Page 1

ISO14001

(Hotaka plant)

ISO9001

AC Servo Actuator

SHA SG and CG series manual

Page 2

Introduction

Introduction

Thank you for purchasing our SHA series AC Servo Actuator.

• Improper handling or use of this product may result in an accident or reduced

life of the product. Read this document carefully and use the product correctly

so that the product can be used safely for many years to come.

• Product specifications are subject to change without notice.

• Keep this manual in a convenient location and refer to it as necessary when

operating or maintaining the actuator.

• The end user of the actuator should have a copy of this manual.

Page 3

SAFETY GUIDE

Indicates a potentiall y hazardous situation, which, if not avoided, could result

Indicates a potentially hazardous situation, which, if not avoided, may result in

Indicates what should b e performed or avoided to prevent non-opera tion or

Space equipment

Apparatus or devices used in special environments

WARNING

CAUTION

CAUTION

SAFETY GUIDE

To use this actuator safely and correctly, be sure to read SAFETY GUIDE and other parts of this

manual carefully. It is im portant to fully understand the information pro vided herein before using the

actuator.

NOTATION

Important safety information you must note is provided herein. Be sure to observe these instructions.

in death or serious personal injury.

minor or moderate personal injury and/or damage to the equipment.

LIMIT ATION OF APPLICATIONS

The equipment listed in this document may not be used for the applications listed below:

・

・Automobile, automotive parts

・Aircraft, aeronautic equipment

・Amusement equipment, sport equipment, game machines

・Nuclear equipment

・Machine or devices acting directly on the human body

・Household apparatus

・Instruments or devices to transport or carry people

・Vacuum equipment

・

If the above list includes your intended application, please consult us.

malfunction of the product or negative effects on its performance or function.

Safety measures are essential to prevent accidents resulting

in death, injury or damage of the equipment due to

malfunction or faulty operation.

3

Page 4

SAFETY GUIDE

CAUTION

WARNING

SAFETY NOTE

ITEMS YOU SHOULD NOTE WHEN USING THE ACTUATOR

• PRECAUTIONS FOR ACTUATORS AT THE APPLICATION DESIGN PHASE

Always use under followings conditions.

The actuator is designed to be used indoors. Observe the following conditions:

・ Ambient temperature: 0℃ to 40℃

・ Ambient humidity: 20% to 80%RH (Non-condensation)

・ Vibration: Max 25 m/s2

・ No contamination by water, oil

・ No corrosive or explosive gas

Follow the exact instructions in the related manuals to install

the actuator in the equipment.

・ Ensure precise alignment of the actuator shaft center and the

corresponding center in the application.

・ Failure to observe this caution ma y lead to vi brati on, r e s ulting in damage of

output elements.

• PRECAUTIONS FOR ACTUATORS IN OPERATION

Comply with the toque limits for the actuator.

・ Be aware, that if by accident, the arm attached to the output elem ent hits a

solid object, the output element may become uncontrollable.

Never connect cables directly to a power supply socket.

・ Each actuator must be operated with a proper driver.

・ Failure to observe this caution may lead to injury, fire or damage of the

actuator.

Do not apply impacts and shocks

・ The actuator directly connects with the encoder so do not use a hammer

during installation.

・ Failure to observe this caution could damage the enc oder and may cause

uncontrollable operation.

Avoid handling of actuators by cables.

・ Failure to observe this caution may damage the wiring, causing

uncontrollable or faulty operation.

4

Page 5

ITEMS YOU SHOULD NOTE WHEN USING THE DRIVER

CAUTION

WARNING

CAUTIONS RELATED TO THE DESIGN

Always use drivers under followings conditions.

The driver generates heat. Use under the following conditions while paying

careful attention to the heat radiation.

・ Mount in a vertical position keeping sufficient clearance.

・ 0℃ to 50℃, 95%RH or below (No condensation)

・ No vibration or physical shock

・ No dust, dirt, corrosive or inflammable gas

Use sufficient noise suppressing means and safe grounding.

A ny n ois e generated on a signa l wire will cause vibration or im proper motion.

Conform to the following conditions.

・ Keep signal and power leads separated.

・ Keep leads as short as possible.

・ Ground act uator and dri ver at on e sin gle po int, m inimum gr ound resis tance

class: D (less than 100 ohms)

・ Do not use a power line filter in the motor circuit.

Pay attention to negative torque by inverse load.

・ Inverse load may cause damages of drivers.

・ Please cons ult our sales office, if you intent to appl y products for inverse

load.

Use a fast-response type ground-fault detector designed for

PWM inverters.

Do not use a time-delay-type ground-fault detector.

Safety measures are essential to prevent accidents resulting

in death, injury or damage of the equipment due to

malfunction or faulty operation.

SAFETY GUIDE

CAUTIONS FO R USAGE

Never change wiring while power is active.

Make sure of power non-active before servicing the products. Failure to

observe this caution may result in electric shock or personal injury.

Do not touch terminals or inspect products at least 5

minutes after turning OFF power.

・ Otherwise residual electric charges may result in electric shock.

・ Make installation of products not easy to touch their inner electric

components.

5

Page 6

SAFETY GUIDE

CAUTION

CAUTION

Do not make a voltage resistance test.

・ Failure to observe this caution may result in damage of the control unit.

・ Please consult our sales office, if you intent to use a voltage resistance

Do not operate control units by means of power ON/OFF

・ Start/stop operation should be performed via input signals.

・ Failure to observe this caution may result in deterioration of electronic

DISPOSAL

All products or parts should be disposed of as industrial

Since the case or the box of drivers ha ve a material indication, classif y parts

test.

switching.

parts.

waste.

and dispose them separately.

6

Page 7

Contents

Introduction ............................................................................................................. 4

SAFETY GUIDE ...................................................................................................... 3

NOTATION ............................................................................................................. 3

LIMIT ATION OF APPLICA TI ONS ........................................................................... 3

SAFETY NOTE ...................................................................................................... 4

Contents .................................................................................................................. 7

Overview 12

1-1 Overview ......................................................................................................... 13

1-2 Model………………………………………………………………………………..14

1-3 Drivers and extension cables ........................................................................ 15

1-4 Specifications ................................................................................................ 16

1-5 Motor shaft brake .......................................................................................... 25

1-6 External dimensions ..................................................................................... 28

1-7 Mechanical accuracy .................................................................................... 40

1-8 One-Way Positi o nal ac c ur acy ....................................................................... 42

Repeatability (CG type) ........................................................................................ 43

Bi-directional repeatability (CG type) .................................................................... 43

1-9

Encoder specifications (Absolute encoder)

.................................................................. 44

1-10 Output Stiffness ....................................................................... 46

Moment stiffness .................................................................................................. 46

Torsional Stiffness ................................................................................................ 47

Torsional Stiffness (Ratio 11: HPF) ....................................................................... 49

1-11 Direction of rotation ................................................................. 50

1-12 Shock resistance ..................................................................... 51

1-13 Vibration resistance ................................................................. 52

1-14 Operable range ........................................................................ 53

1-15 Cable specifications ................................................................. 68

Motor cable specifications .................................................................................... 68

Encoder cable specifications ................................................................................ 69

Page 8

1

2

3

4

5

6

7

8

9

10

11

付

Outline

Selection guidelines 70

2-1 SHA series selection ....................................................................................... 71

Allowable load moment of inertia .......................................................................... 71

2-2 Change in load moment of inertia ................................................................. 75

2-3

Verifying and examining load weights

Maximum load moment load ................................................................................. 77

Verifying life .......................................................................................................... 77

Verifying static safety coefficients ......................................................................... 79

2-4 Examining operating conditions .................................................................... 80

Calculate the actuator rotation speed ................................................................... 80

Calculating and examining load moment of inertia ................................................ 80

Load torque calculation ........................................................................................ 81

Acceleration and deceleration time ....................................................................... 82

Examining effective torque and average rotation speed ....................................... 83

................................................................. 76

Installing the SHA actuator 85

3-1 Receiving Inspection ....................................................................................... 86

Inspection procedure ............................................................................................ 86

3-2 Notices on handling ........................................................................................ 87

Installation and transmission torque ..................................................................... 87

Precautions on installation .................................................................................... 89

Use of positioning pins ......................................................................................... 90

Surface treatments ............................................................................................... 90

3-3 Location and installation .................................................................................. 91

Operating Environment ......................................................................................... 91

Installation ............................................................................................................ 92

1-1 Overview

Options 93

4-1 Options ............................................................................................................ 94

Origin and end limit sensors (option code: L) ........................................................ 94

Option for side exit cables (option code: Y) .......................................................... 94

Output s haft single rev olution absolute model (option code: S)

Stand (CG type only) ............................................................................................ 94

Extension cables .................................................................................................. 97

...................................... 94

Appendix 100

5-1 Unit conversion ........................................................................................... 101

5-2 Calculating moment of inertia ..................................................................... 103

Formula for moment of inertia and mass ............................................................ 103

Moment of inertia of a cylinder ............................................................................ 105

Index ....................................................................................................................... 0

8

Page 9

1-1 Overview

Outline

放熱板:350 *350*18

0

25

50

75

100

125

150

0 20 40 60 80 100 120

回転速度 [r/min]

トルク [Nm]

加減速運転領域

連続使用領域

50%デューティ領域

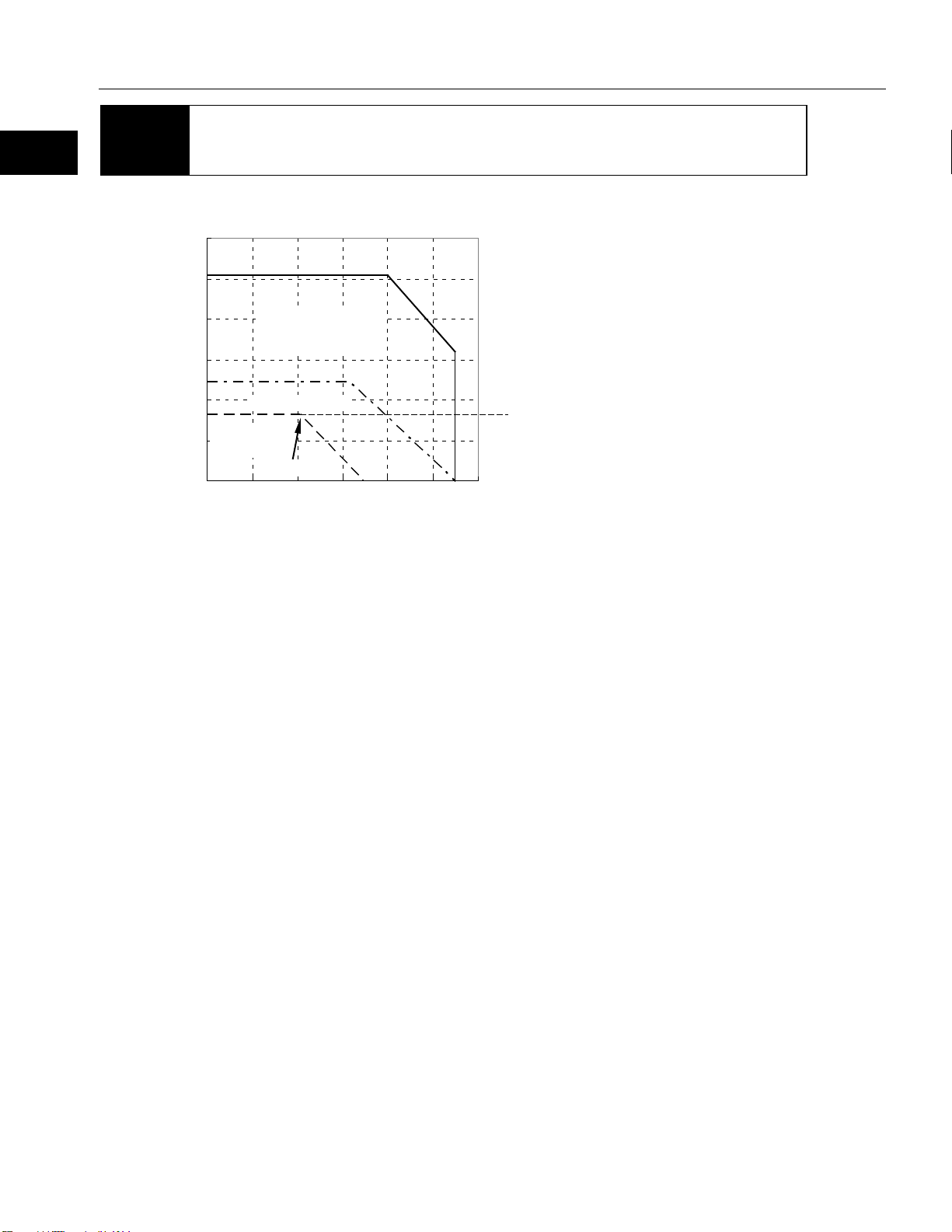

Allowable continuous torque

A

Radiation plate: 350*350*18

Torque [Nm]

Motion range during

accel

deceleration

50% duty range

Continuous

motion range

Rotation speed [rpm]

1 Overview of the SHA series

eration and

9

Page 10

1

2

3

4

5

6

7

8

9

10

11

付

Outline

.

