Page 1

EFFECTIVE: November 3, 2008

jury

Owner’s Manual

SUPPLEMENT

ELECTRIC

CHAIN HOIST

ER2 and NER2

SERIES

8 Ton through 20 Ton Capacity

Code, Lot and Serial Number

WARNING

This equipment should not be installed, operated or

maintained by any person who has not read and understood

all the contents of this manual. Failure to read and comply

with the contents of this manual can result in serious bodily

or death, and/or property damage.

in

Page 2

IMPORTANT INFORMATION ON HOW TO USE THIS MANUAL

This OWNER’S MANUAL SUPPLEMENT is intended for use in combination with the “Owner’s Manual for Electric

Chain Hoist ER2 and NER2 Series 1/8 through 5 Ton Capacity”. Refer to the Table of Contents below to determine

the location(s) of information pertaining to your hoist. References to the “Owner’s Manual for Electric Chain Hoist ER2

and NER2 Series 1/8 through 5 Ton Capacity” will be designated by the use of the a cronym “ER2OM”.

Table of Contents

Section Page Number/Location

1.0 Important Information and Warnings…...………………...………………………………………. ER2OM

1.1 Terms and Summary ER2OM

1.2 Warning Tags and Labels ER2OM

2.0 Technical Information………………………………………………………………………….…..………... 4

2.1 Specifications 4

2.2 Dimensions 5

3.0 Preoperational Procedures ………………………………………………………………………………… 7

3.1 Fill Gear Box with Oil 7

3.2 Chain 8

3.3 Mounting Location 9

3.4 Mounting the Hoist 9

3.5 Electrical Connections 10

3.6 Preoperational Checks and Trial Operation 14

4.0 Operation………………………………………………………………………………………..….. ER2OM

4.1 Introduction ER2OM

4.2 Shall’s and Shall Not’s for Operation ER2OM

4.3 Hoist Controls ER2OM

