Page 1

Flat Hollow Shaft AC Servo Motors

HMA s eries m anual

ISO14001

ISO9001

Page 2

Introduction

Introduction

Thank you for purchasing our HMA series AC servo motor.

Incorrect handling or improper use of this product m ay result in unexpected accidents or a shorter

product life. Read t his manual caref ully and us e the pr oduct corr ectly s o that the product can be used

safely for many years.

The information contained in this manual is subject to change without notice.

Keep this manual in a convenient location and refer to it whenever necessary in operating or

maintaining the product.

The end user of the product should have a copy of this manual.

Page 3

SAFETY GUIDE

1

SAFETY GUIDE

To use this product safely and cor rectly, be sure to read the SAF ETY GUIDE and other parts of this

document carefully and fully understand the information provided here in bef or e using the pr od uct .

NOTATION

Important safety information you must note is provided herein. Be sure to observe these instructions.

Indicates a potentiall y hazardous situatio n, which, if not avoi ded, could result

in death or serious personal injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate personal injury and/or damage to the equipment.

Indicates what should b e performed or avoided to prevent non-operation or

malfunction of the product or negative effects on its performance or function.

LIMIT ATION OF APPLICATIONS

The equipment listed in this document may not be used for the applications listed below:

・

Space equipment

・ Aircraft, aeronautic equipment

・ Nuclear equipment

・ Household apparatus

・ Vacuum equipment

・ Automobile, automotive parts

・ Amusement equipment, sport equipment, game machines

・ Machines or devices acting directly on the human body

・ Instruments or devices to transport or carry people

・

Apparatus or devices used in special environments

If the above list includes your intended application for our products, please consult us.

If this product is utilized in any facility in which human life is

at stake or that may incur material losses, install safety

devices so that accidents do not occur even when the output

control is disabled due to damage.

WARNING

CAUTION

CAUTION

Page 4

SAFETY GUIDE

2

SAFETY NOTE

ITEMS YOU SHOULD NOTE WHEN USING THE MOTOR

CAUTIONS RELATED TO THE DESIGN

Always use the motor under the specified conditions:

The motor is designed to be used indoors. Observe the following conditions:

・ Ambient temperature: 0 to 40℃

・ Ambient humidity: 20 to 80% RH (no condensation)

・ Vibration: Max. 25 m/s2

・ No contamination by water or oil

・ No corrosive or explosive gas

Always follow the instructions in the related manuals to

install the motor in the equipment.

・ Follow the instructions in th e manual t o ensure t hat th e center of the motor

is aligned with the center of the paired unit.

・ Improper alignment may cause vibration or damage to the output shaft.

OPERATIONAL PRECAUTIONS

Do not exceed the allowable torque.

・ Do not apply a torque exceeding the maximum torque.

・ Be aware that, if arms directly attached to the output shaft are hit, the output

shaft may become uncontrollable.

Never connect cables directly to a power supply socket.

・ Motors must be connected to the proper driver to operate.

・ Do not connect a comm ercial power supp ly directly to the motor. Failure to

observe this caution may damage the motor, possibly resulting in a fire.

Do not apply impacts and shocks to the motor.

・ Do not tap the motor with a hammer or other tool be cause an encoder is

connected directly to the motor.

・ If the encoder is damaged, the motor may become uncontrollable.

Do not pull the cables.

・ Pulling the cables can dam age connectors, causing the motor to bec ome

uncontrollable.

CAUTION

WARNING

Page 5

SAFETY GUIDE

3

ITEMS YOU SHOULD NOTE WHEN USING THE DRIVER

CAUTIONS RELATED TO THE DESIGN

Always use the motor under the specified conditions:

The driver generates heat. Take extra caution for radiation and use it under the

following conditions.

・ Mount in a vertical position keeping sufficient distance from other devices to

let heat generated by the driver radiate freely.

・ 0 to 50℃, 95% RH or below (No condensation)

・ No vibration or physical shock

・ No dust, dirt, corrosive, or explosive gas

Use sufficient noise suppressing means and safe grounding.

An y noise gener ated on a signa l wire ca uses vibra tion or improper motion. Be

sure to observe the following precautions.

・ Keep signal and power leads separated.

・ Keep leads as short as possible.

・ Ground the motor and driver at one single point, minimum ground

resistance class: D (less than 100 ohms)

・ Do not use a power line filter in the motor circuit.

Pay attention to negative torque caused by inverse load.

・ An inverse load may cause damage to the driver.

・ Please consult our sales office if you intent to use the motor in such

applications.

Use a fast-response type ground-fault detector designed for

PWM inverters.

When using a fast-response type ground-fault detector, use one that is

designed for PWM inverters. Do not use a time-delay-type ground-fault

detector.

If this product is utilized in any facility in which human life is

at stake or that may incur material losses, install safety

devices so that accidents do not occur even when the output

control is disabled due to damage.

OPERATIONAL PRECAUTIONS

Never change any wiring while the power is active.

Mak e s ure that th e po wer i s not ac ti ve bef or e ser vic in g the products. Failure t o

observe this caution may result in an electric shock or uncontrollable operation.

Do not touch the terminals for at least 5 minutes after turning

OFF the power supply.

・ Even after the power suppl y is turned OFF, electric charge remains in the

driver. In order to prevent electric shock, perform inspections 5 m inutes or

more after the power supply is turned OFF.

・ When installing, make sure that the inner electronic components are hard to

reach.

CAUTION

WARNING

Page 6

SAFETY GUIDE

4

Do not perform a voltage resistance test.

・ Do not perform a Megger t est or voltag e resistance t est. F ailure to obser ve

this caution may result in damage to the control circuit of the driver.

・ Please consult our sales office if you intent to perform such tests.

Do not operate the driver by switching the power ON/OFF.

・ Frequent power ON/OFF operations may cause deterioration of circuit

elements inside the driver.

・ Use command signals to start or stop the motor.

DISPOSAL

The motor and driver must be disposed of as industrial

waste.

W hen disposing of the motor or driver, disassemble it as much as poss ible,

separate parts acc ording to the m aterial des cription ( if indic ated), and dispos e

of them as industrial waste.

CAUTION

CAUTION

Page 7

5

Contents

SAFETY GUIDE .................................................................................................. 1

NOTATION ............................................................................................................. 1

LIMIT ATION OF APPLIC ATIONS ............................................................................ 1

SAFETY NOTE ...................................................................................................... 2

Contents .......................................................................................................... 5

Related manual .................................................................................................. 7

Conformance to overseas standards

......................................................................... 7

Chapter 1 Outlines

1-1 Outlines ...................................................................................................... 1-1

1-2 Model ....................................................................................................... 1-2

1-3 Combinations with drivers and extension cables.......................................... 1-3

1-4 Specifications ............................................................................................... 1-4

1-5 Holding brake ............................................................................................... 1-6

1-6 External dimensions ..................................................................................... 1-7

1-7 Mechanical accuracy .................................................................................. 1-12

1-8 Detector specifications (Absolute encoder) ................................................ 1-13

1-9 Rotation direction ....................................................................................... 1-14

1-10 Shock resistance ...................................................................................... 1-15

1-11 Resistance to vibration ............................................................................. 1-16

1-12 Operable range ........................................................................................ 1-17

1-13 Cable specifications ................................................................................. 1-20

Motor cable specifications ................................................................................. 1-20

Encoder cable specifications ............................................................................. 1-21

Chapter 2 Selection guidelines

2-1 HMA series selection .................................................................................... 2-1

Allowable load inertia moment ............................................................................. 2-1

2-2 Verifying and examining load weights .......................................................... 2-2

2-3 Examining the operating status .................................................................... 2-3

Examining motor rotational speed ....................................................................... 2-3

Calculating and examining load inertia moment ................................................... 2-3

Load torque calculation ....................................................................................... 2-4

Acceleration time and deceleration time .............................................................. 2-5

Evaluating effective torque and average rotational speed .................................... 2-6

Page 8

Contents

6

Chapter 3 Installing t he HMA motor

3-1 Receiving inspection .................................................................................... 3-1

Inspection procedure ........................................................................................... 3-1

3-2 Notices on handling ...................................................................................... 3-2

Installation and transmission torque .................................................................... 3-2

Precautions on installation ................................................................................... 3-3

Use of positioning pins ........................................................................................ 3-4

Motor shaft material ............................................................................................. 3-4

3-3 Location and installation ............................................................................... 3-5

Environment of location ....................................................................................... 3-5

Installation ........................................................................................................... 3-6

Chapter 4 Options

4-1 Options ...................................................................................................... 4-1

Cable taken out from side face (option code: Y) .................................................. 4-1

Extension cables ................................................................................................. 4-2

Appendix

A-1 Unit conversion ............................................................................................ 5-1

A-2 Calculating inertia moment .......................................................................... 5-3

Formulas of mass and inertia moment ................................................................. 5-3

Inertia moment of cylinder ................................................................................... 5-5

Page 9

Related manual

7

Related manual

The related manual is listed below. Use it as a reference as necessary.

Title

Description

AC Servo Driver

HA-800 series manual

The specifications and characteristics of HA-800 series driv er s are explained.

Conformance to overseas standards

The HMA series motors are compliant with the following overseas standards.

UL standards

UL1004-1, UL1004-6 (File No. E243316)

CSA standards

C22.2 No.100

European Low Voltage EC Directives

EN60034-1, EN60034-5

UL nameplate stick er

According to the UL10 04-1, UL1004-6 (File No. E243316) standards , the following spec ifications are

indicated on the HMA series motors.

Nameplate

field

Description

(1)

Output [W] at point A on the graph below

(2)

Voltage [V] between motor wires at point A on the

graph below

(3)

Allowable continuous current [A ]

(4)

Rotational speed at point A on the graph below [r/min]

(5)

Current fundamental frequency [Hz] at point A on the

graph below

(6)

Allowable ambient temperature [℃]

(7)

Number of phases

(1)

(2)

(3)

(4)

(5)

(6)

(7)

UL nameplate sticker

Rated torque

A

Motion range during

acceleration and deceleration

Aluminum radiation plate: 320*320*16

Continuous motion

range

Rotation speed [r/min]

Torque [Nm]

