Page 1

Code and Serial No.

EFFECTIVE: May 2, 2012

This equipment should not be installed, operated or

maintained by any person who has not read and understood

all the contents of this manual. Failure to read and comply

with the contents of this manual can result in serious bodily

injury or death, and/or property damage.

HPC500

Series

Top Running

and

Underhung

End Trucks

½ Ton, 1 Ton, and 2 Ton Capacity

Page 2

Table of Contents

Section Page Number

1.0 Important Information and Warnings………………………………………………….………………….4

1.1 Terms and Summary

1.2 Warning Tags and Labels

2.0 Technical Information………………………………………………………………………..…..…….…..7

2.1 Specifications

2.2 Part Names

3.0 Pre-operational Procedure…………………………………………………..…….................................11

3.1 Runway

3.2 Bridge Beam

3.3 End Trucks

3.4 Pre-operational Checks and Trial Operation

4.0 Operation………………………………………………………………………………………………….19

4.1 Introduction

4.2 Important Information about Operation

5.0 Inspection………………………………………………………………………………………….……...20

5.1 General

5.2 Inspection Classification

5.3 Frequent Inspection

5.4 Periodic Inspection

5.5 Occasionally Used End Trucks

5.6 Inspection Records

5.7 Inspection Methods and Criteria

2

Page 3

6.0 Lubrication……………………………………………………………………….……..…..…...……25

6.1 HPC500 End Trucks

6.2 Other Equipment

7.0 Maintenance & Handling……………………………………………………………………………26

7.1 General

7.2 Storage

7.3 Outdoor Installations

8.0 Troubleshooting ……………………………………………………………………..…….….…….27

9.0 Warranty………………………………………………………………………………...……...……28

10.0 Parts List……………………………………………………………………………...……….……..29

3

Page 4

1.0 Important Information and Warnings

1.1 Terms and Summary

This manual provides important information for

personnel involved with the installation, operation, and

maintenance of this product. Although you may be

familiar with this or similar equipment, it is strongly

recommended that you read this manual before installing,

operating, or maintaining the product.

Danger, Warning, Caution, and Notice

Throughout this manual there are steps and procedures

that can present hazardous situations. The following

signal words are used to identify the degree or level of

hazard seriousness.

Danger indicates an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury, and property

damage.

Warning indicates an imminently

hazardous situation which, if not

avoided, could result in death or

serious injury, and property

damage.

Caution indicates a potentially

hazardous situation which, if not

avoided, may result minor or

moderate injury or property

damage.

Notice is used to notify people of

installation, operation, or

maintenance information which is

important but not directly hazardrelated.

These general instructions deal with the normal installation, operation, and maintenance situations encountered with

the equipment described herein. The instructions should not be interpreted to anticipate every possible contingency

or to anticipate the final system, crane, or configuration that uses this equipment. For systems using the equipment

covered by this manual the supplier and owner of the system are responsible for the system’s compliance with all

applicable industry standards, and with all applicable Federal, State, and Local regulations/codes.

This manual includes instructions and parts information for a variety of hoist types. Therefore, all instructions and

parts information may not apply to any one type or size of specific hoist. Disregard those portions of the instructions

that do not apply.

Record your end trucks’ Code and Serial No. (see Figure 10-1) on the front cover of this manual for identification and

future reference to avoid referring to the wrong manual for information or instructions on installation, operation,

inspection, maintenance, or parts.

Use only Harrington authorized replacement parts in the service and maintenance of this hoist.

4

Page 5

Equipment described herein is not designed for and MUST NOT be used for lifting, supporting, or transporting

people, or for lifting or supporting loads over people.

Equipment described herein should not be used in conjunction with other equipment unless necessary and/or

required safety devices applicable to the system, crane, or application are installed by the system designer, system

manufacturer, crane manufacturer, installer, or user.

Modifications to upgrade, rerate, or otherwise alter this equipment shall be authorized only by the original equipment

manufacturer.

Equipment described herein may be used in the design and manufacture of cranes or monorails. Additional

equipment or devices may be required for the crane and monorail to comply with applicable crane design and

safety standards. The crane designer, crane manufacturer, or user is responsible to furnish these additional items

for compliance. Refer to ANSI/ASME B30.17, Safety Standard for Top-Running Single Girder Cranes; ANSI/ASME

B30.2 Safety Standard for Top-Running Double-Girder Cranes; and ANSI/ASME B30.11 Safety Standard for

Underhung Cranes and Monorails. If a below-the-hook lifting device or sling is used with a hoist, refer to

ANSI/ASME B30.9, Safety Standard for Slings, or ANSI/ASME B30.20, Safety Standard for Below-the-Hook Lifting

Devices.

Hoists and cranes used to handle hot molten material may require additional equipment or devices. Refer to ANSI

Z241.2, Safety Requirements for Melting and Pouring of Metals in the Metalcasting Industry.

Failure to read and comply with any one of the limitations noted herein can result in serious bodily injury or death,

and/or property damage.

It is the responsibility of the owner/user to install, inspect, test, maintain, and operate a hoist in accordance with

ANSI/ASME B30.16, Safety Standard for Overhead Hoists and OSHA Regulations. If the hoist is installed as part

of a total lifting system, such as an overhead crane or monorail, it is also the responsibility of the owner/user to

comply with the applicable ANSI/ASME B30 volume that addresses that type of equipment.

It is the responsibility of the owner/user to have all personnel that will install, inspect, test, maintain, and operate a

hoist read the contents of this manual and applicable portions of ANSI/ASME B30.16, “Safety Standard for

Overhead Hoists”, and OSHA Regulations. If the hoist is installed as part of a total lifting system, such as an

overhead crane, the applicable ANSI/ASME B30 volume that addresses that type of equipment must also be read

by all personnel.

If the hoist owner/user requires additional information, or if any information in the manual is not clear, contact

Harrington or the distributor of the hoist. Do not install, inspect, test, maintain, or operate this hoist unless this

information is fully understood.

A regular schedule of inspection of the hoist in accordance with the requirements of ANSI/ASME B30.16 should be

established and records maintained.

