Page 1

Installation & Operating Manual

The Harman FireLuxe Direct Vent Gas Stove

With Top Cooking Burner System

WARNING: If the information in these

instructions is not followed exactly, a re or

explosion may result causing property

damage, personal injury or loss of life.

- Do not store or use gasoline or other

ammable vapors and liquids in the vicinity of

this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the re department.

- Installation and service must be performed

by a qualied installer, service agency or

the gas supplier.

Report # 135-S-15-5

This appliance may be installed in

an aftermarket, permanently located

manufactured home (USA only) or in a mobile

home, where not prohibited by local codes.

This appliance is for use only with the type of

gas indicated on the rating plate. This appliance

is not convertible for use with other gases,

unless a certied conversion kit is used.

Ce manual est disponsible en Français sur demande.

R6

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

Page 2

AVERTISSEMENT: Assurez-vous de bien suivre

les instructions données dans cette notice pour

réduire au minimum le risque d’incindie ou

d’explosion ou pour éviter tout dommage

matériel, toute blessure ou la mort.

- Ne pas entreposer ni utilizer d’essence ni

d’autres vapeurs ou liquides inammables dans

le voisinage de cet appareil ou de tout autre

appareil.

- QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE

GAZ:

• Ne pas tenter d’allumer d’appareil.

• Ne touchez à aucan interrupteur. Ne pas

vous servir des téléphones se trouvant

dans le bâtiment où vous trouvez.

• Appelez immédiatement votre

fournisseur de gaz depuis un voisin.

Suivezles instructions du fournisseur.

• Si vous ne pouvez rejoindre le fournisseur

de gaz, appelez le service des incindie.

- L’installation et l’entretien doivent être assurés

par un installateur ou un service d’entretien

qualié ou par le fournisseur de gaz.

Cet appareil peut être installé dans une maison

préfabriquée (mobile) déjà installée à demeure

si kes règlements locaux le permettent.

Cet appareil doit être uniquement avec las type

de gaz indiqué sur la plaque signalétique. Cet

appareil ne peut être converti à d’autres gaz,

sauf si une trousse de conversion est utilisée.

Ne pas utiliser cet appareils’il a été plongé,

meme partiellement, dans l’eau. Appeler un

technician qualié pour inspecter l’appareail et

remplacer toute partie du système de commande

et toute commande qui a été plongée dans /’eau.

Attention. Au moment de l’entretien des

commandes, étiquetez tous les ls avant de les

débrancher. Des erreurs de la câblage peuvent

entraîner un fonctionnement inadequate et

dangereux.

S’assurer que l’appareil fonctionne adéquatement

une fois l’entretien terminé.

AVERTISSEMENT. Ne pas utiliser l’appareil

si le panneau frontal en verre n’est pas en place,

est craqué ou brisé. Conez le remplacement du

panneau à un technician agree.

INSTALLATEUR: Laissez cette notice avec l’appareil.

COMSOMMATEUR: Conservez cette notice pour consultation ultérieur.

Page 3

Table Of Contents

IMPORTANT SAFETY INFORMATION 4

SPECIFICATIONS 5

INSTALLATION 6

MASSACHUSETTS REQUIREMENTS 7

VENTING 8

ASSEMBLY 14

LIGHTING AND OPERATION 23

REMOTE CONTROL HANDSET OPERATION & PROGRAMMING 26

MAINTENANCE 28

WARRANTY 30

3

Page 4

Important Safety Information

The installation must conform with local codes or, in the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1 or the Canadian Installation Code, CAN/CGA B149.

A manufactured home (USA only) or mobile home OEM installation must conform with the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280 or when such a standard is not applicable,

the Standard for Manufactured Home Installations, ANSI/BCSBCS A225.1, or Standard for Gas

Equipped Recreational Vehicles and Mobile Housing, CSA Z240.4.

The appliance and its appliance main gas valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa).

The appliance must be isolated from the gas supply piping system by closing its equipment shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi

(3.5kPa).

The installation must provide for adequate ventilation air to the appliance.

This gas appliance must not be connected to a chimney ue serving a separate solid-fuel burning appliance.

The appliance, when installed, must be electrically grounded in accordance with local codes, or, in the

absence of local codes, with the National Electrical Code ANSI/NFPA 70, or the Canadian Electrical Code,

CSA C22. 1.

When the appliance is installed directly on carpeting or non-ceramic tile or other combustible material other

than wood ooring, the appliance shall be installed on a metal or wood panel extending the full width and

depth of the appliance. A commercially available hearth pad meets this requirement.

The appliance area must be kept clear and free from combustible materials, gasoline and other ammable

vapors and liquids.

The ow of combustion and ventilation air must not be obstructed.

Do not use this appliance if any part has been under water. Immediately call a qualifed service technician

to inspect the appliance and to replace any part of the control system and any gas control which has been

under water.

Due to high temperatures, the appliance should be located out of trafc and away from furniture and

draperies.

Children and adults should be alerted to the hazards of high surface temperatures and should stay away to

avoid burns or clothing ignition.

Young children should be carefully supervised when they are in the same room as the appliance.

Clothing or other ammable material should not be placed on or near the appliance.

Any screen or guard removed for servicing an appliance must be replaced prior to operating the appliance.

Installation and repair should be done by a qualied service person. The appliance should be inspected

before use and at least annually by a professional service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. It is imperative that the control compartments,

burners and circulating air passageways of the appliance be kept clean.

WARNING: Do not operate the appliance with the glass front removed, cracked or broken.

Replacement of the glass should be done by a qualied service person.

WARNING: Use only replacement glass, part number 3-40-21001500 and glass gasket, part number

3-44-00539. Do not use substitute materials. Do not strike or slam the glass front. Do

not use abrasive cleaners. Do not clean when hot.

4

Page 5

Specications

MAIN BURNER Natural Gas Propane (LP)

Input Rating-Btu/hr 36000 36000

Min. Input-Btu/hr 23000 23000

Orice-DMS #34 #50

COOKING BURNER

Input Rating-Btu/hr 12000 12000

Min. Input-Btu/hr 3500 3500

Orice-DMS #52 #58

GAS SUPPLY

Manifold Pressure 4.5”w.c./1.1kPa 10.0”w.c./2.5kPa

Min. Supply Pressure 5.0”w.c./1.3kPa 11.0”w.c./2.8kPa

Max. Supply Pressure 10.0”w.c./2.5kPa 13.0”w.c./3.3kPa

Annual Fuel Utilization Efciency (AFUE) 72.7% 74.9%

Steady State Efciency 73.4% 75.6%

It is recommended that the pilot ame be turned off if the appliance will not be in use for an extended pe-

riod of time.

This appliance is equipped for use with the fuel type indicated on the rating plate. Fuel conversion kits that

include the necessary parts and instructions are available from your installer, dealer or Harman Stove Co.

This appliance has been certied by OMNI-Test Laboratories, Inc. to ANSI Z21.88-2005 • CSA 2.33-2005

Vented Gas Fireplace Heaters and CAN1-2.17-M91, Gas-Fired Appliances for Use At High Altitudes.

The FireLuxe is approved for installation at elevations up to 2000 feet in the U.S. and 1370 meters (4500

feet) in Canada without change. If your installation is at an elevation greater than these, consult with the

local authority having jurisdiction for gas product installations to determine their specic requirements for

high altitude installations.

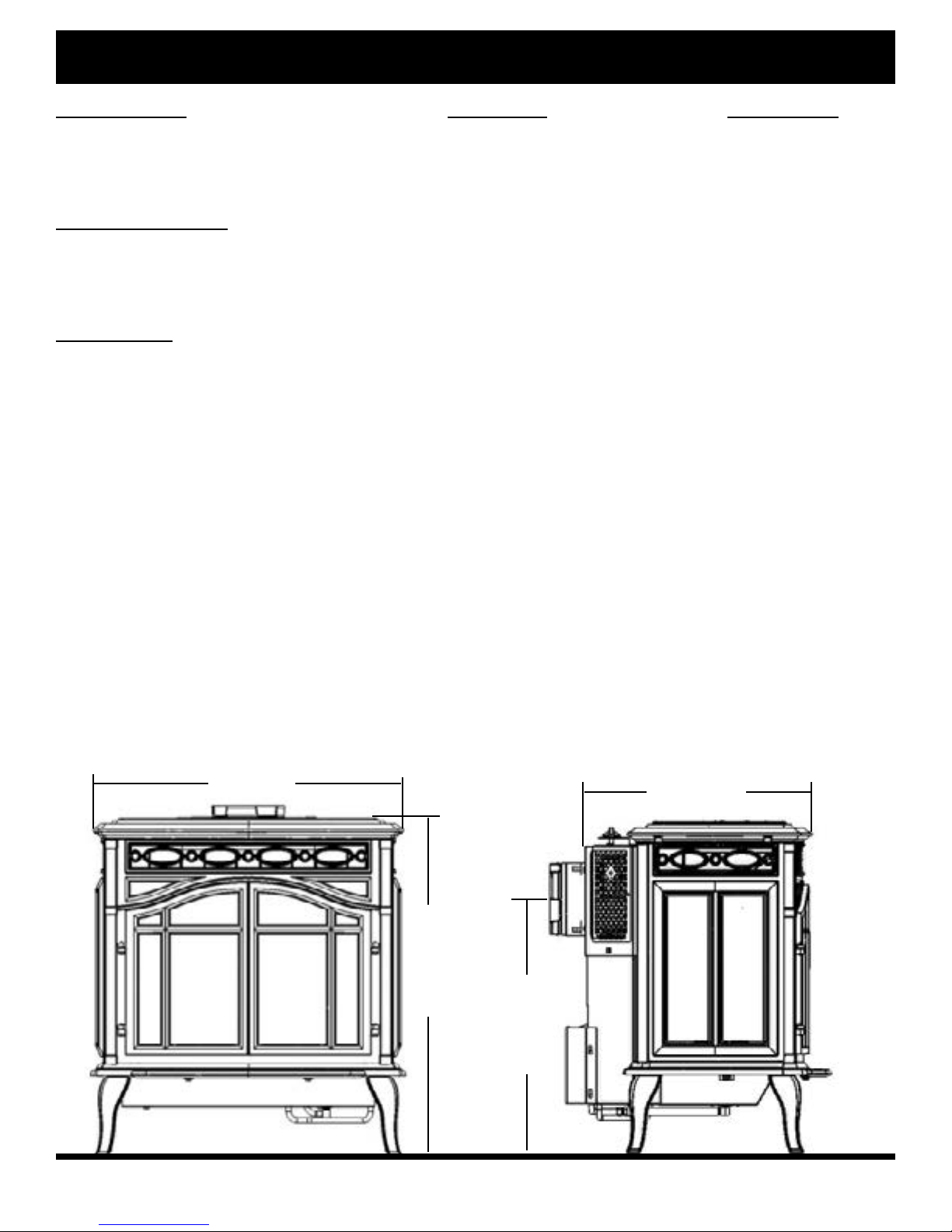

28” (71 cm)

