Harnisch+Rieth G-F 316 E Operating Instructions Manual

Operating instructions

Machine designation: Denture model grinding unit with

Suction and filter unit

Machine type: G-F 316 E

Machine no.: .....................................

Keep for future reference!

Dear customer,

Thank you for the confidence you have placed in us by purchasing this denture model grinding

unit.

For this unit to be of service to you for many years to come, please take the time to read these

operating instructions carefully, especially before using the unit for the first time.

Contents

1 Safety ...................................................................................................................................... 2

1.1 Intended use..................................................................................................................2

1.2 Possible dangers ........................................................................................................... 2

1.3 Approved operators ....................................................................................................... 2

1.4 Safety measures at site of operation .............................................................................2

1.5 Marking of safety references contained in these instructions......................................... 2

2 Initial/Setting into operation ................................................................................................. 3

2.1 Unpacking the unit .........................................................................................................3

2.2 Identification of the unit components ............................................................................. 3

2.3 Initial/setting into operation procedure ........................................................................... 4

2.4 Checking the filter unit ................................................................................................... 4

3 Operation................................................................................................................................5

3.1 Automatic switch-off....................................................................................................... 5

3.2 Changing the disposable filter bag................................................................................. 5

3.3 Changing/cleaning (dry) the ultra-fine filter cartridge .....................................................5

3.4 Changing the carbide metal milling tool ......................................................................... 6

4 Cleaning/maintenance........................................................................................................... 7

4.1 Cleaning the suction channel......................................................................................... 7

4.2 Maintenance .................................................................................................................. 7

5 Electrical fuse protection ...................................................................................................... 7

6 Technical data ........................................................................................................................ 8

7 Warranty conditions .............................................................................................................. 9

8 EC declaration of conformity.............................................................................................. 10

G-F 316 E - 24.02.2002 / Vers.: 2

1

1 Safety

1.1 Intended use

The G-F 316 E denture model grinding unit is intended for use in dental laboratories for spot

grinding dentures. This unit is designed exclusively for milling plasters and other similar

materials.

The filter unit is suitable for extracting dusts of the use category C as stipulated in the BIA

requirements according to ZH 1/487 (i. e. also for dusts hazardous to health).

Unauthorized modifications and additions are not permitted for reasons of safety!

1.2 Possible dangers

The G-F 316 E denture model grinding unit is safe when used as intended. However, when not

used properly or with care its use can lead to injuries (for further details see section

“2.3 Inital/setting into operation procedure“ “Danger“.

− Before leaving the G-F 316 E denture model grinding unit the user should always switch the

unit off at the main switch.

− Potential ignition sources should not be suctioned.

− As the dusts to be extracted are more or less hazardous to health, special care should be

taken that the ultra-fine filter and the PE foil bag are properly inserted and that they are not

damaged!

− Before maintenance work and cleaning, the unit should be switched off and disconnected

from the mains supply (i. e. the mains plug should be pulled).

− Before accessing any of the incorporated electric components, the unit should be

disconnected from the mains supply!

1.3 Approved operators

The operator of the machine should make sure that the operating instructions are accessible to

the operating personnel. The operator should make sure that they have been read and fully

understood by the operating personnel. Only then should they be allowed to operate the

machine.

1.4 Safety measures at site of operation

The installation surface should be flat and stable according to the weight of the denture model

grinding unit.

Foreign bodies should not be inserted through the ventilation openings of the unit.

1.5 Marking of safety references contained in these instructions

Note

Caution

Danger Refers to dangerous situations, in which injuries can occur.

Refers to tips and other particularly helpful pieces of information.

Refers to particular ways of operation or handling, the non-adherence of which can lead

to malfunctioning, damages or other kinds of trouble.

Warning of possible danger. (Caution, danger, refer to documentation).

This sign is also attached to the unit because of the rotating milling tool.

2

G-F 316 E - 24.02.2002 / Vers.: 2

2 Initial/Setting into operation

2.1 Unpacking the unit

1. Put the carton onto a flat surface.

2. Remove the upper packaging material.

3. Lift the unit out of the packaging.

4. Check the accessories.

− Documentation

− Tubular hexagon box wrench (19 mm)

Crossbar ∅ 12 mm for tubular hexagon box wrench (19 mm)

blocking pin ∅ 6 mm with O-ring.......................................................................no. 316 E 640

− Mains supply connection cable ......................................................................... no. 316 E 500