2

Page 3

Section Page Number/Location

5.0 Inspection…………………………….………………………………….…………..…….. 15 and ER2OM

5.1 General ER2OM

5.2 Inspection Classification ER2OM

5.3 Frequent Inspection ER2OM

5.4 Periodic Inspection ER2OM

5.5 Occasionally Used Hoists ER2OM

5.6 Inspection Records ER2OM

5.7 Inspection Methods and Criteria 15 and ER2OM

6.0 Maintenance & Handling…………………………………………………….……………. 18 and ER2OM

6.1 Count/Hour Meter ER2OM

6.2 Lubrication 18 and ER2OM

6.3 Motor Brake 18 and ER2OM

6.4 Load Chain 19 and ER2OM

6.5 Friction Clutch and Mechanical Load Brake with Friction Clutch ER2OM

6.6 Storage ER2OM

6.7 Outdoor Installation ER2OM

7.0 Troubleshooting……………………………………………………………………………….…… ER2OM

3

Page 4

2.0 Technical Information

2.1 Specifications

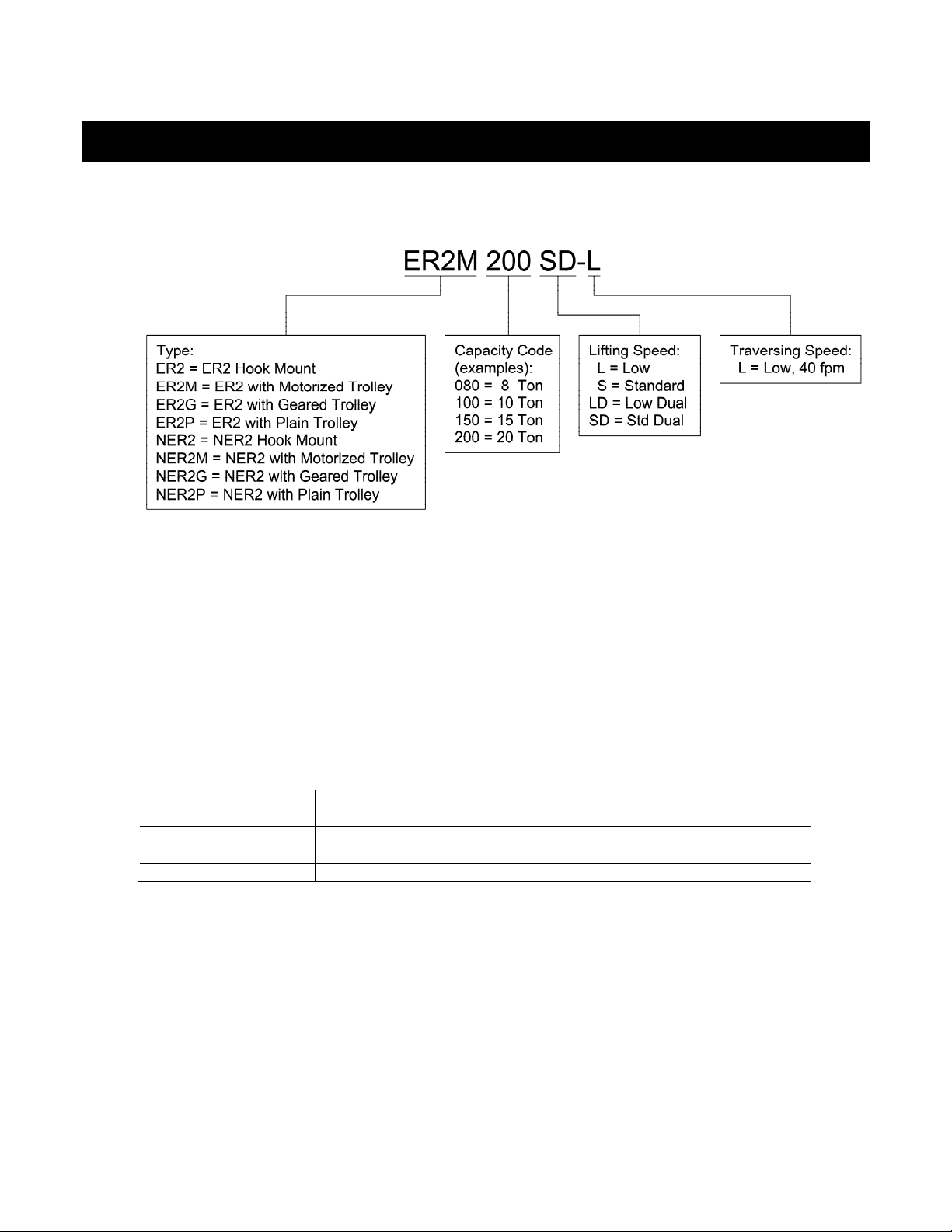

2.1.1 Product Code

2.1.2 Operating Conditions and Environment

Temperature range: -4° to +104°F (-20° to +40°C)

Relative Humidity: 85% or less

Noise Level: 85 dB or less (A scale: measured 1 meter away from electric chai n hoist

Enclosure Rating: Hoist Meets IP 55, Pendant Meets IP65

Supply Voltage:

Single Speed Standard: Reconnectable 208/230 & 460V-3-60

Single Speed Optional: 575V-3-60 or Special Volta ges/Frequenci es Available

Dual Speed Standard: 208/230V-3-6 0 or 460V-3-6 0

Dual Speed Optional: 575V-3-60 or Voltages/Frequencie s Voltages Available

Single Speed Dual Speed

Hoist Duty Rating: ISO M4; FEM 2M; ASME H4

Intermittent Duty Rating:

60% ED

360 starts per hour

40/20% ED

120/240 starts per hour

Short Time Duty Rating: 60 min. 30/10 min.

4

Page 5

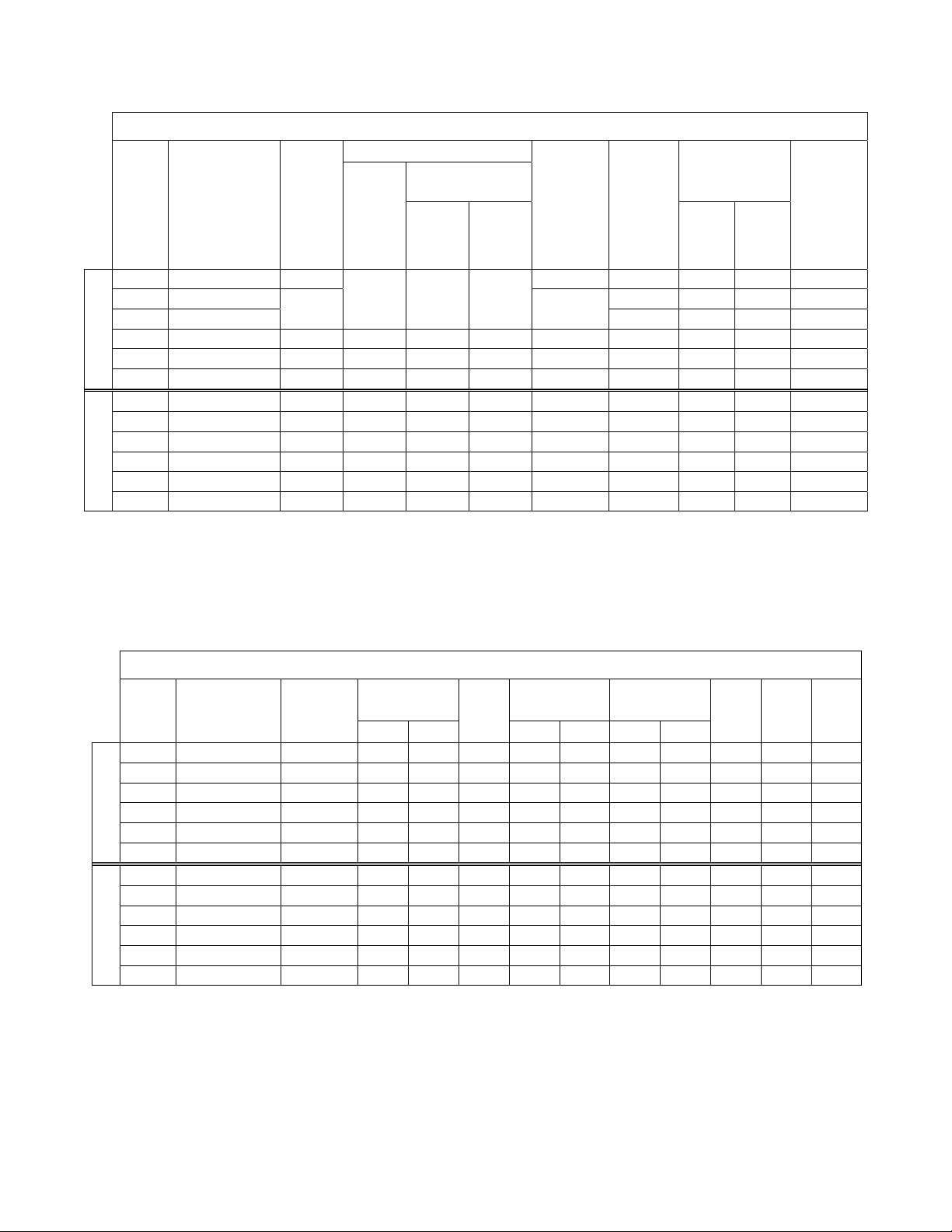

(mm)

Cap.

