Page 1

INSTALLATION INSTRUCTIONS

Harmony Nexus™ Equipment Management System

Fixed Suspension Tube with Fixed Pendant

(REV. A 01/08/13) 10023649

Page 2

A WORD FROM STERIS CORPORATION

This manual contains important information on the installation

procedures for the Fixed Suspension Tube with Fixed Pendant of the

Harmony Nexus™ Equipment Management System. Follow each

step of the installation instructions in the order presented. If you find

any indication of damage to the equipment (no matter how slight),

show it to your supervisor.

To properly install this unit, you will need the Equipment Drawings

(previously furnished), showing all utility service and space

requirements. If drawings cannot be located, replacement copies

may be obtained by writing, faxing or telephoning STERIS giving the

serial and model numbers of your equipment.

Once installed, equipment operation should be tested by a qualified

service technician prior to your usage of the equipment. Any

ancillary equipment (i.e., monitors, video recorders, etc.) that is to be

used with the Harmony Nexus Equipment Management System must

comply with all applicable medical equipment standards.

If STERIS supervision is desired for installing and starting up this

equipment, contact your local STERIS representative.

Indications for Use

Advisory

Harmony Nexus Equipment Management System (EMS) is inteded

for use in hospital facilities where there is a need for ready access to

medical gases, electrical power and audio/visual data services. The

EMS organizes surgical equipment such as endoscopy equipment,

laparoscopic equipment, cautery devices, insufflators, etc. Harmony

Nexus EMS units help hospitals to improve efficiency and safety, and

to maximize total room workflow by ergonomically centralizing all

surgical support equipment:

• As individual unit or in combination with the ceiling supply units

of the Harmony Nexus Equipment Management System

• For communicating and exchanging data, e.g., telephone,

nurse’s call button or computer networking

• For the ergonomic positioning of medical equipment during use

• For supplying medical equipment with electrical power and

medical gases

• To provide additional instrument trays, shelves and supports

The intended user for this equipment includes OR, ER/Trauma

Room, Ambulatory Surgery Center and ICU staff.

A listing of the safety precautions to be observed when installing and

testing this equipment can be found in S

PRECAUTIONS of these instructions. Do not begin installing this

equipment until you have become familiar with this information.

ECTION 1, SAFETY

IMPORTANT: Be sure to check the Occupational Health and Safety

Act, as well as local electric and plumbing codes, for any special

requirements that may pertain to installation of this unit.

©2013, STERIS Corporation. All rights reserved. Printed in U.S.A.

Introduction Installation Instructions 10023649

i

Page 3

Environmental

Conditions

Transport and Storage

NOTE: The following storage conditions apply for up to 15 weeks.

• Temperature: 13 to 158°F (–11 to +70°C)

• Relative Humidity: 10 to 75%

• Barometric Pressure: 0.5 to 1.05 atm STD atmospheric pressure

(500 to 1060 hPa)

• Store only in closed or covered spaces. After 15 weeks, the

values for the Operational Location Requirements (below) apply.

Operational Location Requirements

• The equipment is not suitable for operation in areas where there

is an explosion hazard.

• The Harmony Nexus Equipment Management System is not

suitable for use in the presence of a flammable anesthetic

mixture with air or with oxygen or nitrous oxide.

• The ambient temperature during operation must be kept

between 50 and 104°F (10 and 40°C)

• Relative humidity should stay within a range of 30 to 75%.

• Atmospheric pressure should stay within a range of 0.7 to 1.05

atm STD atmospheric pressure (700 to 1060 hPa).

ii

10023649 Installation Instructions Introduction

Page 4

The base language of this document is

ENGLISH. Any translations must be

made from the base language document.

STERIS Corporation,

Montgomery, Alabama is an

ISO 13485 certified facility.

STERIS Corporation

2720 Gunter Park East

Montgomery, AL 36109 • USA

Class 1 Equipment

Type B Equipment

Ordinary Equipment (enclosed equipment without

protection of ingress of water)

Equipment not suitable for use in the presence of a

flammable anesthetic mixture with air or oxygen or nitrous

oxide.

Suitable for continuous operation.

Canada Only:

Nonflammable medical gas pipeline systems shall comply

with CSA Z7396-1.

Electrical installations in healthcare facilities shall comply

with CSA C22.1 and CAN/CSA-Z32.

Anesthetic gas scavenging systems shall comply with

CSA Z7396.2.

Introduction Installation Instructions 10023649

iii

Page 5

TABLE OF CONTENTS

Section

Number Title Page

1 Safety Precautions................................................................................................................1-1

2 Installation Checklist............................................................................................................2-1

2.1 Tools Required.............................................................................................................................2-1

2.2 Hardware Required...................................................................................................................... 2-1

3 Verify Support Structure ......................................................................................................3-1

4 Overview of Mounting Method.............................................................................................4-1

5 Identifying Mounting Plate Type & Canopy Type...............................................................5-1

5.1 Mounting Plate Type ....................................................................................................................5-1

5.2 Canopy Types.............................................................................................................................. 5-1

5.3 Overview of Mounting Configurations..........................................................................................5-2

6 Mounting Details for the Various Configurations..............................................................6-1

6.1 Tandem Mount Unit – Hood Type Canopy................................................................................... 6-1

6.2 Tandem Mount Unit – Flush Mount Type Canopy ....................................................................... 6-1

6.3 Gas Riser Mounting ...... ... ... ... .... ...................................... .... ... ... ... ... ............................................6-1

7 Installation.............................................................................................................................7-1

7.1 Install Harmony Nexus Equipment Management System............................................................7-2

7.2 Install Bottom Column Cover ..................................................................................................... 7-15

7.3 Install Shelves............................................................................................................................7-17

8 Leveling Column...................................................................................................................8-1

8.1 Leveling Checklist ...................................... ... ............................................................................... 8-1

8.2 Leveling Column .............................................. ... .... ... ... ... ....................................... ... ... ...............8-2

9 Adjustments ..........................................................................................................................9-1

9.1 Adjust Column/Support Head Swivel Adjustment ........................................................................ 9-1

9.2 Adjust Friction Brakes – Column.................................................................................................. 9-2

10 Utility Connections .......................................................................................................... ...10-1

10.1 Final Connection of Gas Services.............................................................................................. 10-1

10.2 Final Connection of Electrical Services......................................................................................10-3

Table of Contents Installation Instructions 10023649

v

Page 6

TABLE OF CONTENTS (CONT’D)

Section

Number Title Page

11 Final Checkout ....................................................................................................................11-1

