Harrington Hoists MR2, TS2 User Manual

This equipment should not be installed, operated or

all the contents of this manual. Failure to read and comply

with the contents of this manual can result in serious bodily

EFFECTIVE: March 11, 2013

ELECTRIC

CHAIN HOIST

NER2 / MR2 / TS2

FOOD GRADE MODEL

1/4 Ton through 2 Ton Capacit i es

Code, Lot and Serial Number

maintained by any person who has not read and understood

injury or death, and/or property damage.

IMPORT ANT INFORMATION ON HOW TO USE THIS MANUAL

This OWNER’S MANUAL SUPPLEMENT for Food Grade Hoists is intended for use in combination with:

“Owner’s Manual for Electric Chain Hoist ER2 and NER2 Series 1/8 through 5 Ton C apaci ty”

“Owner’s Manual for Motorized Trolley MR2 Series 1 Ton through 20 Ton Capacity”

“Owner’s Manual for Manual Trolley TS2/TF2 Ser ies ½ Ton through 5 Ton Capac ity ”

Refer to the Main Table of Contents below to determine the location(s) of information pertaining to your hoist.

References to the Owner’s Manuals listed above will be designated by the use of the acronym “ER2OM”, “MR2OM”,

“TF2TS2OM”.

Main Table of Contents

Chapters Page Number

I Conformance Clarification Statement…………………………………………3

II NER2 Electric Chain Hoist………………………………………………..……….4

III MR2 Motorized Trolley……………………………………………………..……..11

IV TS2 Manual Trolley……………………………………………………..…………15

V Parts List……………………………………………………………………………..21

1.0 NER2……………………………………………………………………………..21

2.0 MR2……………………………………………………………………………….43

3.0 TS2………………………………………………………………………………..59

2

I Conformance Clarificat ion Sta t ement

1.1 Food Grade Options

Harrington ER2 Food Grade hoists are designed for applications which require food grade hoists. All

products should be tested for suitability on a particular application prior to actual use. The

occupational Safety and Health Act of 1970 places the burden of compliance with t he

owner/employer, not the manufacturer. Many OSHA requirements are not concerned or connected

with the manufactured product but are associated with the final installation. It is the owner’s

and user’s responsibility to determine the suitability of a product for any particular use. It is

recommended that all applicable industry, trade association, federal, state and local regulations be

checked. Read all operating instructions and warnings before operation.

1.2 Corrosion Resistance:

Standard Product Features and Benefits

• Nickel plated load chain

• The formulation of NEVASTANE HT/AW WHITE greases complies with the FDA chapter

21 CFR, 178.3570.

• The formulation of NEVASTANE SL oils complies with the FDA chapter 21 CFR,

178.3570.

• White epoxy painted hoist body, hooks, and suspenders

• ASME H4 classification

• Stainless steel and nickel plated components

Optional Product Features and Benefits

• Nickel Diffused Load Chain

• Stainless Steel Trolley Wheels

• Nickel Plated shafts and suspenders

• NEMA 4 pendant

• Pendant Cover

• Stainless Steel bottom hook

• Stainless Steel chain spring and limiting plate

• Stainless Steel chain container

3

II NER2 Electric Chai n Hois t

Section Page Number

1.0 Important In formation and Warnings … …… ………… …………………………………………..…….ER2OM

1.1 Terms and Summary

1.2 Warning Tags and Labels

2.0 Technical Information…………………………………………………………………………...……………6

2.1 Specifications

2.2 Dimensions

3.0 Preoperational Procedures …………………………………………………………………………..

3.1 Gearbox

3.2 Chain

3.3 Mounting Location

3.4 Mounting the Hoist

3.5 Electrical Connections

3.6 VFD Setup (Dual Speed Only)

3.7 Preoperational Checks and Trial Operation

4.0 Operation …………………………………………………………………..……………………….....E

4.1 Introduction

4.2 Shall’s and Shall Not’s for Operation

4.3 Hoist Controls

5.0 Inspection ……………………………………………………………………………………..…..…..

ER2OM

ER2OM

R2OM

5.1 General

5.2 Inspection Classification

5.3 Frequent Inspection

5.4 Periodic Inspection

5.5 Occasionally Used Hoists

5.6 Inspection Records

5.7 Inspection Methods and Criteria

4

Section Page Number

6.0 Maintenance & Handling …………………………………… ...…………………………………………ER2OM

6.1 Count/Hour Meter

6.2 Lubrication – Load Chain, Hooks and Suspension………………………..….8 and ER2OM

6.3 Lubrication – Gearbox…………………………………………………….....…..8 and ER2OM

6.4 Motor Brake

6.5 Load Chain……………………………………………………………………....10 and ER2OM

6.6 Friction Clutch and Mechanical Load Brake with Friction Clutch

6.7 Storage

6.8 Outdoor Installation

6.9 Operational Environment

7.0 Troubleshooting ……………………………………………… ………………………………………….ER2OM

8.0 Warranty ………………………………………………………………………………………………….ER2OM

9.0 Parts List ……………………………………………… …………………… ……… …………………… ……... 21

5

2.1 Specifications

Temperature range:

-4° to +104°F (-20° to +40°C)

Humidity:

85% or less Noise Level:

85 dB or less (A scale: measured 1 meter away from electric chain hoist

Enclosure Rating:

Hoist Meets IP 55

Hoist Duty Rating:

ISO M4/M5; ASME H4

Rating:

360 starts per hour

120/240 starts per hour

Rating:

Lift

Button

Cord

L

Diameter

(mm)

