Page 1

Nautor Furling Installation Manual – C7475/C7550

Page 2

GENERAL SPECIFICATIONS Parts List

■ MAIN COMPONENTS

Halyard Swivel C7475/C7550

Feeder, Toggle/Terminal Assembly

Drum Assembly

C7475

C7550

2 Nautor Furling December 2004

Page 3

GENERAL SPECIFICATIONS Parts List

■ MISCELLANEOUS PARTS

®

Red Loctite

Foil Screws Foil Wedges

Torque Tube Screws 5 mm, 8 mm Allen Wrench

®

Prefeeder Blue Loctite

Super Bonder

■ RIGGER PARTS

C7475

1 Trim Cap

9 Connectors

1 Long Bottom Connector

C7550

1 Trim Cap

10 Connectors

1 Long Bottom Connector

■ FOILS

C7475

9 Foils

1 Special Bottom Foil

C7550

10 Foils

1 Special Bottom Foil

December 2004 Nautor Furling 3

Page 4

PREPARATION Headstay Length

■ HEADSTAY CUT LENGTH

Subtract the following from the headstay length and cut the

stay at that point.

HEADSTAY CUT LENGTH CHART

Clevis Pin Size

-30 rod (11.1 mm)

-40 rod (12.7 mm) — 201 mm

22.2 mm 25.4 mm

187 mm

—

HEADSTAY CUT LENGTH

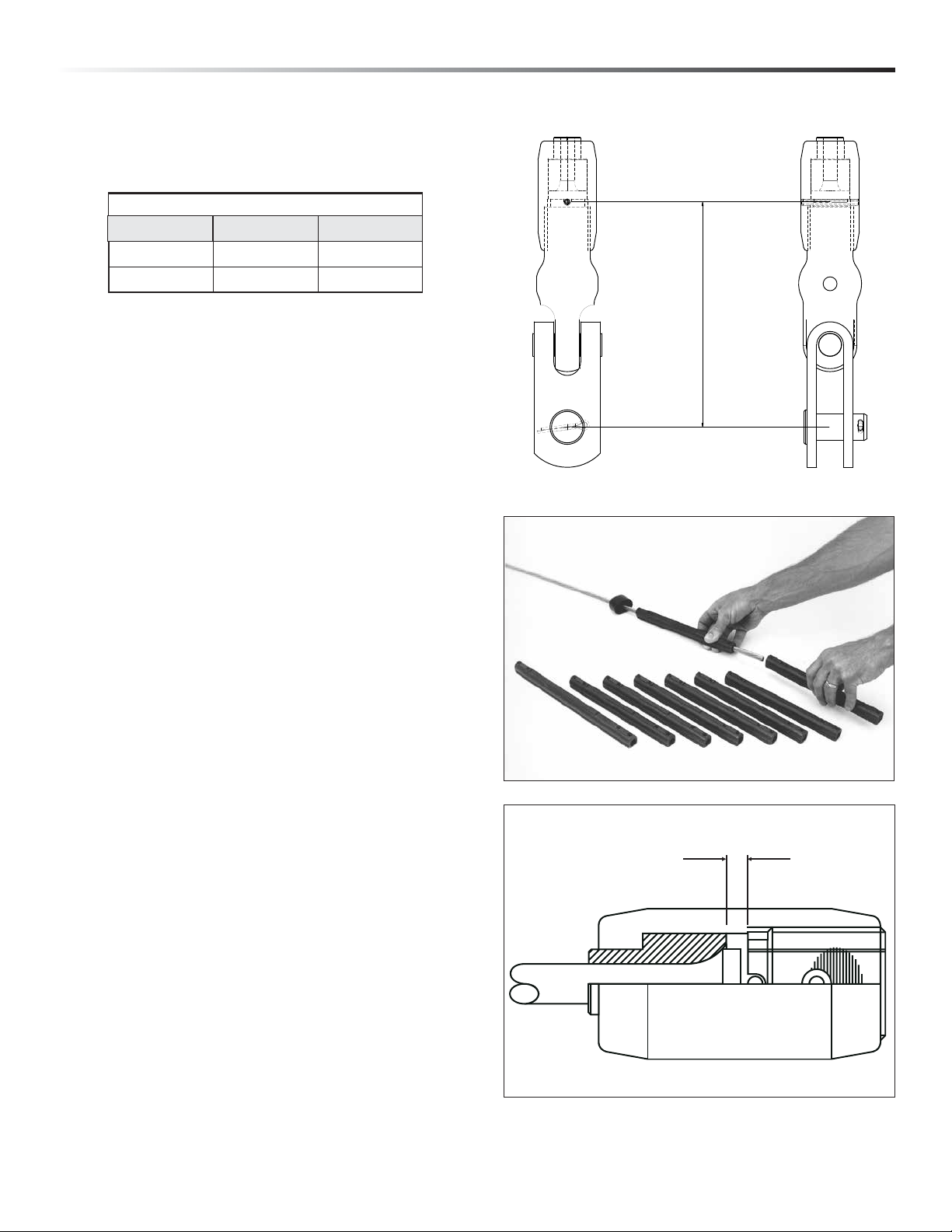

■ STRINGING CONNECTORS ON STAY

Make sure the trim cap is at the top and the correct number

of connectors are used. The long bottom connector must be

slid on the rod last.

■ ROD COLDHEAD HEIGHT

Make sure the length of coldhead does not interfere with the

drive pin.

Distance between the collet bottom and the rollpin is 6.5 mm

6.5 mm

4 Nautor Furling December 2004

Page 5

PREPARATION Foil Length

■ FOIL CUT LENGTH

Foil cut length is based on pin-to-pin length as measured

from center of upper pin (attaches the stay to the mast) to

center of lower pin (attaches the furling unit to the boat).

Measurement includes the masthead toggle.

To check foil length, lay foils alongside stay before cutting

top foil.

■ TOP FOIL CUT LENGTH

