Page 1

Code, Lot and Serial Number

EFFECTIVE: February 3, 2011

This equipment should not be installed, operated or

with the contents of this manual can result in serious bodily

injury or deat h, and/or p ropert y d amag e.

MANUAL

CHAIN HOIST

CB SERIES

MODEL M3

1/2 Ton through 20 Ton Capacity

maintained by any person who has not read and understood

all the contents of this manual. Failure to read and comply

Page 2

Table of Contents

Section Pag e Number

1.0 Important Information and Warnings ………………… ……… …………… …… ………… ……… ……… 4

1.1 Terms and Summary

1.2 Warning Tags and Labels

2.0 Technical Information…………………… …………… ……………… …………… …………… .…………. 7

2.1 Specifications

2.2 Dimensions

2.3 Optional Equipment

3.0 Preoperational Procedures ……………………………………………………………………………… 11

3.1 Chain

3.2 Attachment Points

3.3 Mounting the Hoist

3.4 Preoperational Checks and Trial Operation

4.0 Operation ……………………… …………………………………………………………………………... 13

4.1 Introduction

4.2 Shall’s and Shall Not’s for Operation

4.3 Operation

4.4 Principal and Operation of the Slip Clutch

5.0 Inspection ……………………… ………………………………………………………………………….. 16

5.1 General

5.2 Inspection Classification

5.3 Frequent Inspection

5.4 Periodic Inspection

5.5 Occasionally Used Hoists

5.6 Inspection Records

5.7 Inspection Methods and Criteria

2

Page 3

Section Pag e Number

6.0 Maintenance & Handling …………………………………………………………………………………. 26

6.1 Lubrication

6.2 Disassembly, Assembly and Ad justment

6.3 Hoist Disassembly

6.4 Hoist Assembly

6.5 Storage

6.6 Outdoor Installation

7.0 Troubleshooting ………………………… …………… ……………… …………… ……………… ……… 36

8.0 Warranty …………………………………………………………………………………………………… 39

9.0 Parts List ………………………………… …………… ……………… …………… …………………… … 41

3

Page 4

1.0 Important Information and Warnings

1.1 Terms and Summary

This manual provides impor tant infor mation for personnel involved with the installation, operation and

maintenance of this product. Although you may be familiar with this or similar equipment, it is strongly

recommended that you read this manual before installing, operating, or maintaining the product.

Danger, Warning, Caution, and Notice

Throughout this manual there are steps and procedures that can present hazardous situations. The following

signal words are used to identify the degree or level of hazard seriousness.

Danger indicates an imminently hazardous situation which, if not avoided, will result in

death or serious inj ury, and property damage.

Warning indicates an imminently hazardous situation which, if not avoided, could result in

death or serious inj ury, and property damage.

Caution indicates a potentially hazardous situation which, if not avoided, may result in

minor or moder ate injur y or property damage.

Notice is used to notify people of installation, operation, or maintenance information which

is important but not directly hazard-related.

These general instructions deal with the normal installation, operation, and maintenance situations encountered with

the equipment described herein. The instructions should not be interpreted to anticipate every possible contingency

or to anticipate the final system, crane, or configuration that uses this equipment. For systems using the equipment

covered by this manual, the supplier and owner of the system are responsible for the system’s compliance with all

applicable industry standards, and with all applicable federal, state, and local regulations/codes.

This manual includes instructions and parts information for a variety of hoist types. Therefore, all instructions and

parts information may not apply to any one type or size of specific hoist. Disregard those portions of the instructions

that do not apply.

Record your hoist’s Code, Lot and Serial Number (see Section 9) on the front cover of this manual for identification

and future reference to avoid referring to the wrong manual for information or instructions on installation, operation,

inspection, maintenance, or parts.

Use only Harrington authorized replacement parts in the service and maintenance of this hoist.

4

Page 5

Equipment described herein is not designed for and

people, or for lifting or supporting loads over people.

Equipment described herein should not be used in conjunction with other equipment unless necessary and/or

required safety devices applicable to the system, crane, or application are installed by the system designer, system

manufacturer, crane manufacturer, installer, or user.

Modifications to upgrade, rerate, or otherwise alter this equipment shall be authorized only by the original equipment

manufacturer.

If a below-the-hook lifting device or sling is used with a hoist, refer to ANSI/ASME B30.9, “Safety Standard for

Slings” or ANSI/ASME B30.20, “Safety Standard for Below-the-Hook Lifting Devices”.

Hoists used to handle hot molten material may require additional equipment or devices. Refer to ANSI Z241.2,

“Safety Requirements for Melting and Pouring of Metals in the Metalcasting Industry”.

Failure to read and comply with any one of the limitations noted herein can result in serious bodily injury or death,

and/or property damage.

MUST NOT be used for lifting, supporting, or transporting

It is the responsibility of the owner/user to install, inspect, test, maintain, and operate a hoist in accordance with

ANSI/ASME B30.16, “Overhead Hoists (Underhung)” and OSHA Regulations. If the hoist is installed as part of a

total lifting system, such as an overhead crane or monorail, it is also the responsibility of the owner/user to comply

with the applicable ANSI/ASME B30 volume that addresses that type of equipment.

It is the responsibility of the owner/user to have all personnel that will install, inspect, test, maintain, and operate a

hoist read the contents of this manual and applicable portions of ANSI/ASME B30.16, “Overhead Hoists

(Underhung)” and OSHA Regulations.

If the hoist owner/user requires additional information, or if any information in the manual is not clear, contact

Harrington or the distributor of the hoist. Do not install, inspect, test, maintain, or operate this hoist unless this

information is fully understood.

A regular schedule of inspection of the hoist in accordance with the requirements of ANSI/ASME B30.16 should be

established and records maintained.

5

Page 6

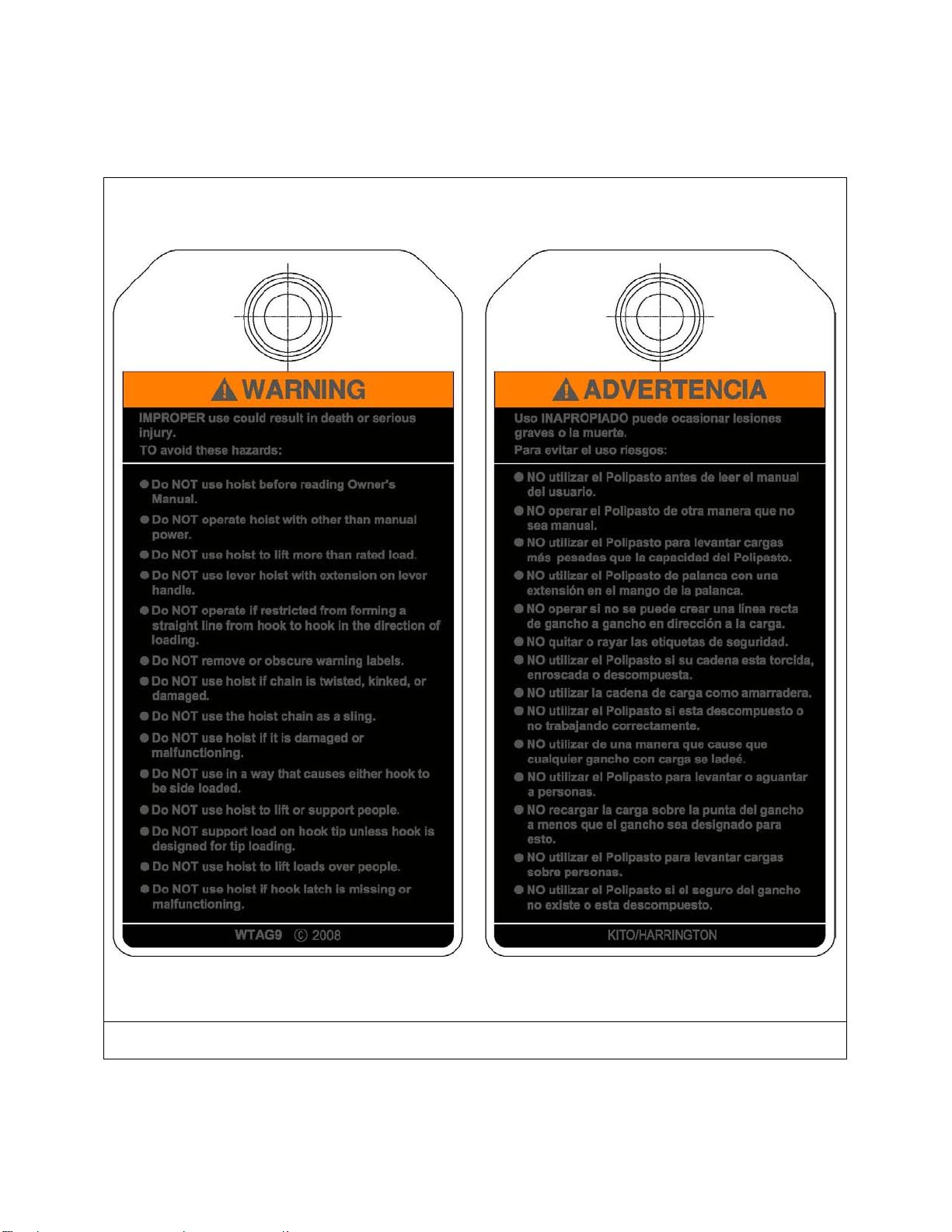

1.2 Warning Tags and Labels

The warning tag illustrated below in Figure 1-1 is supplied with each hoist shipped from the factory. If the tag is

not attached to your hoist’s no-load side of the load chain, order a tag from your dealer and install it. Read and

obey all warnings attached to this hoist. Tag is not shown actual size.

Front Back

Figure 1-1 Warning Tag Attached to Hoist (shown larger for legibility)