x

Weight for

Additional

1/4

NER2003L-FG

1/2

NER2005L-FG

1

NER2010L-FG

1.2

4.8

2.5

7.7 x 1

104

0.89

2

NER2020L-FG

2.4

8.6

4.2

10.2 x 1

161

1.6

1/4

NER2003LD-FG

1/2

NER2005LD-FG

1

NER2010LD-FG

1.2

5.1

2.7

7.7 x 1

99

0.89

2

NER2020LD-FG

2.4

9.1

4.5

10.2 x 1

161

1.6

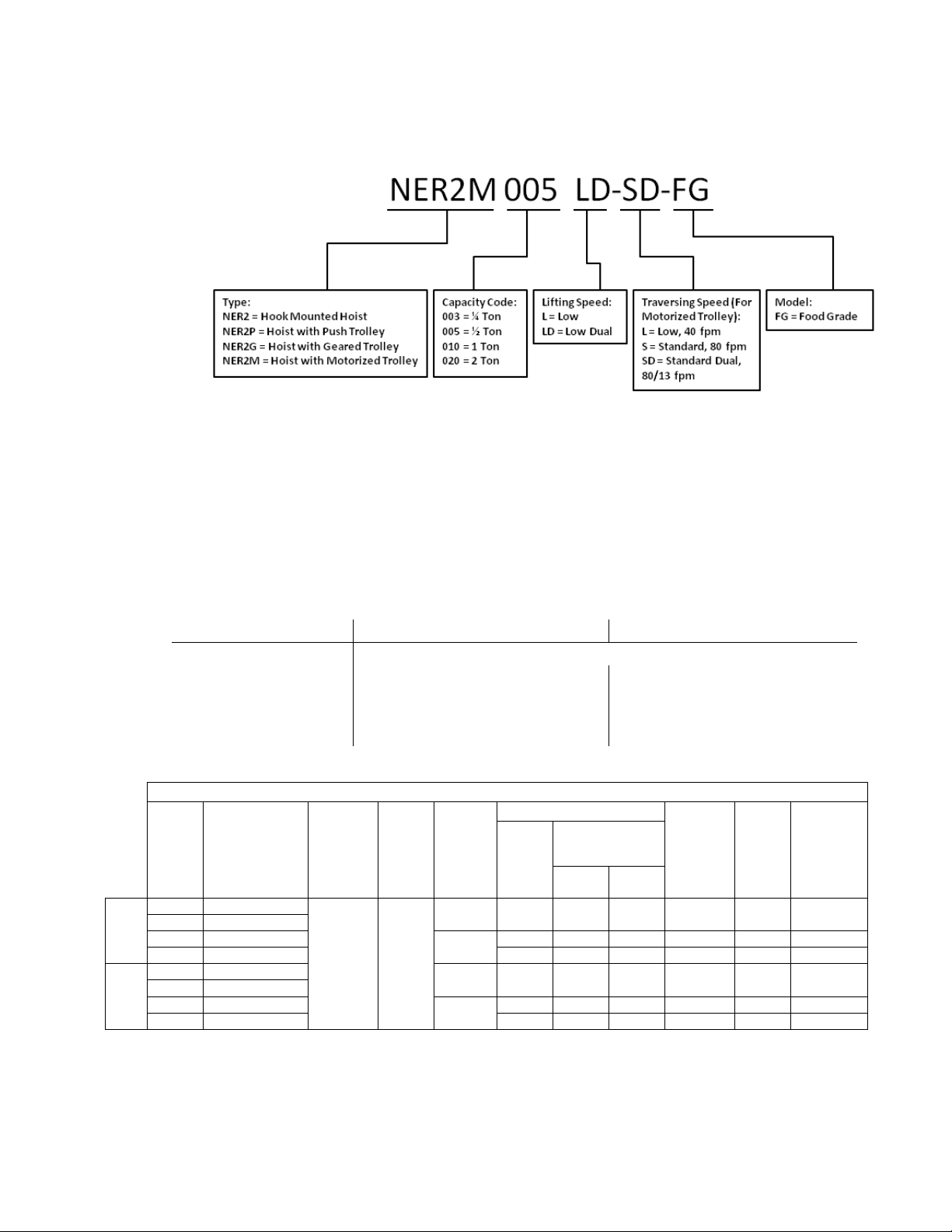

2.1.1 Product Code

2.1.2 Operating Conditions and Environment

Supply Voltage: Single Speed Standard: Reconnectable 208/230-3-60 & 460V-3-60

Dual Speed Standard: 208/230V-3-60 or 460V-3-60

Single Speed Dual Speed

Intermittent Duty

Short Time Duty

60% ED

60 min. 30/10 min.

Table 2-1 Hoist Specifications

Cap.

(Tons)

Single

Speed

Dual

Speed

Product Code

Standard

(ft)

10 8.2

Push

(ft)

Lifting

Speed

(ft/min)

15 0.75 3.4 1.7 6.0 x 1 71 0.54

14

15/2.5 0.75 3.6 1.8 6.0 x 1 68 0.54

14/2.5

Lifting Motor 3 Phase 60 Hz

Output

(Hp)

Rated Current

(amps)

@208 -

230V

@460V

40/20% ED

Load

Chain

Chain Fall

Lines

Net

Weight

(lbs)

One Foot

of Lift

(lbs)

