Page 1

BATTCAR SWITCH SYSTEM

INSTALLATION MANUAL

18 mm

Installation Manual – Intended for specialized personnel or expert users

Introduction

Safety precautions 2

Preassembly

Tools 2

Parts 3 - 4

Sizing/sail modification/switch height 5

Top track length 6

Track length 6

Assembly—Slug-Mount Track

Cut top track to length 7

Check fit of mounting slugs and car 7

Install track 8 - 9

Install switch 10 - 11

Assembly—Drill and Tap Track

Removing old track 12

Mount track to carbon mast 12

General instructions 12

Install switch 13

Install track 14 - 15

Install top stop 15

Commissioning

Loading headboard assembly 16

Loading cars 16

Attaching sail 16

Lazy Jacks 17

Operation

Raising sail 17

Sailmakers Instructions

Dimensions 18

Installing headboard car assembly 18

Distance between attachment points 19

Setting reef points 19

Replacement Parts 20 - 21

Troubleshooting/Warranty 22

4679 11/14

t

Please read these instructions carefully before installing, servicing, or operating the equipment.

This manual may be modified without notice. See: www.harken.com/manuals for updated versions.

PLEASE SAVE THESE INSTRUCTIONS

Page 2

This manual gives technical information on installation and service. This information is destined exclusively

for specialized personnel or expert users. Installation, disassembling, and reassembling by personnel who are

not experts may cause serious damage to property, injury to users, or injury to those in the vicinity of the product.

If you do not understand an instruction, contact Harken.

The user must have appropriate training in order to use this product.

Harken accepts no responsibility for damage or harm caused by not observing the safety requirements and

instructions in this manual. See Limited Warranty, General Warnings, and Instructions at www.harken.com/manuals.

Purpose

Harken Battcars are designed to reduce the size of, or to completely drop the mainsail on a sailboat so wind has little

effect on the sail. Use of this product for other than normal sailboat applications is not covered by the limited warranty.

Safety Precautions

WARNING! This symbol alerts you to potential hazards that can kill or hurt you and others

if you don't follow instructions. The message will tell you how to reduce the

chance of injury.

CAUTION! This symbol alerts you to potential hazards that can hurt you and others if

you do not follow instructions. The message will tell you how to reduce the

chance of injury.

WARNING! Strictly follow all instructions to avoid potential hazards that can kill or hurt you

and others. See www.harken.com/manuals for General Warnings and Instructions.

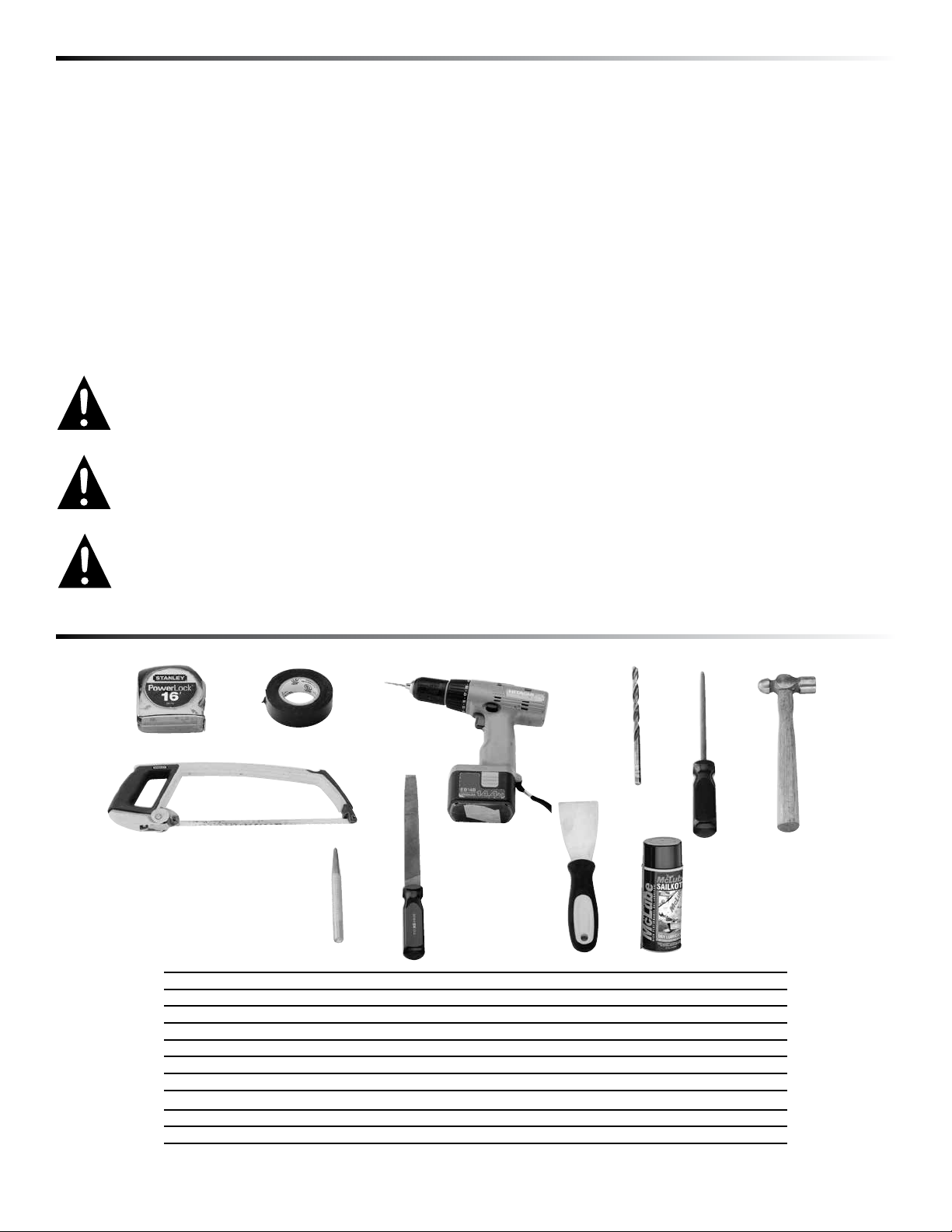

Tools

1

1.Tape measure 8. Center punch

2. Tape (slug mount) 9. File

3. Power drill (screwdriver) 10. Putty knife (slug mount)

4. Drill - 5 mm (

Drill -

4.2 mm (

5. Phillips screwdriver (slug mount) 10-32 or 5 mm tap (drill/tap) – not shown

6. Hammer Transfer punch 5 mm (

7. Hacksaw

Mast-up installation: stepladder secured to the boat.

Work height: 2.13 m (7') above boom

McLube is a registered trademark of McGee Industries, Inc. SailKote is a trademark of McLube, a division of McGee Industries.