− For possible further accessories see note of delivery

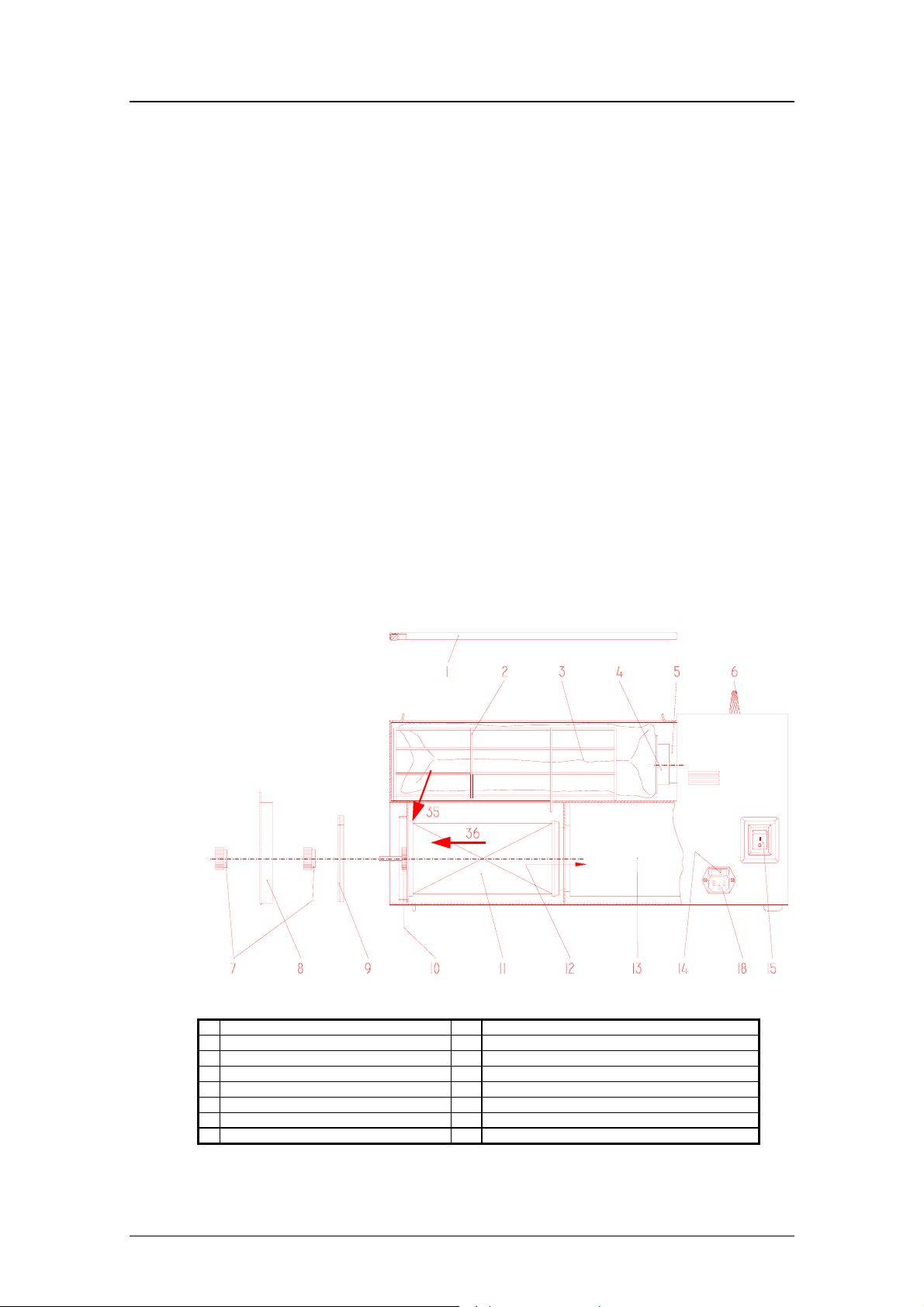

2.2 Identification of the unit components

The G-F 316 E denture model grinding unit comprises the following main elements:

a)

Motor milling spindle

tools upon request).

b)

Incorporated suction and filter unit

blower, a disposable filter bag and a subsequently connected ultra-fine filter cartridge

automatic de-activation device

with collet chuck and conical carbide metal milling tool (other milling

, consisting of a noise-absorbing motor-driven suction

for monitoring the suction unit/process.

with an

Fig. 1: Identification of the unit components

1 Lid (access filter bag) 9 Lid (for ultra-fine filter)

2 Wire basket 10 Knurled nut

3 Disposable filter bag 11 Ultra-fine filter cartridge

4 Plastic connection 12 Opening to suction blower

5 Nozzle 13 Suction blower

6 Milling tool 14 2 fuses for feeble currents 10 A/T

7 Knurled nuts with copper disk 15 Main switch

8 Lid (access ultra-fine filter) 18 Mains connection unit plug (230 V/50 Hz)

G-F 316 E - 24.02.2002 / Vers.: 2

3

Loading...

Loading...