Page 1

Page 2

CONTENTS

Chapter 1 photos and Features of products

Chapter 2 Operating Principle

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Chapter 8

operation details

Exploded Views of the Production

Main Technical Data

Dismantling Procedure

Brief introduction of installation

Fault Analysis of the Product Available

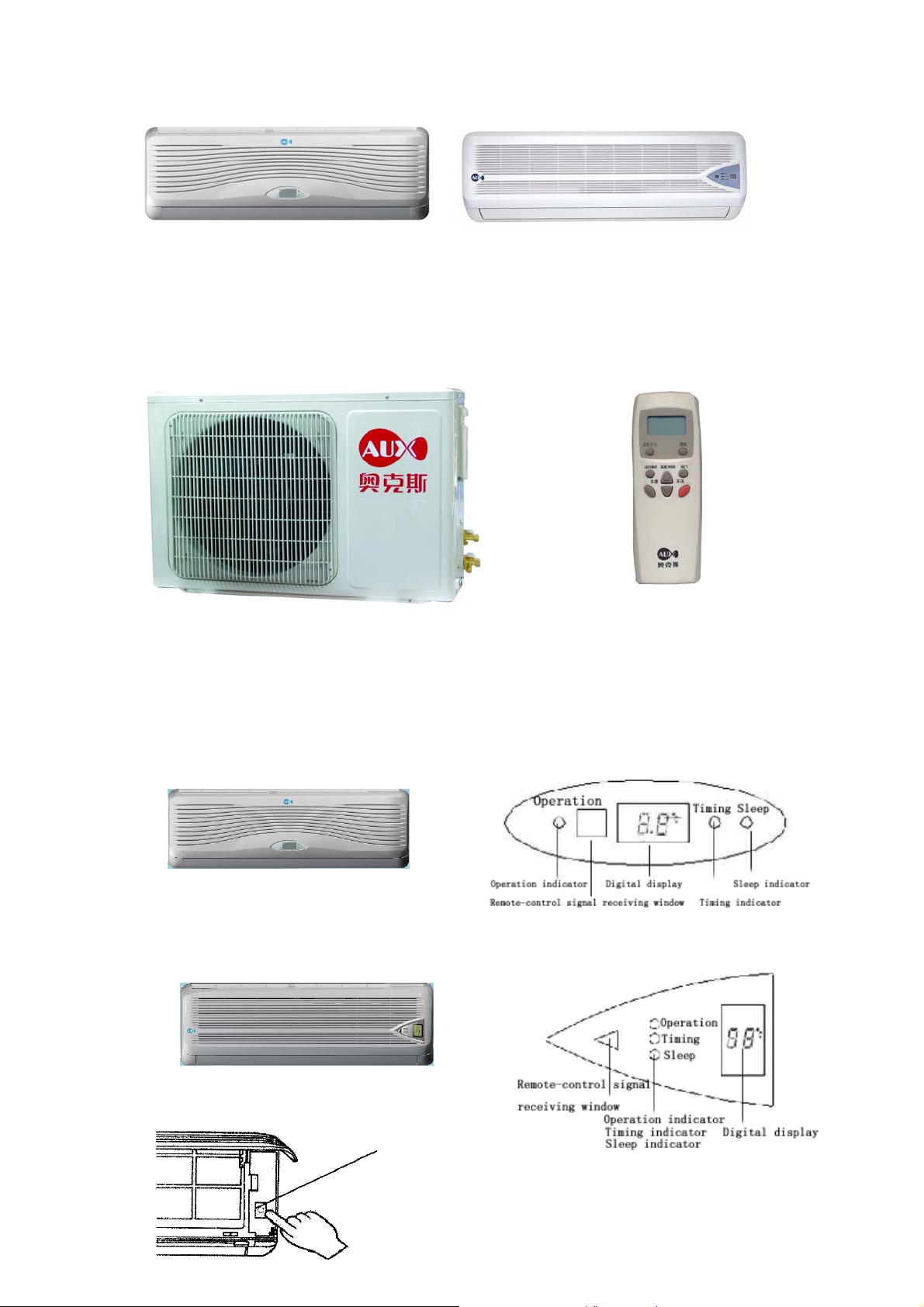

Chapter 1 photos and Features of products

Features of outlook and construction

Page 3

ASW-H07B4/HSAR ASW-H07B4/HSR

ASW-07B4/HSAR ASW-07B4/HSR

ASW-H09A4/HSAR ASW-H09A 4/HSR

ASW-09A 4/HSAR ASW-09A 4/HSR

Deep × width ×high165×802×262 Deep × width ×high165×802×262

Deep × width ×high260×760×540 All types

All types

Operation interface

Inner operation interface of Type HSAR

Inner operation interface of Type HSR

·Emergency operation button of indoor types:

Page 4

Compulsory button

1) When the air-conditioner works with the absence of remote control, it

will stop working by pressing the compulsory button and it will resume

working by pressing the compulsory button once again.

2) When remote control is useless, you can adopt the compulsory

operation by which the air conditioner will go into automatic operation

mode.

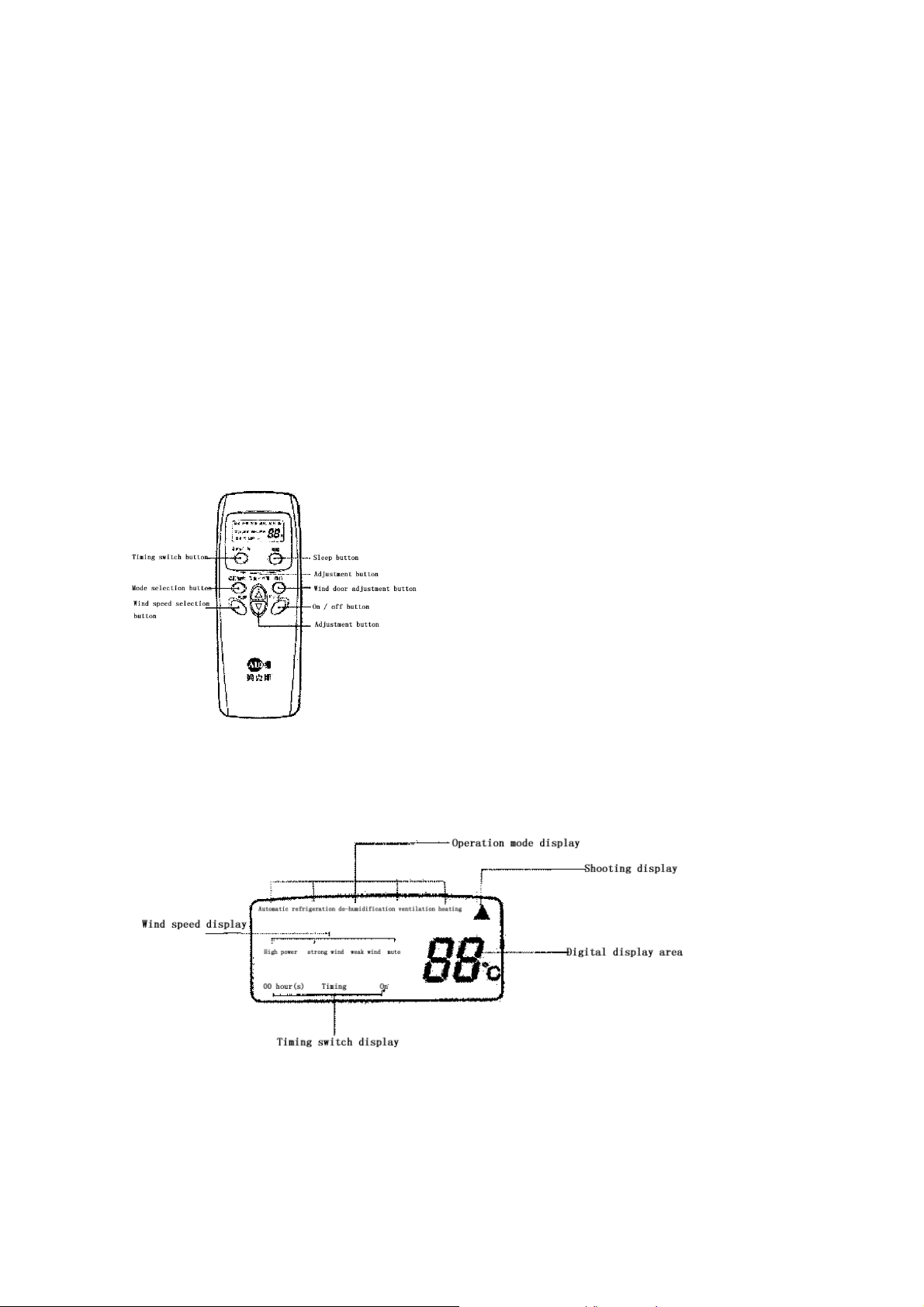

·The operation interface of remote control:

