Page 1

R

Turf Sweeper

& Parts Manual

TV 30

7/11

R

R

Page 2

R

TV 30

Page 3

Thank you for purchasing a Harper Turf Vac.

As with all Harper products, the Turf Vac has been developed through tough design and testing

procedures to produce a top quality machine. This manual gives assembly, operating, and service

information for the model TV30 Turf Vac. Please read and understand all instructional material

included with the Turf Vac or its components before assembling and operating the equipment.

A Turf Vac can present hazards to an operator who follows unsafe procedures in either the

operation or maintenance of the unit. Therefore, SAFETY WARNINGS are presented at certain

locations in the text.

THIS SYMBOL: SAFETY WARNING!

MEANING: Failure to understand and obey this warning may result in injury to you or others.

Whenever this symbol is used, please pay very close attention to the information presented, and

make sure you fully understand. If you do not, contact your dealer or Harper Industries, Inc. for

clarication.

SAFETY WARNING!

ALL SHIELDS AND GUARDS MUST BE IN PLACE FOR PROPER AND SAFE OPERATION

OF THIS EQUIPMENT. WHERE THEY ARE SHOWN REMOVED IN THIS MANUAL, IT IS FOR

PURPOSES OF ILLUSTRATION AND INSTRUCTION ONLY. DO NOT OPERATE THIS

EQUIPMENT UNLESS ALL SHIELDS AND GUARDS ARE IN PLACE.

Harper Industries, Inc. is continually striving to improve the design and performance of its

products. We reserve the right to make changes in specications and design without thereby

incurring any obligation relative to previously manufactured products.

The Harper name is a registered trademark of Harper Industries, Inc. All other brand and product

names are trademarks or registered trademarks of their respective companies.

TV 30

© 2011 Harper Industries, Inc.

R

1

Page 4

LIMITED WARRANTY

The Harper TV30 Turf Vac is warranted against defects in workmanship

and materials for a period of TWELVE MONTHS from the original date of retail

purchase to the original purchaser.

Harper Industries will repair or replace, at our option, any part which our

examination shows to be defective. Warranty is limited to parts, labor and

ground freight delivery of replacement parts. The user will pay freight

charges for parts submitted under this warranty.

No product or part may be returned for warranty consideration without

prior approval from Harper Industries.

This warranty does not apply to parts subjected to misuse, abuse,

alteration, improper or inadequate maintenance, or normal wear (including

belts and broom).

Engines are not covered under this warranty. Refer to manufacturer’s

warranty for specic warranty information. Harper Industries, its agents or

representatives, make or imply no other warranties.

RECORDS

Date of Purchase ______ / ______ / ______

Dealer’s Name _________________________________

Dealer’s Phone _________________________________

Serial Number Machine __________________________

Serial Number Engine ___________________________

R

2

TV 30

Page 5

Table of Contents

OPERATOR SECTION

To the Owner or Operator............................................

Warranty Statement......................................................

Table of Contents..........................................................

Specications................................................................

Control Identication

ROPS...............................................................

Steering Wheel.................................................

Control Panel....................................................

Foot Pedal........................................................

Lift Mechanism.................................................

Fan Housing.....................................................

Sweeper Deck..................................................

Engine..............................................................

Hopper..............................................................

Hopper Door.....................................................

Stabilizer Arms (2)............................................

Hopper Lift Height Decal..................................

Fan ON/OFF.....................................................

Broom ON/OFF.................................................

Hopper ON/OFF................................................

Door OPEN/CLOSE.........................................

Operation Speed HI/LO....................................

Park Brake ON/OFF..........................................

Park Brake Indicator.........................................

Engine Choke (diesel)......................................

Deck Lift............................................................

Throttle.............................................................

Ignition..............................................................

Empty Lift Cylinder............................................

Safety Lock.......................................................

Impeller.............................................................

Liner..................................................................

Mercury Switch.................................................

Safety Guideline

Equipment & Controls......................................

Safety Decals...................................................

Gasoline...........................................................

Guards & Shields..............................................

Battery..............................................................

Hydraulics.........................................................

Before Operation..............................................

During Operation..............................................

Maintenance

Hydraulic System.............................................

Grease Zerk Location.......................................

Air Cleaner........................................................

Cooling System................................................

Engine Oil.........................................................

Fuel Filter..........................................................

Relay Panel......................................................

Standard Torque Chart.................................................

Maintenance Schedule.................................................

10

11

11

12

12

13

13

13

14

PARTS SECTION

Table of Contents

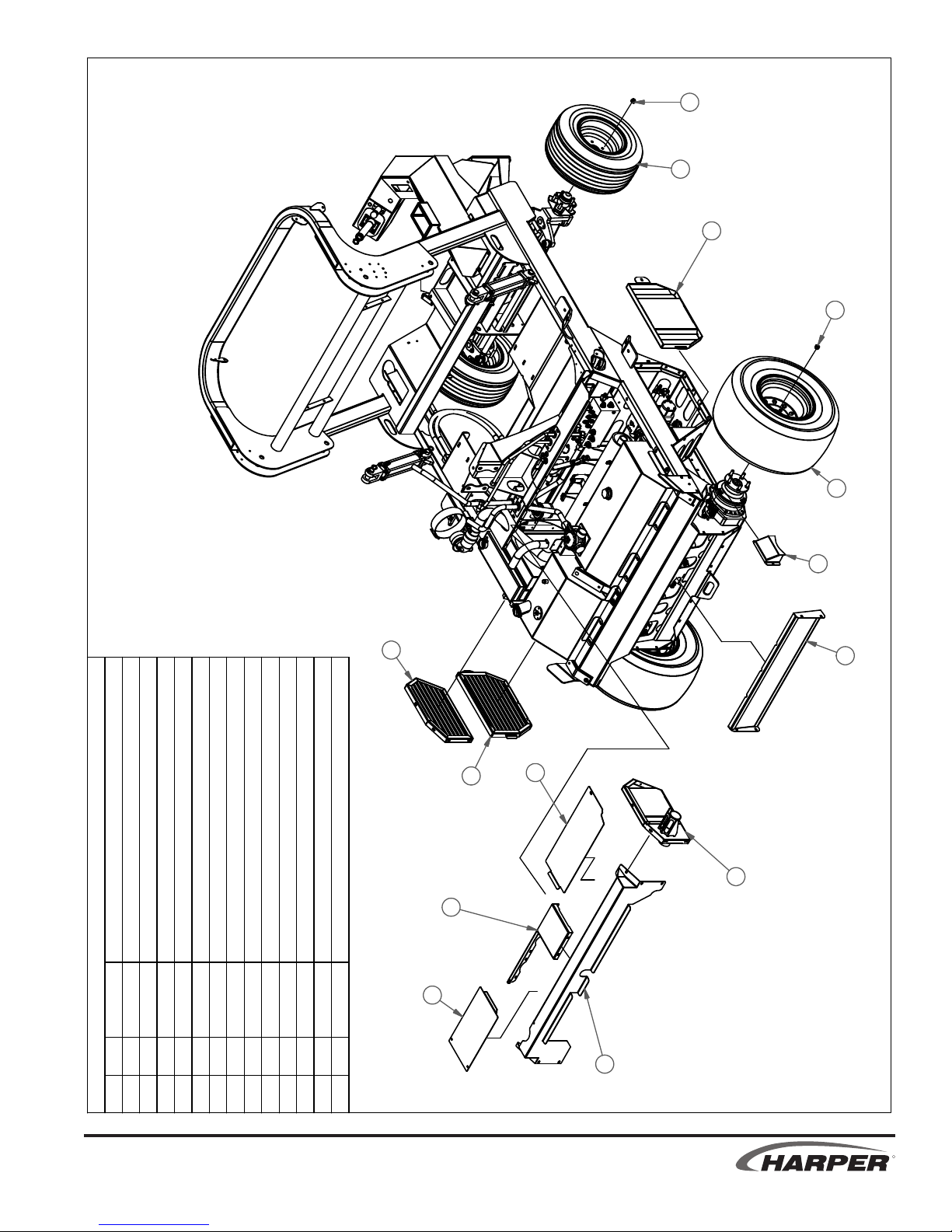

Frame and Engine

Frame Assembly..............................................

Control Arm Assembly.....................................

1

2

3

4

5

5

5

5

5

5

5

5

5

5

5

6

6

6

6

6

6

6

6

6

6

6

6

7

7

7

7

7

8

8

8

8

9

9

9

9

Front Axle Assembly........................................

Engine and Tank Installation...........................

Diesel Engine Assembly..................................

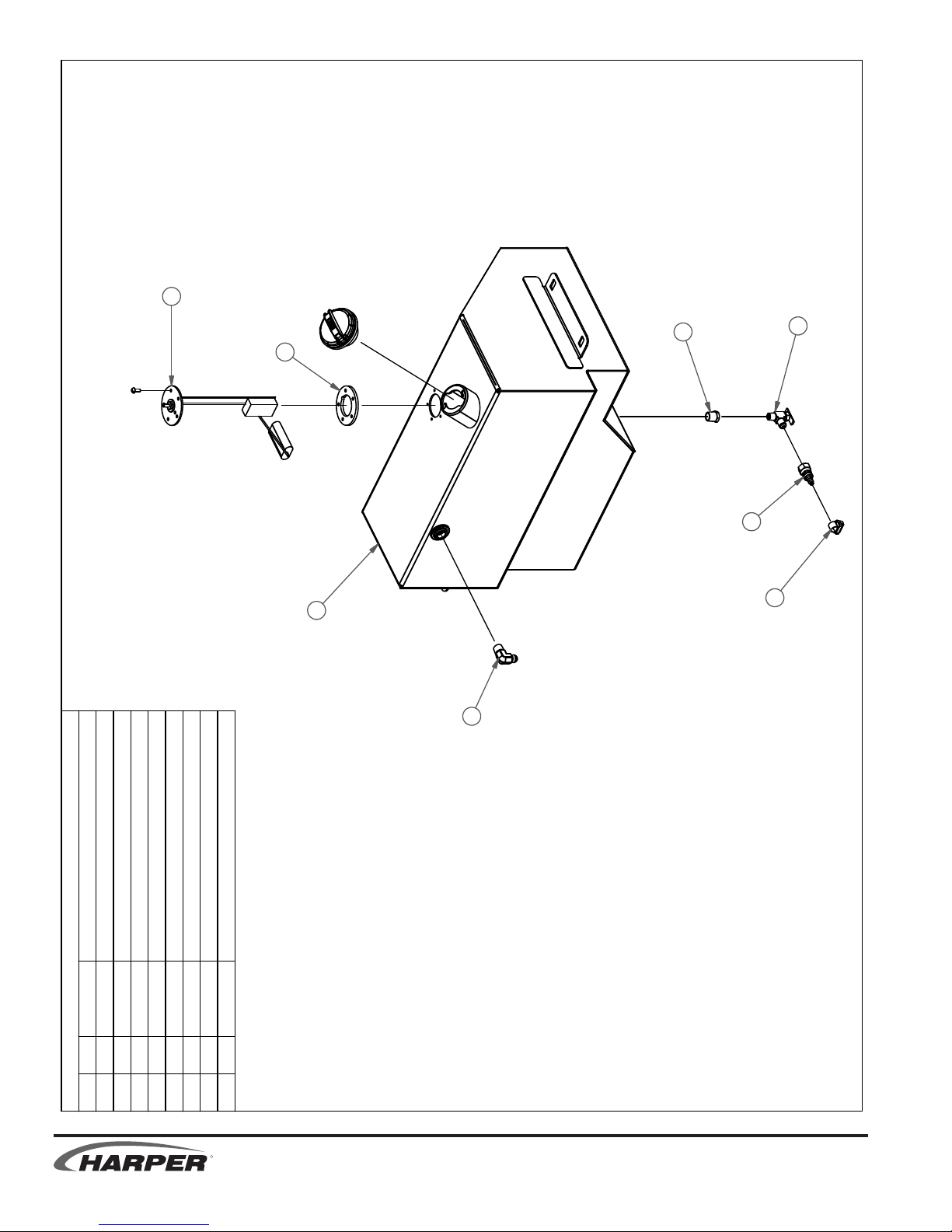

Fuel Tank Assembly.........................................

Engine Shield Assembly..................................

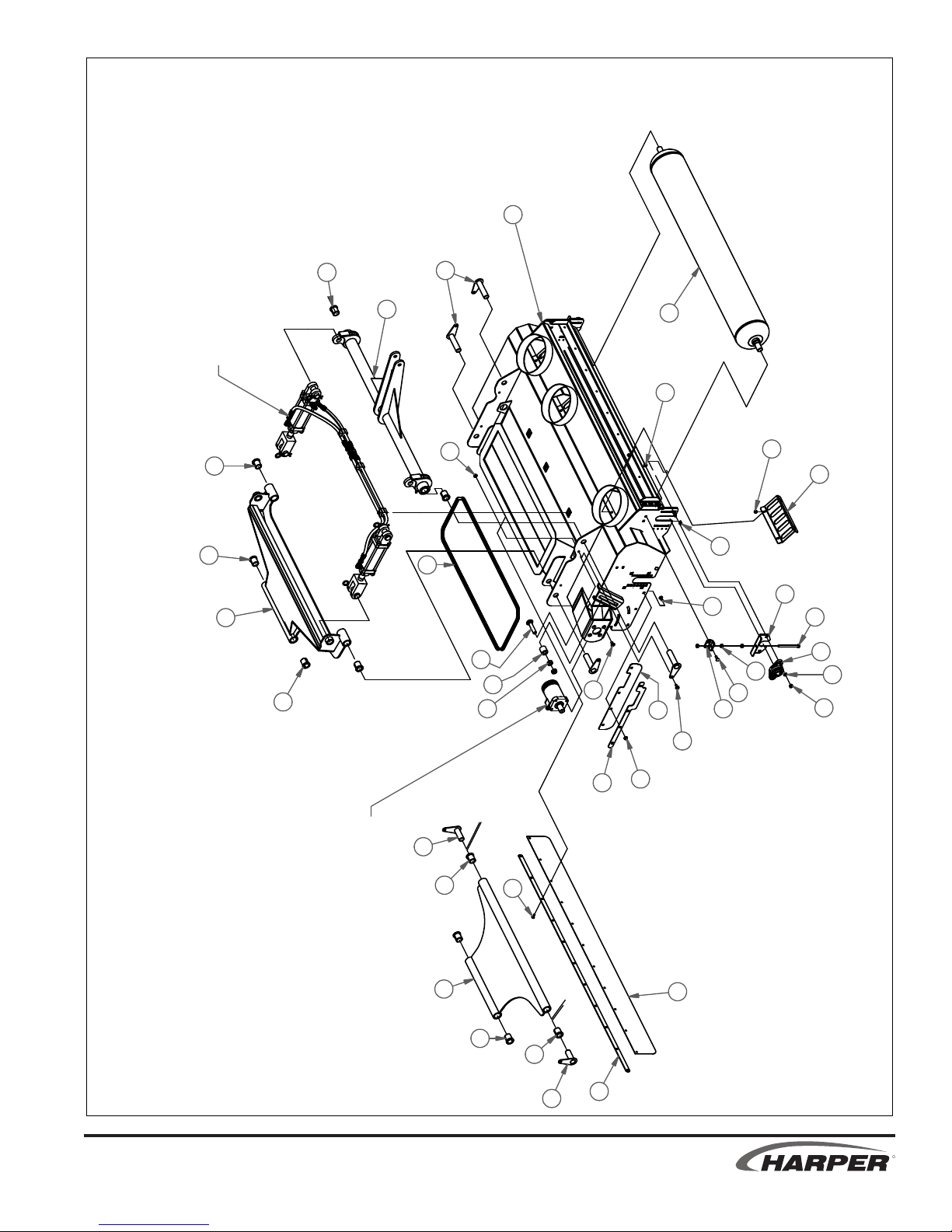

Deck Assembly................................................

Deck Installation..............................................

Broom Kit.........................................................

Finger Kit.........................................................

Verticut/Dethatch Kit........................................

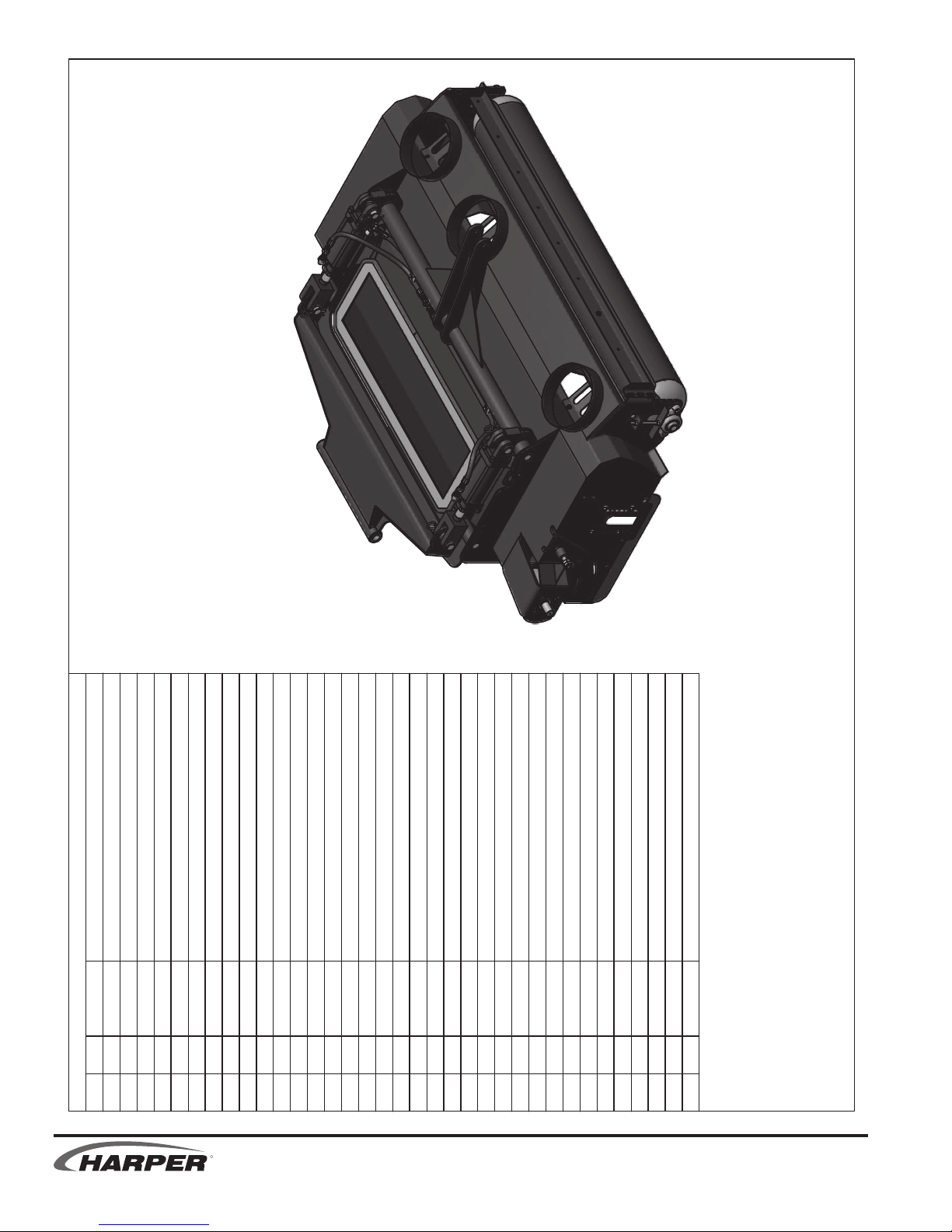

Fan Housing & Hydraulic Cooler Assy.............

Fan Housing Installation..................................

Outrigger Installation.......................................

Hopper and Door Assembly.............................

Hopper Installation..........................................

Operator Station..............................................