Instructions For Worksheet Below:

1 Fill in total pin-to-pin length.

2 Fill in A length.

3 Add A, B, E, F, G and subtract from total pin-to-pin length.

SUM = _________

4 Choose the number from foil multiplier below closest to,

but not greater than, sum from step 3. Fill in D length.

7 x 2133.6 = 14935.2

8 x 2133.6 = 17068.8

9 x 2133.6 = 19202.4

10 x 2133.6 = 21336.0

11 x 2133.6 = 23469.6

12 x 2133.6 = 25603.2

5 Add A, B, D, E, F, G.

Subtract from pin-to-pin length for C (top foil length).

WORKSHEET: DETERMINE TOP FOIL LENGTH

C7550

-40

25.4 mm

PIn

DIMENSIONS

A Center of PIN to Bottom of

C7475

-30

22.2 mm

PIn

_____ _____

Terminal

B Bottom of Terminal to Top of Foil

20 mm

20 mm

C Top Foil _____ _____

D __?__ 84” (2133.6 mm) Foils

(Quantity)

_____

_____

E Feeder Gap 60 mm 76 mm

F Bottom Foil 610 mm 610 mm

G Clevis Pin to Foil 661 mm 674 mm

Total Pin-to-Pin Length _____ _____

December 2004 Nautor Furling 5

Page 6

PREPARATION Foil Length

■ CUTTING TOP FOIL

Once you have checked the top foil length, cut the top foil.

Deburr and clean all shavings from the foil.

Important: Failure to deburr or clean the inside of the foil may

cause it to seize to a connector when installing on rod.

Rough up the top 1” (25 mm) of the foil using a file or

sandpaper.

ASSEMBLY Foils

■ ASSEMBLE FOIL

Slide the trim cap and one connector to the top of the

headstay. Tape other connectors in place or use a pusher wire

longer than foil to hold connectors back.

Slide top foil to top of stay, screw holes toward the bottom.

®

Coat the connector with red Loctite

.

Place a wedge in the indentation with the circular mold mark

towards the connector.

Push the connector into the top foil until it is recessed about

1

/2” (13 mm).

