Harmonic PWRLink II 4800T Product Manual

PWRLink™ II 4800T Series

Optical Transmitter

Product Manual

Manual Part No.: 700-0051934

Rev A

February 2002

PWRLink II 4800T Optical Transmitter Product Manual

ATTENTION

AVERTISSEMENT

ACHTUNG

Pursuant to the pertinent sections of Title 21, (United States) Code of Federal Regulations

(CFR), Chapter I, Subchapter J, and administered by the Center for Devices and Radiological

Health (CDRH), operation under the Food and Drug Administration (FDA), this product,

which produces or receives an optical signal, composed of Laser Radiation, complies with 21

CFR Chapter I, Subchapter J, as applicable to Class I Laser Products with a Class 3B Hazard.

Note!

This laser warning is included in all Harmonic manuals. The intended use of all Harmonic

products, including those products that do not contain lasers, are in systems that contain lasers.

Therefore this warning is important for the safety of all persons operating or maintaining the

equipment.

INTENDED MEANING

SIGNIFICATION

BEDEUTUNG

DANGER: Invisible Laser Radiation, when open or when operating with

fiber disconnected. AVOID DIRECT EXPOSURE TO THE BEAM. Never

operate unit with a broken fiber or with a fiber connector disconnected.

DANGER: Les rayons laser sont invisibles à l´oeil. NE PAS S´EXPOSER

DIRECTEMENT AU FAISCEAU. Ne jamais utiliser l´appareil lorsque la

fibre est interrompue ou un connecteur endommagé ou déconnecté.

VORSICHT: Unsichtbare Laserstrahlung, wenn Abdeckung geöffnet oder

Glasfaserkabel entfernt. DIREKTEN KONTAKT MIT DEM STRAGL

VERMEDIDEN. Das Gerät nicht einschalten, wenn das Glasfaserkabel

beschädigt oder nicht angelchlossen ist.

CAUTION: There are no user serviceable parts inside. Refer all servicing

to qualified service personnel. Other than those specific measurements,

adjustments and tests specified in the manual, make NO attempt to

modify or alter any circuit or assembly in any manner.

ATTENTION: Toute intervention sur cet équipement est formellement

déconseillée par le fabricant. En dehors de réglages décrits dans le

manuel, l´utilisateur doit contacter une personne qualifiée par le fabricant

pour toute modification ou réparation.

VORSICHT: Es sind keine zu wartenden Teile im Gerät, alle

Wartungsarbeiten nur von qualifiziertem Personal ausführen lassen. Ex

dürfen nur die im Handbuch spezifisch aufgeführten Messungen,

Justierungen und Tests vom Benutzer vorgenommen werden.Unter

keinen Umständen, dürfen Modifikationen oder Änderungen jeglicher

Art am Gerät unternommen werden.

INTERNATIONAL SYMBOL

SYMBOLE INTERNATIONAL

INTERNATIONALES SYMBOL

Copyright 2002 Harmonic Inc

Harmonic continues to improve and enhance all product designs. Specifications are subject to change without notice. Harmonic and logo design,

eXchange, MAXLink, METROLink, NETWatch, PWRBlazer, TRANsend, and “Redefining the Network” are trademarks of Harmonic Inc. YAGLink

and PWRLink are registered trademarks of Harmonic Inc. All other names are trademarks or registered trademarks of their respective owners.

RemotelyAnywhere is copyright © 3AM Laboratories PL.

.

Copyright © 2002 Harmonic Inc.

Table of Contents

Chapter 1 Overview

1.1 About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter 2 Installing the PWRLink II Transmitter

2.1 Receiving and Inspecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.2 Installing the Transmitter Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.3 Connecting the Fiber Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4 Connecting the RF Broadband Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.5 Testing RF Signal Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3 User Interface Options

3.1 HLP 4200WD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Transmitter Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.1.2 Transmitter Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.1.3 Transmitter Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.1.4 Transmitter Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.2 NETWatch Site Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.3 Front Panel RF Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.4 Front Panel LED Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Chapter 4 Transmitter Setup