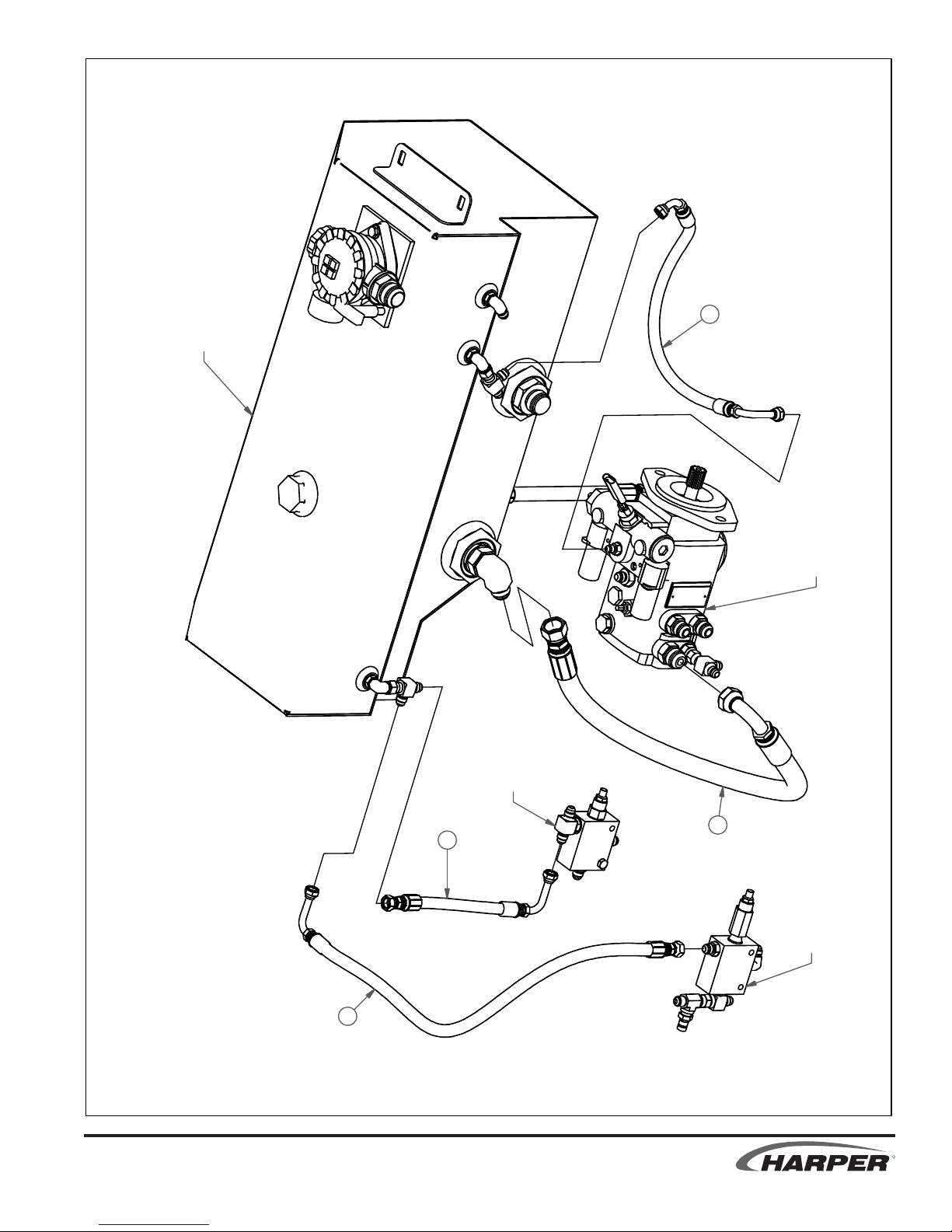

Hydraulic

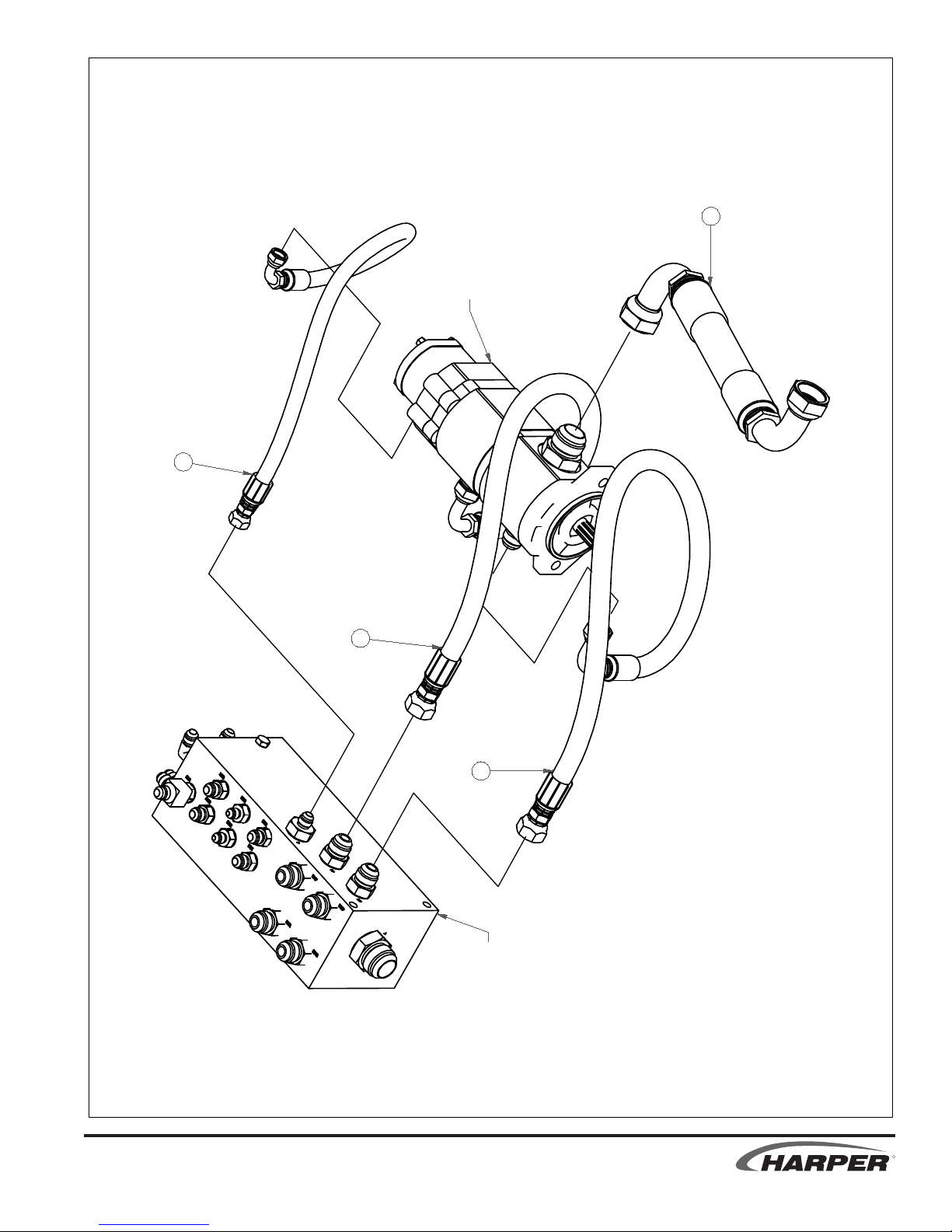

Hydraulic Reservoir Assembly.........................

Wheel Motor Assembly....................................

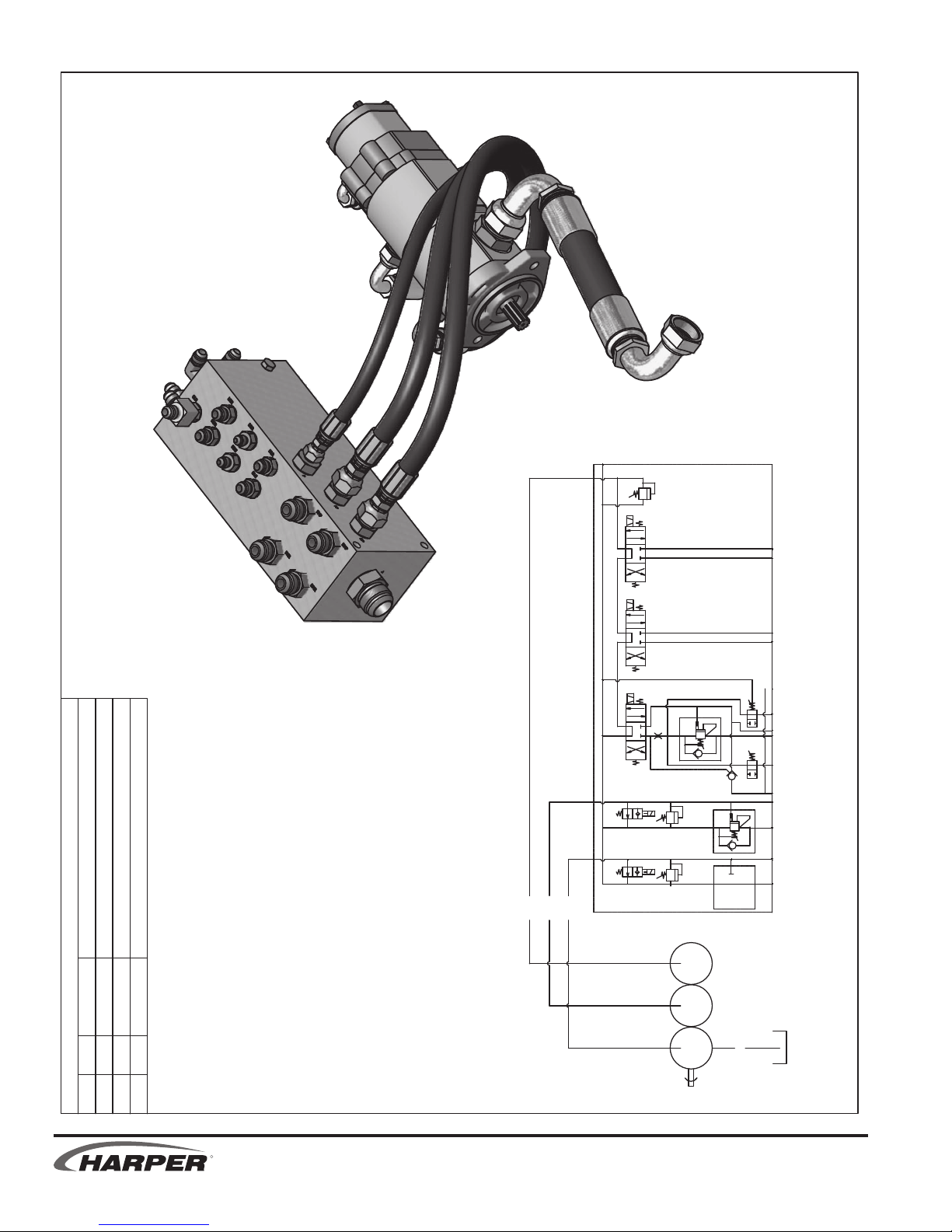

Propulsion Pump Assembly.............................

Triple Section Pump Assembly........................

Master Valve Assembly....................................

Propulsion Valve Assembly..............................

Sequence Valve Assembly..............................

Pressure Reduction Valve Assembly...............

Hydraulic Cylinder Service Parts.....................

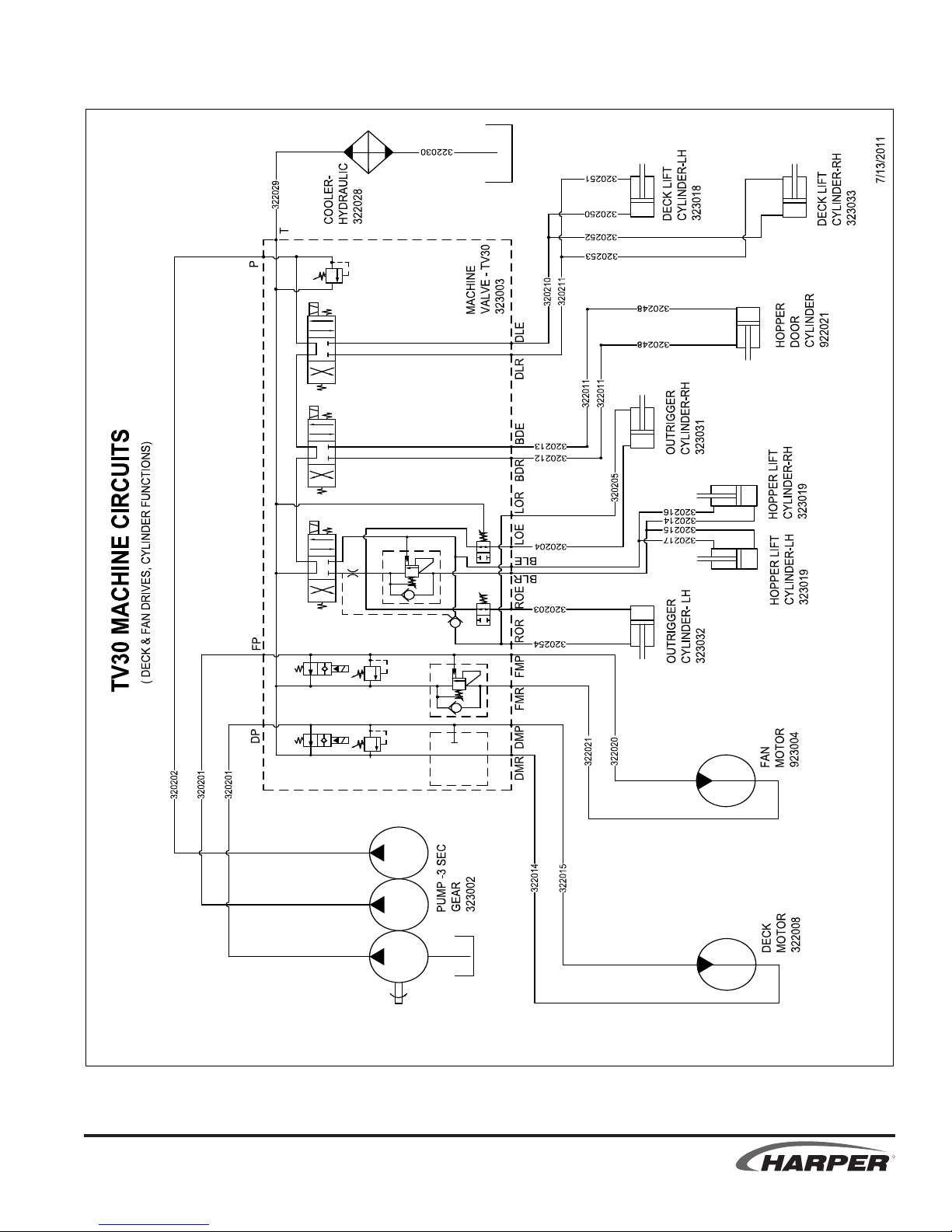

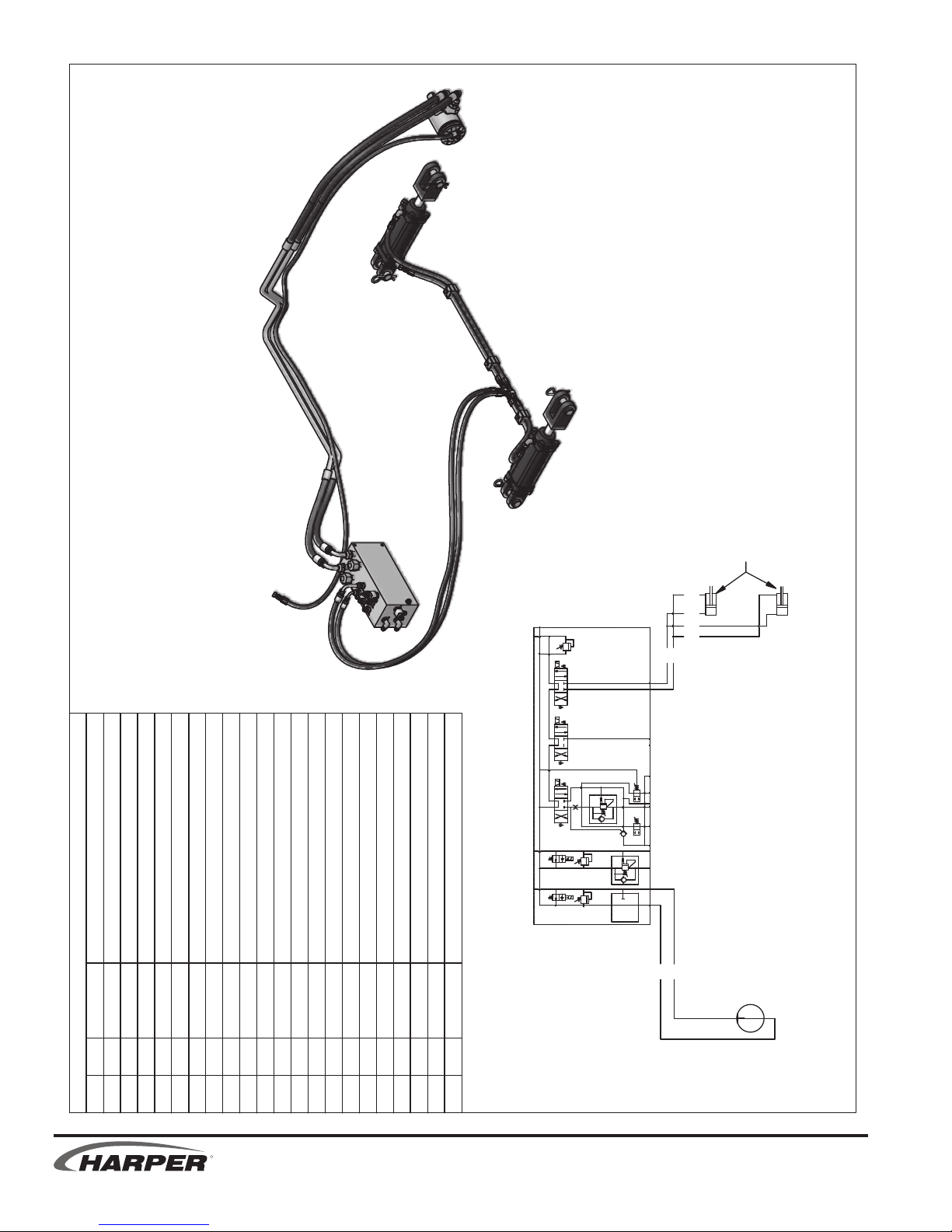

Propulsion System..........................................

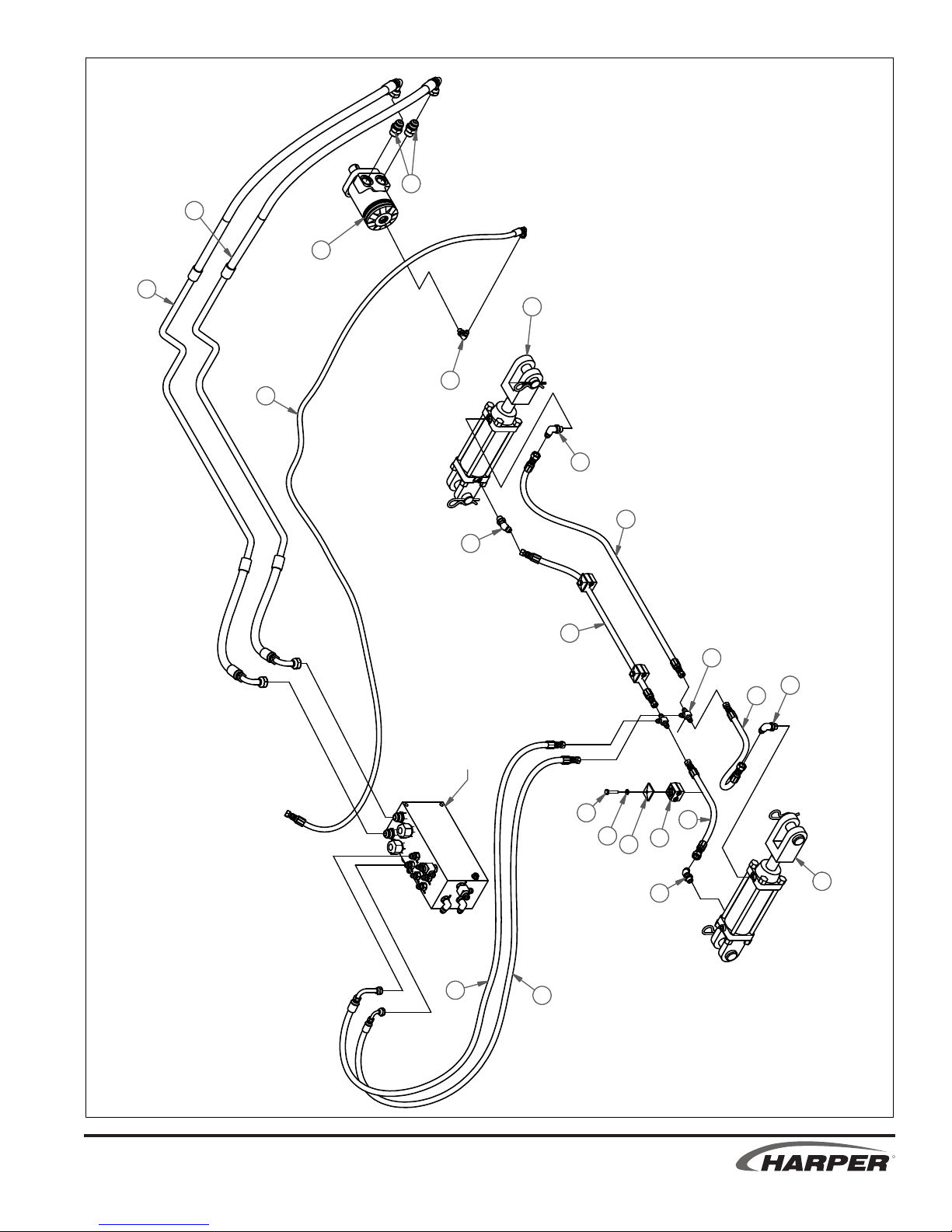

Wheel Motor Plumbing.....................................

Steering System..............................................

Propulsion Suction & Drain Plumbing.............

Machine System..............................................

Triple Section Pump Plumbing........................

Deck Plumbing................................................

Fan Motor Plumbing........................................

Outrigger Plumbing.........................................

Hopper Plumbing............................................

Port Label Abbreviations.................................