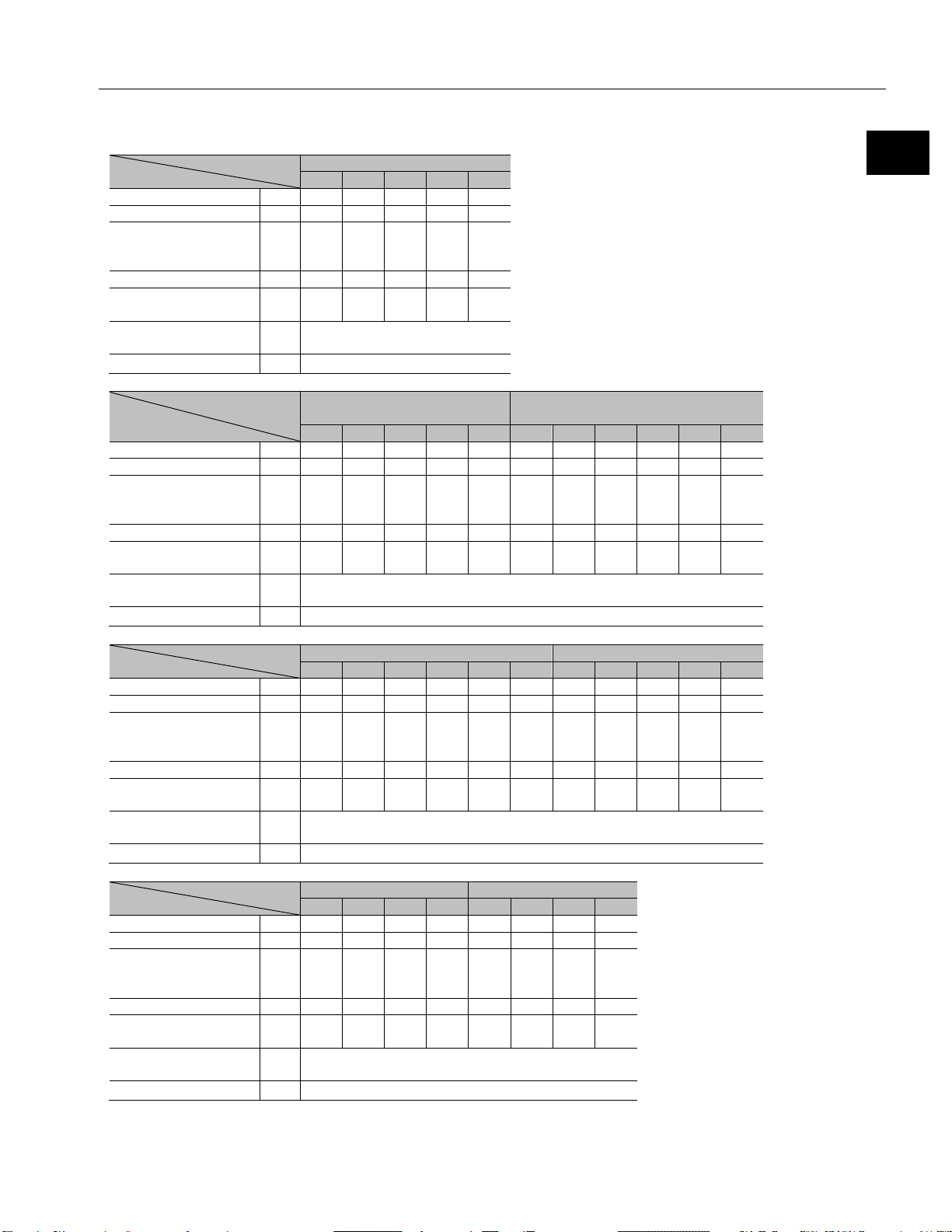

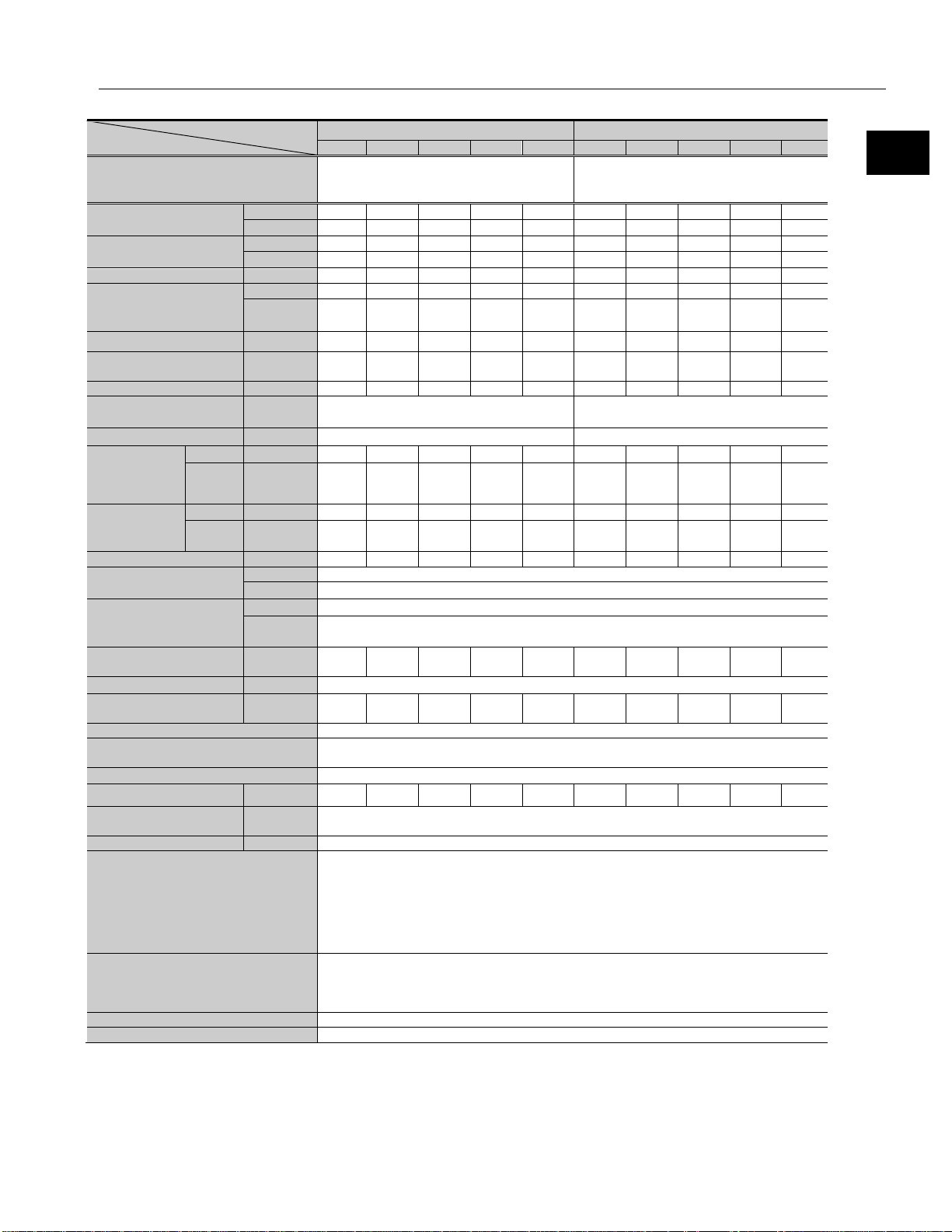

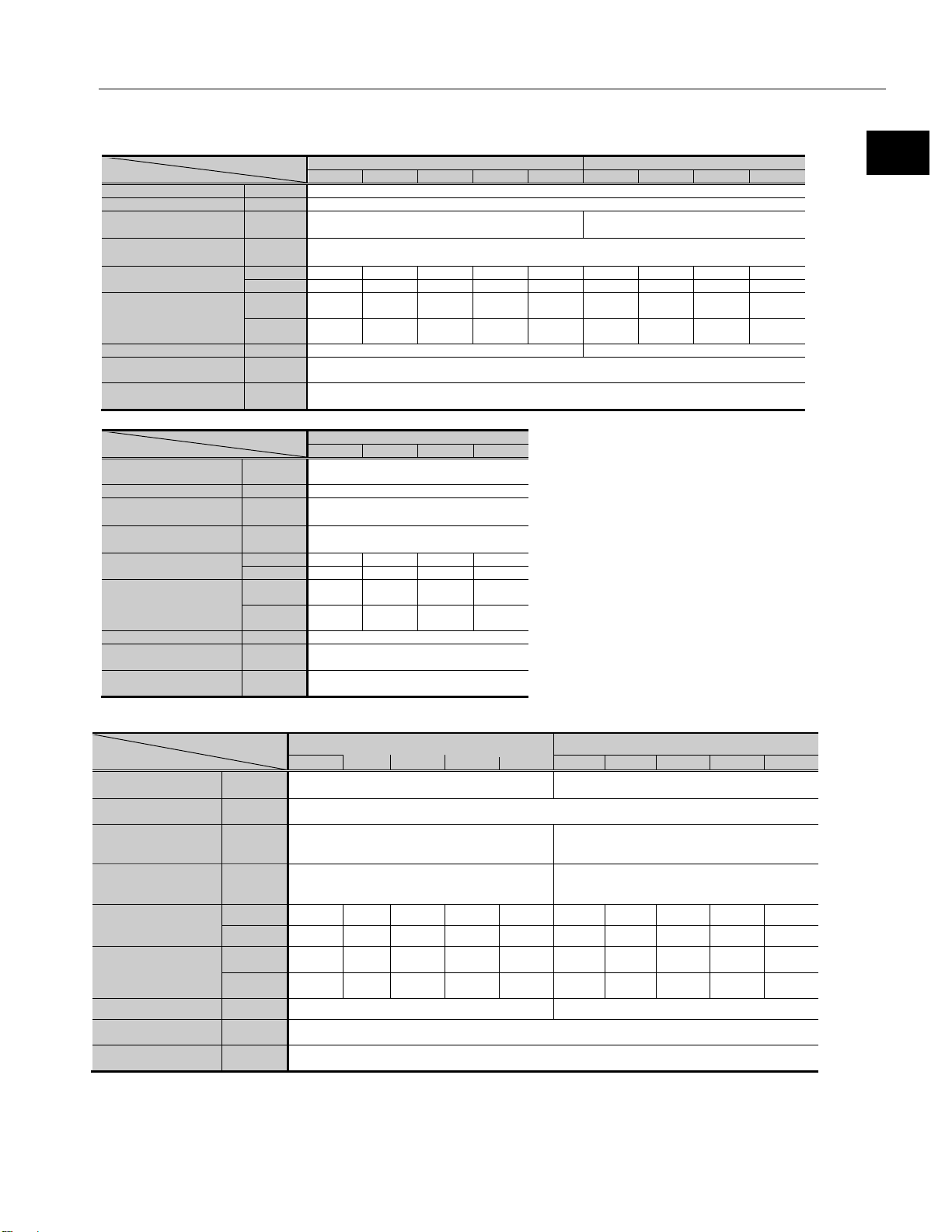

Model

Item

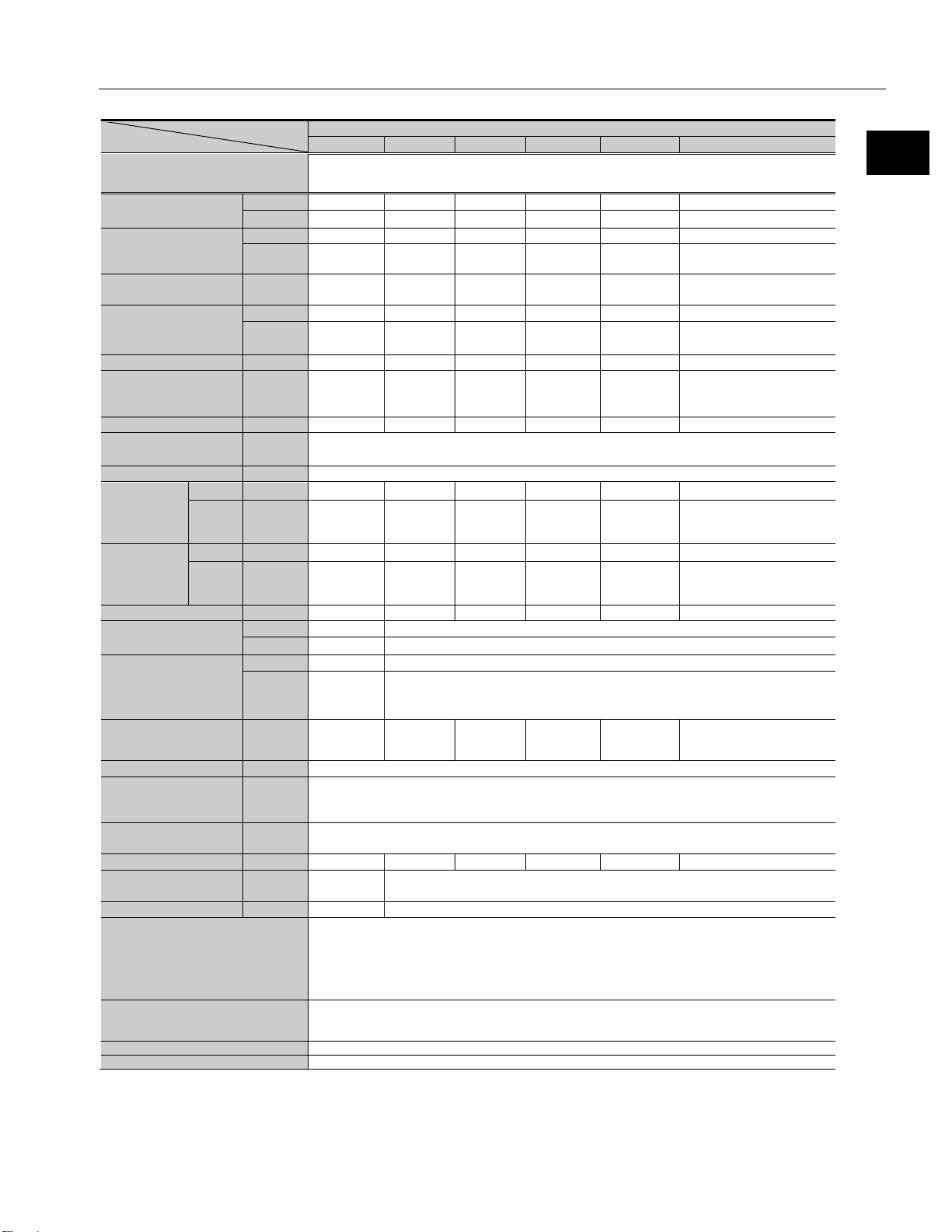

SHA20A

51

81

101

121

161

(1) Output at point A

W

99

109

109

106

86

(2) Voltage at point A

V

113

117

117

119

122

(3) Allowable

current

(4) Speed at point A

rpm

44

30

24

21

17

(5) Frequency at

point A

(6) Allowable range

temperature

(7) Number of phase

3

Model

SHA25A

(Motor input voltage 100V)

51

81

101

121

161

11

51

81

101

121

161

(1) Output at point A

W

165

188

190

178

127

133

175

203

207

178

127

(2) Voltage at point A

V

61

64

65

64

62

101

115

122

125

125

120

(3) Allowable

current

(4) Speed at point A

rpm

45

31

25

21

15

141

41

29

24.5

21

15

(5) Frequency at

point A

(6) Allowable range

temperature

(7) Number of phase

3

Model

Item

SHA32A

SHA40A

11

51

81

101

121

161

51

81

101

121

161

(1) Output at point A

W

240

328

369

373

308

233

487

564

570

560

480

(2) Voltage at point A

V

97

110

114

118

116

115

109

115

115

116

122

(3) Allowable

current

(4) Speed at point A

rpm

115

34

23

20

16.5

12.5

29

20.5

16.5

14

12

(5) Frequency at

point A

(6) Allowable range

temperature

(7) Number of phase

3

Model

Item

SHA58A

SHA65A

81

101

121

161

81

101

121

161

(1) Output at point A

W

897

948

863

731

964

963

958

802

(2) Voltage at point A

V

99

101

101

107

92

92

96

100

(3) Allowable

current

(4) Speed at point A

rpm

12

10

8.5

7.2

10 8 7.4

6.2

(5) Frequency at

point A

(6) Allowable range

temperature

(7) Number of phase

3

SG/HP type

1-1 Overview

Item

continuous

continuous

A

2.1 2.0 2.0 1.9 1.6

rms

Hz 187 203 202 212 228

℃ 40

-

SHA25A (Motor input voltage 200V)

