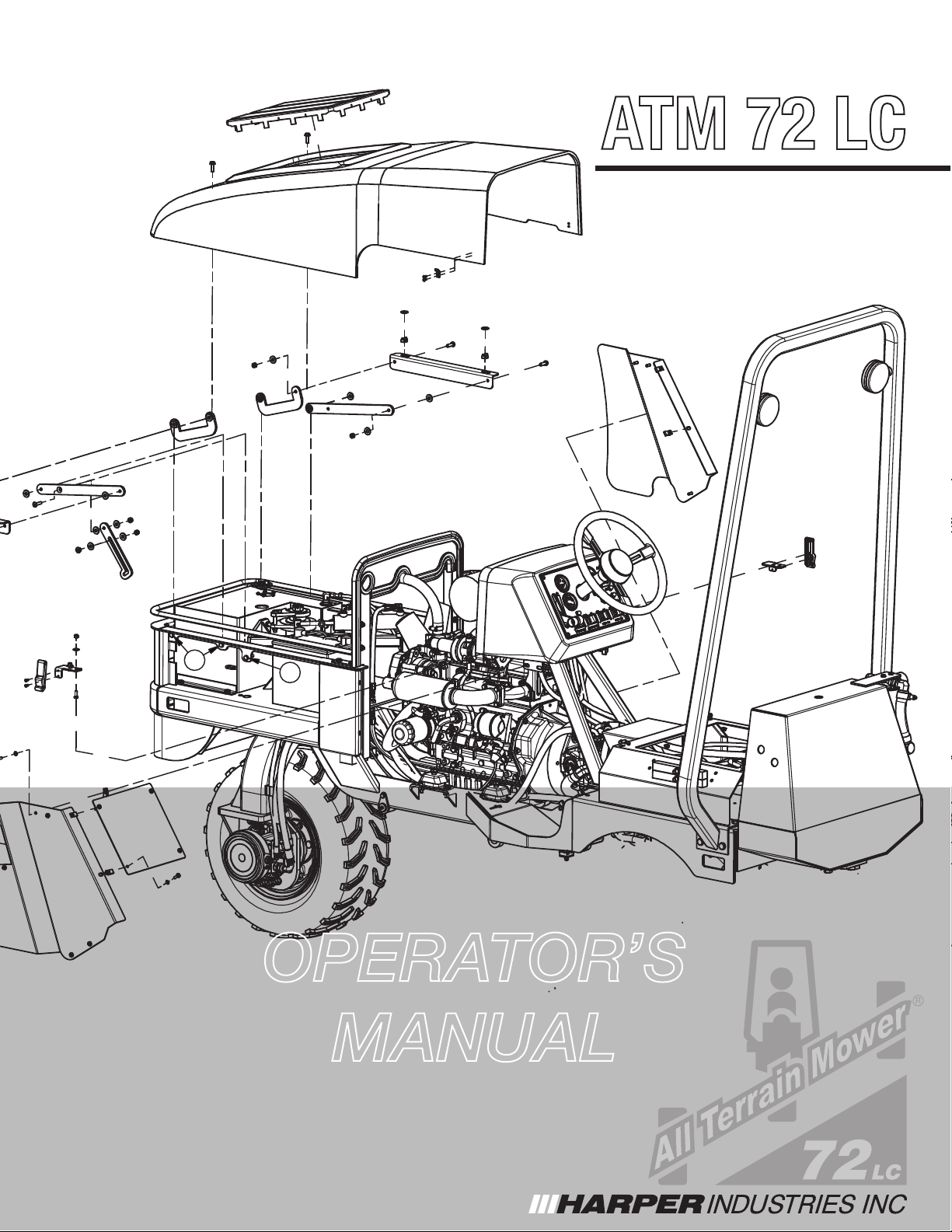

Page 1

ATM 72 LC

R

6

5

OPERATOR’S

MANUAL

ATM 72 LC

3-2019

Page 2

ATM 72 LC

Page 3

Thank you for purchasing a Harper ATM 72.

TO THE OWNER OR OPERATOR:

Please take time to read this manual carefully before operating the ATM 72. Each operator should

be familiar with all safety precautions along with the operating and service procedures. Knowledge

and familiarity will make a difference in how the machine performs.

As with all Harper products, the ATM 72 was developed through tough design and testing procedures to produce a sturdy, dependable machine. This manual gives assembly and operating information. Read and understand all instructional materials included with the unit and its components

before operating or maintaining the equipment.

An All-Terrain Mower can present hazards to an operator who follows unsafe procedures in either

the operation or maintenance of the unit. Therefore, SAFETY WARNINGS are present at certain

locations in the text.

SYMBOL: SAFETY WARNING!

MEANING: Failure to understand and obey this warning may result in injury to you or others.

Whenever this symbol is used, please pay very close attention to the information presented, and

make sure you fully understand. If you do not, contact your dealer or Harper Industries for clarication.

SAFETY WARNING!

All shields and guards must be in place for proper and safe operation of this equipment.

Where they are shown removed in this manual, it is for purposes of illustration and instruction only. Do not operate this equipment unless all shields and guards are in place.

WARNING: Breathing diesel engine exhaust exposes you to chemicals known to

the State of California to cause cancer and birth defects or other reproductive harm.

• Always start and operate the engine in a well-ventilated area.

• If in an enclosed area, vent the exhaust to the outside.

• Do not modify or tamper with the exhaust system.

• Do not idle the engine except as necessary.

For more information go to www.P65warnings.ca.gov/diesel

© 2019 Harper Industries, Inc.

The Harper and DewEze names and the ATM logo are registered trademarks of Harper Industries, Inc. All other brand and product

names are trademarks or registered trademarks of their respective companies.

ATM 72 LC

1

Page 4

LIMITED WARRANTY

Harper Industries, Inc. (HII) warrants to each purchaser of a new Harper ATM from an

authorized dealer or representative, that such equipment is free of manufacturer’s defects

in workmanship and materials which appear while in normal service for a period of ONE

YEAR commencing with delivery to the original user.

The obligation of HII under this warranty is expressly limited, at our option, to replacement

or repair at a service facility designated by Harper Industries or at the manufacturing plant

in Harper, KS. A part will be replaced after inspection discloses it to have been defective.

This warranty does not apply to defects caused by damage or unreasonable use (including failure to provide reasonable and necessary maintenance, or by performing functions

without genuine Harper ATM accessories) while in the possession of the consumer.

Warranty is limited to parts, labor and ground freight delivery of replacement parts. HII

shall not be liable for the consequential damages of any kind, including but not limited to

consequential labor costs or transportation charges in connection with replacement or

repair of defective parts.

This warranty does not apply to parts subjected to misuse, abuse, alteration, improper or

inadequate maintenance, or normal wear (including blades, lters, and battery).

Engines are not covered under this warranty. Refer to manufacturer’s warranty for specic

warranty information. Harper Industries, its agents or representatives, make or imply no

other warranties.

Harper Industries makes no warranty with respect to trade accessories. They are subject

to the warranties of their respective manufacturers.

ANY IMPLIED OR STATUTORY WARRANTIES, INCLUDING ANY WARRANTY OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSLY

LIMITED TO THE DURATION OF THIS WRITTEN WARRANTY. HII makes no other express warranty, nor is anyone authorized to make any on behalf of HII.

For further information please contact your nearest Harper ATM dealer.

RECORDS

Date of Purchase ______ / ______ / ______

Dealer’s Name _________________________________

Dealer’s Phone _________________________________

Serial Number Machine __________________________

Serial Number Engine ___________________________

2

ATM 72 LC

Page 5

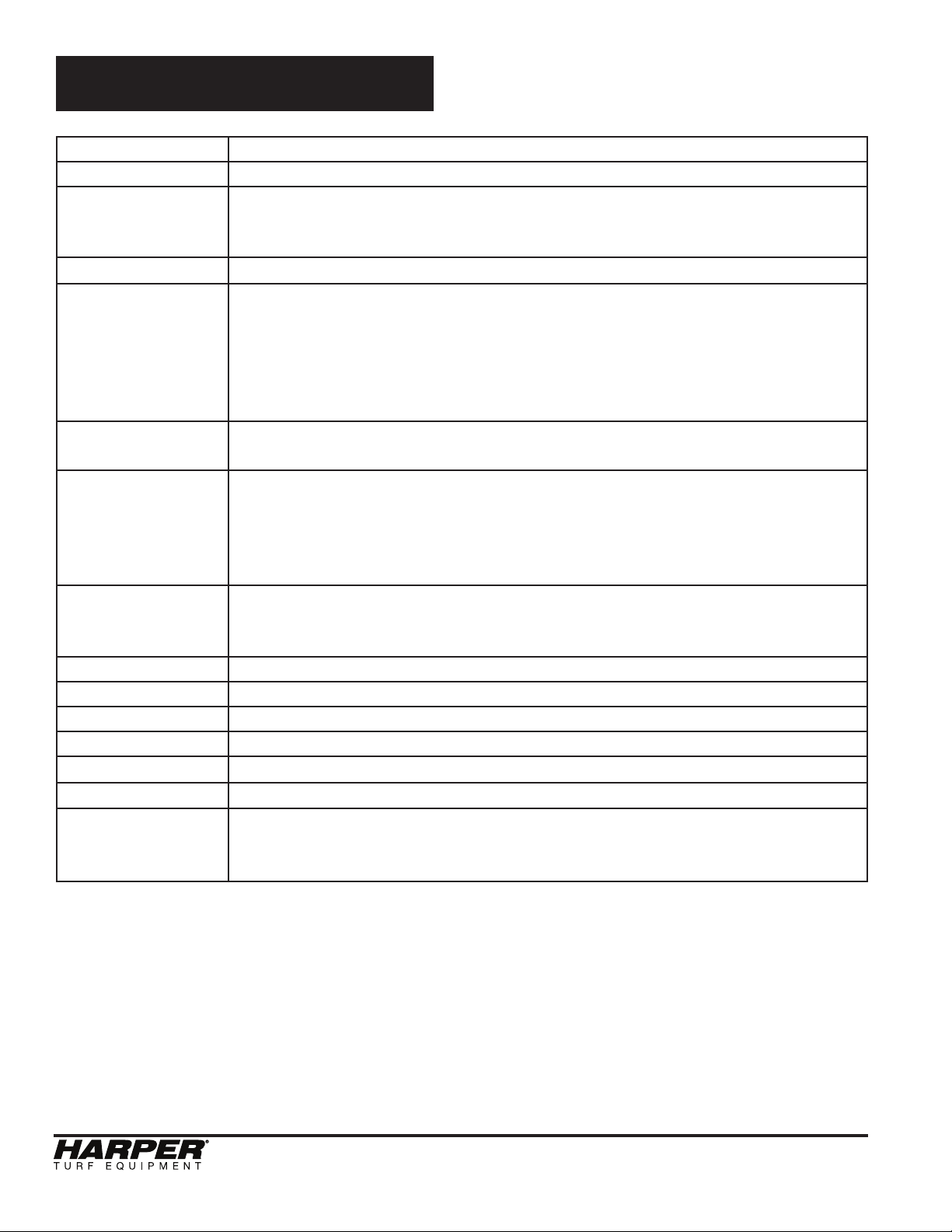

Table of Contents

Introduction

OPERATOR SECTION

To the Owner or Operator.................................................

Warranty Statement..........................................................

Table of Contents..............................................................

Introduction.......................................................................

Specications....................................................................

Control Identication.........................................................

Throttle...............................................................

Mower Switch.....................................................

Deck Lift.............................................................

Lights..................................................................

Ignition................................................................

Park Brake.........................................................

Manual Override.................................................

Deck Wing Raise/Lower.....................................

Manual Leveling.................................................

Inclinometer Switch............................................

Safety Guidelines

Equipment & Controls........................................

Safety Decals.....................................................

Diesel Fuel.........................................................

Guards & Shields...............................................

Battery................................................................

Hydraulics..........................................................

Safety Interlocks/Wiring Logic............................

Before Operation................................................

During Operation................................................

Maintenance

Hydraulic System...............................................

Grease Zerk Locations.......................................

Air Cleaner.........................................................

Cooling System..................................................

Engine Oil..........................................................

Fuel Filter...........................................................

Relay Panel........................................................

Deck Service Mode...........................................

10

10

11

11

12

12

12

1

2

3

4

5

6

6

6

6

6

6

6

6

6

6

6

The objective of Harper Industries in designing the ATM 72 LC was to create a mowing

machine that could function safely and comfortably on slopes and inclines. The result is

an All-Terrain Mower that will automatically

adjust itself to keep the operator in a vertical

position on all slopes up to 34 degrees.

Driving with an automatic leveling device will

be a new and different experience. After

several minutes of driving, the smooth control

and sturdy feel will become comfortable to

you. The security of always sitting upright and

the feel of powerful, positive traction will give

7

7

7

7

8

8

8

8

9

you condence and comfort in most mowing

situations.

However, we urge EXTREME CAUTION or

else your condence in these features get

you into trouble.

REMEMBER: The features of the ATM 72

9

cannot replace good common sense.

Tow Procedure/Transporting

Moving the machine w/o starting.......................

Park Brake Release...........................................

Opening the Bypass Valve.................................

Tie Down Locations............................................

Adjustments

Seat Adjustment.................................................

Deck Lift Adjustment..........................................

Cutting Height....................................................

Leveling..............................................................

Standard Torque Chart.....................................................

Service Parts....................................................................

Service Schedule..............................................................

Operating Guide...............................................................

ATM 72 LC

13

13

13

14

14

15

15

15

16

16

17

19

3

Page 6

Specications

Power Diesel - Kubota V1505-E4B 24.8 HP @ 2300 RPM

Main Frame Welded and formed steel frame

Decks • 2 - 36” decks (72” total cutting width)

• Independently free oating, with rear discharge

• Constructed of reinforced 10 gauge steel

Cutting Height 3 - 6” adjustable cutting height

Hydraulics

Speed

Options • Incline Meter Assembly - Part # 815052

Tires Drive Tire: 25” x 11-12 - 6 ply

Steering Power steering with automotive type steering wheel

Seat Adjustable ride suspension, arm rests, and retractable seat belt

Electrical 12 volt, 40 Amp Electrical System

Dimensions Length – 107 in., Height – 90 in., Width – 74.5 in.

Weight

Liquid Capacities Fuel – 10 Gallon; Hydraulic Fluid – 11.5 Gallon

Safety & Hydraulic

Oil

• Direct hydraulic blade drive (no belts or gear boxes)

• Poclain hydrostat - PM10 variable displacement axial piston pump

• Poclain high efciency axial piston wheel motors with integrated parking

brake.

• Hydraulic lter - 3 micron with indicator

• Hydraulic oil cooler

• 0-7 MPH ground speed

• Foot operated speed control - self-centering to neutral

• Factory Install Wheel Weight Kit - Part # 801005

• Customer Install Wheel Weight Kit - Part # 801004

• White Canopy - Part # 802039

• Red Canopy - Part # 802040

Stabilizer Tire: 16.5” x 6.5 x 8” foam lled

Deck Caster Tire: 11” x 4.00 x 5” foam lled

2480 lbs.

• Includes Certied ROPS with hazard lights (meets ANSI/OPEI B71.4 standards)

• Seat belt

• Crown AW46; ISO 46 Hydraulic Oil

NOTE: Following publication of this manual, certain changes in standard equipment and/or options

may have occurred which would not be included in these pages. Your Harper dealer is the

best source for up-to-date information.

