Harrington Corporation C-900 User Manual

HARCO PVC C-900 GASKETED FITTINGS

THE HARRINGTON CORPORATION

12/16/15

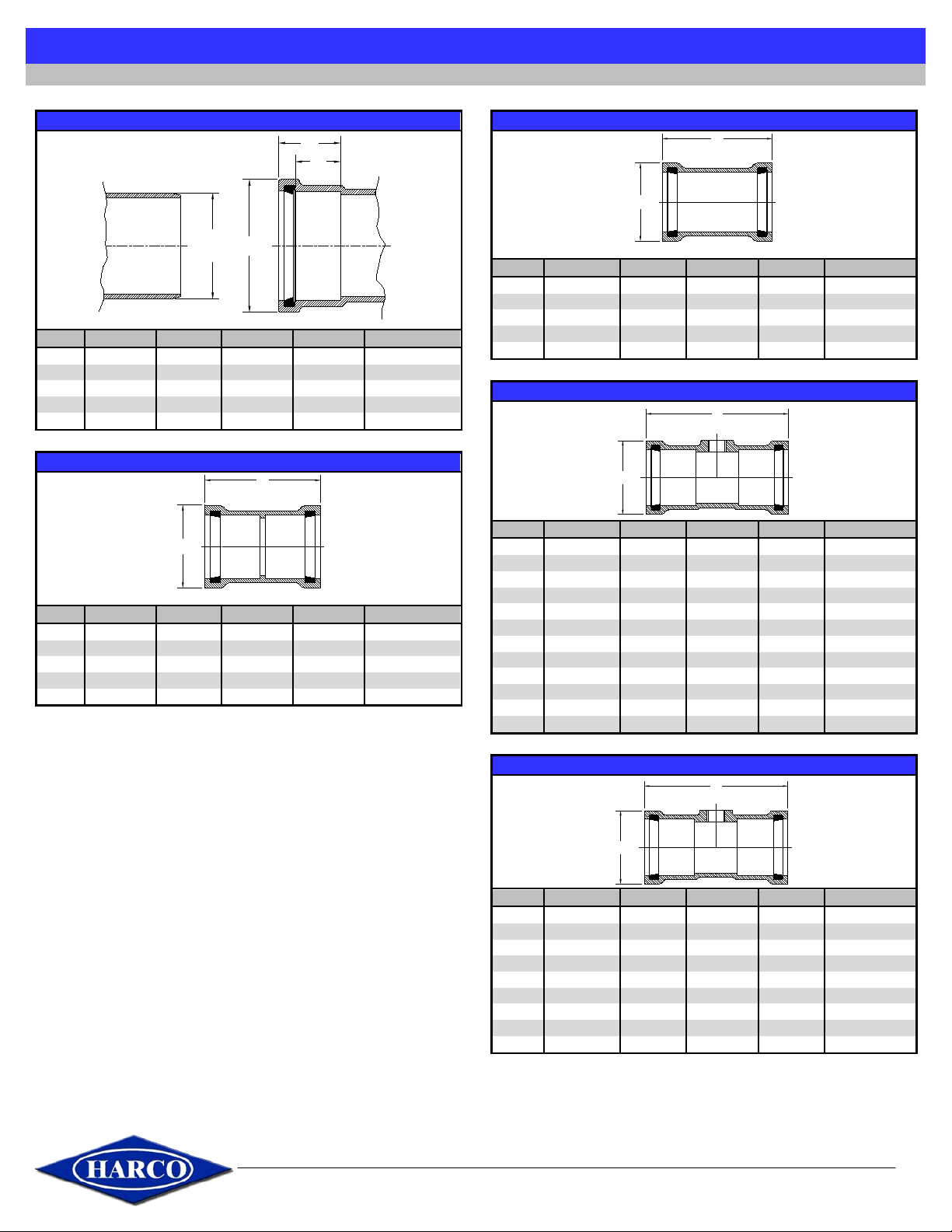

REPAIR COUPLING

A

L

SIZE

PART #

STYLE A L

WT (approx.)