6

Page 7

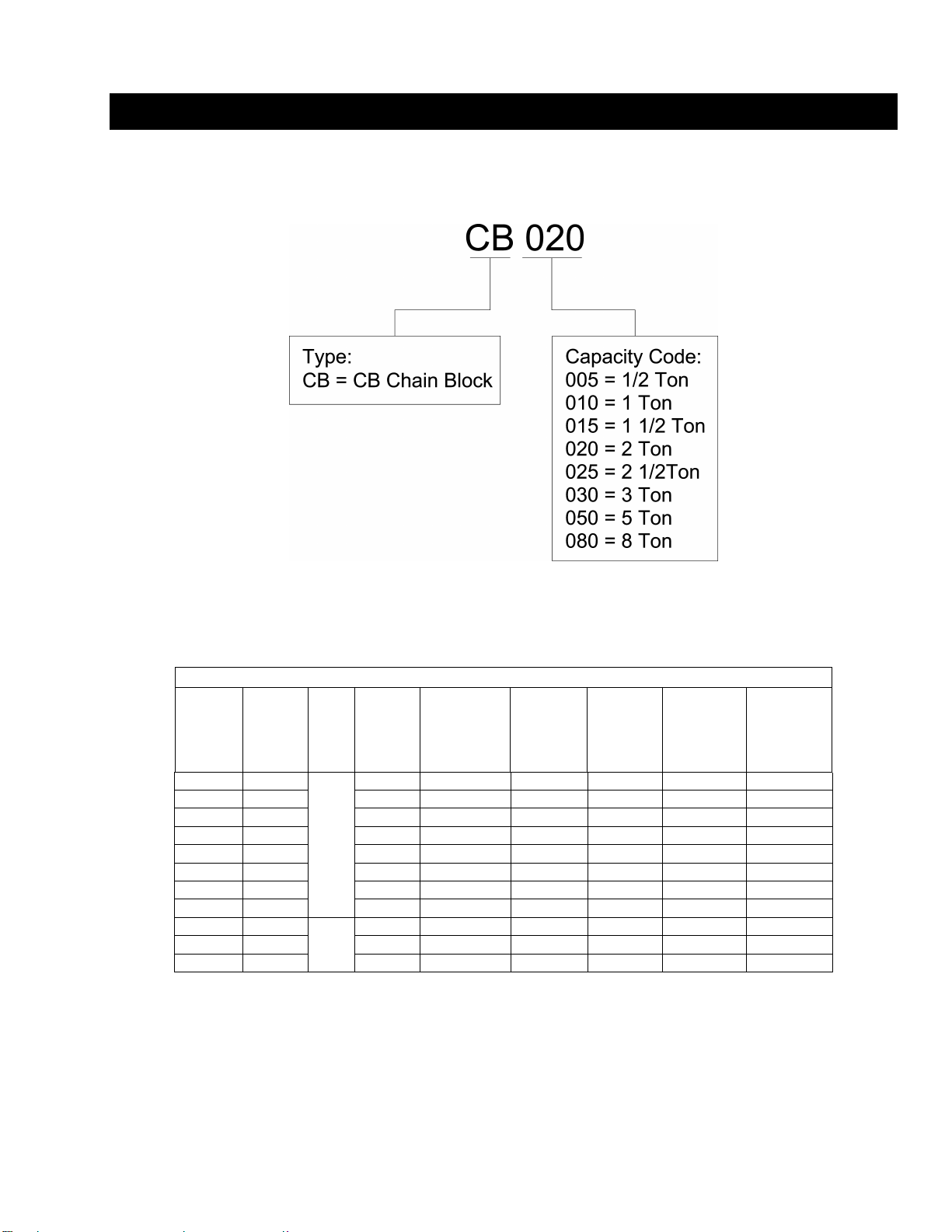

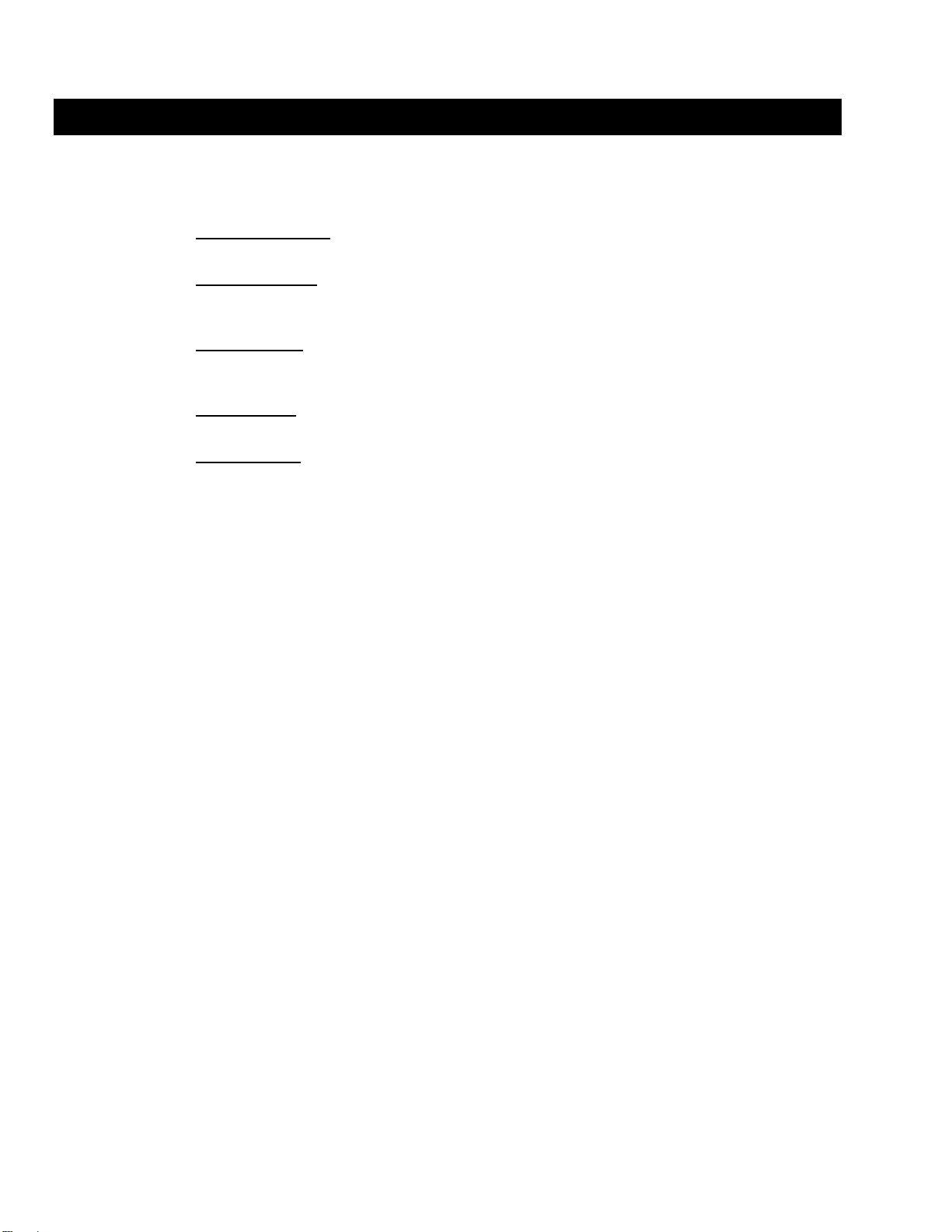

2.0 T echni cal Informati on

2.1 Specifications

2.1.1 Product Code

2.1.2 Operating Conditions and Environment

Temperature range: -4° to +140°F (-20° to +60°C)

Humidity: 100% or less (Not an Underwater Device)

Table 2-1 Hoist Speci ficat ion s

Load Chain

Diameter

(mm) x

Chain Fall

Lines

Overhaul

Ratio

Net

Weight

(lbs)

Lift

(ft)

8

12

Pull to

Lift

Load

(lbs)

48 5.0x1 25 22 23 1.0

72 9.0x4 396 186 203 5.5

Cap.

(Tons)

1½ CB015 70 7.1x1 57 32 33 1.4

2 ½ CB025 66 9.0x1 99 56 58 1.8

10 CB100

15 CB150 74 9.0x6 594 346 368 7.9

20 CB200 72x2 9.0x8 396x2 524 678 10.9

Product

Code

½ CB005

1 CB010 58 6.3x1 43 25 26 1.2

2 CB020 72 8.0x1 70 41 43 1.6

3 CB030 72 7.1x2 114 49 53 2.1

5 CB050 68 9.0x2 198 85 89 3.0

8 CB080 75 9.0x3 297 124 131 4.2

Std.

Shipping

Weight

Approx.

(lbs)

Weight for

Additional

One Foot

of Lift (lbs)

*NOTE: Any lift of chain is available on request. Simply specify the length of chain desired when ordering.

Because Harrington chains are specially heat treated, only authentic Harrington chains should be used on your

hoist. NEVER attempt to lengthen the chain by attaching additional chain links to it or by any other means.

7

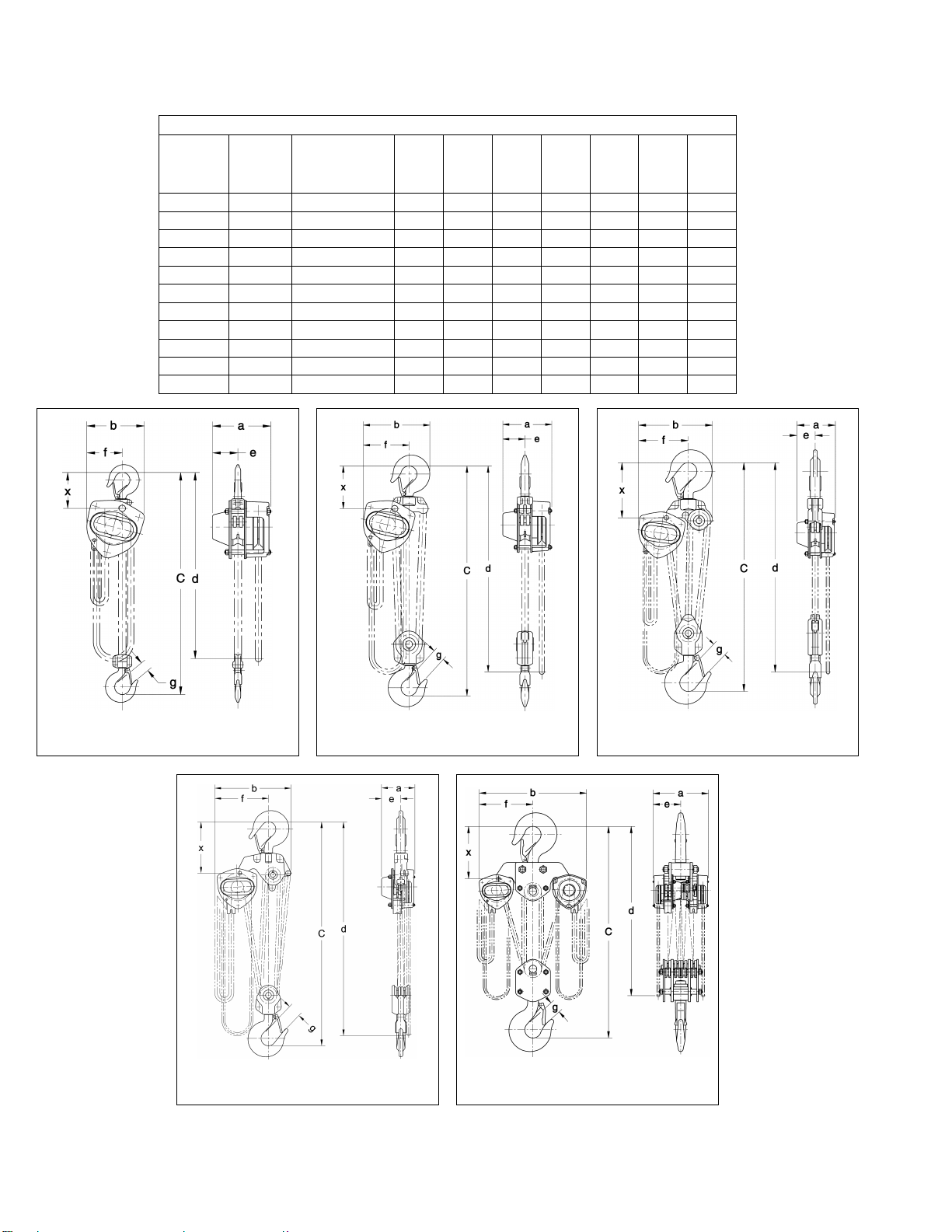

Page 8

CB005 to CB025

CB030 to CB050

CB080

Figure 2-1

Figure 2-2

Figure 2-3

CB100 to CB150

CB200

Figure 2-4

Figure 2-5

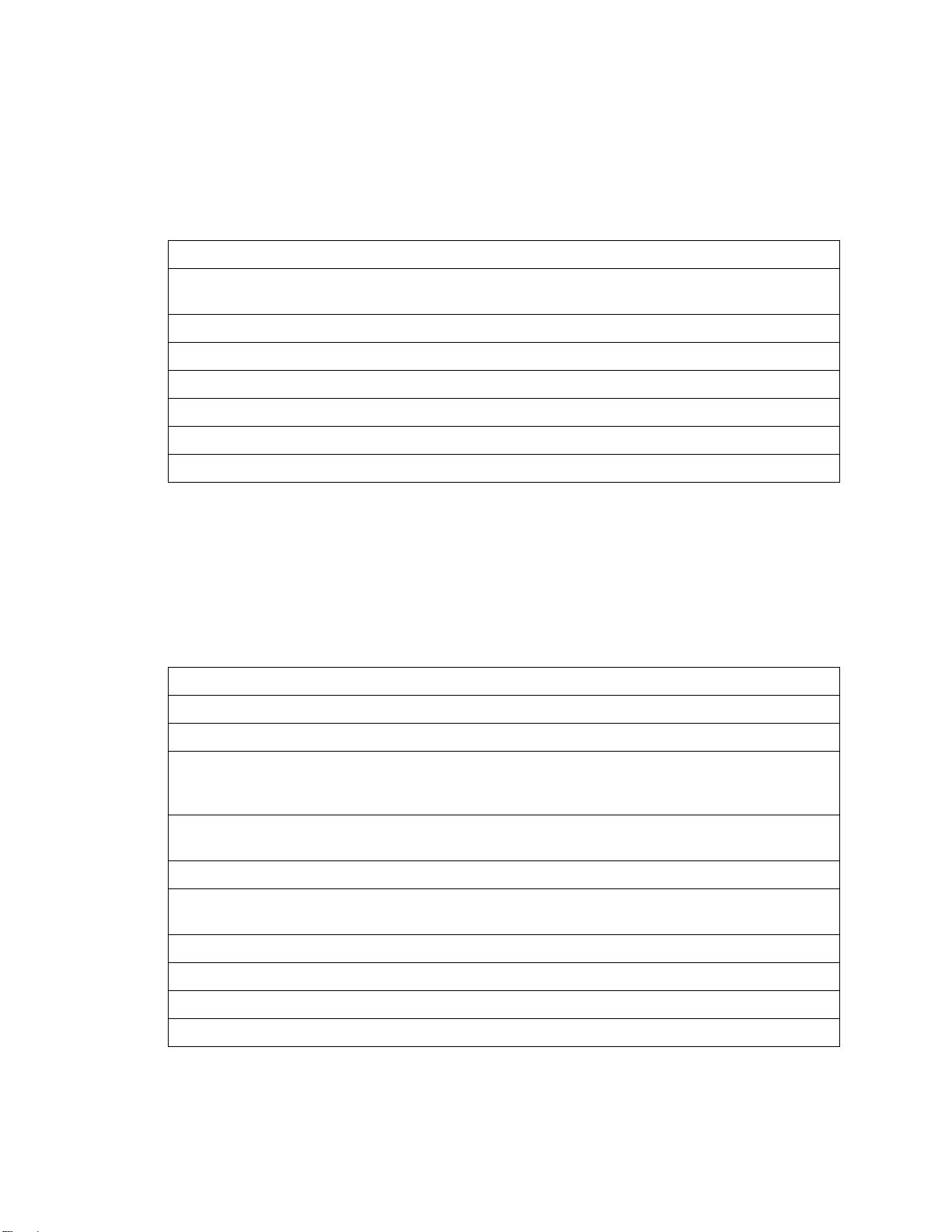

2.2 Dimensions

Cap.

