Page 1

This operation manual covers the following software

●Ver 3.x

100V/200V power supply

AC Servo Driver

HA- 800A series m anual

(for SHA, FHA-Cmini, FHA-C, RSF/RKF series)

versions:

ISO14001

(Hotaka plant)

ISO9001

Page 2

Introduction

Thank you very much for your purchasing our HA-800A series servo driver.

Wrong handling or use of this product may result in unexpected accidents or shorter life of the product.

Read this document carefully and use the product correctly so that the product can be used safely for

many years.

Product specifications are subject to change without notice for improvement purposes.

Keep this manual in a convenient location and refer to it whenever necessary in operating or

maintaining the units.

The end user of the driver should have a copy of this manual.

Page 3

Indicates a potentially hazardous situation, which, if not avoided, may result in

Indicates what should be performed or avoided to prevent non-operation or

malfunction of the product or negative effects on its performance or function.

WARNING

SAFETY GUIDE

To use this driver safely and correctly, be sure to read SAFETY GUIDE and other parts of this

document carefully and fully understand the information provided herein before using the driver.

NOTATION

Important safety information you must note is provided herein. Be sure to observe these instructions.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious personal injury.

minor or moderate personal injury and/or damage to the equipment.

CAUTION

LIMITATION OF APPLICATIONS

The equipment listed in this document may not be used for the applications listed below:

・Space equipment

・Aircraft, aeronautic equipment

・Nuclear equipment

・Household apparatus

・Vacuum equipment

・Automobile, automotive parts

・Amusement equipment, sport equipment, game machines

・Machine or devices acting directly on the human body

・Instruments or devices to transport or carry people

・Apparatus or devices used in special environments

If the above list includes your intending application for our products, please consult us.

Safety measures are essential to prevent accidents resulting

in death, injury or damage of the equipment due to

malfunction or faulty operation.

CAUTION

1

Page 4

SAFETY GUIDE

CAUTION

WARNING

CAUTION

SAFETY NOTE

CAUTIONS FOR ACTUATORS AT APPLICATION DESIGNING

Always use under followings conditions:

The actuator is designed to be used indoors. Observe the following

conditions:

・ Ambient temperature: 0℃ to 40℃

・ Ambient humidity: 20% to 80%RH (Non-condensation)

・ Vibration: Max 24.5 m/S2

・ No contamination by water, oil

・ No corrosive or explosive gas

Follow exactly the instructions in the relating manuals to

install the actuator in the equipment.

・ Ensure exact alignment of motor shaft center and corresponding

center in the application.

・ Failure to observe this caution may lead to vibration, resulting in

damage of output elements.

CAUTION FOR ACTUATORS IN OPERATIONS

Never connect cables directly to a power supply socket.

・ Each actuator must be operated with a proper driver.

・ Failure to observe this caution may lead to injury, fire or damage of

the actuator.

Do not apply impacts and shocks.

・ Do not use a hammer during installation.

・ Failure to observe this caution could damage the encoder and may

cause uncontrollable operation.

Avoid handling of actuators by cables.

・ Failure to observe this caution may damage the wiring, causing

uncontrollable or faulty operation.

Keep limited torques of the actuator.

・ Keep limited torques of the actuator.

・ Be aware, that if arms attached to output element hits by accident an

solid, the output element may be uncontrollable.

2

Page 5

1-1

WARNING

CAUTIONS FOR DRIVERS AT APPLICATION DESIGNING

Always use drivers under followings conditions:

・ Mount in a vertical position keeping sufficient distance to other

devices to let heat generated by the driver radiate freely.

CAUTION

・ 0℃ to 50℃, 95% RH or below (Non condensation)

・ No vibration or physical shock

・ No corrosive, inflammable or explosive gas

Use sufficient noise suppressing means and safe grounding.

・ Keep signal and power leads separated.

・ Keep leads as short as possible.

・ Ground actuator and driver at one single point, minimum ground

resistance class: D (less than 100 ohms)

・ Do not use a power line filter in the motor circuit.

Pay attention to negative torque by inverse load.

・ Inverse load may cause damages of drivers.

・ Please consult our sales office, if you intent to apply products for

inverse load.

Use a fast-response type ground-fault detector designed for

PWM inverters.

・Do not use a time-delay-type ground-fault detector.

Safety measures are essential to prevent accidents resulting

in death, injury or damage of the equipment due to

malfunction or faulty operation.

CAUTION FOR DRIVERS IN OPERATIONS

Never change wiring while power is active.

Make sure of power non-active before servicing the products. Failure to

observe this caution may result in electric shock or personal injury.

Do not touch terminals or inspect products at least 15

・ Otherwise residual electric charges may result in electric shock. In

・ Make installation of products not easy to touch their inner electric

minutes after turning OFF power.

order to prevent electric shock, perform inspections 15 minutes

after the power supply is turned OFF and confirming the

CHARGE lamp is turned OFF.

components.

SAFETY GUIDE

3

Page 6

SAFETY GUIDE

CAUTION

CAUTION

Do not make a voltage resistance test.

・ Failure to observe this caution may result in damage of the control

unit.

・ Please consult our sales office, if you intent to make a voltage

resistance test.

Do not operate control units by means of power ON/OFF

switching.

・ Start/stop operation should be performed via input signals.

・ Failure to observe this caution may result in deterioration of

electronic parts.

DISPOSAL OF AN ACTUATOR, A MOTOR, A CONTROL UNIT AND/OR THEIR

PARTS

All products or parts have to be disposed of as industrial

waste.