4

309-040

M

6.3

8.9

3.4

6

309-060

M

8.6

10.0

6.7

8

309-080

M

11.0

11.3

12.5

10

309-100

M C

13.0

11.3

22

12

309-120

M C

15.5

12.1

36

TAPPED TEE (NPT Thread)

A

L

SIZE

PART #

STYLE A L

WT (approx.)

4 x ¾

351-403

M

6.9

12.0

5.0

4 x 1

351-404

M

6.9

12.0

5.0

4 x 1½

351-406

M

6.9

12.0

5.0

4 x 2

351-408

M

6.9

12.0

5.0

6 x ¾

351-603

M

8.5

13.0

9.2

6 x 1

351-604

M

8.5

13.0

9.2

6 x 1½

351-606

M

8.5

13.0

9.2

6 x 2

351-608

M

8.5

13.0

9.2

8 x ¾

351-803

M

11.0

14.9

16.0

8 x 1

351-804

M

11.0

14.9

16.0

8 x 1½

351-806

M

11.0

14.9

16.0

8 x 2

351-808

M

11.0

14.9

16.0

TAPPED TEE (AWWA Thread)

A

L

SIZE

PART #

STYLE A L

WT (approx.)

4 x ¾

352-403

M

6.9

12.0

4.3

4 x 1

352-404

M

6.9

12.0

4.3

4 x 2

352-408

M

6.9

12.0

4.3

6 x ¾

352-603

M

8.5

13.3

8.5

6 x 1

352-604

M

8.5

13.3

8.5

6 x 2

352-608

M

8.5

13.3

8.5

8 x ¾

352-803

M

11.0

14.9

15.0

8 x 1

352-804

M

11.0

14.9

15.0

8 x 2

352-808

M

11.0

14.9

15.0

BELL SPECIFICATIONS

C

SPIGOT

O.D.

B

A

SIZE

STYLE

A B C

Spigot O.D.

4 M 4.3

3.1

6.3

4.80

6 M 4.8

3.5

8.6

6.90

8 M 5.4

4.0

11.0

9.05

10

Fab

9.0

5.0

13.0

11.10

12

Fab

9.5

5.5

15.5

13.20

COUPLING

A

L

SIZE

PART #

STYLE A L

WT (approx.)

4

308-040

M

6.3

8.9

2.9

6

308-060

M

8.3

10.0

6.0

8

308-080

M

11.0

11.0

11.5

10

308-100

M C

13.0

19.7

27

12

308-120

M C

15.5

22.3

40

Notes:

Call For Other Sizes, Configurations & Gasket Materials

DESIGN DATA

• All lay lengths & weights are approximate and are subject to

change without notice

• Fabricated fitting configurations may vary

Style Legend:

M - Molded fittings are Pressure Class 150 unless otherwise

C - Machined from extruded stock as manufactured by CertainFab - Fabricated fittings are made from sections of C-900 pipe and

The use of anything but properly designed and installed thrust

blocks will reduce the life of plastic fittings. Thrust blocks must be of

poured concrete only and sized for the soil conditions. Joint

restraint products are available.

WARNING: Frequent or severe cyclical pressure surges (water

hammer) can destroy PVC fittings. Please refer to AWWA C-907,

Section A.3.4 for additional details.

noted

Teed Corporation

are not pressure rated

P.O. BOX 10335 • LYNCHBURG, VIRGINIA 24506 • 3721 COHEN PLACE • LYNCHBURG, VIRGINIA 24501

PHONE: (434) 845-7094 • FAX: (434) 845-8562 • E-MAIL: sales@harcofittings.com • WEB: www.harcofittings .c om

HARCO PVC C-900 GASKETED FITTINGS

THE HARRINGTON CORPORATION

12/16/15

CAP

L

A

For this item do not use joint restraint, poured concrete thrust bl ocks only

SIZE

PART #

STYLE A L

WT (approx.)

