Harrington Hoists and Cranes RHN User Manual

EFFECTIVE: December 20, 2012

ELECTRIC

WIRE ROPE

HOIST and TROLLEY

RHN SERIES

2 Ton through 20 Ton Capacity

Hoist Code and Serial Number

This equipment sh ould not be i nstal le d, op erat ed or

maintained by a ny pers on w ho has n ot read and

understood all t he cont ents o f this manu al. Fail ur e to r ead

and comply w ith th e co nte nts of thi s m anual c an res ul t in

serious bodily inj ury or dea th, and/ or pr op erty d amag e.

Table of Contents

Section Page Number

1.0 Important Information and Warnings…………………………………………….……………………. 4

1.1 Terms and Summary

1.2 Warning Tags and Labels

2.0 Technical Information ……………………………. …………………………………………………….. 8

2.1 Specifications

2.2 Dimensions

2.3 Miscellaneous

3.0 Pre-operational Procedures……………………………………………………………………….….. 20

3.1 General Information

3.2 Handling

3.3 Mounting Location

3.4 Assembly, Adjustments and Mounting

3.5 Electrical Connections

3.6 Pendant Installation

3.7 RPU Load Monitor Device

3.8 Hoist Limit Switches and Adjustment

3.9 Pre-operational Checks and Trial Operation

4.0 Operation……………………………………………………………………………………………….. 36

4.1 Introduction

4.2 Shall’s and Shall Not’s for Operation

4.3 Hoist and Trolley Controls

5.0 Inspection……………………………………………………………………………………………….. 39

5.1 General

5.2 Inspection Classification

5.3 Frequent Inspection

5.4 Periodic Inspection

5.5 Occasionally Used Trolley Hoists

5.6 Inspection Records

2

Section Page Number

5.7 Inspection Methods and Criteria

6.0 Maintenance & Handling………………………………………………………………………….…… 52

6.1 Count/Hour Meter

6.2 Lubrication

6.3 Hoist Motor Brake

6.4 Trolley Motor Brake

6.5 Wire Rope

6.6 Reeving and Anchorage

6.7 Storage

6.8 Outdoor Installation

6.9 Optional Environment

7.0 Troubleshooting………………………………………………………………………………………… 65

8.0 Warranty…………………………………………………………………………………………………. 69

9.0 Parts List …………………………………………… …………………………………………………. 70

3

1.0 Important Informat ion and W arnings

1.1 Terms and Summary

This manual provides important informati on for personnel involved with the installation, operation and

maintenance of this product. Although you may be familiar with this or similar equipment, it is strongly recommended

that you read this manual before installing, operating or maintaining the product.

Danger, Warning, Cauti on and Notic e - Throughout this manual there are steps and procedures that can present

hazardous situations. The following signal words are used to identify the degree or level of hazard seriousness.

Danger indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury, and property damage.

Warning indicates an imminently hazardous situation which, if not avoided, could result in death

or serious injury, and property damage.

Caution indicates a potentially hazardous situation which, if not avoided, may result minor or

moderate injury or property damage.

Notice is used to notify people of installation, operation, or maintenance information which is

important but not directly hazard-related.

These general instructions deal with the normal installation, operation, and maintenance situations encountered with

the equipment described herein. The instructions should not be interpreted to anticipate every possible contingency

or to anticipate the final system, crane, or configuration that uses this equipment. For systems using the equipment

covered by this manual, the supplier and owner of the system are responsible for the system’s compliance with all

applicable industry standards, and with all applicable federal, state and local regulations/codes.

This manual includes instructions and parts information for the RH Advantage trolley hoist. Therefore, all instructions

and parts information may not apply to any one type or size of specific trolley hoist. Disregard those portions of the

instructions that do not apply.

Record your trolley hoist’s Product Code and Serial Number on the front cover of this manual for identification and

future reference to avoid referring to the wrong manual for information or instructions on installation, operation,

inspection, maintenance, or parts.

Use only Harrington authorized replacement parts in the service and maintenance of this trolley.

4

Equipment described herein is not designed for and MUST NOT be used for lifting, supporting, or transporting people,

or for lifting or supporting loads over people.

Equipment described herein should not be used in conjunction with other equipment unless necessary and/or

required safety devices applicable to the system, crane, or application are installed by the system designer, system

manufacturer, crane manufacturer, installer, or user.

Modifications to upgrade, rerate, or otherwise alter this equipment shall be authorized only by the original equipment

manufacturer.

Equipment described herein may be used in the design and manufacture of cranes or monorails. Additional

equipment or devices may be required for the crane and monorail to comply with applicable crane design and safety

standards. The crane designer, crane manufacturer, or user is responsible to furnish these additional items for

compliance. Refer to ANSI/ASME B30.17, “Safety Standard for Top-Running Single Girder Cranes”; ANSI/ASME

B30.2 “Safety Standard for Top-Running Double-Girder Cranes”; and ANSI/ASME B30.11 “Safety Standard for

Underhung Cranes and Monorails”.

Hoists, trolleys and cranes, used to handle hot molten material may require additional equipment or devices. Refer to

ANSI Z241.2, “Safety Requirements for Melting and Pouring of Metals in the Metalcasting Industry”.

Electrical equipment described herein is designed and built in compliance with Harrington's interpretation of

ANSI/NFPA 70, “National Electrical Code”. The system designer, system manufacturer, crane designer, crane

manufacturer, installer, or user is responsible to assure that the installation and associated wiring of these electrical

components is in compliance with ANSI/NFPA 70, and all applicable Federal, State and Local Codes.

Failure to read and comply with any one of the limitations noted herein can result in serious bodily injury or death,

and/or property damage.

5

HAZARDOUS VOLTAGES ARE PRESENT IN THE CONTROL BOX, OTHER ELECTRICAL COMPONENTS,

AND CONNECTIONS BETWEEN THESE COMPONENTS.

Before performing ANY mechanical or electrical maintenance on the equipment, de-energize (disconnect) the main

switch supplying power to the equipment; and lock and tag the main switch in the de-energized position. Refer to

ANSI Z244.1, “Personnel Protection – Lockout/Tagout of Energy Sources”.

Only trained and competent personnel should inspect and repair this equipment.

It is the responsibility of the owner/user to install, inspect, test, maintain, and operate a trolley hoist in accordance with

ANSI/ASME B30.16, “Safety Standard for Overhead Hoists”, OSHA Regulations and ANSI/NFPA 70, "National

Electric Code". If the trolley hoist is installed as part of a total lifting system, such as an overhead crane or monorail, it

is also the responsibility of the owner/user to comply with the applicable ANSI/ASME B30 volume that addresses that

type of equipment.

It is the responsibility of the owner/user to have all personnel that will install, inspect, test, maintain, and operate a

trolley hoist read the contents of this manual and applicable portions of ANSI/ASME B30.16, “Safety Standard for

Overhead Hoists”, OSHA Regulations and ANSI/NFPA 70, “National Electric Code”. If the trolley is installed as part of

a total lifting system, such as an overhead crane, the applicable ANSI/ASME B30 volume that addresses that type of

equipment must also be read by all personnel.

If the trolley hoist owner/user requires additional information, or if any information in the manual is not clear, contact

Harrington or the distributor of the trolley. Do not install, inspect, test, maintain, or operate this trolley hoist unless this

information is fully understood.

A regular schedule of inspection of the trolley hoist in accordance with the requirements of ANSI/ASME B30.16 should

be established and records maintained.