Since the case or the box of drivers have a material indication, classify

parts and dispose them separately.

4

Page 7

1-2

s and

Panel display and

Structure of this document

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Function

configuration

Installation/wiring

Startup

Encoder system

I/O signals

operation

Status display

mode/

Alarm mode/

Tune mode

Overviews of driver models, specifications, external dimensions,

etc., are explained.

Receiving inspection, environment, power wiring, noise suppression

and connector wiring are explained.

Startup procedures to be followed when the driver is used for the

first time, from receiving inspection to operation of the actual

system, are explained.

The encoder configuration is different depending on the actuator

model. Details of each actuator are explained.

Details of I/O signal conditions and signal functions are explained.

How to operate the display, operation buttons on the driver's

front panel and overview of operation in each mode is

explained.

Explanation of information displayed in the status display

mode and alarm mode. Operations and details of servo loop

gains, various judgment criteria and acceleration/deceleration

time setting during speed control performed in the tune mode

are explained

.

Chapter 8

Chapter 9

Chapter 10

Chapter 11

Chapter 12

Appendix

System parameter

mode

Test mode

Communication

software (PSF-800)

Troubleshooting

Option

Details of how to assign I/O signals and set their logics, as well as

extended functions such as control mode selection, pulse input

system selection and electronic gear setting, etc., are explained.

Details of how to check the system operation by auto-tuning via

jogging, monitoring of I/O signals and simulated operation of output

signals are explained.

How you can use the dedicated personal computer software to

check I/O signal statuses, rotation speeds and other servo statuses,

perform auto-tuning, set parameters, assign I/O signals and monitor

servo operation waveforms are explained.

Details of how driver alarms and warnings generate are explained.

Options you can purchase as necessary are explained.

The list of default parameters and regenerative resistors are

explained

.

5

Page 8

1-2

Table of contents

SAFETY GUIDE ...................................................................................................... 1

NOTATION ............................................................................................................... 1

LIMITATION OF APPLICATIONS ............................................................................. 1

SAFETY NOTE ........................................................................................................ 2

Structure of this document ....................................................................................... 5

Table of contents ..................................................................................................... 6

Related manual ..................................................................................................... 12

Related actuator/driver standards ......................................................................... 13

Compatible standards ............................................................................................ 14

Conformance to European EC Directives .............................................................. 15

Chapter 1 Functions and configuration

1-1 Overview of drivers .................................................................................... 1-1

Overview of functions ............................................................................................ 1-1

1-2 Function block diagram .............................................................................. 1-2

1-3 Device configuration diagram .................................................................... 1-3

1-4 Driver model .............................................................................................. 1-5

Driver model .......................................................................................................... 1-5

Option.................................................................................................................... 1-5

1-5 Actuator and extension cable combinations ............................................... 1-6

1-6 Driver ratings and specifications ................................................................ 1-7

1-7 Function list .............................................................................................. 1-11

1-8 External drawing ...................................................................................... 1-13

1-9 Name and function of each part of a display panel .................................. 1-15

Chapter 2 Installation/wiring

2-1 Receiving inspection .................................................................................. 2-1

Check procedure ................................................................................................... 2-1

2-2 Installation location and installation ............................................................ 2-2

Installation environment ........................................................................................ 2-2

Notices on installation ........................................................................................... 2-2

Installation procedure ............................................................................................ 2-3

2-3 Connecting power cables........................................................................... 2-5

Allowable cable sizes ............................................................................................ 2-5

Connecting power cables ...................................................................................... 2-6

Protecting power lines ........................................................................................... 2-8

Connecting a ground wire ..................................................................................... 2-8

Power ON and OFF sequences ............................................................................ 2-9

6

Page 9

Table of contents

2-4 Suppressing noise ................................................................................... 2-14

Grounding ........................................................................................................... 2-14

Installing noise filters ........................................................................................... 2-15

2-5 Wiring the driver and motor ...................................................................... 2-17

Connecting the motor .......................................................................................... 2-17

Connecting the encoder ...................................................................................... 2-18

2-6 Wiring the host device ............................................................................. 2-19

Connecting the host device ................................................................................. 2-19

Connecting the personal computer (PSF-800) .................................................... 2-20

Chapter 3 Startup

3-1 Startup procedures .................................................................................... 3-1

Startup procedures ................................................................................................ 3-2

3-2 Turning ON the power for the first time ...................................................... 3-3

Details on control power supply ON ...................................................................... 3-4

Troubleshooting upon power ON .......................................................................... 3-8

3-3 Operation check with the actuator alone .................................................... 3-9

Troubleshooting at operation check .................................................................... 3-10

3-4 Operation check with the actual system .................................................. 3-13

Troubleshooting at actual operation check ......................................................... 3-14

3-5 Manual gain adjustment method .............................................................. 3-15

Position control.................................................................................................... 3-15

Speed control ...................................................................................................... 3-16

Applied servo gain adjustment function .............................................................. 3-18

3-6 Normal operation ..................................................................................... 3-22

Notices for normal operations ............................................................................. 3-22

Daily maintenance/inspection ............................................................................. 3-22

Periodically replaced parts .................................................................................. 3-23

Backup battery .................................................................................................... 3-23

How to replace the backup battery ...................................................................... 3-24

Chapter 4 Encoder system

4-1 Overview of encoders ................................................................................ 4-1

4-2 17-bit absolute encoder ............................................................................. 4-4

Features ................................................................................................................ 4-4

Startup ................................................................................................................... 4-6