(Tons)

1/2 CB005 11.2 6.2 6.3 8.0 2.7 3.9 1.1 3.5

1 CB010 11.6 6.4 6.3 8.0 2.8 3.9 1.1 4.0

1 1/2 CB015 13.8 6.7 7.2 8.0 3.1 4.4 1.3 4.7

2 CB020 14.8 7.2 8.0 8.0 3.4 4.9 1.4 4.9

2 1/2 CB025 16.5 7.6 9.2 8.0 3.6 5.6 1.6 5.4

3 CB030 20.1 6.7 9.3 8.3 3.1 6.4 1.7 5.8

5 CB050 23.6 7.6 11.1 10.0 3.6 7.6 1.8 6.8

8 CB080 30.3 7.6 14.7 10.3 3.6 10.0 2.9 10.8

10 CB100 29.9 7.6 17.2 14.9 4.4 12.1 2.9 11.6

15 CB150 40.2 10.6 19.4 15.9 4.7 13.3 3.1 12.6

20 CB200 46.5 14.7 29.4 16.3 7.4 14.7 3.2 13.8

Product

Code

Table 2-2 Hoist Di mension s

Headroom

c

(in)

a

(in) b (in) d (ft) e (in) f (in) g (in) x (in)

8

Page 9

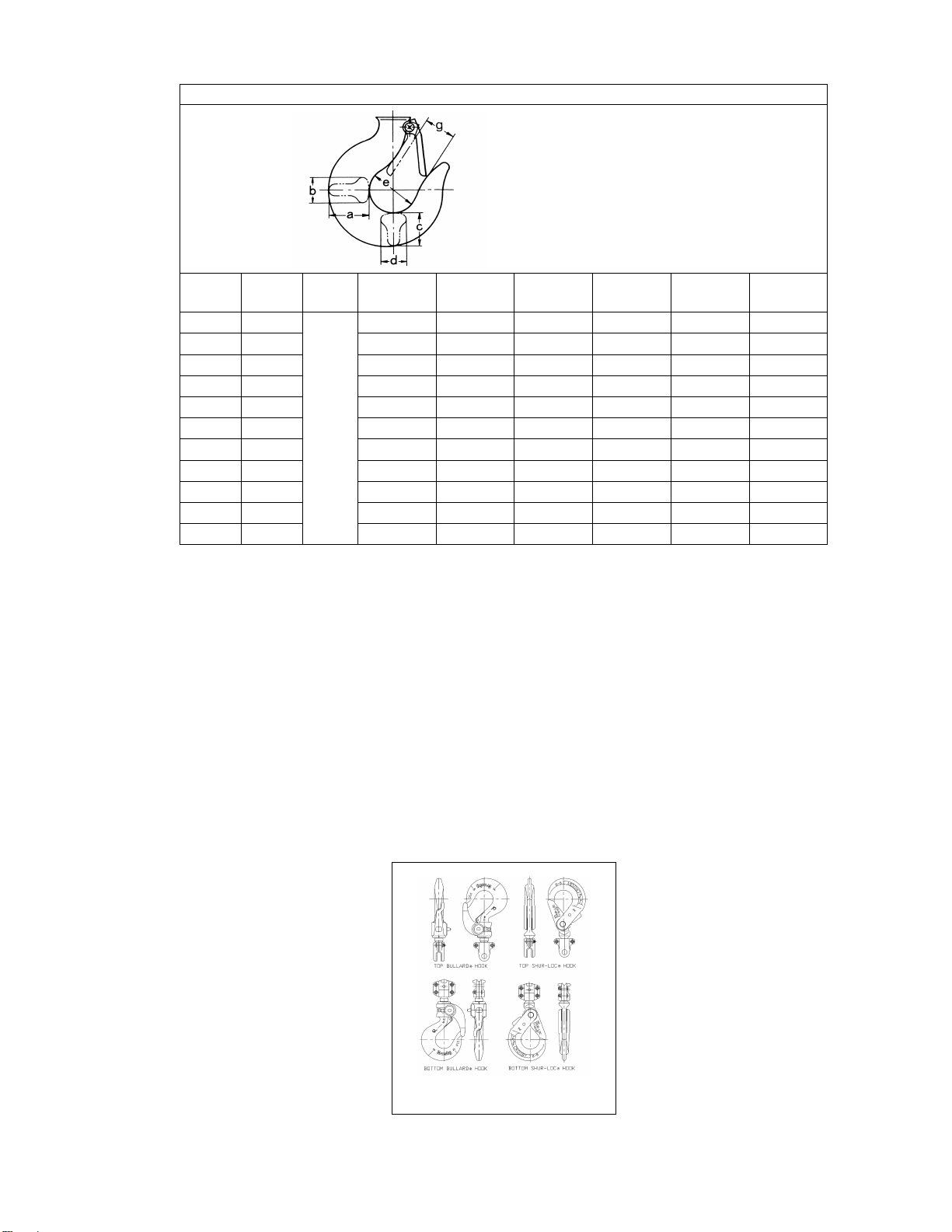

Table 2-3 Hook D imen sion*

T = Top Hook

B = Bottom Hook

Units = inch

Cap.

(Tons)

2 ½ CB025 1.6 1.0 1.3 1.0 2.1 1.6

*Refer to Section 5.7 for in specti on dimension s and limits.

Product

Code

1/2 CB005

1 CB010 1.0 0.6 0.9 0.6 1.7 1.1

1½ CB015 1.2 0.8 1.0 0.8 1.9 1.3

2 CB020 1.4 0.9 1.2 0.9 2.0 1.4

3 CB030 1.8 1.1 1.5 1.1 2.2 1.7

5 CB050 2.2 1.4 1.9 1.4 2.5 1.8

8 CB080 3.0 1.9 2.5 1.9 3.3 2.9

10 CB100 3.0 1.9 2.5 1.9 3.3 2.9

15 CB150 3.7 2.4 3.1 2.4 3.9 3.1

20 CB200 4.2 2.6 3.5 2.6 4.3 3.2

Hook a b c d e g

0.8 0.5 0.7 0.5 1.4 1.1

T & B

2.3 Optional Equipment

2.3.1 Optional Latch Lock Hooks

The Bullard hook has a conventional hook shape with a special, heavy-duty, rotating, spring-

loaded, locking latch. The latch remains locked until it is released by the operator. Refer to Figure

2-6.

The Shur-Loc hook is a special design hook where the latch remains fixed and the hook swings

to unlock. The hook cannot be opened while a load is applied.

Installation of these hooks may change the headroom.

See Section 9.4, Parts List for a complete Latch Lock Hook part listing.

Figure 2-6 Latch Lock Hooks

9

Page 10

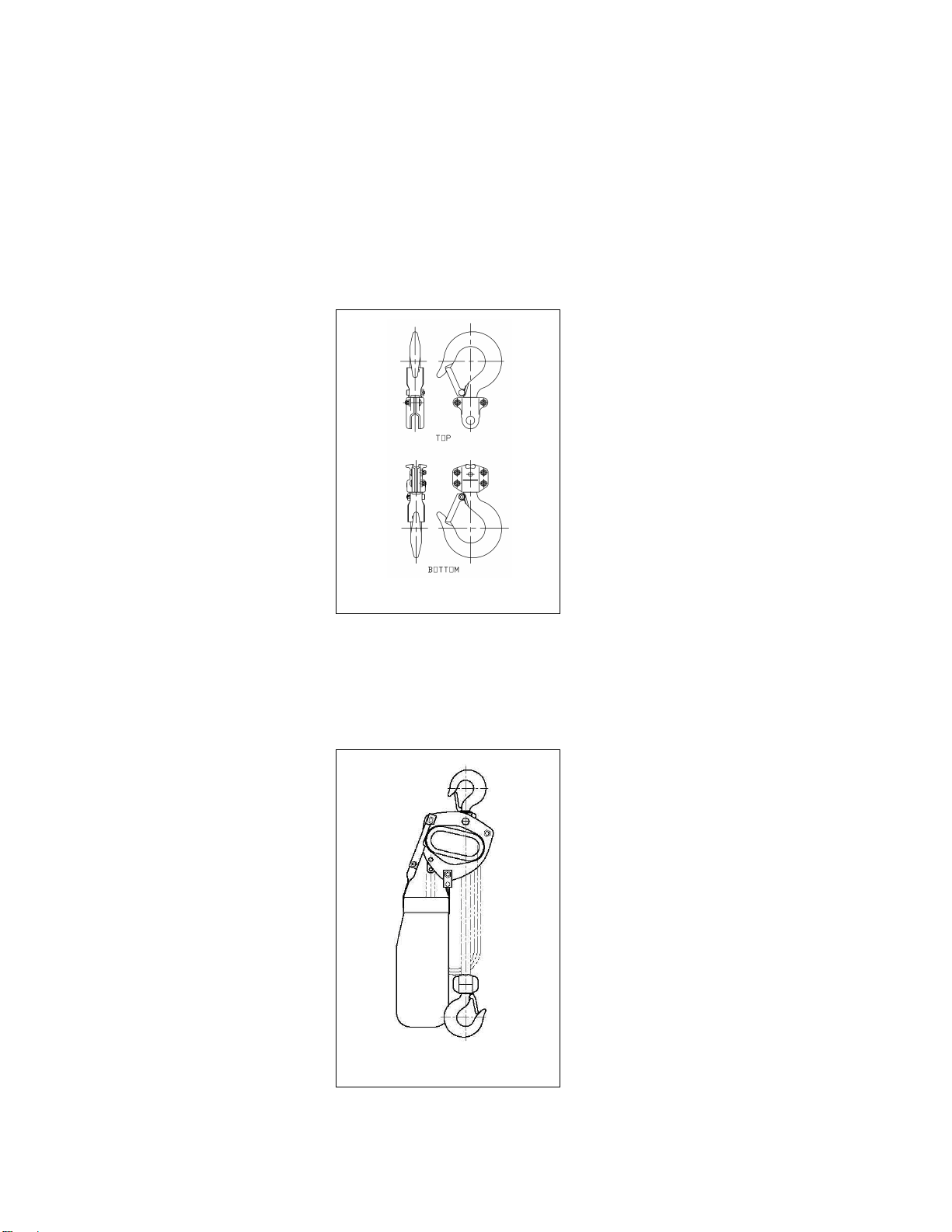

2.3.2 Optional Inspection Hooks

The Inspection Hook is designed to facilitate the inspection of the internal surfaces of the hook

yoke and shank portion of the hook itself. The Inspection Hook is suitable for applications where

inspection of the internal parts of the hook set is required. The inspection hook uses the standard

Harrington hook set and is assembled with high-strength locking fasteners instead of rivets.

Inspection hooks are available in top and bottom versions. Refer to Figure 2-7.

Disassembly and re-assembly involves removal and reinstallation of the yoke fasteners of the

Inspection Hook Set Assembly followed by testing of the hoist prior to returning it to service.

The Inspection Hook is available for CB005 through CB025 hoists.

See Section 9.4, Parts List for a complete Inspection Hook part listing.

Figure 2-7 Inspection Hooks

2.3.3 Optional Chain Containers

Chain containers are sized based on the capacity and lift of the hoist. The containers are

constructed from vinyl coated canvas with a steel frame on top. The containers are prepared

differently depending on the host model. See Harrington document EDOC0154 for sizing

information.

Figure 2-8 CB Chain Container

10

Page 11

3.0 Preoperational Procedu res

3.1 Chain

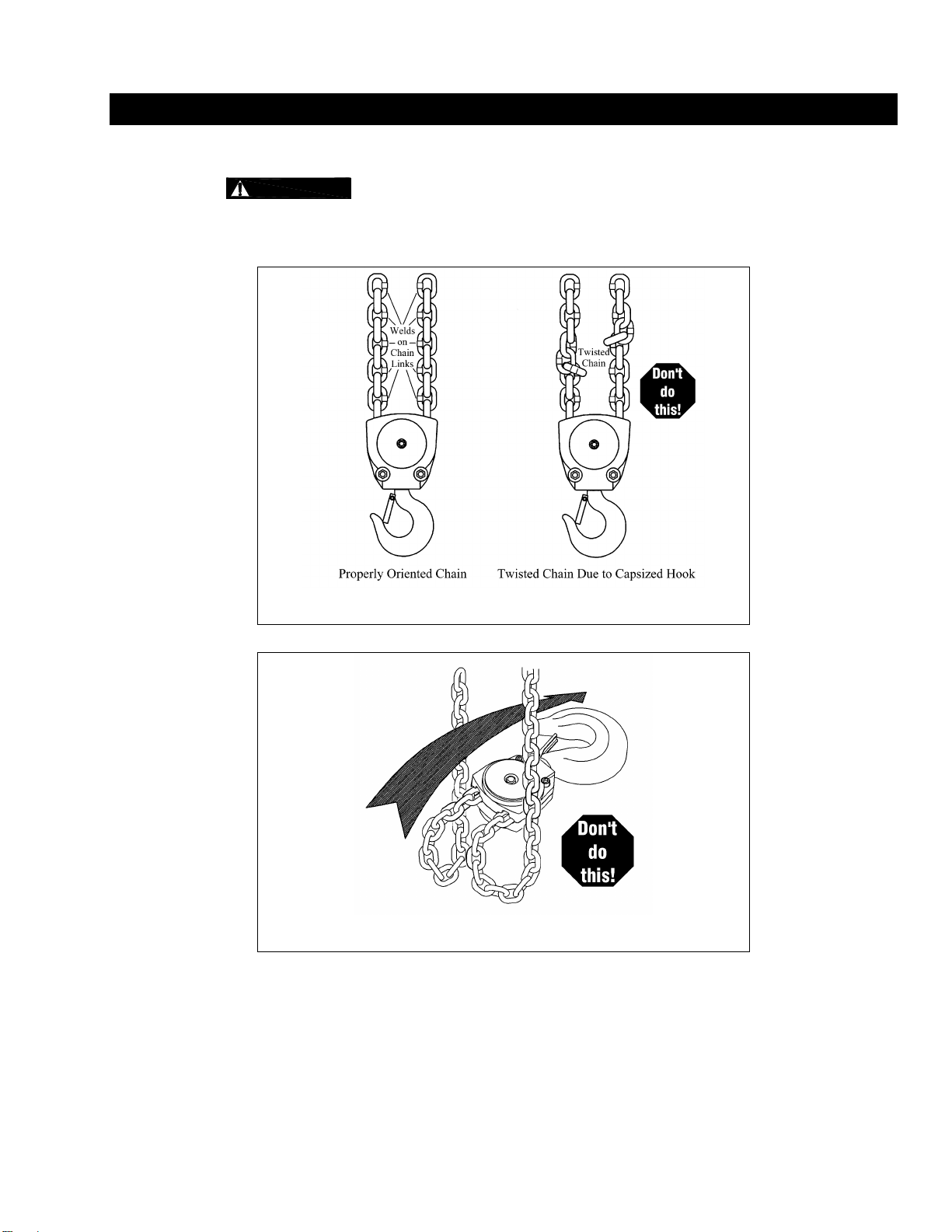

3.1.1

Verify that the load chain is not twisted or tangled prior to operating the hoist.