1.2 Warning Tags and Labels

The End Trucks covered by this owner’s manual may be used as part of a lifting system such as a crane. It is the

responsibility of the supplier and the owner of such a lifting system to provide for and ensure that the lifting

system be equipped with warning labels in accordance with applicable industry standards.

5

Page 6

1.2 Conformance Statement

In order to meet requirements of the Crane Manufacturers Association of America (CMAA), the National Electric

Code (NEC) and the American National Standards Institute (ANSI/ASME) Harrington components include:

Thermal motor protection for all motors.

Rubber bumpers.

Hoists load tested to 125% of rated capacity.

Drop stops for all end trucks.

Rail sweeps for all end trucks.

Recommended bridge beams comply with CMAA.

6

Page 7

2.0 Technical Information

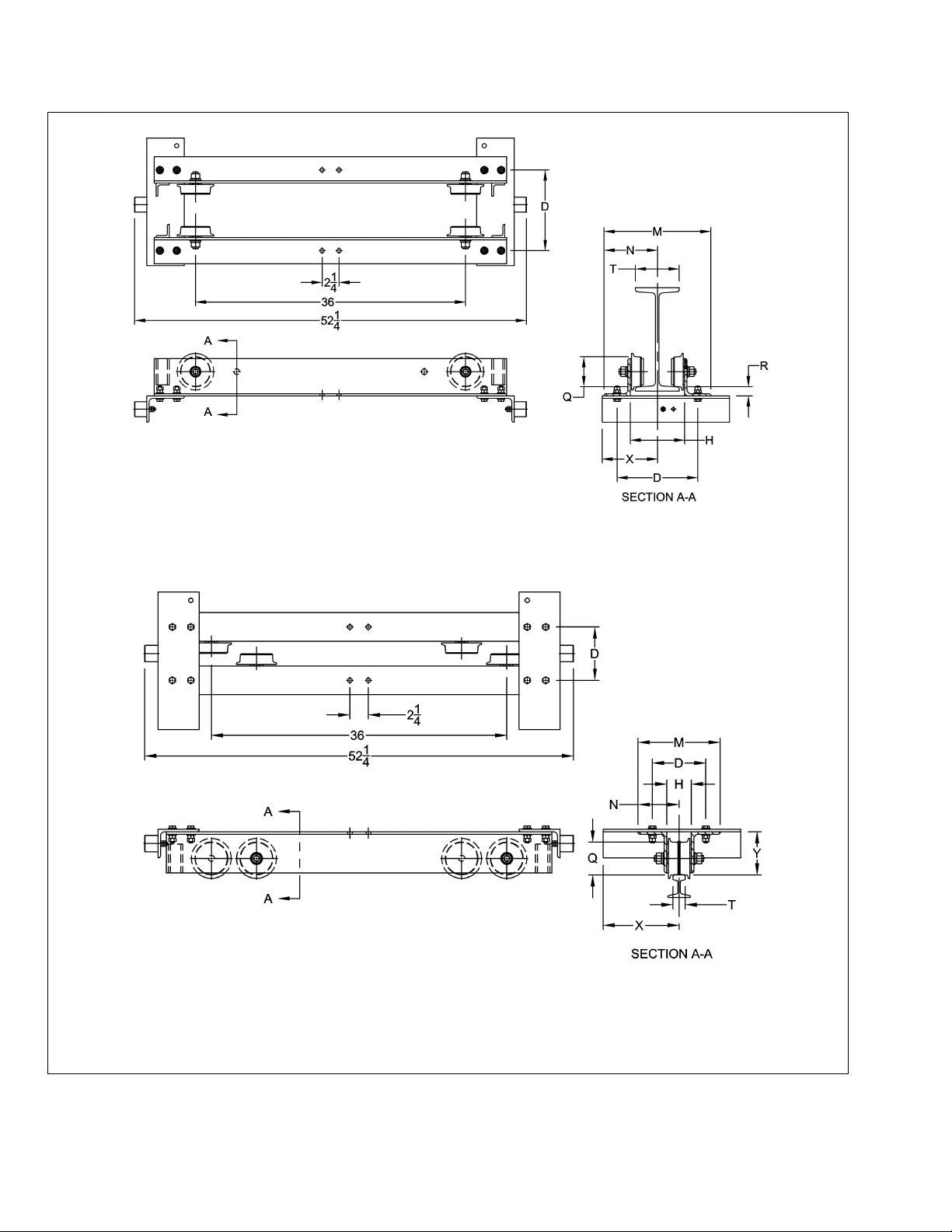

Table 2-1 HPC500 End Truck Specifications & Dimensions (refer to Figure 2-1)

Code

Max.

Span

(ft) T Width of Flange or

Rail Head

(in)

D*

(in)

H*

End

Truck

Frame

Spacing

(in)

M*

End

Truck

Frame

Width

(in)

N

Runway

Ctr. Line to

Outer Edge

of End

Truck

(in)

Q

Wheel

Tread

Diameter

(in)

X

Width

Beyond

Span

(in)

Y

Wheel

Running

Surface to

Bridge

Beam

(in)

R

Wheel

Running

Surface to

Bridge

Beam

(in)

End Truck

Weight

(lbs/pair)

TR

UH

HPC505

24

1.5 - 6

3 - 6

T + 4¾

T + 1¼

T + 7.3

M/2

3.12

10⅛ -

½T

4.3

1.2

156

HPC510

T + 8.3

4.00

5.3

1.2

214

HPC520

3.3 - 6

4.88

5.9

1.1

270

* Formula shown is for S beams & ASCE rail. Add ¼ inch for W beams and rectangular bar.

2.1 Specifications

2.1.1 Product Codes

(a) HPC505 up to ½ Ton capacity

(b) HPC510 up to 1 Ton capacity

(c) HPC520 up to 2 Ton capacity

2.1.2 Description

The HPC500 Series End Truck Kit includes two 4-wheeled end trucks with rubber bumpers,

bridge beam end stops, bridge beam fastener hardware, bridge beam assembly drawing, and this

Owner’s Manual & Parts List. The HPC500 End Truck is designed to meet CMAA requirements

for Class B Medium Duty Cranes. Its convertibility allows it to be assembled for either Top

Running (TR) or Underhung (UH) cranes.

2.1.3 Dimensions

Refer to Table 2-1 and Figure 2-1 below.

