Page 1

RSF Supermini Actuator

RSF Brushless Servo Actuator

Total Motion Control

P r e c i s i o n G e a r i n g & M o t i o n C o n t r o l

Page 2

SAFETY GUIDE

CAUTIO

CAUTIO

G

CAUTIO

CAUTIO

G

CAUTIO

CAUTIO

G

G

G

For actuators, motors, control units and drivers

Read this manual thoroughly before designing the application, installation, maintenance or inspection of the actuator.

Indicates a potentially hazardous situation,

which, if not avoided, could result in death

or serious personal injury.

LIMITATION OF APPLICATIONS:

The equipment listed in this document may not be used for the applications listed below:

Space equipment Automobile, automotive parts

Aircraft, aeronautic equipment Amusement equipment, sport equipment, game machines

Nuclear equipment Machine or devices acting directly on the human body

Household apparatus Instruments or devices to transport or carry people

Vacuum equipment Apparatus or devices used in special environments

If the above list includes your intending application for our products, please consult us.

Safety measures are essential to prevent accidents resulting in death, injury or damage of the equipment due to

malfunction or faulty operation.

CAUTIONS FOR ACTUATORS AT APPLICATION DESIGNING

Always use under followings conditions:

-Ambient temperature: 0˚C to 40˚C

-Ambient humidity: 20% to 80%RH (Non-condensation)

-Vibration: Max 24.5 m/S

-No contamination by water, oil

N

-No corrosive or explosive gas

CAUTION FOR ACTUATORS IN OPERATIONS

Keep limited torques of the actuator.

-Keep limited torques of the actuator.

-Be aware, that if arms attached to output element hits

by accident an solid, the output element may be

uncontrollable.

Do not apply impacts and shocks

-Do not use a hammer during installation

WARNIN

-Failure to observe this caution could damage the

encoder and may cause uncontrollable operation.

manufactured by Harmonic Drive LLC

2

Indicates a potentially hazardous situation, which, if

not avoided, may result in minor or moderate personal

injury and/or damage to the equipment.

NWARNIN

Follow exactly the instructions in the relating

manuals to install the actuator in the equipment.

-Ensure exact alignment of actuator shaft center and

corresponding center in the application.

Failure to observe this caution may lead to vibration,

resulting in damage of output elements.

Never connect cables directly to a power supply

socket.

-Each actuator must be operated with a proper driver.

WARNIN

-Failure to observe this caution may lead to injury, fire or

damage of the actuator.

Avoid handling of actuators by cables.

-Failure to observe this caution may damage the wiring,

WARNIN

causing uncontrollable or faulty operation.

CAUTIONS FOR DRIVERS AT APPLICATION DESIGNING

Always use drivers under followings conditions:

-Mount in a vertical position keeping sufficient distance

to other devices to let heat generated by the driver

radiate freely.

-Ambient temperature: 0˚C to 50˚C

N

-Ambient humidity: less than 95% RH (Non

condensation)

-No contamination by water, oil or foreign matters

-No corrosive, inflammable or explosive gas

Pay attention to negative torque by inverse load.

–Inverse load may cause damages of drivers.

-Please consult our sales office, if you intent to apply

products for inverse load.

Use sufficient noise suppressing means and safe

grounding.

-Keep signal and power leads separated.

-Keep leads as short as possible.

-Ground actuator and driver at one single point, minimum

ground resistance class: D (less than 100 ohms)

-Do not use a power line filter in the motor circuit.

Use a fast-response type ground-fault detector

designed for PWM inverters.

-Do not use a time-delay-type ground-fault detector.

N

CAUTION FOR DRIVERS IN OPERATIONS

WARNIN

Never change wiring while power is active.

-Make sure of power non-active before servicing the

products.

-Failure to observe this caution may result in electric

shock or personal injury.

Do not make a voltage resistance test.

-Failure to observe this caution may result in damage of

the control unit.

-Please consult our sales office, if you intent to make a

N

voltage resistance test.

Do not touch terminals or inspect products at least

5 minutes after turning OFF power.

-Otherwise residual electric charges may result in

electric shock.

-Make installation of products not easy to touch their

inner electric components.

Do not operate control units by means of power

ON/OFF switching.

-Start/stop operation should be performed via input

signals.

N

Failure to observe this caution may result in deterioration

of electronic parts.

DISPOSAL OF AN ACTUATOR, A MOTOR, A CONTROL UNIT AND/OR THEIR PARTS

All products or parts have to be disposed of as industrial waste.

-Since the case or the box of drivers have a material indication, classify parts and dispose them separately.

1

Page 3

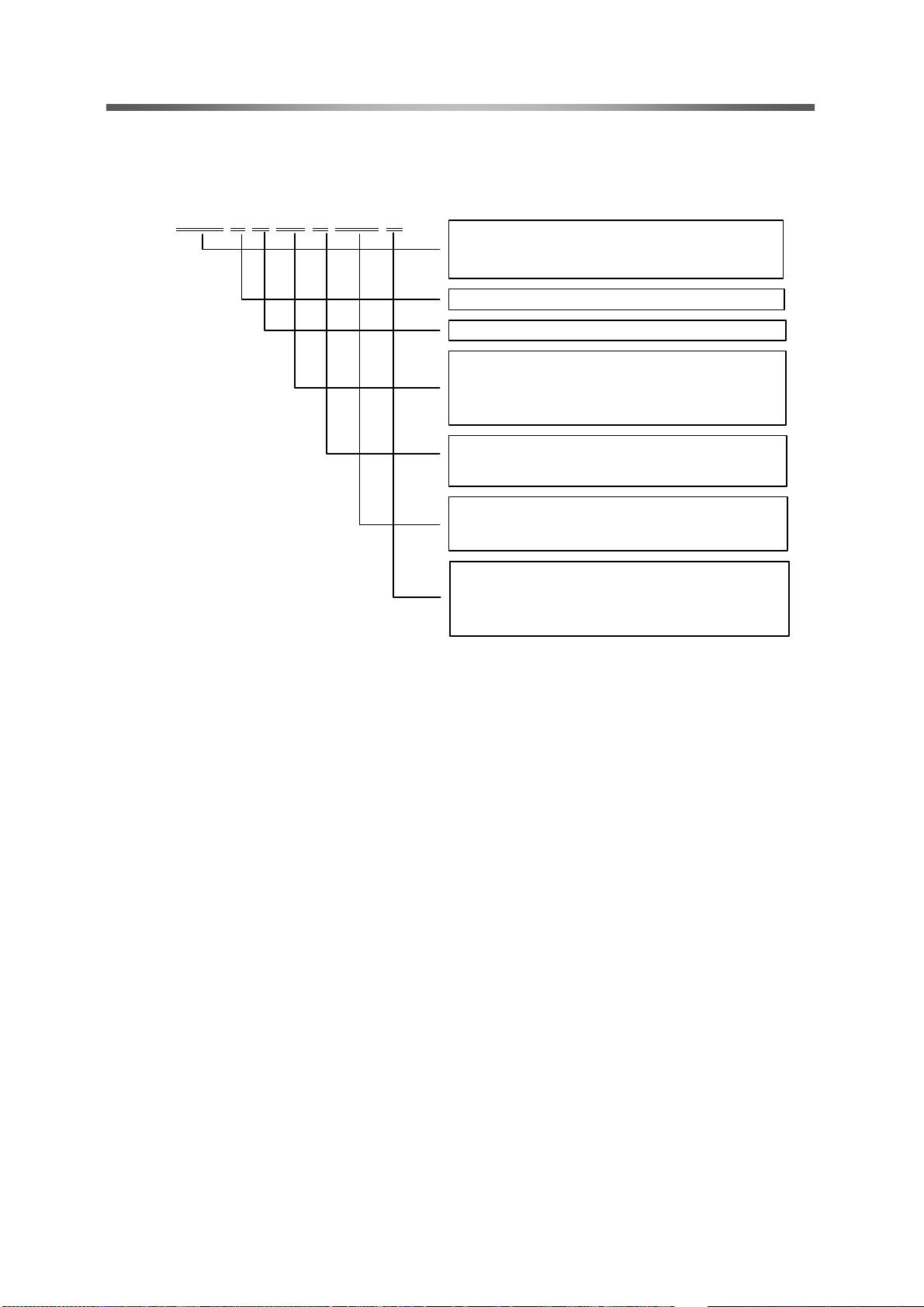

RSF supermini series AC servo actuator manual

Contents

Chapter 1 Overview of the RSF supermini series ................................................................................... 1

1-1 Major characteristics................................................................................................................... 1

1-2 Ordering information ................................................................................................................... 2

1-3 Combinations with drivers .......................................................................................................... 2

1-4 Specifications of RSF supermini actuators................................................................................. 3

1-5 External dimensions of actuators ............................................................................................... 4

1-6 One-way positioning accuracy....................................................................................................6

1-7 Torsional stiffness ....................................................................................................................... 7

1-8 Detector resolution...................................................................................................................... 8

1-9 Mechanical accuracy .................................................................................................................. 8

1-10 Allowable load............................................................................................................................. 9

1-10-1 Allowable radial load and allowable thrust load ............................................................. 9

1-10-2 Radial load when the operating point is different........................................................... 9

1-11 Rotary direction......................................................................................................................... 10

1-12 Impact resistance...................................................................................................................... 10

1-13 Vibration resistance .................................................................................................................. 10

1-14 Torque-speed characteristics.....................................................................................................11

1-15 Cable specifications.................................................................................................................. 13

Chapter 2 Selection of the RSF supermini Series.................................................................................14

2-1 Allowable load moment of inertia.............................................................................................. 14

2-2 Variable load inertia .................................................................................................................. 14

2-3 Verifying loads .......................................................................................................................... 14

2-4 Duty cycles ............................................................................................................................... 15

2-4-1 Actuator speed................................................................................................................ 15

2-4-2 Load moment of inertia ................................................................................................... 15

2-4-3 Load torque.....................................................................................................................15

2-4-4 Acceleration time and deceleration time......................................................................... 16

2-4-5 Calculating equivalent duty............................................................................................. 17

2-4-6 Effective torque and average speed............................................................................... 21

2-4-7 Permissible overloaded time .......................................................................................... 22

Chapter 3 Installing the actuator......................................................................................................... 23

3-1 Receiving Inspection................................................................................................................. 23

3-2 Notice on handling .................................................................................................................... 24

RSF-super_V1_01 - contents 1 -

Page 4

RSF supermini series AC servo actuator manual

3-3 Location and installation ........................................................................................................... 25

3-3-1 Environment of location .................................................................................................. 25

3-3-2 Considerations into External Noise ................................................................................ 25

3-3-2

Installation....................................................................................................................... 26

Chapter 4 Motor shaft retention brake(RSF-5A) ...................................................................................27

4-1 Motor shaft retention brake specifications ................................................................................ 27

4-2 Controlling the brake power supply .......................................................................................... 27

4-2-1 Using a relay cable (Recommended method) ................................................................ 27

4-2-2 Not using a relay cable ................................................................................................... 28

Chapter 5 Options ................................................................................................................................. 29

5-1 Relay cables ............................................................................................................................. 29

5-2 Relay cable wire bound specifications...................................................................................... 30

5-3 Connectors ............................................................................................................................... 31

Appendix 1 Conversion of Unit ...................................................................................................App. 1-1

Appendix 2 Moment of inertia .....................................................................................................App. 2-1

1. Calculation of mass and moment of inertia .................................................................App. 2-1

2. Moment of inertia of circular cylinder...........................................................................App. 2-3

RSF-super_V1_01 - contents 2 -

Page 5

Chapter 1 Overview of the RSF supermini series

Chapter 1 Overview of the RSF supermini series

The RSF supermini series are ultra-small AC servo actuators combining ultra-precision control

deceleration device Harmonic Drive® that provides precision rotation operation at a high torque with

ultra-small AC servo motor developed to make use of the performance of the decelerator.

Actuators with an electromagnetic brake are also included in the lineup. They can meet fail-safe

requirements of equipment to prevent accidents upon power supply failure.

The dedicated servo driver HA-680 is an AC servo driver for 24VDC power supply. The small and

multi-functional HA-680 driver is equipped with position control, speed control, and torque control as

standard to control operation of the RSF supermini series correctly and precisely.

The RSF supermini series can contribute to downsizing of driving of robot joints, semiconductor/LCD

panel manufacturing equipment, machine tools, and other FA equipment. By utilizing its small and

high-torque characteristics, it can also be used for small equipment and for research.

1-1 Major characteristics

◆ Small, lightweight, and high-torque

The RSF supermini series with the precision-control deceleration device Harmonic Drive® realizes a

high torque and has a very high output torque for the outer dimensions compared to the direct driving

method with a high-capacity motor alone.

Also, combination with the dedicated AC servo motor realizes size and weight reduction that are never

possible before.

◆ Standard lineup of actuators with a brake (only RSF-5A)

The standard lineup of AC servo actuators includes the deenergisation operation type actuators with

an electromagnetic brake for the first time for this size of actuators.

Fail-safe requirements of equipment can be met to prevent accidents upon power failure without

providing any external brake or changing the equipment structure to install a brake.

◆ Superior positioning precision

The characteristics of the control deceleration device Harmonic Drive® such as non-backlash and

superior positioning precision realize high-precision mechanisms.

◆ Stable controllability

The high deceleration gear ratio of the control deceleration device Harmonic Drive® provides stable

controllability for large variations of load moment of inertia.

RSF-Super_V1_02 - 1 -

Page 6

Chapter 1 Overview of the RSF supermini series

1-2 Ordering information

Model codes for the RSF supermini series actuators are as follows:

RSF-5 A-50-E 050-C

Model: AC servo actuator

RSF series: Output shaft is of the shaft type.

Frame size: 3 or 5

Design version

Reduction ratio of gearing

30: 1/30

50: 1/50

100: 1/100

Encoder specifications

US: 14 wire incremental encoder (standard)

E: 4 wire incremental encoder (optional)

Encoder pulses on motor shaft

020: 200p/rev (Model 3)

050: 500p/rev (Model 5)

Specifications

C: Standard item(with connector)

BC: With brake(with connector)

SP* Special specification

1-3 Combinations with drivers

The RSF supermini series actuators are used in combination with the HA-680-4B-24 driver.

The HA-680 driver can perform position control, speed control, and torque control.

For details of the driver, refer to “AC Servo Driver for 24VDC Power Supply HA-680 Series Technical

Data.”

The optional relay cable is required for connection between the actuator and the driver.