Origin setting ......................................................................................................... 4-8

Data output ............................................................................................................ 4-9

Remedial actions for errors/warnings .................................................................. 4-13

4-3 13-bit absolute encoder ........................................................................... 4-15

Features .............................................................................................................. 4-15

Startup ................................................................................................................. 4-17

Origin setting ....................................................................................................... 4-18

Data output .......................................................................................................... 4-19

Remedial actions for errors/warnings .................................................................. 4-23

7

Page 10

Table of contents

4-4 Incremental encoder ................................................................................ 4-25

Startup ................................................................................................................. 4-27

Data output .......................................................................................................... 4-28

Remedial action for error ..................................................................................... 4-29

Chapter 5 I/O signals

5-1 I/O signal list .............................................................................................. 5-1

Pin numbers and names of I/O signals ................................................................. 5-1

Models of I/O signal connector CN2 ..................................................................... 5-2

5-2 Input signals: System parameter SP00 to SP16 ........................................ 5-3

Input signal connection circuit ............................................................................... 5-4

Input signal list ...................................................................................................... 5-6

List of parameter set values .................................................................................. 5-7

5-3 Details of input signals ............................................................................... 5-9

5-4 Inputs in each control mode ..................................................................... 5-16

Position command mode ..................................................................................... 5-16

Speed command mode ....................................................................................... 5-20

Torque command mode ...................................................................................... 5-21

5-5 Output signals: System parameter SP20 to SP26 ................................... 5-23

Output signal connection circuit .......................................................................... 5-24

Output signal list.................................................................................................. 5-25

5-6 Details of output signals ........................................................................... 5-26

5-7 Monitor output .......................................................................................... 5-28

Encoder output .................................................................................................... 5-28

Current value data output .................................................................................... 5-28

Analog waveform monitoring ............................................................................... 5-29

Digital signal monitor ........................................................................................... 5-30

5-8 Connection example in control mode ....................................................... 5-31

Connection example with default settings ........................................................... 5-31

Connection example in position control mode .................................................... 5-32

Connection example in speed control mode ....................................................... 5-33

Connection example in torque control mode ....................................................... 5-34

Chapter 6 Panel display and operation

6-1 Operating display panel ............................................................................. 6-1

Overview of modes ............................................................................................... 6-1

Initial panel display ................................................................................................ 6-2

Panel display hierarchy ......................................................................................... 6-3

Operation outline of status display mode .............................................................. 6-4

Operation outline of alarm mode ........................................................................... 6-5

Operation outline of tune mode ............................................................................. 6-6

Operation outline of system parameter mode ....................................................... 6-8

Operation outline of test mode ............................................................................ 6-12

8

Page 11

Table of contents

Chapter 7 Status display mode/alarm mode/tune mode

7-1 Status display mode ................................................................................... 7-1

Status display mode list ......................................................................................... 7-1

7-2 Details of status display mode ................................................................... 7-3

d01, 02: Error pulse count display ......................................................................... 7-3

d04: Overload rate display .................................................................................... 7-4

d05, 06: Feedback pulse display ........................................................................... 7-5

d07, 08: Command pulse display .......................................................................... 7-5

d11: Speed command voltage ............................................................................... 7-6

d12: Torque command voltage .............................................................................. 7-6

d13: Applicable actuator code ............................................................................... 7-7

d16: Regenerative power (HA-800-24 only) .......................................................... 7-8

7-3 Alarm mode ............................................................................................... 7-9

Alarm display ......................................................................................................... 7-9

7-4 Alarm list .................................................................................................. 7-10

AL: Present alarm/warning display ...................................................................... 7-10

AHcLr: Alarm history clear ................................................................................... 7-11

7-5 Tune mode ............................................................................................... 7-12

7-6 Details of tune mode ................................................................................ 7-13

AJ00: Position loop gain ...................................................................................... 7-13

AJ01: Speed loop gain ........................................................................................ 7-13

AJ02: Speed loop integral compensation ............................................................ 7-14

AJ03: Feed-forward gain ..................................................................................... 7-14

AJ04: In-position range ....................................................................................... 7-14

AJ05: Attained speed judgment value ................................................................. 7-15

AJ06: Attained torque judgment value ................................................................ 7-15

AJ07: Zero speed judgment value ...................................................................... 7-15

AJ08 to 10: Internal speed command 1 to 3 ....................................................... 7-16

AJ11: Torque limit ................................................................................................ 7-16

AJ12: Acceleration time constant ........................................................................ 7-17

AJ13: Deceleration time constant ....................................................................... 7-17

AJ14: External speed command offset ............................................................... 7-18

AJ15: External torque command offset ............................................................... 7-18

AJ16: Speed monitor offset ................................................................................. 7-18

AJ17: Current monitor offset ............................................................................... 7-18

AJ20: Feed-forward filter ..................................................................................... 7-19

AJ21: Load inertia moment ratio ......................................................................... 7-19

AJ22: Torque constant compensation factor ....................................................... 7-19

AJ23: Spring constant compensation factor ........................................................ 7-20

AJ24: Positioning Automatic Gain ....................................................................... 7-20

Chapter 8 System parameter mode

8-1 System parameter mode ............................................................................ 8-1

8-2 Function extension parameter ................................................................... 8-3

SP40: CN9-CP3 output signal setting ................................................................... 8-4

SP41: Control mode switching setting .................................................................. 8-4

SP42: Command pulse input pattern setting ......................................................... 8-5