2

2

3

7

9

8

7

/32") (slug mount) 11. McLube® Sailkote™ dry lubricant

5

/32") (drill/tap)

4

10

11

3

/16") (drill/tap) – not shown

5

6

Page 3

Preassembly Parts

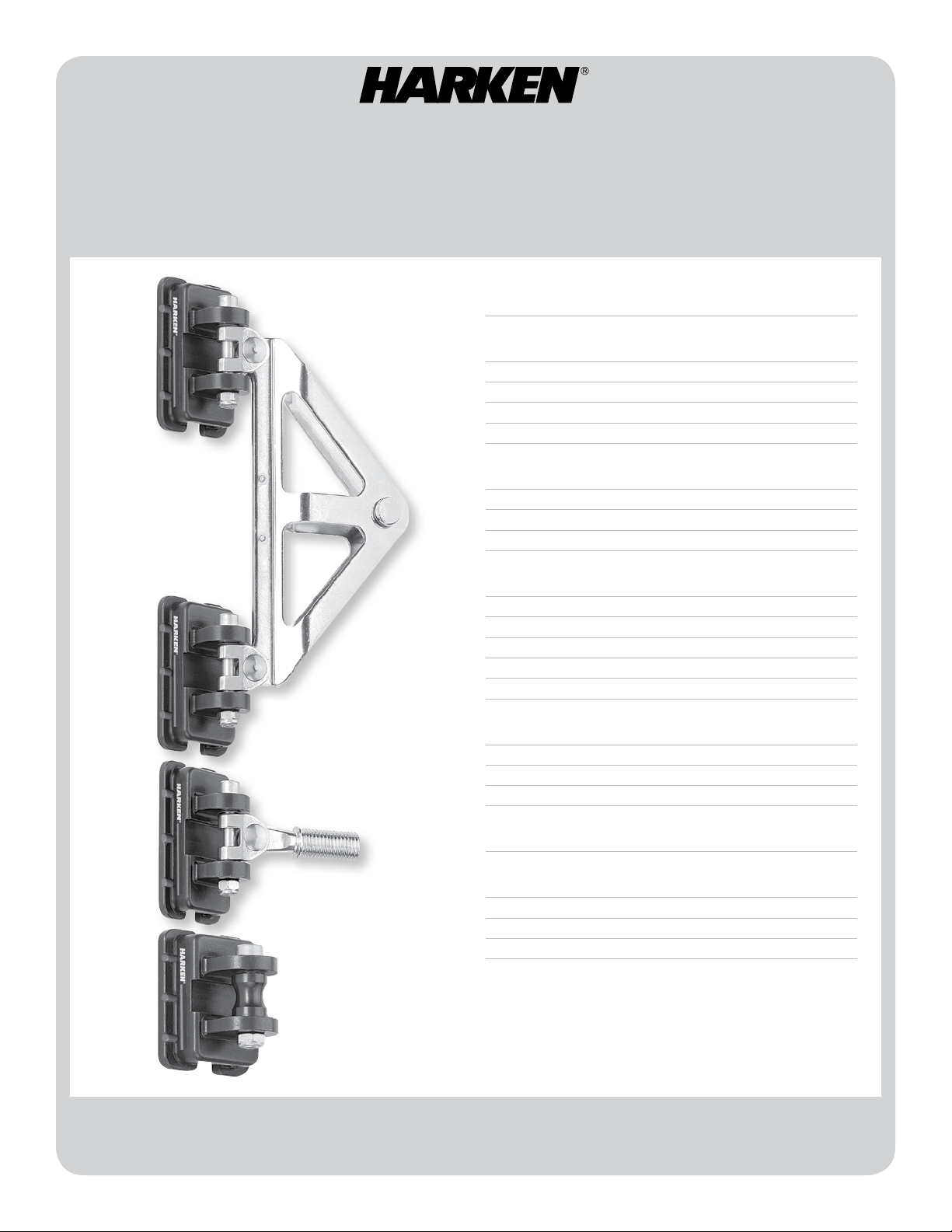

HEADBOARD CAR

(ASSEMBLY)

HC7906

HC7906HL

BATTEN CARS

WITHOUT RECEPTACLE

HC8537

HC7904HL

HC8537HL

INTERMEDIATE

CARS

HC7905

HC7905HL

Cars

Part No. Description System Comments

HC7906

HC7905

HC8537

HC7906HL

HC7905HL

HC8537HL

HC7904HL

*If receptacle is removed, do not mix base intermediate car with batten receptacle cars. See page 16.

Headboard car assembly

Intermediate car Consult sailmaker for quantity required.

Batten car 10 mm threaded stud. Purchase batten receptacle separately.

Headboard car assembly

Intermediate car Consult sailmaker for quantity required. Uses Delrin

Batten car 10 mm threaded stud. Purchase batten receptacle separately. Uses low-friction slider insert.

Batten car 12 mm threaded stud. Purchase batten receptacle separately. Uses low-friction slider insert.

Low-load

High-load

Use regular headboard.

Use regular headboard. Uses low friction slider insert.

SPARE CAR SCREWS

Important! Do not overtighten

screw and nut. Car will bind

and may warp permanently.

®

slider insert.*

Delrin is a registered trademark of E. I. du Pont de Nemours and Company or its affiliates.

3

Page 4

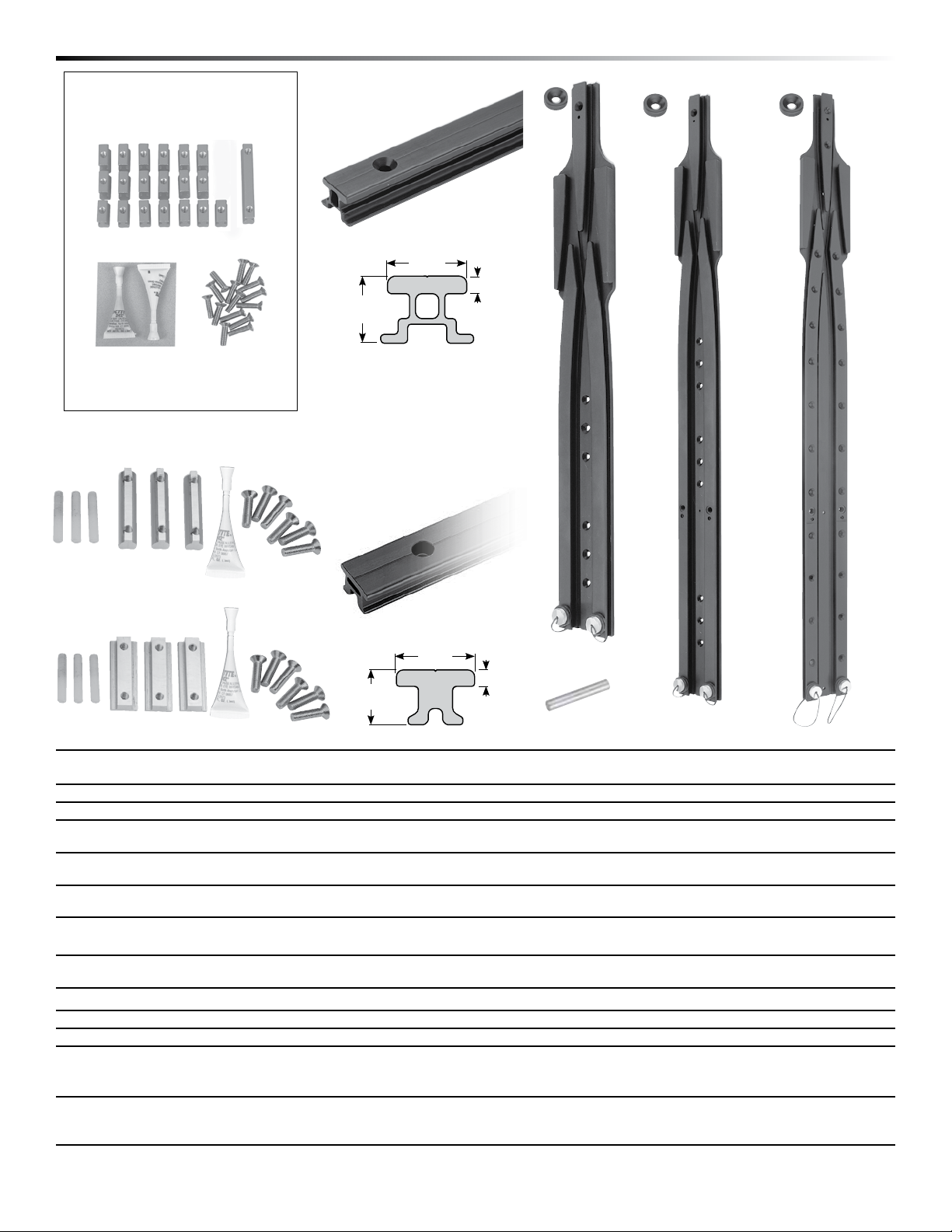

Preassembly Parts

Switch (slug mount) Switch (drill and tap)

