Page 1

INVINCIBLE PELLET INSERT

OWNERS MANUAL

R4

1

Page 2

Contents

Packing List 3

Installation & Assembly 3

Operation 7

ESP Control 10

Maintenance 11

Trouble Shooting 13

Wiring Diagram 14

Feeder Parts 15

Specifications 16

Manufactured by

Harman Stove Company

352 Mountain House Road

Halifax Pa. 17032

(717) 362-9080

2

Page 3

Packing List

Inside Stove:

Hardware Pack

(2) Electrical T erminals

(1) 10-32 x 1/2" Bolt

(1) 1/4 x 20 x 2 1/2" Bolt

(1) Wooden Handle

(1) Brass Knob

(1) Control Board Wired to Stove

(1) Owners Manual

(1) W arranty Activation Coupon

(1) Room Sensing Probe

(2) Side Panels

(1) Ash Pan

Assembly and Installation

(2) Firebricks

(1) Scraper

(1) Flame Guide

(1) Cleaning Brush

(2) 1/2 x 12" Threaded Rods

Inside Wing box

(1) Air Intake Grill

(1) Hardware Pack

(6) 1/4 x 20 x 1/2 Bolts

(6) 10-32 x 1/4 Bolts

(2) 10-32 Nuts

(1) Set of Brass Trim for W ings

Silicone

here

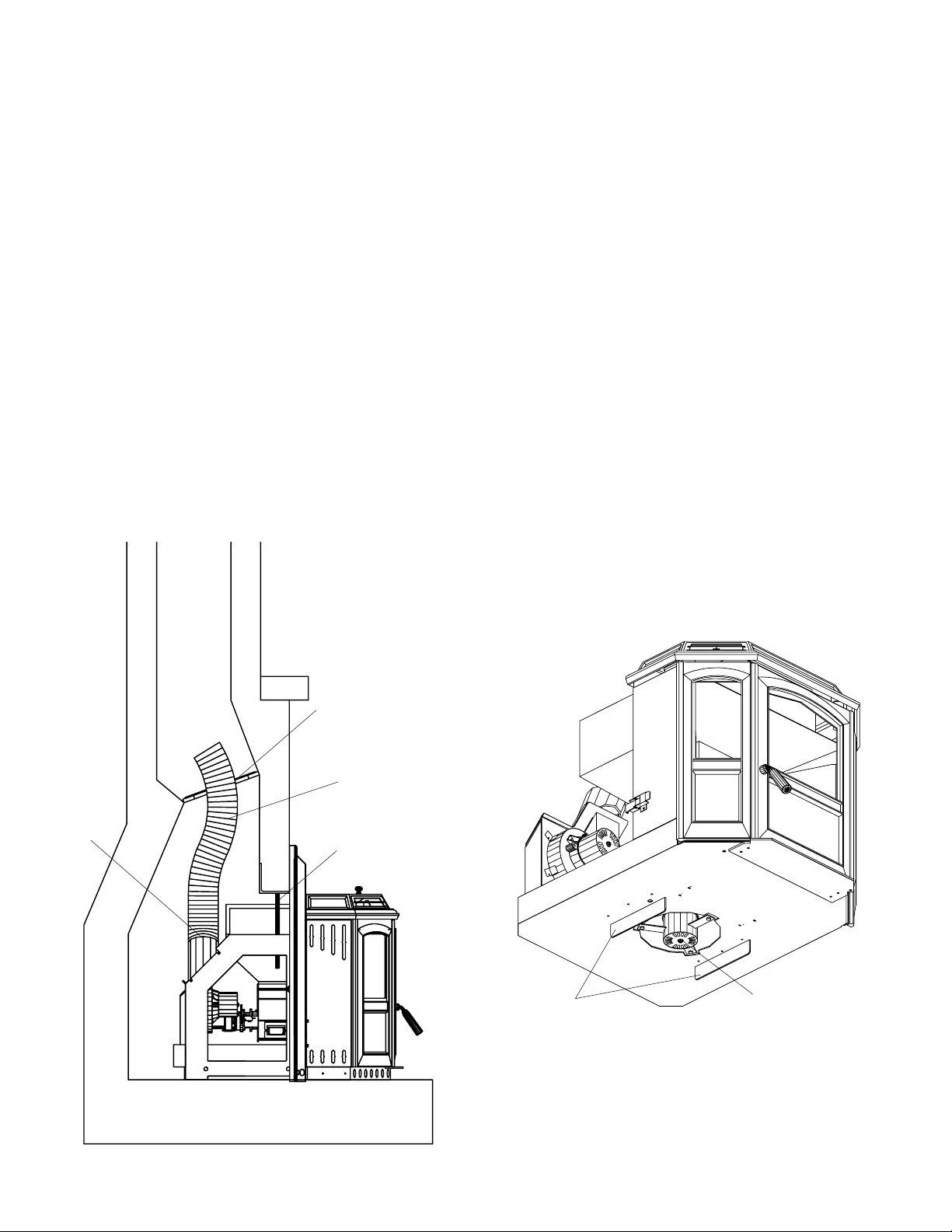

Metal damper

plate

Stainless steel

flex pipe

1/2" threaded rod

Guards

Be careful not to damage the distribution blower

located under the insert. There are guards on both

sides of the motor to allow the insert to rest on a flat

surface, however, extra care should still be taken.