6 Nautor Furling December 2004

Page 7

ASSEMBLY Foils

Use Super Bonder to glue the trim cap to the roughened

foil top.

Slide the next connector to the top of the stay.

Coat half of the connector and the indentation with

®

red Loctite

.

Place a plastic connector wedge in the indentation

closest to the top foil.

Coat foil screws with red Loctite. Screw them into the

connector until tight. Continue assembly.

Slide halyard swivel onto foil, tall end up.

December 2004 Nautor Furling 7

Page 8

ASSEMBLY Foils

Install feeder screws toward bottom, using blue Loctite®

on screws.

Slide lower unit onto foils.

ASSEMBLY Attach Stay

■ ATTACHING STAY TO TOGGLE/TERMINAL ASSEMBLY

Make sure halyard swivel and drum assembly have been

slipped on the foils.

Slip the rod adapter sleeve onto the rod.

Sandwich the nosepiece over the rod and insert into the

main body, narrow end first. Jiggle the sleeve or use a small

screwdriver to push the nosepiece completely into sleeve.

Put several drops of the blue Loctite on the large threads

of the stud. Thread the stud into the main body until the

slot aligns neatly with the hole in the main body.

TIP: Sight through the pin hole to find the optimum thread

engagement. Make sure the stud is threaded far

enough so the pin is securely seated in the slot,

yet not threaded too far to block the pin.

8 Nautor Furling December 2004

Page 9

ASSEMBLY Attach Stay

Hammer the pin into the main body.

®

Clean excess Loctite

from the terminal body. Tape around

sleeve to secure pin.

Lower drum assembly and slip clevis pin and cotter pin

in place.

®

Coat threads of torque tube screws with blue Loctite

.

Raise foils and insert foil screws.

ASSEMBLY Foil Length

Check the clearance between the top of the foil and top

terminal.

TIP: Check clearance when the unit is on the ground,

before raising the headstay into position.

December 2004 Nautor Furling 9

Page 10

ADJUSTMENTS Halyard Wraps

■ HALYARD WRAPS

The most serious problem with furling systems occurs when

the jib halyard wraps around the headstay foil. Halyard wraps

will prevent furling or unfurling and may cause serious damage

to the unit and the halyard. In severe cases, halyard wraps

may cause headstay loss.

To prevent wraps, the halyard must exert a slight pull to

the rear. This allows the foils to turn while the halyard

remains stationary.

■ PREVENT WRAPS

WARNING: The sail must be fitted to the foils before operation.

1 Halyard swivel should be within the top 4” (100 mm)

of the foil.

2 Halyard must pull slightly to the rear (8 - 10°).

3 Halyard must be snug, but not too tight.

TIP: With the sail raised, walk away from the boat and

look at the masthead with binoculars. Use the halyard

swivel as a measurement reference. 4” (100 mm) is

1

/3 the length of the swivel. There should be less foil

exposed above the swivel than

1

/3 of the swivel.

If a halyard wraps, do not force the unit to turn. Attempt

to open the sail by alternately furling in and out slightly.

If the sail can be unfurled, lower the sail by releasing the jib

halyard. Severe halyard wraps can only be cleared by going

aloft and freeing the halyard.

If the sail will not furl or unfurl, it may be possible to remove

the jib sheets and manually wrap the sail around the headstay.

Remember: Testing at the dock does not indicate the halyard

angle is correct. In wave action, the halyard may wrap if the

lead angle is not correct. The 8-10° diverging angle

mentioned above is critical.

8 - 10°

10 Nautor Furling December 2004

Page 11

ADJUSTMENTS Pendants/Halyard Restrainer

■ PENDANTS

If your sail is not long enough to position the halyard swivel properly, you must add a pendant to the sail. Pendants should be plastic coated wire permanently attached to the sail so the height will

be correct. Adjustable length pendants are not acceptable as they

might not be adjusted correctly during a sail change.

■ INSTALL A PENDANT

1 Raise the sail, but do not attach tack shackle.

2 Position the halyard swivel correctly near the top of the

headstay and secure the halyard.

3 Secure a piece of rope to the sail tack. Lead the line through

the tack shackle on the furling drum and tension the sail.