20½” (52 cm)

30½” (77.5 cm)

23¼” (59 cm)

5

Page 6

Installation

Several issues must be addressed when selecting a suitable location for your FireLuxe. The minimum

clearances to combustible construction are listed below. In addition, access to the gas supply and electrical

supply must be considered. The location of the stove will also affect the venting requirements and you must

be certain the location will allow compliance with the venting requirements shown on pages 8 – 13. You

must also insure that your installation provides adequate accessibility clearance for servicing and proper

operation.

When the appliance is installed directly on carpeting or tile or other combustible material other than wood

ooring, the appliance shall be installed on a metal or wood panel extending the full width and depth of the

appliance.

Installation and repair should be done by a qualied service person. The appliance should be inspected

before use and at least annually by a professional service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. It is imperative that the control compartments,

burners and circulating air passageways of the appliance be kept clean.

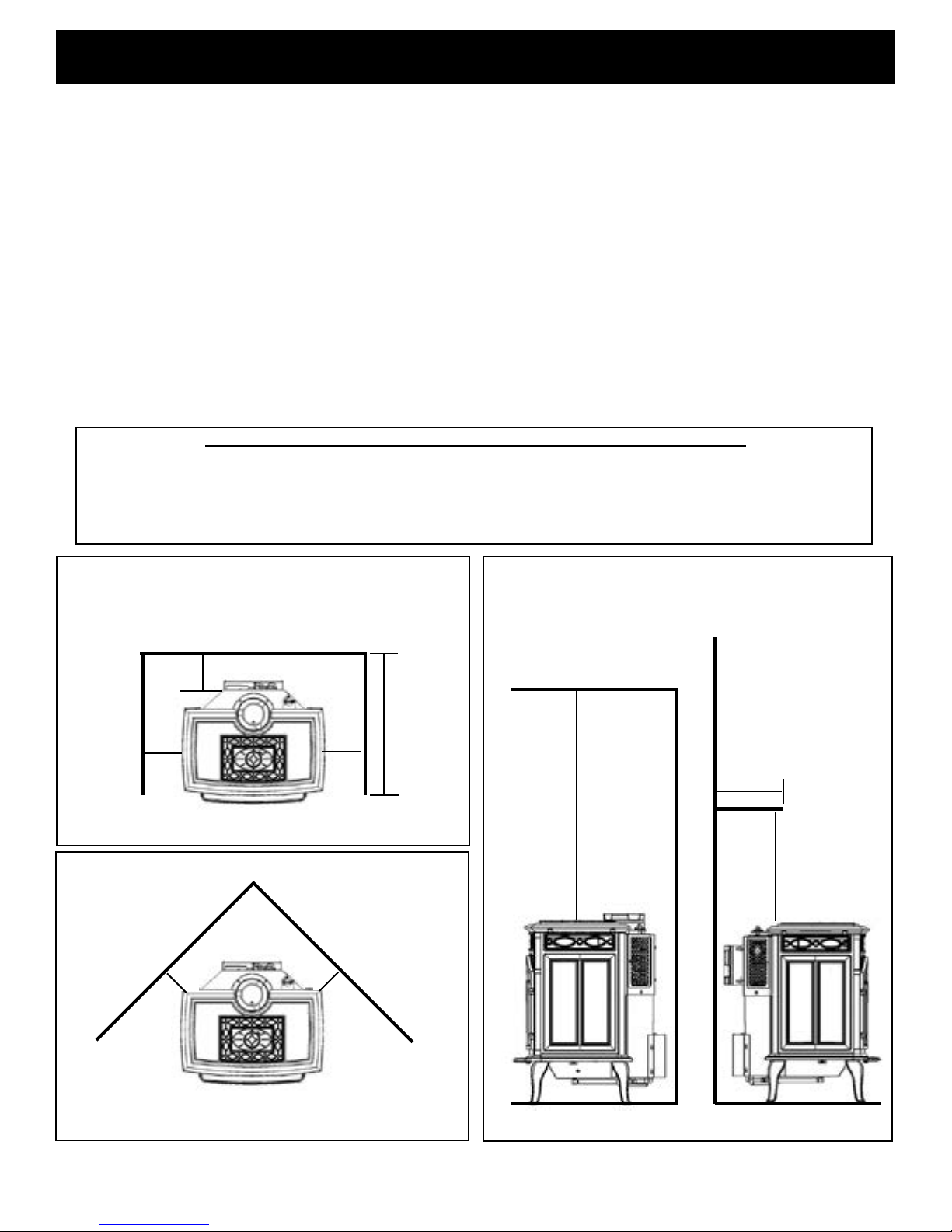

MINIMUM CLEARANCES TO COMBUSTIBLE CONSTRUCTION

Stove to Left Side Wall 6” (150mm) Stove to Corner Wall 6” (150mm)

Stove to Right Side Wall 6” (150mm) Stove to Ceiling 30” (760mm)

Stove to Rear Wall 6” (150mm) Stove to 10” Deep Mantel 30” (760mm)

Max. Alcove Depth 24” (610mm)

A = 6” (150 mm)

B = 6” (150 mm)

C = 6” (150 mm)

D = 24” (610 mm) Max. Alcove Depth

C

A

Sidewalls

E = 6” (150 mm)

E

F = 30” (760 mm)

G = 30” (760 mm)

H = 10” (250 mm) Max.

D

B

H

F

G

E

Corner

Ceiling

Mantel

6

Page 7

Installation

NOTE: If you will be installing the optional warming shelves, make sure to plan for the additional width

that they occupy. For the details, see the information included with the warming shelf kit.

The gas stove is shipped with a exible connector that has a 1/2” NPT female connection. The gas supply

piping should have a separate gas shutoff valve and a 1/8” NPT plugged tapping upstream of the valve.

The stove and its main control valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa). The stove must be isolated

from the gas supply piping system by closing the main control valve during any pressure testing of the

gas supply system at test pressures equal to or less than 1/2 psi (3.5 kPa). After the gas supply has been

connected, apply a soapy water solution to all the ttings to check for gas leaks. Never use a ame to test

for leaks.

REQUIREMENTS FOR THE COMMONWEALTH OF MASSACHUSETTS

This product must be installed by a licensed plumber or gas tter when installed within the Commonwealth

of Massachusetts. If this appliance is installed in a dwelling, building or structure used in whole or in part

for residential purposes and the installation includes a horizontal vent termination that is less than seven

(7) feet above the nished grade in the area of the venting, including but not limited to decks and porches,

a hard-wired carbon monoxide detector with an alarm and battery back-up must be installed on the oor

level of the dwelling, building or structure where the appliance is to be installed.

Additionally, a hard-wired or battery operated carbon monoxide detector with an alarm must be installed

on each additional level of the dwelling, building or structure served by the appliance. It shall be the

responsibility of the property owner to secure the services of qualied licensed professionals for the

installation of hard-wired carbon monoxide detectors.

In the event that the horizontally vented appliance is installed in a crawl space or attic, the hardwired

carbon monoxide detector with alarm and battery back-up may be installed on the next adjacent

oor level.

In the event that this requirement cannot be met at the time of completion of the installation of the

appliance, the owner shall have a period of thirty (30) days to comply with the requirement. However,

during said thirty (30) day period, a battery operated carbon monoxide detector with alarm must be installed.

Each carbon monoxide detector as required in accordance with the above provisions must comply with

NFPA 720 and be ANSI/UL 2034 and IAS certied.

In addition, when the stove is horizontally vented and the vent termination is less than seven (7) feet

above nished grade a metal or plastic identication plate must be permanently mounted to the exterior of

the building at a minimum height of eight (8) feet above grade directly in line with the exhaust vent terminal.

The sign shall read, in print size no less than one-half (1/2) inch in size, “GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS”.

A COPY OF THESE INSTRUCTIONS PLUS ALL VENTING INSTRUCTIONS WHICH INCLUDE

PARTS LISTS, AND/OR ALL VENTING DESIGN INSTRUCTIONS MUST REMAIN WITH THE STOVE AT

THE COMPLETION OF THE INSTALLATION.

ATTENTION INSTALLERS: Mark below which venting system was used in the installation. These

instructions must remain with the FireLuxe Installation & Operation Manual.