Make sure the bottom hook on the 3 (CB030) through the 20 (CB200) Ton multiple fall hoists is not

capsized. See Figures 3-1 and 3-2. Correct all chain irregularities before conducting the first hoist

operation.

Figure 3-1 Twist in Load Chain – Double Fall Model

Figure 3-2 Capsized Hook and Chain – Double Fall Model

11

Page 12

3.2 Attachment Points

3.2.1

components and supporting structure are adequate to support the hoist and its load. If necessary

consult a professional that is qualified to evaluate the adequacy of the suspension location and its

supporting structure.

3.2.2

Prior to attaching the hoist ensure that all attachment points, suspension

See Section 6.6 for outdoor installation considerations.

3.3 Mounting the Hoist

3.3.1 Hook Mounted to a Fixed Location - Attach the hoist’s top hook to the fixed suspension point.

3.3.2

that the hook’s latch is engaged.

Ensure that the fixed suspension point rests on the center of the hook’s saddle and

3.4 Preoperation al Ch ecks an d T ria l Op eratio n

3.4.1

other lifting attachments before use. Inspect all load suspension members for damage prior to use and

replace or repair all damaged parts.

3.4.2

Section 3.1.

3.4.3 Measure and record the “k” dimension of all hooks on hoist. See Table 5-4 under Section 5,

“Inspection”.

3.4.4 Record the hoist's Code, Lot and Serial Number (from the name plate on the hoist; see Section 9) in

the space provided on the cover of this manual.

Confirm the adequacy of the rated capacity for all slings, chains, wire ropes and all

Verify and correct all chain irregularities prior to operating the hoist. Refer to

3.4.5 Ensure that the hoist is properly installed to a fixed point.

3.4.6 Ensure that all nuts, bolts and split pins (cotter pins) are sufficiently fastened.

3.4.7 Confirm proper operation.

Before operating read and become familiar with Section 4 - Operation.

Before operating ensure that the hoist meets the Inspection, Testing and Maintenance

requirements of ANSI/ASME B30.16.

Before operating ensure that nothing will interfere with the full range of the hoist’s operation.

12

Page 13

O SEIZURES, LOSS OF

• Read ANSI/ASME B30.16 and ANSI/ASME B30.10.

4.0 Operation

4.1 Introduction

DO

NOT WALK UNDER A SUSPENDED LOAD

HOIST OPERAT ORS SHALL BE REQUIRED TO READ THE OPER ATION SECTION O F THIS MANUAL, THE

WARNINGS CONTAINED IN THIS MANUAL, INSTRUCTION AND WARNING LABELS ON THE HOIST OR

LIFTING SYSTEM , AND THE OPERATION SECTIONS OF ANSI/ASM E B30.16 and ANSI /ASME B30.10. THE

OPERATOR SHALL ALSO BE REQUIRED TO BE FAMILIAR WITH THE HOIST AND HOIST CONTROLS

BEFORE BEING AUTHORIZED TO OPERATE THE HOIST OR LIFTING SYSTEM.

HOIST OPERATORS SHOULD BE TRAINED IN PROPER RIGGING PROCEDU RES FOR THE AT TACHMENT

OF LOADS TO THE HOIST HOOK .

HOIST OPERATORS SHOULD BE TRAINED TO BE AWARE OF POTENTIAL MALFUNCTIONS OF THE

EQUIPMENT T HAT REQUIRE ADJUST MENT OR REP AIR, AND TO BE IN STRUCTED TO STOP OPERAT ION

IF SUCH MALFUNCTIONS OCCUR, AND T O IMMEDIATELY ADVIS E THEIR SUPERVI SOR SO CORRECT IVE

ACTION CAN BE TAKEN.

HOIST OPERAT ORS SHOULD HAVE NORMAL DEPTH PER CEPTION, FIELD OF VISION, REACTIO N TIME,

MANUAL DEXTERITY, AND COORDINATION.

HOIST OPERATORS SHOULD

PHYSICAL CONTROL, PHYSICAL DEFECTS, OR EMOTIONAL INSTABILITY THAT COULD RESULT IN

ACTIONS OF THE OPERATOR BEING A HAZARD TO THE OPERATOR OR TO OTHERS.

HOIST OPERATORS SHOULD NOT

INFLUENCE OF ALCOHOL, DRUGS, OR MEDICATION.

NOT HAVE A HISTORY OF OR BE PRONE T

OPERATE A HOIST OR LIFTING SYSTEM WHEN UNDER THE

• Read the hoist manufacturer’s Operating and Maintenance Instructions.

• Read all labels attached to equipment.

The operation of a hoist involves more than activating the hoist’s c ontr ols. Per the AN SI/A SME B 30 sta ndar ds , th e us e

of a hoist is subject to certain hazards that cannot be m itigated by engineered features, but onl y by the exercise of

intelligence, care, common sense, and experience in anticipating the effects and results of activating the hoist’s controls.

Use this guidance in conjunction with other warnings, cautions, and notices in this manual to govern the operat ion and

use of your hoist.

13

Page 14

4.2 Shall’s and Shall Not’s for Operation

Improper operation of a hoist can create a poten tially haz ardous

situation which, if not avoided, could result in

and substantial property damage. To avoi d such a poten tially

hazardous situation THE OPERATOR SHALL:

NOT

•

•

•

•

lift more than rated load for the hoist.

use damaged hoist or hoist that is not working

NOT

properly.

use hoist with twisted, kinked, damaged, or

NOT

worn chain.

use hoist if the bottom hook is capsized

NOT

(multiple fall hoists - see Section 3.1).

death or serious injury ,

•

•

•

•

leave load s upported b y the hois t unattended

NOT

unless specific precautions have been taken.

allow the chain, or hook to be used as an

NOT

electrical or welding ground.

allow the chain, or ho ok to be touched by a

NOT

live welding electrode.

NOT

remove or obscure the warnings on the hoist.

•

•

•

•

•

•

•

•

•

•

•

use the hoist to lift, support, or transport

NOT

people.

lift loads over people.

NOT

NOT

apply load unless load chain is properly

seated in the load sheave (and idle sheave for hoist

with multiple chain falls).

use the hoist in such a way that could result in

NOT

shock or impact loads being applied to the hoist.

attempt to lengthen the load chain or repair

NOT

damaged load chain.

NOT

operate hoist when it is restricted from forming

a straight line from hook to hook in the direc tion of

loading.

use load chain as a s ling or wrap load chain

NOT

around load.

apply load if binding prevents equal loading

NOT

on all load-supporting chains.

operate beyond the limits of the load chain

NOT

travel.

support load on hook tip unless hook is

NOT

designed for tip loading.

use in a way that causes either hook to be

NOT

side-loaded.

•

NOT

operate a hoist on which the safety placards

or decals are missing or illegible.

• Be familiar with operating controls, procedures, and

warnings.

• Make sure the unit is securely attached to a

suitable support before applying load.

• Make sure load slings or other approved single

attachments are properl y sized, rigged, and seate d

in the hook saddle.

• Take up slack carefully - make sure load is

balanced and load-holding action is secure bef ore

continuing.

• Make sure all persons stay clear of the supported

load.

• Protect the hoist’s load chain from weld splatter or

other damaging contaminants.

• Report Malfunctions or unusual performances

(including unusual noises) of the hois t and remove

the hoist from service until the malfunction or

unusual performance is resolved.

• Warn personnel before lifting or moving a load.

• Warn personnel of an approaching load.

14

Page 15

Improper operation of a hoist can create a poten tially haz ardous

situation which, if not avoided, could result in

injury

, or property damage. To avoid such a potentiall y haz ardous

situation THE OPERATOR SHALL:

minor or moderate

• Maintain a firm footing or be otherwise secured

when operating the hoist.

• Check brake function by tensioning the hoist prior

to each lift operation.

• Use hook latches. Latches are to retain slings,

chains, etc. under slack conditions only.

• Make sure the hook latches are closed and not

supporting any parts of the load.

• Make sure the load is free to move and will clear all

obstructions.

• Av oid swinging the load or hook.

• Make sure hook travel is in the same direction as

shown on controls.

• Inspect the hoist regularly, replace damaged or

4.3 Operation

1) Face the hand chain wheel side of the hoist.

2) To raise the load, pull hand chain clockwise.

3) To lower the load, pull hand chain counterclockwise.

worn parts, and keep appropriate records of

maintenance.

• Use the hoist manufacturer’s recommended parts

when repairing the unit.

• Lubricate load chain per hoist manufacturer’s

recommendations.

use the hoist load limiting or warning device to

NOT

•

measure load.

•

•

•

allow your attention to be diverted from

NOT

operating the hoist.

NOT

allow the hoist to be subjected to sharp

contact with other hoists, structures, or objects

through misuse.

adjust or repair the hoist unless qualified to

NOT

perform such adjustments or repair.

NOTE: The clicking sound of the pawl when a load is being raised indicates normal operation.

4.4 Principle and Operation of the Slip Clutch

: IMPROPER chain hoist use could result in death or serious injury. To avoid these hazards:

: NEVER disassemble or attempt to adjust the slip clutch assemby. Any attempt to do so will void

the warranty. Contact your closest Harrington Distributor if service is required.

The standard slip clutch device prevents the hoist from being used to lift damaging loads beyond the rated capacity of

the manual chain hoist. When an applied load exceeds the preset value, the hand chain wheel rotates idly. The

mechanism is a friction clutch system located between the hand chain wheel and the mechanical brake.

15

Page 16

5.0 Inspection

5.1 General

5.1.1 The inspection procedure herein is based on ANSI/ASME B30.16. The following definitions are from

ANSI/ASME B30.16 and pertain to the inspection procedure below.

Designated Person

duties to which he/she is assigned.

Qualified Person – a person who, by possession of a recognized degree or certificate of

professional standing, or who, by extensive knowledge, training, and experience, has successfully

demonstrated the ability to solve or resolve problems relating to the subject matter and work.

Normal Service – that distributed service which involves operation with randomly distributed loads

within the rated load limit, or uniform loads less than 65% of rated load for not more than 15% of

the time.

Heavy Service – that service which involves operation within the rated load limit which exceeds

normal service.

Severe Service

– that service which involves normal or heavy service with abnormal operating

conditions.

5.2 Inspection Classification

5.2.1 Initial Inspection – prior to initial use, all new, altered, or modified hoists shall be inspected by a

designated person to ensure compliance with the applicable provisions of this manual.

5.2.2 Inspection Classification – the inspection procedure for hoists in regular service is divided into two

general classifications based upon the intervals at which inspection should be performed. The intervals

in turn are dependent upon the nature of the critical components of the hoist and the degree of their

exposure to wear, deterioration, or malfunction. The two general classifications are herein designated

as FREQUENT and PERIODIC, with respective intervals between inspections as defined below.

5.2.3 FREQUENT Inspection – visual examinations by the operator or other designated personnel with

intervals per the following criteria:

– a person selected or assigned as being competent to perform the specific

Normal service – monthly

Heavy service – weekly to monthly

Severe service – daily to weekly

Special or infrequent service – as recommended by a qualified person before and after each

occurrence.

5.2.4 PERIODIC Inspection – visual inspection by a designated person with intervals per the following

criteria:

Normal service – yearly

Heavy service – semiannually

Severe service – quarterly

Special or infrequent service – as recommended by a qualified person before the first such

occurrence and as directed by the qualified person for any subsequent occurrences.