Distribution Blower

3

Page 4

Mounting Shell

Wings

Brass Trim

After leveling, tighten the two 1/2"

threaded rods up against the

fireplace lintel.

Insert

Fig. 1

The Invincible Insert is made up of three main

parts. They are the mounting shell, the wings, and

the stove insert, fig. 1.

A unique feature of this unit is the fact that

the insert can be removed from the fireplace for

service without removing the mounting shell, the

wings or disconnecting the flue pipe.

Please note that the insert extends through the

rear of the mounting shell and this distance needs

to be considered when installing the shell. The

easiest place to see this is before you remove the

unit from the skid, fig.3.

Installing the Mounting Shell

Before installation, remove the damper and

any accessories from the fireplace. It is intended

that a four inch stainless steel flex pipe shall be

connected to the pipe on the rear of the mounting

shell and extend up through the damper opening.

The pipe shall be sealed at the damper opening

with a metal plate or packed with fiberglass.

Install brass trim on wings with hardware

provided. Bolt wings to shell with button head

bolts.

Place flex pipe up through damper opening

and seal around the pipe. The pipe should be able

to slide down over the flue on the shell, and sealed

with high temp silicone.

Place shell with wings attached into the

fireplace. Level the wings in all directions with

the leveling bolts in the base of the shell. After

leveling, tighten the two 1/2" threaded rods up

against the fireplace lintel, fig. 2. Do not overtighten.

Leveling bolt holes

Fig. 2

Fig. 3

Note extension

4

Page 5

Installing Insert

Slide two four foot long wood 2 x 4's into the

bottom of the shell as shown in fig. 4. Support the

ends of the 2 x 4's by cutting two pieces the proper

height for your hearth. A cross brace between the

two supports is recommended.

Place the insert on top of the 2 x 4's and slide

back until the bottom is started onto the shell.

Unpack the control board and install. This

can be done with the wiring attached by bringing

the control through the wing from the back. The

control can be mounted from the front if the wiring

harness is disconnected and reconnected after

mounting. Be sure to put the green wires on the

stud behind the wing. This stud also has the green

wire from the power cord on it, fig 5.

Next slide the insert to within an inch of

home position. Align the latches on the sides of

the insert and slide in the rest of the way . Always

be sure no wires are being pinched. Latch the two

latches and remove the 2 x 4's. Reattach the side

panels and bottom air intake grill, fig. 6.

Place the Room Sensing Probe in the desired

location and run standard thermostat wire back to

the terminals on the left wing and connect with the

two terminals provided, fig. 7. Connect the power

cord to a 120 volt receptacle.

Control Board

Install green wires on this stud.

Fig. 5

Latch

Standard 2 x 4

Fig. 4

Vertical Support

5

Page 6

Right Side Panel

Final Assembly

Install W ooden Door Handle

with 1/4 x 20 x 2 1/2 bolt.

Install Brass Hopper Knob with

10-32 x 1/2 bolt.

Install the two Firebricks on the

angle iron behind the burn pot as

shown in fig. 7.

Remove tape from Flame Guide

and make sure it is resting on the

burn pot as shown in fig. 7.

Put the ash pan back in the

stove.

Left Side Panel

Room Sensing

Probe

This very small probe can be

placed almost anywhere and go

unnoticed.

Fig. 6

Air Intake Grill

Brass Hopper

Knob

Firebricks

Plug into a 120 volt

receptacle

Flame Guide

Door Handle

Fig. 7

6

Page 7

Operation

Starting First Fire

Be sure the power cord is plugged into a 120 volt

receptacle. This can be verified by the red power

light on the control panel.

Fill the hopper with pellets, fig. 12.

Fig. 9

Fig. 8

Fig. 10

1"

Fill the burn pot with pellets to a level just short

of overflowing, fig. 8.

Adjust feed rate. If this is your first fire or you

are trying different pellets, set the feed adjuster

to "3", fig. 9. This is a conservative number and

will probably need to be increased. After you

know a feed rate setting that works well, use

that setting. Remember too high a feed rate will

waste fuel.

Turn Mode selector to "OFF" and then to

"Stove Temp". This will turn the combustion

blower to high. When starting a fire always turn

the mode selector to "OFF" before selecting the

desired mode. This resets the control for startup.

Turn Temp Dial to 7. This will allow the stove to

burn at maximum for feed rate adjusting purposes.

Apply starting gel to pellets in burn pot and light

the gel. Close the door after lighting.

At this point the distribution and combustion lights

will be on and the feed motor light will be off.

As the temperature of the fire increases, the feed

motor light will come on and pellets will feed

into the burn pot. As the stove temperature

increases the distribution blower speed will

increase.

Fig. 10A

After 30 to 45 minutes it may be necessary to

readjust the feed rate. The feed rate should be

adjusted so there is about one inch of ash in

front of the fire, fig. 10A.