Electrical

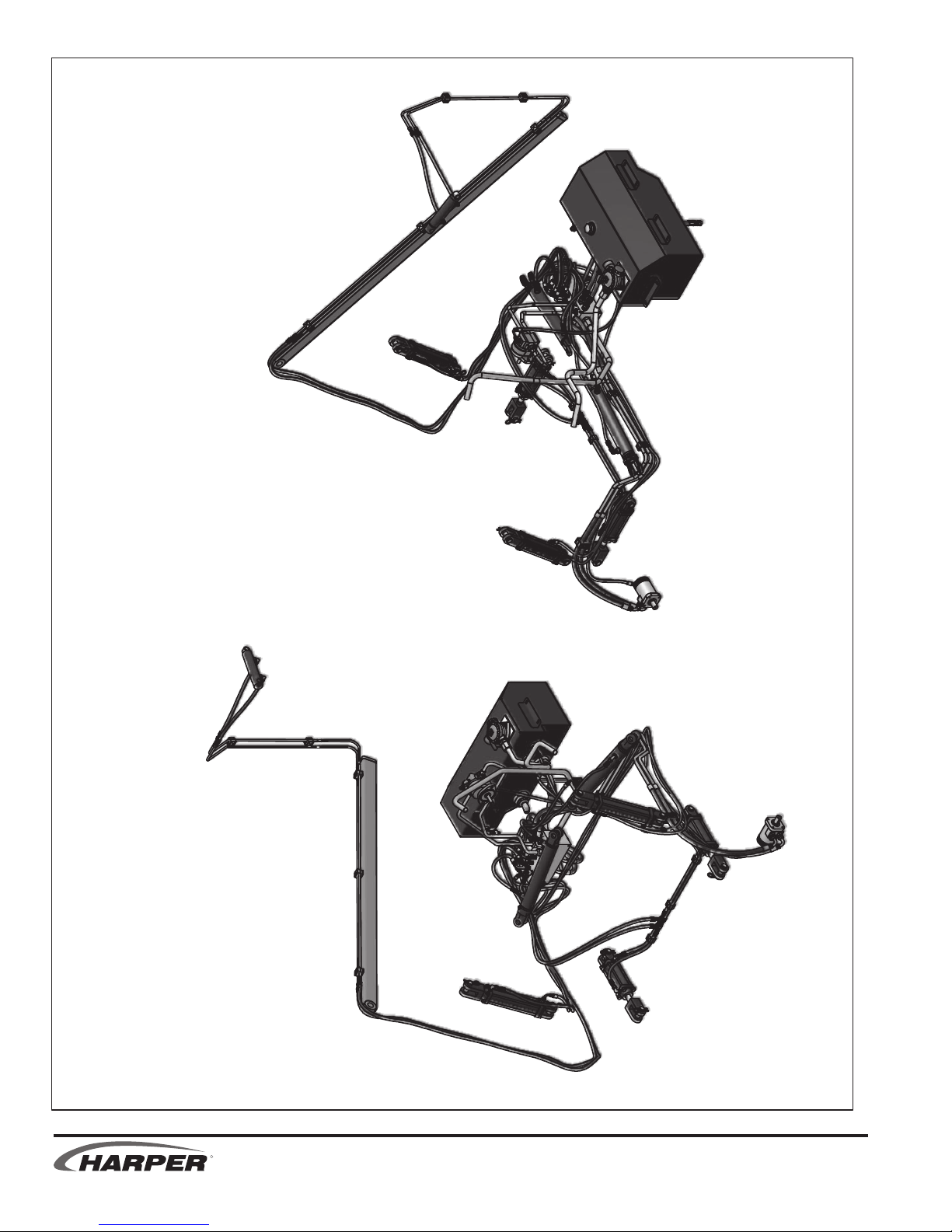

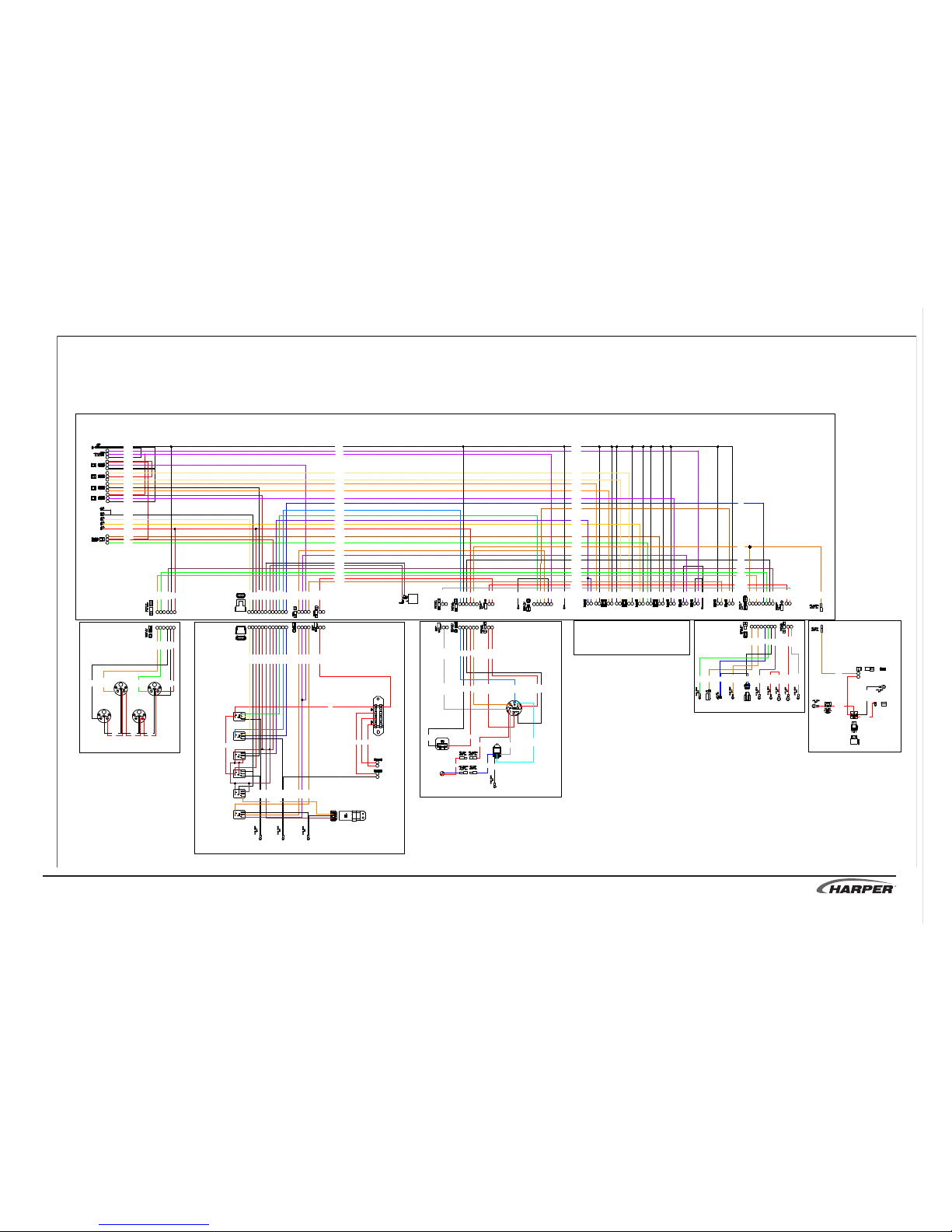

Wiring Schematic Diagram Overview..............

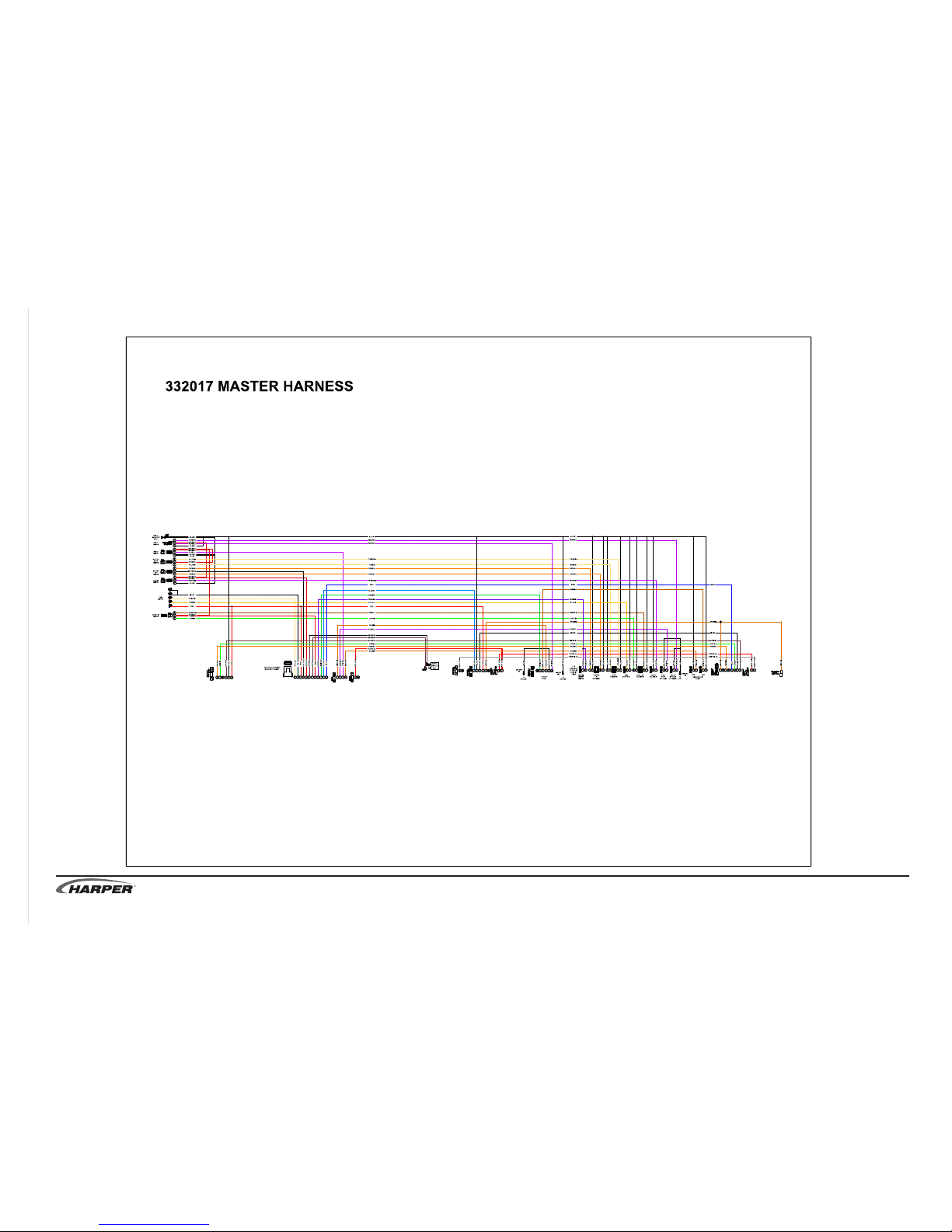

Master Harness...............................................

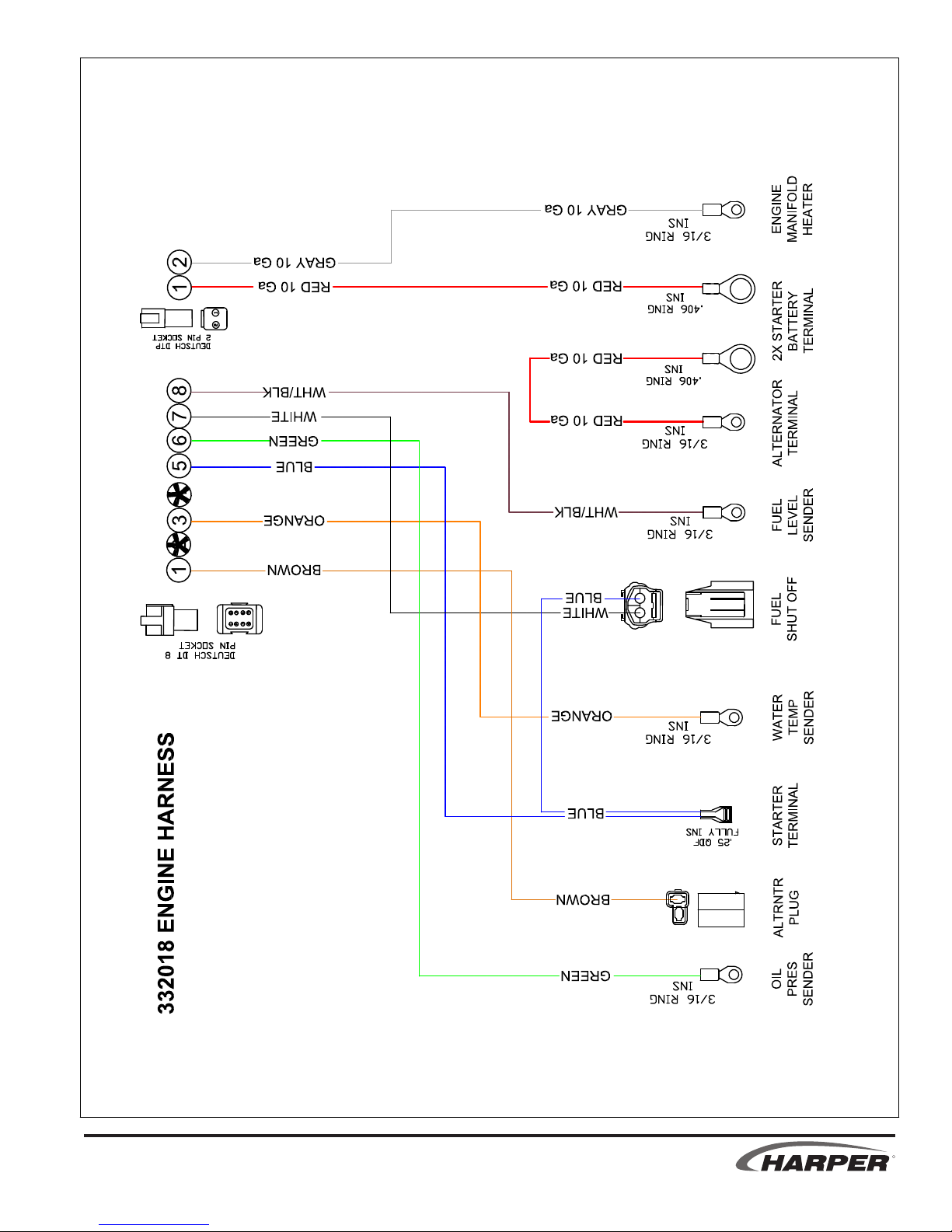

Engine Harness...............................................

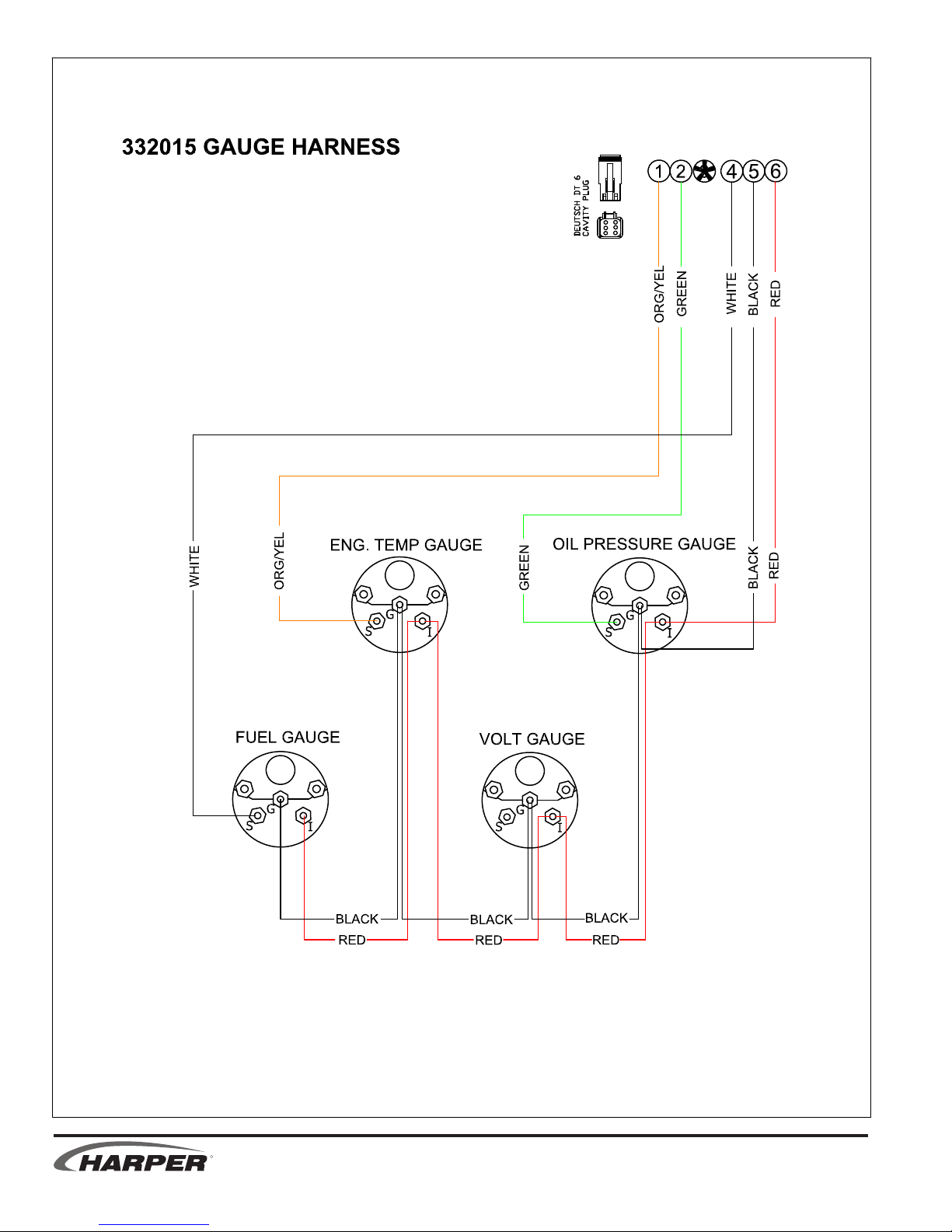

Gauge Harness...............................................

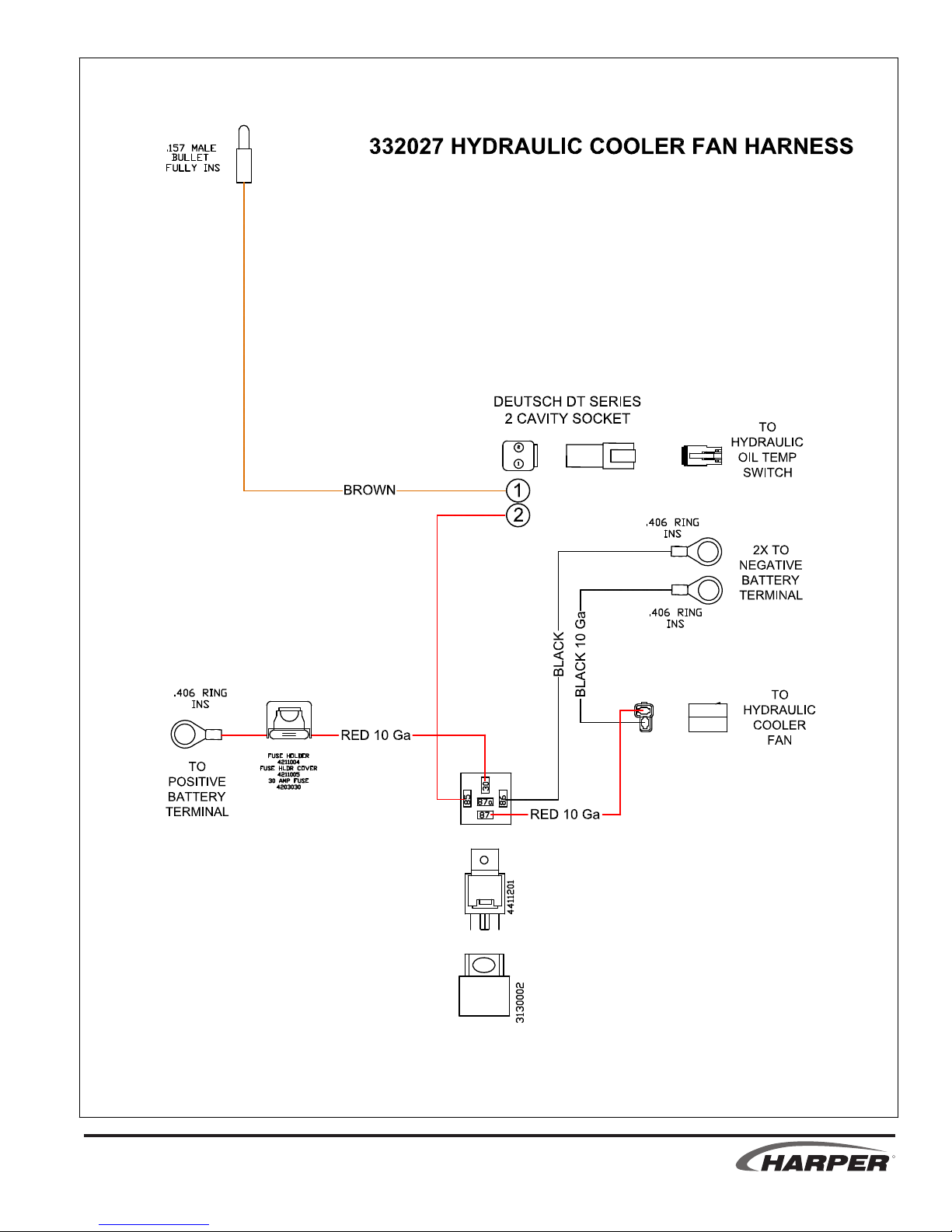

Hydraulic Coller Fan Harness.........................

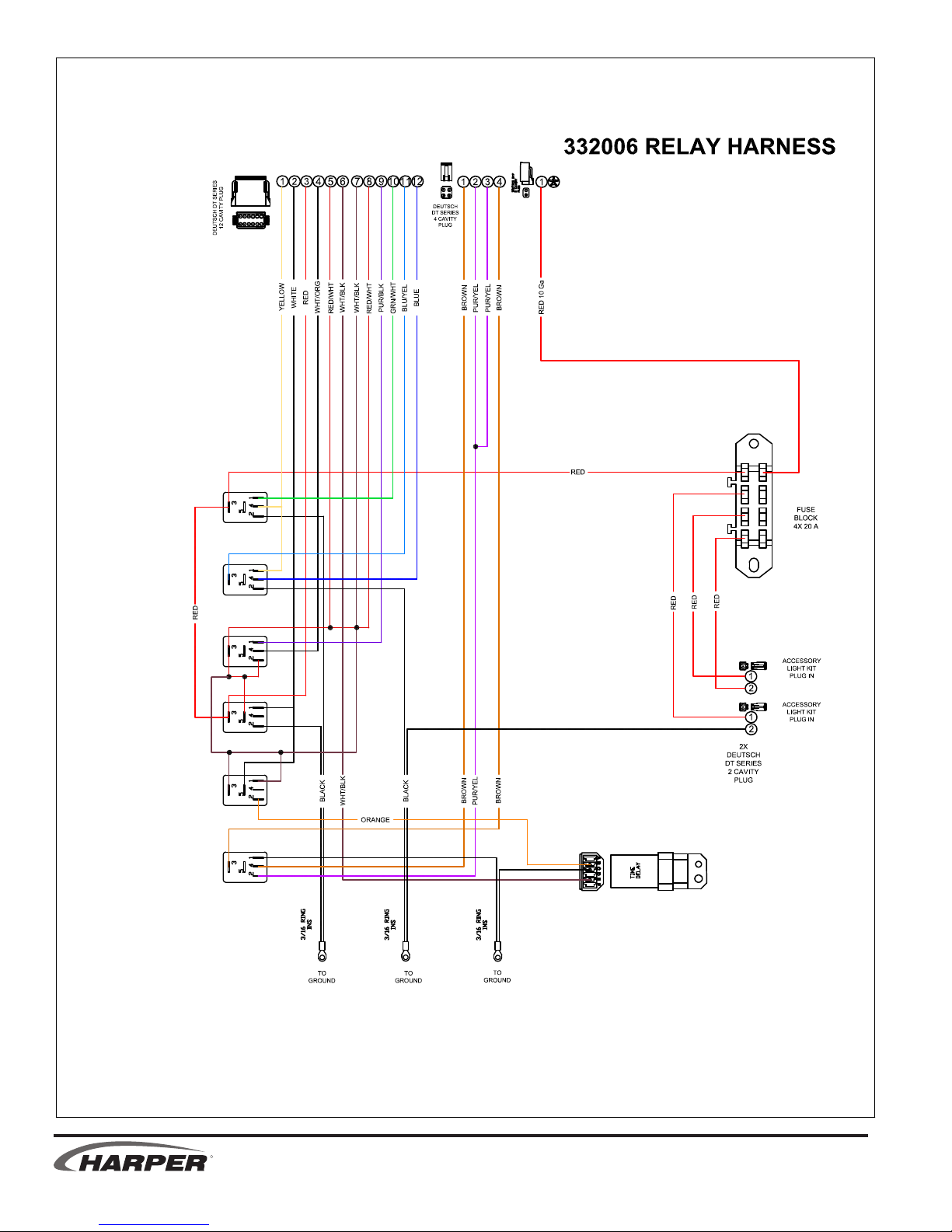

Relay Harness.................................................