6

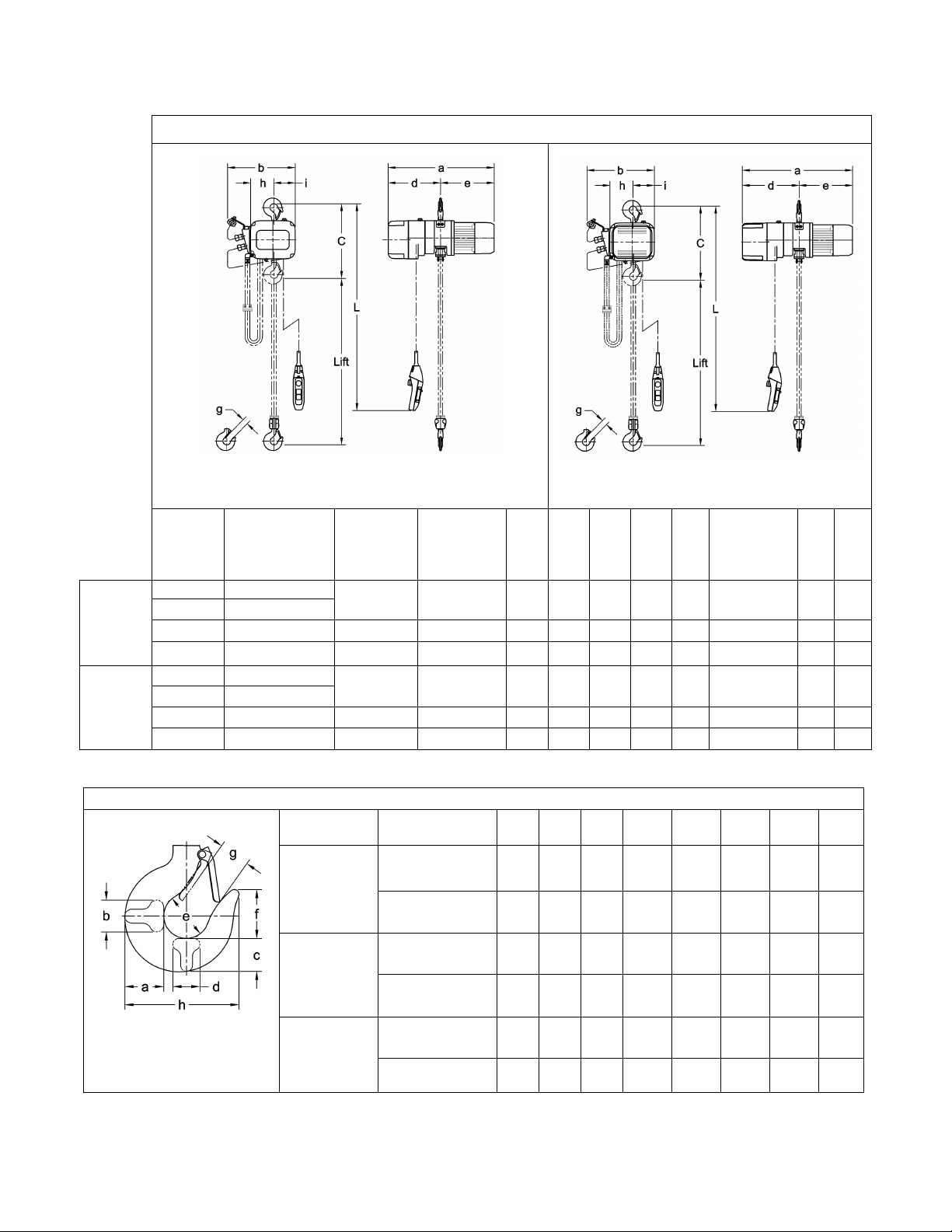

2.2 Dimensions

Hook C

1/4

NER2003L-FG

1/2 NER2005L-FG

1/4

NER2003LD-FG

1/2 NER2005LD-FG

1

NER2010LD-FG

16.9

21.3

24.1

14.8

12.4

11.7

1.2

1.5

5.1

4.6

Table 2-3 Hook Dimensions

(in)

Epoxy Painted

Table 2-2 Hoist Dimensions

Figure 2-1 Single Speed Hoist Dimensions

Capacity

(Tons)

Product Code

Headroom

C

(in)

Headroom

w/Stainless

(in)

Figure 2-2 Dual Speed Hoist Dimensions

a

(in) b (in) d (in) e (in) g (in)

g

w/Stainless

Hook

(in)

h

(in) i (in)

Single

Speed

Dual

Speed

T = Top Hook

B = Bottom Hook

1 NER2010L-FG

2 NER2020L-FG

2 NER2020LD-FG 22.6 23.4 27.9 16.8 14.6 13.3 1.6 1.7 6.3 5.4

Capacity Code

003L, 005L,

003LD, 005LD

010L, 010LD

020L, 020LD

14.6 17.7 20.2 13.7 9.5 10.6 1.1 1.2 4.4 4.2

g

(in)

5.1 4.6

h

16.9 21.2 23.2 14.8 11.4 11.7 1.2 1.5

22.6 23.4 25.4 16.8 12.1 13.3 1.6 1.7 6.3 5.4

14.6 17.7 22.4 13.7 11.8 10.6 1.1 1.2 4.4 4.2

a

b

c

Hook

Stainless Bottom

Epoxy Painted

Top & Bottom

Stainless Bottom

Epoxy Painted

Top & Bottom

Stainless Bottom 2.2 1.4 1.9 1.4 2.4 2.5 1.7 6.3

Top & Bottom

(in)

(in)

(in)

1.5 0.9 1.2 0.9 1.7 1.8 1.2 4.3

1.1 0.7 0.9 0.7 1.4 1.5 1.1 3.7

1.9 1.1 1.6 1.1 2.0 2.2 1.5 5.4

1.5 0.9 1.2 0.9 1.7 1.8 1.2 4.3

2.0 1.3 1.7 1.3 2.1 2.2 1.5 5.7

d

(in)

e

(in)

f

(in)

7

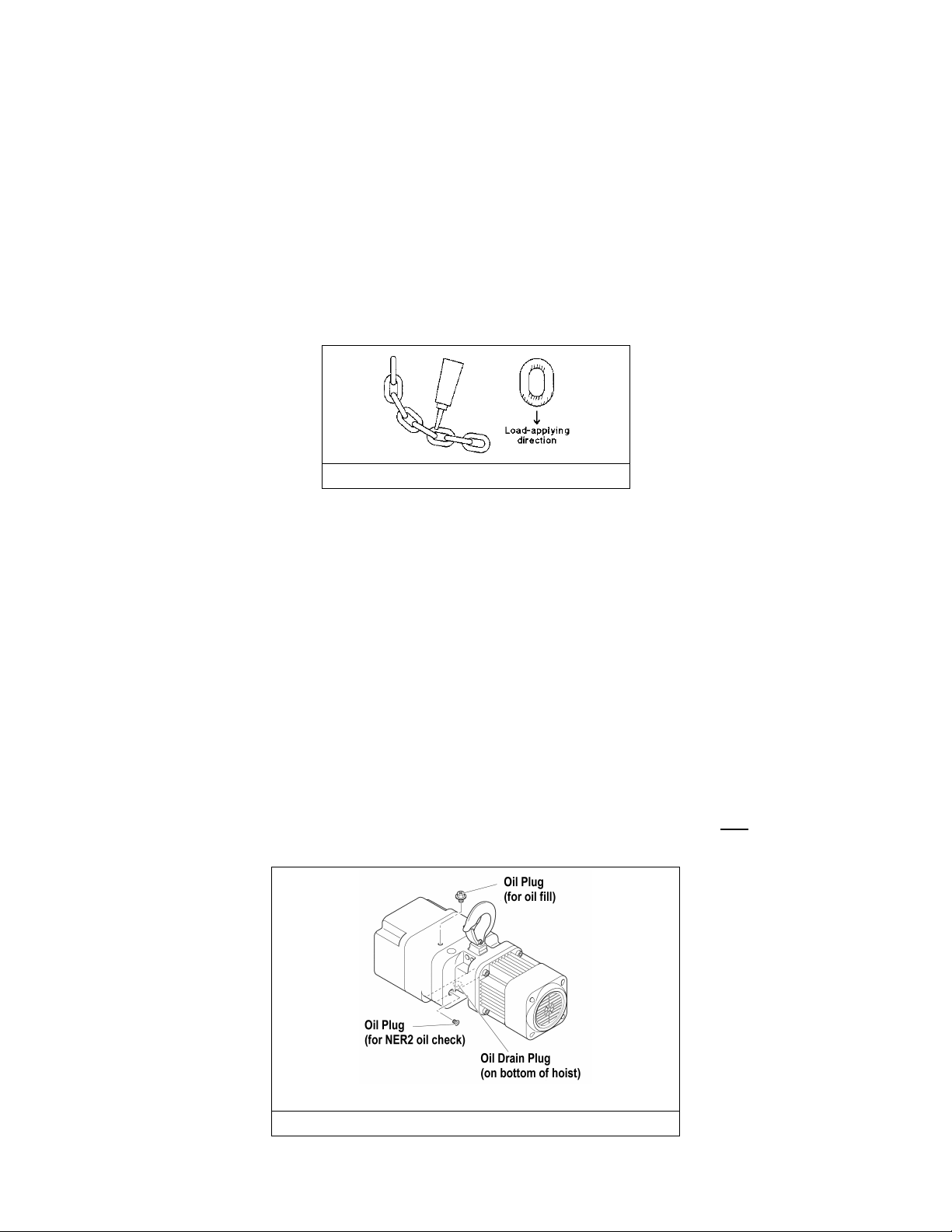

6.2 Lubrication – Load Chain, Hooks, and Suspension

6.2.1 Load Chain

• For longer life, the load chain should be lubricated.