4 Measure the distance from the tack shackle to the

sail tack and have a pendant of this length permanently

attached to the head of the sail.

5 Repeat this procedure for every jib.

TIP: Pendants are used at the head of the sail. Short

pendants may be added at the tack to improve visibility

under the genoa, but remember that visibility is

already improved by shackling to the tack swivel.

Tack pendants increase heeling moment by raising the

sail plan. You may install pendants at both the head

and tack of the sail.

■ HALYARD RESTRAINER

To prevent wraps, the jib halyard must pull slightly to the

rear. On some boats the halyard sheaves are located too

close to the headstay and a halyard restrainer must be used.

Use halyard restrainers only when required by the masthead

geometry. Restrainers tend to limit sail luff length and may

cause problems if not properly installed.

Mount the restrainer as high as possible on the face of the

mast. Position the restrainer so the foils will not hit it when

under load.

8 - 10°

The restrainer should deflect the halyard 8 - 10°. If the angle

is more than 10°, you may experience difficulty in tensioning

the sail luff, friction in furling and possible damage to the foils.

To decrease deflection angles, shorten the luff of the sail.

TIP: Boats used in charter service should consider using a

halyard restrainer, regardless of masthead geometry.

■ HALYARD TENSION

The jib halyard should be firm, but not too tight.

TIP: The luff foil system supports the sail along its entire

length so halyard tension is required only to shape

sails, not to support them.

Use only enough halyard tension to remove some

wrinkles along the luff. Do not tension the halyard

enough to cause vertical wrinkles in the luff.

Use halyard tension to adjust draft position of the sail

to suit sailing conditions. Your halyard should be firm

but not tight. If in doubt, release halyard tension.

To protect the sail, ease the halyard when the boat

is not in use.

December 2004 Nautor Furling 11

Page 12

Corporate Headquarters

N15W24983 Bluemound Rd, Pewaukee, WI 53072 USA

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Web: www.harken.com • Email: harken@harken.com

Harken Australia Pty, Ltd.

1B Green Street, Brookvale, N.S.W. 2100, Australia

Telephone: (61) 2-8978-8666 • Fax: (61) 2-8978-8667

Web: harken.com.au • Email: info@harken.com.au

Harken France

ZA Port des Minimes, BP 3064, 17032 La Rochelle Cedex 1, France

Telephone: (33) 05.46.44.51.20 • Fax: (33) 05.46.44.25.70

158 Beaumont Street, Westhaven, P.O. Box 90689, Victoria St. West, Auckland 1142, New Zealand

ul. Rydygiera 8, budynek 3A, lokal 101, I pi

Mailing address: Harken Sweden AB, Box 64, SE -440 30 Marstrand

Bearing House, Ampress Lane, Lymington, Hampshire S041 8LW, England

Web: harken.fr • Email: info@harken.fr

Harken Italy S.p.A.

Via Marco Biagi, 14, 22070 Limido Comasco (CO) Italy

Telephone: (39) 031.3523511 • Fax: (39) 031.3520031

Web: harken.it • Email: info@harken.it

Harken New Zealand, Ltd.

Telephone: (64) 9-303-3744 • Fax: (64) 9-307-7987

Web: harken.co.nz • Email: harken@harken.co.nz

Harken Polska SP ZOO

ętro, 01-793 Warszawa, Poland

Tel: +48 22 561 93 93 • Fax: +48 22 839 22 75

Web: harken.pl • Email: polska@harken.pl

Harken Sweden AB

Main Office and Harken Brandstore: Västmannagatan 81B

SE-113 26 Stockholm Sweden

Telephone: (46) 0303 61875 • Fax: (46) 0303 61876

Web: harken.se • Email: harken@harken.se

Harken UK, Ltd.

Telephone: (44) 01590-689122 • Fax: (44) 01590-610274

Web: harken.co.uk • Email: enquiries@harken.co.uk

Please visit: http://www.harken.com/locator.aspx

to locate Harken dealers and distributors

M1013/12-04

Loading...

Loading...