Track mounting kit (slug mount)

HC9106, HC9107, HC9108

HC9702, HC9703, HC9704

Slug mount track

a

c

Switch mounting kit (slug mount)

HC8918

a b

HC8919, HC8921

Switch/Track (Slug Mount)

HC8800

18 mm

11

/16"

HC8811

4 mm (

5

/32")

b

15 mm

19

/32"

d

HC8800

HC8811

Drill and tap track

d

c

12.7 mm

1

/2"

18 mm

11

/16"

HC7827

HC7827

HC9597

4 mm (

5

/32")

HC8798

HC8230

HC8799

HC10417

Part No. Description Comments

HC8798

HC8799

HC8918, HC8919

HC8921

HC8800, HC8811

HC9106, HC9107

HC9108

HC9702, HC9703

HC9704

Switch (short) Length: 605 mm (23

Switch (long) Length: 857 mm (333/4"); 1 x switch; 2 x screw-pin endstops; 1 x flathead screw HFS320 (5 x 25 mm); 1 x upper stop H-42662

Switch mounting kit

Track

Track mounting kit

Extra slugs for HC8811

(a) 3 x plastic locator screws HFS1170 (5 X 10 mm); (b) 3 x mounting slugs; (c) 1 x blue Loctite® adhesive; (d) 6 x flathead

screws HFS862 (5 x 10 mm). Purchase 1 kit for each section of track.

Length: 2051 mm (8013/16"); HC8800 hole spacing: 100 mm; HC8811 Hole Spacing: 50 mm;

Note: HC8811–order additional slugs and screws for 50 mm hole spacing.

(a) 19 x mounting slugs 19 mm (3/4"); (b) 1 x splice slug 67 mm (25/8"); (c) 2 x blue Loctite; (d) 21 x HFS1015 flathead screws

(5 x 20 mm).

(a) 10 x mounting slugs 19 mm (3/4"); (b) 1 x splice slug 67 mm (25/8"); (c) 1 x blue Loctite; (d) 10 x HFS1015 flathead screws

(5 x 20 mm).*For sail headboard location at full hoist and when sail is reefed.

13

/16"); 1 x switch; 2 x screw-pin endstops; 1 x flathead screw HFS320 (5 x 25 mm); 1 x upper stop H-42662

Switch/Track (Drill and Tap)—Use for masts without grooves or when slugs will not fit

Part No. Description Comments

HC8230

HC10417

HC7827

HC9597

Loctite is a registered trademark of Henkel AG & Company KGaA.

4

Splice link Joins HC7827 track sections; purchase two (2) for each section of track

Switch Length: 857 mm (33

Length: 3000 mm (1181/8"); hole spacing: 100 mm; purchase stainless steel #10 (5 mm) screws separately (quantity 13.333

Drill/tap track

Drill/tap track

fasteners/meter of track). Do not use open-backed HC8800 or HC8811 track (requires mounting slugs). See page 12 for drill/tap

sizes and mounting instructions.

Length: 2000 mm (783/4"); hole spacing: 50 mm; purchase stainless steel #10 (5 mm) screws separately (quantity 13.333

fasteners/meter of track). Do not use open-backed HC8800 or HC8811 track (requires mounting slugs). See page 12 for drill/tap

sizes and mounting instructions.

3

/4"); Switch may be shortened to 605 mm (2313/16"); 1 x switch; 2 x screw pin endstops; 1 x upper stop H-42662

Page 5

Preassembly Sizing/Sail Modifications

Sizing

Note width and shape of switch and build

a platform on mast to mount.

Sizing

Make sure you have the correct size Battcar system for your boat.

System

18 mm

18 mm HL

Maximum sail area

Monohull Multihull

2

(450 ft2) 30 m2 (325 ft2)

41 m

2

(600 ft2) 46 m2 (500 ft2)

56 m

Track Length and Switch

Height Considerations

Switch height is determined by the number

of cars required for system and the length

of the storage track.

Note: Cars will not pass each other if

top of car is higher than “A” distance.

See chart below.

A

Switch

HC8798

HC8218

HC8799

HC8219

mm in

286 11

540 21

1

/

4

1

/

4

Part No.

Headboard car

HC7906 HC8537 HC7905

HC7906HL

Part No.

Batten car

HC8537HL,

HC7904HL

Intermediate car

Part No.

HC7905HL

Allow 63 mm (21/2") below track to remove car.

INCORRECT

Feeder

Gap

A

Cars can pass each other if not higher than “A”.

Switch

Locate switch so feeder gap does not

interfere with mounting slugs.

A

3852

305 mm

12"

Make sure track is longer than sail luff to

allow for stretch as sail ages. Track must

not block halyard exit.

5

Page 6

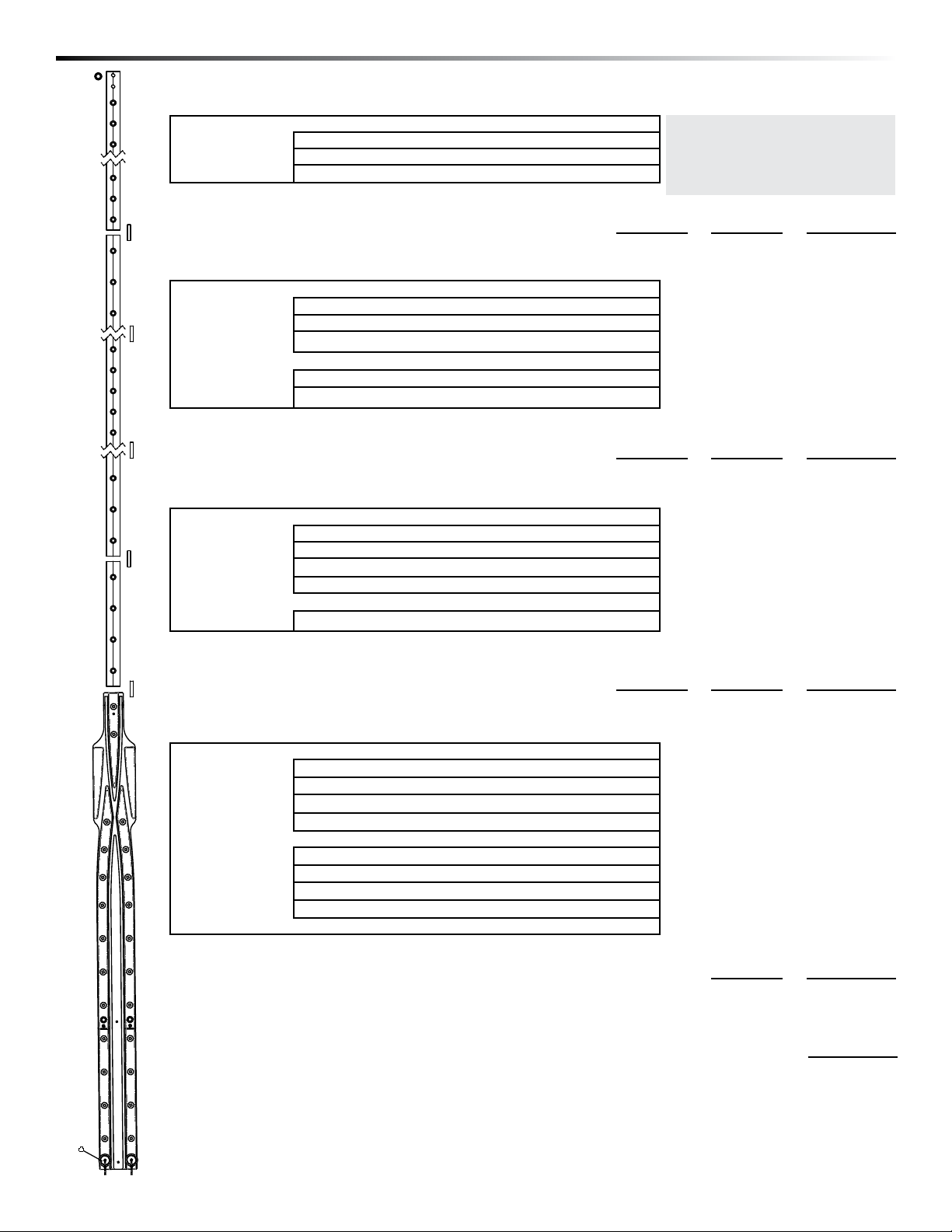

Preassembly Track Length

Layout system using charts to plan track location and lengths.