Features of products

Page 5

1. Fashionable appearance

2. Compact Design

3.7 Hours of Sleep Mode Operation

4. Economy Mode to Reduce Electrical Power Consumption

5.Clean breath efficient biological antibacterial filter gauze made

from green plant elite refined by using international leading

technology, with the function of filtering and suppressing bacteria,

and able to absorb and kill various pathogens and harmful gases

efficiently for a long period, prevent secondary pollution caused due

to microorganism spreading, and ensure the health of your family

6. R407c cold medium is applied, environment-friendly, and avoid

damages to ozonosphere

7. International famous-brand Toshiba Hitachi and Matsushita

compressors are applied

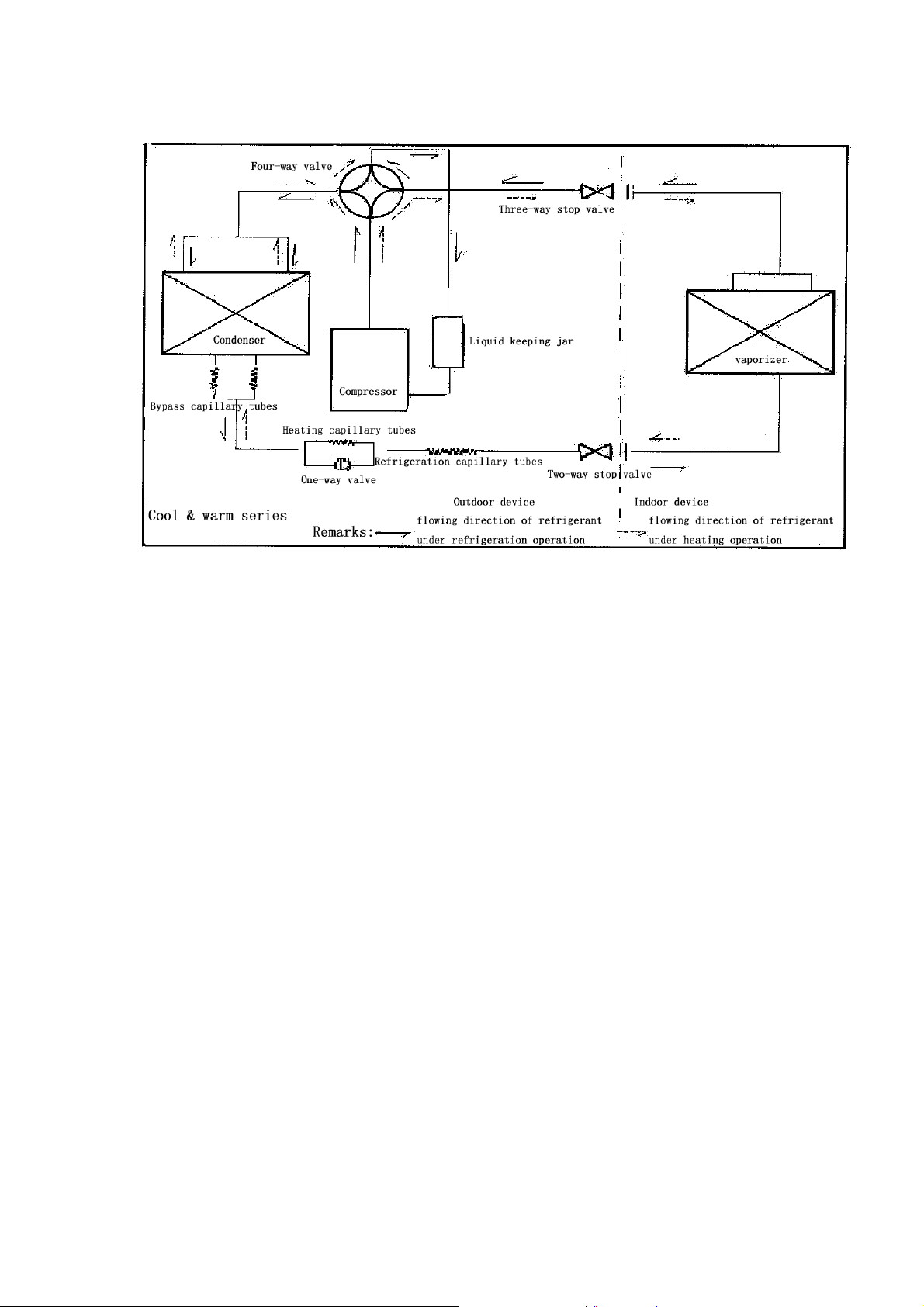

Chapter 2 Operating Principle

. Cooling

After the power supply is switched on, the machine is set to COOL

mode. With the compressor being operated, the low-temperature and

low-pressure refrigerant vapor is sucked into the compressor where it is

Page 6

turned into high-temperature and high-pressure gas. Then it is cooled

down in the outdoor heat exchanger by the air and becomes liquid. After

being throttled by the capillary, the refrigerant liquid comes into the

indoor unit and then it evaporates in the indoor heat, exchanger,

absorbing heat and reducing the room temperature. The evaporated

refrigerant vapor returns to the outdoor unit and is again sucked into the

compressor, completing the cycle. With the refrigerant cycling being kept

on, the objective of lowering the room temperature is fulfilled.

. Heating

After the power supply is switched on, the machine is set to HEAT

mode and the coil of the electromagnetic four-way valve is energized.

After the compressor starts to operate, the high-temperature and

high-pressure refrigerant gas first comes into the heat exchanger of the

indoor unit, where it is cooled, releases heat and increases the room

temperature. The cooled high-pressure refrigerant is then throttle1d in the

outdoor unit and returns to the compressor after evaporation. With such

cycles being maintained, the objective of increasing the room temperature

is fulfilled.

Page 7

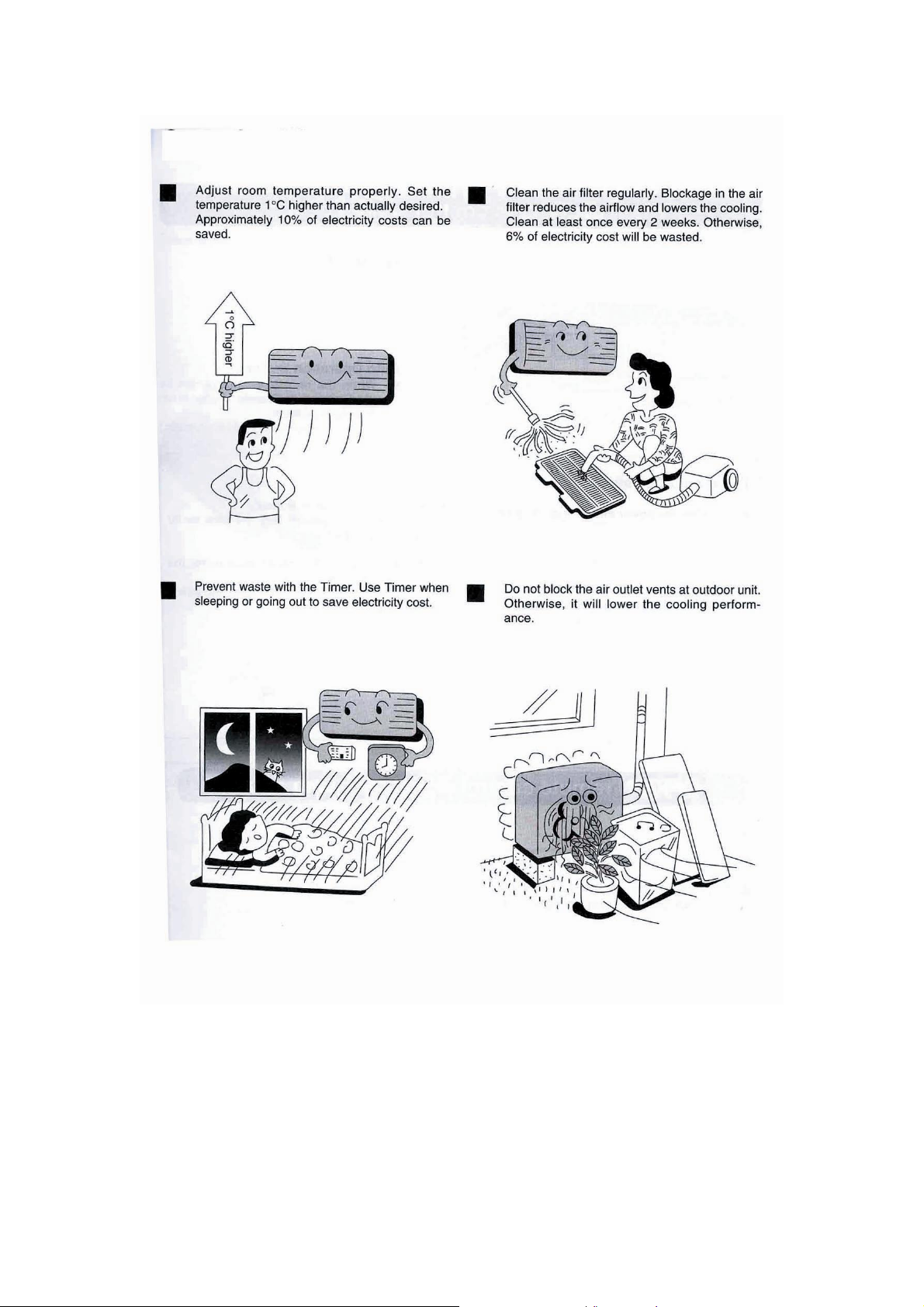

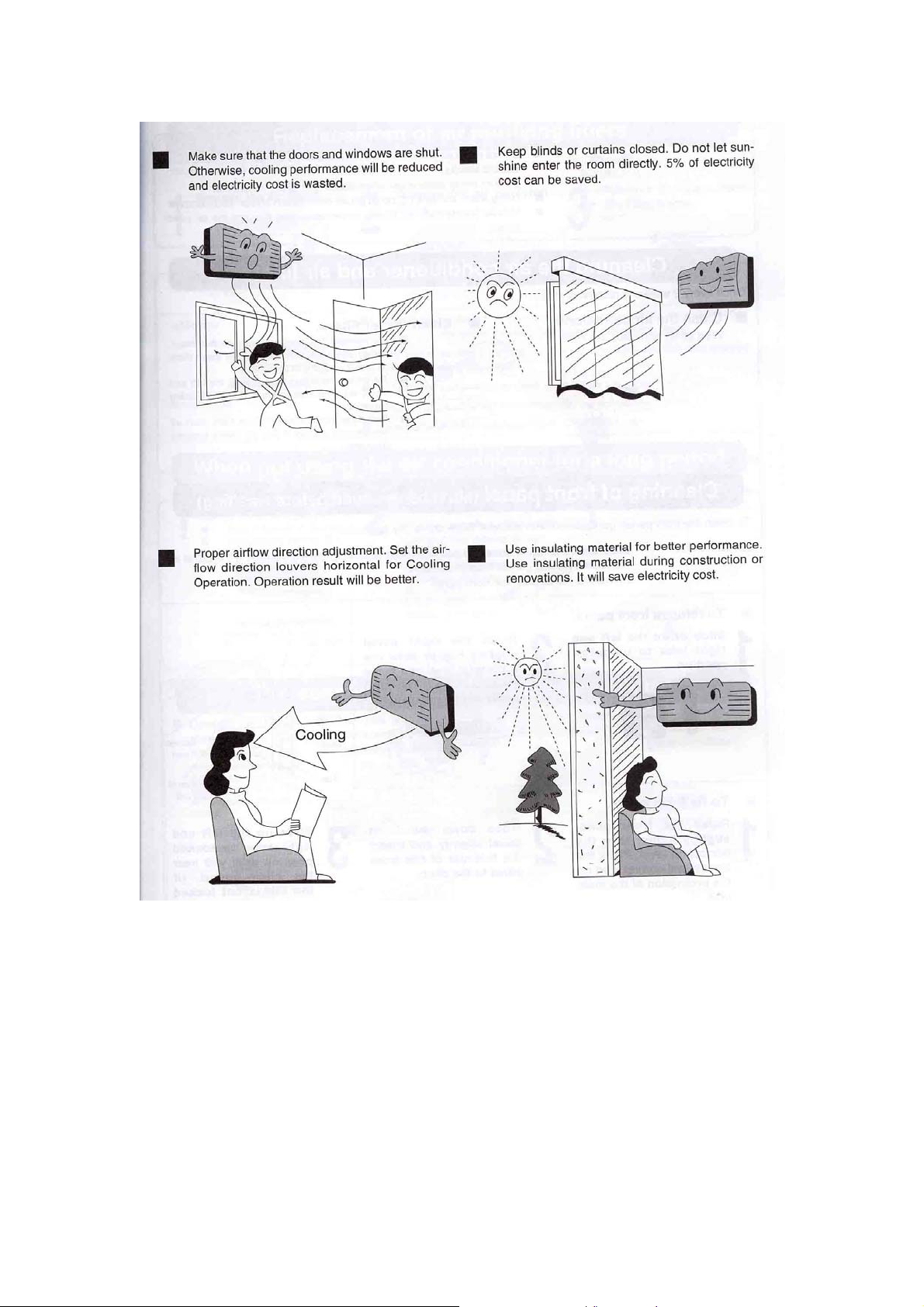

Operation Hints

Page 8

Page 9

Page 10

Chapter 3 operation details

1. Overall

1.1 Protection of compressor

Whatever operation modes the air- conditioner is under, there will

always be 3 minutes' time- delay protection unless it is on for the first

time. When the compressor is switched on, it can not be shut down

within 3 minutes (except under the modes of heating or defrosting)

unless it is powered off or its operation mode is changed.

1.2 The operation indicator will turn light when the air conditioner is

powered on.

1.3 The buzzer will sound immediately after the controlling device

receives a correct and effective signal sent by the remote control.

1.4 Timing function can be applicable to all operation modes while

sleep function can only be applicable to the modes of refrigeration

and heating.

2. Automatic operation mode

2.1 When the air conditioner works, it can detect the indoor temperature

automatically whereby its operation mode can be selected:

refrigeration, heating or dehumidification.

2.2 When the indoor temperature reaches more than 27, the air

conditioner will operate under the mode of refrigeration.

2.3 When the indoor temperature reaches between 20and 27the air

Page 11

conditioner will work under the mode of dehumidification (always

mute).

2.4 When the indoor temperature reaches less than 20, the air

conditioner will work under the mode of heating.

2.5 Under this mode, the air conditioner will operate in the respect of

blowing rate as set and its pendulum leaves will work according to

the requirements of automatic ventilation door.

2.6 Once the operation mode is selected, it will not be able to be

changed. When the air conditioner is shut down and then restarted,

the operation mode will be selected once again based on the

variation of indoor temperature.

2.7 After the operation indicator has been flickering for 20 seconds, it

will turn light steadily (i.e. the determination of operation mode will

start in 20 seconds.)

2.8 This mode has timing function, does not have sleep function.

2.9 Under this operation mode, the temperature can be set and adjusted

by remote control.

3. Refrigeration mode

3.1 Under the refrigeration mode, the range of temperature set by

remote control is between 16and 32.