9

Page 12

Table of contents

SP43: Multiplication of 2-phase input setting ........................................................ 8-5

SP44 to 47: Electronic gear setting ....................................................................... 8-6

SP48: Deviation clear upon servo-ON setting ....................................................... 8-7

SP49: Allowable position deviation ....................................................................... 8-7

SP50: Command polarity ...................................................................................... 8-7

SP51: Speed input factor setting ........................................................................... 8-9

SP52: Zero clamp ................................................................................................. 8-9

SP53: Torque input factor setting .......................................................................... 8-9

SP54: Status display setting ................................................................................ 8-10

SP55: DB enable/disable setting ......................................................................... 8-10

SP56: External speed limit enable/disable .......................................................... 8-10

SP57: External torque limit enable/disable ......................................................... 8-10

SP59: Angle compensation enable/disable setting ............................................. 8-11

SP60: Automatic positioning gain setting enable/disable setting ........................ 8-11

SP61: Encoder monitor output pulses ................................................................. 8-11

SP64: Regenerative resistor selection (HA-800-24 only) .................................... 8-12

SP65: FWD/REV inhibit operation ...................................................................... 8-12

SP66: Absolute encoder function setting ............................................................ 8-12

SP67: Output shaft divide function setting .......................................................... 8-13

SP69: Feed-forward control function setting ....................................................... 8-16

Chapter 9 Test mode

9-1 Test mode .................................................................................................. 9-1

9-2 Details of test mode ................................................................................... 9-2

T00: I/O signal monitor .......................................................................................... 9-2

T01: Output signal operation ................................................................................. 9-3

T02: JOG speed setting ........................................................................................ 9-4

T03: JOG acceleration/deceleration time constant setting .................................... 9-5

T04: JOG operation ............................................................................................... 9-6

T05: Parameter initialization .................................................................................. 9-7

T06: Automatic adjustment of speed command offset .......................................... 9-8

T07: Automatic adjustment of torque command offset .......................................... 9-9

T08: Multi revolution clear ................................................................................... 9-10

T09: Auto-tuning .................................................................................................. 9-11

T10: Auto-tuning displacement ............................................................................ 9-13

T11: Auto-tuning level selection .......................................................................... 9-14

Chapter 10 Communication software

10-1 Overview .................................................................................................. 10-1

Setup ................................................................................................................... 10-1

Initial screen ........................................................................................................ 10-4

Status display ...................................................................................................... 10-7

10-2 Auto-tuning .............................................................................................. 10-9

10-3 Parameter setting .................................................................................. 10-11

10-3-1. Editing and initializing internal parameters of the driver ....................... 10-11

10-4 Assigning I/O signals ............................................................................. 10-13

10-5 Saving and reading set values ............................................................... 10-16

10-5-1. Saving set parameter values ................................................................ 10-16

10-5-2. Reading saved set value files ............................................................... 10-17

10

Page 13

Table of contents

10-5-3. Comparing a saved settings file with internal set values of the driver .. 10-18

10-5-4. Writing a saved settings file to the driver .............................................. 10-20

10-6 Test operation ........................................................................................ 10-22

10-7 Output signal operation .......................................................................... 10-24

10-8 IO monitor .............................................................................................. 10-25

10-9 Waveform monitoring ............................................................................. 10-26

10-10 Alarms.................................................................................................... 10-29

Chapter 11 Troubleshooting

11-1 Alarms and remedial actions .................................................................... 11-1

Alarm list ............................................................................................................. 11-1

Remedial action for alarm ................................................................................... 11-2

11-2 Warnings and remedial actions .............................................................. 11-14

Warning list ....................................................................................................... 11-14

Remedial action for warning .............................................................................. 11-15

Chapter 12 Option

12-1 Option ...................................................................................................... 12-1

Extension cables ................................................................................................. 12-1

Dedicated communication cable ......................................................................... 12-2

Connectors .......................................................................................................... 12-2

Servo parameter setting software ....................................................................... 12-3

Backup battery .................................................................................................... 12-4

Monitor cable ....................................................................................................... 12-4

Appendix

A-1 Default settings .......................................................................................... A-1

A-2 Regenerative resistor ................................................................................. A-7

Built-in driver regenerative resistor and regenerative power ................................. A-7

External regenerative resistor ............................................................................. A-11

Allowable load inertia .......................................................................................... A-14

A-3 List of data retained in the driver .............................................................. A-20

A-4 Driver replacement procedures ................................................................ A-23

A-5 Notices for using SHA-CG(-S) ................................................................. A-25

A-6 Control block diagram .............................................................................. A-31

Position control mode .......................................................................................... A-31

Speed control mode ............................................................................................ A-32

Torque control mode ........................................................................................... A-32