11.1 General ...................................................................................................................................... 11-1

11.2 Test Instrumentation Required...................................................................................................11-1

11.3 Functional Test.............. ... ... ... .... ...................................... .... ... ... ... ... .......................................... 11-1

11.4 Electrical Test............................................................................................................................. 11-1

11.5 Supply Lines Check ................................................................................................................... 11-2

11.6 Leak Test (not provided by STERIS) .........................................................................................11-2

vi

10023649 Installation Instructions Table of Contents

Page 7

LIST OF FIGURES

Figure Title Page

Figure 3-1. Above-Ceiling Support Structure......................................................................................................... 3-2

Figure 3-2. Ceiling Opening for Canopy Mount ..................................................................................................... 3-3

Figure 3-3. Ceiling Access Requirements.............................................................................................................. 3-4

Figure 4-1. Overview of Mounting Details.............................................................................................................. 4-1

Figure 5-1. Mounting Plate Types..........................................................................................................................5-1

Figure 5-2a. Canopy Types ...................................................................................................................................5-1

Figure 5-2b. Typical Mounting Configurations .......................................................................................................5-2

Figure 6-1. Gas Riser Detail .................................................................................................................................. 6-2

Figure 6-2. Plan View from Ceiling ........................................................................................................................6-4

Figure 9-1. Swivel Adjustments ............................................................................................................................. 9-1

Figure 9-2. Friction Brake Assembly...................................................................................................................... 9-2

Figure 10-1. Gas Riser (Detail View) ................................................................................................................... 10-2

Figure 10-2. 6 x 6 Junction Box Detail.................................................................................................................10-4

Figure 10-3. Position Junction Box Over Access Hole......................................................................................... 10-5

Figure 10-4. Position Plate Under Access Hole...................................................................................................10-5

Figure 10-5. Attach Divider .................................................................................................................................. 10-6

Figure 10-6. Secure Chassis Ground Wire..........................................................................................................10-7

Figure 10-7. Secure Metal Conduit to Junction Box ............................................................................................ 10-8

Figure 10-8. Wire Detail.......................................................................................................................................10-9

Table of Contents Installation Instructions 10023649

vii

Page 8

LIST OF TABLES

Table Title Page

Table 1-1. Definition of Symbols.............. ... ... ....................................... ... .... ... ... ... ...............................................1-3

Table 6-1. Gas Riser/Dust Cap Part Numbers ....................................................................................................6-3

Table 7-1. Column Capacity .......................................... ....................................................................................7-17

Table of Contents Installation Instructions 10023649

ix

Page 9

1

!

!

!

!

!

!

!

SAFETY PRECAUTIONS

The following Safety Precautions must be observed when operating or servicing the Harmony Nexus™ Equipment

Management System. WARNING indicates the potential for personal injury and CAUTION indicates the potential

for damage to equipment. For emphasis, certain Safety Precautions are repeated throughout the manual. It is

important to review ALL Safety Precautions before operating or servicing the unit.

Strictly following these Safety Precautions enhances the Customer’s ability to safely and effectively utilize the unit

and helps avoid improper maintenance methods which may damage the unit or render it unsafe. It is important to

understand that these Safety Precautions are not exhaustive; Customers are encouraged to develop their own

safety policies and procedures to enhance and complement these Safety Precautions.

WARNING – EXPLOSION HAZARD:

The ceiling mount system must not be installed where flammable gases or anesthesia are or will be

used. This equipment is not designed for use in a hazardous location as defined in National Fire

Protection Association (NFPA) Flammable Anesthetics Code.

WARNING – PERSONAL INJURY HAZARD:

1

After shipping frame and skid have been dismantled, unit can rotate freely. Do not lean against and/or

use mounted unit for support.

Ensure ceiling gas supply lines are depressurized before removing protecti ve caps.

Connecting electrical equipment to the multiple socket outlet (MSO) effectively leads to creating a

medical electrical (ME) system, and the result can be a reduced level of safety.

WARNING – ELECTRIC SHOCK AND BURN HAZARD:

Disconnect all utilities to the unit before installation. Do not install unless all utilities have been properly

locked out. Always follow OSHA lockout-tagout and electrical safety related work practice standards.

To avoid the risk of electric shock, this equipment must only be connected to a supply mains protective

earth.

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD:

Repairs and adjustments to this equipment should be made only by fully qualified service personnel.

Maintenance performed by inexperienced, unqualified personnel or installation of unauthorized parts

could cause personal injury, invalidate the warranty or result in costly damage. Contact STERIS Service

Engineering representative regarding service options.

Safety Precautions Installation Instructions 10023649

1-1

Page 10

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD (CONT’D):

!

!

!

!

!

!

!

!

!

!

Always lift the assembly of the Equipment Management System (EMS) where indicated by the "Lift Here"

label applied to the packaging. Failure to lift the assembly where indicated could cause the unit to fall

from the forks, causing equip ment damage or personal injury.

Verify air source supplying air to the pneumatic brake system. Lockout/tagout the air source for the

particular EMS unit be fore servicing.

Do not exceed maximum shelf load. Refer to Table 7-1.

The unit and shipping materials weigh approximately 1,000 lb (454 kg). To ensure safety, adequately

rated equipment must be used to move or lift unit.

Two people are required to install the shelf.

CAUTION – POSSIBLE EQUIPMENT DAMAGE:

Do not remove arm support shipping brack et s or shipping fr ame fr om skid. Set up of supply colu mn m ust

be conducted with protective packaging intact.

Carefully rotate support head when adjusting rotational stops. Rotating the support head completely

around (360°) will twist and kink gas lines and electrical wires located inside the column.

Care should be taken not to damage bolts when lifting main unit.

Be careful not to drop any hardware into the mouth of the distance tube.

Never set up supply column without the packaging protection.