3.2 Shut-down of four-way valve;

3.3 The condition on which the compressor starts is that the indoor

Page 12

temperature reaches more than the temperature set plus 1while the

condition on which the compressor shuts down is that the indoor

temperature reaches less than the temperature set minus 1.And

when the indoor temperature is equal to that set, the original

operation mode will be kept.

3.4 Under the mode of refrigeration, the function of preventing indoor

coiled pipe from being frozen will be effective.

3.5 The indoor wind speed will be as set. And the pendulum leaves will

work according to the instructions sent by remote control.

4. Dehumidification operation

4.1 The temperature range set and controlled is between 16and 32.

The temperature will be set by remote control.

4.2 The four-way valve is shut down.

4.3 The wind speed gear-changes to “mute". And the pendulum leaves

works according to the instructions sent by remote control;

4.4 The function of preventing indoor coiled pipe from being frozen is

effective.

4.5 When the indoor temperature reaches less than 16, the function of

dehumidification is out of use.

4.6 When the indoor temperature reaches more than 16 , the

compressor will be switched on and work intermittently. The time

when the compressor shuts down depends on T ring and T ring-T set.

Page 13

When the compressor is shut down, the outdoor fan and indoor fan

will stop working.

When T ring≥23

T set <T ring-1, the compressor will be working for 8 minutes and then

stopping for 3 minutes in cycles.

T set≥T ring-1, the compressor will be working for 3 minutes and then

stopping for 6 minutes in cycles.

And when T ring <23

T set ≤T ring-1, the compressor will be working for 3 minutes and

then stopping for 4 minutes in cycles.

T set >T ring-1, the compressor will be working for 3 minutes and then

stopping for 6 minutes in cycles.

5. Function of ventilation control

5.1 Under the mode of ventilation, the outdoor fan assembly will

always be shut down.

5.2 The indoor fan will operate as set in the respect of air quantity

without the gear- change of “high power".

5.3 The pendulum leaves will work according to the instructions sent

by remote control.

6. Heating function

6.1 Under the mode of heating, the temperature range set is between 16

and 32. And the temperature will be set by remote control.

Page 14

6.2 When the air conditioner is powered on, the outdoor fan, four- way

valve and compressor will start at the same time while when it is

shut down, the outdoor fan and compressor will be shut down at the

same time and so will the four- way valve after 2 minutes' delay.

6.3 Under the mode of heating, the compressor can not be shut down

within 3 minutes after it is powered on unless the operation mode is

changed or the air conditioner is turned off.

6.4 There is a 3 temperature compensating function. The temperature

measured at the in-blow vent minus 3 automatically can be

regarded as that compared with the temperature set (This function

does not exist under other circumstances).

6.5 According to the temperature set, the condition upon which the

compressor will be switched on is indoor temperature≤ temperature

set-1 While the condition upon which it will be switched off

is indoor temperature is indoor temperature≥ temperature + 1.

When the indoor temperature is equal to that set, the original

operation mode will be kept.

6.6 Indoor fan control:

6.6.1 Heating operation and prevention of cold wind

When the compressor works:

1. During the rising process of the temperature of coiled pipe,

the indoor fan will not start if the temperature of the coiled

Page 15

pipes is less than 25.

2. When the temperature of coiled pipe reaches less than 35

But more than 25, The indoor fan will work under the

mode of “ mute". If the temperature of coiled pipe ascends

to 25and then descends, it will stop working only when

the temperature is lowered to 22.

3. When the temperature of coiled pipe reaches more than 35

, the indoor fan will operate as set in the respect of wind

speed. If the temperature of coiled pipe ascends to 35

And then descends, it will enter into the operation mode of

“ mute" only when the temperature is lowered to 30.

6.6.2 Afterheat-blowing function:

6.6.2.1 When the compressor stop working:

1. When the temperature of coiled pipe is more than 35, the indoor

fan will operate as set in respect of wind speed.

2. When the temperature of coiled pipe is more than 25, but less

than 35, The indoor fan will operate under the mode of “ mute"

3. When the temperature of coiled pipe is less than 25, the indoor

fan will stop working.

6.6.2.2 The afterheat-blowing function when the air conditioner is just

shut down: If the temperature of indoor coiled pipe reaches more

than 30, The indoor fan will operate under the mode of “ mute"; If

Page 16

it lowers to less than 30, the indoor fan will be shut down; And the

time when the afterheat blows will last less than 40 seconds after

the indoor fan is turned off.

6.7 Defrosting operation:

6.7.1The conditions upon which the outdoor sensor goes into operation are

as below:

1. Under the circumstance of heating, if T external coiled pipe is at the

temperature of less than -6 which lasts 2 minutes and the

accumulated working time of compressor reaches more than 50

minutes (if there is any power cut-off or shut-down by remote

control, the accumulated working time of compressor shall be

re-calculated), the defrosting interval will be more than 50 minutes

and the compressor will be working 5 minutes continually.

2. If there is any damage to the external coiled pipe, the accumulated

working time of compressor will reach 50 minutes (if there is any

power cut-off, shut-down by remote control or defrosting, the

accumulated working time of compressor shall be re-calculated)

and the defrosting operation will last 10 minutes.

6.7.2 Once one of the following conditions is satisfied, the defrosting will

end:

1. The temperature of T external coiled pipe is more than 12.

2. Defrosting duration is more than 12 minutes.

Page 17

6.7.3 The requirements of defrosting operation:

1. Sleep indicator flickers at the speed of 1 time per second

2. When defrosting operation starts, the compressor and indoor fan

will stop working while outdoor fan and four-way valve will

continue to work.

3. The four-way valve and outdoor fan will stop operating in 30

seconds.

4. 15 seconds after that, the compressor starts and goes into

defrosting operation.

5. After the defrosting ends, the compressor stops working. And

the four-way valve and outdoor fan begins to work in 20

seconds.

6. 20 seconds after that, the compressor starts and goes into heating

operation. And the indoor fan enters into the prevention mode of

cold wind.

6.8 Auxiliary electric heating function

6.8.1 Only if the following conditions are satisfied under the

heating operation, can the auxiliary electric heating go into

operation automatically.

a. The compressor works for 4 minutes by heating pump

b. Indoor temperature is less than 22;

c. The temperature set-indoor temperature is more than 3;

Page 18

d. Indoor fan goes into operation;

e. Indoor coiled pipe temperature is less than 48

6.8.2 Once one of the following conditions is satisfied, auxiliary

electric heating operation will end:

a. Indoor temperature is more than 22.

b. The temperature set –indoor temperature is less than 2.

c. When Indoor coiled pipe temperature is more than 52, the

electric heating operation will end.

d. Indoor temperature sensor becomes abnormal.

6.8.3 If compressor or indoor fan stops working, the electric

heating will stop operating as well.

6.8.4 During the operation of compressor, if the auxiliary electric

heating stops working, it can be restarted only in 1 minute.

7. Sleep operation

7.1 When the air conditioner enters into the mode of sleep, the indoor

wind speed will turn into the air quantity of “mute”.

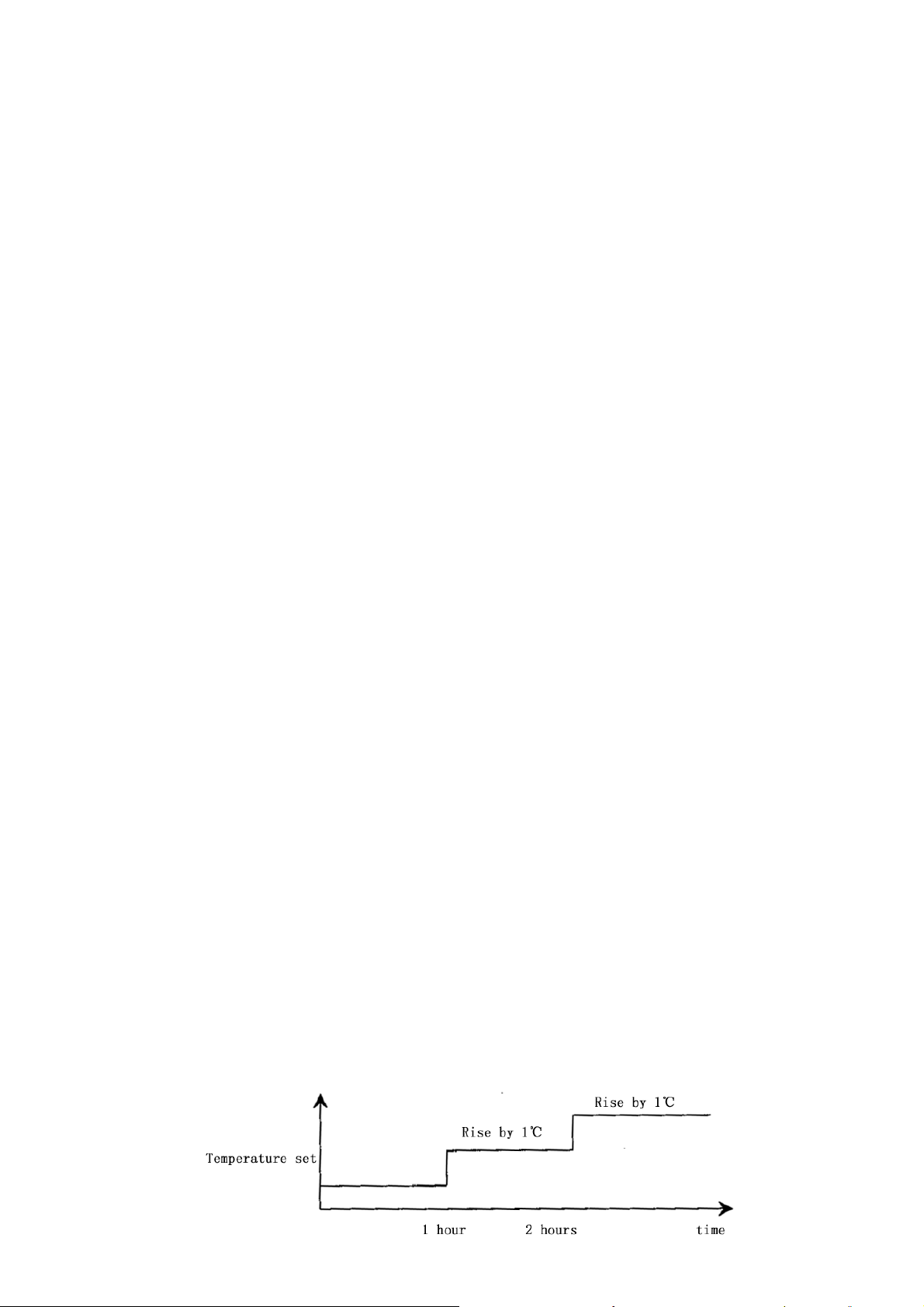

7.2 When the sleep operation goes under the mode of refrigeration,

the temperature set rises by 1 automatically every one hour. And

the air conditioner will be powered off after sleep mode has

worked for 7 hours.

