Page 1

r

y

y

EFFECTIVE: May 1, 2006

EFFECTIVE: May 1, 2006

Owner’s Manual

AIR

POWERED

CHAIN HOIST

TCR SERIES

MODEL TCR

10 Ton and 25 Ton Capacity

Code, Lot and Serial Number

WARNING

This equipment should not be installed, operated o

maintained by any person who has not read and understood

all the contents of this manual. Failure to read and compl

with the contents of this manual can result in serious bodil

injury or death, and/or property damage.

Page 2

Table of Contents

Section Page Number

1.0 Important Information and Warnings…………………………………………………………………4

1.1 Terms and Summary

1.2 Warning Tags and Labels

2.0 Technical Information………………………………………………………………………………… 8

2.1 Specifications

2.2 Dimensions

2.3 Part Names

3.0 Pre-operational Procedures………………………………………………………………………... 12

3.1 Air Supply System Requirements

3.2 Air Supply Capacity And Regulation

3.3 Lubrication

3.4 Filtration

3.5 Air Dryer

3.6 Piping, Hoses And Fittings

3.7 Mounting Location

3.8 Connecting Hoist to Air Supply

3.9 Mounting the Hoist

3.10 Optional Chain Container

3.11 Non-Stationary Application

3.12 Preoperational Checks and Trial Operation

4.0 Operation……………………………………………………………………………………………. 19

4.1 Introduction

4.2 Shall’s and Shall Not’s for Operation

4.3 Hoist Controls

4.4 Adjusting the Controls

4.5 Operation of the Load Limiter

2

Page 3

Section Page Number

5.0 Inspection………………………………………………………………………….………………… 24

5.1 General

5.2 Inspection Classification

5.3 Frequent Inspection

5.4 Periodic Inspection

5.5 Occasionally Used Hoists

5.6 Inspection Records

5.7 Inspection Methods and Criteria

6.0 Lubrication…………………………………………………………………………………………... 31

6.1 Air Hoist Lubrication

6.2 Load Chain Lubrication

6.3 Hooks and Suspension Components

7.0 Maintenance & Handling…………………………………………………………………………… 32

7.1 Load Limiter

7.2 Brake

7.3 Load Chain

7.4 Pendant

7.5 Load Sheave Inspection

7.6 Storage

7.7 Outdoor Installation

8.0 Troubleshooting…………………………………………………………………………………….. 38

9.0 Warranty…………………………………………………………………………………………….. 40

9.0 Parts Information……………………………………………………………………………………. 41

3

Page 4

1.0 Important Information and Warnings

1.1 Terms and Summary

This manual provides important information for personnel involved with the installation, operation and maintenance

of this product. Although you may be familiar with this or similar equipment, it is strongly recommended that you read

this manual before installing, operating or maintaining the product.

Danger, Warning, Caution and Notice - Throughout this manual there are steps and procedures that can present

hazardous situations. The following signal words are used to identify the degree or level of hazard seriousness.

DANGER

WARNING

CAUTION

NOTICE

These general instructions deal with the normal installation, operation, and maintenance situations encountered with

the equipment described herein. The instructions should not be interpreted to anticipate every possible contingency

or to anticipate the final system, crane, or configuration that uses this equipment. For systems using the equipment

covered by this manual, the supplier and owner of the system are responsible for the system’s compliance with all

applicable industry standards, and with all applicable federal, state and local regulations/codes.

This manual includes instructions and parts information for a variety of hoist types. Therefore, all instructions and

parts information may not apply to any one type or size of specific hoist. Disregard those portions of the instructions

that do not apply.

Danger indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury, and property damage.

Warning indicates an imminently hazardous situation which, if not avoided, could result in death or

serious injury, and property damage.

Caution indicates a potentially hazardous situation which, if not avoided, may result minor or

moderate injury or property damage.

Notice is used to notify people of installation, operation, or maintenance information which is

important but not directly hazard-related.

CAUTION

Record your hoist’s Code and Serial Number (see Section 3.11.6 and Figure 10-1) on the front cover of this manual

for identification and future reference to avoid referring to the wrong manual for information or instructions on

installation, operation, inspection, maintenance, or parts.

Use only Harrington authorized replacement parts in the service and maintenance of this hoist.

4

Page 5

WARNING

Equipment described herein is not designed for and MUST NOT

or for lifting or supporting loads over people.

Equipment described herein should not be used in conjunction with other equipment unless necessary and/or

required safety devices applicable to the system, crane, or application are installed by the system designer, system

manufacturer, crane manufacturer, installer, or user.

Modifications to upgrade, rerate, or otherwise alter this equipment shall be authorized only by the original equipment

manufacturer.

Equipment described herein may be used in the design and manufacture of cranes or monorails. Additional

equipment or devices may be required for the crane and monorail to comply with applicable crane design and safety

standards. The crane designer, crane manufacturer, or user is responsible to furnish these additional items for

compliance. Refer to ANSI/ASME B30.17, “Safety Standard for Top-Running Single Girder Cranes”; ANSI/ASME

B30.2 “Safety Standard for Top-Running Double-Girder Cranes”; and ANSI/ASME B30.11 “Safety Standard for

Underhung Cranes and Monorails”.

If a below-the-hook lifting device or sling is used with a hoist, refer to ANSI/ASME B30.9, “Safety Standard for

Slings” or ANSI/ASME B30.20, “Safety Standard for Below-the-Hook Lifting Devices”.

be used for lifting, supporting, or transporting people,

Hoists, trolleys and cranes, used to handle hot molten material may require additional equipment or devices. Refer to

ANSI Z241.2, “Safety Requirements for Melting and Pouring of Metals in the Metalcasting Industry”.

Failure to read and comply with any one of the limitations noted herein can result in serious bodily injury or death,

and/or property damage.

5

Page 6

DANGER

HAZARDOUS AIR PRESSURE IS PRESENT IN THE HOIST, IN THE SUPPLY OF COMPRESSED AIR TO THE

HOIST, AND IN THE CONNECTIONS BETWEEN COMPONENTS.

Before performing ANY maintenance on the equipment, de-energize the supply of compressed air to the

equipment, and lock and tag the supply device in the de-energized position. Refer to ANSI Z244.1, “Personnel

Protection - Lockout/Tagout of Energy Sources.”

Only trained and competent personnel should inspect and repair this equipment.

NOTICE

It is the responsibility of the owner/user to install, inspect, test, maintain, and operate a hoist in accordance with

ANSI/ASME B30.16, “Safety Standard for Overhead Hoists”, OSHA Regulations. If the hoist is installed as part of a

total lifting system, such as an overhead crane or monorail, it is also the responsibility of the owner/user to comply with

the applicable ANSI/ASME B30 volume that addresses that type of equipment.

It is the responsibility of the owner/user to have all personnel that will install, inspect, test, maintain, and operate a

hoist read the contents of this manual and applicable portions of ANSI/ASME B30.16, “Safety Standard for Overhead

Hoists” and OSHA Regulations. If the hoist is installed as part of a total lifting system, such as an overhead crane, the

applicable ANSI/ASME B30 volume that addresses that type of equipment must also be read by all personnel.

If the hoist owner/user requires additional information, or if any information in the manual is not clear, contact

Harrington or the distributor of the hoist. Do not install, inspect, test, maintain, or operate this hoist unless this

information is fully understood.

A regular schedule of inspection of the hoist in accordance with the requirements of ANSI/ASME B30.16 should be

established and records maintained.

6

Page 7

1.2 Warning Tags and Labels

The warning tag illustrated below in Figure 1-1 is supplied with each hoist shipped from the factory. If the tag is not

attached to your hoist (for pendant control, the warning tag is attached to the pendant hose; for the pull cord control, the

warning tag is attached to the up cord), order a tag from your dealer and install it. See parts list in the parts section of

this manual. Read and obey all warnings attached to this hoist. Tag is not shown actual size.

front back

Figure 1-1 Warning Tag Attached to Air Hoist

7

Page 8

2.0 Technical Information

2.1 Specifications

2.1.1 Product Code

2.1.2 Operating Conditions and Environment

Temperature range: +14° to +140°F (-10° to +60°C)

Relative Humidity: 85% or less

Supply Air: 60 to 90 pounds per square inch

Air Consumption: 170 to 220 cubic feet minute

Air Lubrication Requirements: Minimum 10 to 15 drops per minute (2-3 cc/min) of oil

Air Filtration Requirements: Maximum 5 micron air filter or finer

Load Limiter: Adjustable; Factory set to 125% of rated capacity

Standard

Lift

(ft)

Cap.