6

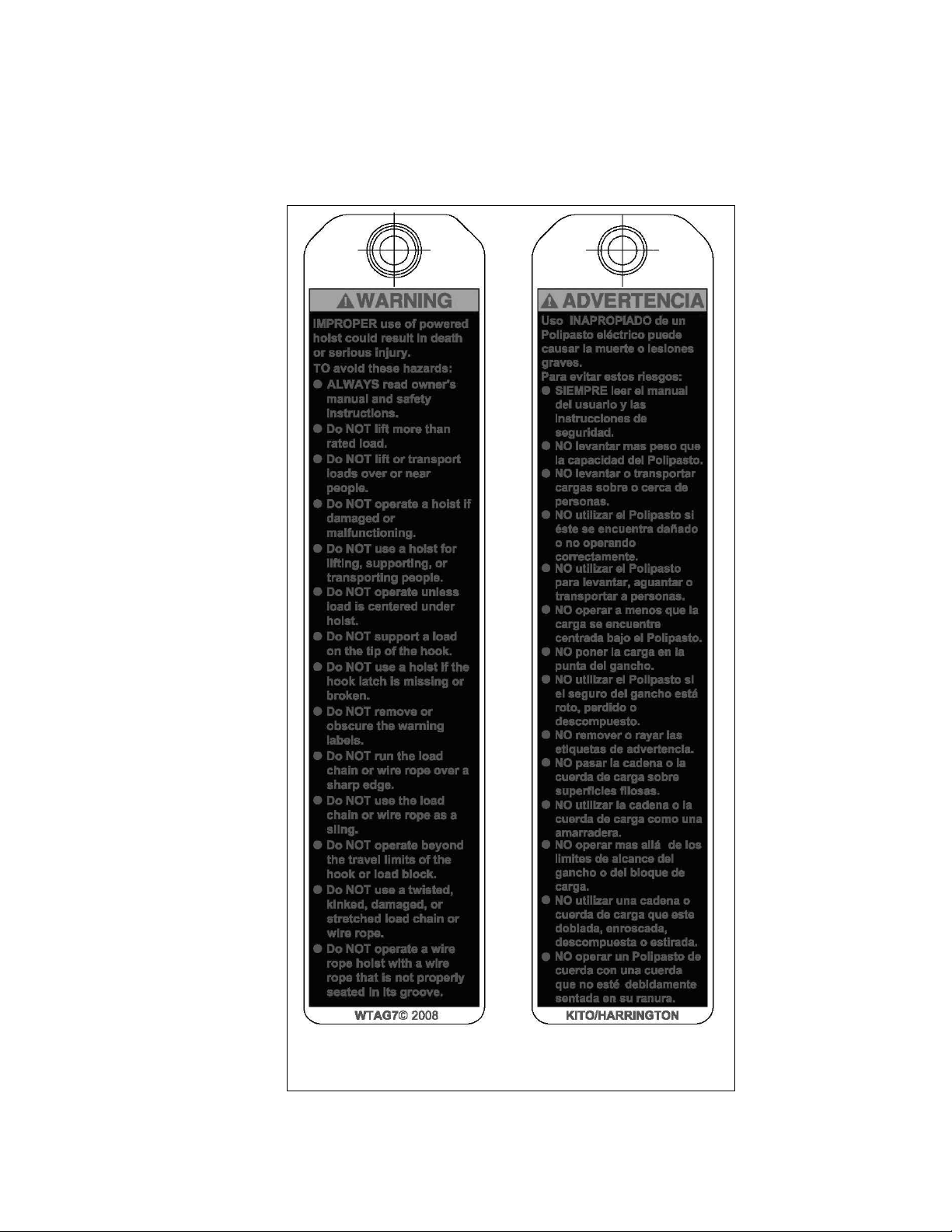

1.2 Warning Tag and Labels

The warning tag illustrated below in Figure 1-1 is supplied with each RHN hoist and trolley hoist shipped from

the factory. If the tag is not attached to the pendant cord for your hoist/trolley, order a tag from your dealer and

install it. Read and obey all warnings attached to this Trolley Hoist. Tag is not shown actual size.

front back

Figure 1-1 Warning Tag Attached to Trolley Hoist

7

2.0 Technical Informat ion

2.1 Specifications

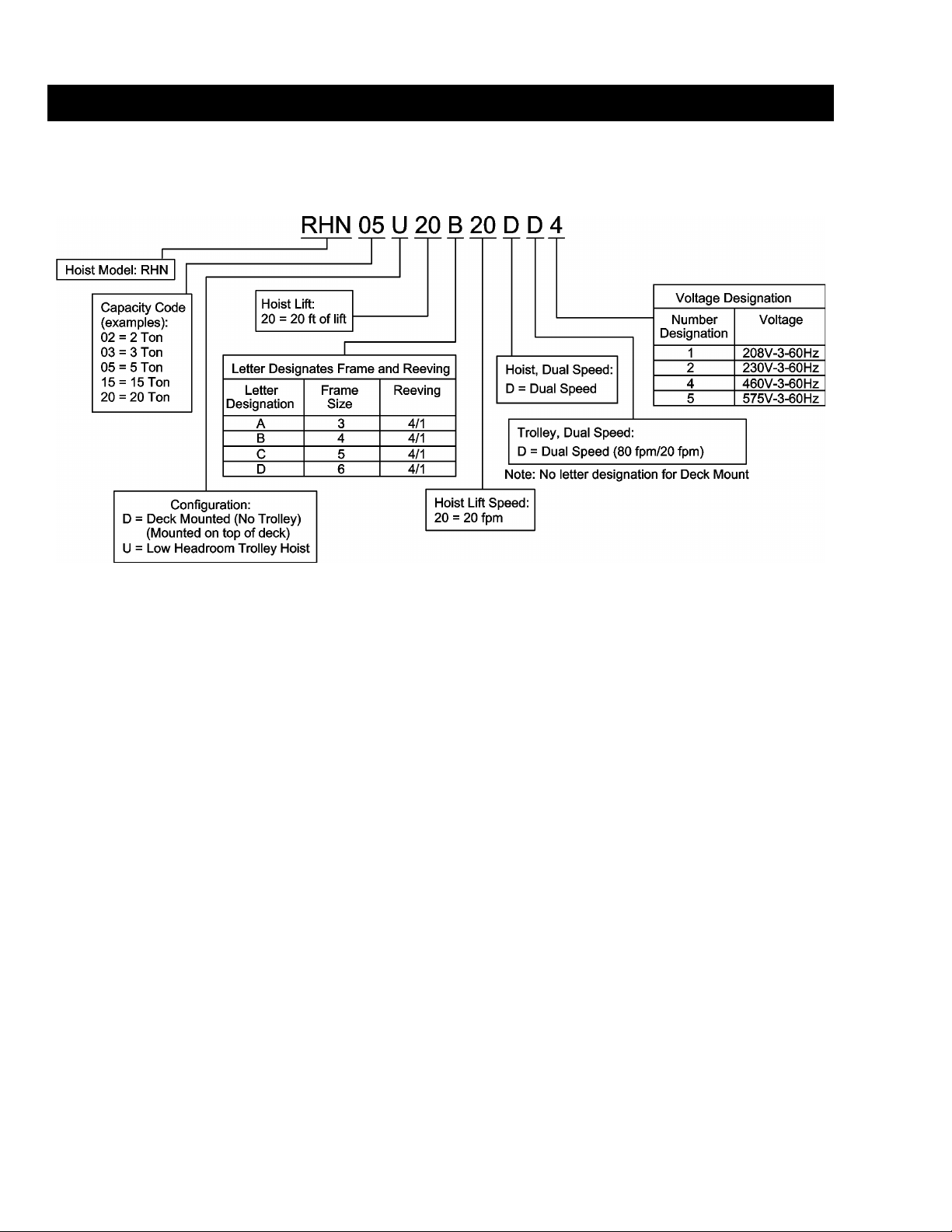

2.1.1 Product Code:

2.1.2 Operating Conditions and Environment

Temperature Range: +14° to +104°F (-10° t o +40°C)

Humidity: 80% or less

Electrical Enclosure Rating: IP55

Brake Enclosure Rating: IP66

Supply Voltage: 208V or 230V or 460V or 575V-3ph-60Hz

Control Voltage: 110V-1ph-60Hz

Noise Rating: less than 85 dba at full speed (A scale: measured 1 meter

away from electric wire rope hoist)

8

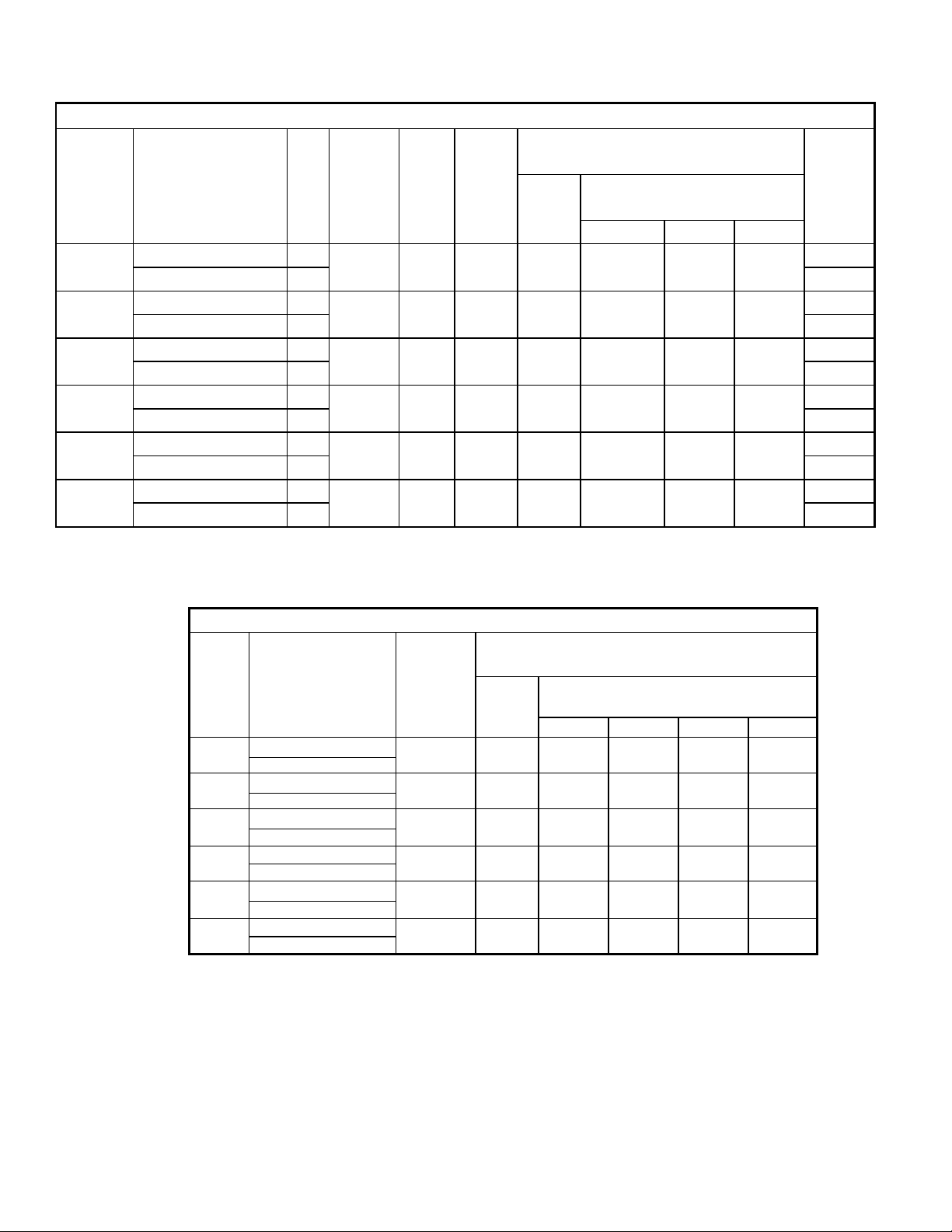

Table 2-1 Deck Mounted Hoist Specifications

Capacity

(Ton)

