Page 1

document rev

INSTRUCTION SHEET

Commercial Products Group

2519-4th Ave, Moline, IL61265

800.521.8219 : 800.225.4109

www.cpglifesafety.com

POWERTONE® SPEAKERSPOWERTONE® SPEAKERS

POWERTONE® SPEAKERS

POWERTONE® SPEAKERSPOWERTONE® SPEAKERS

SPHPSPHP

SPHP

SPHPSPHP

(With or without Strobe Warning Light)

SAFETY MESSAGE

People's lives depend on your safe installation, test, operation,

and maintenance of our products. Read, understand, and

follow all safety messages and instructions. Refer to "Safety

Messages for Equipment Used in Fire-Protective Signaling

Systems" and any other documentation shipped with equipment before performing any system related duty.

I. GENERAL.

These two PowerTone models are 25 Vrms and 70

Vrms, indoor/outdoor rated, selectable power output (0.5 to

15 watts) loudspeakers for use with fire alarm signalling

systems such as CPG’s PowerTone system. They are

designed to reproduce electronically generated warning

tones, which command rapid recognition, and full range

voice communication. They are suitable for use in areas

with high ambient noise levels. These speakers are equipped

with a blocking capacitor to allow use in supervised alarm

signalling systems. The PowerTone Model SPHP speaker

is also available with an optional 24VDC strobe light

attached. All strobes are listed by Underwriters Laboratories in their respective categories.

regarding the attached strobe and message label(s) attachment, refer

to Model V1971 strobe instruction sheet (CPG Part No. 2561088 or

2561090) or Model VST strobe instruction sheet (CPG Part No.

2561310). Model V1971 may be used outdoors when Model VW outdoor

kit is employed; otherwise, Model V1971 is for indoor use only. Model

VST may be used for indoor use only. Speaker projectors on all

models are adjustable and may be repositioned to obtain

desired sound distribution.

II. SPECIFICATIONS.

Operating 25 Vrms or 70 Vrms

Voltage

For additional information

256882 0209

III. INSTALLATION.

A.

Unpacking.

After unpacking the speaker, examine it carefully

for possible damage that may have occurred in transit. If

equipment has been damaged, immediately file a claim with

the carrier stating extent of damage. Carefully check all

shipping labels and tags for special instructions before

removing or destroying them.

B.