A

B

C

Top track—variable-length

Length Hole Spacing

mm in mm

Standard track—slug-mount

Length Hole Spacing

mm in mm

2051 80

Standard track—drill and tap

Length Hole Spacing

3000 118

High-load track—slug-mount

Length Hole Spacing

mm in mm

2051 80

Place in reefed headboard areas on larger boats.

High-load track—drill and tap

2000 78

13

/

16

1

/

8

13

/

16

3

/

4

Total Track Length __________

75

Length Quantity

100

75

Length Quantity

50

50

Top Track Length A __________

- SUM __________

X =

1

+

X =

+

D

Switch—slug-mount

Length

mm in

605 2313/

857 333/

Switch—drill and tap

Length

mm in

605 2313/

857 333/

Short drill and tap switch is created by shortening switch.

16

4

16

4

Length Quantity

—

—

—

—

—

—

—

—

X =

+

=1

Quantity

SUM

Enter SUM above to

calculate Top Track Length.

2

6

Page 7

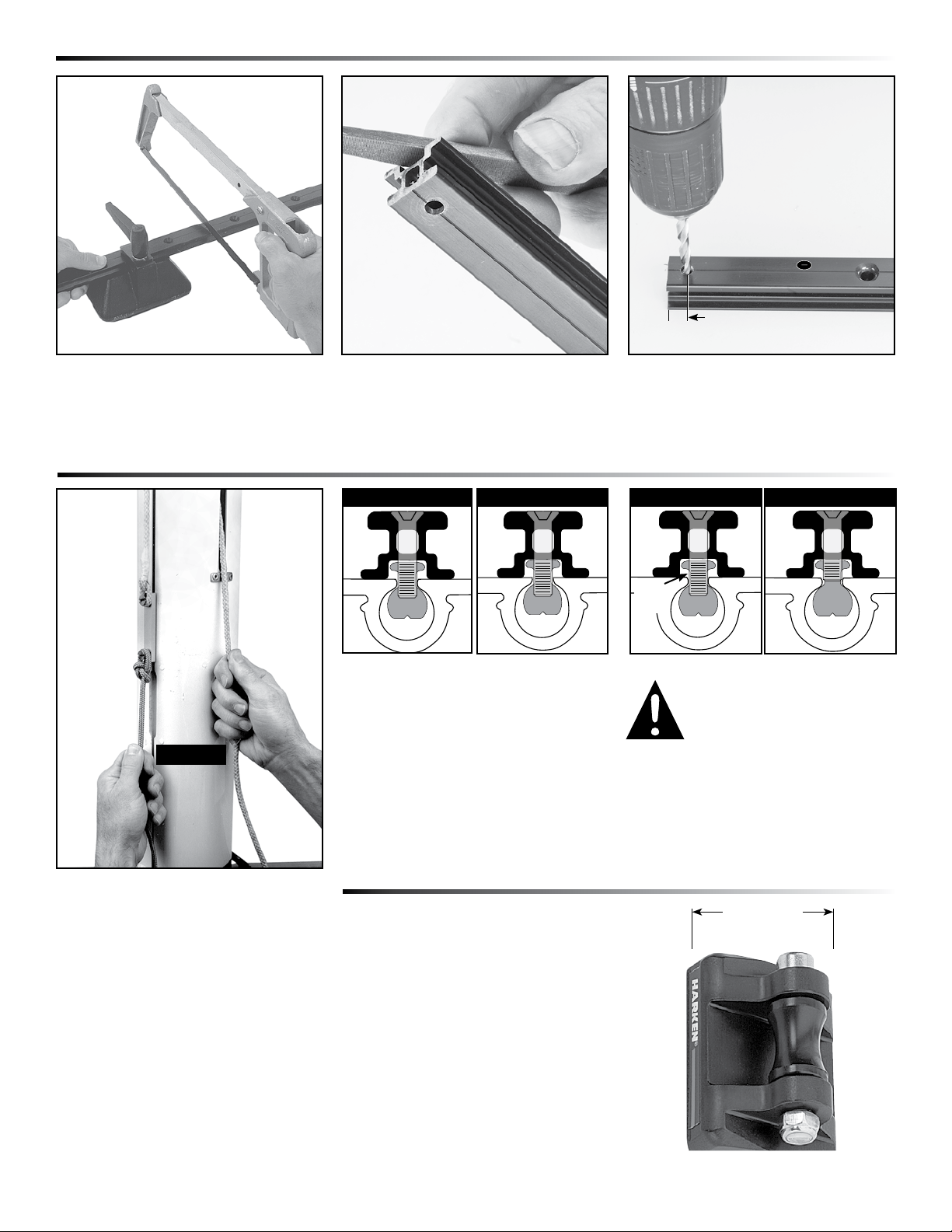

Assembly—Slug-Mount Cut Top Track to Length

Cut variable length top track.

Check Fit of Mounting Slugs and Car

Check fit

Deburr cut.

Slightly round track corners that will

slide against mast.

CORRECT

Slug

Will Tighten

INCORRECT

Slug

Will Not Tighten

Test track: Put mounting slug in groove,

track section on mast. Tighten with screw.

Make sure track will tighten to mast before

slug contacts track underside.

Mounting screw must be long enough for

mast groove. If necessary, purchase longer

screws.

10 mm (

3

/8")

Drill 5.5 mm (7/32") hole in cut end

of track for endstop.

CORRECT INCORRECT

10 or

more

Slug

Slug

Warning! Some masts might not

allow enough screw engagement

into slug. Screws need a minimum

of 10 threads (turns) engaged to

hold track to mast.

Turn screw 360° at least 10 times after

threads engage slug.

67 mm (25/8") splice slug must fit feeder

opening. File opening to make longer.

Use halyard with retrieval line to run

67 mm (25/8") splice slug up mast to

check for burrs in groove.

Mast prebend: Might require straightening

before installation.

Clear of Trysail Track?

Cars must clear storm trysail track.

Tracks often converge above spreaders.

Aft face of mast must be flat

or convex.

42 mm (121/32")

7

Page 8

Assembly—Slug-Mount Install Track

Note: When using HC8811 track,

put slugs at 50 mm intervals at sail

headboard location at full hoist and

when sail is reefed. Otherwise skip holes

so slugs are at 100 mm hole spacing.

Full hoist

High-load track with

50 mm hole spacing.

Slip top track slugs into mast groove. Use

32 mm (3/4") mounting slug for top stop.

Mast-up: Tape top stop slug even with top

of upper track. Tape other slugs in place.

Loctite is a registered trademark of Henkel AG & Company KGaA.

One drop blue Loctite® adhesive into each

splice slug hole.

100 mm

omit every other

screw and slug.

Thread 5 mm x 25 mm endstop screw

through endstop, track, and into slug.

Mast-up: Remove tape. Tighten screw

to hold track.

8

Slide slugs into place with putty knife.

Loosely install 5 mm x 20 mm screws.

Tip: Use putty knife to see if screws

are loose enough to slide in groove.

Remember: Tracks may stick when

reaching a spliced area on mast.