2

3

5

7 ½

10

15

20

*See Section 2.1.1 for place holder designation

Product Code*

RHN02D-20A-20D- 20

RHN02D-33A-20D- 33 375

RHN03D-20A-20D- 20

RHN03D-33A-20D- 33 375

RHN05D-20B-20D- 20

RHN05D-33B-20D- 33 485

RHN08D-20C-20D- 20

RHN08D-33C-20D- 33 1102

RHN10D-20C-20D- 20

RHN10D-33C-20D- 33 1102

RHN15D-20D-16D- 20

RHN15D-33D-16D- 33 2436

RHN20D-20D-16D- 20

RHN20D-33D-16D- 33 2436

Lift

(ft.)

Dual Speed Hoist Lifting Motor

Reeving

(Parts/

reeving)

Rope

Dia.

(mm)

Lifting

Speed

(ft/min)

Output

(Hp)

Hi/Low

4/1 7 20/3.5 5.8/0.9 17.0/8.4 8.3/4.0 6.6/3.2

4/1 7 20/3.5 5.8/0.9 17.0/8.4 8.3/4.0 6.6/3.2

4/1 9 20/3.5 7.2/1.2 22.0/11.0 10.0/5.4 8.2/4.3

4/1 12.5 20/3.5 14.8/2.1 42.0/21.0 20.0/10.0 16.0/8.0

4/1 12.5 20/3.5 14.8/2.1 42.0/21.0 20.0/10.0 16.0/8.0

4/1 20 16/2.5 24.1/4.0 67.0/27.0 32.0/13.0 25.6/10.4

4/1 20 16/2.5 24.1/4.0 67.0/27.0 32.0/13.0 25.6/10.4

3 Phase, 60 Hz

Current Draw

(amps) - Hi/Low

208&230V 460V 575V

Net

Weight

(lbs)

353

353

452

1025

1025

2271

2271

9

Table 2-3 Ultra-Low Headroom Trolley Hoists Trolley Specifications

Standard

Flange Range

RHN02U-20A-20DD-

RHN02U-33A-20DD-

RHN03U-20A-20DD-

RHN03U-33A-20DD-

RHN05U-20B-20DD-

RHN05U-33B-20DD-

RHN08U-20C-20DD-

RHN08U-33C-20DD-

RHN10U-20C-20DD-

RHN10U-33C-20DD-

RHN15U-28D-12DD-

RHN15U-46D-12DD-

Capacity

(Ton)

7 ½

10

15

Table 2-2 Ultra-Low Headroom Trolley Hoists Hoist Specifications

Reeving

Product Code*

2

3

5

RHN02U-20A-20DD- 20

RHN02U-33A-20DD- 33 650

RHN03U-20A-20DD- 20

RHN03U-33A-20DD- 33 650

RHN05U-20B-20DD- 20

RHN05U-33B-20DD- 33 831

RHN08U-20C-20DD- 20

RHN08U-33C-20DD- 33 1872

RHN10U-20C-20DD- 20

RHN10U-33C-20DD- 33 1872

RHN15U-28C-12DD- 28

RHN15U-46C-12DD- 46 3439

*See Section 2.1.1 for place holder designation.

Capacity

(Tons)

Lift

(Parts/

(ft.)

reeving)

Product Code

Dual Speed Hoist Lifting Motor

Rope

Dia.

(mm)

Lifting

Speed

(ft/min)

Output

(Hp)

Hi/Low

4/1 7 20/3.5 5.8/0.9 17.0/8.4 8.3/4.0 6.6/3.2

4/1 7 20/3.5 5.8/0.9 17.0/8.4 8.3/4.0 6.6/3.2

4/1 9 20/3.5 7.2/1.2 22.0/11.0 10.0/5.4 8.2/4.3

4/1 12.5 20/3.5 14.8/2.1 42.0/21.0 20.0/10.0 16.0/8.0

4/1 12.5 20/3.5 14.8/2.1 42.0/21.0 20.0/10.0 16.0/8.0

4/1 14 12/2.0 14.8/2.1 42.0/21.0 20.0/10.0 16.0/8.0

B*

(in)

Output

(Hp)

Hi/Low

208V 230V 460V 575V

3 Phase, 60 Hz

Current Draw

(amps) - Hi/Low

208&230V 460V 575V

Dual Speed Traversing Motor

80 and 20 ft/min

Current Draw

(amps) - Hi/Low

Net

Weight

(lbs)

617

617

767

1766

1766

3086

2

3

5

7 ½

10

15

*Optional wider flange ranges available up to 19.7 inches. Consult factory.

3.25-12 0.59/0.15 3.0/2.3 2.6/2.0 1.3/1.0 1.0/0.8

3.25-12 0.59/0.15 3.0/2.3 2.6/2.0 1.3/1.0 1.0/0.8

3.63-12 0.59/0.15 3.0/2.3 2.6/2.0 1.3/1.0 1.0/0.8

4.63-12 0.89/0.21 3.7/2.8 3.2/2.4 1.6/1.2 1.3/1.0

4.63-12 0.89/0.21 3.7/2.8 3.2/2.4 1.6/1.2 1.3/1.0

8.75-12 2.01/0.48 6.9/3.2 6.0/2.8 3.0/1.4 2.4/1.1

10

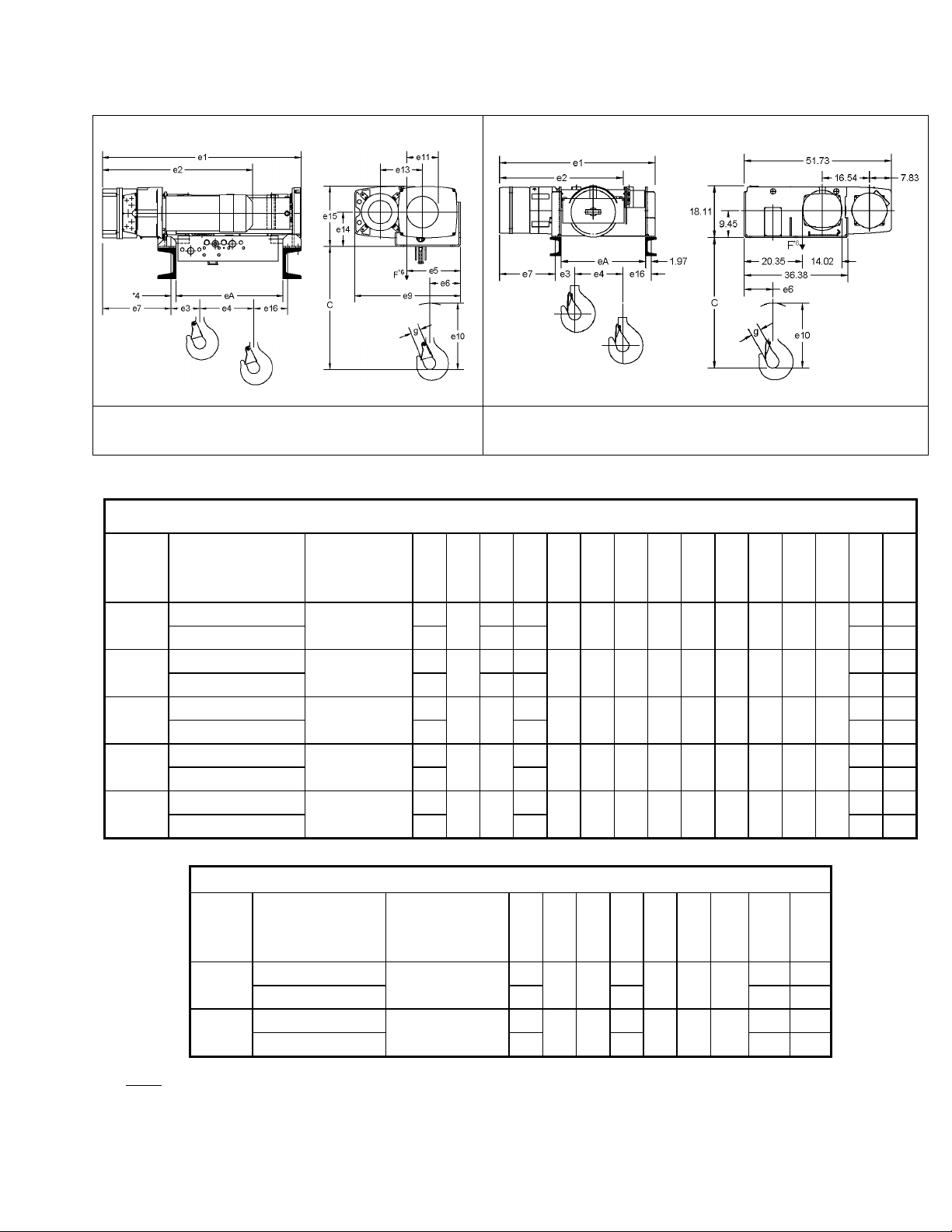

2.2 Dimensions

Table 2-4 Deck Mounted Hoist Dimensions (2-10 ton)**

Figure 2-1 2-10 ton Deck Mounted Hoist

Dimensions (See T able 2-4)