(Tons)

Product

Code

Table 2-1 Hoist Specifications

Push

Button

Hose

(ft)

Up/Down Speeds

(ft/min @ 90 psi)

L

No Load w/Full Load No Load w/Full Load

Air Consumption Rates

(cubic ft/min @ 90 psi)

Up/Down

Load Chain

Diameter

(mm)

Chain Fall

Lines

x

Net

Weight

(lbs)

Weight for

Additional

One Foot

of Lift

(lbs)

10 TCR10000P2 8.8 7.2/5.9 5.1/7.6 220/180 180/210 16 x 2 476 3.8

Model

Pendant

25 TCR25000P2

10

9.4 2.1/1.6 1.8/2.2 210/190 170/200 22 x 2 1082 7.0

10 TCR10000C2 8.1 7.2/5.9 5.1/7.6 220/180 180/210 16 x 2 465 3.8

Cord

Model

25 TCR25000C2

10

8.7 2.1/1.6 1.8/2.2 210/190 170/200 22 x 2 1074 7.0

8

Page 9

2.2 Dimensions

j

j

TCR10000P2 TCR25000P2

Table 2-2 TCR with Pendant Control Dimensions

Cap.

(Tons)

Product

Code

Headroom

C

(in)

a

(in)

b

(in)

d

(in)

e

(in)

g

(in)

h

(in)

(in)

i

(in)

10 TCR10000P2 35.0 21.7 18.4 9.7 12.0 1.6 7.4 11.0 2.4

25 TCR25000P2 56.7 27.5 18.7 14.3 13.2 3.1 6.4 12.3 4.9

TABLE 2-3 TCR WITH CORD CONTROL DIMENSIONS

TCR10000C2 TCR25000C2

Cap.

(Tons)

Product

Code

Headroom

C

(in)

a

(in)

b

(in)

d

(in)

e

(in)

g

(in)

h

(in)

(in)

i

(in)

10 TCR10000C2 35.0 21.7 18.4 9.7 12.0 1.6 7.4 11.0 2.4

25 TCR25000C2 56.7 27.5 18.7 14.3 13.2 3.1 6.4 12.3 4.9

9

Page 10

Table 2-4 Top and Bottom Hook Dimension*

Units = inch

Product Code a b c d e f g h

TCR10000C/P2

TCR25000C/P2

2.8 2.4 2.4 2.2 2.4 2.6 1.6 7.1

4.9 3.5 3.9 3.5 4.9 4.9 3.1 13.1

*Refer to Section 5.7 for inspection dimensions and limits.

2.3 Part Names

Figure 2-1 Hoist Part Identification Diagrams – 10 Ton TCR10000C2 and TCR10000P2

10

Page 11

Figure 2-2 Hoist Part Identification Diagrams – 25 Ton TCR25000P2 and TCR25000C2

11

Page 12

3.0 Preoperational Procedures

3.1 Air Supply System Requirements

3.1.1

3.1.2

3.1.3

NOTICE

air hoist with required pressure and flow. Otherwise the hoist may operate poorly or may fail to

operate. See Section 3.2.

CAUTION

supply is the primary source of lubrication to the hoist. Therefore, a dedicated air supply lubricator must

be used with the hoist. Refer to Section 3.3.

CAUTION

ensure its proper operation. The air must be clean and free of debris such as dirt and rust. Refer to

Section 3.4 for filtration requirements. The air must also be dry; free of moisture and water. Refer to

Section 3.5.

Pressure and Flow - Verify that the air supply system has capacity to supply your

Lubrication - The hoist requires lubrication for proper operation. The oil in the air

Air Quality - Good air quality is essential to prevent damage to your hoist and to

3.2 Air Supply Capacity And Regulation

3.2.1 Capacity - The air supply system must be capable of delivering the required airflow (cfm) to the hoist

inlet port. Without the required airflow the hoist will not operate properly or may not operate at all. See

Section 2.0 for your hoists air consumption requirements. In determining if your system is capable of

supplying the required airflow, consider the following:

Capacity of compressor(s) and tank

Other air consuming equipment

Flow restrictions such as pipes, hoses, valves and fittings

Inadequate capacity will cause a significant drop in pressure when the hoist is operated, and could

cause poor performance or failure to operate.

3.2.2 Regulation - The hoist requires a constant supply of air at a pressure of between 60 and 90 psi. If the

air supply is not regulated or is regulated at a pressure greater than 90 psi, then a regulator must be

used. The regulator may be located anywhere upline of the lubricator in the air supply to the hoist.

3.3 Lubrication

3.3.1

3.3.2

CAUTION

as follows:

1) Best location - At the hoist inlet. In this case the lubricator can be either the mist type or drop

type.

2) Second best location - No more than 15 feet away from the hoist, at the same elevation or

above the hoist inlet. In this case the mist type lubricator must be used.

3) Third best location - No more than 15 feet away below the hoist. In this case the mist type

lubricator must be used.

CAUTION

minute (2 to 3 cc/minute). The hoist’s exhaust will emit a fine oil mist when properly lubricated.

3.4 Filtration

3.4.1

CAUTION

microns in size. Therefore, the hoist must have a 5 micron filter

upstream of the lubricator.

The hoist must be supplied with its own lubricator. The lubricator must be located

The lubricator must be set to deliver the equivalent of 10 to 15 drops of oil per

The air entering the hoist inlet must not contain any particulate greater than 5

in its air supply. The filter must be

12

Page 13

3.4.2 The filter servicing the hoist can also service other hoists and air consuming equipment. In this case,

the air filter must be in sized for the total air consumption of the equipment it is servicing.

3.5 Air Dryer -

supply system to ensure that dry air

this moisture will cause corrosion on internal hoist components during periods when the hoist is idle leading to

hoist malfunction.

CAUTION

3.6 Piping, Hoses And Fittings

3.6.1

CAUTION

Since moisture tends to accumulate in compressed air systems, corrosion may result if the system is

not periodically drained.

Arrange for a drain in the air supply piping at the lowest point in the piping, and

Periodically drain the system to remove moisture/water from the system and to prevent corrosion.

Filter, regulator (if equipped), and lubricator must be arranged in the order shown in Figure 3-2.

System Configuration - The system should be configured as shown in Figure 3-1.

To prevent corrosion and hoist malfunction, employ an air dryer in the air

is supplied to the hoist. If there is moisture in the air supplied to the hoist,

Figure 3-1 Diagram of Air Supply Configuration (Typical)

Figure 3-2 Typical Air Supply Filter, Regulator and Lubricator.

13

Page 14

3.6.2

3.6.3

NOTICE

Piping - Pipe should be sized to accommodate the hoist airflow requirements.

Table 3-1 gives recommended pipe sizes.

Table 3-1 Air Supply Pipe and Hose Sizes

Model

Diameter of Supply

Pipe

Diameter of Supply

Hose

TCR10000P2

TCR25000C2

TCR10000P2

Inside diameter

1.25 inch or larger

Inside diameter

1.0 inch or larger

TCR25000C2

NOTICE

Hoses - The connection from the air supply system piping to the hoist must be

made with a flexible pressure hose. Due to normal line losses in air supply lines:

Do not use hose smaller than specified in Table 3-1, and

Limit the length of the hose to that specified in Figure 3-3.

If your application exceeds these requirements consult factory.

3.6.4

Figure 3-3 Typical Arrangements of Filter, Regulator and Lubricator and

Maximum Air Supply Hose Lengths

CAUTION

Fittings - Important considerations regarding fittings in the hoist's air supply

include:

When connecting air supply components, remove all dirt or debris from the connecting surfaces of

the hoses, pipes, fittings, or threaded fasteners to prevent contaminants from entering the hoist.

Keep airflow restrictions such as quick disconnect fittings, bends, elbows, and adapters to a

minimum.

14

Page 15

3.6.5

CAUTION

purging procedures to prevent contaminants or moisture from entering the hoist.

Before connecting the hoist to its air supply line; perform the proper draining and

3.7 Mounting Location

3.7.1

3.7.2

WARNING

are adequate to support the hoist and its loads. If necessary consult a professional that is qualified to

evaluate the adequacy of the suspension location and its supporting structure.

