Page 1

Maintenance

The Invincible Insert is designed to need little

maintenance mechanically . However, The

stove must be cleaned when needed to

maintain top performance.

AS NEEDED

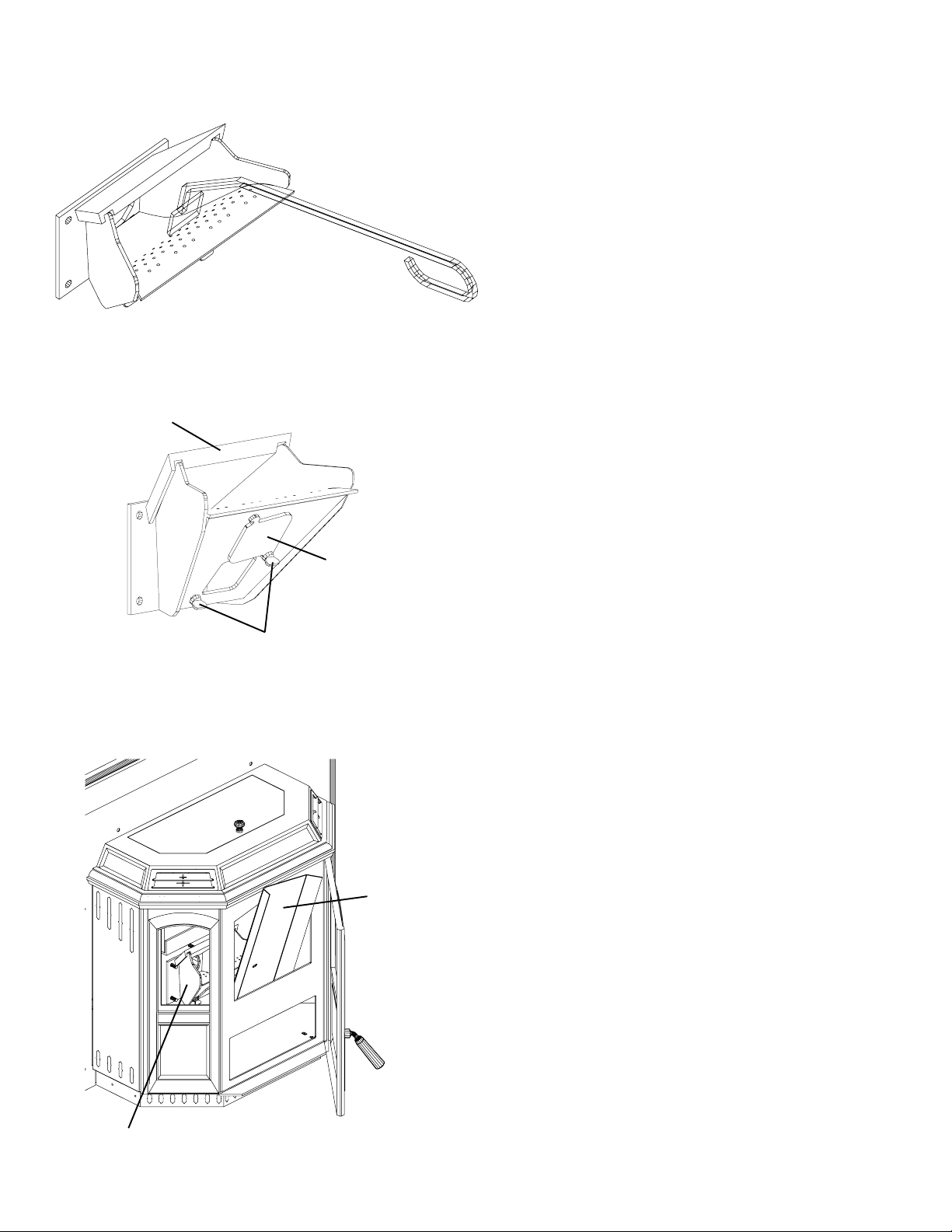

Burn Pot

Flame Guide

Fig. 15

Fig. 14

Thumb

Screws

Scraper

Slide Plate

* Fill hopper with pellets and remove ashes.

* Clean burn pot (scrape carbon loose with

scraper), fig. 14. If the fire is pushing out

more in the middle of the burnpot than before

or pushing partially burned pellets off the

edge, these are indications that the burnpot

needs cleaned.

*Remove, clean, and inspect flame guide for

warpage and replace as needed, fig. 15. The

flame guide is an expendable part and may

need to be replaced in a few years.