16

Page 17

5.3 Frequent Inspection

5.3.1 Inspections should be made on a FREQUENT basis in accordance with Table 5-1, “Frequent

Inspection.” Included in these FREQUENT Inspections are observations made during operation for

any defects or damage that might appear between Periodic Inspections. Evaluation and resolution of

the results of FREQUENT Inspections shall be made by a designated person such that the hoist is

maintained in safe working condition.

All functional operating mechanisms for proper operation and adjustment, maladjustment and

unusual sounds.

Hoist braking system for proper operation

Hooks and latches in accordance with ANSI/ASME B30.10

Hook latch operation

Load chain in accordance with Section 5.7

Load chain reeving for compliance with Section 3.1 and 6.4

Hoist support for damage

Table 5-1 Frequent Inspection

5.4 Periodic Inspect ion

5.4.1 Inspections should be made on a PERIODIC basis in accordance with Table 5-2, “Periodic Inspection.”

Evaluation and resolution of the results of PERIODIC Inspections shall be made by a designated

person such that the hoist is maintained in safe working condition.

5.4.2 For inspections where load suspension parts of the hoist are disassembled, a load test per ANSI/ASME

B30.16 must be performed on the hoist after it is re-assembled and prior to its return to service.

Requirements of frequent inspection.

Evidence of loose bolts, nuts, or rivets.

Evidence of worn, corroded, cracked, or distorted parts such as load blocks, suspension housing,

chain attachments, clevises, yokes, suspension bolts, shafts, gears, bearings, pins, rollers and

locking and clamping devices.

Evidence of damage to hook retaining nuts or collars and pins, and welds or rivets used to secure

the retaining members.

Evidence of damage or excessive wear of load and idler sheaves.

Evidence of worn, glazed or oil contaminated friction disks; worn pawls, cams or ratchet; corroded,

stretched, or broken pawl springs in brake mechanism.

Evidence of damage to supporting structure.

Table 5-2 Periodic Inspection

Function label on hoist for legibility.

Warning label properly attached to the hoist and legible (see Section 1.2).

End connection of load chain.

17

Page 18

5.5 Occasionally U sed Hoi sts

5.5.1 Hoists that are used infrequently shall be inspected as follows prior to placing in service:

Hoist Idle More Than 1 Month, Less Than 1 Year

Section 5.3.

Hoist Idle More Than 1 Year

5.6 Inspection Records

5.6.1 Dated inspection reports and records should be maintained at time intervals corresponding to those

that apply for the hoist’s PERIODIC interval per Section 5.2.4. These records should be stored where

they are available to personnel involved with the inspection, maintenance, or operation of the hoist.

5.6.2 A long range chain inspection program should be established and should include records of

examination of chains removed from service so a relationship can be established between visual

observation and actual condition of the chain.

5.7 Inspection Methods and Criteria

5.7.1 This section covers the inspection of specific items. The list of items in this section is based on those

listed in ANSI/ASME B30.16 for the Frequent and Periodic Inspection.

5.7.2 Frequent Inspection - Not intended to involve disassembly of the hoist. Disassembly for further

inspection would be required only if frequent inspection results so indicate. Disassembly and further

inspection should only be performed by a qualified person trained in the disassembly and re-assembly

of the hoist.

5.7.3 Periodic Inspection - Disassembly of the hoist is required. Disassambly should only be performed by a

qualified person trained in the disassembly and re-assembly of the hoist.

Table 5-3 Hoist Inspection Methods and C riter ia

: Inspect per FREQUENT Inspection criteria in

: Inspect per PERIODIC Inspection criteria in Section 5.4.

Item Method Discard Limit/Criteria Action

Functional operating

mechanisms.

Visual, Auditory Mechanisms should be properly adjusted and

should not produce unusual sounds when operated.

Components should not be deformed, scarred, or

show significant wear. Refer to Figures 5-2, 5-3 and

5-4.

Hooks – Stretch Measure The "k" dimension should not be greater than 1.05

times that measured and recorded at the time of

purchase (See Section 3.4). If recorded "k" values

are not available for hooks when new, use nominal

"k" values from Table 5-4.

Hooks – Fretting

wear

Hooks – Surface

Condition

Hooks –

Deformation

Hooks – Bent Shank

or Neck

Measure The "u" and "t" dimensions should not be less than

discard value listed in Table 5-4.

Visual Should be free of gouges, deep nicks, dents, weld

splatter, and significant corrosion.

Visual Should be free of twists and deformations. See

Figure 5-1.

Visual Shank and neck portions of hook should be free of

deformations.

Hooks – Swivel Visual, Function Bearing parts and surfaces should not show

significant wear, and should be free of dirt, grime,

and deformations. Hook should rotate freely with no

roughness. See Figure 5-1.

Repair or replace

as required.

Replace.

Replace.

Replace.

Replace.

Replace.

Clean/lubricate, or

replace as required.

18

Page 19

Table 5-3 Hoist Inspection Methods and C riter ia

Item Method Discard Limit/Criteria Action

Hooks – Yoke

Assembly

Hooks – Idle Sheave

and Shaft (Multiple

Fall Hoist)

Hooks – Hook

Latches

Yoke – Top Pin Hole

Deformation

Top Pin –

Deformation

Yoke – Chain Pin

Hole Deformation

Visual Should be free of significant rust, weld splatter,

nicks, and gouges. Holes should not be elongated,

fasteners should not be loose, and there should be

no gap between mating parts.

Visual, Function Pockets of Idle Sheave should be free of significant

wear. Idle Sheave surfaces should be free of nicks,

gouges, dirt, and grime. Bearing parts and surfaces

of Idle Sheave and Axle should not show significant

wear. Idle Sheave should rotate freely with no

roughness or significant free play.

Visual, Function Latch should not be deformed. Attachment of latch

to hook should not be loose. Latch spring should

not be missing and should not be weak. Latch

movement should not be stiff - when depressed and

released latch should snap smartly to its closed

position.

Visual, Measure The "d" dimension of the top pin hole should not be

greater than the discard value listed in Table 5-5.

Visual, Measure The pin should be free of scars or significant

deformation. The “d" dimension should not be less

than discard value listed in Table 5-6.

Measure The "d" dimension of the chain pin hole should not

be greater than the discard value listed in Table 5-5.

Tighten or replace

as required.

Clean/lubricate, or

replace as required.

Replace.

Replace Hook Set

Replace

Replace Hook Set

or yoke.

Chain Pin –

Deformation

Load Chain – Pitch

and Wire Diameter

Load Chain –

Surface Condition

Load Chain –

Lubrication

Load Chain –

Reeving

Lifting System –

Components

Visual, Measure The pin should be free of scars or significant

deformation. The “d" dimension should not be less

than discard value listed in Table 5-7.

Measure The "P" dimension should not be greater than

discard value listed in Table 5-8. The "d" dimension

should not be less than discard value listed in Table

5-8.

Visual Should be free of gouges, nicks, dents, weld

splatter, and corrosion. Links should not be

deformed, and should not show signs of abrasion.

Surfaces where links bear on one another should

be free of significant wear.

Visual, Auditory Entire surface of each chain link should be coated

with lubricant and should be free of dirt and grime.

Chain should not emit cracking noise when hoisting

a load.

Visual Chain should be reeved properly through Load

Sheave. On multiple fall hoists chain should be

installed properly and free of twists. Refer to

Section 3.1.

Visual, Function Components should not be deformed, scarred, or

show significant wear.

Replace

Replace. Inspect

Load Sheave (and

Idle Sheave for

multiple fall hoists).

Replace.

Clean/lubricate (see

Section 6.0).

Reeve/Install chain

properly.

Replace.

19

Page 20

Table 5-3 Hoist Inspection Methods and C riter ia

Item Method Discard Limit/Criteria Action

Braking System –

Components

Brake – Damage to

Brake Surface

Braking System –

Friction Disc

Braking System –

Friction Plate

Braking System –

Bushing

Braking System –

Bushing

Braking System –

Ratchet Disc

Visual Brake Pawl, Pawl Pin, and Pawl Spring should not

be deformed, scarred, or show significant wear.

Refer to Figure 5-2 (34 & 33).

Visual Damage due to scratching or gouging by foreign

matter. Refer to Figure 5-2 (37, 38, & 40).

Visual The surface of the friction plate should be free of

scars, gouges, and wear. Refer to Figure 5-2 (36).

Visual, Measure The surface of the friction plate should be free of

grease, oil, scars, gouges and wear and have

uniform thickness. The outer thickness should not

be thinner than the inner thickness. The thickness

should not be less than the discard value listed in

Table 5-9.

Measure The bushing should have uniform thickness. The “t”

dimension should not be less than the discard value

listed in Table 5-10.

Visual When slightly heated, the bushing should be so

lubricated that lubricant oozes off the surface. Refer

to Figure 5-2 (39). Type of oil to be used: ISO

VG68 or equivalent.

Measure The “D” dimension should not be less than the

discard value listed in Table 5-11.

Replace.

Replace.

Replace.

Replace.

Replace.

Soak bushing in

machine oil for one

day.

Replace.

Refer to Figure 5-2 (38).

Load Sheave Visual Pockets of Load Sheave should be clean and free

Replace.

of significant wear. Refer to Figure 5-3 (14).

Load Gear Visual Teeth have excessive wear or damage. Refer to

Replace.

Figure 5-4 (25).

Hand Wheel Visual Large wear or deformation on the surface of hand

Replace.

wheel. The hand wheel touches the cover.

Frame and

Mechanical

Components

Visual, Auditory,

Function

Hoist components including load blocks,

suspension frame, chain attachments, clevises,

yokes, suspension bolts, shafts, gears, bearings,

Replace.

stripper, pins, and rollers should be free of cracks,

distortion, significant wear, and corrosion. Evidence

of same can be detected visually or via detection of

unusual sounds during operation. Refer to Figures

5-4 & 5-5.

Chain Guide Visual Excessive wear or press mark. Replace.

Bolts, Nuts and

Rivets

Warning Labels Visual Warning Labels should be affixed to the hoist (see

Visual, Check

with Proper Tool

Bolts, nuts, and rivets should not be loose,

deformed, or corroded.

Tighten or replace

as required.

Replace.

Section 1.2) and they should be legible.

Hoist Capacity Label Visual The label that indicates the capacity of the hoist

Replace.

should be legible and securely attached to the hoist.

20

Page 21

Figure 5-1 Top & Bottom Hook Checks

Table 5-4 Top Hook & Bottom Hook Dimens ions

Standard

Discard

Standard

Discard

Twisted Hook

Hook Swivel

“k” Measured When New:

Top: _________________________

Bottom: ______________________

Nominal "k"

Product Code

CB005 1.76 (44 .6) 0.67 (17.0) 0.60 (15.3) 0.48 (12.1) 0.43 (10.9)

CB010 1.92 (48 .8) 0.86 (21.8) 0.77 (19.6) 0.63 (16.0) 0.57 (14.4)

CB015 2.22 (56 .3) 1.04 (26.5) 0.94 (23.9) 0.77 (19.5) 0.69 (17.6)

CB020 2.36 (59 .9) 1.18 (30.0) 1.06 (27.0) 0.86 (21.8) 0.77 (19.6)

CB025 2.52 (64.1) 1.32 (33.5) 1.19 (30.2) 0.96 (24.3) 0.86 (21.9)

CB030 2.72 (69 .1) 1.48 (37.5) 1.33 (33.8) 1.07 (27.2) 0.97 (24.5)

CB050 3.06 (77 .8) 1.87 (47.5) 1.69 (42.8) 1.36 (34.5) 1.22 (31.1)

CB080 4.56 (115.9) 2.48 (63.0) 2.23 (56.7) 1.87 (47.5) 1.69 (42.8)

CB100 4.56 (115.9) 2.48 (63.0) 2.23 (56.7) 1.87 (47.5) 1.69 (42.8)

CB150 5.52 (140.2) 3.15 (80.0) 2.84 (72.0) 1.97 (50.0) 1.77 (45.0)

CB200 5.62 (142.8) 3.54 (90.0) 3.19 (81.0) 2.21 (56.0) 2.09 (53.1)

Dimension*

inch (mm)

"u" Dimension

inch (mm)

"t" Dimension

inch (mm)

*These values are nominal since the dimension is not controlled to a tolerance. The "k"

dimension should be measured when the hook is new - this becomes a reference measurement.

Subsequent measurements are compared to this reference to make determinations about hook

deformation/stretch. See Section 5.7, “Hooks - Stretch”.