Simpson DuraVent GS AmeriVent Direct Security Secure Vent Selkirk DT Excel Direct

7

Page 8

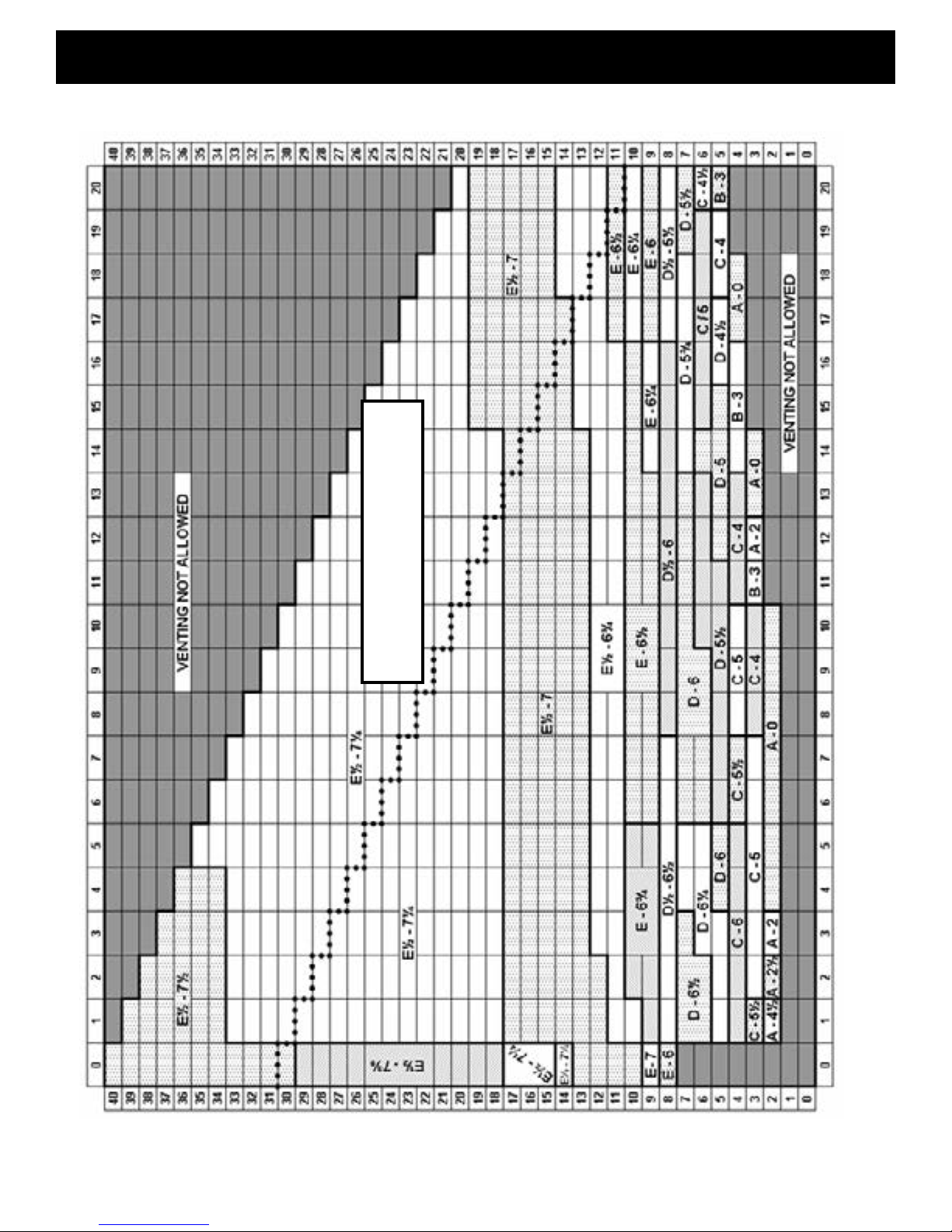

Venting

The FireLuxe Gas Stove has been tested and listed for installation with 4” X 6 5/8” Simpson DuraVent GS,

AmeriVent Direct, Security Secure Vent, ICC Excel Direct and Selkirk DT direct venting components. The total

vent length may not exceed 40 feet, including vertical rise and horizontal run. The vent lengths are measured

from the stove, not the oor. The minimum vertical rise required is 2 feet. The maximum allowed horizontal

vent run is 20 feet when the venting includes at least 5 feet of vertical rise. The maximum allowed horizontal

vent run for vertical rises of less than 5 feet is shown in the venting charts. No more than three elbows may

be used in any installation. The venting charts include the use of one elbow. For the second or third elbows

that are included in the installation, add 4 feet to the actual horizontal run for each elbow to determine the

equivalent horizontal run for the installation.

The venting charts allow a simple way to determine the recommended initial settings for both the air inlet

and exhaust restrictors. These settings have been determined by extensive testing and will be a good starting

point while setting up the stove. Small adjustments from these settings may be needed to account for specic

installation variables. Please see the instructions on pages 21 - 22 for how to adjust the restrictors.

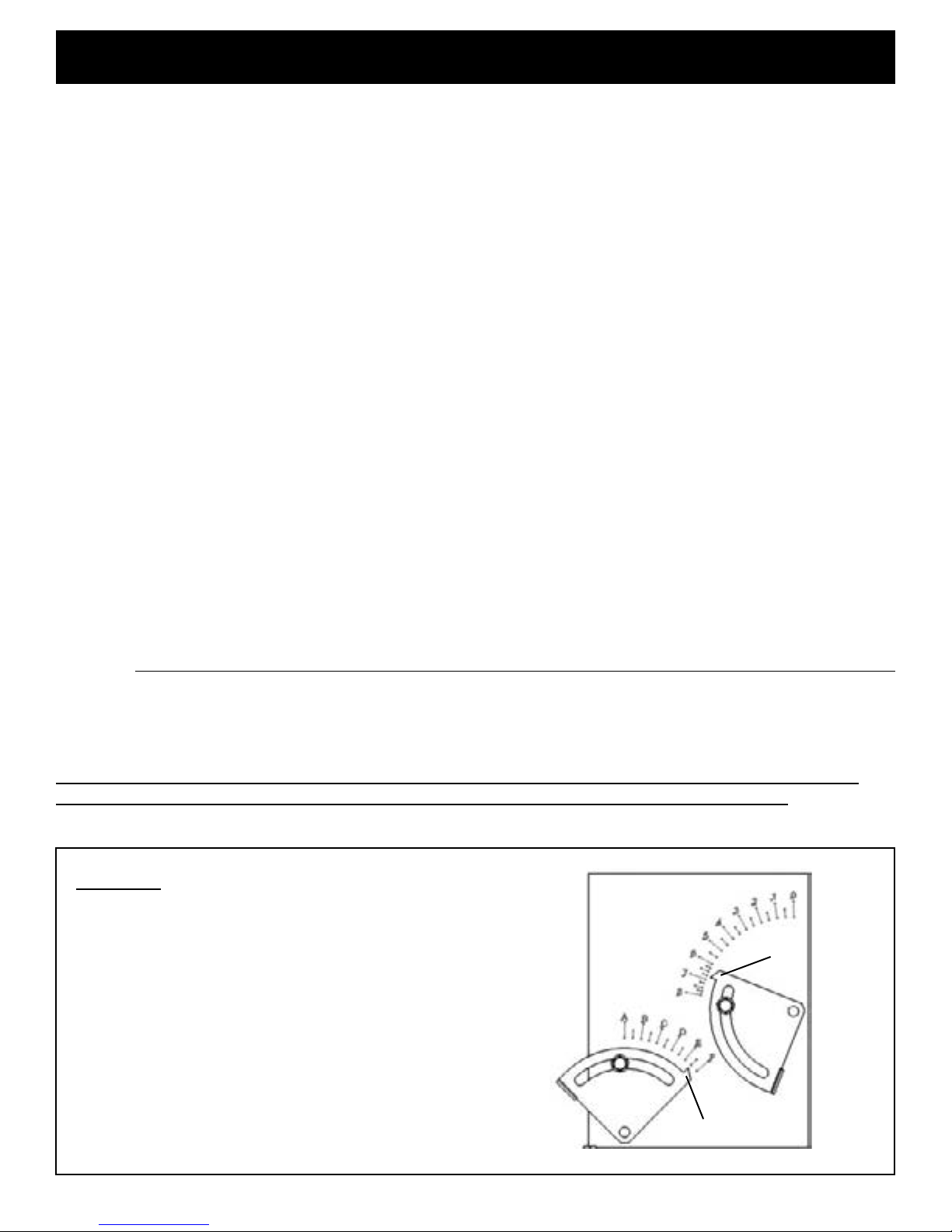

The letters (A-E) designate the position of the air inlet restrictor. When ½ is added to the letter designation, this

indicates that the position is halfway between adjacent letters. The numbers (0-8) indicate the position of the

exhaust restrictor. When ⅛, ¼, ⅜, ½, or ¾ is added to the number designation, this indicates that the position

is fractionally between adjacent numbers. For example, 5¼ is one-fourth the way between 5 and 6.

To use the charts, determine the horizontal run length and vertical rise length (in feet) for your installation.

If more than one elbow is used, add 4 feet to the actual horizontal run length for each additional elbow to

get the equivalent horizontal run for the chart. Note: Remember that a maximum of three elbows is allowed.

Select the venting chart for the fuel type (Natural Gas or Propane (LP) Gas) and nd the box on the chart that

corresponds to the vertical rise and actual horizontal run (or equivalent horizontal run, if two or three elbows

are used) and read the settings for the inlet air restrictor (A-E) and exhaust restrictor (0-8).