1-2

10023649 Installation Instructions Safety Precautions

Page 11

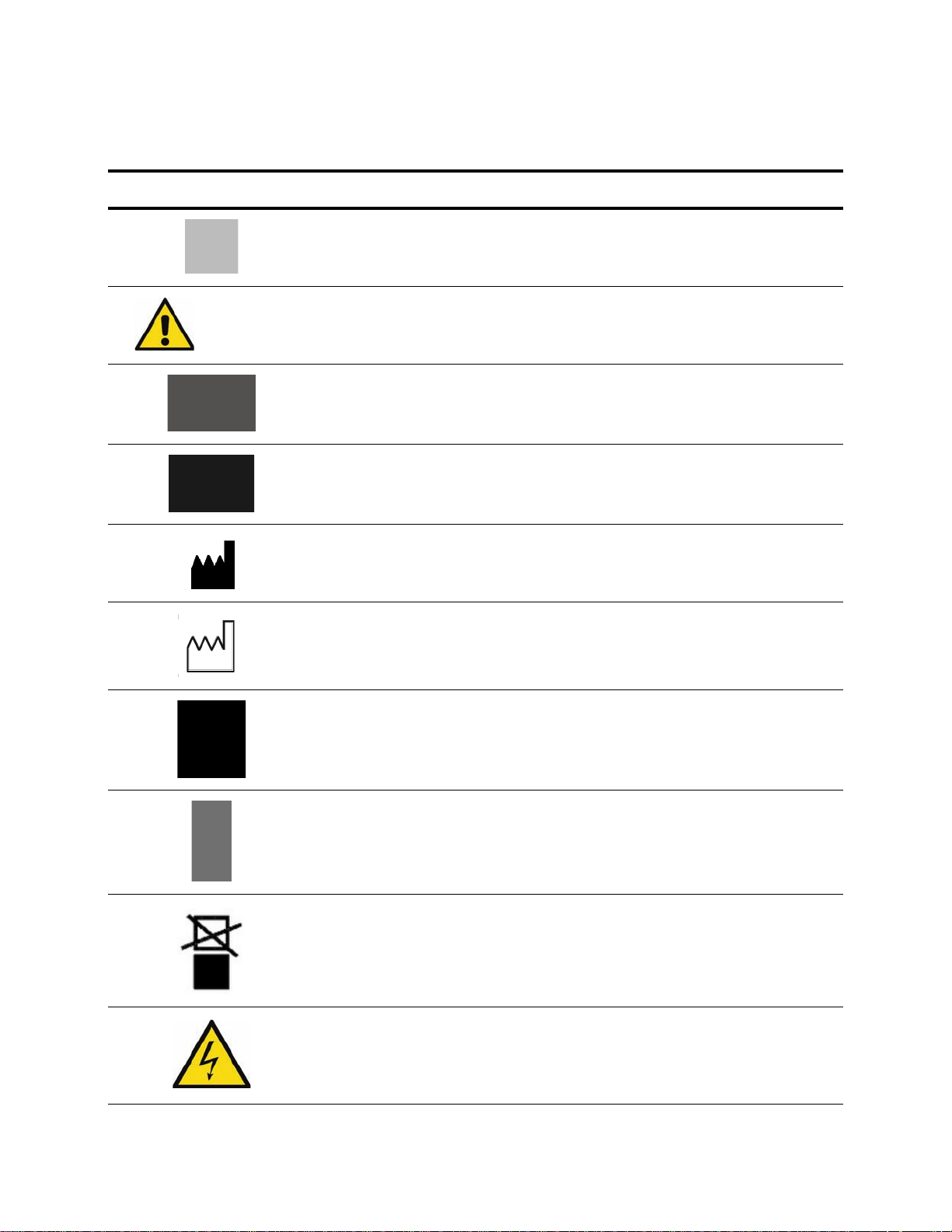

The following symbols may appear on the Harmony Nexus Equipment Management System and packaging:

Table 1-1. Definition of Symbols

Symbol Definition

Protective Earth (Ground)

Attention, consult manual for further instructions

or

Serial Number of Unit

Equipment or Reorder Number

Symbol indicating the legal manufacturer name and address

Symbol indicating the date of manufacture (yyyy/mm)

Keep dry

Fragile, handle with care

Do not stack

Symbol indicating high voltage

Safety Precautions Installation Instructions 10023649

1-3

Page 12

Table 1-1. Definition of Symbols (Continued)

Symbol Definition

V~ Voltage Rating of Unit, Alternating Current

A Amperage Rating of Unit

Hz Frequency Rating of Unit

1-4

10023649 Installation Instructions Safety Precautions

Page 13

INSTALLATION CHECKLIST

2

2.1 Tools Required

2.2 Hardware Required

• Lifting device (e.g., Genie® Lift™1) with minimum 600 lb (272 kg)

capacity. If Equipment Management System (EMS) unit is

greater than 600 lb (272 kg), then two lifting devices are

required.

• P764331-622, Lift, Material Genie, 350 lb (159 kg)

• P764331-944, Genie Superlift, 650 lb (295 kg)

• Spirit level or digital level (P764335-021, Digital Level)

• Open-end wrenches 19 mm, 24 mm and 30 mm

• Torque wrench with standard and metric sockets

• Metric Allen wrench set

• Multimeter capable of measuring volts and ohms

• Volumetric Pressure Gauge

®

• LOCTITE

0.5 mL pouch)

• Leak Detection Fluid

• Screwdrivers

The hardware listed below is referenced in these instructions. It is

required for proper installation of this equipment, and is provided by

STERIS unless otherwise noted.

242 (R005300-554 bottle, or 129377-290 single use

2

❑ 7/8-9 UNC x 16" long allthread ASTM A354 Grade BD steel alloy

(or SAE Grade 8), six required

❑ 7/8" flat washer, 24 required

❑ 7/8" lock washer, 12 required

❑ 7/8-9 UNC nuts, ASTM A354 grade BD (or SAE grade 8)

steel alloy, 48 required

❑ Structural framework (not provided by STERIS)

❑ Structural mounting plate (not provided by STERIS)

❑ Two 6.0" (152 mm) dia. access holes required in center of plate

❑ Support hangers (not provided by STERIS)

❑ 24 x 24" (610 x 610 mm) access panel (not provided by STERIS)

1. Genie® Lift™ is a registered trademark of Genie Industries, a Terex Company.

2. LOCTITE

Installation Checklist Installation Instructions 10023649

®

is a registered trademark of Henkel Corporation.

2-1

Page 14

!

!

VERIFY SUPPORT STRUCTURE

Before installing the Harmony Nexus™ Equipment Management

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: Unit and shipping

materials weigh approximately

1000 lb (454 kg). To ensure safety,

adequately rated equipment must

be used to move or lift unit.

CAUTION – POSSIBLE

EQUIPMENT DAMAGE: Care

should be taken not to damage

bolts when lifting main unit.

System:

1. Verify Customer’s ceiling mount meets dimensions as specified

in Figure 3-1 and Figure 3-2.

2. Verify that hardware is on site (either in the room where the EMS

unit is to be installed or hanging from the structural mounting

plate). If hardware cannot be located, contact STERIS.