NOTICE

Prior to mounting the hoist ensure that the suspension and it supporting structure

See Section 7.6 for outdoor installation considerations.

3.8 Connecting Hoist to Air Supply

3.8.1

WARNING

OF COMPRESSED AIR TO THE HOIST, AND IN THE CONNECTIONS BETWEEN COMPONENTS.

HAZARDOUS AIR PRESSURE IS PRESENT IN THE HOIST, IN THE SUPPLY

3.8.2 Shut off the air supply and stop the airflow completely. Lock out and tag out in accordance with ANSI

Z244.1 “Personnel Protection -Lockout/Tagout of Energy Sources”.

3.8.3

3.8.4 Apply approximately 10-15 drops of turbine oil (see approved lubricant under Section 6.0 Lubricants)

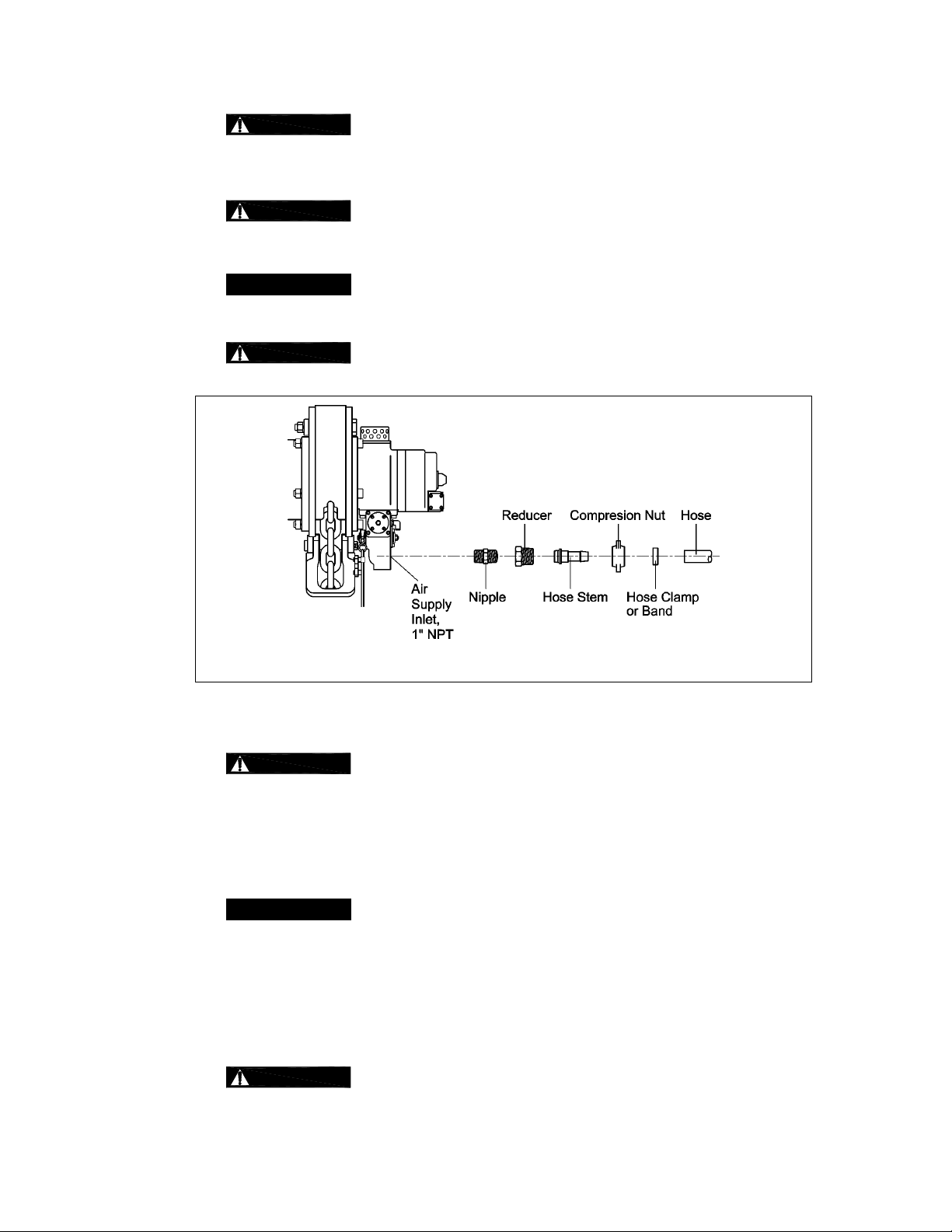

3.8.5 Make connections to air supply; reference Figure 3-4. Use a reducing adapter at the hoist valve

3.8.6

CAUTION

clear any debris and water.

into the hose before attaching to the hoist.

section for hose sizes larger than 1 inch.

NOTICE

the hoist first (Section 3.9) followed by connecting the air supply (Section 3.8).

3.9 Mounting the Hoist

3.9.1 Manual Trolley - Follow instructions in Owner’s Manual provided with the trolley.

3.9.2 Motorized Trolley - Follow instructions in Owner’s Manual provided with the trolley.

3.9.3 Hook Mounted to a Fixed Location - Attach the hoist’s top hook to the fixed suspension point.

3.9.4

WARNING

that the hook’s latch is engaged .

Figure 3-4 Typical Air Supply Connection

Before connecting the air supply hose to the hoist, always purge the air hose to

Where conditions dictate, the installation sequence can be reversed by mounting

Ensure that the fixed suspension point rests on the center of the hook’s saddle and

15

Page 16

3.10 Non-Stationary Application

3.10.1 For applications such as rental fleets or construction sites where the hoist is moved from place-toplace, a filter and lubricator are still required. Consult factory for recommended methods.

3.10.2 Connections and fittings must be kept clean and care taken to prevent dirt, debris and moisture from

entering the hoist.

3.10.3 Recommended practice for removing the hoist from an installation:

Run the hoist briefly with well lubricated air

Disconnect the air supply line

Inject a small quantity (approximately 20 drops) of oil into the hoist’s inlet port

Plug the inlet port

3.11 Preoperational Checks and Trial Operation

3.11.1

3.11.2

CAUTION

Check for the availability of required operating air pressure of between 60 PSI to

90 PSI at the hoist's inlet port before trying to operate the hoist.

WARNING

Verify that the load chain is not twisted or tangled and that the bottom hook is not

capsized prior to operating the hoist. Correct all chain irregularities before conducting the first hoist

operation. See Figures 3-5 and 3-6.

Figure 3-5 Twist in Load Chain

16

Page 17

Figure 3-6 Capsized Hook and Chain

3.11.3

3.11.4

WARNING

Confirm the adequacy of the rated capacity for all slings, chains,

wire ropes and all other lifting attachments before use. Inspect all load suspension

members for damage prior to use and replace or repair all damaged parts.