(Tons)

Product

Code

Lifting

Speed

(ft/min)

Table 2-1 Hoist Specifications

Motor

Rated Current

(amps)

Output

(Hp)

208V -

230V

460V

Load

Chain

Diameter

x

Chain Fall

Load

Sheave

Pockets

Lines

8 (N)ER2080S* 7.5 11.2 x 3 5 362 359 5.5

10 (N)ER2100L 5 617 615 7.4

10 (N)ER2100L-LG

10 (N)ER2100S 11 4.7 x 2 16.4 x 2 7.9 x 2 11.2 x 4 5 668 666 7.4

Single Speed

15 (N)ER2150S 7.5 4.7 x 2 16.4 x 2 7.9 x 2 11.2 x 6 5 891 886 11.4

20 (N)ER2200S 5.5 4.7 x 2 16.4 x 2 7.9 x 2 11.2 x 8 5 1049 1045 14.8

8 (N)ER2080SD* 7.5/2.5 4.7 17.3 8.3 11.2 x 3 5 358 366 5.5

10 (N)ER2100LD 5.5/2 4.7 17.3 8.3 11.2 x 4 5 609 622 7.4

10 (N)ER2100LD-LG 5.5/2 4.7 17.3 8.3 11.2 x 4 5 569 578 7.4

10 (N)ER2100SD 11/3.5 4.7 x 2 17.3 x 2 8.3 x 2 11.2 x 4 5 650 677 7.4

Dual Speed

15 (N)ER2150SD 7.5/2.5 4.7 x 2 17.3 x 2 8.3 x 2 11.2 x 6 5 873 899 11.4

20 (N)ER2200SD 5.5/2 4.7 x 2 17.3 x 2 8.3 x 2 11.2 x 8 5 1032 1058 14.8

*Available lug mount only. Push button cord dimension (L) is to center of lug ho le.

**Although both 208/230 & 460 Volts are shown together, the dual speed hoist motors are NOT reconnectable.

5.5

4.7 16.4 7.9

11.2 x 4

5 573 571 7.4

Net Weight

(lbs)

NER ER

Weight for

Addnl.

One Foot

of Lift

(lbs)

2.2 Dimensions

Cap.

(Tons)

10 (N)ER2100L 53.9 29.0 32.5 38.3 13.3 16.8 15.7 16.8 3.2 13.3 20.0

10 (N)ER2100L-LG 40.9 29.0 32.5 26.9 13.3 16.8 15.7 16.8 3.2 13.3 8.5

10 (N)ER2100S 53.9 31.4 33.6 33.4 15.7 16.8 15.7 16.8 3.2 - -

Single Speed

15 (N)ER2150S 62.8 31.4 33.6 40.2 15.7 16.8 15.7 16.8 3.4 - 20 (N)ER2200S 67.3 31.4 33.6 47.2 15.7 16.8 15.7 16.8 4.0 - -

10 (N)ER2100LD 53.9 31.5 32.5 38.3 15.8 16.8 15.7 15.7 3.2 13.3 20.0

10 (N)ER2100LD-LG 40.9 31.5 32.5 26.9 15.8 16.8 15.7 15.7 3.2 13.3 8.5

10 (N)ER2100SD 53.9 31.5 33.6 33.4 15.8 16.8 15.8 16.8 3.2 - -

Dual Speed

15 (N)ER2150SD 62.8 31.5 33.6 40.2 15.8 16.8 15.8 16.8 3.4 - 20 (N)ER2200SD 67.3 31.5 33.6 47.2 15.8 16.8 15.8 16.8 4.0 - -

Product Code

8 (N)ER2080S 40.3 29.0 32.5 23.2 13.3 16.8 15.7 16.8 2.4 11.1 7.1

8 (N)ER2080SD 40.3 31.5 32.5 23.2 15.8 16.8 15.7 15.7 2.4 11.1 7.1

Headroom

C

(in)

Table 2-2 Hoist Dimensions

NER

a

(in)

ER

b

(in)

NER

d

(in)

ER NER ER

e

(in)

g

(in) h (in) i (in)

5

Page 6

Figure 2-1 – NER2080S Figure 2-2 – NER2080SD

Figure 2-3 – NER2100S Figure 2-4 – NER2100SD

Table 2-3 Hook Dimensions*

Capacity Code

080S

100L, 100S T & B

T = Top Hook

B = Bottom Hook

Units = in.(mm)

*Refer to EROM Section 5.7 for inspection dimensions and limits.