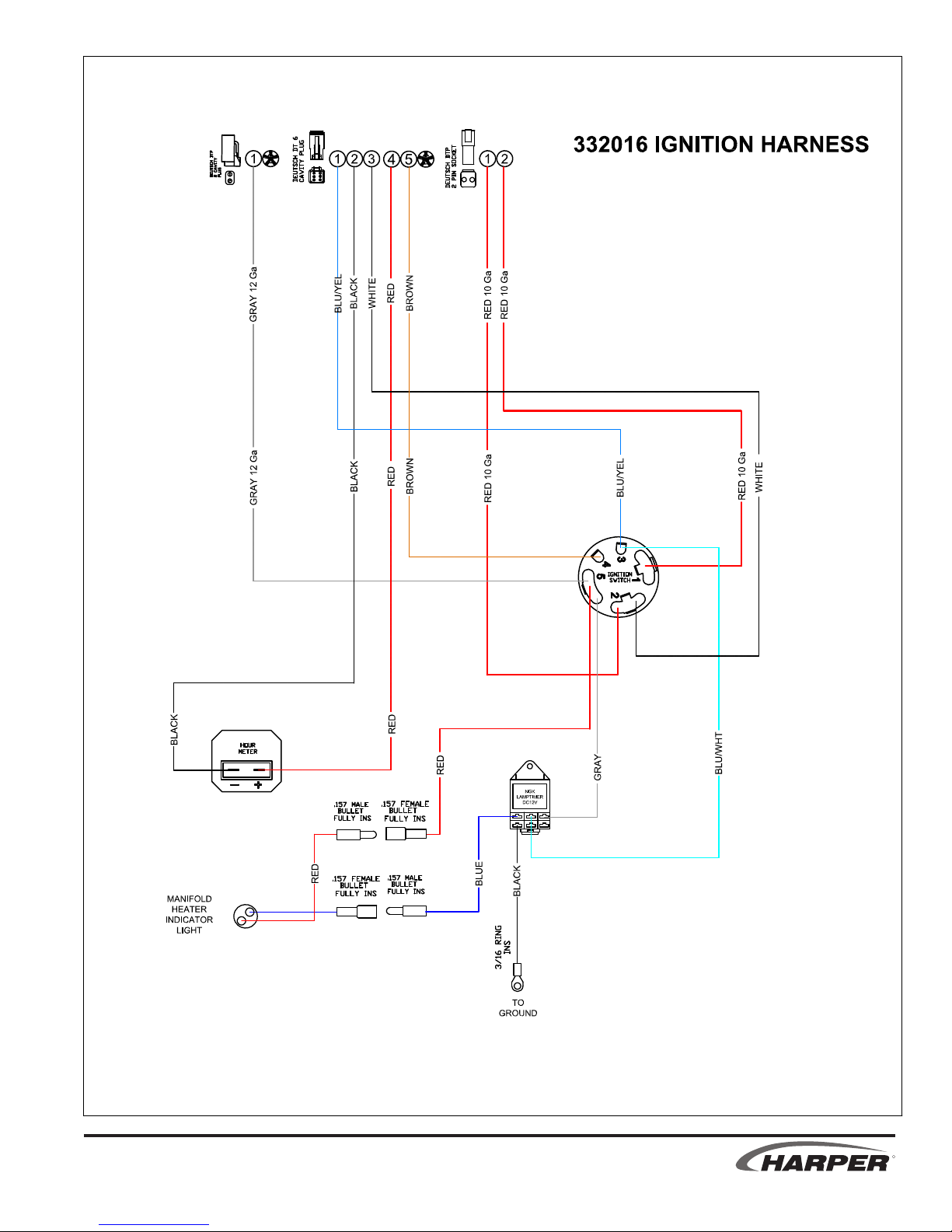

Ignition Harness..............................................

Electrical Assemblies.......................................

Light Package Installation (Optional)...............

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

1.13

1.14

1.15

1.16

1.17

1.18

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

2.17

2.18

2.19

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

TV 30

R

3

Page 6

Specications

Power Diesel - Kubota 44 hp 4-Cylinder (available Spring 2010)

Conguration Self-contained, 4-wheel conguration with front steering, two rear

drive wheels, and a rear mounted, high-lift, debris hopper with patented

recirculating vacuum air technology

Sweeper Head 60” single sweeping reel with nylon bristle brush, follows all terrain with two

caster wheels mounted on sweeper head (vertical and horizontal oat), rises to

transport position, lowers to operating position by hydraulic cylinder

Fan 25” diameter with 6-blade radial fan, fan housing includes UHMW liner

Debris Hopper Capacity – 3.5 cubic yards

Stabilizers Two side stabilizers, auto-deploy

Lift Rises 6’4” above the ground to dump debris into vehicle or container

Lift Safety Slope sensor (7% grade) and lift capacity sensor

Drive Hydrostatic pump directly coupled to engine drives two Poclain high-efciency pis -

ton drive hydraulic motors on rear wheels with two speed operation and differential

lock, foot operated pedal for forward and reverse drive

Speed Innitely variable, 0-8 mph low (operation), 0-14 mph high (transport), 0-7 mph

reverse Braking Dynamic braking through the hydrostatic drive system, mechani-

cally applied and hydraulically released parking brake on rear wheels

Main Frame ¼” and 7 gauge steel frame

Tires/Wheels Front (2) 20-10x10 4-ply premium turf tire, Rear (2) 26-12x12 6-ply premium turf

tires

Compaction 11.2 psi in front, 7.8 psi in rear

Steering Power steering with automotive type steering wheel, tilt steering

Controls/Gauges Hydraulic lift/lower of debris hopper

Hydraulic open/close of debris hopper tailgate

Hydraulic raise/lower of sweeping mechanism head assembly

Solid State max grade detection for dump circuit

Seat Tethered, high back, adjustable position

Electrical 12 volt, electronic key start

Dimensions Length – 144 in., Height – 89 in., Width – 65 in., Wheel Base – 84 in.

Weight 4260 lbs.

Liquid Capacities Fuel – 11 Gallon; Hydraulic Fluid – 19 Gal

Safety & Includes Certied ROPS and seatbelt, outriggers for safety during dumping and a

Conformance solid state max grade detection system for dumping system

Hydraulic Oil Terresolve EL 3068, bio-based, high-performance, ISO 68 – viscosity, severe ser-

vice

NOTE: Following publication of this manual, certain changes in standard equipment and/or options

may have occurred which would not be included in these pages. Your Harper dealer is the

best source for up-to-date information.

R

4

TV 30

Page 7

Control Identication

ROPS – Roll-Over Protective Structure is

certied and designed to protect operator in

case of a roll-over. Always wear a safety belt.

Steering Wheel – steering is hydraulically

controlled. Turning radius of the sweeper

head is approximately 46 in. Steering wheel

angle may be adjusted with tilt knob.

Control Panel –

all functions of the turf

vac may be controlled

from the operator’s seat.

ROPS

HOPPER

HOPPER

DOOR

Foot Pedal –

hydrostatic pump is

controlled by pushing

STEERING

WHEEL

foot pedal forward

and backward.

CONTROL

PANEL

Lift Mechanism –

raises the bottom of

the hopper to a

height of 6’4” to

FOOT PEDAL

dump into a

vehicle or container.

Use extreme caution

when raising the

hopper as the top can

reach approximately 13½ feet.

Fan Housing – surrounds the impeller and is

protected on the inside by a plastic liner.

MECHANISM

FAN HOUSING

SEAT

BELT

STABILIZER ARM

SWEEPER DECK

ENGINE

Hopper Door – opens, closes and locks

when the switch is activated by the operator.

LIFT

Sweeper Deck – has a 60” rotating brush

and is designed to keep the vacuum concentrated on the ground.

Engine – Diesel – 44 HP Kubota

Hopper – stores up to 3½ cubic yards of

material. Always empty hopper at end of

operation.

TV 30

Stabilizer Arms (2) – extend automatically

before hopper is raised and retract after hop-

per is lowered. Make sure stabilizer arms

are stowed completely before sweeping.

R

5

Page 8

Hopper Lift Height Decal – always keep the

height of the turf vac in mind during operation

and be alert for wires, branches, etc. If this

decal is damaged, replace it immediately.

Fan ON/OFF – turn fan on while engine is

from low (diesel) to mid-throttle (gasoline).

Broom ON/OFF – turn broom on while engine is from low (diesel) to mid-throttle (gasoline).

Hopper UP/DOWN – raise hopper with

extreme caution. Stabilizer arms will extend

before hopper raises and will retract after

hopper is lowered. Make sure stabilizer

arms are stowed completely before

sweeping.

Park Brake Indicator – light illuminates

when key switch is on and park brake is set.

Engine Choke (diesel) – use engine choke

when starting a cold engine. Choke may not

be needed if engine is warm.

Door OPEN/CLOSE – hopper door is hydraulically opened and closed with switch.

Operation Speed HI/LO – ALWAYS SWEEP

WITH TRANSMISSION IN LOW. Use high

range when traveling between operations.

Park Brake ON/OFF – set park brake when

unit is not in use or is parked on an incline.

Make sure park brake is disengaged before

operation.

R

Deck Lift – sweeper deck height may be

adjusted for conditions and performance.

Throttle – adjust engine speed with throttle.

Start at low throttle, allow engine to warm up,

then operate unit at full throttle.

Ignition – turn key to right to start unit.

Remove key when unit is not in use. Never

leave unit unattended with key in ignition.

TV 30

6

Page 9

Hopper Lift Cylinder – hopper may be

raised to empty debris into a vehicle or container.

Safety Lock – use safety lock whenever

maintenance is performed. Make sure weight

of raised hopper rests on safety lock by

relieving pressure on cylinder with switch.

Remove safety lock before lowering hopper.

Mercury Switch – senses incline of unit.

Level adjustment is set at factory and does

not require adjustment. If seal is broken, war-

ranty may be voided.

SAFETY WARNING!

DO NOT OPEN SEALED MERCURY

SWITCH Mercury is highly toxic. If mer-

cury switch container is replaced, return

old container to Harper Industries for

disposal.

SAFETY WARNING!

Do not leave Turf Vac unattended, or

attempt any service or inspection unless

the machine has come to a complete stop

and the engine has been shut off.

Impeller – impeller is enclosed in fan hous-

ing. Make sure unit is turned off and key is

removed from ignition before attempting any

service.

Liner – inspect liner frequently for wear.

Replace liner before it wears through to fan

housing.

TV 30

R

7

Page 10

Safety Guidelines

Equipment & Controls

• Read and understand this manual.

• Altering this equipment in any manner

which adversely affects its operation,

performance, durability, or use will void

the warranty and may cause hazard ous conditions.

• Know the location and function of all

controls and how to stop this equip ment quickly in an emergency before

you operate the equipment.

• Keep all nuts, bolts and screws tight to

help ensure safe operation of this

equipment.

• Use genuine factory parts or parts with

equivalent characteristics, including

type, strength and material. Failure to

do so may result in product malfunc tion and possible injury to the operator

and/or others.

• If hardware is not secure, or if some of

the hardware is over-tightened, equi pment failure may result, posing pos sible safety hazards.

• To prevent possible eye injury, always

wear SAFETY GLASSES while oper ating equipment.

Safety Decals

• If safety related or instructional decals

become illegible or are removed, re place them immediately. New decals

may be obtained from your local Harp er Dealer.

• If you replace parts that have such

decals attached to them, make sure

the decals are replaced with current

versions, and are on the replacement

parts before the machine is operated

again.

Diesel Fuel

• Always use an approved container for

transporting diesel fuel.

• Do not allow open ames or sparks

while performing maintenance or refu eling.

• Never remove fuel tank cap or add

fuel when engine is running or while it

is hot.

• Only use ultra low sulfer diesel.

• Never ll fuel tank indoors. Fumes are

heavy and will sink to the lowest point,

collect and become hazardous.

• Wipe up spilled fuel immediately.

• Do not store fuel in a room with an ap-

pliance that has a gas pilot or electri cal switch that may cause sparks.

• Always store diesel outside in a safe ty can (a can with ame arrestor and

pressure relief valve in pour spout).

• Never store the equipment with fuel in

the tank inside a building where fumes

may reach an open ame or spark.

• Allow the engine to cool before storing

in any enclosure.

• Be certain to provide adequate ventila-

tion if an engine must be run indoors -

exhaust fumes are dangerous.

SAFETY WARNING!

Diesel fuel is extremely ammable and can

be highly explosive.

Guards & Shields

• Keep all safety devices in place.

• Replace all worn, damaged, unusable,

missing or lost safety shields and

guards before operating the equip ment.

• Keep the equipment in good operating

condition.

R

8

TV 30

Page 11

Battery

SAFETY WARNING!

Batteries can produce explosive gas.

Use extreme caution when working on

the battery.

• Ventilate when charging battery or us-

ing in an enclosed space.

• DO NOT produce sparks from cable

clamps, tools, or other sources; and

DO NOT allow ames or smoking in

the vicinity of the battery.

• Shield eyes when working near bat-

tery.

Hydraulics

SAFETY WARNING!

Escaping uid under pressure can

penetrate skin causing serious injury.

To prevent serious injury or death:

• Relieve pressure on system before

repairing, adjusting or disconnecting.

• Wear proper hand and eye protection

when searching for leaks.

• Use wood or cardboard instead of

hands when looking for leaks.

• Keep all components in good repair.

• Do not use any type of heat, (welding,

soldering, cutting torch, etc) near

pressurized lines.

Before Operation

• Before operating this equipment, read

and understand the Owner’s Manual.

• Do not allow children to operate this

machine.

• Wear approved eye and ear protection

and other appropriate safety equip ment while operating the machine.

• Check tire pressure and ll to

specications.

• Engine settings are preset and should

not be changed; any change can dam age moving parts and void the war ranty.

• Before starting the machine, visually

inspect all nuts, bolts and other fasten-

ers to see that they are properly se-

cured. Nuts, bolts and other fasteners

should be checked every 8 to 10 hours

of operation for proper alignment and

tightness.

• Replace damaged or missing safety

decals.

• Use factory authorized parts or their

equivalent.

• Make sure that all bearings or hinging

parts are greased and or oiled prop-

erly.

During Operation

• Always keep a re extinguisher near

the Turf Vac during operation.

• Keep clothing and all body parts away

from rotating parts.

• When sweeping material into the

machine, make certain there are no

foreign materials such as rocks, cans,

bottles or other hard materials includ-

ed. Sweeping hard materials will re

duce the life of the plastic liner in the

blower housing.

• If a foreign object should strike the

broom or blower mechanism and

cause an unusual noise or vibration,

shut the engine off immediately and

allow it to come to a complete stop.

Disconnect the spark plug wire from

the spark plug and the power unit. Do

the following:

1. Inspect for damage.

2. Repair or replace any damaged

parts.

3. Check for and tighten any loose

bolts, nuts, fasteners or parts.

• Keep the engine area clean from de-

bris and other accumulations to lessen

the possibility of re.

TV 30

R

9

Page 12

Maintenance

Hydraulic System

• The hydraulic system of the TV30D is

lled at the factory with Terresolve

EnviroLogic 3068 High Performance

Biodegradable Hydraulic Fluid which

has an ISO of 68.

• The TV30D has a 10 micron, beta

rated hydraulic oil filter designed for

long life.

Oil Return

Oil Filter

Hydraulic Reservoir

Dip Stick

• The hydraulic oil level should be moni-

tored daily with the oil dip stick located

on the top of the hydraulic oil reservoir

next to the lter indicator.

• Keep the hydraulic oil near the full

mark at all times. Do not over fill.

• Fill reservoir through the fill location on

top of the reservoir.

• For additional protection, there is also

a mid-pressure filter (part no. 322009).

Mid-Pressure Filter

Filter Indicator

Oil Fill

• On a daily basis, monitor the needle in

the filter indicator while the fan is

running to get an accurate reading.

Yellow

Green

Filter Indicator

Red

Filter Element

• The element (part no. 823004) does

not need replaced until the needle is in

the red portion of the gauge.

• To replace element, remove cap and

twist element counter-clockwise. In sert new element, turn clockwise and

replace cover.

• To get to the mid pressure filter, the

cover must first be taken off by remov ing the bolt on top of the cover.

To get to the mid-

pressure lter.

To get to the engine oil ll,

dipstick, or fuel lter.

R

10

TV 30

Page 13

Grease Zerk Locations

Left Side Right Side

Front Axle (R)

Front Pivot*

Front Axle (L)

Deck Lift (L)

Broom (L)

Roller (L)

Front Pivot Zerk

Front Axle Zerks

PROCEDURE

1) Park on level ground and set park

brake.

2) Lower broom to the ground.

3) Turn off TurboVac.

4) Give 2 to 3 shots of grease after every

10 hours of use.

* same zerk

Air Cleaner

• Make sure intake is always free of

debris.

• When engine is turned off, loosen

clamps on air cleaner to access pri-

mary and secondary elements.

• Replace both elements according to

the Maintenance Schedule.

Roller (R)

Air Intake

Deck Lift (R)

Clamps (3)

Front Pivot*

Broom (R)

TV 30

Primary Element

Secondary Element

R

11

Page 14

Cooling System

Engine Oil

Hydraulic

Oil

Cooler

Radiator

Radiator Fill

Coolant Recovery

Bottle

• Clear hydraulic oil cooler and radiator

of debris with pressurized air daily or

as needed.

• Remove screen on side of oil cooler

to clean properly. It is released by

pulling the tabs located on top and bot tom of the screen.

• Remove vent in front of radiator if

needed to clean.

• Check radiator level daily and only

when engine is cool and not running.

• Remove cap (radiator fill) slowly to

relieve any pressure that may be built

up.

• Fill up radiator with coolant (50% wa-

ter/ 50% antifreeze) until coolant is vis ible in neck of radiator.

• Make sure that the coolant recovery

bottle has at least 1” of coolant in bot tom. The presence of coolant in the

revocery bottle does not mean radiator

is full.

SAFETY WARNING

Hot Coolant and steam from the radiator

can cause severe burns. Never open the

radiator cap of a hot engine.

Engine Oil Fill

Dipstick

Engine Oil Filter

• The dipstick and engine oil fill are lo-

cated on the back left side of the en gine.

• The engine oil filter is located at the

back of the engine and it is obtainable

from the bottom.

• To get to the engine oil fill or dipstick,

the cover must first be taken off by

removing the two wing bold on the top

of the cover (see image on previous

page spread).

PROCEDURE

• Check engine oil level only when en-

gine is turned off.

• Keep engine oil level between the

FULL and ADD marks on dipstick at all

times. DO NOT OVER-FILL.

• Add engine oil (S.A.E. 10W30) through

the engine oil fill location.

• Replace the engine oil according to

the Maintenance Schedule.

• Replace the engine oil filter according

to the Maintenance Schedule.

SAFETY WARNING

Keep dipstick and oil fill cap secured

tightly. Engine oil may escape through

these orifices when engine is running

causing severe burns.

R

12

TV 30

Page 15

Fuel Filter

Standard Torque Chart

Fuel Filter

• Fuel filter is located under the same

cover as the engine oil fill and dipstick

at the back left side of the engine.

• The Fuel Shut-off valve is located

directly under the fuel tank itself, and

to get to it, the rear shield must first be

removed (see fuel tank schematic in

parts section for details on placement

of fuel shut-off).

SAFETY WARNING!

Refer to the Standard Torque Chart when-

ever bolts, nuts or screws are tightened.

Relay Panel

• Refer to the parts section for relay and

corresponding functions.

PRECAUTIONS

• When tightening two or more fasteners

on the same part, DO NOT tighten

the fasteners completely one at a

time. To avoid distortion, first tighten

all fasteners in sequence to one-third

of torque value, then tighten to

two-thirds of torque value, then tighten

to full value.

TV 30

R

13

Page 16

Maintenance Schedule

• See the Kubota Operation and Maintenance Manual provided with the TV30D for a

detailed description of all maintenance and service procedures for the engine.

• For the TV30D, Harper Industries recommends the following:

Daily or Before Starting Engine

Check for leaks, smell of fuel, loose or damaged parts...........Repair as needed.

Check radiator and oil cooler...................................................Blow off debris as needed.

Check air cleaner intake..........................................................Clear debris as needed.

Check engine coolant level ......................................................50% antifreeze, 50% water

Check engine oil level..............................................................SAE10W30

Check hydraulic oil level..........................................................Terresolve EL 3068

Fill fuel tank.............................................................................Clean #2 diesel fuel

Visually inspecting fittings and hoses......................................Tighten or replace as needed.

Grease.....................................................................................See Grease Locations.

Check Tire Pressure................................................................Inflate to 30 PSI

Check lights.............................................................................Replace as needed.

Check hydraulic filter indicator (engine and fan running)........Replace filter (823004) when

needle is in the red.

Every 50 hours

Check of fuel pipes and clamp bands.....................................See Kubota Manual

Draining water separator.........................................................See Kubota Manual

100 Hour Maintenance Perform these and all previous items:

Check outer air cleaner element.............................................Harper part no. 502009

• (Change if element appears dusty due to severe conditions.)

Change engine oil...................................................................SAE10W30

• (Refer to Kubota manual for oil type and procedure.)

Check battery..........................................................................Clean terminals if necessary.

250 Hour Maintenance

Change outer air cleaner element..........................................Harper part no. 502009

Check inner air cleaner element.............................................Harper part no. 502010

• (Change if element appears dusty due to severe conditions.)

Check battery electrolyte level

Check fan belt tightness..........................................................Tighten as needed.

Check radiator hoses and clamp bands..................................Tighten or replace as needed.

Check intake air lines..............................................................Clear debris as needed.

Annual or 500 Hour Maintenance Perform these and all previous items:

Change engine oil filter...........................................................Harper part no. 302058

• (Refer to Kubota manul for filter type and procedure.)

Change fuel filter....................................................................Harper part no. 302057

• (Refer to Kubota manul for filter type and procedure.)

Change mid-pressure filter.....................................................Harper part no. 322009

Check hydraulic oil condition.................................................19 gal. Terresolve EL 3068

Change inner air cleaner element..........................................Harper part no. 502010

Removal of sediment in fuel tank

Cleaning of water jacket (radiator interior)

Replacement of fan belt

Cleaning of water separator

R

14

TV 30

Page 17

1000 Hour Maintenance Perform these and all previous items:

Change hydraulic oil................................................................19 gal. Terresolve EL 3068

Check valve clearance

Every One or Two Months Perform these and all previous items:

Recharge battery

1500 Hour Maintenance Perform these and all previous items:

Check of fuel injection nozzle injection pressure

3000 Hour Maintenance Perform these and all previous items:

Check turbo charger

Check injection pump

Check fuel injection timer

Every Two Years Maintenance Perform these and all previous items:

Change radiator coolant (L.L.C.)

Replacement of battery

Replacement of radiator hoses and clamp bands

Replacement of fuel pipes and clamp bands

Replacement of fan belt (or every 500 hours)

Date of Maintenance:______________ Hours:________ Performed by:_________________

• Forwarrantyreplacementorrepairofdieselengine,contactKubotaEngineAmerica

Corporation directly. Refer to www.kubotaengine.com for a service location.