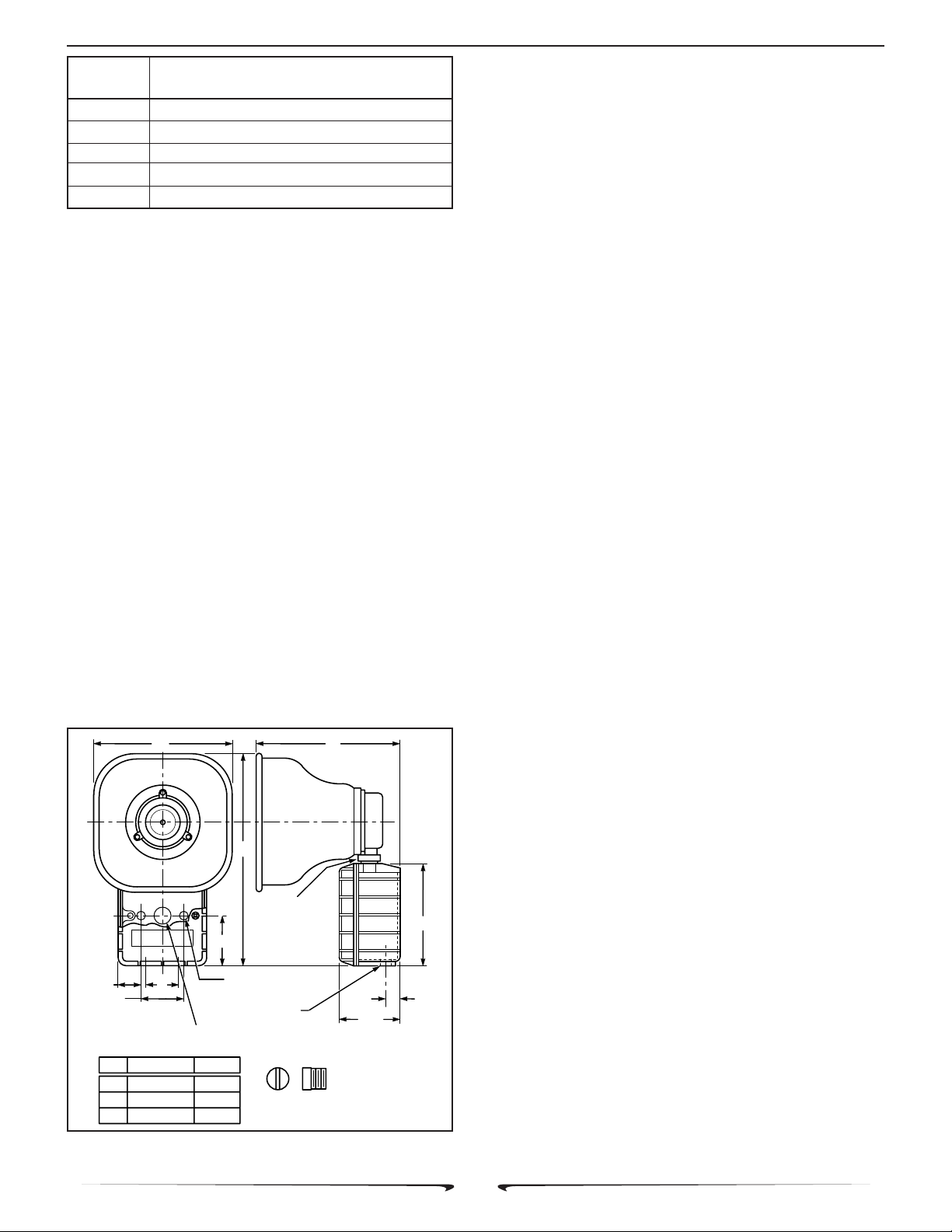

Mounting Arrangements (see figure 1).

The speaker can be mounted on any relatively flat

surface. Conduit connection can be made to two 1/2"

threaded openings at the bottom of the housing or to 7/8"

knockout in rear of housing. A 1/2" conduit plug is supplied

for field installation if one of the 1/2" threaded openings is

not utilized. After the mounting location and mounting

method have been selected, proceed with the applicable

instructions below.

WARNING

Property damage, serious injury, or death could occur if an

accumulation of water, snow, dust, etc. resides in the speaker

projector, severely reducing or preventing operation of this

device. Mount the unit so speaker projector is pointed horizontally or slightly downward.

1. Flat Surface Mounting

a. Remove and retain the two screws that

secure cover to housing. Remove the cover.

b. Select the mounting location and place

rear of housing against mounting surface.

C

Power Input 0.5 W, 1 W, 2 W, 7 W and 15 W

(selectable)

Weight 5 lb. (2.25kg)

(approx.)

Size 11-7/8" (302mm) high, 8-1/8" (206mm)

wide, 8" (203mm) deep.

Construction Aluminum enclosure painted with red

enamel. Amplifier housing sealed

with neoprene rubber gasket.

Approval Agency Listings:

Underwriters Laboratories Inc.

Model SPHP: File S6476(Guide UUMW

California State Fire Marshal—7230-1517:110

New York City—(Listing is pending.)

Audibility information is shown in table 1.

c . Using the mounting holes (two (2) inside

housing) as a template, scribe drill position marks on the

mounting surface. See figure 1 for mounting hole locations

and dimensions.