Page 19

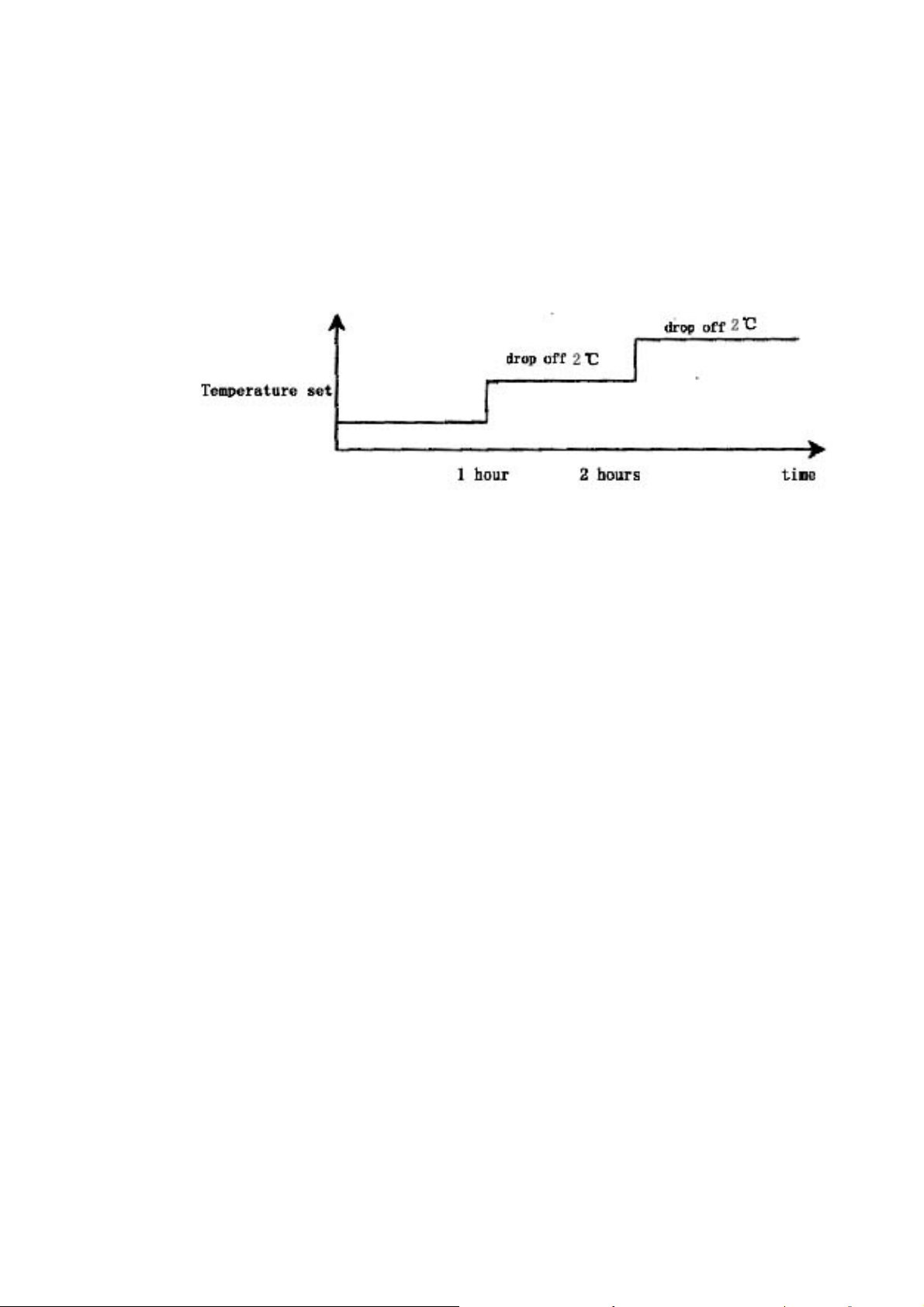

7.3 When the sleep operation goes under the mode of heating, the

temperature set drops by 2 automatically every one hour. And the air

conditioner will be powered off after sleep mode has worked for 7

hours.

7.4 When the button of mode selection is pressed down, the function

of sleep will be cancelled.

7.5 Sleep operation is effective under the modes of refrigeration and

heating. When sleep button is pressed down, the sleep operation

can begin or end.

7.6 Sleep function does not exist under the automatic mode, the

situation of dehumidification or the circumstance of ventilation.

8. Timing operation

8.1 When timing is set, timing indicator will turn light.

8.2 The time set by timing is 12 hours at most. The timing unit is 1

hour. Even if the operation mode is changed, the timing function

will still work.

8.3 Power-off at a fixed time

Page 20

The power-off at a fixed time can be set only if the air conditioner

is on. And it continues to work though the power-off at a fixed

time has been already set. When it comes to the fixed time, the

indoor and outdoor fans will be shut down.

8.4 Power-on at a fixed time

The power-on at a fixed time can be set only if the air conditioner

is on. And it continues to be off though the power-on at a fixed

time has been already set. When it comes to the fixed time, the

indoor and outdoor fans will start to operate.

9. Emergency switch

When the soft-touch switch is pressed, the air conditioner will be

powered on and the operation indicator will flicker (1 time per

second). And it goes into the mode of automatic operation in 20

seconds. When the soft-touch is pressed once again, it will be

powered off. When the air conditioner goes under the mode of

automatic operation, the air door will assume the appearance of

automatic air door. Under the mode of heating or refrigeration,

the temperature set will be 24 and the wind speed will turn that

under the “high power” mode. Under the dehumidification

operation, the temperature set will be T ring-2 and the air

conditioner can work upon the instructions sent by remote

control.

Page 21

10. Overload control and various protection functions:

10.1 Temperature control (overheat protection).

10.1.1 This function can only be applied to the mode of heating, not

others.

10.1.2 When the temperature of indoor coiled pipe reaches more than

57, outdoor fan will stop working.

10.1.3 When the temperature of indoor coiled pipe drops to less than

52, outdoor fan will resume to operate normally.

10.2 Temperature cut-off control function (overheat protection)

10.2.1 This function can only be applied to the mode of heating, not

others.

10.2.2 When the temperature of indoor coiled pipe reaches more than

64which lasts more than 10 seconds, the compressor and

outdoor fan will all stop working.

10.2.3 After 3 minutes’ shut-down, the compressor will resume to

operate if the temperature of indoor coiled pipe drops to less than

52.

10.3 Function of preventing indoor coiled pipe from being frozen

(supercooling protection).

10.3.1 This function can only be applied to the operation mode of

refrigeration or dehumidification, not others.

10.3.2 When the temperature of indoor coiled pipe drops to -2

Page 22

which lasts more than 2 minutes, the compressor will stop

operating and the indoor fan will go by air quantity set.

10.3.3 When the compressor stops working, it can only be restarted

only if the temperature of indoor coiled pipe rises to more than 7

or the power-off of the compressor lasts more than 6 minutes.

10.4 Protection function of short or open circuit of temperature senor

10.4.1 Powered on, when it is detected that the T ring signal sent by

indoor environment temperature senor is abnormal, the air

conditioner will work under the mode of heating and will not be

powered off if the signal received from remote control is

“heating” or it will work under the mode of refrigeration and will

not be powered off if the signal received from remote control is

“refrigeration” or it will work for 8 minutes and then stop for 3

minutes with the wind speed of “mute cycle dehumidification” if

the signal received from remote control is “dehumidification”.

Besides, the signal of automatic mode sent by remote control

will not be effective, nor will the signal of automatic button

power-on and the related breakdown can be indicated at the

same time.

10.4.2 When it is detected that the T internal coiled pipe signal sent

by indoor coiled pipe temperature sensor is abnormal, the

freezing-proof, cold-wind-proof and overheat-proof functions

Page 23

will be screened. Under the mode of heating, when the

compressor is powered on, indoor fan will be started after 30

seconds’ delay with the wind speed as set while when

compressor is powered off, indoor fan will be turned off after 30

seconds’ delay and the related breakdown can be indicated at the

same time.

10.4.3 When it is detected that the T external coiled pipe signal sent

by outdoor coiled pipe temperature sensor is abnormal, the air

conditioner will work for 50 minutes, defrost for 10 minutes and

heat in cycles if the signal received from remote control is

“heating” and the related breakdown can be indicated at the

same time while the air conditioner will not be powered off and

will operate normally if the signal received from remote control

is heating or defrosting or ventilation and the related breakdown

can be indicated at the same time.

10.5 disposal of indoor PG electric motor abnormity

When indoor PG electric motor is loaded with voltage, the indoor

fan will operate under the mode of “weak wind” automatically if

the pulse signal feed backed by the indoor electric motor is not

detected within 12 seconds. If the feedback signal detected is

normal, the indoor fan will resume the turning speed set and the

related breakdown indication will be disappear.

Page 24

10.6 Function of charatron display

When the controller is normal, there will be no charatron display

under the circumstance of power-off. When air conditioner is

powered on, the charatron will display room temperature under the

normal situation. If the temperature set is changed, the charatron

will show the temperature set which sparkles at the rate of 1 time

per second. Then it will display room temperature once again in 5

seconds. The display range of room temperature is 0~79.

11. Function of breakdown indication

HS, HSA series (charatron); HV (VFD display)

Breakdown cause Display way Display priority

class

PG feedback abnormity

T ring abnormity

T internal coiled pipe

abnormity

T external coiled pipe

abnormity

E4 1

E1 2

E3 3

E2 4

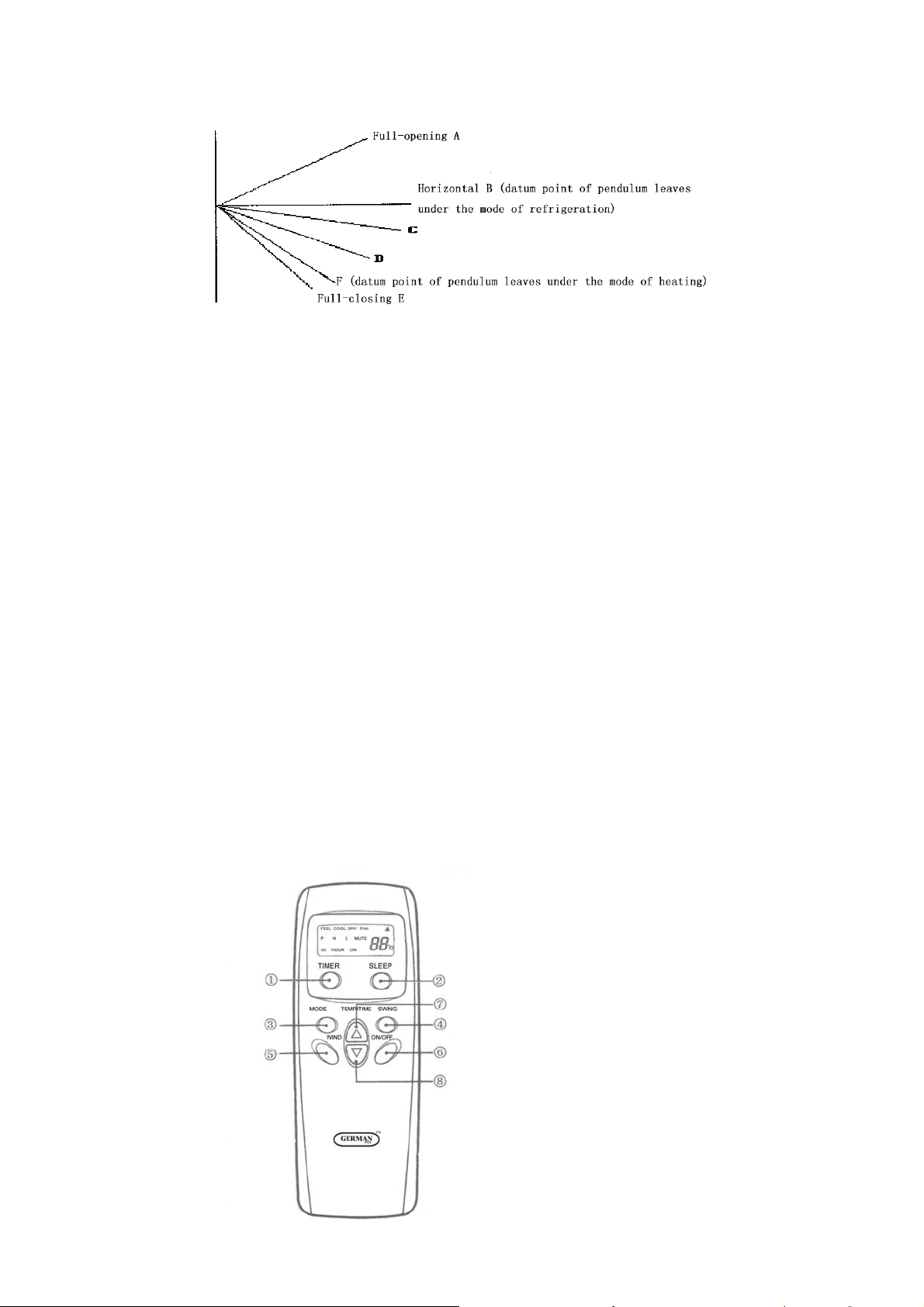

12. Adjustment function of air door direction by pendulum

leaves

Page 25

12.1 When the air conditioner is powered on for the first time, the

pendulum leaves will move to the direction of full-opening and then

to the direction of full-closing wherever they are placed.