50 mm

reef position.

High-load track with

50 mm hole spacing.

100 mm

omit every other

screw and slug.

Page 9

Assembly—Slug-Mount Install Track

Hold full-length track piece up to mast.

Loosely install top screw.

Use putty knife to slide additional slugs

and splice slug into place. Loosely install

all nineteen 5 mm x 20 mm screws.

Slide tracks up enough to fit next track.

Mast-up: Hold upper tracks. Loosen screw

that holds tracks. Slide track up. If screws

bind in mast groove opening, loosen them

until track slides. Tighten new bottom

screw securely.

CAUTION! Do not let tracks

drop. Severe injury to hands

and/or fingers can result.

Repeat until full-length tracks installed.

Loosen top screw. Slide top track up and

position next 2.05 m (6'87/8") track.

Mast-up: Tighten bottom screw to

hold track.

Loctite is a registered trademark of Henkel AG & Company KGaA.

Slide 19 mounting slugs and splice slug

into mast groove.

Mast-up: Tape in place.

One drop blue Loctite® adhesive into

each hole.

Hold switch in place and make sure there

is 64 mm (21/2") below for loading cars.

9

Page 10

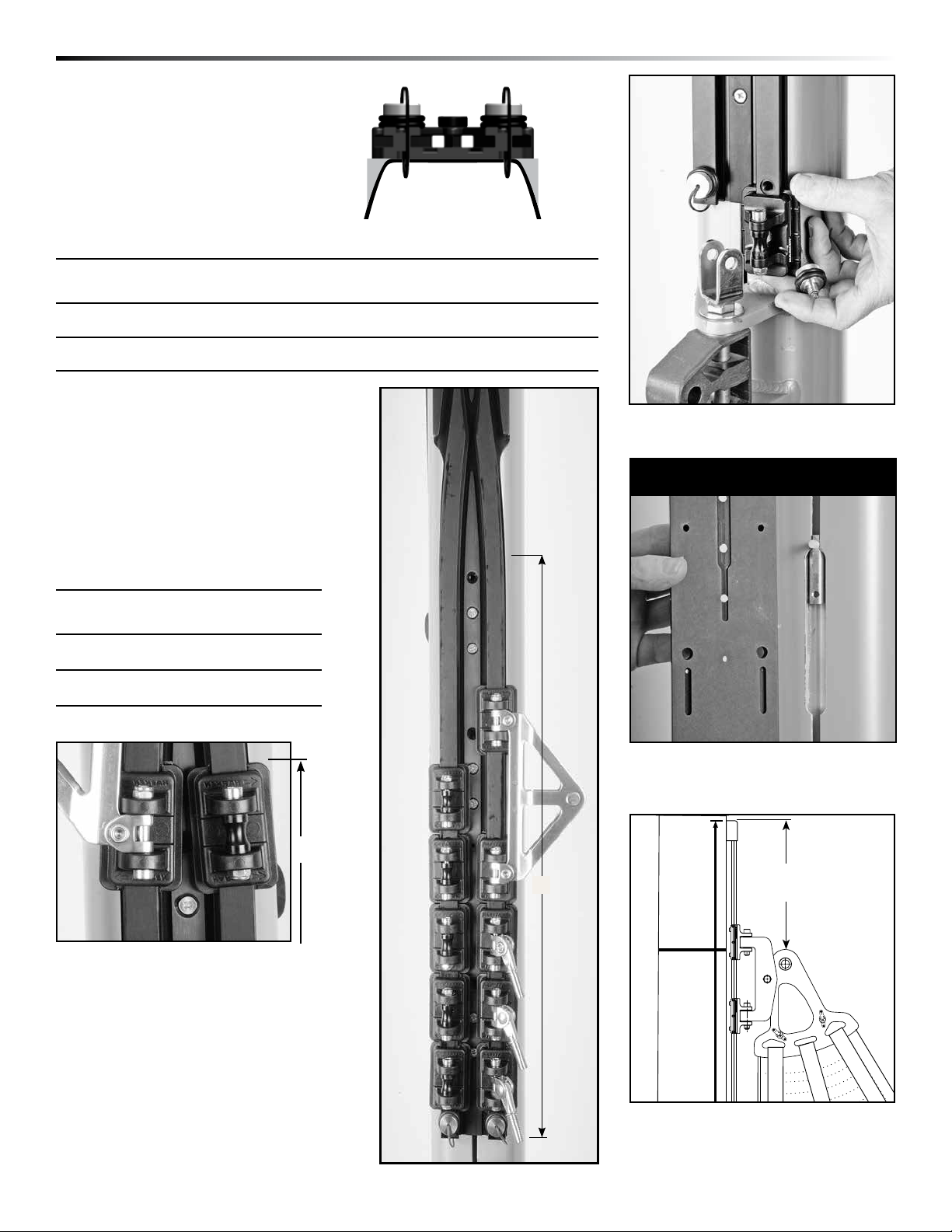

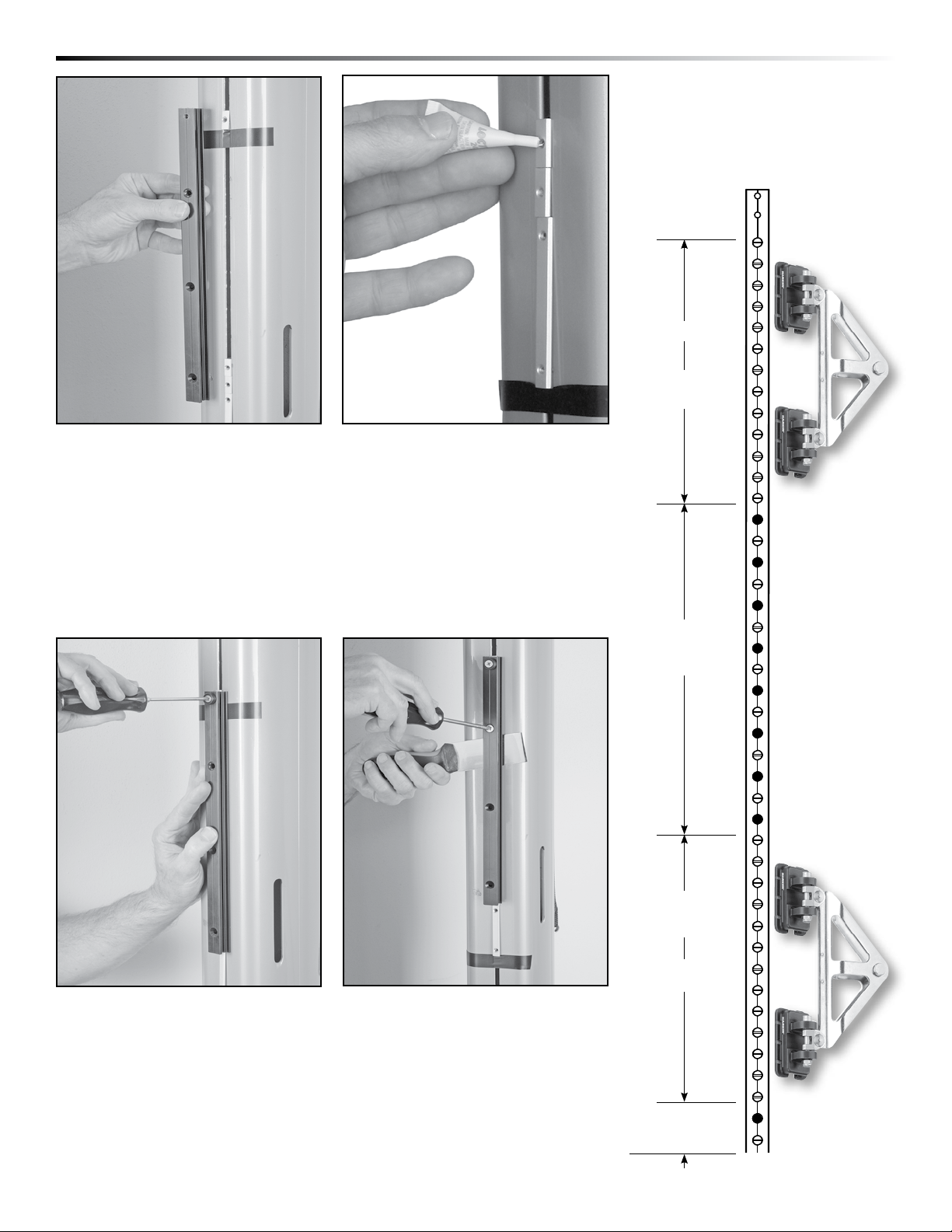

Assembly—Slug-Mount Install Track

2

1

Switch

bottom

Note location of bottom of switch and

storage tracks on mast. Refer to chart

below and put marks on mast at two (2)

or three (3) locations as shown. Make

sure slug is not located at feeder gap.

