Page 1

PWRS-E.Compact

Please read these instructions carefully before operating equipment.

PowerSeat

PWRS-E

Instruction Manual

English Translation

Rev. 00 FT

UPS_30/01-2014

Page 2

Page 3

01-30-14 ENGLISH 3

Page 4

4 ENGLISH 01-30-14

Page 5

Index

Introduction

About this Manual

Glossary and Symbols

General Information

Identification Data and Plates on the Device

Model of Declaration of Compliance

Standard References

FCC Verification

IC Certification

Technical Support Information

Safety Precaution

General Advice

Intended Use

Improper Use

Safety Devices

Personal Protective Equipment (PPE)

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

7

7

8

9

9

10

11

12

12

12

13

13

13

14

14

14

Residual Risks

Safety Informations

Power Supply Informations

Power Supply Description

General

Dimensions

Technical Data

Light Interface

Safety Informations

Using the Power Supply

Cleaning the Power Supply

PowerSeat PWRS-E

Device Description

General

Dimensions

Safe Working Load

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

14

15

16

16

16

17

17

18

18

19

19

20

20

20

21

22

Rope Requirements

Vibration

Noise Emission

Technical Data

Motor

Using the Device

01-30-14 ENGLISH 5

page

page

page

page

page

page

22

22

22

22

23

23

Page 6

Index

Checking the Device Before Use

Adjusting the Accelerator Control Position

Adjusting the Control Lever Position

Primary Rope Installation Procedure

Wiring the Power Supply System

Preparing to Ascent

Ascent Procedure 1

Ascent Procedure 2

Using PowerSeat with a fixed Anchorage

Descent Procedure 1

Descent Procedure 2

Fixed Anchorage Descent Procedure

Transport and Storage

PowerSeat PWRS-E.Compact

Description of Compact version

General

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

23

25

26

27

29

30

32

34

35

37

38

38

38

39

39

39

Dimension

Using the Compact version Device

Checking the Compact version Device Before Use

Primaru Rope Installation Procedure on Compact version

Preparing to Ascent with the Compact version

Ascent Porcedure with the Compact version

Using Compact version PowerSeat with a Fixed Anchorage

Descent Procedure with the Compact version

Fixed Anchorage Descent Procedure with the Compact version

Converting the PowerSeat PWRS-G inthe Compact version

Maintenance

Cleaning

Maintenance

Dismalting and Disposal

Diagnosis and Fault Finding

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

40

41

41

41

43

43

44

46

46

46

48

48

48

48

49

PowerSeat and Motor

Power Supply

Maintenance Schedule

Worldwide Limitied Warranty

6 ENGLISH 01-30-14

page

page

page

page

49

49

50

54

Page 7

Introduction

ABOUT THIS MANUAL

This User Manual is an integral part of the device and aims to provide all the information needed for its safe

and correct use and for proper maintenance.

If there are instructions you do not understand, contact Harken.

Keep the manual in a safe place for future consultation. This manual may be modified without notice. Updated

versions are available on www.power-seat.com.

This manual is for qualified operators (refer to the Safety Information chapter for more information). Improper

use of the device or incorrect maintenance could cause severe damage or death.

Harken accepts no responsibility for damage, personal injury or death caused by failure to observe the safety

information and instructions in this Manual. The device must be used exclusively by qualified operators in

possession of a certificate for temporary work at height with the use of access and positioning systems using

ropes according to the current regulations of the Nation in which the device is used. This manual thus supplies

information exclusively regarding the correct use of the device and does not substitute the training and

certification needed for temporary work at height with the use of access and positioning systems using ropes.

01-30-14 ENGLISH 7

Page 8

Introduction

GLOSSARY AND SYMBOLS

Intended Use – use of the device according to the information supplied in the instructions for use.

Improper Use – use of the device in a way different from that indicated in the instructions for use.

Qualified Operator – persons who have attended specialisation, training etc courses and are certified for

temporary work at height with the use of access and positioning systems using ropes according to the

current regulations of the Nation in which the device is used.

User – qualified operator of the device

Anchorage – point of attachment of the rope or device to a fixed point.

Primary (working) rope – main rope used for ascending or descending using the device (approved

according to EN 1891).

Secondary (backup) rope – safety rope to protect the operator from falling if the primary rope breaks

(approved according to EN 1891).

Fall Arrest – individual protection device that brakes the fall of the user (EN353/2 approved).

Text preceded by the following symbols contains very important information or instructions, especially

in regards to safety.

Failure to observe these may lead to:

danger for operators

invalidity of the contract warranty

refusal of the manufacturer to accept responsability

WARNING!

this denotes the existence of the potential danger, which could cause injury or damage if the information or instructions are not followed

NOTE!

this denotes important information concerning the device

8 ENGLISH 01-30-14

Page 9

General Information

i

PWRS-E/PWRS-E.Compact

Serial No. / N. di serie

rope di ameter

diametr o fune

2006/42/EC

2004/108/EC

Safe Working Load (SWL)

300 kg

via Marco Biagi, 14

22070, Limido Comasco (CO) - Italy

www.harken.com

(+39) 031 3523511

PowerSeat

ø 10-12,7 mm EN1891

Year/Anno

AAAA

i

PWRS-E/PWRS-E.Compact

Serial No. / N. di serie

rope diameter

diametro fune

2006/42/EC

2004/108/EC

Safe Working Load (SWL)