• The load chain lubrication should be accomplished after cleaning the load chain with an acid

free cleaning solution.

• Apply only Harrington Hoist, Inc. food grade lubricant (Part No. 2AFG003S1951) to the bearing

surfaces of the load chain links as indicated by the shaded areas in Figure 6-2. Also apply the

lubricant to the areas of the load chain (shaded areas in Figure 6-2) that contact the load

sheave. Ensure that the lubricant is applied to the contact areas in the load sheave pockets.

Figure 6-2 Chain Grease Application

• The load chain should be lubricated every 3 months (more frequently for heavier usage or

severe conditions).

6.2.2 Hooks and Suspension Components

• Hooks – Bearings should be cleaned and lubricated at least once per year for normal usage.

Use only Nevastane HT/AW 2 White Drum food grade lubricating grease. Clean and lubricate

more frequently for heavier usage or severe conditions.

• Suspension Pins – Lubricate at least twice per year for normal usage; more frequently for

heavier usage or severe conditions.

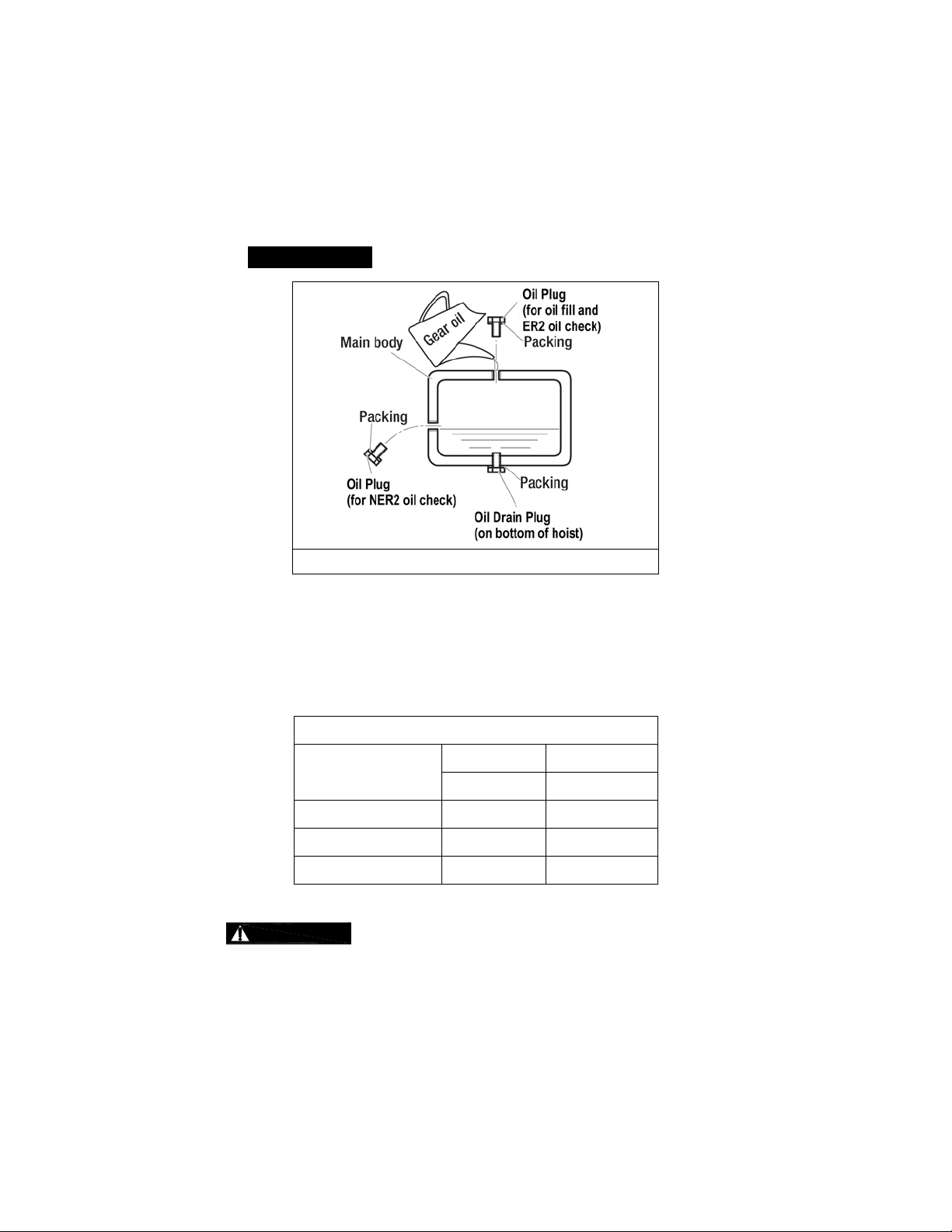

6.3 Lubrication - Gearbox

6.3.2 DETERMINING OIL LIFE - Refer to Section 6.1.3 in the ER2OM when estimating gear oil life

based on operations.

6.3.3 NER2 OIL LEVEL – The oil level is checked by removing the oil plug on the side of the hoist as

shown in Figure 6-3 for NER2 hoists. The oil level should be just below the hole when the hoist is

level.

NER2 Hoists

Figure 6-3 Oil Plug Locations

8

Figure 6-4

6.3.5 REPLACING OIL – Change gear oil at least once every 5 years. The oil should be

changed more frequently depending on the hoist's usage and operating environment. Refer to

Section 6.1.3. Follow the procedure below for replacing the gearbox oil for your hoist:

• To drain the current oil from the hoist remove “Oil Plug” on top of the hoist and the “Oil

Drain plug” on the bottom of the hoist. Allow the old oil to drain completely. Refer to

Figure 6-4 for oil plug locations.

•

Dispose of the used oil in accordance with local reg ulatio ns .

Oil Filling Diagram

• Ensure that the oil plugs for the oil level check holes and the drain hole are reinstalled

and secured into the hoist body.