ATM 72 LC

4

Page 7

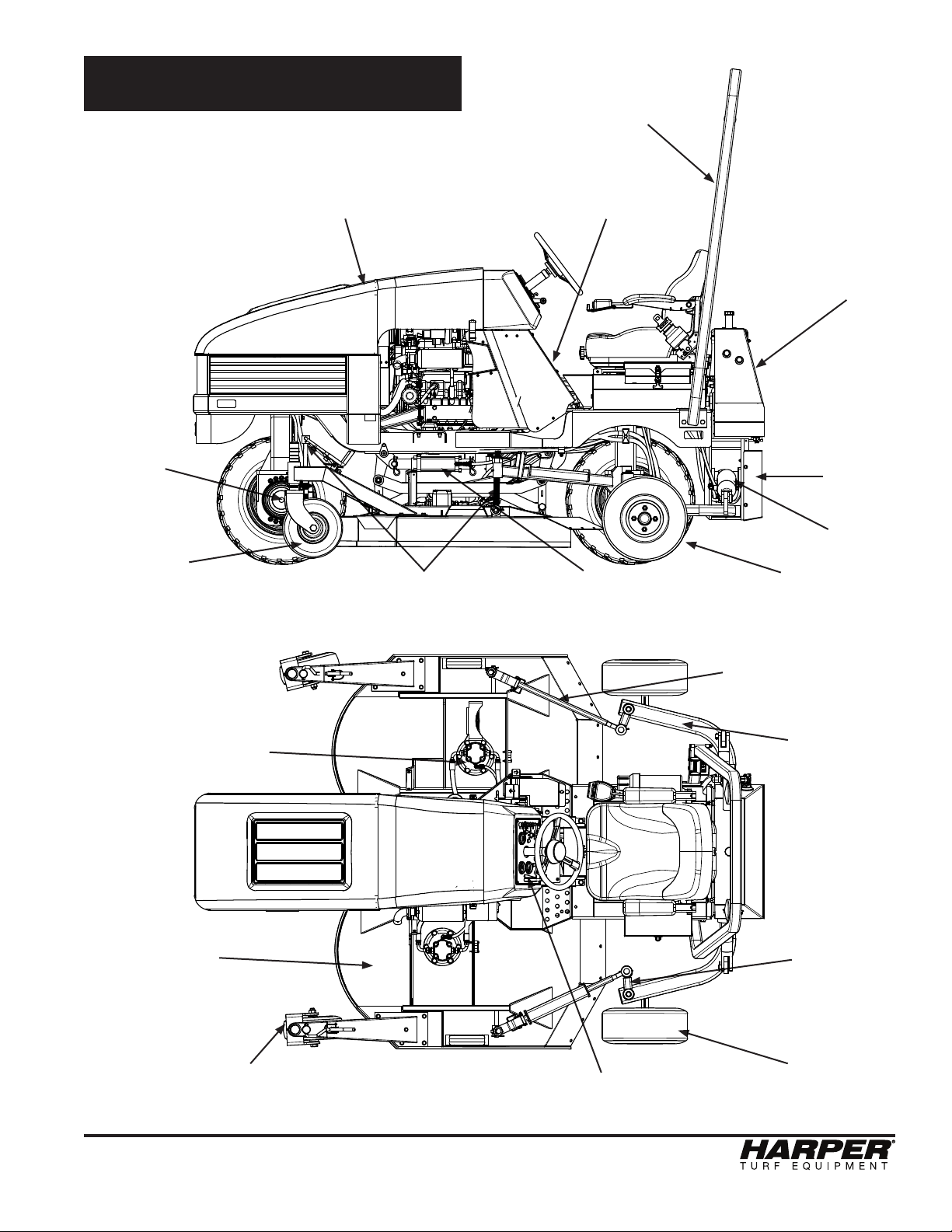

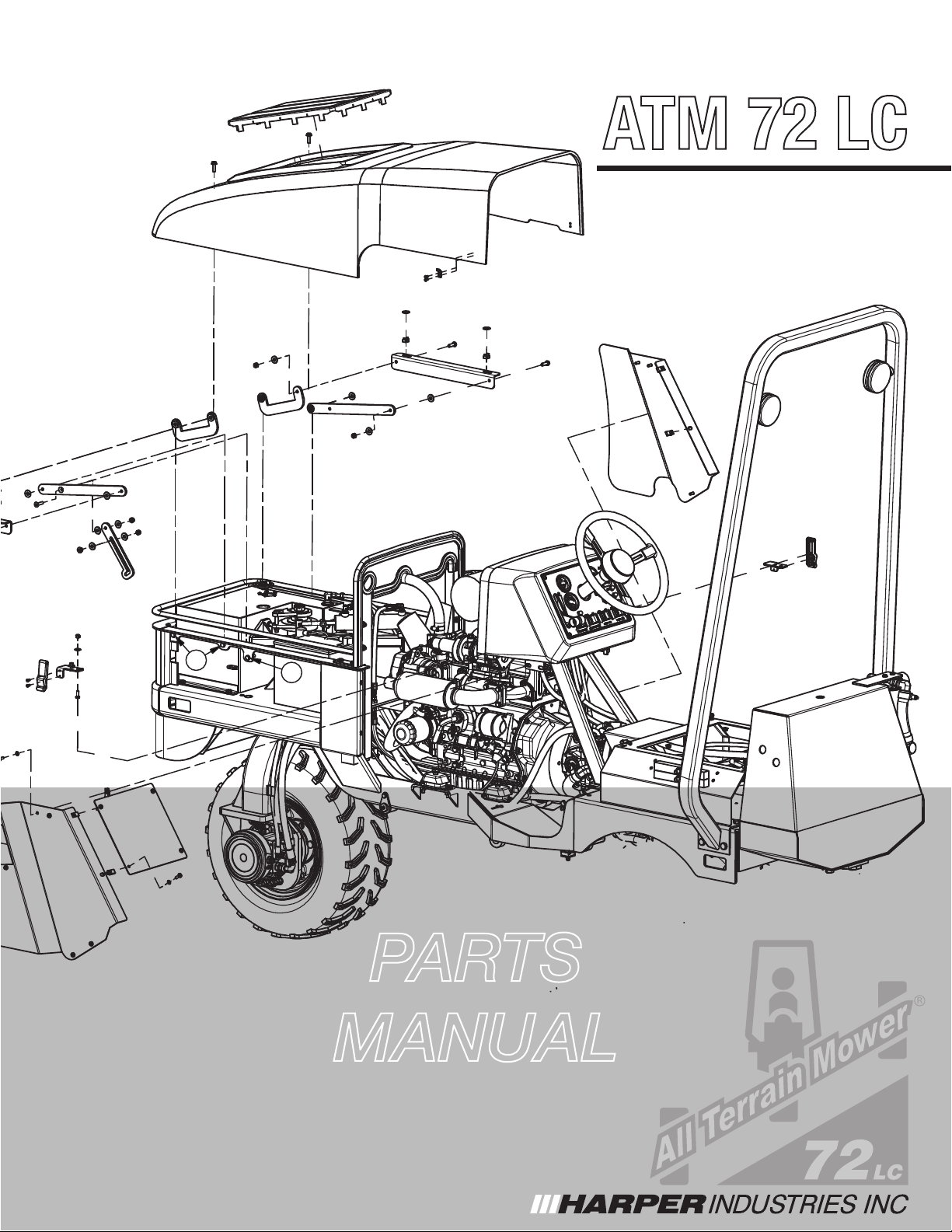

Control Identication

Diesel Fuel Tank

(located under hood

at front of mower)

Roll Over

Bar

Tow Valve & Neutral

Safety Switch

(located behind

cowling and above

propulsion pump)

Wheel

Motor

Caster

Wheel

Outside

Deck Height

Adjustment

CowlingHood

Deck Lift

Cylinder

Hydraulic

Reservoir

Inclinometer

Module

Leveling

Cylinders

Stabilizer

Wheel

Supporting

Arm

Deck

Motor

Cutting

Deck

Caster

Wheel

ATM 72 LC

Stabilizer

Arm

Equalizer

Arm

Stabilizer

Control

Wheel

Panel

5

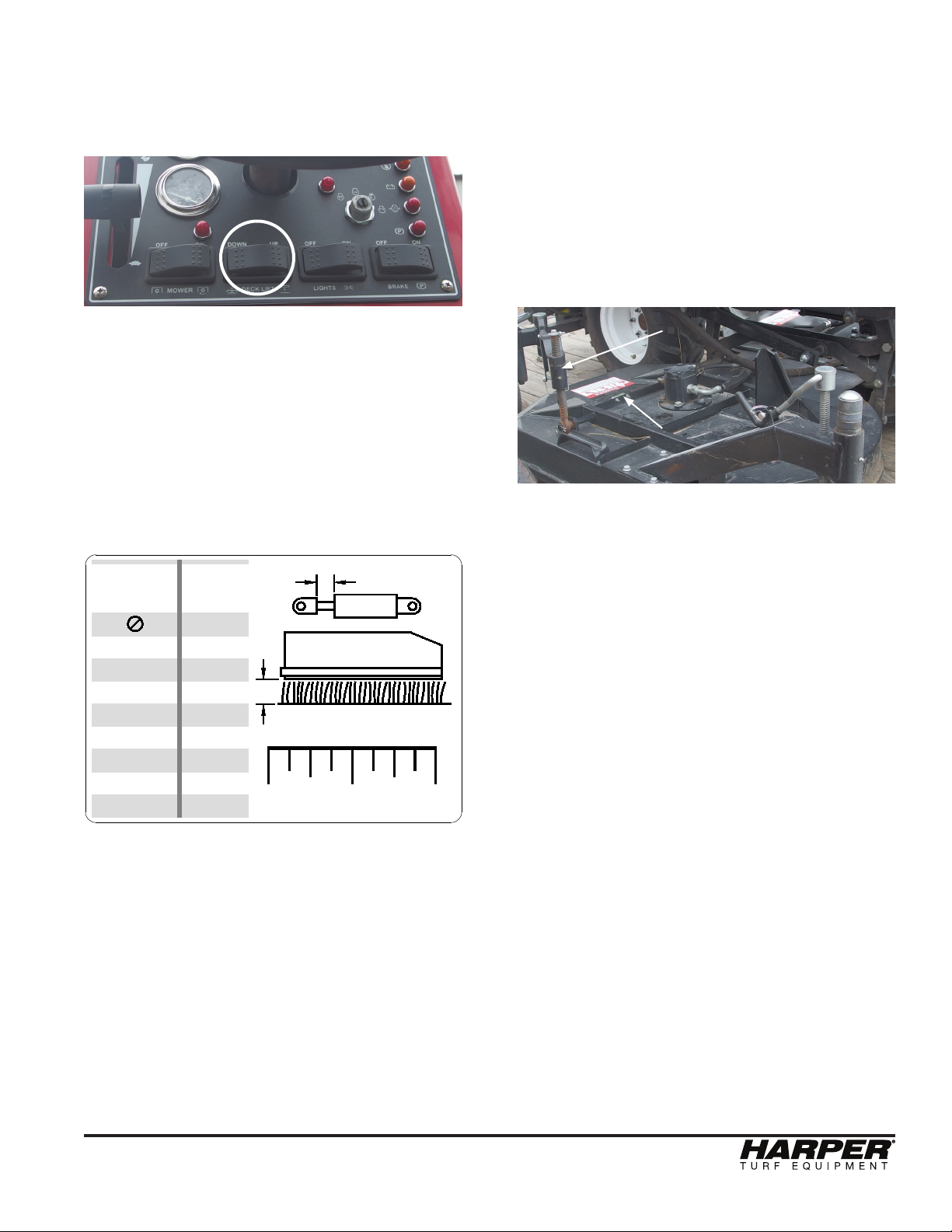

Page 8

Engine Temp

Hydr. Level

Throttle

Mower Deck

Deck Lift Lights BrakeMower

Throttle – adjust engine speed with throttle.

Start at low throttle, allow engine to warm up,

then operate unit at full throttle.

Mower Switch – turns the deck blades on

and off allowing user to cut the grass.

Deck Lift Switch – raises and lowers the

mower deck.

Lights Switch – turns on headlights.

Leveling

Momentary

Lockout

Reset

Engine

Battery

Pre-Heat

Engine Oil

Ignition

Parking Brake

Momentary Reset Switch– resets the auto

level function after the machine has been

locked out. Once the machine is level, the

reset button can be pushed to turn on the

auto level function.

Mower Deck Light – is on when the mower

blades are engaged.

Engine Pre-Heat Light – turns on when the

key is in the pre-heat position.

Ignition – turn the key to the left until the

pre-heat light turns off. Then, turn key to right

to start unit. Remove key when unit is not in

use. Never leave unit unattended with key in

ignition.

Park Brake – set park brake when unit is not

in use or is parked on an incline. Make sure

park brake is disengaged before operation.

Engine Temp Light – turns on when the engine temp exceeds 215° F.

Hydraulic Level Light – turns on when the

hydraulic oil is low.

Leveling Lockout Light – turns on when the

auto level funtion has been locked out.

ATM 72 LC

6

Page 9

Battery Light – is on when the charging system voltage is low.

Engine Oil Light – turns on when the oil

pressure drops below 7 psi.

Parking Brake Light – is on when the park

brake is applied

Manual

Leveling

Manual

Auto/Manual

Leveling

Leveling

.

Manual Leveling Switch – one is located

on the arm rest and the other on the ROPS.

Both of these switches perform the same

function. One is intended to be used while

in the operator’s seat and the other for when

standing behind the machine. They are used

to manually tilt the machine left or right.

Auto/Manual Leveling Switch – determines

if the machine is leveled automatically using

the signal from the inclinometer module or

leveled only using the manual leveling switch.

Inclinometer Module – senses if the machine is off center/vertical. The machine can

lean to either side up to 34° before reaching

its limit.

• The inclinometer module includes a

dual axis (XY) accelerometer. It

measures the force caused by

movement of the sensor (accelera tion). Gravity puts a force on the

sensing elements that can be mea sured. The sensor is an analog device

with a voltage for X and a voltage for

Y. The module uses the voltage

outputs from the sensor to determine

the angle of the machine.

• When the inclinometer module mea sures an angle 4 degrees or greater

from center, it sends a +12 V signal to

the hydraulic valve to operate the

appropriate leveling cylinder to return

the machine to an upright position.

SAFETY WARNING!

Do not leave ATM 72LC unattended, or

attempt any service or inspection unless

the machine has come to a complete stop

and the engine has been shut off.

ATM 72 LC

7

Page 10

Safety Guidelines

Equipment & Controls

• Read and understand this manual.

• Altering this equipment in any manner

which adversely affects its operation,

performance, durability, or use will void

the warranty and may cause hazard ous conditions.

• Know the location and function of all

controls and how to stop this equip ment quickly in an emergency before

you operate the equipment.

• Keep all nuts, bolts and screws tight to

help ensure safe operation of this

equipment.

• Use genuine factory parts or parts with

equivalent characteristics, including

type, strength and material. Failure to

do so may result in product malfunc tion and possible injury to the operator

and/or others.

• If hardware is not secure, or if some of

the hardware is over-tightened, equi pment failure may result, posing pos sible safety hazards.

• To prevent possible eye injury, always

wear SAFETY GLASSES while oper ating equipment.

• Always wear a respirator when work ing in dry/dusty conditions.

Diesel Fuel

• Always use an approved container for

transporting diesel fuel.

• Do not allow open ames or sparks

while performing maintenance or refu eling.

• Never remove fuel tank cap or add

fuel when engine is running or while it

is hot.

• Only use ultra low sulfur diesel.

• Never ll fuel tank indoors. Fumes are

heavy and will sink to the lowest point,

collect and become hazardous.