TV 30

R

15

Page 18

R

TV 30

Page 19

Parts Section

TV 30

R

Page 20

R

TV 30

Page 21

Table of Contents

PARTS SECTION

Table of Contents

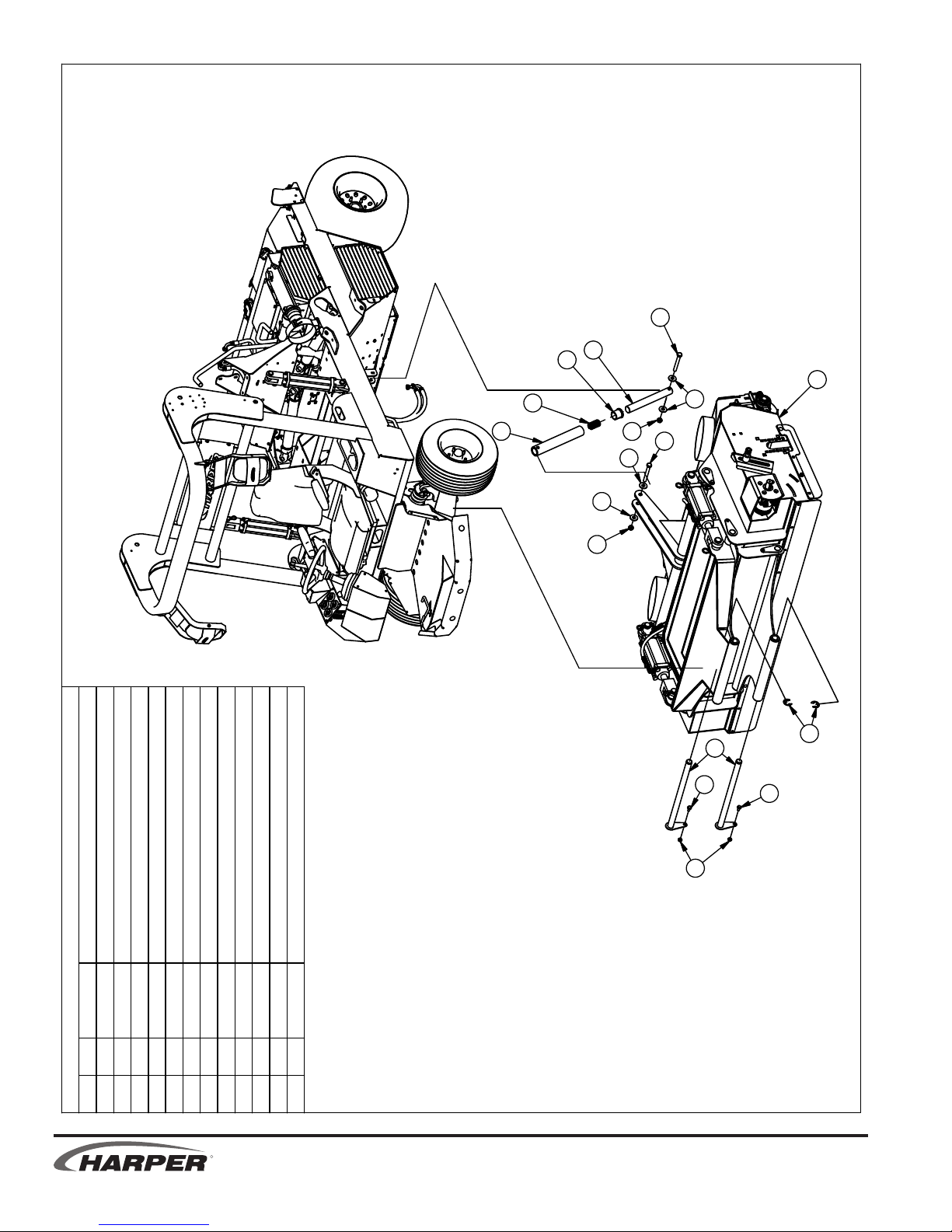

Frame and Engine

Frame Assembly...............................................

Control Arm Assembly......................................

Front Axle Assembly.........................................

Engine and Tank Installation............................

Diesel Engine Assembly...................................

Fuel Tank Assembly..........................................

Engine Shield Assembly...................................

Deck Assembly.................................................

Deck Installation...............................................

Broom Kit..........................................................

Finger Kit..........................................................

Verticut/Dethatch Kit.........................................

Fan Housing & Hydraulic Cooler Assy..............

Fan Housing Installation...................................

Outrigger Installation........................................

Hopper and Door Assembly..............................

Hopper Installation...........................................

Operator Station...............................................

Hydraulic

Hydraulic Reservoir Assembly..........................

Wheel Motor Assembly.....................................

Propulsion Pump Assembly..............................

Triple Section Pump Assembly.........................

Master Valve Assembly.....................................

Propulsion Valve Assembly...............................

Sequence Valve Assembly...............................

Pressure Reduction Valve Assembly................

Hydraulic Cylinder Service Parts......................

Propulsion System...........................................

Wheel Motor Plumbing.....................................

Steering System...............................................

Propulsion Suction & Drain Plumbing..............

Machine System...............................................

Triple Section Pump Plumbing.........................

Deck Plumbing.................................................

Fan Motor Plumbing.........................................

Outrigger Plumbing..........................................

Hopper Plumbing.............................................

Port Label Abbreviations..................................

Electrical

Wiring Schematic Diagram Overview...............

Master Harness................................................

Engine Harness................................................

Gauge Harness................................................

Hydraulic Coller Fan Harness..........................

Relay Harness..................................................

Ignition Harness...............................................

Electrical Assemblies........................................

Light Package Installation (Optional)................

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

1.13

1.14

1.15

1.16

1.17

1.18

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

2.17

2.18

2.19

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

TV 30

R

Page 22

R

TV 30

Page 23

PARTS

FRAME & ENGINE

SECTION

TV 30

R

Page 24

FRAME ASSEMBLY

6/7/2011

BOLT, 1/2-13 X 2.75 HEX

PARTS LIST

1 4 110017 BOLT, 5/16-18 X 1.75

2 53 110020 Bolt, 5/16-18 X 0.75 in Carriage

3 4 110129

4 16 110290 NUT, 1/4-20 WIZ FLANGE

ITEM QTY PART # DESCRIPTION

5 16 110358 Bolt, 1/4-20 X 0.625 in Carriage

Bolt, 3/8-16 X 1 in Carriage

NUT, 5/16-18 WIZ FLANGE

6 20 110419 BOLT, 1/2-13 X 1.75

7 2 110437 BOLT, 3/8-16 X 0.75, WIZ FLANGE

8 8 110556

9 4 110603 NUT, 5/16-18 LOCK (NYLON)

10 78 110606

11 24 110610 NUT, 1/2-13

12 10 110645 NUT, 3/8-16 WIZ FLANGE

13 8 110665 WASHER, 5/16" FLAT STANDARD

R

WASHER, 3/4" FLAT SAE

14 24 110666 WASHER, 1/2" LOCK

15 2 110678

16 1 110862 WASHER - THRUST, IGUS MTI-24

17 2 110888 SNAP RING - EXT, 1-1/2

18 2 110889 CLEVIS PIN - 3/4 X 3.5

19 2 200029 COTTER PIN, 5/32 X 1

FILLER - REAR RADIATOR

20 6 302019 PAD - LIFT ARM

21 1 302053 FILLER - FRONT RADIATOR

22 1 302054

23 1 311189 GUIDE - LINKAGE, HOPPER, LH

24 1 311190 GUIDE - LINKAGE, HOPPER, RH

PIN - FRONT AXLE, TV30

25 1 311363 BRACKET - SUPPORT, RETURN AIR

26 2 311459 KEEPER - AXLE PIVOT, LOWER

27 1 311462

28 1 311521 SCREEN - SIDE, REAR BELLY, LH

29 1 311522 SCREEN - SIDE, REAR BELLY, RH

ARM - CONTROL, ASSEMBLY

MOTOR - WHEEL, HYDRAULIC, POCLAIN, RH

30 1 311569 SCREEN - REAR AXLE

31 1 315106 FRAME - WELDED, TV30

32 1 315110

33 1 315117 AXLE - FRONT, ASSEMBLY

34 2 315180 MOUNT - ENGINE, FRONT, WELDMENT

35 1 315181 MOUNT - ENGINE, REAR, LH, WELDMENT

36 1 315182 MOUNT - ENGINE, REAR, RH, WELDMENT

37 1 315209 FRAME - BELLY INTAKE SCREEN, WLDMNT

38 2 315210 SCREEN - BELLY, INTAKE, WELDMENT

39 2 322004

40 1 510174 GREASE ZERK, 1/4-28 ST

TV 30

1.1

Page 25

28

6/7/2011

36

35

34

25

30

SEE HYDRAULIC

1

13

2

12

34

7

2

24

23

20

SECTION

8

13

9

11

14

8

22

6

10

15

19

4

12

5

12

4

29

37

38

21

16

FRAME ASSEMBLY

31

17

26

3

10

27

17

40

2

SEE CONTROL

ARM ASSEMBLY

18

SEE FRONT

AXLE ASSEMBLY

TV 30

R

ii 1.1

Page 26

19

7/18/2011

8

1

CONTROL ARM ASSEMBLY

ASSEMBLY NOTES:

SECURE ITEM No. 12, HARPER PRT No. 110860

2) LEAVE 1-5/8" to 1-3/4" PROTRUDING

1) WITH LOCTITE RED

TORQUE ITEM No. 5, HARPER PRT No. 110610

12

16

15

18

17

13

3

22

21

14

SECURE ITEM No. 6, HARPER PRT No. 110615

2) WITH LOCTITE BLUE

1) AGAINST ITEM No. 5, HARPER PRT No. 110610

TO XX Ft/Lbs

4

2

20

9

11

7

DESCRIPTION

BOLT, 5/16-18 X 1.75

PARTS LIST

NUT, 1/4-20, UNITORQUE LOCK

11017422

11001721

PART #

QTY

ITEM

NUT, 1/2-131106101

BOLT, 1/4-20 X .5011051523

NUT, 10-24 RIVET ALUMINUM11083548

NUT, 1/2-13, UNITORQUE LOCK

NUT, 5/16-18, UNITORQUE LOCK

11060024

WASHER, 1/2" FLAT STANDARD1106582

BUSHING - IGUS, 1 3/4 x 1 1/2 x 1 1/211085219

11061516

7

5

R

STUD - 1/2-13 X 2-1/2

PLUG - 11/16", NON-VENTED110884113

WASHER - .531 X 2.0, FENDER, CS HRD110856111

SPRING - POLYURETHANE DISC, 1/2" FLAT

110855210

110860112

SPRING - COMPRESSION, 3/4 X 2.0

110886114

10

KNOB - TILT ADJUSTMENT 302014116

SPACER - TILT ADJUSTMENT311358318

ARM - CONTROL, WELDMENT

PLATE - NOTCHED, TILT ADJUSTMENT

PLATE - THRUST, PIVOT, STEERING BOX

302004115

311357117

315110119

HOUSING - SPRING, WELDMENT315172122

PIN - TILT ADJUSTMENT, WELDMENT

STEERING BOX - MOUNT, WELDMENT315111120

315126121

5

6

TV 30

1.2 1.3

Page 27

22

12/1/2011

16

FRONT AXLE ASSEMBLY

GREASE CAP3120011

DESCRIPTIONPART #QTY

10

1

2928

2

29

21

5

20

17

13

11

15

12

7

18

25

27

HUB ASSEMBLY SERVICE PARTS

14

4

9

24

6

8

GREASE SEAL

NUT - CROWN, 1-143102611

HUB - 5 ON 4-1/2, 1750 Lbs

STUD - WHEEL, 1/2 - 20 NF3120035

3120041

3120021

INNER RACE3120071

OUTTER RACE3120051

INNER BEARING3120081

OUTER BEARING3120061

COTTER PIN, 5/32 X 2

5109931

26

21

2

3

19

DESCRIPTIONPART #QTYITEM

Parts List

BEARING - THRUST, 1.0 ID X 5/8 T10204321

BOLT, 5/16-18 X 0.75, WIZ FLANGE11044422

NUT, 3/8-16 GR 511082625

BOLT, 3/8-24 X 2.511049713

WASHER, 3/4" FLAT SAE11067844

BUSHING - IGUS MFI2832-24

11085326

CLEVIS PIN - 3/4 X 3.5110889 49

NUT - JAM, 3/4-16 UNF, LH110891110

NUT - JAM, 3/4-16 UNF, RH110892111

SPRING - COMPRESSION, 6 X 4 X .625

BUSHING - 2.0 OD X 1.5 ID x 2.0, 660 BRNZ11085727

11085828

23

28

27

TIE ROD - TV30311254117

TIE ROD END - LH

ROLL PIN, 1/4 X 1.5200028113

SET SCREW - 3/8 X 2, SQU HD110921212

TIE ROD END - RH311012116

COTTER PIN, 5/32 X 1200029414

311011115

PIN - STEERING CYLINDER311406118

SECTION

SEE HYDRAULIC

KEEPER - 3/8" HEX311461119

GREASE ZERK, 1/4-28 ST510174428

AXLE - FRONT, WELDMENT315117120

KINGPIN - TV30, WELDMENT315136221

SPINDLE - TV30, LH, WELDMENT

SPINDLE - TV30, RH, WELDMENT315138123

MOUNT - SUSPENSION, LOWER, WELDMENT

315137122

315139224

HUB - 5 ON 4-1/2, 1750 Lbs342004227

CYLINDER - STEERING, 1-3/4 X 6323010126

MOUNT - SUSPENSION, UPPER, WELDMENT315140225

BUSHING - 1-1/4 OD X 1.0 ID510821429

TV 30

R

1.3

Page 28

ENGINE & TANK INSTALLATION

12/1/2011

DESCRIPTION

NUT, 1/4-20 WIZ FLANGE110290213

Bolt, 1/4-20 X 0.625 in Carriage110358214

NUT, 1/4-20, UNITORQUE LOCK11017412

SCREW, 10-24 X 0.75, HEX, FLG11008241

Parts List

PART #

QTY

ITEM

BOLT, 3/8-16 X 2.2511049367

BOLT, 5/16-18 X 1, WIZ FLANGE11045926

BOLT, 5/16-18 X 0.75, WIZ FLANGE

11044435

R

NUT, 1/4-20

NUT, 5/16-18 WIZ FLANGE11060659

NUT, 5/16-18 LOCK (NYLON)11060328

NUT, 3/8-16 WIZ FLANGE1106451012

WASHER, 1/4" FLAT STANDARD110673113

NUT, 3/8-16 LOCK NYLON INSERT110618611

110609110

PAD - LIFT ARM302019121

Bolt, 5/16-18 X 1 in Carriage110871215

Bolt, 3/8-16 X 0.75 in Carriage1108941016

WASHER, 3/8" FLAT STANDARD110676614

GROMMET - 3/8 ID X 1-1/4 OD, 1/16 X 1110942119

GROMMET - 1.0 ID X 1-3/4 OD, 1/16 X 1-3/8

GROMMET - 5/8 ID X 1-1/2 OD, 1/16 X 1-1/4110940218

110939217

INTAKE TUBE ASSEMBLY

STOP - SCREEN, FRONT, LH311319123

GROMMET - 5/16 ID X 1.0 OD, 1/16 X 3/4110943120

302040122

MOUNT - AIR CLEANER311476126

STOP - SCREEN, LOWER 311325225

STOP - SCREEN, FRONT, RH311320124

MOUNT - ESCUTCHEON

ESCUTCHEON - RETURN OIL

ESCUTCHEON - FAN MOTOR SUPPLY311547128

311558129

311533227

FILLER - TANK SIDE311586132

FILLER - REAR FUEL TANK311585131

STOP - SCREEN, REAR, LH315165133

FILLER - HYDRAULIC TANK REAR311584130

STOP - SCREEN, REAR, RH WELDMENT

315166134

ENCLOSURE - FRONT ENGINE, LH315221137

ENCLOSURE - FRONT ENGINE, RH315220136

BOLT - THROTTLE PIVOT, WELDMENT315218135

FILTER - FUEL343008140

WELDMENT, TANK BRACKET315225138

REDUCER - SILICONE, 2-1/2 x 2

342036139

CLAMP, HOSE #32 2.00"500107143

AIR CLEANER - 2-1/2", ENGINAIRE

CONTROL - PUSH, LEVER, THROTTLE353001142

343009141

TV 30

1.4

Page 29

30

12/1/2011

SECTION

SEE HYDRAULIC

3

28

18

20

19

17

4

36

4

27

29

34

25

24

37

15

8

21

12

38

16

31

32

ASSEMBLY

SEE FUEL TANK

33

4

25

ENGINE & TANK INSTALLATION

23

3

14

35

13

42

1

10

40

2

343008 Service Parts

PART DESCRIPTION DETAILS

302057 FUEL FILTER SEE MAINTENANCE SECTION

6

9

2243

39

11

41

6

9

7

7

14

11

26

5

ENGINE

ASSEMBLY

SEE DIESEL

TV 30

R

ii 1.4

Page 30

DIESEL ENGINE ASSEMBLY

6/6/2011

BOLT, 1/2-13 X 1.75

BOLT, M10x1.25 x 20 Gr 10.9

NUT, 3/8-16 LOCK NYLON INSERT

PARTS LIST

1 2 110155 WASHER, 3/8" FLAT SAE

2 2 110178 BOLT, 3/8-16 X 1.5 SHCS

3 2 110419

4 8 110426 BOLT, 5/16-18 X 0.5, WIZ FLANGE

5 1 110459 BOLT, 5/16-18 X 1, WIZ FLANGE

6 1 110469 BOLT, M8x1.25 x 20 Gr 10.9

7 4 110493 BOLT, 3/8-16 X 2.25

8 17 110560

9 1 110606 NUT, 5/16-18 WIZ FLANGE

10 4 110618

11 2 110658 WASHER, 1/2" FLAT STANDARD

12 2 110666 WASHER, 1/2" LOCK

ITEM QTY PART # DESCRIPTION

R

13 2 110672 WASHER, 3/8" LOCK

WASHER, 3/8" FLAT STANDARD

14 1 110674 WASHER, 5/16" LOCK

15 4 110676

16 17 110689 WASHER, 10mm LOCK

17 1 302017 CLEVIS - THROTTLE

SUPPORT - PUMP, HYDRAULIC

MOUNT - MOTOR, LH, WELDMENT

18 10 302041 ISOLATOR - MOUNT

19 1 302052 SLEEVE - EXHAUST, TV30

20 1 311376

21 1 311474 BAFFLE - LOWER RADIATOR

22 1 315183

23 1 315184 MOUNT - MOTOR, RH, WELDMENT

24 1 315185 MOUNT - RADIATOR, WELDMENT

ADAPTER - PUMP, KUBOTA 1505, KIT

25 1 315186 MOUNT - KUBOTA THROTTLE, WELDMENT

26 1 332004 SENDER-WATER TEMP,3/8 NPT,HGH RNG

27 1 342011

28 1 342012 MUFFLER - KUBOTA 1505

29 1 342034 HOSE - RADIATOR, LOWER, TV30

RADIATOR - TV30 DIESEL

30 1 342035 HOSE - RADIATOR, UPPER, TV30

31 1 343002 ENGINE - DIESEL, KUBOTA, 1505

32 1 343005

33 1 353001 CABLE - THROTLE

34 1 530068 OIL PRESSURE SENDER

35 4 720107 CLAMP, HOSE #20 1.25"