• Refill the gear case with the correct quantity and type of new oil or until the oil level is

within the range shown in Table 6-6. Refer to Figure 6-4.

Table 6-6 Amount of Gear Oil

Capacity Code

003L/005L 0.57 0.54

010L 0.66 0.62

020L 1.37 1.30

may prevent the fr iction clu tch fr om working proper ly and m ay affect the a bility of the hoist to

hold the load. Onl y lu bricants with NSF H1 compliance m ay be used in f ood grade hoists.

Refer to the following for the correct type of gearbox oil:

NER Gear Oil:

Harrington standard: Ne vas tane SL 320 (Total Lubricants)

Using an incorrect type/grade of gearb ox oil or the wrong quantit y of oil

Quarts Liters

NER2 NER2

9

6.5 Load Chain

6.5.2 After chaining a unit, be s ure to clean any exp osed portions of bottom yoke bolts that have been

treated with thread locking compound. Conduct a thorough inspection of these bolts after

torquing to ensure there is no ex cess thread lock ing compound on t he expos ed portions. Failure

to do so could affect the hoist’s compliance with the application’s food grade requirements.

10

III MR2 Mot orized Trolley

Section Page Number

1.0 Important Information and Warnings………………...……………………………………….....….MR2OM

1.1 Terms and Summary

1.2 Warning Tag and Labels

2.0 Technical Information…………… ……………………………………….………….…………………..….13

2.1 Specifications

2.2 Dimensions

3.0 Pre-operational Procedures..……………………………………………………………................MR2OM

3.1 Assembly and Adjustment

3.2 Mounting Location

3.3 Installation of Trolley onto Beam

3.4 Electrical Connections

3.5 VFD Setup (Dual Speed Only)

3.6 Pre-operational Checks and Trial Operation

4.0 Operation………………………………………………………………………………………………MR2OM

4.1 Introduction

4.2 Shall’s and Shall Not’s for Operation

4.3 Trolley and Hoist Controls

5.0 Inspection………………………………………………………………………..…………………….MR2OM

5.1 General

5.2 Inspection Classification

5.3 Frequent Inspection

5.4 Periodic Inspection

5.5 Occasionally Used Trolleys

5.6 Inspection Records

5.7 Inspection Methods and Criteria

11

Section Page Number

6.0 Maintenance & Handling……………………………………………………………………………..MR2OM

6.1 Count/Hour Meter (Dual Speed Only)

6.2 Lubrication……………………………………………………..………………..14 and MR2OM

6.3 Brake

6.4 Storage

6.5 Outdoor Installation

6.6 Operational Environment

7.0 Troubleshooting……………………………………………………..………………………………..MR2OM

8.0 Warranty……………………………………………………………...………………………………. MR2OM

9.0 Parts List……………………………………………………………………………………………………...43

12

2.0 Specifications

Temperature Range:

-4° to +104°F (-20° to +40°C)

Humidity:

85% or less (no condensation)

hoist)

Enclosure Rating:

Trolley Meets IP55, Pendant Meets IP 65

Available

Dual Speed – 27/13% ED with 78/162 starts per hour

Trolley Duty Rating:

ISO M4/5; ASME H4

Current Draw

(amps)

208V or

230V

7.03 to 12.00

6.03 to 12.00

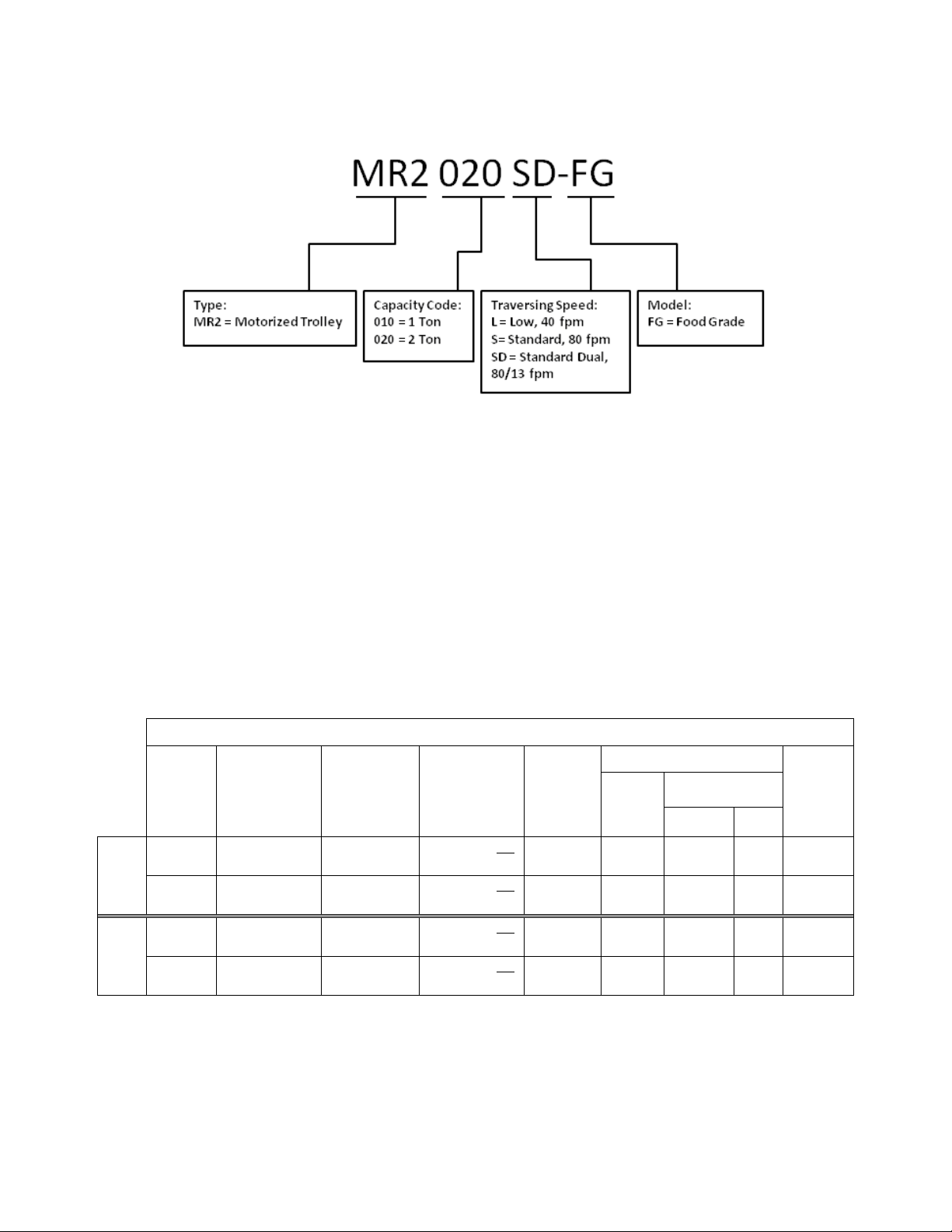

2.1.1 Product Code for MR2 Trolley Alone:

2.1.2 Operating Conditions and Environment

Noise Level: 85 dB or less (A scale: measured 1 meter away from the electric chain