• Wipe up spilled fuel immediately.

• Do not store fuel in a room with an ap pliance that has a gas pilot or electri cal switch that may cause sparks.

• Always store diesel outside in a safe-

ty can (a can with ame arrestor and

pressure relief valve in pour spout).

• Never store the equipment with fuel in

the tank inside a building where fumes

may reach an open ame or spark.

• Allow the engine to cool before storing

in any enclosure.

• Be certain to provide adequate ventila tion if an engine must be run indoors -

exhaust fumes are dangerous.

SAFETY WARNING!

Diesel fuel is extremely ammable and can

be highly explosive.

Safety Decals

• If safety related or instructional decals

become illegible or are removed, re place them immediately. New decals

may be obtained from your local Harp er Dealer.

• If you replace parts that have such

decals attached to them, make sure

the decals are replaced with current

versions, and are on the replacement

parts before the machine is operated

again.

Guards & Shields

• Keep all safety devices in place.

• Replace all worn, damaged, unusable,

missing or lost safety shields and

guards before operating the equip ment.

• Keep the equipment in good operating

condition.

ATM 72 LC

8

Page 11

Battery

SAFETY WARNING!

Batteries can produce explosive gas.

Use extreme caution when working on

the battery.

• Ventilate when charging battery or us ing in an enclosed space.

• DO NOT produce sparks from cable

clamps, tools, or other sources; and

DO NOT allow ames or smoking in

the vicinity of the battery.

• Shield eyes when working near bat tery.

Hydraulics

SAFETY WARNING!

Escaping uid under pressure can

penetrate skin causing serious injury.

To prevent serious injury or death:

• Relieve pressure on system before

repairing, adjusting or disconnecting.

• Wear proper hand and eye protection

when searching for leaks.

• Use wood or cardboard instead of

hands when looking for leaks.

• Keep all components in good repair.

• Do not use any type of heat (welding,

soldering, cutting torch, etc) near

pressurized lines.

Safety Interlocks/Wiring Logic

• To start the machine, it must be in

neutral and the blades must be off.

• To turn the mower blades on, the

operator must be in the seat, and the

hydraulic oil temperature must be

below 190° F.

• There is a 2 second time delay added

to the seat switch to account for

bounce.

• The park break is applied when the

operator is out of the seat.

• Leveling

1. Valves on the cylinders are open

when in auto mode or when the

manual switch is activated to level the

machine.

2. If the inclinometer senses that the

machine is not stable or that the

machine has changed angle at a quick

rate, the valves on the leveling

cylinders are closed to lock the

machine in its current position. When

this happens, the leveling lockout indi cator light on the dash will be illumi nated. To reset the auto level

function, press the momentary reset

switch on the dash.

Before Operation

• Before operating this equipment, read

and understand the Owner’s Manual.

• Do not allow children to operate this

machine.

• Wear approved eye and ear protection

and other appropriate safety equip ment while operating the machine.

• Check tire pressure and ll to

specications.

• Engine settings are preset and should

not be changed; any change can dam age moving parts and void the war ranty.

• Before starting the machine, visually

inspect all nuts, bolts and other fasten ers to see that they are properly se cured. Nuts, bolts and other fasteners

should be checked every 8 to 10 hours

of operation for proper alignment and

tightness.

• Replace damaged or missing safety

decals.

• Use factory authorized parts or their

equivalent.

• Make sure that all bearings or hinging

parts are greased and or oiled prop erly.

ATM 72 LC

9

Page 12

During Operation

• Always keep a re extinguisher near

the mower during operation.

• Keep clothing and all body parts away

from rotating parts.

• Keep the engine area clean from de bris and other accumulations to lessen

the possibility of re.

Maintenance

Hydraulic System

• The hydraulic system of the ATM72LC

is lled at the factory with Crown AW

46 hydraulic oil that has an ISO of 46.

• The ATM72LC has a 3 micron, beta

rated hydraulic oil filter designed for

long life.

Oil Fill

Sight

Glasses

(left hand side)

Hydraulic

Reservoir

Oil Filter

• On a daily basis, monitor the needle in

the filter indicator when the oil is at

normal operating temperature.

Yellow

Red

Green

The following list of hydraulic fluids are compatible and can be mixed with Crown hydraulic fluid. MIXING OTHER OILS THAT ARE

NOT INCLUDED ON THIS LIST COULD

CAUSE GELLING AND DAMAGE TO THE

HYDRAULIC COMPONENTS. If another

type of oil is desired, then the system must

be completely drained and flushed first.

Appropriate replacements:

ISO 46: Recommend for running in ambient

air temperatures of 32°F-110°F, and it contains a kinematic viscosity rating around 46

cSt at 40°C. (1cSt = 1mm²/s)

• Mobil DTE 25

• Mobil DTE 15M

• Amoco Rykon Premium Oil ISO 46

• Chevron Rykon Premium Oil ISO 46

• Conoco Hydroclear AW MV 46

• Exxon Univis N 46

• Pennzoil AWX MV 46

• Shell Tellus T 46

• Texaco Rando HDZ 46

Filter Indicator

Hydraulic

Filter

• The filter (part no. 822044) does

not need replaced until the needle is in

the red portion of the gauge.

• To replace filter , twist the filter

counter-clockwise. Replace with new

filter by turning it clockwise until tight.

• The hydraulic oil level should be moni tored daily with the hydraulic tank’s

sight glasses on the left hand side of

the hydraulic tank.

• Keep the hydraulic oil just above the

lower sight glass at all times.

• Fill reservoir through the fill location on

top of the reservoir.

10

ATM 72 LC

Page 13

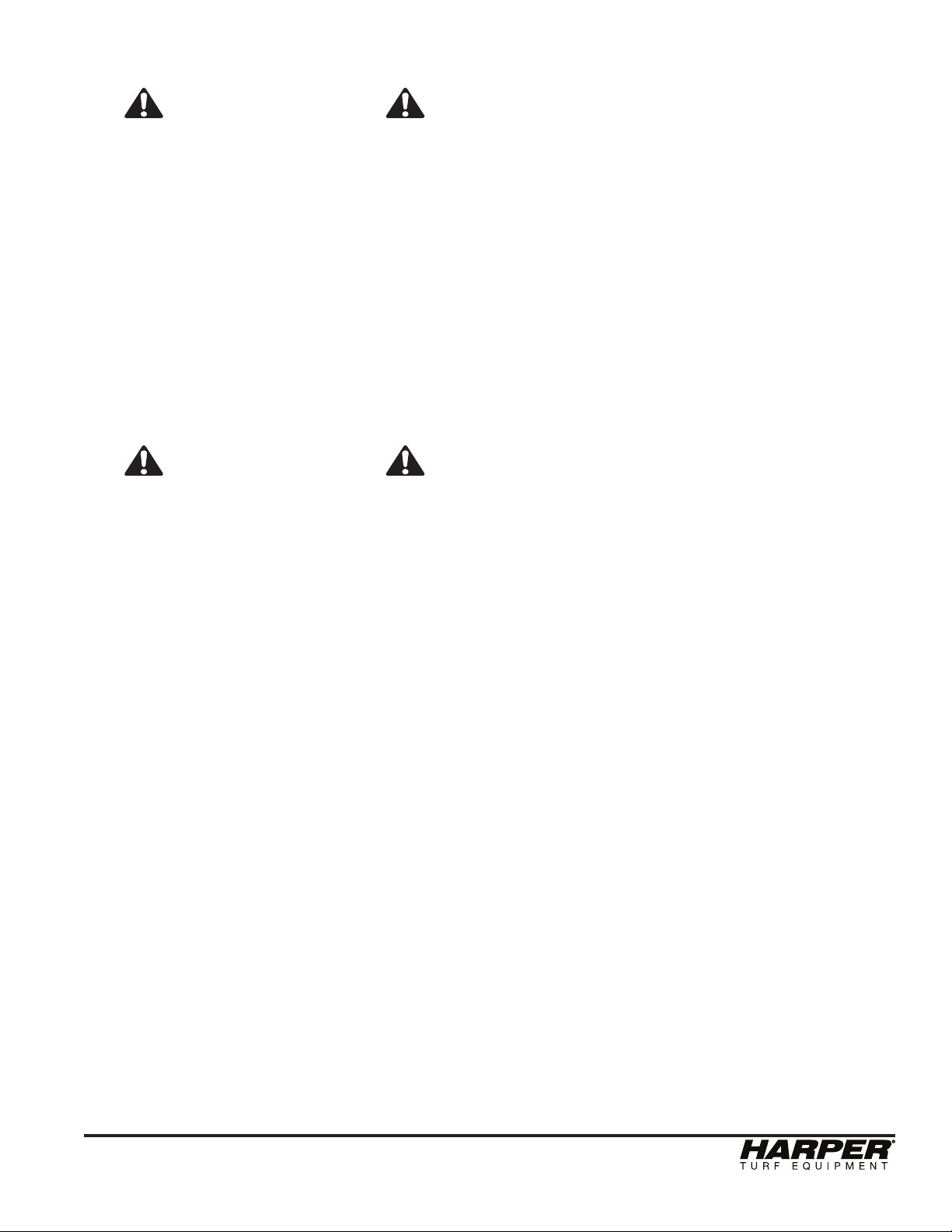

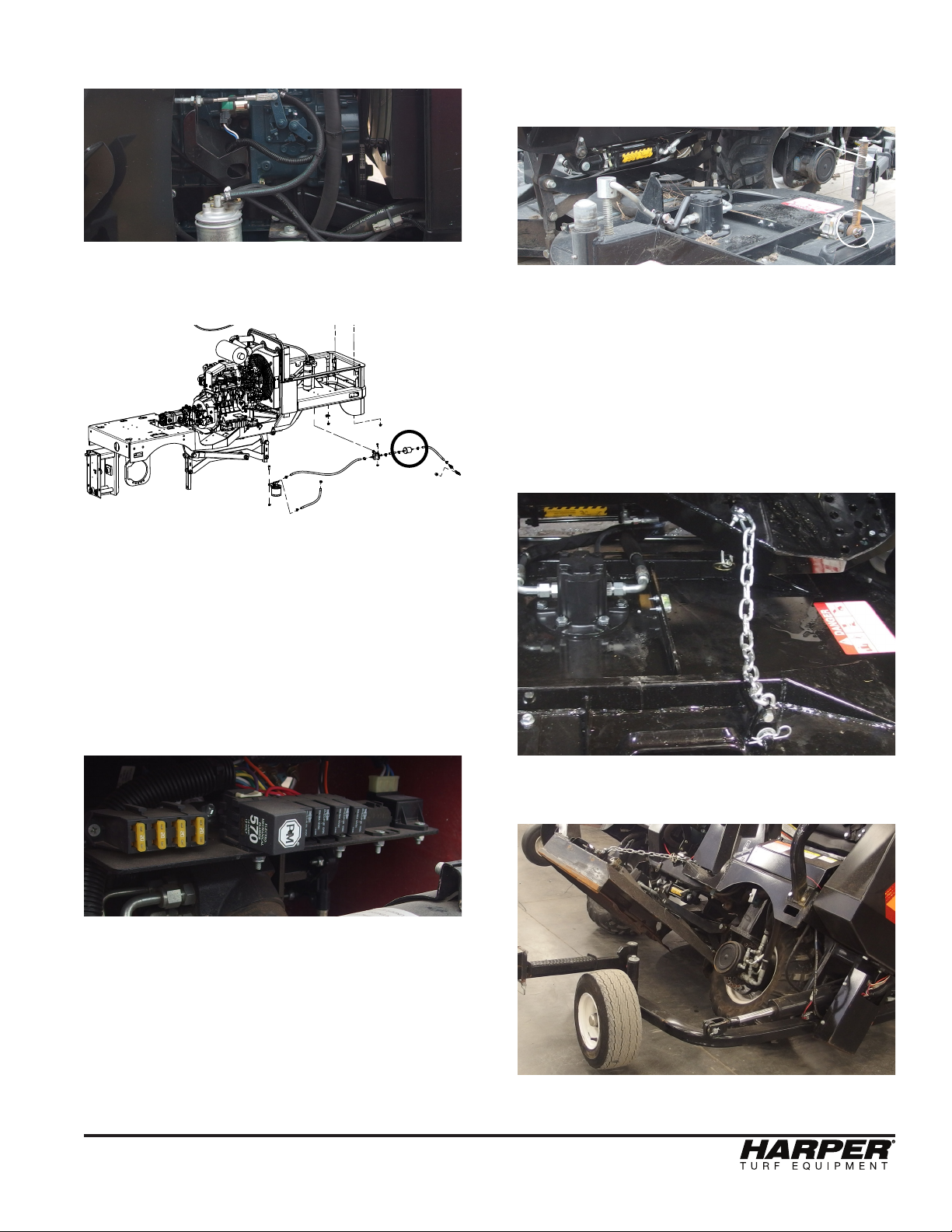

Grease Zerk Locations

*

*

*

* Denotes a second grease zerk identical to this one on the other side.

PROCEDURE

1) Park on level ground and set park

brake.

2) Turn off ATM.

3) Give 2 to 3 shots of grease after every

10 hours of use.

*

Air Cleaner

Air Filter

Air Intake

• Make sure intake is always free of

debris.

• When engine is turned off, remove the

wing bolt.

• Replace the air filter according to the

Maintenance Schedule.

(view from the bottom)

ATM 72 LC

11

Page 14

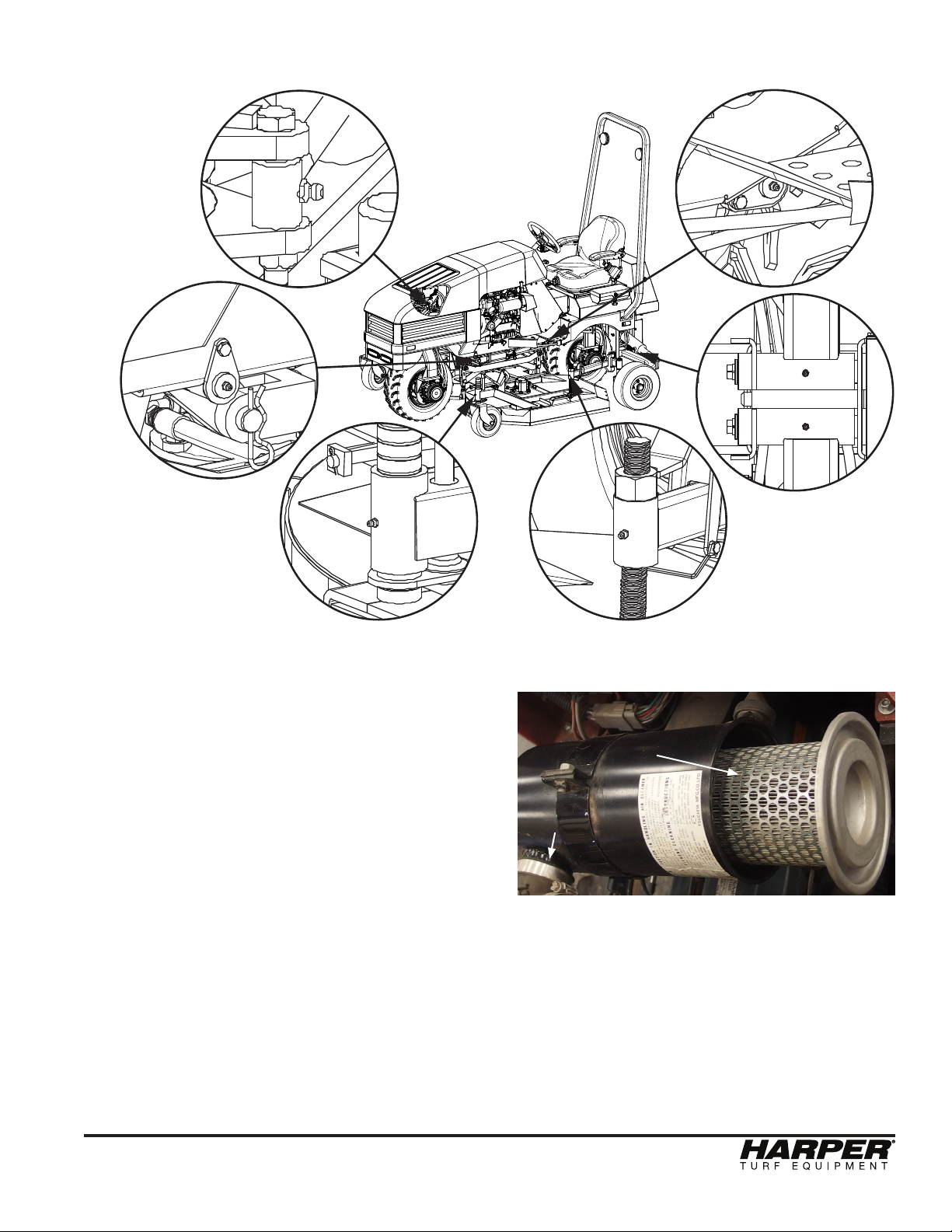

Cooling System

Engine Oil

Hydraulic

Oil Cooler

Radiator Fill

Radiator

Coolant Recovery

Bottle

• The radiator and hydraulic oil cooler

are located side by side in the same

aluminum heat exchanger.