See page 6.

Wide

section

Back of

switch

Flat slug: Load slug into mast so plastic

locator screw is at bottom.

Slug will fasten in “wide section” of slot.

Back of

switch

Narrow

section

Round slug: Load slug into mast so plastic

locator screw is at top.

Slug will fasten in “narrow section” of slot.

Part

No.

HC8798

HC8799

Switch length

603 mm

(

23

857 mm (33

1 2 3

mm in mm in mm in

3

/

4

)

79 31/8219 85/8— —

3

108 43/4335 133/16475 1811/

/

4

)

16

Load slugs.

10

Tighten screw so slug stays in place at

location from chart above.

Check fit (round slug shown).

Page 11

Assembly—Slug-Mount Install Switch

Install switch over slugs so plastic locator

screw is through center hole.

Install connector screw using blue Loctite®

adhesive on screw. If necessary loosen

plastic locator screws.

Install screw in open slug hole using blue

Loctite adhesive.

Round slug will go below/flat slug above.

Loctite is a registered trademark of Henkel AG & Company KGaA.

Remove plastic locator screw and replace with

mounting screw. Use blue Loctite adhesive.

11

Page 12

Assembly—Drill and Tap Mount General Instructions

Part No. Comments

HC7827

—

HC8230

HC8218

HC8219

Track

1

Length: 3000 mm (118

Do not use HC8800 or HC8811 for drill and tap.

#10 (5 mm) flathead screws (not included); 131/3 fasteners/meter of track.

Splice links. Order one per section of track.

Length: 605 mm (23

Switch: 605 mm (23

Includes two screw-pin endstops and one upper stop.

/8") Determine track length. See page 6.

Track Fasteners

Switch

13

/16")

13

/16") and storage track: 252 mm (915/16").

Drill

Tap

Removing Old Track

Track on mast: Before removing, scribe pencil line down either side of track.

Track off mast: Attach string to mast to line up track during installation.

Mount Track to Carbon Mast

Consult with mast builder. Use suitable reinforcing plates when fastening track to carbon spars.

Drill and Tap Sizes

mm in

4.2 mm

5 x .80 mm 10-32

HC7827

12.7 mm

(1/2")

5

/32

18 mm

(11/16")

4 mm (

HC7827

5

/32")

General Instructions

When mounting tracks, work using a straight edge reference line along mast. Do not let tracks vary from this line.

Tape track in place and center punch hole at bottom using a transfer punch.

Tip: Use low-speed drill with tap for cutting threads.

IMPORTANT! Use blue Loctite® adhesive instead of oil to lubricate tap.

Drill and tap single hole. Fasten track using

this single screw and align side-to-side

correctly. Use tape to hold in place.

Move up several holes and use transfer

punch to mark a second hole. Remove track.

Drill and tap hole.

Fasten track using two screws. Mark all remaining

holes using punch. Remove track. Drill and tap all

holes. Before installing track make sure upper

end has splice piece inserted.

Use threadlocker or epoxy to secure screw.

Specific instructions follow.

Loctite is a registered trademark of Henkel AG & Company KGaA.

12

Page 13

Assembly—Drill and Tap Mount Install Switch

Insert splice link into switch track.

Using a plastic hammer, tap link into place.

Carefully align track and tape in place.

Use a transfer punch to mark a single hole.

Remove track. Drill and tap. Fasten with

single screw, no adhesive.

Realign track and mark a second hole using

transfer punch. Screw to mast using two

screws, no adhesive.

Mark remaining holes using transfer punch.

Remove track. Drill and tap remaining holes.

Mount switch to mast using threadlocker

or epoxy on screws as required.

13

Page 14

Assembly—Drill and Tap Mount Install Track

HC10417 only

If shortening is required, use lines scribed on

switch track to indicate cut line. Make sure you

add 254 mm (10") to the upper track length.

Before mounting track, move endstops and

tether to new locations.

Tip: Move one at a time so you can see how

the line is run through the deadend hole.

Carefully align track. Use transfer punch to mark

holes. Drill, tap, and mount as directed above.

Important! Do not use epoxy or threadlocker

on screws because gate track is removed for

loading cars.

14

Page 15

Assembly—Drill and Tap Mount Install Track

With track off mast, tap upper splice link

into track using procedures outlined above.

Follow general instructions (page 15)

for drilling and taping a single hole.

Always make sure tracks are aligned.

Install Top Stop

Use H-42662 as top stop.

15

Page 16

Commissioning Slug-Mount / Drill and Tap Mount

Lubricate cars onshore before loading.

Before bringing headboard assembly or

cars onboard boat, spray underbody track

slot (see arrows above) with a light coating

of McLube

®

Sailkote™ adhesive.

Loading headboard assembly.

Note location of guide pegs on the feet

of cars. Guide pegs must be on same

side. Also cars must be loaded so pegs

are on inside of switch. Plain foot will be

on outside. If loading on left, plain foot

WARNING! Overspray from

McLube will cause slippery

must be on left. If loading on right, plain

foot must be on right.

decks which can result in

loss of footing. Cover decks

or spray cars off boat.

Tip: To load headboard car assembly,

angle headboard. Roll car onto tracks.

If necessary, remove headboard assembly.

IMPORTANT! When all cars are aluminum, do not mix

intermediate cars with other cars. See below.

Batten/headboard car

with low friction slider.

Hole in hole

Hole in Hole

Hole in batten/

headboard car

Intermediate car

with Delrin® slider.

No hole in

intermediate car

Loading cars.

Pegs on foot of car guide it to correct

side. Pegs must be on inside.

Tip: Load cars on right track – plain foot

on right; left track – plain foot on left.

Attaching sail

Important: Tighten until screw is even

with plastic insert in nut. Do not overtighten.

Car will bind and can warp permanently.

If cars are off track and sail attaching hardware removed, do not mix intermediate base

cars with batten or headboard base cars. All cars have center hole in aluminum car. Low

friction sliders have a hole in the plastic visible from below and from hole in aluminum car.

Part No. Description Slider Material Hole in Plastic Slider

HC7904HL

HC8537HL

HC7906HL

HC7905YHL

McLube is a registered trademark of McGee Industries, Inc. SailKote is a trademark of McLube, a division of McGee Industries.

Delrin is a registered trademark of E. I. du Pont de Nemours and Company or its affiliates.

16

12 mm batten car Low friction Yes

10 mm batten car Low friction Yes

Headboard cars Low friction Yes

Intermediate car Delrin No

If screw extends below

nut, it is overtightened.

Page 17

Commissioning Lazy Jacks

H

A

R

K

E

N

H

A

R

K

E

N

Use shockcord to hold Lazy Jacks open

so Battcars and battens will not catch on

them. This will also help stop slapping of

Lazy Jacks on sail.