Examples are shown below and on page 9.

The FireLuxe is shipped with a Simpson DuraVent GS starter section that is specically designed for the

FireLuxe. Regardless of the venting brand you chose, you must use the provided DuraVent starter section.

All of the venting brands listed for use with the FireLuxe are compatible with the provided starter section. For

venting system installation details, refer to the instructions provided with the venting system you have chosen.

Each brand has specic installation requirements that must be followed to insure a safe and functional venting

system for your FireLuxe.

Note: The FireLuxe is shipped from the factory with restrictor settings for 2 feet of vertical rise and 1 foot

of horizontal run and for the fuel type listed on the rating plate attached to the rear of the stove.

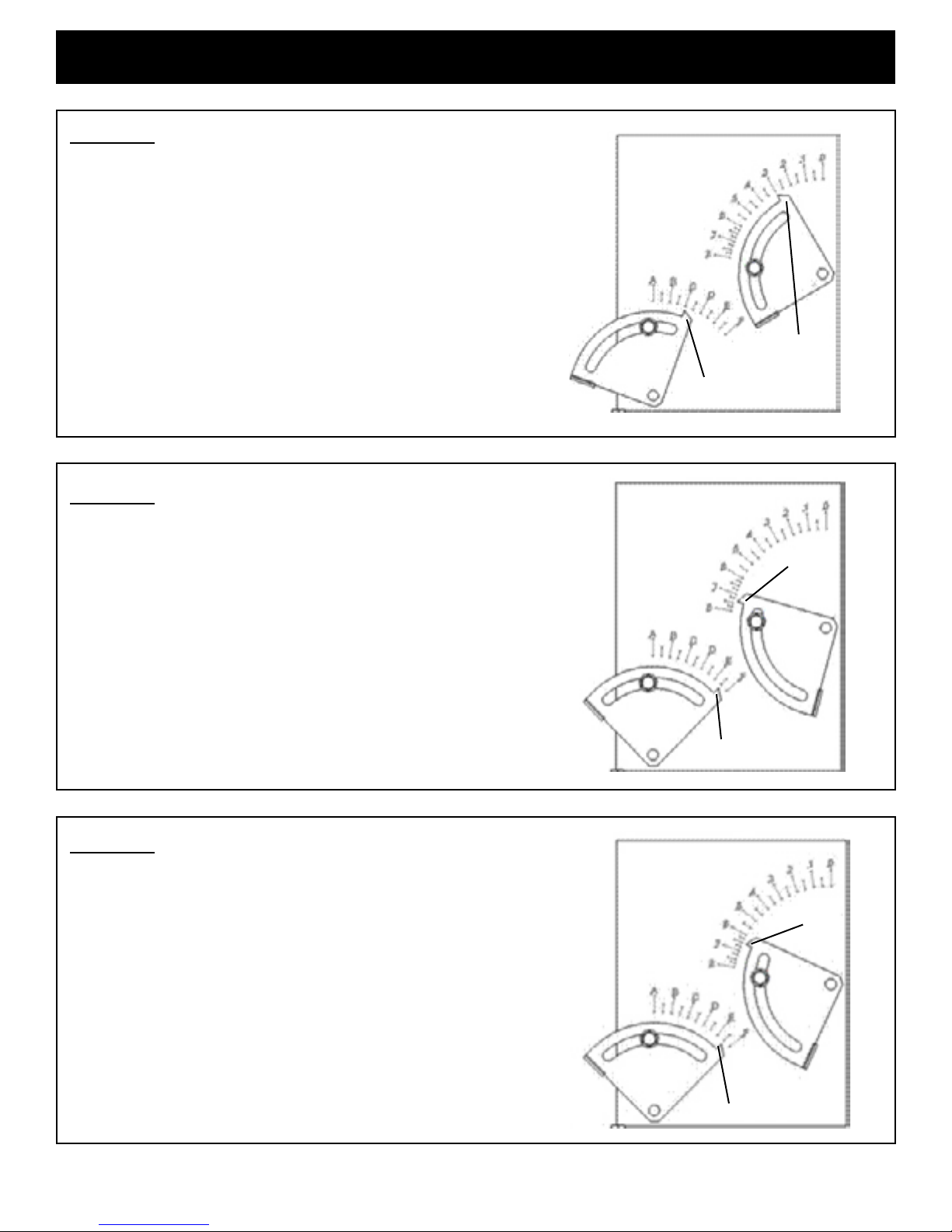

Example 1

Fuel = Propane (LP)

Vertical Rise = 15 feet

Exhaust

Horizontal Run = 8 feet

Elbows = 1 (one)

Equivalent Horizontal Run = 8 feet

6¾

Air Restrictor Setting = E½

Exhaust Restrictor Setting = 6¾

E½

Inlet Air

8

Page 9

Example 2

Fuel = Propane (LP)

Vertical Rise = 6 feet

Horizontal Run = 8 feet

Elbows = 3 (three)

Equivalent Horizontal Run = 16 feet (8+4+4)

Air Restrictor Setting = C

Exhaust Restrictor Setting = 3

Example 3

Venting

3

Exhaust

C

Inlet Air

Fuel = Natural Gas

Vertical Rise = 22 feet

Horizontal Run = 0 feet

Elbows = 0 (none)

Equivalent Horizontal Run = 0 feet

Air Restrictor Setting = E½

Exhaust Restrictor Setting = 7⅜

Example 4

Fuel = Propane (LP)

Vertical Rise = 12 feet

Horizontal Run = 4 feet

Elbows = 1 (one)

Equivalent Horizontal Run = 4 feet

Exhaust

7⅜

E½

Inlet Air

Exhaust

Air Restrictor Setting = E½

Exhaust Restrictor Setting = 6½

6½

E½

Inlet Air

9

Page 10

Venting

Natural Gas Venting

IF YOUR VENTING CONFIGURATION

FALLS ABOVE THIS DOTTED LINE,

SEE PAGE 12

Horizontal Run - In Feet

Vertical Rise - In Feet

10

Page 11

Venting

Propane (LP) Gas Venting

IF YOUR VENTING CONFIGURATION

FALLS ABOVE THIS DOTTED LINE,

SEE PAGE 12

Vertical Rise - In Feet

11

Horizontal Run - In Feet

Page 12

Venting

PLEASE NOTE: If your specic venting conguration falls in a box in the venting charts (on pages 10 &

11) that is above the dotted line (••••), you must use one of the approved direct vent venting systems

that utilizes a stainless steel inner liner. The dotted line corresponds to a total vent length of 30 feet including

vertical rise and horizontal run. This requirement is part of the ANSI standards and is based on testing

conducted to determine where the exhaust gas temperature drops to the point where condensation might

occur in the vent pipe. The standards require the use of corrosion resistant liner materials if that specic

total vent length is exceeded.

VENTING INTO AN EXISTING MASONRY OR CLASS A CHIMNEY

The FireLuxe has been tested and found to be in compliance when using an existing chimney as the air

conduit for the direct venting system. However, before proceeding, check with the local authority

having jurisdiction to see if this type of installation is allowed in your area.

This type of installation is used when replacing an existing wood-burning stove with a FireLuxe direct vent

gas stove. Check with the installer or venting manufacturer to see if they have the needed components

or kits for this type of installation. Also, check the vent manufacturer’s installation instructions for the

specic details and requirements for this type of installation. The chimney must be in good condition with

no cracks or leaks for this type of installation (including the cleanout door) and the venting components

must be completely sealed where they meet the existing chimney. The chimney must not be connected to

any other appliances. Note: If your chimney has been problematic when using your woodstove (low draft,

backdrafts, etc.) performance problems may also occur when the chimney is used with a gas appliance.

VENTING INTO AN EXISTING FIREPLACE

The FireLuxe may be vented through an existing replace chimney. The replace opening must be at least

28” high. All clearances to adjacent combustible materials, including the mantel, must be in conformance

with the clearances shown on Page 6 of this manual. A special adapter and components are required to

convert the co-axial rear vent starter to a co-linear conguration that will allow separate 3” diameter exible

metal ducts (one for the air and one for the exhaust) to pass through the damper opening in the replace

and to run to the top of the chimney. A second special adapter is required at the top of the chimney to rejoin

the exible ducts back to a co-axial conguration and allow the use of standard vertical vent caps.

This chimney top adapter must be sealed to the top of the chimney to prevent air leakage. Check with the

installer or venting manufacturer to see if they have the needed components or kits for this type of installation.

Also, check the vent manufacturer’s installation instructions for the specic details and requirements for

this type of installation Note: Some gas stove manufacturers allow the air duct to terminate a few feet

above the replace damper. This is not allowed for the FireLuxe. Both the air duct and the exhaust duct

must run the full length from the stove adapter to the chimney top adapter.

When venting through a replace, the air and exhaust restrictors should be set using the charts below. The

minimum vent rise allowed is 10

feet. The maximum vent rise is

35 feet. Use the settings on the

charts that are the closest to your

actual vent rise. For example, if

your vent rise is 17 feet, use the

settings for 15 feet. If the vent

rise is 18 feet, use the settings for

20 feet. Note: The vent rises are

measured from the centerline of

the rear vent starter.

NATURAL GAS PROPANE (LP) GAS

Vert. Rise Restrictor Settings

feet Air Exhaust

10 C 4 1/2

15 D-1/2 6

20 D-1/2 6 1/2

25 D-1/2 6 1/2

30 D 6

35 C 4 1/2

Vert. Rise Restrictor Settings

feet Air Exhaust

10 A 0

15 D 5 1/2

20 D 6 1/4

25 D 6 1/4

30 C 1/2 5 1/2

35 C 4 1/2

12

Page 13

= Vent Terminal

V

Venting

Vent Termination Clearances

Venting terminals shall not be recessed into a wall or siding.