300 kg

via Marco Biagi, 14

22070, Limido Comasco (CO) - Italy

www.harken.com

(+39) 031 3523511

PowerSeat

ø 10-12, 7 mm EN1891

Year/Anno

AAAA

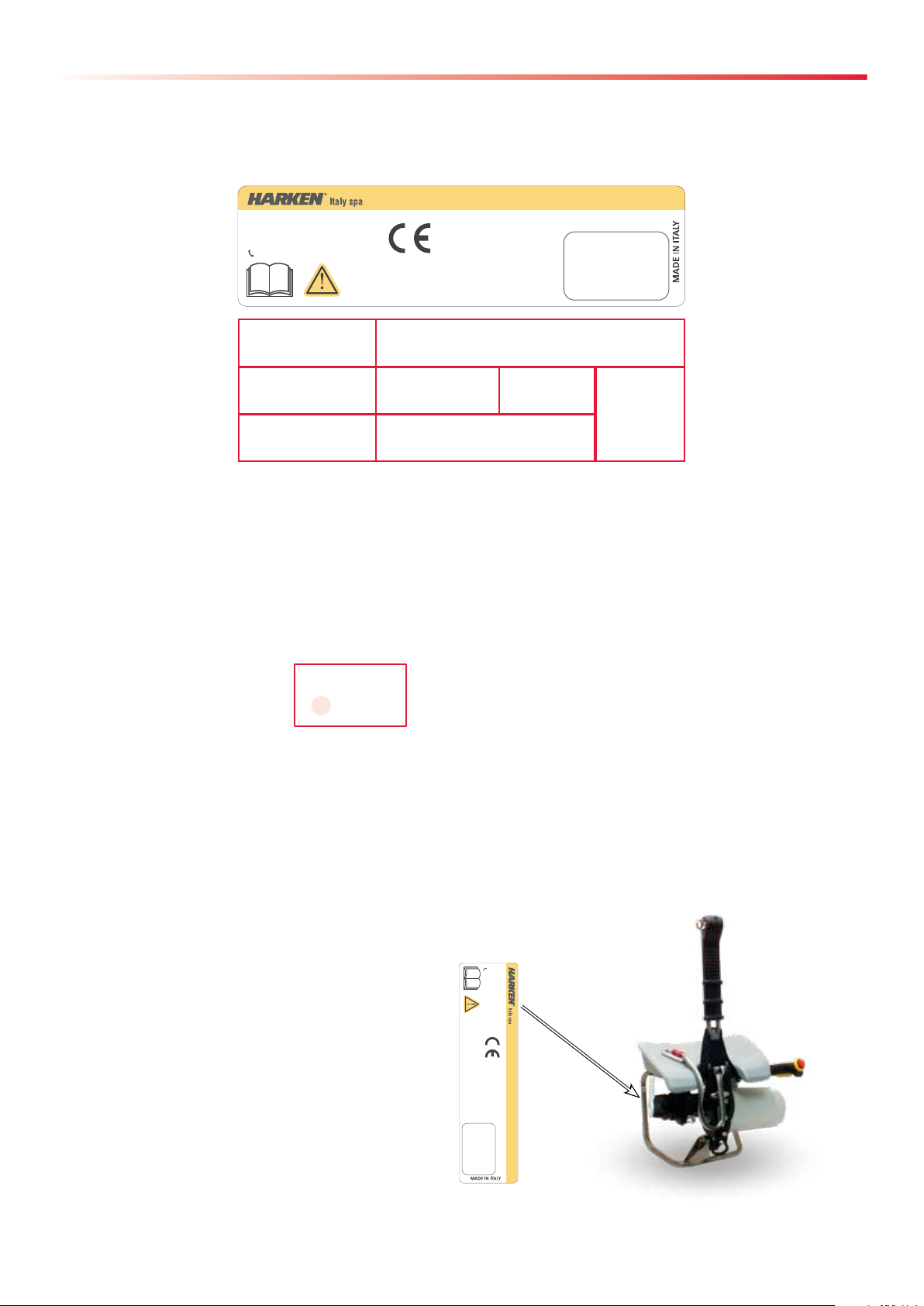

IDENTIFICATION DATA AND PLATES ON THE DEVICE

Each device is identified by a CE plate on which the reference data of the device are inscribed indelibly. Always

quote these references when contacting the manufacturer or service centres.

1

3

4 5

2

6

7 8

1. name of manufacturer

2. name of product and model

3. manufacturer's identification data

4. CE mark according to 2006/42/CE

5. year of manufacture

6. serial number in the format:

S XXXXX

XXXXXXXXX

last two numbers of the year of manufacture of the device (e.g. 13 = the year 2013)

7. pictogram instructing you to read the manual before using the device

8. safety instruction on the diameter of the rope to use: minimum 10 mm, maximum 12.7 mm: this rope must

be EN 1891 certified, plus indication of the Safe Working Load (SWL) of the device

The CE plate is on the chassis of the device:

01-30-14 ENGLISH 9

Page 10

General Information

MODEL FOR DECLARATION OF COMPLIANCE

DECLARATION OF EC COMPLIANCE

1. (All. IIA Dir. 2006/42/CE)

Via Marco Biagi, 14, 22070 Limido Comasco (CO) Italy

Telephone: +39 031/3523511, Fax: +39 031/3520031

Email: italy@harken.it, Web: www.harken.it

hereby declares that the machine:

LIFTING SYSTEM OF PEOPLE AND THINGS BY USING TECHNICAL ROPES

POWERSEAT PWRS-E.Compact

The undersigned

Harken Italy S.p.A.

Model

POWERSEAT PWRS-E

Serial Nr.

Year of Manufacture

YYYY

complies with the essential requirements defined by the following directives:

Directive 2006/42/CE of the European Parliament and Council of 17th May 2006 on machinery, and

amending Directive 95/16/CE;

Directive 2004/108/CE of the European Parliament and Council of 15 dicembre 2004 on the approximation of the laws of the Member States relating to electromagnetic compatibility;

Regulations reference: UNI EN ISO 12100:2010, EN 60204-1, EN ISO 13850, EN ISO 13849-1, EN ISO

13857, CEI EN 61000-6-2, CEI EN 61000-6-4

and authorises

Name and Surname:

Adress: HARKEN ITALY S.p.A. Via Marco Biagi, 14 CAP: 22070 Province: Como

Città: Limido Comasco Nazione: Italia

to carry out the technical file for it

Certification services: Bureau Veritas Italia S.p.A.

HARKEN ITALY S.p.A.

Certificatio Nr: XXXX-XXXX-XX-XXXX-XX-XXXX

Date of issue: MM/YYYY

Limido Comasco, lì DD/MM/YYYY

Legal representative

10 ENGLISH 01-30-14

Page 11

General Information

STANDARD REFERENCES

The device has been manufactured in conformity with the TECHNICAL REGULATIONS listed below:

Reference technical standards

UNI EN ISO 12100:2010 Safety of machinery -- General principles for design -- Risk assessment and risk reduction

UNI EN ISO 13850:2008 Safety of machinery - Emergency stop system, functional aspects

UNI EN ISO 13857:2008 Safety of machinery -- Safety distances to prevent hazard zones being reached by upper and lower limbs

UNI EN 349:2008 Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

UNI EN 1037:2008 Safety of machinery - Prevention of unexpected start-up

EN ISO 13849-1:2008 Safety of machinery – Safety-related parts of control systems – Part 1: General principles for design

EN ISO 13849-2:2008 Safety of machinery – Safety-related parts of control systems – Part 2: Validation

UNI EN ISO 13732-1:2007 Ergonomics of the thermal environment - Methods for the assessment of human responses to contact with

surfaces - Part 1: Hot surfaces

UNI EN 614-1:2006 Safety of machinery - Ergonomic design principles - Part 1: Terminology and general principles

UNI EN 614-2:2009 Specification and qualification of welding procedures for metallic materials - Welding procedure test - Part

2: Arc welding of aluminium and its alloys

UNI EN 953:2009 Safety of machinery - Guards - General requirements for the design and construction of fixed and movable

guards

UNI EN 1005-1:2009 Safety of machinery - Human physical performance - Part 1: Terms and definitions

UNI EN 1005-3:2009 Safety of machinery - Human physical performance - Part 3: Recommended force limits for machinery

operation

UNI EN 1005-4:2009 Safety of machinery - Human physical performance - Part 4: Evaluation of working postures and move-

ments in relation to machinery

UNI EN ISO 3746:2011 Acoustics - Determination of sound power levels and sound energy levels of noise sources using sound

pressure - Survey method using an enveloping measurement surface over a reflecting plane

UNI EN ISO 11204:2010 Acoustics -- Noise emitted by machinery and equipment -- Determination of emission sound pressure lev-

els at a work station and at other specified positions applying accurate environmental corrections

UNI EN ISO 4871:2009 Acoustics - Declaration and verification of noise emission values of machinery and equipment

UNI EN ISO 7000:2012 Graphical symbols for use on equipment -- Registered symbols

CEI EN 61000-6-2 Electromagnetic compatibility (EMC) - Part 6-2: Generic standards - Immunity for industrial environments

CEI EN 61000-6-4 Electromagnetic compatibility (EMC) - Part 6-4: Generic standards - Immunity for industrial environments

CEI EN 61558-2-2 Safety of power transformers, power supply units and similar - Part 2-2: Particular requirements for control

transformers

CEI EN 60204-1:2006 Safety of machinery - Electrical equipment of machines. Part 1: General rules

01-30-14 ENGLISH 11

Page 12

General Information

FCC VERIFICATION

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

1) this device may not cause harmful interference

2) this device must accept any interference received, including interference that may cause undesired

operation

NOTE!

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC rules. These limits are designed to provide

reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that the interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that of the receiver.

- Consult the dealer or an experienced radio/TV technician for help.

IC CERTIFICATION

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing Equipment

Regulations.

TECHNICAL SUPPORT INFORMATION

The PowerSeat is covered by a warranty, as laid down in the general conditions of sale. If during the warranty

period the device proves defective or suffers breakages, as indicated in the warranty, the manufacturer, after

checking the device, will repair or replace the defective components. You are reminded that modifications

carried out by the user, without explicit written authorisation from the manufacturer, will invalidate the

warranty and relieve the manufacturer of any responsibility for damage caused by the defective product. The

same considerations apply when spare parts that are not original or different from those explicitly indicated by

the manufacturer as “safety devices” are used. For all these reasons we advise customers to contact Harken

Technical Support.