WARNING

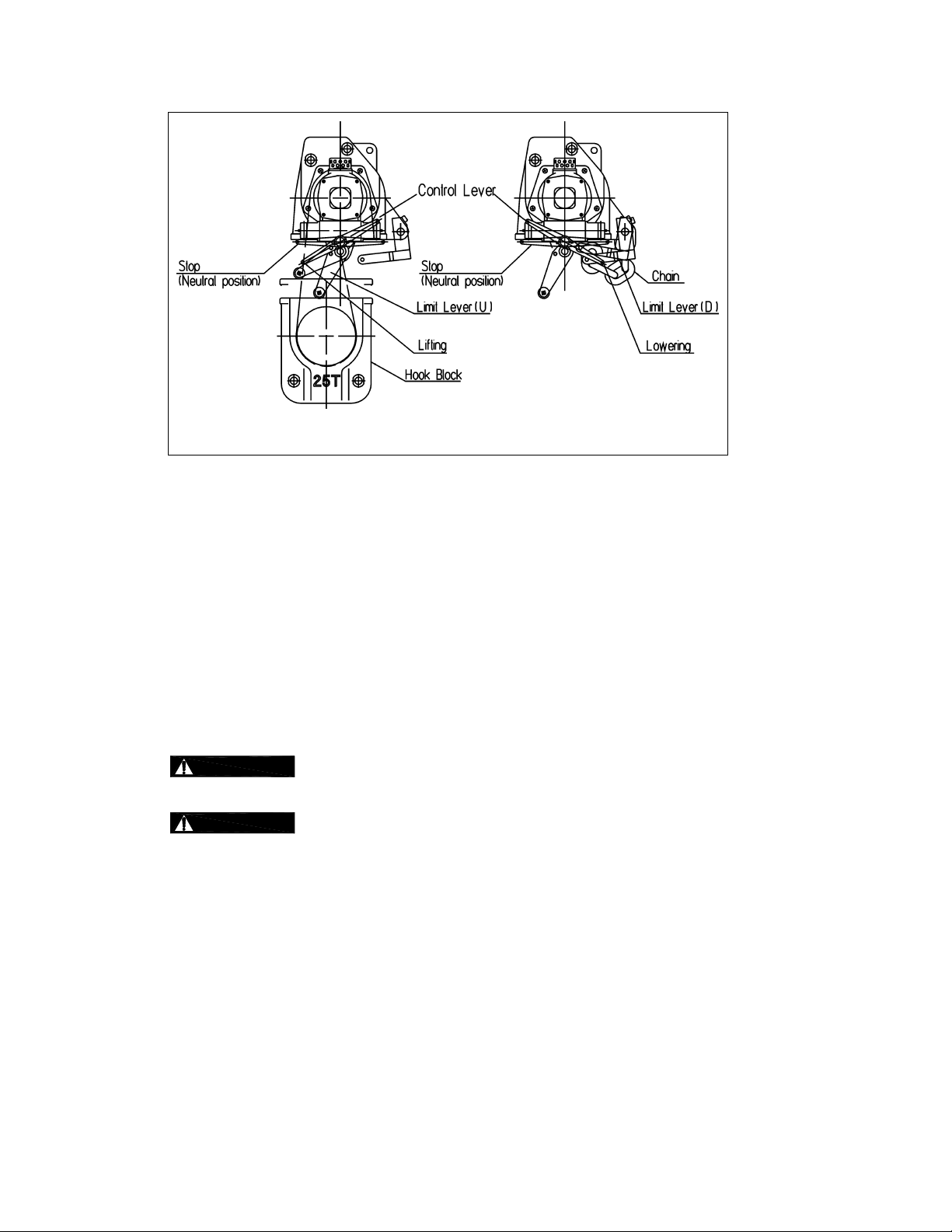

Verify that the Chain/Limit Levers are operational and can move

freely in both the up and down directions. For reference see Figure 3-7.

Figure 3-7 Limit Switch Components – 10 Ton TCR10000C2 and TCR10000P2

17

Page 18

Figure 3-8 Limit Switch Components – 25 Ton TCR25000C2 and TCR25000P2

3.11.5 Measure and record the “K” dimension of all hooks on hoist. See Table 5-6 under Section 5,

“Inspection”. Always use the same side of the hook to measure and record the "K" dimension.

3.11.6 Record the hoist Code Number and Serial Number (from the nameplate on the hoist – see Section 10)

in the space provided on the cover of this manual.

3.11.7 Ensure that the hoist is properly installed to either a fixed point, or trolley, whichever applies.

3.11.8 If hoist is installed on a trolley, ensure that

trolley is properly installed on the beam, and

stops for the trolley are correctly positioned and securely installed on the beam.

3.11.9 Ensure that all nuts, bolts and split (cotter) pins are sufficiently fastened.

3.11.10 For hoists with pendant controls, Ensure that the Pendant Hoses and Strain Relief Chain are properly

attached to the hoist. See Section 7.4.

3.11.11

CAUTION

Check Air Supply - Check air supply before everyday use. Ensure proper air

quality and air pressure.

3.11.12

CAUTION

Check the lubricator for proper function and adequate oil level.

3.11.13 Confirm proper operation.

Before operating read and become familiar with Section 4 - Operation.

Before operating ensure that the hoist (and trolley) meets the Inspection, Testing and Maintenance

requirements of ANSI/ASME B30.16.

Before operating ensure that nothing will interfere with the full range of the hoist’s (and trolley’s)

operation.

3.11.14 Proceed with trial operation to confirm proper operation.

Initially operate slowly under no load in both directions. Verify controls agree with hoist direction.

Perform inspections per Section 5.3, “Frequent Inspections”.

18

Page 19

4.0 Operation

4.1 Introduction

DANGER

DO NOT

WALK UNDER A SUSPENDED LOAD

WARNING

HOIST OPERATORS SHALL BE REQUIRED TO READ THE OPERATION SECTION OF THIS MANUAL, THE

WARNINGS CONTAINED IN THIS MANUAL, INSTRUCTION AND WARNING LABELS ON THE HOIST OR

LIFTING SYSTEM, AND THE OPERATION SECTIONS OF ANSI/ASME B30.16 and ANSI/ASME B30.10. THE

OPERATOR SHALL ALSO BE REQUIRED TO BE FAMILIAR WITH THE HOIST AND HOIST CONTROLS

BEFORE BEING AUTHORIZED TO OPERATE THE HOIST OR LIFTING SYSTEM.

HOIST OPERATORS SHOULD BE TRAINED IN PROPER RIGGING PROCEDURES FOR THE ATTACHMENT

OF LOADS TO THE HOIST HOOK.

HOIST OPERATORS SHOULD BE TRAINED TO BE AWARE OF POTENTIAL MALFUNCTIONS OF THE

EQUIPMENT THAT REQUIRE ADJUSTMENT OR REPAIR, AND TO BE INSTRUCTED TO STOP OPERATION

IF SUCH MALFUNCTIONS OCCUR, AND TO IMMEDIATELY ADVISE THEIR SUPERVISOR SO CORRECTIVE

ACTION CAN BE TAKEN.

HOIST OPERATORS SHOULD HAVE NORMAL DEPTH PERCEPTION, FIELD OF VISION, REACTION TIME,

MANUAL DEXTERITY, AND COORDINATION.

HOIST OPERATORS SHOULD NOT

PHYSICAL CONTROL, PHYSICAL DEFECTS, OR EMOTIONAL INSTABILITY THAT COULD RESULT IN

ACTIONS OF THE OPERATOR BEING A HAZARD TO THE OPERATOR OR TO OTHERS.

HOIST OPERATORS SHOULD NOT

INFLUENCE OF ALCOHOL, DRUGS, OR MEDICATION.

OVERHEAD HOISTS ARE INTENDED ONLY FOR VERTICAL LIFTING SERVICE OF FREELY SUSPENDED

UNGUIDED LOADS. DO NOT

ARE NOT FREELY SUSPENDED, OR LOADS THAT ARE GUIDED.

USE HOIST FOR LOADS THAT ARE NOT LIFTED VERTICALLY, LOADS THAT

HAVE A HISTORY OF OR BE PRONE TO SEIZURES, LOSS OF

OPERATE A HOIST OR LIFTING SYSTEM WHEN UNDER THE

NOTICE

• Read ANSI/ASME B30.16 and ANSI/ASME B30.10.

• Read the hoist manufacturer’s Operating and Maintenance Instructions.

• Read all labels attached to equipment.

19

Page 20

The operation of an overhead hoist involves more than activating the hoist’s controls. Per the ANSI/ASME B30

standards, the use of an overhead hoist is subject to certain hazards that cannot be mitigated by engineered features,

but only by the exercise of intelligence, care, common sense, and experience in anticipating the effects and results of

activating the hoist’s controls. Use this guidance in conjunction with other warnings, cautions, and notices in this manual

to govern the operation and use of your overhead hoist.

4.2 Shall’s and Shall Not’s for Operation

Improper operation of a hoist can create a potentially hazardous

situation which, if not avoided, could result in death

and substantial property damage. To avoid such a potentially

hazardous situation THE OPERATOR SHALL:

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

• NOT

lift more than rated load for the hoist.

operate unless load is centered under hoist.

use damaged hoist or hoist that is not working

properly.

use hoist with twisted, kinked, damaged, or

worn chain.

use hoist if the bottom hook is capsized

(double fall hoists - see Section 3.11).

use the hoist to lift, support, or transport

people.

lift loads over people.

apply load unless load chain is properly

seated in the load sheave (and idle sheave for hoist

with two chain falls).

use the hoist in such a way that could result in

shock or impact loads being applied to the hoist.

attempt to lengthen the load chain or repair

damaged load chain.

operate hoist when it is restricted from forming

a straight line from hook to hook in the direction of

loading.

use load chain as a sling or wrap load chain

around load.

apply the load to the tip of the hook or to the

hook latch.

apply load if binding prevents equal loading

on all load supporting chains.

operate beyond the limits of the load chain

travel.

operate hoist with missing/damaged chain

WARNING

springs, shock absorbers, stoppers, striker plates or

limit locks.