Capacity

(Tons)

2

3

5

7 ½

10

Product Code*

RHN02D-20A-20D-

RHN02D-33A-20D- 52.5

RHN03D-20A-20D-

RHN03D-33A-20D- 52.5

RHN05D-20B-20D-

RHN05D-33B-20D- 52.9

RHN08D-20C-20D-

RHN08D-33C-20D- 60.4

RHN10D-20C-20D-

RHN10D-33C-20D- 60.4

Min. Headroom

C

(in)

22.6

22.6

25.6

32.5

32.5

Table 2-5 Deck Mounted Hoist Dimensions (15 & 20 ton)**

e1

(in)

40.9

40.9

41.3

48.0

48.0

Figure 2-2 15-20 ton Deck Mounted Hoist

Dimensions (See T able 2-5)

e2

e3

e4

e5

e6

e7

e9

e10

e11

e13

e14

e15

(in)

(in)

(in)

(in)

(in)

(in)

(in)

(in)

(in)

(in)

(in)

(in)

6.3 4.6

29.6

6.2 7.6 22.1 33.8

6.3 4.6

29.6

6.2 7.6 22.1 33.8

31.2 6.4

39.3 9.5

39.3 9.5

9.0 4.8 13.9 21.3 11.5 4.9 7.2 6.3 11.0

9.0 4.8 13.9 21.3 11.5 4.9 7.2 6.3 11.0

4.3

11.2 5.9 14.3 22.0 13.8 6.6 8.8 7.2 12.9

7.2 22.2 33.8

4.6

14.1 7.5 17.2 28.6 18.2 8.6 11.7 9.4 16.9

7.8 21.8 37.0

4.6

14.1 7.5 17.2 28.6 18.2 8.6 11.7 9.4 16.9

7.8 21.8 37.0

e16

eA

(in)

(in)

13.3 22.2

13.3 22.2

13.5 22.2

12.6 24.6

12.6 24.6

Capacity

(Tons)

15

20

Notes:

*See Section 2.1.1 for place holder designation

** See Table 2-10 and Table 2-11 for attachment point dimensions

Product Code*

RHN15D-20D-16D-

RHN15D-33D-16D- 66.6

RHN20D-20D-16D-

RHN20D-33D-16D- 66.6

Min. Headroom

C

(in)

37.0

37.0

e1

(in)

54.4

54.4

e2

e3

(in)

(in)

43.7 13.4

43.7 13.4

e4

e6

e7

e10

e16

eA

(in)

(in)

(in)

(in)

(in)

(in)

4.6

10.9 19.5 29.7

7.6 24.9 41.9

4.6

10.9 19.5 29.7

7.6 24.9 41.9

15.7 29.7

15.7 29.7

11

†

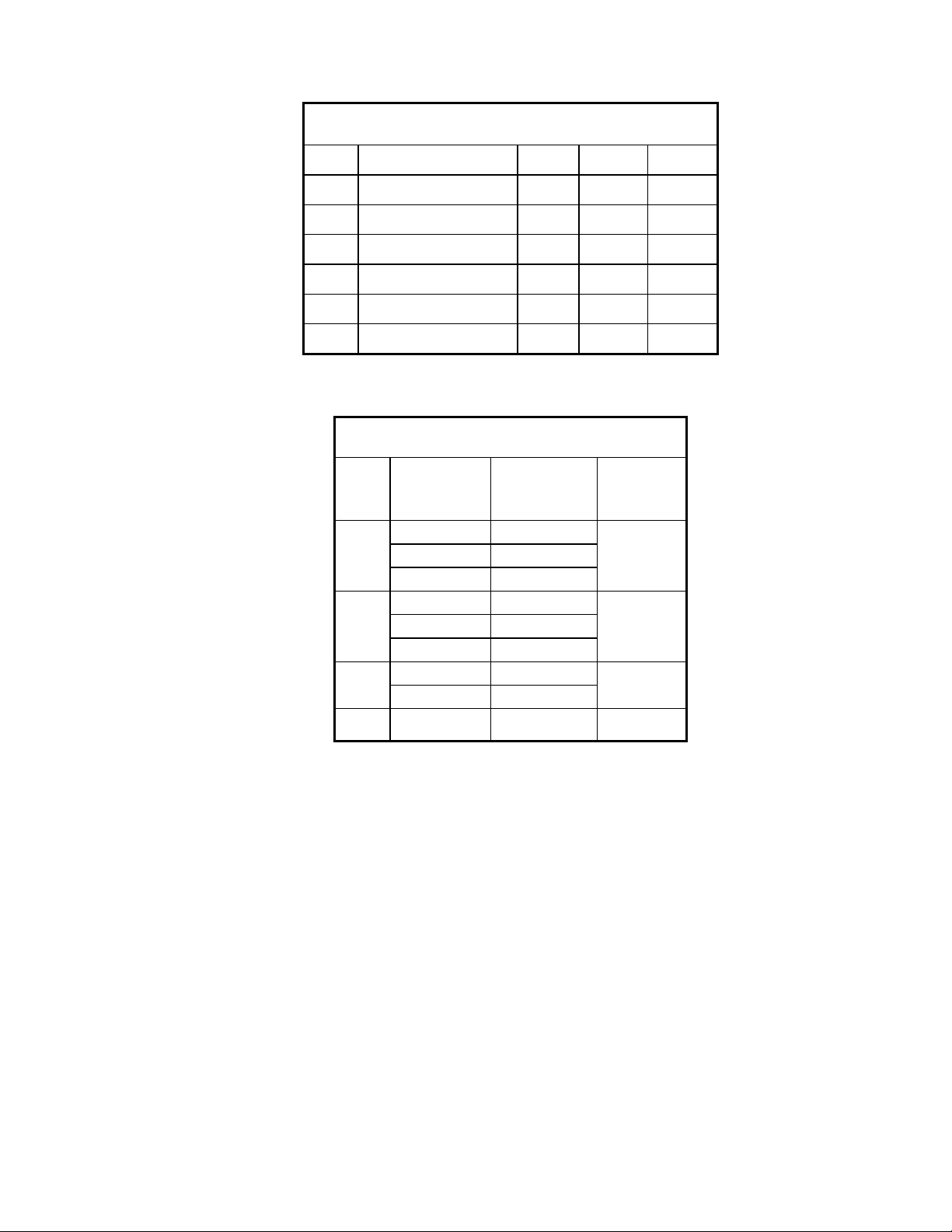

Table 2-6 Ultra-Low Headroom Trolley Hoist Dimensions

e1

e4

e10

d1

d2

d3

f1

f2

f3

f5

f6

u1

u2

u3

u4

Capacity

(Tons)

2

3

5

7 ½

10

15*

Product Code*1

RHN02U-20A-20DD- 40.3 4.6

RHN02U-33A-20DD- 51.9 7.6 10.7 41.6 34.1 9.0 17.4

RHN03U-20A-20DD- 40.3 4.6

RHN03U-33A-20DD- 51.9 7.6 10.7 41.6 34.1 9.0 17.4

RHN05U-20B-20DD- 41.2 4.3

RHN05U-33B-20DD- 54.6 7.2 8.1 8.1 10.9 47.3 40.0 15.8 17.0

RHN08D-20C-20DD- 47.2 4.6

RHN08U-33C-20DD- 59.6 7.8 15.0 46.1 37.0 12.6 16.6

RHN10U-20C-20DD- 47.2 4.6

RHN10U-33C-20DD- 59.6 7.8 15.0 46.1 37.0 12.6 16.6

RHN15U-28D-12DD- 65.6

RHN15U-46D-12DD- 79.7† 7.7 15.2 69.5

(in)

(in)

(in)

(in)

(in)

(in)

(in)

11.5 28.6 18.0 3.7 13.9 8.9 6.5 6.1

11.5 28.6 18.0 3.7 13.9 8.9 6.5 6.1

13.8 30.8 18.2 3.7 13.5 9.1

18.2 37.0 22.9 4.5 16.1 11.4 10.7 9.8

18.2 37.0 22.9 4.5 16.1 11.4 10.7 9.8

†

4.6

23.0 44.4 25.2 6.6 24.5 11.8

(in)

(in)

(in)

(in)

(in)

11.9 30.0 22.4 9.1

11.9 30.0 22.4 9.1

7.7 6.5 12.1 29.8 22.4 9.9

15.7 33.7 24.6 12.6

15.7 33.7 24.6 12.6

10.0 10.0

16.7 49.4

(in)

(in)

†

40.7 15.9

60.8 23.7 29.4

u5

(in)

(in)

5.1 5.9

5.1 5.9

5.6 5.6

6.7 6.7

6.7 6.7

8.7 8.7

Notes:

* Refer to Table 2-7 for motor dimensions m0, m1, and m2. Motor dimension m0 may extend past the counterweight depending on the

hoist model and flange width B.

