Page 1

Commercial Products Group

2519 – 4th Ave, Moline IL 61265

(800) 577 5758

Model ASHH

PowerTone® Amplified Speaker For Hazardous Locations

DOCUMENT REV CN

256886

C

1107

People's lives depend on your safe installation, test, operation, and

SAFETY MESSAGE

maintenance of our products. Read, understand, and follow all safety

messages and instructions. Refer to "Safety Messages for Equipment

Used in Fire-Protective Signaling Systems" and any other documentation

shipped with equipment before performing any system related duty.

GENERAL

This PowerTone Model ASHH is a continuous duty, polarized,

indoor/outdoor rated, high output, amplified speaker for use with fire

alarm systems. It is suitable for use in areas with high ambient noise

levels that require a loud distinctive signal. A Model UTC tone card

(purchased separately) with different tone settings may be used (see

table 2). In addition, one of two available Model PTCK plug-in connector

cards can be used. The Model PTCK plug-in connector cards will allow

use of externally generated tone or voice signals (see table 2) from a

remote audio amplifier.

The PowerTone Model ASHH is suitable for use in NEC Class I, Groups

A, B, C & D, Division 2; Class II, Groups F & G, Division 2; and Class III

hazardous locations. The speaker projector is adjustable and may be

repositioned to obtain desired sound distribution.

INSTALLATION

Unpacking

After unpacking the amplified speaker, examine it carefully for possible

damage that may have occurred in transit. If equipment has been

damaged, immediately file a claim with carrier stating extent of damage.

Carefully check all shipping labels and tags for special instructions before

removing or destroying them.

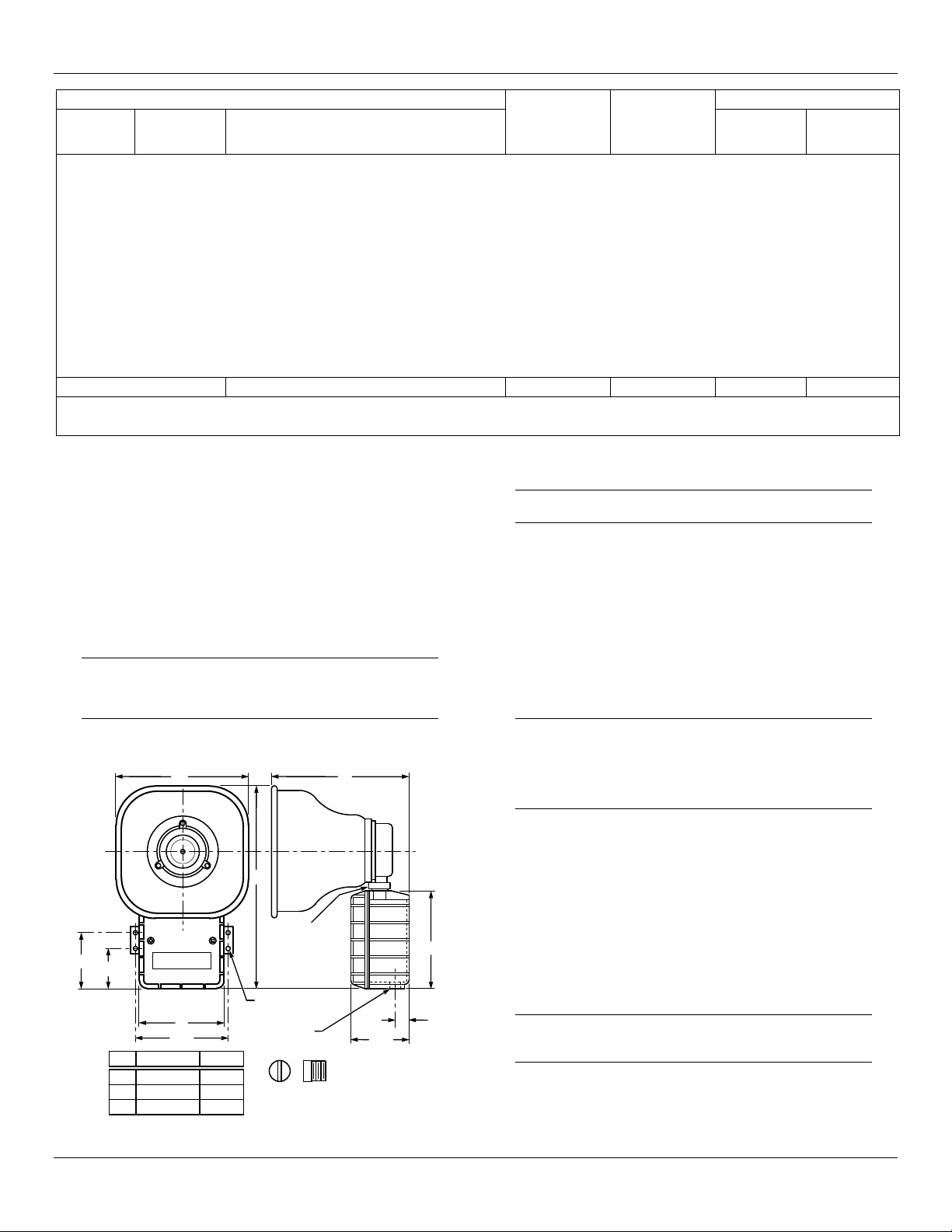

Mounting Arrangements

CAUTION

To maintain the hazardous location rating of the Model ASHH,

do not use the 7/8” knockout (concealed conduit mounting).