7

Page 8

Underhung

Top Running

Figure 2-1 HPC500 End Truck Dimensions (refer to Table 2-1)

8

Page 9

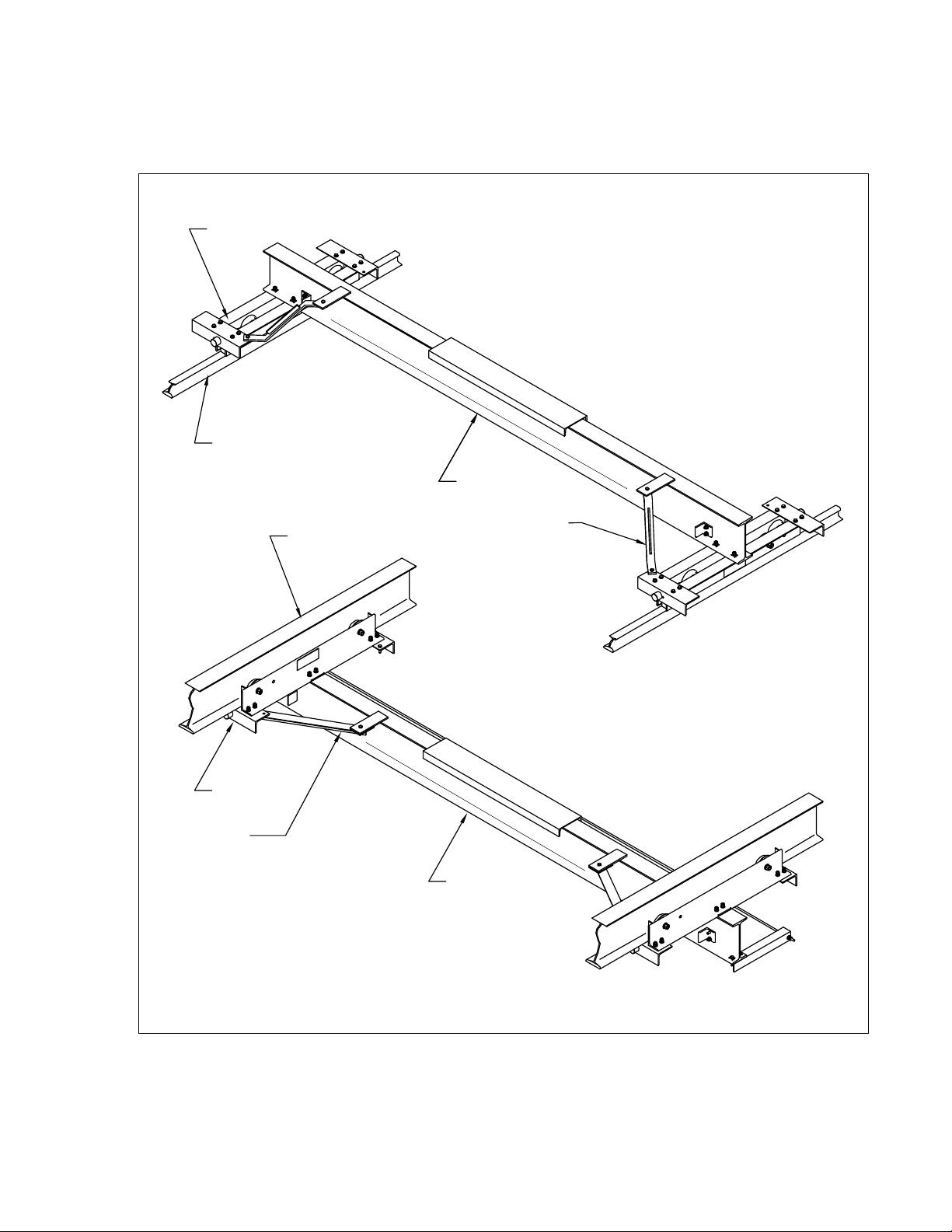

2.2 Part Names

END TRUCK

BRIDGE BEAM

BRIDGE BEAM

END TRUCK

BRACE

BRACE

TOP RUNNING

UNDERHUNG

RUNWAY RAIL

RUNWAY BEAM

Figure 2-2 Part Names – Crane System

9

Page 10

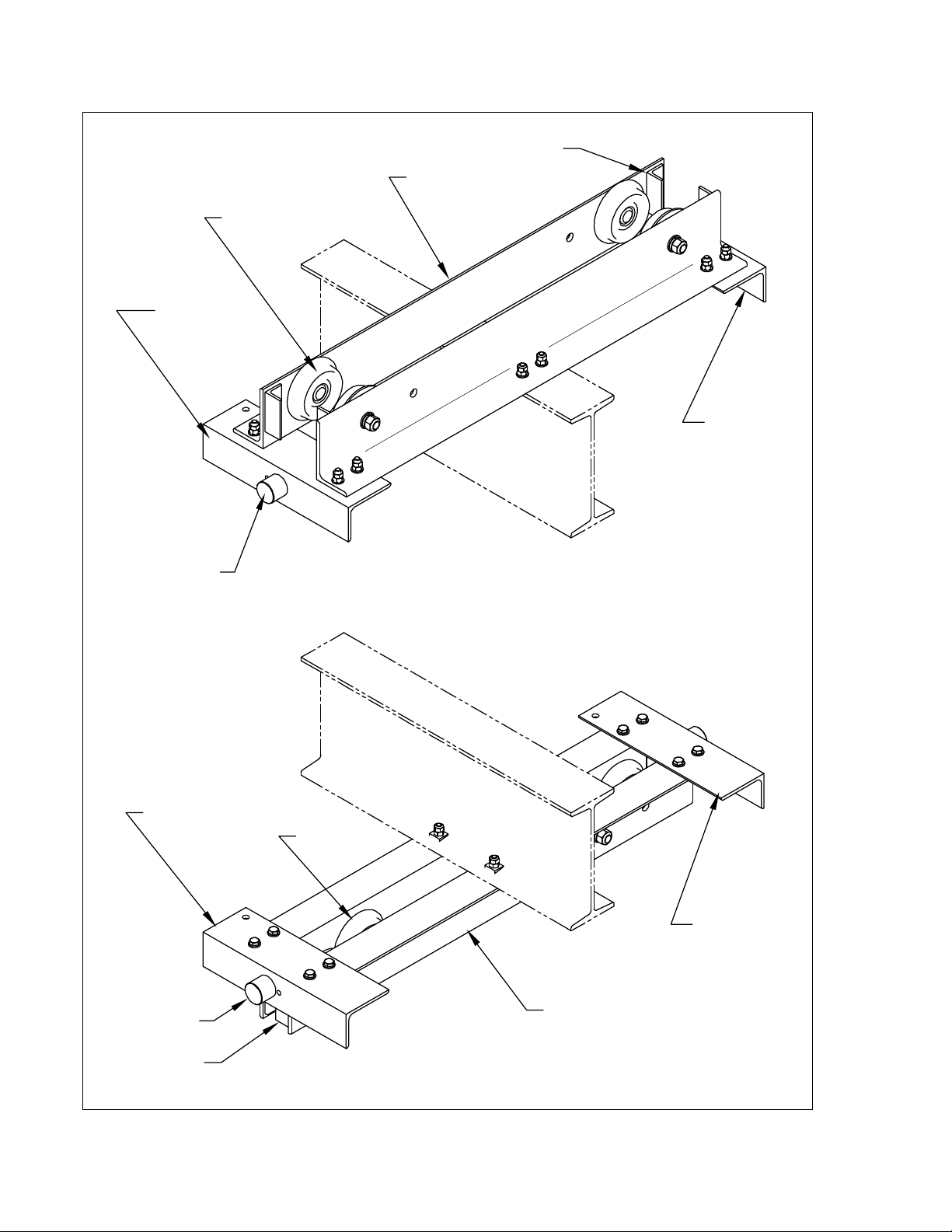

UNDERHUNG

TOP RUNNING

BUMPER

WHEEL

FRAME

END

BRACKET B

SWEEP

END

BRACKET A

BUMPER

END

BRACKET B

WHEEL

FRAME

SWEEP

END

BRACKET A

Figure 2-3 Part Names – End Truck

10

Page 11

3.0 Pre - operational Procedures

End Truck

Beam Flange Width

Beam Depth

HPC505

3 to 6 inches

5 inches

HPC510

3 to 6 inches

6 inches

HPC520

3.33 to 6 inches

8 inches

3.1 Runway

3.1.1

installed, and supported. The runway must meet the requirements of CMAA Specification 74.

3.1.2

3.1.3

and/or the crane system should be performed under the supervision of a Qualified Person (see Section

5 for the definition of Qualified Person).

3.1.4 Underhung – When HPC500 end trucks are assembled in the Underhung configuration, they are

designed to fit runway beams as follows. If your runway beam does not meet these dimensional

requirements, contact your supplier for help.

3.1.5 Top Running – When HPC500 end trucks are assembled in the Top Running configuration, they are

designed to fit rail or square bar with a width between 1½ and 6 inches. Most commonly HPC500 end

trucks set up for Top Running applications use any of the following sizes of ASCE Rail:: 25#, 30#, 35#,

or 40#. Alternately, you can use any of the following sizes of square bar: 1½ inch, 1¾ inch, or 2 inch.

3.1.6 End Stops – The owner/installer must make sure that the runway beams are equipped with end stops

to prevent the end trucks (or crane) from rolling off the end of the runway beams.

Crane systems must be intalled on runways that are properly designed, fabricated,

Read through all steps completely before proceeding with installation.

All operations associated with the assembly and installation of the end trucks

means “greater than or equal to”

3.2 Bridge Beam

3.2.1

3.2.2

and/or the crane system should be performed under the supervision of a Qualified Person (see Section

5 for the definition of Qualified Person).