36 1 832001 STARTER GROUND

TV 30

1.5

Page 31

4

32

24

18

18

8/11/2011

8

15

7

21

5

35

30

FAN - P/N: 342033

31

18

35

18

23

10

22

29

17

18

18

25

9

16

DIESEL ENGINE ASSEMBLY

DETAILS

343002 Service Parts

DESCRIPTION

PART

26

34

36

19

27

28

ENGINE OIL FILTER SEE MAINTENANCE SECTION

302058

36

11

33

14

6

12

3

16

8

SEE HYDRAULIC

SECTION

20

1

13

18

2

18

TV 30

R

ii 1.5

Page 32

12/5/2011

4

FUEL TANK ASSEMBLY

6

5

3

2

8

1

7

DESCRIPTION

ADAPTER, 5HB-6FBX12037811

ADAPTER, 6MJ-6MP9012050012

TANK - FUEL, WELDMENT

PARTS LIST

PART #

QTY

ITEM

SENDER - FUEL LEVEL, ELECTRIC

31514113

33200514

CLAMP, HOSE #10 .50"5200981

GASKET, FUEL SENDER5001721

FITTING, REDUCER 3/8 X 1/4 NPT

VALVE, FUEL SHUT OFF 6MB-4MP

50020916

80202318

7

5

R

1.6 1.7

TV 30

Page 33

ENGINE SHIELD ASSEMBLIES

1

7/18/2011

3

9

1

2

4

8

7

DESCRIPTION

NUT - LUG 1/2-20

COVER - WHEEL MOTOR

LID - ENGINE ENCLOSURE3115651

26" MULTI-TRACK TIRE & WHEEL

PARTS LIST

PART #

QTY

ITEM

10x20 TIRE & WHEEL ASSEM - FRONT 30201123

110617201

30200822

SCREEN - DIESEL EXHAUST

31156124

31519016

5

SCREEN - INTAKE, WELDMENT31520719

PANEL - RADIATOR EXHAUST, WELDMENT3152051

7

ENCLOSURE - REAR ENGINE, WELDMENT

GUARD - UPPER RADIATOR, LOUVERED, WELDMENT

31520618

315208110

SCREEN - REAR INLET315223113

LID - ENGINE ENCLOSURE, WELDMENT315215111

ENCLOSURE - UPPER ENGINE, WELDMENT

315217112

12

11

5

6

10

13

TV 30

R

1.7

Page 34

PARTS LIST

DESCRIPTIONPART #QTYITEM

Bolt, 5/16-18 X 0.75 in Carriage11002081

NUT, 5/8-11 JAM11003922

BOLT, 3/8-16 X .75 FLT HD SKT HD

11012643

Bolt, 1/4-20 X 0.75 in Carriage110154234

NUT, 1/4-20 WIZ FLANGE110290235

Bolt, 1/4-20 X 0.625 in Carriage110358126

BOLT, 5/16-18 X 0.75, WIZ FLANGE11044467

BOLT, 3/8-16 X 4.5 TAP

11058128

NUT, 5/16-18 WIZ FLANGE110606149

WASHER, 3/8" LOCK

110672410

NUT, 3/8-16 GR 51108261011

Bolt, 5/16-18 X 1 in Carriage110871412

Bolt, 5/8-11 X 3 in Carriage110895113

SKIRT - DECK, RUBBER, FRONT302018114

SKIRT - DECK, RUBBER, SIDE

302034215

SCRAPPER - DECK ROLLER, RUBBER302049116

RETAINER - DECK SKIRT311335217

SPACER - IDLER311370118

BAFFLE - DECK, RETURN AIR311382319

RETAINER - DECK SKIRT, FRONT

311383120

BRACKET - ROLLER ADJUSTMENT, DECK311389221

BRACKET - ROLLER ADJUSTMENT, BEARING

311391222

BRACKET - ROLLER ADJUSTMENT, DECK311505123

RETAINER - SCRAPPER, DECK ROLLER311528124

CANVAS RING - EDGE GUARD, 5/32311587125

DECK WELDMENT315100126

LINKAGE - DECK MOUNT, UPPER, WELDMENT

315108127

LIFT - DECK, REAR, WELDMENT315112128

PIN - DECK, LOWER, WELDMENT315160229

PIN - DECK, WELDMENT315161430

MOUNT - SCRAPPER, DECK ROLLER, WELDMENT315177131

LINKAGE - DECK MOUNT, LOWER, WELDMENT

315193132

ROLLER - TV30 DECK, WELDMENT315197133

BEARING - 1", 2 - BOLT FLNG, MED DUTY342008234

BUSHING, MFI-1620-248001241035

DECK ASSEMBLY

12/2/2011

R

TV 30

1.8 ii 1.8

Page 35

12/2/2011

26

SEE HYDRAULIC

SECTION

35

35

27

DECK ASSEMBLY

35

28

35

30

33

9

9

6

25

1

13

18

2

3

15

21

5

19

22

8

34

11

12

10

11

TV 30

7

9

17

29

SECTION

35

4

SEE HYDRAULIC

32

35

35

29

20

14

R

ii 1.8

Page 36

12/2/2011

1

9

12

8

6

5

DECK INSTALLATION

DESCRIPTION

BOLT, 1/2-13 X 4.0

10

4

1

5

5

4

7

11

2

3

2

BUSHING, IGUS MFI-2024-24

10 1 315113 TUBE - LIFT LINK, WELDMENT

11 2 315162 PIN - DECK MOUNT, WELDMENT

12 1 800129

PARTS LIST

PART #

QTY

ITEM

NUT, 1/2-13, UNITORQUE LOCK

BOLT, 5/16-18 X 0.75, WIZ FLANGE

110658 WASHER, 1/2" FLAT STANDARD

1 2 110003

2 2 110444

3 2 110606 NUT, 5/16-18 WIZ FLANGE

4 2 110615

54

TV30 - BUILD STATION No. 5 - DECK

SPRING - COMPRESSION, 1-3/16 OD X 2. L, K 800

2 110913 RETAINING RING, 1" EXIT E

6 1 110861

7

8 1 305045

9 1 311133 ROD - LIFT LINK

R

1.9

TV 30

Page 37

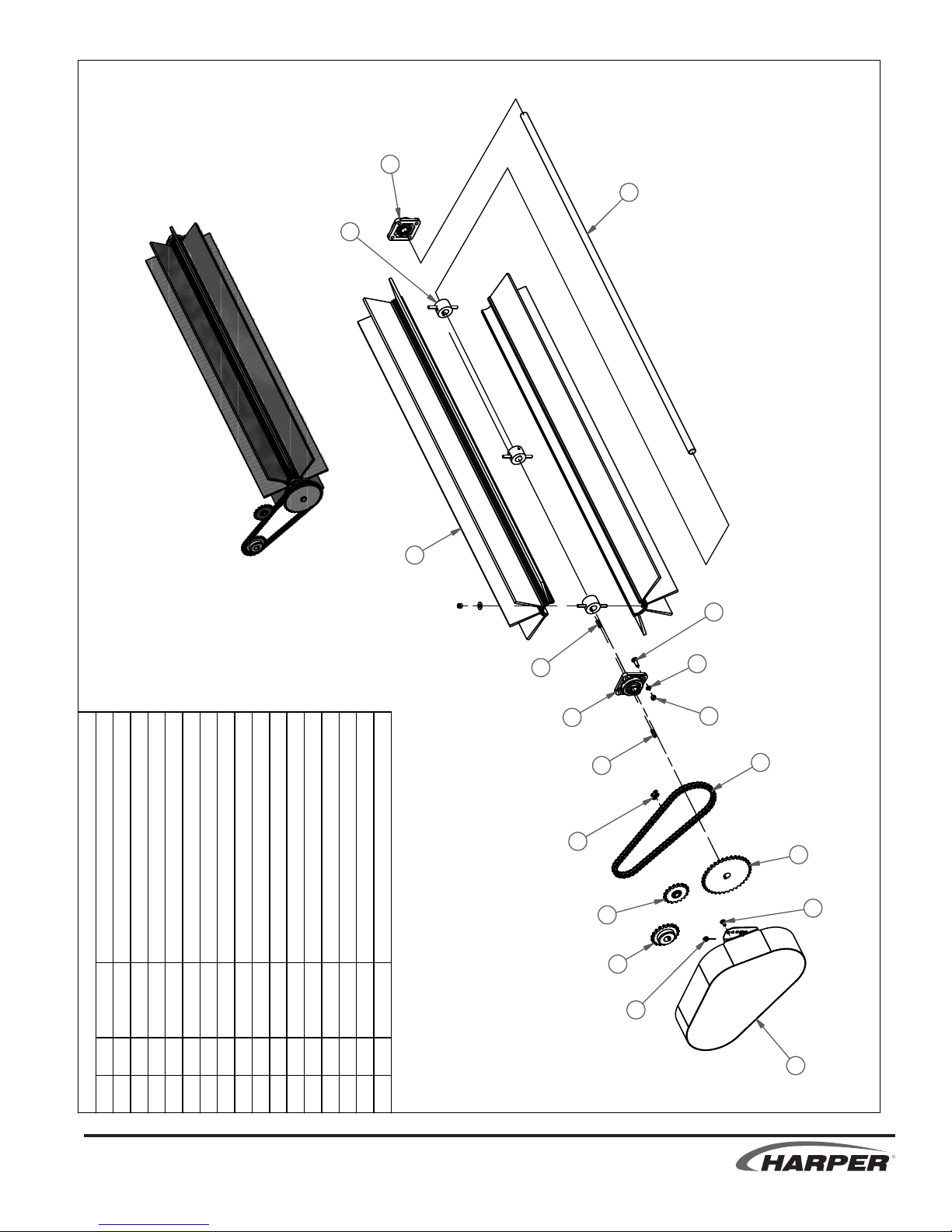

HARPER PRT No. 300044

KIT - ROTOR, BROOM, TV30D

12/2/2011

15

9

16

8

2

14

15

14

6

DESCRIPTION

Bolt, 3/8-16 X 1.25 in Carriage

Bolt, 5/16-18 X 0.75 in Carriage

Parts List

11040282

11002041

PART #

QTY

ITEM

NUT, 3/8-16 GR 51108261

WASHER, 3/8" LOCK

NUT, 5/16-18 WIZ FLANGE110606

11067284

4

5

3

BROOM, 60 in, TV30

SHAFT - BROOM, DECK31136919

CONNECTING LINK, #50 CHAIN

CHAIN - No 50 67 PIN W/O CONNECTOR1420061

30200318

14001116

7

SPROCKET - IDLER, 5017342007111

SHIELD - DECK BRUSH DRIVE, WELDMENT

315167110

KEY, 1/4 X 1/4 X 1.25 in

SPROCKET - 50B19 X 1

SPROCKET - 50B35 X 1342017113

342016112

FLANGE, 2 1/8 X 1, TJ-16973002316

BEARING - 1", 4 BLT FLNG

510089214

942093215

11

12

3

4

5

7

13

1

10

TV 30

R

1.10

Page 38

17

P

5

Y

)

0

7

T

8

0

0

.

.

4

7

(

0

.

2

1

12/2/2011

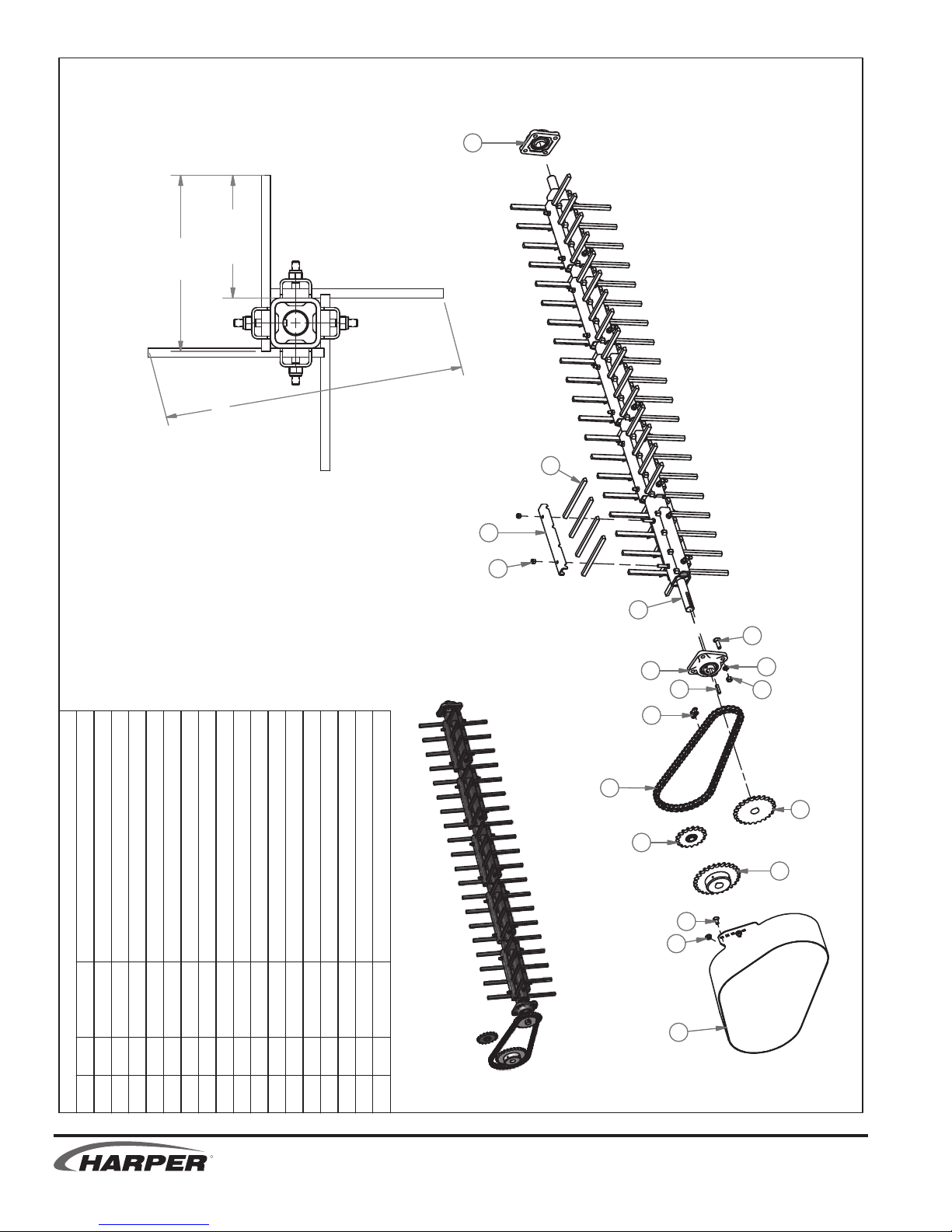

HARPER PRT No. 300040

10

KIT - ROTOR, FINGER, TV30D

DESCRIPTIONPART #QTYITEM

NUT, 5/16-18 LOCK (NYLON)

Bolt, 3/8-16 X 1.25 in Carriage11040282

Bolt, 5/16-18 X 0.75 in Carriage11002041

Parts List

NUT, 3/8-16 GR 511082686

WASHER, 3/8" LOCK11067285

NUT, 5/16-18 WIZ FLANGE11060644

FINGER - RUBBER302042809

CONNECTING LINK, #50 CHAIN14001117

CLAMP - RUBBER FINGER

CHAIN - No 50 67 PIN W/O CONNECTOR

SPROCKET - IDLER, 5017342007113

SHAFT - FINGER ROTOR, WELDMENT315179112

SHIELD - DECK BRUSH DRIVE, WELDMENT315167111

1/4" KEYSTOCK510089116

SPROCKET - 50B27 X 1342026114

SPROCKET - 50B24 X 1

BEARING - 1", 4 BLT FLNG942093217

3

9

12

2

17

16

7

8

13

1

4

5

6

15

14

110603403

14200618

3114032010

R

342030115

11

TV 30

1.11 1.12

Page 39

17

4

20

23

22

9

3

21

5

12/2/2011

HARPER PRT No. 300033

2

6

11

1

17

8

PARTS LIST

KIT - ROTOR, VERTICUT/DETHATCH, TV30D

DESCRIPTION

KEY, 3/8 X 3/8 X 1.75 in

PART #

7

16

6

15

31-2/1 ,TUN0160118

SetScrew, 3/8-16 X 0.75

Bolt, 1/2-13 X 1.75 in Carriage

WASHER, 1/2" LOCK

NUT, 5/16-18 WIZ FLANGE

SPROCKET - 60SF48

BUSHING - QD, SF, 1

SHIELD - DETHATCH ROTOR DRIVE

BEARING, 4FNG 1 1/2"

SPROCKET - IDLER, 6011

ROLLER CHAIN - No. 60, 74 PIN W/O CNCTR

WASHER - CUP, ROTOR

SPACER - VERTI CUTTER, 2 IN

12

14

19

13

18

6

10

QTY

1 1 100567

2 8 110042

ITEM

1 110332 COLLAR - 1-1/2" SPLIT

3 2 110107 NUT, 3/8-16 HEX JAM GR 2

6 7 110606

7

4 2 110325

5

9 1 311400 SHAFT - VERTICUTTER, TV30

8 8 110666

11 1 315195 GUARD - SHIELD SUPPORT, WELDMENT

10 1 315194

TV 30

21 29 970803

22 30 970804 DISC - DETHATCH, 10 Ga, 11 POINT

12 1 342022

15 1 342040

13 1 342023 SPROCKET - 60SK30

14 1 342024

18 1 942067 BUSHING, SK 1 1/2

16 1 410442 CONNECTING LINK, #60 CHAIN

19 1 942102

17 2 410851

20 1 970475 NUT - HEX, JAM, 1-3/4 - 5 UNC

23 1 970805

R

1.12

Page 40

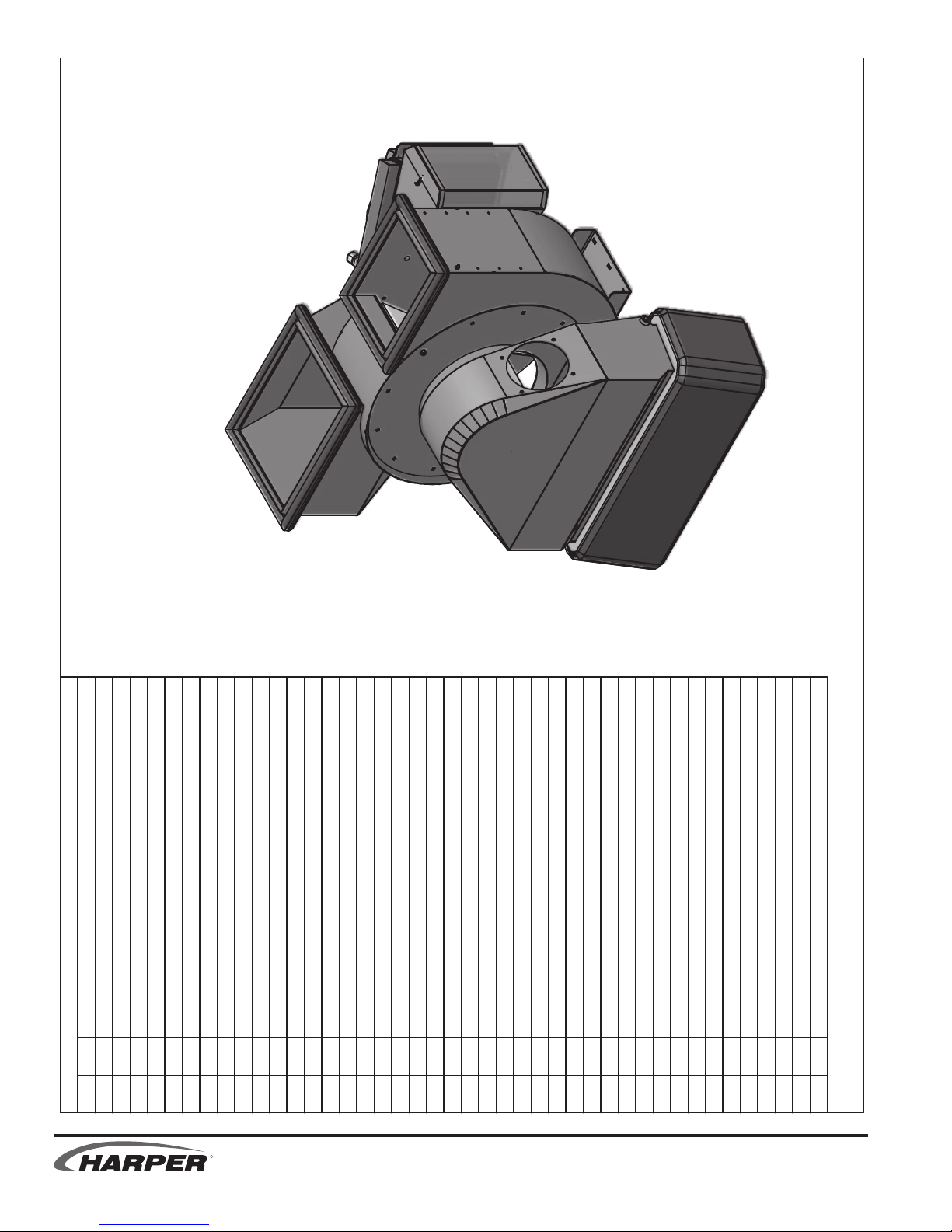

FAN HOUSING

7/15/2011

& HYDRAULIC COOLER ASSEMBLY

POP RIVET, 1/8

PARTS LIST

NUT, 1/2-13

BOLT, 1/4-20 X .75

PLUG - 11/16", NON-VENTED

RING - CANVAS, TV30

GASKET - FAN EXHAUST

CANVAS RING - EDGE GUARD, 5/32

FAN - HOUSING WELDMENT

FAN - 16", 12V, 20A, HYDRAULIC COOLER

1 17 110020 Bolt, 5/16-18 X 0.75 in Carriage

2 4 110042 Bolt, 1/2-13 X 1.75 in Carriage

3 4 110063

4 4 110093 SetScrew, 3/8-16 X 1.25

5 4 110290 NUT, 1/4-20 WIZ FLANGE

6 16 110326 Bolt, 1/4-20 X 1 in Carriage

7 4 110468 BOLT, 1/4-20 X 0.75, WIZ FLANGE

8 18 110561

9 21 110606 NUT, 5/16-18 WIZ FLANGE

10 4 110610

11 34 110630 NUT, 1/4-20 LOCK (NYLON INSERT)

12 12 110645 NUT, 3/8-16 WIZ FLANGE

ITEM QTY PART # DESCRIPTION

R

13 4 110666 WASHER, 1/2" LOCK

14 4 110826 NUT, 3/8-16 GR 5

15 2 110884

16 3 110890 PLUG - 1-1/4", FINISHING

17 12 110894 Bolt, 3/8-16 X 0.75 in Carriage

18 2 120515 ADAPTER - TUBING CONNECTOR, 1", 16MB

19 1 302001 LINER - FAN, TV30

20 1 302021

21 1 302022 GASKET - RETURN AIR

22 1 302023

23 1 311188 SHAFT - IMPELLER, TV30

24 4 311380 STRAP - HOLD DOWN, LINER

25 1 311493 SHROUD - COOLER FAN

26 1 311494 MOUNT - CORE, HYDRAULIC COOLER

27 1 311587

28 1 311588 AIR FUNNEL FLANGE SEAL - RUBBER, TRIMLOK

29 1 311589 HOPPER INLET SEAL - RUBBER, TRIMLOK

30 1 311590 RETURN AIR SEAL - RUBBER, TRIMLOK

31 1 315114 IMPELLER WELDMENT

32 1 315115

33 1 315122 FUNNEL - WELDMENT

34 1 315158 ADAPTER - FAN EXHAUST, WELDMENT

35 1 315159 ADAPTER - RETURN AIR, WELDMENT

36 1 315198 BREATHER - HYDRAULIC COOLER, WELDMENT

37 1 322028 COOLER - HYDRAULIC, TV30

38 1 332019 SWITCH - TEMP, HYDRAULIC OIL

39 1 333003

40 1 342009 BEARING, 4FNG 1 1/2", HD

41 2 810126 LATCH, FEMALE

42 1 940113 KEY, 3/8 X 5

TV 30

1.13

Page 41

39

1

5

25

7

18

23

10

13

34

20

17

2

30

9

40

18

37

38

1

9

1

36

3

41

26

11

32

7/15/2011

FAN HOUSING & HYDRAULIC COOLER ASSEMBLY

21

24

35

8

29

28

19

6

42

12

33

4

14

15

27

31

16

22

TV 30

R

ii 1.13

Page 42

4

FAN HOUSING INSTALLATION

10

2

20

SECTION

13

SEE HYDRAULIC

3

14

5

16

18

17

1

2

11

7

19

9

8

12

8

9

6

6

7/15/2011

15

3

BOLT, 7/16-14 X 1.25

NUT, 1/2-13

WASHER, 7/16" LOCK

COVER - ACCESS, FUNNEL

WASHER, 1/2" FLAT STANDARD

WASHER, 3/8" FLAT STANDARD

HUB, COUPLING 1-1/2" BORE

COVER - HOSE PORT, FUNNEL

PILLOW BLOCK BEARING, (1.5)

DESCRIPTION

BOLT, 1/2-13 X 1.75

KEY, 3/8 X 3/8 X 1.75 in

PARTS LIST

PART #

6 110612 NUT, 3/8-16 GR 2

QTY

1 1 100567

2 6 110419

ITEM

6 110556 Bolt, 3/8-16 X 1 in Carriage

3 8 110426 BOLT, 5/16-18 X 0.5, WIZ FLANGE

6 6 110610

7

4 2 110539

5

9 6 110666 WASHER, 1/2" LOCK

8 10 110658

R

11 6 110672 WASHER, 3/8" LOCK

12 6 110676

10 2 110671

13 1 305044 TV30 - BUILD STATION No. 4 - FAN HOUSING

15 1 311212

14 1 311211

18 1 922069 LOVEJOY COUPLER SPIDER

16 1 922067 COUPLING, 5/8" BORE

19 1 940103

17 1 922068

20 1 970291 ADAPTER PLATE

TV 30

1.14 1.15

Page 43

8

7/15/2011

OUTRIGGER INSTALLATION

6

9

DESCRIPTION

BOLT, 5/8-11 X 1.25

BOLT, 5/16-18 X 1, WIZ FLANGE

PARTS LIST

PIN - CYLINDER, OUTRIGGER

WASHER, 5/8" FLAT STANDARD

BUSHING, MFI-1620-24

OUTRIGGER - RH, WELDMENT

2

3

10

4

7

1

5

PART #

1 315119 OUTRIGGER - LH, WELDMENT

QTY

1 2 110026

2 2 110459

ITEM

2 110655 WASHER, 5/8" LOCK

3 2 110606 NUT, 5/16-18 WIZ FLANGE

6 2 311334

7

4 2 110650

5

9 2 315163 PIN - OUTRIGGER MOUNT, WELDMENT

8 1 315120

10 4 800124

TV 30

R

1.15

Page 44

8/10/2011

DOUBLE COVERPLATE

PARTS LIST

PARTS LIST

ITEM QTY PART # DESCRIPTION

LATCH HOUSING - LH, WELDMENT

PIN - CYLINDER, 3/4 IN, WELDMENT

HOPPER AND DOOR ASSEMBLY

2 810278 PLASTIC BUMPER, MOTOR GUARD

45 1 315145 CROSS TUBE - DOOR, WELDMENT

46 1 315146 LIFT LINK - WELDMENT

47 1 315147

48 1 315148 LATCH HOUSING - RH, WELDMENT

49 1 315149 LATCH - LH, WELDMENT

50 1 315150 LATCH - RH, WELDMENT

51 2 315151 LINK - LATCH, WELDMENT

52 3 315152

53 1 315153 PIN - CYLINDER, 1 IN, WELDMENT

54 1 522105

55

BOLT, 5/8-11 X 2.0

NUT, 1/4-20 WIZ FLANGE

BOLT, 5/16-18 X 0.75, WIZ FLANGE

NUT, 5/16-18 WIZ FLANGE

WASHER, 5/8" FLAT STANDARD

WASHER, 5/16" FLAT STANDARD

SPRING - COMPRESSION, 5/8 X 3.0

DEFLECTOR - DEBRIS, HOPPER, WELDMENT

CROSS TUBE - PIVOT, WELDMENT

1 53 110020 Bolt, 5/16-18 X 0.75 in Carriage

2 3 110155 WASHER, 3/8" FLAT SAE

3 17 110290

4 4 110298 WASHER, 1/4" FLAT SAE

5 4 110328 BOLT, 5/16-18 X 1 FLT HD SKT

6 1 110354 BOLT, 1/4-20 X 2.0 HEX HEAD

7 2 110358 Bolt, 1/4-20 X 0.625 in Carriage

8 2 110382

9 6 110440 BOLT, 3/8-16 X 1, WIZ FLANGE

10 4 110444

11 1 110494 BOLT, 3/8-16 X 3.25

12 3 110538 BOLT, 5/16-18 X 3.0

ITEM QTY PART # DESCRIPTION

R

13 2 110540 BOLT, 3/8-16 X 4.5

14 7 110603 NUT, 5/16-18 LOCK (NYLON)