12.2 When the air conditioner is powered off, the pendulum leaves will

move up to “close” position immediately wherever they are placed

after the fan comes to an end.

12.3 Under the mode of refrigeration, the pendulum leaves will first move

to the full-opening position and then move to the horizontal position

and at last move under the mode set while under the mode of heating,

they will first move to the full-opening position and then backswing by

5 and at last work under the mode set (for details, please see the

following diagram).

12.4 Pendulum wind: automatic air door and manual air door will be

controlled by one button.

12.5 When the pendulum leaves move from full-opening position to

full-closing position at the time of power-on or from starting position

to full-closing position at the time of power-off, the speed will be 20

per second while the speed under the instruction situation will be 5

per second.

Swing angle under the mode of refrigeration: BD is 35±2

Swing angle under the mode of heating: FC is 40±2

Backswing angle under the mode of heating: EF is 5

Page 26

13.Self-checking function of controller

After the automatic button is pressed, the air conditioner will be

powered on and enter into the process of self-checking:

Buzzer sounds two times→ operation indicator turns on → timing

indicator turns on→compressor acts→four-way valve acts→outdoor

fan acts→electric heating acts→indoor fan acts→buzzer sounds one

time which means that air conditioner goes into the state of

order-waiting and the self-checking comes to an end.

14. Remote control

Name and functions of the button on the remote control

Page 27

(1) Timing ON/OFF button: set the timing mode. After each pressing, the

mode will be changed. It shows in the following display.

ON OFF CLEAR

(2) Sleeping button: which enables you to start the automatic operation

in sleeping mode and stops by pressing on it again.

(3) Selection button for operation mode: which enables you to select

different operation modes, after each pressing, the operation mode will

be changed. It shows in the following display.

AUTOMATIC COOL DRY FAN HEAT

Remarks: Only cool type remote control has no heat mode

(4) Wind direction adjusting button: press the button, the horizontal

airflow direction plate can adjust automatically. When you have the

desired wind direction, please press it again, the airflow direction plate

will maintain the same position.

(5) Fan speed selection button: you can select fan speed from “Power”,

“High”, “Low”, and “Mute”.

P H L MUTE

(6) ON/OFF button: you can start the air-conditioner by pressing this

button and stop its operation by pressing it again.

(7) Setting button▲: Press the button, the setting temperature or timer

Page 28

will increase.

(8) Setting button▼: Press the button, the setting temperature or timer will

decrease.

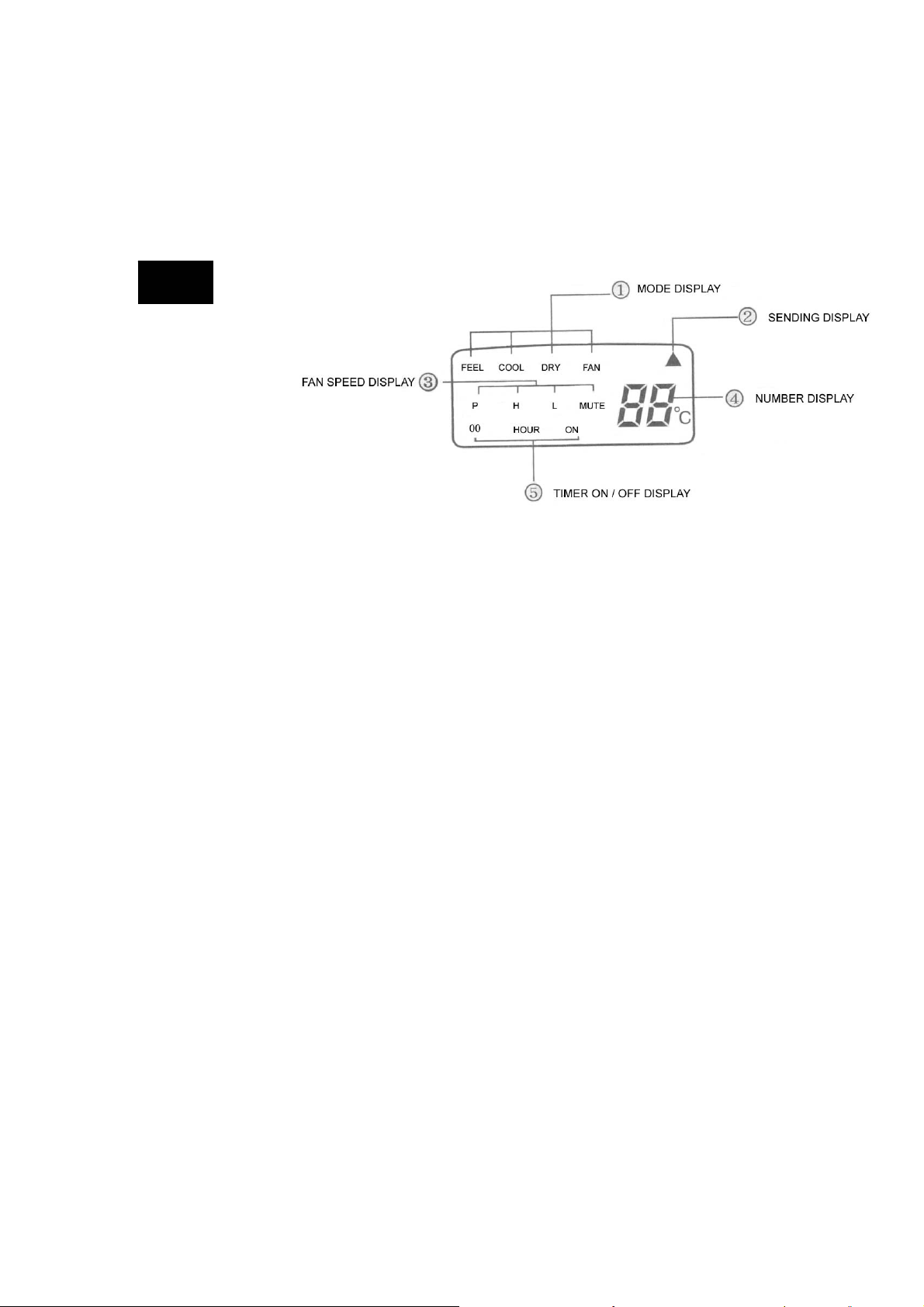

Display

(1) Mode display: press the MODE button, it shows the current

operation mode. You can select “Automatic”, “Cool”, “Dry”,

and “Fan”“heat” operation mode. (cold wind type has no

heating mode)

(2) Sending display: when the remote control sends correct and

effective signal each time, the sign displays intermittently

each time.

(3) Fan speed display: press the “WIND” button, the fan speed

will display. You can select fan speed from “Power”, “High”,

“Low”, and “Mute”.

(4)Number display: which displays the setting temperature, in

the circulation operation mode, the temperature number does

not display.

Page 29

(5)Timer ON/OFF display: which displays the timer states, “the

timer ON” and “the timer OFF” do not set at the same time.

Remark: For illustration, all display items are listed here. When

the mode operates, the relevant items display on the remote

control.

Application

Fix batteries

(1) Slide open the cover according the direction indicated by

arrowhead.

(2). Put into two AAA new batteries, position the batteries to right

electric poles (+&-).

(3)Put back the cover.

Make sure to connect the wire to independent power source socket

before you use the remote control.

Automatic operation mode

(1) Press the MODE button, select the automatic operation mode.

(2) Press the TEMP/TIME button, set the temperature, temperature

can be set at 1

o

C difference range from 16-32 oC.

(3) Press the WIND button, you can select fan speed from “Power”,

“High”, “Low”, “Mute”.

(4) Press the ON/OFF button, the operation indicator is on, the

air-conditioner starts to operate in the Automatic mode.

Press the button again, the air-conditioner stops.

Page 30

Cooling/heating operation mode (cold wind type has no heating

operating)

(1) Press the MODE button, select the Cooling operation mode.

(2) Press the TEMP/TIME button, set the temperature, temperature

can be set at 1 difference range from 16-32

o

C.

(3)Press the WIND button, you can select fan speed from “Power”,

“High”, “Low”, “Mute”.

(4)Press the ON/OFF button, the operation indicator is on, the

air-conditioner starts to operate in the Cooling mode.

Press the button again, the air-conditioner stops.

Drying operation mode

(1) Press the MODE button, select the Drying operation mode.

(2) Press TEMP/TIME button, set the temperature, temperature can be set

o

at 1

C difference range from 16-32 oC.

(3) Press the ON/OFF button, the operation indicator is on, the

air-conditioner starts to operate in the Drying mode.

Press the button again, the air-conditioner stops.

Remark: In the drying operation mode, the fan speed is automatically set

to “Mute”.

Circulation operation mode

(1) Press the MODE button, select the Circulation operation mode.

(2) Press the WIND button, you can select fan speed from “High”, “Low”,

“Mute”. In the circulation operation mode, you cannot select the speed

of “Power”.

(3) Press the ON/OFF button, the operation indicator is on, the

air-conditioner starts to operate in the Circulation mode.

Press the button again, the air-conditioner stops.

Remark: In the circulation operation mode, you cannot set the temperature.

Page 31

Timer setting

Set the “Timer ON” (it operates only when the air -conditioner shuts off.)

(1) Press the TIMER button, select the “Timer ON”, the remote control

display “00 HOUR ON”; “ON” displays intermittently.

(2) Press the TEMP/TIME button, set the time. When “ON” stops

intermittently, the “Timer ON” can be set.

Set the “Timer OFF” (it operates only when the air-conditioner is

running.)

(1) Press the TIMER button, select the “Timer OFF”, the remote control

display “00 HOUR OFF”; “OFF” displays intermittently at the same

time.

(2) Press the TEMP/TIME button, set the time. When “OFF” stops

intermittently, the “Timer OFF” can be set.

Remark: The remote control can only be set within 12 hour intervals.

Sleeping operation mode

(1) Press the SLEEP button, the sleeping indicator light of indoor unit

flashes.

(2) After the setting of sleeping mode, the cooling operation enables the

set temperature to increase 1

o

C after 1 hour and another 1 oC

automatically after another hour.

(3) After the setting of sleeping mode, the cooling operation enables the

set temperature to increase 2

after 1 hour and another 2

automatically after another hour.

(4) The air-conditioner runs in sleeping mode for 7 hours and stop

automatically.

Remark: 1. in sleeping mode the fan speed changes automatically to

“Mute”.

2. Press the MODE button, WIND button or ON/OFF button, the

Page 32

remote control clears sleeping mode away.

Attention:

Aimed the remote control at the receiver on the air-conditioner.

The remote control should be within 8 meters away from the

receiver.

No obstacles between the remote control and receiver.

Don’t drop or throw the remote control.

Don’t put the remote control under the strong sunrays or heating

facilities and other heating sources.

Use two AAA batteries, don’t use rechargeable batteries.

Take the batteries out of remote control before stop using for long.

When the noise of transmitting signal can’t be heard from indoor

unit or the transmission symbol on the display screen doesn’t

flare, batteries need be replaced.

If reset phenomenon occurs on pressing the button of the remote

control, power of the batteries is deficient and need to be

replaced.