13

Page 14

Assembly

UNPACKING AND PLACING THE FIRELUXE

By now, you will have removed the shipping carton from the base pallet. The FireLuxe is shipped on

specially designed shipping supports that keep the weight of the stove off the legs to avoid damaging them

during transit. Cut the strapping that secures the stove to the pallet. The stove must be lifted straight up to

disengage it from the shipping brackets. The best place to lift is at the base of the stove sides. The stove

top and front have to be removed in order to unpack and install the logs and top cooking burner parts.

Removing them now will reduce the weight and make it easier to lift the stove. Also, locate the ashlip and

ashlip mounting hardware and set aside in a safe location. It will be installed later.

First, remove the cast iron stove top. This is accomplished by simply lifting up on the top as it is a gravity

t. The top is heavy and extra care should be taken when handling it, especially if the stove is enameled.

Set the top aside on a padded surface. A carpeted oor is a good choice.

Remove the top cooking grill and the cooking burner cover plate and set aside for now. They are packed in

bubble wrap or foam packing and are located on the now exposed top of the stove’s rebox.

Remove the stove front by lifting it straight up to disengage the tabs that secure it to the sides. Once it is

disengaged, you can move the front away from the stove body. Note: The front doors may have a tendency

to swing open while you are handling the front. Placing a small piece of masking tape around the two doors

where they meet at the center will keep the doors from moving. Set the front aside with the back side down

taking extra care if it is enameled.

With these parts removed and set aside, lift the stove up and off the pallet and set it near to its installation

position. Like any cast iron stove, it is best to pick the stove up while adjusting its position rather than

dragging it on its legs. This reduces the chances of damaging a leg or chipping enamel or of damaging the

hearth surface. This is the best time to install the optional blower kit if being used. See the instructions

included with the blower kit.

The legs have leveling screws that will allow you to compensate for irregularities on the surface under the

stove. Using as little adjustment as possible for each leveling screw, adjust them as needed to get the stove

as level as possible both side to side and front to back. This is important since the FireLuxe includes a top

cooking burner and having the stove level will reduce the likelihood of spillage while cooking.

The FireLuxe is shipped set up for the fuel type indicated on the rating plate attached to the rear of the

stove. Note: If you need to switch fuels, please see the instructions included with the appropriate fuel

conversion kit. The logs are shipped in protective material inside the rebox and do need to be unpacked

and

installed on the burner.

With the stove top and front removed and safely set aside

during the unpacking process, unlatch each of the three

glass frame latches by pulling forward on the latch nger

tabs while lifting up. See the adjacent illustration. This

will allow the glass frame to tip slightly forward. The glass

is loose in the frame, held in place only by friction from

the gasket so it is very important to support both the glass

and the frame when handling. Place your thumbs on the

outside of the glass frame and wrap your ngers around

the frame and onto the glass. Squeeze the frame and glass

while moving. Carefully lift the glass frame and glass up

and off the stove. Set the glass and frame aside on a padded

surface. The outside of the frame should be facing

down so the glass will stay in place.

14

Page 15

Assembly

LOGS AND EMBERS

Slide the logs and packing out of the rebox and set on the oor. Carefully unpack each of the four logs

and three loose ember pieces. The logs and embers are somewhat fragile and will not survive being

dropped from any signicant height. Remove the protective cover material from the top of the burner.

Each of the four logs is unique and must be placed in a precise location on top of the burner. The burner

and log system is designed to facilitate correct placement of the logs. Flat recessed areas on the burner top

are keyed to each of the four main logs. The rear logs also have locating pins with corresponding sockets

in the logs. The following illustration highlights these features.

Place the left rear log rst. There is a recessed area in the burner top as well as a locating pin and a

corresponding socket in the log. Line-up the socket over the pin and place the log in the recess.

Place the right rear log next. There is a recessed area on the top of the burner that corresponds to the

shape of the base of the log. Simply place the log in the recess. The following illustration shows the proper

positions for the two rear logs.

15

Page 16

Assembly

Place the left front log next. Again, there is a recess on the burner top that corresponds to the shape of the

at base of the log. Place the left end of the log in the recess and rest the right end on the left rear log using

the illustration below as a guide. Place the right front log last. Again, place the at base of the log in the

corresponding recess in the burner top per the illustration below.

There are three loose ember pieces. Each ember piece has a specic location on the burner. Refer to the

illustration below to get the proper placement and orientation for each ember piece. If you look carefully,

you will see that each ember has features that will help you in placement relative to the burner surface and

the logs.

16

Page 17

Assembly

When correctly placed, the logs and embers will look like the illustration below.

After the logs and embers have been placed, the next

step is to replace the glass panel and frame. Carefully

pick up the glass and glass frame assembly by grasping

the sides of the frame and using your thumbs and

ngers to hold the glass in place within the gasket and

frame.

With the glass frame (and glass) at a slight angle

(leaving room for your ngers between the frame and

the rebox) insert the bottom edge of the frame into

the frame retainer located on the bottom front of the

rebox. Take care to center the frame from left to

right. Once the bottom edge is in place, move your

ngers out of the way and press the top of the frame

against the rebox while pushing down to be sure the

frame is fully engaged in the frame retainer. Hold the

frame in place with one hand and engage the three

glass frame latches by pulling out and down while

hooking them over the frame.

Top or Rear Vent

The FireLuxe has provisions for either top or rear venting but is shipped from the factory set-up for top

venting. The rear position is sealed with a special cover plate. If your installation requires rear-venting,

you will need to reverse the positions of the starter section and the cover plate.

Remove the four screws that secure the vent starter section ange to the stove and remove the starter.

There are two ceramic ber gaskets that seal the starter to the stove. These gaskets are very important!

Take care in handling these gaskets as they are somewhat fragile and will tear. Remove the vent cover plate

from the rear of the stove following the same procedure as the starter. Install the cover plate on the top vent

opening.

17

Page 18

Assembly

Be sure that the inner and outer gaskets are in

their proper positions. Install and tighten the

four screws. Finally, install the vent starter

section in the rear vent position. Again,

make sure that the inner and outer gaskets are

in their proper positions and install and

tighten the four screws.

At this time, you will also want to install the

optional cast iron plate that lls in the top vent

cutout on the stove top. With the bottom of

the top facing up, place the ller plate in the

cutout with the ller plate edge molding

aligned with the edge molding on the top. Using

the bracket and three fasteners included

with the ller plate kit, secure the ller plate

to the top. See the illustration included with

the optional ller plate kit for more information.

It is now time to install the ashlip on the stove front and to install the stove front and stove top.

The ashlip is secured to the front using two brackets and four 1/4 – 20 hex head bolts. With the front facing

down on a padded surface, align the mounting bosses on the ashlip with the mounting bosses on the front.

Install the two “L”-shaped brackets with the slotted end on the ashlip. Tighten the bolts to the front but leave

the bolts to the ashlip nger tight. Carefully turn the front over. Adjust the ashlip so that it is tight

against the lower

molding on the front.

Tighten the ashlip

bolts. Take care with

an enamel stove to

prevent chipping.

Replace the stove

front by aligning the

outer edges with the

stove sides while the front is about ½ to 1” above its nal position. This is to allow the sheet metal tabs that

secure it to the sides to be above the mating cast iron tabs on the sides. Carefully push the front in while

allowing it to slide down. All four tabs (two top and two bottom) should engage with the sides. Once the front

has reached the proper position, check the vertical alignment by looking at the alignment of the edges of

the front to the casting details on the side. They should be parallel. If they are not, simply push or pull on the

front until a good visual alignment is obtained. Take extra care with this procedure if your stove is enameled.

Just move in small increments as you line up the tabs and lower the front into place. If you take your time,

you will avoid chipping. Remove any

masking tape used to secure the doors.

Next, install the brass diffuser ring and top burner

cover on the cooking burner. This is a small round

disk that sits on top of the brass diffuser ring on the

top burner. If you look at the back side of the diffuser,

you will see alignment tabs. They correspond to

alignment locations on the burner. The cover is simply

centered in the diffuser.

18

Page 19

Assembly

Next, reinstall the top. This is a gravity t. Carefully align the inner edge of the top with the outer edges of

the sides and front. Lower the top down into place. Check to see if it is level and push down as needed to

get the proper alignment relative to the aesthetic details on the front and sides.

Finally, install the top cooking grate. This simply sits over the burner. A raised border on the stove top

denes the cooking grate position.

BATTERY INSTALLATION OR REPLACEMENT

The batteries used to power the burner control systems on the FireLuxe should last a full season or more

with normal use. Battery life for the main burner control system will be reduced if you are manually modulating

the ame up and down on a frequent basis.

There are three battery locations.

The electronic ignition module for the cooking burner is located behind an access panel located on the

right rear of the stove (when looking from the stove front). A single fastener secures the panel. Simply

remove fastener and the panel to access the single 9-volt battery. Unsnap the old battery from the module

and replace with a fresh one. Use a high quality long-life alkaline battery. Replace the access panel and

fastener. Refer to the illustrations below.

The remote control handset is powered by a 9-volt battery.

There is a low battery indicator on the handset display panel.

To replace the battery, remove the access cover from the

rear of

the handset and unsnap the old battery. Replace with a high

quality long-life alkaline battery and reinstall the cover.