• NOT

unless specific precautions have been taken.

• NOT

electrical or welding ground.

• NOT

live welding electrode.

• NOT

• Be familiar with operating controls, procedures, and

warnings.

• Make sure the unit is securely attached to a

suitable support before applying load.

• Make sure load slings or other approved single

attachments are properly sized, rigged, and seated

in the hook saddle.

• Take up slack carefully - make sure load is

balanced and load-holding action is secure before

continuing.

• Make sure all persons stay clear of the supported

load.

• Protect the hoist’s load chain from weld splatter or

other damaging contaminants.

• Report malfunctions or unusual performances

(including unusual noises) of the hoist and remove

the hoist from service until the malfunction or

unusual performance is resolved.

• Make sure hoist limit switches function properly.

• Warn personnel before lifting or moving a load.

• Warn personnel of an approaching load.

or serious injury,

leave load supported by the hoist unattended

allow the chain, or hook to be used as an

allow the chain, or hook to be touched by a

remove or obscure the warnings on the hoist.

20

Page 21

CAUTION

Improper operation of a hoist can create a potentially hazardous

situation which, if not avoided, could result in minor

, or property damage. To avoid such a potentially hazardous

injury

situation THE OPERATOR SHALL:

• Maintain a firm footing or be otherwise secured

when operating the hoist.

• Check brake function by tensioning the hoist prior

to each lift operation.

• Use hook latches. Latches are to retain slings,

chains, etc. under slack conditions only.

• Make sure the hook latches are closed and not

supporting any parts of the load.

• Make sure the load is free to move and will clear all

obstructions.

• Avoid swinging the load or hook.

• Make sure hook travel is in the same direction as

shown on controls.

• Inspect the hoist regularly, replace damaged or

worn parts, and keep appropriate records of

maintenance.

or moderate

• Use the hoist manufacturer’s recommended parts

when repairing the unit.

• Lubricate load chain per hoist manufacturer’s

recommendations.

• NOT

• NOT

• NOT

• NOT

• NOT

use the hoist load limiting or warning device to

measure load.

use limit switches as routine operating stops.

They are emergency devices only.

allow your attention to be diverted from

operating the hoist.

allow the hoist to be subjected to sharp

contact with other hoists, structures, or objects

through misuse.

adjust or repair the hoist unless qualified to

perform such adjustments or repairs.

4.3 Hoist Controls

4.3.1 For hoists mounted to motorized trolleys follow the control instruction included in the trolley ‘s Owner’s

Manual.

4.3.2 Pendant Control - When using the pendant control depress the up lever to raise the hoist or the down

lever to lower the hoist as shown in Figure 4-1 below. To stop motion release the lever switches.

Figure 4-1 Pendant Control

21

Page 22

4.3.3 Cord Control - When using a hoist with cord control, pull down on the appropriate colored cord to raise

or lower the hoist. White indicates the raise control and red indicates lowering control. Release the

cords to stop the hoist. Refer to Figure 4-2 below.

4.3.4

CAUTION

Make sure the motor completely stops before reversing direction.

4.4 Adjusting the Controls

4.4.1 For pendant control, the speed can be adjusted by the amount the lever is depressed. As shown below

in Figure 4-3, by depressing the lever slightly, you will be able control the hoist’s motions slowly and

with more precision. By depressing the lever further, the speed of the hoist will be increased until the

lever is fully depressed.

4.4.2 For the cord type control, adjust the speed by varying the amount of pull on the cord. Refer to Figure

4-4.

Figure 4-4 Cord Control Speed Adjustment

Figure 4-2 Cord Control

22

Page 23

4.5 Operation of the Load Limiter

4.5.1 If a hoist is used to lift a load that exceeds the hoists rated capacity, the load limiter will cause the hoist

to automatically stop lifting.

4.5.2 If the hoist stops lifting automatically, lower and remove the load from the hoist.

4.5.3 If the load is at or below the hoist’s capacity rating and the hoist stops lifting automatically, the load

limiter may need adjustment.

Check air line pressure to ensure adequate pressure at the hoist.

If pressure is adequate, adjust the load limiter. For load limiter adjustment, refer to Section 7.

23

Page 24

5.0 Inspection

5.1 General

5.1.1 The inspection procedure herein is based on ANSI/ASME B30.16. The following definitions are from

ANSI/ASME B30.16 and pertain to the inspection procedure below.

Designated Person - a person selected or assigned as being competent to perform the specific

duties to which he/she is assigned.

Qualified Person - a person who, by possession of a recognized degree or certificate of

professional standing, or who, by extensive knowledge, training, and experience, has successfully

demonstrated the ability to solve or resolve problems relating to the subject matter and work.

Normal Service - that distributed service which involves operation with randomly distributed loads

within the rated load limit, or uniform loads less than 65% of rated load for not more than 25% of

the time.

Heavy Service - that service which involves operation within the rated load limit which exceeds

normal service.

Severe Service - that service which involves normal or heavy service with abnormal operating

conditions.

5.2 Inspection Classification

5.2.1 Initial Inspection - prior to initial use, all new, altered, or modified hoists shall be inspected by a

designated person to ensure compliance with the applicable provisions of this manual.

5.2.2 Inspection Classification - the inspection procedure for hoists in regular service is divided into two

general classifications based upon the intervals at which inspection should be performed. The intervals

in turn are dependent upon the nature of the critical components of the hoist and the degree of their

exposure to wear, deterioration, or malfunction. The two general classifications are herein designated

as FREQUENT and PERIODIC, with respective intervals between inspections as defined below.

5.2.3 FREQUENT Inspection - visual examinations by the operator or other designated personnel with

intervals per the following criteria:

Normal service - monthly

Heavy service - weekly to monthly

Severe service - daily to weekly

Special or infrequent service - as recommended by a qualified person before and after each

occurrence.

5.2.4 PERIODIC Inspection - visual inspection by a designated person with intervals per the following criteria:

Normal service - yearly

Heavy service - semiannually

Severe service - quarterly

Special or infrequent service - as recommended by a qualified person before the first such

occurrence and as directed by the qualified person for any subsequent occurrences.

24

Page 25

5.3 Frequent Inspection

5.3.1 Inspections should be made on a FREQUENT basis in accordance with Table 5-1, “Frequent

Inspection.” Included in these FREQUENT Inspections are observations made during operation for

any defects or damage that might appear between Periodic Inspections. Evaluation and resolution of

the results of FREQUENT Inspections shall be made by a designated person such that the hoist is

maintained in safe working condition.

All functional operating mechanisms for maladjustment and unusual sounds.

Operation of limit switch and associated components

Hoist braking system for proper operation

Hooks in accordance with ANSI/ASME B30.10

Hook latch operation

Load chain in accordance with Section 5.7

Load chain reeving for compliance with Section 3.11 and 7.3

Table 5-1 Frequent Inspection

Air valves and components for leakage or damage

5.4 Periodic Inspection

5.4.1 Inspections should be made on a PERIODIC basis in accordance with Table 5-2, “Periodic Inspection.”

Evaluation and resolution of the results of PERIODIC Inspections shall be made by a designated

person such that the hoist is maintained in safe working condition.

5.4.2 For inspections where load suspension parts of the hoist are disassembled, a load test per ANSI/ASME

B30.16 must be performed on the hoist after it is re-assembled and prior to its return to service.

Requirements of frequent inspection.

Evidence of loose bolts, nuts, or rivets.

Evidence of worn, corroded, cracked, or distorted parts such as load blocks, suspension housing,

chain attachments, clevises, yokes, suspension bolts, shafts, gears, bearings and pins.

Evidence of damage to hook retaining nuts or collars and pins, and welds or rivets used to secure

the retaining members.

Evidence of damage or excessive wear of load and idler sheaves.

Evidence of excessive wear on motor vanes or on load brake.