4.1 Factory-Optimized Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.1 Returning to Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.2 Fine Tuning Each Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.3 Autosetup, Automatic Gain Control, and Manual Gain Control . . . . . . . . 4-3

4.3.1 Autosetup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3.2 Automatic Gain Control (AGC) and Manual Gain

Control (MGC) 4-6

4.4 Setup via HLP 4200WD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.4.1 Step-by-Step Setup Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

4.4.2 Fine Tuning the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

4.4.3 Resetting the Transmitter to Factory Defaults . . . . . . . . . . . . . . . . . 4-8

4.5 Setup via NETWatch Site Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.6 Setup via the Transmitter’s Front Panel Controls . . . . . . . . . . . . . . . . . . . . . 4-9

Chapter 5 Maintenance

5.1 Cleaning Fiber Optic Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Cleaning Patch Cord or Pigtail Fiber Optical Connectors . . . . . . . . 5-2

5.1.2 Cleaning Transmitter Module Optical Connectors . . . . . . . . . . . . . 5-2

5.2 Fan Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

PWRLink II 4800T Optical Transmitter Product Manual Rev A (2/02) i

Chapter 6 Troubleshooting

6.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.2 In Case of Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3 Warranty Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.4 Limitations of Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

6.5 Exclusive Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Appendix A Technical Specifications

A.1 Link Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Optical Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.3 RF Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.4 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.5 Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

A.6 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

A.7 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

A.8 Models Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Appendix B HLP 4200WD Menu Display

ii Copyright © 2002 Harmonic Inc.

1.1 About This Manual

This instruction manual is a complete guide to installation, configuration and

operation of PWRLink™ II 4800T series optical transmitters. The models that

are covered by this manual are listed in Appendix A, Section A.2.

• Chapter 1 provides a description of the PWRLink II transmitter.

• Chapter 2 describes the installation procedure.

• Chapter 3 introduces the user interfaces.

• Chapter 4 describes how to set up and configure the transmitter.

• Chapter 5 outlines maintenance procedures.

• Chapter 6 provides instructions on what to do in the event of problems.

• Appendix A provides complete technical specifications.

• Appendix B shows additional user interface details.

• Appendix C provides a list of Harmonic’s offices.

1

Overview

1.2 Description

The PWRLink II 4800T transmitter is a compact plug-in module designed for

use in the Harmonic HLP 4200 equipment platform. An HMC 4000 module

carrier is needed to mount the transmitter in the platform. Harmonic has

optimized the PWRLink II 4800T series family of transmitter modules for

high-performance transmission of RF broadband information over optical

fiber networks.

The PWL 4800T has the following key features:

• Transmission bandwidth from 45 MHz to 870 MHz

• Optical performance with 76 PAL (System B/G) analog channels plus

additional digital loading

• Internal monitoring and control using 32-bit microprocessor

• Local control of operating parameters—provided by the HLP 4200

platform

• Remote control and monitoring—provided by NETWatch Site Controller

• Autosetup feature that adjusts RF pad for optimum modulation

performance

• Automatic gain control and manual gain control modes of operation

PWRLink II 4800T Optical Transmitter Product Manual Rev A (2/02) 1–1

Overview

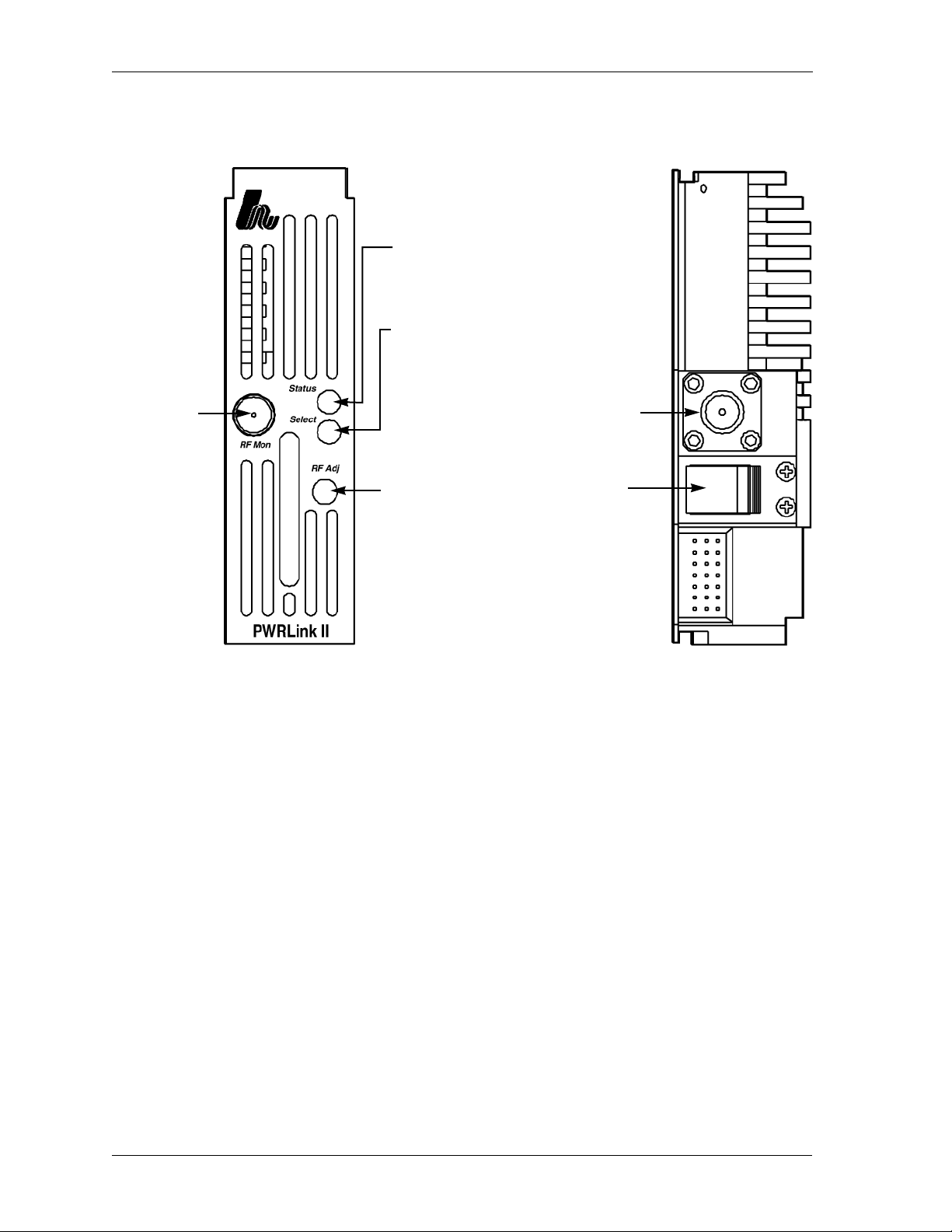

Figure 1-1 shows front and rear panel features of the PWL 4800T transmitter

module.

Status LED: Bi-state LED

illuminates green when the

module is functioning properly, or

red during an alarm or power up

Select LED: Yellow-colored LED

illuminates when the module is

selected through the front panel

display of the HLP 4200WD

RF Monitor:

Monitor point for

RF signal at the

transmitter input

RF In: Female

F connector

RF Pad Adjustment

PWL49FRP

Optical Out

PWL49REP

Figure 1-1. PWL 4800T front and rear panel features

Transmitter performance is optimized by combining state-of-the-art 1310 nm

DFB (distributed feedback) laser technology and patented pre-distortion

linearization circuitry. Harmonic has designed the PWRLink II family for

integration into networks with advanced element management systems; each

transmitter module employs a microprocessor-based communication and

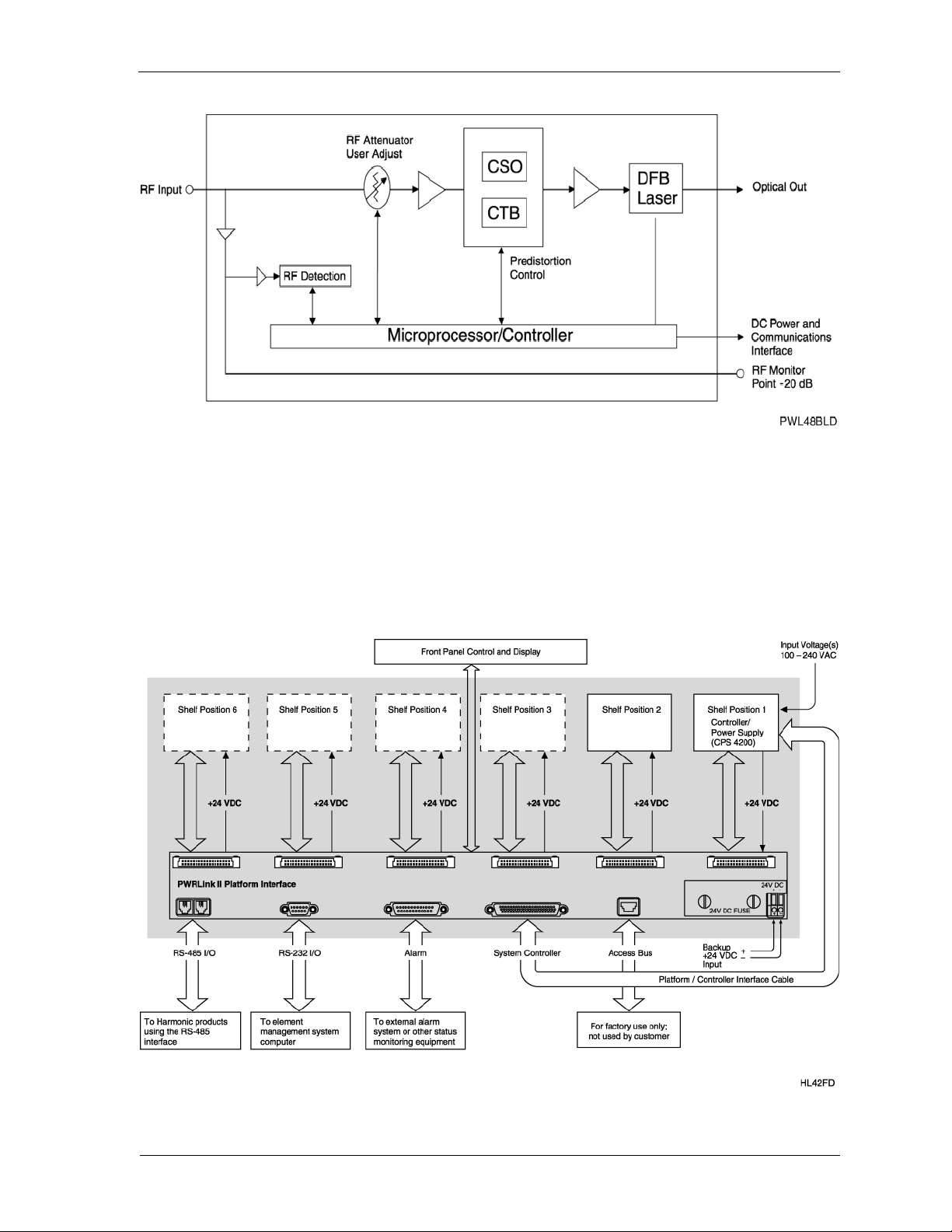

monitoring architecture. Figure 1-2 is a block diagram of the PWL 4800T

transmitter.

The transmitter’s microprocessor continuously monitors and controls all

critical transmitter parameters in order to optimize performance over both

time and temperature changes. The microprocessor-controlled parameters

include:

• Input signal attenuation pad

• Laser power, temperature, and bias

• Electrical circuit temperature and setpoints

1–2 Copyright © 2002 Harmonic Inc.

Figure 1-2. PWL 4800T block diagram

Description

The PWL 4800T transmitter is a compact plug-in module that mounts easily

in Harmonic’s HLP 4200 platform via the HMC 4000 module carrier. See

Figure 1-3 for a functional diagram of the HLP 4200 platform. The transmitter

module draws power from the platform’s 24 VDC power bus, and

communicates with the platform controller via the platform communication

bus.