RSF-Super_V1_02 - 2 -

Page 7

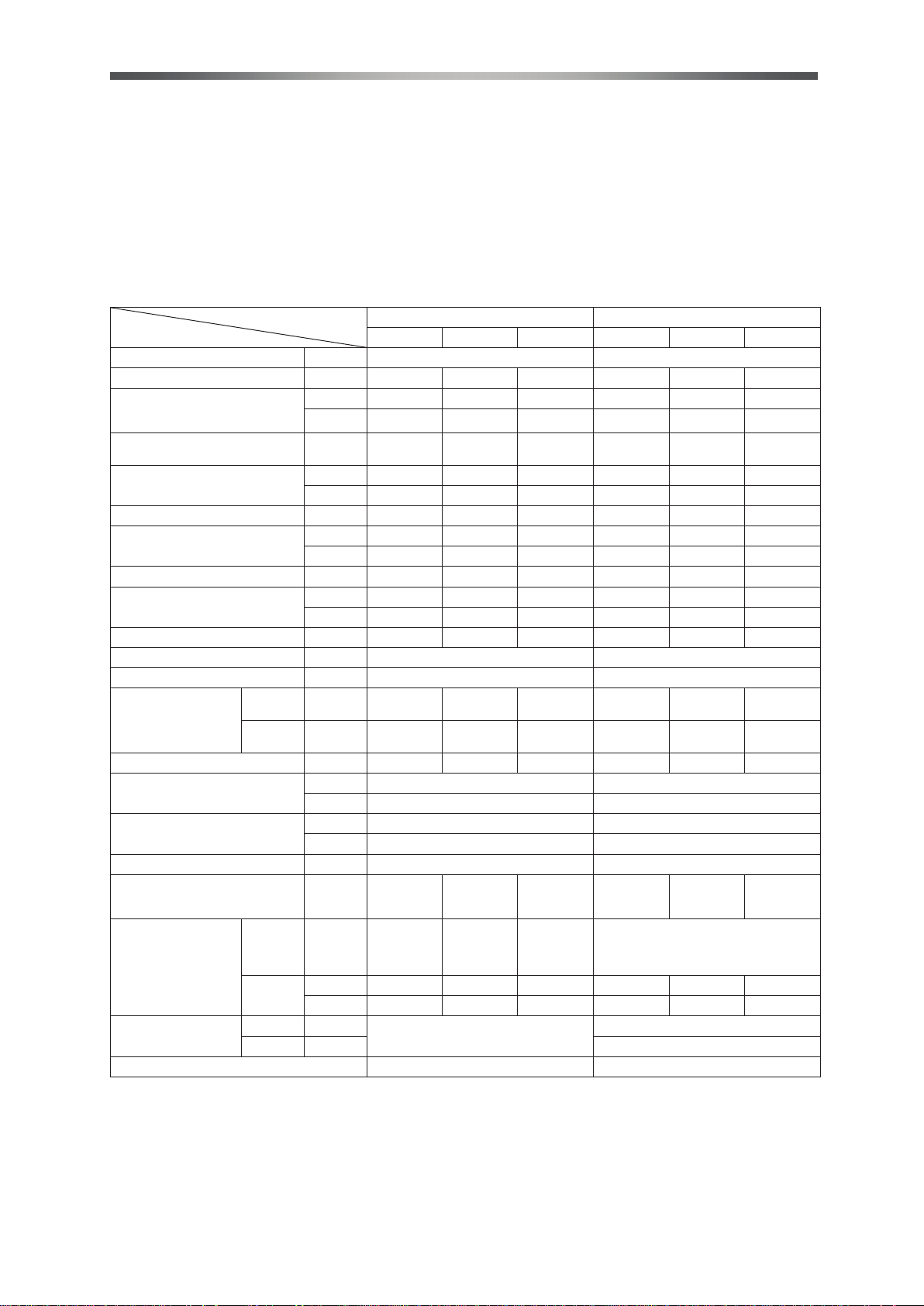

Chapter 1 Overview of the RSF supermini series

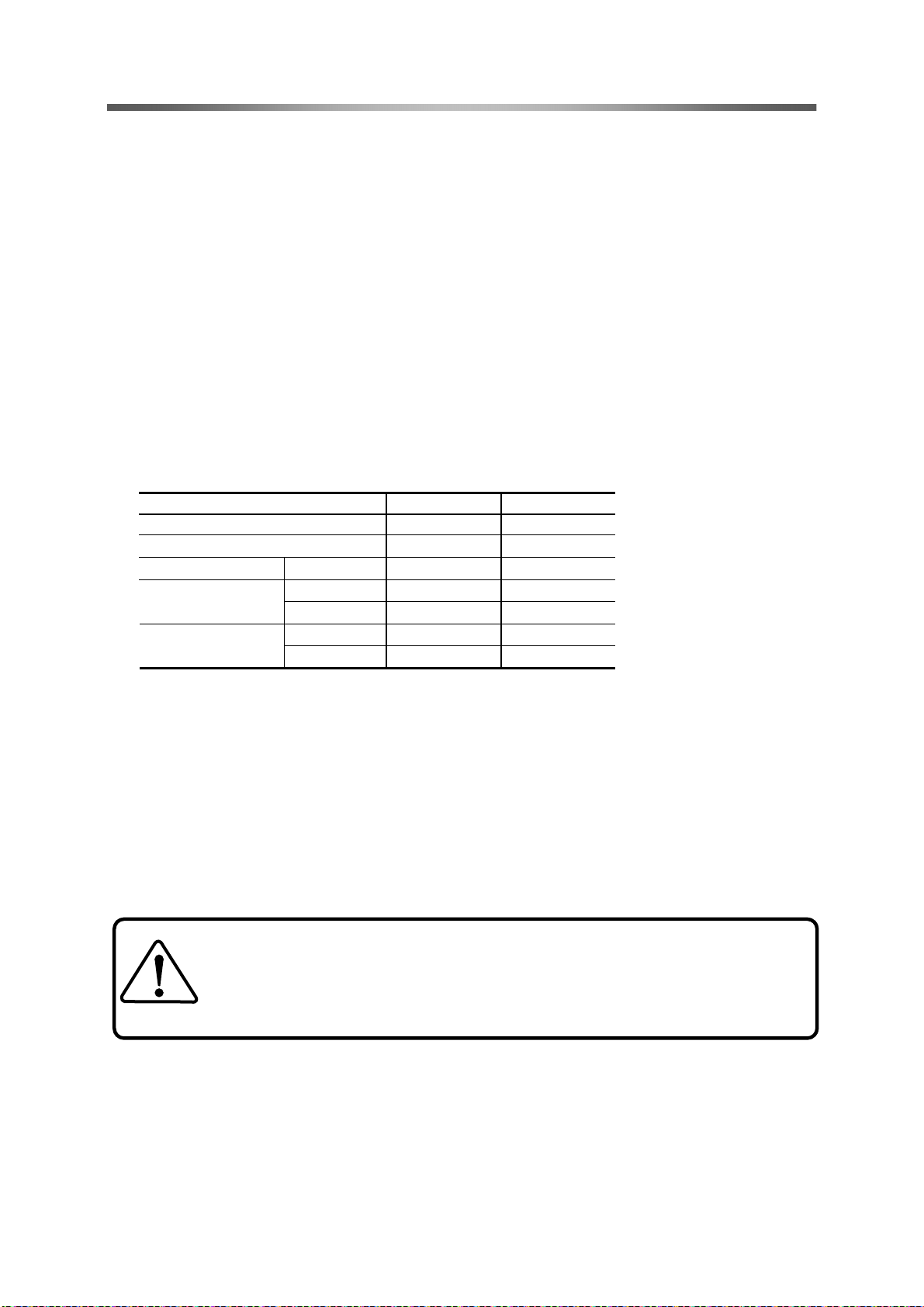

1-4 Specifications of RSF supermini actuators

Specifications of actuators are as follows:

Time rating: Continuous Service temperature:

0~40˚C

Excitation method: Permanent magnet type Storage temperature:

-20~+60˚C

ts /ecivreS B :ssalc noitalusnI orage humidity: 20~80%RH (no condensation)

Withstanding voltage: AC500V/min Vibration resistance: 49m/s

2

Insulation resistance: DC500V 100MΩor more Lubricant: Grease (Harmonic Grease)

Structure: Totally enclosed self cooling

type

Item

Chapter 1 Overview of the RSF supermini series

1-4 Specifications of RSF supermini actuators

Specifications of actuators are as follows:

Time rating: Continuous Service temperature:

0~40˚C

Excitation method: Permanent magnet type Storage temperature:

-20~+60˚C

ts /ecivreS B :ssalc noitalusnI orage humidity: 20~80%RH (no condensation)

Withstanding voltage: AC500V/min Vibration resistance: 49m/s

2

Insulation resistance: DC500V 100MΩor more Lubricant: Grease (Harmonic Grease)

Structure: Totally enclosed self cooling

type

Note 1: The table shows typical output values of actuators.

Note 2: The values in the table above are obtained when it is combined with the combined driver (HA-680-4B-24).

Note 3: All values are typical.

Note 4: The moment of inertia is the total value of the motor shaft and Harmonic Drive moment of inertia values

converted to the output side. The values in parentheses are for equipment with a brake.

Note 5: The encoder resolution is (motor shaft encoder resolution when multiplied by 4) x (gear ratio).

Power Supply Voltage V DC24 DC24

Allowable Continuous Current A 0.68 0.63 0.49 1.11 0.92 0.76

Allowable Continuous Torque

(during operation at allowable

continuous rotation speed)

Allowable Continuous Rotation Speed

(output shaft)

Allowable Continuous Stall Torque

Instantaneous Maximum Current A 1.2 1.1 0.8 2.3 2.2 1.7

Maximum Torque

Maximum Speed r/min 333 200 100 333 200 100

Torque Constant

MEF constant V/(r/min) 0.015 0.025 0.050 0.04 0.07 0.13

Phase Resistance (at 20˚C)

Phase Inductance mH 0.18 0.27

Moment of Inertia

Note 4

Gear ratio 30 50 100 30 50 100

Allowable Radial Load

(output shaft central value)

Allowable Thrust Load

Encoder Pulses (motor shaft) Pulse 200 500

Encoder Resolution

(Output shaft: when multiplied by 4)

Note 5

Motor Shaft Brake

Mass

Combined Driver HA-680-4B-24 HA-680-4B-24

GD2/4 kg•m

J kgf•cm•s21.07x10

Input

Power

Supply

Voltage

Retention

Torque

w/o brake g

w/ brake g 86.0 (except clamp filter)

Model

30 50 100 30 50 100

N•m 0.03 0.06 0.08 0.18 0.29 0.44

Kgf•cm 0.31 0.61 0.82 1.83 2.95 4.48

r/min 150 90 45 150 90 45

N•m 0.04 0.08 0.12 0.28 0.44 0.65

kgf•cm 0.41 0.82 1.22 2.85 4.48 6.62

N•m 0.09 0.15 0.21 0.5 0.9 1.4

kgf•cm 0.92 1.53 2.14 5.10 9.17 14.3

N•m/A 0.11 0.18 0.40 0.30 0.54 1.1

kgf•cm/A 1.12 1.84 4.08 3.06 5.51 11.22

Ω

2

0.11x10

N 40 90

kgf 4.0 9.1

N 130 270

kgf 13.2 27.5

Pulse/

Rotation

V — — — DC24

N•m — — — 0.18 0.29 0.44

kgf•cm — — — 1.83 2.95 4.48

24,000 40,000 80,000 60,000 100,000 200,000

RSF-3A RSF-5A

1.34 0.82

-4

-4

31.0 (except clamp filter)

0.29x10

2.98x10

-4

-4

1.17x10

11.90x10

0.66x10

-4

(0.11x10-3)

0.67x10

-4

(1.13x10-3)

-4

-3

66.0 (except clamp filter)

1.83x10

(0.31x10-3)

1.87x10

(3.15x10-3)

-4

-4

7.31x10

(1.23x10-3)

7.45x10

(12.6x10-3)