*1 - See Section 2. 1. 1 for place holder designation

*3 - Refer to Table 2-8 for flange range dimension B (Trolleys are suitable for use on S or W shaped beams)

*4 - Refer to Table 2-8 for headroom dimension C

*5/*6 – Observe clearance dimensions

† - For the 15t trolley hoist model, this measurement is to the end of the trolley frame because it extends past the drum cover shown in the

figure.

u6

(in)

8.7

8.7

8.3

7.4

7.4

20.3

12

Dimensions

Capacity

(Tons)

m0

(in)

m1

(in)

m2

(in)

RHN02U-20A-20DD-

RHN02U-33A-20DD-

RHN03U-20A-20DD-

RHN03U-33A-20DD-

RHN05U-20B-20DD-

RHN05U-33B-20DD-

RHN08U-20C-20DD-

RHN08U-33C-20DD-

RHN10U-20C-20DD-

RHN10U-33C-20DD-

RHN15U-28D-12DD-

RHN15U-46D-12DD-

Table 2-8 Ultra-Low Headroom Trolley Hoist

Headroom Dimensions

Headroom, C

(in)

Table 2-7 Ultra-Low Headroom Trolley Motor

Product Code*

2

3

5

7 ½

10

15

*See Section 2.1.1 for place holder designation

Capacity

(Tons)

2

3

5

7 ½

10

Flange Range, B

(in)

3.25-4.69 22.0

6.69-12 17.6+(0.58*T)

3.625-4.69 26.2

6.69-12 27.5-(0.23*T)

4.625-6.69 33.1-(0.29*T)

6.69-12 33.4-(0.35*T)

20.6 7.4 1.3

20.6 7.4 1.3

20.6 7.4 1.3

22.4 9.5 0.8

22.4 9.5 0.8

26.5 10.1 1.3

Headroom, C*

(in)

for 6 inch

Flange

21.7 4.69-6.69 23.4-(0.29*T)

26.0 4.69-6.69 26.6-(0.10*T)

31.4

15 8.75-12 40.8-(0.31*T) 38.0**

*T in formulas is the exact beam flange width in inches.

**Headroom value for 9 inch flange.

13

2.3 Miscellaneous

Table 2-9 Hook Dimension*

Units = inch

Capacity

(Tons)

2

3

5

7 ½

10

15

20

*Refer to Section 5.6 for inspection dimensions and limits.

**Product codes represent deck/base mounted hoists (except RHN15U), but hook dimensi ons also apply to ultra-low

trolley hoists. See Section 2.1.1 for place holder designation

Product Code** a b c d e f g h

RHN02D-20A-20D-

RHN02D-33A-20D-

RHN03D-20A-20D-

RHN03D-33A-20D-

RHN05D-20B-20D-

RHN05D-33B-20D-

RHN08D-20C-20D-

RHN08D-33C-20D-

RHN10D-20C-20D-

RHN10D-33C-20D-

RHN15U-28D-12DD-

RHN15U-46D-12DD-

RHN15D-20D-16D-

RHN15D-33D-16D-

RHN20D-20D-16D-

RHN20D-33D-16D-

2.2 1.8 1.9 1.5 2.2 2.5 1.6 5.8

2.2 1.8 1.9 1.5 2.2 2.5 1.6 5.8

2.6 2.1 2.3 1.8 2.5 2.8 1.7 6.6

3.1 2.5 2.6 2.1 2.8 3.1 1.9 7.7

3.1 2.5 2.6 2.1 2.8 3.1 1.9 7.7

3.9 3.1 3.3 2.6 3.5 4.0 2.4 10.1

4.9 3.9 4.2 3.3 4.4 5.0 3.2 12.0

4.9 3.9 4.2 3.3 4.4 5.0 3.2 12.0

14

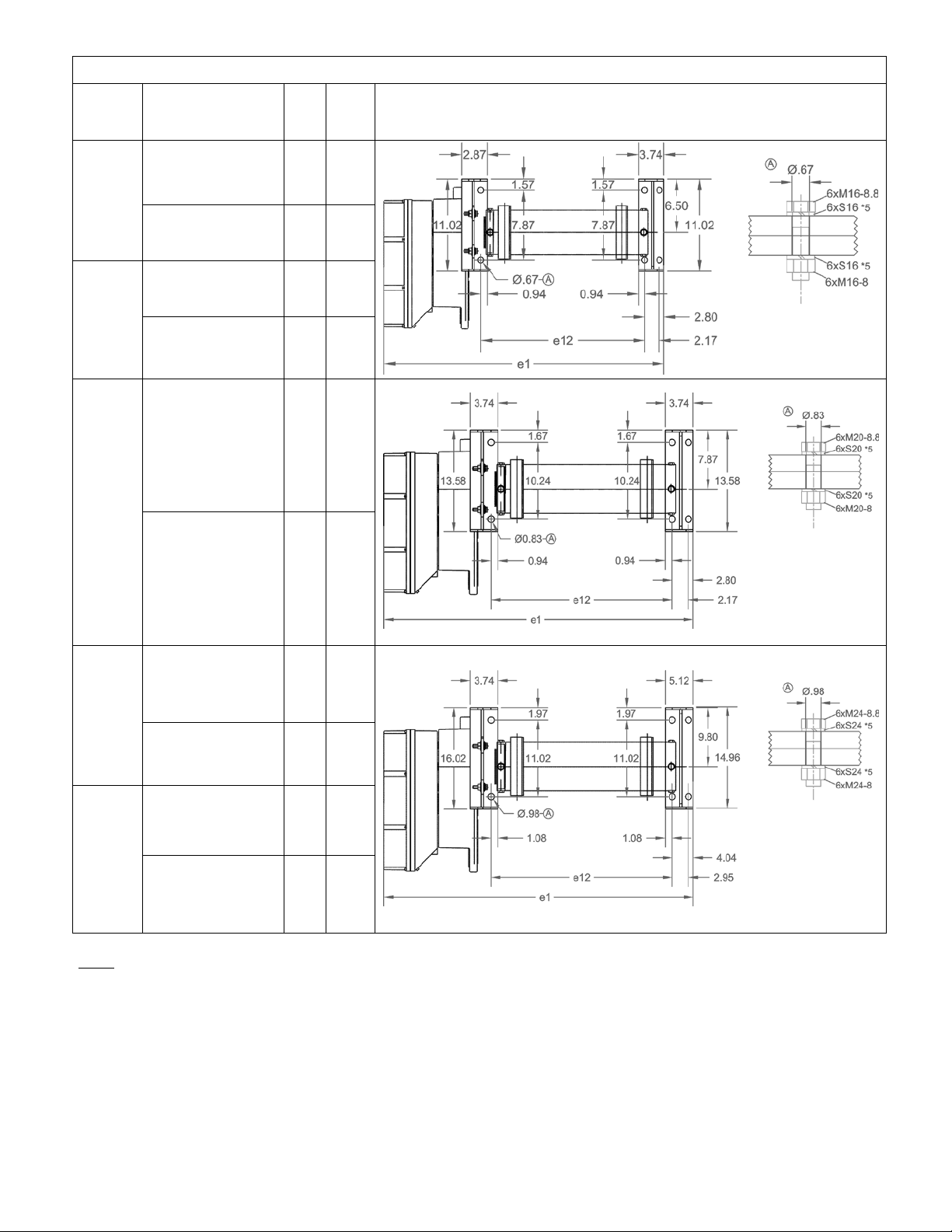

Table 2-10 Deck Mounted Hoist Attachment Point Dimensions (2-10 ton)

Capacity

(Tons)

2

3

5

e1

Product Code*

RHN02D-20A-20D- 40.9 24.2

RHN02D-33A-20D- 52.5 35.8

RHN03D-20A-20D- 40.9 24.2

RHN03D-33A-20D- 52.5 35.8

RHN05D-20B-20D- 41.3 24.2

(in)

e12

(in)

Deck/Base Mounted

RHN05D-33B-20D- 52.9 35.8

RHN08D-20C-20D- 48.0 26.8

7 1/2

RHN08D-33C-20D- 60.4 39.2

RHN10D-20C-20D- 48.0 26.8

10

RHN10D-33C-20D- 60.4 39.2

Notes:

*See Section 2.1.1 for place holder designation

*5 – Lock washer

15

Table 2-11 Deck Mounted Hoist Attachment Point Dimensions (15 & 20 ton)

Capacity

(Tons)

15

20

Notes:

*See Section 2.1.1 for place holder designation

*5 – Lock washer (Schnorr)

Product Code*

RHN15D-20D-16D- 54.4

RHN15D-33D-16D- 66.6 45.9

RHN20D-20D-16D- 54.4

RHN20D-33D-16D- 66.6 45.9

e1

(in)

e2

(in)

43.7

43.7

e12

(in)