Page 10

Conformance to overseas standards

8

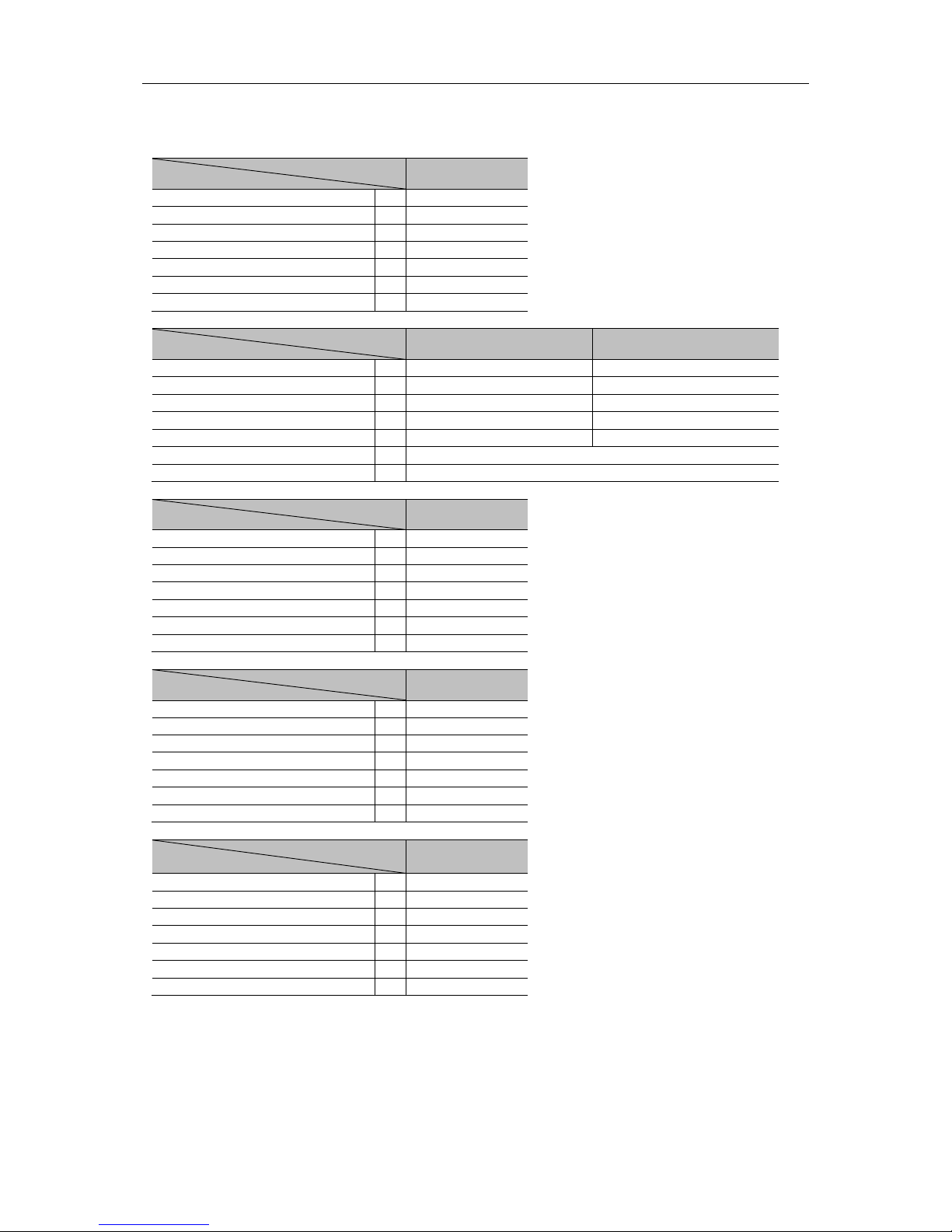

The values displayed on the name plate for each model are shown below.

Model

Item

HMAC08

(1) Output at point A

W

163

(2) Voltage at point A

V

130

(3) Allowable continuous current

A

2.1

(4) Speed at point A

r/min

3,000

(5) Frequency at point A

Hz

250

(6) Allowable ambient temperature

℃

40

(7) Number of phases

-

3

Model

Item

HMAB09

(Motor input voltage 200 V)

HMAB09

(Motor input voltage 100 V)

(1) Output at point A

W

251

251

(2) Voltage at point A

V

136

71

(3) Allowable continuous current

A

2.5

4.3

(4) Speed at point A

r/min

3,000

3,000

(5) Frequency at point A

Hz

250

250

(6) Allowable ambient temperature

℃

40

(7) Number of phases

-

3

Model

Item

HMAB12

(1) Output at point A

W

406

(2) Voltage at point A

V

129

(3) Allowable continuous current

A

4.2

(4) Speed at point A

r/min

2,500

(5) Frequency at point A

Hz

208

(6) Allowable ambient temperature

℃

40

(7) Number of phases

-

3

Model

Item

HMAB15

(1) Output at point A

W

754

(2) Voltage at point A

V

125

(3) Allowable continuous current

A

7.8

(4) Speed at point A

r/min

2,000

(5) Frequency at point A

Hz

167

(6) Allowable ambient temperature

℃

40

(7) Number of phases

-

3

Model

Item

HMAA21A

(1) Output at point A

W

1,320

(2) Voltage at point A

V

100

(3) Allowable continuous current

A

20.0

(4) Speed at point A

r/min

1,000

(5) Frequency at point A

Hz

133

(6) Allowable ambient temperature

℃

40

(7) Number of phases

-

3

Page 11

Page 12

Chapter 1

Outlines

This chapter explains the features, functions and specifications of the motor.

1-1

Outlines ············································································· 1-1

1-2 Model ················································································ 1-2

1-3 Combinations with drivers and extension cables ························· 1-3

1-4 Specifications ······································································ 1-4

1-5 Holding brake ······································································ 1-6

1-6 External dimensions ····························································· 1-7

1-7 Mechanical accuracy ·························································· 1-12

1-8 Detector specifications (Absolute encoder) ······························ 1-13

1-9 Rotation direction ······························································· 1-14

1-10 Shock resistance ····························································· 1-15

1-11 Resistance to vibration ····················································· 1-16

1-12 Operable range ······························································· 1-17

1-13 Cable specifications ························································· 1-20

Page 13

1-1 Outlines

1-1

Outlines

1-1 Outlines

All HMA series AC servo motor models feature a ho llow bore structure and compact design. Wires,

pipes, ball screws, or laser beams go through the hollow bore dependin g on the mechanism design

required for your applications.

HMA series AC servo motors play an important role in driving various factory automation (FA)

equipment, such as ro bot j oints , al ig nment mechanisms f or s em i-conduc tor s an d LC D de v ices , ATC of

metal-cutting machines, printing machine roller drives, etc.

Comes standard with a 17-bit magnetic absolute encoder

The HMA series AC servo motors are equipped with a highly reliable 17-bit magnetic absolute encoder*

with safety function. The serial communication requires fewer cables and provides not only a multi

revolution counting func tion which is a m ust-have feat ure of m otors, but it als o has an internal b ackup

battery to retain absolute positions even when the encoder cable is disconnected briefly.

The encoder also consta ntly compares two sets of detec ted angles. If any abnorm ality is found, the

encoder's built-in failsafe function outputs a signal to the host system. This helps you build a safe

system.

* Model No. 08 is equipped with an optical encoder.

Supporting a more compact control board and open network control with a

dedicated driver

The dedicated HA-800 s eries drivers f eature a thin design, con tributing to the r eduction in the c ontrol

board size. It also allows you to control your motor on a MECHATROLINK-II or CC-Link network.

Page 14

1-2 Model

1-2

Outlines

1

Appe

1-2 Model

The model names for the HMA series motors and how to read the symbols are explained below.

Model example:

HMA B 09 A 200 - 10 S17b A - C Y - SP

(1) (2) (3) (4) (5) - (6) (7) (8) - (9) (10) - (11)

(1) Model: HMA series AC servo motor

(2) Motor version symbol

A Model No. 21A

B Model Nos. 09, 12, 15

C Model No. 08

(3) Model Nos.: 08, 09, 12, 15, 21A

(4) Brake

A Without brake

B With brake

(5) Applicable servo driver input voltage

100 100 V

200 200 V

(100 V is compatible with model No. 09 only.)

(6) Encoder format

10 Compliant with format A, transmission rate: 2.5 Mbps, 1-on-1 connection

(7) Encoder type, resolution

S17b 17-bit multi-turn absolute encoder, 131,072 pulses/revolution

(8) Encoder phase angle: Phase difference between the voltage induced in motor phase U and

absolute origin

A 0 degree

(9) Connector specification

C With standard connector

N Without connector

(10) Option symbol

Y Cable taken out from the side

(Please contact us for model No. 08. This option is not available for model No. 21A.)

(11) Special specification

No description Standard product

SP Special specification product

Page 15

1-3 Combinations with drivers and extension cables

1-3

Outlines

1-3

Combinations with drivers and extension cables

The combinations of HMA motors, HA-800 drivers and extension cables are as follows:

HMAC08

HMAB09

HMAB12

HMAB15

HMAA21A

I/O command type

HA-800A

-3D/E-200

HA-800A

-3D/E-200

(HA-800A

-6D/E -100)

HA-800A

-6D/E-200

HA-800A

-24D/E-200

HA-800A

-24D/E -200

MECHATROLINK-II type

HA-800B

-3D/E-200

HA-800B

-3D/E -200

(HA-800B

-6D/E -100)

HA-800B

-6D/E-200

HA-800B

-24D/E-200

HA-800B

-24D/E -200

CC-Link type

HA-800C

-3D/E-200

HA-800C

-3D/E -200

(HA-800C

-6D/E -100)

HA-800C

-6D/E-200

HA-800C

-24D/E-200

HA-800C

-24D/E -200

Extension

cables

(option)

For motors

EWD-MB**-A06-TN3

EWD-MB**

-A06-TMC

EWD-MB**

-D09-TMC

For

encoders

EWD-S**-A08-3M14

EWD-S**

-D10-3M14

*1: ** in the extension cable model indicates the cable length: 03 = 3m, 05 = 5m, 10 = 10m

*2: The driver models shown in parentheses are used when combined with motors whose applicable servo driver

input voltage is 100 V.

Page 16

1-4 Specifications

1-4

Outlines

1

Appe

1-4 Specifications

The specifications of the HMA series motors are shown below.