-4

-3

-3-

Page 8

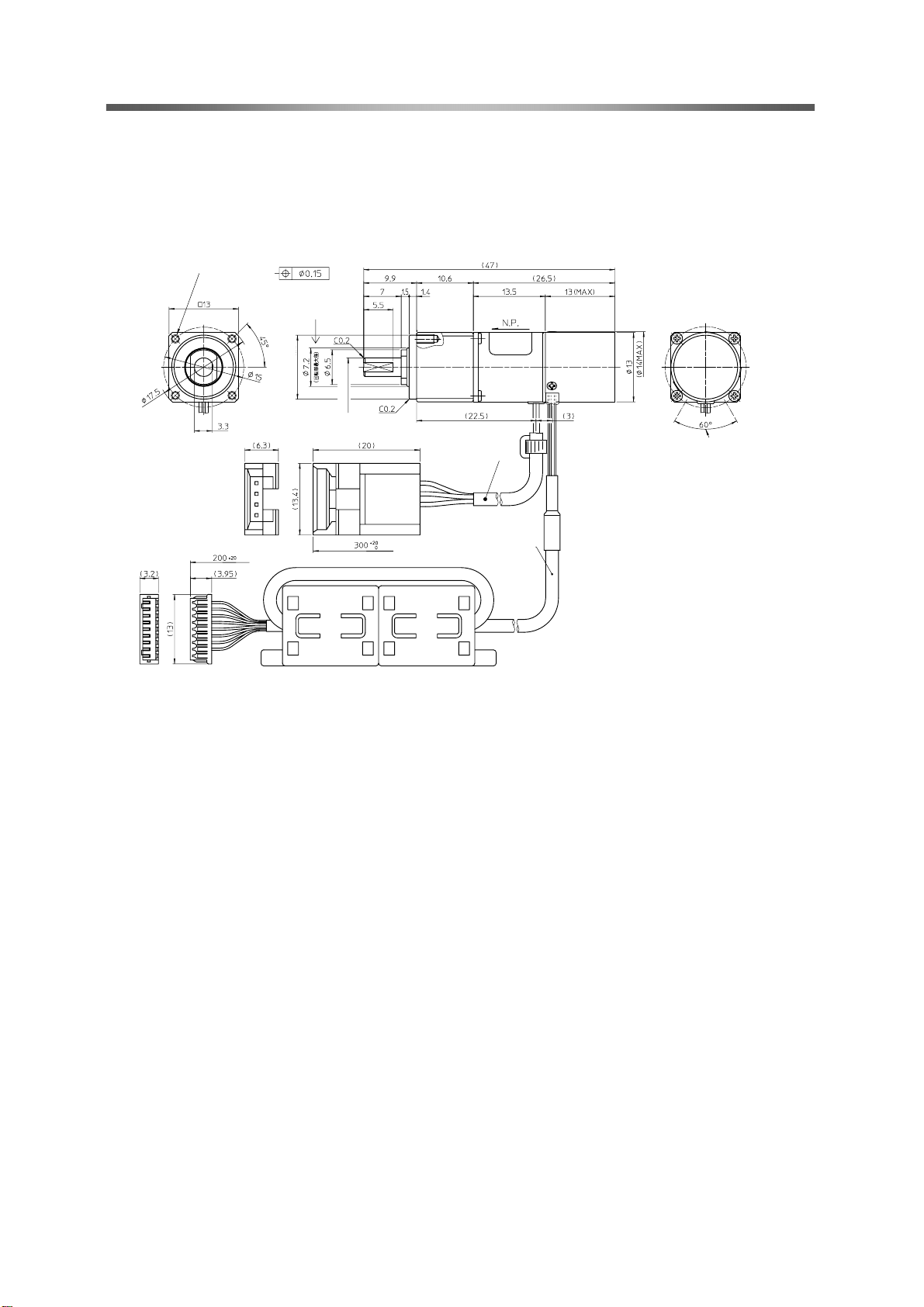

Chapter 1 Overview of the RSF supermini series

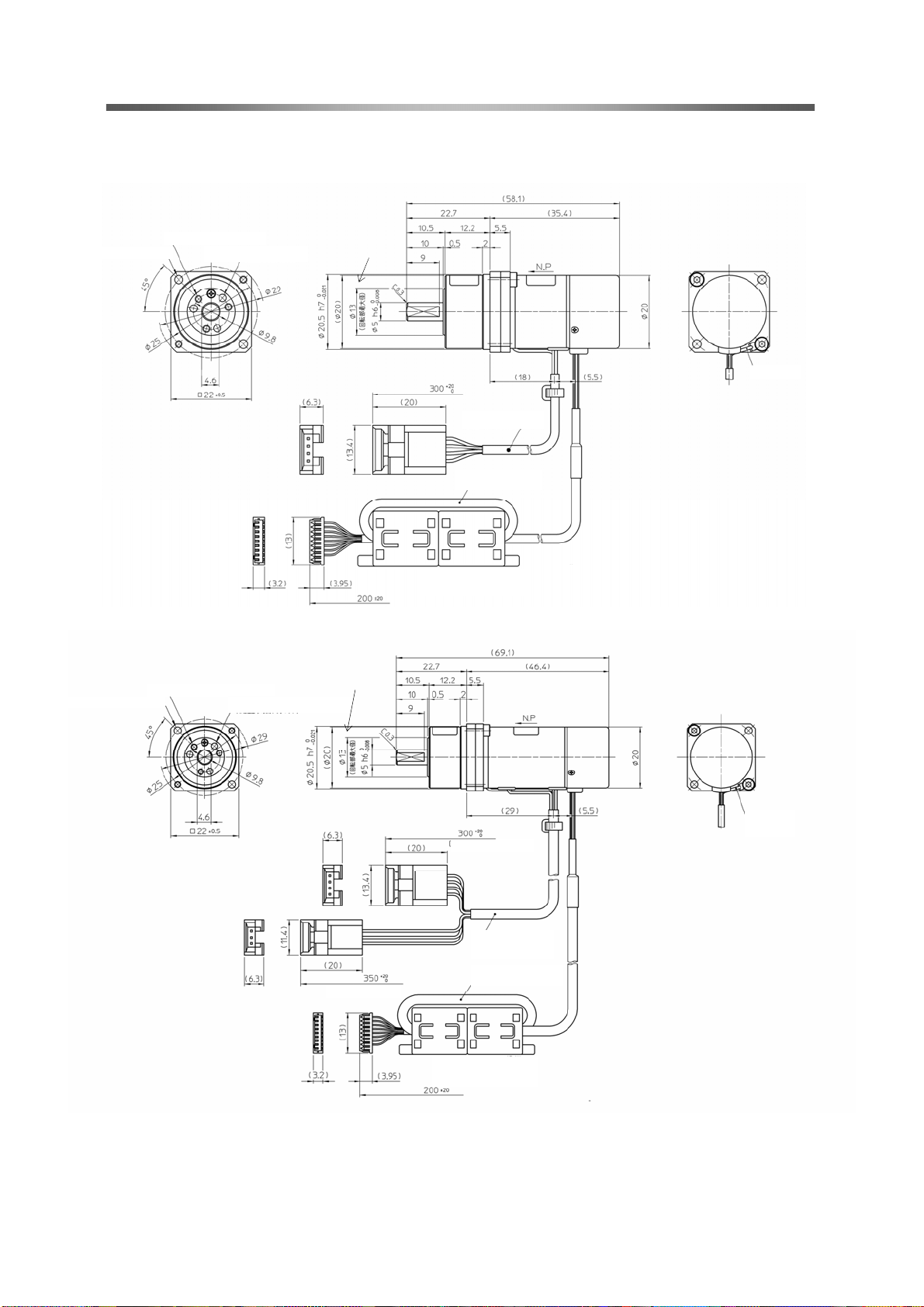

1-5 External dimensions of actuators

The external drawings are shown as follows:

■ RSF-3

B-XXX-E020-C

4-M1.6 tap 3.2

evenly spaced

Maximum diameter

of rotation part

0

-0.018

φ12 h7

0

-0.008

φ3.5 h6

Motor lead wire

Encoder lead wire

Line locating range of Encoder cable wire

Clamp filter(2) ZCAT1518-0730(TDK)

Note) For detailed outside dimensions, check the delivery specification drawing issued by us.

RSF-Super_V1_02 - 4 -

Page 9

■ RSF-5A-XXX-E050-C

Chapter 1 Overview of the RSF supermini series

3-M2x3 evenly spaced

2-φ2.3 evenly spaced

3-φ2x2.5 evenly spaced

■ RSF-5A-XXX-E050-BC

■ RSF-5A-XXX-E050-BC(with brake)

3-M2x3 evenly spaced

3-φ2x2.5 evenly spaced

2-φ2.3 evenly spaced

Maximum diameter

of rotation part

Maximum diameter

of rotation part

Motor lead wire

Encoder lead wire

Clamp filter

ZCAT1518-0730(TDK)

FG line

Motor lead wire

FG line

Brake lead wire

Motor and

Brake lead wire

Encoder lead wire

Note) For detailed outside dimensions, check the delivery specification drawing issued by us.

Clamp filter

ZCAT1518-0730(TDK)

RSF-Super_V1_02 - 5 -

Page 10

Chapter 1 Overview of the RSF supermini series

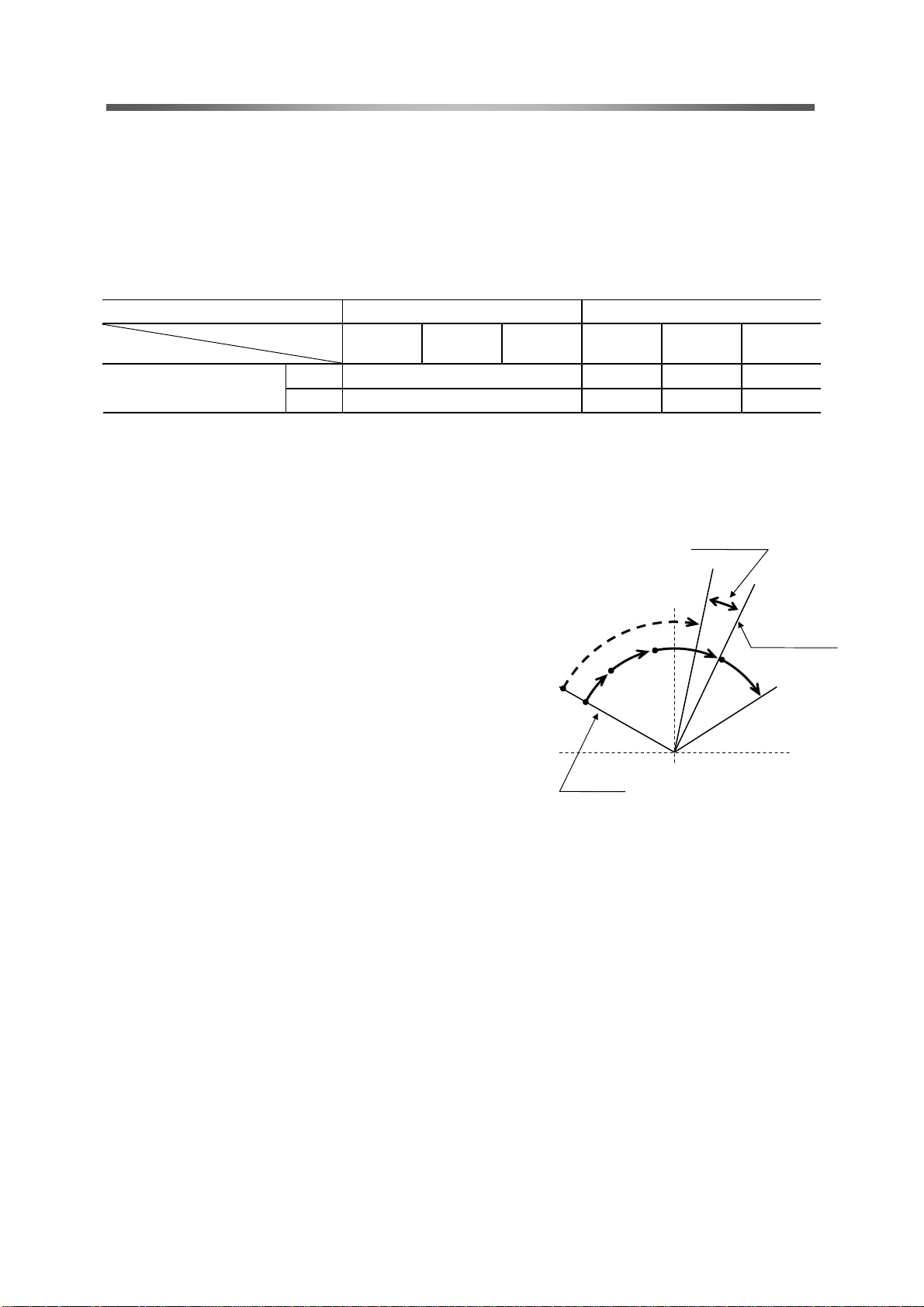

1-6 One-way positioning accuracy

The following table shows the “one-way positioning accuracy” and “repeated positioning accuracy.”

The following table contains representing values. (JIS B 6201:1987)

The one-way positioning accuracy of RSF supermini actuators is almost equal to the angular

positioning accuracy of the Harmonic® drive gearing, because the effect on the positioning error of the

built-in motor is reducted to its 1/30 or 1/50 or 1/100 by the gearing.

The accuracy for each gear ratio is shown below.

Mode RSF-3B RSF-5A

Gear ratio

Item

30 50 100 30 50 100

One-way positioning accuracy

arc min 10 4 3 3

-3

rad 2.9×10

1.20×10

■ Reference

(Accuracy display and measurement method according to JIS B 6201: 1987)

● One-way positioning of rotation shaft motion

First, perform positioning at any one position in a fixed

direction. This position is the reference position. Next,

One-way positioning

accuracy

perform positioning in succession in the same direction,

and measure the difference between the angle actually

rotated from the reference position and the desired angle

at each position. The maximum difference in one

rotation among these values is taken as the

measurement value. Measurement of equipment with

the continuous positioning function for rotational motion

shall be done once per 30 degrees or 12 positions

throughout the entire rotation range as a rule.

Start position

-3

0.87×10-3 0.87×10

Positional difference

-3

Actual position

RSF-Super_V1_02 - 6 -

Page 11

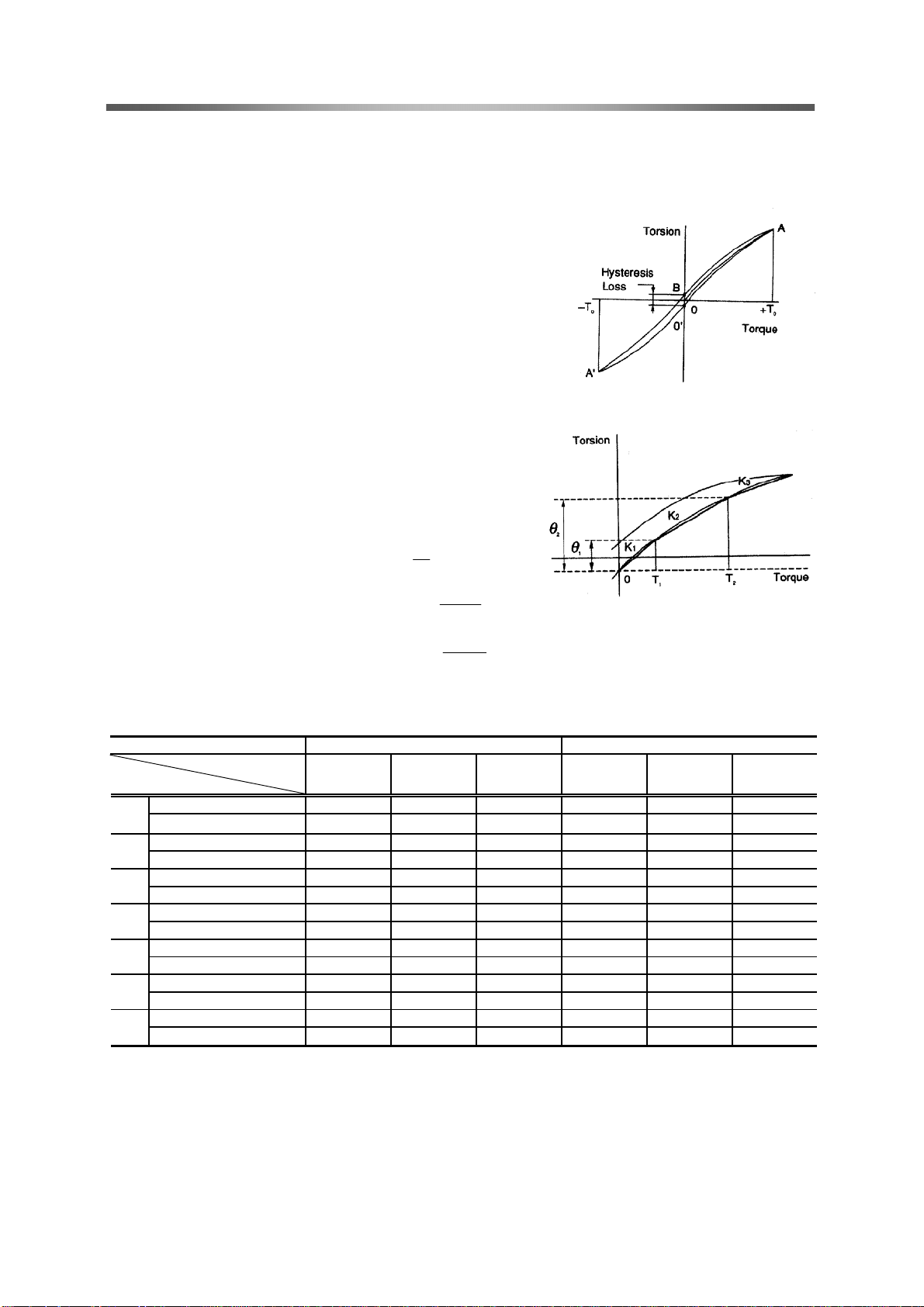

Chapter 1 Overview of the RSF supermini series

1-7 Torsional stiffness

When a torque is applied to the output flange of the actuator with the motor locked, the resulting

torsional wind up is near proportional to the torque.