• Clear hydraulic oil cooler and radiator

of debris with pressurized air daily or

as needed.

• Check radiator level daily and only

when engine is cool and not running.

• Remove cap (radiator fill) slowly to

relieve any pressure that may be built

up.

• Fill up radiator with coolant (50% wa ter/ 50% antifreeze) until coolant is vis ible in neck of radiator.

• Make sure that the coolant recovery

bottle has at least 1” of coolant in bot tom. The presence of coolant in the

recovery bottle does not mean radiator

is full.

• Do NOT operate the machine if the

engine temperature exceeds 220°F.

Severe engine damage may occur if

the machine is continuously operated

above 215°F. If overheating does

occur, diagnose the cooling system

and ensuring proper coolant levels and

proper air flow across the radiator.

SAFETY WARNING

Hot Coolant and steam from the radiator

can cause severe burns. Never open the

radiator cap of a hot engine.

Engine Oil Fill

Dipstick

Engine Oil Filter

• The dipstick and engine oil fill are lo cated on top of the engine.

• The engine oil filter is located on the

left side of the engine as viewed from

the operator’s seat.

• To get to the engine oil fill or dipstick,

the hood should be raised.

PROCEDURE

• Check engine oil level only when en gine is turned off.

• Keep engine oil level between the

FULL and ADD marks on dipstick at all

times. DO NOT OVER-FILL.

• Add engine oil (S.A.E. 10W30) through

the engine oil fill location.

• Replace the engine oil/filter according

to the Maintenance Schedule.

SAFETY WARNING

Keep dipstick and oil fill cap secured

tightly. Engine oil may escape through

these orifices when engine is running

causing severe burns.

above 25°C (77°F) SAE30 or SAE10W-30

SAE15W-40

-10°C - 25°C

(14°F - 77°F)

SAE10W-30

SAE15W-40

below -10°C (14°F) SAE10W-30

• Filled with SAE10W-30 from the

factory, 6.0 L capacity, and change

after the first 50 hours.

12

ATM 72 LC

Page 15

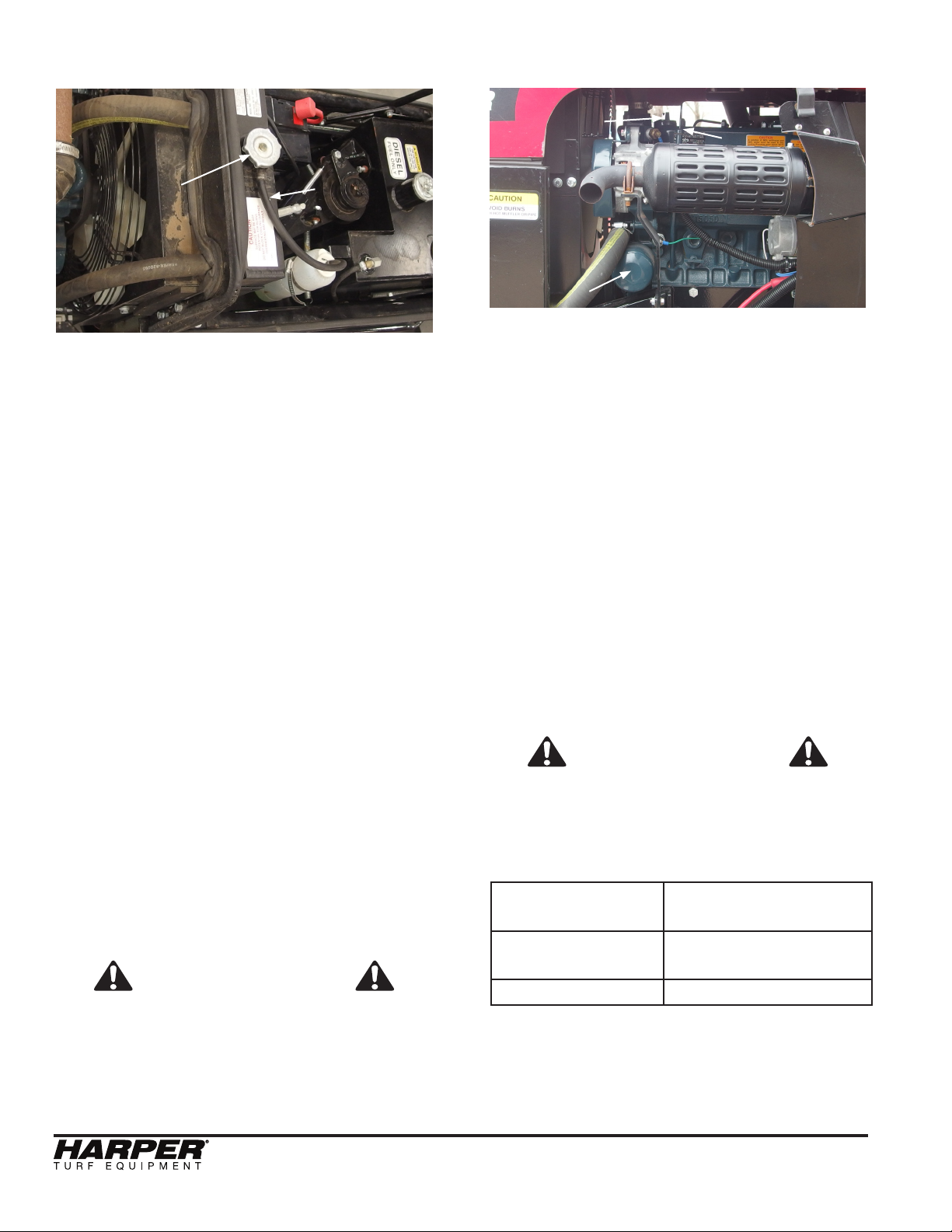

Fuel Filter

Fuel Filter

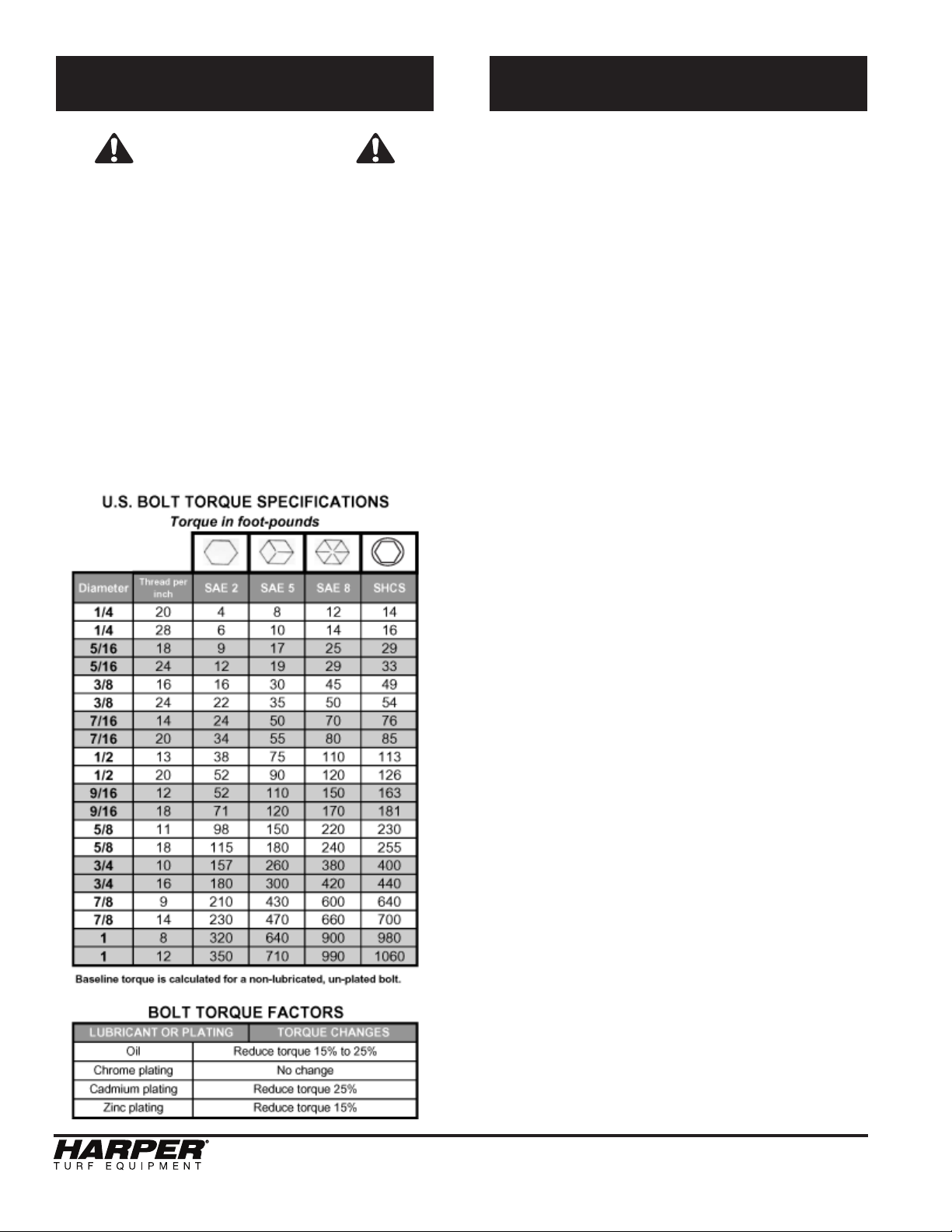

Deck Service Mode

• Remove hairpin cotter and at-washer

and swing out support arm.

Support Arm

• Fuel filter is located on the right side

of the machine when viewed from the

operator’s seat.

Smaller

Fuel Filter

• There is also a smaller in line fuel filter

on the bottom of the front right corner

of the machine leading from the fuel

tank to the main fuel filter.

• The Fuel Shut-off valve is located

on the lower right side of the fuel tank.

It can be accessed from below the

machine.

Pin

• Connect chain to deck and replace

pin

• With Manual Override switch, lean

mower all the way left or right. Then

insert chain into chain cutout located

on the step. Install the lynch pin in

the bottom side of the step for added

safety. After that lean the mower to

the opposite side.

Relay Panel

• Located under the hood behind the

dash of the mower.

ATM 72 LC

• Block deck up before working under

the deck.

13

Page 16

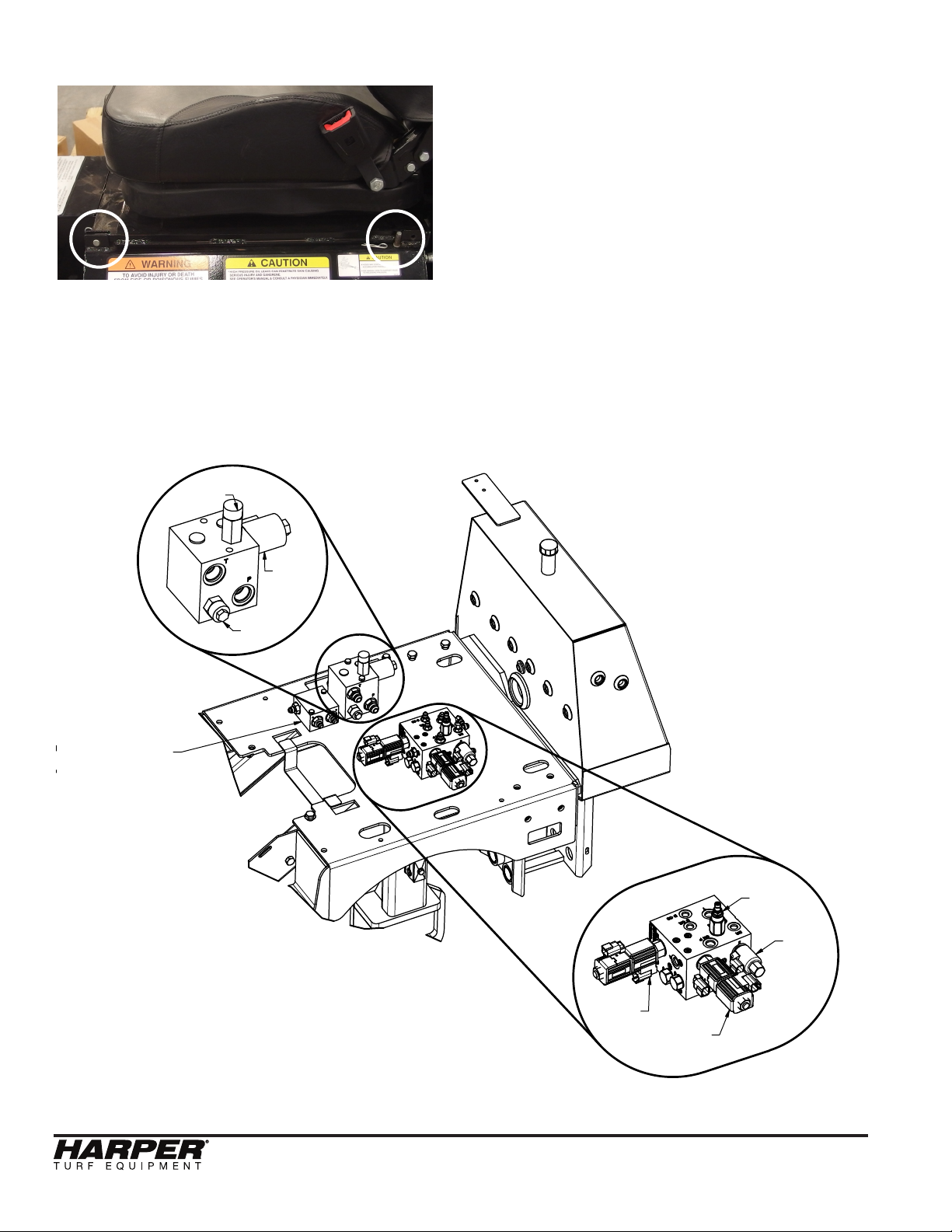

Hydraulic Valves

• To get to the hydraulic valves, either

remove the two rear pins holding the

seat down and rotate the seat forward

or remove all (4) pins holding the seat

down and remove the seat all together.