A

4.7 4.7 4.7 4.5 3.7 3.0 3.0 3.0 2.9 2.6 2.1

rms

Hz 191 209 210 212 201 129 174 196 206 212 201

℃

-

40

continuous

A

6.0 6.0 6.0 5.7 5.0 4.1 9.0 9.0 9.0 8.8 7.2

rms

Hz 105 145 155 168 166 168 123 138 139 141 161

℃

-

40

continuous

A

17.7 17.8 16.4 13.4 22.0 21.9 20.1 16.3

rms

Hz 130 135 137 155 108 108 119 133

℃

-

40

10

Page 11

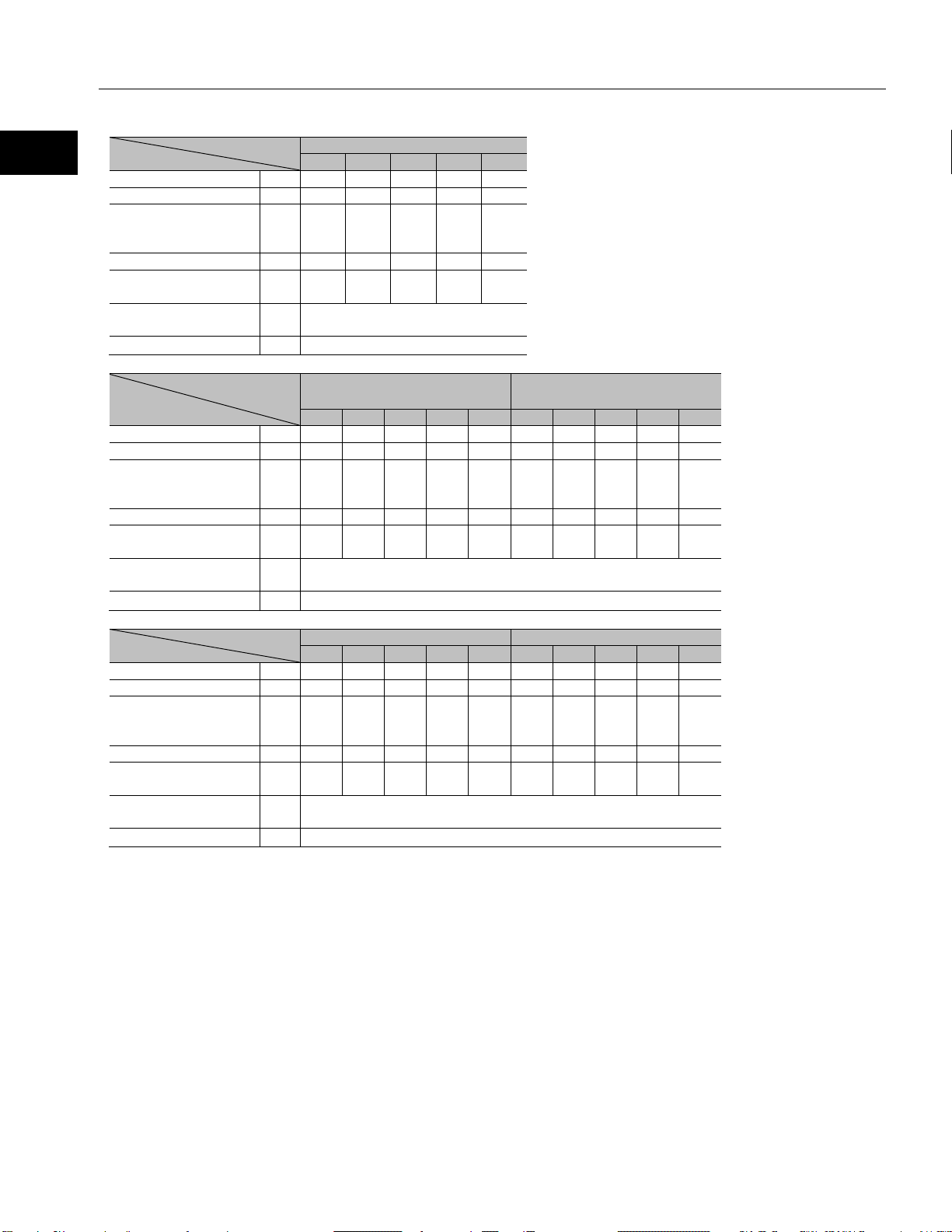

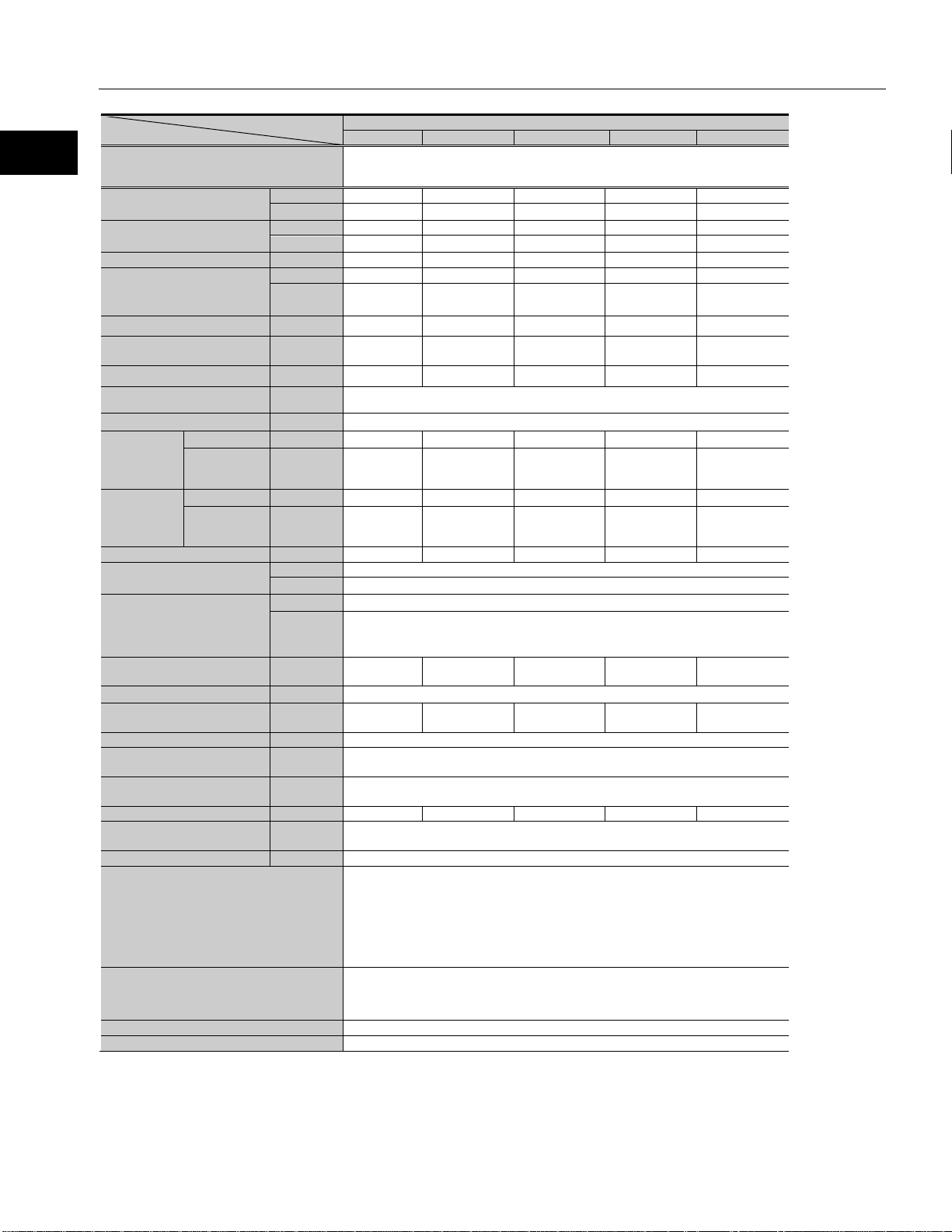

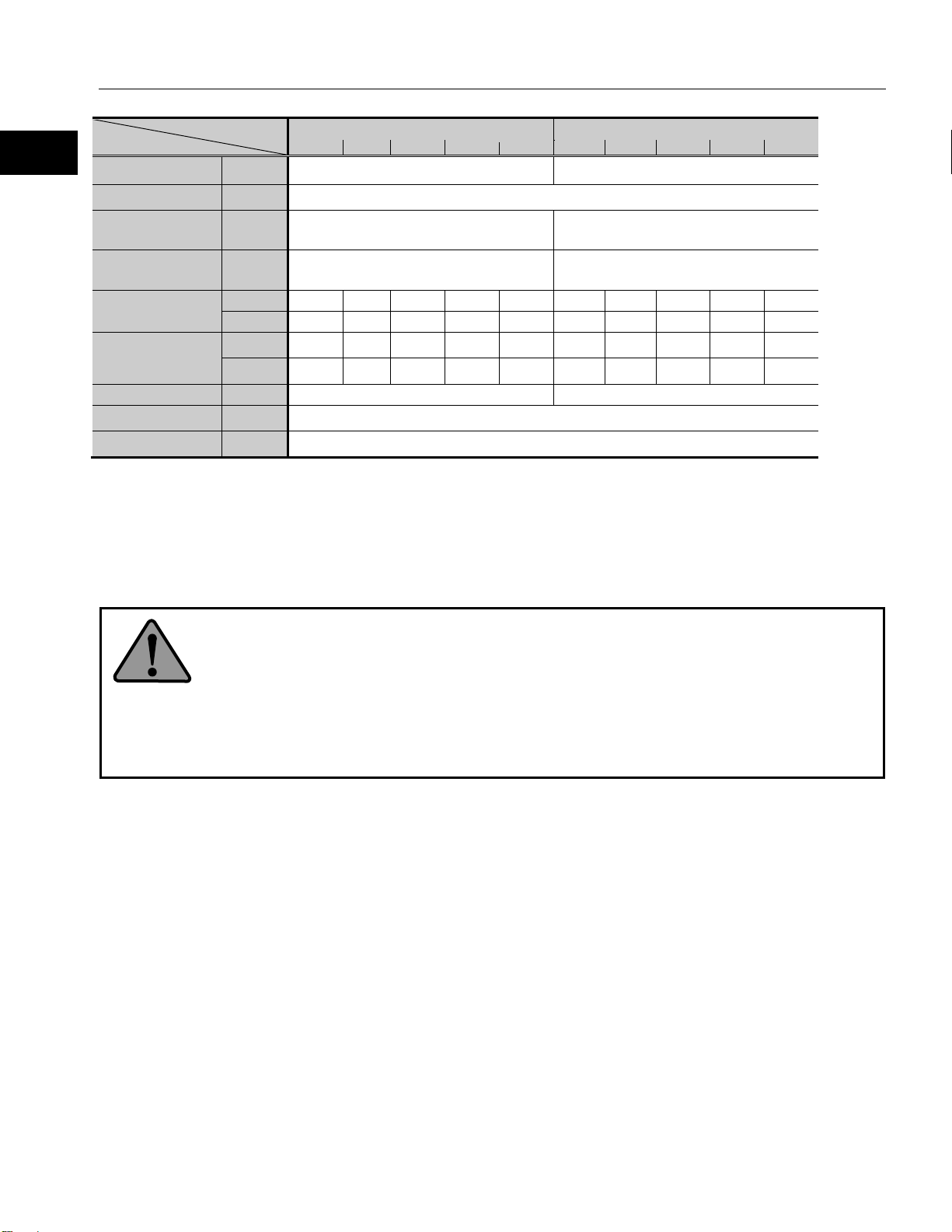

1-1 Overview

Outline

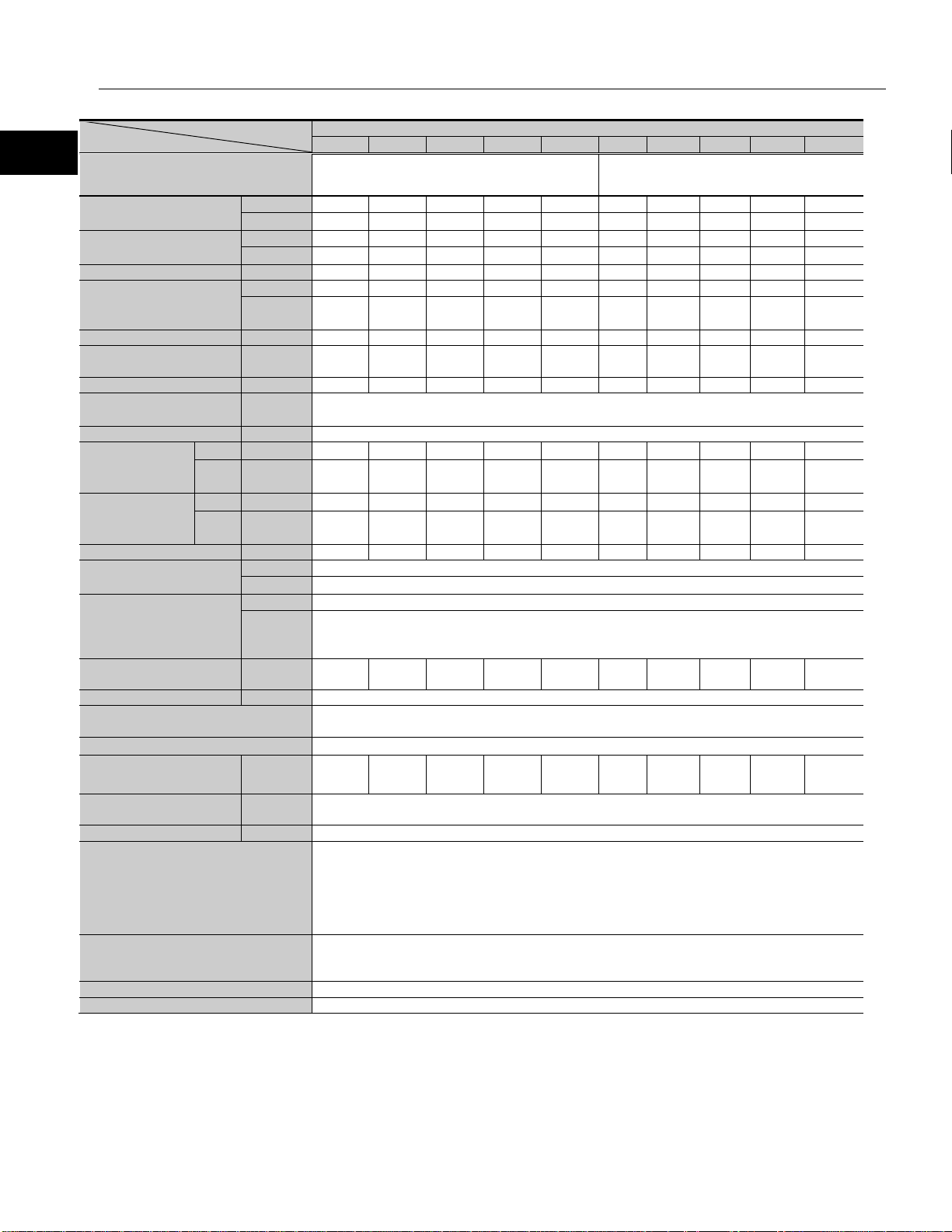

Model

Item

SHA20A

50

80

100

120

160

(1) Output at point A

W

97

108

108

106

85

(2) Voltage at point A

V

112

116

116

119

122

(3) Allowable

current

(4) Speed at point A

rpm

44

29.5

24

21

17

(5) Frequency at

point A

(6) Allowable range

temperature

(7) Number of phase

3

Model

SHA25A(Motor input voltage

100V)

SHA25A((Motor input

voltage 200V)

50

80

100

120

160

50

80

100

120

160

(1) Output at point A

W

167

191

192

174

127

177

201

204

174

127

(2) Voltage at point A

V

62

65

65

63

61

115

121

123

123

119

(3) Allowable

current

(4) Speed at point A

rpm

47

32

25.5

20.5

15

42

29

24

20.5

15

(5) Frequency at

point A

(6) Allowable range

temperature

(7) Number of phase

3

Model

Item

SHA32A

SHA40A

50

80

100

120

160

50

80

100

120

160

(1) Output at point A

W

321

372

373

308

233

493

558

568

568

488

(2) Voltage at point A

V

109

114

117

116

115

109

114

115

116

123

(3) Allowable

current

(4) Speed at point A

rpm

34

23.5

20

16.5

12.5

30

20.5

16.6

14.2

12.2

(5) Frequency at

point A

(6) Allowable range

temperature

(7) Number of phase

3

CG type

Item

continuous

continuous

A

2.1 2.1 2.1 2.0 1.7

rms

Hz 183 197 200 210 227

℃

-

A

4.7 4.7 4.7 4.5 3.7 3.0 3.0 3.0 2.6 2.1

rms

Hz 196 213 213 205 200 175 193 200 205 200

℃

-

40

40

continuous

A

6.0 6.0 5.7 5.0 4.1 9.0 9.0 9.0 8.8 7.2

rms

Hz 142 157 167 165 167 125 137 138 142 163

℃

-

40

11

Page 12

1

2

3

4

5

6

7

8

9

10

11

付

Outline

Chapter 1

Overview

This chapter explains the features, functions and specifications of the actuator.

1-1 Overview ············································································· 13

1-2 Model ················································································· 14

1-3 Drivers and extension cables ··················································· 15

1-4 Specifications ······································································· 16

1-5 Motor shaft brake ·································································· 25

1-6 External dimensions ······························································ 28

1-7 Mechanical accuracy ····························································· 40

1-8 Position al ac cur acy ······························································· 42

1-9

Encoder specifications (Absolute encoder)

1-10 Output Stiffness ································································· 46

1-11 Direction of rotation ····························································· 50

1-12 Shock resistance ································································ 51

1-13 Vibration resistance ···························································· 52

1-14 Operable range ·································································· 53

1-15 Cable specifications ···························································· 68

············································· 44

1-1 Overview

12

Page 13

1-1 Overview

Outline

1-1 Overview

The SHA series of AC Servo Actuators provide high torque and high accuracy rotary motion. These AC Servo Actuators are

each composed of a Harmonic Drive® speed reducer for precise control and a flat, high performance AC servo motor with an

integral absolute multi-turn encoder. The SHA series AC Servo Actuators all feature a large hollow shaft through the axis of

rotation.

There are 3 types of speed reducers: SG with SHG series incorporated, HP with HPF series incorporated, and CG with the

CSG series incorporated. They are an advanced version of current FHA series AC Servo Actuators having a flat, hollow

structure.

One key feature of the SHA actuators is their compact size. The outside diameter has been minimized, providing a maximum

torque/volume ratio which is approximately double that of conventional FHA actuators. A through hole is provided in the

center of the actuator, through which wiring, air lines, laser beams or concentric shafts may be passed.

The HA-800 series driver is a dedicated family of servo drive units for position/speed control, developed exclusively for driving

SHA series actuators. The small, multi-functional drivers control the SHA series actuators' operations with great accuracy and

precision. Additionally, the REL driver series may be used, which provides interface to many network field buses.

◆ Improved Torque Density

High-torque SHG or CSG series Harmonic Drive® speed reducers are incorporated into the actuator for precise control and

the outer diameter of the actuator has been reduced by 20% compared to our conventional products. As a result, the maximum

torque/volume ratio has approximately doubled compared to our previous actuator designs. Based on maximum torque, you

can select a model which is one size smaller. Also, the output torque is much higher than direct drive motors of similar

volume/weight. This is another reason why the SHA series has an outstanding performance advantage.

◆ Expanded product lineup

6 models are available for SG, accommodating high torque up to 3,400 Nm. The SHA line als o inc lud es m ode ls with reduction

ratios of 51 to 161. CG series has 4 fra me sizes available with 5 reduction ratios of 50:1 to 160:1.

◆ Modular design

The components of the SHA series, such as speed reducers, output shaft bearing, motor, brake and encoder, are arranged

based on a modular design. We can also custom-design a model to meet your specific requirements. Please contact your

HDLLC sales representative for details.