The upper right figure shows the torsional stiffness

characteristics of the output flange applying torque starting

from zero to plus side [+T

trajectory is called torque-torsion characteristics which

typically follows a loop 0→A→B→A’→B’→A as illustrated.

The torsional stiffness of the RSF supermini actuator is

expressed by the slope of the curve that is a spring rate

(wind-up) (unit:N・m/rad).

The torsional stiffness may be evaluated by dividing

torque-torsion characteristics curve into three major regions.

The spring rate of each region is expressed K

respectively.

K

1: spring rate for torque region 0-T1

2: spring rate for torque region T1-T2

K

3: spring rate for torque region over T2

K

0] and minus side [–T0]. This

1, K2, and K3

The wind-up for each region is expressed as follows:

◆ wind-up for torque region 0-T

◆ wind-up for torque region T

◆ wind-up for torque region over T

1:

1-T2:

2:

The following table shows average values of T

different gear ratios.

Model RSF-3B RSF-5A

Symbol

Nm 0.016 0.016 0.016 0.075 0.075 0.075

T1

Kgf m 0.0016 0.0016 0.0016 0.0077 0.0077 0.0077

Nm/rad 27 30 34 90 110 150

K1

Kgf m/arc min 0.0008 0.0009 0.0010 0.003 0.003 0.004

x10-4 rad 5.9 5.3 4.7 8.7 6.9 5

θ1

arc min 2.0 1.8 1.6 3 2.4 1.7

Nm 0.05 0.05 0.05 0.22 0.22 0.22

T2

Kgf m 0.005 0.005 0.005 0.022 0.022 0.022

Nm/rad 40 47 54 110 140 180

K2

Kgf m/arc min 0.0012 0.0014 0.0016 0.003 0.004 0.005

x10-4 rad 12.5 10.6 9.3 22 18 13

θ2

arc min 4.2 3.6 3.1 7.5 6 4.4

Nm/rad 51 57 67 120 170 200

K3

Kgf m/arc min 0.0015 0.0017 0.0020 0.004 0.005 0.006

Gear ratio

30 50 100 30 50 100

T

=ϕ

1K

1

TT −

1

+θ=ϕ

2

K

2

2

TT −

+θ=ϕ

3

K

1 through T3, K1 through K3, and θ1 through θ2 for

RSF-Super_V1_02 - 7 -

Page 12

Chapter 1 Overview of the RSF supermini series

1-8 Detector resolution

An encoder with 500 pulses per rotation is incorporated in the motor unit of the RSF supermini series

actuators, and the motor output is decelerated by 1/30, 1/50, or 1/100 by the precision control

decelerator Harmonic Drive®. Therefore, the resolution per one rotation of the actuator output shaft

is 30, 50, or 100 times of the actual encoder resolution. In addition, the encoder signal is electrically

multiplied by 4.

The following table shows the resolution at the output shaft for different gear ratios.

Model RSF-3B RSF-5A

Item

Detector resolution

(when multiplied by 4)

Angle per one pulse

Gear ratio

Pulse/Rotation 24,000 40,000 80,000 60,000 100,000 200,000

Angle second

(arc sec)

30 50 100 30 50 100

54 32.4 16.2 21.6 12.96 6.48

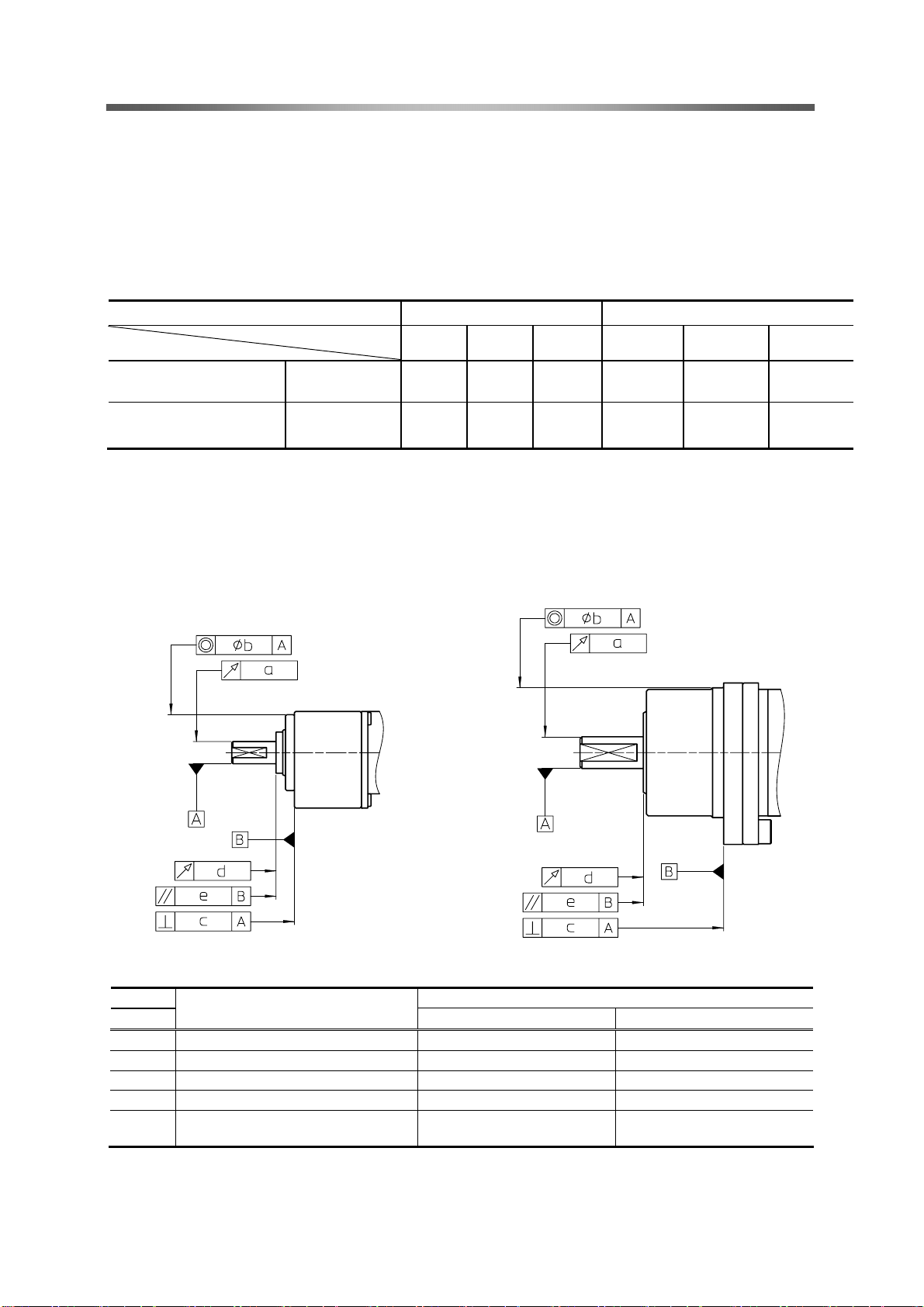

1-9 Mechanical accuracy

The machining accuracy of the output flange and the mounting flange of RSF supermini actuators are

indicated in the table below.

RSF-3B RSF-5A

Machined accuracy of the output flange * T.I.R. unit: mm

Symbol Accuracy value

Model

a Runout of the tip of the output shaft

b Concentricity of installed spigot joint

c Squareness of installation surface

d Output flange surface contact

Parallelism of installation surface

e

and output flange

*) T.I.R(Total Indicator Reading): Indicates the total amount of dial gage reading when the measurement unit is

rotated once.

Machined parts

RSF-3B RSF-5A

0.03 0.03

0.02 0.04

0.02 0.02

0.005 0.005

0.015 0.015

RSF-Super_V1_02 - 8 -

Page 13

Chapter 1 Overview of the RSF supermini series

1-10 Allowable load

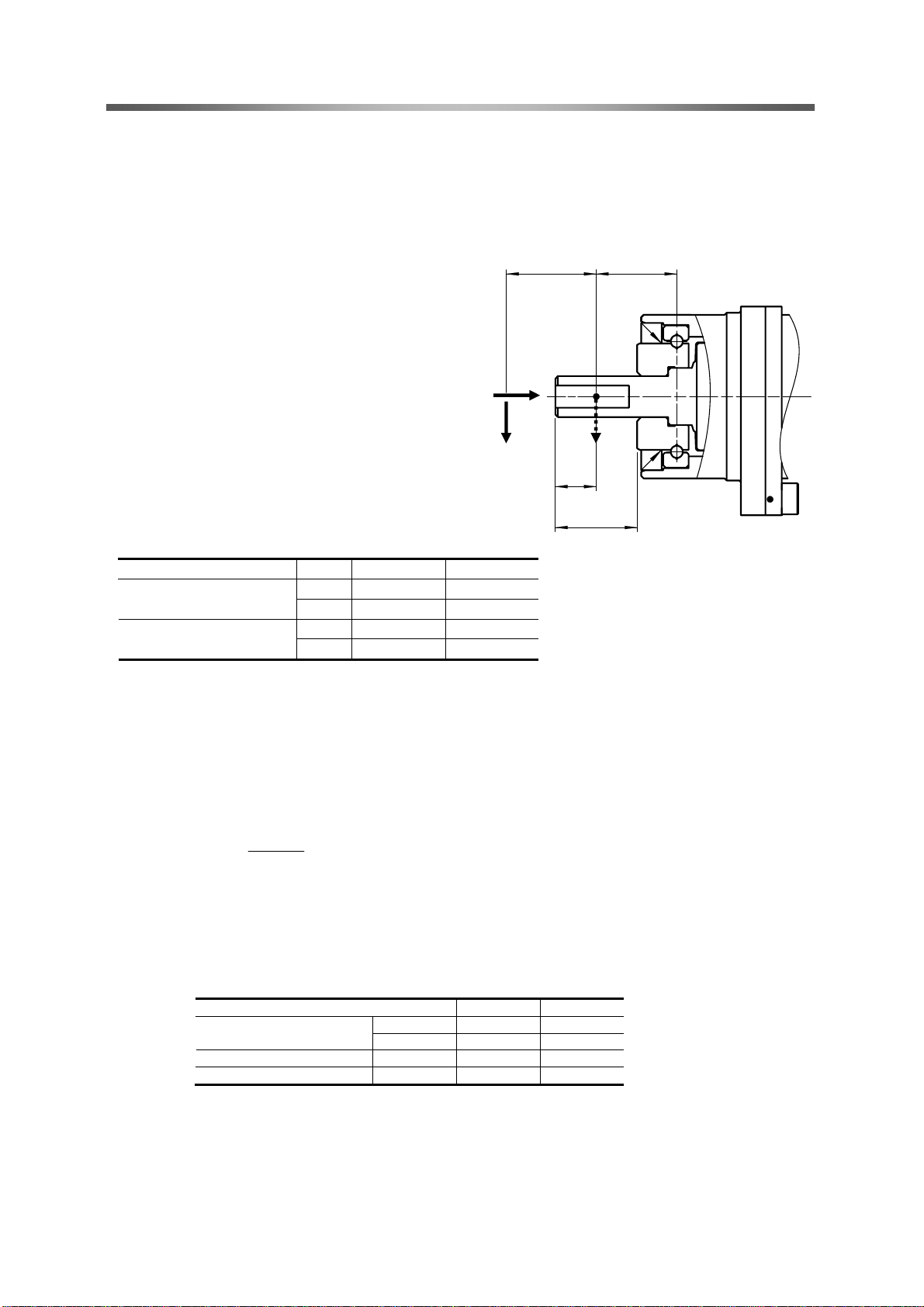

1-10-1 Allowable radial load and allowable thrust load

The gear head used in the RSF supermini series incorporates the high-precision 4-point contact ball

bearing for direct support of external load (output part).

The allowable radial load and thrust load of the

output shaft are shown below.

L

R

L

a

The allowable radial load F

is obtained with

r

respect to the center (L/2) 0 point of the output

shaft.

The values in the following table are designed

by considering the life of the bearing.

F

S

0 point

The allowable values must not be exceeded.

F

R

L/2

F

r

Model Unit RSF-3B RSF-5A

Allowable radial load (Fr)

Allowable thrust load (FS)

N

kgf

N

kgf

36 90

3.6 9.1

130 270

13 27

L

1-10-2 Radial load when the operating point is different

If the operating point of radial load is different, the allowable radial load value is also different.

The relation between radial load position L

following formula.

The allowable values must not be exceeded.

L

a

F+=

R

F

: Allowable radial load at distance L

R

F

: Allowable radial load at the 0 point [N]

r

L

: Distance from the bearing starting point to the 0 point [mm]

a

L

: Distance from the position where radial load is exerted to the 0 point [mm]

R

F

r

LL

Ra

L : Shaft length [mm]

Model RSF-3B RSF-5A

Allowable radial load (Fr)

La mm 8.6 9.85

L mm 7 10

N 36 90

kgf 3.6 9.1

and allowable radial value FR is obtained from the

R

from the 0 point [N]

R

RSF-Super_V1_02 - 9 -

Page 14

Chapter 1 Overview of the RSF supermini series

1-11 Rotary direction

The rotary direction of the RSF supermini series actuators when a forward rotation command is given

from the HA-680 driver is forward rotation seen from the output shaft side (i.e. counterclockwise: CW).

The rotary direction of the HA-680 can be switched by using the Parameter → “20: Rotary direction

command” setting.

“20: Rotary direction command” setting

Value FWD command REV command Setting

0 FWD rotation REV rotation Default

1 REV rotation FWD rotation

* The model shape is RSF-5A. RSF-3B is also the same.

* For details of the driver, refer to “AC Servo Driver

HA-680 Series Technical Data.”