Table 5-2 Periodic Inspection

Evidence of damage of supporting structure or trolley, if used.

Function labels on pendant control stations for legibility.

Warning label properly attached to the hoist and legible (see Section 1.2).

End connections of load chain.

25

Page 26

5.5 Occasionally Used Hoists

5.5.1 Hoists that are used infrequently shall be inspected as follows prior to placing in service:

Hoist Idle More Than 1 Month, Less Than 1 Year: Inspect per FREQUENT Inspection criteria of

Section 5.3 above.

Hoist Idle More Than 1 Year: Inspect per PERIODIC Inspection criteria of Section 5.4 above.

5.6 Inspection Records

5.6.1 Dated inspection reports and records should be maintained at time intervals corresponding to those

that apply for the hoist’s PERIODIC interval per Section 5.2.4. These records should be stored where

they are available to personnel involved with the inspection, maintenance, or operation of the hoist.

5.6.2 A long range chain inspection program should be established and should include records of

examination of chains removed from service so a relationship can be established between visual

observation and actual condition of the chain.

5.7 Inspection Methods and Criteria

5.7.1 This section covers the inspection of specific items. The list of items in this section is based on those

listed in ANSI/ASME B30.16 for the Frequent and Periodic Inspection. In accordance with ANSI/ASME

B30.16, these inspections are not intended to involve disassembly of the hoist. Rather, disassembly for

further inspection would be required if frequent or periodic inspection results so indicate. Such

disassembly and further inspection should only be performed by a qualified person trained in the

disassembly and re-assembly of the hoist.

Table 5-3 Hoist Inspection Methods and Criteria

Item Method Criteria Action

Functional operating

mechanisms.

Visual, Auditory Mechanisms should be properly adjusted and

should not produce unusual sounds when

operated.

Limit Switch Function Proper operation. Actuation of limit switch should

stop hoist.

Chain Lever/Limit

Lever Assembly

Visual, Function Lever should not be bent or significantly worn and

should be able to move freely.

Braking System Function Braking distance should not exceed

approximately five chain links.

Hooks - Surface

Condition

Visual Should be free of significant rust, weld splatter,

deep nicks, or gouges.

Repair or replace

as required.

Repair or replace

as required.

Replace.

Repair or replace

as required.

Replace.

Hooks - Fretting

wear

Measure The “u” dimension should not be less than

minimum value listed in Table 5-6.

Hooks - Stretch Measure The “K” dimension should not exceed the

maximum value for replacement from Table 5-6

(See Section 3.11).

26

Replace.

Replace.

Page 27

Table 5-3 Hoist Inspection Methods and Criteria (continued)

Item Method Criteria Action

Hooks - Bent Shank

or Neck

Hooks - Yoke

Assembly

Hooks - Swivel

Bearing

Hooks - Idle Sheave

and Axle (Bottom

Hook on Double Fall

Hoist)

Hooks - Hook

Latches

Visual Shank and neck portions of hook should be free

of deformations

Visual Should be free of significant rust, weld splatter,

nicks, gouges. Holes should not be elongated,

fasteners should not be loose, and there should

be no gap between mating parts.

Visual, Function Bearing parts and surfaces should not show

significant wear, and should be free of dirt, grime

and deformations. Hook should rotate freely with

no roughness.

Visual, Function Pockets of Idle Sheave should be free of

significant wear. Idle Sheave surfaces should be

free of nicks, gouges, dirt and grime. Bearing

parts and surfaces of Idle Sheave and Axle

should not show significant wear. Idle Sheave

should rotate freely with no roughness or

significant free play.

Visual, Function Latch should not be deformed. Attachment of

latch to hook should not be loose. Latch spring

should not be missing and should not be weak.

Latch movement should not be stiff - when

depressed and released latch should snap

smartly to its closed position.

Replace.

Clean/Lubricate, or

replace as required.

Clean/lubricate, or

replace as required.

Clean/lubricate, or

replace as required.

Replace.

Load Chain Surface Condition

Visual Should be free of rust, nicks, gouges, dents, and

weld splatter. Links should not be deformed, and

should not show signs of abrasion. Surfaces

where links bear on one another should be free of

significant wear.

Load Chain - Pitch Measure The “L” dimension should not be greater than

maximum value listed in Table 5-7.

Load Chain Lubrication

Visual, Auditory Entire surface of each chain link should be coated

with lubricant and should be free of dirt and grime.

Chain should not emit cracking noise when

hoisting a load.

Load Chain Reeving

Visual Chain should be reeved properly through Load

Sheave (and Idle Sheave for double fall hoist) refer to Section 3.11. Chain, limit locks and

stoppers should be installed properly - refer to

Section 7.3.2.

Bolts, Nuts and

Rivets

Visual, Check

with Proper Tool

Bolts, nuts and rivets should not be loose. Tighten or replace

Replace.

Replace, inspect

Load Sheave (and

Idle Sheave for

double fall hoist).

Clean/lubricate

(see Sections 6.0).

Reeve/Install chain

properly.

as required.

27

Page 28

Table 5-3 Hoist Inspection Methods and Criteria (continued)

Item Method Criteria Action

Housing and

Mechanical

Components

Visual, Auditory,

Vibration,

Function

Hoist components including load blocks,

suspension housing, chain attachments, clevises,

yokes, suspension bolts, shafts, gears, bearings,

pins and rollers should be free of cracks,

distortion, significant wear and corrosion.

Evidence of same can be detected visually or via

detection of unusual sounds or vibration during

operation.

Chain Separator Visual, Measure The Chain Guide/Side Plate should be free of

cracks, distortion, significant wear and corrosion.

The “L” and "W" dimension should not be greater

than maximum value listed in Table 5-5.

Motor Brake Measure, Visual Motor brake dimension should be within the

allowable limits of Table 5-4. See Section 7.2 for

gaining access to motor brake. Braking surfaces

should be clean, free of grease/oil and should not

be glazed.

Load Sheave Visual Pockets of Load Sheave should be free of

significant wear. See Section 7.5 to gain visual

access to the load sheave.

Pendant Control

Levers

Visual,

Function

Depressing and releasing pendant control levers

should cause hoist to operate.

Pendant - Housing Visual Pendant housing should be free of cracks and

mating surfaces of parts should seal without gaps.

Replace

Replace

Replace

Replace.

Repair or replace

as necessary.

Replace.

Pendant - Tubing Visual, auditory Tubing to pendant control switches should not be

loose or be leaking air.

Repair or replace

as necessary.

Pendant - Labels Visual Labels denoting functions should be legible. Replace.

Warning Labels Visual Warning Labels should be affixed to the hoist (see

Replace

Section 1.2) and they should be legible.

Hoist Capacity Label Visual The label that indicates the capacity of the hoist

Replace.

should be legible and securely attached to the

hoist.

28

Page 29

Table 5-4 Brake Disc Dimension

Hoists

TCR10000C2

TCR10000P2

TCR25000C2

Parts View

Figure No.

Std Dimension

Inch (mm)

Minimum Value for Replacement

Inch (mm)

T = 0.16 (4.0) T = 0.10 (2.5)

TCR25000P2

Table 5-5 Chain Guide/Side Plate Dimensions

Hoists

Parts View

Figure No.

Std Dimension

Inch (mm)

Maximum Value for Replacement

Inch (mm)

TCR10000C2

TCR10000P2

TCR25000C2

TCR25000P2

146

L = 1.57 (40)

W = 2.36 (60)

L = 2.20 (55.8)

161 & 162

W = 3.82 (97)

L = 1.69 (42.8)

W = 2.48 (63)

L = 2.36 (60)

W = 4.02 (102)

29

Page 30

Table 5-6 Top Hook & Bottom Hook Dimensions

Dimensions K and U should be measured and recorded below prior to any use when the hook is first placed into service.

Hoists

Parts View

Figure No.

Recorded Dimension

When New

Maximum/Minimum Value

for Replacement

TCR10000C2

TCR10000P2

TCR25000C2

TCR25000P2

Product Code

165

180

Parts View

Figure No.

Top Hook K = _______________

Top Hook U = _______________

Bottom Hook K = ____________

Bottom Hook U = ____________

Top Hook K = _______________

Top Hook U = _______________

Bottom Hook K = ____________

Bottom Hook U = ____________

Table 5-7 Chain Dimensions

“P” Dimension

Standard Discard Standard Discard

inch (mm)

For K if the measured dimension

exceeds 1.05 times the recorded new

dimension, the hook should be

replaced.