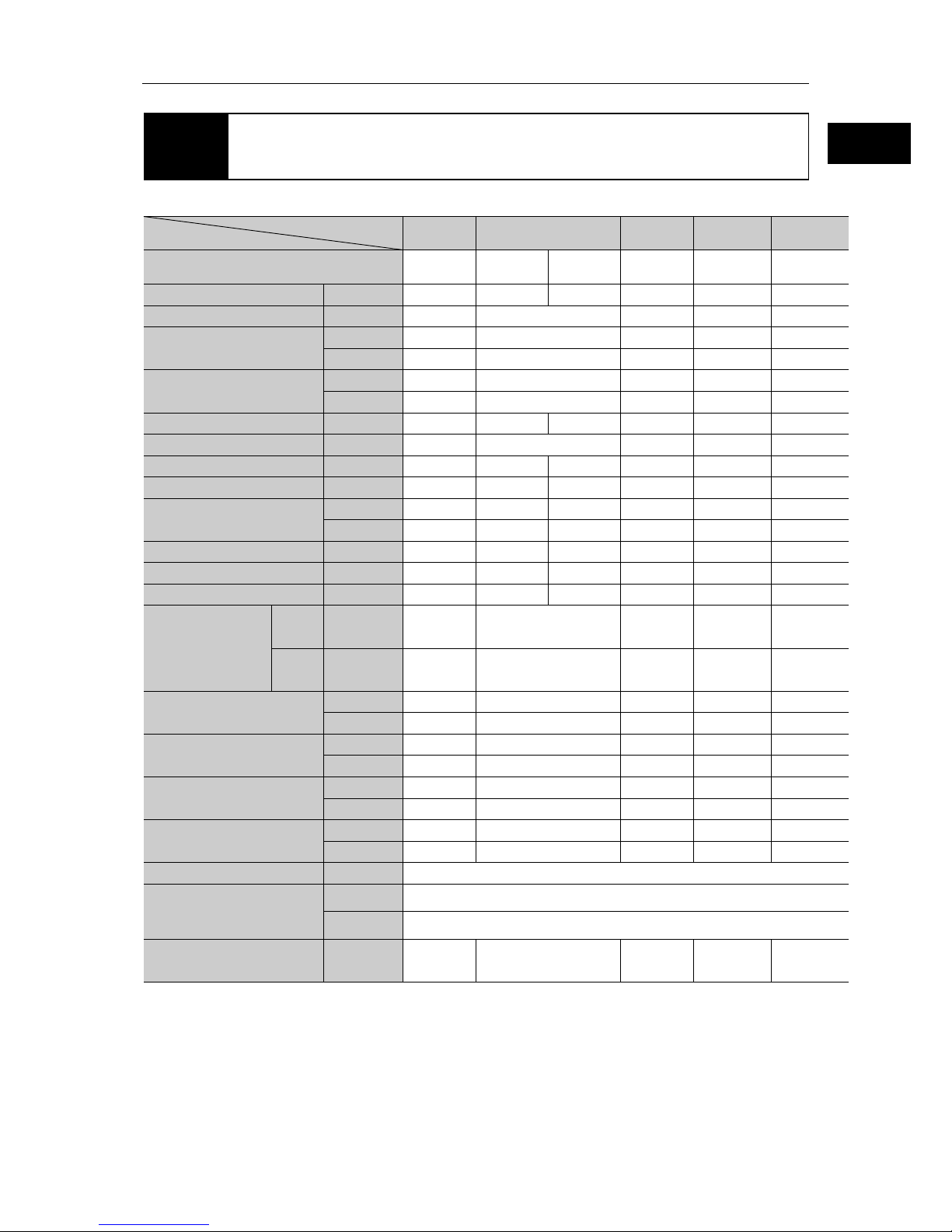

Model

Item

HMAC08 HMAB09 HMAB12 HMAB15 HMAA21A

Compatible drivers

HA-800□-3

D/E-200

HA-800□-3

D/E-200

HA-800□-6

D/E-100

HA-800□-6

D/E-200

HA-800□-2

4D/E-200

HA-800□-2

4D/E-200

Input power supply V

200 200 100 200 200 200

Rated output W

163 251 406 754 1,320

Maximum momentary

torque*1

Nm

1.8 3.0 6.6 13 33

kgf・m

0.18 0.31 0.67 1.33 3.37

Rated torque

*1*2

Nm

0.52 0.80 1.55 3.60 12.6

kgf・m

0.053 0.082 0.158 0.367 1.29

Max. rotational speed*1 r/min

6,000 5,600 4,800 4,800 4,000 3,000

Rated rotational speed r/min

3,000 3,000 2,500 2,000 1,000

Instantaneous max. current*1 A

6.5 8.9 15.4 18 29 55

Rated current

*1*2

A

2.1 2.5 4.3 4.2 7.8 20.0

Torque constant*1

Nm/A

0.35 0.41 0.24 0.44 0.54 0.72

kgf・m/A

0.036

0.042

0.024

0.045

0.055

0.073

MEF constant*3 V/(r/min)

0.037 0.043 0.025 0.046 0.057 0.075

Phase resistance (20℃)

Ω

1.43 1.2 0.4 0.33 0.19 0.028

Phase inductance mH

2.5 3.0 1.0 1.4 1.2 0.29

Inertia moment

Values in

parentheses are for

models with a

brake.

GD2/4

×10-4 kg・m2

0.734 1.78 6.45 15.8 125

(0.828)

(2.16)

(6.83)

(19.8)

(141)

J

×10-4kgf

・

cm・s2

7.49 18.2 65.8 161 1,280

(8.45) (22.1) (69.7) (202) (1,444)

Allowable radial load

(when stationary)

N

800

800

1,200

2,400

4,500

kgf

81.6 81.6 122 245 459

Allowable axia l lo a d

(when stationary)

N

1,900 2,400 3,600 5,000 14,000

kgf

194 245 367 510 1,429

Rated radial load

(at rated rotational speed)

N

175 185 233 530 1,040

kgf

17.9 18.9 23.8 54.1 106.1

Rated axial load

(at rated rotational speed)

N

100

105

130

180

880

kgf

10.2 10.7 13.3 18.4 89.8

Encoder type

Absolute encoder

Encoder resolution

Single-turn

detector

217 (131,072)

Multi-turn

detector*4

216 (65,536)

Mass

Values in parentheses are for

models with a brake.

kg

1.4 2.0 3.4 5.5 17.5

(1.5) (2.1) (3.8) (6.2) (19.7)

Page 17

1-4 Specifications

1-5

Outlines

Environmental conditions

Operating temperature: 0 to 40℃/Storage temperature: -20 to 60℃

Service/storage humidity: 20 to 80% RH (no condensation)

Resistance to vibration: 25m/s

2

(frequency: 10 to 400Hz)

Resistance to impact: 300 m/s

2 *5

No dust, metal powder, corrosive gas, inflammable gas, or oil mist.

To be used indoors, no direct sunlight.

Altitude: less than1,000 m above sea level

Motor insulation

Insulation resistance: 100 MΩ or more (500 VDC insulation tester)

Dielectric strength: 1,500 VAC/1 min

Insulation class: A

Mounting direction

Can be installed in any direction.

Protection structure

Totally enclosed self-cooled type (IP54)

The table above shows the typical values.

*1: Indicates typical characteristics when combined with our driver (driven using an ideal sine wave).

*2: Values after the temperatur e ha s ri sen and sa tur at ed when installed on the fol lowing aluminum radiation plate s.

HMAC08: 320×320×16 [mm]

HMAB09: 350×350×18 [mm]

HMAB12: 400×400×20 [mm]

HMAB15: 500×500×25 [mm]

HMAA21A: 650×650×30 [mm]

*3: Value of the phase-induced voltage co nsta nt multiplied by 3.

*4: The multi-turn detector range is -32,768 to 32,767.

*5: For testing conditions, refer to [1-10 Shock resistance] (P1-15) and [1-11 Resistance to vibration] (P1-16).

Motor operation is not guaranteed in applications where vibr ation s an d im pac ts are continuously applied for a

long period of time.

Page 18

1-5 Holding brake

1-6

Outlines

1

Appe

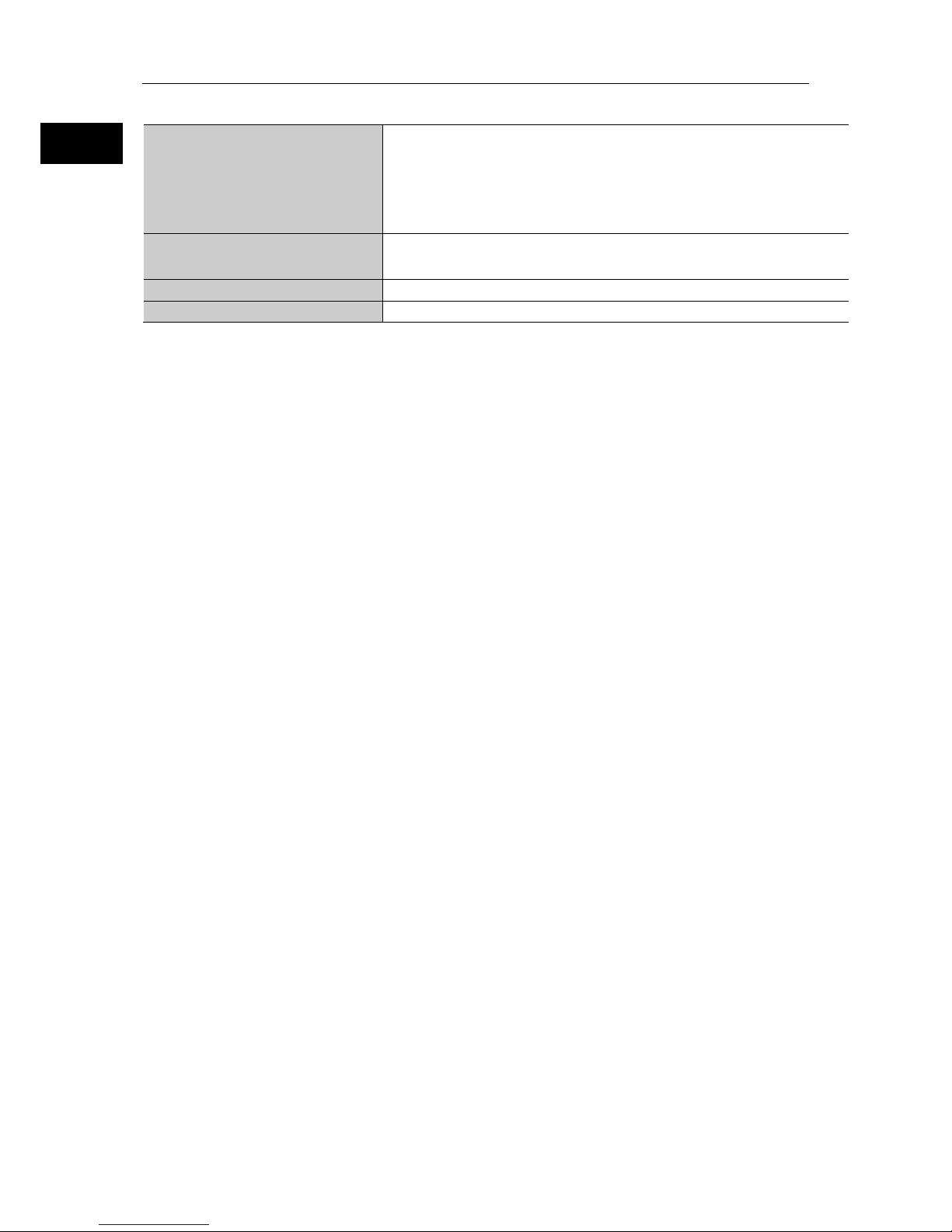

1-5 Holding brake

The brakes equipped on H MA series motors are us ed to hold th e m otor shaf t in plac e when the power

is cut off. With some m odels (H MAB09, 12), the m otor's bui lt-in circuit controls the voltage supplied to

the brake in order to reduce the power consumption while the brake is actuated.

Always us e a DC po wer suppl y that has a proper brak e exc itation voltag e and is capable of outp utti ng

enough current during suction.

Specifications

Model

Item

HMAC08 HMAB09 HMAB12 HMAB15 HMAA21A

Type

Dry non-excitation actuation ty pe

Power-saving control No Yes No

Brake excitation voltage V 24 VDC ± 10% (no polarity) *1

Current consumption

during suction

A 0.37 0.8*2 0.8*2 0.7 0.9

Current consumption

during holding

A 0.37 0.3 0.3 0.7 0.9

Holding torque

Nm 0.6 1.0 2.0 4.0 15

kgf·m

0.06 0.102 0.204 0.408 1.53

Allowable number of

normal brakings*3

100,000 times

Allowable number of

emergency stops *4

200 times

*1: The power supply for the brake is not included in the product. Use a power supply that is capable of outputting

enough current during brake suction.

*2: The duration the current is supplied during suction is 0.5 second or less for the power supply of 24VDC ± 10%.

*3: When the brake is activated at the rotational speed of 150 r/min or less.

*4: When the brake is activated at the rotational speed of 3,000 r/min, provided that the inertia moment of load is 3

times or less than that of the motor .