CAUTION

Before drilling holes in any surface, ensure that both sides of

surface are clear of items that could be damaged.

d. Secure the unit to a wooden mounting

surface with #10 x 1" wood screws. If mounting on a metal

surface, drill 13/64" diameter holes and secure the unit with

#10 screws, lockwashers and nuts.

e. Route power and supervision leads through

conduit to the audible signal. Install a 1/2" electrical connector at the bottom of the audible signal. Route wires through

conduit and electrical connector into the audible signal

- 1 -

Page 2

256882 SPHP Instruction Sheet

POWER UL SOUND LEVEL

TA P @ 10' dB(A)

0.5watt 87

1 watt 93

2 watt 96

7 watt 99

15 watt 102

Table 1. Power Tap Setting vs. Sound Output on

Model SPHP.

housing. Install supplied 1/2" conduit plug if only one 1/2"

conduit entrance is used.

WARNING

Property damage, serious injury or death could occur if the

projector is mishandled during installation or over time. DO

NOT rotate the projector more than 180 degrees or internal

speaker wiring may be damaged.

f . Reposition speaker projector if necessary

to obtain desired sound coverage. Loosen collar nut (see

figure 1) and move projector to desired position.

g. Before reinstalling the housing cover, read

paragraph III.C. Electrical Connections below and make the

necessary electrical connections.

2. Concealed Conduit Moounting.

a. Remove and retain the two screws that

secure cover to housing. Remove the cover.

b. Remove the 7/8" knockout at rear of hous-

ing.

c. Install the conduit connection.

AC

NOTE

If installation on an existing electrical box is desired, an optional

Model CC adapter plate is required.

d. Select the mounting location and place

rear of housing against mounting surface.

e. Using the two (2) mounting holes as a

template, scribe drill position marks on the mounting surface. See figure 1 for mounting hole locations and dimensions.

CAUTION

Before drilling holes in any surface, ensure that both sides of

surface are clear of items that could be damaged.

f. Secure the unit to a wooden mounting

surface with #10 x 1" wood screws. If mounting on a metal

surface, drill 13/64" diameter holes and secure the unit with

#10 screws, lockwashers and nuts.

WARNING

Property damage, serious injury or death could occur if the

projector is mishandled during installation or over time. DO

NOT rotate the projector more than 180 degrees or internal

speaker wiring may be damaged.

g. Reposition speaker projector if necessary

to obtain desired sound coverage. Loosen collar nut (see

figure 1) and move projector to desired position. Install two

1/2" conduit plugs in the unused bottom entryways (one

plug supplied).

h. Before reinstalling the housing cover, read

paragraph III.C. Electrical Connections below and make the

necessary electrical connections.

C.

Electrical Connections.

2-3/4

1-13/16

2-9/16

A

B

C

2

7/8 DIA. CONCEALED CONDUIT KNOCK OUT

MOUNTING (IN REAR OF HOUSING)

INCHES MM

8-1/8

11-7/8

8

.201 DIA. 2 HOLES

206

302

203

Figure 1. Model SPHP Speaker Dimensions.

B

COLLAR

NUT

(MOUNTING)

2 x 1/2-14 NPT

5-5/8

13/16

3-3/8

1/2" CONDUIT PLUG

SUPPLIED

290A2627-06A

National Electrical Code as well as local codes

must be adhered to in installation of these models. All

electrical wiring must be routed through approved conduit

and fittings.

1. Model SPHP (without Strobe Light Option).

a. See figures 2 and 3. Connect the audio

common (-) leads to the speaker’s common terminal and

audio positive (+) leads to desired wattage terminal.

WARNING

An uninsulated section of a single conductor must NOT be

looped around a terminal and used as two separate connections. NFPA 72 requires that the wire is severed to provide

electrical supervision of the connection.

b. See Figure 3. Connect the yellow lead,

found in the speaker, to the 25V or 70V terminal as

appropriate.

- 2 -

Page 3

256882 SPHP Instruction Sheet

290B2627-07

RED

24 VDC

STROBE

POWER

BLK

+

-

RED

BLK

RED

BLK

RED

25 OR 75 VRMS

SPEAKER

SIGNAL SOURCE

BLK

+

-

5

WARNING

Property damage, serious injury, or death could occur if the

housing is not closed properly.

c. Be sure the neoprene rubber cover gasket

is properly seated in the housing groove and reinstall the

housing cover.

