Page 1

Commercial Products Group

document rev

2519-4th Ave, Moline, IL61265

800.521.8219 : 800.225.4109

www.cpglifesafety.com

INSTRUCTION SHEET

FHEXFHEX

FHEX

FHEXFHEX

VIBRATONE® EXPLOSION-PROOF VIBRATORY HORNVIBRATONE® EXPLOSION-PROOF VIBRATORY HORN

VIBRATONE® EXPLOSION-PROOF VIBRATORY HORN

VIBRATONE® EXPLOSION-PROOF VIBRATORY HORNVIBRATONE® EXPLOSION-PROOF VIBRATORY HORN

256884 0209

A

SAFETY MESSAGE TO INSTALLERS

People’s lives depend on your safe installation of our products. It

is important to read, understand and follow all instructions shipped with

this product.

Selection of mounting location for this device, its controls and

routing of wiring should be made by the Facilities Engineer and the Safety

Engineer. Listed below are some other important safety instructions and

precautions you should follow:

• This unit must be installed by a qualified electrician in

accordance with NFPA 72, and National and local Electrical and Fire Codes, under the direction of the authority

having jurisdiction.

• Do not connect this unit to system wiring when circuits

are energized.

• For optimum sound distribution do not install this device

where objects would block any portion of front of speaker.

• All effective warning horns produce loud sounds which,

in certain circumstancs, may cause permanent hearing

loss. Take appropriate precautions such as wearing

hearing protection. Recommendations in OSHA Sound

Level Standard (29 CFR 1910) should not be exceeded.

• After installation, ensure that all bolts threaded joints are

tightened.

• After installation and completion of initial system test, a

program for periodic testing of this device must be

established. Refer to NFPA 72, local Fire Codes and the

authity having jurisdiction for this information.

• After installation and completion of initial system test

provide a copy of this instruction sheet to all personnel

responsible for operation, periodic testing and maintenance of this equipment.

Failure to follow all safety precautions and instructions may result

in property damage, serious injury, or death to you and others.

A. GENERAL.

The Vibratone Model FHEX is a hazardous location, intermittent

duty, polarized, 24 Volt dc, indoor/outdoor rated, high output, vibratory

horn for use with fire alarm systems. This model is suitable for use in

hazardous locations NEC Class I, Groups C, & D; Class II, Groups E,

F and G and has factory sealed leads.

B. SPECIFICATIONS.

Operating 24 Vdc

Voltage

Current 0.96A - 1.44 A

Duty cycle 5 min. on—5 min. off

Weight (approx.) 10 lb. (4.536kg)

Size 12" (305mm) high, 6-7/8"

Construction Heavy corrosion resistant cast

Approval Agency Listings:

Underwriters Laboratories Inc.

File E190785(Guide UJPX) Listed as a

HAZARDOUS LOCATION AUDIBLE

SIGNAL FOR FIRE ALARM SERVICE.

California State Fire Marshal—(Listing is pending.)

New York City—(Listing is pending.)

Audibility:

94 dBA, UL omni-directional sound pressure rating.

116 dBA, Sound Power measurement.

100 dBA on axis at 10' in Anechoic chamber.

C. INSTALLATION.

1.

Unpacking.

damage that may have occurred in transit. If equipment has been

damaged, immediately file a claim with carrier stating extent of damage.

Carefully check all shipping labels and tags for special instructions

before removing or destroying them.

Conduit connection can be made to 3/4" threaded opening in splicing

condulet attached to this device (see figure 1).

After unpacking the horn, examine it carefully for possible

Property damage, serious injury or death could occur if this

product’s explosion-proof housing is damaged. The horn

mechanism contains no user serviceable parts. Therefore,

DO NOT loosen or remove clamp ring, which holds mechanism into housing, or any of the six screws on the front of the

horn grille. Loosening or removing any of these six screws

may disturb factory adjustment of horn mechanism and cause

the horn to malfunction. Attempting to remove the horn

mechanism from the horn housing may damage the horn

mechanism.

2.