* Open burn pot clean-out slide plate by

loosening the two thumb screws and rotating

the slide plate clockwise, fig. 15. Remove fly

ash and replace slide plate.

* Clean glass. A dry paper towel will do the

job in most cases. If a cleaning fluid is used,

do not allow fluid to run down into the slot at

the bottom of the corner glass. Always keep

these slots clean. (Always wear gloves).

Burn Pot

Fig. 16

Remove Vertical

Baffles through

the top door

opening

ANNUALLY (or as needed)

* Remove vertical baffles from firebox by first

removing the thumb screws. Next rotate the

baffles around to the front and remove

through the door opening, fig. 16. This exposes the divider baffles which can be removed by first removing the thumb screws,

fig. 18.

11

Page 2

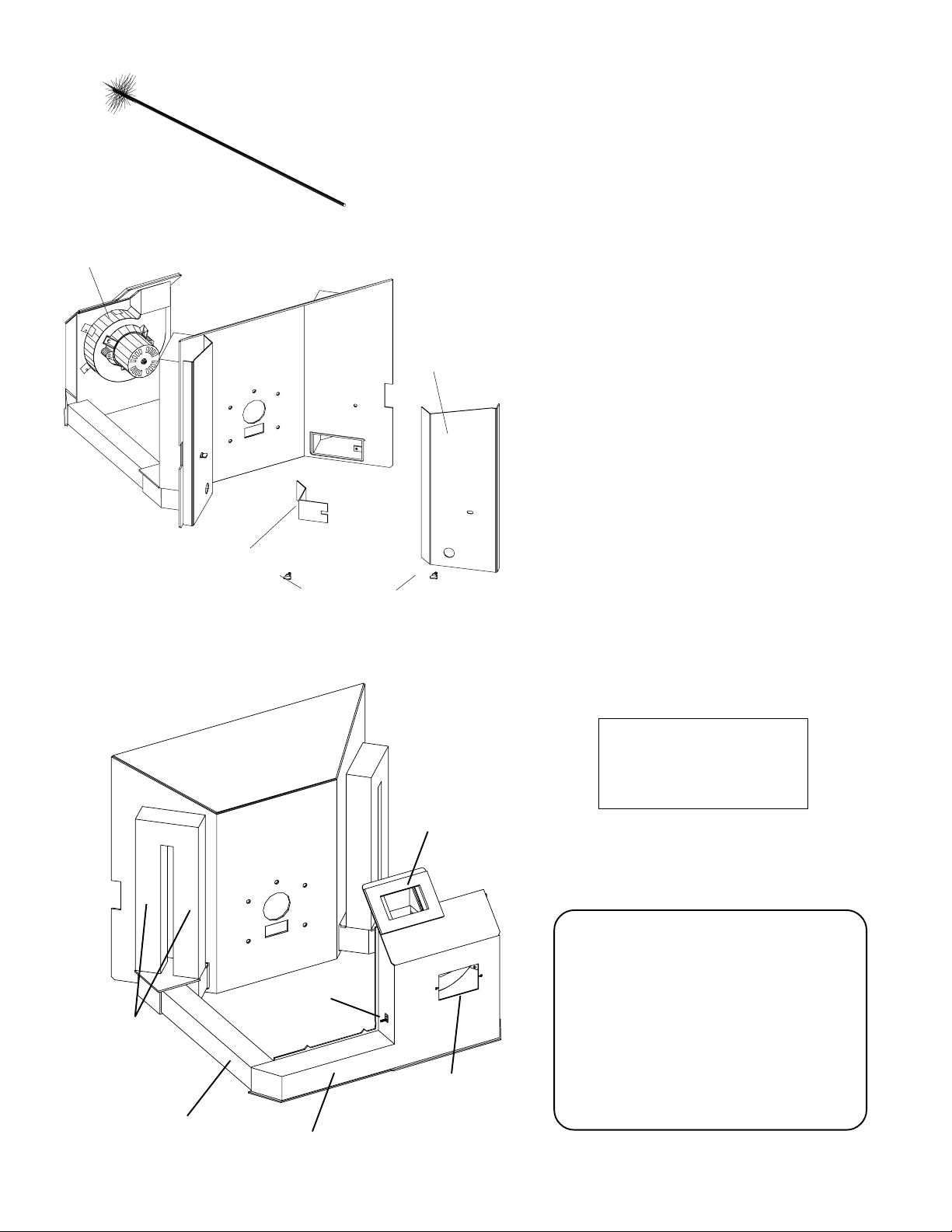

Combustion

Blower

Fig. 17

Flexible Brush

Vertical

Baffle

*Clean fly ash from heat exchanger tubes with

flexible brush (Fig 17). There are two

vertical tubes on each side and a horizontal

side tube which runs front to back. There is

also a horizontal tube across the back which

can be cleaned through the rear access port

(Fig, 18). After the fly ash is brushed loose,

use a vacuum cleaner to extract to extract

the residue.