Figure 1-3. HLP 4200 functional diagram

PWRLink II 4800T Optical Transmitter Product Manual Rev A (2/02) 1–3

Overview

For additional information on the HLP 4200 platform and its associated

communication and power buses, see the HLP 4200 Product Manual. For

further information on the platform controller and power supply options,

see the CPS 4200 or CPS 4248 manual.

1.3 Applications

The PWRLink II DFB transmitter is designed to operate alone or with other

systems, depending on the application:

• Alone, in local distribution and narrowcasting applications

• In combination with Harmonic’s MAXLink™ 1550 nm transmission

system, for complete broadband network solutions

The PWL 4800T provides an ultra-linear RF input-to-optical output (1310 nm)

response for the simultaneous transmission of analog video and digital

signals in the 45 to 870 MHz frequency band.

The 1310 nm optical signal transmitted by a PWRLink II module can be

received by optical receivers and nodes manufactured by Harmonic or other

major broadband equipment manufacturers. To learn more about equipment

compatibility and broadband network design and optimization, contact

customer service. See Appendix C, Harmonic Inc. – Offices .

1–4 Copyright © 2002 Harmonic Inc.

2

Installing the PWRLink II Transmitter

This chapter describes how to:

• Receive and inspect the PWRLink II transmitter

• Install the transmitter module in the HLP 4200 platform

• Connect the fiber cable

• Connect the RF broadband input

• Test RF signal input

2.1 Receiving and Inspecting

As you unpack your unit, inspect the shipping container and equipment for

damage. Save the shipping material for future use.

If the container or the equipment is damaged, notify both the freight carrier

and Harmonic. See Appendix C, Harmonic Inc. – Offices for contact

information.

CAUTION: Before removing equipment from its antistatic bag, touch a

ground point for several seconds. A suitable ground point is an

unpainted part of the chassis of a grounded piece of equipment.

2.2 Installing the Transmitter Module

CAUTION: To protect yourself from potential injury and to protect the

equipment from further damage, do not perform any

operational tests if the equipment appears to be damaged.

The PWRLink II transmitter module plugs into the HMC 4000 module carrier,

shown in Figure 2-1 on page 2-2. The transmitter module is held in the carrier

by a spring-loaded tab on the front handle of the carrier. You can place the

HMC 4000 carrier into any desired position in the HLP 4200 platform.

The PWRLink II module can be plugged into the carrier either with the carrier

already mounted in the HLP 4200 platform, or prior to mounting the carrier

into the platform. The HLP 4200 platform can be powered and operational

during the plug-in process.