3.2.3 Size – For the use of either a MANUAL or ELECTRIC HOIST on your HPC500 crane, use Table 3-1 to

select the beam to use as the Bridge Beam.

Read through all steps completely before proceeding with installation.

All operations associated with the assembly and installation of the end trucks

11

Page 12

Table 3-1 Bridge Beams for a MANUAL or ELECTRIC HOIST on an HPC500 Crane

Important information about this table:

Includes 15% Allowance for Electric Hoist Load Factor.

Based on Harrington’s manual chain hoist product.

For spans greater than 10 ft., braces between end truck & bridge beam should be used.

Cap.

(Tons)

Maximum Allowable Span (ft)

10

15

20

24

½

S8 X 18.4

S8 X 18.4

S8 X 18.4

S10 X 25.4

1

S8 X 18.4

S8 X 18.4

S10 X 25.4

S10 X 25.4

2

S10 X 25.4

S10 X 25.4

S12 X 31.8

S12 X 31.8

C8 X 11.5

2

1

4

D

2

1

4

D

SPAN

D/2

D/2

Figure 3-1 Bridge Beam Flange Holes – UNDERHUNG & TOP RUNNING

10

2

2

10

BEAM FLANGE HOLES

(from Fig. 3-1)

SPAN

Figure 3-2 Bridge Beam Web Holes - UNDERHUNG

3.2.4 Fabrication – Preparation of the Bridge Beam for assembly with the HPC500 End Trucks requires that

holes be drilled in the beam as follows. Refer to Table 2-1 and Figure 2-1 for definitions of all letter

variables used for dimensions. NOTE – For S6 beams mounting plates must be welded to the beam.

Refer to the Bridge Beam Assembly Drawing (Underhung: Drawing. No. 62673; Top Running:

Drawing. No. 62672) for details.

Underhung – Drill eight 9/16” diameter holes through the top flange as shown in Figure 3-1. Drill

four 9/16” diameter holes through the web as shown in Figure 3-2.

Top Running – Drill eight 9/16” diameter holes through the bottom flange as shown in Figure 3-1.

Drill four 9/16” diameter holes through the web as shown in Figure 3-3.

12

Page 13

7

2

2

BEAM FLANGE HOLES

(from Fig. 3-1)

SPAN

7

Figure 3-3 Bridge Beam Web Holes – TOP RUNNING

HEX-HEAD

CAP SCREW

END STOP

SPRING WASHER

HEX NUT

BRIDGE BEAM

BRIDGE BEAM

END STOP

Figure 3-4 End Stop Installation

3.2.5 End Stop Installation – This step covers the installation of the end stops onto the bridge beam.

Locate the holes that were installed in the web of the bridge beam (step 3.2.4 above). These are

the holes for attaching the end stops to the bridge beam.