12 ENGLISH 01-30-14

Page 13

Safety Precautions

GENERAL ADVICE

WARNING!

read the instructions in this manual attentively and carefully follow the indications it contains before

using the PowerSeat

Use of the PowerSeat is restricted to qualified operators who are certified for temporary work at height with

the use of access and positioning systems using ropes according to the current regulations of the Nation in

which the device is used.

Harken is not responsible for damage caused by the PowerSeat to people, animals or property in the case of:

- use of the PowerSeat by operators without proper certification

- improper use of the PowerSeat

- lack of proper maintenance, as indicated in the Maintenance chapter of this Manual

- unauthorised modifications or changes

- use of spare parts that are not original or specific for the model

- total or partial failure to observe the instructions

- usage contrary to specific national regulations

INTENDED USE

The PowerSeat is designed to help qualified operators ascend a rope using the engine and descend using a

passive manual device. The PowerSeat is not safety equipment and is not a Personal Protective Equipment.

It must always be used in combination with a secondary rope to which is connected the fall arrest device fixed

to the operator’s harness by a cord with an energy absorber, and must satisfy the requirements of EN 363 on

individual systems for the protection against falling from heights.

In order to use the PowerSeat a risk analysis, and rescue plan must have been drawn up, as required by

current regulations of the nation where the device is used on temporary work at height and the use of access

and positioning systems using ropes.

The following guidelines must also be considered:

- ISO 22846: Personal equipment for protection against falls (Part 1/Part 2)

- IRATA: International Code of Practice.

- C(HSW)R: The Construction (Health, Safety and Welfare) Regulations.

- LOLER: The Lifting Operations and Lifting Equipment Regulations.

- MHSWR: The Management of Health and Safety at Work Regulations.

- PUWER: The Provision and Use of Work Equipment Regulations

This list is not complete and it is the responsibility of the qualified operator to be aware of current regulations

in his country on temporary work at height and the use of access and positioning systems using ropes or

other regulations relating to his specific sector of work.

01-30-14 ENGLISH 13

Page 14

Safety Precautions

IMPROPER USE

The machine must not be used:

- for purposes different from those outlined in “Intended use” chapter, or for purposes not mentioned in this

manual or different from those mentioned

- if unauthorised modifications or interventions have been carried out

- in an explosive atmosphere

- after it has fallen from a height of more than 1mtr onto a hard surface. In this case the device must be

returned to the manufacturer or to a Harken authorised repair centre.

SAFETY DEVICES

The following safety devices are installed:

- Fall arrest attachment consists of strap and carabiner locked to the main support plate certified according to

EN 1275; EN 362 Standards.

- Plastic cover on the central support for protecting the device from contact shocks and rope jamming.

- Shaped plastic guard between the descending knob and the rope entry on the winch to prevent the rope

jamming and tangling.

- Plastic cover containing the electric motor to protect from hot parts.

PERSONAL PROTECTIVE EQUIPMENT (PPE)

The device bears an adhesive label reminding you of the obligation:

- to use gloves

RESIDUAL RISKS

You must pay attention to the following residual risks present when using PowerSeat:

WARNING! ROTATING PARTS TRAPPING RISK

Always wear clothing and protective gloves that are form tting. Avoid loose gloves or

clothing and always follow the instructions in the manual.

WARNING! RISK OF FALLING

Always use personal protective equipment and always follow the instructions of the manual.

WARNING! HOT PARTS

See Notes reported in the electrical equipment description.

WARNING!

The plug of the machine / power supply must be suitable for the socket. Never modify the plug.

Conformed plugs and suitable sockets reduce risk of electric shock.

14 ENGLISH 01-30-14

Page 15

SAFETY INFORMATIONS

WARNING!

Do not use the electric cable for other purpose then those intended, and in particular do not use the

cable to carry or suspend the device, or to disconnect the plug. Do not go near the cable to heat

sources, oil, sharp edges or moving parts of the machine.

Damaged or tangled cables increase risk of electrical shock.

WARNING!

Do not use the device with faulty switches.

Devices or control systems with faulty switch are dangerous and require maintanance.

WARNING!

Do not remove the motor carter.

Safety Precautions

01-30-14 ENGLISH 15

Page 16

Power Supply Informations

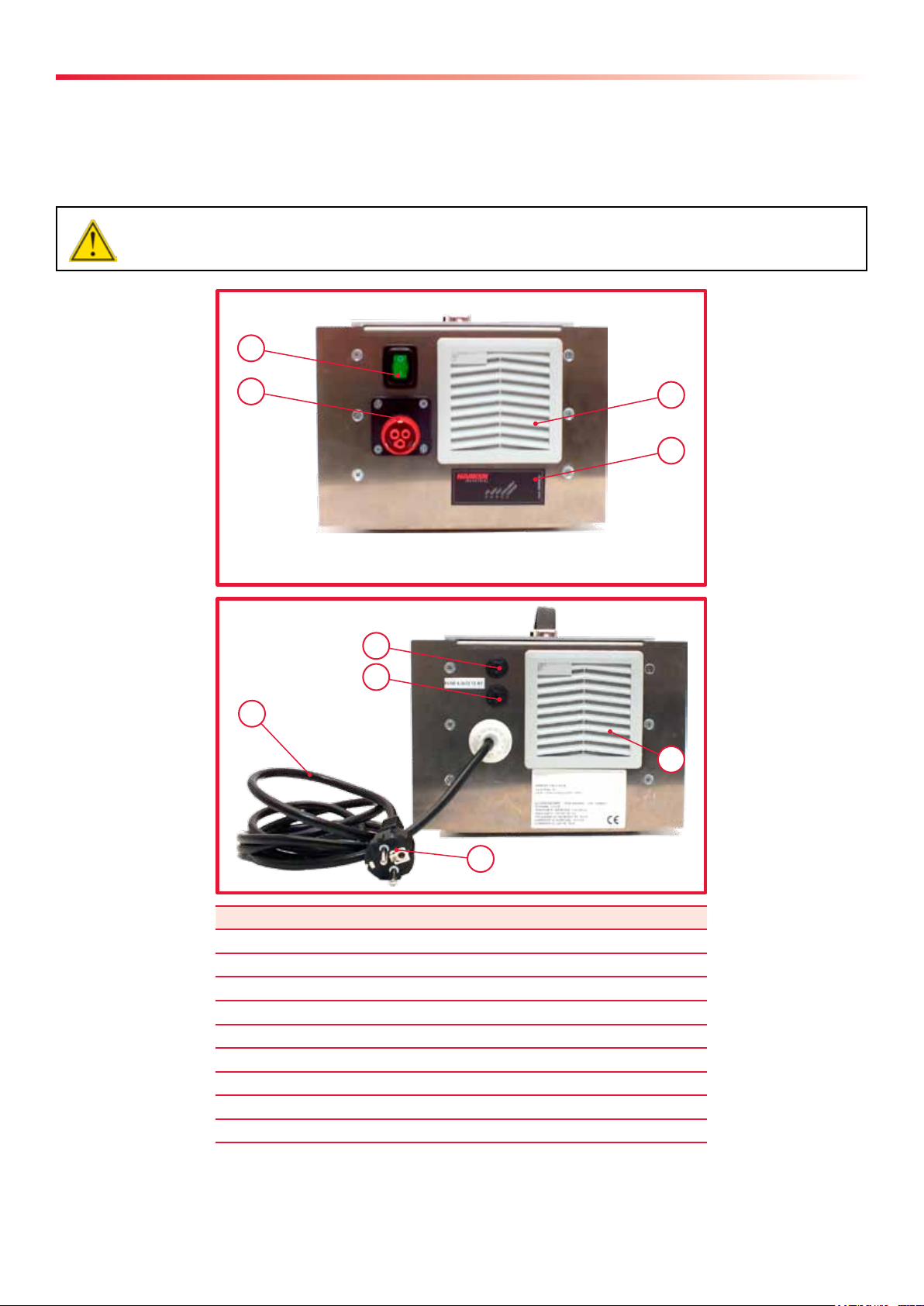

POWER SUPPLY DESCRIPTION - GENERAL

The PowerSeat Power Supply is an electronic unit specifically designed to supply only the PowerSeat electric

motor.