The amplified speaker can be mounted on any relatively flat surface.

Conduit connections can be made to two 1/2" threaded openings at the

bottom of the housing or to 7/8" knockout in rear of housing. A 1/2"

conduit plug is supplied for field installation if one of the 1/2" threaded

openings is not utilized. After the mounting location and mounting method

have been selected, proceed with the applicable instructions below (see

figure 1).

WARNING

Property damage, serious injury, or death could occur if an

accumulation of water, snow, dust, etc. resides in the speaker

projector, severely reducing or preventing operation of this

device. Mount the unit so speaker projector is pointed

horizontally or slightly downward.

Flat Surface Mounting

1. Remove and retain the two screws that secure cover to housing.

Remove the cover.

WARNING

Property damage, serious injury, or death could occur if any

objects are in front of speaker, severely reducing optimum

sound distribution. For maximum effectiveness, ensure that the

front of the speaker is clear of obstructions.

Specification Rating

UL Listed File S6476 (Guide UEAY, UUMW)

CSFM Listed 7135-1517:123

NYC MEA Approved MEA 11-92-E Vol V

Operating voltage Regulated 24VDC

Supervisory voltage 24VDC max

Operating current (includes tone

card or connector card)

Weight (approx) 5 lb (2.25kg)

Size 11-7/8" (302mm) high, 8-1/8" (206mm)

Construction Aluminum enclosure painted with red

Environmental rating Outdoor wet

Temperature range -40° to +151° F (-40° to +66° C)

Relative Humidity 95% Non-condensing

Hazardous Locations Class I, Groups A, B, C, D, Division 2

1. Select the mounting location and place rear of housing against

mounting surface.

2. Using the mounting holes (four (4) in external mounting bracket) as a

template, scribe drill position marks on the mounting surface. See

figure 1 for mounting hole locations and dimensions.

Before drilling holes in any surface, ensure that both sides of

surface are clear of items that could be damaged.

3. Secure the unit to a wooden mounting surface with #10 x 1" wood

screws. If mounting on a metal surface, drill 13/64" diameter holes and

secure the unit with #10 screws, lockwashers and nuts.

4. Route power and supervision leads through conduit to the audible

signal. Install a 1/2" electrical connector at the bottom of the audible

signal. Route wires through conduit and electrical connector into the

audible signal housing. Install supplied 1/2" conduit plug if only one

1/2" conduit entrance is used.

Property damage, serious injury or death could occur if the

projector is mishandled during installation or over time. DO

NOT rotate the projector more than 180 degrees or internal

speaker wiring may be damaged.

File E190743 (Guide UGKZ)

0.225A (5.4W)

.06A standby

wide, 8" (203mm) deep.

enamel. Amplifier housing sealed with

neoprene rubber gasket.

Class II, Groups F, G, Division 2

Class III

WARNING

WARNING

- 1 -

Page 2

Model ASHH PowerTone® Amplified Speaker For Hazardous Locations Document #256886

290A3359

5-5/8

13/16

3-3/8

5-1/2

2-1/4

3-1/4

5

INCHES MM

A

B

C

206

302

203

8-1/8

11-7/8

8

COLLAR

NUT

B

A C

.201 DIA. 4 HOLES

(MOUNTING)

1/2-14 NPT

1/2" CONDUIT PLUG

SUPPLIED

Tone Card Sound (Model UTC) Audibility

Selection Name Description

Audible

Frequency (Hz)

Repetition rate

(cycles/min)

dB(A)

Sound Power

UL dB(A)

Sound

Pressure

TM1 Wail Conventional siren 550-1250 11 118.1 97.5

TM2 Yelp Rapid siren 550-1250 3.3 Hz 118.0 97.4

TM3 Hi-Lo Alternating high and low 560 and 760 50 116.9 96.3

TM4 Bell Bell, struck repeatedly 800 50 115.8 95.2

TM5 Yeow Descending high to low, repeated 1300 and 550 36 118.0 97.4

TM6 Horn Steady horn 470 Continuous 112.2 91.6

TM7 Beep Slow intermittent horn 470 50 110.8 90.2

TM8 Stutter Rapid intermittent horn 470 5 110.3 89.7

TM9 Slow Whoop Slow ascending, low to high – repeated 420 and 1160 15 116.1 95.5

TM11 Temporal

Slow Whoop

NFPA coded slow whoop (fire alarm use only) 420 and 1160 15 113.9 93.3

Connector card model Rated voltage

PTCK25 25 VRMS 112.4 97.8

PTCK70 70 VRMS 112.2 97.6

Table 2: Tone and connector card ratings for Model ASHH

5. Reposition speaker projector if necessary to obtain desired sound

coverage. Loosen collar nut (see figure 1) and move projector to

desired position.