DECK

VALVE

LOOP

FLUSH

VALVE

PRESSURE

RELIEF

COUNTER

BALANCE

VALVE

MOWER

BLADE

COIL &

SOLENOID

AUXIALLARY

VALVE

PRESSURE

RELIEF

BRAKE

RELEASE

COIL &

SOLENOID

14

DECK LIFT

COILS &

SOLENOID

LEVELING

COILS &

SOLENOID

ATM 72 LC

Page 17

Tow Procedure

Moving the machine without starting the

engine

• In order to move the machine without

the engine running, the park brakes

must be released and the bypass

valve must be opened on the propul sion pump.

• After towing the unit, follow procedure

in opposite order to remove brake

release tool and install new plastic

plug.

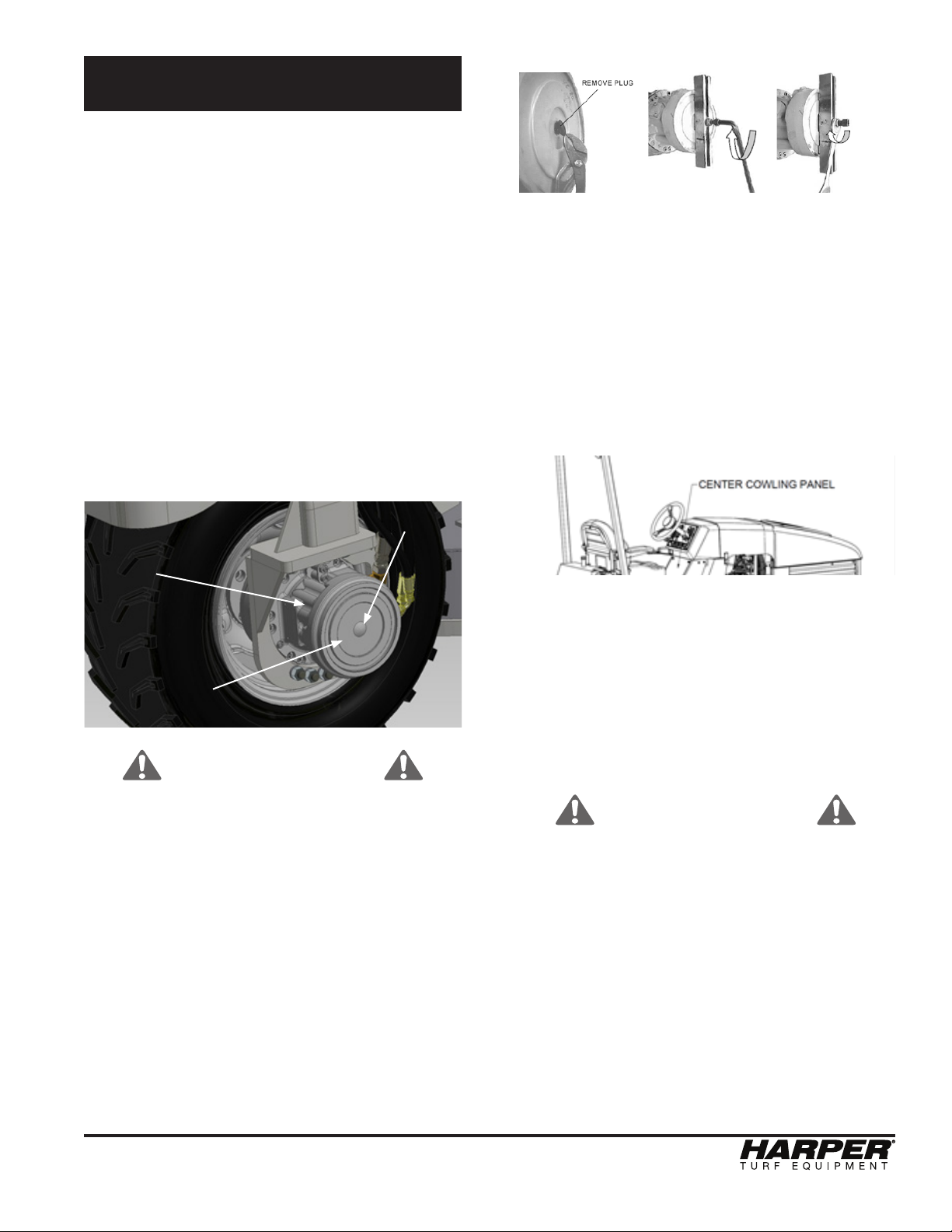

Park Brake Release

• Both of the wheel motors contain a

park brake that is mechanically applied

and hydraulically released. Whenever

the engine is off (zero system pres sure), the brakes are applied.

• Always release the park brakes when

towing or pushing the unit.

Plastic Plug

Wheel Motor

Park Brake

Release

(behind cover)

PRECAUTION

• Towing or pushing the unit with the

park brakes applied may cause seri ous damage to internal brake parts.

PROCEDURE

1. Remove plastic plug from the center of the

park brake housing.

2. Install brake release tool (P/N 575064)

by placing on brake housing and tighten ing the screw into the piston. These tools

can be found inside the toolbox.

3. Tighten the nut until the motor shaft turns

freely.

Opening the Bypass Valve

• The bypass valve is located on the

top side of the propulsion pump be tween the high-pressure ports. The

valve can be accessed by removing

the center cowling panel.

• Open the bypass valve when moving

the machine for short distances. The

bypass valve connects the high-pres sure ports A & B. Only use this valve in

an emergency case and for a short

distance.

• The bypass valve is not a tow valve and

can not be used to pull the machine for

a long distance.

PRECAUTIONS

• The bypass valve is intended only for

moving a vehicle a very short distance

and is not intended for towing a vehicle

behind a truck or tractor. Note: Serious

damage to the hydrostatic drive will

result if the vehicle is towed.

• Close the bypass valve tightly when

nished moving unit. Failure to close

valve tightly will result in full or partial

loss of power.

ATM 72 LC

15

Page 18

PROCEDURE

• To open the bypass valve, turn it coun ter-clockwise. It can be completely re

moved from the pump housing.

However, to avoid oil leakage, only turn

the valve 2 turns.

• After the machine has been moved,

reinstall the bypass valve and reinstall

the center cowling panel.

Tie Down Locations

Adjustments

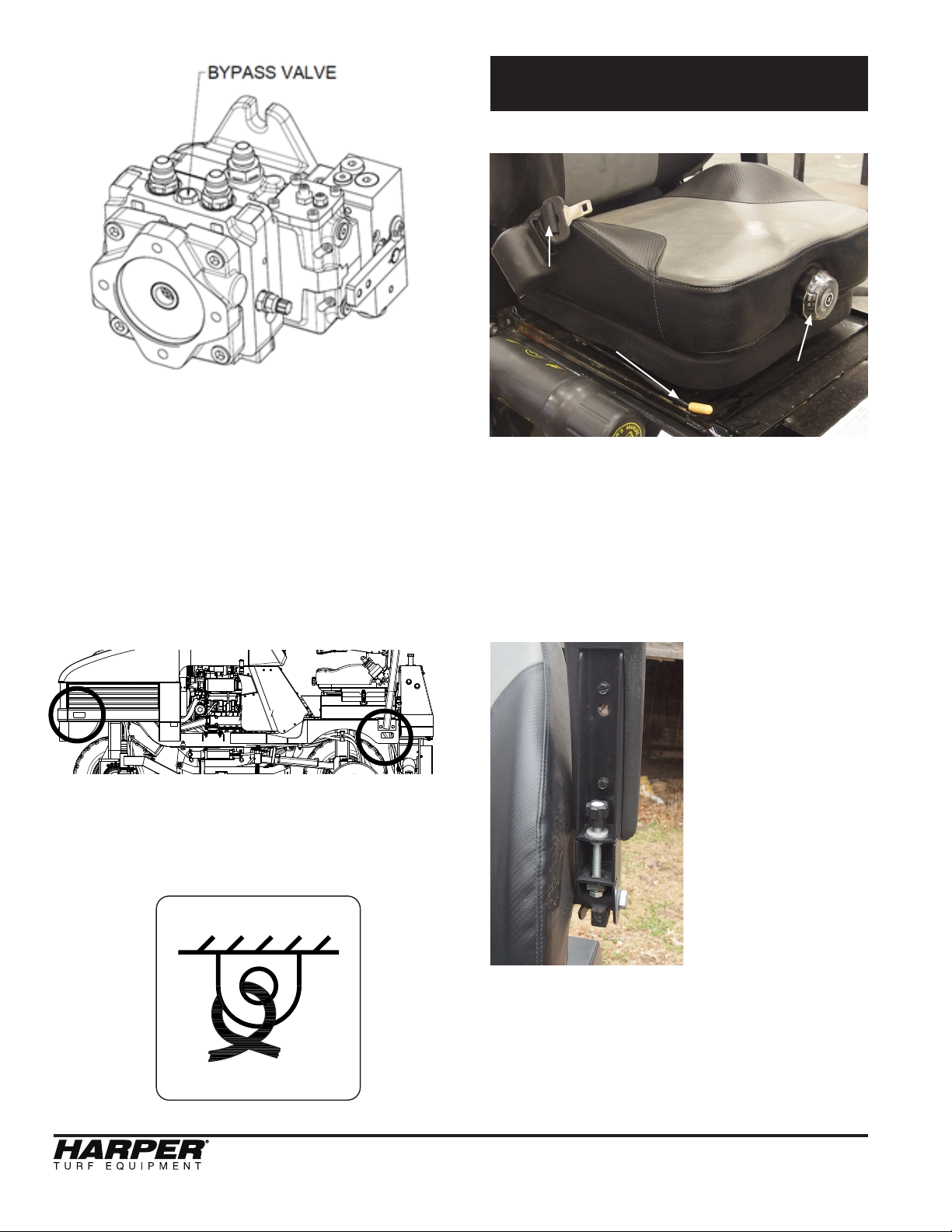

Seat Adjustment

Seat Belt

Seat Front to

Back Lever

Seat Firmness

Knob

• The lever with the yellow handle

controls the chair’s forward and back

movement to allow for either more or

less leg room.

• The round knob adjusts the ride quality.

Turn the knob clock-wise for a rmer

ride, and counter-clockwise for a softer

ride.

There are (4) tie down locations designated on

the machine that are located at the front and

rear of each side of the machine, and they are

accompanied by the following decal:

• Adjust the

screw to change

the angle of the

arm rests.

Arm Rest

Angle Screw

• The seat

belt is retractable

and will lock up

on impact or

accident.

16

ATM 72 LC

Page 19

Cutting Height

X

Y

802068

1 2

0.25"

0.50"

0.75"

1.00"

1.25"

1.50"

1.75"

X

CYLINDER

SPACER

Y

CUT

HEIGHT

2.00"

3.00"

3.25"

3.50"

4.00"

4.50"

4.75"

5.00"

5.50"

6.00"

• Park the machine on level ground.

• Start the machine and raise the deck

using the switch on the dash.

• Using the crank located on the caster

wheels, raise the caster wheels so that

the deck is not supported by the caster

wheel. Turn CCW until the wheel is not

touching the ground. Repeat this step

for both sides.

• Using the outer deck screw adjustment,

adjust the deck so that it is level with

the center of the deck. A bubble level

is mounted on the deck for ease of

adjustment. Repeat for both sides.

• Using the decal on the side of the frame

or the picture below, identify the

cylinder spacer(s) needed to achieve

the desired cut height. The cylinder

spacers are located in the tool box on

the LH side of the seat frame. The

spacers provided include:

2 - 0.25”

1 - 0.50”

1 - 1.00”

Outer Deck

Adjustment

Hand Crank

Level

• Lastly, adjust both caster wheels down

until they touch the ground.

• Install the cylinder spacer(s) onto the

deck lift cylinder (see pg. 5 for

location).

• Lower the deck all the way down using

the switch on the dash.

• The outer deck height is controlled by

the arm linkage attached to the

stabilizer arm.

ATM 72 LC

17

Page 20

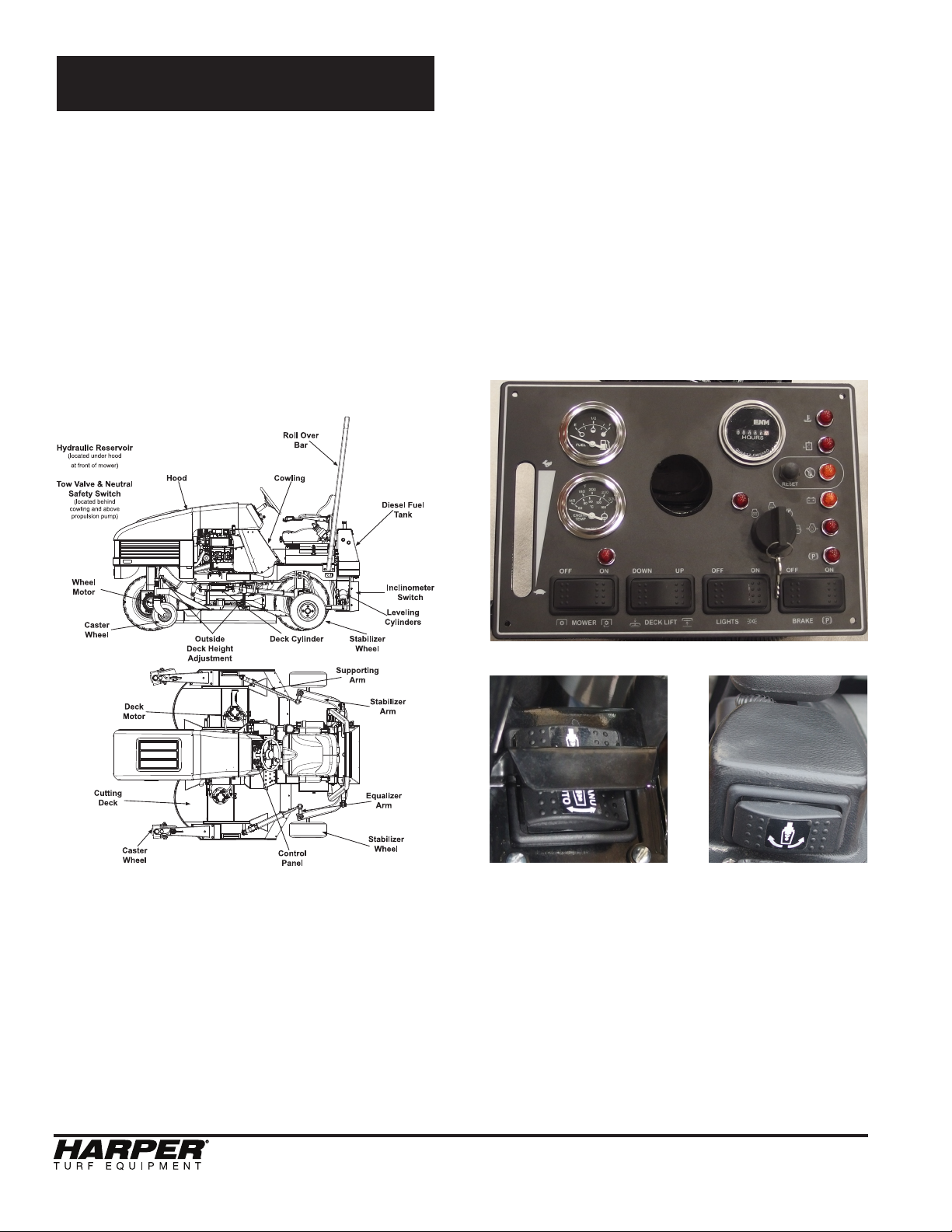

Standard Torque Chart Service Parts

SAFETY WARNING!