Supply Voltage: Standard 208-230/460V-3-60, Optional 575V-3-60, Special Voltages

Intermittent Duty Rating:

Single Speed – 40% ED 240 starts per hour

Single

Dual

Capacity

(Ton)

1 MR2010L/S-FG 2.28 to 5.00

Speed

2 MR2020L/S-FG 3.23 to 6.02

1 MR2010SD-FG 2.28 to 5.00

Speed

2 MR2020SD-FG 3.23 to 6.02

Product Code

Beam Flange

Table 2-1 Trolley Specifications

Standard

Range

(in)

Optional Beam

Flange Range

(in)

5.01 to 6.02 OR

6.03 to 12.00

6.03 to 7.02 OR

5.01 to 6.02 OR

6.03 to 7.02 OR

7.03 to 12.00

(Hp)

Motor***

460V

Min.

Allowable

Radius

for Curve

(in)

31.5* 0.54 3.0 1.5 68

31.5** 0.54 3.0 1.5 84

31.5 0.54 3.0 1.5 75

31.5 0.54 3.0 1.5 93

Output

Approx.

Net

Weight

(lbs)

13

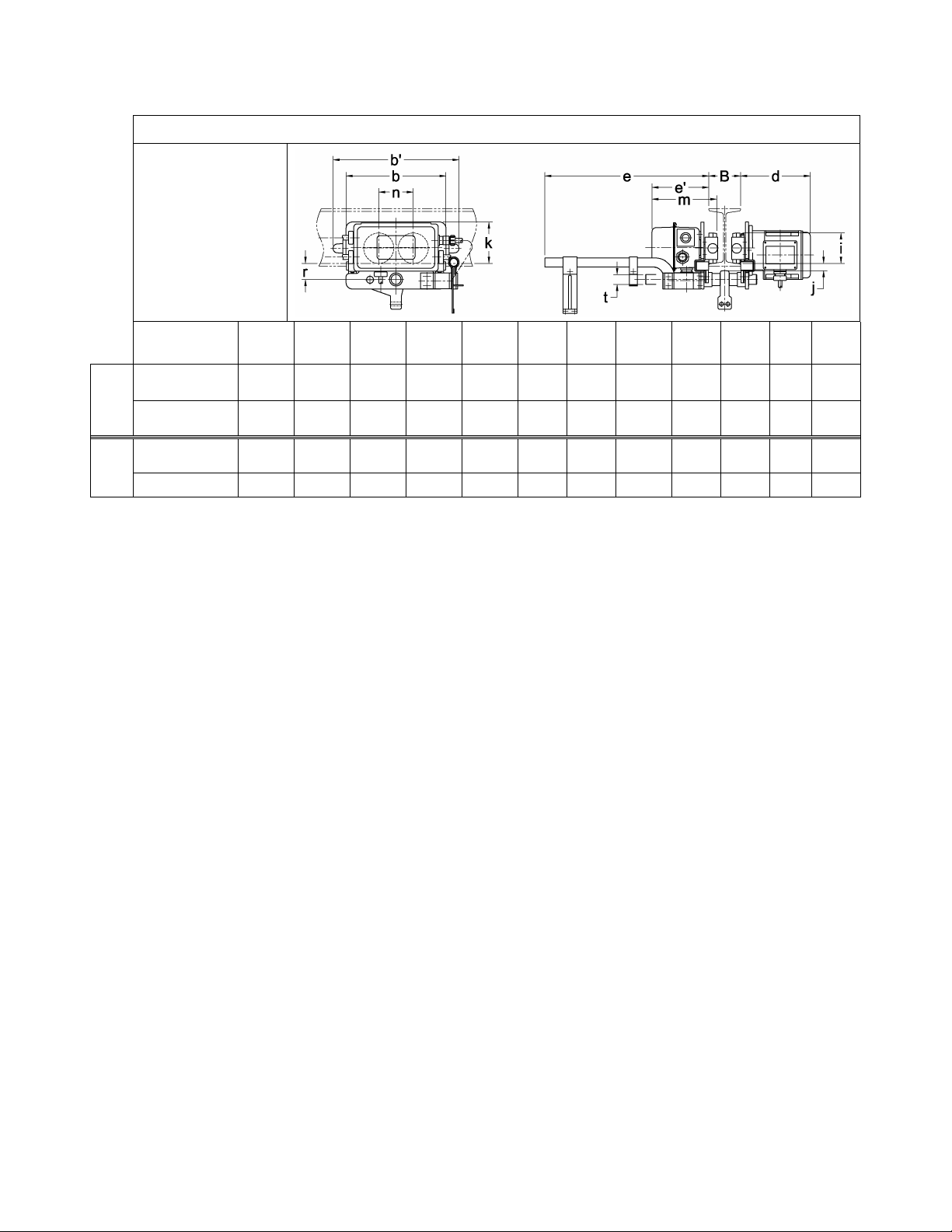

2.2 Dimensions

Table 2-2 Trolley Dimensions

For NER2003L-FG to

NER2020L-FG

Product

Code

MR2010L/S-FG 12.4 15.6 8.7 20.3 7.1 3.74 0.9 5.1 8.1 4.3 2.0 1.22

Single

Speed

MR2020L/S-FG 12.8 16.4 8.9 20.5 7.2 4.33 1.1 4.9 8.4 4.7 2.4 1.42

MR2010SD-FG 12.4 15.6 8.7 20.3 7.1 3.74 0.9 5.1 8.1 4.3 2.0 1.22

Dual

Speed

MR2020SD-FG 12.8 16.4 8.9 20.5 7.2 4.33 1.1 4.9 8.4 4.7 2.4 1.42

6.2 Lubrication

6.1.1 Lubricate the following trolley components with only Nevastane HT/AW 2 White Drum food grade

lubricating grease.

6.1.2 Track Wheel Gear – Clean and re-grease the Track Wheel gears and motor output pinion every

three months (more frequently for heavier usage or severe conditions). Do not use an excessive

amount of grease and avoid getting any grease on the running surfaces of the Track Wheels or

the beam.