The holding brake cannot be used for deceleration.

Do not use the holding brake more than the allowable number of normal

brakings (100,000 times at the rotational speed of 150 r/min or less) or allowable

number of emergency stops (200 times at the rotational speed of 3,000 r/min,

provided that the inertia moment of load is 3 times or less than that of the

motor).

Exceeding the allowable number of normal brakings and allowable number of

emergency stops may cause the holding torque to decrease and consequently

become unusable as a brake.

WARNING

Page 19

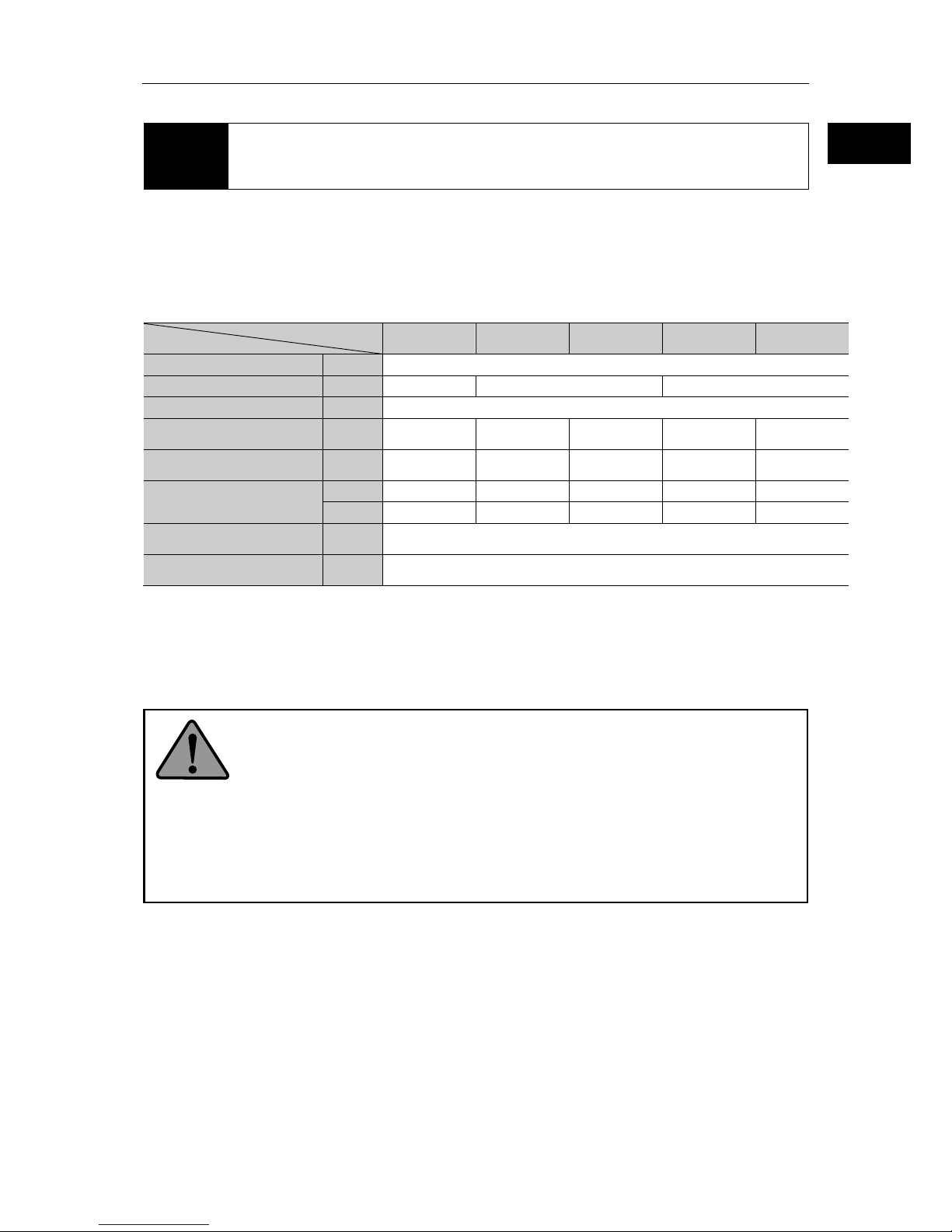

1-6 External dimensions

1-7

Outlines

1-6 External dimensions

The external dimensions of the HMA series motors are shown below.

HMAC08 (with/without brake)

Unit: mm (third angle projection)

Note: For details on external dimensions, see our ill ustrated specifications.

Tolerances may vary with the product manufacturing method (foundry piece, mac hi ne

-finished good).

Contact us for the differential range of the size that is not described.

Encoder cable

Motor cable

(Cable outer diameter:

(Cable outer diameter:

Motor connector

Encoder connector

Housing :

Tab contact:

Housing

Pin contact Pin contact

R0.4 or less

R0.4 or less

15 or less

Page 20

1-6 External dimensions

1-8

Outlines

1

Appe

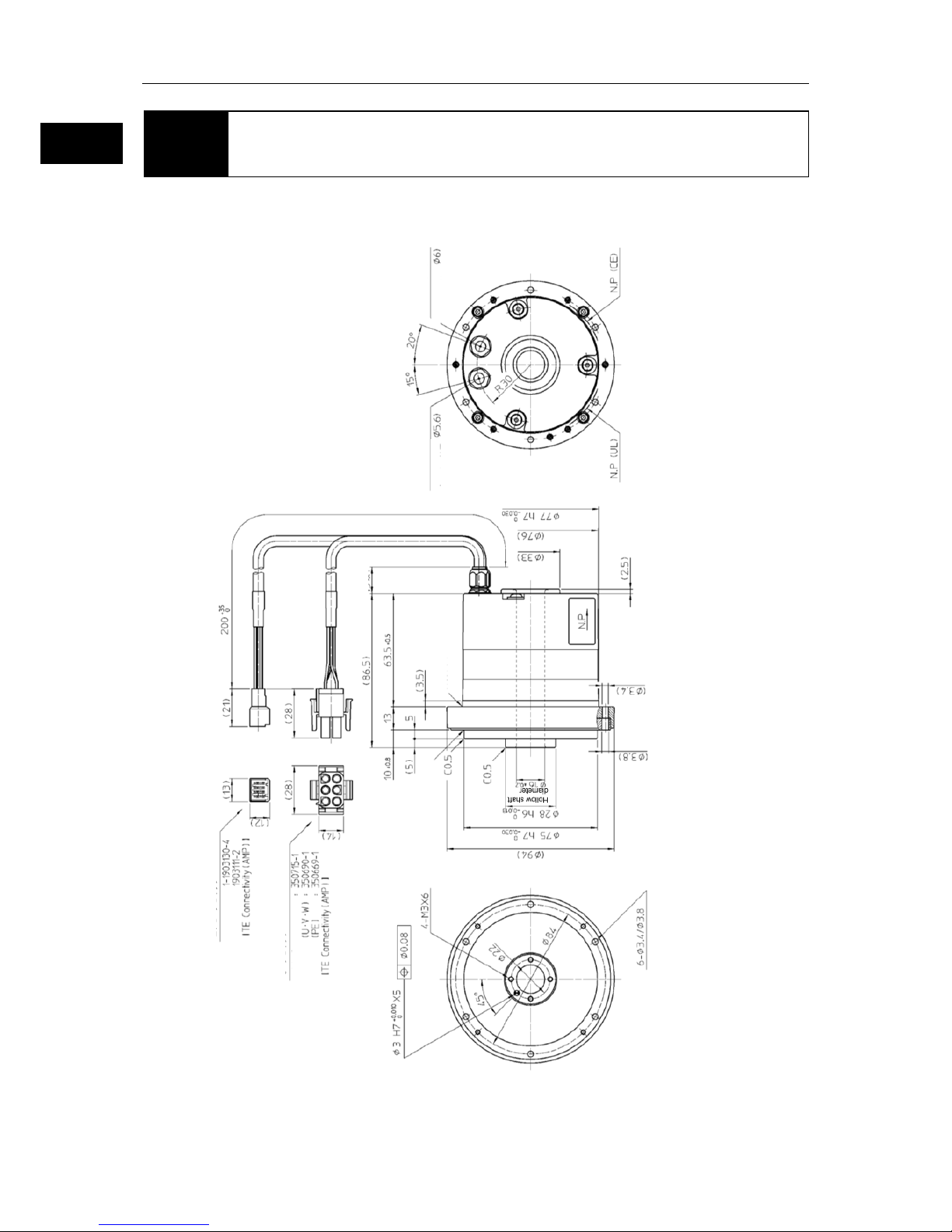

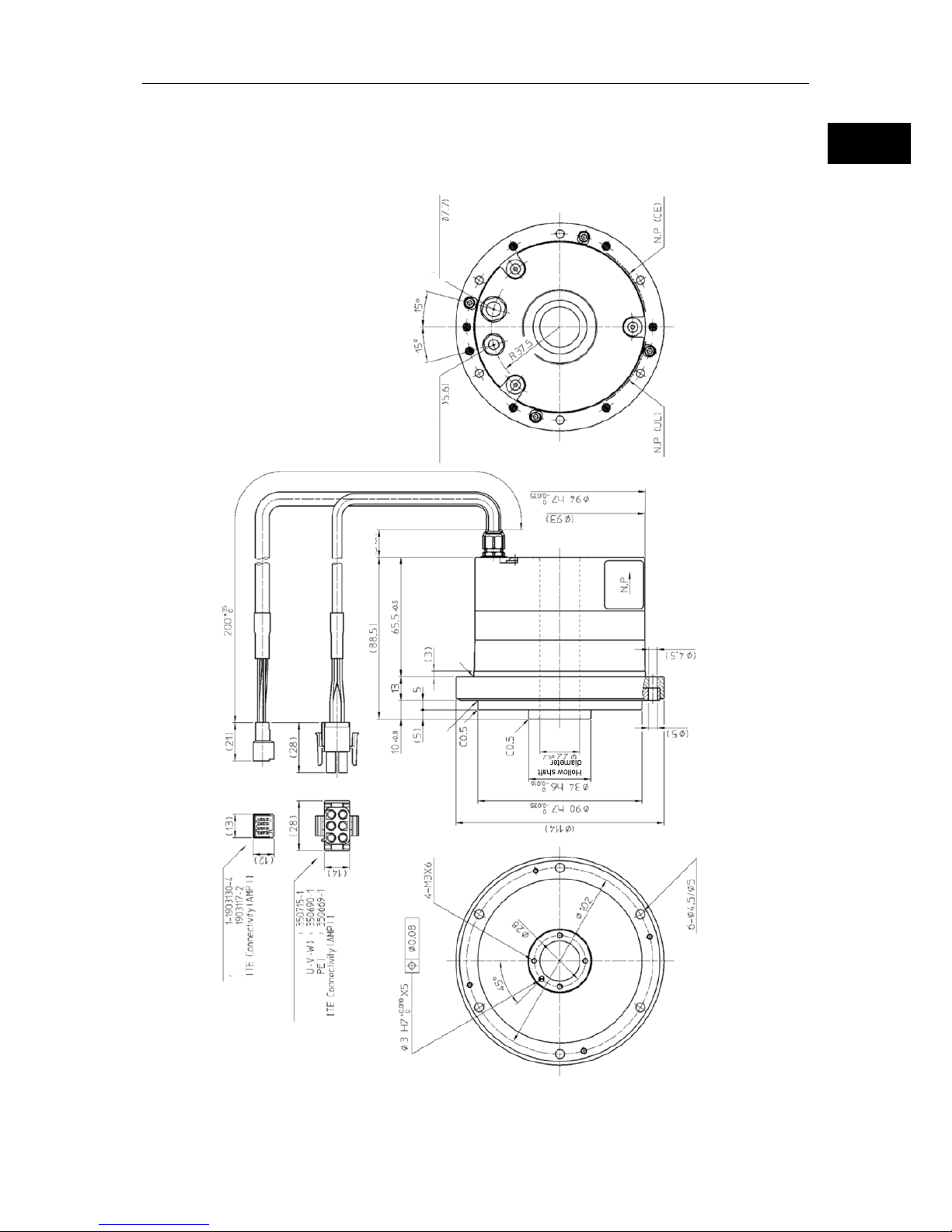

HMAB09 (with/without brake)

Unit: mm (third angle projection)

Note: For details on external dimensions, see our illustrated specifications.