Attach the four (4) end stops to the bridge beam in accordance with Figure 3-4. Fully tighten the

fasteners by applying 75 ft-lb of torque.

13

Page 14

3.3 End Trucks

4 REF.

1

3

4

REF.

1 REF.

4

1

2

REF.

17 REF.

D

EXISTINGØ

9

16

HOLES

BRACKET "A" (AS

SHOWN)

BRACKET "B" (OPPOSITE HAND)

Ø

9

16

- 2 HOLES (DRILL THESE HOLES)

FORMULA

FOR "D"

D = T + 5

D = T + 4

3

4

D = T + 5

D = T + 4

3

4

BEAM WITH FLAT FLANGE

BEAM WITH TAPERED FLANGE

RECTANGULAR SHAPED RAIL

ASCE RAIL

UNDERHUNG

TOP

RUNNING

RUNNING

SURFACE

CRANE

CONFIG.

"D" DIMENSION (INCHES)

T = I-BEAM FLANGE OR RAIL HEAD

- WIDTH MEASUREMENT

Figure 3-5 End Bracket Holes

3.3.1

3.3.2

Read through all steps completely before proceeding with installation.

All operations associated with the assembly and installation of the end trucks

and/or the crane system should be performed under the supervision of a Qualified Person (see Section

5 for the definition of Qualified Person).

3.3.3 End Bracket Preparation – Prior to assembling the end trucks prepare the four (4) end brackets (2 end

brackets per end truck) as follows:

Measure “T” for the runway that the end trucks will be installed on. For Underhung “T” is the flange

width of the runway beam; for Top Running “T” is the width of the rail head or square bar

(whichever is being used).

Drill two 9/16” diameter holes in each of the four (4) end brackets in accordance with Figure 3-5.

3.3.4 Wheel Assembly Installation – Install the Wheel Assemblies to the end trucks as shown in Figure 3-6.

Make sure you locate the Wheel Assemblies properly for your application (Underhung or Top Running)

as shown in Figure 3-7. To prevent the axle from turning when tightening the hex nut, use an airpowered nut driver. Then, finalize the installation by applying torque to each wheel’s hex nut as follows.

75 ft-lb for HPC505

200 ft-lb for HPC510 and HPC520

14

Page 15

WHEEL

ASSEMBLY

FLAT WASHER

(HPC 505 ONLY)

FRAME*

FLAT WASHER

LOCK

WASHER

HEX NUT

*NOTE: DROP

STOP NOT

SHOWN FOR

CLARITY.

Figure 3-6 Wheel Assembly Installation

Underhung

Top Running

Figure 3-7 Wheel Mounting Locations

3.3.5 Verify “H” Dimension – The “H” dimension is the End Truck Frame Spacing (see Table 2-1 and Figure

2-1). By verifying the “H” dimension you verify that the end bracket holes are correct for proper fit of the

end truck onto the runway. Proceed as follows:

Calculate the “H” dimension for your application. For S Beams and ASCE Rail H = T + 1¼

(inches). For W Beams and Square Bar H = T + 1½ (inches). Note: T is the measurement from

step 3.3.3 above.

Refer to Figure 2-3 and Figure 3-9 and assemble the frames and end brackets together. As you

tighten the fasteners (don’t fully tighten yet – this comes later) measure the actual “H” dimension in

accordance with Figure 3-8. Verify that the measured “H” dimension and the calculated “H”

dimension are the same.

Match mark the end brackets to the frames to ensure the “H” dimension is held for the following

steps.

15

Page 16

END BRACKET

FRAME

RUNWAY BEAM

APPROX.

3

16

APPROX.

3

16

UNDERHUNG

H

Figure 3-8 Verify “H” Dimension

HEX-HEAD

CAP

SCREW

FLAT

WASHER

HEX NUT

FLAT

WASHER

HEX NUT

RUNWAY BEAM

UNDERHUNG

HEX NUT

FLAT

WASHER

HEX NUT

FLAT

WASHER

RUNWAY RAIL

HEX-HEAD CAP

SCREW

TOP RUNN ING

Figure 3-9 End Truck Assembly & Installation

3.3.6 End Truck Assembly & Installation – Here the assembly of the end trucks is completed and they are

installed onto the runway. Orientation of the end trucks on the runway is important. Make sure you put

each end truck onto the runway so that the hole in the end bracket for the brace is on the inside of the

runway (see Figure 2-2).

Underhung – apply the following steps for each end truck:

- Disassemble a frame from the end truck.

- Place the frame with the end brackets still attached to it onto the runway beam so its wheels

- In the same manner place the other frame on the opposite side of the runway beam and

ride on the lower flange of the runway beam in accordance with the Underhung part of Figure

3-9.

reassemble this frame to the end brackets, again in accordance with the Underhung part of

Figure 3-9.

16

Page 17

- Ensure that the “H” dimension is correct as determined in step 3.3.5 above, and tighten the

HEX-HEAD

CAP SCREW

TAPER

WASHER

HEX NUT

FLAT WASHER

HEX NUT

UNDERHUNG

BRIDGE

BEAM

END TRUCK

FRAME

4 PER

END

TRUCK

4 PER

END

TRUCK

HEX-HEAD

CAP SCREW

TAPER

WASHER

HEX NUT

FLAT

WASHER

HEX NUT

TOP RUNNING

4 PER

END

TRUCK

4 PER

END

TRUCK

END TRUCK

FRAME

BRIDGE

BEAM

Figure 3-10 Bridge Beam Installation – Attaching the Bridge Beam to the End Truck

fasteners by applying 75 ft-lb of torque.

Top Running – apply the following steps for each end truck:

- Ensure that the “H” dimension is correct as determined in step 3.3.5 above, and tighten the

fasteners by applying 75 ft-lb of torque.

- Place the end truck onto the runway rail (or square bar) in accordance with the Top Running

part of Figure 3-8.