PWRLink II 4800T Optical Transmitter Product Manual Rev A (2/02) 2–1

Installing the PWRLink II Transmitter

PL49CRR

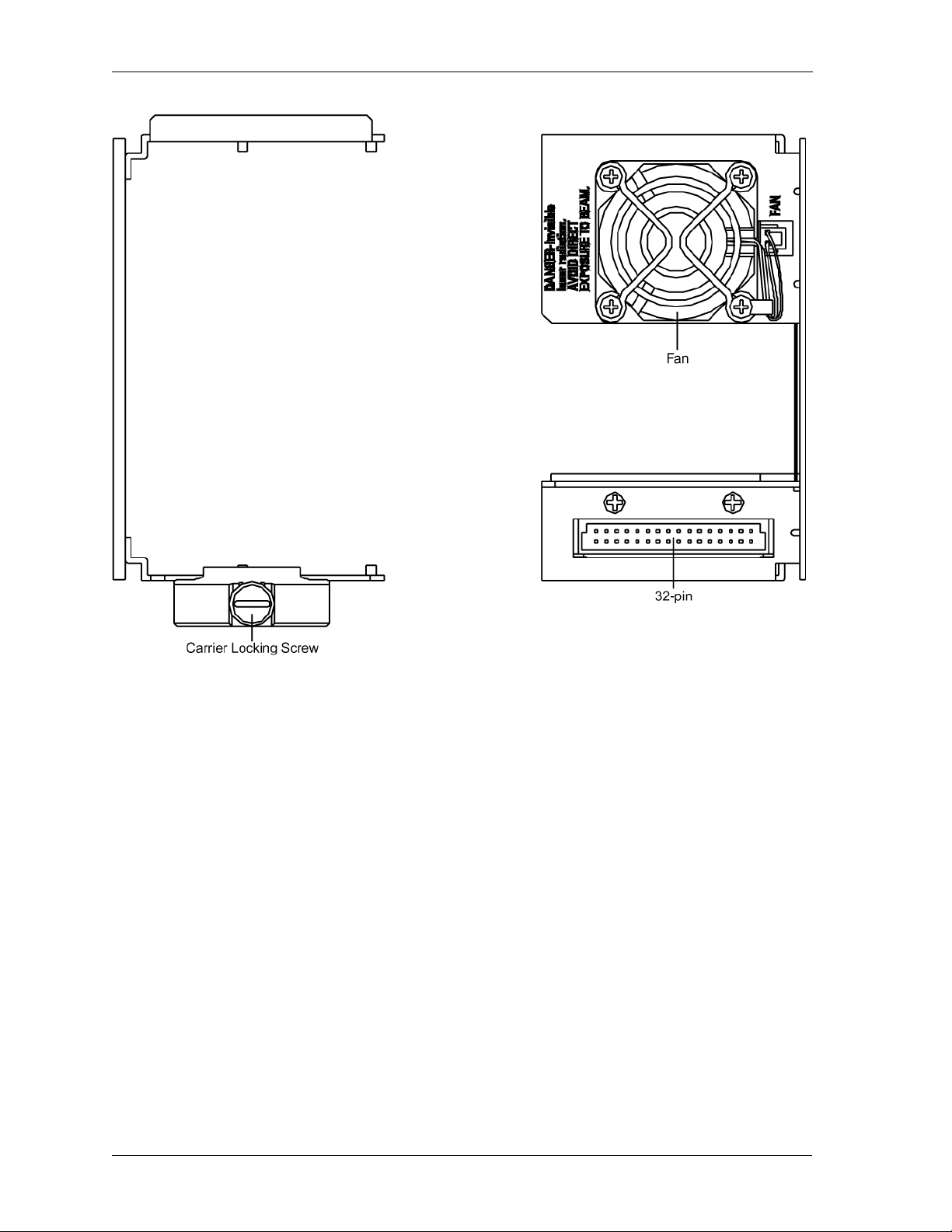

Figure 2-1. HMC 4000 module carrier front and rear panel features

To install the transmitter module in the HMC 4000 carrier:

• Insert the transmitter into the carrier until it locks into position.

To remove the transmitter module from the HMC 4000 carrier:

• Press down the spring-loaded tab on the carrier, then pull out the module.

To install the HMC 4000 carrier in the HLP 4200 platform:

1. Lower the HLP 4200 platform’s control/display panel.

2. Slide the HMC 4000 carrier into any available slot in the platform until it is

properly seated.

3. Lock the carrier into position with the carrier locking screw, shown in

Figure 2-1.

The PWRLink II transmitter receives power from the HMC 4000 carrier.

The carrier is powered by the +24 VDC bus of the HLP 4200.

For additional information on the HLP 4200 platform, see the HLP 4200

Instruction Manual. For additional information on platform controllers and/or

power supply options, see the respective Harmonic manual for each

component .

2–2 Copyright © 2002 Harmonic Inc.

2.3 Connecting the Fiber Cable

The optical output connector of the PWRLink II transmitter is located on the

rear of the module, as shown in Figure 1-1 on page 1-2.

DANGER: Invisible Laser Radiation. AVOID EXPOSURE TO BEAM .

Never operate unit with a broken fiber or with a fiber connector

disconnected.

To connect fiber optic cable to the transmitter output:

1. Verify that the transmitter module has been mounted into the HLP 4200

platform, as described in Section 2.2.

2. Determine the connector type on the PWRLink II transmitter. The

standard optical connector recommended by Harmonic is SC/APC. Other

connector types can be special ordered.

3. Verify that the type of connector on the fiber cable is the same as what is

on the PWRLink II transmitter, for example the SC/APC.