Tolerances may vary with the product manufacturing method (foundry piece, mac hi ne

-finished good).

Contact us for the differential range of the size that is

not described.

Encoder cable

Motor cable

(Cable outer diameter:

(Cable outer diameter:

Motor connector

Encoder connector

Housing

Pin contact Pin contact

Housing :

Tab contact:

R0.4 or less

R0.4 or less

15 or less

Page 21

1-6 External dimensions

1-9

Outlines

HMAB12 (with/without brake)

Unit: mm (third angle projection)

Note: For details on external dimensions, see our illustrated specifications.

Tolerances may vary with the product manufacturing method (foundry piece,

machine-finished good).

Contact us for the differential range of the size that is not described.

Encoder cable

Motor cable

(Cable outer diameter:

(Cable outer diam eter:

Motor connector

Encoder connector

Housing :

Tab contact:

Housing

Pin contact Pin contact

R0.4 or less

R0.4 or less

15 or less

Page 22

1-6 External dimensions

1-10

Outlines

1

Appe

HMAB15 (with/without brake)

Unit: mm (third angle projection)

Note: For details on external dimensions, see our illustrated specifications.

Tolerances may vary with the product manufacturing method (foundry piece, mac hi ne

-finished good).

Contact us for the differential range of the size that is not described.

Encoder cable

Motor cable

(Cable outer diameter:

(Cable outer diameter:

Motor connector

Encoder connector

Housing :

Tab contact:

Housing

Pin contact Pin contact

R0.4 or less

R0.4 or less

15 or less

Page 23

1-6 External dimensions

1-11

Outlines

HMAA21A (with/without brake)

Unit: mm (third angle projection)

Note: For details on external dimensions, see our illustrated specifications.

Tolerances may vary with the product manufacturing method (foundry piece, mac hi ne

-finished good).

Contact us for the differential range of the size that is not described.

Encoder connector

Motor connector

Fix the angle

Install the relay cable connector

Eye bolt

(Supplied parts)

R0.4 or less

R0.4 or less

Page 24

1-7 Mechanical accurac y

1-12

Outlines

1

Appe

1-7 Mechanical accuracy

The mechanical accur acies of the output s haft and m ounting f lange f or HMA series motors ar e shown

below:

Unit: mm

Accuracy items

HMAC08

HMAB09

HMAB12

HMAB15

HMAA21A

1. Output shaft surface runout 0.020 0.020 0.020 0.040 0.040

2. Deflection of output shaft 0.020 0.020 0.020 0.040 0.040

3. Squareness of the mounting surface

to the output shaft

0.080 0.080 0.080 0.090 0.100

4. Squareness of the mounting surface

to the output shaft

0.060 0.065 0.065 0.085 0.090

5. Concentricity of the mounting surface

to the output shaft

0.050 0.050 0.050 0.050 0.060

6. Concentricity of the mounting surface

to the output shaft

0.045 0.045 0.045 0.055 0.065

Note: All values are T.I.R. (Total Indicator Reading).

The methods for measurement are as follows:

1 Output shaft surface runout

The indicator on the fixed part measur es the

axial runout (maximum runout width) of the

end surface of the output shaft per

revolution.

2 Deflection of output shaft

The indicator on the fixed part measur es the

radial runout (maxim um runout width) of the

output shaft of the output shaft unit per

revolution.

3,4 Squareness of the mounting surface to

the output shaft

The indicator on the output shaft reference

position measures the axial runout

(maximum runout width) of the outermost

circumference of the mounting sur face (both

on the output shaft side and opposite side)

per revolution.

5,6 Concentricity of the mounting surface to

the output shaft

The indicator on the output shaft reference

position measures the radial runout

(maximum runout width) of the fitting part

(both on the output shaf t side and opposite

side) per revolution.

A

1

2

3 A

5 A

◎

4 A

6 A

◎

Page 25

1-8 Detector specifications ( Absol ute encoder)

1-13

Outlines

1-8

Detecto r s pe ci fications (Absolute encoder)

Absolute encoders i nstalled in the HMA series are m ulti-turn a bsol ute enc oders . T he encoder co nsists

of a single-turn detector f or detecting the motor s haft position, and a multi-turn d etector for detecting

the number of revolutions.

The encoder constantl y detects the abso lute position of the machine and store s it by means of the

battery backup, regardless of whether the driver or external controller power is turned ON or OFF.

Accordingly, once the origin is detected when the machine is instal led, originating is not requir ed for

subsequent power ON operations. This facilitates the recovery operation after a power failure or

breakdown.

The single-turn absol ute position detector and the accum ulation counter that detects the num ber of

revolutions are both m ade dual-redundant, where data is constantly checked between two identica l

devices while the po wer is O N to ensure a highly relia ble design th at allows se lf-detect ion of encoder

errors should they occur.

In addition, a backup capac itor is installed in the encoder to reta in absolute positions even when the

driver-encoder extensi on cable is disconnected for initial startup of the device, et c. (internal backup).

However, the backup capacitor has a limited life and its performance deteriorates. Therefore, it is

recommended that you rep lace the battery in the batter y backup built in the HA-800 driver while the

driver is receiving power.

Specifications

Type*1

Magnetic sensor/electronic battery backup type

(Single-turn optical sensor, multi-

turn magnetic sensor/electronic battery backup

type)

Resolution

Single-turn

detector

217: 131,072 pulses

Multi-turn

detector

216: 65,536 (-32,768 to 32,767)

Maximum allowable motor

shaft rotational speed

7,000 r/min*2

Safety/redundancy

・ Check method in which two identical single-turn detectors are compared

・ Check method in which two identical cumulative revolution counters that detect

the number of revolutions are compared

Backup time by external

battery

1 year (when power is not supplied)

Backup time by internal

battery

30 minutes (after 3 hours of charge, ambient temperature of 25℃, axis stopped)

(For backup while the driver and encoder are disconnected briefly)

*1: HMAC08 is equipped with an optical encoder; other models are equipped with a magnetic encoder.

*2: This is the rotational speed limit of the encoder and is different from the rotational speed that the motor can

drive.

Page 26

1-9 Rotation direction

1-14

Outlines

1

Appe

Counterclockwise rotation dire ctio n

1-9 Rotation direction

As a default, the rotation d irection is defined as counterclock wise (CCW) rotation as vi ewed from the

output shaft when a FWD command pulse is given from an HA-800 dr iver.

This rotation direction can be changed on the HA-800 driver b y selecting [SP50: Command pol arity

setting] under [System parameter mode 3].

"SP50: Command polarity" setting

Set value

FWD command pulse

REV command pulse

Setting

0

CCW (counterclockwise) direction

CW (clockwise) dire ct i o n

Default 1 CW (clockwise) dire ct i o n

CCW (counterclockwise) direction

Page 27

1-10 Shock resistance

1-15

Outlines

1-10 Shock resistance

The shock resis tance of the motor is as f ollows, and this value is the same in up /down, left/right an d

front/rear directions:

Shock acceleration: 300 m/s

2

In our shock resistance tes t, the motor is tested three times in each direction. Motor operation is not

guaranteed in applications where impacts exceeding the above value are constantly applied.

Page 28

1-11 Resistance to vibration

1-16

Outlines

1

Appe

1-11 Resistance to vi br ation

The resistance to vibration of the motor is as f ollows, and this value is the sam e in up/down, left/right

and front/rear directions:

Vibration acceleration: 25 m/s

2

(frequency: 10 to 400 Hz)

In our test, the motor is tested for 2 hours in each direction at a vibration frequency sweep period of 10

minutes.

Page 29

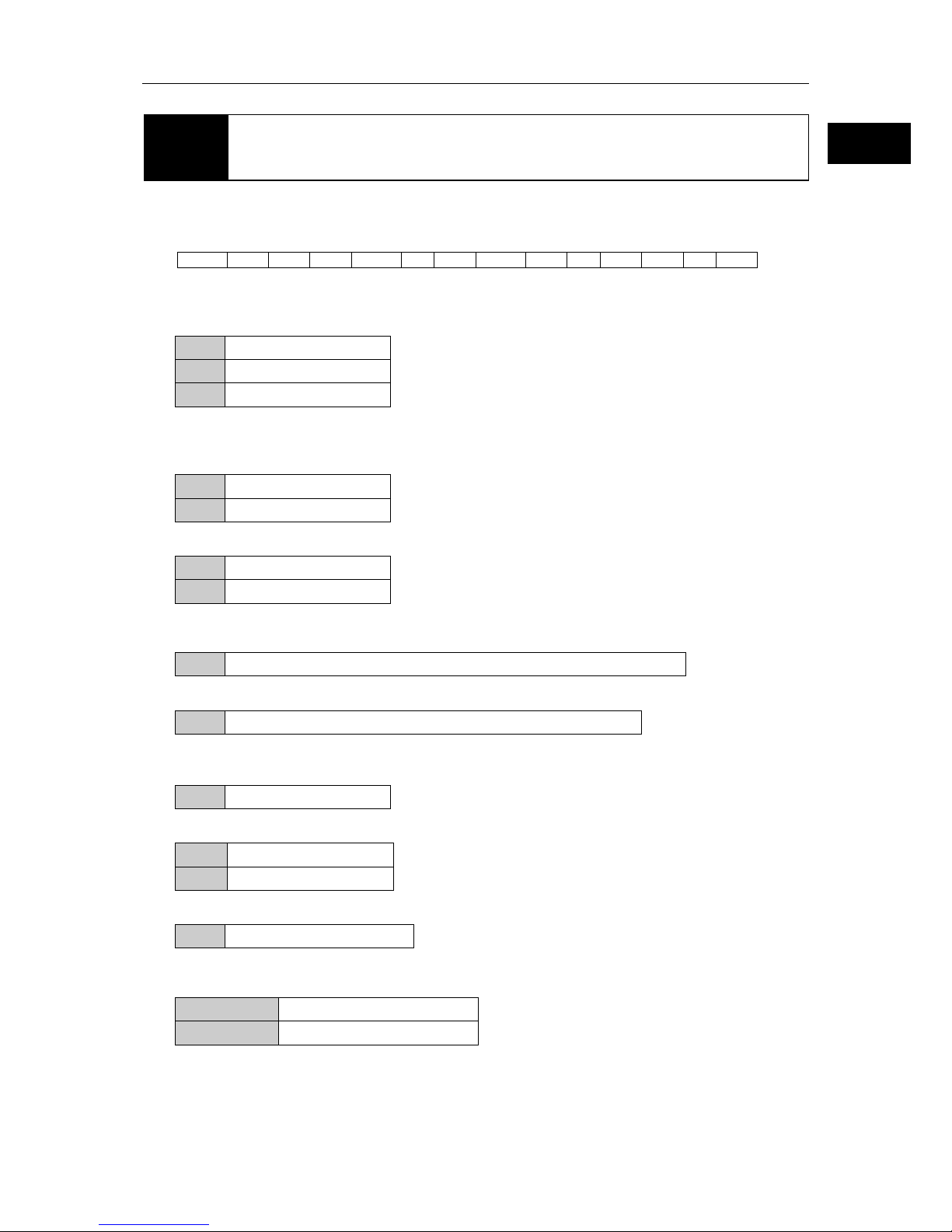

1-12 Operable range

1-17

Outlines

1-12 Operable range

The graphs on the following pages indicate the operable ranges of HMA series motors when combined

with an HA-800 driver. For details, refer to [2-1 HMA series selection].