33.7

33.7

Deck/Base Mounted

16

RHN02D-20A-20D-

1817

1902

654

1292

295

169

393

393

RHN02D-33A-20D-

1950

2149

582

1122

328

147

393

393

RHN03D-20A-20D-

2700

3043

1038

2067

472

270

629

629

RHN03D-33A-20D-

2906

3439

916

1795

524

235

629

629

RHN05D-20B-20D-

4171

4683

1618

3151

736

415

984

984

RHN05D-33B-20D-

4480

5272

1435

2744

814

362

984

984

RHN08D-20C-20D-

6989

5019

3625

5051

978

741

1475

1475

RHN08D-33C-20D-

7758

6054

3112

4278

1129

627

1475

1475

RHN10D-20C-20D-

9041

6692

4763

6735

1304

988

1967

1967

RHN10D-33C-20D-

10042

8072

4076

5703

1506

836

1967

1967

RHN15D-20D-16D-

9297

14086

5835

13988

1894

1684

3147

3147

RHN15D-33D-16D-

10384

16989

4931

12154

2227

1445

3147

3147

RHN20D-20D-16D-

12088

16707

7449

17186

2367

2105

3934

3934

RHN20D-33D-16D-

13494

20243

6316

14899

2784

1807

3934

3934

Figure 2-5 Deck Mounted Hoist, 2-10 Ton

Reaction Forces (See Table 2-12)

Figure 2-6 Deck Mounted Hoist, 15-20 Ton

Reaction Forces (See Table 2-12)

Table 2-12 Reaction Forces at Rated Load, Deck Mounted

Capacity

(Tons)

2

3

5

7 ½

10

15

20

See Section 2.1.1 for place holder designation

Product Code

F1

(lbs)

F2

(lbs)

F3

(lbs)

F4

(lbs)

Q1

(lbs)

Q2

(lbs)

Q3

(lbs)

Q4

(lbs)

Moment*,

M

T

(ft-lbs)

232*

372*

770*

1514*

2019*

**

**

*For 2-10t capacities, the customer’s substructu re must account for

the moment MT (torque) from the rope drum. Therefore it must be

torsion resistant and level, (max permissible offset, Y = .0787in.)

**For 15-20t capacities, the design structure accounts for the

moment, and the forces are diverted to the fixation points.

17

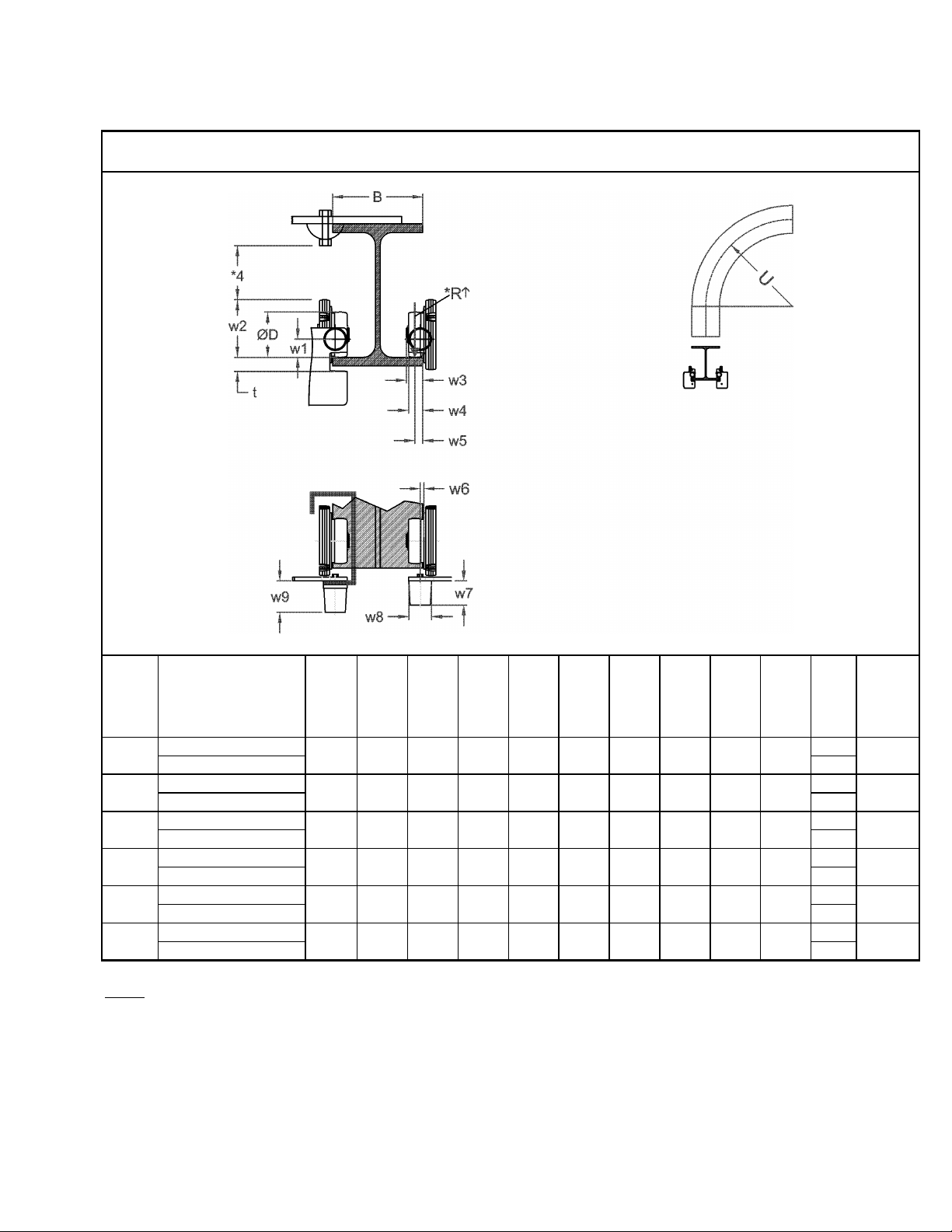

Trolley

Table 2-13 Wheel Pair Reaction Forces at Ra te d Lo ad ,

Ultra-Low Headroom Monorail

Capacity

(Tons)

2

3

5

7 1/2

10

15

20

Notes:

*See Section 2.1.1 for place holder designation

Product Code*

RHN02U-20A-20DD- 2985 2939

RHN02U-33A-20DD- 3632 2411

RHN03U-20A-20DD- 4292 4285

RHN03U-33A-20DD- 5253 3487

RHN05U-20B-20DD- 6629 7288

RHN05U-33B-20DD- 7167 6675

RHN08D-20C-20DD- 9102 12320

RHN08U-33C-20DD- 12011 9860

RHN10U-20C-20DD- 11783 16192

RHN10U-33C-20DD- 15641 12898

RHN15U-28D-12DD- 22045 17881

RHN15U-46D-12DD- 22226 18478

N/A

N/A

R1

(lbs)

R2

(lbs)

18

∅

2*

U

Maximum

Thickness

(in)

RHN02U-20A-20DD-

37.4*

RHN02U-33A-20DD-

56.8*

RHN03U-20A-20DD-

37.4*

RHN03U-33A-20DD-

56.8*

RHN05U-20B-20DD-

37.4*

RHN05U-33B-20DD-

56.8*

RHN08D-20C-20DD-

41.0*

RHN08U-33C-20DD-

61.7*

RHN10U-20C-20DD-

41.0*

RHN10U-33C-20DD-

61.7*

RHN15U-28D-12DD-

N/A

RHN15U-46D-12DD-

≤

Table 2-14 Trolley Wheel Dimensions

Wheel

Capacity

(Tons)

2

3

5

7 1/2

10

15

Product Code *5

Dia.

(in)

3.1 1.6 4.1 1.2 1.1

3.1 1.6 4.1 1.2 1.1

3.9 1.6 5.1 1.5 1.2

5.5 1.5 6.9 N/A 1.8

5.5 1.5 6.9 N/A 1.8

7.9 1.7 10.5 N/A 1.8

D

w1

(in)

Notes :

* Smaller bend radius upon request

** – ( ) with sloping flange

*R – See page 18 for reaction forces R1 and R2

*2 – only up to B

*4 – Observe clearance dimensions

*5 – See Section 2.1.1 for place holder designation

7.9 inches

w2

(in)

w3

(in)

(ft)

N/A

Flange

t

0.96

0.96

1.04

1.46

1.46

1.81

w4

(in)

w5

(in)

0.5

(0.6)**

0.5

(0.6)**

0.7

(0.9)**

0.9

(1.3)**

0.9

(1.3)**

0.9

(1.3)**

w6

(in)

0.2 2.1 2.0 2.5

0.2 2.1 2.0 2.5

0.2 2.1 2.0 2.5

0.5 2.1 2.5 2.5

0.5 2.1 2.5 2.5

0.5 2.1 2.5 2.5

w7

(in)

w8

(in)

w9

(in)

19

3.0 Pre-operational Pr ocedur es

3.1 General Information

3.1.1 When the RHN trolley hoist or deck mounted hoist is incorporated into lifting systems utilizing other

equipment, follow and complete all pre-operational procedures and instructions provided with the

equipment. Special wiring considerations must also be taken to complete the integration of the

RHN trolley hoist or deck mounted hoist into the system.

3.1.2 The RHN hoist is delivered pre-assembled on a pallet with a wooden frame. The frame is wrapped in

plastic for additional protection. (see Figure 3-1). During shipment and storage prior to installation, the

trolley hoist should be kept between –4° and +140°F (-20° and +60°C) and the relative humidity must

not exceed 80%. The standard packaging is not watertight and rainproof.