21

Page 22

Table 5-5 Chain Pin Hole and Top Pin Hol e Wear D imensions

Table 5-7 Chain Pin Wear Dimensions

Hole Diameter (d)

Product Code

CB005 0.252 (6.4) 0.272 (6.9) 0.480 (12.2) 0.500 (12.7)

CB010 0.319 (8.1) 0.339 (8.6) 0.480 (12.2) 0.500 (12.7)

CB015 0.350 (8.9) 0.370 (9.4) 0.638 (16.2) 0.658 (16.7)

CB020 0.394 (10.0) 0.413 (10.5) 0.638 (16.2) 0.658 (16.7 )

CB025 0.445 (11.3) 0.465 (11.8) 0.638 (16.2) 0.658 (16.7)

CB030 0.350 (8.9) 0.370 (9.4) 0.646 ( 16.4 ) 0.665 (16.9)

CB050, CB080,

CB100

CB150 0.445 (11.3 ) 0.465 (11.8) 0.638 (16.2) 0.658 (16.7)

CB200 N/A N/A 0.638 (1 6.2) 0.658 (16.7)

Chain Pin Hole

inch (mm)

Standard Discard Standard Discard

0.445 (11.3) 0.465 (11.8) 0.646 (16.4) 0.665 (16.9)

Top Pin Hole

inch (mm)

Table 5-6 Body Top Pin Wear Di mensions

Product Code

CB005, CB010

CB015, C B020,

CB025, CB030,

CB050, C B080,

CB100, CB150,

CB200

“d” Dimension

inch (mm)

Standard Discard

0.472 (12) 0.433 (11)

0.630 (16) 0.591 (15)

Product Code

CB005 0.244 (6.2) 0.23 2 (5 .9)

CB010 0.311 (7.9) 0.29 5 (7 .5)

CB015, C B030 0.343 (8.7) 0.327 (8 .3)

CB020 0.386 (9.8) 0.370 (9.4)

CB025, CB050,

CB080, CB100,

CB150

“d” Dimension

inch (mm)

Standard Discard

0.437

(11.1)

0.417

(10.6)

22

Page 23

Table 5-8 Chain Wear Dimens ions

Product Code

CB005 2.97 (75.5) 3.06 (77.7) 0.20 (5.0) 0.18 (4.5)

CB010 3.76 (95.5) 3.87 (98.3) 0.25 (6.3) 0.22 (5.7)

CB015, CB030 4.17 (106.0) 4.30 (109.1) 0.28 (7.1) 0.25 (6.4)

CB020 4.76 (121.0) 4.91 (124.6) 0.32 (8.0) 0.28 (7.2)

CB025, CB050,

CB080, CB100,

CB150, CB200

“P” Dimension

inch (mm)

Standard Discard Standard Discard

5.35 (136.0) 5.51 (140.0) 0.35 (9.0) 0.32 (8.1)

“d” Dimension

inch (mm)

Figure 5-2 Brake Assembly

23

Page 24

Thickness

Standard

Discard

inch (mm)

inch (mm)

Table 5-9 Friction Plate Wear Dimensions

Product Code

All

0.118 (3.0) 0.098 (2.5)

inch (mm)

Table 5-10 Brake Bushing Wear Dimensions

A Dimension

Product Code

CB005, C B010,

CB015, CB030

CB020, CB025,

CB050, CB080,

CB100, CB15 0,

CB200

Standard Discard

0.118 (3.0) 0.07 9 (2 .0)

0.157 (4.0) 0.118 (3.0)

Table 5-11 Brake Ratchet Disc Wear Dimensions

D Dimension

Product Code

CB005, C B010,

CB015, CB030

CB020

CB025, CB050,

CB080, CB100,

CB150, CB200

Standard Discard

2.71 (69) 2.60 (66)

3.23 (82) 3.11 (79)

4.65 (118) 4.53 (115)

24

Page 25

Figure 5-3 Pocket Wheel

Figure 5-4 Load Gear Assembly

Figure 5-5 Top Hook Assembly

25

Page 26

6.0 Maintenance and H andling

6.1 Lubrication

6.1.1 Load Chain

For longer life, the load chain should be lubricated.

The load chain lubrication should be accomplished after cleaning the load chain with an acid free

cleaning solution.

Apply Harrington lubricating grease (Part No. ER1BS1951) or an equivalent to industrial general

lithium grease, NLGI No. 0, to the bearing surfaces of the load chain links as indicated by the

shaded areas in Figure 6-1. Also apply the grease to the areas of the load chain (shaded areas in

Figure 6-1) that contact the load sheave. Insure that the grease is applied to the contact areas in

the load sheave pockets.

Machine or gear oil (grade ISO VG 46 or 68 oil or equivalent) may be used as an alternative

lubricant but must be applied more frequently.

Figure 6-1 Chain Grease Application

The chain should be lubricated every 3 months (more frequently for heavier usage or severe

conditions).

For dusty environments, it is acceptable to substitute a dry lubricant.

6.1.2 Hooks and Suspension Components:

Hooks – Bearings should be cleaned and lubricated at least once per year for normal usage.

Clean and lubricate more frequently for heavier usage or severe conditions.

Hook Yokes and Latches – Lubricate the hook yokes and hook latches at least twice per year for

normal usage; more frequently for heavier usage or severe conditions.

Suspension Pins - Lubricate the chain pin and the top pin at least twice per year for normal usage;

more frequently for heavier usage or severe conditions.

6.1.3 Applying Grease to Gears:

Remove gear case as instructed in Section 6.3.

Remove old grease and replace the new grease (NLGI No. 3), at annual inspection.

Temperature range of standard grease is -20˚C (-4˚F) to + 60˚C (140˚F). If the hoist is used at

temperatures below -20˚C (-4˚F) or above 60˚C (140˚F), consult the manufacturer or dealer since

some parts should be changed.

Table 6-1 General Lubrication

Parts to be Lubricat ed Name of Oil

Mechanical Brake P arts:

Ratchet Disc, P aw l Pin,

Screw parts of Pini on

Machine or

Gear Oil

Amount of Lubrication

and Lubricating Method

Wipe off oil with w aste

cloth after applying

proper amount of oil.

Frequency of

Lubrication

When the hand pull

becomes extremely heavy

in lowering operat ions.

26

Page 27

Table 6-2 Tools Required fo r Hoist D isassem bly

6.2 Disassembly , Assembly and Adjustment

6.2.1

1) Perform proper disassembly or assembly in accordance with this manual.

2) The hoist utilizes dry friction plates; they are not to be lubricated.

3) Do not extend the load chain.

4) Remove old grease on the disassembled parts.

5) Replace components with Harrington Hoist approved parts.

6) To reassemble, apply new grease, and use a new split pin and snap ring.

6.2.2 Tools – The following tools are required to disassemble/reassemble the hoist.

No. Tool Operation

1 Snap ring pliers Opening a snap ring

2 Metric socket wrenches Slotted nuts

3 Metric hex keys (Allen wrenches) Socket head cap screws

4 Metric wrenches Bolts and nuts

5 Phillips screwdriver Machine screws

6 Pliers (Needle Nose) Split pins

7 Soft-face (Dead blow) hammer

8 Wooden Blocks Elevate hoist

6.3 Hoist Disassemb ly

Proceed as follows (Note: Figures in brackets are Figure Numbers in Parts List):

1) Orient a hoist with wheel cover side up.

2) Unscrew three nuts [45] (with the spring washers [46]) fixing the wheel cover [44] and remove the

wheel cover from the side plate A [11].

3) Remove the hand chain [48] from the hand wheel [40].

4) Pull out the split pin [43] from the wheel stopper pin [42] and remove the wheel stopper pin and the

wheel stopper [41] from the pinion [17].

*NOTE: If the hoist has an over load limiter, instead of step 4, remove the left hand threaded nut from

the pinion.

5) Remove the hand wheel [40] from the pinion [17] by turning the hand wheel counterclockwise.

*NOTE: If the hand wheel is too tight to turn by hand, put the hand chain back on the hand wheel and

pull it down hard. It will release the brake.

6) Remove two friction plates [37], the ratchet disc [38] and the bushing [39] from the friction disc [36].

7) Unscrew the friction disc [36] from the pinion [17] by turning counterclockwise holding the end of

the pinion with your fingers.

8) Remove the snap ring [35] from the pawl pin (on the side plate A) and then remove the pawl [34]

and pawl spring A [33] and B [33].

27

Page 28

9) For 8 ton capacity and under:

Pull the split pin [24] out from the stopper pin [23] and remove the load chain [47] and the stopper

pin from the stopper [22].

10) For 10 ton capacity and above:

Pull the split pin [52] out from the end pin [51] and remove the load chain [47] and the end pin.

Unscrew two socket bolts (with the spring washers) fixing the stoppers [114] and remove the

stoppers.

11) Remove the load chain [47] from the load sheave [14] by pulling the load chain toward the bottom

hook.

12) Remove the split pin [5] from the top pin [4], then remove the top pin and the top hook [1] from the

side Plate A [11] and B [13].

13) Place hoist with gear case side (or nameplate side) up.

14) Unscrew three nuts [31] (with the spring washers [32]) fixing the gear case [29], remove the gear

case from the side plate B [13], and remove the ball bearing [28] from the gear case.

15) Remove two pairs of the gear #2 [27] (1/2T has one pair) from the side plate B [13].

16) Remove the snap ring [26] from the load sheave [14], then the load gear [25] from the load

sheave.

17) Remove the side plate B [13] from the side plate A [11] and then take the ball bearing [16] out

from the side plate B.

18) Remove the guide rollers [20], load sheave (attached to the pinion [17]), stripper [21] and the

anchorage (stopper) [22] (for 10 Ton capacity and above: cross guide [53]) from the side plate A

[11], then remove the ball bearing [15] from the side plate A.

19) Remove the snap ring [19] in the load sheave [14].

20) Remove the pinion [17] and the roller bearing [18] from the load sheave [14].

*NOTE: Hold the load sheave by hand and remove the bearing by tapping the pinion with a rubber

mallet.

21) Pull the split pin [10] out from the slotted nut [9] and remove the slotted nut and chain pin from the

bottom hook [6].

6.4 Hoist Assembly

6.4.1

Inspect and replace any worn or damaged parts per Table 5-3.

Secure all nuts, bolts and split pins firmly.

Replace all split pins and retaining rings.

6.4.2 Assembly

1) Apply grease t o the rollers of the roller bearin g [18] and ins ert the pinion [17] ( from t he side of the

brake screw) into the ro ller bearing and inser t them together into t he load sheave [ 14]. Fix them

with a snap ring [19].

*NOTE: The arrow* on the outer side of the roller bearing should face the gear side. When

inserting, use a screwdriver on the bearing and tap it with a rubber mallet. See Fig. 6-1.

: Always make sure that the snap ring is correctly seated.

28

Page 29

Figure 6-1 Load S heave/P inion As sembly

2) Grease the bal ls of the ball bearing [15]. Or ient side pla te A [11] with br ake cover s ide down and

insert the ball bearing [15] (with a snap ring side up) into the side A.

3) Insert the load shea ve [14] w ith a part of s pline side (pini o n gear side) up into the ba ll bear ing [15].

The stripper [21] must be inserted as well. See Figure 6-2.

Figure 6-2 Side Plate / Load Sheave Assembly

4) For 8 ton capacity and below:

Put the guide rollers [20] and the anchorage (stopper) [22] in the side plate A [11].

For 10 ton and larger capacities:

Put the guide rollers [20] and the cross guide [53] in the side plate A [11].

*NOTE: Put the cross guide so that the longer are fits to the side plate A.

5) Grease the bal ls of the ball bearing [16]. Ins ert it with the snap ring sid e down to the shaft of the

load sheave [14]. See figure 6-3.

*NOTE: Make sure the snap ring side of the ball bearing is oriented toward the load sheave.

29

Page 30

Figure 6-3 Side Plate Assembly

6) Join the side plate B [13] to the side plate A [11].

*NO TE: In case it is diff icult to join the two, tap it with a rubber mallet. Be caref ul not to let the

stripper, guide roller or stopper fall down.

7) Mesh the load gear [25] with the splines of the load sheave [14] and fix it with a snap ring [26].

: Always make sure the snap ring is completely seated at the bottom of the

groove.

8) Grease the two pa irs of the gear #2 [27], the load gear [25], and the gear of the pinion [17]. Put

them in the gear plain bearing (bearing A) of the side plate B [13]. Letters “O” and “V” on the gears

must face each other as sho wn in figure 6-4 belo w. Do not for get to appl y grease to the bos s on

the both sides of the gear #2.

*NOTE: It is not necessary to adjust the letters in case of the 1/2T model, for it has only one pair of

the gear #2.

Figure 6-4 Gear Train Assembly

9) Grease the bal ls of the ball bearing [28] and i nsert it with the snap ring down into th e end of the

pinion [17] shaft.

10) Join the gear case [29] to the side plate A [11] and fix them with the three spring washers [32] and

nuts [31].

30

Page 31

11) Place the top hook [1] between side plates A [11] and B [13]. Then insert top pin [4] and fix it with

the split pin [5].

12) Place the hand wheel [40] side upward.

13) Reeve the load chain [47] turning the pinion clockwise through the space between the left (bottom

hook side) guide roller [20] and the load sheave [14]. See figure 6-6.

load sheave. Pull it out between the right guide roller (no load side) and the load sheave.

: Always bend the split pin securely after inserting it into the top pin.

Figure 6-5 Gear Train Assembly

: Put the welded part of the vertical chain link outward and reeve it through the

For 10 ton capacities and above, pass the no load end of the chain through the cross guide [53].

*NOTE: It is recomm ended for this process to position the unit s o that the side plate A [11] faces left

and the side plate B [13] faces right.

31

Page 32

Figure 6-6 Reeving Assembly

14) For 8 ton capacity and below:

Pull the end of the load chain [47] out between the right guide roller [20] and the loa d sheave [14]

(no load side) and insert it to the anchorage (stopper) [22]. Insert the stopper pin [23] and fix it with

a split pin [24].