Refer to the Standard Torque Chart whenever bolts, nuts or screws are tightened.

PRECAUTIONS

• When tightening two or more fasteners

on the same part, DO NOT tighten

the fasteners completely one at a

time. To avoid distortion, first tighten

all fasteners in sequence to one-third

of torque value, then tighten to

two-thirds of torque value, then tighten

to full value.

• All lug nuts should be torqued to

140 ft-lbs (190 N-m).

Filters

Engine Air Filter.......................

Engine Oil Filter.......................

Fuel Filter (Cannister)..............

Fuel Filter (Inline)....................

Hydraulic Oil Filter...................

Belts

Engine Fan Belt.......................

Blades

RH Swinging Blade Set...........

LH Swinging Blade Set............

Swinging Blades Bolt Kit

(1 Deck Only) ...............

RH Fixed Blade Set.................

LH Fixed Blade Set..................

Fixed Blades Bolt Kit

(1 Deck Only)................

802064

302058

302057

302103

822044

802063

500269

500268

500319

500271

500270

500320

Wheels and Tires

Stabilizer Wheel Assembly......

Caster Wheel Assembly...........

Drive Wheel.............................

Drive Tire.................................

Drive Wheel and Tire Assy.......

800057

800093

842019

842020

843007

18

ATM 72 LC

Page 21

ATM 72 LC

19

Page 22

Service Schedule

Daily or Before Starting the Engine

□ Check Engine Oil Level...................................... SAE 10W30

• (See Maintenance section for details)

□ Check Hydraulic Oil Level.................................. Crown AW46

• (See Maintenance section for details)

□ Check Fuel Level............................................... Clean #2 Diesel Fuel

□ Visually Inspect.................................................. Fan belt, bolts, fittings, hoses, or any

damaged parts

□ Check Radiator & Oil Cooler.............................. Clean off debris as needed

□ Check Engine Screens………...…..................... Clear debris as needed to ensure proper

air flow

□ Check Air Cleaner Intake................................... Clear debris as needed

□ Check Engine Coolant Level.............................. 50% anti-freeze, 50% water

□ Grease............................................................... Refer to page 10

□ Check Drive Tires............................................... Visually inspect tires to ensure proper

inflation & no damage

Every 50 Hours

□ Change Engine Oil & Filter................................. After initial 50 hours, change engine oil

• (every 200, thereafter)

□ Change Inline Fuel Filter.................................... After initial 50 hours, change filter

• (P/N: 302103, every 200 thereafter)

□ Check Tire Pressure........................................... Inflate drive tires to 15 psi

□ Check of Fuel Pipes & Clamps........................... See Kubota Manual for details

□ Check Lug nuts................................................... Torque to 140 ft-lbs

Every 100 Hours

□ Check Engine Air Filter....................................... Clean or replace as needed (P/N: 802064)

□ Check Fan Belt Tightness.................................. Tighten as needed

□ Check Hydraulic Oil Filter................................... Replace when needed (P/N: 822044)

Every 200 Hours

□ Change Engine Oil............................................. SAE 10W30 or other approved oil

• (See engine manual)

□ Change Engine Oil Filter..................................... P/N: 302058

□ Check Intake Air Lines........................................ Clear debris as needed

□ Replace In-line Fuel Filter…………...................... P/N: 302103

□ Check Radiator Hoses & Clamps....................... Repair or replace as necessary

Every Year

□ Replace Engine Air Filter.................................... P/N: 802064

□ Check Hydraulic Oil Condition............................ Crown AW46

• (See Maintenance section for details)

□ Check Battery..................................................... Clean terminals if necessary

20

ATM 72 LC

Page 23

Every 500 Hours

□ Replace Engine Fan Belt.................................... P/N: 802063

□ Replace Cannister Fuel Filter............................. P/N: 302057

Every 1500 Hours

□ Check fuel injection nozzle injection pressure ...See Kubota Manual

□ Change Hydraulic Oil......................................... Crown AW46

• (See Maintenance section for details)

Every 3000 Hours

□ Check Fuel Injection Pump

Every Two Years

□ Change Engine Coolant..................................... 50% anti-freeze, 50% water

□ Replace Battery.................................................. P/N: 832011

□ Replace radiator hoses and clamp bands.......... See parts manual

□ Replace fuel hoses and clamp bands................ See parts manual

□ Replace air intake hose...................................... See parts manual

ATM 72 LC

21

Page 24

ATM72 LC Operating Guide

BEFORE OPERATION

• Safety Checklist

o Read and understand the Operator’s Manual (located in the manual holder to the left of

the seat).

o Clear all foreign objects such as rocks, bottles or other hard materials that lay in the area

to be mowed.

o Follow all procedures described in the Maintenance section.

o Fill with #2 diesel fuel, if needed, while engine is cool.

o Visually check tires.

o Visually inspect machine for loose ttings, fasteners, hoses, etc.

o Know the location and function of all controls and how to stop quickly in an emergency.

o Adjust seat to a comfortable position.

o Fasten safety belts.

Throttle

Mower Deck

Engine

Pre-Heat

Ignition

Momentary

Reset

Engine Temp

Hydr. Level

Leveling

Lockout

Battery

Engine Oil

Parking Brake

Deck Lift Lights BrakeMower

Manual

Leveling

Manual

Auto/Manual

Leveling

Leveling

• Perform the daily maintenance checklist (For details, see the maintenance section of the Opera tor’s Manual).

o Check engine oil level o Grease all zerks (see page 10)

o Check hydraulic oil level o Check drive tires

o Check fuel level

o Visually inspect the fan belt, bolts, fittings, hoses, or any damaged parts

o Check radiator and oil cooler

o Check engine screens

o Check Air cleaner intake

o Check engine coolant level

22

ATM 72 LC

Page 25

STARTING

• To start the machine, it must be in neutral and the mower blades must be turned off.

• Turn the key over until the mower starts, and release the key.

• Set the cutting height following the direction laid out on page 15.

DURING OPERATION

• FASTEN SEAT BELT

• To prevent possible eye injury, always wear SAFETY GLASSES while operating machine.

• Park Brake – Make sure the park brake is disengaged before operation. Set the park brake

when unit is not in use or is parked on an incline. The indicator light illuminates when the park

brake is set.

• The park break is applied when the operator is out of the seat.

• Throttle – Start at low throttle. After allowing engine to warm up, operate machine at full throttle.

• To turn the mower blades on, the operator must be in the seat, and the hydraulic oil temp

must be below 190° F.

• Mower Switch - Used to engage the mower blades.

• Manual Override Switch - It is used when the operator would like to lean the mower either way

on their own using the Manual Leveling Switch on the right arm rest, otherwise it should be left

alone to allow the machine to auto-level itself up to 34° either way.

• Deck Wing Raise/Lower - This switch can raise and lower he deck wings in order to avoid

obstacles that may be in the machines path. Be sure to disengage the Mower Switch before

raising deck wings.

• Lights Switch - Use the lights as needed to avoid obstacles that could damage the machine or

harm the operator in any way.

ATM 72 LC

23

Page 26

NOTES

Harper Industries, Inc.

151 E. Highway 160

Harper, KS 67058

Website: www.harperindustries.com

Telephone: 620-896-7381

Toll-Free: 800-835-1042

Fax: 620-896-7129

E-mail: info@harperindustries.com

ATM 72 LC

Page 27

ATM 72 LC

R

6

5

PARTS

MANUAL

ATM 72LC

7-2019

Page 28

ATM 72LC

Page 29

Table of Contents

Parts Section

Frame & Assemblies

Front Steering Assembly...................................

Rear Stabilizer Arm Assembly...........................

Deck Linkage Installation..................................

Engine Assembly..............................................

Engine Installation............................................

Fuel Tank Installation........................................

Steering Tower and Foot Pedal Installation......

Console Assembly............................................

ROPs and Steering Wheel Installation.............

Electrical Assembly...........................................

Hood and Cowling Installation..........................

Toolbox and Deck Lift Assembly.......................

Seat and Screens Assembly.............................

Wheel and Tire Installation...............................

Deck Assembly.................................................

Deck Installation...............................................

Decal Layout.....................................................

Hydraulic Systems

Hydraulic Schematic.........................................

Hydraulic Tank Assembly..................................

Propulsion Pump and Wheel Motor Assy..........

Valve Assemblies..............................................

Valve and Tank Installation...............................

Propulsion System............................................

Propulsion Circuit ..............................................

Propulsion Plumbing - Pump and Valves..........

Propulsion Plumbing - Wheel Motors...............

Machine Hydraulic System...............................

Gear Pump Assembly and Plumbing................

Steering Circuit.................................................

Steering Plumbing............................................

Auxilary Circuit..................................................

Deck Lift Plumbing............................................

Leveling Plumbing............................................

Deck Circuit......................................................

Deck Plumbing..................................................

Oil Cooler Plumbing..........................................

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

1.13

1.14

1.15

1.16

1.17

2.1

2.2

2.3

2.4

2.5

2.6

2.7

2.8

2.9

2.10

2.11

2.12

2.13

2.14

2.15

2.16

2.17

2.18

2.19

Electrical Systems

Electircal Schematic Overview.........................

Engine Harness................................................

Relay Harness..................................................

Master Harness................................................

Instrument Panel Harness................................

Electrical Wiring Logic......................................

AuxiallaryValve-CoilWiringidentication.......

Options

Wheel Weight Kit..............................................

3.1

3.2

3.3

3.4

3.5

3.6

3.7

4.1

ATM 72LC

Page 30

ATM 72LC

Page 31

Section 3

Frame & Assemblies

ATM 72LC

Page 32

15

23

4/23/2019

10

3

1

8

5

14

2

11

6

21

12

13

17

4

1

4

24

19

25

20

18

16

22

9

7

FRONT STEERING ASSEMBLY

SEAL51010813

DESCRIPTION

NUT, 3/8-16 HEX JAM GR 21101071

Parts List

PART #ITEM

BOLT, 3/8-16 X 1.251104254

BOLT, 1/2-13 X 2.0 SHCS1101663

WASHER, 2.25 x .75 x .25T1101142

NUT, 1/2-131106107

BOLT, 3/8-16 X 2.5

NUT, 3/4-10, SLOTTED1106076

1104365

WASHER, 1/2" LOCK1106669

NUT, 3/8-16, UNITORQUE LOCK1106218

BEARING51010612

ADAPTER, 4MJ-4MB9012023510

COTTER PIN, 1/8 X 1.7541026111

RACE51020916

BOTTOM SEAL81029718

COTTER PIN, 1/8 X 151017615

GREASE ZERK, 1/4-28 ST51017414

BEARING LOWER81029919

KEY, 1/4 X 1/4 X 1.0 in

SPACER, STEERING TOWER81030020

51022817

STEERING CYLINDER82301523

STEERING ARM ASSY81053321

MOTOR, WHEEL 30.5 CI82302624

BEARING CUP, 3.250 X .6584201625

SPINDLE WELDMENT, FRONT WHEEL

81508122

ASSEMBLY STATION #1: 875001

ATM 72LC

1.1

Page 33

13

19

2

4

15

18

1

1

4

2

4/23/2019

11

3

11

12

21

5

9

17

8

16

11

12

17

8

11

5

9

6

REAR STABILIZER ARM ASSEMBLY

2

4

DESCRIPTIONPART #ITEM

Parts List

BOLT, 1/2-13 X 2.0 SHCS

BUSHING, 1-1/2 X 1-1/4 X 1-1/2 1020191

WASHER, 1.875 X .563 X .125, FLAT1100522

1101663

NUT, 1/2-131106106

BOLT, 1/2-13 X 1.251104425

NUT, CASTLE 3/4-161106137

WASHER, 1/2" LOCK1106669

WASHER, 3/4 FLAT SAE

BOLT, 1/2-13 X 1, WIZ FLANGE1102204

WASHER, 1/2" FLAT STANDARD

1106588

11067810

HUB ASSEMBLY51023513

COTTER PIN, 1/8 X 1.2551046314

GREASE ZERK, 1/4-28 ST51017412

BUSHING, 1.5 X 1.25 X 2.0 SPLIT CG/ID20202311

BUSHING81031917

EQUALIZER ARM ASSY

81013015

VERTICAL SHAFT81061018

PIN, STABILIZER PIVOT81022316

15

18

1

13

MOTOR, WHEEL 30.5 CI82302621

WELDMENT, LH STABILIZER ARM

WELDMENT, RH STABILIZER ARM81510019

81510120

CASTELLATION ALIGNS WITH HOLE

3. BACK OFF NUT UNTIL FIRST

2. TORQUE NUT TO 50 FT LBS

ROTATING HUB

HUB INSTALLATION

1. TIGHTEN NUT ON SPINDLE WHILE

DESCRIPTION

RACE, BEARING

BEARING, ROLLER

SEAL, CR12407

LUG NUT, 1/2-20

4

QTY

510235 HUB - SERVICE PARTS

110617

PART #

4. INSTALL COTTER PIN IN HOLE

CAP, DUST

510465 2

510466 2

510467 1

510469 1

20

1

2

4

10

7

14

ASSEMBLY STATION #1: 875001

ATM 72LC

1.2

Page 34

ATM 72LC

Page 35

Parts List

DESCRIPTIONPART #ITEM

BOLT, 3/4-10 X 5.01100701

BOLT, 3/4-10 X 4.0 GR 5 HEX HEAD

1103302

BOLT, 5/16-18 X 2.01103783

BOLT, 5/16-18 X 1-1/41104214

BOLT, 3/4-10 X 2.5110454

5

NUT, 5/16-18 WIZ FLANGE1106066

NUT, 3/4-10, UNITORQUE LOCK

1106257

ADAPTER, 4MJ-6MB901202208

CYLINDER - 2 x 4, SAE-6, TIE ROD

3230189

GREASE ZERK, 1/4-28 ST51017410

WELDMENT, UPPER DECK LIFT LINKAGE81507411

WELDMENT, DECK CONNECTING LINK81507512

WELDMENT, DECK PIN81507613

WELDMENT, FRONT DECK PIVOT BAR

81507714

WELDMENT, REAR DECK PIVOT BAR81507815

WELDMENT, DECK LIFT PIVOT81508916

WELDMENT, LOWER DECK LIFT LINKAGE81509017

DECK LINKAGE

INSTALLATION

15

7

11

3

13

10

6

14

8

9

8

7

1

5

17

12

2

7

7

16

7

5

7

5

2

12

4/23/2019

ASSEMBLY STATION #2: 875002

4

ATM 72LC

1.3

Page 36

LOCTITE

APPLY

BLUE

28

57

17

25

37

1

2

(13 IN)

1

14

51

44

30

46

19

45

59

49

11

18

22

21

15

17

25

38

29

14

31

4

41

3

24

19

10

27

5

4

47

TORQUE TO 37 IN-LB (DRY)

M8 x 1.25 - CLASS 12.9

9

23

8

54

SEE HYDRAULIC

53

SECTION FOR PUMP DETAILS

40

FILTER, INLINE FUEL

ELEMENT, AIR FILTER

CANISTER, FUEL FILTER

FILTER, OIL

62

843005 Engine - Service Parts

PART # DESCRIPTION

302057

302058

302103

HOSE, AIR CLEANER

PUMP, ELECTRIC FUEL

BELT, ENGINE FAN

802062

802063

802064

802065

7/17/2019

ENGINE ASSEMBLY

32

39

32

MANUFACTURING NOTE:

INTAKE HOSE, AIR INTAKE

CANNISTER, ENGINE FAN,

FUEL FILTER, AND MUFFLER

KIT INCLUDED WITH ENGINE

42

33

5

61

58

63

32

60

26

64

52

43

24

16

22

12

35

36

7

34

33

19

48

20

13

6

22

50

25

17

ASSEMBLY STATION #2: 875002

1.4

ATM 72LC

Page 37

7/17/2019

FUSE, 50 AMP

Parts List

33 132014 INSULATOR CAP, (ALTERNATOR)

34 132092 FUSE COVER, BUSS CFCOVER-1R

35 132093 FUSE HOLDER, BUSS CFBAR1-M8XSP

36 132150

37 302057 CANISTER, FUEL FILTER

38 315186 Weldment, Kubota Throttle Mnt

39 332004 Sender, Water, 3/8 Npt

ITEM PART # DESCRIPTION

40 342011 ADAPTER - PUMP, KUBOTA 1505, KIT

HOSE, LOWER RADIATOR

41 540079 BEARING, BALL, 1620RS

42 801002 HOSE, UPPER RADIATOR

43 801003

44 802065 HOSE, AIR CLEANER

45 810826 MOUNT, AIR CLEANER

SUPPORT, EXHAUST

CABLE, POSITIVE BATTERY

46 810885 BRKT, NEUTRAL CENTERING

47 810888 BRKT, PUMP LEVER

48 810900

49 815096 WELDMENT, NEUTRAL CENTERING

50 815097 WELDMENT, LH ENG/RAD MOUNT

51 815098 WELDMENT, RH ENG/RAD MOUNT

52 815099 WELDMENT, RADIATOR MOUNT

53 823024 PUMP, PM10 PROP 1.24 CI/.43 CI

54 823025 PUMP, DOUBLE GEAR 1.16 CI / .49 CI

55 830063

56 832001 CABLE, GROUND

57 832002 SWITCH ROLLER PLUNGER

MUFFLER KIT, KUBOTA C31

58 832076 Switch, 190 F Temp, 8MB, N.C. Rising

59 832079 SWITCH, 215 F TEMP, 6MP, N.O. RISING

60 842017

61 842018 FAN, ENGINE COOLING

62 843005 ENGINE, KUBOTA V1505 TIER 4F (25hp)

63 843006 COOLING PACKAGE, RADIATOR & OIL

64 942204 EXHAUST ELBOW 1 3/8

ENGINE ASSEMBLY

Parts List

ITEM PART # DESCRIPTION

ATM 72LC

BOLT, 1/2-13 X 1.0

WASHER, 5/16" FLAT SAE

110141 NUT, M8 X 1.25 WIZFLANGE

1 100361 CLAMP, HOSE #4 .25 MINI

2 100756 Hose, 5/16 High Pressure Fuel

3 102074 Clamp, Adel .75w x 1.25id x .406 Hole

4 110069

5 110074 Hex Nut M6 X 1.0 Thd

6 110086

7

8 110155 WASHER, 3/8" FLAT SAE

BOLT, 1/2-13 X 1.75

BOLT, M8x1.25 x 30 Gr 10.9

9 110178 BOLT, 3/8-16 X 1.5 SHCS

10 110377 BOLT, 5/16-18 X 1-1/2

11 110419

12 110442 BOLT, 1/2-13 X 1.25

13 110444 BOLT, 5/16-18 X 0.75, WIZ FLANGE

14 110459 BOLT, 5/16-18 X 1, WIZ FLANGE

15 110469 BOLT, M8x1.25 x 20 Gr 10.9

16 110486

17 110560 BOLT, M10-1.25 X 20 HHCS 8.8 PLAIN

18 110600 NUT, 5/16-18, UNITORQUE LOCK

19 110606 NUT, 5/16-18 WIZ FLANGE

20 110610 NUT, 1/2-13

WASHER, 3/8" LOCK

BOLT, 3/8 X .625 SHOULDER SHCS

21 110658 WASHER, 1/2" FLAT STANDARD

22 110666 WASHER, 1/2" LOCK

23 110672

24 110674 WASHER, 5/16" LOCK

25 110689 WASHER, 10mm LOCK

26 110779 CLAMP, 1 1/2" EXHAUST

27 110931 BOLT, M6x1 x 25 Gr 8.8

28 111070

29 111089 BOLT, M8x1.25 x 16 Gr 8.8

30 111149 SPRING, TENSION .625 x .069 x 3.0

31 111150 ROD END, 5/16-24 RH, FEMALE

32 112101 CLAMP, 1.50", T-BOLT

ASSEMBLY STATION #2: 875002

ii 1.4

Page 38

4/26/2019

Molding, Bulb1003601

DESCRIPTIONPART #ITEM

Parts List

Molding, Edge1003653

Hose, 5/16, Vacuum Tube1020014

CLAMP, HOSE #4 .25 MINI1003612

BOLT, 3/8-16 X 1.251104257

Foam Tape, 3/8 X 1 1/41020886

D-SEAL, RUBBER 1.00" x 1.00" x 16.25"1020045

BOLT, M12x1.75 x 45 Gr 10.91105779

BOLT, 5/16-18 X 0.75, WIZ FLANGE

WASHER, 1/2" LOCK11066612

NUT, 5/16-18 WIZ FLANGE

WASHER, 1/2" FLAT STANDARD11065811

NUT, 3/8-16 GR 5

WASHER, 3/8" LOCK11067213

WASHER, 3/8" FLAT STANDARD11067614

MOTOR MOUNT80002118

CLAMP, HOSE #36 2.25"51100317

Elbow, 2.0" x 2.0" 90 Deg Silicone34205016

BAFFLE, HOOD81076521

BRKT, RH HOOD BAFFLE MOUNTING

BRKT, LH HOOD BAFFLE MOUNTING 81076319

CABLE, GROUND83200124

TUBE, AIR INTAKE81082722

TUBE, AIR INTAKE81087523

CLAMP, SUBTANK

SUBTANK BRACKET84004326

SUBTANK, RESERVOIR84004225

HOOD FOAM, 2x3x20"85011528

1104448

11060610

17

16

17

11082615

81076420

12

9

84004427

11

24

7

14

18

14

15

13

22

17

23

17

16

3

10

19

8

3

(8.25")

3

(13.5)

8

ENGINE

INSTALLATION

21

20

5

1

2

6

28

25

27

6

28

4

(18")

8

2

26

FUEL TANK

ATTACHES TO

10

ASSEMBLY STATION #2: 875002

ATM 72LC

1.5

Page 39

20

13

1

3

(11.5")

4/26/2019

18

16

9

INSTALL ADEL CLAMP ON

10

5

22

17

SECURE HEADLIGHT WIRES

FRONT LEFT MOUNTING BOLT TO

11

1

7

9

23

19

12

3

(2.5")

21

4

1

1

3

(34")

1

(13")

1

6

14

1

15

8

2

(64")

1

FUEL TANK INSTALLATION

DESCRIPTIONPART #ITEM

Parts List

CLAMP, HOSE #4 .25 MINI1003611

ATM 72LC

FILTER, FUEL30210316

Hose, 3/16, Low Perm1007082

NUT, 1/4-20 WIZ FLANGE

Hose, 5/16 High Pressure Fuel1007563

BOLT, 3/8-16 X 1, WIZ FLANGE1104405

BOLT, 5/16-18 X 1, WIZ FLANGE

1104596

1102904

NUT, 3/8-16 WIZ FLANGE1106459

NUT, 5/16-18 WIZ FLANGE1106068

BOLT, 1/4-20 X 0.75, WIZ FLANGE110468

7

SCREW, 10-32 X 1/2 MACH SEAL

CLAMP, ADEL .75WX.5IDx.406 HOLE11072610

11205311

Adapter, 3hb-4fj12065514

ADAPTER, 5HB-6FBX12037813

ADAPTER, 4MJ-6MP9012004012

CANISTER, FUEL FILTER30205715

FUEL CAP80201919

GASKET, FUEL SENDER50017217

FITTING, REDUCER 3/8 X 1/4 NPT50020918

PUMP, ELECTRIC FUEL80206221

WELDMENT, FUEL TANK81508422

VALVE, FUEL SHUT OFF 6MB-4MP80202320

SENDER, FUEL LEVEL, 17.0" TANK DEPTH

83207823

ASSEMBLY STATION #2: 875002

1.6

Page 40

31

25

24

21

23

24

7

3.50" - CTR TO CTR

ROD END ASSEMBLY

5

22

27

DETAIL B

2

30

37

2

22

36

14

11

9

34

12

42

29

16

2.75" - CTR TO CTR

ROD END ASSEMBLY

45

31

31

35

29

16

44

10

4/26/2019

18

DETAIL A

1

B

41

43

4

STEERING TOWER & FOOT PEDAL INSTALLATION

8

9

33

40

12

15

20

17

38

28

18

26

39

3

32

6

13

19

A

4

1

ASSEMBLY STATION #3: 875003

1.7

ATM 72LC

Page 41

4/26/2019

STEERING TOWER & FOOT PEDAL INSTALLATION

Parts List

ITEM PART # DESCRIPTION

Parts List

ITEM PART # DESCRIPTION

CLEVIS - THROTTLE

BUSHING, IGUS, FOOT PEDAL

24 120249 ADAPTER, 4MJ-6MB

25 120319 ADAPTER, 6MJ-6MB

26 302017

27 323046 MOTOR, STEERING ORBITAL

28 510094 SCREW, 10-24 X 1, RHMS

29 540075 BEARING, ROD END 1/4-28 W/STUD

30 540079 BEARING, BALL, 1620RS

31 800128

32 802057 CABLE, THROTTLE

33 810847 BRKT, RELAY & FUSE MOUNTING

34 810884 SUPPORT, FOOTREST

35 810886 LINKAGE, 1/4-28 FOOT PEDAL

BOLT, 1/2-13 X 1, WIZ FLANGE

1 100373 TRACTION PAD, FLEX-TREAD, 5.50"

2 110069 WASHER, 5/16" FLAT SAE

3 110220

4 110226 ROLL PIN, 3/8 X 1.25

5 110377 BOLT, 5/16-18 X 1-1/2

BOLT, 3/8-16 X 1, WIZ FLANGE

6 110403 BOLT, 1/2-13 X 2.5

7 110421 BOLT, 5/16-18 X 1-1/4

8 110440

9 110444 BOLT, 5/16-18 X 0.75, WIZ FLANGE

10 110556 Bolt, 3/8-16 X 1 in Carriage

11 110600 NUT, 5/16-18, UNITORQUE LOCK

12 110606 NUT, 5/16-18 WIZ FLANGE

COLUMN, STEERING

LINKAGE, 5/16-24 FOOT PEDAL

36 810887

37 810888 BRKT, PUMP LEVER

38 812012

39 815086 WELDMENT, STEERING TOWER

40 815087 WELDMENT, STEERING ORBITAL MOUNT

NUT, 1/2-13

NUT, 10-24 LOCK NYLON INSERT

13 110610

14 110623 NUT, 5/16-24

15 110631

16 110632 NUT, 1/4-28, UNITORQUE LOCK

17 110640 Hex Nut M10

WELDMENT, REVERSE FOOT PEDAL

41 815091 WELDMENT, FWD FOOT PEDAL

42 815092 WELDMENT, FWD FOOT PEDAL PIVOT

43 815093

44 815094 WELDMENT, REV FOOT PEDAL PIVOT

45 815095 WELDMENT, FOOT PEDAL MOUNT

WASHER, M10, LOCK

18 110645 NUT, 3/8-16 WIZ FLANGE

19 110666 WASHER, 1/2" LOCK

20 110689

21 111055 STUD, M10 X 1.5 X 42 GRADE 8.8

22 111150 ROD END, 5/16-24 RH, FEMALE

23 120222 ADAPTER, 6MJ-6MB90

ATM 72LC

ASSEMBLY STATION #3: 875003

ii 1.7

Page 42

7/17/2019

CONSOLE ASSEMBLY

HOUR METER53000912

DESCRIPTIONPART #ITEM

Parts List

Tape, 1.00 X .005 Poly Protective1020251

BOLT, 1/4-20 X 1-1/41104304

1/4-20 U-TYPE TAPPED HOLE

BOOT, PUSHBUTTON SWITCH SEALING1021232

1100713

SCREW, 10-32 X 1 PHILLIPS1107516

WASHER, 1/4" FLAT STANDARD1106735

LIGHT, RED INDICATOR1321519

NUT, 10-32 THREADED INSERT1107527

LIGHT, AMBER INDICATOR

SWITCH, SPST MOMENTARY, N.C. 1320908

13215210

GAUGE, FUEL53006513

SWITCH, IGNITION33203111

PANEL, DASH81083016

COWLING DASH81200217

SWITCH, SPDT, ON-ON

DECAL, DASH OVERLAY80205614

COWLING BRACKET, SIDE

81060415

TEMPERATURE GAUGE83000818

SWITCH, PADDLE, CARLING (29261)

SWITCH, PADDLE, CARLING (280063)83200319

83200420

MOUNT, SWITCH (VMS)83202423

SWITCH, PADDLE, CARLING (29253)83200521

ALARM, PANEL MOUNT, CONTINUOUS TONE83208224

83201822

1

17

5

15

4

3

5

7

3

9

8

10

9

14

16

15

23

2

9

22

21

11

24

12

6

23

20

19

13

18

9

ASSEMBLY STATION #3: 875003

ATM 72LC

1.8

Page 43

2/25/2019

NUT, 1/2-131106102

DESCRIPTIONPART #ITEM

BOLT, 1/2-13 X 1.51104291

Parts List

Cap, Center Steering

WASHER, 1/2" LOCK1106663

Nut, Steering Wheel, 13/16-20 UNEF5020885

5020874

ROPS, ATM 728101258

HAZARD LIGHT5301186

STEERING WHEEL552002

7

ROPS & STEERING WHEEL INSTALLATION

5

7

4

2

8

3

6

1

2

3

1

ASSEMBLY STATION #4: 875004

ATM 72LC

1.9

Page 44

ATM 72LC

Page 45

29

30

5

21

23

4/29/2019

28

20

ELECTRICAL

11

ASSEMBLY

17

3

24

22

1

20

16

2

Parts List

SWITCH, PADDLE, CARLING (29261)

19

PART # DESCRIPTION

33

25 810747 SWITCH SHIM

26 810847 BRKT, RELAY & FUSE MOUNTING

27 830063 CABLE, POSITIVE BATTERY

28 832003 SWITCH, PADDLE, CARLING (280063)

29 832004

30 832007 SWITCH MOUNT, END

31 832011 BATTERY, SEALED GEL W/ L TERMINAL

32 832024 MOUNT, SWITCH (VMS)

33 832061 MANUAL OVERRIDE, AUX SW HARNESS

34 835027 HEADLIGHT ASSEMBLY, FLUSH MOUNT LED

ITEM

35 970876 BRKT, BATTERY HOLD DOWN

8

32

29

6

2

25

8

4

8

26

Parts List

SCREW, 10-24 X 0.5, RHMS

SAFETY SWITCH BRACKET

15

13

9

12

35

6

14

LAMP TIMER

MOUNT GLOW

MOUNT FUSE BLOCK

WITH TABS LOCATED ON TOP

ATM 72LC

PART # DESCRIPTION

13 132069 BATTERY TERMINAL COVER, POSITIVE

14 132070 BATTERY TERMINAL COVER, NEGATIVE

15 132099 Micro Relay

16 332036 Inclinometer Switch, Solid-State

17 510960

18 530051 GROUND CABLE

19 530118 HAZARD LIGHT

20 710587 SCREW, 3/16 X .75 TEK SELF-TAP

21 810611 LEVELING SWITCH BRACKET

22 810665 LEVELING SWITCH GUARD, FRONT

23 810666 LEVELING SWITCH GUARD, BACK

ITEM

31

9

7

10

24 810680

18

4

34

Parts List

PART # DESCRIPTION

1 110119 NUT, 10-24 LOCK

ASSEMBLY STATION #3: 875003

2 110164 SCREW, 10-24 UNCX0.75 Flt Hd Mach

ITEM

NUT, 5/16-18 LOCK (NYLON)

