Harrington SEQM010SD-SD-20 User Manual

EQ/SEQ Electric Chain Hoists

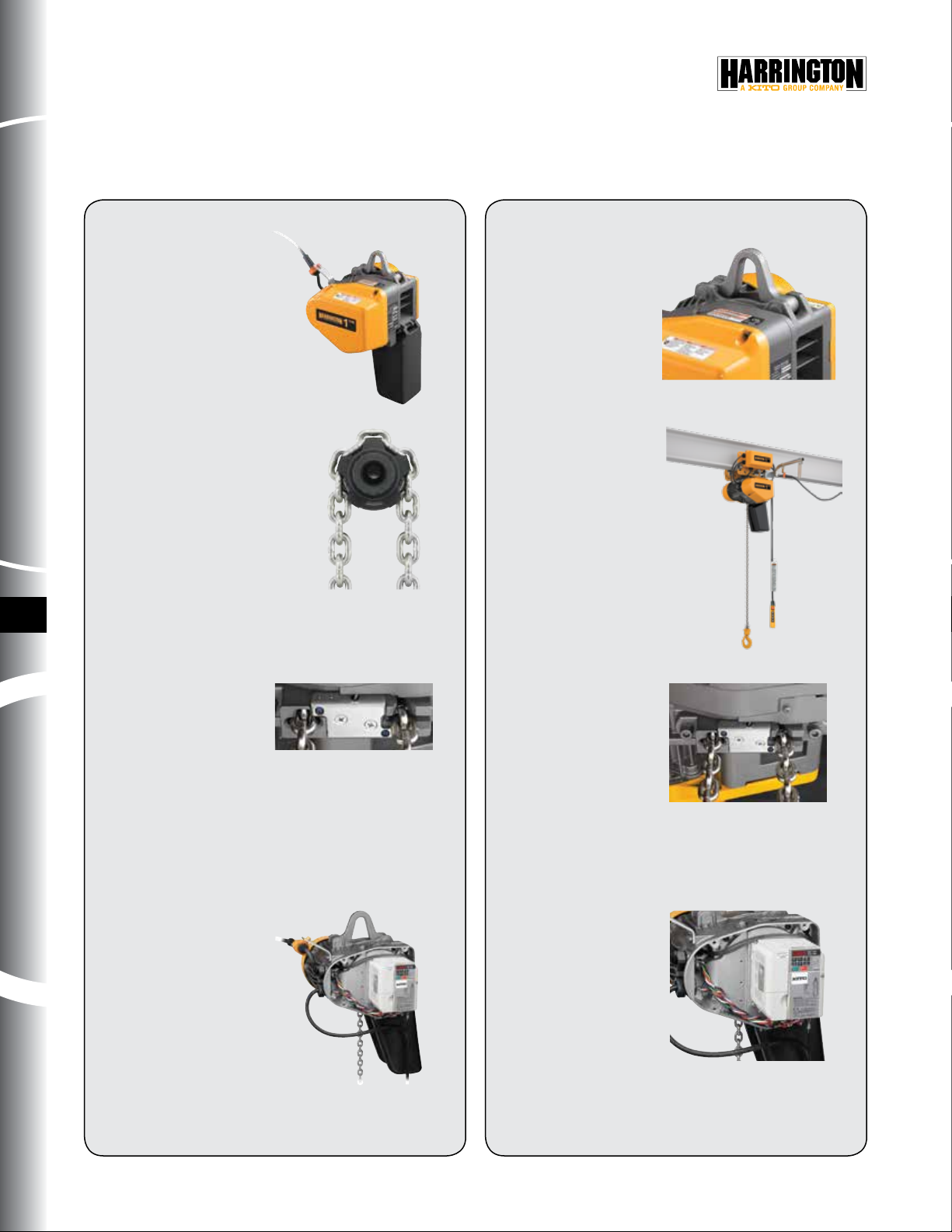

Simple

Construction

Low maintenance due

to no transformer,

no magnetic contactor,

no brake contactor and

no brake coil.

Unique Load Sheave

Increased number of pockets

reduces chain vibration and

increases chain life. Five

pockets standard.

4

Optional

Suspension Bar

External connecting

shaft allows for quick

change from hook

mount to suspension

bar mount.

No-Load

High-Speed

Hoist speeds 1.3 times

faster when working

with less than 30% of

full load.

Limit Switches

Low-profile upper and

lower limit switches

are standard.

Dual Speed VFD

“Under-the-cover” VFD

standard. Speed ratio

is 6:1.

Unique

Chain Guide

Provides quiet and

smooth guiding of

chain. Heavy cast

iron construction.

Standard Count

Hour Meter

Records and displays

the number of lifting/

lowering starts

and hoist on time

which is valuable

for preventive

maintenance. Integral

to VFD.

HARRINGTON ELECTRIC CHAIN HOISTS

Green Initiative

Built smarter without the

use of harmful materials.

Environmentally friendly.

RoHS compliant.

Perpendicular

Orientation

PT push, GT geared

and MRQ motorized

trolley mount hoists

are configured as

perpendicular to

the beam.

Certified

CSA listed to:

UL 508, UL 508A, UL 1004

CSA Std. C22.2 No 33-M1984 (R2004)

CSA Std. C22.2 No 14-13

CSA Std. C22.2 No. 66.1-06 (R2011)

High Strength, Corrosion

and Wear Resistant

Load Chain

Grade 80, super strength,

nickel-plated load chain,

certified to DIN standards, uses

unique technology to greatly

increase resistance to fatigue

and wear.

5

Friction Clutch

Friction clutch is standard

on EQ/SEQ models.

Provides consistent

performance over a

wide temperature range.

Pull-Rotor

Motor Brake

Extremely durable and

reliable, this advanced

design contains no

brake coil to fail like

conventional disc

brakes. 5-year hoist

brake warranty.

High Air Flow

Cooler motor and

brake attributed

to an engineered

motor fin, fan

blade and fan

cover design.

Pendant Controls

Ergonomic design for

operator comfort. Red

button emergency

stop is standard on

all pendants.

EQ/SEQ Electric Chain Hoists

Compact Aluminum Body

Die-cast body is lightweight and offers low headroom – one

of the best in the industry. Paint is electrostatically applied.

Completely Sealed Body

Suitable for both indoor and outdoor applications, including

harsh environments. (Consult Owner’s Manual for details.)

Gaskets throughout the hoist provide for an IP55 rating.

Pull-Rotor Motor Brake

Extremely durable and

reliable, this advanced

design contains no

brake coil to fail like

conventional disc brakes.

Optional

Suspension Bar

For low headroom or

enclosed track trolley

applications. Easily

changed from top

hook to suspension bar.

6

External Motor Fan

Functions to quickly eliminate resistor,

motor and brake heat. This results

in improved hoist duty rating and

greatly lengthens brake life. Motor is

totally enclosed, fan cooled (TEFC).

Extreme Duty Motor

Increased performance through 30/10-minute

duty rating, H4 classification, Class B

insulation, cooling fins and external thermal

motor protection.

Chain Container

Durable plastic containers

are standard.

Corrosion Resistant

Load Chain

Nickel-plated, Grade 80, DIN

chain for superb durability

and strength.

Heavy-duty hook latches are standard.

Forged Carbon Steel Hooks

Under excessive loads will open

gradually and not fracture. Ball

bearings produce smooth rotation.

Bottom hook will swivel 360 degrees.

Loading...

Loading...