Power Supply convert the AC voltage (110 - 230VAC, 50/60 Hz) into 48VDC voltage and powers the motor.

WARNING!

Do not use the Power Supply of the PowerSeat to power other electric products.

1

2

8

9

5

4

3

7

6

Pos. Description

1 0/1 Switch

2 48 Vdc Socket

3 Light Interface

4 Frontal Cooling Grid

5 Electric Cable

6 Plug

7 Back Cooling Grid

8 Fuse

9 Fuse

16 ENGLISH 01-30-14

Page 17

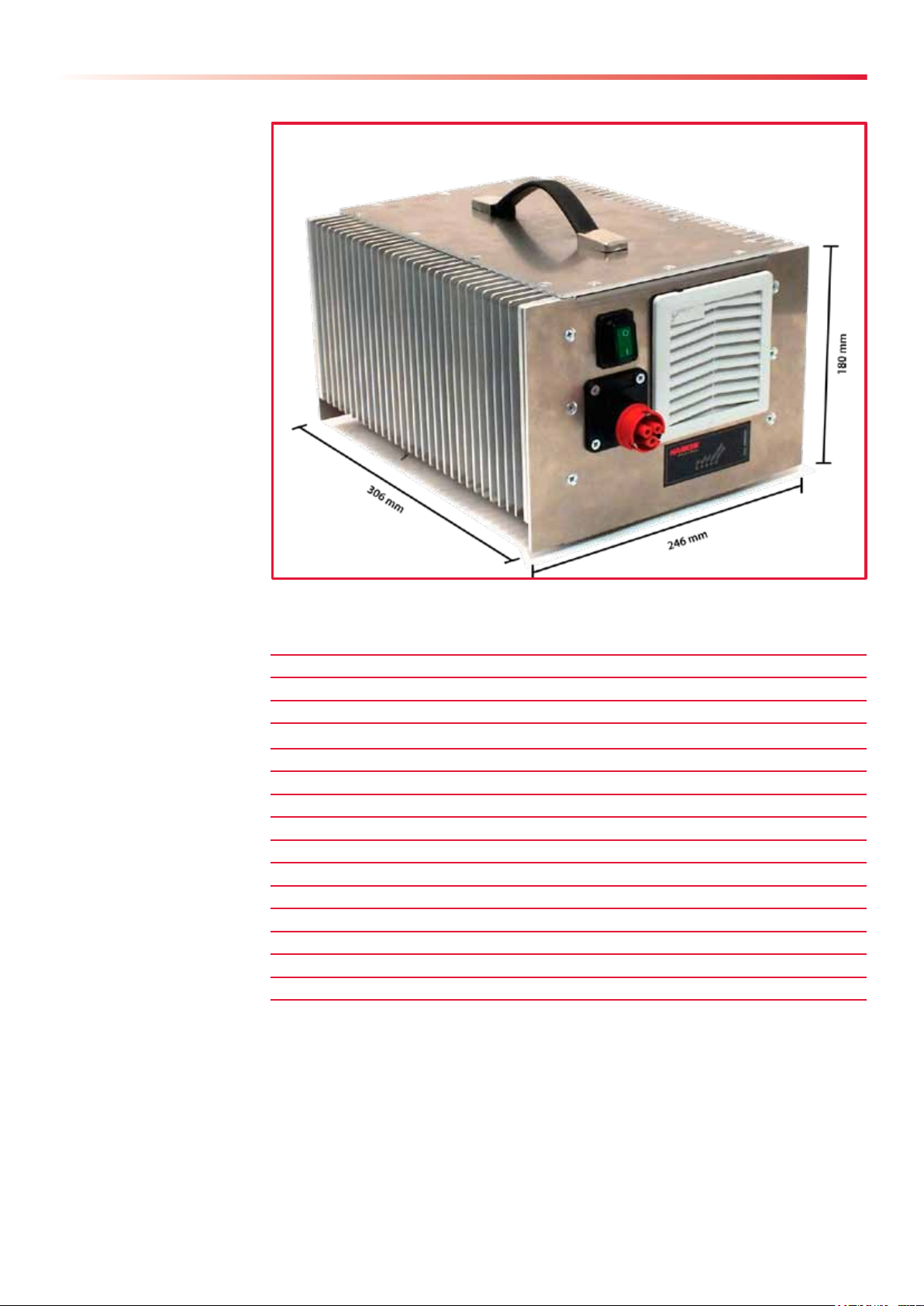

POWER SUPPLY DESCRIPTION - DIMENSION

Power Supply Informations

POWER SUPPLY DESCRIPTION - TECHNICAL DATA

Dimensions 246x306x180 mm (LxPxH)

Weight 8,5 kg

Supply Voltage 110-230 Vac

Frequency 50/60 Hz

Cable Schuko Tipo 16 A, 230 Vac

Max Output Voltage 54 Vdc

Max Output Current 25 A

Max Power 1200 W

Fuse 20 A T

Overloading Protection Electronic Control

Overtemperature Protection Electronic Control

Ingress Protection Rating IP54

Operating Environment Temperature 0° C - 40° C

Max non-condensing Humidity 85%

Working Conditions Internal or External Use

01-30-14 ENGLISH 17

Page 18

Power Supply Informations

POWER SUPPLY DESCRIPTION - LIGHT INTERFACE

"0/I" switch turn on and turn off Power Supply. The LED Interface, placed on the front side, provides indication

on the operating status of the supply using 5 LED alarms.

Alarm Description

Line It shows that there is electrical power on the supply cards.

It turns on few seconds after the switch has been activated "0/I" and it indicates that voltage inside the power supply are correct,

and the power supply will be soon usable.

Ready It shows that the power supply is providing voltage accross output connectors.

It turns on to indicate precharge voltage reaches a suitable value of the power supply power stages, when this LED is on it is possible to take energy from the power supply output.

Fault Indicates a serious fault of the power supply or a load anomaly.

Normally off, the lighting of this led indicates a very serious failure of the power supply and is necessarily an extraordinary maintenance.

Overcurrent Indicates an overload connected to the output of the power supply.

Normally off, this led illuminates to indicate that there is an overload connected at the output of the power supply.

The LED may light up for short periods at the begining of the use, this is a normal function and should not create suspected mal-

function of the power supply to the load.

Overtemp Indicates that the temperature inside the power supply or heatsink is too high.

Normally off, the ignition of this LED indicates that the power supply's internal temperature is close to 70° C. When this LED

turns on the power supply turns off not providing tension to the load, until temperature drops below 50° C.

SAFETY INFORMATIONS

WARNING!

Do not use the Power Supply in potentially ammable or explosive zone. The Power Supply can

reach high temperature when exposed to sunlight.

WARNING!

Use the Power Supply according to environmental specications! An improper use can damage

electronic circuits.

WARNING!

In use the Power Supply can reach high temperatures, around 50°/60° C. Pay attention to place it

away from objects that can be damaged!

18 ENGLISH 01-30-14

Page 19

Power Supply Informations

WARNING!

Before connecting the Power Supply to the AC voltage make sure that voltage is within the range

specied in the Power Supply technical data.

WARNING!