150S

200S

Hook a b c d e g

B

T & B

T & B

3.3

(83.5)

3.3

(83.5)

4.1

(104)

4.6

(118)

2.2

(55.0)

2.2

(55.0)

2.8

(70.0)

3.3

(83.0)

2.9

(73.0)

2.9

(73.0)

3.4

87.0)

3.9

(99.5)

1.9

(48.0)

1.9

(48.0)

2.4

(60.0)

2.8

(70.0)

3.3

(85.0)

3.3

(85.0)

3.9

(100.0)

4.3

(110.0)

2.4

(62.0)

2.4

(62.0)

3.1

(79.0)

3.4

(86.0)

6

Page 7

3.0 Preoperational Procedures

3.1 Gear Box

3.1.1 The gearbox is filled with the correct amount of oil at the time of shipment. The oil level must be verified

prior to operation. The ER2 and NER2 hoists hav e different checki ng procedu res. Refer to Sectio n 6.3

of the ER2OM for specific checking procedures. Use the 050L Capacity Co de to determine the correct

“Check Distance” for the ER2 Large Capacity hoist.

3.1.2 Refer to Section 6.3 of the ER2OM when repl acing the gear oil. Use the 050L Capa city Code to

determine the correct amount of gear oil.

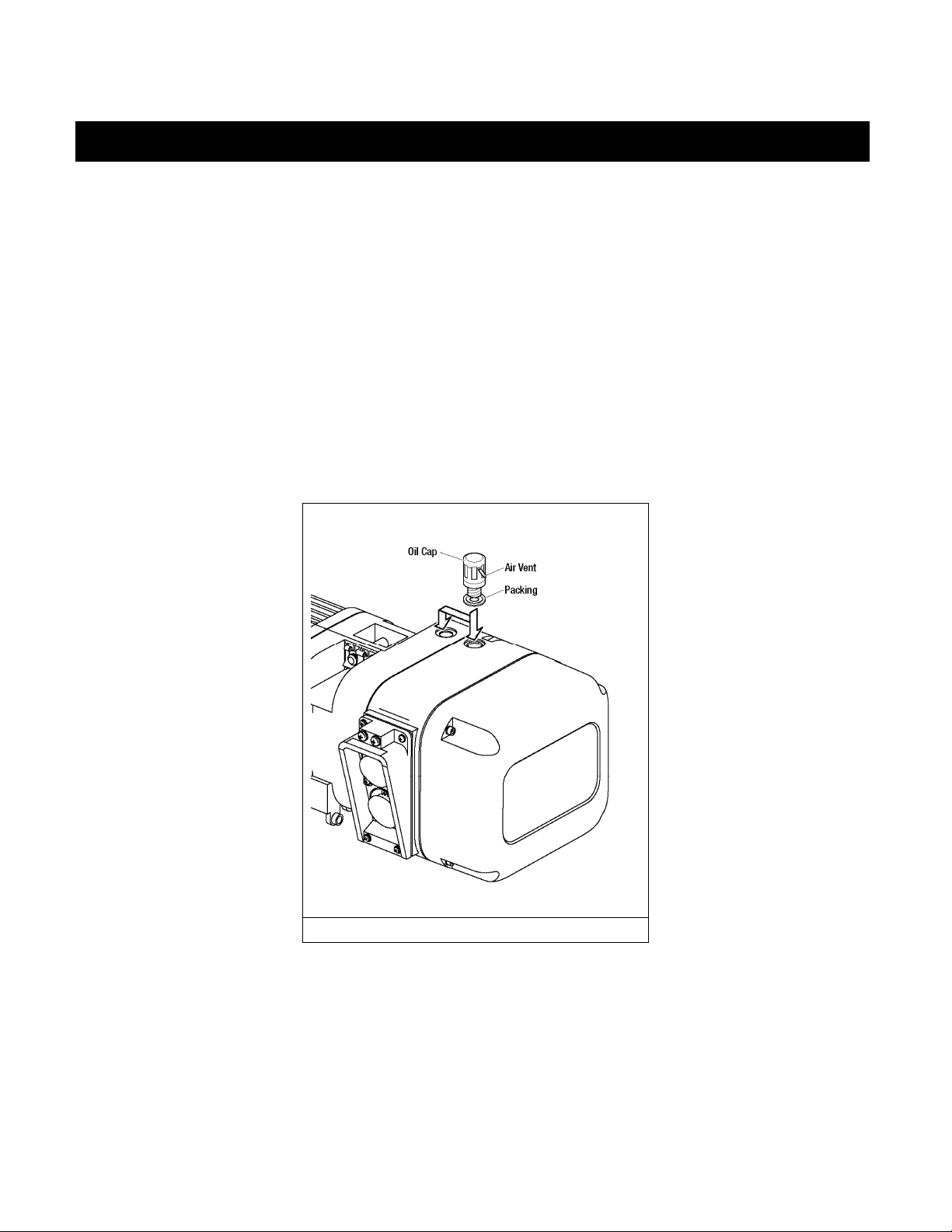

3.1.3 All ER2, mechanical load brake installed, hoist s are shipped with a separate air vent ed oil cap. This

vented oil cap must be installed prior to use . To install, remove an existing oi l cap and replac e with the

vented oil cap (refer to Figure 3-1).

3.1.4 There are two oil fill holes located in the top of the gear case on the ER2 hoist. For ER2 coupled to

MR2 trolley, there are some flange widths that make it necessary to relocate the oil cap assembly to the

other oil fill hole. This will prevent interference with trolley side plate. Refer to Figure 3-1.

Figure 3-1 Vented Oil Cap Installation

7

Page 8

3.2 Chain

3.2.1 The quantity and location of the chain com ponents inclu ding chain springs and st oppers depe nds on

the hoist model and capacity. Never ope rate the hoist with in correct, missing or damaged ch ain

components. Refer to the hoist' s nameplate, Table 3-2, and Figure 3-2 and ensure that all chain

components are in the correct location and properly i nstalled.