Attach one end to lower spreader tips and

other to Lazy Jacks. Make sure shockcord

is long enough so boom can swing all the

way out without damaging spreaders.

Operation Raising Sail

When raising, lowering, or reefing sail, make sure sail

is not loaded and cars pass easily through switch.

Watch sail and cars carefully. Stop hoisting immediately

if any binding is detected.

Possible sources of binding:

Cars bind at switch.

Reef line binds on fingers.

Reef line binds between car and switch.

Headboard binds on Lazy Jacks.

Correct the binding problem or luff sail before

resuming hoist. If forced, the fingers that extend

into switch may be damaged, requiring expensive

switch and car replacement. Lazy Jacks may also

be damaged.

Important! When using an electric halyard winch,

be especially vigilant when raising sail. Luff sail.

Watch for any binding or jamming at the switch.

Stop hoist immediately if any occurs.

If winch operator does not have a good view of switch

cars, station a crew member with a good view and

communication to operator.

Crew member must be able to communicate

problems to the winch operator immediately.

IMPORTANT! Watch for

binding at switch. Stop

hoisting immediately.

If there is a jam, damage to switch and cars will

occur very quickly resulting in expensive repairs

unless hoisting is stopped.

Important! Make sure reef outhaul loads are not applied

to cars when in switch. Damage to switch and cars will

occur, resulting in expensive repairs.

17

Page 18

Sailmakers Instructions Slug-Mount / Drill and Tap Mount

C

B

HC7906

HC7906HL

D

C

B

B

E

A

A

D

E

A

F

HC7905

HC7905HL

HC7904HL

HC8537HL

HC8537

E

D

Dimensions (measured from aft face of mast)

Part No. Description in mm in mm in mm in mm mm mm

A B C boltrope setback D E pin Ø F stud Ø

HC7906

HC7905

HC8537

HC7906HL

HC7905HL

HC7904HL

HC8537HL

Headboard car 7

Intermediate car 2

Batten car (10 mm stud) 2

Headboard car 7

Intermediate car 2

Batten car (12 mm stud) 2

Batten car (10 mm stud) 2

13

/

16

1

/

2

1

/

2

13

/

16

1

/

2

1

/

2

1

/

2

A B C boltrope setback D E pin Ø F stud Ø

Part No. Description in mm in mm in mm in mm mm mm

HC7906

HC7905

HC8537

HC7906HL

HC7905HL

HC7904HL

HC8537HL

Headboard car 7

Intermediate car 2

Batten car (10 mm stud) 2

Headboard car 7

Intermediate car 2

Batten car (12 mm stud) 2

Batten car (10 mm stud) 2

13

/

16

1

/

2

1

/

2

13

/

16

1

/

2

1

/

2

1

/

2

Mounted on slug mount track

198 11/

63 11/

63 11/

198 11/

63 11/

63 1

63 1

4

4

4

4

4

1

/

4

1

/

4

Mounted on drill tap track

198 11/

63 11/

63 11/

198 11/

63 11/

63 1

63 1

8

8

8

8

8

1

/

8

1

/

8

31 29/

31 29/

31 29/

31 29/

31 29/

31 2

31 2

29 215/

29 215/

29 215/

29 215/

29 215/

29 2

29 2

16

16

16

16

16

9

/

16

9

/

16

32

32

32

32

32

15

/

32

15

/

32

65 43/

65 3/

65 39/

65 43/

65 3/

65 3

65 3

62 41/

62 3/

62 37/

62 41/

62 3/

62 3

62 3

16

4

16

16

4

3

/

4

9

/

16

16

4

16

16

4

5

/

8

7

/

16

106 6 —

19 6 —

90 6 10

106 6 —

19 6 —

95 6 12

90 6 10

103 6 —

19 6 —

88 6 10

103 6 —

19 6 —

92 6 12

88 6 10

Installing Headboard Car Assembly

Headboard coupler attaches to standard headboards. Some headboard modification required.

Maximum thickness of headboard plates and sail: 14 mm (9/16").

100mm

(4")

51 mm (2")

Min 9.5 mm

3

(

/8")

Coupler attachment hole

Drill 11 mm (

is 101 mm (4") from top of headboard and 51 mm (2")

from front edge of boltrope.

Leave at least 9 mm (

plate and front edge of coupler attachment hole.

18

7

/

16

") coupler attachment hole so center

3

/

8

") between front of headboard

Coupler

attachment hole

Halyard attachment hole

Use aft hole if headboard has two (2).

If not, drill second hole to accept halyard shackle pin.

Locate hole approximately 64 mm (2

64 mm

1

(2

/2")

Halyard

attachment

hole

1

/

2

") aft of existing hole.

Page 19

Sailmaker's Instructions Slug-Mount / Drill and Tap Mount

Distance Between Attachment Points

Battens and intermediate cars placed at sailmaker's discretion.

Maximum distance between attachment points is 1.2 m - 1.35 m (4' - 4'6").

Distance may be slightly greater. Contact Harken to discuss sail reshaping

to eliminate luff flutter.

Note: Adding battens may reduce stack height by eliminating luff cars.

CORRECT

DIAGRAM A

INCORRECT

Loaded cars must

not ride in this area

while sailing.

DIAGRAM B

Setting reef points

Space reef points halfway between sail attachment points. Battens or reef points

may need to be moved. Diagram A.

Note: Batten fittings and cars cannot handle reefing outhaul or downhaul loads.

Transfer loads to a tack fitting. Diagram B.

Important! When setting up reef, make sure cars are not loaded when they are

in the switch area. If reef outhaul loads are applied to switch, switch and cars

will be damaged resulting in expensive repairs. Instruct operators not to raise

or lower sails with high loads on cars while in the switch area. Harken is not

responsible for damage to the switch area due to reef loads, or for raising or

lowering a sail when the sail is loaded.

19

Page 20

Replacement Parts

6

HC7906

5

2

HC8537

2

4

3

HC7905

4

2

3

4

3

1

1

Part No. Qty Description

1

2

3

4

5

6

H-40882 2 Car

H-36184B 1 Headboard receptacle

HFS1059 2 Screw SHCS M6 x 40 mm*

HFS852 2 Nut M6 locking

H-24211A 1 Clevis pin

HFS181 1 Cotter pin

*SHCS = Socket head cap screw.

HC7906

Part No. Qty Description

1

2

3

4

1

2

3

4

H-40882 1 Car

MP-0708 1 Delrin

HFS1059 1 Screw SHCS M6 x 40 mm*

HFS852 1 Nut M6 locking

Part No. Qty Description

H-40882 1 Car

H-36490A 1 Threaded stud

HFS1059 1 Screw SHCS M6 x 40 mm*

HFS852 1 Nut M6 locking

*SHCS = Socket head cap screw.

HC7905

HC8537

1

®

roller

Delrin is a registered trademark of E. I. du Pont de Nemours and Company or its affiliates.

20

Page 21

Replacement Parts

7

8

2

HC7904HL

HC7906HL

4

6

HC7906HL

Part No. Qty Description

1

H-59240 (w/MP-171 pegs) 2 Car with guide pegs

2

3

4

5

6

7

8

H-36184B 1 Headboard receptacle

HFS1059 2

HFS852 2 Nut M6 locking

H-45064 4 Igus bushing

4913 4 Harken label

HFS181 1 Cotter pin

H-24211A 1

1

Screw SHCS

M6 x 40 mm*

3

/8 x 1.1"

Clevis pin

5

2

HC8537HL

3

4

HC7905HL

2

5

2

3

5

4

6

1

6

1

3

5

4

6

1

3

HC7904HL

Part No. Qty Description

1

H-59240 (w/MP-171 pegs) 1 Car with guide pegs

2

3

4

5

6

H-37120A 1 Threaded stud

HFS1059 1

HFS852 1 Nut M6 locking

H-45064 2 Igus bushing

4913 2 Harken label

Screw SHCS

M6 x 40 mm*

*SHCS = Socket head cap screw.