19

Page 20

Assembly

The main heating valve battery pack is located at the center rear of the stove. A removable valve access

panel covers the valve components and simply lifts up and off the stove back. The batteries are located in

the control module next to the actual valve. The battery access cover lifts and slides off to expose the four

AA batteries. Note the orientation of each battery as you replace the old with new as this is critical to the

operation of the control. Use only high quality long-life alkaline batteries. Replace the battery cover and

the valve access panel. Refer to illustrations below.

NOTE: The control module is secured to the valve bracket with hook-and-eye strips and can be pulled

away from the bracket if necessary to gain better access to the battery cover and compartment. Be certain

not to dislodge the wiring from the control module and be sure to place the module back it its original position

after the batteries and cover are installed.

GAS CONNECTION

The FireLuxe is shipped from the factory with a exible gas connector that has a 1/2” NPT female connection.

The gas supply piping should have a separate gas shut-off valve and a 1/8” NPT plugged tapping upstream

of the valve. The FireLuxe and its inlet regulator. Main burner valve and cooking burner valve must

be disconnected from the gas supply piping system during any pressure testing of that system at test

pressures in excess of 1/2 psi (3.5kPa). The FireLuxe must be isolated from the gas supply piping system by

closing the main control valve during any pressure testing of the gas supply system at test pressures equal

to or less than 1/2 psi (3.5kPa). After the gas supply has been connected, apply a soapy water solution to

all the ttings to check for gas leaks. Never use a ame to test for leaks.

20

Page 21

Assembly

PRIMARY AIR ADJUSTER

Your FireLuxe gas stove was shipped from the factory

equipped for the fuel type indicated on the rating

plate that is attached to the rear of the stove and the

primary burner air adjuster was set at the factory at the

recommended position for that fuel. If you will be using

the alternate fuel please see the instructions included

with the optional fuel conversion kit. This includes

instructions for the proper setting for the primary air

adjuster.

The recommended setting for propane is the fully-open

position. This corresponds to the adjuster screw fully

backed out. The recommended setting for natural gas

is the fully-closed position. This corresponds to the

adjuster screw fully screwed in.

Making small adjustments to the primary air setting will

let you adjust the way the ames look for your particular

installation. See the reference to primary air adjustment

in the section below that discusses the air inlet and

exhaust outlet restrictors.

AIR INLET AND EXHAUST OUTLET RESTRICTORS

The FireLuxe is equipped with externally adjustable restrictors for both the inlet air and the exhaust outlet.

This makes it possible to ne tune the direct vent system for the specic conditions of your installation.

The recommended settings are keyed to the specic details of your venting conguration.

To access the restrictor adjustment guide plates, you must rst remove the access plate. Looking at the

stove from the front, this plate is located on the upper left rear of the stove. If you have the optional blower,

the access plate also contains the blower speed control. Remove the single fastener that secures the

access plate. Set the plate aside (or if the blower is installed, let the plate hang on the wiring). Next remove

the heat shield. This is held in place with a single fastener located at the lower front corner of the shield. With

the fastener removed, tilt the heat shield as needed and remove. Refer to the illustrations below.

21

Page 22

Assembly

You will now see the two guide plates. The guide plates have a

pointer that corresponds to a letter scale for the air adjustment and

number scale for the exhaust adjustment. These are the letters and

numbers that are referenced in the venting charts on pages 10 and

11 and shown in detail in the examples shown on pages 8 and 9. To

change the setting, loosen the guide plate locking screws. Next

rotate each guide plate to the recommended setting for your

installation shown in the appropriate venting chart for natural gas

or for propane (LP) gas. Once the settings are correct, tighten the

locking

screws.

It is a good idea to test re the stove before you replace the heat

shield and access cover. Follow the lighting and operation

instructions starting on page 23. Allow the stove to burn for at least

20-30 minutes at high re while observing the ame. Although the

ames will become more luminescent as the stove heats up, the

tips of the ames should not be dark or sooty or extending so high

as to touch the bafe. If they are, some additional adjustment is

needed. First, check the position of the primary burner air adjuster.

For propane, the primary air adjuster should be in the fully-open

position. If it is not, loosen the adjuster screw locknut back out the adjuster screw. If no difference in the

ame appearance is noted, a small adjustment of the exhaust restrictor should be tried next. This can be

done with the stove operating but care must be taken not to touch hot surfaces while making the adjustment.

Loosen the exhaust guide plate locking screw and move the setting down by ¼ increment. For example,

move from a setting of 6 ½ to a setting of 6 ¼ . Tighten the locking screw and observe the ames. Repeat the

process until ame tips shorten and become lighter in color. No more than one full increment of adjustment

should be used. If no change in the ame appearance is noted after that, consult with a Harman Stove

Company representative.

If, after 20-30 minutes at high re, the ames are short or blue, the re is probably getting too much air.

You should rst reduce the primary burner air by loosening the adjuster screw locknut and turning the

adjuster screw in one turn. See the illustration on page 21 for the location of the primary air adjuster screw.

Wait a few minutes and observe the ames again. Make another one turn adjustment. If the ame appearance

has not changed after two turns of the adjuster screw, it is likely that there is another cause for the

short or blue ames. Note: Do not turn the primary air adjustment screw in more than two turns. The

ames should not have dark or sooty tips and should not be extending so high as to touch the bafe. If

adjusting the primary burner air doesn’t improve the ame appearance, a small adjustment of the inlet air

restrictor can be made. This can be done with the stove operating but care must be taken not to touch hot

surfaces while making the adjustment. Loosen the inlet air restrictor guide plate locking screw and move the

setting up by ¼ increment. For example, move from a setting of E to a setting of E ¼. Tighten the locking

screw and observe the ames. Repeat the process until ame tips begin to extend and become more yellow

in color. Note: DO NOT OVER-ADJUST THE INLET AIR RESTRICTOR. The ames should not have dark

or sooty tips and should not be extending so high as to touch the bafe.

Once all adjustments are made, make sure the inlet air and exhaust restrictor guide plate locking screws are

tight and replace the heat shield, heat shield fastener and the access plate and fastener. If an adjustment

was made to the primary burner air, tighten the locknut on the adjustment screw to lock in the new setting.

22

Page 23

Lighting & Operation

FOR YOUR SAFETY - READ BEFORE LIGHTING

WARNING: If you do not follow these instructions exactly, a re or explosion may

result causing property damage, personal injury or loss of life.

THIS APPLIANCE HAS TWO SEPARATE BURNER AND GAS CONTROL SYSTEMS. ONE SYSTEM

IS FOR THE MAIN HEATING BURNER AND THE SECOND IS FOR THE TOP COOKING BURNER.

A. BEFORE OPERATING EITHER BURNER SYSTEM, smell around the appliance area for gas. Be

sure to smell next to the oor because some gas is heavier than air and will settle on the oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light the appliance.

• Do not touch any electric switch; do not use any telephone in your building.

• Immediately call your gas supplier from a neighbor’s telephone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re department.

B. Use only your hand to operate the gas controls. Never use tools. If a knob will not push in or turn by

hand, don’t try to repair it, call a qualied service technician. Force or attempted repair may result in a

re or explosion.

C. Do not use this appliance if any part has been under water. Immediately call a qualied service technician

to inspect the appliance and to replace any part of the control system which has been under water.

LIGHTING INSTRUCTIONS - Main Burner

AUTOMATIC IGNITION

1. STOP! Read the safety information above.

2. This appliance is equipped with an igntion device that automatically lights the pilot. When using the

remote handset, do not try to manually light the pilot.

3. Push the OFF button on the remote handset to insure the appliance is off.

4. Wait ve (5) minutes to clear out any gas. Then, smell for gas, including near the oor. If you smell gas,

STOP! Follow A. in the safety information above. If you do not smell gas, proceed to step 5.

5. Turn the MAN knob to the ON, full counterclockwise position. Refer to Fig.1 on page 24.

6. Simultaneously press and hold the (star) and ▲(up arrow) on the remote control unit (see Fig.2)

until a short acoustic signal conrms the start sequence has begun; release the buttons. Continuing signals conrm the ignition sequence is in progress. Once pilot ignition is conrmed, there is gas ow to the

burner.

WARNING: When pilot ignition is conrmed, the valve motor turns automatically to maximum Flame

height.

Note: If the pilot does not stay lit after several tries, turn the main valve knob to OFF, full clockwise

position. Proceed to step 8.

7. Set the thermostat to the desired setting or use the remote control to adjust ame. In standby mode:

press ▲(up arrow) to increase the ame height, press ▼(down arrow) to decrease ame height or to set

appliance at pilot ame. See page 26 for remote handset programming instructions.

8. If the appliance will not operate, follow instructions “TO TURN OFF GAS TO MAIN BURNER” on the

next page and call your service technician or gas supplier.

23

Page 24

Lighting & Operation

MANUAL IGNITION

1. STOP! Read the safety information on the top of page 23.

2. Locate the valve on the back of the stove. Turn the main valve knob to the OFF, full clockwise

position.

3. Wait ve (5) minutes to clear out any gas. Then smell for gas including near the oor. If you smell

gas, STOP! Follow A in the safety information on page 23. If you don’t smell gas, proceed to Step 4.

4. Visually locate the pilot at the center rear of the rebox. Refer to Fig. 3 below.

5. With the MAN-knob in MAN position, a manual pilot valve operator is accessible (Refer to Fig. 1).

• Fully push down the manual pilot valve operator using a small screwdriver or pen tip and hold in

to start pilot gas ow. Immediately light the pilot by rapidly depressing the piezo igniter button

on the valve (See Fig. 1). Once the pilot ame is observed, continue to hold in the manual pilot

valve operator for about one (1) minute. Release the manual pilot valve operator. If the pilot

does not stay lit, repeat steps 2 through 5.