3.2.2 When the hoist is used without a chain co ntainer, the free end of the chain is attached to the hoi st body

as shown in Figure 3-2. Connect the “no load” en d of the chain to Chai n Guide A and t he pre-install ed

socket bolt and lock nut. Make sure the chain remains free of t wists and the chain Stopper is i nstalled

on the correct link. Refer to Table 3-2 for proper placement of Stopper.

Figure 3-2 Chain Component Arrangement

Table 3-2 Chain Stopper Placement

Capacity Code Without Chain Container With Chain Container

080S, 100L, 100S,

150S, 200S

*Tightening torque for the Stopper Bolt: 10 N-m (7 lb-ft)

3.2.3 When the optional canvas chain container(s) i s used, unfold it fully a nd install it on the hoi st body(i es)

as shown in Figure 3-3. In this case the free en d of the chain is not att ached to the ho ist body and the

chain stopper is installed on the third link from the free end. To place the chain into the ch ain

container(s), feed the chain into the chain contai ner(s) beginnin g with the free end. T ake care to avoi d

twisting or tangling the chain. NEVER put all the chain into the container(s) at once. Lumped or

twisted chain may activate the down limit switch and stop the hoi st during lowering.

3.2.4

CAUTION

stored in the container. The amount of chain the container must hold i s equal to the lift on th e hoist.

DO NOT use a chain container with a storage capacity less than the lif t length on the hoi st. If all of the

chain can not be stored in the container, the limit switch will not operate properly.

Each chain container indicates the maximum lengt h of the load chain that can be

th

15

link from the free end 3rd link from the free end

8

Page 9

(N)ER2080S to (N)ER2100 L

3.2.5 When using an optional steel chain container, refer to the instructions and/or assembly drawing(s)

provided with the container for correct assembly and attachment.

3.2.6

3.2.7 Lubricate the entire length of the load chain wit h the supplied tub e(s) of grease pe r the instructions in

WARNING

Make sure the bottom hook is not capsized. See Figure 3-4. Correct all chain irregularities before

conducting the first hoist operation.

Section 6.2.1.

3.3 Mounting Location

(N)ER2100S to (N)ER2200 L

Figure 3-3 Installation of Chain Container

Verify that the load chain is not twisted or tangled prior to operating the hoist.

Figure 3-4 Capsized Hook and Chain

3.3.1

3.3.2

WARNING

structure are adequate to support the hoist and its loads. If necessary consult a p rofessional that is

qualified to evaluate the adequacy of the suspen sion location and its supp orting structu re.

NOTICE

3.4 Mounting the Hoist

3.4.1 Manual Trolley - Follow instructions in Owner’s Ma nual provided with t he trolley.

3.4.2 Motorized Trolley - Follow instructions i n Owner’s Manual provided with the trolley.

3.4.3 Hook Mounted to a Fixed Location - Attach the hoist’s top hook to the fixed suspension point.

Prior to mounting the hoist ensure that the suspensio n and the supporti ng

See Section 6.8 of the ER2OM for outdoor installation considerations.

9

Page 10

3.4.4 Lug Mounted ER2080S and ER2100L-LG – To m aintain proper bala nce when the h oist is not loaded,

it is necessary to install a stabilizing shaft to prevent the hoist from pivoting on the main support shaft.

Refer to Figure 2-1 and Figure 2-2 for the size and location of the main support and stablizing holes in

the hoist’s top suspension plates.

3.4.5

WARNING

that the hook’s latch is engaged.

3.5 Electrical Connections

3.5.1

3.5.2

3.5.3

3.5.4

3.5.5

3.5.6

CAUTION

CAUTION

NER2 hoist. Use of such devices may cause the motor brake and other electrical compo nents to

malfunction. Variable frequency drives MAY be used with the single speed E R2/NER2 hoi sts, contact

Harrington Hoists, Inc. for more information.

DANGER

been de-energized (disconnected). Lock out and tag out in a ccordance with ANSI Z 244.1 “Personnel

Protection -Lockout/Tagout of Energy Sources”.

DANGER

maintenance on the dual speed ( VFD con trol) trolley or hoi st within 5 minute s of de-energizing

(disconnecting) the trolley or hoist. This time allows the internal VFD capacitor to safely discharge.

DANGER

operation.

CAUTION

and low lifting speeds. The speeds come preset from the factory (Se e Table 3-6, ER2OM ). Speed

(frequency) can be customized. Refe r to Section 3.6.10 of ER2OM, fo r hoist specific spee d ranges and

instructions.

Ensure that the fixed suspension point rests on the center of the hook’s saddle and

Ensure that the voltage of the electric power supply is prope r for the hoist or trolley.

Do NOT apply electronic soft-start control or voltage varying controls to the ER2 or

Before proceeding, ensure that the electrical supply for t he hoist or trolley has

To avoid a shock hazard, DO NOT perform ANY mechanical or elect rical

Do NOT remove power to the dual speed (VFD control) hoi st or trolley during

All dual speed hoists are equiped with a VFD. The VFD is used to control the high

3.5.7 The following instructions apply when the hoist is hook mount ed to a fixed su spension point or install ed

on a manual trolley. The hoist is controlled by a pendant with two push butto ns – one for lifting a nd one

for lowering. Refer to the appropriate trolley Owner’ s Manual if the ho ist is installed o n a motorized

trolley. Special wiring considerations must be taken if th e trolley is used with a troll ey other than an

MR2 model.