- Since the end truck will not stay balanced on the runway in this condition, temporarily support it

so that it stays safely balanced in position until the bridge beam is installed.

3.3.7 Bridge Beam Installation – This step covers the installation of the bridge beam onto the end trucks.

Underhung – As shown in Figure 2-2 for Underhung cranes, the bridge beam is attached to the

under side of the end trucks.

- Attach the bridge beam to the under side of the end trucks in accordance with the Underhung

part of Figure 3-10. Do not yet fully tighten the fasteners.

- Ensure the crane is square in accordance with Figure 3-11 and proceed to fully tighten the

fasteners by applying 75 ft-lb of torque.

Top Running – As shown in Figure 2-2 for Top Running cranes, the bridge beam is attached to the

upper side of the end trucks.

- Attach the bridge beam to the upper side of the end trucks in accordance with the Top

Running part of Figure 3-10. Do not yet fully tighten the fasteners.

- Ensure the crane is square in accordance with Figure 3-11 and proceed to fully tighten the

fasteners by applying 75 ft-lb of torque.

17

Page 18

90°

90°

END

TRUCK

BRIDGE

BEAM

Figure 3-11 Crane Squareness

3.4 Pre-operational Checks and Trial Operation

3.4.1 Record the end trucks’ Code and Serial No. from the nameplate (see Figure 10-1) in the space

provided on the cover of this manual.

3.4.2 Ensure that the end trucks are properly installed on the runway beams/rails.

3.4.3 If the end trucks are used as part of an overhead travelling bridge crane, then make sure that the bridge

beam is properly designed, fabricated, and installed.

3.4.4 If a hoist/trolley is used in the system:

Ensure the hoist/trolley is properly installed in accordance with the manufacturer’s requirements

and recommendations.

Ensure that the end stops on the bridge beam for the trolley motion are installed correctly and

securely.

3.4.5 Prepare for Trial Operation

Before operating become familiar with operating the equipment (see Section 4 – Operation).

If a hoist/trolley is used in the system, perform pre-operational checks in accordance with the

manufacturer’s requirements and recommendations.

3.4.6 Trial Operation

If the end trucks are used as part of an overhead travelling bridge crane, then move the crane

along the entire length of the runway. Ensure that the crane has proper clearance from

obstructions. Check for proper alignment and clearances of the crane and the end trucks to the

runway (refer to Figure 3-8 and Figure 3-11). Adjust as necessary. Make sure that after any

adjustments the fasteners are properly secured and tightened.

Perform inspections in accordance with Section 5.3, “Frequent Inspections”.

If a hoist/trolley is used in the system, perform trial operation in accordance with the manufacturer’s

requirements and recommendations.

3.4.7 Load Test – perform a load test in accordance with ASME B30.11, “Monorails and Underhung Cranes”,

or ASME B30.17, “Overhead and Gantry Cranes (Top Running Bridge, Single Girder, Underhung

Hoist)”, whichever applies.

18

Page 19

4.0 Operation

4.1 Introduction

Specific operation instructions are not provided herein because the HPC500 series end trucks are used in

systems not covered by this Owner’s Manual. Nevertheless, operation of systems using the HPC500 end trucks

is an EXTREMELY IMPORTANT issue – following is important information about operation.

4.2 Important Information About Operation

Do not walk under a suspended load.

Do not use HPC500 end trucks in systems that lift, support, or transport people.

Operators shall read materials pertaining to the operation of the equipment. For systems

using the HPC500 series end trucks, the supplier and/or owner of the system is/are responsible for providing

information for use by the operator for the safe operation of the system. Sources for such materials include:

Manufacturer – If a hoist/trolley (or some other type of equipment) is used in the system, then the

manufacturer should provide materials for the operation of the hoist/trolley (or other equipment).

CMAA – The Crane Manufacturer’s Association of America (CMAA) publishes a Crane Operator’s

Manual. Contact the CMAA at (704) 676-1190 or www.mhia.org/cmaa.

HMI – The Hoist Manufacturer’s Institute (HMI) publishes a Hoist Operator’s Manual. Contact the

HMI at (704) 676-1190 or www.mhia.org/hmi.

ASME – The American Society of Mechanical Engineers publishes safety standards pertaining to

the type of equipment that could be used in a system with the HPC500 end trucks. Examples are

listed below. Contact the ASME at (800) 843-2763 or www.asme.org.

- ASME B30.11, “Monorails and Underhung Cranes”

- ASME B30.16, “Overhead Hoists (Underhung)”

- ASME B30.17, “Overhead and Gantry Cranes (Top Running Bridge, Single Girder, Underhung

Hoist)”

Labels – Labels attached to equipment used in systems provide information important to the safe

operation of the equipment.

Operators should be trained to be aware of potential malfunctions of the equipment that

require adjustment or repair, and to be instructed to stop operation if such malfunctions occur, and to immediately

advise their supervisor so corrective action can be taken.

Operators should have normal depth perception, field of vision, reaction time, manual

dexterity, and coordination.

Operators should not have a history of, or be prone to siezures, loss of physical control,

physical defects, or emotional instability that could result in actions of the operator being a hazard to the operator

or others.

Operators should not operate equipment when under the influence of alcohol, drugs, or

medication.

Improper operation of systems using the HPC500 end trucks can create a potentially

hazardous situation which, if not avoided, could result in death or serious injury, and substatial property damage.

To avoid such a potentially hazardous situation the operator shall be familiar with, and shall obey, the operating

requirements and guidelines for the system.

19

Page 20

5.0 Inspection

5.1 General

5.1.1 The inspection instructions herein are limited to the HPC500 Series End Trucks and Harrington-

designed HPC500 Cranes, and are based on the use of these products for overhead cranes and

monorails as defined by the following standards.

ANSI/ASME B30.11 Monorails and Underhung Cranes

ANSI/ASME B30.16 Overhead Hoists (Underhung)

ANSI/ASME B30.17 Overhead and Gantry Cranes (Top Running Bridge, Single

inspection should be determined and overseen by a Qualified Person (see definition below).