FWD: CW rotation

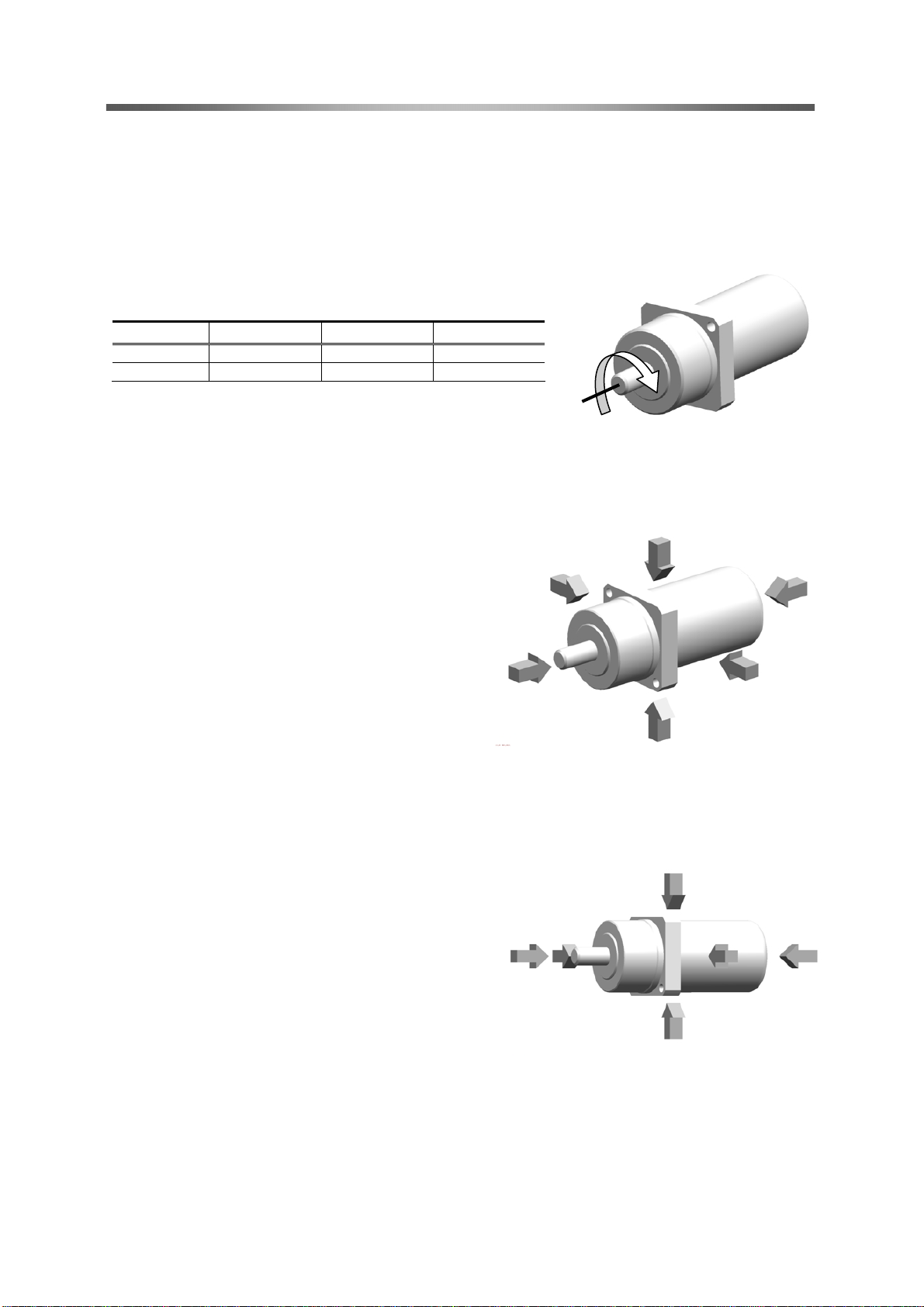

1-12 Impact resistance

The impact resistance of the actuators is as follows.

Impact acceleration: 300 m/s

Direction: top/bottom, right/left, front/back

Repeating times: three

However, do not apply impact to the output shaft.

2

1-13 Vibration resistance

The vibration resistance of the actuators for

up/down, left/right, and front/back is as follows.

2

Vibration acceleration: 49m/s

(5G)

Front

Right

Right

Top

Bottom

Impact resistance

Top

Left

Back

Left

Back

Frequency: 10~400Hz

This specification does not guarantee fretting wear

of mechanism components due to micro vibrations.

RSF-Super_V1_02 - 10 -

Front

Horizontal

installation

Bottom

Vibration resistance

Page 15

Chapter 1 Overview of the RSF supermini series

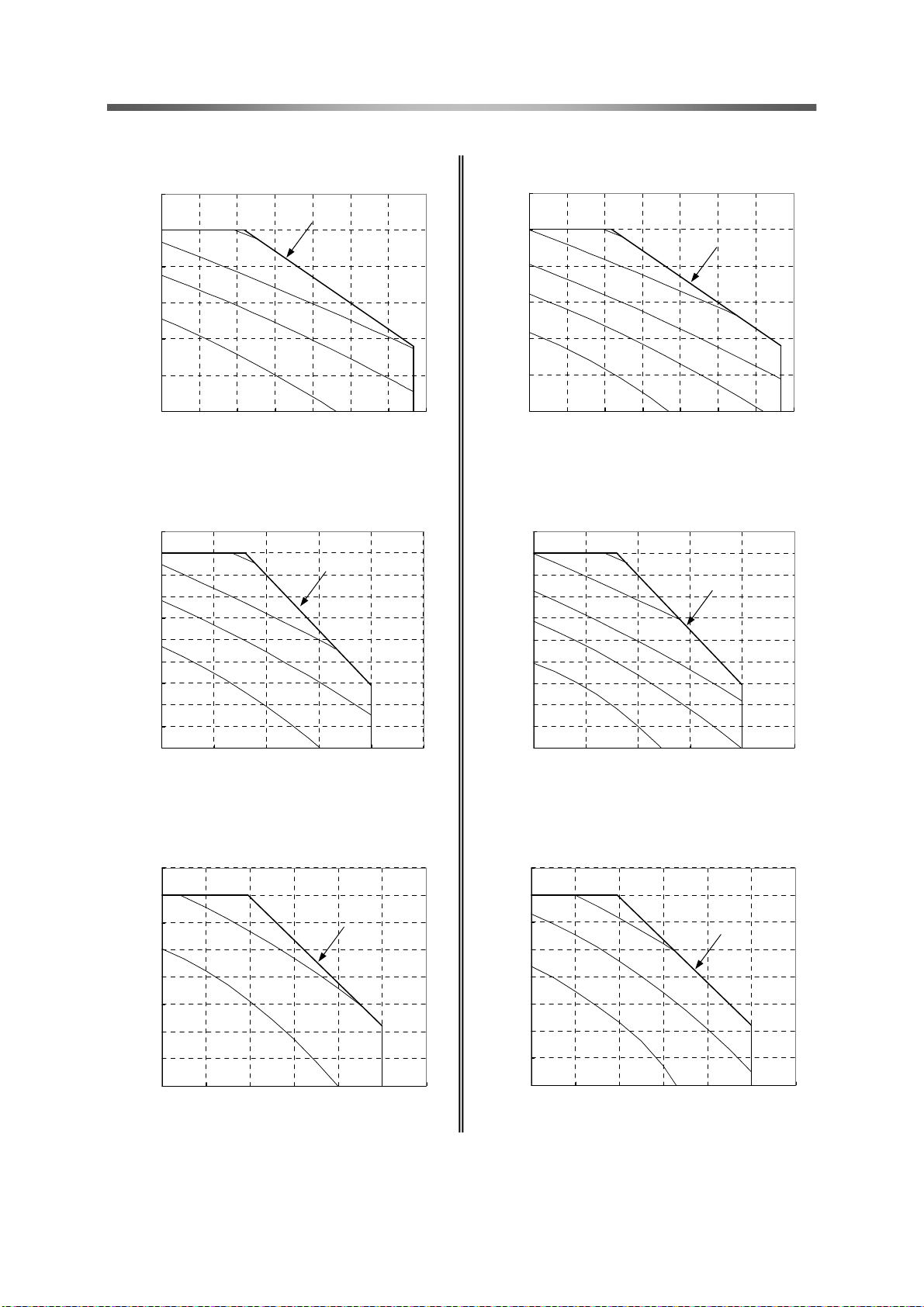

1-14 Torque-speed characteristics

The following graphs show the usable ranges of the RSF supermini series actuators.

• Acceleration and deceleration range:

The range allows instantaneous operation like acceleration and deceleration, usually.

• Continuous duty range:

The range allows continuous operation for the actuator.

• 50% duty range:

The range allows the 50% duty time operation of a cycle time.

■ RSF-3

■ RSF-3

■ RSF-3B-100-E020-C

Note: The values of the graph are obtained when the aluminum radiation plate shown at the upper right of the

Note: Even in the continuous range, if it is used continuously in one direction, please consult with us.

B-30-E020-C

B-50-E020-C

graph.

0.10

0.08

加減速運転領域

0.06

0.04

トルク[Nm]

Torque [Nm]

0.02

Continuous range 50% duty range

0.00

0 50 100 150 200 250 300 350

0.20

0.15

0.10

トルク[Nm]

Torque [Nm]

0.05

0.00

0.25

0.20

0.15

0.10

トルク[Nm]

Torque [Nm]

0.05

0.00

Continuous

連続運転領域

0 50 100 150 200 250

Continuous

連続運転領域

0 20 40 60 80 100 120

Acc./dec. range

連続運転領域

加減速運転領域

Acc./dec. range

range

加減速運転領域

Acc./dec. range

range

Radiation plate 80×85×3 (mm)

50%デューティ使用領域

回転速度[r/min]

Speed [r/min]

Radiation plate 80×85×3 (mm)

50% duty range

50%デューティ使用領域

回転速度[r/min]

Speed [r/min]

Radiation plate 80×85×3 (mm)

50% duty range

50%デューティ使用領域

回転速度[r/min]

Speed [r/min]

放熱板:85×85×3[mm]

放熱板:85×85×3[mm]

放熱板:85×85×3[mm]

RSF-Super_V1_02 - 11 -

Page 16

Chapter 1 Overview of the RSF supermini series

■ RSF-5A-30-E050-C, RSF-5A-30-E050-BC

0.6

0.5

Radiation plate 150×150×3 (mm)

Acc./dec. range

0.4

0.3

トルク[Nm]

0.2

Torque [Nm]

0.1

Continuous range 50% duty range

0.0

0 50 100 150 200 250 300 350

回転速度[r/min]

Speed [r/min]

■ RSF-5A-30-E050-C, RSF-5A-50-E050-BC

1.0

Radiation plate 150×150×3 (mm)

0.8

Acc./dec. range

0.6

0.4

トルク[Nm]

Torque [Nm]

0.2

Continuous range 50% duty range

0.0

0 50 100 150 200 250

Speed [r/min]

回転速度[r/min]

■ RSF-5A-30-E050-C, RSF-5A-100-E050-BC

1.5

1.2

Acc./dec. range

0.9

0.6

トルク[Nm]

Torque [Nm]

0.3

Continuous range 50% duty range

0.0

0 20406080100120

Note: The values of the graph are obtained when the aluminum radiation plate shown at the upper right of the

graph.

Note: Even in the continuous range, if it is used continuously in one direction, please consult with us.

Radiation plate 150×150×3 (mm)

回転速度[r/min]

Speed [r/min]

RSF-Super_V1_02 - 12 -

Page 17

Chapter 1 Overview of the RSF supermini series

1-15 Cable specifications

The following tables show specifications of the cable for the motor and the encoder of the RSF

supermini actuators.

Motor cable

Pin No. Color Signal name Remark

1 Red (RED) U Motor phase-U

2 White (WHT) V Motor phase-V

3 Black (BLK) W Motor phase-W

4 Green (GRN) FG Grounding

Connector used Housing: PALR-04VF (with retainer)

Contact: S(B)PAL-001T-P0.5

Recommended connector Housing: PARP-04V (with retainer)

Contact: S(B)PA-001T-P0.5

Manufactured by J.S.T. Mfg Co., Ltd

Brake lead wire

Pin No. Line color

1 Blue (BLU)

2 Yellow (YEL)

3 Gray (GRY)

Connector used Housing: PALR-03VF (with retainer)

Contact: S(B)PAL-001T-P0.5

Recommended connector Housing: PARP-03V (with retainer)

Contact: S(B)PA-001T-P0.5

Encoder lead wire

Pin No. Color Signal name Remark

1 White (WHT) A A phase output

2 Green (GRN) B B phase output

3 Yellow (YEL) Z Z phase output

4 Brown (BRW) U U phase output

5 Blue (BLU) V V phase output

6 Orange (ORG) W W phase output

7 Red (RED) +5V Power supply input

8 Black (BLK) GND Power supply input

9

Connector used Housing: 51021

Terminal: 50058

Manufactured by J.S.T. Mfg Co., Ltd

Manufactured by Molex

RSF-Super_V1_02 - 13 -

Page 18

(

)

(

)

+

Chapter 2 Selection of the RSF supermini Series

Chapter 2 Selection of the RSF supermini Series

2-1 Allowable load moment of inertia

To make full use of high precision and high performance of the RSF supermini series actuator, perform

temporary selection by considering the load moment of inertia and rotation speed.

As a guideline, the load moment of inertia should be 3 to 5 times the moment of inertia of the actuator.

For the moment of inertia of the actuator, refer to “1-4 Specifications of RSF supermini actuators.”

Refer to appendix 1 for the calculation of moment inertia.

The rotation speed cannot exceed the maximum rotation speed of the actuator. For the maximum

rotation speed, refer to “1-4 Specifications of RSF supermini actuators.”

2-2 Variable load moment of inertia

RSF supermini series actuators include Harmonic Drive® gearing that has a high reduction ratio.

Because of this there are minimal effects of variable load moment of inertias to the servo drive system.

In comparison to direct servo systems this benefit will drive the load with a better servo response.

For example, assume that the load moment of inertia increases to N-times during its motion (for

example, robot arms). The effect of the variable load moment of inertia to the [total inertia converted

into motor shaft] is as follows:

The symbols in the formulas are:

: total moment of inertia converted into

J

S

L: Ratio of load moment of inertia to motor inertia

motor shaft

J

: moment inertia of motor N: variation ratio of load moment of inertia

M

R: reduction ratio of RSF supermini series

◆ Direct drive

NL1

Before:

L1JJ M +=S

After:

=S

Ratio:

NL1J'J M

+

/JsJs'

=

L1

+

◆ RSF supermini actuator drive

⎛

⎜

Before:

M=S

⎜

⎜

⎝

In the case of the RSF supermini actuator drive, as the reduction ratio is [R=30], [R=50], or [R=100] and

the square of the reduction ratio [R

⎞

L

⎟

+

1JJ

After:

⎟

2

⎟

R

⎠

2

=900], [R2=2500], or [R2=10000] the denominator and the

⎛

⎜

M=S

⎜

⎜

⎝

⎞

NL

⎟

+

1J'J

Ratio:

⎟

2

⎟

R

⎠

+

/JsJs'

=

11R/L

2

R/NL

2

+

numerator of the ratio are almost [1]. Then the ratio is [F≒1]. This means that drive systems are hardly

affected by the load moment of inertia variation. Therefore, it is not necessary to take the load moment

of inertia variation in consideration for selecting an RSF supermini actuator or for setting up the HA-680

driver.