Do not open Power Supply cover and do not modify the power supply.

USING THE POWER SUPPLY

The PowerSeat Power Supply can be used in indoor and outdoor environments.

Place the Power Supply away from any heat sources. Keep a clean area around the Power Supply, not less

than 50 mm on all sides, to ensure a sufficient ventilation for cooling.

It is recommended, whenever possible, do not expose the Power Supply to direct sunlights, and do not place it

in humid environments.

To turn on and turn off use the switch on the frontal panel.

Position " I " - in addition to the light in the switch itself, which indidates the presence of main AC voltage,

after few seconds it turns on the "Line" light. To obtain voltage accross output connectors it needs to wait a

few seconds more, when "Ready" green light will turn on.

Position " 0 " - the Power Supply turns off immediately, no Wa.

CLEANING THE POWER SUPPLY

The Power Supply can be cleaned with a wet rag with alcool or detergent. Do not use solvent or aggressive

detergent, they can have chimical reactions with alumium Power Supply container, damage connection plastic

parts and the LEDs. Do not spray or pour any liquid on the Power Supply if it is powered.

Periodically remove and replace ventilation filters (it depends on using environment).

Using the Power Supply in a dusty environment, frequently remove dust inside the channels of ventilation,

accurately remove the dust with dry compressed air or with a brush.

WARNING!

Before cleaning the Power Supply turn off it and disconnect all cables.

WARNING!

Before using the Power Supply make sure that all connection cables and the Power Supply itself are

completely dry, to minimize the risk of electric shock.

01-30-14 ENGLISH 19

Page 20

PowerSeat PWRS-E

DEVICE DESCRIPTION - GENERAL

The PowerSeat is designed to help qualified operators ascend a rope and descend using a passive manual

device.

The rope must be inserted in its housing in the vertical tube, through the deflector sheave, wrapped round the

winch drum and locked in the rope grab.

When the engine is started, a transmission system rotates the drum and creates a traction force on the rope.

Electrical motor supplies power during the ascent, start and stop is an electrical system and the control system

is provvided with an anti-panic system and an emergency button.

During descent the engine is switched off and the operator uses the lever to open the rope grab and allow the

rope to slide round the drum in a controlled descent.

17

16

1

2

3

25

4

6

5

7

8 9 11 12

Pos. Description

1 Seat

2 Snap-hook

3 Strop

4 Knob

5 Cover

6 Rope grab

7 Stripper arm

8 Winch Drum

9 Reduction gear casing

10 Clamp

11 Damper

12 Anchorage point

13 Front plate

19

20

10

13

21

14

23

Pos. Description

14 Motor Cover

15 Protection

16 Front tube

17 Eyebolt

18 Pin

19 Emergency button

20 Accelerator lever

21 Accelerator control

22 Frame

23 Power cable

24 Cable anchorage eyebolt

25 Control lever

18

15

22

24

20 ENGLISH 01-30-14

Page 21

DEVICE DESCRIPTION - DIMENSIONS

PowerSeat PWRS-E

01-30-14 ENGLISH 21

Page 22

PowerSeat PWRS-E

DEVICE DESCRIPTION - SAFE WORKING LOAD

The Safe Working Load of the PowerSeat is 300 Kg (661,4 lb).

WARNING!

Do not apply a load greater than the Safe Working Load to the PowerSeat.

DEVICE DESCRIPTION - ROPE REQUIREMENTS

WARNING!

Use only EN1891 certied ropes with a diameter of between 10 - 12.7 mm (3/8" - 1/2").

WARNING!

Use only ropes in good condition.

WARNING!

For correct maintenance of ropes consult the rope Usage Manual.

DEVICE DESCRIPTION - VIBRATIONS

Vibration values measured are below the limits set by the reference standards:

Hand-arm <2,5 (A(8)m/s), Whole body <0,5 (A(8)m/s).

DEVICE DESCRIPTION - NOISE EMISSION

The values of the measured noise emissions are below the limits allowed under the applicable standards - ISO 3746:

- Average surface acoustic pressure level weighted A:

(L

- Acoustic power level weighted A (L

(medio)) < 80 dB(A)

pfA,d

) < 90 dB(A)

WA

22 ENGLISH 01-30-14

Page 23

PowerSeat PWRS-E

DEVICE DESCRIPTION - TECHNICAL DATA

Below are the principal technical data of the PowerSeat obtained with a rope 11mm (7/16") in diameter at a

temperature of 20°C at sea level.

Rope Semi static 10mm-12.7mm (1/8"-1/2") EN1891 rope

Safe working load 300 kg (661,4 lb)

Maximum Load on Seat 150 kg (330,7 lb)

Ascent speed 110 V 13 m/min (120 kg) (42.7 ft/min (264,5 lb))

8,5 m/min (300 kg) (27,9 ft/min(661,4 lb))

Ascent speed 230 V 13 m/min (120 kg) (42.7 ft/min (264,5 lb))

10 m/min (300 kg) (27,9 ft/min(661,4 lb))

Reduction Ratio 48,6:1

Device Weight 19 kg (41,9 lb)

Dimensions 815 x 538 x 326 mm (32,1" x 21,2" x 12,8")

Recommended working temperature range 0°C +40°C

Ingress Protection Rating IP 54

DEVICE ESCRIPTION - MOTOR

Motor Brushless electric

Nominal Voltage 48 Vdc

Net Power 0,8 kW

Thermal Protection Activation temp. 100°C (212°F)

Continuous operation distance suggested 780 m (120 kg (264,5 lb))

100 m (300 kg (661,4 lb))

USING THE DEVICE - CHECKING THE DEVICE BEFORE USE

Before and after every use, visually inspect the PowerSeat for traces of wear, damage or breakage. If such traces are

present, do not use the device. If the worn or defective parts are not immediately replaced, the manufacturer will

assume no responsibility for resulting damage or accidents.

In particular:

Check that the strop and carabiner are

Check the movement of the rope grab cover.

intact.

01-30-14 ENGLISH 23

Page 24

PowerSeat PWRS-E

Check that the rope grab knob is working by

rotating the control lever and releasing it

(CLOSE JAW).

Check that the rope grab knob is working by

rotating the cotrol lever and releasing it

(OPEN JAW).

Inspect all screws and check that the marker on the screws and on the plate are aligned.

In case of any misaligned contact a HARKEN service center.

Ispect the lever control screw, and all screws

that secure the seat to the frame and check

that they are properly tightened.

24 ENGLISH 01-30-14

Rotate the winch drum clockwise by hand

and make sure that it cannot rotate

anticlockwise.

Page 25

PowerSeat PWRS-E

Verify the functionallity of the emergency

button, pushing the emergency button and

verifying the stop of the device.

Rotate clockwise the emergency button to

rearm the device.

Verify the functionallity of the anti-panic

system:

push the accelerator lever to start the

device, and push further the accelerator

lever up to the stop, and verify the stop of

the device.

Release the accelerator lever to disarm the

anti-panic system.

NOTE!

Before every use carry out a function check with the device unloaded to check for any problems

with the engine.

USING THE DEVICE - ADJUSTING THE ACCELERATOR CONTROL POSITION

Before using the device verify the position of the accelerator control so that it is ergonomically comfortable for

the operator, depending on the use that is expected.

1. Untight the first screw of the accelerator

control using an hex key n°4.

01-30-14 ENGLISH 25

2. Completely untight the second screw of the

accelerator control using an hex key n°4, pay

attention to not lose the self-locking nut.

Page 26

PowerSeat PWRS-E

3. Slide out the accelerator control from the

support.

NOTE!

Pay attention not to pass

the accelerator control's

cable outside of the

devise frame.

4. Change position to the support and replace

the accelerator control.

6. Tighten the support's screws.

USING THE DEVICE - ADJUSTING THE CONTROL LEVER POSITION

Before using the device it is possible set up the position of the control lever so that it is ergonomically

comfortable for the operator, depending on the use that is expected.