4. Verify that the fiber cable connector has been cleaned properly. If the fiber

cable connector needs to be cleaned, follow the cleaning procedure

outlined in Section 5.1.1 Cleaning Patch Cord or Pigtail Fiber Optical

Connectors on page 5-2.

5. Verify that the PWRLink II optical connector has not been exposed to any

contamination. If you suspect that the connector may have been exposed

to contamination (for example, by a dirty fiber cable connector), follow the

cleaning procedure outlined in Section 5.1.2 Cleaning Transmitter Module

Optical Connectors on page 5-2.

Connecting the Fiber Cable

NOTE: Any contamination of either the fiber cable or PWRLink II

transmitter connector can significantly degrade optical link

performance. This degradation will most likely manifest itself

as poor carrier-to-noise (CNR) performance.

6. For SC-type optical connectors, note the key characteristics of the mating

connectors and align them accordingly. Gently insert the fiber cable

connector into that of the PWRLink II transmitter until the connector

clicks into place.

For FC-type optical connectors, note the key characteristics of the mating

connectors and align them accordingly. Gently insert the fiber cable

connector into that of the PWRLink II transmitter and tighten the rotating

sleeve of the connector. Do not overtighten!

2.4 Connecting the RF Broadband Input

The PWRLink II transmitter broadband RF connector is located on the rear

panel of the module, as shown in Figure 1-1 on page 1-2.

The PWRLink II female F connector accepts a 75 ohm impedance coaxial cable

terminated with a male F-type connector. The male F connector on the cable

should have a center pin diameter in the range of 0.64 mm to 0.8 mm. Insert

PWRLink II 4800T Optical Transmitter Product Manual Rev A (2/02) 2–3

Installing the PWRLink II Transmitter

the signal source connector into the PWRLink II module RF input connector

and tighten securely. The input video signal level must be between 16 dBmV

and 22 dBmV per analog video channel based on 76 PAL channels.

NOTE: To ensure performance integrity, use RG-59 coaxial cable. Use of a

connector with a center pin diameter greater than 0.8 mm can

damage the input RF connector.

2.5 Testing RF Signal Input

Once you have connected the RF signal source, you can use the RF monitor to

verify the presence of the RF signal input to the transmitter. The RF monitor is

a test connector (female F-type) located on the front panel of the transmitter

module, as shown in Figure 1-1 on page 1-2. The monitor level is 20 dB below

the input level to the transmitter ±1 dB.

2–4 Copyright © 2002 Harmonic Inc.

User Interface Options

This chapter describes:

• HLP 4200WD display

• NETWatch Site Controller

• Front panel RF adjustment

• Front panel LED indicators

3

Each PWRLink II transmitter module employs a microprocessor, which makes

it easy for you to communicate with and control the transmitter. This chapter

describes three options for such communication and control. The options are:

• HLP 4200WD push buttons and display

The HLP 4200WD interface provides the most comprehensive means

of monitoring and controlling PWRLink II transmitter performance.

The Autosetup and Reset to Factory Settings commands are available only

through this interface. For initial setup of the transmitter, Harmonic

recommends using the HLP 4200WD display, if available.

• NETWatch Site Controller Element Management System

Once installed and configured, NETWatch Site Controller provides a

straightforward way to monitor and control a network of multiple

PWRLink II transmitters, either locally or remotely.

• PWRLink II transmitter front panel RF adjustment

The RF adjustment potentiometer on the front panel of each PWRLink II

transmitter module (shown in Figure 1-1 on page 1-2 as RF Pad

Adjustment) can be used to set the internal RF pad level. Use this interface

only if the first two interface options are not available.

3.1 HLP 4200WD Display

The PWRLink II transmitter can be configured and monitored conveniently

via the push buttons and LCD display of the HLP 4200WD equipment

platform.

Figure 3-1 on page 3-2 provides a flowchart of the commands and messages in

the Main menu, which is at the top of the HLP 4200 WD platform interface

hierarchy. In this figure, push-button commands are framed in ovals, and

resultant display messages are framed in rectangular boxes.

PWRLink II 4800T Optical Transmitter Product Manual Rev A (2/02) 3–1

Loading...

Loading...