2-3 Verifying loads

The RSF supermini series incorporates a precision 4-point contact ball bearing for direct support of

external load. To make full use of the performance of the RSF supermini series, check the maximum

load moment, life of the 4-point contact ball bearing, and static safety factor.

For detailed calculation methods for the maximum load moment, life of the 4-point contact ball bearing,

and static safety factor, refer to the “Harmonic Drive® CSF Mini series” catalogue.

RSF-super_V1_02 - 14 -

Page 19

Chapter 2 Selection of the RSF supermini Series

2-4 Duty cycles

When a duty cycle includes many frequent start and stop operations, the actuator generates heat by big

starting and braking current. Therefore, it is necessary to study the duty cycle profile.

The study is as follows:

2-4-1 Actuator speed

Calculate the required RSF supermini

actuator speed (r/min) to drive the load.

Rotary speed (r/min) =

For linear motion, convert with the formula

below:

Select a reduction ratio from [30], [50] and

[100] of an RSF supermini actuator of which

the maximum speed is more than the

required speed.

Liner speed (mm/min)

Pitch of screw(mm)

Screw pitch (mm)

Speed (r/min)

45r/min

90r/min

100r/min

150r/min

200r/min

333r/min

Linear speed (mm/min)

2-4-2 Load moment of inertia

Calculate the load moment of inertia driven by the RSF supermini series actuator.

Refer to appendix 1 for the calculation.

Tentatively select an RSF supermini actuator referring to section [2-1 allowable load moment of inertia]

with the calculated value.

2-4-3 Load torque

Calculate the load torque as follows:

◆ Rotary motion

The torque for the rotating mass [W] on the friction

ring of radius [r] as shown in the figure to the right.

rW8.9T ××μ×=

T: torque (N・m)

μ: coefficient of friction

W: mass (kg)

r: radius of friction face (m)

The load torque is restricted by the allowable load of the actuator (refer to “1-10 Allowable load”) and

load moment of inertia as well as by the load driven by the actuator.

Examine them carefully before using the actuator.

Friction:μ

Mass: W

Radius: r

RSF-super_V1_02 - 15 -

Page 20

Chapter 2 Selection of the RSF supermini Series

◆ Horizontal linear motion

The following formula calculates the torque for horizontal linear motion of mass [W] fed by the screw of

pitch [P].

P

××μ×=

W8.9T

π×

2

Pitch: P

T: torque (N・m)

μ: coefficient of friction

W: mass (kg)

P: screw pitch (m)

◆ Vertical linear motion

The following formula calculates the torque for vertical linear

motion of mass [W] fed by the screw of pitch [P].

P

W8.9T

××=

π×

2

2-4-4 Acceleration time and deceleration time

Calculate acceleration and deceleration times for the selected actuator.

Acceleration:

()

JJt

LAa

2

×+=

60

N

π×

×

(1)

−

LM

TT

Mass: W

Friction: μ

Mass: W

Pitch: P

Deceleration:

()

JJt

LAd

2

π×

60

×

×+=

N

−×+

T

a: acceleration time (sec)

d: deceleration time (sec)

T

J

A: actuator inertia (kg・m

J

L: load moment of inertia (kg・m

2

)

2

)

N: actuator speed (r/min)

T

M: maximum torque of actuator (N・m)

T

L: load torque (N・m)

note that the polarity of the load torque is plus (+) for counter direction of revolution , and

minus (-) for same direction.

The friction torque of the actuator T

T

F=KT×IM-TM (3)

K

T : Torque constant [N・m/A]

M : Maximum current [A]

I

(N・m) can also be obtained from the following formula:

F

(2)

LFM

TT2T

Speed

N

Time

ta td

RSF-super_V1_02 - 16 -

Page 21

r

p

● Example: 1

The load conditions are:

Chapter 2 Selection of the RSF supermini Series

• Rotary speed: 140r/min

• Load moment of inertia: 0.9×10

-3

kg・m2

• Load torque is so small as to be negrected.

• Acceleration/deceleration time is 0.03sec (30msec) or less.

(1) Compare these conditions with the “1-4 Specifications of RSF supermini actuators” and

temporarily select RSF-5A-50.

(2) Obtain J

A=1.83×10

-4

kg・m2, TM =0.9 N・m, KT=0.54 N・m/A, and IM =2.2A from “1-4 Specifications of

RSF supermini actuators.”

(3) The friction torque of the actuator is T

F = 0.54×2.2-0.9 = 0.29 N・m from Formula (3) on the

previous page.

(4) Therefore, the shortest acceleration time and deceleration time can be obtained from Formula (1)

and Formula (2), as follows:

t

a = (0.183×10

t

d = (0.183×10

-3

+0.9×10-3)×2×π/60×140/0.9 = 0.018 sec (18msec)

-3

+0.9×10-3)×2×π/60×140/(0.9+2×0.29) = 0.011 s (11msec)

(5) Because the assumed acceleration/deceleration time is 0.03sec (30msec) or less, the temporarily

selected actuator can be used for acceleration/deceleration, based on the result of (4).

(6) If the calculation results of the acceleration/deceleration time do not fall within the desired time

range, examine them again as follows.

• Try to reduce the load moment of inertia.

• Re-examine the gear ratio and gear head model.

2-4-5 Calculating equivalent duty

The load conditions, which are torque, speed,

moment of inertia, acceleration/deceleration time,

loading time, are limited by the actuator to drive the

load. To select the proper actuator, the equivalent

duty of the load should be calculated.

S

eed

N

ts: stop time

The %ED (percent equivalent duty) is:

tKtKtK

dLdrLraLa

ED%

=

t

×+×+×

100

×

(4)

where, ta: acceleration time in second

td: deceleration time in second

tr: driving time in second

t: single cycle time in second

K

La: duty factor for acceleration time

Lr: duty factor for driving time

K

Ld: duty factor for deceleration time

K

RSF-super_V1_02 - 17 -

ta

To rq u e

Ta, Tr, Td: output torque

t

t: duty cycle

td

Td

Time

ts

Time

Page 22

Chapter 2 Selection of the RSF supermini Series

◆ Example 2: getting duty factors of KLa, KLr and KLd

As a result of Calculation Example 1 shown below, the selected actuator RSF-5A-50 works fine, so

RSF-5A-50 can be used for duty factor graphs.

Operation conditions:

• The inertial load is accelecated at the maximum torque of the actuator, and decelerated at the

maximum torque after operation at a fixed speed.

• The movement angle θ of one cycle is 120°.

• The duration of one cycle is 0.4 (s).

• The other conditions are the same as Calculation Example 1.

(1) KLa and KLd: The average speed during the rotation speed change from 0 to 140r/min is 70r/min.

From the duty factor graphs, K

Lr: Tr≒0 for the inertial load. Similarly, from the duty factor graphs, KLr≒0.29 can be read.

(2) K

La=KLd≒1.5 can be obtained.

(3) The movement angle can be obtained from the area in the “Rotation speed-Time” diagram above.

In other words, the movement angle θ can be expressed as follows:

θ = (N / 60) x {tr + (ta + td) / 2} x 360

Solving the formula above for tr (operation time at a fixed speed of N), the following can be

obtained.

tr = θ/ (6 x N) – (ta + td) / 2

Substituting θ= 120° and ta= 0.03(s), td= 0.03(s), and N= 140r/min from Example 1, tr=0.113(s).

(4) Because the cycle time is 0.4(s), the %ED is obtained as follows:

%ED = (1.5x 0.03 + 0.29 x 0.113 + 1.5 x 0.03) / 0.4 x 100 = 30.7%

Because the value of %ED obtained is below 100, continuous repeated operation of this cycle can

be done.

If the %ED is exceeded 100%, correct the situation by:

• Changing the speed-time profile

• Reducing load moment of inertia

RSF-5A-50-E050-C

1.0

0.8

0.6

0.4

トルク[Nm]

Torque [Nm]

0.2

Estimation line for

KL=0.29

KL=0.33

0.67

Radiation plate: 150×150×3[mm]

(1) KLa, KLd

1.5

1

Allowed range

(2) KLr

0.0

0 50 100 150 200 250

RSF-super_V1_02 - 18 -

70

140

回転速度[r/min]

Speed [r/min]

Page 23

Graphs of duty factor

RSF-3

B-30-E020-C

Chapter 2 Selection of the RSF supermini Series

0.1

0.09

0.08

0.07

0.06

0.05

0.04

トルク [Nm]

Torque [Nm]

0.03

0.02

0.01

1.5

1.0

0.67

KL=0.33

0

0 50 100 150 200 250 300 350

回転速度 [r/min]

Radiation plate: 85×85×3[mm]

Speed [r/min]

Allowed range

運転可能領域

RSF-3B-50-E020-C

RSF-3B-100-E020-C

0.16

0.14

0.12

0.1

0.08

0.06

トルク [Nm]

Torque [Nm]

0.04

0.02

0.25

0.15

トルク [Nm]

Torque [Nm]

Radiation plate: 85×85×3[mm]

運転可能領域

Allowed range

1.5

1.0

0.67

KL=0.33

0

0 50 100 150 200 250

Speed [r/min]

回転速度 [r/min]

Radiation plate: 85×85×3[mm]

Allowed range

0.2

0.1

0.67

KL=0.33

運転可能領域

0.05

0

RSF-super_V1_02 - 19 -

0 20 40 60 80 100 120

Speed [r/min]

回転速度 [r/min]

Page 24

Torque [Nm]

Torque [Nm]

Torque [Nm]

Chapter 2 Selection of the RSF supermini Series

RSF-5A-30-E050-C

0.6

0.5

0.4

0.3

トルク「Nm]

0.2

0.1

0.0

0 50 100 150 200 250 300 350

0.67

KL=0.33

Radiation plate: 150×150×3[mm]

Allowed range

1.5

1

Speed [r/min]

回転速度[r/min]

RSF-5A-50-E050-C

1.0

0.9

0.8

0.7

0.6

0.5

トルク[Nm]

0.4

0.3

0.2

0.1

0.0

KL=0.33

0 50 100 150 200 250

Radiation plate: 150×150×3[mm]

1.5

1

0.67

Allowed range

回転速度[r/min]

Speed [r/min]

RSF-5A-100-E050-C

1.6

1.4

1.2

1.0

0.8

トルク「Nm]

0.6

0.4

0.2

KL=0.33

Radiation plate: 150×150×3[mm]

Allowed range

0.67

RSF-5A-30-E050-BC

0.6

0.5

0.4

0.3

トルク[Nm]

Torque [Nm]

0.2

0.1

0.0

KL=0.33

0 50 100 150 200 250 300 350

Radiation plate: 150×150×3[mm]

2

1.5

1

0.67

Speed [r/min]

回転速度[r/min]

Allowed range

RSF-5A-50-E050-BC

1.0

0.9

0.8

0.7

0.6

0.5

トルク[Nm]

0.4

Torque [Nm]

0.3

KL=0.33

0.2

0.1

0.0

0 50 100 150 200 250

Radiation plate: 150×150×3[mm]

2

Allowed range

1.5

1

0.67

Speed [r/min]

回転速度[r/min]

RSF-5A-100-E050-BC

1.6

1.4

1.2

1.0

0.8

トルク[Nm]

0.6

Torque [Nm]

0.4

0.2

KL=0.33

Radiation plate: 150×150×3[mm]

1

0.67

Allowed range

0.0

0 20 40 60 80 100 120

RSF-super_V1_02 - 20 -

Speed [r/min]

回転速度[r/min]

0.0

0 20 40 60 80 100 120

Speed [r/min]

回転速度[r/min]

Page 25

Chapter 2 Selection of the RSF supermini Series

2-4-6 Effective torque and average speed

Addionally to the former studies, the effective torque and the average speed should be studied.

(1) The effective torque should be less than allowable continuous torque specified by the driver.

(2) The average speed should be less than allowable continuous speed of the actuator.

Calculate the effective torque and the average speed of an operating cycle as shown in “2-4-5

Calculating equivalent duty”.

m: effective torque (N・m)

m

T

=

()

22

tTttT

rrdaa

×++×

t

N

tNt

t

dra

×+×+×

2

N

av

N

2

=

t

If the calculation results for the effective torque and average rotation speed are not within the range of

continuous usage in the graph shown in “1-14 Usable range,” take measures to reduce the duty.

T

T

a: maximum torque (N・m )

T

r: load torque (N・m)

a: acceleration time (s)

t

d: deceleration time (s)

t

r: running time at constant speed (s)

t

t: time for one duty cycle (s)

av: average speed (r/min)

N

N: driving speed (r/min)

◆ Example 3: getting effective torque and average speed

Effective torque and average speed are studied by using the operation conditions of Example 1 and 2.

1) Effective torque

From the parameters of T

2

T

m ⋅=

=

()

a = 8.3 N・m, Tr = 0 N・m, ta = 0.113 s, tr = td = 0.03 s, t=0.4 s,

03.003.09.0

+×

mN349.0

4.0

The value exceeds the allowable continuous torque (0.29 N・m) of RSF-5A-50 temporarily selected in

Example 1, so continuous operation cannot be done using the cycle set in Example 2. The following

formula is the formula for effective torque solved for t. By substituting the value of allowable

continuous torque in T

t

=

Substituting 0.9 N・m for T

d :

t

t

=

()

2

()

0.29

Namely, when the time for one duty cycle is set more than 0.578 s, the effective torque [T

less than 2.9 N・m, and the actuator can drive the load with lower torque than the continuous torque

continuously.

of this formula, the allowable value for one cycle time can be obtained.

m

22

rrdaa

tTttT

×++×

2

m

T

a, 0 N・m for Tr , 0.349 N・m for T

0.030.030.9

+×

2

=

]s[578.0

, 0.03 s for ta , 0.113 s for tr, and 0.03 s for

m

m] becomes

2) Average speed

From the parameters of N = 140 r/min, ta = 0.03 s, tr = 0.113 s, td = 0.03 s, t = 0.4 s

140

N

av =

=

2

0.1131400.03

140

0.03

×+×+×

2

][r/min64.34

0.578

As the speed is less than the continuous speed (90 r/min) of RSF-5A-50, it is possible to drive it

continuously on new duty cycle.