1. Loose the control lever screw using an

hex key n°5.

26 ENGLISH 01-30-14

2. Place the control lever on one of 3 possible position.

Page 27

sible position.

PowerSeat PWRS-E

3. Tighten the control lever screw.2. Place the control lever on one of 3 pos-

USING THE DEVICE - PRIMARY ROPE INSTALLATION PROCEDURE

1. Place the PowerSeat on the ground.

2. Pull open the clamp and slide the front

tube into the housing.

WARNING!

Slide the front tube correctly into its housing until the red reference mark is no longer visible.

01-30-14 ENGLISH 27

Page 28

PowerSeat PWRS-E

3. Pass the rope inside the pin. 4. Fit the rope into the front tube.

5. Pass the rope round the pulley. 6. Make sure the rope has been fitted correctly

into its housing.

7. Wind the rope clockwise around the winch

drum.

8. Pass the rope over the stripper arm.

WARNING!

Take at least two turns of the rope around the winch drum, and if it slips under load increase the

number of turns to a maximum of four, taking care not to overlap the rope.

28 ENGLISH 01-30-14

Page 29

PowerSeat PWRS-E

NOTE!

The number of turns needed round the winch drum depends on the load and the condition of the

rope.

Check the device's descending capacity in its working conguration.

Before use ascend with the device, no more than 1 mtr (3,28 ft) and check, according to the descent procedure 1, that it's descending smoothly.

In case of difculties unwind the rope, and reduce the turns to not less than 2 wraps, until you have

the optimal conguration.

9. Fit the rope into the rope grab. Raise the

cover to make this easier.

11. Close the protective cover with the strap.

10. Position the rope inside the stopper.

01-30-14 ENGLISH 29

Page 30

PowerSeat PWRS-E

USING THE DEVICE - WIRING THE POWER SUPPLY SYSTEM

WARNING!

Before wiring the Power Supply to the device completely unroll the power cable to allow a device

proper use, and verify the integrity of the cable and its connectors.

01. Connect the power cable to the device

socket.

03. Connect the 48V power cable to the Power

Supply.

02. Fasten the cable snap-hook to the cable

anchorage eyebolt.

04. Connect the Power Supply plug to the

110/230V power line.

05. Turn on the Power Supply pressing the

"0/I" switch. For voltage will need to wait a few

seconds until the first two LED alarms are both

lighting.

30 ENGLISH 01-30-14

06. Verify that the Power Supply systemis

working checking the LED alarms Line and

Ready are lighting and try to operate the

device.

Page 31

PowerSeat PWRS-E

USING THE DEVICE - PREPARING TO ASCEND

Install two ropes, Primary and Secondary, with separate anchorage points. Each rope must support at least 15

kN.

Install the Primary (or working) rope on the device as directed "Primary Rope Installation Procedure"

paragraph.

Attach the Secondary (or backup) rope is attached to the operator using a fall arrest device (EN353/2

approved) and energy absorber (EN355 approved).

Both ropes must be EN1891 Class A certified and have a diameter of between 10 (1/8" ) and 12.7 mm (1/2").

In the case of fault or breakage of the device or of the primary rope, the load will be immediately transferred

to the secondary rope through the fall arrest device, thus constituting the anti-fall system.

WARNING!

Use the PowerSeat only with the primary and secondary ropes installed so as to create the anti-fall

system described above.

To use the PowerSeat the operator must also wear:

1. A full EN 361 and EN813 certified harness to which the device is attached at the lower front attachment and

the fall arrest device at the upper front attachment

2. An EN 795 B certified waist strop connected to the two side attachments of the harness and passing

outside the front tube of the PowerSeat

3. Appropriate Individual Personal Protective Equipment (PPE) (e.g. helmet, gloves and protective glasses)

4. Suitable clothing, form fitting so it cannot catch on moving parts

1

9

10

4

7

8

3

2

6

11

Pos. Description

1 Primary Rope

2 Secondary Rope

3 Fall Arrest Device

4 Upper Front Attachment

5 Full Harness

6 Waist Strop

7 Lower Front Attachment

8 Side Attachment Points

9 Helmet

10 Protective Glasses

11 Gloves

WARNING!

Do not use the PowerSeat in the case of illness, tiredness or if under the inuence of drugs or

alcohol.

01-30-14 ENGLISH 31

Page 32

PowerSeat PWRS-E

WARNING!

Keep your hands, feet and clothing etc away from the moving parts of the device.

WARNING!

During the ascent the motor cover could become hot. Handle the device with care to avoid injury.

WARNING!

During the use of the device any knots on the rope, if they are involved in the device circuit, may

damage the device and cause dangerous conditions.

NOTE!

Before using the PowerSeat make sure that the power cable length is greater than the distance

between the Power Supply and the higher ascenting point of the device.

USING THE DEVICE - ASCENT PROCEDURE 1

Pos. Description

1

2

3

4

5

1 Fall Arrest Device

2 Upper Front Attachment

3 Lower Front Attachment

4 Waist Strop

5 Side Attachment Points

1. Install the primary rope on the device as indicated in the "Primary Rope Installation Procedure" paragraph.

2. Wire the power supply system as described in the "Wiring the Power Supply System" paragraph.

3. Supply voltage to the motor by turning on the 48V Power Supply.

4. Sit on the device.

5. Connect the fall arrest device to the harness as described in the “Preparing to Ascend” paragraph.

32 ENGLISH 01-30-14

Page 33

PowerSeat PWRS-E

6. Connect the waist strop to the two side attachment points of the harness, passing it outside the front tube

of the PowerSeat.

7. Connect the snap-hook provided with the device to the lower front attachment point of the harness.

8. Adjust the position of the accelerator

control so it is ergonomically comfortable for

the operator.

9. To ascent, push the accelerator lever to the

first detent.

WARNING!

Before using the device check that the rope is correctly installed.

WARNING!

Before using the device test the functionallity of the emergency button and the anti-panic system.

01-30-14 ENGLISH 33

Page 34

PowerSeat PWRS-E

USING THE DEVICE - ASCENT PROCEDURE 2

1. Install the primary rope on the device as indicated in the “Primary Rope Installation Procedure” paragraph.

2. Wire the Power Supply system as described in the "Wiring the Power Supply System" paragraph.

3. Adjust the position of the accelerator control so it is ergonomically comfortable for the operator as

indicated in the "Adjusting the Accelerator Control Position" paragraph.

4. Supply voltage to the motor by turning on the 48V Power Supply.

5. Operate the device and position it at the height of the operator’s shoulders.

6. Connect the fall arrest device to the harness as described in the “Preparing to Ascent” paragraph.

Lower Front

Attachment

to PowerSeat

Upper front

Attachment

to Fall Arrest

7. Connect the snap-hook supplied with the device to the lower front attachment point of the harness.

In ascent procedure 2 the Waist strop is not used

8. To ascent, push the accelerator lever to the first detent.

WARNING!

Before using the device check that the rope is correctly installed.

WARNING!

Before using the device test the functionallity of the emergency button and the anti-panic system.

34 ENGLISH 01-30-14

Page 35

USING THE DEVICE - USING POWERSEAT WITH A FIXED POINT

NOTE!

To use the PowerSeat with a xed point at least two operators are necessary. One operates the

device and the second is connected by the primary rope to the device and to the secondary rope by

the (EN353/2 approved) fall arrest device. Both ropes must be EN1891 certied and have a diameter

of between 10 (1/8") and 12.7 mm (1/2"). The secondary rope must have an anchorage point that

supports at least 15kN. The device is connected to a xed anchorage point on the ground which

must support at least 15kN.

PowerSeat PWRS-E

1. Pull the clamp and slide out the front tube.

3. Remove the seat.

2. Unscrew the four screws that fix the seat to

the chassis with a n°5 hex key.