: Make sure the load chain is not twisted and the split pin in the stopper pin is bent

securely.

Figure 6-7 8 Ton & Below Anchorage Assembly

32

Page 33

For 10 ton capacity and above:

Connect the no load end of the load chain [47] to the end pin [51] which is to be inserted from gear

case [29] side. Use a split pin [52] to secure the end pin. Assemble stoppers [114] to the ninth link

from the no load end of the load chain by socket bolts and spring washers.

*NOTE: Threaded hole of one stopper shall face to non-threaded hole of the other stopper.

Socket bolt shall be inserted from the non-threaded side.

Figure 6-8 10 Ton & Above Anchorage Assembly

15) Apply m achine oil to the pawl pin (in s ide plate A [11]) and j oin the pawl spring A [33], and B [33]

and the pawl [34] respectively to it. Fix them with a snap ring [35]. See figure 6-9.

seated at the bottom of the groove.

16) Attach the friction disc [36] to the pinion [17] shaft (while turning the pawl [34] counterclockwise).

17) Wipe out any dirt on the friction disc [36], friction plates [37] and both sides of the ratchet disc [38]

and check if the oil of the bushing [39] (bushing with o il in it) is adequate. T hen place the f rict ion

plate, bushing, ratchet disc and f ric tion plate res pec tively on the friction disc. (Mak e sure that the

ratchet disc and the pawl mesh properly). See figure 6-9.

and dirt on the brake. The gear of the ratchet disc should point at the pawl. Otherwise, the hand wheel

cannot be assembled later. In case the bushing does not have oil inside, soak it in turbine oil for a day.

Install it without wiping the oil.

: Make sure the pawl spring is touching the pa wl and the snap ring is com pletely

: Since the brake is a “dry system ” , NEVER apply oil. Wipe out thoroughly an y oil

33

Page 34

Figure 6-9 Pawl & Brake Assembly

18) Wipe out any dirt on the brake surface of the hand wheel [40] and apply machine oil to the

threaded part of it. Screw it on the pinion [17] shaft all the way down.

19) Place the wheel stopper [4 1] on the h ead of the pi nion [17], inser t the wheel s topper pin [42] and

fix it with a split pin [43].

: Never forget to bend the split pin after inserting into the wheel stopper pin.

20) Put the hand chain [48] around the hand wheel [40]. See figure 6-10.

Figure 6-10 Hand Wheel Assembly

34

Page 35

21) Assem ble the wheel cover [44] to the s ide plate A [11] and f ix them with the spring washer [46]

and the nut [45].

22) Insert the oth er end of the load c hain [47] to the bottom hook [6] and fix them with the chain pin

[8], slotted nut [9] and split pin [10]. See figure 6-11.

: Always bend the split pin securely.

Figure 6-11 Bottom H ook A ssembly

6.5 Storage

6.5.1

hazards:

ALWAYS store the hoist in a no load condition.

ALWAYS wipe off all dirt and water.

ALWAYS oil the chain, hook pins and hook latches.

ALWAYS hang in a dry place.

ALWAYS check the hoist for abnormalities (according to the regular inspection procedures) when

using the hoist after a period of non-use (Refer to section 5.5).

: IMPROPER chain hoist use could result in death or serious injury. To avoid these

6.6 Outdoor Installation

6.6.1 For hoist installations that are outdoors, the hoist should be covered or brought inside when not in use.

6.6.2 Possibility of corrosion on components of the hoist increases for installations where salt air and high

humidity are present. Make frequent and regular inspections of the hoist’s condition and operation

35

Page 36

Pawl shaft

Pawl

7.0 Troubleshooting

Read and comply with instructions in this manual and use the hoist properly.

Checking the sounds from the hoist in operation is a critical inspection. Note hoist sounds during operation.

If a defect is found in the hoist, stop using it immediately and check the cause of the defect.

Only Trained and competent personnel should inspect and repair the hoist.

Table 7-1 Troubleshooting Guide

Note on proper operation:

When lifting, the hoist should make clicking sounds when moving the hand wheel.

When lowering, the hoist should not make clicking sounds when moving the hand wheel.

Symptom Cause Remedy

Hoist will not lift –

Slight clicking

Hoist will not lift –

Not Clicking

Hoist will not lift –

Hand wheel will not

operate

Improper assembly of ratchet disc, disc

installed backwards, and making incorrect

contact with the pawl.

Reassemble the pawl and ratchet disc

properly. Ensure that clicking sounds are

heard before reuse.

Clean and lubricate pawl and pawl shaft.

Pawl not engaging ratchet disc:

Dirt or corrosion between pawl and pawl

shaft.

Faulty pawl spring Replace pawl spring

Loose selector pawl spring Perform hoist maintenance.

Reassemble gears properly and ensure

smooth operation before reuse.

Ensure the ‘0’ & “V”

marks of gear #2 are aligned properly, as

shown.

Gear #2 improperly timed

36

Page 37

Twisted Chain

Capsized Hook and Chain

Double Fall Models

Symptom Cause Remedy

Hoist will lift

intermittently –

Slight or irregular

clicking

During operation, hoist

idles or load drifts

Poor pawl movement caused by faulty pawl

spring. The spring is loose or damaged.

Mis-assembly of pawl spring

Poor contact of load sheave and load chain

caused by improper chain-reeving.

Perform maintenance and/or repair.

Reassemble it properly and ensure to check

click sound of the pawl before reuse.

Reassemble properly and ensure proper

lifting before reuse.

Reset the capsized hook.

Hoist will not lift all the

way (multiple fall

hoists)

Hoist does not lift load

smoothly.

Capsized hook

Improper assembly of gear OR bearing

broken.

Disassemble and reassemble gear train

and/or replace bearing.

37

Page 38

Improper braking may cause improper load lowering. The hoist utilizes dry friction discs; do not

apply oil to friction surfaces.

Table 7-1 Troubleshooting Guide

Symptom Cause Remedy

Over tightened brake

Pull down hard (possibly with 2 people) on

the hand chain to loosen brake.

Replace the rusty components and perform

hoist maintenance.

Remove the object and clean the surfaces.

Replace if the friction surface is scarred.

Replace the rusty component and perform

hoist maintenance.

Reassemble properly as shown and ensure

hoist functions properly before reuse.

Load will not go down

The hoist left under load for a long period

Shock loaded during operation

Brake rusted tight

A foreign object between friction surfaces.

Brake slip caused by significant rust

Mis-assembly of friction plates, i.e. friction

plates missing or at one side as shown.

Load drifts or slips

when lowering

Cracked friction plate caused by overload

Replace the friction plate and use the hoist

properly within rated capacity.

Friction plate wear caused by very frequent

and long term use.

38

Perform hoist maintenance.

Page 39

8.0 Warranty

All products sold by Har ring ton Hoists , Inc. are warr anted to be free fro m defects in material and

workmanship from date of shi pment by Harring ton for the foll ow ing periods:

Manual Hoists, Trolleys, & B eam C lamp s - 2 y ears

NER/ER Hoists En han ced Feat ur es Mod els – 3 years

Electric Hoists, Air Hoists & Trolleys, Crane Components - 1 year

Spare / Replace ment Par ts - 1 year

NER/ER “The Guardian” Electromagn eti c Sm art Te chn ology Brake – 10 years

The product mus t be us ed i n acc ord ance w i th ma nufact ur er’s r ec ommend atio ns and must not hav e

been subject t o ab use, l ack o f mai nte nance , misuse, neg li gence, or unaut horiz ed repairs or

alterations.

Should any de fect i n m aterial or w orkma nshi p occ ur during t he ab ove t ime peri od i n a ny pr odu ct,

as determined by H arri ng ton Hoi st ’s ins pec tion of the pro duc t, H arri ngton H oi sts, Inc . agr ees , at i ts

discretion, eit her to r epl ace ( not incl udi ng i nstal l atio n) or r epai r the p art or pr oduc t free of c harg e

and deliver s aid it em F .O.B . H arri ngton Hoi sts , Inc . pl ace o f busin ess to c ust omer.

Customer must obtai n a Retur n G oods Aut hori zat ion as di rec ted by Har r ing ton or Harrington’s

published repai r c ent er pr ior to shi ppi ng prod uct for w arr anty eval uati on. An expl anati on of the

complaint mus t acc omp any th e pr odu ct. Pro duct m ust be r etur ned frei g ht pre paid . U pon r epai r,

the product w ill be cov er ed for the r em ain der of the original war ranty per iod. Replace ment p arts

installed aft er th e or ig inal w arr anty perio d w il l only be eli gi ble for r epla c ement (no t incl udi ng

installation) for a period of one year from the ins tallati on date. If it is determined there is no defect,

or that the de fect r es ult ed fr om ca uses not w i thi n the s cop e of Harr ing ton’ s w arrant y, t he cust omer

will be respons ible for th e cos ts of re turni ng the prod uct.

Harrington Hoi sts, Inc . d iscl aims any a nd al l o ther w arrant ies of any ki nd ex pres sed or i mpli ed as t o

the product’s merch ant ability or fitness for a parti cular appli catio n. Harri ngton wi ll not be liabl e for

death, injuri es t o per son s or pr op erty or for i nci dent al, c onti ng ent, s peci al or c ons eque ntial

damages, loss or expen se ari sing in co nnecti on w ith the use or in abil ity w hatev er , reg ardles s o f

whether damage, los s o r ex pens e res ults fr om a ny ac t or failur e t o act by Har ring ton, w heth er

negligent or w il lful, or from any o th er reas on

39

Page 40

This Page Intentionally Left Blank

40

Page 41

9.0 Parts List

When ordering Parts, please provide the Hoist model number, lot number, and serial number located on the Hoist

nameplate (see Figure 9-1 below).

Reminder: Per Sections 1.1 and 3.4.4 to aid in ordering parts and product support, record the hoist Code, Lot and Serial

Number in the space provided on the cover of this manual.

Figure 9-1 - M3CB Nameplate

The parts list is arranged into the following sections:

Section Page

9.1 1/2 to 20 Ton Parts………………….…………………………………………………...……….……...42

9.2 3 to 20 Ton Parts………………….…………………………………………………...……….……......46

9.3 CB Slip Clutch Device………………………………………………………………….….…….……… 50

9.4 Optional Hooks……………………..……………….………………………………….….…….……… 51

9.5 Optional Chain Containers…………………………………………………………….….…….……… 53

41

Page 42

9.1 1/2 to 20 Ton Parts

Figure 9-2 – ½ to 20 Ton Parts

42

Page 43

9.1 1/2 to 20 Ton Parts

Fig.

No.

Part Name

Qty

per

Hoist

1/2 1 1½ & 3 2

Capacity (T)

2½ - 5 - 8 10 - 15 - 20

*1 Top Hook Set 1 CF001005 CF001010 *CF001015 M3001A020 *M3001A025

*2 Latch Assembly 1 CF071005 CF071010 *CF071015 CF071020 CF071050

*3

Suspender G 1 M3003010

Suspender 1 M3004015 M3004020 M3004025

4 Top Pin 1 M3163005 M3163010 M3163015 M3163020 M3163025

5 Split Pin 1 9009423 9009424

*6 Bottom Hook Set 1

M3021A005 M3021A010 *M3021A015 M3021A020 *M3021A025

*7 Latch Assembly 1 CF071005 CF071010 *CF071015 CF071020 *CF071030

*8 Chain Pin 1 M3041005 M3041010 *M3041015 M3041020 *M3041025

*9 Slotted Nut 1 M3049005 M2049010 *M2049010 *M2049020

*10 Split Pin 1 9009402 *9009411 *9009412

Side Plate A Ass’y 1 M3101005 M3101010 M3101015 M3101020 M3101025

11

Side Plate A Ass’y

(M3B Model)

1

M3B101025

12 Nameplate F 1 C3BA0059806

Side Plate B Ass’y 1 M3102005 M3102010 M3102015 M3102020 M3102025

13

Side Plate B Ass’y

(M3B Model)

1

M3B102025

14 Load Sheave 1 M3116005 M3116010 M3116015 M3116020 M3116025

15 Ball Bearing 1 M3140005 M3140020

16 Ball Bearing 1 M3145005 M3140005 M3140020

Pinion 1 M3111005 M3111010 M3111015 M3111020 M3111025

17

Pinion

(M3B Model)

1

M3B111025

18 Roller Bearing 1 M3130005 M3130020

19 Snap Ring 1 M3118005 M3118020

20 Guide Roller 2 M3161005 M3161010 M3161015 M3161020 M3161025

21 Stripper 1 M3162005 M3162010 M3162015 M3162020 M3162025

22 Anchorage 1 M3176005 M3176010 M3176015 M3176020 M3176025

23 Stopper Pin 1 M3177005 M3177010 M3177015 M3177020 M3177025

24 Split Pin 1 9009412 9009415-5

25 Load Gear 1 M3114005 M3114010 M3114015 M3114020 M3114025

26 Snap Ring 1 9047123 9047128 9047132

27

Gear No. 2 Ass’y

Gear No. 2 Ass’y

(M3B Model)

1 M3112005

M3112010 M3112015 M3112020 M3112025

2

M3B112025

28 Ball Bearing 1 M3135005 M3135020

29 Gear Case Ass’y 1 M3103005 M3103010 M3103015 M3103020 M3103025

30

Nameplate B w/

Rivets

Nameplate B w/

Rivets (M3B

M3800005 M3800010 *M3800015 M3800020

1

*M3800025

Model)

31 Nut 3 9093424 9093427 9093433

*Part number applies to 1½ or 2½ Ton capacities only. See additional parts list for 3, 5, and 8 Ton capacities.