15 49 110606

16 8 110616 NUT, 5/16", J-TYPE, CAGE, .5C

110766 SCREW, 1/4-20 X 1.0, FLAT HEAD TORX

4

17 4 110618 NUT, 3/8-16 LOCK NYLON INSERT

18 8 110630 NUT, 1/4-20 LOCK (NYLON INSERT)

19 2 110639 NUT, 5/8-11, UNITORQUE LOCK

20 4 110650

21 2 110656 WASHER, 3/8" FLAT SPECIAL

22 14 110665

23 1 110673 WASHER, 1/4" FLAT STANDARD

24 2 110676 WASHER, 3/8" FLAT STANDARD

25

26 4 110804 NUT, 3/8-16 U-TYPE .75L

27 2 110887

28 4 110897 JamHexNut 3_8-24 UNF

29 4 110984 SCREW, 1/4-20 X 1.25 FLAT HEAD TORX

30 1 122003 DOUBLE HOSE CLAMP

31 2 200029 COTTER PIN, 5/32 X 1

32 1 311248 BAFFLE - RETURN AIR, TV30

33 2 311285 MOUNT - LINKAGE, LATCH

34 1 311286 SKIRT - HOPPER, FRONT

35 1 311287 SKIRT - HOPPER, LH

36 1 311288 SKIRT - HOPPER, RH

37 1 311510 SHIM - TV30 DOOR LATCH

38 1 315125 HOPPER WELDMENT

39 1 315131

40 1 315132 SCREEN -PRIMARY, WELDMENT

41 1 315133 SCREEN -SECONDARY, WELDMENT

42 1 315134 DOOR - TV30, WELDMENT

43 1 315143 CROSS TUBE - HOPPER, WELDMENT

44 1 315144

TV 30

1.16

Page 45

14

22

45

50

48

8/11/2011

SEE HYDRAULIC

SECTION

17

21

53

52

8

20

43

1

6

54

9

22

22

14

52

22

44

12

21

11

30

1

51

12

46

52

2212

2

31

8

20

20

19

18

23

19

20

37

51

18

42

1

17

24

29

A

HOPPER AND DOOR ASSEMBLY

32

TV 30

26

41

1

16

26

10

40

16

5

39

15

36

34

7

38

35

1

3

55

25

18

28

33

51

27

49

15

2

47

31

4

2

DETAIL A

13

R

ii 1.16

Page 46

1

9

11

17

3

4

16

8

10

15

7/15/2011

2

5

7

13

HOPPER INSTALLATION

DESCRIPTION

BOLT, 5/16-18 X 1-1/2

NUT, 5/16-18 LOCK (NYLON)

BOLT, 5/16-18 X 0.75, WIZ FLANGE

PARTS LIST

6

14

FNU 61-4_3 tuNxeHmaJ29801128

NUT, 3/8-16 WIZ FLANGE

HOPPER ASSEMBLY

PIN - DECK, LOWER, WELDMENT

LIFT ARM - HOPPER, UPPER, WELDMENT

BRACE - LIFT ARM, HOPPER, WELDMENT

STOP - HOPPER LIFT CLINDER, WELDMENT

7

PART #

8 110606 NUT, 5/16-18 WIZ FLANGE

QTY

3 16 110556 Bolt, 3/8-16 X 1 in Carriage

1 2 110377

ITEM

4 2 110603

2 8 110444

16 110851 BUSHING - IGUS, 1-1/4 x 1 x 3/4 fng (RFI-1620-12)

6 16 110645

7

5

9 2 140016 PIN, LOCK, 1/4 X 2-1/4, SQ WIRE

11 2 315154 LIFT ARM - HOPPER, LOWER, WELDMENT

12 1 315155

10 1 314002

R

13 2 315156 END - LIFT ARM, HOPPER, WELDMENT

15 8 315160

14 1 315157

16 1 315176 LIFT ARM - HOPPER, UPPER, RH, WELDMENT

17 2 315196

TV 30

1.17

Page 47

17

25

7/18/2011

5

4

7

23

9

20

15

22

10

11

16

OPERATOR STATION

13

8

18

27

28

19

2

3

26

14

21

6

12

1

24

DESCRIPTION

Bolt, 5/8-11 X 2 in Carriage

Bolt, 3/8-16 X 1.25 in Carriage

PART LIST

PART #

QTY

3 2 110422 BOLT, 5/16-18 X .75

1 4 110391

2 4 110402

ITEM

BOLT, 5/16-18 X 0.75, WIZ FLANGE

4 4 110444

NUT, 5/16-18 LOCK (NYLON)

4 110606 NUT, 5/16-18 WIZ FLANGE

3 110468 BOLT, 1/4-20 X 0.75, WIZ FLANGE

6 4 110603

7

5

NUT, 5/8-11, UNITORQUE LOCK

NUT, 3/8-16 LOCK NYLON INSERT

9 3 110630 NUT, 1/4-20 LOCK (NYLON INSERT)