4. Adjust the position of the accelerator control so it is ergonomically comfortable for the operator as

indicated in the "Adjusting the Accelerator Control Position" paragraph.

5. Place the control lever position following the "Adjusting the Control Lever Position" paragraph.

6. Install the primary rope on the device as indicated in the “Primary rope installation procedure” paragraph.

In this case the primary rope will be used to lift the second operator.

7. Wire the Power Supply system as described in the "Wiring the Power Supply System" paragraph.

8. Connect the anchorage point on the front plate of the device with the fixed anchorage point on the ground.

9. Supply voltage to the motor by turning on the 48V Power Supply.

10. To ascent, push the accelerator lever to the first detent.

01-30-14 ENGLISH 35

Page 36

PowerSeat PWRS-E

NOTE!

Before using the PowerSeat places on the ground be sure that the cable or the stand of the accelerator control are not under the device chassis.

WARNING!

To use the PowerSeat in the xed point conguration the primary rope under load must leave the

winch with a lateral and frontal angle of between ± 6°.

Max Angle ±6°

Max Angle ±6°

Anchorage

Point

Anchorage Point

To the anchorage

To the anchorage

WARNING!

Before using the device check that the rope is correctly installed.

WARNING!

Before using the device test the functionallity of the emergency button and the anti-panic system.

36 ENGLISH 01-30-14

Page 37

USING THE DEVICE - DESCENT PROCEDURE 1

PowerSeat PWRS-E

1. With one hand grasp the rope leaving the

winch.

To facilitate descent, a carabiner can

be fixed to the ring on the front tube

and the primary rope passed through

it.

2. With the other hand, turn the control lever

clockwise to allow the rope to slip on the winch

drum and permit a controlled descent. To adjust

descent speed, manually control the speed at

which the rope leaves the winch by holding

rope with arm out and bringing it in towards the

winch drum.

To stop the descent, release the control lever.

NOTE!

Take care not to overbalance when getting off the seat.

Lower the PowerSeat until the operator's feet are rmly on the ground, but the unit is still suspended. Stand up and move on the seat. Now the device can be lowered to the ground and released

from the rope.

01-30-14 ENGLISH 37

Page 38

PowerSeat PWRS-E

USING THE DEVICE - DESCENT PROCEDURE 2

1. With one hand grasp the rope leaving the

winch.

2. With the other hand, turn the control

lever clockwise to allow the rope to slip on

the winch drum and permit a controlled

descent. To adjust descent speed, manually

control the speed at which the rope leaves

the winch. To stop the descent, release the

control lever.

USING THE DEVICE - FIXED ANCHORAGE DESCENT PROCEDURE

1. With one hand grasp the rope leaving the winch.

2. With the other hand, turn the control lever clockwise to allow the rope to slip on the winch drum and permit

a controlled descent. To adjust descent speed, manually control the speed at which the rope leaves the winch.

To stop the descent, release the control lever.

USING THE DEVICE - TRANSPORT AND STORAGE

Transport the device using the box provvided at time of purchase. To transport the device disconnect the

Power Supply system. When not in use the device must be stored in its box in order to protect it from knocks

and shock. Protect the device from humidity and temperature range. The temperature required for storage

must be in the range -25°C/+55°C, and for periods not exeeding 24 hours the maximum temperature can

reach +70°C. The humidity is not expected to exeed 80%. Do not allow the device to come into contact with

corrosive substances. Clean the device before storing.

38 ENGLISH 01-30-14

Page 39

PowerSeat PWRS-E.Compact

DESCRIPTION OF COMPACT VERSION - GENERAL

The PowerSeat Compact version maintains every device key features described in the "Device Description"

paragraph.

This device version is designed to optimize the qualified operator's work when he works without seat or using

the device with a fixed anchorage.

1

2

10

4

5

6

7

8 9 11 12

Pos. Description

1 Short Tube

2 Front Plate

3 Control Lever

4 Knob

5 Cover

6 Rope Grab

7 Stripper Arm

8 Winch Drum

9 Reduction Gear Casing

10 Clamp

11 Damper

16

17

15

14

20

18

13

Pos. Description

12 Anchorage Point

13 Snap-hook

14 Strop

15 Motor Cover

16 Emergency Button

17 Accelerator Lever

18 Accelerator Control

19 Frame

20 Power Cable

21 Cable anchorage eyebolt

3

19

21

01-30-14 ENGLISH 39

Page 40

PowerSeat PWRS-E.Compact

DESCRIPTION OF COMPACT VERSION - DIMENSIONS

40 ENGLISH 01-30-14

Page 41

PowerSeat PWRS-E.Compact

USING THE COMPACT VERSION DEVICE - CHECKING THE COMPACT VERSION DEVICE BEFORE USE

Before and after using the PowerSeat Compact version follow the procedure described in the "Checking the Device

Before Use" paragraph.

USING THE COMPACT VERSION DEVICE - PRIMARY ROPE INSTALLATION PROCEDURE ON COMPACT VERSION

1. Place the PowerSeat on the ground. 2. Pull open the clamp and slide the short tube

into the housing.

WARNING!

Slide the front tube correctly into its housing until the red reference mark is no longer visible.

3. Remove the strop from upper anchorage

point.

01-30-14 ENGLISH 41

4. Fasten the strop on the lower anchorage

point.

Page 42

PowerSeat PWRS-E.Compact

5. Pass the primary rope inside the pins.

7. Make sure the rope has been fitted correctly

into its housing.

6. Pass the rope round the pulley.

8. Wind the rope clockwise around the winch

drum.

WARNING!

Take at least two turns of the rope around the winch drum, and if it slips under load increase the

number of turns to a maximum of four, taking care not to overlap the rope.

NOTE!

The number of turns needed round the winch drum depends on the load and the condition of the

rope.

Check the device's descending capacity in its working conguration.

Before use ascend with the device, no more than 1 mtr (3,28 ft) and check, according to the descent procedure 1, that it's descending smoothly.

In case of difculties unwind the rope, and reduce the turns to not less than 2 wraps, until you have

the optimal conguration.

42 ENGLISH 01-30-14

Page 43

PowerSeat PWRS-E.Compact

9. Pass the rope over the stripper arm.

10. Position the rope inside the stopper.

10. Fit the rope into the rope grab. Raise the

cover to make this easier.

USING THE COMPACT VERSION DEVICE - PREPARING TO ASCENT WITH THE COMPACT VERSION

To use the PowerSeat Compact version follow the procedure described in "Preparing to Ascent" paragraph.

WARNING!

Leggere attentamente il paragrafo "Procedura di preparazione alla risalita" prima di utilizzare la macchina.

USING THE COMPACT VERSION DEVICE - ASCENT PROCEDURE WITH THE COMPACT VERSION

1. Install the primary rope following "Primary Rope Installation Procedure on Compact version" paragraph.

2. Wire the power supply system as described in the "Wiring the Power Supply System" paragraph.

3. Adjust the position of the accelerator control so it is ergonomically comfortable for the operator as

indicated in the "Adjusting the Accelerator Control Position" paragraph.

4. Supply voltage to the motor by turning on the 48V Power Supply.

5. Operate the device and position it at the height of the operator’s shoulders.

6. Connect the fall arrest device to the harness as described in the “Preparing to Ascent” paragraph.

01-30-14 ENGLISH 43

Page 44

PowerSeat PWRS-E.Compact

7. Connect the snap-hook supplied with the device to the lower front attachment point of the harness.

Fall Arrest

Device

Lower Front

Attachment to

PowerSea

In ascent procedure 2 the Waist strop is not used

8. To ascent, push the accelerator lever to the first detent.

WARNING!

Before using the device check that the rope is correctly installed.

WARNING!