* Clean combustion blower through access

port in rear of unit. In extreme cases the

motor assembly can be removed for better

access to the blades. Be careful not to tear

the gasket.

The blower is sealed to the mounting plate

with silicone and will need to be pried loose

if the blower housing ever needs to be

replaced.

Divider Baffle

Fig. 18

Vertical Heat

Exchanger Tubes

Side Heat

Exchanger Tube

Thumb Screws

Docking Gasket

ESP Probe

Rear Heat Exchanger Tube

Rear Access

Port

* Clean ESP probe. This can be done by

removing the probe or by reaching through

the access port (Fig. 19). Inspection can be

improved by removing the probe.

* Check the docking gasket to make sure it is

in good condition (Fig 19).

Note: Fig. 18 & 19 show heat

exchanger and rear firebox

only. This is done to better

illustrate cleaning.

Fig. 19

This unit has been designed and

tested to be operated with the door

closed. The door should only be

opened to remove ashes. Normally

the door open time to remove the

ashes is less than 10 seconds and

does not pose a problem. Keep

hopper lid closed except when

loading.

12

Page 3

Tr ouble Shooting

FEEDER DOES NOT FEED

1. No pellets in hopper.

2. Feed motor will not run until ESP

senses 165 deg. F. Maybe you did not put

enough pellets in the burn pot before lighting

the fire.

3. Feed motor has failed.

4. Something is restricting flow in the hopper

or causing the slide plate to stick.

P AR TICIALLY BURNED PELLETS

1. Feed rate too high.

2. Draft too low. (check burn pot clean- out

slide and door gasket).

3. Burn pot or heat exchanger tubes may need

cleaned.

4. Combination of all.

SMOKE SMELL

Seal the vent pipe joints and connection to

stove with silicone.

FIRE HAS GONE OUT

1. No pellets in hopper.

2. Feed rate too low.

3. Something is restricting fuel flow .

4. Feed motor or draft motor has failed.

5. Power failure.

SMOKE IS VISIBLE COMING OUT OF

VENT

1. Air-fuel ratio is too rich.

A. Feed rate too high.

B. Draft too low caused by a gasket leak.

LOW HEA T OUTPUT

1. Feed rate too low

2. Draft too low because of gasket leak.

3. Poor quality or damp pellets

4. Combination of 1. and 2.

STATUS LIGHT ERROR MESSAGES

Refer to page 10.

Helpful Hints

Cleaning Burn Pot

Whenever your stove is not burning, take the

opportunity to scrape the burn pot to remove

carbon buildup. A vacuum cleaner is handy to

remove the residue. Be sure the stove is cold if you

use a vacuum.

Carbon buildup can be scraped loose with the

fire burning using the special tool provided with

your stove. Scrape the floor and sides of the burn

pot. The carbon will be pushed out by the incoming

fuel. Always wear gloves to do this.

Removing Ashes

Turn the Stove Temp Dial to number 1 ap-

Fuels

All W ood pellets

Cardboard pellets

W alnut shell pellets

75% Corn, 25% Wood pellets

proximately 30 minutes before removing ashes.

This will result in a cooler stove and ash pan.

Maximum settings are not needed in most

cases. Always remember the maximum feed rate

and do not exceed. Too high a feed rate will push

partially burned fuel off the end of the burn pot,

wasting fuel and causing the glass to get dirty .

Using a lower feed rate than maximum is recommended when maximum heat output is not required.

Keep the stove free of dust and dirt.

13

Page 4

NEVER PULL THE PLUG

TO KILL THE FIRE

14

Page 5

Invincible Insert Feeder

15

Page 6

14 1/2"

12 1/2"

42"

31"

25"

24"

The INVINCIBLE INSERT operates at varying sound levels and

types of sounds depending on the

mode of operation. This is normal

and is not a problem.

12"

W ALL

Specifications

Weight 354 lbs.

Blower Size 190 cfm

Hopper Capacity 40 lbs.