4

349-040

M

6.3

4.5

2.1

6

349-060

M

8.6

5.2

4.5

8

349-080

M

11.0

6.0

8.5

6

350-060

M

8.0

5.0

4.5

10

349-100

Fab

13.0

13.7

7.0

12

349-120

Fab

15.5

17.8

10.0

REDUCER (GxS)

A

L

(Molded f itting shown)

SIZE

PART #

STYLE A L

WT (approx.)

6 x 4

316-0604

M

4.7

9.4

4.0

8 x 6

316-0806

M

5.3

10.5

7.7

8 x 4

316-0804

Fab

8.0

16.2

14.0

10 x 4

316-1004

Fab

9.6

18.3

22.0

10 x 6

316-1006

Fab

11.0

20.5

28.0

10 x 8

316-1008

Fab

10.5

20.7

27.0

12 x 4

316-1204

Fab

9.6

20.3

35.0

12 x 6

316-1206

Fab

11.4

21.9

38.0

12 x 8

316-1208

Fab

10.5

23.7

45.0

12 x 10

316-1210

Fab

10.5

24.0

43.0

C-900 BELL x FLANGE ADAPT E R

A

L

These fittings use SCH-40 PVC fittings. SCH-40 PVC Fittings DO NOT HAVE LONG TERM

systems is at users’ risk.

SIZE

PART #

STYLE A L

WT (approx.)

4

354-040

M

6.3

11.5

7.3

6

354-060

M

8.6

13.3

14.2

8

354-080

M

11.0

15.8

25.7

Notes:

Call For Other Sizes, Configurations & Gasket Materials

REDUCER (GxG)

A

C

L

(Molded fitting shown)

SIZE

PART #

STYLE

A C L

WT (approx.)

6 x 4

317-0604

M

6.3

8.6

13.6

10.4

8 x 6

317-0806

M

8.6

11.0

15.3

19.6

8 x 4

317-0804

Fab

6.3

11.0

18.5

14.0

10 x 4

317-1004

Fab

6.3

13.0

23.1

22.0

10 x 6

317-1006

Fab

8.6

13.0

25.4

28.0

10 x 8

317-1008

Fab

11.0

13.0

25.5

27.0

12 x 4

317-1204

Fab

6.3

15.5

25.5

35.0

12 x 6

317-1206

Fab

8.6

15.5

27.0

38.0

12 x 8

317-1208

Fab

11.0

15.5

28.9

45.0

12 x 10

317-1210

Fab

13.0

15.5

29.0

43.0

MANHOLE ADAPTER

A

SAND COATING

L

(Molded f itting shown)

SIZE

PART #

STYLE A L

WT (approx.)

4

357-040

M

8.9

6.5

3.4

6

357-060

M

10.0

8.8

8.0

8

357-060

M

11.3

11.2

15.0

10

357-100

Fab

13.3

18.0

24.0

12

357-120

Fab

15.8

18.0

28.0

SINGLE BELL MALEHOLE ADAPTER

A

L

SIZE

PART #

STYLE

A

L

WT(approx.)

8

358-080S

M

11.1

5.7

6.3

10

358-100S

M

13.1

9.0

11.0

12

358-120S

M

15.6

9.0

18.0

CLEAN OUT ADAPTER (HUB)

(Non-Pressure)

L

SIZE

PART #

STYLE

L

WT(approx.)

4

359-040

M (Solvent Weld)

3.3

0.6

6

359-060

M (Solvent Weld)

4.4

1.3

DESIGN DATA

(Molded fitting shown)

PRESSURE RATING (See Section 6.3.2 of ASTM D2466). Use of these adapters in pressure

• All lay lengths & weights are approximate and are subject to

change without notice

• Fabricated fitting configurati o ns may vary

Style Legend:

M - Molded fittings are Pressure Class 150 unless otherwise

noted

Fab - Fabricated fittings are made from sections of C-900 pipe and

are not pressure rated

P.O. BOX 10335 • LYNCHBURG, VIRGINIA 24506 • 3721 COHEN PLACE • LYNCHBURG, VIRGINIA 24501

PHONE: (434) 845-7094 • FAX: (434) 845-8562 • E-MAIL: sales@harcofittings.com • WEB: www.harcofittings .c om

Loading...

Loading...