43

Page 44

9.1 1/2 to 20 Ton Parts

Fig.

No.

Part Name

Qty

per

Hoist

1/2 1 1½ & 3 2

Capacity (T)

2½ - 5 - 8 10 - 15 - 20

32 Spring Washer 3 9012711 9012712 9012713

33

Pawl Springs

Assembly

1 C3BA0055179

34 Pawl 1 M3155005

35 Snap Ring 1 9047110

36

37

38

39

40

Friction Disc

Friction Disc

(M3B Model)

Friction Plate

Friction Plate

(M3B Model)

Ratchet Disc

Ratchet Disc

(M3B Model)

Bushing

Bushing (M3B

Model)

Hand Wheel

Hand Wheel

(M3B Model)

1

2

1

1

M3115005 M3115015 M3115020 M3115025

1

M3153005 M3153020

M3B153025

M3151005 M3151020

M3B151025

M3152005 M3152020

M3B152025

M3154005 M3154020

M3B154025

M3B115025

41 Wheel Stopper 1 CF159005 CF159010

Wheel Stopper

42

Pin

1 M2167005

43 Split Pin 1 9009410

Wheel Cover

44

Ass’y

1 M3171005 M3171015 M3171020 M3171025

45 Nut 3 9093424

46 Spring Washer 3 9012711

47 Load Chain 1@ ft. LCCF005 LCCF010 LCCF015 LCC3020 LCC3025

48 Hand Chain 1@ ft. HCCF005

49 Warning Tag 1 WTAG9

50

Chain Stopper

Link

1 L4045030

115 Slip Clutch Label 1 C3YU0059802 C3YU0209802

116 Harrington Label 1 M3700005 M3700015 M3700020 M3700025

*Part number applies to 1½ or 2½ Ton capacities only. See additional parts list for 3, 5, and 8 Ton capacities.

44

Page 45

This Page Intentionally Left Blank

45

Page 46

9.2 3 to 20 Ton Parts

Figure 9-3 - 3 to 20 Ton Parts

46

Page 47

9.2 3 to 20 Ton Parts

Fig.

No.

51 End Pin 1 M3B164100

52 Split Pin 1 9009415-5

53 Cross Guide 1 M3B176100

54 Top Hook Set

55

Top Hook Ass’y 1 L42001090

56 Latch Assembly 1 CF071030 M3072050 L41071090 M3072150 M3072200

2 M31051150

57

3 M31051150

58 Shaft Assembly 1 M3053050

59A Top Yoke A 1 M3011075 M3011100 M3016150

59B Top Yoke B 1 M3012075 M3012100 M3017150

60 Socket Bolt

1 90912116

61 Lever Nut

1 L4082090

- Socket Bolt 2 M3086100

- U-Nut 2 9098516

62 Top Susp. Shaft 2 M3010150 M3010200

63 Top Yoke 2 M3011200

64

2 M35012200

- Top Plate B 1 M3014150

65 Guide

6 M3018150

66 Stay Bolt 2 M3019150 M3019200

- Top Plate 1 M3043150

67 Top Shaft 1 M3053150 M3053200

68 Key Plate 2 M2056150

- Collar 2 M3066150

70 Socket Bolt 4 9091270

71 Nut 4 9093458

72 Nut 4 9093445

73 Spring Washer 4 9012711

74 Spring Washer 4 9012717

75 Spring Washer 4 9012721

Part Name

Top Hook 1 M3001150 M3001200

Idle Sheave

Ass’y

Top Plate A

Assembly

Qty

per

Hoist

1 M3001A030 M3001A050 M3001A075 M3001A100 M3001A150

2 M3001A200

1 M3051050

3 90912116

3 L4082090

1 M35012150

4 M3018150

3 5 8 10 15 20

Capacity (T)

47

Page 48

9.2 3 to 20 Ton Parts

Fig.

No.

77

78

80 Latch Assembly 1 CF071030 M3072050 L41071090 M3072150 M3072200

2 M3051050

81

3 M31051150

4 M31051150

82

83

84 Socket Bolt

3 9091296

3 L4082060

85

U-Nut 2 9098516

86 Guide

8 M3018150

87 Hook Support 2 M3026150 M3026200

88 Bottom Yoke 1 M3030150 M3030200

89 Bottom Plate A

2 M3034200

90 Bottom Plate B 1 M3035150 M3035200

91 Bottom Plate C 1 M3036200

92 Stay Bolt 4 M3038150 M3038200

93 Collar A 2 M3039200

94 Collar B 4 M3040200

95 Bottom Shaft 1 M3054150 M3054200

96 Key Plate 2 M2056150

97 Washer A 2 M3058200

98 Collar 4 M3066200

99

100 Socket Bolt 4 9091270

101 Nut 8 9093445

102 Spring Washer 4 9012711

103 Spring Washer 8 9012717

104

105 Bolt 4 9093350

Part Name

Bottom Hook

Set

Bottom Hook 1 M3021150 M3021200

Bottom Hook

Assembly

Idle Sheave

Assembly

Shaft Assembly 1 CF053030 M3053050

Bottom Shaft

Assembly

Bottom Yoke

Assembly

Lever Nut

Nameplate A w/

Rivets

Tongued

Washer

Qty

per

Hoist

1 M3021A030 M3021A050 M3021A075 M3021A100 M3021A150 M3021A200

1 M3021030 M3021050 L42001090

1 CF051030 M3051050

1

1 M3031030 M3031050 M3031075 M3031100

2 9091296 90912116 M3088100

2 L4082060

6 M3018150

1 M3034150

1 M3069150 M3069200

4 M3091150

3 5 8 10 15 20

M3054100

L4082090

Capacity (T)

48

Page 49

9.2 3 to 20 Ton Parts

Fig.

No.

106 Chain Pin 1 M3041030 M3041075

107 Slotted Nut 1 M2049010 M2049020

108 Split Pin 1 9009411 9009412

109

110 Load Chain 1@ ft. LCCF015 LCC3025

111 Hand Chain

112 Warning Tag

113

114

Part Name

Nameplate B w/

Rivets

Nameplate B w/

Rivets (M3B

Model)

Chain Stopper

Link

Stopper

Assembly

Qty

per

Hoist

1 M3800030 M3800080 M3800030

1

2 M3B800200

1@ ft. HCCF005

2@ ft. HCCF005

1 WTAG9

2 WTAG9

1 L4045030

2 L4045030

1

2 M3045100

3 5 8 10 15 20

M3800050 M3B800100 M3B800150

M3045100

Capacity (T)

49

Page 50

9.3 CB Slip Clutch Device

50

Figure 9-4 Slip Clutch

FIG NO. PART NAME QTY

1 OLL ASSEMBLY

2 PINION

M3B C3BYA111025

3 HAND WHEEL

M3B C3BYA1115025

4 WASHER

M3B C3YA208020

5 NUT (left hand thread)

M3B C3YA209020

6 Split Pin

M3B 9009417

M3

M3

M3

M3

M3

M3

1

1

1

1

1

1

M3B M3B025OD

1/2 T 1 T 1 1/2 & 3 T 2 T 2 1/2-5 T 8-10-15-20 T*

M3CB005OD M3CB010OD M3CB015OD M3CB020OD M3CB025OD

C3YA111005 C3YA111010 C3YA111015 C3YA111020 C3YA111025

C3YA1115005 C3YA1115010 C3YA1115015 C3YA1115020 C3YA1115025

C3YA208005 C3YA208020

C3YA209005 C3YA209020

9009415 9009417

CAPACITY

*20 Ton capacity requires Quantities of 2.

Page 51

9.4 Optional Hooks

Figure 9-5 Bullard

Bullard

*Hoist with Bullard® Hook(s) must have WTAG6 and WTAG9 installed. (See page 6 for WTAG9).

®

Hooks

Fig. No. Name

®

Top Hook

Bullard

1

Complete Set

2 Bullard® Hook Assembly 1 60160 60162 60164 60165 60166

3 Top Yoke Kit 1 TYKITCB005 TYKITCB010 TYKITCB015 TYKITCB020 TYKITCB025

4 Button Head Screw 2 9012601 9012602

5 Flexloc® Nut 2 9012603 9012604

6 Warning Tag 1 WTAG6*

7

8 Bullard® Hook Assembly 1 60160 60162 60164 60165 60166 60168 60169

9 Bottom Yoke Kit 1 BYKITCB005 BYKITCB010 BYKITCB015 BYKITCB020 BYKITCB025

10 Button Head Screw 4 9012601 9012602

11 Flexloc® Nut 4 9012603 9012604

12 Warning Tag* 1 WTAG6*

®

Bottom Hook

Bullard

Complete Set

Parts

Per

Hoist

1 6027601 6027602 6027603 6027604 6027605

1 6027801 6027802 6027803 6027804 6027806 6027807 6027808

½ T 1T 1½T 2T 2½T 3T 5T

®

, Shur-Loc® and Inspection Hooks

51

Page 52

9.4 Optional Hooks

Shur-Loc

Fig. No. Name

2

3 Top Yoke Kit 1 TYKITCB005 TYKITCB010 TYKITCB015 TYKITCB020 TYKITCB025

4 Button Head Screw 2 9012601 9012602

5 Flexloc® Nut 2 9012603 9012604

6 Warning Tag 1 WTAG6*

8

9 Bottom Yoke Kit 1 BYKITCB005 BYKITCB010 BYKITCB015 BYKITCB020 BYKITCB025

10 Button Head Screw 4 9012601 9012602

11 Flexloc® Nut 4 9012603 9012604

12 Warning Tag 1 WTAG6*

*Hoist with Shur-Loc® Hook(s) must have WTAG6 and WTAG9 installed. (See page 6 for WTAG9).

Inspection Hooks

Fig. No. Name

1

2 Hook W/Latch & Yoke 1 M3001A005IH M3001A010IH M3001A015IH M3001A020IH M3001A025IH

3 Button Head Screw 2 9012601 9012602

4 Flexloc® Nut 2 9012603 9012604

6

7 Hook W/Latch & Yoke 1 M3021A005IH M3021A010IH M3021A015IH M3021A020IH M3021A025IH

8 Button Head Screw 2 9012601 9012602

9 Flexloc® Nut 2 9012603 9012604

®

Hooks

Shur-Loc

1

Complete Set

Shur-Loc

Assembly

Shur-Loc

7

Complete Set

Shur-Loc

Assembly

Top Hook Complete

Set

Bottom Hook Complete

Set

®

®

®

®

Top Hook

Hook

Bottom Hook

Hook

Parts

Per

Hoist

1 6030201 6030202 6030203 6030204 6030205

1 60140 60142 60144 60145 60146

1 6030101 6030102 6030103 6030104 6030106

1 60140 60142 60144 60145 60146

Parts

Per

Hoist

1 M3001A005IK M3001A010IK M3001A015IK M3001A020IK M3001A025IK

1 M3021A005IK M3021A010IK M3021A015IK M3021A020IK M3021A025IK

½T 1T 1½T 2T 2½T

½ T 1T 1½T 2T 2½T

52

Page 53

9.5 Optional Chain Containers

Figure 9-6 M3CB Optional Chain Container

CF4 OPTIONAL CHAIN CONTAINERS

Fig. No. Name

“05” Chain Container

(BKC1) Assembly

1 Chain Container 1 50545 50545 50545 50545

2 Front Hanger Ass’y 1 5048305 5048305 5048305 5048305

3 Back Hanger 1 5048304 50940 5048304 50940

4 Washer 2 9012513 9012513 9012513 9012513

5 Nut 1 9093424 9093424 9093424 9093424

6 Lock Washer 1 9005310 9005310 9005310 9005310

7 Hex Head Bolt 1 9093327 9093327 9093327 9093327

8 Lock-Nut 1 9098506 9098506 9098506 9098506

9 Spacer 1 5048301 5048301

“10” Chain Container

(BKD1) Assembly

1 Chain Container 1 30090 30090 30090 30090

2 Front Hanger Ass’y 1 5048305 5048305 5048305 5048305

3 Back Hanger 1 5048304 50940 5048304 50940

4 Washer 2 9012513 9012513 9012513 9012513

5 Nut 1 9093424 9093424 9093424 9093424

6 Lock Washer 1 9005310 9005310 9005310 9005310

7 Hex Head Bolt 1 9093327 9093327 9093327 9093327

8 Lock-Nut 1 9098506 9098506 9098506 9098506

9 Spacer 1 5048301 5048301

Parts

Per

Hoist

1 60461 60463 60461 60463

1 60462 60464 60462 60464

½T 1T 1½T 2T 2½T 3T 5T

53

Page 54

NOTES

54

Page 55

NOTES

55

Page 56

www.harringtonhoists.com

Harrington Hoists, Inc. Harrington Hoists – Western Division

401 West End Avenue 2341 Pomona Rd. #103

Manheim, PA 17 54 5-1703 Corona, CA 928 80-6973