3

Verify Support Structure Installation Instructions 10023649

3-1

Page 15

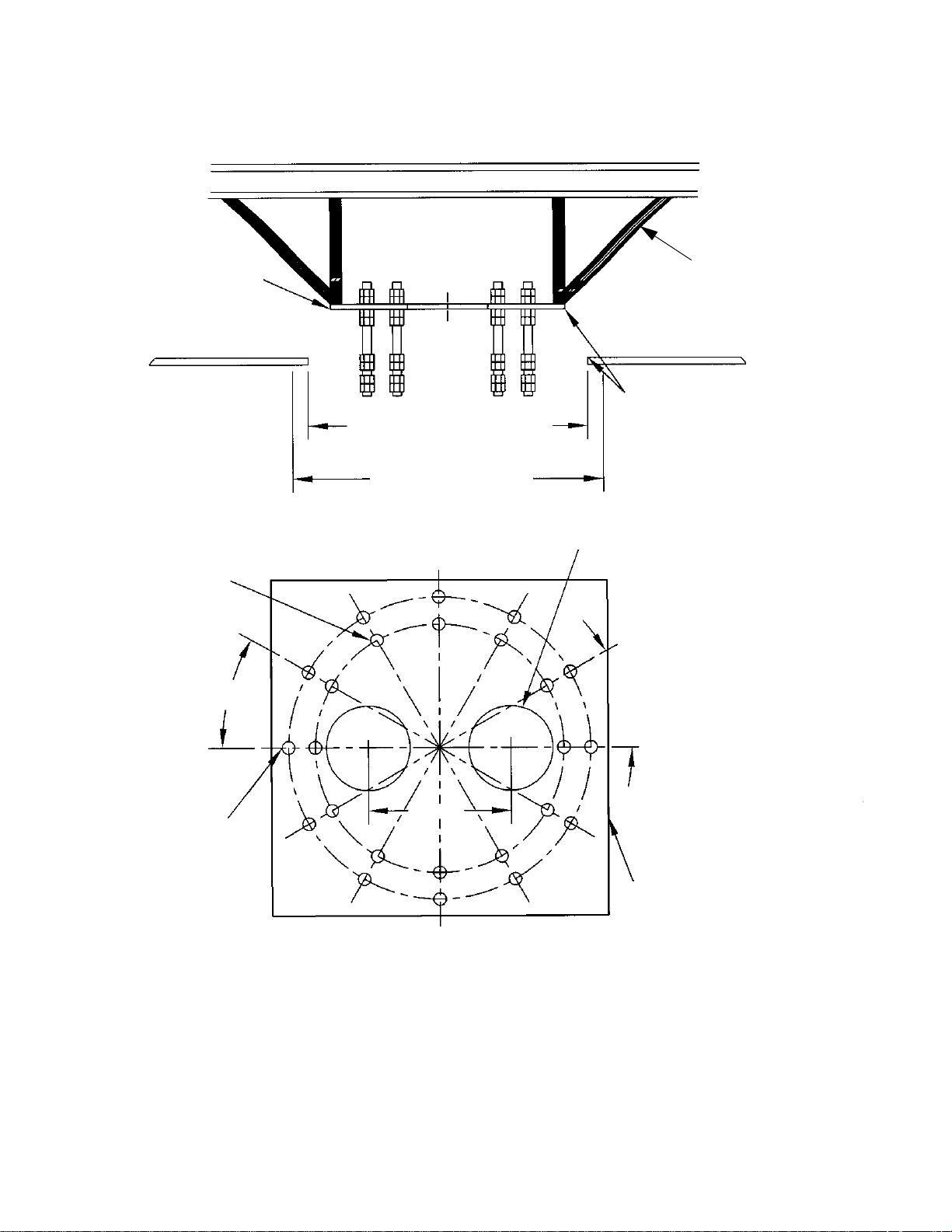

Structural Mounting Plate

( May Be Provided by

STERIS)

Structural Bracing

(Not provided by STERIS)

23" (584 mm) Square Rough

Opening in Finished Ceiling

23-5/8" (600 mm) Square Required

Area for Canopy Hood

IMPORTANT:

Ensure that plate is installed with

edges parallel to 23" (584 mm) square

rough opening in finished ceiling.

Single Mount Unit Bolt Hole Pattern

Shown on 18.500 B.C.

30° Typ.

Tandem Mount Unit Bolt Hole

Pattern

15/16" Through, 12 Equally

Spaced as Shown on 22.500 B.C.

6.0" Dia. Through Holes, two Required

(Provided by STERIS)

30° Typ.

Structural Mounting Plate

(Provided by STERIS)

10.63

(270 mm)

