate-of-rise

349-1048 1251B Ion smoke detector – low profile

349-1046 2251, 2251B Photo smoke detector – low profile

349-1056 2251BR Photo smoke detector to be used with DNR/DNRW duct smoke detector

349-1047 2251TB Photo/thermal multicriteria detector (Acclimate)

349-1071 2251TMB Photo/thermal multicriteria detector (Acclimate)

349-1049 5251B Fixed temperature heat detector, 135°

349-1059 5251H Fixed temperature heat detector, 190°

System Sensor Model Description

B

C

D

29

Page 34

1

2

3

A

B

HSI #780-0867 FireSpy Tracker Installation Manual

Harrington

Part No.

349-1050 5251RB Rate-of-rise heat detector

5251P

5251RP

Contents

349-1055 DH200RPL Duct smoke detector, photoelectric

349-1057 DH200PL Duct smoke detector with auxiliary relay contacts

BEAM200, 200S BEAM200, 200S Beam smoke detector

DNR DNR,

Bases

349-0496 B501B Addressable analog detector base

349-0525 B501BH, B501BH-2 Addressable analog detector base w/sounder

349-1023 B501BHT,

349-0757 B210LP Base, low profile

349-0647 B224RB Relay base

349-0856 B224BI Isolator base

B200SR Sounder base

Accessories

349-0667 M502M Conventional zone interface module*

349-1069 CZ-6 Conventional zone interface module, 6 zones*

349-0509 M500M, M500MB Input module

349-0497 M501M Input module, miniature

349-1020 M500DM Input module, 2 inputs

349-1068 IM-10 Input module, 10 inputs

349-1021 M500S Supervised output module

349-1067 SC-6 Supervised output module, 6 outputs

349-1022 M500R Relay module

349-1066 CR-6 Relay module, 6 relays

349-0511 M500X, M500XB Isolator module

* Refer to manufacturer’s documentation for compatible 2-wire detectors

System Sensor Model Description

Duct smoke detector (use with 2251BR head)

DNRW

Addressable analog detector base w/sounder, temporal

B501BHT-2

B.2.2. Harrington Signal

ISpy Series

Harrington

Part No.

Detectors

IS800 ISpy Heat detector (Apollo Discovery)

IS801 ISpy Ion smoke detector (Apollo Discovery)

IS802 ISpy Photo smoke detector (Apollo Discovery)

IS803 ISpy Photo/heat multicriteria detector (Apollo Discovery)

Harrington Signal

Model

Series Description

30

Page 35

HSI #780-0867 FireSpy Tracker Installation Manual

Harrington

Part No.

IS818 ISpy Beam smoke detector

Bases

IS804 ISpy 4” mounting base

IS805 ISpy Short-circuit isolator mounting base

IS806 ISpy 6” mounting base

IS807 ISpy 6” low profile mounting base

IS808 ISpy 4” low power relay mounting base

IS809 ISpy E-Z fit mounting base

IS821 ISpy 6” mounting base

Accessories

IS810 ISpy Short-circuit Isolator

IS811 ISpy Switch monitor module

IS812 ISpy Priority switch monitor module

IS813 ISpy Switch monitor input-output module

IS814 ISpy Sounder control module

IS815 ISpy Mini switch monitor unit

IS816 ISpy Mini priority switch monitor module

TSpy Series

Harrington

Part No.

Detectors