Pendant Cord

The Pendant Cord connects to the hoist via an 8-pin (8P) Plu g and Socket. Make this con nection

as follows:

Refer to Figure 3-5 or 3-6 depending on the Product Code.

For ER2080S and ER2100L - Insert the 8P Plug into the 8P Socket on the hoi st body and

hand tighten the Lock Ring. Install the stra in relief cable to the botto m of the hoist bo dy.

For ER2100S, ER2150S and ER2200S - Insert t he 8P Plug into the 8P Socket on the switch

box and hand tighten the Lock Ring. Install the strain relief cable ont o the cord strain reli ef

stopper located at the 8P socket.

10

Page 11

Power Supply Cable - Hoist Connec tion

The Power Supply Cable connects to the hoi st via a 4-pin (4P) plug and socket or a direct fitting

depending on the product code. Make this connection as follows:

Refer to Figure 3-5 or 3-6 depending on the product code.

For ER2080S and ER2100L insert the 4P p lug of the Power Supply Cab le into the 4P Socket

on the hoist and hand tighten the Lock Ring.

For ER2100S, ER2150S, and ER2200S – The po wer supply cable should b e pre-installed to

the switch box and properly connected.

Install the Cable Support Arm (pre-installed on t he Power Supply Cable) on to the Socket

Holder or Switch Box depending on the p roduct code. Use the pre-in stalled Machine Scre ws

and Lock Washers.

Use care to avoid twisting or kinki ng the Power Supply Cable.

Insert the 4P Plug into the 4P Socket on the hoist and hand -tighten the Lock Ring.

Figure 3-5 Pendant and Power Supply Cable Conne ctions

for ER2080S and ER2100L

11

Page 12

Figure 3-6 Pendant and Power Supply Cable Conne ctions

for ER2100S, ER2150S and ER2200S

Figure 3-7 Power Supply Cable Festoo ning and Guide Wire Location

12

Page 13

Power Supply Cable - Installation

If the hoist is hook mounted to a fixed support ensure that the Power Supply Cable is properly

installed and supported between the hoi st and the electri cal power sup ply.

If the hoist is installed on a manual trolley, then th e Power Supply Cable mu st be installed al ong

the beam that the trolley runs on. For curved beams a specia l cable suspension sy stem will be

needed, and this instruction does not appl y. For straight beams in stall the Power Su pply Cable as

follows:

Refer to Figure 3-7.

Install the Cable Hangers on to the Power Supply Cable spa cing them every 5 feet.

Install a Guide Wire system pa rallel to the Brid ge Beam. Pass the G uide Wire throu gh the

Cable Hangers and the Wire Guide.

Make sure the Guide Wire i s properly tensi oned and the Power S upply Cable i s not twisted o r

kinked.

3.5.8 Connection to Electrical Power Source - The red, blue, and black wires of the Power Supply Cable

should be connected to an Electric Power Disconnect Switch or Circuit Breaker. This connection

should be made so that the hoist is phased properly. Refer t o Section 3.6.11 for instructions on how to

check for correct power supply phase connection.

3.5.9 Fuse/Breaker Capacity -The hoist's power supply should be equipped with ove rcurrent protection such

as fuses, which should be selected for 110% to 120% of total listed full load am perage, and sho uld be

dual element time-delay fuses. Refer to the motor nameplate(s) for the full load amperage draw.

3.5.10

DANGER

shock hazard when touching any part of the hoi st or trolley. In the Power Sup ply Cable the ground wire

will be either Green with Yellow stripe or solid Green. It should always be connect ed to a suitable

ground connection. Do not paint the trolley wheel ru nning surfa ces of the beam as this can affect

grounding.

Grounding - An improper or insufficient gr ound connecti on creates an electrical

13

Page 14

3.6 Preoperational Checks and Trial Operation

3.6.1 Refer to the hoist’s nameplate and record t he hoist's Code, Lot a nd Serial Numbe r in the space

provided on the cover of this manual.

3.6.2

3.6.3

3.6.4 Measure and record the “k” dimension of all hooks on hoist. See Ta ble 5-4 under Section 5

3.6.5 Ensure that the hoist is properly installed to either a fixe d point, or trolley, whichev er applies.

3.6.6 If hoist is installed on a trolley, ensure that

3.6.7 Ensure that all nuts, bolts and split pins (cotter pins) are suffici ently fastened.

3.6.8 Pull down on the Pendant and ensure that the Cord Strain Relief Cable takes t he force, not the

3.6.9

3.6.10 Confirm proper operation.

WARNING

other lifting attachments before use. Inspect all load suspension m embers for da mage prior to us e and

replace or repair all damaged parts.

WARNING

Section 3.2 of this manual.

“Inspection”, of this manual.

trolley is properly installed on the beam, an d

stops for the trolley are correctly positioned and securely installe d on the beam.

Pendant Cord.

CAUTION

the rated value, electrical devices may not function normally.

Confirm the adequacy of the rated capacity for all slings, chain s, wire ropes and all

Verify and correct all chain irregularities prior to op erating the hoist. Ref er to

Check supply voltage before everyday use. If the voltage vari es more than 10% of

Before operating read and become familiar with Section 4 – Operation in the ER2OM.

Before operating ensure that the hoist (and trolley) meets the In spection, Testing an d Maintenanc e

requirements of ANSI/ASME B30.16.

Before operating ensure that nothing will interfere with the full range of t he hoist’s (and trolley’s)

operation.