◆ Standar d 17-bit mag netic absolute encoder

The newly developed AC servo motors are equipped with our original, highly reliable 17-bit magnetic* absolute encoder with

safety functions. The serial communication reduces wiring and provides not only a multi-turn encoder, which is a must-have

feature on actuators with speed reducers, but it also has an internal backup to retain absolute positions even when the

encoder cable is disconnected for short periods of time.

The encoder circuitry also constantly compares two separate sets of encoder signals. If any abnormality is detected, the

encoder's built-in failsafe function outputs an alarm signal to the host system.

*SHA 20 comes with an optical encoder.

◆ Support for network control s

By using a dedicated HA-800 series driver, you can control your actuator on a MECHATROLINK-II or CC-Link network. The

REL series drivers support EtherCat, CANOpen, and Dev ice N et.

◆ For high speeds

Also supports high speeds in combination with the HPF hollow shaft planetary speed reducer.

13

Page 14

1

2

3

4

5

6

7

8

9

10

11

付

Outline

SHA

32 A 101

SG - B 12 A 200 -

10

S17b

A - C L -

SP

(1)

(2)

(3)

(4)

(5) -

(6)

(7)

(8)

(9) -

(10)

(11)

(12) -

(13)

(14) -

(15)

A

Size: 58, 65 (SG only)

08

Size: 20

B

With brake

(10) Encoder format

With standard connector

(for extension cables)

Output shaft single revolution absolute

model (CG only)

Blank

Standard product

1-2 Model

Model numbers for the SHA series actuators and how to interpret them are explained below.

Examples of standard models

(1) Model: SHA series actuator

(2) Size: SG: 20, 25, 32, 40, 58, 65

(3) Version: A: Standard, Y: Yaskawa compatible, M: Mitsubishi compatible, P: Panasonic compatible

(4) Reduction ratio (R:1)

Reduction ratio 11 is for the HPF hollow shaft planetary (Size 25, 32)

Reduction ratios 50 and higher are for the HarmonicDrive

(5) Gearhead

(6) Motor version symbol

(7) Motor size

(8) Brake

(9) Motor input voltage

:

CG: 20, 25, 32, 40

HP: 25, 32

HPF SHG CSG

51 51:1 50 50:1

81 81:1 80 80:1

11 11:1

HP HPF hollow shaft planetary

SG HarmonicDrive® SHG series

CG HarmonicDrive® CSG series

B Size: 25, 32, 40

C Size: 20

09 Size: 25

12 Size: 32

15 Size: 40

21 Size: 58, 65 (SG only)

A Without brake

100 100V (Size 25 only)

200 200V

LV

101 101:1 100 100:1

121 121:1 120 120:1

161 161:1 160 160:1

48V DC to 90V DC

(Size 20, 25,32)

®

gears

10 A-Format (2.5Mbps, 1 to 1 connection)

00 Incremental Encoder

14 Panasonic Format

16 Mitsubishi Format (not available in size 20)

17 Yaskawa Format (not available in size 20)

(11) Encoder type, resolution

S17b

D250 D250: Incremental encoder (size 25, 32, and 40)

(12) Encoder phase angle: Phase difference between

induced voltage in motor phase U and absolute origin

A 0 degree

B 30 Dgree

(13) Connector specification

C

N With Pigtails

(14) Option symbol

L With near origin and end limit sensors

Y Side exiting cable

V With mounting stand (CG only)

S

(Please contact us for option-compatible models.)

(15) Special specification

SP____ Special specification code

17-bit absolute encoder, 131,072

pulses/revolution (Nikon-A format)

1-2 Model

14

Page 15

1-3 Drivers and extension cables

Outline

HA-800A-6 D/E -

200

HA-800B-6D/E -

200

HA-800C-6D/E -

200

HA-800□-6D/E:

TMC

Encoder

cable

1-3 Drivers and ext ension cables

The proper combination of SHA actuators, drivers, and extension cables are as follows:

SHA20A SHA25A SHA32A SHA40A SHA58A SHA65A

REL Servo Drive

HA-800 Standard

I/O command type

REL-230-18 REL-230-18

HA-800A-

HA-800A-

3D/E -200

3D/E-200

(HA-800A-

6D/E -100)

REL230-36

REL 230-40

HA-800A6D/E -200

200

or

HA-800A-24D/E -

HA-800A-

24D/E -200

HA-800A-

24D/E -

200

HA-800

MECHATROLINK

HA-800 CC-Link

Extension

cables

(option)

Motor

cable

HA-800B-

3D/E -200

HA-800C3D/E -200

HA-800B3D/E -200

(HA-800B-

6D/E -100)

HA-800C3D/E -200

(HA-800C-

6D/E -100)

EWD-MB**-A06-TN3

(Driver side connector

supplied separately)

EWD-S**-A08-3M14 EWD-S**-D10-3M14

HA-800B6D/E -200

HA-800C6D/E -200

200

or

HA-800B-24D/E -

200

or

HA-800C-24D/E -

EWD-MB**-A06-

TN3

HA-800□-24D/E:

EWD-MB**-A06-

HA-800B-

24D/E -200

HA-800C-

24D/E -200

EWD-MB**-D09-TMC

** in the extension cable model indicates the cable length: 03 = 3m, 05 = 5m, 10 = 10m

The models shown in parenthesis are those with 100V motor input voltage combinations.

HA-800B-

24D/E -

200

HA-800C-

24D/E -

200

15

Page 16

1

2

3

4

5

6

7

8

9

10

11

付

Outline

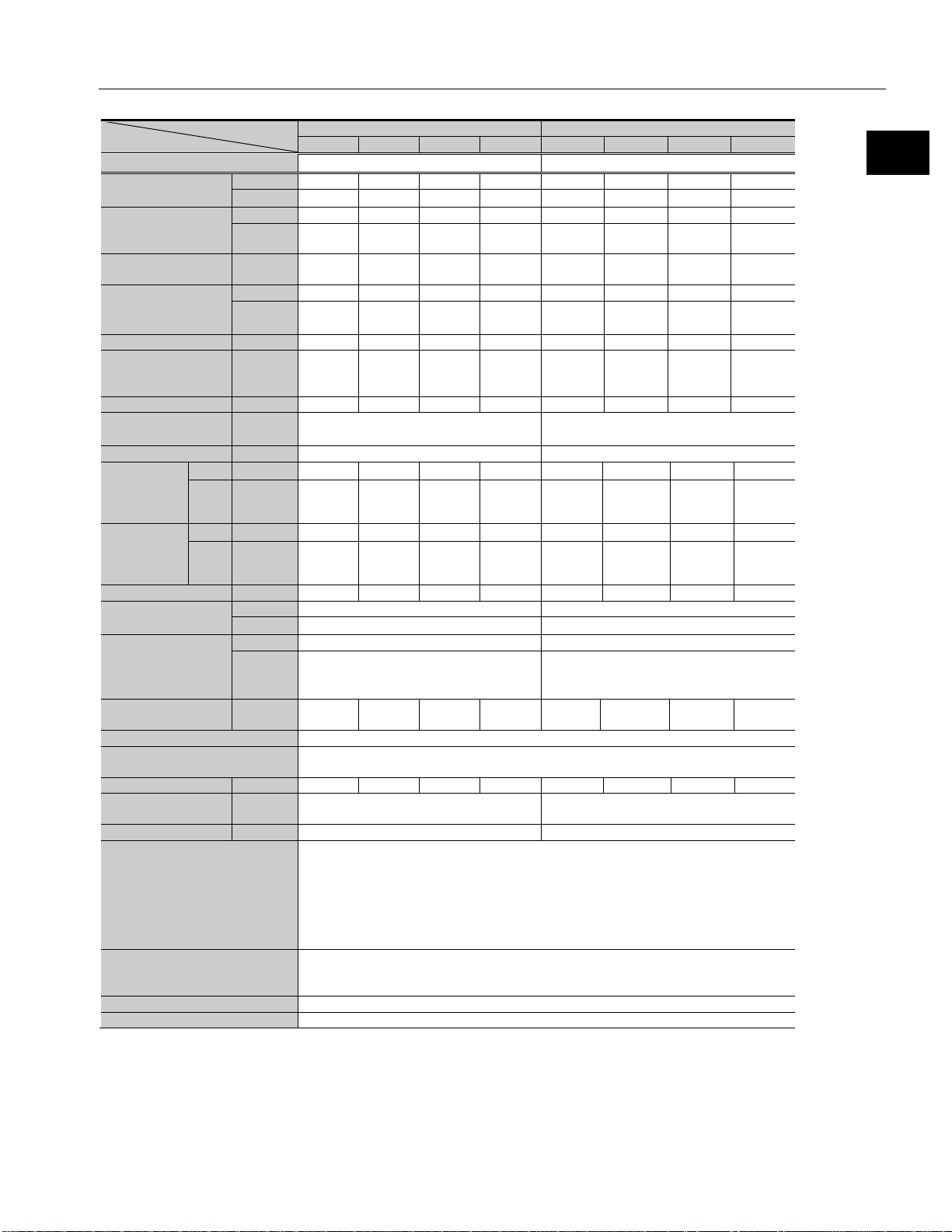

Model

Item

SHA20A

51

81

101

121

161

REL-230-18

HA-800□-3D/E-200

Nm

73

96

107

113

120

kgf・m

7.4

9.8

10.9

11.5

12.2

Allowable continuous

torque

Nm

21

35

43

48

48

kgf・m

2.1

3.6

4.4

4.9

4.9

Max. rotational speed*1

rpm

117.6

74.1

59.4

49.6

37.3

Nm/A

16.5

27

33

40

53

kgf・m/A

1.7

2.7

3.4

4.1

5.4

Max. current*1

A

rms

6.0

4.9

4.5

4.0

3.4

Allowable continuous

current

EMF constant*3

V/(rpm)

1.9

3.0

3.7

4.5

5.9

Phase resistance

(20℃)

Ω

Phase inductance

mH

2.5

(without brake)

GD2/4

kg・m2

0.23

0.58

0.91

1.3

2.3

J

kgf・cm・s2

2.4

6.0

9.3

13

24

GD2/4

kg・m2

0.26

0.65

1.0

1.4

2.6

J

kgf・cm・s2

2.6

6.6

10

15

26

Reduction ratio

51:1

81:1

101:1

121:1

161:1

moment load

Nm

187

kgf・m

19.1

Nm/rad

25.2×104

kgf・m/arc min

7.5

One-way positional

accuracy

Encoder type

Absolute encoder

Single motor revolution

Encoder resolution

Motor multi revolution

counter

Output resolution

Pulse/rev

6,684,672

10,616,832

13,238,272

15,859,712

21,102,592

Mass

(without brake)

Mass (with brake)

kg

2.1

Environmental conditions

Operating temper ature: 0 to 40℃/Storage temperature: -20 to 60℃

Altitude: les s than 1,000 m above sea level

Motor insulation

Insulation resistance: 100MΩ or more (by DC500V insulation tester)

Insulation cl ass: A

Mounting direction

Can be installed in any di rection.

Protection structure

Totally enclosed self-cooled type (IP54)

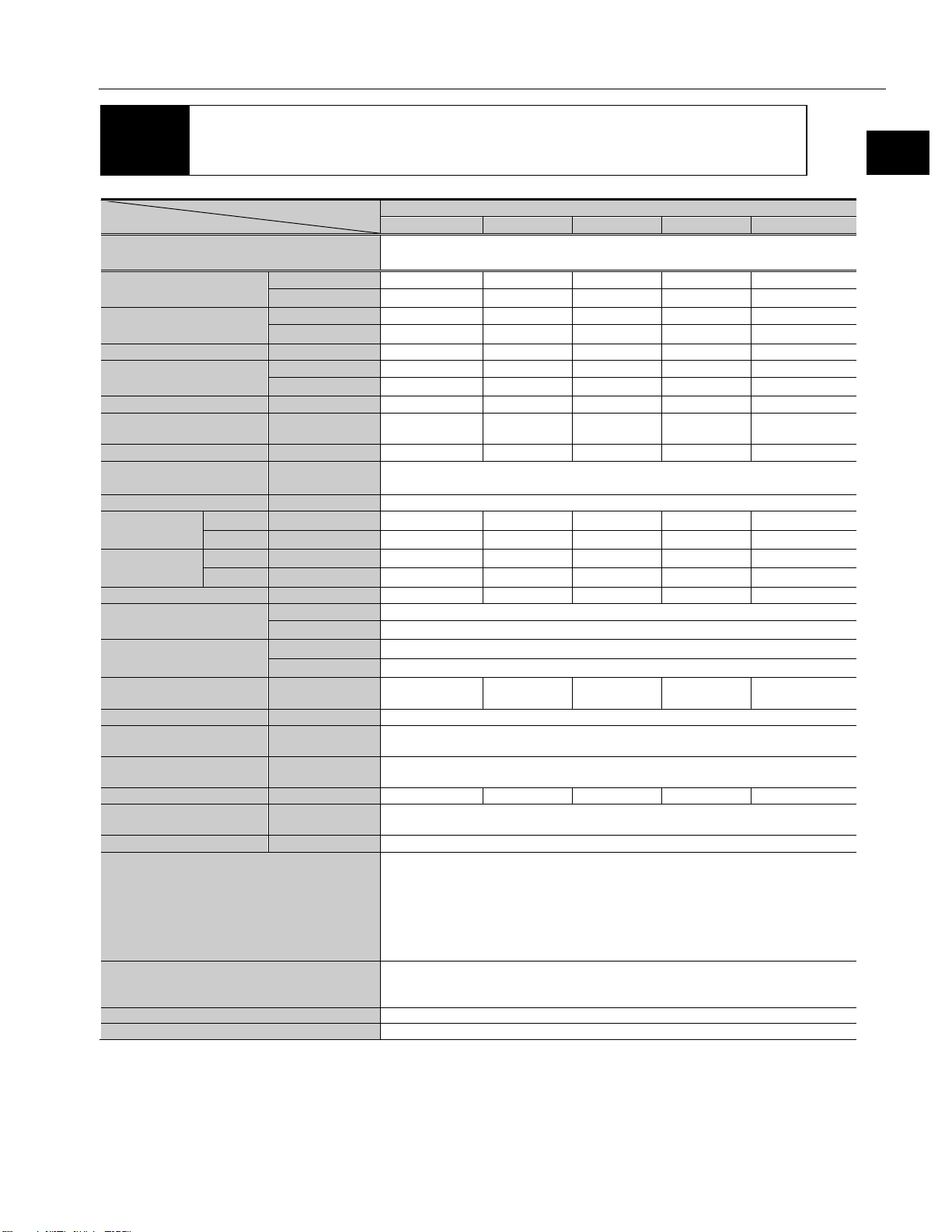

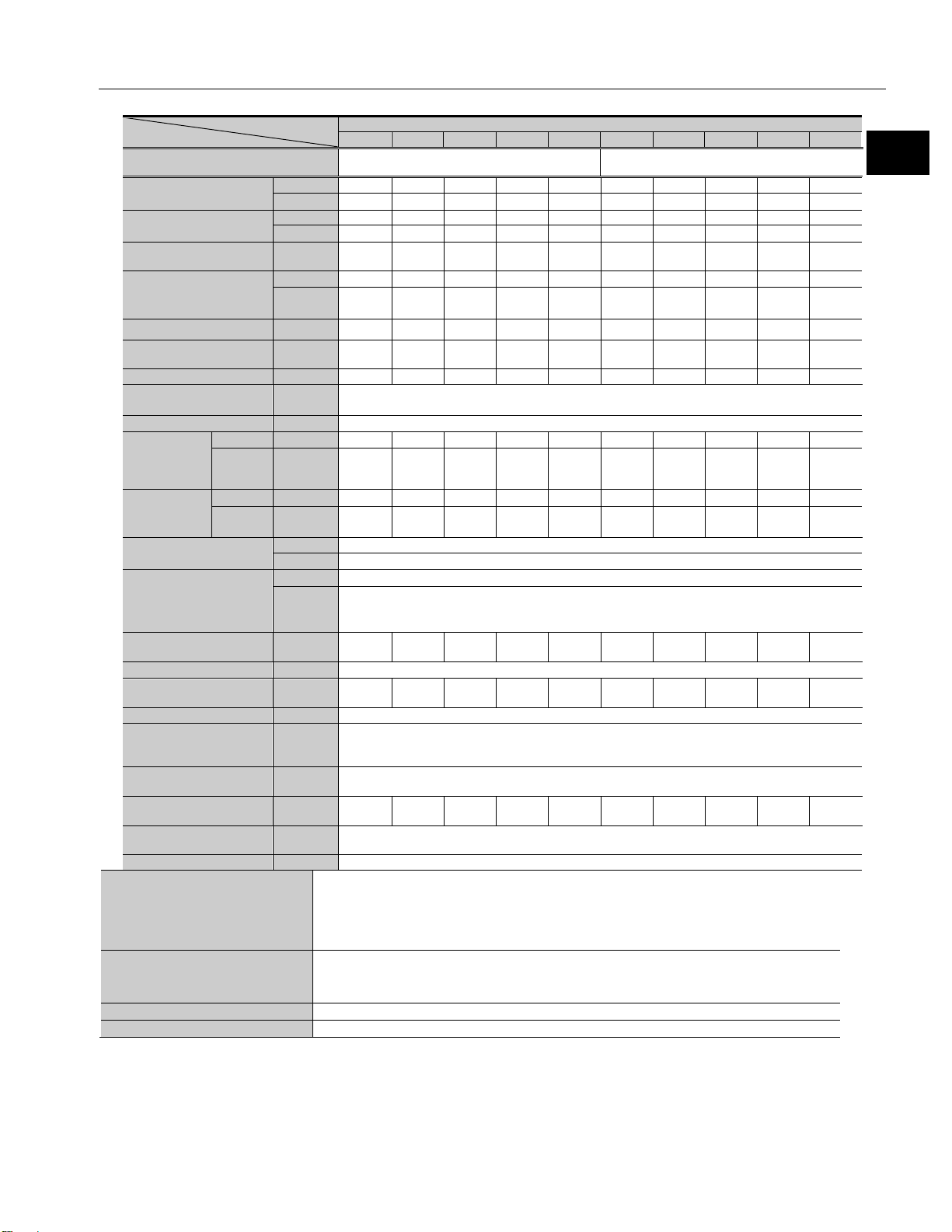

1-4 Specifications

SG type

Servo Drive

Max. torque*1

*1*2

Torque constant*1

A

2.1 2.0 2.0 1.9 1.6

*1*2

rms

1-4 Specifications

Inertia moment

Inertia moment

(with brake)

Moment stiffness

Permissible

arc-sec

kg 2.0

60 50 50 50 50

Operating humidity/storage humidity: 20 to 80%RH (no condensation)

Resistance to vibr ation: 25 m/s

300 m/s

No dust, no metal powder, no corrosive gas, no inflammable gas , no oil mist

To be used indoors, no direct sunlight

2 *4

1.4

217(131,072)

216(65,536)

2

(frequenc y: 10 to 400Hz)/Shock resistance:

Dielectric strength: AC1,500V/1 min

The table shows typical output values of actuators.