3.1.3 The RHN trolley hoist or deck mounted hoist is shipped pre-lubricated and the gear box(s) are filled

with the correct amount and type of oil. Follow the lubrication requirements in Section 6.1 after the

trolley hoist is placed into service.

3.2 Handling

3.2.1 Transportation – When moving the hoist or trolley hoist prior to installation, do not remove hoist from

crate. Always move hoist/trolley hoist utilizing a fork lift, pallet jack or hoist/crane system. Do NOT stack

or place anything on top of the trolley hoist or crate. Avoid swinging and unbalanced conditions.

3.2.2 Lift points – When a pallet/crate is not practical, use of RHN lifting location is acceptable. The RHN

deck mounted hoist is equipped with lifting lugs to facilitate lifting, while the RHN trolley hoist is

equipped with openings in the vertical tubes to accept hooks or slings (see

lifting do NOT support the deck mount hoist or trolley hoist any other way.

Figure 3-1 Packaged as delivered

Figures 3-2 and 3-3). While

20

Figure 3-2 Lift Point for Deck Mount

3.3 Mounting Location

3.3.1

adequate and capable of withstanding the forces generated by the hoist and the load. Therefore,

the substructure must be torsion resistant and level (See

mounting the RHN trolley hoist ensure that the trolley beam and its supporting structure are adequate to

support the trolley hoist and its load. (See Table 2-13). If necessary consult a professional that is

qualified to evaluate the adequacy of the suspension location and its supporting structure.

3.3.2 Ensure that there is adequate vertical and horizontal clearance along the entire range of the trolley

hoist’s motion.

3.3.3

Prior to mounting the RHN deck mounted hoist, ensure that the substructure is

See Section 6.8 for outdoor installation considerations.

Figure 3-3 Lift Point for Trolley Hoist

Table 2-12 for more details). Prior to

21

3.4 Assembly, Adjustments and Mounting

When installing the trolle y hoist on a beam, ALWAYS raise the hoist into position with the

trolley assembled together and securely attached to a pallet. Raise the trolley hoist with a forklift, lifting platform,

or other similar means. NEVER use slings to raise and install the trolley hoist onto the beam (see Figure 3-4).

Using a forklift or another suitable means, position the pallet so that the horizontal axis of the beam is parallel to

the horizontal axis of the hoist (see Figure 3-5)

Note: Unless specified when ordered, the RHN Trolley hoist is factory set to accommodate a 12 inch (306mm) beam

flange. If a smaller flange width is necessary, the driveshaft position and/or length may require a change as well (See

Table 3-1). If the supplied trolley drive shaft is too long for the desired flange, a short trolley drive shaft can be ordered, or

the existing shaft can be cut down to the appropriate length. Use caution and always wear eye protection when cutting

the trolley drive shaft with a powered saw or a manual saw. Deburr the cut end of shaft before reinstalling. The RHN is

equipped with the maximum number of counterweights necessary for the standard (advertised) flange range for each

capacity. If the flange range exceeds 12 inches (306mm), some counter weight may need to be removed to achieve

proper balance.

3.4.1 RHN Trolley Hoist Installation

1) Make sure the mounting location complies with Section 3.3.

2) Before attempting to install the trolley hoist, verify beam width and the “c” dimension (see Figure 3-6).

See Table 3-1 for dimensions respective values. If adjustment is not necessary, move onto section

Section 3.4.1 (step 8). If adjustment is necessary move onto step 3, below.

3) Determine the correct driveshaft length for your application.

a. If a shorter driveshaft length is required, it is necessary to replace or cut the existing driveshaft to the

appropriate length. (See Table 3-2)

b. If a longer driveshaft length is required, it is necessary to replace the existing driveshaft with one of

the appropriate length. (See Table 3-2)

4) Determine the correct Snap Ring Position on the driveshaft, for your application. (2 ton – 10 ton)

Each driveshaft has multiple Snap Ring positions shown as X3 and X4. These different positions allow

the Trolley Driveshaft to be inserted at two different depths within the motor housing. This gives the

drive shaft the ability to accommodate a range of beam flange widths before it necessary to change the

shaft length.(See Table 3-2)

5) Accessing the Drive Shaft for replacement, shortening and/or Snap Ring relocation.

a. Carefully remove the trolley motor by loosening and removing the 4 trolley motor mounting bolts. It

may be necessary to disconnect the trolley motor cable, if there is not enough slack to allow for the

motor to be safely supported, as work is being performed. With the bolts removed, the motor can

slide off of the drive shaft.

b. With the motor removed and safely placed out of the way, the driveshaft can pulled out of the trolley

assembly.

6) Adjust the trolley flange to fit beam width.

a. Working on the trolley motor side of the hoist, (the side closest to the large rectangular counter

weights), loosen the nuts (2) on the two threaded shafts (1) of the trolley hoist. DO NOT loosen the

nuts closest to the hoist. NEVER move the hoist side of the trolley. (See Figure 3-6 and Figure

3-11)

22

b. With the nuts (2) loosened enough to allow the trolley frame to move, slide the trolley motor side of

the hoist outward or inward to meet the desired flange width. Tighten nuts (2) with a torque wrench,

to 155 ft lbs (210 Nm). (See Figure 3-6 and Figure 3-11.)

7) Installing the Drive Shaft

a. 2Ton – 10Ton Trolley Hoist

Install Snap Rings (S) on to Driveshaft (D) in position X3 or X4 depending on flange width (B)

of the runway beam and length (L) of drive shaft (D). Slide Drive Shaft through drive pinions

and install trolley motor. (See Figures 3-8, and 3-9. Also see Tables 3-2 and 3-3.)

b. 15 Ton Trolley Hoist

Insert drive shaft (5) into the two drive pinions (6) from the counterweight side, then assemble

spacer tube (7) and adjusting ring (8). (See Figure 3-11).

Adjust drive shaft (5) so that on the hoist side of the shaft end projects between “min. 0in. (0mm)”

and “max. 4.72 in.(120mm)” beyond the drive pinion (6) and on the counterweight side the shaft end

projects between “min. 1.89 in. (48 mm)” and “max. 6.30in. (160 mm)” beyond the trolley frame (10).

(See Figure 3-11).

Lock adjusting ring (8) with the adjusting screw so that there is approximately "3 mm” space

between spacer tube (7) and the adjusting ring (8) when spacer tube (7) is against drive pinion (6).

After fitting travel drive, check drive shaft (5) for ease of movement. (See Figure 3-11).

8) Mounting the Trolley Hoist to the beam.

a. Install any additional devices, if any (power supply cords or pendants, for instance – see Section

3.5), onto the trolley hoist. If the trolley hoist is not secured to a pallet, place and secure it to one

making sure that the trolley hoist is completely stable.

b. Before attempting to install the trolley hoist, verify beam width and the “c” dimension (see Figure 3-

6). See Table 3-1 for dimensions respective values. Adjust flange width if necessary. (See Section

3.4.1 Step 6)

c. If the end of the runway beam is accessible, slide the trolley hoist onto the end of the runway

beam. Check clearance f/2 ( Figure 3-7 and Table 3-1). Adjust if necessary. (See Section

3.4.1 Step 6).

If the end of the runway beam is not accessible, the trolley flange width will nee d to be opened

up to allow the Trolley Hoist to fit around the beam. (See Section 3.4.1 Step 6).

23

Table 3-1 Trolley Clearances and Wheel Diameters

in

mm

in

mm

in

mm

in

mm

RHN02

RHN03

RHN05

4

100

B+2 5/8

B+67

1/16

1.5

5 3/4

147

RHN08

RHN10

RHN15

8

200

B+3 5/8

B+67

1/16

1.5

7 3/8

187

Figure 3-4 Lift Point for Deck Mount

Figure 3-6 Trolley Hoist Clearances 2 Ton – 10 Ton

Figure 3-5 Lift Point for Trolley Hoist

Figure 3-7 Trolley Hoist Clearances

Hoist

Wheel Diameter c f/2 y

3 1/8 80 B+2 5/8 B+67 1/16 1.5 5 3/8 137

5 1/2 140 B+2 5/8 B+67 1/16 1.5 6 3/8 162

24

Table 3-2 Drive Shaft Length and Positions for

Fig 3-8, 3-9 and 3-11

Drive Shaft

Shaft Length

“L” (mm)

Snap Ring

Position “S”

3.25-5.71 (82-145)

X3

5.75-7.68 (146-195)

X4

7.72-9.84 (196-250)

X3

9.88-12.05 (251-306)

X4

12.09-13.78 (307-350)

X3

13.82-15.71 (351-399)

X4

15.75-17.72 (400-450)

X3

17.76-19.69 (451-500)

X4

3.63-5.71 (92-145)

X3

5.75-7.68 (146-195)

X4

7.72-9.84 (196-250)

X3

9.88-12.05 (251-306)

X4

12.09-13.78 (307-350)

X3

13.82-15.71 (351-399)

X4

15.75-17.72 (400-450)

X3

17.76-19.69 (451-500)

X4

4.63-7.87 (117-200)

X3

7.91-12.20 (201-310)

X4

12.24-15.75 (311-400)

X3

15.79-19.69 (401-500)

X4

6.69-8.66 (170-220)

20.08 (510)

8.70-15.75 (221-400)

29.13 (740)

15.79-19.69 (401-500)

30.71 (780)

Figure 3-8

Figure 3-9

Hoist

Beam Flange Width

in. (mm)

15.35 (390)

RHN02

19.49 (495)

RHN03

23.43 (595)

27.36 (695)

15.35 (390)

19.49 (495)

RHN05

23.43 (595)

RHN08

RHN10

RHN15

27.36 (695)

19.88 (505)

27.95 (695)

See Figure 3-11

25

Table 3-3 L3 and L4 Dimensions from

Fig 3-8 and 3-9

Hoist

L3+/- 2 in. (mm)

L4+/-2 i n. (mm)

RHN02, RHN03,

RHN05

3.8 (96.4) 1.82 (46.4)

RHN08, RHN10 4.9 (124.6) 1.82 (46.4)

RHN15 See Figure 3-11

Figure 3-11 Trolley Hoist Clearances 15 Ton

26

3.5 Electrical Connection s

3.5.1

3.5.2

lifting or traversing motors. Use of such devices may cause the motor brake and other electrical

components to malfunction. For variable frequency drives contact Harrington for more information.