2. Model SPHP (with Strobe Light Option).

DANGER

A high voltage shock hazard may be present inside the strobe

light, even if power is not connected. It is recommended that

strobe light NOT be opened. If access to the printed circuit

board assembly is required (removal or replacement of

damaged unit), disconnect unit from power source and wait

5 minutes.

a. See figure 2. Connect the strobe light’s red

(+) lead to the power source positive (+) lead. Connect the

strobe light’s black (-) lead to the power source negative () lead.

WARNING

IV . TESTING/OPERATING.

A. After installation is complete, be sure to test the

system to verify that each speaker and optional strobe light

operates satisfactorily. If it is found that the unit is too loud

for its location, a lower wattage tap may be selected.

Carefully remove the housing cover and move the positive

(+) lead to a lower wattage tap (see Figure 4). Reinstall the

housing cover and retest.

An uninsulated section of a single conductor must NOT be

looped around a terminal and used as two separate connections. NFPA 72 requires that the wire is severed to provide

electrical supervision of the connection. In addition, common

strobe leads must NOT be terminated within the same wire nut.

b. See figures 2 and 3. Connect the audio

common (-) leads to the speaker’s common terminal and

audio positive (+) leads to desired wattage terminal.

c. See figure 3. Connect the yellow lead,

found in the speaker, to the 25V or 70V terminal as

appropriate.

d. Be sure the neoprene rubber cover gasket

is properly seated in the housing groove and reinstall the

housing cover.

5W1W2W

COM

7W

15W

25V

70V

Figure 2. Typical Installation Wiring.

NOTE: LETTERS APPEAR ON THIS SIDE OF TERMINAL STRIP. SHOWN

HERE ON MOUNTING BRACKET FOR REFERENCE ONLY.

SPEAKER INTERNAL YELLOW LEAD TO BE CONNECTED TO 25V OR 70V

TERMINAL, DEPENDING UPON EXTERNAL SIGNAL SOURCE VOLTAGE.

YEL

POSITIVE (+) LEADS TO 1 OF 5 AVAILABLE WATTAGE TERMINALS.

COMMON (-) LEADS TO COMMON TERMINAL

290A335

Figure 3. Internal Multi-tap Wiring Set-up.

- 3 -

Page 4

256882 SPHP Instruction Sheet

WARNING

Property damage, serious injury, or death could occur if the

housing is not closed properly.

B . After completion of initial system test, establish a

program for periodic testing of this device. Refer to NFPA

72, local Fire Codes and the authority having jurisdiction for

this information.

WARNING

Unauthorized repair/servicing of the unit may result in degradation of performance and/or property damage, serious

injury, or death to you or others. If a malfunctioning unit is

encountered, do not attempt any field repair/retrofit of parts.

VI. SERVICE.

This product is covered by a 5 year warranty. See CPG

terms and conditions for more details.

C. Provide a copy of these instructions for the Safety

Engineer, system operator(s) and maintenance personnel.

V . MAINTENANCE.

A . Periodically check this device to verify that there

are no foreign substances in, or in front of, the speaker

which will reduce its effectiveness.

B . Testing should be periodically performed. Refer to

NFPA 72, local Fire Codes and the authority having jurisdiction for information.

C. In the event a volume adjustment or other repair is

required, be sure to refer to the Safety Message For

Maintenance Personnel before proceeding.

The factory will service your equipment or provide

technical assistance with any problem that cannot be

handled locally with satisfaction or promptness.

If any unit is returned to factory for repair, it can be

accepted only if we are notified by mail or phone in advance

of its arrival. Such notice should clearly indicate service

requested and give all pertinent information regarding nature of problem and, if possible, its cause.

Communications and shipments should be addressed

to:

Technical Service Department

Commercial Products Group

2519 - 4th Avenue

Moline, IL 61265

800.521.8219 • FAX 800.225.4109

PowerTone is a registered trademark of Commercial Products Group (CPG).

- 4 -

Loading...

Loading...