3.6.11 Proceed with trial operation to confirm proper operatio n.

Verify that the controls agree with hoist direction. Make sure that depression of the up button lifts

the load chain and depression of the down butto n lowers the load chain hook. If the l oad chain

does not move in the correct direction when the push but tons are pushed, th e power supply is

phased incorrectly. In this case, turn off the power source or breaker switch

the three wires at the power source. The hook will then move in accordance with the directions of

the push button.

Perform inspections per Section 5.2, “Frequent Inspections” in the ER2OM.

then reverse any two of

14

Page 15

5.0 Inspection

NOTICE

Use this table in conjunction with Table 5-3 of th e ER2OM. The entries in this table replace in their entirety

Item Method Criteria Action

The information listed in this section is intended t o supplement Sectio n 5.7 of the ER2OM.

Table 5-3 Hoist Inspection Methods and Criteria

the corresponding entries in Table 5-3 of the ER2OM.

Hooks - Fretting

wear

Hooks - Stretch Measure The "k" dimension should not be greater than 1.15

Load Chain - Pitch

and Wire Diameter

Load Chain –

Reeving and

Evening

Measure The "u" and "t" dimensions should not be less

than discard value listed in Table 5-4

times that measured and recorded at the time of

purchase (See Section 3.6). If recorded "k"

values are not available for hooks when new, use

nominal "k" values from Table 5-4.

Measure The "P" dimension should not be greater th an

maximum value listed in Table 5-5. The "d"

dimension should not be less than minimum value

listed in Table 5-5.

Visual Chain should be reeved properly through Load

and Idle Sheaves - refer to Section 6.4. Chain,

Chain Springs, Stoppers, and Chain Pin should be

installed properly - refer to Section 3.2. For

double body hoists, chain should be evenly

distributed – equal length of chain in e ach chain

container or equal lengths of chain on no -load

side of each hoist body.

Replace.

Replace.

Replace. Inspect

Load and Idle

Sheaves.

Reeve/Install chain

properly.

Lower hook until

lower limit switch is

activated on both

hoist bodies.

Chain springs should not be deformed or

Chain Springs Visual

compressed. Refer to Table 5-6 for Chai n Spring

dimensions.

15

Replace.

Page 16

Table 5-4 Top Hook & Bottom Hook Dimensions

“k” Measured When New:

Top: _________________________

Bottom: ______________________

Capacity Code

080S

100L, 100S

150S

200S

Nominal "k"

Dimension*

inch (mm)

4.76(121) 2.86(72.6) 2.72(69) 1.89(48) 1.8(45.6)

5.16(131) 3.43(87) 3.26(82.7) 2.36(60) 2.24(57)

5..6(142) 3.91(99.4) 3.72(94.5) 2.76(70) 2.62(66.5)

7.13(181) 4.4(112) 4.19(106.4) 2.8(71) 2.66(67.5)

"u" Dimension

inch (mm)

Standard Discard Standard Discard

"t" Dimension

inch (mm)

* These values are nominal since the dime nsion is not co ntrolled to a toleran ce. The "k"

dimension should be measured when the hook is new - this becomes a reference measurement.

Subsequent measurements are compared to this reference to m ake determination s about hook

deformation/stretch. See Section 5.7 of ER2OM, “Hooks - Stretch”.

Table 5-5 Chain Wear Dimensions

Capacity Code

080S, 100L, 100S,

150S, 200S

“P” Dimension

inch (mm)

Standard Discard Standard Discard

6.18 (157.0) 6.37 (161.7) 0.44 (11.2) 0.42 (10.6)

“d” Dimension

inch (mm)

16

Page 17

Table 5-6 Chain Spring Length Dimensions

Capacity Code

080S, 100L, 100S, 0150S, 200S

“Length” - inch (mm)

Standard Discard

6.3 (160) 6.0 (152)

17

Page 18

6.0 Maintenance and Handling

6.2 Lubrication

6.2.1 Load Chain

Refer to 6.2.1 of the ER2OM.

6.2.2 Hooks and Suspension Components:

Refer to 6.2.2 of the ER2OM.

6.2.3 Gear Box:

Refer to 6.3 of the ER2OM except use the f ollowing table for checking oil level.

Table 6-1 ER (Mechanical Load brake Equipped ) Gear Oil Check Distances

Capacity Code

080S, 100L, 100S, 0150S, 200S 5.12 130

Check Distance

(inches)

Check Distance

(millimeters)

6.3 Motor Brake - Use the table below in conjunction with Section 6.4 of the ER2OM.

Table 6-2 Motor Brake Wear/Gap Dimensions

Capacity Code

080S, 100L, 100S, 150S, 200S

"Gap" Discard Dimension - inch (mm)

0.043 (1.1)

18

Page 19

6.4 Load Chain

6.4.1 Lubrication and Cleaning – refer to Section 6.2 of ER2OM.

6.4.2 Load Chain Replacement for ER2080S and ER2100L:

1)

2)

3)

4) For hoist s without a ch ain containe r, remove the socket bolt, lock nut, a nd attach the no-lo ad side of the

5) Remove t he Stopper an d Chain Spring f rom the no-load side of the chain for reuse on the n ew chain .

6) Using an op en link, attach the ne w chain to the end link of the old chain on th e no-load sid e. The end

7) Operate th e hoist down to m ove the new chain tho ugh the hoist body. Stop when a sufficient amo unt

8) Complete reeving as follows:

9) Remove t he Snap Ring and Chain Pin that attach th e old chain to t he chain holder fo r use on the new

10) Connect the end li nk of the new chain to the chain h older with the Chai n Pin and Snap Ri ng. Ensure

CAUTION

following procedures.