• Note: If the pilot does not stay lit after several tries, turn the main valve knob to OFF and proceed

to step 7.

6. Turn the MAN-knob to the ON, full counterclockwise position.

7. If the appliance will not operate, follow the instructions “TO TURN OFF GAS TO MAIN BURNER”

and call your service technician or gas supplier.

TO TURN OFF GAS TO MAIN BURNER

1. Press the OFF button on the remote (if available).

2. Turn the main valve knob to the OFF full clockwise position.

LIGHTING INSTRUCTIONS - COOKING BURNER

1. Stop! Read the safety information shown on the top of page 23.

2. Locate the cooking burner gas control knob at the top right rear of the appliance. Refer to Fig. 4 below

for more information.

3. With the valve in the OFF position, push down on the knob and turn counterclockwise to the H

(High) position. The cooking burner has a built-in electronic ignition system and the burner will ignite

automatically. If the burner does not light within ve (5) seconds, turn the knob to the OFF, full clockwise

position and call your service technician or gas supplier.

4. Adjust the burner for the desired cooking heat level.

TO TURN OFF GAS TO COOKING BURNER

1. To turn the cooking burner off, turn the knob to the OFF, full clockwise position.

24

Page 25

Lighting & Operation

COOKING BURNER OPERATION

The cooking burner on your FireLuxe functions like a cooking burner on any conventional kitchen range.

A battery-powered ame-sensing automatic ignition system lights the burner when you depress the control

knob and rotate counterclockwise to the High (H) position. You will hear a clicking sound and can observe

the spark arcing from the igniter electrode to the burner body. Once the burner is lit, the ame sensor will

shut off the spark. If, for any reason, the sensor does not detect a ame, the igniter will automatically resume

sparking until the ame is detected again. (will occur when open burning, with no cook pot or pan.)

The ames should be blue and evenly distributed around the perimeter of the burner. See the illustration

below.

Adjust the ame for the desired heat level by rotating the knob. To turn the burner off, rotate the knob

clockwise to the OFF position. (See g. 4 on page 24.)

Refer to the lighting instructions on page 24 and the lighting and operating instructions on the permanent

metal label attached by cable to the rear of the stove.

WARNING: THE COOKING BURNER IS FOR ATTENDED USE ONLY. DO NOT LEAVE “ON”

UNATTENDED FOR ANY REASON.

WARNING: CHILDREN AND ADULTS SHOULD BE ALERTED TO THE HAZARDS OF HIGH SURFACE

TEMPERATURES AND SHOULD STAY AWAY TO AVOID BURNS OR CLOTHING IGNITION. YOUNG

CHILDREN SHOULD BE CAREFULLY SUPERVISED WHEN THEY ARE IN THE SAME ROOM AS

THE APPLIANCE. CLOTHING OR OTHER FLAMMABLE MATERIAL SHOULD NOT BE PLACED ON

OR NEAR THE APPLIANCE.

WARNING: BASED ON SAFETY CONSIDERATIONS, THE COOKING BURNER FLAME SHOULD BE

ADJUSTED SO IT DOES NOT EXTEND BEYOND THE EDGE OF THE COOKING UTENSIL.

WARNING: BASED ON SAFETY CONSIDERATIONS, DO NOT USE THE COOKING BURNER FOR

SPACE HEATING UNDER ANY CIRCUMSTANCES.

PILOT AND MAIN BURNER OPERATION

Follow the lighting instructions on pages 23 – 24. When the pilot is lit and operating properly, it should

look like the illustration above. One ame will be directed at the pilot thermocouple and the other will be

emanating toward the burner. If the pilot ames do not resemble the illustration above, see the instructions

on page 26 for pilot ame adjustment.

After the main burner ignites and has been in operation for a few minutes, the ames should look like the

illustration on the top of page 26. Flame height will vary depending on the ring rate but ames should be

burning in all of the indicated areas.

25

Page 26

Lighting & Operation

Main Valve Knob

Pilot Gas

adjustment

screw. (turn with

screwdriver)

MAN- knob

REMOTE CONTROL HANDSET

OPERATION AND PROGRAMMING

Setting °C/24 hour or °F/12 hour clock

(Display and timer / Thermostat handsets)

1. Press OFF and ▼ (down arrow) until display

changes from farenheit / 12 hour clock to

Celsius / 24 hour clock and vice-versa.

Setting the Time

(Display and Timer / Thermostat handsets)

1. The display will ash after either:

a. Installing the battery or

b. Simultaneously pressing the ▲ (up arrow)

and ▼ (down arrow).

2. Press ▲ (up arrow) to set the hour, and the ▼

(down arrow) to set the minutes.

3. Press OFF to return to manual mode or simply

wait and it will automatically return to manual

mode.

PILOT FLAME ADJUSTMENT

The pilot ow is factory set to maximum. The pilot

ame should envelope 3/8” to 1/2” of the

thermocouple. See the illustration above.

The adjustment screw can be reached through the

MAN-knob. See top illustration above.

1. Turn the Man-knob to the ON position.

2. It is now possible to pierce through a lm on the

cover with a screwdriver to reach the adjustment

screw beneath.

3. Turn the adjustment screw clockwise to decrease

or counterclockwise to increase the pilot ame.

Automatic Pilot Mode With Thermostat Remote

If there is no transmission from the handset to the

receiver within a 6 hour period, the appliance will go

to standby (pilot) mode.

Flame Height Adjustment

In “MAN” mode: Press ▲ (up arrow) to increase the

ame height. Press ▼ (down arrow) to decrease the

ame height or set the appliance at pilot ame. For

ne adjustments, tap the up/down arrows.

26

Page 27

Lighting & Operation

TEMP MODE - Daytime Temperature Mode

(appliance must be in standby mode; pilot ignited):

The room temperature is measured and compared

to the set temperature. The ame height is

automatically adjusted to achieve the daytime set

temperature setting.

TEMP MODE - Night time setback temperature

mode (appliance must be in standby mode; pilot

ignited) The room temperature is measured and

compared to the setback temperature. The ame

height is automatically adjusted to achieve the night

time setback temperature setting.

TIMER MODE - (appliance must be in the

standby mode; pilot ignited) The timer setting allows

you to set two (2) burner ON times and two (2)

burner OFF times for every 24 hours.

NOTE: The display shows the set temperature

every 30 seconds.

Changing the Mode of Operation

Briey pressing the SET button changes the mode

of operation in the following order:

and back to

Setting The Timer

1. Select timer mode by briey pressing the SET

button.

2. Press and hold SET until “TIMER” is displayed on

the lower right hand side.

3. Press and hold SET until the P1 ☼ (sun symbol)

and the time display ashes. Set the hour by

pressing the ▲ (up arrow) and set the minutes by

pressing the ▼ (down)

4. Briey press SET for the next burner cycle time.

EXAMPLE: P1 (moon symbol) continue through

P2 ☼(sun symbol) and P2 (moonsymbol).

5. Once all four (4) times are set, press OFF or

simply wait to complete programming.

NOTE: “MAN” mode can also be reached by

pressing either the ▲(up arrow) or the ▼(down

arrow)

“MAN” Mode- Manual Flame Height Adjustment

1. Press ▲(up arrow) to turn on the main burner.

2. Press ▲(up arrow) to increase the ameheight.

3. Press ▼(down arrow) to decrease the ame

height or to go to pilot standby.

NOTE: While pressing either button, a symbol

indicating transmission appears on the display. The

receiver conrms transmission with an acoustic

signal (or beep).

Setting The Temperature

1. Select either the mode or the mode

by briey pressing the SET button.

2. Hold the SET button until the TEMP display

ashes.

3. Set the desired temperature with▲or▼up or

down arrow button(s).

NOTE: 4.5°C / 40°F is the min. temperature setting.

4. Press OFF or simply wait, and the display will go

to the temperature control mode.

NOTE: To turn off the night setback temperature

control, decrease the night time temperature until

[---] appears on the display.

Radio Frequency Inteference

A frequency code is preset for the valve receiver

and remote handset, but can be changed if you

are experiencing interference from other devices.

To change the code:

1. Change DIP switch position.

RESET

Receiver Reset Button

Dip Switch in Remote Handset

Battery Compartment

2. Press and hold the receiver’s reset button until

you hear two (2) acoustic signals. After the second,

longer, signal, release the reset button and within

the next twenty(20) seconds, press the▼(down

arrow) on the remote handset til you hear and

additional long signal that conrms the new code

is set. ( above )

27

Page 28

Maintenance

A qualied service agency should conduct an annual inspection and maintenance of your FireLuxe including

the overall installation and venting to keep it running safely. The following procedures should be performed only

by a qualied service person. The gas supply should be turned off and the stove should be completely cool

whenever a maintenance procedure is performed. All parts of the appliance that are removed for servicing must

be replaced prior to operation.

WARNING: Do not operate the appliance with the glass front removed, cracked or broken Replacement

of the glass should be done by a qualied service person.

WARNING: Use only replacement glass, part number 3-40-21001500 and glass gasket, part number

3-44-00539. Do not use substitute materials. Do not strike or slam the glass front

REPLACING THE GLASS

The glass mounting system consists of the glass panel, special glass gasket and the metal glass frame.

Should the glass need to be replaced, you must use the glass replacement parts that can be obtained from

your authorized Harman dealer. When replacing the glass, you must use a new glass gasket. Use the following

procedure and refer to the illustrations on pages 14 and 17 of this manual.