6.1.3 Gear Box – The reduction gearing in the motor should be cleaned and lubricated at least once

per year for normal usage. Clean and lubricate the reduction gear assembly more frequently for

heavier usage or severe conditions. Gain access to the gears by removing the four bolts that

mount the motor assembly to the trolley Side Plate. Make sure to properly orient and reuse the

neoprene gasket between the motor and Side Plate.

b b' d e e' i j k m n r t

6.1.4 Suspension Pins, Bolts and Shafts – Grease at least twice per year for normal usage (more

frequently for heavier usage or severe conditions).

14

IV TS2 Manual Trolley

Section Page Number

1.0 Important Informa t ion and Warnings………………….…………………………………………. TS2OM

1.1 Terms and Summary

1.2 Warning Tags and Labels

2.0 Technical Information …………………………………………….………………….……..........……. 17

2.1 Specifications

2.2 Dimensions

2.3 Optional Equipment

3.0 Pre-operational Procedures…………………………………………………………………….... TS2OM

3.1 Manual Hoist Adjustment for Trolley

3.2 Electric Hoist Adjustment for Trolley

3.3 Air Power Hoist Adjustment for Trolley

3.4 Trolley Assembly

3.5 Mounting Location

3.6 Installation of Trolley onto Beam

3.7 Electrical/Air Connections

3.8 Pre-operational Checks and Trial Operation

4.0 Operation………………………………………………………………………………………...…. TS2OM

4.1 Introduction

4.2 Shall’s and Shall Not’s for Operation

4.3 Trolley Controls

5.0 Inspection………………………………………………………………………………………….. TS2OM

5.1 General

5.2 Inspection Classification

5.3 Frequent Inspection

15

Section Page Number

5.4 Periodic Inspection

5.5 Occasionally Used Trolleys

5.6 Inspection Records

5.7 Inspection Methods and Criteria

6.0 Maintenance & Handling………………………………………………………………………….. TS2OM

6.1 Lubrication……………………………………………………….……………….19 and TS2OM

6.2 Storage

6.3 Outdoor Installation

7.0 Warranty…………………………………………………………………………………………..…TS2OM

8.0 Parts List…………………………………………………………………………………………………... 59

8.1 TS2 Push Trolley Parts – 1/4 to 2 Ton

8.2 TS2 Geared Trolley Parts – 1/4 to 2 Ton

16

2.1 Specifications

Temperature Range:

-4° to +104°F (-20° to +40°C)

Humidity:

85% or less

Min.

(in)

Min.

(in)

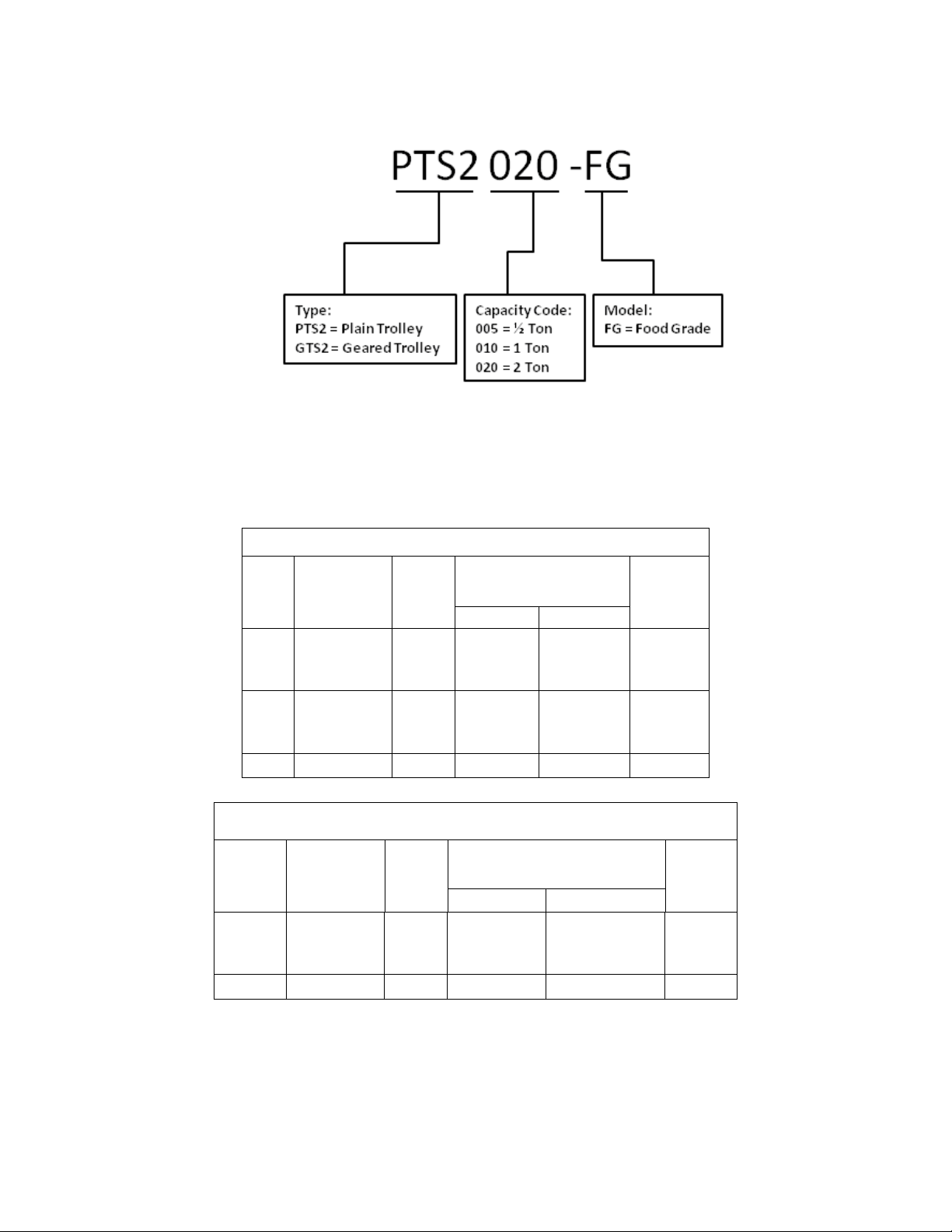

Product Code for TS2 Trolley Alone:

Operating Conditions and Environment

Table 2-1 PTS2 Trolley Specifications

Cap.

(Tons)

Product Code

1/2 PTS2005-FG 43.3 2.28 to 4.00

1 PTS2010-FG 51.2 2.28 t o 5.00

2 PTS2020-FG 59.1 3.23 t o 6.02 6.03 to 12.00 31

Radius

for

Curve

Flange Width Adjustability

B

(in)

Standard Option

4.01 to 8.00

or

8.01 to 12.00

5.01 to 8.00

or

8.01 to 12.00

Approx. Net

Weight

(lbs)

10

18

Table 2-2 GTS2 Trolley Specifications

Cap.