8 4 110618

11 4 110650 WASHER, 5/8" FLAT STANDARD

10 4 110639

TV 30

SEAT

WASHER, 5/16" LOCK

WASHER, 5/16" FLAT STANDARD

12 4 110665

13 4 110672 WASHER, 3/8" LOCK

14 2 110674

HOLDER, MANUAL

BOOT - STEERING, TV30

BOLT, 10-24 X .375 STAINLESS, PHILLIPS

211747 FRICTION WASHER 1.5"

110850 ISOLATOR - BUMPER, 64865K1, 250 LB

4

4

15 3 110788

18

16

19 1 302002

17 1 152004

20 1 302015 HOLDER - CUP, MOLDED

SHIELD - ROPS, TV30

21 1 302016

22 1 311129 CAP - END, STEERING BOX

23 1 311195

24 1 311372 BUMPER - TV30

MIRROR

STEERING WHEEL

BASE -MIRROR, LH, WELDMENT

26 1 315174 BASE -MIRROR, RH, WELDMENT

27 2 502027

25 1 315173

28 1 550004

R

1.18

Page 48

R

TV 30

Page 49

PARTS

HYDRAULIC

SECTION

TV 30

R

Page 50

12/2/2011

823004 Service Parts

O-RING, SQUARE FOR CAP

PART DESCRIPTION

802041

15

1

CAP, FILTER

GUAGE, OIL FILTER

852004

822002 FILTER REPLACEMENT

822017

822018 FILTER BREATHER

14

3

2

4

12

10

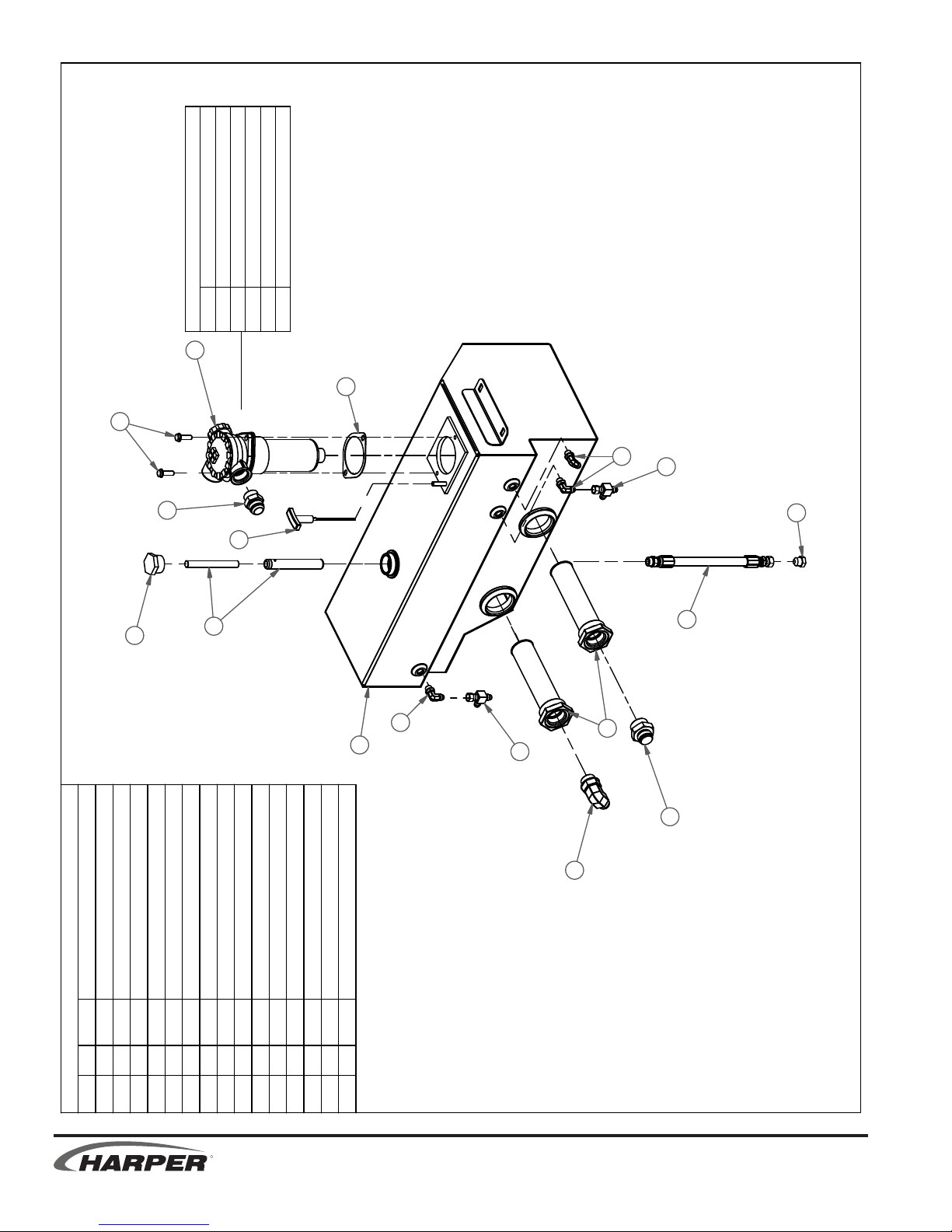

HYDRAULIC RESERVOIR ASSEMBLY

DESCRIPTION

ADAPTER, 6MJ-6MB9012022233

ADAPTER, 16MJ-16MB12035514

ADAPTER, 6MJ-6FJX-6MJ12021622

BOLT, 3/8-16 X 1.25, WIZ FLANGE

PARTS LIST

13

3

8

PLUG - 8-MJ

ADAPTER, 16MJ-20MB1203611

ADAPTER, 12MJ-20MB901205801

PLUG - TANK CLEANER

HOSE - RESERVOIR DRAIN32026419

TANK - HYDRAULIC, TV30, WLDMNT

STRAINER - SUCTION, SAE-20/-16322012211

DIP STICK - TV30, HYDRAULIC TANK

FILTER ASSY W/ELEMENT

GASKET - RETURN OIL FILTER

CLEANER - HYDRAULIC OIL, MGNTC323006113

2

11

7

9

5

6

11016121

PART #

QTY

ITEM

5

31514218

12054916

7

R

322010110

322025112

822029114

823004115

TV 30

2.1 2.2

Page 51

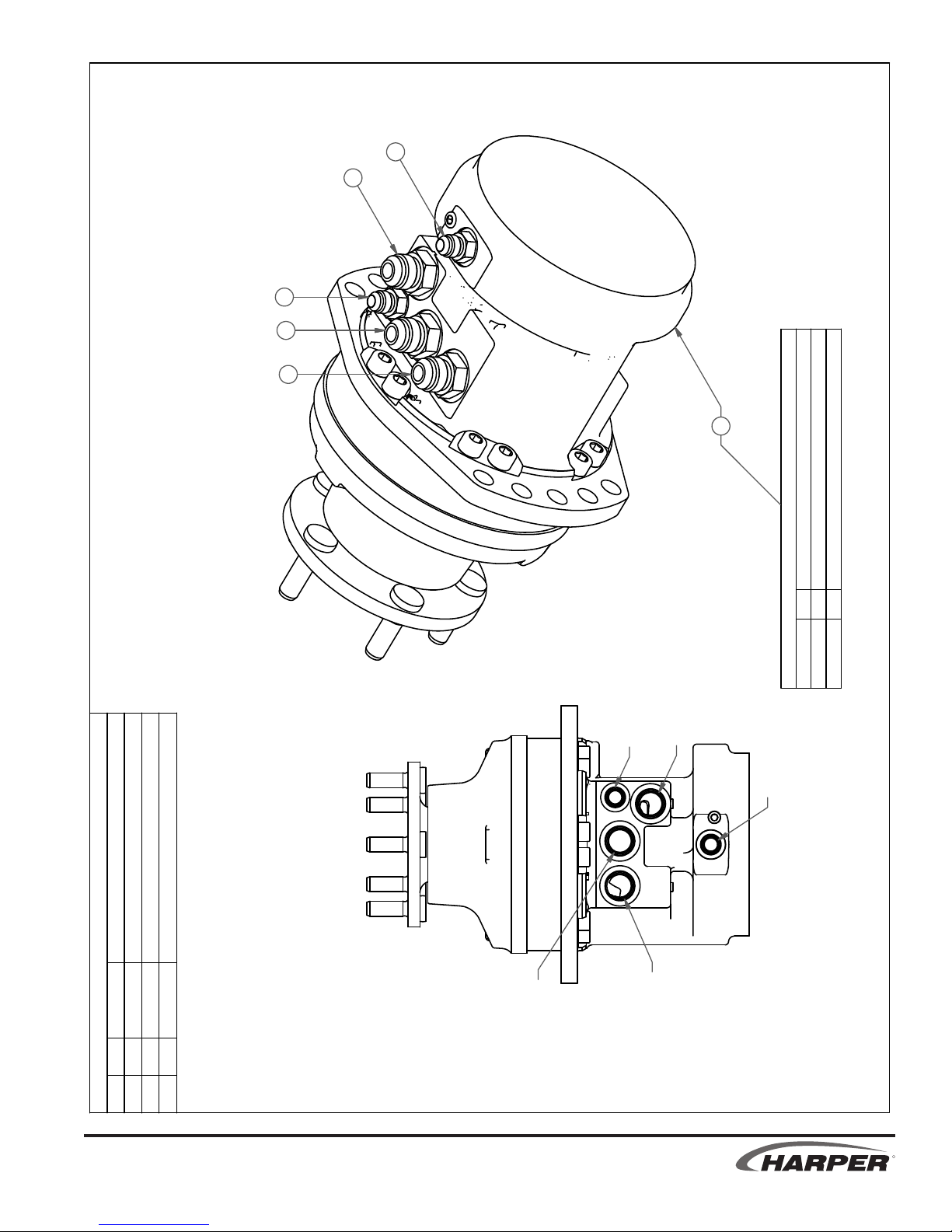

2

1

2

1

1

3

DISCRIPTION

7/28/2011

WHEEL MOTOR ASSEMBLY

CD

A1

322004 Service Parts

WHEEL MOTOR, NUT - LUG 1/2-20

WHEEL MOTOR, STUD

QTY

PART #

110607 6

322058 6

BR

DESCRIPTION

ADAPTER, 6MJ-6MB12031922

ADAPTER, 10MJ-10MB12025131

Parts List

MOTOR - WHEEL, HYDRAULIC, POCLAIN32200413

R

A2

PART #

QTY

ITEM

TV 30

R

2.2

Page 52

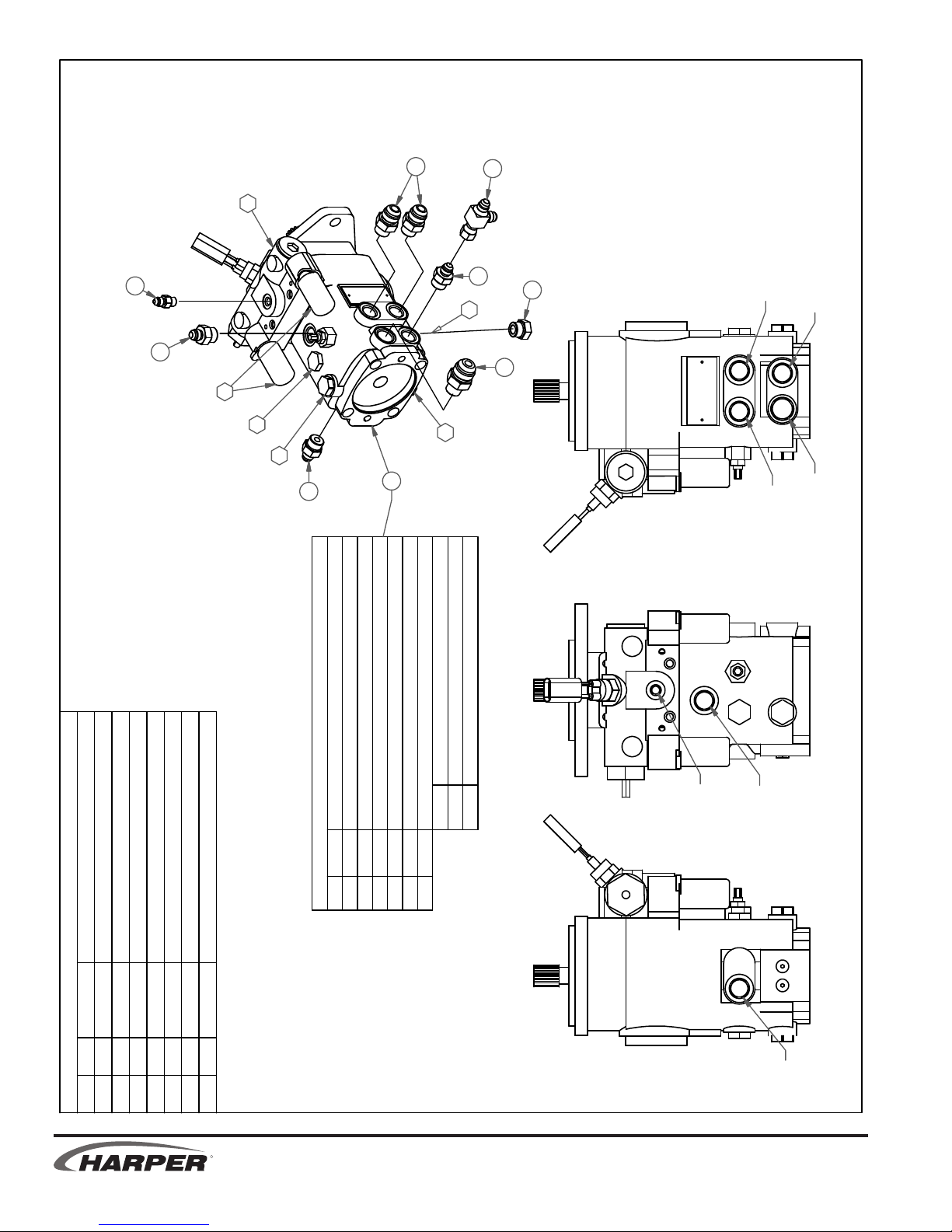

7/28/2011

6

12

1

PROPULSION PUMP ASSEMBLY

2

3

9

8

10

3

7

3

8

11

5

4

PB

PA

OUTLET

CS

DESCRIPTION

ADAPTER, 4MJ-4MB1202331 2

ADAPTER, 6MJ-8MB1202393 3

ADAPTER, 12MJ-8MB1202501 4

ADAPTER, 6MJ-6FJX-6MJ1202161 1

Parts List

PART #

QTY

1

345

2

ITEM

ADAPTER, 10MJ-8MB1204932 6

PLUG, O-RING -8, EXTERNAL HEX120372

PUMP, PROPULSION 1.35/.43 CHRG ELEC3230011

4 5

7

6

R

323001 Service Parts

VALVE, IMPLEMENT PRESSURE RELIEF

VALVE, PROPULSION PRESS RELIEF

SOLONOID, PROPULSION PUMP

822021 PROPULSION PUMP SEAL KIT

-

8 822038

9 322044

ITEM PART # DESCRIPTION

10 322045

SEAL KIT, CA HOUSING, PAPER

SEAL KIT, CA HOUSING, O-RING

HOUSING, CA PROPULSION PUMP O-RING

822039

CP

822042

822034

VALVE, CHARGE PRESSURE RELIEF

ELECTRICAL PROPULSION PUMP CONTROLER

322046

333001

11

12

CD

CR

TV 30

2.3 2.4

Page 53

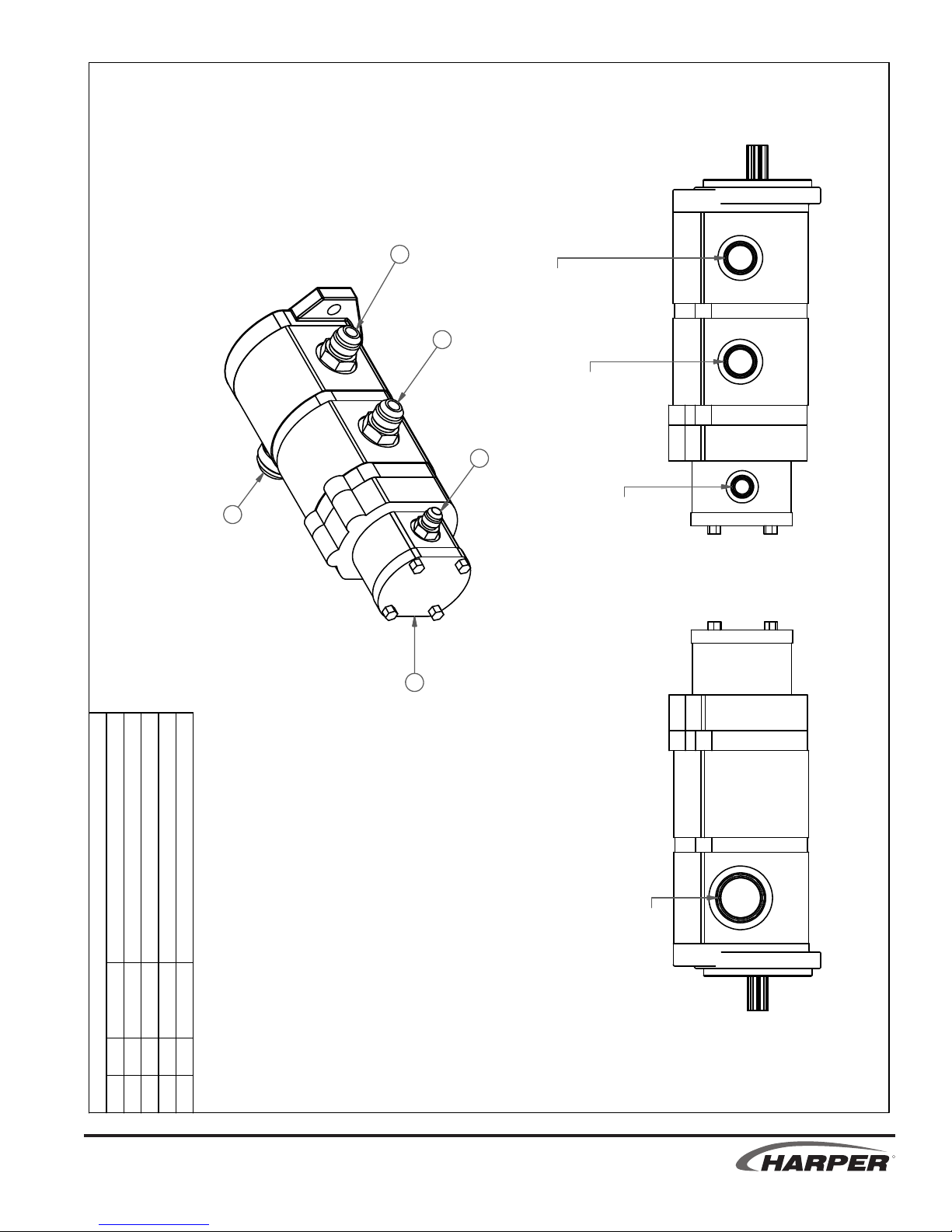

8/1/2011

2

2

3

4

FRONT (DECK) SECTION OUTLET

TRIPLE SECTION PUMP ASSEMBLY

MIDDLE (FAN) SECTION OUTLET

1

SMALL END (IMPLEMENT) SECTION OUTLET

DESCRIPTION

Parts List

PART #

ADAPTER, 6MJ-6MB12031913

ADAPTER, 10MJ-10MB12025122

PUMP - HYDRAULIC, 3 SEC

32300211

ADAPTER, 16MJ-16MB12035514

SUCTION INLET

QTY

ITEM

TV 30

R

2.4

Page 54

5

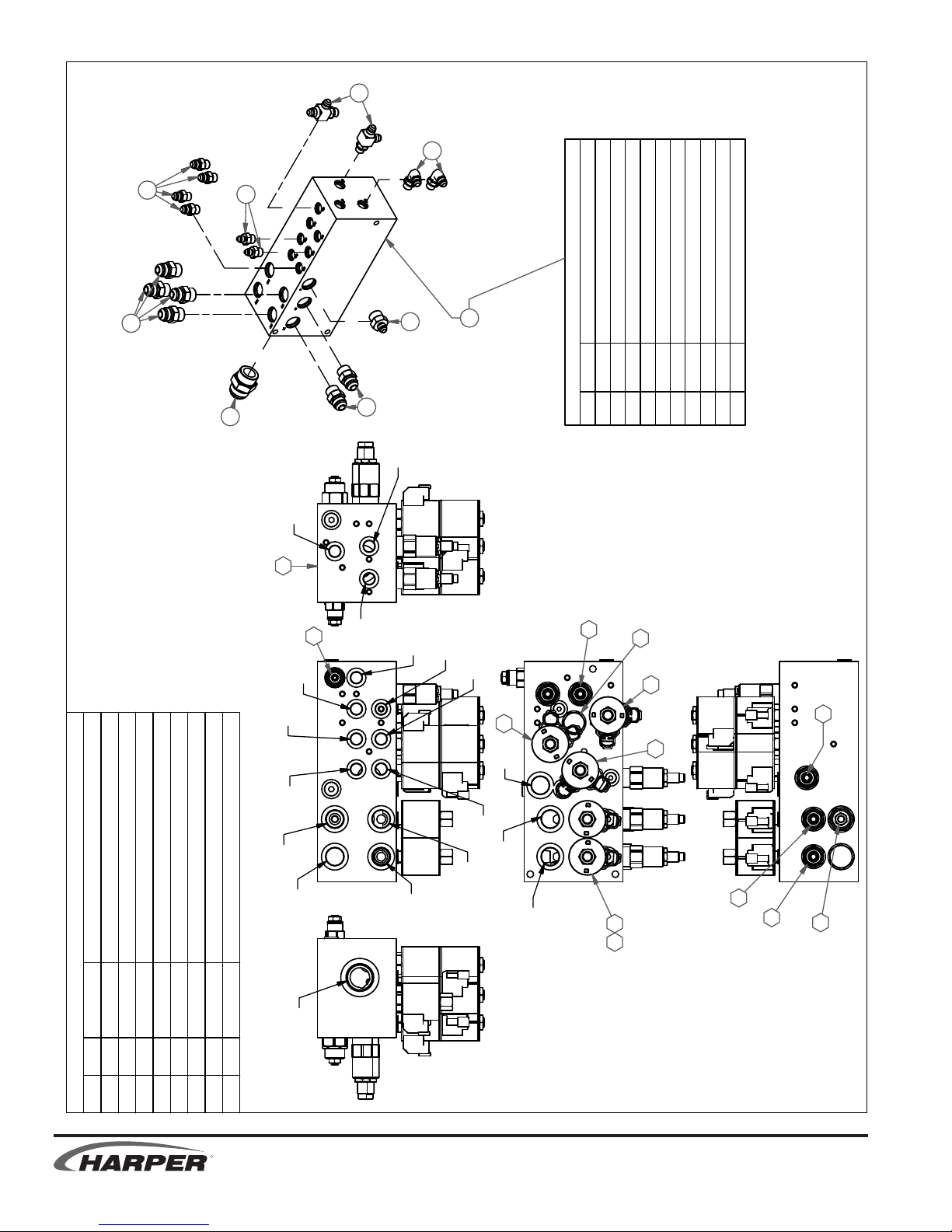

MASTER VALVE ASSEMBLY

2

6

4

3

1

7

4

8

323003 Service Parts

ITEM PART # DESCRIPTION

C'BALANCE VALVE

N.O. SOL VALVE

8.00 SEQ VALVE

322033 22.5 RELIEF VALVE12322034 27.0 RELIEF VALVE

820232

10 322032 25.0 RELIEF VALVE

11

13 322035

14

15 522163 VDC ER COIL

16 322038 3P 4W SOL VALVE

17 322039

18 322040 VALVE BODY

19 522160 PILOT CHECK VALVE

12/2/2011

LOE

DLE

18

13

BLR

BDE

ROE

BLR

LOR

BDR

16

P

17

19

16

10

16

DLE

DLR

PF

DESCRIPTIONPART #QTYITEM

PARTS LIST

ADAPTER, 4MJ-6MB12024923

ADAPTER, 6MJ-10MB12014411

ADAPTER, 6MJ-6MB9012022222

ADAPTER, 6MJ-6MB12031946

ADAPTER, 10MJ-10MB12025164

ADAPTER, 6MJ-6MB-6MJ12027925

VALVE BLOCK - TV30

ADAPTER, 16MJ-16MB12035517

32300318

FMR

FMP

DMR

DMP

DP

1415

11

12

13

T

1

342

869

R

2.5 2.6

TV 30

Page 55

3

8/15/2011

3

1

4

PROPULSION VALVE ASSEMBLY

LCD

BR1

LA1

1

2

5

4

LA2

11

9

6

7

DR

LR

CP

PA

8

10

PB

1314

12

DESCRIPTION

PARTS LIST

PART #

QTY

ITEM

ADAPTER, 6MJ-6MB12031933

ADAPTER, 10MJ-12MB12025332

ADAPTER, 6MJ-6MB 4512021931

Jic(-10) to Male O-ring (-12), 45 degrees

VALVE - CONTROL, PROPULSION, TV303230081

120410

5

5

4

323008 Service Parts

MANIFOLD BODY

6 322049

ITEM PART # DESCRIPTION

TV 30

RA2

DIVERTER VALVE, 100PSI SPRING

3POS 4WAY SOLENOID VALVE

RA1

RR

322057 CHECK VALVE 3PSI SPRING

11 322054 2POS 3WAY SOLENOID VALVE

8 322051

9 322052 12VDC DEUTSCH COIL

12 322055 CHECK VALVE

10 322053 12VDC DEUTSCH COIL S SERIES

7 322050

14

13 322056 REMOVABLE ORIFICE

RCD

BR2

R

2.6

Page 56

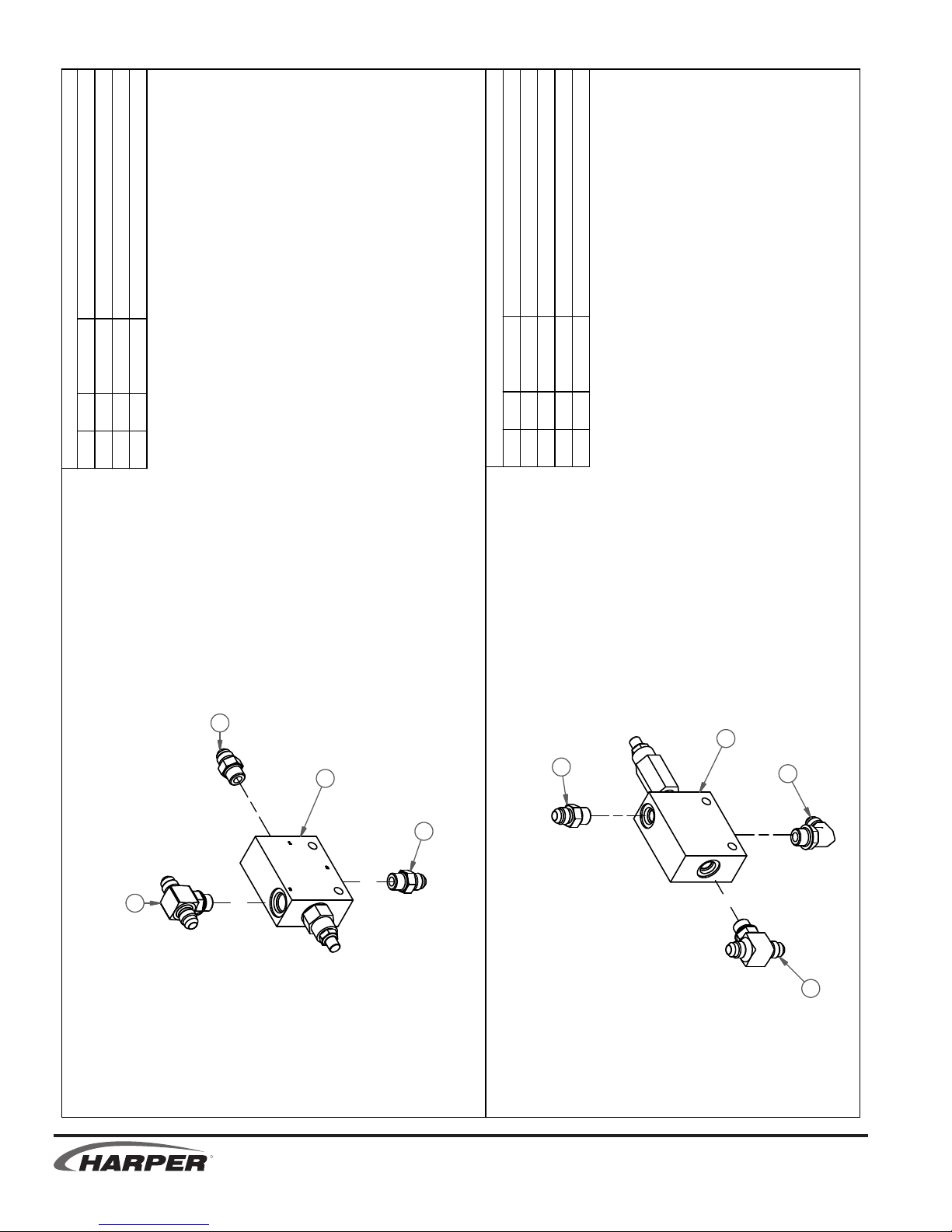

8/15/2011

PARTS LIST

DESCRIPTIONPART #QTY

ADAPTER, 6MJ-6MB12031922

ADAPTER, 6MJ-6MJ-6MB12009211

VALVE - SEQUENCE, PROPULSION, TV3032300713

ITEM

DESCRIPTIONPART #QTY

PARTS LIST

ITEM

ADAPTER, 6MJ-6MB12031913

ADAPTER, 6MJ-6MB9012022212

ADAPTER, 6MJ-6MJ-6MB12009211

VALVE - PRESSURE REDUCING

32301514

SEQUENCE VALVE ASSEMBLY

2

4

3

2

1

3

2

1

PRESSURE REDUCTION VALVE ASSEMBLY

R

2.7 2.8

TV 30

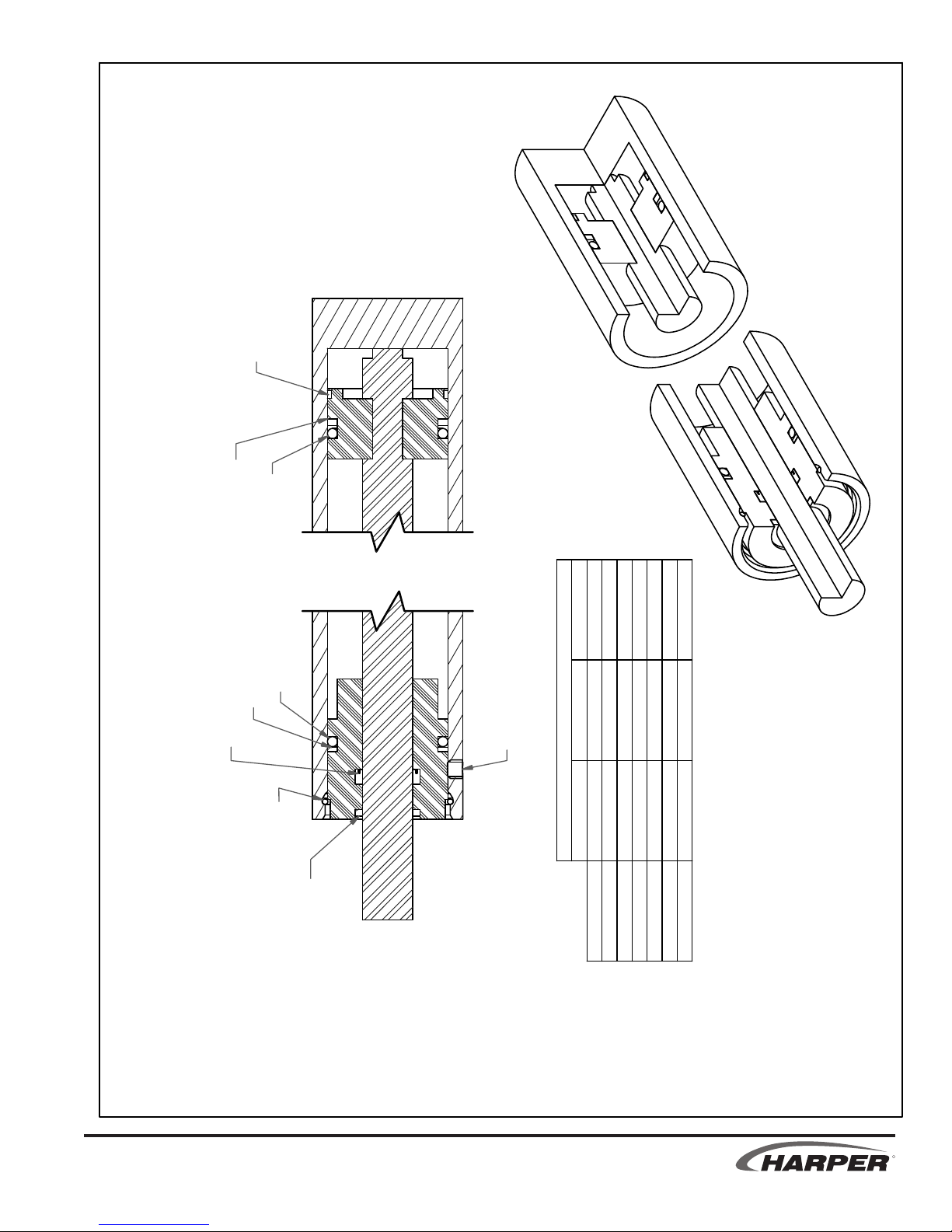

Page 57

TEFLON RING

8/1/2011

WEAR RING

O-RING

HYDRAULIC CYLINDER SERVICE PARTS

BACK-UP

U-CUP

O-RING

RETAINING RING

-

-

Retaining Ring

SET-SCREW

WIPER

Seal Kit

Service Parts

323010 322047 322048

323032 220534 220092

323018 220387-323033 220387

Cylinder Part #

Steering

LH Deck Lift

323019 220387

323031 220534 220092

922021 922076 520459

Hopper Lift

RH Deck Lift

LH Outrigger

Hopper Door

RH Outrigger

TV 30

R

2.8

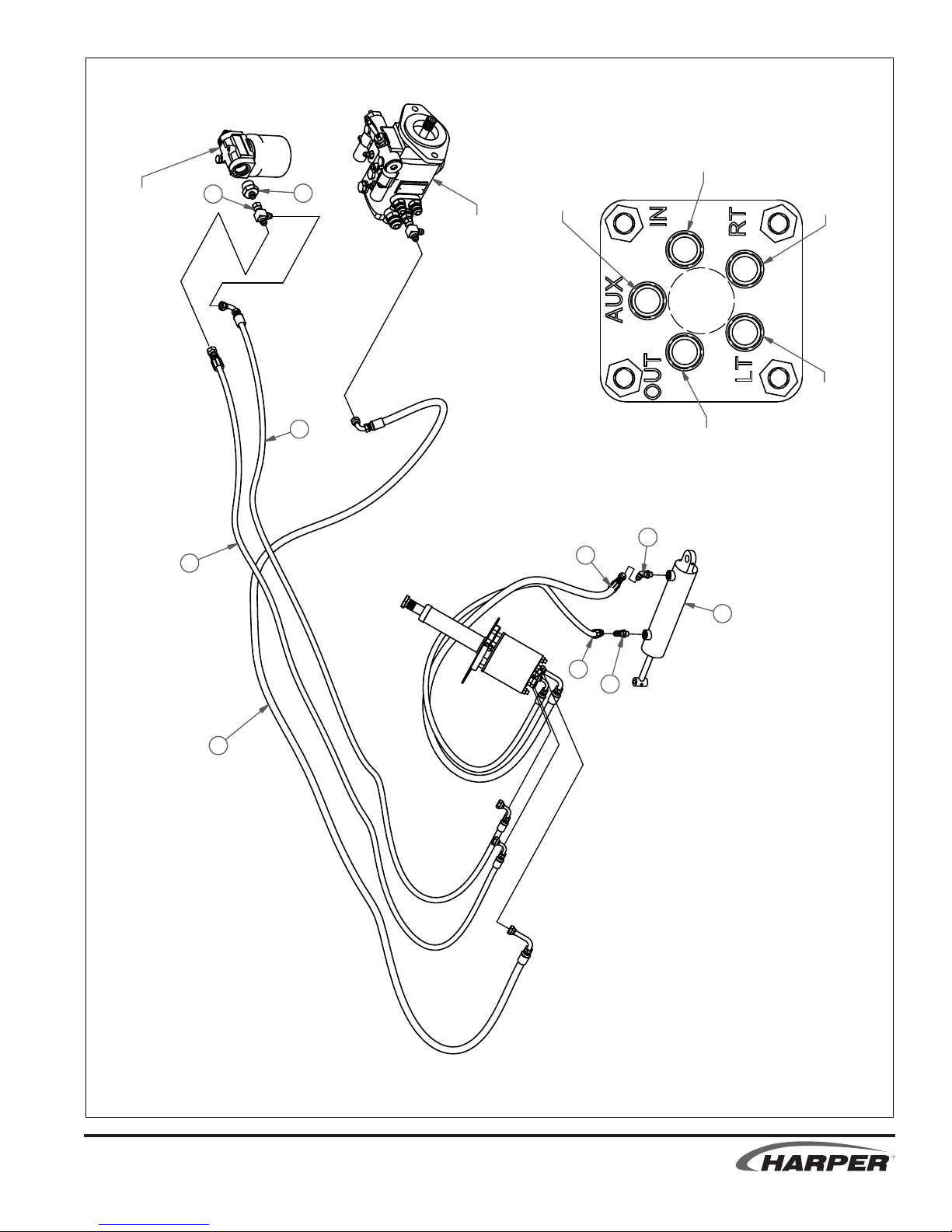

Page 58

7/7/2011

PROPULSION SYSTEM

R

TV 30

2.9

Page 59

TV 30

R

ii 2.9

Page 60

8/11/2011

PROPULSION PLUMBING

LA1

RBRLBR

LA2

LCD

LR

RR

RCD

RA1

RA2

VAVLE -

CONTROL

PROPULSION

CP

PA

VALVE

SEQUENCE

DESCRIPTIONPART #QTYITEM

ADAPTER, 6MJ-12MB1203642 1

HOSE - SEQUENCE VALVE INLET3202251 2

HOSE - SEQUENCE VALVE OUTLET

HOSE - PROPULSION "A" PRESSURE3202401 4

Parts List

HOSE - PROPULSION "B" PRESSURE3202411 5

HOSE - PRESSURE REDUCTION VALVE SUPPLY3202551 6

HOSE - PROPULSION VALVE CHG PRESSURE SUPLY3202561 7

FILTER - MID-PRESSURE

HOSE - PILOT CONTROL PRESSURE3202611 9

HOSE - PROPULSION VALVE CASE DRAIN

MID

PRESSURE

320260

320256