1. Continuous motion range

This indicates a range in which the motor can be operated cont inuously as sho wn by the relationshi p

between the torque and rot ationa l spee d. Note th at val ues are m eas ured with the radiat ion pl ate liste d

on the graphs installed.

2. Motion range during acceleration and deceleration

This indicates a range in which the motor can be operated instantaneously as shown by the

relationship between the t orque and rotati onal speed. This r ange is normally used for acceleration or

deceleration.

Page 30

1-12 Operable range

1-18

Outlines

1

Appe

■HMAC08

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

0 1000 2000 3000 4000 5000 6000

トルク [Nm]

回転速度 [r/min]

アルミ放熱板:320x320x16 mm

加減速運転領域

連続使用領域

■HMAB09 *200 VAC type

0

0.5

1

1.5

2

2.5

3

3.5

0 1000 2000 3000 4000 5000 6000

トルク [Nm]

回転速度 [r/min]

アルミ放熱板:350×350×18 mm

加減速運転領域

連続使用領域

■HMAB09 *100 VAC type

0

0.5

1

1.5

2

2.5

3

3.5

0 1000 2000 3000 4000 5000

トルク [Nm]

回転速度 [r/min]

アルミ放熱板:350×350×18 mm

加減速運転領域

連続使用領域

Motion range during

acceleration and deceleration

Motion range during

acceleration and deceleration

Motion range during

acceleration and deceleration

Continuous

motion range

Continuous

motion range

Continuous

motion range

Rotation speed [r/min]

Rotation speed [r/min]

Rotation speed [r/min]

Torque [Nm]

Torque [Nm]

Torque [Nm]

Aluminum radiation plate: 320*320*16

Aluminum radiation plate: 350*350*18

Aluminum radiation plate: 350*350*18

Page 31

1-12 Operable range

1-19

Outlines

■HMAB12

0

1

2

3

4

5

6

7

0 1000 2000 3000 4000 5000

トルク [Nm]

回転速度 [r/min]

アルミ放熱板:400×400×20 mm

加減速運転領域

連続使用領域

■HMAB15

0

2

4

6

8

10

12

14

0 500 1000 1500 2000 2500 3000 3500 4000

トルク [Nm]

回転速度 [r/min]

アルミ放熱板:500×500×25 mm

加減速運転領域

連続使用領域

■HMAA21A

0

5

10

15

20

25

30

35

0 500 1000 1500 2000 2500 3000

トルク [Nm]

回転速度 [r/min]

アルミ放熱板:650×650×30 mm

加減速運転領域

連続使用領域

Motion range during

acceleration and deceleration

Motion range during

acceleration and deceleration

Motion range during

acceleration and deceleration

Continuous

motion range

Continuous

motion range

Continuous

motion range

Rotation speed [r/min]

Rotation speed [r/min]

Rotation speed [r/min]

Torque [Nm]

Torque [Nm]

Torque [Nm]

Aluminum radiation plate: 400*400*20

Aluminum radiation plate: 500*500*25

Aluminum radiation plate: 650*650*30

Page 32

1-13 Cable specifications

1-20

Outlines

1

Appe

1-13 Cable specifi cations

The following tables show the specifications of the motor and encoder cables for the HMA series

motors.

Motor cable specifications

Model Nos. 08, 09, 12, 15

Pin No. Color

Name

Without brake

With brake

1

Red

Motor phase-U

Motor phase-U

2

White

Motor phase-V

Motor phase-V

3

Black

Motor phase-W

Motor phase-W

4

Green/Yellow

PE

PE

5

Blue

No connection

Brake

6

Yellow

No connection

Brake

Connector pin layout

Model No. 21A

Pin No.

Color

(extension cable)

Name

Without brake

With brake

A

Blue

No connection

Brake

B

Yellow

No connection

Brake

C

-

No connection

No connection

D

Red

Motor phase-U

Motor phase-U

E

White

Motor phase-V

Motor phase-V

F

Black

Motor phase-W

Motor phase-W

G

Green/Yellow

PE

PE

H - PE

PE I -

No connection

No connection

Connector pin layout

Connector model: CE05-2A24-11PGHS-D (by DDK)

Connector model: 350715-1

Pin model:

Model Nos.

08, 09

Model Nos.

12, 15

Motor UVW

350690-1

350547-1

Brake

350690-1

350690-1

Motor PE

350669-1

350669-1

by AMP

Page 33

1-13 Cable specifications

1-21

Outlines

Encoder cable specifications

Model Nos. 08, 09, 12, 15

Pin No.

Color

Signal name

Remarks

1A

Red

Vcc

Power supply input +5V

1B

Black

GND (Vcc)

Power supply input 0V (GND)

2A

Yellow

SD+

Serial signal differential output (+)

2B

Blue

SD-

Serial signal differential output (-)

3A

-

No connection

-

3B

Shielded

FG

4A

Orange

Vbat

Battery +

4B

Gray

GND (bat)

Battery - (GND)

Connector pin layout

Model No. 21A

Pin No.

Color

Signal name

Remarks

1

Orange

Vbat

Battery +

2

Gray

GND (bat)

Battery - (GND)

3

NC

No connection

4

Red

Vcc

Power supply input +5V

5

Black

GND (Vcc)

Power supply input 0V (GND)

6

NC

No connection

7

NC

No connection

8

Yellow

SD+

Serial signal differential output (+)

9

Blue

SD-

Serial signal differential output (-)

10 - FG

Connector pin layout

Connector model: CM10-R10P (D3)-01 (by DDK)

Connector model: 1-1903130-4

Pin model: 1903111-2, 1903116-2, or 1903117-2

by AMP

1B

1A

4A

4B

Page 34

Chapter 2

Selection guidelines

This chapter explains how to select a proper HMA series motor.

2-1

HMA series selection ···························································· 2-1

2-2 Verifying and examining load weights ······································· 2-2

2-3 Examining the operating status ··············································· 2-3

Page 35

2-1 HMA series selection

2-1

Selection guidelines

2-1 HMA series selection

Allowable load inertia moment

To maximize the performance of the HMA series, make a tentative selection of a motor so that the max.

rotational speed and allowable load inertia moment ratio are equal to or lower than the values shown in

the table below.

The allowable load inertia moment ratios in the table below are reference values for the following

cases:

(1) Controllable range: where the motor is ac c elerat ed/ dec el erat e d gra dually or high respo ns iven es s

is not required.

(2) Stable control rang e: where higher respons iveness is required t o shorten the transie nt vibration

period during positioning or stable operation at a constant speed is required.

Model No.

HMAC08

HMAB09

HMAB12

HMAB15

HMAA21A

Allowable

rotational speed

(r/min)

6,000

5,600

(4,800)*

4,800 4,000 3,000

Inertia moment

(without brake)

×10

-4

kg・m2

0.734

1.78

6.45

15.8

125

×10

-4

kgf・cm・s2

7.49

18.2

65.8

161

1,280

Inertia moment

(with brake)

×10

-4

kg・m2

0.828

2.16

6.83

19.8

141

×10

-4

kgf・cm・s2

8.45

22.1

69.7

202

1,444

Allowable load

inertia moment

ratio

(1)

Controllable

range

10 times or less than inertia moment

(2) Stable

control range

3 times or less than inertia moment

*: The values in parentheses are values for motors with 100 V input voltage.

Refer to [A-2 Calculating inertia moment] (P5-3) for the calculation of inertia moment.

When a load with a large inertia moment is operated frequently, a greater regenerative energy is

produced during brak ing. If the prod uced regenerat ive energy exceeds the absorptio n capacity of the

built-in regenerative res istor of the servo dri ver, an additional regenerat ive resis tor mus t be connected

externally to the driver. For details, refer to the manual of your driver.

Page 36

2-2 Verifying and examining load weights

2-2

Selection guidelines

2

Appe

2-2

Verifying and examining load weights

Ensure that the load appli ed to the output shaft of the HMA series motor does not exc eed the max.

radial load and max. ax ial load wh en stationary and also that th e lo ad d oes not e x ceed the r at ed r ad ia l

load and rated axial load at the rated rotational speed.

Refer to the following formulas (1) and (2) to calculate the radial load and axial load.

Verify the static safety coefficient (fs).

Specifications of the main roller bearing

The following table shows the specifications of the main roller bearings.

Table 1: Specifications of the main roller bearings

Item

Model

Offset amount

(R)

Rated radial

load

Rated axial

load

Allowable radialload

(when stationary)

Allowable axial load

(when stationary)

mm N N N N

HMAC08

17.8

175

100

800

1,900

HMAB09

21.7

185

105

800

2,400

HMAB12

25.0

233

130

1,200

3,600

HMAB15

27.3

530

180

2,400

5,000

HMAA21A

39.5

1,040

880

4,500

14,000

◆

Formula (1): Max. radial load, max. axial load

)+(≧ RLrr Fr F ×

max

(Fa=0)

La a F

a

F ×≧

max

(Fr=0)

Symbols in calculation formula

Fr

max

Max. radial load

N

Refer to Fig.1.

Fa

max

Max. axial load

N

Refer to Fig.1.

Fr

Radial load

N

Refer to Fig.1.

Fa

Axial load

N

Refer to Fig.1.

Lr, La

――――

mm

Refer to Fig.1.

R

Offset amount

mm

Refer to Fig.1 and Table 1.

Fig. 1: External load action diagram

◆

Formula (2): Rated radial load, rated axial load

)+(≧ RLrr Fr F ×

ave

(Fa=0)

Laa F a F ×≧

ave

(Fr=0)

Symbols in calculation formula

Fr

ave

Rated radial load

N

Refer to Fig.1.

Fa

ave

Rated axial load

N

Refer to Fig.1.

Fr

Radial load

N

Refer to Fig.1.

Fa

Axial load

N

Refer to Fig.1.

Lr, La

――――

mm

Refer to Fig.1.

R

Offset amount

mm

Refer to Fig.1 and Table 1.