11

Page 14

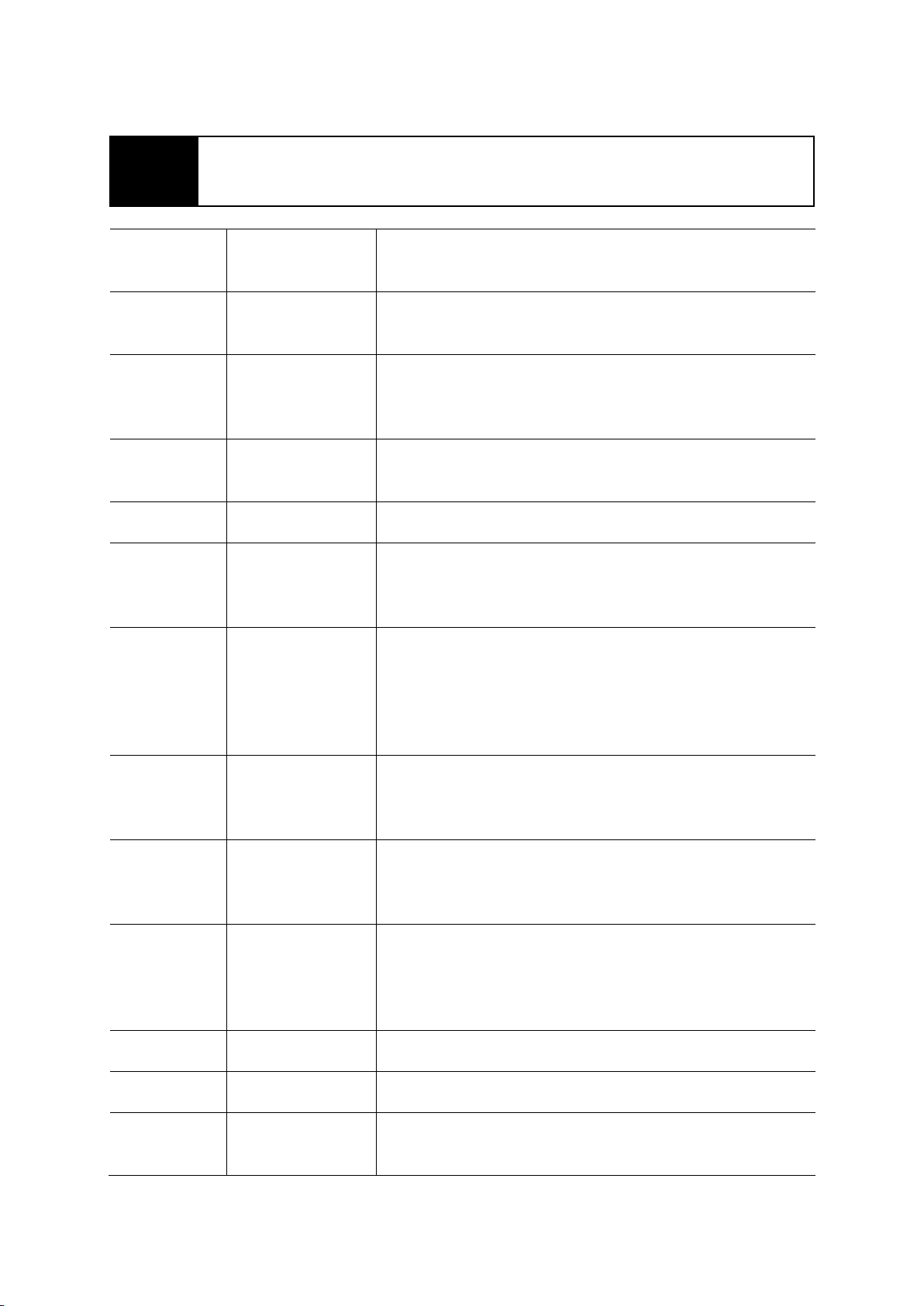

1-3

Title

Description

Related manual

The table below lists related manual. Check each item as necessary.

AC Servo Actuator

SHA series manual

AC Servo Actuator

FHA-C series manual

AC Servo Actuator

FHA-Cmini series manual

AC Servo Actuator

RSF/RKF series manual

The specifications and characteristics of SHA-20A to SHA-65A actuators are

explained.

The specifications and characteristics of FHA-17C to FHA-40C actuators are

explained.

The specifications and characteristics of FHA-8Cmini to FHA-14Cmini actuators

are explained.

The specifications and characteristics of RSF-17 to RSF-32 and RKF-20 to

RKF-32 actuators are explained.

12

Page 15

1-4

Maximum

current (A)

Related actuator/driver standards

Function

Rated current (A)

HA-800*-1 HA-800*-3 HA-800*-6 HA-800*-24

1.5 3 6 24

Overseas

standard

Applicable actuator

FHA-8C-xx-E200 200 ○

FHA-11C-xx-E200 200 ○

FHA-14C-xx-E200 200 ○

FHA-17C-xx-E250 200 ○ ○

FHA-25C-xx-E250 200 ○ ○

FHA-32C-xx-E250 200 ○ ○

FHA-40C-xx-E250 200 ○ ○

FHA-8C-xx-12S17b 200

FHA-11C-xx-12S17b 200

FHA-14C-xx-12S17b 200

FHA-17C-xx-S248 200 ○ ○

FHA-25C-xx-S248 200

FHA-32C-xx-S248 200 ○ ○

FHA-40C-xx-S248 200 ○ ○

FHA-8C-xx-E200 100 ○

FHA-11C-xx-E200 100 ○

FHA-14C-xx-E200 100 ○

FHA-17C-xx-E250 100 ○ ○

FHA-25C-xx-E250 100 ○ ○

FHA-32C-xx-E250 100 ○ ○

FHA-8C-xx-12S17b 100

FHA-11C-xx-12S17b 100

FHA-14C-xx-12S17b 100

FHA-17C-xx-S248 100 ○ ○

FHA-25C-xx-S248 100 ○ ○

FHA-32C-xx-S248 100 ○ ○

Voltage

UL/c

UL

○ ○

CE Encoder type

4.0 9.5 19 55

General-purpose I/O

MECHATROLINK

CC-Link HA-800C

UL/cUL ○

CE

TUV ○

-1C-200

-1C-200

Wire-saving

incremental

17-bit absolute

13-bit absolute

Wire-saving

incremental

17-bit absolute

13-bit absolute

-1C-200

-3C-200

-3C-200

-6C-200

-6C-200

-1D/E-200

-1D/E-200

-1D/E-200

-3A-200

-3A-200

-6A-200

-6A-200

-1C-100

-1C-100

-1C-100

-3C-100

-6C-100

-6C-100

-1D/E-100

-1D/E-100

-1D/E-100

-3A-100

-6A-100

-6A-100

HA-800A

HA-800B

○

13

Page 16

Related actuator/driver standards

Maximum

current (A)