RSF-super_V1_02 - 21 -

Page 26

Chapter 2 Selection of the RSF supermini Series

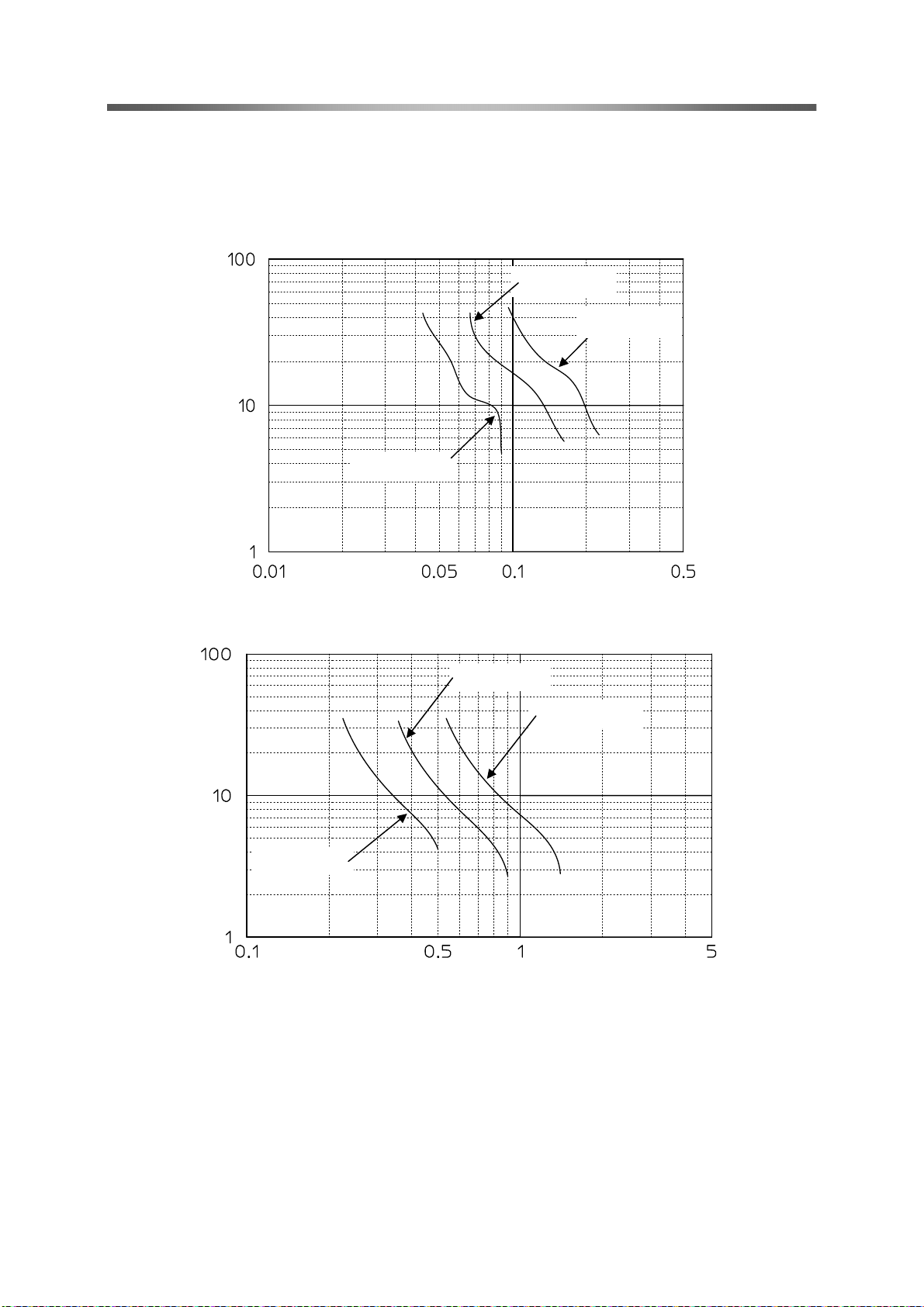

2-4-7 Permissible overloaded time

In case RSF supermini series is intermittently operated in allowable continuous torque or more, the

overloaded time is limited by the protective function in the driver even if the duty cycle is allowed. The

limits are shown in the figure below.

RSF-3B-50

RSF-3B-100

Loaded time [s]

Loaded time [s]

RSF-3B-30

Torque [Nm]

RSF-5A-50

RSF-5A-100

RSF-5A-30

Torque [Nm]

RSF-super_V1_02 - 22 -

Page 27

Chapter 3 Installing the actuator

Chapter 3 Installing the actuator

3-1 Receiving Inspection

Check the following when products are received.

● Inspection procedure

(1) Check the shipping container and item for any damage that may have been caused during

transportation. If the item is damaged, immediately report the damage to the dealer it was

purchased from.

(2) A label is attached on the right side of the RSF supermini series actuator. Confirm the products you

ordered by comparing with the model on the [TYPE] line of the label. If it is different, immediately

contact the dealer it was purchased from.

The model code is interpreted as follows:

RSF-5 A-50-E 050-C

For details of model symbols, refer to “1-2 Models” on page 2.

RSF series actuator

Frame size

Design version

Reduction ratio of Harmonic drive® gearing

Encoder specifications

Number of pulses of the encoder

Specification

(3) On the label of the HA-680 driver, the model code of the actuator to be driven is indicated on the

[ADJUSTED FOR USE WITH] line. Match the actuator with its driver so as not to confuse the item

with the other actuators.

WARNING

(4) The HA-680 driver is for 24VDC supply voltage only. Any power supply voltage other than

24VDC cannot be used.

WARNING

Only connect the actuator specified on the driver label.

The drivers have been tuned for the actuator specified on the driver label. Wrong

combination of drivers and actuators may cause low torque problems or over current

that may cause physical injury and fire.

Do not connect a supply voltage other than the voltage specified

on the label.

The wrong power supply voltage (other than 24VDC) may damage the driver resulting

physical injury and fire.

RSF-super_V1_02 - 23 -

Page 28

Chapter 3 Installing the actuator

3-2 Notice on handling

Handle RSF supermini series actuators with care, specifically:

WARNING

CAUTION

Do not plug the actuators directly into a commercial line power

source.

This could burn out the actuator, potentially resulting in a fire and/or electrical hazard.

(1) Do not apply impact or unnecessary excessive force to output

flange of actuators.

(2) Do not put actuators on in a location where the driver could

easily fall.

(3) The allowable temperature for storage is from -20°C to +60°C.

Do not expose it to the sunlight for a long time and do not

store it in areas with widely fluctuating temperatures.

(4) The allowable relative humidity for storage is less than 80%.

Do not storage it in highly humid place or in a place where

temperature changes excessively during the course of a day.

(5) Do not store units in locations with corrosive gas or particles.

RSF-super_V1_02 - 24 -

Page 29

Chapter 3 Installing the actuator

3-3 Location and installation

3-3-1 Environment of location

The environmental conditions of the location for RSF supermini series actuators must be as follows.

Service temperature: 0°C to 40°C

When the actuator is installed in a closed space, the temperature in the

space may be higher than the atmosphere because of heat emission by the

actuator. Design the closed space size, ventilation system, and device

locations so the ambient temperature near the actuator is always less than

40°C.

Service humidity: 20 to 80% relative humidity, without condensation

Make sure no water condensation occurs at the place where there is a large

temperature change in a day or due to frequent heat-and-cool cycles due to

the operation of the actuator.

2

Vibration: less than 49m/sec

Impact: less than 300 m/sec

Make sure the actuator is in an area free from: dust, water condensation, metal powder, corrosive

gas, water, water drops, and oil mist.

(10Hz~400Hz)

2

Locate the driver indoors. Do not expose it to the sunlight.

3-3-2 Considerations into External Noise

Pay sufficient attention when installing the actuator: The actuator may malfunction by external noise

depending on the conditions of installation.

Make sure that the FG line of RSF-5A is securely grounded.

Because RSF-3B does not have any FG line from the motor enclosure. Thus, when using it,

make sure that that enclosure is securely grounded to the body of the equipment through the gear

head house. In addition, make sure that the body of the equipment is securely grounded.

Do not bind the motor line and encoder signal line together.

Do not draw any external power line (i.e., driver power supply line, 100/200 VAC line.), actuator

signal line, and motor line through the same pipe or duct or bind them together.

The noise tolerance values of RSF supermini equipment are listed below.

They are guide values from a measurement that were performed using a standard relay cable in a

noise test environment while the clamp filter included with the product was installed to the equipment.

Note that the noise tolerance values in your actual environment of use may differ from them.

Model

Noise tolerance (encoder signal line)

RSF-3B RSF-5A

Vk0.2 Vk5.1

RSF-super_V1_02 - 25 -

Page 30

Chapter 3 Installing the actuator

3-3-3 Installation

Since the RSF supermini series actuator is a high precision servo mechanism, great care is required for

proper installation.

Install the actuator taking care not to damage accurately machined surfaces. Do not hit the actuator

with a hammer. Take note that actuators provide a glass encoder, which may be damaged by impact.

● Procedure

(1) Align the axis of rotation of the actuator and the load mechanism precisely.

Note 1: Very careful alignment is required especially when a rigid coupling is applied. Slight

differences between centerlines will cause failure of the output shaft of the actuator.

Note 2: When installing the actuator to a coupling, use a plastic hammer to avoid excessive

physical shocks.

(2) Fasten the flange of the actuator with flat washers and high strength bolts. Use a torque wrench

when tightening the fasteners.

The recommended tightening torque is shown in the table below:

Model RSF-3B RSF-5A

Number of bolts 4 2

Bolt size M1.6

Installation PCD mm

Wrenching torque

Transfer torque

Recommended bolt: JIS B 1176 bolt with hexagonal hole; Strength category: JIS B 1051 12.9 or greater

N・m

kgf・cm

N・m

kgf・cm

15

0.26

0.03

3.0

0.2

(3) For wiring operation, refer to “AC Servo Driver for 24VDC Power Supply HA-680 Series Technical

Data.”

M2

25

0.25

0.03

2.0

0.2

(4) Motor cable and encoder cable

Do not pull the cable. Do not hang the actuator with the cable. If you do, the connection part

may be damaged. Install the cable with slack not to apply tension to the actuator. Especially, do

not use the actuator under any condition where the cable is bent repeatedly.

CAUTION

Do not disassemble and re-assemble the actuator.

The Harmonic Drive Systems, Inc. does not guarantee the actuator that has been

reassembled by others than the authorized persons by the Harmonic Drive Systems,

Inc.

RSF-super_V1_02 - 26 -

Page 31

Chapter 4 Motor shaft retention brake

Chapter 4 Motor shaft retention brake(RSF-5A)

The RSF supermini series provides an actuator with a motor shaft retention brake as standard (Option

symbol: B), which can meet the fail-safe requirement without any additional brake.

The brake has 2 coils; one for releasing brake, and another for retaining the released state. By

controlling the currents through the coils, power consumption during retention of brake release can be

reduced.

4-1 Motor shaft retention brake specifications

Gear ratio

Item

Method

Brake operating voltage V 24VDC±10%

Current consumption during release

(at 20°C)

Current consumption during retention

of release (at 20°C)

Retention torque Note 1

Moment of inertia Note 1

Weight Note 2 g 86.0

Number of allowable brake

operations

Note 1: This is a value at the output shaft of the actuator.

Note 2: This is a value for the entire actuator.

Note 3: The motor shaft rotation speed is controlled as shown in the following table.

Gear ratio

Note 3 100,000 times

1:30 5.0

1:50 3.0

1:100 1.5

A 0.8

A 0.05

N・m 0.18 0.29 0.44

kgf・cm 1.84 2.96 4.49

(GD2/4)

kg・cm2

(J)

kgf・cm・s

Output shaft rotation speed

2

[r/min]

30 50 100

Single disc dry type deenergisation operation type

(Separate attraction coil and retention coil)

0.111 10-3 0.309 10-3 1.234 10-3

1.132 10-3 3.151 10-3 12.58 10-3

Motor shaft rotation speed

[r/min]

150

4-2 Controlling the brake power supply

4-2-1 Using a relay cable (Recommended method)

The optional relay cables for brakes (EWA-B -JST 03-TMC) incorporate a circuit that controls the

brake current.

You don’t have to control the brake current, so it is recommended to use the actuator with a brake in

combination with a relay cable for brakes.

If the relay cable for brakes is used, brake can be operated by turning on/off the brake power supply.

The power supply for the brake (that can output 24VDC±10%) shall be provided by the customer. Use

a power supply unit that can output the current during release as described in “4-1 Motor shaft retention

brake specifications.”

The supply duration of the current consumption during release is 0.5sec or less at 24VDC±10%.

RSF-super_V1_02 - 27 -

Page 32

Chapter 4 Motor shaft retention brake

4-2-2 Not using a relay cable

If the optional relay cable for brakes (EWA-B -JST 03-TMC) is not used, the customer must control the

brake power supply to the brake release coil and release retention coil.

Supply the power upon brake release and during brake release retention, as shown below.

Lead wire color Applied voltage

Upon brake

release

During release

retention

During brake use

Supply the power to the coils according to the following time chart.

Gray/Yellow

Blue/Yellow

Gray/Yellow 0VDC

Blue/Yellow 24VDC±10%

Gray/Yellow

Blue/Yellow

Brake released Brake ON

Brake release Brake release retained

24VDC±10%

0VDC

Brake release coil

Wiring: Gray/Yellow (GND)

Brake release retention coil

Wiring: Blue/Yellow (GND)

Control the power supply so that the duration in which the power is supplied to the brake release coil

(gray/yellow) is 100ms or less. The brake will not be released only by the power supply to the brake

release retention coil. To release the brake, also supply the power to the brake release coil.

Warning

The power supply to the brake must be controlled.

Control the power supply to the brake as described in “4-2 Controlling the brake power

supply.” If the current flows continuously to the attraction coil, the actuator burns due

to temperature rise, causing fire or electric shock.

Warning

Be careful not to exceed the number of allowable brake operations

(Refer to “4-1 Motor shaft retention brake specifications”).

If the number is exceeded, the retention torque drops and it cannot be

used as a brake.

RSF-super_V1_02 - 28 -

Page 33

Chapter 5 Options

Chapter 5 Options

5-1 Relay cables

There are relay cables that connect the RSF supermini series actuator and driver.

There are 3 types of relay cables for encoders, motors, and brakes. Select an appropriate type

according to the model of the actuator you ordered.

● Relay cable model (XX indicates the cable length 3m, 5m, or 10m.)