5.1.2 The following definitions are from the standards listed in Section 5.1.1 above:

Designated Person - a person selected or assigned as being competent to perform the specific

Qualified Person - a person who, by possession of a recognized degree or certificate of

Normal Service - service which involves operating at less than a certain percentage of rated load

Girder, Underhung Hoist)

For systems that are not addressed by these standards, the appropriate

duties to which he/she is assigned.

professional standing, or who, by extensive knowledge, training, and experience, has successfully

demonstrated the ability to solve or resolve problems relating to the subject matter and work.

and less than a specified frequency. Refer to the applicable ANSI/ASME B30 standards for the

specific definition for your application.

Heavy Service - that service which involves operation within the rated load limit which exceeds

normal service.

Severe Service - that service which involves normal or heavy service with abnormal operating

conditions.

5.2 Inspection Classification

5.2.1 Initial Inspection – Prior to initial use, a Designated Person shall inspect the equipment to verify

compliance with the applicable provisions of this manual.

5.2.2 Inspection Intervals – Inspections are divided into two general classifications based upon the intervals

at which inspection should be performed. The intervals in turn are dependent upon the nature of the

critical components and the degree of their exposure to wear, deterioration, or malfunction. The two

general classifications are designated as FREQUENT and PERIODIC, with respective intervals

between inspections as defined below.

5.2.3 FREQUENT Inspection – Visual examinations by the operator or other Designated Person with

intervals per the following criteria:

Normal service - monthly

Heavy service - weekly to monthly

Severe service - daily to weekly

Special or Infrequent Service – as recommended by a Qualified Person

5.2.4 PERIODIC Inspection – Visual inspection by a Designated Person with intervals per the following

criteria:

Normal service - yearly

Heavy service - semiannually

20

Page 21

Severe service - quarterly

Table 5-1 Periodic Inspection

Requirements of frequent inspection.

Deformed, cracked on corroded members

Loose or missing bolts, nuts, pins or rivets.

Worn, cracked, or distorted parts such as pins, bearings, wheels, shafts, gears, rollers, locking

and clamping devices, bumpers, stops, and wheel running surfaces (rail or flange).

Function, instruction, and warning labels for legibility and replacement.

If a hoist/trolley is included in the system, perform inspection in accordance with the

manufacturer’s recommendations for PERIODIC inspection.

Special or Infrequent Service – as recommended by a Qualified Person

5.3 Frequent Inspection

5.3.1 Use the following as guidance for inspections to be made on a FREQUENT basis.

Inspect all functional operating mechanisms for:

- Proper Operation

- Proper Adjustment

- Unusual Sounds

If a hoist/trolley is included in the system, perform inspection in accordance with the manufacturer’s

recommendations for FREQUENT inspection.

Continually observe during operation. Any defects or damage must be reported and shall be

evaluated and resolved by a Designated Person such that the equipment is maintained in safe

working condition.

5.4 Periodic Inspection

5.4.1 Use the following as guidance for inspections to be made on a PERIODIC basis.

Inspect in accordance with Table 5-1.

Results of PERIODIC inspections must be reported and shall be evaluated and resolved by a

Designated Person such that the equipment is maintained in safe working condition.

21

Page 22

5.5 Occasionally Used End Trucks and Cranes

5.5.1 End Trucks and cranes that are used infrequently shall be inspected as follows prior to placing in

service:

Idle More Than 1 Month, Less Than 1 Year: Inspect per FREQUENT Inspection criteria of Section

5.3 above.

Idle More Than 1 Year: Inspect per PERIODIC Inspection criteria of Section 5.4 above.

5.6 Inspection Records

Dated inspection reports and records should be maintained for PERIODIC inspections. These records should

be stored where they are available to personnel involved with the inspection, maintenance, or operation of the

equipment.

5.7 Inspection Methods and Criteria

5.7.1 This section covers the inspection of specific items. In accordance with the standards listed in

paragraph 5.1 above, these inspections are not intended to involve disassembly. Rather, disassembly

for further inspection would be required if FREQUENT or PERIODIC inspection results so indicate.

Only a Qualified Person trained in the disassembly and re-assembly of the equipment should perform

such disassembly and further inspection.

5.7.2 Table 5-2 below gives Methods, Criteria, and Corrective Action for the inspection of components of

HPC500 End Trucks and Cranes.

22

Page 23

Table 5-2 Inspections Methods and Criteria

Component

Item

Method

Criteria

Corrective Action

Runway

Fasteners

Check tightness

Measure torque

Fasteners must be sufficiently tight.

Refer to torque values listed in

Section 3.

Tighten

Wheel Running

Surfaces

Visual

The surfaces on which the end

truck wheels run must be free of oil,

grease or paint.

Clean/remove

contaminants

Wheel Running

Surfaces

Visual

The surfaces on which the end

truck wheels run must not be worn

excessively.

Replace.

Dimensions

Measure

The span, straightness, elevation

must be within allowed tolerances

as specified by CMAA Spec. 74.

Adjust/repair

Bridge

Beam

Bridge Beam

Visual

Measure

The beam must not be deformed or

damaged.

Repair or replace

Welded parts

Visual

NDT

Welds to be in accordance with

weld specifications of CMAA Spec.

74.

Repair

Lower Flange

Visual

The travel surface must not be

worn excessively.

Replace

Fasteners

Check tightness

Measure torque

Fasteners must be sufficiently tight.

Refer to torque values listed in

Section 3.

Tighten

Deflection

Measure

Deflection at mid-span under rated

load must be less than 1/600 of the

span.

Repair , replace, or

down-rate

Capacity

Label(s)

Visual

Label(s) must be legible and

securely attached.

Repair or replace

End Truck

Wheel Tread

Measure

Wheel diameter must not be less

than the “Min. Value for

Replacement” listed in Table 5-3.

Replace

Wheel Flange

Visual

Wheel flange must not be worn

excessively.

Replace

Fasteners

Check tightness

Measure torque

Fasteners must be sufficiently tight.

Refer to torque values listed in

Section 3.

Tighten

23

Page 24

Table 5-3 Wheel Tread Diameter

End Truck Code

Standard Value

(in)

Min. Value for

Replacement

(in)

HPC505

3.12

2.97

HPC510

4.00

3.81

HPC520

4.88

4.66

24

Page 25

6.0 Lubrication

6.1 HPC500 End Trucks

6.1.1 There are no lubrication requirements for the HPC500 Series End Trucks for the following reasons.

The wheel bearings are sealed and permanently lubricated.