For U if the measured dimension is

less than .9 times the recorded new

dimension, the hook should be

replaced.

“d” Dimension

inch (mm)

TCR10000C2

TCR10000P2

TCR25000C2

TCR25000P2

182 8.86 (225) 9.00 (228.5) 0.63 (16) 0.61 (15.5)

179 12.99 (330) 13.14 (333.8) 0.87 (22) 0.85 (21.5)

30

Page 31

6.0 Lubrication

6.1 Air Hoist Lubrication

6.1.1 See Section 3.0 for lubrication requirements.

6.1.2

6.1.3 Additional lubrication to the reduction gears is not necessary. When disassembling the hoist for service

CAUTION

recommended amount is 10-15 drops/minute (2-3cc/min.). Refer to Table 6-1 below for the approved

lubricant for use with your air hoist.

or repair, apply new grease to the gears before reassembling the hoist.

Lubrication to the motor will be provided primarily by the air supply lubricator. The

6.2 Load Chain Lubrication

6.2.1 For longer life, lightly coat the load chain with machine or gear oil. Ensure that the oil is applied to the

bearing surfaces of the load chain links.

6.2.2 The load chain lubrication should be accomplished after cleaning the load chain with acid free cleaning

solution. Use approved lubricant in Table 6-1 or equivalent.

6.2.3 For dusty environments, it is acceptable to substitute a dry lubricant.

6.3 Hooks and Suspension Components

6.3.1 Hooks - Bearings should be cleaned and lubricated at least once per year for normal usage. Clean and

lubricate more frequently for heavier usage or severe conditions.

6.3.2 Suspension Pins - Lubricate at least twice per year for normal usage; more frequently for heavier usage

or severe conditions.

Table 6-1 Table of Approved Lubricants

Application Part Location Lubrication Grade

Air motor Lubricator Turbine Oil

Load chain & pocket

wheel

Hook bearings &

suspension pins

Gears and Bearings Gear Section Grease

Load chain Machine or gear oil

Top & bottom hook

sets

Grease

ISO VG 32-56 or

equivalent

ISO VG 46-68 or

equivalent

National Lubricating

Grease #3

National Lubricating

Grease #2

31

Page 32

7.0 Maintenance and Handling

7.1 Load Limiter

7.1.1 The purpose of the load limiter is to prevent using the hoist in an overload situation. When lifting, the

hoist will stop automatically if the load is above the rated capacity of the hoist.

7.1.2 The adjustment is factory set to actuate at approximately125% of rated capacity (based on supply air

pressure of 90 PSI). Note: the load limiter may need adjustment to compensate for air supply

pressures significantly less than 90 PSI.

Figure 7-1 Load Limiter screw adjustment location

7.1.3 Adjustment Procedure

1) Before proceeding with the load limiter adjustment, note the following:

a.

WARNING

Adjusting the load limiter involves operating the hoist. Personnel involved

in the adjustment procedure should read, understand, and follow Section 4, "Operation".

b. For the adjustment procedure, the hoist should be connected to an air supply (see Section 3.1)

and it should initially be without a load on its hook.

c. Start this procedure with an unloaded hoist. All adjustments to the load limiter should be made

with the load in a resting position so that the load chain is not tensioned.

d. For the adjustment procedure: OUT means the counter-clockwise (CCW) direction, and IN

means the clockwise (CW) direction.

e. The pressure of the air supply at the hoist’s inlet port (acceptable range is 60 to 90 PSI) affects

the performance of your air hoist, including the actuation point of the load limiter. Therefore,

ensure that during the adjustment procedure the air pressure at the hoist's inlet port is the

same as that which the hoist will experience in normal operation. The relationship between air

supply pressure and load limiter actuation is:

For a given load limiter setting, as pressure decreases, the actuation point increases.

f. When the load limiter is adjusted and working properly, the hoist will operate and lift the load a

short distance before the load limiter automatically stops lifting.

2) Refer to Figure 7-1. Loosen the lock nut and slowly turn the adjustment screw OUT until it is loose and

no longer is in contact with the internal load limiter spring – as this occurs the screw should become

easier to turn. Stop turning the screw once it is loose and easier to turn.

3) Turn the adjustment screw IN just enough so that it begins to contact the internal load limiter spring –

as this occurs the screw should become slightly harder to turn.

32

Page 33

4) Put a load equal to the desired actuation point on the hoist's hook (do not exceed 125% of the hoist's

rated capacity). Begin to slowly lift the load, then increase the lifting speed. Return the load to its

resting position so the load chain is not under tension.

5) If the load limiter prevents lifting, turn the adjustment screw IN one full turn.

6) Repeat steps 4 and 5 until the load limiter allows lifting.

7) Turn the adjustment screw OUT ¾ of a turn.

8) Attempt to lift the rated capacity load again, beginning slowly, then increasing the lifting speed.

9) If the load limiter does not allow lifting, then turn the adjustment screw IN ¼ turn.

10) Repeat steps 8 and 9 until the load limiter allows lifting.

11) Turn the adjustment screw IN ¼ turn. Then, while holding the adjustment screw, tighten the lock nut to

secure the setting.

7.2 Brake

7.2.1 For Load Brake setup and adjustment procedure consult factory.

7.2.2 Inspect the brake disc in accordance with Section 5.7, Table 5-3.

7.2.3 The following is the hoist brake inspection procedure. Refer to Figure 7-2.

1)

WARNING

HAZARDOUS AIR PRESSURE IS PRESENT IN THE HOIST, IN THE

SUPPLY OF COMPRESSED AIR TO THE HOIST, AND IN THE CONNECTIONS BETWEEN

COMPONENTS. Shut off the air supply and stop the airflow completely. Lock out and tag out in

accordance with ANSI Z244.1 “Personnel Protection -Lockout/Tagout of Energy Sources”.

2) Do NOT turn or remove the brake adjustment screw located in the center of the brake cover.

3) Gradually back out all four hex socket cap screws from brake cover to slowly decrease spring

tension of brake piston against brake disc.

4) Remove brake cover from the motor housing top of gear case. Keep brake piston, springs, seals,

etc. together inside the brake cover.

5) Remove brake disc for inspection and measurement. Refer to "Motor Brake" in Table 5-3, "Hoist

Inspection Methods and Criteria".

6) Prior to reassembly, clean all surfaces of debris, dirt and loose paint.

7) Reassemble in reverse order. Torque all mounting hardware evenly during the reassembly

process.

33

Page 34

7.3 Load Chain

7.3.1 Lubrication and Cleaning

Figure 7-2 Brake Inspection Diagram

Clean the chain with an acid-free cleaning solution. The load chain should be kept clean and

lubricated.

Lubrication - Clean and lubricate the load chain per Section 6 at least once every 3 months for

normal usage. Clean and lubricate more frequently for heavier usage or severe conditions.

7.3.2 Replacement

1)

CAUTION

following procedures. The hoist must accessible and must be hanging from the top hook

assembly.

2)

WARNING

exact size, grade and construction as the original chain.

3)

CAUTION

Chain Guides and Idle Sheave, and replace parts if necessary. Remove old chain. Remove hook

set assemblies, limit locks, stoppers and end connections from the chain for reuse on new chain. If

the load chain is being replaced due to damage or wear out, prevent its reuse by destroying the old

chain.

4) Remove the existing Load Chain – Lower the bottom hook assembly until it rests on the ground or

is supported by some other means. Disconnect the no-load and load end of the load chain from

the hoist. Run the hoist in the down direction to remove the chain form the hoist body.

5) Run the hoist in the up or down direction until the load sheave is positioned as shown in Figure 7-3.

An air supply line must be connected to the hoist in order to perform the

Be certain that the replacement chain is obtained from Harrington and is the

When replacing load chain, check for wear on mating parts, i.e. Load Sheave,

6) Without operating the hoist, tie a wire to the end of the new load chain, then thread the wire

through the hoist over the load sheave. Pull the wire so that the load chain enters the hoist

making certain that the first link is a standing link and that its weld is facing away from the

centerline of the hoist.