*1: Typical characteristics when combined (driven by ideal sine wave) with our drivers.

*2: Value after temperature rise and saturation when the 320 x 320 x 16 [mm] aluminum radiation plate is installed.

*3: Value of phase induced voltage constant multiplied by 3.

*4: For testing conditions, refer to [1-12 Shock resistance] (P51) and [1-13 Vibration resistance ] (P52).

16

Page 17

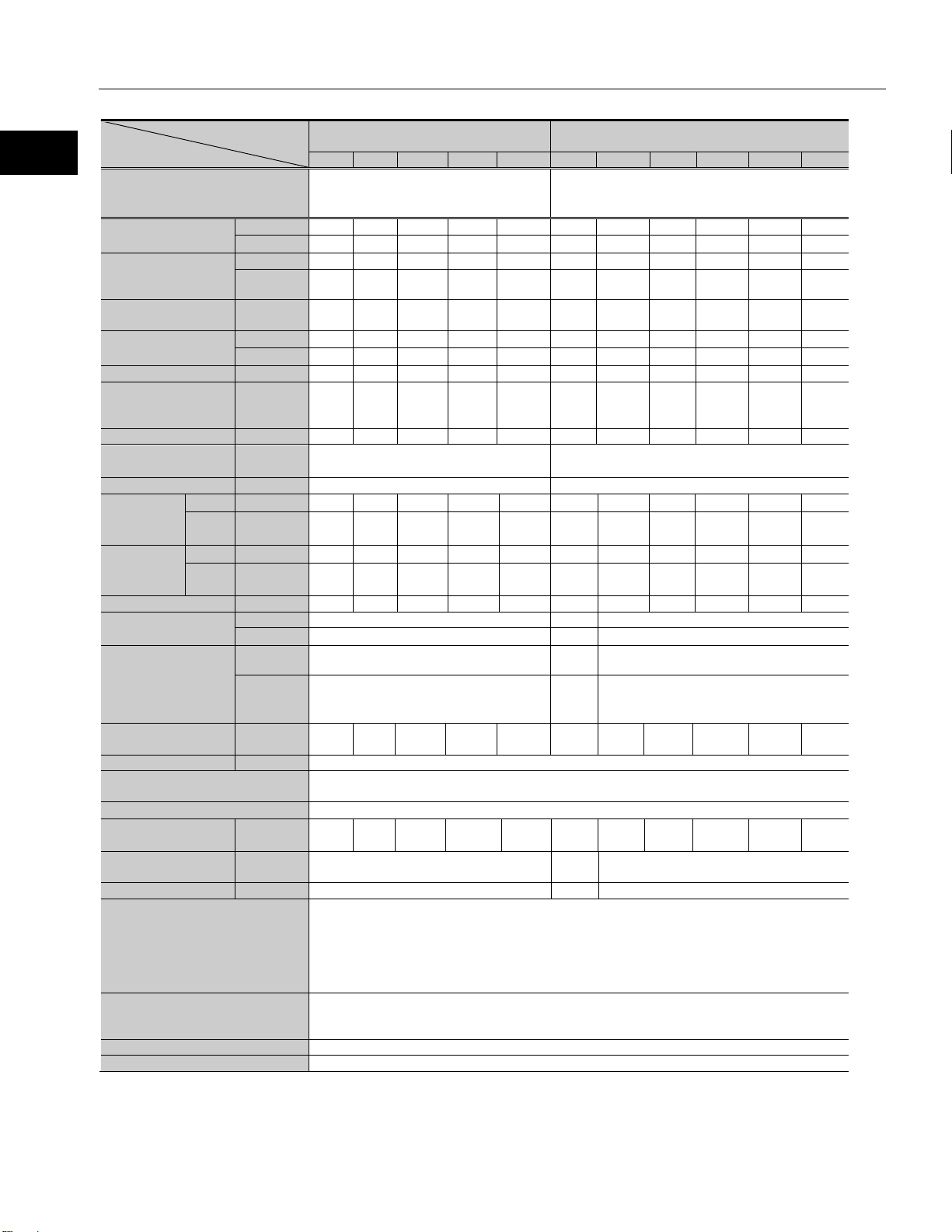

1-4 Specifications

Outline

SHA25A

(Motor input voltage 100V)

51

81

101

121

161

11

51

81

101

121

161

REL-230-18

HA-800□-3D/E-200

Nm

127

178

204

217

229

26

127

178

204

217

229

kgf・m

13

18.2

20.8

22.1

23.4

2.7

13

18.2

20.8

22.1

23.4

Allowable

torque

Nm

35

58

73

81

81

9.0

41

67

81

81

81

Max. rotational

speed*1

Nm/A

rms

11.1

17.9

22

27

36

4.2

19

31

39

46

62

kgf・m/A

1.1

1.8

2.3

2.7

3.6

0.43

2.0

3.2

4.0

4.7

6.3

Max. current*1

A

rms

14.9

13.0

12.1

10.9

9.0

8.9

8.6

7.5

7.0

6.3

5.2

Allowable

current

EMF constant*3

V/(rpm)

1.3

2.0

2.5

3.0

4.0

0.47

2.2

3.5

4.3

5.2

6.9

Phase resistance

(20℃)

Phase inductance

mH

1.0

3

GD2/4

kg・m2

0.56

1.4

2.2

3.2

5.6

0.029

0.56

1.4

2.2

3.2

5.6

kgf・cm・

s2

GD2/4

kg・m2

0.66

1.7

2.6

3.7

6.6

0.034

0.66

1.7

2.6

3.7

6.6

kgf・cm・

s2

Reduction ratio

1:51

1:81

1:101

1:121

1:161

1:11

1:51

1:81

1:101

1:121

1:161

Permissible

moment load

Nm

258

410

258

kgf・m

26.3

41.8

26.3

37.9

x 104

kgf・

min

One-way positional

accuracy

Encoder type

Magnetic absol ute encoder

Single motor revolution

Encoder resolution

Motor multi revolution counter

2

16

65,536)

10,61

832

Mass

(without brake)

Mass (with brake)

kg

3.1

5.1

3.1

Environmental conditions

Operating temper ature: 0 to 40℃/Storage temperature: -20 to 60℃

Altitude: les s than 1,000 m above sea level

Motor insulation

Insulation resistance: 100MΩ or more (by DC500V insulation tester)

Insulation cl ass: A

Mounting direction

Can be installed in any direction.

Protection structure

Totally enclosed self-cooled type (IP54)

SG/HP type

Item

Model

SHA25A (Motor input voltage 200V)

Servo Drive

Max. torque*1

continuous

*1*2

Torque constant*1

continuous

*1*2

Inertia moment

(without brake)

Inertia moment

(with brake)

REL-230-18

HA-800□-6D/E-100

kgf・m

rpm

A

rms

Ω

J

J

3.6 5.9 7.4 8.2 8.2 0.92 4.2 6.8 8.2 8.2 8.2

94.1 59.3 47.5 39.7 29.8 509.1 109.8 69.1 55.4 46.3 34.8

4.7 4.7 4.7 4.5 3.7 3.0 3.0 3.0 2.9 2.6 2.1

0.4 1.2

5.7 14 22 32 57 0.30 5.7 14 22 32 57

6.7 17 26 38 67 0.35 6.7 17 26 38 67

REL-230-36

Nm/rad

Moment stiffness

m/arc

50 40 40 40 40 120 50 40 40 40 40

6,684,

672

6,

Output resolution

arc-sec

Pulse/rev

kg

Operating humidity/storage humidity: 20 to 80%RH (no condensation)

Resistance to vibration: 25 m/s

No dust, no metal powder, no corrosive gas, no inflammable gas , no oil mist

To be used indoors, no direct sunlight

Dielectric strength: AC1,500V/1 min

The table shows typical output values of actuators.

*1: When combined with a HA-800 driver.

*2: Value after temperature rise and saturation when the 350 x 350 x 18 [mm] aluminum radiation plate is installed.

*3: Value of phase induced voltage constant multiplied by 3.

*4: For testing conditio ns, ref er to [1-12 Shock resistance] (P51) and [1-13 Vibration resistance ] (P52).

17

39.2 x 104

11.6 11.3 11.6

217(131,072)

(

13,238,

272

15,859,

712

21,102,

592

1,441,

792

6,684,

672

10,616,

832

2.95 5.0 2.95

2

(

frequency: 10 to 400Hz

)/Shock r esistance: 300 m/s

39.2 x 104

13,238,

272

15,859,

712

2 *4

21,102,

592

Page 18

1

2

3

4

5

6

7

8

9

10

11

付

Outline

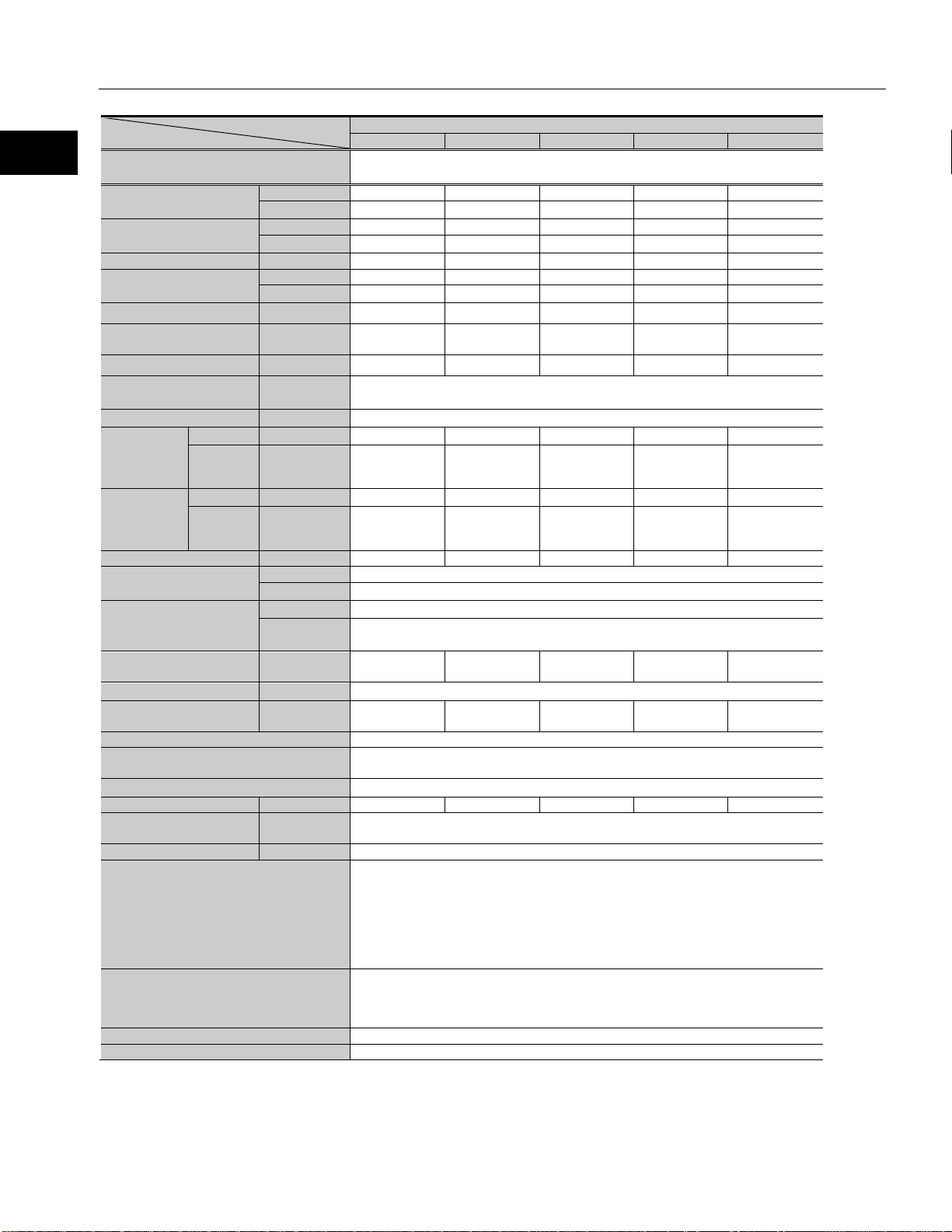

SG/HP type

Model

Item

SHA32A

11

51

81

101

121

161

Nm

62

281

395

433

459

484

kgf・m

6.3

28.7

40.3

44.2

46.8

49.4

Allowable

torque

Nm

20

92

153

178

178

178

Max. rotational

speed*1

Nm/A

rms

4.5

21

33

42

50

66

kgf

・

m/A

rms

Max. current*1

A

rms

19

17.3

15.2

13.5

12.2

9.9

Allowable

current

EMF constant*3

V/(rpm)

0.51

2.3

3.7

4.7

5.6

7.4

Phase resistance

(20℃)

Phase inductance

mH

1.4

Inertia

brake)

GD2/4

kg・m2

0.091

2.0

5.1

8.0

11

20

・

Inertia

brake)

GD2/4

kg・m2

0.11

2.3

5.9

9.2

13

23

・

Reduction ratio

1:11

1:51

1:81

1:101

1:121

1:161

Permissible

moment load

Nm

932

580

kgf・m

95

59.1

Nm/rad

86.1 x 104

100 x 104

kgf・

min

Encoder type

Magnetic absol ute encoder

Single motor

Encoder resolution

Motor multi

revolution counter

Output resolution

Pulse/rev

1,441,792

6,684,672

10,616,832

13,238,272

15,859,712

21,102,592

Mass

(without brake)

Mass (with brake)

kg

9.7

6.2

Environmental conditions

Operating temperature: 0 to 40℃/Storage temperature: -20 to 60℃

Altitude: less than 1,000 m above sea level

Motor insulation

Insulation resistance: 100MΩ or more (by DC500V insulation tester)

Insulation class: A

Mounting direction

Can be installed in any direction.

Protection structure

Totally enclosed self-cooled type (IP54)

1-4 Specifications

Servo Drive

Max. torque*1

continuous

Torque constant*1

continuous

moment

(without

moment

(with

*1*2

*1*2

J

J

REL-230-18, REL-230-36

HA-800□-6D/E-200

kgf・m

rpm 436.4 94.1 59.3 47.5 39.7 29.8

A

6.0 6.0 6.0 5.7 5.0 4.1

rms

Ω 0.33

kgf

cm・s2

kgf

cm・s2

2.1 9.4 15.6 18.2 18.2 18.2

0.46 2.1 3.4 4.2 5.1 6.8

0.93 21 52 81 117 207

1.1 24 60 94 135 238

Moment stiffness

One-way positional

accuracy

revolution

m/arc

arc-sec 120 50 40 40 40 40

217(131,072)

216(65,536)

kg 9.4 5.9

25.7 29.6

Operating humidity/storage humidity: 20 to 80%RH (no cond en sation)

Resistance to vibration: 25 m/s

No dust, no metal powder, no corrosive gas, no inflammable gas, no oil mist

To be used indoors, no direct sunlight

Dielectric strength: AC1,500V/1 min

The table shows typical output values of actuators.