Page 33

Page 34

ASW-H07B4/HSAR ASW-07B4/HSAR

Type

ASW-H07B4/HSR ASW-H07B4/HSR

Rated cooling capacity (W/BTU) 2300/7800 2300/7800

Rated heating capacity (W/BTU) 2600/8870

Rated cooling current (A) 3.9 3.8

Rated heating current (A) 4.1

Rated cooling power (W) 860 830

Rated heating power(W ) 870

Air circulate (m3/h) 380 380

Power supply (V, Hz) 220~240, 50 220~240, 50

Refrigerant R407C R407C

Dehumidifying capacity(Kg/h) 0.9 0.9

EER 2.7 2.8

Indoor unit 37 37

Noise dB(A)

Outdoor unit 50 50

Indoor unit 165×802×262 165×802×262 Dimensions

(mm)

Dimension(mm)

Weight (kg)

Outdoor unit 260×760×540 260×760×540

Indoor unit 240×855×330 240×855×330 Packing

Outdoor unit 368×882×585 368×882×585

Indoor(net/gross) 9.5/11 9.5/11

Outdoor(net/gross) 33/35 32/34

Applicable room aream2 914 914

Page 35

Chapter 5 Main Technical Data

Page 36

ASW-H09A4/HSAR ASW-09A4/HSAR

Type

ASW-H09A4/HSR ASW-09A4/HSR

Rated cooling capacity (W/BTU) 2500/9000 2500/9000

Rated heating capacity (W/BTU) 2800/9550

Rated cooling current (A) 4.1 4.0

Rated heating current (A) 4.1

Rated cooling power (W) 900 880

Rated heating power(W ) 900

Air circulate (m3/h) 420 420

Power supply (V, Hz) 220~240, 50 220~240, 50

Refrigerant R407C R407C

Dehumidifying capacity(Kg/h) 0.95 0.95

EER 2.8 2.85

Indoor unit 38 38

Noise dB(A)

Outdoor unit 50 50

Indoor unit 165×802×262 165×802×262 Dimensions

(mm)

Outdoor unit 260×760×540 260×760×540

Indoor unit 240×855×330 240×855×330 Packing

Dimension(mm)

Outdoor unit 368×882×585 368×882×585

Indoor(net/gross) 9.5/11 9.5/11

Weight (kg)

Outdoor(net/gross) 33/35 32/34

Applicable room aream2 1015 1015

Page 37

NOTE: 1.Specifications are standard values calculated based on rated

operation conditions, they will vary in different working condition

2. Our company has quick technical improvement. There will be no

prior notice for any change of technical data. Please read the

nameplate on the air conditioner

Chapter 6 Dismantling Procedure

Page 38

Indoor Unit

Operating step Photo

1. To remove the panel and connecting wire

cover.

· Take off the screws of the connecting wire

cover and remove the cover.

· Then remove the panel.

2. To remove the air filter.

3. To remove the inter frame assembly

Take off three screws of inter frame

assembly

Then take off the inter frame assembly

4. To remove the electric control box

Take off one screw

Loose one obverse clip

Remove the electric control box

Page 39

5. To remove the water-collecting plate

assembly

Loose three obverse clips

Take off the electric control box

6. To remove the evaporator assembly

Take off one screws of right locating

cover and two screws of left locating

cover

Remove the pipe strap

Remove the evaporator assembly

Page 40

7. To remove the through-flow fan

Take off the screws of though-flow fan

Remove the though-flow fan

8. To remove the motor

Take off three screws of right locating

cover

Remove the motor

Page 41

Outdoor Unit

Operating step Photo

1. To remove the top cover assembly

Take off six screws of top cover

2. To remove the panel assembly

Loose screws of panel assembly

Take off panel

3. To remove the right plate assembly

Loose nine screws of left plate

assembly

Take off right plate

Page 42

4.To remove the axial-flow fan and fan

motor

5.To remove the electric assembly

Page 43

Chapter 7 Brief introduction of installation

The installation of air-conditioner shoul d meet with the “Installation Instruction”.

The machine must be installed correctly by professional technicians according to the “Installation

Instruction”.

Guide to customer

z The customer should provide a suitable power supply source, its voltage should be in the

range of 90-110% of its rated voltage.

z The power supply circuit should have MCB leakage protection. The capacity should be more

than 1.5 times of the maximum current.

z Must use independent circuit and suitable grounding socket matching with the plug of

air-conditioner.

z The wiring must be installed by qualified electrician according to the electrical safety

requirements.

z The air-conditioner must be well grounded, the switch of the main power of air-conditioner

must be reliably grounded.

z The power supply wire, must be changed by qualified electrician.

Installation Instruction

Installation order:

Selection of the installation position Installing the air-conditioner

Page 44

Expelling the air in the pipes and the indoor unit Connecting the pipes and wires

Testing

Selection of the installation position

Indoor Unit

z There is no heating and steaming source

nearby.

z No obstacles for installation position

from nearby.

z Keep good air circulation.

z Convenient to adopt measures to reduce

noises.

z Don’t install them near the

doorway.

z Make sure to have the distance

specified in the picture between the ceiling,

wall, furniture and other obstacles.

z 2 meters high above the floor.

Outdoor Unit

z In case that you put up a canopy to protect it from rains and sunrays, pay attention not to

cause any obstacles for the heating dispersion for the condenser.

z Don’t keep animals or plants near the installa tion location for the hot air from the out door unit

will affect them.

z Make sure to have the distance specified in the picture between ceiling, wall, furniture and

other obstacles.

z Stay away from heating source and inflammable air.

z The installation base and supporting frame should be strong and secure. The machine should

be at a level surface.

Installation of the Outdoor Unit

z The outdoor unit must be firmly fixed to

avoid falling in strong wind.

z Install on the cement base as in the

drawing.

z If it is installed at seaside or at a place high

above the ground and with strong wind, the AC should be in stalled agai n st the wal l to ensu re

the normal operation of the fan and the blocking plate should be used.

Page 45

z If it is an overhanging installation , the str ucture of th e mounting wall should b e made of s olid,

cement or materials with equivalent strength, and of sufficient support capacity. Otherwise,

measures such as reinforcement, support or vibration damping should be adopted.

Installation of the Indoor Unit

z First make changes to wall and make sure th at is hard and secure. Using four “+” type screws

to fasten the installation board onto the wall. Keep it level in horizontal direction and

perpendicular in vertical dire cti on. Otherwise it might cause w at er drips when air-co nd iti oner

is running in cooling operation.

z Drill 70mm diameter pipe hole at the left lower or right lower side of the installation board.

The hole shall slant outward slightly.

z Hang the indoor unit to the

board and make sure the

machine is in the middle of the

board.

z Push the machine towards

the left lower and right lower

side of the installation board

until the hangers enter tightly

into the grooves (it produces

“click” sound)

Check the water discharge

1. Take off the frame from the unit

cover.

Take off the front frame for

maintenance according to the

Page 46

following steps:

z As shown in the picture on the right, take off two covers from the front frame and then

unfasten two fixture screws.

z Pull the front frame towards yourself and take it off.

To put the front frame back, reverse the steps.

You should check whether the front frame is firmly fixed into the fixture groove on the top.

2. Check the water discharge

z Pour a cup of water into groove.

z Check whether the water flow through the water discharge hole.

Pipe Connection

z Connect the pipe to the unit: point to the center of

pipe and fasten the connectio n screw at first by

hand and then by wrench until it is tightly

fastened. The fastening direction is shown in

the picture.

z Pointing towards the center of pipe, fasten the screw

with strength.

z Wrench the screw in the end until you hear th e

“click” sound.

The fixing of pipe

z Wrap up all pipe, water discharge and

connection wire from top to below.

z Cover the connection parts with

insulation material and fix them with two

plastic rings.

z Wrap up the pipes with tape alongside the wall

and fix them to the wall with clips. These

Page 47

steps are usually adopted when outdoor unit is installed below the indoor unit.

z In case that you want to have additional water discharge pipe, the end of pipe should be

within certain distance from the floor (to prevent water from draini ng back into the pipe). Fix

it onto the wall so it won’t be swayed by wind.

z Wrap the pipes and connection wire well from

below to top.

z Wrap up the pipes that are rounded up in the

way shown in the picture so it can prevent

water from entering the room.

z Use clips or other fixture to fasten the pipes

to the walls.

Expelling the air in the pipes and the indoor unit

Expelling the air: humid air in the refrigerating system might cause trouble of compressor.

z Take off the cover from the stop valve

and T -branch valve.

z Take off the auxiliary cover from the

T-branch valve.

z Turn the stop valve rod anti-clock wise to

an angle of 90 degree, keep it open for 8

seconds and close the valve.

z Check whether there is air leakage at all

connection parts of pipes.

z Push the top rod of T-branch valve by

hexagon wrench to expel air.

z Repeat the third and fifth steps.

z Open the stop and T-branch valve with a hexagon wrench to make the unit operate.

z No leakage is allowed, please check all the piping connecti on parts. You must test the leakage,

generally, it can be tested by soap water.

Electrical connection

z Unscrew the screw, take off the control panel cover from the unit.

z Cooling type: connect the wire to the relate d connection point on the panel and conne ct the

signal connection plug.

Page 48

Remarks: yellow and green cord should be connected to connection point with mark.

z Fasten the fixture of wire to control panel.

z Screw up the control panel cover to its original place.

Test running

z Make sure that the pipes and wires are connected.

z Make sure that both the liquid valve and gas valve on the side are completely open.

1. The connection of power source

¾ Connect the wire to independent power source socket.

¾ Preparation of remote control.

¾ Run the air-conditioner in cooling operation mode for 30 minutes or longer.

2. Performance evaluation

¾ Test the out and in air temperature.

¾ Make sure that the temperature difference between the out and in air is grea ter than 8

o

C.

Page 49

Items of attention

z Fix the machine firmly, otherwise it will produce noise and vibration.

z Install the outdoor unit where it will not disturb your neighbor.

Electrical connection diagram:

COOL SERIES HEAT PUMP

Indoor unit electric connection diagram

Page 50

COOL SERIES HEAT PUMP

Outdoor unit electric connection diagram

Chapter 8 Fault Analysis of the Product Available and

Typical Examples

1 Procedure of deciding the faults

Before maintaining the air conditioner, firstly you should know the

phenomena of the faults, decide the location of the faults, analyze the

reason the faults occur, and then search for ways to solve the faults. The

detailed procedures are: Look, Listen, Touch, Measure, Analyze

Look: Observe air conditioner’s running. I.e., vibration;

condensation on evaporator; leakage; electrical and mechanical

connection, etc.

Listen: Listen to kinds of sounds of the running air conditioner.

Identify the abnormal noise from the sounds.

Touch: Touch the key position and position faulty. Touch the temp

of air circulation to decide the heating or cooling effect; as far to

abnormal sound, besides adopt “listen”, you should touch the frame, the

pipe of the air conditioner to feel the vibration. Touch the easily heated

parts, i.e. compressor, motor, touch them to feel the temp.(Wa rning: High

temp).

Measure: Measure the parameters of the air conditioner and

relevant parts by some instruments. Usually used instruments:

amperemeter, voltmeter multimeter thermometer, etc, i.e., Use

multimeter to test whether the capacitor is open, the insulation of the wire

and the parameters of other electrical parts; use the thermometer to

measure temp of airflow.

Analyze: Analyze the above results, decide the reason and location

Page 51

of faults, and seek the solutions.

2 Types of Normal Faults

The type of faults is various. The normal faults can come down to six

types: leaks, block, open circuit, burnt, lock, scrape.

LeakMainly is leakage of R407C from cooling pipe system and

parts; leakage of condensation water from indoor units; electrical leakage

from electrical system and wires.

BlockMainly is block of the pipe system, block of capillary, block

of strainer or valve.

Open CircuitMainly is open circuit of electrical circuit, include:

fuse blowing out, connectors broke.

BurntMainly is burnout of fan motor, of compressor, of capacitor,

of transformer.

LockMainly is lock of compressor, four-way valve.

ScrapeMainly is scrape of indoor/outdoor fan and nearby parts,

and sound abnormally.

3 Examples

3.1 Leakage and seepage of indoor unit

Reason Check to be made Proposed remedy

Improper installation.