7

Page 8

Scrape floor of burn pot with scraper to

remove any carbon build-up before

starting a new fire.

Fig. 11

When filling hopper be sure to

remove any pellets from ledge

before closing lid.

Starting a fire after pr oper

Feed Rate is known.

Clean burn pot with scraper (supplied).

Fill the hopper with pellets.

Fill the burn pot with pellets to a level just short

of overflowing.

Adjust feed rate to proper setting.

After you know what feed rate works well, then

use that setting. (For example a setting of "5"

produces 1" or more of ash on the burn pot with

the brand of pellets you are using.) Remember,

too high a feed rate will waste fuel.

Turn Mode selector to "OFF" and then to the

desired mode.

Turn Temp Dial to the desired temperature. In

Room Temp Mode this would be the outer scale

marked in degrees. In Stove Temp Mode this

would be the inner scale marked from 1 to 7.

Apply starting gel to pellets in burn pot as shown

on fig. 10 and light the gel. Close the door after

lighting.

At this point the distribution and combustion lights

will be on and the feed motor light will be off.

As the temperature of the fire increases, the feed

motor light will come on and pellets will feed

into the burn pot. As the stove temperature

increases the distribution blower speed will

increase.

Fig. 12

8

Page 9

Fig. 13

This setting will produce medium heat with the

distribution blower on "low".

This setting will produce a room temperature of 70

degrees with the distribution blower at medium speed.

When to use "Stove Temp

Mode"

In "Stove Temp Mode" the Stove Temp Dial

determines the temperature of the stove. Heat

output and fuel consumption will remain constant. This makes it possible to tell how long a

hopper full of pellets will last. The distribution

blower speed will vary according to the position

of the mode selector, fig. 13.

When to use "Room Temp

Mode"

In "Room Temp Mode" heat output is controlled automatically by the Room Sensing Probe.

When the Room Sensing Probe calls for heat, the

stove will increase output. When the Room Sensing Probe is getting close to the set temperature,

the stove will begin to level off output and keep the

fire burning at just the right temperature to maintain that setting.

High output is determined by the feed rate.

The maximum feed rate should be set for 1" of ash

in front of fire.

In "Room T emp Mode" fuel consumption is

sacrificed for exact room temperature. Therefore,

as it gets colder more pellets will be burned

automatically.

The distribution blower speed will vary

according to the position of the mode selector, fig.

13.

This setting will produce continuous maximum heat output

with the distribution blower at full speed.

Shut-Down Procedure

To kill the fire or stop burning the stove, Turn

the Mode Selector to "OFF". This will cause the

fire to diminish and burn out. When the fire burns

out and the stove cools down everything will stop.

If you pull the plug to shut down the stove, all

motors will stop. This may cause incomplete

combustion and smoke in the firebox. If the load

door is opened the smoke may escape.

The best way to shut down the stove is simply

let it run out of pellets, then the stove will shut

down automatically .

9

Page 10

Power Light

Indicates power to the

control.

Secondary

function: Blinks every

15 seconds when the

feed adjuster is in

"Test Mode". This

verifies feeder switch

operation.

Status Light

Blinks to Indicate

errors listed below.

Indicates Power to

distribution blower.

Indicates Power to

combustion blower.

ESP CONTROL

Feed adjuster

Sets the maximum feed

rate

Test

Runs all motors at

full speed for two

minutes to check

operation. After two

minutes the stove

will go to minimum

burn and the blowers

will alternate from

high to low every two

minutes to remind

you that you are still

in "Test Mode".

Distribution Blower

speed adjustment range.

Indicates Power to

the feed motor.

Temp dial

Allows you to adjust the Room temperature

in Room Temp Mode using the outer scale

marked in degrees Fahrenheit. It also

allows you to adjust the stove temperature

while in Stove Temp Mode using the inner

scale marked from 1 to 7.

Status light error messages:

1 Blink: Indicates control board self diagnostic

failure. This requires a manual reset*.

2 Blinks: Indicates that the feeder position switch

has not sensed the slide plate in the home position

for 30 minutes. This means that the slide plate may

be stuck do to a foreign object in the fuel or the

switch has failed. If the switch has failed the stove

will operate normally , however if turned to the

"OFF " position the stove will go to minimum burn

and will only shut down when it runs out of fuel. If

the slide plate frees its self the status light will

Mode Selector

Allows you to choose between Room

Temp Mode, Stove Temp Mode, or OFF.

Also allows you to vary the distribution

blower speed by turning the knob to the

high or low side of each mode.

automatically reset. If the error continues call your

Harman Dealer.

3 Blinks: Indicates ESP (Exhaust Sensing Probe)

failure. This requires a manual reset*.

4 Blinks: Can occur only in Room T emp Mode

and indicates Room Sensing Probe failed or not

installed. If a Room Sensing Probe is then installed

the status light will automatically reset.

* Manual reset, disconnect power cord for a few

seconds and reconnect. If error still occurs call

your Dealer.

10

Loading...

Loading...