I/O

-3D/E

-200

-3D/E

-200

-200

-6D/E

-200

-24D/E

-200

-24D/E

-200

-24D/E

-200

-100

Function

Rated current (A)

HA-800*-1 HA-800*-3 HA-800*-6 HA-800*-24

1.5 3 6 24

Overseas

standard

Applicable actuator

SHA20Axxxx-C08x200-xxS17bA

SHA25Axxxx-B09x200-xxS17bA

SHA32Axxxx-B12x200-xxS17bA

SHA40Axxxx-B15x200-xxS17bA

SHA58Axxxx-A21x200-xxS17bA

SHA65Axxxx-A21x200-xxS17bA

SHA25Axxxx-B09x100-xxS17bA

Voltage

200

UL/c

UL

200 ○ ○

○ ○

200 ○ ○

200 ○ ○

200

200 ○ ○

100 ○ ○

○ ○

4.0 9.5 19 55

General-purpose

MECHATROLINK

CC-Link HA-800C

UL/cUL ○

CE ○

TUV ○

CE Encoder type

17-bit absolute

HA-800A

HA-800B

-6D/E

-6D/E

Compatible standards

Motor & Actuator

UL 1004-1 (Rotating Electrical Machines - General Requirements)

UL 840 (Insulation Coordination Including Clearances and Creepage Distances for Electrical

Equipment)

CSA-C22.2 No. 100 (Motors and Generators), CSA-C22.2 No. 0.2 (Insulation Coordination)

(UL File No. E243316)

EN60034-1 (Low Voltage Directive)

* The compatible Motor and Actuator standards vary depending on the model.

For details, refer to the individual catalogue.

Driver

<HA-800A-1*, HA-800A-3*, HA-800A-6*, HA-800A-24*>

UL 508C (Power Conversion Equipment)

CSA-C22.2 No.14 (Industrial Control Equipment)

(UL File No. E229163)

EN61800-5-1 (Low Voltage Directive)

EN61800-3 (EMC Directive)

14

Page 17

Related actuator/driver standards

1)

Host controller

Actuator,

Surge

protector

3)

DC24V

Noise

filter

2)

Circuit

: Toroidal core

: Ferrite core

: Metal clamp

Conformance to European EC Directives

We conduct the Low Voltage Directive and EMC Directive conformance check test related to CE

marking for the HA-800 series drivers at the third party authentication agency in order to ease CE

marking by customer's device.

Precautions on conformance to EMC Directives

We fabricated a model that embeds AC Servo Driver and AC Servo Actuator or Motor in a

control board for our AC servo system and use the model to comply with standards related to

EMC Directives.

In your actual use, using conditions, cable length and other conditions related to wiring may be

different from the model.

For these reasons, it is necessary that the final equipment or devices incorporating AC Servo

Driver and AC Servo Actuator comply with EMC Directives.

We introduce peripheral devices used in our model such as noise filter to make it easy for you to

comply with EMC Directives when incorporating and using this product.

Standard related to EMC Directives

Motor/driver

EN55011: 2009/A1:2010(Group 1 Class A)

EN61800-3: 2004/A1:2012(Category C2, 2nd environment)

IEC61000-4-2: Electrostatic discharge immunity

IEC61000-4-3: Radio frequency field immunity

IEC61000-4-4: Electrical fast transient/burst immunity

IEC61000-4-5: Surge immunity

IEC61000-4-6: Immunity to conducted disturbances, induced by radio-frequency

IEC61000-2-1: Voltage dip and voltage variations immunity

IEC61000-2-4: Low frequency conducted disturbance

IEC60146-1-1 Class B

Configuration of peripheral devices

Installation environment (conditions): Please observe the following installation environment in

order to use this product safely.

1) Overvoltage category: III

2) Pollution degree: 2

Model configuration diagram

breaker

1) Encoder cable 2) Motor cable (motor power and holding brake)

3) Interface cable

Control board

HA-800

series driver

motor

power

supply

15

Page 18

Related actuator/driver standards

(1) Input power supply

200V input type

Main circuit power: 3 phase/single phase, 200 to 230V (+10%, -15%), 50/60Hz

Control power supply: Single phase, 200 to 230V (+10%, -15%), 50/60Hz

100V input type

Main circuit power: Single phase, 100 to 115V (+10%, -15%), 50/60Hz

Control power supply: Single phase, 100 to 115V (+10%, -15%), 50/60Hz

(2) Circuit breaker

Use a circuit breaker complying with IEC standard and UL standard (UL Listed) for the power

input area.

(3) Noise filter

Use a noise filter complying with EN55011 Group 1 Class A.

(For details, refer to the next page.)

(4) Toroidal core

Install toroidal core in the power input area.

Depending on the noise filter, 4-turn input to L1, L2, L3, and ground or 1-turn input to L1, L2,

and L3, not including ground, may be valid.

(For details, refer to the next page.)