34

Page 35

7) While pulling on the wire, SLOWLY operate hoist in the DOWN direction to thread the load chain

over the load sheave. Make sure the chain feeds smoothly while operating the hoist. If binding

occurs, stop and SLOWLY operate the hoist in the up direction to the back the chain out, then

reorient the load sheave as instructed in step 5 before attempting to reinsert the load chain.

8) Operated the hoist in the down direction until sufficient there is sufficient load chain to reeve the

hoist.

9) Reeve the chain through the bottom hook assembly. Remove the wire from the Load chain and

attach the no-load and load end of the load chain to the hoist. Ensure that chain remains free of

twists.

10) After installation has been completed, perform steps outlined in Section 3.12 "Preoperational

Checks and Trial Operation".

10 Ton TCR10000P2 & TCR10000C2 25 Ton TCR25000P2 & TCR25000C2

Figure 7-3 Diagram showing chain replacement

35

Page 36

7.4 Pendant

7.4.1 The following procedure covers the installation of a pendant control station.

1) Attach the strain relief chain and the three hoses to the pendant station.

2) Attach the strain relief chain to the hoist valve body with the socket bolt as shown in Figure 7-4.

3) Attach the three hoists to the fittings on the hoist's valve body. Refer to Figure 7-4 and make sure

the up, down and supply hoses are attached to the correct locations.

4)

NOTICE

When attaching tubes take care not to bend or kink tubing. This will result in

the air flow being restricted and poor response to the pendant controls.

5) Attach the hoist to supply air. Check for leaks and properoperation.

6)

WARNING

The pendant hoses hoist must be connected so that its direction of operation

corresponds to the up-and-down lever on the pendant control; i.e. pushing the up button must

cause the hook to raise. If the hoist does not operate correctly, shut off the air supply to the hoist

and correct the pendant connections.

Figure 7-4 Pendant Hose and Strain Relief Connections

36

Page 37

7.5 Storage

7.5.1 Whenever the hoist is to be placed into storage, place extra lubricating oil into the air inlet opening and

circulate the air motor before plugging the inlet. Make certain that no debris, dirt or moisture is allowed

to enter the air hoist through air inlet opening during preparations for storage.

7.5.2 The storage location should be clean and dry.

7.6 Outdoor Installation

7.6.1 For hoist installations that are outdoors, the hoist should be covered when not in use.

7.6.2 In order to prevent internal corrosion from occurring, the hoist must be operated using proper quality air

at least once per week by raising and lowering the hoist one full cycle. Note: the possibility of corrosion

in the valve section of the hoist increases for areas where salt air and high humidity are present. For

such situations you may need to operate your hoist more often than once per week.

37

Page 38

8.0 Troubleshooting

WARNING

HAZARDOUS AIR PRESSURE IS PRESENT IN THE HOIST, IN THE SUPPLY OF COMPRESSED AIR TO

THE HOIST, AND IN CONNECTIONS BETWEEN COMPONENTS.

Before performing ANY maintenance on the equipment, de-energize the supply of compressed air to the

equipment, and lock and tag the supply device in the de-energized position. Refer to ANSI Z244.1, “Personnel

Protection - Lockout/Tagout of Energy Sources.”

Only Trained and competent personnel should inspect and repair this equipment.

Table 8-1 Troubleshooting Guide

Symptom Cause Remedy

Does not operate

Lifting speed is slow

Unable to lift rated load

Lack of air pressure or loss of air

supply.

Seizure of Main Spool, Brake Spool,

or Air Motor.

Seizure of brake or brake

mechanism fails to release.

Bending or crimping of pendant

control hose(s)

Hoist is overloaded.

Low air pressure at hoist inlet port.

Air supply hose or piping is too small.

Malfunction of brake. Repair at service facility.

Bending or crimping of pendant

control hose(s)

Lack of sufficient oil in air supply to

hoist

Exhaust Silencer clogged Clean or replace.

Air flow capacity of compressed air

system insufficient

Air motor vanes or bearings worn Repair at service facility.

Air supply to hoist contains dirt or

debris

Lack of air pressure or loss of air

supply.

Improper adjustment of load limiter. Adjust Load Limiter. See Section 7.1.

Repair or adjust air supply or filters.

Repair at service facility.

Repair at service facility.

Correct or repair the bend or crimp in

control hose(s)

Reduce the load to the rated capacity

of hoist.

Repair or adjust air supply or filters.

Check for air line obstruction.

Replace hose or piping sizes with

recommended sizes in Section 3.0.

Correct or repair the bend or crimp in

control hose(s)

Increase oil in air supply to hoist in

accordance with requirements in

Section 3.0.

Increase air flow capacity of

compressed air system to

requirements in Section 2.0.

Filter the air supply to the hoist in

accordance with the requirements in

Section 3.0.

Repair or adjust air supply or filters.

38

Page 39

Table 8-1 Troubleshooting Guide (continued)

Symptom Cause Remedy

Hoist moving in wrong

direction (pendant control)

Pendant control hoses are

terminated to incorrect ports on hoist

body.

Connect the control tubes in

accordance with Section 7.4.

Hoist is overloaded. Reduce load to hoist rated capacity.

Hoist lowers but will not lift

Faulty pendant control or control

hose(s)

Lack of air pressure or partial loss of

or leakage in air supply.

Repair or replace pendant control or

control hose(s)

Repair or adjust air supply or filters.

Inject approx. 20 drops of oil into inlet

Hoist continues running after

pendant or cord is released

Main Spool sticking

port to lubricate the main spool. If

spool still sticks, repair at service

facility.

Valve in Pendant Handle stuck Repair at service facility

Hoist drifts excessively when

hoist is stopped

Brake is not holding. Repair brake at service facility.

39

Page 40

9.0 Warranty

Warranty explanation and terms.

All products sold by Harrington Hoists, Inc. are warranted to be free from defects in material and

workmanship from date of shipment by Harrington for the following periods:

Manual Hoists & Trolleys - 2 years

Air and Electric Powered Hoists, Trolleys, and Crane Components - 1 year

Spare / Replacement Parts - 1 year

The product must be used in accordance with manufacturer’s recommendations and must not have

been subject to abuse, lack of maintenance, misuse, negligence, or unauthorized repairs or

alterations.

Should any defect in material or workmanship occur during the above time period in any product,

as determined by Harrington Hoist’s inspection of the product, Harrington Hoists, Inc. agrees, at its

discretion, either to replace (not including installation) or repair the part or product free of charge

and deliver said item F.O.B. Harrington Hoists, Inc. place of business to customer.

Customer must obtain a Return Goods Authorization as directed by Harrington or Harrington’s

published authorized repair center prior to shipping product for warranty evaluation. An explanation

of the complaint must accompany the product. Product must be returned freight prepaid. Upon

repair, the product will be covered for the remainder of the original warranty period. If it is

determined there is no defect, or that the defect resulted from causes not within the scope of

Harrington’s warranty, the customer will be responsible for the costs of returning the product.

Harrington Hoists, Inc. disclaims any and all other warranties of any kind expressed or implied as to

the product’s merchantability or fitness for a particular application. Harrington will not be liable for

death, injuries to persons or property or for incidental, contingent, special or consequential

damages, loss or expense arising in connection with the use or inability whatever, regardless of

whether damage, loss or expense results from any act or failure to act by Harrington, whether

negligent or willful, or from any other reason.

40

Page 41

10.0 Parts Information

A complete parts list is available from Harrington Hoists and is supplied separately with your hoist. The parts list is also

available from Harrington's web site (www.harringtonhoists.com) or from any Harrington facility (see back cover of this

manual).

When ordering Parts, please provide the Hoist code number located on the Hoist nameplate (see fig. below).

Reminder: Per Sections 3.11.6 and 1.1 to aid in ordering Parts and Product Support, record the Hoist code number and

serial number in the space provided on the cover of this manual.

Figure 10-1 TCR Nameplate

41

Page 42

NOTES

42

Page 43

NOTES

43

Page 44

www.harringtonhoists.com

Harrington Hoists, Inc. Harrington Hoists – Western Division

401 West End Avenue 2341 Pomona Rincon Rd. #103

Manheim, PA 17545-1703 Corona, CA 92880-6973

Phone: 717-665-2000 Phone: 951-279-7100

Toll Free: 800-233-3010 Toll Free: 800-317-7111

Fax: 717-665-2861 Fax: 951-279-7500

TCROM1025

Loading...

Loading...