Indoor drain position is

lower than outdoor or

slanting installation of

indoor unit

Water collecting plate is

blocked

Water collecting plate or

drain pipe is cracked

Loosen wrap belt,

heat-preservation layer is

bad or layer behind indoor

units is bad

High ambient relative

humidity, low temp/speed

of air flow

Observe if the

condensation water drain

out, if the indoor unit is

declining

Check if the plate is

blocked

Check the location, ensure

if it is cracked

Connecting pipe bleed the

water, condensation water

exists behind the indoor

unit, the wall is wet and

turn colors

Water is blow out from air

outlet, or water drips from

the outlet. Lower speed of

air flow

Level the indoor unit and

adjust the height

Remove the matters block

the plate

Replace the plate or pipe

Rewrap the connecting

pipe, add new

heat-preservation layer

Suggest set the units to

dehumidifying mode at

high speed of air flow, to

lower relative humidity;

if the high speed is still

felt lower, the fan motor

must be checked

3.2 Poor cooling or heating effect

Page 52

Reason Check to be made Proposed remedy

The cooling/heating load of

the room is heavy or the

room is not closed perfectly

Calculate the area of the

Enlarge the capacity of

the units, improve the

room, check the close of the

leakproofness of the

room

room

Insufficient refrigerant

R407C

Measure the operating

current

Air intake temp is too low,

condensation water on air

Too much R407C

intake pipe is too much,

temp of discharge is too high

Effect of heat exchange is

too poor

Some of the windings of

motor fan is short-circuit,

so cause speed decline

Dust on outdoor condenser

and indoor filter is too much

Speed of indoor/outdoor fan

is too low, air circulation is

small

Check if the installation is

Running condition is too

proper; outdoor temp is too

bad

high when heating

No high-low pressure

Convexity exists in

compressor or valve or lock

of compressor

difference, no clear temp

difference in air intake inlet

or discharge outlet of

compressor

Openness of check valve is

too small or the system

partly or completely

Check the openness; partly

frost on outdoor pipe system

blocked

3.3 Big noise or abnormal sound

Reason Check to be made Proposed remedy

Foreign matters in wind

Check if they are Clear away

guide or impeller fan

Fan is distorted or in bad

Check them

balance

Open the unit or move the

Improper location of fan, so

fan manually, find the

fan touches the housing

location

Bearing of the fan is

Check the bearing Replace the bearing

sluggish or destroyed

Add R407C welding

the leaked point

Discharge a little

R407C

Cleanup filter and

condenser

Repair or replace motor

Improve the condition,

use auxiliary heating

Replace compressor or

valve

Open the valve; use

high pressure N

to

2

clean out the block

Replace indoor/outdoor

fan

Adjust the position

Page 53

Connecting pipe vibrates

due to improper

installation, or touch the

lower frame

Outdoor pipes touches

Abrasion of the parts of

compressor

3.4 Frequently switch on/off of the compressor

Reason Check to be made Proposed remedy

Running voltage is too low Measure the voltage

Discharge temp is too high

caused by insufficient of

R407C, compressor is

protected by overheat

Temp sensor is too close to

evaporator or moved

Air inlet/outlet of heat

exchange is blocked or low

speed of fan motor; indoor

air filter is too dirty or

blocked

Too much R407C

Bad insulation of

compressor, high operating

current, overcurrent proof

Improper temp set

3.5 Promptly protected by halt after compressor starts

Reason Check to be made Proposed Remedy

Insufficient R407C

Mixed with air in the

system, vacuum is not good

Check the connecting pipe

Check the vibration of the

pipes, check if them touch

Check if the sound of

compressor is normal

Check condensation of air

intake pipe or measure if

operating current is lower

than rated current

Check the position of

sensor

Check indoor/outdoor heat

exchange, speed of motor,

air inlet/outlet

Too much condensation

water on air intake pipe,

high operating current

Check start or operating

current

Check actual ambient

temp

Little or no condensation

water on air intake pipe,

operating current is lower

than rated current

Power varies when

running

Tidy up the pipes,

eliminate the noise source

Tidy up the pipes

Replace the compressor

Add measures of voltage

stabilization

Check leakage point,

welding or add R407C

Adjust the position or

replace the sensor

Cleanup the filter, remove

the obstacle

Discharge a little R407C

Replace compressor

Reset

Add R407C

Vacuumize the system,

recharge R407C

Page 54

Blocked caused by water or

impurity

Damaged compressor, high

start current

3.6 The units blow out cool air when in heating mode

Reason Check to be made Proposed Remedy

Operating current is lower

than rated current, part of

the unit frosts heavily

Check the windings and

insulation of compressor

and if it is locked

use high pressure N

to

2

clean out the block,

revacuumize and recharge

R407C

Replace the compressor

Four-way valve doesn’t

work

Listen to the units if there

is sounds of valve’s

working when heating or

cooling

Faults of control interrupter

Check the circuit Repair or replace the

or other relevant circuits of

the valve

Insufficient R407C causes

the insufficient heating

capacity

Little condensation water

on outdoor air intake pipe,

low operating current

Connexity of compressor Same temp of air intake

inlet and discharge outlet

of the compressor, no

condensation in air intake

inlet

3.7 The units doesn’t work

Reason Check to be made Proposed Remedy

Bad connection of the

power plugs, or no power

Check the socket Repair or replace

plug

Outdoor fuse or indoor fuse

Check if the fuse is good Replace the fuse

is burnt

Low voltage Measure the voltage

Measure actual indoor

temp, compare to the set

temp(in cooling set temp

Wrong indoor tem p set

should be lower than the

actual, in heating, is

higher)

Replace the valve

control board

Add R407C

Replace the compressor

Heighten the voltage of

the power supply system

Reset the temp

Page 55

Wrong running mode of

indoor units set

3.8 Cannot receive the remote control signal

Reason Check to be made Proposed Remedy

Check if running mode of

two indoor units is the

same( it is not available if

one is heating and another

is cooling

Reset

Damaged remote control or

low battery

Short-circuit of connections

of main control board to

switch board

Running mode of two

indoor units is not the same

Indoor units are in test

mode

RemarksThe above mentioned “faults” are the faults possibly occur, we

will continue to collect the faults and analysis.

Check if the indication is

normal

Replace the remote

control or battery

Check the board Replace the components

Check if one is heating

Reset

and another is cooling

Open the air intake grill to

see the running mode

Adjust test mode to

remote control mode

Page 56

CONTENTS

Chapter 1 photos and Features of products

Chapter 2 Operating Principle

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Chapter 8

operation details

Exploded Views of the Production

Main Technical Data

Dismantling Procedure

Brief introduction of installation

Fault Analysis of the Product Available

Page 57

Chapter 1 photos and Features of products

Features of outlook and construction

ASW-H12A4/HSAR ASW-H12A4/HSR

ASW-12A4/HSAR ASW-12A4/HSR

Deep × width ×high176×890×296 Deep × width ×high176×890×296

Deep × width ×high260×760×540 All types

All types

Operation interface

Inner operation interface of Type HSAR

Inner operation interface of Type HSR

Page 58

·Emergency operation button of indoor types:

Compulsory button

1) When the air-conditioner works with the

absence of remote control, it will stop

working by pressing the compulsory button and it will resume working

by pressing the compulsory button once again.

2) When remote control is useless, you can adopt the compulsory

operation by which the air conditioner will go into automatic operation

mode.

·The operation interface of remote control:

Features of products

1. Fashionable appearance

2. Compact Design

3.7 Hours of Sleep Mode Operation

4. Economy Mode to Reduce Electrical Power Consumption

Page 59

5.Clean breath efficient biological antibacterial filter gauze made

from green plant elite refined by using international leading

technology, with the function of filtering and suppressing bacteria,

and able to absorb and kill various pathogens and harmful gases

efficiently for a long period, prevent secondary pollution caused due

to microorganism spreading, and ensure the health of your family

6. R407c cold medium is applied, environment-friendly, and avoid

damages to ozonosphere

7. International famous-brand Toshiba Hitachi and Matsushita

compressors are applied

Chapter 2 Operating Principle

. Cooling

After the power supply is switched on, the machine is set to COOL

mode. With the compressor being operated, the low-temperature and

low-pressure refrigerant vapor is sucked into the compressor where it is

turned into high-temperature and high-pressure gas. Then it is cooled

down in the outdoor heat exchanger by the air and becomes liquid. After

being throttled by the capillary, the refrigerant liquid comes into the

indoor unit and then it evaporates in the indoor heat, exchanger,

Page 60

absorbing heat and reducing the room temperature. The evaporated

refrigerant vapor returns to the outdoor unit and is again sucked into the

compressor, completing the cycle. With the refrigerant cycling being kept

on, the objective of lowering the room temperature is fulfilled.

. Heating

After the power supply is switched on, the machine is set to HEAT

mode and the coil of the electromagnetic four-way valve is energized.

After the compressor starts to operate, the high-temperature and

high-pressure refrigerant gas first comes into the heat exchanger of the

indoor unit, where it is cooled, releases heat and increases the room

temperature. The cooled high-pressure refrigerant is then throttle1d in the

outdoor unit and returns to the compressor after evaporation. With such

cycles being maintained, the objective of increasing the room temperature

is fulfilled.

Page 61

Operation Hints

Page 62

Page 63

Page 64

Chapter 3 operation details

1. Overall

1.1 Protection of compressor

Whatever operation modes the air- conditioner is under, there will

always be 3 minutes' time- delay protection unless it is on for the first

time. When the compressor is switched on, it can not be shut down

within 3 minutes (except under the modes of heating or defrosting)

unless it is powered off or its operation mode is changed.

1.2 The operation indicator will turn light when the air conditioner is

powered on.

1.3 The buzzer will sound immediately after the controlling device

receives a correct and effective signal sent by the remote control.

1.4 Timing function can be applicable to all operation modes while

sleep function can only be applicable to the modes of refrigeration

and heating.

2. Automatic operation mode

2.1 When the air conditioner works, it can detect the indoor temperature

automatically whereby its operation mode can be selected:

refrigeration, heating or dehumidification.

2.2 When the indoor temperature reaches more than 27, the air

conditioner will operate under the mode of refrigeration.

2.3 When the indoor temperature reaches between 20and 27the air

Page 65

conditioner will work under the mode of dehumidification (always

mute).

2.4 When the indoor temperature reaches less than 20, the air

conditioner will work under the mode of heating.

2.5 Under this mode, the air conditioner will operate in the respect of

blowing rate as set and its pendulum leaves will work according to

the requirements of automatic ventilation door.

2.6 Once the operation mode is selected, it will not be able to be

changed. When the air conditioner is shut down and then restarted,

the operation mode will be selected once again based on the

variation of indoor temperature.

2.7 After the operation indicator has been flickering for 20 seconds, it

will turn light steadily (i.e. the determination of operation mode will

start in 20 seconds.)

2.8 This mode has timing function, does not have sleep function.

2.9 Under this operation mode, the temperature can be set and adjusted

by remote control.

3. Refrigeration mode

3.1 Under the refrigeration mode, the range of temperature set by

remote control is between 16and 32.

3.2 Shut-down of four-way valve;

3.3 The condition on which the compressor starts is that the indoor

Page 66

temperature reaches more than the temperature set plus 1while the

condition on which the compressor shuts down is that the indoor

temperature reaches less than the temperature set minus 1.And

when the indoor temperature is equal to that set, the original

operation mode will be kept.

3.4 Under the mode of refrigeration, the function of preventing indoor

coiled pipe from being frozen will be effective.

3.5 The indoor wind speed will be as set. And the pendulum leaves will

work according to the instructions sent by remote control.

4. Dehumidification operation

4.1 The temperature range set and controlled is between 16and 32.

The temperature will be set by remote control.

4.2 The four-way valve is shut down.

4.3 The wind speed gear-changes to “mute". And the pendulum leaves

works according to the instructions sent by remote control;

4.4 The function of preventing indoor coiled pipe from being frozen is

effective.

4.5 When the indoor temperature reaches less than 16, the function of

dehumidification is out of use.

4.6 When the indoor temperature reaches more than 16 , the

compressor will be switched on and work intermittently. The time

when the compressor shuts down depends on T ring and T ring-T set.

Page 67

When the compressor is shut down, the outdoor fan and indoor fan

will stop working.

When T ring≥23

T set <T ring-1, the compressor will be working for 8 minutes and then

stopping for 3 minutes in cycles.