*1: When combined with a HA-800 driver.

*2: Value after temperature rise and saturation when the 400 x 400 x 20 [mm] aluminum radiation plate is installed.

*3: Value of phase induced voltage constant multiplied by 3.

*4: For testing conditio ns, ref er to [1-12 Shock resistance] (P51) and [1-13 Vibration resistance ] (P 52).

2

(frequency: 10 to 400Hz)/Shock resistanc e: 300 m/s

2 *4

18

Page 19

1-4 Specifications

Outline

Model

Item

SHA40A

51

81

101

121

161

51

81

101

121

161

Nm

340

560

686

802

841

523

675

738

802

841

kgf・m

34.7

57.1

70

81.8

85.8

53.4

68.9

75.3

81.8

85.8

Allowable continuous

torque

Nm

94

158

198

237

317

160

263

330

382

382

kgf・m

9.6

16.1

20.2

24.2

32.3

16.3

26.8

33.7

39

39

Max. rotational speed*2

rpm

78.4

49.4

39.6

33.1

24.8

78.4

49.4

39.6

33.1

24.8

Nm/A

rms

25

41

51

61

81

25

41

51

61

81

kgf

・

m/A

rms

Max. current*2

A

rms

18

18

18

17.9

14.6

26.7

21.8

19.4

17.9

14.6

Allowable continuous

current

EMF constant*4

V/(rpm)

2.9

4.6

5.7

6.8

9.1

2.9

4.6

5.7

6.8

9.1

Phase resistance

(20℃)

Phase inductance

mH

1.2

GD2/4

kg・m2

5.0

13

20

28

50

5.0

13

20

28

50

kgf・cm・

s2

GD2/4

kg・m2

6.1

15

24

34

61

6.1

15

24

34

61

kgf・cm・

s2

Reduction ratio

1:51

1:81

1:101

1:121

1:161

1:51

1:81

1:101

1:121

1:161

Permissible

moment load

Nm

849

kgf・m

86.6

Nm/rad

179 x 104

kgf・

min

One-way positional

accuracy

Encoder type

Magnetic absol ute encoder

Single motor revolution

Encoder resolution

Motor multi revolution counter

2

16

65,536)

Mass

(without brake)

Mass (with brake)

kg

10.7

Environmental conditions

Operating temper ature: 0 to 40℃/Storage temperature: -20 to 60℃

Altitude: les s than 1,000 m above sea level

Motor insulation

Insulation resistance: 100MΩ or more ( by D C 500V insulation tester)

Insulation cl ass: A

Mounting direction

Can be installed in any di rection.

Protection structure

Totally enclosed self-cooled type (IP54)

SG type

Servo Drive HA-800□-6D/E-200*1

Max. torque*2

*2*3

Torque constant*2

*2*3

Inertia moment

(without brake)

Inertia moment

(with brake)

REL-230-36, REL-230-40

HA-800□-24D/E-200

2.6 4.1 5.2 6.2 8.2 2.6 4.1 5.2 6.2 8.2

A

6.0 6.0 6.0 6.0 6.0 9.0 9.0 9.0 8.8 7.2

rms

Ω 0.19

J

J

51 130 202 290 513 51 130 202 290 513

62 157 244 350 619 62 157 244 350 619

Moment stiffness

m/arc

53.2

arc-sec 50 40 40 40 40 50 40 40 40 40

217(131,072)

(

Output resolution

Pulse/rev

6,684,

672

10,616,

832

13,238,

272

15,859,

712

21,102,

592

6,684,

672

10,616,

832

13,238

,272

15,859,

712

21,102,

592

kg 9.9

Operating humidity/storage humidity: 20 to 80%RH (no condensati on)

Resistance to vibration: 25 m/s

2

(

frequency: 10 to 400Hz

)/Shock r esistance: 300 m/s

2 *5

No dust, no metal powder, no corrosive gas, no inflammable gas , no oil mist

To be used indoors, no direct sunlight

Dielectric strength: AC1,500V/1 min

The table shows typical output values of actuators.

*1: If a HA-800□-6D/E driver is combined with a SHA40A actuator, the maximum torque and allowable continuous torque are limited.

*2:

When combined with HA-800 driver.

*3: Value after temperature rise and saturation when the 500 x 500 x 25 [mm] aluminum radiation plate is installed.

*4: Value of phase induced voltage constant multiplied by 3.

*5: For testing conditio ns, ref er to [1-12 Shock resistance] (P51) and [1-13 Vibration resistance ] (P 52).

19

Page 20

1

2

3

4

5

6

7

8

9

10

11

付

Outline

SG type

Model

Item

SHA58A

SHA65A

81

101

121

161

81

101

121

161

Servo Drive

HA-800□-24D/E-200

HA-800□-24D/E-200

Nm

1924

2067

2236

2392

2400

2990

3263

3419

kgf・m

196

211

228

244

245

305

333

349

Allowable

torque

Nm

714

905

969

969

921

1149

1236

1236

Max. rotational

speed*1

Nm/A

rms

54

68

81

108

54

68

81

108

kgf

・

m/A

rms

Max. current*1

A

rms

45

39

36

30

55

55

51

41

Allowable

current

EMF constant*3

V/(rpm)

6.1

7.6

9.1

12.1

6.1

7.6

9.1

12.1

Phase resistance

(20℃)

Phase inductance

mH

0.29

0.29

Inertia

brake)

GD2/4

kg・m2

96

149

214

379

110

171

245

433

・

Inertia

brake)

GD2/4

kg・m2

106

165

237

420

120

187

268

475

・

Reduction ratio

1:81

1:101

1:121

1:161

1:81

1:101

1:121

1:161

Permissible

moment load

Nm

2180

2740

kgf・m

222

280

Nm/rad

531 x 104

741 x 104

kgf・

min

One-way positional

accuracy

Encoder type

Magnetic absol ute encoder

Single motor revolution

Encoder resolution

Output resolution

Pulse/rev

Mass

(without brake)

Mass (with brake)

kg

32

40

Environmental conditions

Operating temper ature: 0 to 40℃/Storage temperature: -20 to 60℃

Altitude: les s than 1,000 m above sea level

Motor insulation

Insulation resistance: 100MΩ or more (by DC500V insulation tester)

Insulation cl ass: A

Mounting direction

Can be installed in any di rection.

Protection structure

Totally enclosed self-cooled type (IP54)

Max. torque*1

1-4 Specifications

continuous

Torque constant*1

continuous

moment

(without

moment

(with

Moment stiffness

*1*2

*1*2

J

J

kgf・m 73 92 99 99 94 117 126 126

rpm

A

rms

Ω

kgf

cm・s2

kgf

cm・s2

m/arc

37.0 29.7 24.8 18.6 34.6 27.7 23.1 17.4

5.5 6.9 8.3 11.0 5.5 6.9 8.3 11.0

17.7 17.8 16.4 13.4 22.0 21.9 20.1 16.3

0.028 0.028

980 1520 2180 3870 1120 1740 2500 4420

1090 1690 2420 4290 1230 1910 2740 4850

158 220

arc-sec

kg

The table shows typical output values of actuators.

*1: When combined with HA-8 00 driver.

*2: Value after temperature rise and saturation when the 650 x 650 x 30 [mm] aluminum radiation plate is installed.

*3: Value of phase induced voltage constant multiplied by 3.

*4: For testing conditio ns, ref er to [1-12 Shock resistance] (P51) and [1-13 Vibration resistance ] (P 52).

40 40 40 40 40 40 40 40

10,616,832 13,238,272 15,859,712 21,102,592 10,616,832 13,238,272 15,859,712 21,102,592

Operating humidity/storage humidity: 20 to 80%RH (no condensati on)

Resistance to vibr ation: 25 m/s

2 *4

m/s

No dust, no metal powder, no corrosive gas, no inflammable gas , no oil mist

To be used indoors, no direct sunlight

Dielectric strength: AC1,500V/1 min

217(131,072)

29.5 37.5

2

(frequency: 10 to 400Hz)/Shock res istance: 300

20

Page 21

1-4 Specifications

Outline

Actuator Model

Item

SHA20A

50

80

100

120

160

REL-230-18

HA-800□-3D/E-200

Nm

73

96

107

113

120

kgf・m

7.4

9.8

10.9

11.5

12.2

Allowable continuous

torque

Nm

21

35

43

48

48

kgf・m

2.1

3.6

4.4

4.9

4.9

Max. rotational speed*1

rpm

120

75

60

50

37.5

Nm/A

rms

16

26

33

39

53

kgf・m/A

rms

1.7

2.7

3.4

4.0

5.4

Max. current*1

A

rms

6.1

5.0

4.6

4.1

3.4

Allowable continuous

current

EMF constant*3

V/(rpm)

Phase resistance

(20℃)

Ω

Phase inductance

mH

2.5

Inertia

brake)

GD2/4

kg・m2

0.21

0.53

0.82

1.2

2.1

Inertia

brake)

GD2/4

kg・m2

0.23

0.60

0.94

1.3

2.4

Reduction ratio

1:50

1:80

1:100

1:120

1:160

Permissible moment

load

Nm

187

kgf・m

19.1

Nm/rad

25.2×104

kgf・m/arc

min

One-way positional

accuracy

Repeatability

arc-sec

5

Bi-directional

repeatability

Encoder type

Magnetic absolut e encoder

Single motor revolution

Encoder resolution

Motor multi revolution counter

2

16

65,536)

Output resolution

Pulse/rev

6,553,600

10,485,760

13,107200

15,728,640

20,971,520

Mass

(without brake)

Mass (with brake)

kg

2.7

Environmental conditions

Operating temper ature: 0 to 40℃/Storage temperature: -20 to 60℃

Altitude: les s than 1,000 m above sea level

Motor insulation

Mounting direction

Can be installed in any di rection

Protection structure

Totally enclosed self-cooled type (IP54)

CG type

Servo Drive

Max. torque*1

*1*2

Torque constant*1

*1*2

moment

(without

moment

(with

A

2.1 2.1 2.1 2.0 1.7

rms

1.8 2.9 3.7 4.4 5.9

1.4

J kgf・cm・s2 2.1 5.4 8.0 12 22

J kgf・cm・s2 2.4 6.1 9.6 14 24

Moment stiffness

arc-sec 60 50 50 50 50

arc-sec 75 30 30 30 30

kg 2.6

Operating humidity/storage humidity: 20 to 80%RH (no condensati on)

Resistance to vibrat ion: 25 m/s

300 m/s

No dust, no metal powder, no corrosive gas, no inflammable gas, no oil mist

To be used indoors, no direct sunlight

Insulation resistance: 100MΩ or more (by DC500V insulation tester)

Dielectric strength: AC1,500V/1 min

Insulation cl ass: A

The table shows typical output values of actuators.

*1: Typical characteristics when combined with our HA-800 driver.

*2: Value after temperature rise and saturation when the 350 x 350 x 18 [mm] aluminum radiation plate is installed.

*3: Value of phase induced voltage constant multiplied by 3.

*4: For testing conditions, refer to [1-12 Shock resistance] (P51) and [1-13 Vibration resistance ] (P52).

21

2 *4

7.5

±

217(131,072)

(

2

(frequency: 10 to 400H z)/Shock resistance:

Page 22

1

2

3

4

5

6

7

8

9

10

11

付

Outline

CG type

Item

SHA25A(Motor input voltage 100V)

SHA25A(Motor input voltage 200V)

50

80

100

120

160

50

80

100

120

160

REL-230-18

HA-800□-6D/E-100*1

REL-230-18

HA-800□-3D/E-200

Nm

127

178

204

217

229

127

178

204

217

229

kgf・m

13

18.2

20.8

22.1

23.4

13

18.2

20.8

22.1

23.4

Allowable continuous

torque

Nm

34

57

72

81

81

40

66

81

81

81

kgf・m

3.5

5.8

7.3

8.2

8.2

4.1

6.8

8.2

8.2

8.2

Max. rotational speed*1

rpm

96

60

48

40

30

112

70

56

46.7

35

Nm/A

rms

10.9

17.7

22

27

35

19

31

38

46

61

kgf・

m/A

rms

Allowable continuous

current

EMF constant*3

V/(rpm)

1.2

2.0

2.5

3.0

4.0

2.1

3.4

4.3

5.2

6.9

Phase resistance

(20℃)

Ω

Phase inductance

mH

1.0

3.0

Inertia

brake)

GD2/4

kg・m2

0.50

1.3

2.0

2.9

5.1

0.50

1.3

2.0

2.9

5.1

・

Inertia

(with brake)

GD2/4

kg・m2

0.60

1.5

2.4

3.4

6.1

0.60

1.5

2.4

3.4

6.1

kgf・cm・

s2

Reduction ratio

mH

50:1

80:1

120:1

1:120

160:1

50:1

80:1

120:1

1:120

160:1

Nm

258

kgf・m

26.3

Nm/rad

39.2×104

kgf・m/arc

min

One-way positional

accuracy

Repeatability

arc-sec

5

Bi-directional positional

accuracy

Encoder type

Magnetic absolute encoder

Single motor revolution

Encoder resolution

Motor multi revolution counter

2

16

65,536)

6,553,

600

10,485,

760

13,107,

200

15,728,

640

20,971,

520

6,553,

600

10,485,

760

13,107,

200

15,728,

640

20,971,

520

Mass

(without brake)

Mass (with brake)

kg

4.1

Environmental conditions

Motor insulation

Mounting direction

Can be installed in any direction

Protection structure

Totally enclosed self-cooled type (IP54)

1-4 Specifications

Model

Servo Drive

Max. torque*1

*1*2

Torque constant*1

Max. current*1

*1*2

moment

(without

moment

Permissible moment load

Moment stiffness

J

J

REL-230-36

1.1 1.8 2.3 2.7 3.6 1.9 3.1 3.9 4.7 6.3

A

rms

A

rms

kgf・cm

s2

15.1 13.2 12.2 11.0 9.0 8.7 7.6 7.0 6.3 5.2

4.7 4.7 4.7 4.5 3.7 3.0 3.0 3.0 2.6 2.1

0.4 1.2

5.1 13 20 29 52 5.1 13 20 29 52

6.1 16 24 35 62 6.1 16 24 35 62

11.6

REL-230-36

arc-sec

arc-sec

Output resolution

Pulse/rev

kg 3.95

The table shows typical output values of actuators.

*1: Typical characteristics when combined (driven by ideal sine wave) with our drivers.

*2: Value after temperature rise and saturation when the 350 x 350 x 18 [mm] aluminum radiation plate is installed.

*3: Value of phase induced voltage constant multiplied by 3.

*4: For testing conditions, refer to [1-12 Shock resistance] (P51) and [1-13 Vibration resistance ] (P52).

50 40 40 40 40 50 40 40 40 40

±

60 25 25 25 25 60 25 25 25 25

217(131,072)

(

Operating temperature: 0 to 40℃/Storage temperature: -20 to 60℃

Operating humidity/storage humidity: 20 to 80%RH (no condensation)

Resistance to vibration: 25 m/s

No dust, no metal powder, no corrosive gas, no inflammable gas, no oil mist

To be used indoors, no direct sunlight

Altitude: less than 1,000 m above sea level

Insulation resistance: 100MΩ or more (by DC500V insulation tester)

Dielectric strength: AC1,500V/1 min

Insulation class: A

2

(frequency: 10 to 400Hz)/Shock resistance: 300 m/s

2 *4

22

Page 23

1-4 Specifications

Outline

Model

Item

SHA32A

50

80

100

120

160

REL-230-18

HA-800□-6D/E-200

Nm

281

395

433

459

484

kgf・m

28.7

40.3

44.2

46.8

49.4

Allowable continuous

torque

Nm

90

151

178

178

178

kgf・m

9.2

15.4

18.2

18.2

18.2

Max. rotational speed*1

rpm

96

60

48

40

30

Nm/A

rms

20

33

41

49

66

kgf・

m/A

rms

Max. current*1

A

rms

17.7

15.4

13.7

12.2

10

Allowable continuous

current

Ω

Max. current*1

mH

1.4

Inertia

brake)

GD2/4

kg・m2

1.7

4.3

6.7

9.7

17

・

Inertia

brake)

GD2/4

kg・m2

2.0

5.1

7.9

11

20

・

Reduction ratio

50:1

80:1

100:1

120:1

160:1

Nm

580

kgf・m

59.2

Nm/rad

100×104

kgf・

min

One-way positional

accuracy

Repeatability

arc-sec

4

Bi-directional

repeatability

Encoder type

Magnetic absolute encoder

Single motor rev olution

Encoder resolution

Motor multi revolution

counter

Output resolution

Pulse/rev

6,553,600

10,485,760

13,107,200

15,728,640

20,971,520

Mass

(without brake)

Mass (with brake)

kg

8.0

Environmental conditions

Motor insulation

Mounting direction

Can be installed in any direction.