Motor

Page 37

2-3 Examining the operating status

2-3

Selection guidelines

2-3 Examining the operating status

The motor generates heat if started/stopped repeatedly or operated continuously at high speed.

Accordingly, evaluate whether or not the generated heat can be accommodated.

Evaluate as follows:

Examining motor rotational speed

Calculate the required rotational speed (r/min) of the load driven by an HMA series motor.

For linear operation, use the rotational speed conversion formula below:

Check that this rotational speed is less than the max. rotational speed of the HMA series motor.

Calculating and examining load inertia moment

Calculate the inertia moment of the load driven by an HMA series motor.

Refer to [A-2 Calculating inertia moment] (P5-3) for the calculation.

Based on the calculation result, make a tentative selection of an HMA series motor referring to

[Allowable load inertia moment] (P2-1).

Screw pitch [mm]

Linear travel speed [mm/min]

(mm) pitch feedScrew

(mm/min) speed travel Linear

(r/min) speed Rotation =

Page 38

2-3 Examining the operating status

2-4

Selection guidelines

2

Appe

Load torque calculation

Calculate the load torque as follows:

Rotary motion

The rotary torque for rot ating mass W on the ring of

radius r from the center of rotation is shown in the

figure to the right.

T: Rotary torque (Nm)

μ: Friction coefficient

W: Mass (kg)

r: Average radius of friction side (m)

The right graph gives a calculation example

where the friction coefficient μ is assumed to be

0.1 and the horizontal axis and vertical axis

represent the mass and rotational radius of

friction side, respectively. The motor toque

shown in the graph indicates 20% of the

maximum torque.

Linear operation (horizontal operation)

The rotary torque for when mass W moves horizontally due to the screw of pitch P is shown below.

T: Rotary torque (Nm)

μ: Friction coefficient

W: Mass (kg)

P: Screw feed pitch (m)

Linear operation (vertical operation)

The rotary torque for when mass W moves vertically due to the screw of pitch P is shown below.

π×

××µ×=

2

P

W8.9T

π×

××=

2

P

W8.9

T

rW8

.

9T

××µ×

=

Example of rotary torque calculation (friction coefficient = 0.1)

HMA: torque of maximum torque is shown.

Radius: r

Mass: W

Friction: μ

Pitch: P

Mass: W

Mass: W

Pitch: P

Friction: μ

Radius r of friction side (mm)

Mass W (kg)

Page 39

2-3 Examining the operating status

2-5

Selection guidelines

Acceleration time and deceleration time

Calculate the accelerat ion and d eceler ation t im es for the m otor tentat ivel y selecte d using t he fol lowing

formula.

Acceleration time:

Deceleration time:

ta: Acceleration time (s)

td: Deceleration time (s)

k: Acceleration reduction coefficient 1 to 1.5

The total positioning time may become

shorter if the acceleration is lowered for

the purpose of reducing the sett ling time

after positioning.

J

M: Inertia moment of motor (kg・m

2

)

J

L: Inertia moment of load (kg・m

2

)

N: Rotational speed of motor (r/min)

T

M: Maximum momentary torque (Nm)

T

F: Motor friction torque (Nm)

T

F = KT × IR -TR

KT: Torque constant (Nm/A)

T

R: Rated torque (Nm)

IR: Rated current (A)

TL: Load torque (Nm): The polarity is positive (+) when the torque is applied in the rotation direction, or

negative (-) when it is applied in the opposite direction.

Calculation example 1

Select a motor that best suits the following operating conditions:

・ Rotational speed: 4800 r/min

・ Inertia moment of load: 2.0×10

-4

kg・m2

・ Since the load mechanism is mainly inertia, the load torque is negligibly small.

(1) According to the conditions above, tentatively select an HMAC08 from the table in section 2-1.

(2) From the rating table, the following values ar e obt ai ned: J

M = 0.734 × 10

-4

kg・m2, TM = 1.8 Nm,

T

R = 0.52 Nm, KT =0.35 Nm/A, IR = 2.1 A

(3) Based on the ab ove for mula, the m otor's friction to rque T

F is calculated as 0.3 5 × 2.1 - 0.52 =

0.215 Nm.

(4) If k = 1.3, the acceleration time and decelerati on time can be obtained as follows fr om the

above formulas:

t

a = 1.3 × (0.734 + 2.0) × 10

-4

× 2 ×π/ 60 × 4,800 / 1.8 ≒ 0.099 s

t

d = 1.3 × (0.734 + 2.0) × 10

-4

× 2 ×π/ 60 × 4,800 / (1.8 + 2 × 0.215) ≒ 0.080 s

(5) If the calculated acceleration/deceleration times are too long, correct the situation by:

・ Reducing the inertia moment of load

・ Selecting a motor with a larger frame size

ta

td

N

Time

Rotational speed

( )

LM

LMa

TT

N

60

π2

JJkt

−

×

×

×+×=

(

)

L

FM

L

Md

TT

2T

N

60

π

2

J

Jk

t

+

×+

×

×

×

+

×=

Page 40

2-3 Examining the operating status

2-6

Selection guidelines

2

Appe

Evaluating effective torque and average rotational speed

One way to check if the heat gener ated f rom the mot or during operat ion woul d present a pr oblem is to

determine if the point of op eration, de term ined b y the effec tive torque an d averag e rotati onal spee d, is

inside the continuous motion range explained in [1-12Operable range].

Using the following f ormula, calcu late the effecti ve torque Tm and averag e rotational spe ed N

av when

the motor is operated repeatedly in the drive pattern shown to the right.

Ta: Acceleration time from speed 0 to N (s)

t

d: Deceleration time from speed N to 0 (s)

t

r: Operation time at constant speed N (s)

t: Cycle time (s)

T

m: Effective torque (Nm)

T

a: Torque during acceleration (Nm)

T

r: Torque at constant speed (Nm)

T

d: Torque during deceleration (Nm)

Nav: Average rotational speed (r/min)

N: Rotational speed at constant speed (r/min)

Calculation example 2

The calculation method is explained below using HMAC08 as an example.

Operating conditions: Accelerate an inertia load and then let it move at a constant speed,

followed by deceleration, based on conditions similar to those used in calculation example 1. The

travel angle per cycle is 3,600° and the cycle time is 0.8 seconds.

(1) T he travel angle is calculat ed from the area of the r otational speed vs. tim e diagram shown

above. In other words, the travel angle is calculated as follows:

θ = (N / 60) x {t

r+ (ta + td) / 2} x 360

Accordingly, tr = θ/ (6 x N) – (ta + td) / 2

When θ = 3,600° and ta = 0.099 (s), td = 0.080 (s), N = 4,800 (r/min) in calculation example 1,

are applied to this formula, tr is calculated as 0.035 (s).

(2) Next , calculate the torque dur ing accelerat ion and torque during dece leration. Bas ed on the

acceleration/deceleration time formulas in the preceding section, the relational expressions for

torque during acceleration and torque during deceleration if k = 1 are as follows:

T

a = (J

M

+ JL) x 2 xπ/ 60 x N / ta + TL

T

d = (J

M

+ JL) x 2 xπ/ 60 x N / td -2 x TF - TL

When the values in calculation example 1 are applied to this formula, T

a = 1.38 (Nm) and Td =

1.29 (Nm) are obtained.

(3) Calculate t he effec tive t orque. Appl y the values in ( 1) an d (2), T

r = 0 (Nm), an d t = 0.8 ( s) to

the above formulas.

(4) Calculate the average rotational speed. Apply the values in (1), N = 4,800 (r/min), and t = 0.8

(s) to the above formulas.

t

tTtTtT

T

d

2

dr

2

ra

2

a

m

×+×+×

=

t

t

2

Nt

Nt2N

N

dra

av

×+×+×

=

Nm 0. 64

0. 8

0. 0801. 290. 03500. 0991. 38

T

222

m

=

×+×+×

=

0. 8

0. 08024, 8000. 0354, 8000. 09924, 800

N

av

×+×+×

=

Time

Tr

ts: Stoppedtime

Ta, Tr, Td: Output torques

ta

td N tr

Time

Rotational speed

t: Cycle time

ts

Ta

Torque

Td

= 750 r/min

Page 41

2-3 Examining the operating status

2-7

Selection guidelines

(5) The f igure on th e right s hows the po ints of operation d eterm ined by the effective torq ue and

average rotational speed calculated above, plotted on the graph of operable range of HMAC08,

exceeding the continuous motion range. The conclus ion is that this motor c annot be operated

continuously under these conditions. Accordingly,

◆the operation pattern

◆load (possible reduction)

◆motor model No.

etc., must be reevaluated.

The following formula is a modified version

of the formula for effective torque. By

applying the value of allowable continuo us

torque to T

m

in this formula, the allow able

cycle time can be calculated.

2

22

2

m

ddr

raa

T

tT

tTtT

t

×+×+×

=

Apply the following: T

a = 1.38 Nm, Tr= 0 Nm, Td = 1.29 Nm, T

m

= 0.52 Nm, ta = 0.099 s, tr= 0.035

s, t

d = 0.080 s. Then, the following equation is obtained:

t = (1.38

2

x 0.099 + 1.292 x 0.080)/ 0.522 = 1.19 s

Based on the result, setti ng the c ycle time to 1.2 s econds or more to pr ovide a longer stop tim e

gives T

m = 0.52 Nm or less, thereby permitting continuous operation within the rated torque.

The aforementioned continuous motion range represents an allowable range where the

motor installed on a specified aluminum radiati on plate is operated under natural air

cooling. If the radiation area of the mounting member is small or heat conduction of the

material is poor, adjust the operating conditions to keep the r ise in the motor's ambient

temperature to 40 K or less as a guide.

Operable range of HMAC08

Torque [Nm]

Motion range during

acceleration and deceleration

Continuous motion

range

Aluminum radiation plate: 320*320*16

Rotation speed [r/min]

Page 42

Chapter 3

Installing the HMA motor

This chapter explains how to install the motor.

3-1

Receiving inspection ····························································· 3-1

3-2 Notices on handling ······························································ 3-2

3-3 Location and instal lat ion ························································ 3-5

Page 43

3-1 Receiving inspection

3-1

Installing the HMA motor

3-1 Receiving inspection

Check the following items after unpacking the box.

Inspection procedure

1 Check the items thoroughly for damage sustained during transportation.

If any item is damaged, immediately contact the dealer.

2 Check if the motor is what you ordered.

The nameplate is found on the end face or the s ide of the HMA series motor. Check the TYPE

field on the nameplate t o confirm that it is the m odel you have ordere d. If any item is different

from what you ordered, immediately contact the dealer.

Refer to section [1-2 Model] (P1-2) in this manual for details of the model codes.

3 Check if the driver combinations are correct.

The compatible HMA series motor models are shown in the ADJUSTED FOR USE WITH field of

the nameplate on the HA-800 driver.

4 Check if the driver input voltages being input are correct.

The driver's model cod e is shown in the TYPE field of the dri ver's nameplate. The last three

digits of this model code indicate the input voltage.

100: Single-phase 100 V power supply

200: 3-phase/single-phase 200 VAC power supply

If the input voltage to be supplied is different from the voltage listed on the nameplate,

immediately contact the dealer it was purchased from.

Do not combine the driver with a motor that is not specified on the

name plate.

The characteristics of the driver have been adjusted according to the motor.