(Tons)

1 GTS2010-FG 51.2 2.28 to 5.00

2 GTS2020-FG 59.1 3.23 to 6.02 6.03 to 12.00 42

Product Code

Radius

for

Curve

Flange Width Adjustability

B

(in)

Standard Option

5.01 to 8.00

or

8.01 to 12.00

Approx.

Net

Weight

(lbs)

27

17

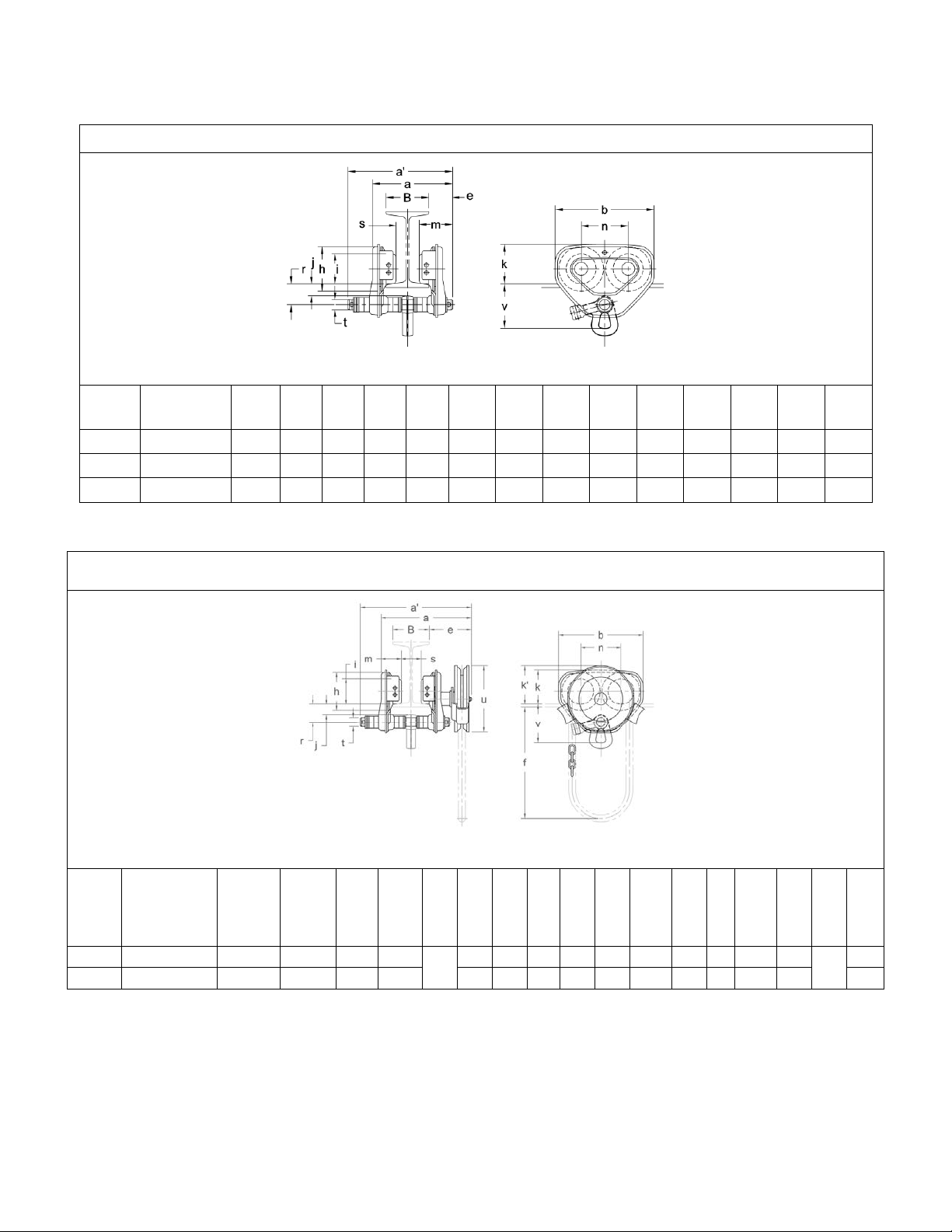

2.2 Dimensions

a

(in)

Table 2-3 PTS2 Trolley Dimensions

PTS2005 to PTS2020

Cap.

(Tons)

1/2 PTS2005-FG 6.8 8.0 7.2 1.8 3.2 2.36 0.7 3.0 2.7 3.3 1.5 B-1.8 0.87 3.7

1 PTS2010-FG 8.5 9.8 9.3 2.2 4.2 2.80 1.1 3.7 3.1 4.4 2.0 B-1.9 0.98 4.2

2 PTS2020-FG 10.4 11.8 11.0 2.7 5.0 3.35 1.3 4.4 3.8 5.2 2.4 B-2.3 1.26 5.1

Product

Code

max

a'

(in) b (in) e (ft) h (in) i (in) j (in) k (in) m (in) n (in) r (in) s (in) t (in) v (in)

Table 2-4 GTS2 Trolley Dimensions

GTS2010 to GTS2020

Cap.

(Tons)

1/2-1 GTS2010-FG 10.8 13.6 9.3 6.0

Product Code

2 GTS2020-FG 13.7 15.2 11.0 6.1 5.0 3.35 1.3 4.4 4.3 2.8 5.2 2.4 B-1.9 1.26 5.1

a

max*

(in)

a’

max

(in)

b

(in) e (in) f (ft.) h (in)

4.2 2.80 1.1 3.7 4.2 2.2 4.4 2.0 B-1.8 0.98

10.5

i

(in) j (in) k (in)

k'

(in) m (in) n (in) r (in) s (in) t (in) u (in) v (in)

7.2

18

4.2

6.1 Lubrication

6.1.1 Lubricate the following trolley components with only Nevastane HT/AW 2 White Drum food grade

lubricating grease.

6.1.2 Track Wheel Gear – Clean and re-grease the Track Wheel gears and Hand Wheel output pinion every

three months (more frequently for heavier use). Do not use an excessive amount of grease and avoid

getting any grease on the running surfaces of the Track Wheels or the beam.

6.1.3 Trolley Wheel Bearings do not need to be lubricated and must be replaced if worn or damaged.

6.1.4 Suspension Pins, Bolts, and Shafts – Grease at least twice per year for normal usage (more frequently

for heavier usage or severe conditions).

19

This Page Intentionally Left Blank

20

Loading...

Loading...