3-2

10023649 Installation Instructions Verify Support Structure

Figure 3-1. Above-Ceiling Support Structure

Page 16

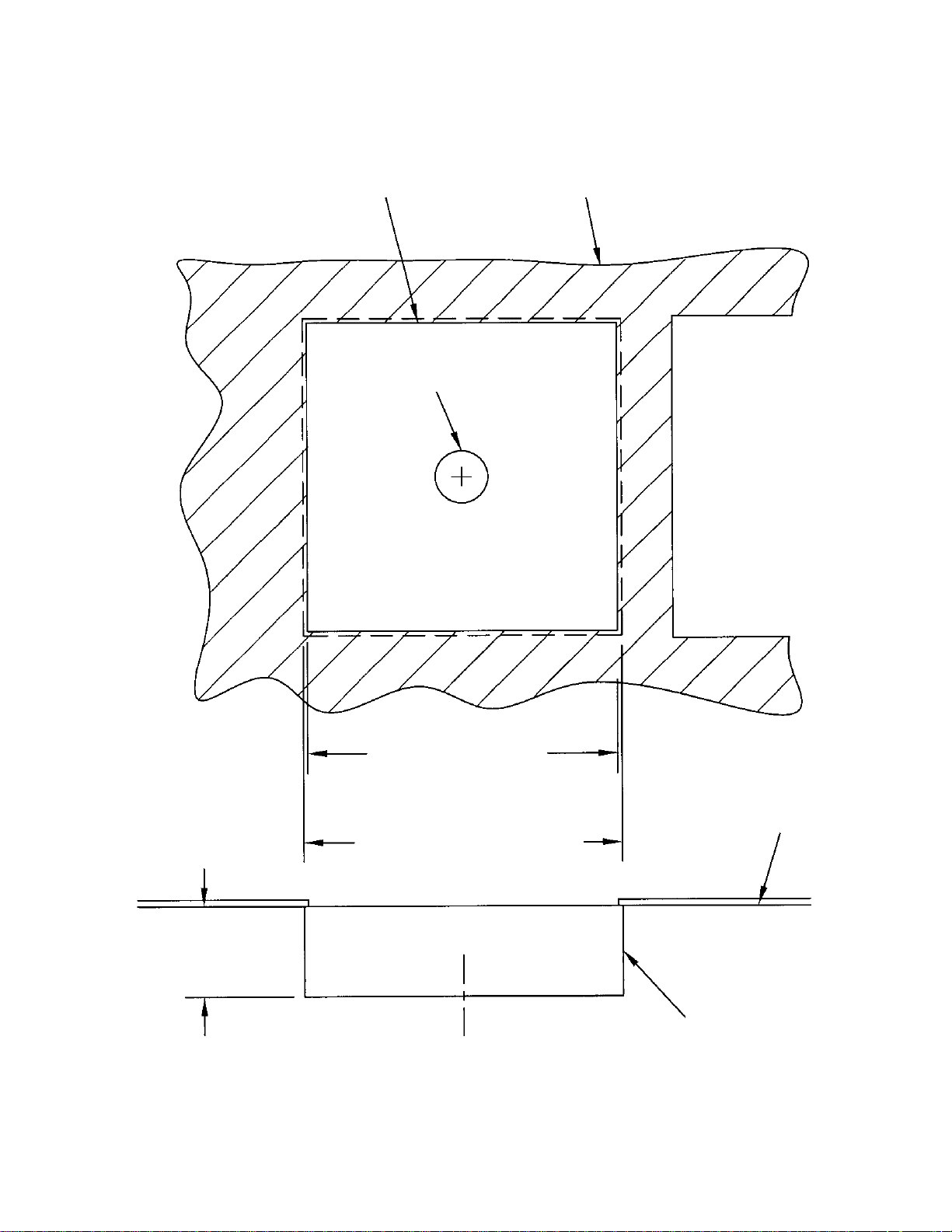

Ref. Hole in Finished Ceiling

Finished Ceiling

Hole in Canopy Hood

Access Opening 24 x 24"

(610 x 610 mm) for Access

to Above Ceiling Hardware

23" (584 mm) Square Rough

Opening in Finished Ceiling

23-5/8" (600 mm) Square Required Area

for Canopy Hood

3.56" (90.4 mm) Ref.

Finished Ceiling

Canopy Hood

(Provided by STERIS)

Verify Support Structure Installation Instructions 10023649

Figure 3-2. Ceiling Opening for Canopy Mount

3-3

Page 17

Figure 3-3. Ceiling Access Requirements

3-4

10023649 Installation Instructions Verify Support Structure

Page 18

OVERVIEW OF MOUNTING METHOD

4

Figure 4-1. Overview of Mounting Details

Overview of Mounting Method Installation Instructions 10023649

4-1

Page 19

A

B

IDENTIFYING MOUNTING PLATE TYPE & CANOPY TYPE

5.1 Mounting Plate

5

Single mount plate (see Figure 5-1).

Typ e

Figure 5-1. Mounting Plate Types

5.2 Canopy Types

There are two types of canopies

a. Canopy Hood – for a single mount unit

b. Flush Mount – for a single mount unit

Figure 5-2a. Canopy Types

Identifying Bearing/Ceiling Plate Type & Canopy Type Installation Instructions 10023649

5-1

Page 20

Figure 5-2b. Typical Mounting Configurations

Flush Mount

Type Canopy

Hood Type Canopy Mount

5.3 Overview of

Mounting

Configurations

Harmony Nexus EMS mounting configurations are made up from

various combinations of the two types of mounting plates and the two

canopy types.

1. Single mount unit

• Mounting plate

• Hood type canopy

2. Single mount unit

• Mounting plate

• Flush mount type canopy

5-2

10023649 Installation Instructions Identifying Bearing/Ceiling Plate Type & Canopy Type

Page 21

MOUNTING DETAILS FOR THE VARIOUS CONFIGURATIONS

6.1 Gas Riser Mounting

6

• The Gas Riser Mounting Bracket must be installed on the

structural plate by using 1/4-20 UNC screws provided.

• 6" (152 mm) clearance is required above structural mounting

plate for gas supply hook-up.

Mounting Details for the Various Configurations Installation Instructions 10023649

6-1

Page 22

CAUTION – POSSIBLE

!

Gas Riser Bracket

(Provided by STERIS)

Gas Riser Bracket

(Provided by STERIS)

Male D.I.S.S. Fitting

w/Cap

Copper Tube

GAS RISER

(Provided by STERIS)

Structural Plate

(Provided by STERIS)

Support Hangers

(Not Provided by

STERIS)

Gas Riser Bracket

(Provided by STERIS)

Flexible Gas Hose

(Provided by STERIS)

6"

(152 mm)

16"

(406 mm)

6"

(152 mm)

Fire Wrap – If Required

(Not Provided by STERIS)

Finished Ceiling

Gas Riser

(Provided by STERIS)

Support Hanger

(Not Provided by STERIS)

Support

Structure

Structural Plate

(Provided by STERIS)

Gas Supply from

Zone Valve

EQUIPMENT DAMAGE: Do not

remove arm support shipping

brackets or shipping frame from

skid. Set up supply column must

be conducted with protective

packaging intact.

Figure 6-1. Gas Riser Detail

6-2

10023649 Installation Instructions Mounting Details for the Various Configurations

Page 23

Table 6-1. Gas Riser/Dust Cap Part Numbers

Gas Riser Part Number Gas Dust Cap Part Number

136812-668 WAGD 150824-808

136812-669 Oxygen 150824-807

136812-670 Vacuum 150824-806

136812-671 Med Air 150824-806

136812-672 Nitrogen 150824-806

136812-673 Carbon Dioxide 150824-806

136812-674 Nitrous Oxide 150824-806

Mounting Details for the Various Configurations Installation Instructions 10023649

6-3

Page 24

Ceiling Access Panel Located Between Gas

Riser and PES Vacuum Pump Motor for

Greatest Accessibility to Utility Connections

Access Panel

24 x 24" (610 x 610 mm)

1 Required

(Not Provided by STERIS)

PES Vacuum

Pump Motor

Gas Riser (Provided by

STERIS)

2' (1 m) Max.

Gas Riser Bracket

(Provided by STERIS)

Support Structure

Figure 6-2. Plan View from Ceiling

6-4

10023649 Installation Instructions Mounting Details for the Various Configurations

Page 25

Harmony Nexus

Equipment Management System

INSTALLATION

Personnel Required: (Two)

7

Personal Protective Equipment Required:

• Safety Goggles or Safety Glasses

• Gloves • Steel-Toe Shoes • Hard Hat

Special Tools:

• Lifting device (e.g., Genie® Lift™1) with minimum 600 lb (272 kg) capacity. If Equipment Management System

(EMS) unit is greater than 600 lb (272 kg), then two lifting devices are required.