HC7905HL

Part No. Qty Description

1

H-45530 (w/MP-171 pegs) 1 Car w/guide pegs

2

3

4

5

6

*SHCS = Socket head cap screw.

Delrin is a registered trademark of E. I. du Pont de Nemours and Company or its affiliates.

MP-0708 1 Delrin

HFS1059 1

HFS852 1 Nut M6 locking

H-45064 2 Igus bushing

4913 2 Harken label

Screw SHCS

M6 x 40 mm*

®

roller

*SHCS = Socket head cap screw.

Part No. Qty Description

1

H-59240 (w/MP-171 pegs) 1 Car with guide pegs

2

3

4

5

6

*SHCS = Socket head cap screw.

H-36490A 1 Threaded stud

HFS1059 1

HFS852 1 Nut M6 locking

H-45064 2 Igus bushing

4913 2 Harken label

HC8537HL

Screw SHCS

M6 x 4 mm*

21

Page 22

Problem Probable Cause

Cut end of top or bottom track at joint. Make sure the anodized end is toward the full-length track.

Tracks do not butt up against each other.

Track weight pulling tracks apart.

Mounting slugs do not fit. Slugs wrong size. Different size slug required. Contact your dealer.

Mounting screws will not tighten. Incorrect mounting slug used. Different size slug required. Contact your dealer.

Solution

Tracks will come together when you loosen the

bottom screw and push the tracks up the mast.

Slugs catching on mast splice.

Corners of cut track catching. Use file to round off corners of track.

Track will not slide up mast.

Mast has too much prebend. Ease backstay and/or straighten mast.

Paint or other material clogging mast groove. Clean out groove.

Sail headboard does not fit inside coupler. Ring was not pressed far enough. Take sail to sailmaker.

Loosen screws slightly. If necessary have someone

at splice area to wiggle the slug past the splice.

Troubleshooting

Problem Probable Cause Solution

Slider damaged or missing. Check and/or replace slider.

Spray a small amount of McLube

in underbody track slot of all cars. If possible spray cars

Too much friction.

Cars bind.

Stud threaded too tightly into receptacle. Back off threaded stud two turns.

Cap screws and nuts are overtightened on plastic cars. Loosen nut until screw end is even with plastic in nut.

off boat. If this is not possible, use a drop cloth to keep

overspray off deck. McLube will cause slippery decks

which can result in loss of footing (page 16).

®

Sailkote™ lubricant

Can't raise sail, cars stop at switch. Car loaded upside down. Pins in car on wrong side. Remove car, flip it around and reload.

Nut on Battcar is not holding. Locknut has been used too many times. Get new 6 mm locknut.

Batten receptacle does not rotate. Nuts are too tight. Loosen nuts slightly.

Cars jam when raising sail. Headboard or cars are catching on Lazy Jacks.

Sail will not go all the way up. Sail is too tall or sheave is too far forward. Have sail shortened or move sheave aft.

Vertical post or pin on batten receptacle bending. Reef loads are being transferred to batten receptacle.

Reef tack fitting will not reach reef hook. Reef point too close to sail attachment. Move intermediate car sail attachment.

Delrin is a registered trademark of E. I. du Pont de Nemours and Company or its affiliates. Loctite is a registered trademark of Henkel AG & Company KGaA.

McLube is a registered trademark of McGee Industries, Inc. SailKote is a trademark of McLube, a division of McGee Industries.

Use topping lift or rod vang and shockcord to pull

Lazy Jacks out to shrouds.

Transfer reef downhaul and outhaul loads to mast

or boom gooseneck.

Maintenance

Harken equipment is designed for minimal maintenance, but some maintenance is required for optimum and safest possible operation and to comply with

the Harken limited warranty. In general, the most important aspect of maintenance is to keep your equipment clean by frequently flushing with fresh water.

In corrosive atmospheres, stainless parts may show discoloration around holes, rivets, and screws. This is not serious and may be removed with a fine abrasive.

With the exception of winches, do not use grease unless specifically recommended in the instruction sheet.

Flush blocks thoroughly with fresh water. Periodically, disassemble the blocks and clean with detergent and fresh water. Lubrication is not required.

IMPORTANT! Exposure to some teak cleaners and other caustic solutions can result in discoloration of part and is not covered

under the Harken warranty.

Warranty

For additional safety, maintenance, and warranty information: www.harken.com/manuals or the Harken catalog.

22

Page 23

Sail Control

Ultimate

FURLING

Q

&

A

HOW CAN I REDUCE HEEL

AND GET BETTER CONTROL

WITH A REEFED SAIL?

Harken MKIV roller reefing

and furling units solve the

inefficient shape of

reefed sails with

independent head

and tack swivels.

The independent

swivels allow the

middle to furl first,

flattening the sail

and reducing heel.

WITH HARKEN MKIV

JIB REEFING AND FURLING

Easy Shorthanded Cruising

Instead of changing sails, simply furl

or unfurl to suit the conditions.

Safe and Convenient

The ability to reef makes it easy to reduce

speed and gain visibility off the bow—

all from the safety of your cockpit.

Bob Grieser Photo

Small outer drums fit on narrow bows

TOP 25 FURLING Q&A:

www.harken.com/usa

Our Tech Service Team is ready to answer your furling questions. Call 262-691-3320 or email harken@harken.com

9 rows of ball bearings cut friction

and evenly distribute the load

Large inner spool diameter

increases pulling power

TECH TIP #4

You can have total sail shape and

reefing control from your cockpit

by adding ball bearing genoa lead

cars to your low-friction Harken

furling system.

Page 24

Corporate Headquarters

N15W24983 Bluemound Rd, Pewaukee, WI 53072 USA

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Web: www.harken.com • Email: harken@harken.com

Harken Australia Pty, Ltd.

1B Green Street, Brookvale, N.S.W. 2100, Australia

Telephone: (61) 2-8978-8666 • Fax: (61) 2-8978-8667

Web: harken.com.au • Email: info@harken.com.au

Harken France

ZA Port des Minimes, BP 3064, 17032 La Rochelle Cedex 1, France

Telephone: (33) 05.46.44.51.20 • Fax: (33) 05.46.44.25.70

ul. Rydygiera 8, budynek 3A, lokal 101, I pi

Mailing address: Harken Sweden AB, Box 64, SE -440 30 Marstrand

Bearing House, Ampress Lane, Lymington, Hampshire S041 8LW, England

Web: harken.fr • Email: info@harken.fr

Harken Italy S.p.A.

Via Marco Biagi, 14, 22070 Limido Comasco (CO) Italy

Telephone: (39) 031.3523511 • Fax: (39) 031.3520031

Web: harken.it • Email: info@harken.it

Harken New Zealand, Ltd.

158 Beaumont Street

Unit 11, Orams Marine Centre

Westhaven, Aukland, 1010, New Zealand

Telephone: (64) 9-303-3744 • Fax: (64) 9-307-7987

Web: harken.co.nz • Email: harken@harken.co.nz

Harken Polska SP ZOO

ętro, 01-793 Warszawa, Poland

Tel: +48 22 561 93 93 • Fax: +48 22 839 22 75

Web: harken.pl • Email: polska@harken.pl

Harken Sweden AB

Main Office and Harken Brandstore: Västmannagatan 81B

SE-113 26 Stockholm Sweden

Telephone: (46) 0303 61875 • Fax: (46) 0303 61876

Web: harken.se • Email: harken@harken.se

Harken UK, Ltd.

Telephone: (44) 01590-689122 • Fax: (44) 01590-610274

Web: harken.co.uk • Email: enquiries@harken.co.uk

Please visit: http://www.harken.com/locator.aspx

to locate Harken dealers and distributors

Printed in USA 4679 12/14

Loading...

Loading...