Protection structure

Totally enclosed self-cooled type (IP54)

CG type

Servo Drive

REL-230-36

Max. torque*1

*1*2

Torque constant*1

*1*2

A

rms

2.1 3.4 4.2 5.0 6.7

6.0 6.0 5.7 5.0 4.1

EMF constant*3 V/(rpm) 2.3 3.7 4.6 5.5 7.4

Phase resistance(20℃)

moment

(without

J

moment

(with

J

0.33

kgf・cm

s2

kgf・cm

s2

17 44 68 99 175

20 52 81 116 207

Permissible moment load

The table shows typical output values of actuators.

*1: Typical characteristics when used with HA-800.

*2: Value after temperature rise and saturation when the 400 x 400 x 20 [mm] aluminum radiation plate is installed.

*3: Value of phase induced voltage constant multiplied by 3.

*4: For testing conditions, refer to [1-12 Shock resistance] (P51) and [1-13 Vibration resistance ] (P52).

23

Moment stiffness

m/arc

arc-sec

arc-sec

40 30 30 30 30

60 25 25 25 25

29.6

217(131,072)

216(65,536)

kg 7.7

Operating temperature: 0 to 40℃/Storage temperature: -20 to 60℃

Operating humidit y/storage humidity: 20 to 80%RH (no condensation)

Resistance to vibration: 25 m/s

No dust, no metal powder, no corrosive gas, no inflammable gas, no oil mist

To be used indoors, no direct sunlight

Altitude: less than 1,000 m above sea level

Insulation resistance: 100MΩ or more (by DC500V insulation tester)

Dielectric strength: AC1,500V/1 min

Insulation class: A

2

(frequency: 10 to 400Hz)/Shock resistance: 300 m/s

±

2 *4

Page 24

1

2

3

4

5

6

7

8

9

10

11

付

Outline

CG type

Model/Ratio

Item

SHA40A

50

80

100

120

160

50

80

100

120

160

REL-230-36, REL-230-40

HA-800□-6D/E-200

REL-230-36, REL-230-40

HA-800□-24D/E-200

Nm

333

548

686

802

841

523

675

738

802

841

kgf・m

34.0

55.9

70.0

81.8

85.8

53.4

68.9

75.3

81.8

85.8

Allowable continuous

torque

Nm

92

156

196

235

315

157

260

327

382

382

kgf・m

9.4

15.9

20.0

24.0

32.1

16.0

26.5

33.3

39

39

Nm/A

rms

25

40

50

60

80

25

40

50

60

80

kgf・

m/A

rms

A

Allowable continuous

current

EMF constant

V/(rpm)

2.8

4.5

5.6

6.7

9.0

2.8

4.5

5.6

6.7

9.0

Phase resistance

(20℃)

Phase inductance

mH

1.2

Inertia

brake)

GD2/4

kg・m2

4.8

12

19

27

49

4.8

12

19

27

49

・

Inertia

(with brake)

GD2/4

kg・m2

5.8

15

23

33

59

5.8

15

23

33

59

kgf・cm・

s2

Permissible moment

load

Nm

849

kgf・m

86.6

Nm/rad

179×104

kgf・

min

One-way positional

accuracy

Repeatability

arc-sec

4

Bi-directional

repeatability

Encoder type

Magnetic absolute encoder

Single motor

Encoder resolution

Motor multi revolution

count

6,553,

600

10,485,

760

13,107,

200

15,728,

640

20,971,

520

6,553,

600

10,485,

760

13,107,

200

15,728,

640

20,971,

520

Mass

(without brake)

Mass (with brake)

kg

13.8

Environmental conditions

Altitude: less than 1,000 m above sea level

Motor insulation

Mounting direction

Can be installed in any direction.

Protection structure

Totally enclosed self-cooled type (IP54)

1-4 Specifications

Combined driver

Max. torque*2

*2*3

Max. rotational speed*2 rpm 80 50 40 33.3 25 80 50 40 33.3 25

Torque constant*2

Max. current*1

*1*2

moment

(without

moment

Moment stiffness

rms

A

rms

Ω 0.19

kgf・cm

J

J

s2

m/arc

2.5 4.1 5.1 6.1 8.2 2.5 4.1 5.1 6.1 8.2

18 18 18 17.6 14.3 27.2 22 19.6 18 14.7

6.0 6.0 6.0 6.0 6.0 9.0 9.0 9.0 8.8 7.2

49 124 194 280 497 49 124 194 280 497

59 150 235 338 601 59 150 235 338 601

*1

53.2

arc-sec

arc-sec

revolution

Output resolution

217(131,072)

216(65,536)

Pulse/rev

kg 13.0

The table shows typical output values of actuators.

*1: If a HA-800□-6D/E driver is combined with a SHA40A actuator, the maximum torque and allowable continuous torque are limited.

*2: Typical characteristics when combined (driven by ideal sine wave) with our drivers.

*3: Value after temperature rise and saturation when the 500 x 500 x 25 [mm] aluminum radiation plate is installed.

*4: Value of phase induced voltage constant multiplied by 3.

*5: For testing conditions, refer to [1-12 Shock resistance] (P51) and [1-13 Vibration resistance ] (P52).

40 30 30 30 30 40 30 30 30 30

±

50 20 20 20 20 50 20 20 20 20

Operating temperature: 0 to 40℃/Storage temperature: -20 to 60℃

Operating humidity/storage humidity: 20 to 80%RH (no condensation)

Resistance to vibration: 25 m/s

No dust, no metal powder, no corrosive gas, no inflammable gas, no oil mist

To be used indoors, no direct sunlight

Insulation resistance: 100MΩ or more (by DC500V insulation tester)

Dielectric strength: AC1,500V/1 min

Insulation class: A

2

(frequency: 10 to 400Hz)/S hock resistance: 300 m/s

2 *4

24

Page 25

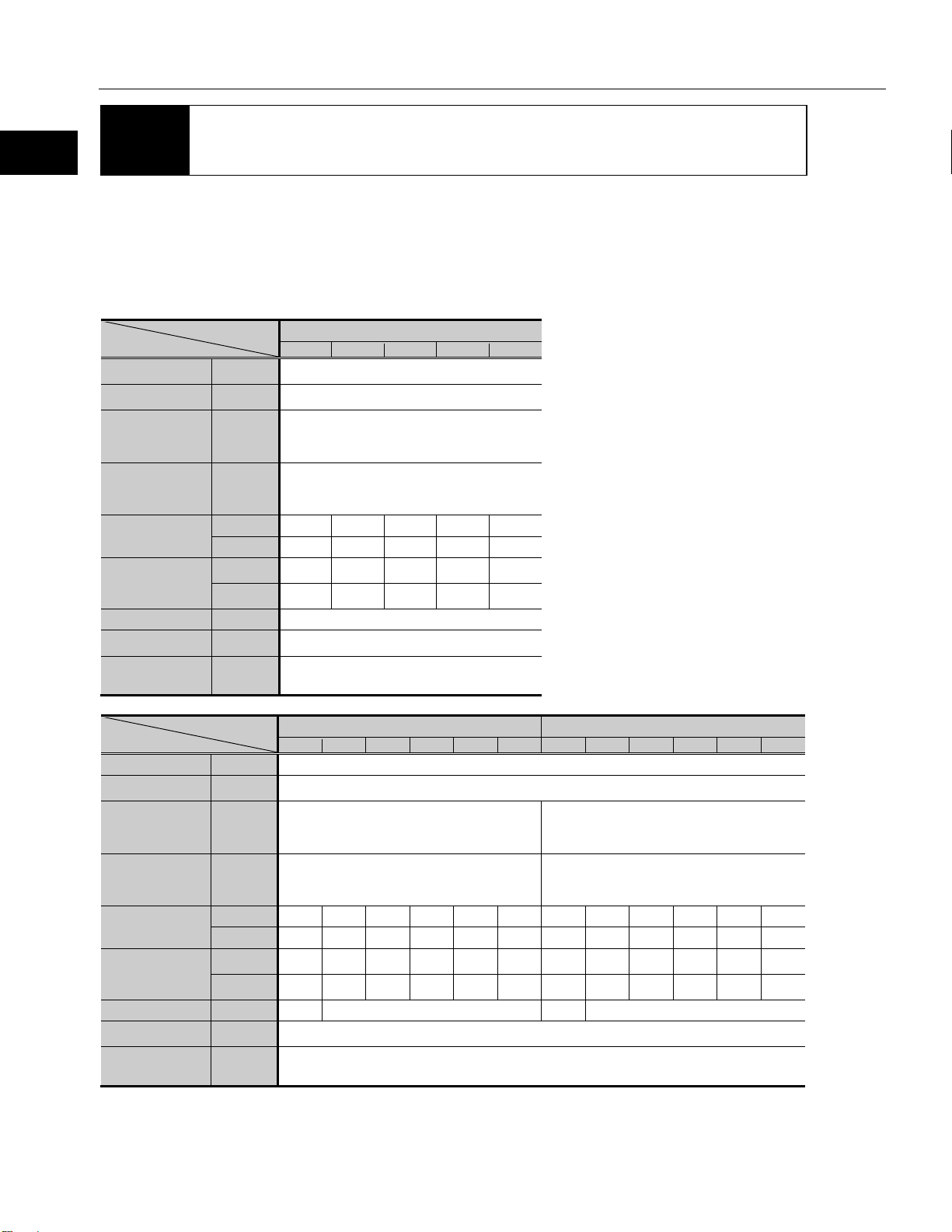

1-5 Motor shaft brake

Outline

Model

51

81

101

121

161

Dry non-excitation actuation type (without power-

saving control)

Brake excitation

voltage

Current

(at 20℃)

Current

(at 20℃)

(GD2/4)

kg·m2

(J)

kgf·cm·s2

Allowable number

of normal stops*5

Allowable number

stops*6

11

51

81

101

121

161

11

51

81

101

121

161

Brake excitation

voltage

Current

(at 20℃)

Current

(at 20℃)

(GD2/4)

kg·m2

(J)

kgf·cm·s2

Allowable number

of normal stops*5

Allowable number

stops*6

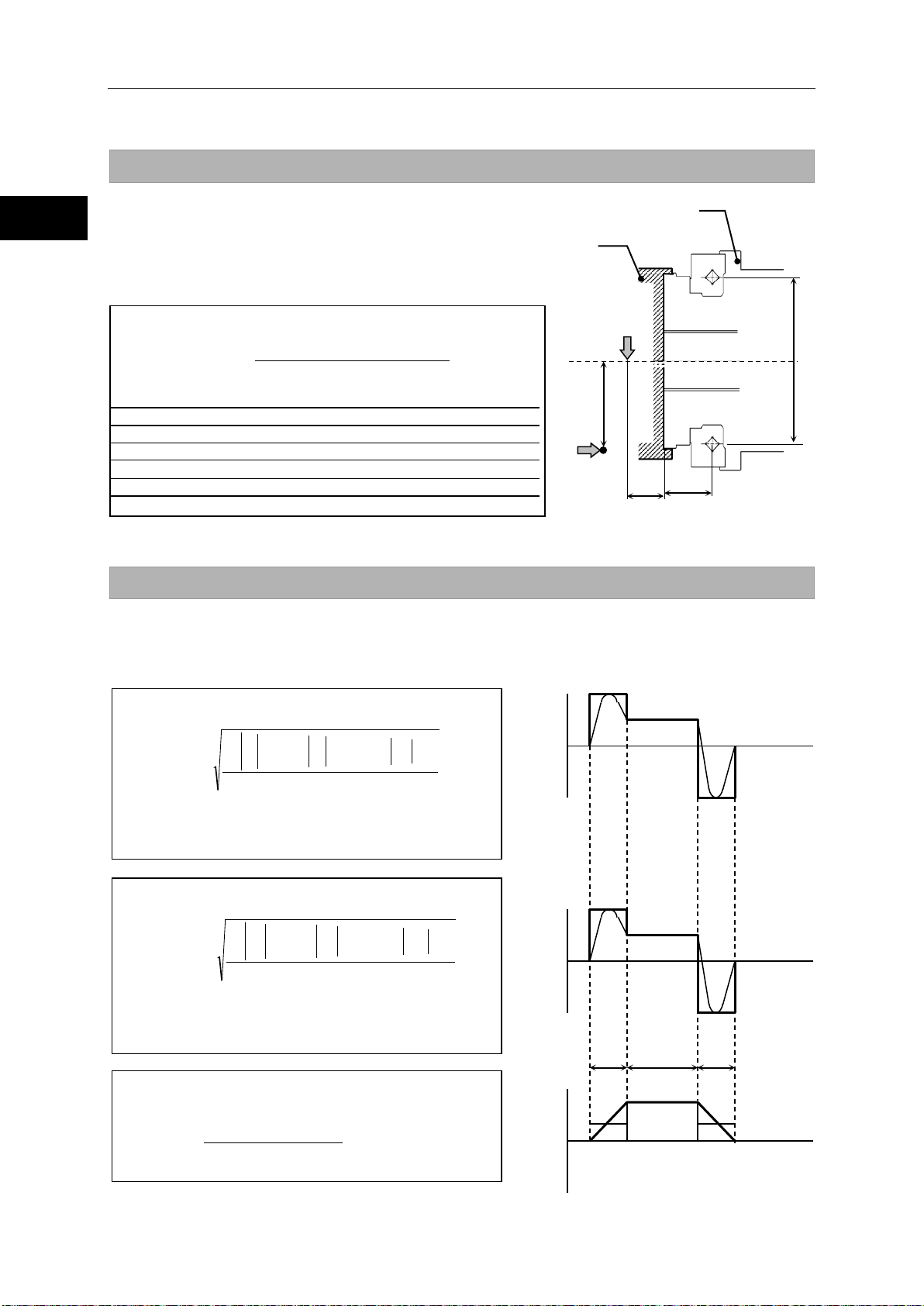

1-5 Motor shaft brake

The brake is used to hold the motor shaft in place when the power is turned off. With smaller sizes (SHA25A, 32A), the

actuator's built-in circuit controls the voltage supplied to the brake in order to reduce the power consumption while the brake is

actuated.

Be sure to use a DC power supply having proper brake excitation voltage and capable of outputting enough current for the

brake actuation (release).