3.5.3

de-energized (disconnected). Lock out and tag out in accordance with ANSI Z244.1 “Personnel

Protection -Lockout/Tagout of Energy Sources”.

3.5.4 Installing Power Supply Cord

1) Refer to Figure 3-12, Figure 3-13 and the wiring diagram provided with the Hoist.

2) Remove Control Cover.

3) Loosen the cable fitting located on the lower side of the electrical enclosure and insert the Power

Supply Cable. Pull through enough cable to reach the power supply terminal and securely tighten

the cable fitting.

4) Connect the 3 phase power leads (L1, L2 and L3) and the ground lead of the Power Supply Cable

to the power supply terminal. Make sure the terminals are securely tightened and each lead is

completely isolated.

5) Replace the Control Cover. Be careful to not damage the seal or sealing surfaces and make sure to

securely tighten all fasteners or latches.

Ensure that the voltage of the electric power supply is proper for the trolley hoist.

Do NOT apply electronic soft-start control or voltage varying controls to the RHN

Before proceeding, ensure that the electrical supply for the hoist or trolley has been

Figure 3-12

Figure 3-13

27

3.6 Pendant Installation

1) Refer to Figure 3-14, Figure 3-15 and the wiring diagram and the interconnection diagram provided with

the Hoist.

2) Remove Control Cover.

3) Loosen the cable fitting located on the lower side of the electrical enclosure and insert the Pendant

Cable. Pull through enough cable to reach the terminals then securely tighten the cable fitting.

4) Attach a strain relief cable or chain between the pendant and hoist. The cable should attach to the small

plate located at the bottom of the electrical enclosure under the gear box.

5) Access to terminal strip: The terminal strip is mounted on DIN rail, located on the lower portion of the

control box.

6) Connect the individual pendant leads to the correct terminals as shown on the interconnection diagram.

Make sure the terminals are securely tightened and each lead is completely isolated.

7) Reinstall the Control Cover. Be careful to not to pinch any wires wire closing and tightening down the

Control Cover.

Figure 3-14

3.6.1 Connection to Electrical Power Source - The 3 power leads of the Power Supply Cable (normally red,

white, and black wires) should be connected to an electric power disconnect switch or circuit breaker.

This connection should be made so that the hoist is phased properly. Refer to Section 3.9.4 for

instructions on how to check for correct power supply phase connection.

3.6.2 Fuse/Breaker Capacity - The trolley and hoist's power supply should be equipped with overcurrent

protection such as fuses, which should be selected for 110% to 120% of total listed full load amperage,

and should be dual element time-delay fuses. For the total full load amperage draw, add the amperage

draws shown on the motor nameplates of ALL lifting and traversing motors.

3.6.3

shock hazard when touching any part of the hoist or trolley. In the Power Supply Cable the ground wire

will be either Green with Yellow stripe or solid Green. It should always be connected to a suitable

ground connection. Do not paint the trolley wheel running surfaces of the beam as this can affect

grounding.

Grounding - An improper or insufficient ground connection creates an electrical

Figure 3-15

28

3.7 RPU Load Monitor Device

The RHN hoist is equipped with the RPU Load Monitor Device. The RPU version (SLE21 or SLE22) is located

on the front cover of the RPU unit. The main function of this device is to evaluate the load conditions of the hoist

(overload protection, temperature monitoring of the hoist and trolley motors, and displaying the operating hours of

the hoist.

3.7.1 Monitoring of Load Conditions – After powering up the hoist, the RPU will run through an internal test

cycle, for approximately 4 seconds. The test will be finalized when the user initially operates the hoist in

the up or down direction. At this time the “err” light will illuminate temporarely as well as the LEDs II and

III. If the internal test cycle was completed successfully without resulting in error, the hoist will function.

3.7.2 Temperature Monitoring – The hoist and trolley motors are equipped with PTC thermistors that are

directly linked to the RPU. If an excessive motor temperature condition has developed, the RPU will not

allow the load to be lifted or lowered until the excessive temperature condition is no longer present. The

LED display on the RPU will display and “err”. See Table 7-2.

3.7.3 Count/Hour Meter – See section 6.1 for Count/Hour meter details.

3.7.4 Load Testing RHN – The RPU Load Monitoring device is designed to sense an overload of the hoist and

cut-off power when subjected to a lifting load of 110% of the rated RHN capacity. Due to this load

monitoring feature, a Crane Test function is used when conducting a load test of 125% of the rated

capacity. The crane test function temporarily changes the overload cut-off from 110% rated capacity to

137.5% rated capacity. This temporary load test override for both RPU versions (SLE21 or SLE22) is

accomplished by following the applicable instructions below:

For Model SLE21:

1. Remove RPU cover.

2. Press the S5 button, hold for more than 3 seconds, and release. (The S5 button is located directly

below the red “err” LED). Figure 3-16.

3. Notice the “err” LED is flashing. This will continue to flash for 30 minutes. After 30 minutes, the

RPU reboots and the overload cut-off returns to 110% of the rated capacity.

For Model SLE22:

1. Loosen the screw on the RPU cover and remove the cover.

2. Execute the following steps in less than 12 seconds:

a. Press the S5 button for more than 3 seconds. (The S5 button is located directly below the red

“err” LED). See Figure 3-16.

b. Release the S5 button for 1 second.

c. Press the S5 button for more than 3 seconds.

3. If an error occurs in the sequence of step 2, the “err” LED flashes 3 times. After this error signal, the

crane test function can be activated again by following the sequence in step 2.

4. If the sequence in step 2 is followed correctly, then the “err” LED will flash for 30 minutes. After 30

minutes, the RPU reboots and the overload cut-off returns to 110% of the rated capacity.

5. To deactivate the crane test, either press the S5 button until the red LED no longer flashes or reboot

the device.

29

↑↑

↑↑

↑↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↑

↓

↓

Figure 3-16

3.8 H oist Limit S witches and Adjustment

The RHN wire rope hoist is equipped with a geared limit switch in the hoist control panel box. The limit switch is

equipped with four switches, all of which are utilized for standard hoist functions. The four limit switch positions are

as follows: S1 (Upper Safety Limit), S2 (Lower Limit), S3 (Upper Limit), and S4 (Speed Transition Limit).

The wire rope hoist is also equipped with a BLS (Block Limit Switch) as a standard feature.

3.8.1 Description and order of the limit switch function, including BLS as hook travels in the UP direction – See

Figure 3-17.

(Speed Transiti on Geared Limit ): As the hook travels in the up direction, the first switch

S4

position to activate will be S4

deactivated when the S4

switch position S3

(Upper Geared Limit): When the S3↑switch position is activated, hook travel is disabled in the up

S3

(Upper Limit).

. If the hoist is being operated in the up direction, high speed will be

switch is activated. The hoist will then remain in low speed until reaching the

direction. The hoist can still be operated in down direction.

BLS

(Block Ope rate d Upper Limit S witch): See also Figure 3-19.

In addition to the geared limit switch, there is also a block operated upper limit switch (BLS

on the hoist. The BLS

the cable that holds the switch in the closed position. The BLS

Geared Limit) switch position activates first and the BLS

switch opens when the hook block lifts a weight and releases the tension from

is adjusted so that the S3↑(Upper

second as a “back-up” safety.

(Upper Safety Geared Limit): In the event of a major malfunction where the upper limit switch

S1

(S3

) and the block operated upper limit switch (BLS↑) are overrun, the S1↑switch position is

activated and disables all directional movement and control. The only way to operate the hoist after the

switch has been activated is to eliminate the source of the problem and bridge (jumper) terminals

S1

110 to 116 on the terminal strip located at the bottom of the hoist control panel box. WARNING: If the

S1 Geared Limit Switch pos ition has been ac tivated, a major m alfunctio n has occurr ed.

Therefore, the equipment should be ins pected by a quali fied indi vidual befor e att empting to

resume hoist operati on.

3.8.2 Description and order of the limit switch function as the hook travels in the DOWN direction – See

Figure 3-18.

(Speed Transition Ge ared Li mit): When the hook is located at the S3 (Upper Geared Limit)

S4

position, and moving in the down direction, the hoist will remain at low speed until the hook is below the

) installed

30