3 110441 BOLT, 5/16-18 X 4.0

4 110444 BOLT, 5/16-18 X 0.75, WIZ FLANGE

5 110603

6 110606 NUT, 5/16-18 WIZ FLANGE

7 110608 NUT, 5/16-18

8 110631 NUT, 10-24 LOCK NYLON INSERT

9 110665 WASHER, 5/16" FLAT STANDARD

BOLT, 5/16-18 X 9.0

10 110674 WASHER, 5/16" LOCK

11 110788 BOLT, 10-24 X .375 STAINLESS, PHILLIPS

12 111016

1.10

Page 46

1021271

1103586

11060311

11063013

11077218

81057022

81087429

81200432

7/18/2019

3

HOOD & COWLING

INSTALLATION

19

27

6

2

30

5

8

15

4

14

24

16

13

10

14

20

3

4

14

14

14

11

7

14

11

8

25

9

22

11

21

29

1

32

23

14

12

16

2

18

16

2

17

18

2

8

6

26

16

24

14

4

8

31

18

28

5

19

3

ASSEMBLY STATION #4: 875004

ATM 72LC

1.11

Page 47

7/18/2019

LATCH50009919

DESCRIPTIONPART #

RIVET, POP, 5/32 X .3781101023

Parts List

1/4-20 U-TYPE TAPPED HOLE1100712

Seal, Rubber "D", .70 x .50 w/ .30 Flap1021271

NUT, 5/16-18, CAGE TINNERMAN1102584

BOLT, 5/16-18 X 1-1/41104217

NUT, 1/4-20 WIZ FLANGE

Bolt, 1/4-20 X 0.625 in Carriage1103586

BOLT, 1/4-20 X .75

BOLT, 5/16-18 X 1.01104238

NUT, 5/16-18 WIZ FLANGE

NUT, 5/16-18 LOCK (NYLON)11060311

BOLT, 5/16-18 X 1, WIZ FLANGE1104599

NUT, 1/4-20 LOCK (NYLON INSERT)11063013

WASHER, 1/4 NYLON11069816

WASHER, 1/4" FLAT STANDARD11067315

WASHER, 5/16" FLAT STANDARD11066514

BOLT, 5/16-18 X 1.25 82° FLATHEAD

HOOD LIFT ARM, REAR81056820

HOOD LIFT ARM, FRONT

HOOD LIFT ARM, REAR LEFT81056921

SCREW, 1/4-20 X 1 SS PHILLIPS PAN HEAD11077218

TOP SCREEN81062525

SAFETY CATCH81057123

COWLING, LEFT81081926

COWLING, RIGHT81082027

COWLING, CENTER

HOOD LIFT BRACKET

COWLING, EXHAUST81082128

HOOD, DEWEZE RED81200432

Bracket, Hood Mount, Left81091831

Bracket, Hood Mount, Right81091730

HOOD & COWLING INSTALLATION

11060612

1102905

ITEM

11056110

11073017

81057022

81057224

81087429

ASSEMBLY STATION #4: 875004

ATM 72LC

ii 1.11

Page 48

2/26/2019

3

5

2

TOOL - 805016

DESCRIPTIONPART #ITEM

1

3

2

4

1

6

Parts List

BOLT, 3/8-16 X 1.251104252

WASHER, 3/8" FLAT SAE

NUT, 3/8-16, UNITORQUE LOCK1106213

1101551

CHAIN, 1/4 COIL

BRKT, DECK LIFT8108895

Pin, Lynch 5/16 x 1 3/44112874

9703046

DECK LIFT ASSIST

INTO 5TH LINK

INSTALL BOLT

4

4

7

9

1

Parts List

TOOLBOX ASSEMBLY - 805017

6 112106 Keeper, Draw Latch

7 311729 HINGE, 6" ALUMINUM W/ HOLES

8 810911 BASE, TOOLBOX

ITEM PART # DESCRIPTION

9 810912 LID, TOOLBOX

1

3

6

5

8

2

Parts List

LATCH, RUBBER T-HANDLE DRAW

3

2

1 110119 NUT, 10-24 LOCK

2 110339 SCREW, 10-24X1.25 PAN HEAD PHPS

3 110631 NUT, 10-24 LOCK NYLON INSERT

4 110788 BOLT, 10-24 X .375 STAINLESS, PHILLIPS

ITEM PART # DESCRIPTION

5 112105

ATM 72LC

1.12

Page 49

7/18/2019

SPRING

DESCRIPTIONPART #ITEM

Parts List

CYLINDER STOP, 1/4" THICK1020771

BOLT, 3/8-16 X 1, WIZ FLANGE

SCREW, 1/4-20 X .75, WH SELF TAP1101992

NUT, 5/16-18 WIZ FLANGE1106066

BOLT, 1/4-20 X 0.75, WIZ FLANGE1104685

BOLT, 5/16-18 X 0.75, WIZ FLANGE1104444

NUT, 1/4-20 LOCK (NYLON INSERT)1106307

HOLDER, MANUAL

NUT, 3/8-16 WIZ FLANGE

BOLT, 10-24 X .375 STAINLESS, PHILLIPS1107889

CLEVIS PIN, 5/16"55004813

SEAT, I3M SUSPENSION30207811

CLIP, HAIRPIN 3/32 x 1.62531202212

TOOL, BRAKE RELEASE57506416

CYLINDER STOP, 1" THICK

CYLINDER STOP, 1/2" THICK57200314

BOX, PLASTIC, MANUAL OVERRIDE80203517

SWITCH SHIM

BIN, REAR STORAGE81081121

ASSEMBLY, TOOLBOX80501719

TOOL, DECK LIFT ASSIST80501618

GRILL, FRONT81502224

COWLING, LOWER

MOUNT, ARM REST SWITCH81081823

GRILL, SIDE LEFT81504526

GRILL, SIDE RIGHT81502325

WELDMENT, SEAT BASE

MOUNT, SWITCH (VMS)83202430

WELDMENT, SEAT MOUNT81508828

SWITCH, PADDLE, CARLING (29261)83200429

MANUAL OVERRIDE, AUX SW HARNESS83206131

1104403

15200410

1106458

57200515

81074720

81081222

81507927

94205532

4

21

4

16

19

18

PLACE DECK LIFT

TOOL INSIDE TOOLBOX

6

6

1

15

14

26

27

11

28

6

3

8

12

32

13

3

7

31

17

SEAT & SCREENS INSTALLATION

9

30

29

ATM 72LC

10

5

22

20

2

23

4

32

32

25

32

24

ASSEMBLY STATION #4: 875004

1.13

Page 50

6/3/2019

1

TO 140 FT-LBS

TORQUE LUGNUTS

DESCRIPTIONPART #

LUGNUT, 1/2-20 GR 51106171

Parts List

ITEM

TIRE & WHEEL ASSY, 72LC8430073

FILLED STABILIZER TIRE ASSEMBLY8000572

WHEEL, 12 X 8.50

TIRE, 25x11-12 440 MAG

843007 - Service Parts

842019

842020

PART # DESCRIPTION

FRONT WHEEL ASSY

SAME AS REAR WHEEL

3

801005 - FACTORY INSTALL

OPTIONAL WHEEL WEIGHT KIT

801004 - CUSTOMER INSTALL

1

2

WHEEL & TIRE INSTALLATION

ASSEMBLY STATION #4: 875004

ATM 72LC

1.14

Page 51

DESCRIPTIONPART #ITEM

Parts List

BOLT, 1/2-20 X 1.5, GR81100512

LEVEL, SURFACE MOUNT1021191

BOLT, 3/4-10 X 6.75, HHCS1102725

BOLT, 1/2-13 X 1, WIZ FLANGE1102204

SCREW, 1/4-20 X .50 SLOT FLAT-HD

PLUG, 7/16", NYLON, SNAP LOCK1102836

BOLT, 1/2-13 X 1.751104199

NUT, 8-32 LOCK NYLON

SCREW, 8-32X1.5 PAN HEAD PHPS1103447

BOLT, 1/2-13 X 1.2511044211

BOLT, 3/8-16 X 1, WIZ FLANGE

NUT, 1/2-13, UNITORQUE LOCK11061512

NUT, 3/8-16 WIZ FLANGE

NUT, 3/4-10, UNITORQUE LOCK11062513

NUT, 1/2-20, UNITORQUE LOCK11063514

WASHER, 1/2 FLAT SPECIAL 1.5 OD11066016

ROLL PIN, 1/4 X 0.7511070019

WASHER, M5 FLAT STAINLESS

WASHER, 1/2 EXT. TOOTH LOCK11068118

WASHER, 7/16" FLAT STANDARD11067017

ROLL PIN, 1/4 X 1.520002823

ADAPTER, 4MJ-4MB9012023521

KEY, 1/4 X 1/4 X 1.0 in51022824

ADAPTER, 10MJ-10MB12025122

BLADE, LEFT51113527

BLADE, RIGHT51113426

PIN, WIRE LOCK51096225

CASTER WHEEL ASSY80009329

BUSHING, MFI-1620-2480012430

BUSHING, BLADE MOUNT51113628

BUSHING, MSI-1620-16

COVER, VINYL, 1/2 RND X 6.080200131

WASHER, BLADE MOUNT81036035

HUB, BLADE MOUNT MACHINED81035834

PLASTIC BUMPER, MOTOR GUARD81027833

CRANK PIVOT81039338

BLADE MOUNT81036136

BLADE SADDLE81036437

DUST CAP81200141

DECK WELDMENT, LEFT81040540

DECK WELDMENT, RIGHT

CASTER YOKE WELD ASSY81500242

CASTER ARM WELD ASSY, LEFT

ADJUSTMENT SCREW WELD ASSY81500343

1103458

1100673

11044010

11064515

11101320

80200432

26

39

22

9

DESCRIPTIONPART #ITEM

Parts List

CASTER ARM WELD ASSY, RIGHT81500645

22

MOTOR, DECK, BI-DIRECTIONAL, 1.65 CI82301646

46

45

16

24

12

34

36

14

37

14

21

81040439

2

28

16

19

28

2

16

81500544

2/26/2019

35

11

18

33

22

7

26

27

3

21

1

46

DECK ASSEMBLY

38

ATM 72LC

22

9

20

8

40

27

6

25

23

31

15

13

10

29

44

4

41

32

17

43

30

42

5

ASSEMBLY STATION #4: 875004

1.15

Page 52

15

5

21

2

2

7/18/2019

5

25

24

23

20

22

6

28

18

1

15

16

30

20

14

12

17

3

32

19

19

13

31

1

4

8

7

7

29

26

27

9

11

10

4

DECK INSTALLATION

DESCRIPTIONPART #

Parts List

TRACTION PAD, FLEX-TREAD 2.75" x 1.0'1004491

ITEM

BOLT, 3/4-10 X 5.01100704

WASHER, 1/4" FLAT SAE1102986

BOLT, 1/2-13 X 1, WIZ FLANGE

WASHER, 1.25 OD X .75 ID X .0751100683

WASHER, 1.875 X .563 X .125, FLAT SPECIAL1100522

1102205

NUT, 3/4-16 JAM LH1108919

WASHER, 3/4" FLAT SAE1106788

NUT, JAM 3/4-16 UNF RH11089210

NUT, 3/4-10, UNITORQUE LOCK1106257

JACK SCREW, 3/4-16 X 4.011115911

COTTER PIN, 3/16 X 251017514

GREASE ZERK, 1/4-28 ST51017413

Pin, Hairpin Cotter, 1/8 X 2.375

50015612

PIN, WIRE LOCK

COTTER PIN, 1/8 X 151017615

ROLL PIN, 3/16 X 0.7551040316

SCREW, 3/16 X .75 TEK SELF-TAP71058718

51096217

EQUALIZER ARM ASSY81013021

BUSHING, IGUS MFI-2024-2480012920

BUSHING, 1.25 X 1.0 X .75 SPLIT STEEL80002619

PIN ASSY, EQUILIZER ARM MOUNT

81023822

VERTICAL SHAFT81061025

PLASTIC DECK COVER

BUSHING, 1.25 X .75 X .7581080226

HANDLE, HEIGHT ADJUSTMENT81091628

LINK, LH THREAD ADJUSTABLE 81084327

HOLD DOWN ROD, CENTER DECK COVER81047723

81048924

W/TREAD-GRIP STEP

OUTER DECK ARM WELDMENT,

OUTER DECK ARM WELDMENT, W/O STEP

81502830

81502729

WELDMENT, DECK ADJUSTMENT81510732

SLIDE ASSY SHORT, OUTER DECK ADJ81504231

ASSEMBLY STATION #4: 875004

ATM 72LC

1.16

Page 53

3/4/2019

Parts List

DECAL, DIESEL FUEL

DECAL, FUEL

DECAL, SERVICE RADIATOR

DECAL, DANGER, ROTATING BLADES

DECAL, BATTERY

302106

500252

500254

PART # DESCRIPTION

500255

DECAL, EPA STANDARDS

DECAL, RECYCLE BATTERY

800187

800195

902186

DECAL LAYOUT - TOP VIEW

500252

500252

800187

902186

302106

800195

500255

(PLACE ON

500254

FRONT OF TANK)

ATM 72LC

ASSEMBLY STATION #4: 875004

1.17

Page 54

3/4/2019

Parts List

802067

DECAL, SWITCH MANUAL LEVEL CTL

DECAL, TILT

DECAL, ATM 72LC LOGO, SILVER

DECAL, HIGH PRESSURE OIL

DECAL, 72LC STRIPE, RIGHT

500256

802033

802054

PART # DESCRIPTION

802058

DECAL, TIE DOWN POINT

DECAL, MANUAL/AUTO LEVEL

802059

802066

802067

802054

DECAL LAYOUT - RH SIDE

802066

802033

802059

802067

500256

802058

ASSEMBLY STATION #4: 875004

ATM 72LC

ii 1.17

Page 55

3/4/2019

902204

500079

802067

500256

800186

500253

202133

PLATE

Parts List

DECAL LAYOUT - LH SIDE

802056

SERIAL NUMBER

802066

500257

802068

802053

802067

DIESEL EXHAUST

DECAL, PROP 65, BREATHING

DECAL, SLOW MOVING VEHICLE

DECAL, HIGH PRESSURE OIL

DECAL, OPERATING ON SLOPES

DECAL, ATM 72LC LOGO, SILVER

DECAL, TIE DOWN POINT

DECAL, CUT HEIGHT

DECAL, READ OPERATOR'S MANUAL

DECAL, HOT MUFFLER

DECAL, 72LC STRIPE, LEFT

DECAL, ISO 46 HYDRAULIC OIL

202133

500079

PART # DESCRIPTION

500253

ATM 72LC

500256

500257

800186

802053

802066

802067

802068

902204

ASSEMBLY STATION #4: 875004

iii 1.17

Page 56

Section 4

Hydraulic Systems

ATM 72LC

Page 57

ATM 72LC

2.1

Page 58