Specifications

SG/HP type

Item

Type

V DC24V ± 10% (no polarity)*1

SHA20A

consumption

during suction

consumption

during holding

Holding torqu e*3

Inertia moment*3

(Actuator total)

(with brake)

Mass (with brake)*4 kg 2.1

of emergency

A

0.37

rms

A

Sam e as curre nt consumption during suctio n

rms

Nm 31 49 61 73 97

kgf·m 3.1 5.0 6.2 7.4 9.9

0.26 0.65 1.0 1.4 2.6

2.7 6.6 10 15 26

100,000 times

200 times

Item

Type Dry non-excitation actuation type (with power-saving control)

consumption

during suction

consumption

during holding

Model

V DC24V ± 10% (no polarity)*1

A

0.8*2 0.8*2

rms

A

0.3 0.3

rms

SHA25A SHA32A

Holding torqu e*3

Inertia moment*3

(Actuator total)

(with brake)

Mass (with brake)*4 kg 5.1 3.1 9.7 6.2

of emergency

25

Nm 11 51 81 101 121 161 22 102 162 202 242 322

kgf·m 1.1 5.2 8.3 10 12 16 2.2 10 17 21 25 33

0.034 0.66 1.7 2.6 3.7 6.6 1.7 2.3 5.9 9.2 13 23

0.35 6.7 17 26 38 67 17 24 60 94 135 238

100,000 times

200 times

Page 26

1

2

3

4

5

6

7

8

9

10

11

付

Outline

SG

Model

Item

SHA40A

SHA58A

51

81

101

121

161

81

101

121

161

Type Dry non-excitation actuation type (without power-saving control)

Brake excitation voltage

V

DC24V ± 10% (no polarity)*1

Current consumption

during suction (at 20℃)

Current consumption

during holding (at 20℃)

Nm

204

324

404

484

644

1220

1520

1820

2420

kgf·m

21

33

41

49

66

124

155

185

246

(GD2/4)

kg·m2

(J)

kgf·cm·s2

Mass (with brake)*4

kg

10.7

32

Allowable number of

normal stops*5

Allowable number of

emergency stops*6

Model

Item

SHA65A

81

101

121

161

Dry non-excitation actuation type (wi tho ut

power-saving control)

Brake excitation voltage

V

DC24V±10% (no polarity)*1

Current consumption

during suction (at 20℃)

Current consumption

during holding (at 20℃)

Same as current consumption during

suction

Nm

1220

1520

1820

2420

kgf·m

124

155

185

246

(GD2/4)

kg·m2

(J)

kgf·cm·s2

Mass (with brake)*4

kg

40

Allowable number of

normal stops*5

Allowable number of

emergency stops*6

Model

50

80

100

120

160

50

80

100

120

160

Dry non-excitation actuation type (without power-

saving control)

Dry non-excitat ion actuation type (with power-

saving control)

Brake excitation

voltage

Current consumption

20℃)

Current consumption

20℃)

(GD2/4)

kg·m2

(J)

kgf·cm·s2

Allowable number of

normal stops*5

Allowable number of

emergency stops*6

Holding torqu e*3

Inertia moment*3

(Actuator total)

(With brake)

Type

A

0.7 0.9

rms

A

Same as current consumption during suct io n

rms

6.1 15 24 34 61 106 165 237 420

62 157 244 350 619 1090 1690 2420 4290

100,000 times

200 times

A

0.9

rms

1-5 Motor shaft brake

A

rms

Holding torqu e*3

Inertia moment*3

(Actuator total)

(With brake)

100,000 times

200 times

120 187 268 475

1230 1910 2740 4850

CG

type

Item

Type

V

during suction (at

during holding (at

Holding torqu e*3

Inertia moment*3

(Actuator total)

(With brake)

Mass (with brake)*4 kg 2.7 4.1

A

0.37 0.8 *2

rms

A

Same as current consum pt io n during suction 0.3

rms

Nm

kgf·m

30 48 60

3.1 4.9 6.1

0.23 0.6 0.94

2.4 6.1 9.6

100,000 times

200 times

SHA20A SHA25A

DC24V±10%(no polarity)*1

72 96 50 80 100 120 160

7.3 9.8 5.1 8.2 10 12 16

1.3 2.4 0.60 1.5 2.4 3.4 6.1

14 24 6.1 16 24 35 62

26

Page 27

1-5 Motor shaft brake

Outline

Model

50

80

100

120

160

50

80

100

120

160

Dry non-excitation actuation type (with power-

saving control)

Dry non-excitat ion actuation type (without

power-saving control)

Brake excitation

voltage

Current consumption

20℃)

Current consumption

20℃)

(GD2/4)

kg·m2

(J)

kgf·cm·s2

Allowable number of

normal stops*5

Allowable number of

emergency stops*6

WARNING

Item

SHA32A SHA40A

Type

during suction (at

during holding (at

Holding torqu e*3

Inertia moment*3

(Actuator total)

(With brake)

Mass (with brake)*4 kg 8.0 13.8

V DC24V±10%(no polari t y)*1

A

0.8 *2 0.7

rms

A

0.3 Sam e as cur re nt cons um pt io n during suction

rms

Nm 100 160 200 240 320 200 320 400 480 640

kgf·m 10 16 20 24 33 20 33 41 49 65

2.0 5.1 7.9 11 20 5.8 15 23 33 59

20 52 81 116 207 59 150 235 338 601

100,000 times

200 times

*1: Power supply is user’s responsibility. Use a power supply capable of outputting enough current consumption during suction for the brake.

*2: The durat i on for current c onsum ption during suction is 0.5 second or less for the power supply of DC24V ± 10%.

*3: The values are converted for the output shaft of the actuator.

*4: The values present total mass of the actuator.

*5: The s ervice tim e for normal holdi ng is assured when the brake activates at motor shaft rotation speed of 150 rpm or less.

*6: The s ervice time for emergency stop is assured when the brake activates at motor speed of 3,000 rpm or less provided the load inertia

moment is 3 times of less than that of the actuator.

The motor shaft holding brake cannot be used for deceleration.

Do not use the holding brake more than the allowable number of normal brakings (100,000

times at the motor shaft rotation speed of 150 rpm or less) or allowable number of

emergency stops (200 times with the motor shaft rotation speed of 3,000 rpm, provided

the load inertia moment is 3 times or less than that of the actuator).

Exceeding the allowable number of normal stops or allowable number of emergency stops

may deteriorate holding torque, and may co nsequently fail to properly serve as a brake.

27

Page 28

1

2

3

4

5

6

7

8

9

10

11

付

Outline

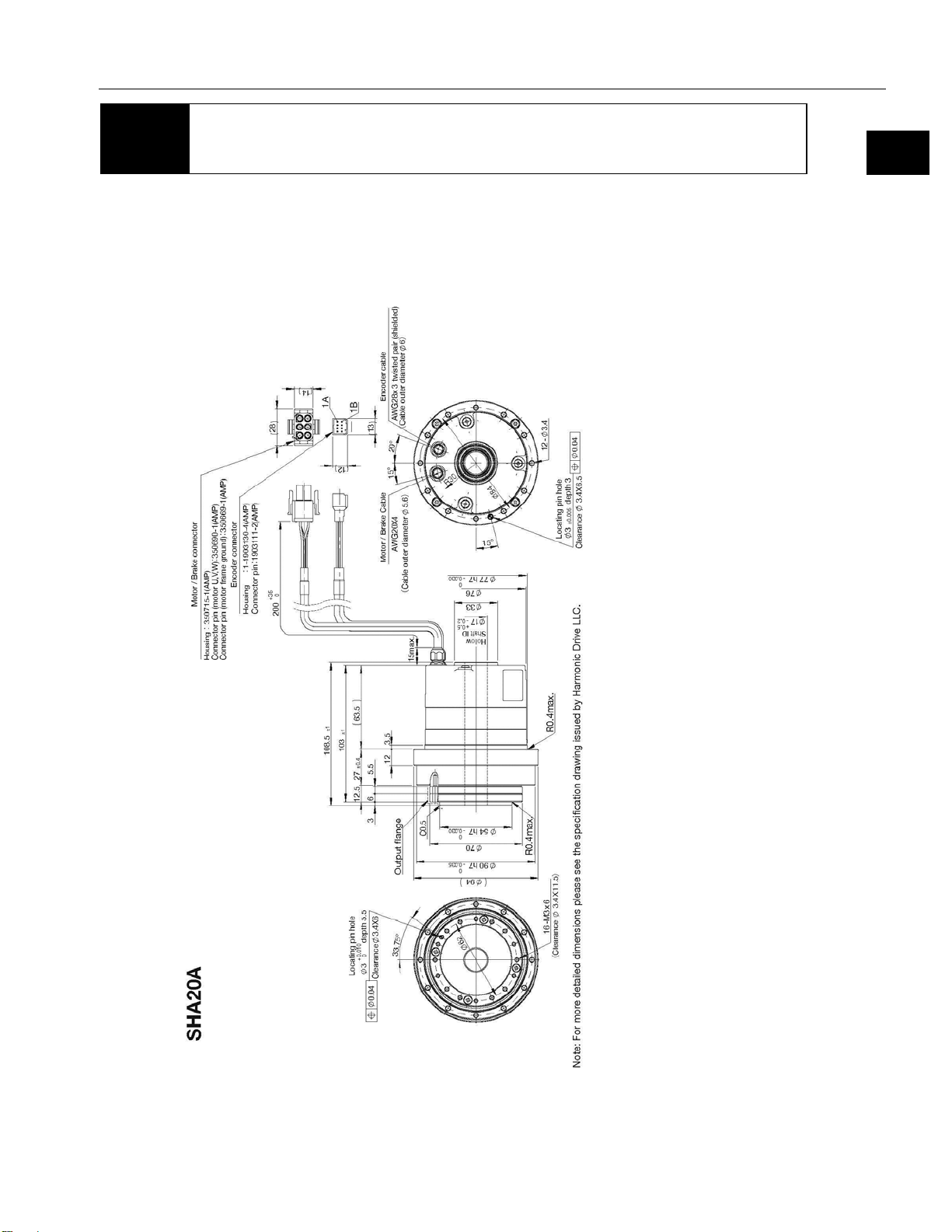

Note: The dimension toleranc es that are not specified vary depending on the manufacturing method. Pleas e ch eck t he

confirmation drawing or contact us

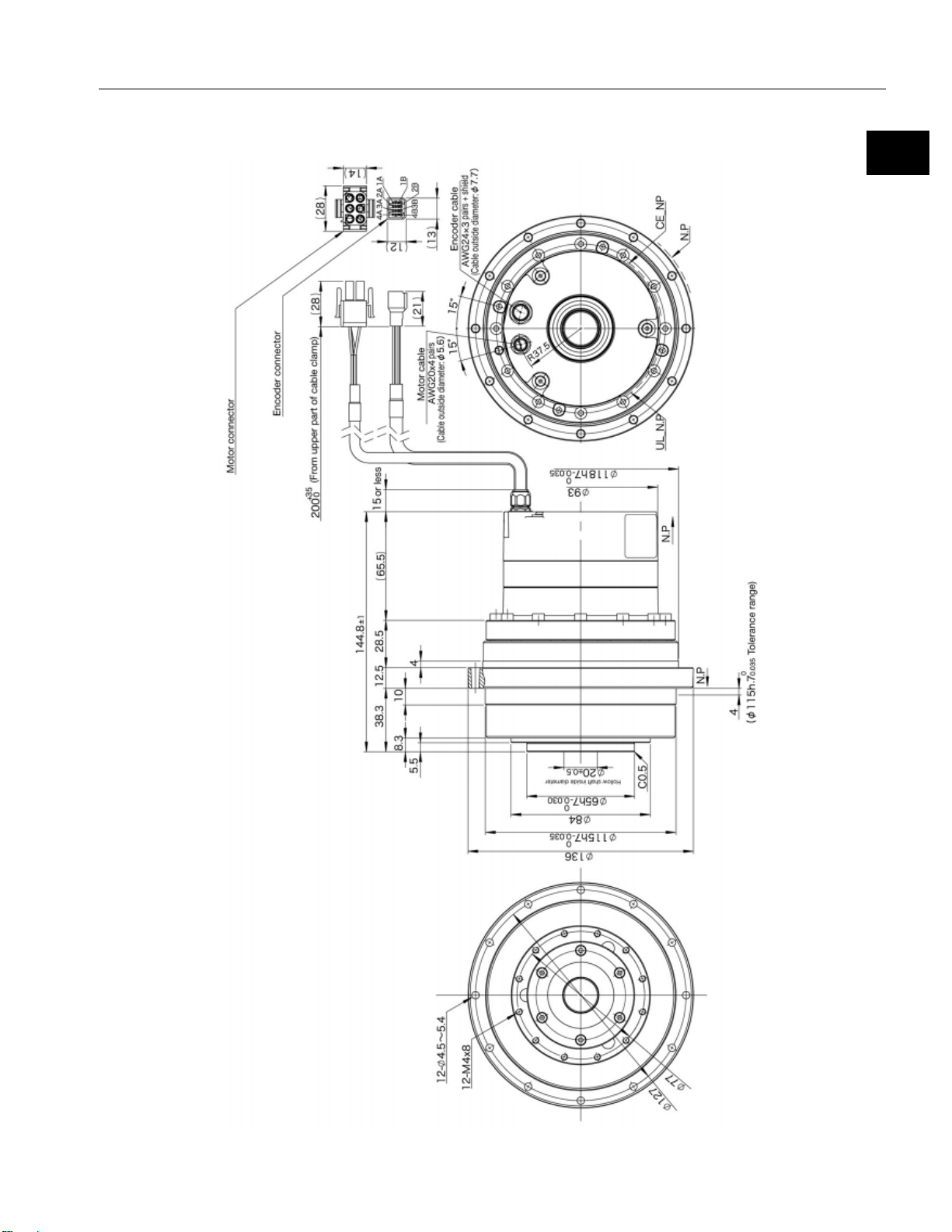

1-6 External dimensions

SHA20A-SG

Unit: mm

1-6 External dimensions

for dimension tolerances not shown

28

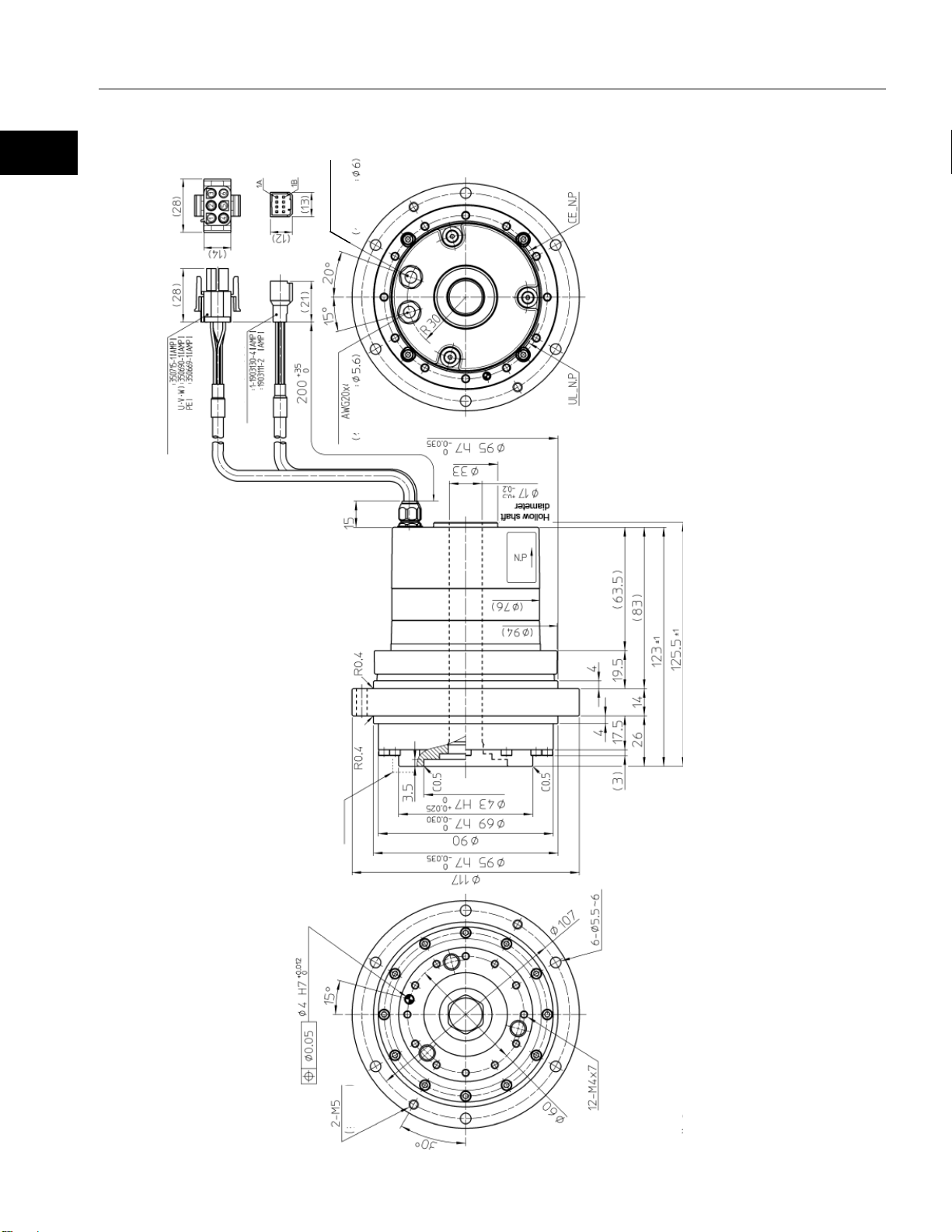

Page 29

1-6 External dimensions

Outline

Encoder cable

AWG28 x 3 sets

with shield

Cable outer

diameter

Motor connector

Housing

Pin contact (Motor

Pin contact (Motor

Encoder connector

Housing

Tab contact

Motor cable

Cable outer

diameter

4-core

Output rotary unit

Jacking

holes

Note: The dimension toleranc es that are not specified vary depending on the manufacturing method. P leas e chec k t he

confirmation drawing or contact us for dimension tolerances not shown

LipC0.5 chamfering

Depth 7

or less

or less

or less

SHA20A-CG

Unit: mm

29

Page 30

1

2

3

4

5

6

7

8

9

10

11

付

Outline

Note: The dimension tolerances that are not specified vary depending on the manufacturing method. Please check the

confirmation drawing or contact us for dimension toleranc

SHA25A-HP Unit: mm

1-6 External dimensions

es not shown

30