There are no other components that are lubricated or which require lubrication.

6.2 Other Equipment

6.2.1 If a hoist/trolley (or some other type of equipment) is used in the system, then perform lubrication of the

hoist/trolley (or other equipment) in accordance with the manufacturer’s requirements and

recommendations.

25

Page 26

7.0 Maintenance and Handling

7.1 General

7.1.1 The HPC500 Series End Truck is designed to be MAINTENANCE-FREE.

If a hoist/trolley (or some other type of equipment) is used in the system, then perform maintenance and handling

of the hoist/trolley (or other equipment) in accordance with the manufacturer’s requirements and

recommendations.

7.2 Storage

7.2.1 Whenever the end trucks are to be placed into storage, place extra grease onto all exposed unpainted

parts such as the wheels and fasteners. Make certain that no debris or moisture is allowed to

accumulate on the end truck.

7.2.2 The storage location should be clean and dry.

7.3 Outdoor Installations

For outdoor installations the HPC500 Series End Trucks should be protected from the weather when not in use.

26

Page 27

8.0 Troubleshooting

Table 8-1 Troubleshooting Guide

Trouble

Cause

Remedy

End Trucks do not move

smoothly along the runway

Runway system is out of tolerance

Make sure the span of the runway

system is within the allowable

tolerance of CMAA Spec 74.

Make sure the straightness of each

runway is within the allowable

tolerance of CMAA Spec 74.

Make sure the elevation of each

runway is within the allowable

tolerance of CMAA Spec 74.

Make sure that each runway is at the

same elevation within the allowable

tolerance of CMAA Spec 74.

Span of the crane does not match the

span of the runway system

Adjust to make the spans match.

The crane is not square

Adjust to make the crane square –

see Section 3.3.

Damaged end truck wheel(s)

Replace damage wheel(s).

End Trucks’ bumpers do not

contact the runway end stops

simultaneously

The crane is not square

Adjust to make the crane square –

see Section 3.3.

The end stops are not located

correctly on the runways.

Relocate the end stops on the runway

to their correct locations.

Use Table 8-1, “Troubleshooting Guide” below to troubleshoot any problems you may encounter with the HPC500

Series End Truck or Crane.

27

Page 28

9.0 Warranty

Warranty explanation and terms.

All products sold by Harrington Hoists, Inc. are warranted to be free from defects in material

and workmanship from date of shipment by Harrington for the following periods:

Manual Hoists, Trolleys, & Beam Clamps - 2 years

NER/ER Hoists Enhanced Features Models – 3 years

Electric Hoists, Air Hoists and Trolleys, Crane Components - 1 year

Spare / Replacement Parts - 1 year

NER/ER “The Guardian” Electromagnetic Smart Technology Brake – 10 years

The product must be used in accordance with manufacturer’s recommendations and must

not have been subject to abuse, lack of maintenance, misuse, negligence, or unauthorized repairs

or alterations.

Should any defect in material or workmanship occur during the above time period in any

product, as determined by Harrington Hoist’s inspection of the product, Harrington Hoists, Inc.

agrees, at its discretion, either to replace (not including installation) or repair the part or product free

of charge and deliver said item F.O.B. Harrington Hoists, Inc. place of business to customer.

Customer must obtain a Return Goods Authorization as directed by Harrington or Harrington’s

published repair center prior to shipping product for warranty evaluation. An explanation of the

complaint must accompany the product. Product must be returned freight prepaid. Upon repair,

the product will be covered for the remainder of the original warranty period. Replacement parts

installed after the original warranty period will only be eligible for replacement (not including

installation) for a period of one year from the installation date. If it is determined there is no defect,

or that the defect resulted from causes not within the scope of Harrington’s warranty, the customer

will be responsible for the costs of returning the product.

Harrington Hoists, Inc. disclaims any and all other warranties of any kind expressed or

implied as to the product’s merchantability or fitness for a particular application. Harrington will not

be liable for death, injuries to persons or property or for incidental, contingent, special or

consequential damages, loss or expense arising in connection with the use or inability whatever,

regardless of whether damage, loss or expense results from any act or failure to act by Harrington,

whether negligent or willful, or from any other reason.

28

Page 29

10.0 Parts List

Figure 10-1 HPC500 Series End Truck Nameplate

(showing Code filled in for HPC505 End Truck)

When ordering Parts, please provide the Code number located on the end truck nameplate (see Figure 10-1 below).

Reminder: Per Sections 1.1 and 3.4.1, to aid in ordering Parts and Product Support, record the end trucks’ Code and

Serial No. in the space provided on the cover of this manual.

29

Page 30

Table 10-1 Parts List for HPC500 Series End Trucks

Figure

Number

Qty/Pr

HPC505

HPC510

HPC520

PART NAME

1 4 52391

52390

62674

Frame Assembly

2

2

62675

End Bracket A – Standard Flange Range

62678

End Bracket A – Extended Flange Range

3

2

62676

End Bracket B – Standard Flange Range

62679

End Bracket B – Extended Flange Range

6 2 80065

80066

80067

Name Plate

7

8

9003903

Nut 8 8

9003905

9003908

Nut 9 4

9004603

Bumper

10

16

9005209

Flat Washer

8 9005212

11 8 9005313

9005317

Lock Washer

12

40

9012515

Flat Washer

13

8

9043514

Tapered Washer

14

16

9093374

Bolt

15

8

9093376

Bolt

16

52

9093433

Nut

17 8 9200011

9200012

9200013

Wheel Assembly

18

4

6245909

End Stop

19

4

9012713

Spring Washer

20

4

9093146

Bolt

30

Page 31

NOTES

31

Page 32

www.harringtonhoists.com

Harrington Hoists, Inc. Harrington Hoists - Western Division

401 West End Avenue 2341 Pomona Rd. #103

Manheim, PA 17545 Corona, CA 92880-6973

Phone: 717-665-2000 Phone: 951-279-7100

Toll Free: 800-233-3010 Toll Free: 800-317-7111

Fax: 717-665-2861 Fax: 951-279-7500

HPC500OM

Loading...

Loading...