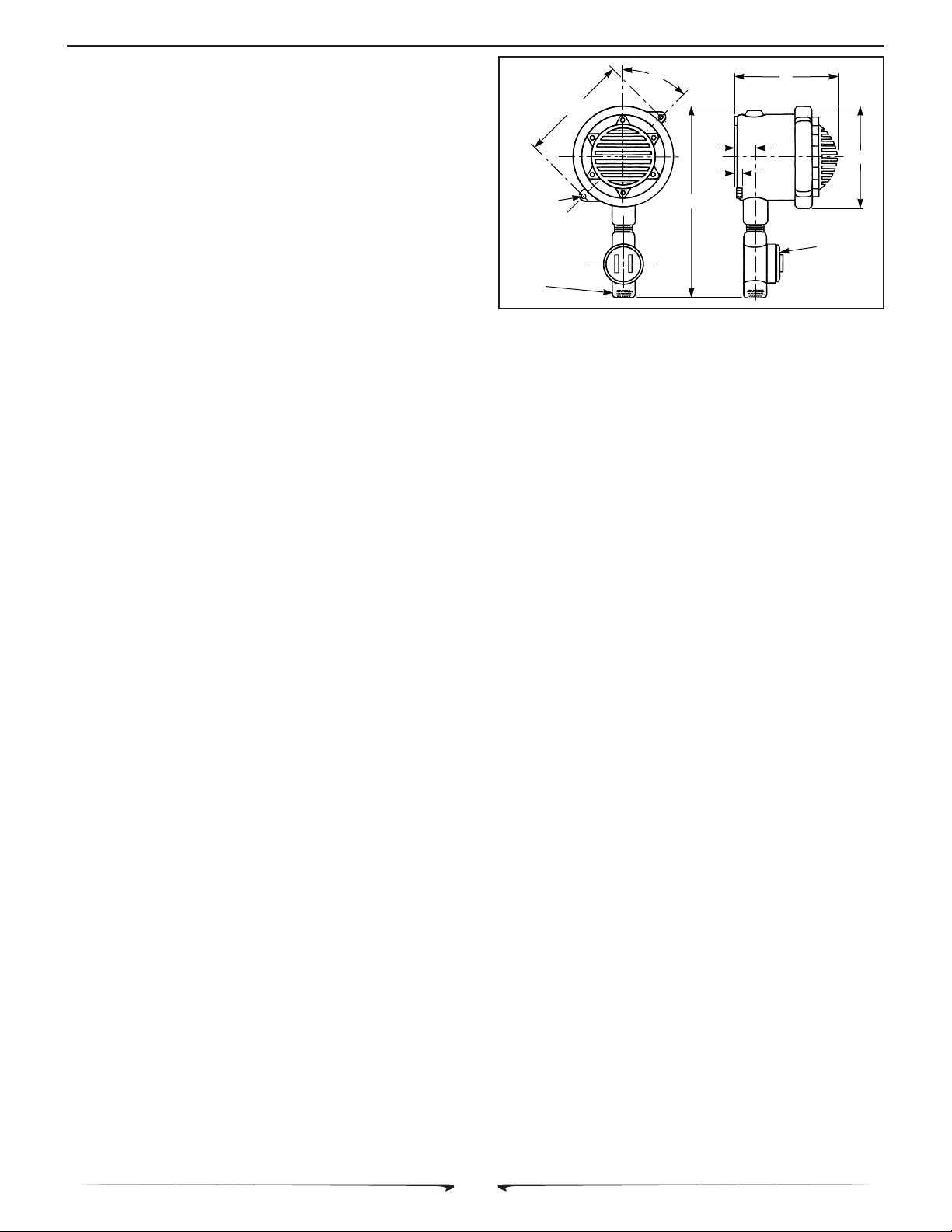

Mounting Arrangements (see figure 1).

Property damage, serious injury, or death could occur if an

accumulation of water, snow, dust, etc. resides in the horn’s

grille, severely reducing or preventing operation of this device.

Mount the unit so the grille is pointed horizontally or slightly

downward.

This device can be mounted on any relatively flat surface.

(175mm) wide, 6" (152mm) deep.

aluminum enclosure.

Splicing condulet, tapped for 3/4"

conduit.

Stainless steel diaphragm.

Exterior painted with red enamel.

Leads factory sealed.

WARNING

WARNING

- 1 -

Page 2

256884

FHEX Instruction Sheet

WARNING

Property damage, serious injury, or death could occur if any

objects are in front of the horn’s grille, severely reducing

optimum sound distribution. For maximum effectiveness,

ensure that the front of the grille is clear of obstructions.

a. Select mounting location.

b. Using the horn as a template, scribe drill position marks

on the mounting surface. See figure 1 for mounting hole locations and

dimensions.

CAUTION

Before drilling holes in any surface, be sure both sides of

surface are clear of anything that could be damaged.

c. Drill holes at the previously scribed drill position marks

to accommodate 3/8" diameter bolts.

d. Secure the horn to the mounting surface with 3/8"

diameter hex head bolts, lockwashers, and hex nuts.

Electrical Connection.

3.

DANGER

To avoid electrical shock, do not connect wires when circuits

are energized.