• P764331-622, Lift, Material Genie, 350 lb (159 kg) capacity

• P764331-944, Genie Superlift, 650 lb (259 kg) capacity

• Spirit level or digital level (P764335-021, Digital Level)

• Open-end wrenches 19 mm, 24 mm and 30 mm

• Torque wrench with standard and metric sockets

• Metric Allen wrench set

• Multimeter capable of measuring volts and ohms

• Volumetric Pressure Gauge

®

• LOCTITE

• Leak Detection Fluid

• Screwdrivers

242 (R005300-554 bottle, or 129377-290 single use 0.5 mL pouch)

2

1. Genie® Lift™ is a registered trademark of Genie Industries, a Terex Company.

2. LOCTITE

Installation Installation Instructions 10023649

®

is a registered trademark of Henkel Corporation.

7-1

Page 26

7.1 Install Harmony

STEP

1

Mounting Hardware and

Accessories Package

(May Consist of

Multiple Packages)

Nexus Equipment

Management System

Step 1: Remove separate packages, miscellaneous mounting hardward and/or unattached

7-2

10023649 Installation Instructions Installation

accessories from shipping container.

NOTE: Do not remove brackets/supports that hold the unit to the skid.

NOTE: Verify all audio/visual cabling is present per sales order.

Page 27

STEP

2

NOTE: Dimensions

are in inches.

Step 2: Install intermediate plate and canopy mounting plate to support structure.

7-3

Installation Installation Instructions 10023649

Page 28

STEP

3

7/8" All Thread

7/8" Nut (x2)

7/8" Flat Washer

Step 3: Install All Thread, 7/8" nuts and 7/8" washers around the structure plate.

7-4

10023649 Installation Instructions Installation

Page 29

STEP

4

7/8" Nut

7/8" Flat Washer

7/8" Lock Washer

Lower Mounting

Plate Hardware

Step 4: Install All Thread, 7/8" nuts, 7/8" flat washers and 7/8" lock washers surrounding the

bottom of structure plate.

• Install lower 7/8" nuts and 7/8" flat washers such that the top of mount plate is 6-8"

(152-203 mm) below bottom of structure plate.

Installation Installation Instructions 10023649

7-5

Page 30

STEP

5

7/8" Flat Washer

7/8" Lock Washer

7/8" Regular Nut

M5 Flat Washer

M5 Lock Washer

M5 Screw

NOTE: Slots in canopy

mounting plate are arc

shaped to allow for

canopy alignment with

ceiling opening.

Step 5: Raise mount plate up to the lower mounting hardware.

• Install 7/8" nuts, flat washers and lock washers on bottom of mount plate.

• Level mount plate using three or four nuts.

• When mounting plate is level, tighten remaining nuts.

• Torque all 7/8" hardware to 80 ft•lb (356 N•m).

7-6

10023649 Installation Instructions Installation

Page 31

STEP

6

M16 Regular Nut

M16 Flat Washer

M16 Lock Washer

M16 Regular Nut

Step 6: Thread M16 All Thread into threaded holes in mounting plate.

• Install M16 lock washers and M16 regular nuts in order to secure M16 All Thread to

mounting plate.

• Install M16 nuts and flat washers such that top of mounting plate is 3.25" (83 mm) from

top of drop tube weldment.

Installation Installation Instructions 10023649

7-7

Page 32

STEP

7

Step 7: On unit, arrange hoses and cables so they do not cross one another.

7-8

10023649 Installation Instructions Installation

Page 33

STEP

8

Flange

Shipping Frame

Shipping Skid

Important: Lifting Equipment Must Be Rated

for at Least 600 lb (272 kg). Two Lifts Are

Required If EMS Unit Is Heaver Than 600 lb

(272 kg).

Step 8: Use lifting device to raise unit, including shipping frame and skid, to a height where all

mounting bolts can be aligned with holes in unit upper mount. Align bolts with upper

mount, then raise unit.

• Thread cables and hoses through center of ceiling plate.

• Raise unit fully.

Installation Installation Instructions 10023649

7-9

Page 34

STEP

9

Cotter Pin

M16 Lock Washer

M16 Regular Nut

Step 9: Install M16 lock washers and M16 regular nuts in order to secure M16 drop tube

weldment.

• Install cotter pins on bottom of All Thread (four places).

7-10

10023649 Installation Instructions Installation

Page 35

STEP

10

Step 10: Dismantle shipping crate and lower skid.

• Verify distance tube flange is secured with lock washers, nuts and cotter pins.

• Level column with nuts surrounding distance tube flange.

• Level drop tube weldment as described in Section 8.

• After leveling procedure, tighten all mounting hardware to 80 ft•lb (356 N•m).

7-11

Installation Installation Instructions 10023649

Page 36

STEP

11

M5 Threaded Rod

M5 Flat Washer

M5 Jam Nut

Step 11: Install six M5 threaded rods into canopy mounting plate for canopy cover mounting.

• Install M5 flat washer and jam nut at approximately 1-1/2" (38 mm) from upper end of

threaded rod.

7-12

10023649 Installation Instructions Installation

Page 37

STEP

12

M5 Jam Nut

M5 Adapter Nut

Measure 3.19" from Ceiling

Step 12: Install adapter nuts into threaded rods approximately 1/2" to 5/8".

• Lock adapter nut in place with M5 jam nut.

NOTE: For hood type canopy, adapter should hang 3.19" below ceiling. For flush mount type

canopy, adapter should hang 0.44" below ceiling.

• After verifying clearance, use upper M5 jam nut to lock threaded rods in position.

Installation Installation Instructions 10023649

7-13

Page 38

STEP

13

Canopy Seal

M5 Flat Washer

M5 Lock Washer

M5 Screw

M5 Lock Washer

M5 Screw

Step 13: Place two halves of canopy hood around bearing and connect them with four sets of M5

hardware (screw, flat washer, lock washer).

• Thread canopy seal onto upper surface of canopy wall.

• Raise canopy hood and insert M5 screws through hood into adapter nuts on M5

threaded rods installed previously.

• Tighten screws.

7-14

10023649 Installation Instructions Installation

Page 39

7.2 Install Bottom

STEP

1

Threaded Rods

(x2)

STEP

2

Washer

Nut

Column Cover

Step 1: Insert two flat rods with threaded rods into column such that threaded rods drop out of

column.