Before using the device test the functionallity of the emergency button and the anti-panic system.

USING THE COMPACT VERSION DEVICE - USING COMPACT VERSION POWERSEAT WITH A FIXED ANCHORAGE

NOTE!

To use the PowerSeat with a xed point at least two operators are necessary. One operates the

device and the second is connected by the primary rope to the device and to the secondary rope by

the (EN353/2 approved) fall arrest device. Both ropes must be EN1891 certied and have a diameter

of between 10 (1/8") and 12.7 mm (1/2"). The secondary rope must have an anchorage point that

supports at least 15kN. The device is connected to a xed anchorage point on the ground which

must support at least 15kN.

1. Adjust the position of the accelerator control so it is ergonomically comfortable for the operator as

indicated in the "Adjusting the Accelerator Control Position" paragraph.

2. Set the control lever position following the "Adjusting the Control Lever Position" paragraph.

3. Install the primary rope on the device as indicated in the “Primary rope installation procedure on Comapct

version” paragraph. In this case the primary rope will be used to lift the second operator.

4. Wire the power supply system as described in the "Wiring the Power Supply System" paragraph.

44 ENGLISH 01-30-14

Page 45

PowerSeat PWRS-E.Compact

5. Connect the anchorage point on the front plate of the device with the fixed anchorage point on the ground.

6. Supply voltage to the motor by turning on the 48V Power Supply.

7. To ascent, push the accelerator lever to the first detent.

NOTE!

Before using the PowerSeat places on the ground be sure that the cable or the stand of the accelerator control are not under the device chassis.

WARNING!

To use the PowerSeat in the xed point conguration the primary rope under load must leave the

winch with a lateral and frontal angle of between ± 6°.

Max Angle ±6°

Max Angle ±6°

Anchorage

Point

Anchorage Point

To the anchorage

To the anchorage

WARNING!

Before using the device check that the rope is correctly installed.

WARNING!

Before using the device test the functionallity of the emergency button and the anti-panic system.

01-30-14 ENGLISH 45

Page 46

PowerSeat PWRS-E.Compact

USING THE COMPACT VERSION DEVICE - DESCENT PROCEDURE WITH THE COMPACT VERSION

1. With one hand grasp the rope leaving the

winch.

2. With the other hand, turn the control

lever clockwise to allow the rope to slip on

the winch drum and permit a controlled

descent. To adjust descent speed, manually

control the speed at which the rope leaves

the winch. To stop the descent, release the

control lever.

USING THE COMPACT VERSION DEVICE - FIXED ANCHORAGE DESCENT PROCEDURE WITH THE COMPACT VERSION

1. With one hand grasp the rope leaving the winch.

2. With the other hand, turn the control lever clockwise to allow the rope to slip on the winch drum and permit

a controlled descent. To adjust descent speed, manually control the speed at which the rope leaves the winch.

To stop the descent, release the control lever.

USING THE COMPACT VERSION DEVICE - CONVERTING THE POWERSEAT PWRS-G IN THE COMPACT VERSION

To obtain the Compact version from PowerSeat PWRS-G it is required to buy the short tube and follow the

procedure described below:

1. Pull open the clamp and slide out the front

tube.

46 ENGLISH 01-30-14

2. Unscrew the four screws that fix the seat to

the chassis with a n°5 hex key.

Page 47

PowerSeat PWRS-E.Compact

3. Remove the seat. 4. Pull open the clamp and slide the short tube

into the housing.

WARNING!

Slide the front tube correctly into its housing until the red reference mark is no longer visible.

5. Remove the strop from upper anchorage

point.

6. Fasten the strop on the lower anchorage

point.

01-30-14 ENGLISH 47

Page 48

Maintenance

CLEANING

Regularly clean and dry the device with a damp cloth to remove accumulated dirt. Do not use a direct jet of

water or a high pressure water jet cleaner. Do not use degreasing products, solvents or abrasive pastes.

MAINTENANCE

Before and after every use visually inspect the PowerSeat for traces of wear, damage or breakage. Refer to the

“Checking the device before use” paragraph for more detail on this inspection.

Every year, once a year send the device to the manufacturer or to an authorized Harken Service Center for a

complete inspection.

The first year, the device must be sent to the manufacturer within 12 months from the date of purchase. The

non-observance of such condition invalidates the warranty of the machine.

The maintenance must be recorded in the Maintenance Schedule.

Dismantling and Disposal

When the device is dismantled, it is necessary to separate the parts in plastic, those in metal and

electrical components, which must be sent to differentiated disposal centres in accordance with

the regulations of the country where the device is dismantled.

48 ENGLISH 01-30-14

Page 49

POWERSEAT AND MOTOR

Problem Possible Causes Possible Solutions

The rope slips on the

winch drum

- too few turns around the winch drum

- take another turn of the rope round the winch

drum

Diagnosis and Fault Finding

- diameter of rope not in prescribed range

The engine does not start - incorrect engine starting procedure

- incorrect Power Supply starting procedure

- engine fault

- it is activated the motor thermal protection

Limited lifting capacity - engine malfunctioning

- overload condition

Difficult descent - too many wraps on winch drum

- rope grab system possible malfunctioning

- replace the rope

- refer to "Wiring the Power Supply System" paragraph in this User Manual

- verify that the emergency button is disarmed

- verify the integrity of the cable and its connectors

- verify that the input voltage it is in the correct

range

- refert to Power Supply "Diagnosis and Fault

Finding" paragraph

- contact Harken for more informations

- wait until the motor temperature is below the

block temperature. This operation may take several

tens of minutes.

- contact Harken Tech Service for more informations

- reduce the load

- unwind the rope, reducing wraps. Leave at least 2

wraps on winch drum

- contact Harken Tech Service for more informations

POWER SUPPLY

LED alarm Possible Causes Possible Solutions

LED "Line" off - power cable is not connected

- fuse is blown

- Power supply fault

LED "Fault" on - serious Power Supply fault - contact Harken for more informations

LED "Overcurrent" e "Fault" on- output overcurrent - remove the overcurrent condition, turn off the

LED "Overtemperature" on - incorrect Power Supply positioning

- blocked or inadeguated ventilation

- Power Supply thermal protection is activated

- check the power cable is not damaged

- verify that the plug is correctly wired

- change the fuse (6,3x32 16AT)

- if the green switch light is on contact Harken Tech

Service for more informations

Power Supply, wait 15 seconds and turn on the

Power Supply

- verify the Power Supply location and that the

space around itself is sufficient for its cooling

- verify that the power supply is far from heat

sources and not exposed to sunlights

- verify the ventilation grid cleaning and replace if

necessary

- wait that the Power Supply temperature is below

the block temperature

01-30-14 ENGLISH 49

Page 50

Maintenance Schedule

Owner name

Product name and Model

Serial Number

Engine Serial Number

Year of manufacture

Date of purchase

Date of first use

Maintenance interval Annual

Maintenance Schedule

Date of Service Description of Service

Name and Signature of

Maintanance Operator

Date of Next

Intervention

50 ENGLISH 01-30-14

Page 51

Maintenance Schedule

Date of Service Description of Service

Name and Signature of

Maintanance Operator

Date of Next

Intervention

01-30-14 ENGLISH 51

Page 52

52 ENGLISH 01-30-14

Page 53

Page 54

Manufacturer/EU Representive

Via Marco Biagi 14, 22070 Limido Comasco (CO), Italy

Harken Italy S.p.A.

Tel 031.3523511; Fax 031.3520031

Web: www.harken.it

Email: info@harken.it

Worldwide Limited Warranty

Refer to the Harken World Limited Warranty on the website at:

http://www.harkenindustrial.com/technical-information/warranty/

The product warranty is accepted only if it has been maintained as specified in this Manual by Harken authorized personnel and is

accompanied by Maintenance Schedule properly compiled

Loading...

Loading...