T set≥T ring-1, the compressor will be working for 3 minutes and then

stopping for 6 minutes in cycles.

And when T ring <23

T set ≤T ring-1, the compressor will be working for 3 minutes and

then stopping for 4 minutes in cycles.

T set >T ring-1, the compressor will be working for 3 minutes and then

stopping for 6 minutes in cycles.

5. Function of ventilation control

5.1 Under the mode of ventilation, the outdoor fan assembly will

always be shut down.

5.2 The indoor fan will operate as set in the respect of air quantity

without the gear- change of “high power".

5.3 The pendulum leaves will work according to the instructions sent

by remote control.

6. Heating function

6.1 Under the mode of heating, the temperature range set is between 16

and 32. And the temperature will be set by remote control.

Page 68

6.2 When the air conditioner is powered on, the outdoor fan, four- way

valve and compressor will start at the same time while when it is

shut down, the outdoor fan and compressor will be shut down at the

same time and so will the four- way valve after 2 minutes' delay.

6.3 Under the mode of heating, the compressor can not be shut down

within 3 minutes after it is powered on unless the operation mode is

changed or the air conditioner is turned off.

6.4 There is a 3 temperature compensating function. The temperature

measured at the in-blow vent minus 3 automatically can be

regarded as that compared with the temperature set (This function

does not exist under other circumstances).

6.5 According to the temperature set, the condition upon which the

compressor will be switched on is indoor temperature≤ temperature

set-1 While the condition upon which it will be switched off

is indoor temperature is indoor temperature≥ temperature + 1.

When the indoor temperature is equal to that set, the original

operation mode will be kept.

6.6 Indoor fan control:

6.6.1 Heating operation and prevention of cold wind

When the compressor works:

1. During the rising process of the temperature of coiled pipe,

the indoor fan will not start if the temperature of the coiled

Page 69

pipes is less than 25.

2. When the temperature of coiled pipe reaches less than 35

But more than 25, The indoor fan will work under the

mode of “ mute". If the temperature of coiled pipe ascends

to 25and then descends, it will stop working only when

the temperature is lowered to 22.

3. When the temperature of coiled pipe reaches more than 35

, the indoor fan will operate as set in the respect of wind

speed. If the temperature of coiled pipe ascends to 35

And then descends, it will enter into the operation mode of

“ mute" only when the temperature is lowered to 30.

6.6.2 Afterheat-blowing function:

6.6.2.1 When the compressor stop working:

1. When the temperature of coiled pipe is more than 35, the indoor

fan will operate as set in respect of wind speed.

2. When the temperature of coiled pipe is more than 25, but less

than 35, The indoor fan will operate under the mode of “ mute"

3. When the temperature of coiled pipe is less than 25, the indoor

fan will stop working.

6.6.2.2 The afterheat-blowing function when the air conditioner is just

shut down: If the temperature of indoor coiled pipe reaches more

than 30, The indoor fan will operate under the mode of “ mute"; If

Page 70

it lowers to less than 30, the indoor fan will be shut down; And the

time when the afterheat blows will last less than 40 seconds after

the indoor fan is turned off.

6.7 Defrosting operation:

6.7.1The conditions upon which the outdoor sensor goes into operation are

as below:

1. Under the circumstance of heating, if T external coiled pipe is at the

temperature of less than -6 which lasts 2 minutes and the

accumulated working time of compressor reaches more than 50

minutes (if there is any power cut-off or shut-down by remote

control, the accumulated working time of compressor shall be

re-calculated), the defrosting interval will be more than 50 minutes

and the compressor will be working 5 minutes continually.

2. If there is any damage to the external coiled pipe, the accumulated

working time of compressor will reach 50 minutes (if there is any

power cut-off, shut-down by remote control or defrosting, the

accumulated working time of compressor shall be re-calculated)

and the defrosting operation will last 10 minutes.

6.7.2 Once one of the following conditions is satisfied, the defrosting will

end:

1. The temperature of T external coiled pipe is more than 12.

2. Defrosting duration is more than 12 minutes.

Page 71

6.7.3 The requirements of defrosting operation:

1. Sleep indicator flickers at the speed of 1 time per second

2. When defrosting operation starts, the compressor and indoor fan

will stop working while outdoor fan and four-way valve will

continue to work.

3. The four-way valve and outdoor fan will stop operating in 30

seconds.

4. 15 seconds after that, the compressor starts and goes into

defrosting operation.

5. After the defrosting ends, the compressor stops working. And

the four-way valve and outdoor fan begins to work in 20

seconds.

6. 20 seconds after that, the compressor starts and goes into heating

operation. And the indoor fan enters into the prevention mode of

cold wind.

6.8 Auxiliary electric heating function

6.8.1 Only if the following conditions are satisfied under the

heating operation, can the auxiliary electric heating go into

operation automatically.

a. The compressor works for 4 minutes by heating pump

b. Indoor temperature is less than 22;

c. The temperature set-indoor temperature is more than 3;

Page 72

d. Indoor fan goes into operation;

e. Indoor coiled pipe temperature is less than 48

6.8.2 Once one of the following conditions is satisfied, auxiliary

electric heating operation will end:

a. Indoor temperature is more than 22.

b. The temperature set –indoor temperature is less than 2.

c. When Indoor coiled pipe temperature is more than 52, the

electric heating operation will end.

d. Indoor temperature sensor becomes abnormal.

6.8.3 If compressor or indoor fan stops working, the electric

heating will stop operating as well.

6.8.4 During the operation of compressor, if the auxiliary electric

heating stops working, it can be restarted only in 1 minute.

7. Sleep operation

7.1 When the air conditioner enters into the mode of sleep, the indoor

wind speed will turn into the air quantity of “mute”.

7.2 When the sleep operation goes under the mode of refrigeration,

the temperature set rises by 1 automatically every one hour. And

the air conditioner will be powered off after sleep mode has

worked for 7 hours.

Page 73

7.3 When the sleep operation goes under the mode of heating, the

temperature set drops by 2 automatically every one hour. And the air

conditioner will be powered off after sleep mode has worked for 7

hours.

7.4 When the button of mode selection is pressed down, the function

of sleep will be cancelled.

7.5 Sleep operation is effective under the modes of refrigeration and

heating. When sleep button is pressed down, the sleep operation

can begin or end.

7.6 Sleep function does not exist under the automatic mode, the

situation of dehumidification or the circumstance of ventilation.

8. Timing operation

8.1 When timing is set, timing indicator will turn light.

8.2 The time set by timing is 12 hours at most. The timing unit is 1

hour. Even if the operation mode is changed, the timing function

will still work.

8.3 Power-off at a fixed time

Page 74

The power-off at a fixed time can be set only if the air conditioner

is on. And it continues to work though the power-off at a fixed

time has been already set. When it comes to the fixed time, the

indoor and outdoor fans will be shut down.

8.4 Power-on at a fixed time

The power-on at a fixed time can be set only if the air conditioner

is on. And it continues to be off though the power-on at a fixed

time has been already set. When it comes to the fixed time, the

indoor and outdoor fans will start to operate.

9. Emergency switch

When the soft-touch switch is pressed, the air conditioner will be

powered on and the operation indicator will flicker (1 time per

second). And it goes into the mode of automatic operation in 20

seconds. When the soft-touch is pressed once again, it will be

powered off. When the air conditioner goes under the mode of

automatic operation, the air door will assume the appearance of

automatic air door. Under the mode of heating or refrigeration,

the temperature set will be 24 and the wind speed will turn that

under the “high power” mode. Under the dehumidification

operation, the temperature set will be T ring-2 and the air

conditioner can work upon the instructions sent by remote

control.

Page 75

10. Overload control and various protection functions:

10.1 Temperature control (overheat protection).

10.1.1 This function can only be applied to the mode of heating, not

others.

10.1.2 When the temperature of indoor coiled pipe reaches more than

57, outdoor fan will stop working.

10.1.3 When the temperature of indoor coiled pipe drops to less than

52, outdoor fan will resume to operate normally.

10.2 Temperature cut-off control function (overheat protection)

10.2.1 This function can only be applied to the mode of heating, not

others.

10.2.2 When the temperature of indoor coiled pipe reaches more than

64which lasts more than 10 seconds, the compressor and

outdoor fan will all stop working.

10.2.3 After 3 minutes’ shut-down, the compressor will resume to

operate if the temperature of indoor coiled pipe drops to less than

52.

10.3 Function of preventing indoor coiled pipe from being frozen

(supercooling protection).

10.3.1 This function can only be applied to the operation mode of

refrigeration or dehumidification, not others.

10.3.2 When the temperature of indoor coiled pipe drops to -2

Page 76

which lasts more than 2 minutes, the compressor will stop

operating and the indoor fan will go by air quantity set.

10.3.3 When the compressor stops working, it can only be restarted

only if the temperature of indoor coiled pipe rises to more than 7

or the power-off of the compressor lasts more than 6 minutes.

10.4 Protection function of short or open circuit of temperature senor

10.4.1 Powered on, when it is detected that the T ring signal sent by

indoor environment temperature senor is abnormal, the air

conditioner will work under the mode of heating and will not be

powered off if the signal received from remote control is

“heating” or it will work under the mode of refrigeration and will

not be powered off if the signal received from remote control is

“refrigeration” or it will work for 8 minutes and then stop for 3

minutes with the wind speed of “mute cycle dehumidification” if

the signal received from remote control is “dehumidification”.

Besides, the signal of automatic mode sent by remote control

will not be effective, nor will the signal of automatic button

power-on and the related breakdown can be indicated at the

same time.

10.4.2 When it is detected that the T internal coiled pipe signal sent

by indoor coiled pipe temperature sensor is abnormal, the

freezing-proof, cold-wind-proof and overheat-proof functions

Page 77

will be screened. Under the mode of heating, when the

compressor is powered on, indoor fan will be started after 30

seconds’ delay with the wind speed as set while when

compressor is powered off, indoor fan will be turned off after 30

seconds’ delay and the related breakdown can be indicated at the

same time.

10.4.3 When it is detected that the T external coiled pipe signal sent

by outdoor coiled pipe temperature sensor is abnormal, the air

conditioner will work for 50 minutes, defrost for 10 minutes and

heat in cycles if the signal received from remote control is

“heating” and the related breakdown can be indicated at the

same time while the air conditioner will not be powered off and

will operate normally if the signal received from remote control

is heating or defrosting or ventilation and the related breakdown

can be indicated at the same time.

10.5 disposal of indoor PG electric motor abnormity

When indoor PG electric motor is loaded with voltage, the indoor

fan will operate under the mode of “weak wind” automatically if

the pulse signal feed backed by the indoor electric motor is not

detected within 12 seconds. If the feedback signal detected is

normal, the indoor fan will resume the turning speed set and the

related breakdown indication will be disappear.

Page 78

10.6 Function of charatron display

When the controller is normal, there will be no charatron display

under the circumstance of power-off. When air conditioner is

powered on, the charatron will display room temperature under the

normal situation. If the temperature set is changed, the charatron

will show the temperature set which sparkles at the rate of 1 time

per second. Then it will display room temperature once again in 5

seconds. The display range of room temperature is 0~79.

11. Function of breakdown indication

HS, HSA series (charatron); HV (VFD display)

Breakdown cause Display way Display priority

class

PG feedback abnormity

T ring abnormity

T internal coiled pipe

abnormity

T external coiled pipe

abnormity

E4 1

E1 2

E3 3

E2 4

12. Adjustment function of air door direction by pendulum

leaves

Page 79

12.1 When the air conditioner is powered on for the first time, the

pendulum leaves will move to the direction of full-opening and then

to the direction of full-closing wherever they are placed.

12.2 When the air conditioner is powered off, the pendulum leaves will

move up to “close” position immediately wherever they are placed

after the fan comes to an end.

12.3 Under the mode of refrigeration, the pendulum leaves will first move

to the full-opening position and then move to the horizontal position

and at last move under the mode set while under the mode of heating,

they will first move to the full-opening position and then backswing by