Wrong combinations of drivers and motors may cause insufficient torque or

overcurrent that may cause motor burnout, i n jury or fire.

Do not connect a power supply with a voltage that is not specified

on the driver's nameplate.

Connecting a power supply with an input voltage that is not specified on the

nameplate may result in damage to the driver, injury or fire.

WARNING

Page 44

3-2 Notices on handling

3-2

Installing the HMA motor

3

Appe

3-2 Notices on handling

Practice caution and observe the following notices when handling HMA series motors.

(1) Do not apply any excessive force or impact, especially to the motor's

output shaft.

(2) Do not place HM A series motors on a tab le, shelf, etc., where the motor

could easily fall.

(3) Do not connect the motor terminals directly to the power supply. The motor

may burn out and cause a fire or electric shock.

(4) The allowable storage temperature is -20 to +60 ゚ C. Do not expose the

motor to direct sunlight for long periods of time or store it in areas at low

or high temperatures.

(5) The allowable relative storage humidity is 80% or less. In particular, do not

store the motor in a very humid place or in areas where there are large

temperature changes between day and night.

(6) Do not use or store the motor in locations subject to flammable or

corrosive gases or dust particles.

(7) The large model (HMAA21A) is heavy. Handling these models may cause

lower back pain, or injury if the motor drops or topples and you are pinned

underneath. Handle your motor with due care by wearing safety shoes,

take other proper precautions, and also use supporting jigs.

Installation and transmission torque

Examples of m otor assem bly are sho wn bel ow. Use high-tension bo lts and tighte n them with a tor que

wrench to control the tigh te nin g tor qu e. Us e f lat was he r s becaus e the t ig hten in g t or que is high and the

motor flange is made of aluminum.

Motor assembly example

Assembly example 1 Assembly example 2

CAUTION

Motor fixing parts

Motor fixing parts

Fixing washer

Fixing washer

Output shaft fixing parts

Output shaft fixing parts

Page 45

3-2 Notices on handling

3-3

Installing the HMA motor

Recommended tightening torque and transmission torque

Model

Item

HMAC08

HMAB09

HMAB12

Output

shaft

motor

Output

shaft

motor

Output

shaft

motor

Number of bolts, size

4-M3

6-M3

4-M3

6-M4

4-M3

6-M5

Bolt

installation

P.C.D.

mm 22 84 28 102 36 132

Tightening

torque

Nm

2.0

2.0

2.0

4.5

2.0

9.0

kgf・m

0.20

0.20

0.20

0.46

0.20

0.92

Transmission

torque

Nm

18

103

23

215

30

446

kgf・m

1.8

10.5

2.4

22.0

3.1

45.5

Model

Item

HMAB15

HMAA21A

Output

shaft

Motor

Output

shaft

Motor

Number of bolts, size

4-M4

6-M6

4-M5

8-M8

Bolt

installation

P.C.D.

mm 50 158 74 226

Tightening

torque

Nm

4.5

15.3

9.0

37.0

kgf・m

0.46

1.56

0.92

3.8

Transmission

torque

Nm

70

755

167

2,630

kgf・m

7.2

77.1

17.0

268.2

Note 1: The female thread material is assumed to withstand the bolt tightening torque.

2: Recommended bolt: Hexagonal bolt per JIS B 1176 Strength category: JIS B 1051 12.9 or higher

3: Calculation conditions Torque efficiency: 0.2 Tightening efficiency: 1.4 Tightening friction coefficient:

0.15

Precautions on installation

When designing the assembly, note that application of an y abnormal or excessive f orce that causes

deformation of the insta llation s urf ace m a y result i n pe rf orm ance drop. To deliver optimal perform anc e

of the HMA series motors, pay attention to the following points:

Wa rping and deformation on the mounting surface

Blockage caused by foreign matter

Burrs, rising and abnormal position accuracy around tapped mounting holes

Insufficient chamfering of mounting faucet joint

Abnormal circularity of mounting faucet joint

Page 46

3-2 Notices on handling

3-4

Installing the HMA motor

3

Appe

Use of positioning pins

The HMA series motors have positioning pin holes in the output shaft. Use these pin holes as

necessary. For details, refer to [1-6 Extern al dim ens ion s ] (P1-7) or the illustrated specifications.

*1. Do not drive in positioning pins, but keep proper fitting clearances to the motor shaft. Failure to

do so may result in damage to the motor, deformation of the motor shaft, or decreased pin

positional accuracy.

Motor shaft material

The HMA series motors use the following materials, however, they are not completely rust-proof.

Location

Material

Housing

No treatment (aluminum material is exposed)

Hollow shaft (output shaft)

SUS

Bolt

Chrome plating

Example of use of positioning pins

Positioning pin*

1

Output shaft fixing part

Page 47

3-3 Location and installation

3-5

Installing the HMA motor

3-3 Location and installation

Environment of loca ti on

The environmental co nditions of the ins tallation location f or HMA series motors are as follows. A lways

observe these conditions to determine an appropriate installation location.

◆ Operating temperature: 0 to 40℃

The temperature in the cabinet may be higher than the atmosphere depending on

the power loss of housed devices and size of the cabinet. Plan the cabinet size,

cooling system, and device locations so the ambient temperature of the motor is

kept 40℃ or below.

◆ Operating humidity: Relative humidity of 20 to 80%. Make sure no condensation occurs.

Take note that condensation is likely to occur in a place where there is a large

temperature change between day and night or when the motor is started/stopped

frequently.

◆ Vibration: 25 m/s2 (10 to 400Hz) or less (Refer to [1-11 Resistance to vibration] (P1-16))

◆ Impact: 300 m/s2 or less (Refer to [1-10 Shock resistance] (P1-15))

◆ Use environment: Free from condensation, metal powder, corrosive gases, water, oil mist, flammable

gases, etc.

◆ Protection class: Standard products are structurally designed to meet the

IP-54 requirements.

However, rotating and sliding areas (oil seal areas, all models) and connectors (HMAC08,

HMAB09, HMAB12, HMAB15) are not IP-54-compliant. Connectors of HM AA21A are warrantied

as installed.

◆ Use the motor indoors or within an enclosure. Do not expose it to direct sunlight.

◆ Altitude: less than1,000 m above sea level

The protection class against contact and entry of foreign

matter is as follows:

5: Protected against entry of dust/dirt. Entry of forei gn matter

caused by incomplete protection must not affect the

operation of the system.

The protection class against water entry is as follows:

4: Protected against water splashed from all directions.

Page 48

3-3 Location and installation

3-6

Installing the HMA motor

3

Appe

Installation

When installing an HMA series motor, ensure that it is installed accurately and do not tap with a

hammer, etc. The motor houses an encoder. Excessive impact may damage the encoder.

Installation procedure

1 Align the axis of rotation of the motor and the

load mechanism precisely.

Note 1: Perform this alignment carefully, especially when a

rigid coupling is used. Even slight misalignment

may cause the allowable load of the motor to be

exceeded, resulting in damage to the output shaft.

2 Connect the driver and wiring.

An extension cable is provided. U se it w hen wirin g the dr iver. For details on wirin g , refer to [1-13

Cable specifications] (P1-20) and the manual of your HA-800 driver.

3 Wire the motor cable and encoder cable.

Do not pull the cables with a strong force. Doing so may damage the connectors. Install the cable

with slack and do not to appl y any tension to the m otor. Provide a sufficient bending radius (at

least six times the cable diameter), especially when the cable flexes.

Do not bring stro ng magnetic bodies (magnet chuck s, permanent magnet s, etc.) near

the rear cover of the motor. Encoder abnormality may result.

This encoder retains absolute positions when the power is turned OFF by means of the

driver's battery or its o wn built-in capacitor. If the encoder cable is disconn ected for

maintenance, etc., turn ON the driver power and charge the backup capacitor first.

After 3 hours of charge, the encoder cable can be disconnected for 30 minutes,

provided that the axis is stopped and ambient temperature is 25℃. However, when the

backup capacitor is deteriorated, the absolute positions may not be retained.

Do not disassemble/reassemble the motor.

The motor uses many precision parts. If the motor is

disassembled/reassembled by the customer, it may cause motor burnout or

uncontrollable operation, resulting in a fire or injury.

WARNING

Output

shaft

Flange

Page 49

3-3 Location and installation

3-7

Installing the HMA motor

Page 50

Chapter 4

Options

This chapter provides information on the options.

4-1

Options ·············································································· 4-1

Page 51

4-1 Options

4-1

Options

4-1 Options

Cable taken out from side face (option code: Y)

The cables (motor and encoder wires) are taken out from the side face of the motor.

Use this option if the m otor is housed in a system and there is not e nough space at the rear of the

housing.

Please contact us for model No. 08. This option is not available for model No. 21A.

For details on the option where cables can be taken out from the side, contact our sales office.

Page 52

4-1 Options

4-2

Options

4

Appe

Extension cables

These extension cables are used to connect the HMA series motors and HA-800 drivers.

Two types of extension cables are available for motors ( inclu di ng brak e wire) and abs ol ute enc od ers .

Y ou must use an extension cable to connect y our HMA series motor and HA-800

driver.

For motors

Motor model Nos. 08, 09, 12

EWD-MB**-A06-TN3

Motor model No. 15

EWD-MB**-A06-TMC

Cable length (03 = 3m, 05 = 5m, 10 = 10m)

Cable length (03 = 3m, 05 = 5m, 10 = 10m)

[Motor side]

(Model No. 15)

Cable length

(Unit: mm)

Outer diameter φ7.8

Cable length

Outer diameter φ7.8

(Unit: mm)

[Motor side]

(Model Nos. 08, 09, 12)

[Motor side]

(Model No. 15)

[Driver side]

[Driver side]

Solder processing

Wiring display seal

Solder processing

Brake: blue

Brake: blue

Brake: yellow

Brake: yellow

PE: green/yellow

PE: green/yellow

W: black

V: white

U: red

W: black

Page 53

4-1 Options

4-3

Options

Motor model No. 21A

EWD-MB**-D09-TMC

Cable length (03 = 3m, 05 = 5m, 10 = 10m)

Cable length

Outer diameter φ13.4

(Unit: mm)

[Motor side]

(Model No. 21A)

[Driver side]

Waterproof cable clamp

Angle plug

U: red

V: white

W: Black

PE: green/yell ow

Brake: blue

Brake: yellow

Page 54

4-1 Options

4-4

Options

4

Appe

For absolute encoder

Motor model Nos. 08, 09, 12, 15

EWD-S**-A08-3M14

Motor model No. 21A

EWD-S**-D10-3M14

Cable length (03 = 3m, 05 = 5m, 10 = 10m)

Cable length (03 = 3m, 05 = 5m, 10 = 10m)

[Motor side]

Cable length

(Unit: mm)

Outer diameter φ8.4

[Motor side]

Cable length

Outer diameter φ8.4

(Unit: mm)

[Driver side]

[Driver side]

Page 55

4-1 Options

4-5

Options

Page 56

Chapter 5

Appendix

A-1 Unit conversion ································································· 5-1

A-2 Calculating inertia moment ·················································· 5-3

Page 57

Unit conversion

5-1

Appendix

13-1 Unit conversion

This manual employs the SI system for units. Conversion factor s between the SI system and other

systems are as follows:

(1) Length

SI system

m

Unit

ft.

in.

Factor