MOUNTING

HOLE

CENTERS

13/32" DIA.

MOUNTING

HOLES (2)

3/4" I.P.S.

OUTLET

6-1/2"

45°

6"

7/8"

1/2"

12"

CONNECTIONS

Figure 1. Model FHEX Mounting Dimensions.

3. Provide a copy of these instructions for the Safety Engineer,

system operator(s) and maintenance personnel.

SAFETY MESSAGE TO OPERATORS

Even if your warning system is operating properly, it may not

be completely effective. People may not hear or heed your

warning signal. You must recognize this fact and ensure that

your warning signal achieves its intended effect through

proper test/training sequences within your specific

application(s).

6-7/8"

REMOVABLE

COVER FOR

WIRE

290A2627-22

adhered to in the installation of this device. All electrical wiring must be

National Electrical Code as well as local codes must be

routed through conduit and fittings approved for explosion-proof instal-

lations.

WARNING

Property damage, serious injury, or death could occur if

independent conductors are terminated together; both wires

of the same polarity must be used as two separate connections. NFPA 72 requires that the wires be terminated independently to provide electrical supervision of the connection.

a. Remove splicing condulet cover. See figure 2. Connect

the device’s red (+) leads to the power source positive (+) lead. Connect

the device’s black (-) leads to the power source negative (-) lead.

WARNING

Property damage, serious injury, or death could occur if the

condulet cover is not closed properly. To reduce the possibility

of explosion, splicing condulet cover must be kept tightly

closed while circuits are energized.

b. Replace splicing condulet cover and tighten.

D. TESTING/OPERATING.

WARNING

Under certain conditions these devices are capable of producing sounds loud enough to cause hearing damage. Adequate hearing protection should be worn if standing within

close proximity to device while testing. Recommendations in

the OSHA Sound Level Standard (29 CFR 1910) should not

be exceeded.

1. After installation is complete, be sure to test the system to

verify that each horn operates satisfactorily.

E. MAINTENANCE.

SAFETY MESSAGE

TO

MAINTENANCE PERSONNEL

Failure to follow all safety precautions and instructions may result

in property damage, serious injury, or death to you or others. People’s

lives depend on your safe maintenance of our products. Read and

understand all warnings in paragraph C. INSTALLATION. In addition,

listed below are some other safety messages and precautions you

should follow:

• Read and understand all instructions before performing

maintenance on this unit.

• Do not perform maintenance on this unit when circuits are

energized.

• Periodic checks should be made to ensure that effectiveness of this device has not been reduced because

speaker has become clogged with a foreign substance

or because objects have been placed in front of the

speaker.

• Any maintenance to this unit MUST be performed by a

trained electrician in accordance with NEC guidelines

and local codes.

• Never alter this unit in any manner. Safetyin hazardous

locations may be jeopardized if additional openings or

alterations are made to this device.

• The nameplates, which contain cautionary or other

information of importance to maintenance personnel,

should not be obscured if exterior of device is painted.

1. Periodically check this device to verify that there are no

foreign substances in, or in front of, the horn’s grille which will reduce

its effectiveness.

2. After completion of initial system test, establish a program for

periodic testing of this device. Refer to NFPA 72G, local Fire Codes and

the authority having jurisdiction for this information.

2. Testing should be periodically performed. Refer to NFPA

72G, local Fire Codes and the authority having jurisdiction for information.

- 2 -

Page 3

256884

FHEX Instruction Sheet

VIBRATORY

HORN

MODEL

FHEX

24 VDC

HORN POWER

RED(+)

(

-

)

BLK

RED

BLK

Figure 2. Typical Horn Installation Wiring.

WARNING

Unauthorized repair/servicing of the unit may result in degradation of performance and/or property damage, serious

injury, or death to you or others. If a malfunctioning unit is

encountered, do not attempt any field repair/retrofit of parts.

F. SERVICE.

The factory will service your equipment or provide technical

assistance with any problem that cannot be handled locally with

satisfaction or promptness.

If any unit is returned to factory for repair, it can be accepted only

if we are notified by mail or phone in advance of its arrival. Such notice

should clearly indicate service requested and give all pertinent information regarding nature of problem and, if possible, its cause.

Communications and shipments should be addressed to:

Technical Service Department

Commercial Products Group

2519 - 4th Avenue

Moline, IL 61265

800.521.8219 • FAX 800.225.4109

Vibratone is a registered trademark of Federal Signal

Corporation.

RED

BLK

RED

BLK

290A2627-23

END OF THE LINE DEVICE

RECOMMENDED BY

CONTROL UNIT SUPPLIER

- 3 -

Loading...

Loading...