(5) Motor cable, encoder cable

Use shield cables for the motor cable and encoder cable.

Clamp ground the shield of the motor cable and encoder cable near the driver and motor.

If you use FHA-8C/11C/14C or RSF-8B/11B/14B, insert the ferrite core into the motor

cable and encoder cable

(6) Interface cable

If you use the HA-800C driver, use ferrite core for the interface cable.

(7) Surge protector

Install the surge absorber in the AC power input area. Remove the surge absorber when you

perform voltage resistance test of AC/DC machine/system with built-in surge absorber.

(The surge absorber may be damaged.)

(8) Ground

In order to prevent electric shock, make sure to connect the ground wire of the control board

(control cabinet) to the ground terminal of the AC Servo Driver.

Moreover, do not tighten the connection to the ground terminal of the AC Servo Driver

together.

(near the motor).

16

Page 19

Model

Specifications

Manufacturer

Remarks

Line 440

Rated current: 20 A

Line 440

Rated voltage: Line-Line 440

Rated current: 40 A

Rated voltage: AC250V

Rated current: 10A

turn input

to L1, L2, and L3,

Rated voltage: AC250V

Rated current:

Rated voltage: AC250V

Rated current: 40A

Rated voltage: AC500V

Rated current: 10A

Rated voltage: AC500V

Rated current: 20A

Rated voltage: AC500V

Rated current: 30A

Enable the 4-turn

Refer to (3) and (5).

Model

Outer diameter

Inner diameter

Manufacturer

MA070R-63/38/25A

65 mm

36 mm

JFE Ferrite Corporation

Corporation

Model

Manufacturer

TDK Corporation

TDK Corporation

TDK Corporation

Model

Manufacturer

RAV-781BXZ-4

Okaya Electric Industries Co., Ltd.

RAV-781BWZ-4

Okaya Electric Industries Co., Ltd.

LT-C32G801WS

Soshin Electric Co., Ltd.

LT-C12G801WS

Soshin Electric Co., Ltd.

Recommended parts for compliance with EMC

(1) Noise filter

Rated voltage: Line-

RF3020-DLC

to 550V

Related actuator/driver standards

RASMI ELECTRONICS LTD.

RF3030-DLC

RF3040-DLC

HF3010A-UN

HF3030A-UN

HF3040A-UN

HF3010-SZC

HF3020-SZC

HF3030-SZC

SUP-P5H-EPR

SUP-P10H-EPR

3SUP-H5H-ER-4

3SUP-H10-ER-4

(2) Toroidal core

Rated voltage: Lineto 550V

Rated current: 30 A

to 550V

30A

Rated voltage: AC250V

Rated current: 5A

RASMI ELECTRONICS LTD.

RASMI ELECTRONICS LTD.

Soshin Electric Co., Ltd.

Soshin Electric Co., Ltd.

Soshin Electric Co., Ltd.

Soshin Electric Co., Ltd.

Soshin Electric Co., Ltd.

Soshin Electric Co., Ltd.

Okaya Electric Industries

Co., Ltd.

Enable the 4-turn

input to L1, L2, L3,

and ground for

toroidal core.

Enable 1-

not including ground

for toroidal core.

input to L1, L2, L3,

and ground for

Rated voltage: AC250V

Rated current: 10A

Rated voltage: AC250V

Rated current: 5A

Okaya Electric Industries

Co., Ltd.

Okaya Electric Industries

Co., Ltd.

toroidal core.

Moreover, install

insulation

transformer and

ferrite core at the

Rated voltage: AC250V

Rated current: 10A

Okaya Electric Industries

Co., Ltd.

power input area.

LRF624520MK 66 mm 41 mm

(3) Ferrite core

(4) Surge protector

ZCAT3035-1330

ZCAT2032-0930

ZCAT2132-1130

Nippon Chemi-Con

17

Page 20

Related actuator/driver standards

phase

FHA-8,11C

0.15

FHA-14C

0.25

FHA-17C RSF-17

0.4

MAC08 MAB09

Insulation transformer

(5)

The use of the insulation transformer is recommended in the place thought that the noise

environment is severe though HA-800 series have an enough noise tolerance though it doesn't

use the insulation transformer.

Driver Model

HA-800A-1* 3

No. of

Power capacity (kVA)

HA-800A-3* 3

HA-800A-6* 3

HA-800A-24* 3

SHA20 SHA25 FHA-25C RSF-20,25 RKF-20,25

SHA25 0.8

SHA32 FHA-32C RSF-32 RKF-32 MAB12 1.5

SHA40 FHA-40C MAB15 1.8

SHA40 MAB15 2.5

SHA58 SHA65 3.5

MAA21 5.5

0.8

18

Page 21

1-5

Chapter 1

Functions and configuration

Outlines of driver models, specifications, external dimensions, etc., are explained in this

chapter.

Overview of drivers ···························································· 1-1

1-1

1-2 Function block diagram ······················································· 1-2

1-3 Device configuration diagram ··············································· 1-3

1-4 Driver model ····································································· 1-5

1-5 Actuator and extension cable combinations ····························· 1-6

1-6 Driver ratings and specifications ··········································· 1-7

1-7 Function list ····································································· 1-11

1-8 External drawing ····························································· 1-13

1-9 Name and function of each part of a display panel ·················· 1-15

Page 22

1-1 Overview of drivers

1

2

3

4

5

6

7

8

9

10

11

Appe

Functions and configuration

1-1 Overview of drivers

The HA-800 driver series are dedicated servo drivers for SHA series, FHA-C series, RSF series and

other actuators which are ultra-thin and feature a hollow shaft structure. These actuators utilize speed

reducer HarmonicDrive

The HA-800 drivers provide many superior functions to allow various actuators to excel in

performance.