16"

6"

FLOOR PROTECTOR

BTU Range 7000 to 53000

Heating Capacity 1700 Square Feet

Fuel Wood Pellets

Flue Size 4" Round

Fuse Rating 5 AMP

16

Page 7

HARMAN GOLD WARRANTY

6 YEAR TRANSFERABLE LIMITED

WARRANTY (Residential)

1 YEAR LIMITED W ARRANTY (Commer cial)

Harman Stove Company warrants its products to be free from defects in material or workmanship, in normal use

and service, for a period of 6 years from the date of sales invoice and for mechanical and electrical failures, in normal

use and service, for a period of 3 years from the date of sales invoice.

If defective in material or workmanship, during the warranty period, Harman Stove Company will, at its option,

repair or replace the product as described below.

The warranty above constitutes the entire warranty with respect to Harman Stove Company products. HARMAN STOVE COMPANY MAKES NO OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING

“ANY” W ARRANTY OF MERCHANTABILITY, OR W ARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. No employee, agent, dealer, or other personis authorized to give any warranty on behalf of Harman Stove

Company. This warranty does not apply if the product has been altered in any way after leaving the factory. Harman

Stove Company and its agents assume no liability for “resultant damages of any kind” arising from the use of its

products. In addition, the manufacturer and its warranty administrator shall be held free and harmless from liability

from damage to property related to the operation, proper or improper, of the equipment.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE F ACE

HEREOF .

THESE WARRANTIES APPLY only if the device is installed and operated as recommended in the user’s

manual.

THESE WARRANTIES WILL NOT APPLY if abuse, accident, improper installation, negligence, or use beyond

rated capacity causes damage.

HOW TO MAKE A CLAIM - Any claim under this warranty should be made to the dealer from whom this

appliance was purchased. Then contact is made with manufacturer, giving the model and serial numbers, the date of

purchase, your dealer’s name and address, plus a simple explanation of the nature of the defect. Extra costs such as

mileage and overtime are not covered. Nuisance calls are not covered by these warranties.

THIS WARRANTY IS LIMITED TO DEFECTIVE PAR TS - REPAIR AND/OR REPLACEMENT

AT HARMAN STOVE COMPANY’S OPTION AND EXCLUDES ANY INCIDENTAL AND CONSEQUENTIAL DAMAGES CONNECTED THEREWITH.

WARRANTY EXCLUSIONS: Failure due, but not limited to, fire, lightning, acts of God, power failures and/or

surges, rust, corrosion and venting problems are not covered. Damage and/or repairs to cabinets and all exterior

components, including but not limited to, remote controls, filters, fuses, knobs, glass, gaskets, door packing, fire brick

or tile, ceramic logs sets, paint, batteries or battery back-up and related duct work are not covered. Additional or

unusual utility bills incurred due to any malfunction or defect in equipment and the labor cost of gaining access to or

removal of a unit that requires special tools or equipment are not covered. Maintenance needed to keep the stove in

“good operating condition” is not covered. This includes, but is not limited to, cleaning, adjustment of customer

controls and customer education. Labor, materials, expenses and/or equipment needed to comply with law and/or

regulations set forth by any governmental agencies are not covered.

This Warranty provides specific legal rights and the consumer may have other rights that vary from state to

state.

In the event of change in ownership, the remaining portion of this warranty may be transferred to the new

owner by sending the new owner information and a transfer fee of $25.00 US to the Harman Stove Company.

PLEASE READ THE LITERA TURE BY THE MANUF ACTURER FOR THE VARIOUS ACCESSOR Y

DEVICES. THE MANUF ACTURER WARRANTS THESE ACCESSORY DEVICES, NOT HARMAN STOVE

COMP ANY OR THEIR WARRANTY ADMINISTRA TOR. FUR THERMORE, THESE ACCESSOR Y DEVICES

MUST BE INST ALLED AND USED ACCORDING T O THE RECOMMENDATIONS OF THE MANUFACTURER.

REMEDIES - The remedies set forth herein are exclusive and the liability of seller with respect to any contract or

sale or anything done in connection therewith, whether in Contract, in tort, under any warranty, or otherwise, shall

not, except as herein expressly provided, exceed the price of the equipment or part of which such liability is based.

CLARIFY - The above represents the complete warranty, which is given in connection with stoves, manufactured by Harman Stove Company. No other commitments, verbal or otherwise, shall apply except by a written

addendum to this warranty.

17

Loading...

Loading...