Step 2: Attach bracket with washers and nuts.

7-15

Installation Installation Instructions 10023649

Page 40

STEP

3

Screws (x4)

Step 3: Place cover onto bottom and secure with four screws.

7-16

10023649 Installation Instructions Installation

Page 41

7.3 Install Shelves

STEP

1

Mounting Clamps

Washers (x8)

Screws (x8)

!

WARNING – PERSONAL INJURY AND/OR EQUIPMENT DAMAGE HAZARD: Two people are

required to install the shelf.

Step 1: Lift shelf to desired height. Use lifting device if necessary.

• Position mounting clamps on opposite side of rails.

• Secure mounting clamps with washers (x8) and screws (x8).

Table 7-1. Column Capacity

45" (1143 mm), 35" (889 mm) and 25" (635 mm) Length Column Weight Capacity without Accessories

Number of Shelves Average Weight Load Per Shelf

5 38 lb (17 kg)

4 56 lb (25 kg)

3 85 lb (39 kg)

Do not exceed maximum shelf load of 85 lb (39 kg).

The maximum loading for column is the average of the loaded weight per shelf times number of shelves. Do not exceed

maximum weight of 85 lb (39 kg) on a single shelf. Maximum column load is 350 lb (159 kg) which includes 32 lb (14.5 kg)

for each shelf plus weight of equipment.

7-17

Installation Installation Instructions 10023649

Page 42

STEP

2

Step 2: Installation complete.

7-18

10023649 Installation Instructions Installation

Page 43

Harmony Nexus

Equipment Management System

LEVELING COLUMN

8.1 Leveling Checklist

8

Personnel Required: (Two)

Personal Protective Equipment Required:

• Safety Goggles or Glasses

•Gloves

• Steel-Toe Shoes

•Hard Hat

Parts Required:

• Shelf/Shelves

Special Tools:

• Genie

®

Lift™

1

• Ladder (8’ [2 m])

• Spirit Level or Digital Level (

P764335-021, Digital Level)

• Weight Scale

• 24 mm wrench

1. Genie® Lift™ is a registered trademark of Genie Industries, a Terex Company.

8-1

Leveling Column Installation Instructions 10023649

Page 44

8.2 Leveling Column

STEP

1

Step 1: Place digital level on column.

• Adjust nuts until column is level.

8-2

10023649 Installation Instructions Leveling Column

Page 45

Setscrew

Fixed Stop

ADJUSTMENTS

9

9.1 Adjust Column/

Support Head Swivel

Adjustment

See Figure 9-1.

NOTE: The swiveling range of the supply column is 320° and can be

limited up to 50° (45° increment).

1. To set swiveling range, loosen two screws in ring above top

column cover and lift up to allow access to bearing.

NOTE: Perimeter of bearing has 14 M8 threaded holes. A M8

socket head cap setscrew with washer is screwed into one of the

holes as a stop.

Figure 9-1. Swivel Adjustments

2. To limit swiveling range further, insert an additional screw

accordingly or relocate existing second stop screw (supplied

with product) to the desired location.

3. Reinsert top column cover onto supply column.

Adjustments Installation Instructions 10023649

9-1

Page 46

9.2 Adjust Friction Brakes – Column

See Figure 9-2.

Loosen two screws in ring above top column cover and lift up to

access brake.

NOTE: There are setscrews that adjust the friction brake. Adjust

middle screw first. If braking is still insufficient, adjust outer

setscrews.

Figure 9-2. Friction Brake Assembly

9-2

10023649 Installation Instructions Adjustments

Page 47

!

UTILITY CONNECTIONS

10

10.1 Final Connection of Gas Services

WARNING–PERSONAL

INJURY HAZARD: Ensure

ceiling gas supply lines are

depressurized before

removing protective caps.

1. Locate gas lines with Diameter Index Safety System (D.I.S.S.)

connectors protruding from the bearing plate of the Harmony

Nexus Equipment Management System.

2. Match gas type coding connectors of Harmony Nexus EMS with

those projecting downward from ceiling plate.

3. Connect gas lines:

a. Remove plastic bag and protective caps from ceiling supply

lines on connectors of Harmony Nexus EMS.

NOTE: DISS con nectors are size inde xed to prevent inte rconnection

of incorrect gas lines. If connectors do not ma te easily, do not force.

Check gas type coding, stamped on side of fitting, before p roceedin g.

b. Connect gas lines of Harmony Nexus EMS to ceiling supply

lines. Tighten fittings securely and test for leaks.

Normal Settings

• Nitrogen – Supply gauge 160 psi ± 2% accuracy

• Instrument air: 125 psi ± 2% accuracy

Gauge Information

• Range: 1-300 psi

• Accuracy: 0-100 ± 3%

100-200 ± 2%

200-300 ± 3%

4. Once all gas lines have been connected, set gas supply lines

away from any moving parts on or around the bearing plate and

junction boxes.

Utility Connections Installation Instructions 10023649

10-1

Page 48

Support Hangers

(Not Provided by STERIS)

Gas Riser Bracket

(Provided by STERIS)

Structural Plate

(Provided by STERIS)

6"

(152 mm)

Flexible Gas Hose

(Provided by STERIS)

Hose

Latch Rough-In

Trim

Latch Valve

Copper Tube

Male D.I.S.S. Fitting w/Cap

DETAIL – Gas Riser

(or Pipette)

16"

(406 mm)

6"

(152 mm)

Gas Riser Bracket

Figure 10-1. Gas Riser (Detail View)

10-2

10023649 Installation Instructions Utility Connections

Page 49

10.2 Final Connection

!

of Electrical Services

WARNING – ELECTRIC

SHOCK AND BURN HAZARD:

• Disconnect all utilities to the

unit before installation. Do not

install unless all utilities have

been properly locked out.

Always follow OSHA lockouttagout and electrical safety

related work practice

standards.

• To avoid the risk of electric

shock, this equipment must

only be connected to a supply

mains protective earth.

NOTE: Qualification:

• Electrical connection of the EMS system may only be performed

by a qualified electrician.

• Verify OR room is equipped with an isolation transformer.

• Please observe all applicable safety precautions. Review

ECTION 1, SAFETY PRECAUTIONS.

S

• Prewired circuits are contained in flexible conduits.

• The number of circuits and how they are divided is dependent

upon each individual user’s requirements.

• The circuits and conductors are identified, specified and listed

on the equipment data plate.