Overview of functions

Shorter positioning stabilization time using original control logic (compared to

HA-655)

By utilizing the characteristics of HarmonicDrive® in the control logic, positioning overshoot and

undershoot are suppressed and the positioning stabilization time is reduced significantly.

Adopting an I/O signal function assignment method

Desired functions can be selected from a wide range of functions and assigned to I/O signals

according to specific applications.

Also, multiple functions can be assigned to a single input terminal for an input signal, which

adds to usability.

Auto-tuning function

The auto-tuning function allows the driver to estimate the load and automatically set an

appropriate servo gain in the test mode.

Control mode switching

You can use an input signal to switch the control mode applied to the current operation.

The following switching patterns are supported:

Position control mode ↔ Speed control mode

Position control mode ↔ Torque control mode

Speed control mode ↔ Torque control mode

Position control mode

The pulse speed and pulse count specified by an external pulse train are used to implement

smooth speed control and high-accuracy positioning control.

Speed control mode

An external analog speed command (DC±10V) or internal speed command via parameter is

used to smoothly control the rotation speed and direction of the actuator at high accuracy.

Torque control mode

An external analog torque command (DC±10V) is used for the torque control of the motor.

®

for precision control and AC servo motors.

1-1

Page 23

1

10

9

8

7

6

5

4

3

2

1

Appe

Functions and configuration

*1: The HA-800-1 has no built-in regenerative resistor.

Analog command

Encoder I/F

Operation I/F

Power amplifier

RS-232C I/F

Operation part

R1

R2

U

V

W

CN2

R3

External type

Current

detection

Cooling fan

Diode

bridge

Battery option

*1

*2

Torque command I/F

Output signal I/F

DA

Analog monitor I/F

Digital monitor I/F

TB2

CN3

CN9

CN1

TB1

TB1

Regenerative

S

T r s

1-2 Function block diagram

An internal function block diagram of this driver is shown.

R

Control

power

supply

Pulse command I/F

Input signal I/F

ENC monitor I/F

circuit

Overcurrent

detection

Voltage

detection

Charge

lamp

Gate drive

Control

calculation

Control part

1-2 Function block diagram

Dynamic

brake

Ground

*3

*2: The HA-800-6 and higher models come with a cooling fan.

*3: A battery is required if an absolute encoder is used.

1-2

Page 24

1-3 Device configuration diagram

1

2

3

4

5

6

7

8

9

10

11

Appe

Functions and configuration

⇧

Encoder cable

CN2

TB1

Drive cable

For I/O signals

Servo actuator

Magnetic

TB2

1-3 Device configuration diagram

A basic configuration diagram of this driver is shown.

HA-800A-1,3,6-200

*1: The customer should provide marked devices separately.

*2: The configuration in the case of 3-phase AC200V is

Control power supply*1

Power supply cable*1

shown here. Depending on the actuator model, the driver

can be used with single-phase AC200V or AC100V.

Refer to P2-6 for the connection example.

Power supply*1

Circuit breaker*1

Surge absorber*1

Noise filter*1

switch*1

Main power

supply*1

Host device*1

CN1

Dedicated

CN3

Personal computer*1

Communication software

communication

cable

Install

(PSF-800)

1-3

Page 25

1-3 Device configuration diagram

1

10

9

8

7

6

5

4

3

2

1

Appe

Functions and configuration

Encoder cable

CN1

Host device*1

CN2

Drive cable

CN3

For I/O signals

Power supply

Circuit breaker

Surge absorber

Noise filter

Control power supply

Main power supply

⇧

Dedicated

HA-800A-24-200

*1: The customer should provide marked devices separately.

*2: Dedicated to AC200V 3-phase (Main circuit power)

Refer to P2-7 for the connection example.

Magnetic switch*1

Power supply cable*1

*1

*1

*1

*1

*1

*1

communication

cable

Personal computer*1

Install

Communication software

(PSF-800)

Servo actuator

1-4

Page 26

1-4 Driver model

1

2

3

4

5

6

7

8

9

10

11

Appe

Functions and configuration

800A

I/O command type

800B

MECHATROLINK type

800C

CC-Link type

1

1.5 A

3

3 A 6 6 A

24

24 A

A

13-bit absolute encoder

C

4-wire wire-saving incremental

encoder

D

17-bit absolute encoder

200

AC200V

100

AC100V

Blank

Standard

SP

Special

product

HA-800A-3A-200-SP

1-4 Driver model

The following explains how to read the driver model name and symbol, as well as options.

Driver model

*: For details on the available encoders, see Chapter 4.

Model: AC Servo Driver HA series

Series: 800 series

Rated output current:

Available encoder*:

B 14-wire incremental encoder

E 17-bit encoding incremental model

Input voltage:

Custom specification code:

product

Option

Extension cables (optional)

Refer to [1-5 Actuator and extension cable combinations].

Dedicated communication cables (optional)

Model EWA-RS03

Connectors (optional)

Model CNK-HA80A-S1/CNK-HA80A-S2/CNK-HA80A-S1-A/CNK-HA80A-S2-A

Servo parameter setting software

PSF-800 (Downloadable from our website http://www.hds.co.jp/)

Backup battery for absolute encoder

HAB-ER17/33 (attached to the shipped driver)

1-5

Loading...

Loading...