(1) For encoders

EWA-E××

-M09-3M14

(2) For motors

EWA-M××

-JST04-TN2

Round crimp-style

terminal

1.25-4

Mfg by Omron

XW4B-06B1-H1

(3) For brakes

Wafer right angle type

53048-0910

Mfg by Molex

Cable length (03=3m, 05=5m, 10=10m)

Shield

E Green/Yellow

Cable length (03=3m, 05=5m, 10=10m)

Clamp filter

ZCAT2032-0930 (TDK)

W Black

V White

U Red

Clamp filter

ZCAT2032-0930 (TDK)

Connector: 10114-3000VE

Cover: 10314-52F0-008

Mfg by 3M

Mfg by J.S.T. Mfg. Co., Ltd.

PARP-04V

EWA-B××

-JST03-TMC

Cable length (03=3m, 05=5m, 10=10m)

Round crimp-style

terminal

1.25-4

RSF-super_V1_02 - 29 -

Application of 24VDC (non polar)

Mfg by J.S.T. Mfg. Co., Ltd.

PARP-03V

Page 34

Chapter 5 Options

5-2 Relay cable wire bound specifications

The following tables show the wire bound specifications of the relay cables.

(1) For encoders (EWA-E -M09-3M14 )

Actuator side

Pin NO.

1 A phase 6 W phase 1 +5V 8 GND

2 B phase 7 +5V 2 B+ phase 9 U+ phase

3 Z phase 8 GND 3 Z+ phase 10 U- phase

4 U phase 9 N.C. 4 B- phase 11 V+ phase

5 V phase 5 A+ phase 12 V- phase

Driver side

Signal

name

Pin NO.

Connector: 53048-0910

(2) For motors (EWA-M -JST04-TN2)

Actuator side

Pin NO. Signal name Signal name Connector

1 U phase U phase

2 V phase V phase

3 W phase W phase

4 FG FG

Connector Housing: PARP-04V

Driver side

Retainer: PMS-04V-S

Contact: S(B)PA-001T-P0.5

Signal

name

Molex

Pin NO.

Shield

J.S.T. Mfg Co.,Ltd

Signal

name

6 Z- phase 13 W+ phase

7 A- phase 14 W- phase

Connector: 10114-3000VE

Cover: 10314-52F0-008

Round crimp-style terminal 1.25-4

Pin NO. Signal name

XW4B-06B1-H1

Omron

With insulating coating

3M

(3) For brakes (EWA-B -JST03-TMC)

Actuator side

Pin NO. Wire color Wire color Connector

1 Red

2 White

3 Black

Power supply side for brake

Housing: PARP-03V

Contact: S(B)PA-001T-P0.5

Connector Retainer: PMS-03V-S

J.S.T. Mfg Co.,Ltd

Red, black

(nonpolar)

Round crimp-style terminal 1.25-4

With insulating coating

RSF-super_V1_02 - 30 -

Page 35

Chapter 5 Options

5-3 Connectors

There are 2 types of connectors for the driver for different set types:

● Connector model: CNK-HA68-S1

For CN1, CN2, actuator line connection, power supply connection ......................... 4 types

● Connector model: CNK-HA68-S2

For CN2, power supply connection...........................................................................2 types

Connector for CN1

Mfg by Sumitomo 3M

Connector type: 10114-3000VE

Case type: 10314-52F0-008

Connector for actuator connection

Mfg by Phoenix Contact

Model: MC1.5/6 – ST – 3.81

Or

Mfg by Omron

Model: XW4B – 06B1 – H1

Connector for CN2

Mfg by Sumitomo 3M

Connector type: 10150-3000VE

Case type: 10350-52F0-008

Connector for power supply

Mfg by Phoenix Contact

Model: MC1.5/5 – ST – 3.81

Or

Mfg by Omron

Model: XW4B – 05B1 – H1

RSF-super_V1_02 - 31 -

Page 36

Appendix 1 Conversion of unit

Appendix 1 Conversion of unit

This technical manual basically uses the SI unit system. The conversion coefficients between the SI unit

system and other unit systems are shown below.

(1) Length

SI unit m Unit ft. in.

Coefficient 0.3048 0.0254

Unit ft. in.

Coefficient 3.281 39.37 SI unit m

(2) Linear speed

SI unit m/s Unit m/min ft./min ft./s in/s

Coefficient 0.0167 5.08x10-3 0.3048 0.0254

Unit m/min ft./min ft./s in/s

Coefficient 60 196.9 3.281 39.37 SI unit m/s

(3) Linear acceleration

SI unit m/s2 Unit m/min2ft./min2 ft./s2 in/s2

Coefficient 2.78 x10-48.47x10-5 0.3048 0.0254

Unit m/min2 ft./min2 ft./s2 in/s2

Coefficient 3600 1.18x104 3.281 39.37 SI unit m/s2

(4) Force

SI unit N Unit kgf lb (force) oz (force)

Coefficient 9.81 4.45 0.278

Unit kgf lb (force) oz (force)

Coefficient 0.102 0.225 4.386 SI unit N

(5) Mass

SI unit kg Unit lb. oz.

Coefficient 0.4535 0.02835

Unit lb. oz.

Coefficient 2.205 35.27 SI unit kg

RSF-super_V1_02

-Appendix 1-1 –

Page 37

(6) Angle

Appendix 1 Conversion of unit

SI unit rad Unit Deg. Min. Sec.

Coefficient 0.01755 2.93x10-4 4.88x10

Unit Deg. Min. Sec.

Coefficient 57.3 3.44x103 2.06x105 SI unit rad

(7) Angular speed

SI unit rad/s Unit Deg./s Deg./min r/s r/min

Coefficient 0.01755 2.93x10-4 6.28 0.1047

Unit

Coefficient 57.3 3.44x103 0.1592 9.55 SI unit rad/s

Deg./s Deg./min

r/s r/min

(8) Angular acceleration

SI unit rad/s2 Unit Deg./s2 Deg./min2

Coefficient 0.01755 2.93x10-4

Unit Deg./s2 Deg./min2

Coefficient 57.3 3.44x103 SI unit rad/s2

(9) Torque

SI unit Nm Unit kgfm lbft lbin ozin

Coefficient 9.81 1.356 0.1130 7.06x10

Unit kgfm lbft lbin ozin

Coefficient 0.102 0.738 8.85 141.6 SI unit Nm

-6

-3

(10) Moment of inertia

SI unit kgm2

Unit kgfms

Coefficient 0.102 10.2 23.73 0.7376 3.42x10

2

kgfcms

2

lbft2 lbfts2 lbin2 lbins2 ozin2 ozins2

3

8.85 5.47x104 141.6

Unit kgfms

Coefficient 9.81 0.0981 0.0421 1.356 2.93x10

SI unit kgm2

2

kgfcms

2

lbft2 lbfts2 lbin2 lbins2 ozin2 ozins2

-4

0.113 1.829x10-5 7.06x10

(11) Torsional spring constant, moment of rigidity

SI unit Nm/rad

Unit kgfm/rad

Coefficient 0.102 2.97 x10-5 1.78x10

Unit kgfm/rad Kgfm/arc min kgfm/Deg. lbft/Deg. lbin/Deg.

Coefficient 9.81 3.37 x104 562 77.6 6.47

SI unit Nm/rad

kgfm/arc min

kgfm/Deg. lbft/Deg. lbin/Deg.

-3

0.0129 0.1546

-3

RSF-super_V1_02

-Appendix 1-2 –

Page 38

A

A

Appendix 2 Calculations of moment of inertia

Appendix 2 Calculations of moment of inertia

1. Calculation formulas for mass and moment of inertia

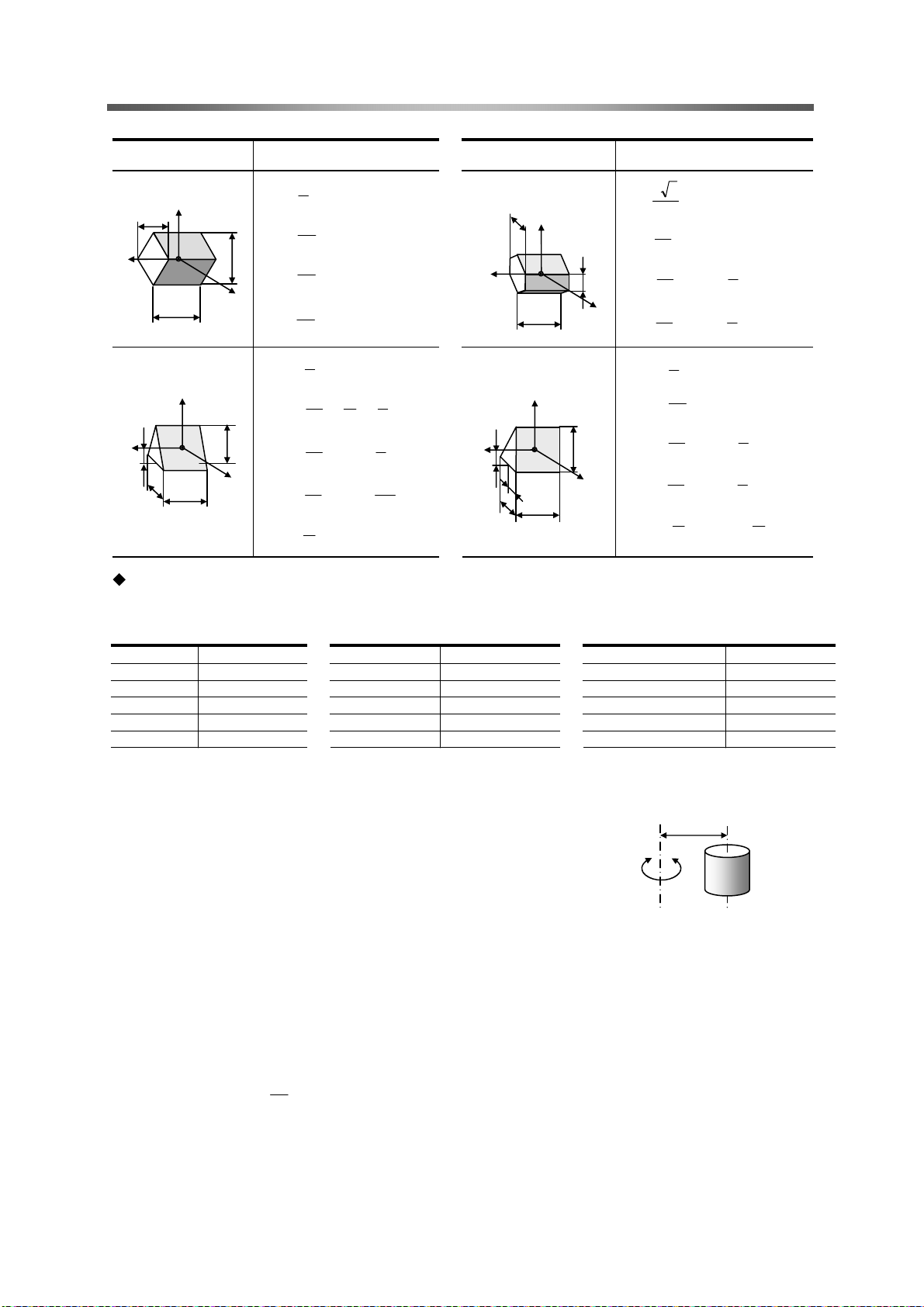

(1) When center of revolution and line of center of gravity match

Calculation formulas for mass and moment of inertia are shown below.

m: Mass (kg)

Ix, Iy, Iz: moment of inertia (kgm

2

) making Axes x, y and z as centers of revolution

G: Distance from edge surface of center of gravity

ρ: Specific gravity

Units - Length: m, mass: kg, moment of inertia: kgm

Shape of object

Circular cylinder Round pipe

z

R

x

y

L

Tilted circular cylinder Sphere

R

θ

Mass, inertia,

position of center of gravity

ρLRm2π=

1

Ix =

Iy

Iz

2

Rm

2

⎛

1

⎜

⎜

4

⎝

⎛

1

⎜

⎜

4

⎝

2

⎞

L

2

⎟

+=

Rm

Rm

⎟

3

⎠

2

⎞

L

2

⎟

+=

⎟

3

⎠

ρLRm2π=

Shape of object

z

R1

x

R2

L

R1: Outside diameter

R2: Inside diameter

y

R

1

m

I

=

θ

12

(

{}

)

2222

θθ

sinLcos13R

++×

L

Mass, inertia,

position of center of gravity

2

R

+= π

2

2

)

RRm

2

L

2

)

++=

RRm

2

L

2

)

++=

RRm

2

3

Ix +=

Iy

Iz

m π=

I =

2

⎛

Rm

⎜

1

⎝

1

2

(

1

2

⎧

1

⎪

2

(

⎨

1

4

⎪

⎩

⎧

1

⎪

2

(

⎨

1

4

⎪

⎩

4

ρ3R

3

2

2

Rm

5

2

⎞

ρL

⎟

⎠

2

⎫

⎪

⎬

3

⎪

⎭

2

⎫

⎪

⎬

⎪

⎭

Elliptic circular cylinder Cone

z

B

x

L

Prism Regular square pipe

B

z

x

RSF-super_V1_02

y

C

y

C

Ix +=

Iy

Iz

Ix +=

Iy +=

Iz +=

16

1

4

12

12

1

4

12

1

1

ρLBCm π=

1

⎛

⎜

m

⎜

⎝

⎛

⎜

m

⎜

⎝

1

22

(

C

B

(

(

(

)

CBm

22

⎞

L

⎟

+=

⎟

3

4

4

ρA BCm =

⎠

22

⎞

L

⎟

+=

⎟

3

⎠

22

)

CBm

22

)

ACm

22

)

BAm

x

D

x

z

R

G

y

L

B

z

y

- Appendix 2-1 -

m ππ=

Ix =

Iy +=

Iz +=

G =

Ix +=

Iy ++=

Iz ++=

ρL2R

3

3

2

Rm

10

3

(

80

3

(

80

L

4

()

1

()

{}

3

1

2

{}

6

1

2

{}

6

22

)

L4Rm

22

)

L4Rm

ρD-B4AD=m

2

2

DD-Bm

2

()

()

2

DD-BAm

2

2

DD-BAm

Page 39

A

r

A

A

A

Shape of object

z

B

x

Equilateral triangular

prism

z

G

x

B

Appendix 2 Calculations of moment of inertia

Mass, inertia,

position of center of gravity

1

ρ

ABC

m =

2

1

Ix +=

C

Iy +=

y

Iz +=

m =

Ix

C

Iy

y

Iz

G =

24

24

24

(

1

(

1

1

ρABC

2

B

1

m

(

2

12

1

Am

(

12

1

Am

(

12

C

3

Shape of object

msirp nogaxeh ralugeR msirp cibmohR

22

CBm

)

22

)

2ACm

22

2ABm

2

2

2

+=

C

)

3

2

22

+=

C

)

3

2

B

2

+=

)

2

B√ 3

x

Right-angled triangular

prism

G

x

z

Ix =

Iy

B

y

Iz

z

1