1. Turn the stove completely off and allow it to cool completely.

2. Remove the Stove Top and Stove Front. See instructions on page 14.

3. If the glass is broken, be sure to wear gloves and eye protection.

4. Unlatch the three glass frame latches by pulling forward on the latch nger tabs while lifting up. This will allow

the glass frame to tip slightly forward. The glass is loose in the frame, held in place only by friction from the gasket

so it is very important to support both the glass and the frame when handling. Place your thumbs on the outside

of the glass frame and wrap your ngers around the frame and onto the glass. Squeeze the frame and glass

while moving. Carefully lift the glass frame and glass up and off the stove. Set the glass and frame aside on a

padded surface. If the glass is broken, do this over spread out newspaper to catch all loose material. The outside

of the frame should be facing down to give access.

5. Carefully remove the old glass and gasket material. If the glass is broken, wear gloves and eye protection.

6. Be sure to remove any broken glass from the burner and logs.

7. Install the new glass gasket onto the glass panel following the instructions included with glass panel.

8. With the thin section of the glass gasket facing the inside of the glass frame, carefully press the new glass

panel/gasket assembly into the glass frame by rst inserting the top edge under the two gasket retainers and

then pressing the sides and bottom edge into the frame.

9. Carefully pick up the glass and glass frame assembly by grasping the sides of the frame and using your

thumbs and ngers to hold the glass in place within the gasket and frame.

10. With the glass frame (and glass) at a slight angle (leaving room for your ngers between the frame and the

rebox) insert the bottom edge of the frame into the frame retainer located on the bottom front of the rebox.

Take care to center the frame from left to right. Once the bottom edge is in place, move your ngers out of the

way and press the top of the frame against the rebox while pushing down to be sure the frame is fully engaged

in the frame retainer. Hold the frame in place with one hand and engage the three glass frame latches by pulling

out and down while hooking them over the frame.

11. Replace the Stove Front and Stove Top. See instructions on page 18.

WARNING: Never clean the glass while it is hot. Do not use abrasive cleaners or cleaners containing

ammonia.

NOTE: A micro-ber cleaning cloth and plain water is recommended by the glass manufacturer.

When the batteries need replacement, the remote handset shows a low battery indicator “BATT”. The Ignition

and Control Module will give three short beeps when the valve motor operates. The cooking burner Ignition

Module will stop sparking. See the instructions on pages 19 - 20 for details on changing batteries.

CLEANING THE GLASS

BATTERY REPLACEMENT

28

Page 29

Maintenance

INSPECTING THE VENTING

An inspection of both the inner and outer vent pipes and the vent terminal should be made as part of the annual

service appointment. The venting must have no blockage and be in good repair. The vent manufacturer’s

instructions may provide specic details on vent inspection. Any vent sections that are disassembled

must be reassembled and sealed as required.

This appliance should be inspected before use and at least annually by a qualied service person.

More frequent cleaning may be required due to excessive dust or lint from carpeting, bedding materials,

pets, etc. It is imperative that control compartments and circulating air passageways of this

appliance be kept clean.

CLEANING THE LOGS, BURNER AND FIREBOX

During the annual inspection and maintenance appointment, the service person should clean the logs, embers,

burner and rebox. To gain access to the rebox, logs and burner, follow the instructions on page 14 of this

manual.

An extra-soft brush should be used to gently clean the logs, embers and burner as they are extremely fragile.

DO NOT USE A VACUUM CLEANER TO CLEAN THE LOGS, EMBERS OR BURNER.

A vacuum cleaner may be used to clean the metal parts of the rebox. Replace the logs and embers after

cleaning. Follow the instructions on pages 15 –17 of this manual to insure proper placement of the logs and

embers on the burner.

AIR FLOW

The FireLuxe utilizes a convection air heat exchange system to maximize heat delivered from the stove. It is

important that air ows freely through the convection air system and out the front and side air grills. Do not

place objects under the stove that will block the convection air inlet ow or in front of any air grill. If the optional

convection air blower is installed, check the blower during the annual service appointment for any build-up of

dust, lint or pet hair.

COOKING BURNER SYSTEM

As with any conventional range top, the FireLuxe cooking burner will require routine cleaning. The porcelain

enameled drip pan should contain most normal cooking spills. To clean, simply remove the cooking grate and

wipe the drip pan with a moist sponge or paper towel. Be sure that the stove is cool before cleaning. The

cooking grate also has a porcelain enamel nish for easy cleaning. We recommend handwashing, rather than

the dishwasher. Spills on the top of the stove should be wiped up immediately to prevent them from baking on.

OPTIONAL CONVECTION AIR BLOWER SYSTEM (Part No. 1-00-05895)

(For additional information, please see instructions included with the blower kit.)

CAUTION: Label all wires prior to disconnection

when servicing. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

WARNING: Electrical Grounding Instructions. This

appliance is equipped with a three-prong (grounding)

plug for your protection against shock hazard and should

be plugged directly into a properly grounded three-prong

receptacle. Do not cut the grounding prong from this

plug.

Check the blower for any build-up of dust, lint, or pet hair

during the annual service appointment.

29

Page 30

HARMAN GOLD WARRANTY

6 YEAR TRANSFERABLE LIMITED

WARRANTY (Residential)

1 YEAR LIMITED WARRANTY (Commercial)

Harman Stove Company warrants its products to be free from defects in material or workmanship, in normal use and

service, for a period of 6 years from the date of sales invoice and for mechanical and electrical failures, in normal use and

service, for a period of 3 years from the date of sales invoice.

If defective in material or workmanship, during the warranty period, Harman Stove Company will, at its option, repair or

replace the product as described below.

The warranty above constitutes the entire warranty with respect to Harman Stove Company products. HARMAN STOVE

COMPANY MAKES NO OTHER WARRANTY, EXPRESSED OR IMPLIED, INCLUDING “ANY” WARRANTY

OF MERCHANTABILITY, OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. No employee, agent,

dealer, or other person is authorized to give any warranty on behalf of Harman Stove Company. This warranty does not

apply if the product has been altered in any way after leaving the factory. Harman Stove Company and its agents assume

no liability for “resultant damages of any kind” arising from the use of its products. In addition, the manufacturer and its

warranty administrator shall be held free and harmless from liability from damage to property related to the operation, proper

or improper, of the equipment.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.

THESE WARRANTIES APPLY only if the device is installed and operated as recommended in the user’s manual.

THESE WARRANTIES WILL NOT APPLY if abuse, accident, improper installation, negligence, or use beyond rated

capacity causes damage.

HOW TO MAKE A CLAIM - Any claim under this warranty should be made to the dealer from whom this appliance

was purchased. Then contact is made with manufacturer, giving the model and serial numbers, the date of purchase, your

dealer’s name and address, plus a simple explanation of the nature of the defect. Extra costs such as mileage and overtime

are not covered. Nuisance calls are not covered by these warranties.

THIS WARRANTY IS LIMITED TO DEFECTIVE PARTS - REPAIR AND/OR REPLACEMENT AT

HARMAN STOVE COMPANY’S OPTION AND EXCLUDES ANY INCIDENTAL AND CONSEQUENTIAL

DAMAGES CONNECTED THEREWITH.

WARRANTY EXCLUSIONS: Failure due, but not limited to, re, lightning, acts of God, power failures and/or surges,

rust, corrosion and venting problems are not covered. Damage and/or repairs including but not limited to; remote controls,

lters, fuses, knobs, glass, ceramic brick panels, ceramic ber afterburners, combustion packages, door packing, tile, ceramic

log sets, paint, batteries or battery backups and related duct work are not covered. Also excluded from this warranty are

consumable or normal wear items including but not limited to; ame guides, grates, coal bars, afterburner hoods, re brick,

gaskets. Additional exclusions for corn stoves are burn pot housing weldment, burn pot grate weldment (pellet or corn),

burnpot front plate (pellet or corn), burnpot front plate lock, grain caps, corn auger extension, ceramic insert, and ceramic

insert plate. Additional or unusual utility bills incurred due to any malfunction or defect in equipment and the labor cost of

gaining access to or removal of a unit that requires special tools or equipment are not covered. Maintenance needed to keep

the stove in “good operating condition” is not covered. This includes, but is not limited to, cleaning, adjustment of customer

controls and customer education. Labor, materials, expenses and/or equipment needed to comply with law and/or regulations

set forth by any governmental agencies are not covered.

This Warranty provides specic legal rights and the consumer may have other rights that vary from state to state.

In the event of change in ownership, the remaining portion of this warranty may be transferred to the new owner by sending

the new owner information and a transfer fee of $25.00 US to the Harman Stove Company.

PLEASE READ THE LITERATURE BY THE MANUFACTURER FOR THE VARIOUS ACCESSORY DEVICES.

THE MANUFACTURER WARRANTS THESE ACCESSORY DEVICES, NOT HARMAN STOVE COMPANY

OR THEIR WARRANTY ADMINISTRATOR. FURTHERMORE, THESE ACCESSORY DEVICES MUST BE

INSTALLED AND USED ACCORDING TO THE RECOMMENDATIONS OF THE MANUFACTURER.

REMEDIES - The remedies set forth herein are exclusive and the liability of seller with respect to any contract or sale or

anything done in connection therewith, whether in Contract, in tort, under any warranty, or otherwise, shall not, except as

herein expressly provided, exceed the price of the equipment or part of which such liability is based.

CLARIFY - The above represents the complete warranty, which is given in connection with stoves, manufactured by Harman

Stove Company. No other commitments, verbal or otherwise, shall apply except by a written addendum to this warranty.

Page 31

For replacement parts and customer service, contact your

Harman Stove Dealer.

Manufactured by:

352 MOUNTAIN HOUSE ROAD

HALIFAX, PA 17032

R5 ver. 06/23/12

Loading...

Loading...