WARNING

size, grade and construction as the o riginal chain. T he new load chain must hav e an odd number of

links so that both its end links have the same orientation. If the load chain is being replace d due to

damage or wear out, destroy the old chain to preve nt its reuse.

CAUTION

Chain Guides and Idle Sheaves, and replace part s if necessary.

chain to Chain Guide A.

Inspect and replace any damaged or worn parts.

link of the new load chain should be connected so that the weld ed portions of th e load chain's stan ding

links are oriented to the outside as they pass over the Load Sh eave. Refer to Figu re 6-3.

of new chain is accumulated on the load side.

• For ER2080S pull down on Part

sheaves. Secure the new chain at Part

the new chain from running back through the idl e sheaves. Remove the open link attachi ng the

new chain to the old chain.

• For ER2100L pull up on Part

sheaves. Secure the new chain at Part

chain from running back through the idle sh eaves. Remove the o pen link attaching the new chain

to the old chain.

chain. Inspect and replace any damaged o r worn parts.

that the chain remains free of twists. Attach the remaining chain components to the chain referring to

Section 3.2 for the proper locations. For hoists without a ch ain container, atta ch the no-load sid e of the

chain to Chain Guide A with the socket bolt, and lock nut. See Figure 3-2.

The hoist must be properly powered and operational in orde r to perform the

Be certain that the replacement chain is obtained from Harrington and is the exa ct

When replacing load chain, check for wear on mati ng parts, i.e. Load S heave,

d until new chain is fe d through the uppe r and lower idle

d directly below the upper su spension plat es to prevent

d until the new chain is fed throu gh the upper an d lower idle

d directly above the lower idle sh eave to prevent the new

11)

12) After installation has been completed, perform steps outlined in Section 3.6 "Preoperational Checks

WARNING

3.2.

and Trial Operation".

Make sure the Stopper and Chain Spri ngs are properly inst alled. Refer to S ection

19

Page 20

Figure 6-3 Chain Replacement for 080S and 100 L

6.4.3 Load Chain Replacement for ER2100S, ER2150S and ER2200S:

1)

CAUTION

The hoist must be properly powered and operational in orde r to perform the

following procedures.

2)

WARNING

Be certain that the replacement chain is obtained from Harrington and is the exa ct

size, grade and construction as the o riginal chain. T he new load chain must hav e an odd number of

links so that both its end links have the same orientation. If the load chain is being replace d due to

damage or wear out, destroy the old chain to preve nt its reuse.

3)

CAUTION

When replacing load chain, check for wear on mati ng parts, i.e. Load S heave,

Chain Guides and Idle Sheaves, and replace part s if necessary.

4) For hoist s without cha in contain ers, remove the so cket bolts, lock nuts, and atta ch the end links of t he

chain to Chain Guide A on both hoist bodies.

5) Remove t he Stopper an d Chain Spring f rom one end of the ol d chain. Inspe ct and replace any

damaged or worn parts.

6) Using an op en link, attach the ne w chain to the end link of the old chain wh ere the Stopper and Chain

Spring were removed. The end link of the new lo ad chain should be connected so that th e welded

portions of the load chain's standing lin ks are orient ed to the outside as they pass over the Load

Sheave. Refer to Figure 6-4.

7) Install the St opper and Chain Spring to the free en d of the new chain. Refer to Se ction 3.2 in this

supplement for the correct location.

8) Disable Hoist Body B by unpluggi ng its 8P plug. Operate Hoist B ody A in the down dire ction to move

the new chain through the hoist until a sufficient qua ntity of chain has a ccumulated between th e hoist

bodies. Re-enable Hoist Body B by re-inserting its 8P plug.

9) Disable Hoist Body A by unpluggi ng its 8P plug. Operate Hoist B ody B in the up direction to move the

new chain through the hoist until a sufficient quantity of new chain has passed through Hoi st Body B.

Re-enable Hoist Body A by re-inserting its 8P plug.

10) Remove the open l ink attaching the n ew chain to the old chain.

20

Page 21

11) Remove the remaining Stoppe r and Chain Spri ng from the old chain. Inspect a nd replace any

damaged or worn parts. Install the Stopper and Ch ain Spring to the en d of the new chain. Refer to

Section 3.2 in this supplement for correct location.

12) For hoist s without a chain container, attach the ends of the chain to Chain Guide A on each body wit h

the socket bolt, and lock nut (see Figure 3-2). Ensure that all ch ain parts remain f ree of twists and

correct any if found.

13) Even out the chain by o perating the hoi st down until the down Limit Swit ch on both hoist b odies is

activated.

14)

WARNING

Make sure the Stopper and Chain Spri ngs are properly inst alled. Refer to S ection

3.2 in this supplement.

15) After installation has been completed, perform steps outlined in Section 3.6 "Preoperational Checks

and Trial Operation".

Figure 6-4 Chain Replacement for 100S, 150S, 200S

21

Page 22

www.harringtonhoists.com

Harrington Hoists, Inc. Harrington Hoists – Western Division

401 West End Avenue 2341 Pomona Rd. #103

Manheim, PA 17545 Corona, CA 92880-6973

Phone: 717-665-2000 Phone: 909-279-7100

Toll Free: 800-233-3010 Toll Free: 800-317-7111

Fax: 717-665-2861 Fax: 909-279-7500

ER2LCOMSup

Loading...

Loading...