NOTE: Construction Detail: When wire stripping is required, the strip

length should be 8mm (5/16”). Str ay wir e st ra n ds a r e n ot pe r mit te d t o

be outside the crimp nuts. See Figure 10-8.

Utility Connections Installation Instructions 10023649

10-3

Page 50

Figure 10-2. 6 x 6 Junction Box Detail

1. Locate hardware kit P/N P129387-619 (provided by STERIS)

consisting of:

P093933-105 –Junction Box –Bottomless (6 x 6"), Qty. 1

P124290-106 –Screw 1/4"-20 UNC x 0.5" long, Qty. 8

P150824-544 –Lock Washer 1/4", Qty. 8

P093933-104 –Divider –Junction Box, Qty. 1

P093933-098 –Plate, Junction Box – Bottom, Qty. 1

2. Locate junction box –bottomless 6 x 6” (152 x 152 mm).

3. Position junction box over one of the two 6” (152 mm) dia.

access holes on top surface of structural plate holes. See Figure

10-3.

10-4

10023649 Installation Instructions Utility Connections

Page 51

Figure 10-3. Position Junction Box Over Access Hole

4. Secure junction box using two screws 1/4”-20 UNC x 0.5” long.

5. Locate junction box bottom plate.

6. Position plate under the same 6” (152 mm) dia. access hole on

the bottom surface of structural plate holes. See Figure 10-4.

Figure 10-4. Position Plate Under Access Hole

7. Secure small plate to bottom surface of large structural plate

using four screws 1/4”-20 UNC x 0.5” long by inserting screws

into existing tapped holes in structural plate. See Figure 10-3

8. Attach divider (if required) by using #8-32 UNC x 3/8 screws

(provided by STERIS). See Figure 10-4.

Utility Connections Installation Instructions 10023649

10-5

Page 52

Figure 10-5. Attach Divider

Connect Duplex/Simplex Circuits

9. Knock out one (of 10 provided) 7/8" dia. access holes in junction

box bottom plate.

10. Carefully route electrical conduit up to bottom plate and insert

stranded conductors through the 7/8" dia. hole.

11. Secure (bulkhead mount) flexible conduit connector(provided by

STERIS) to bottom plate using plastic nut (provided by STERIS).

12. Secure green chassis ground wire (running external to black

flexible conduit) using 1/4" green ground screw and 1/4" star

washer (provided by STERIS) to bottom surface of Customer

support structure plate. See Figure 10-6.

13. Use crimp nuts (provided by STERIS) to securely connect each

circuit to power supply.

14. Locate Customer supplied dedicated ground wire and run wire

to ground screw on structural plate. See Figure 10-6.

10-6

10023649 Installation Instructions Utility Connections

Page 53

Figure 10-6. Secure Chassis Ground Wire

15. Verify resistance between ground screw and junction boxes

does not exceed 0.1 Ohm.

16. Run a continuity test on all electrical connections.

17. Run an insulation test per conduit.

18. Replace access panel.

19. Turn electrical supply ON.

20. Verify all circuits are operating properly by measuring output

voltages.

21. Turn electrical supply OFF.

NOTE: Customer must bring power via Customer supplied metal

conduit to junction box (provided by STERIS)

a. Knock out the 7/8" dia. access holes in the side of junction

box. See Figure 10-2 and Figure 10-7.

b. Secure Customer supplied metal conduit to junction box.

Utility Connections Installation Instructions 10023649

10-7

Page 54

Figure 10-7. Secure Metal Conduit to Junction Box

!

Important: Verify all electrical power is OFF before making final

connection. Review S

WARNING – ELECTRIC SHOCK AND BURN HAZARD:

• Disconnect all utilities to the unit before installation. Do not

install unless all utilities have been properly locked out.

Always follow OSHA lockout-tagout and electrical safety

related work practice standards.

• To avoid the risk of electric shock, this equipment must only

be connected to a supply mains protective earth.

NOTE: Stranded conductors installed by Customer must be filled with

wire end connector sleeves or via use of a crimp nut.

NOTE: A terminal block is not provided by STERIS.

c. Connect power supply lines using Customer supplied onsite

circuit diagram and in conjunction with STERIS circuit

diagram. See Figure 10-8.

d. Use crimp nuts to securely connect circuit to above ceiling

electrical supply.

ECTION 1, SAFETY PRECAUTIONS.

10-8

10023649 Installation Instructions Utility Connections

Page 55

Figure 10-8. Wire Detail

Utility Connections Installation Instructions 10023649

10-9

Page 56

!

FINAL CHECKOUT

11

11.1 General

WARNING – PERSONAL INJURY

AND/OR EQUIPMENT DAMAGE

HAZARD: Repairs and

adjustments to this equipment

should be made only by fully

qualified service personnel.

Maintenance performed by

inexperienced, unqualified

personnel or installation of

unauthorized parts could cause

personal injury, invalidate the

warranty, or result in costly

damage. Contact your STERIS

Engineering Service

representative regarding service

options.

11.2 Test

Instrumentation

Required

Every unit must be tested and inspected according to this procedure

whenever a part is adjusted, repaired or replaced. Items which do

not comply to test procedures must be corrected or retested.

Important: Complete and mail in the Pre-In-service Checkout Card –

P764331-894, to begin warranty period. Contact STERIS.

• Voltmeter

• Ohmmeter

• Calibrated volumetric pressure test gauge –

must read 0 to 200 psig (0 to 1,379 KpA)

11.3 Functional Test

11.4 Electrical Test

Final Checkout Installation Instructions 10023649

1. Compressed air (if applicable) may be contaminated. Verify

availability of nitrogen or industrial air.

2. Verify electrical supplies are connected to unit.

3. Verify rotational stops are set to prevent support head and

accessories from striking walls or other equipment.

1. Measure voltage at each electrical receptacle. Measured

voltage should be equal to voltage supplied to unit.

2. Check each grounding pin for impedance (0.1 ohms maximum).

11-1

Page 57

11.5 Supply Lines Check

1. Check gases, medical air and compressed air pressures

supplied to unit. Refer to equipment drawing for recommended

pressures.

2. Check correct gases are supplied to proper corresponding

outlets.

3. Inspect all lines for chafing or kinking. Damaged lines must be

replaced.

4. Using leak detection fluid, check all line connections for leaks.

NOTE: NFPA certification and/or verification of gas supply line s is not

by STERIS.

11.6 Leak Test (not

provided by STERIS)

Leak test, using clean, oil-free, dry Nitrogen, for all gas lines (during

test procedure) in accordance with applicable codes.

11-2

10023649 Installation Instructions Final Checkout

Loading...

Loading...