6. Before reinstalling the housing cover, read section Electrical

Connections below and make the necessary electrical connections.

Electrical Connection

National Electrical Code as well as local codes must be adhered to in the

installation of these models. All electrical wiring must be routed through

approved conduit and fittings as specified.

WARNING

Property damage, serious injury, or death could occur if

independent conductors are terminated together. NFPA 72

requires that the wires be terminated independently to provide

electrical supervision of the connection.

Property damage, serious injury, or death could occur if the

housing is not closed properly.

Tone Card Installation

1. See figure 2. Connect the device’s red (+) leads to the power source

positive (+) lead. Connect the device’s black (-) leads to the power

source negative (-) lead.

2. Plug the desired tone card into the socket as shown in figure 3.

3. To ensure a proper seal, be sure that the neoprene rubber cover

gasket is properly seated in the housing groove and reinstall the

housing cover.

PTCK Connector Kit Installation

WARNING

Property damage, serious injury, or death could occur if

independent conductors are terminated together; both wires of

the same polarity must be used as two separate connections.

NFPA 72 requires that the wires be terminated independently

to provide electrical supervision of the connection, for both the

24 Vdc speaker power and 25 VRMS or 70 VRMS audio lines.

1. See figure 2. Connect the device’s red (+) leads to the power source

positive (+) lead. Connect the device’s black (-) leads to the power

source negative (-) lead.

2. Plug the desired PTCK connector card (purchased separately) into the

socket as shown in figure 3.

3. Connect the white leads from the connector card to the audio input

and outputs.

4. To ensure a proper seal, be sure that the neoprene rubber cover

gasket is properly seated in the housing groove and reinstall the

housing cover.

NOTE

Check with authority having jurisdiction for proper application

of EOL resistor and power supervision relay required (see

figure 4).

- 2 -

Figure 1: Model ASHH Dimensions

Page 3

Model ASHH PowerTone® Amplified Speaker For Hazardous Locations Document #256886

290A2627-10B

VOLUME CONTROL

AMPLIFIER BOARD

+ RED

RED

BLK

- BLK

INSTALL

TONE CARD HERE

P2

24VDC

SPEAKER

MODEL ASHH

RED

BLK

(SERIES B)

RED

BLK

DEVICE

RECOMMENDED

-

BY CONTROL

UNIT

SUPPLIER

290B3360

END OF LINE

+

Figure 2: Typical Tone Card Installation Wiring

Figure 3: Tone/Connector Card Installation

OPERATION/TESTING

WARNING

Under certain conditions these devices are capable of

producing sounds loud enough to cause hearing damage.

Adequate hearing protection should be worn if standing within

close proximity to device while testing. Recommendations in

the OSHA Sound Level Standard (29 CFR 1910) should not be

exceeded.

Property damage, serious injury, or death could occur if the

housing is not closed properly. To reduce possibility of

explosion, housing cover must be kept tight (all eight bolts fully

tightened) while circuits are energized.

After installation is complete, be sure to test the system to verify that

each amplified speaker operates satisfactorily.

After completion of initial system test, establish a program for periodic

testing of this device. Refer to NFPA 72, local Fire Codes and the

- 3 -

INTERNAL PTCK

CONNECTOR CARD

(25 OR 70 VRMS

SUPPLIED

SEPARATELY)

25 OR 70 VRMS

AUDIO

24 VDC

POWER

END OF THE LINE DEVICE

RECOMMENDED BY

CONTROL UNIT SUPPLIER.

POWER SUPERVISION

WHT

WHTWHT

(+)

(-)

RED

BLK

RED

BLK

WHTWHT

WHT

RED

BLK

WHT

WHT

RED

BLK

RELAY MODEL

A77-716-02 BY

SYSTEM SENSOR, OR

MODEL R64 BY

UNITED SECURITY

PRODUCTS, OR

MODEL PAM-2, BY

AIR PRODUCTS &

CONTROLS LTD.

290A2627-12B

Figure 4: Typical connector card (PTCK) installation wiring

Page 4

Model ASHH PowerTone® Amplified Speaker For Hazardous Locations Document #256886

authority having jurisdiction for this information.

Provide a copy of these instructions for the Safety Engineer, system

operator(s) and maintenance personnel.

MAINTENANCE

Periodically check this device to verify that there are no foreign

substances in, or in front of, the speaker which will reduce its

effectiveness.

Testing should be periodically performed. Refer to NFPA 72, local Fire

Codes and the authority having jurisdiction for information.

In the event a repair is required, be sure to refer to the Safety Message to

Maintenance Personnel before proceeding.

SERVICE

The factory will service your equipment or provide technical assistance

with any problem that cannot be handled locally with satisfaction or

promptness.

If any unit is returned to factory for repair, it can be accepted only if we

are notified by mail or phone in advance of its arrival. Such notice should

clearly indicate service requested and give all pertinent information

regarding nature of problem and, if possible, its cause.

To get help with problems or questions not covered in these instructions,

contact the Technical Service Department.

PowerTone is a registered trademark of Commercial Products Group.

- 4 -

Loading...

Loading...