Page 1

INSTRUCTION SHEET

Halyard Restrainers

944/945

N15W24983 Bluemound Rd, Pewaukee, WI 53072-4974

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Web: www.harken.com • Email: harken@harken.com

Strictly follow all instructions to avoid an accident, damage

to your vessel, personal injury or death. See www.harken.com/

manuals for additional safety information.

To be used if angle between halyard and headstay is less than 7°. This

is common on masts where halyard sheave is very close to headstay.

USE ONLY IF NECESSARY

If halyard angle is greater than 7° and halyard is wrapping a halyard

restrainer may not be necessary. Halyard swivel must be near top of

foils and headstay must be tight. This will prevent halyard wraps in

most cases. Consult furling instruction manual.

Tools and Supplies

Method Rivet Tap U.S. Tap Metric

Fasteners

(not included)

Drill Ø

Tap Size —

3

(6)

/16"

SS Rivets

13

/64" (5 mm)

(6) 10-32 x 3/8 SS

Machine Screw RH

5

/32" 4.2 mm

10-32 5 x .80 mm

(6) 5 x .80 x 10 mm

SS Machine Screw TH

Drill • Pliers • Heavy-duty rivet gun or screwdriver

Mounting Instructions

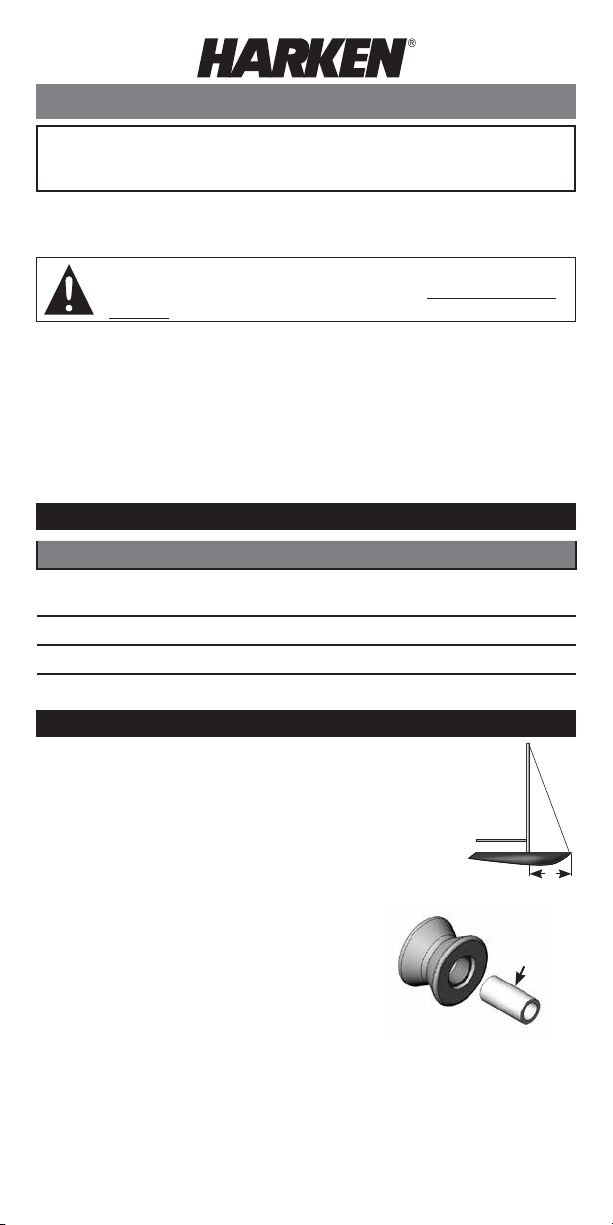

1. Hoist tallest sail that will be used.

If mast is down, angle headstay out to stemhead

chainplate (“J” dimension). Measure luff length of

tallest sail and position restrainer as directed below.

Installations aloft should be performed by rigging

professionals only.

J

2. Remove sheave from restrainer, install wire

and re-fasten sheave. Note: Be careful to not

lose stainless steel sleeve when removing

sheave. Make sure forward side of restrainer

Don't lose

stainless

steel sleeve

is parallel to headstay. Do not install upside

down. See drawing on reverse side. Bend cotter

pin so clevis pin will not fall out.

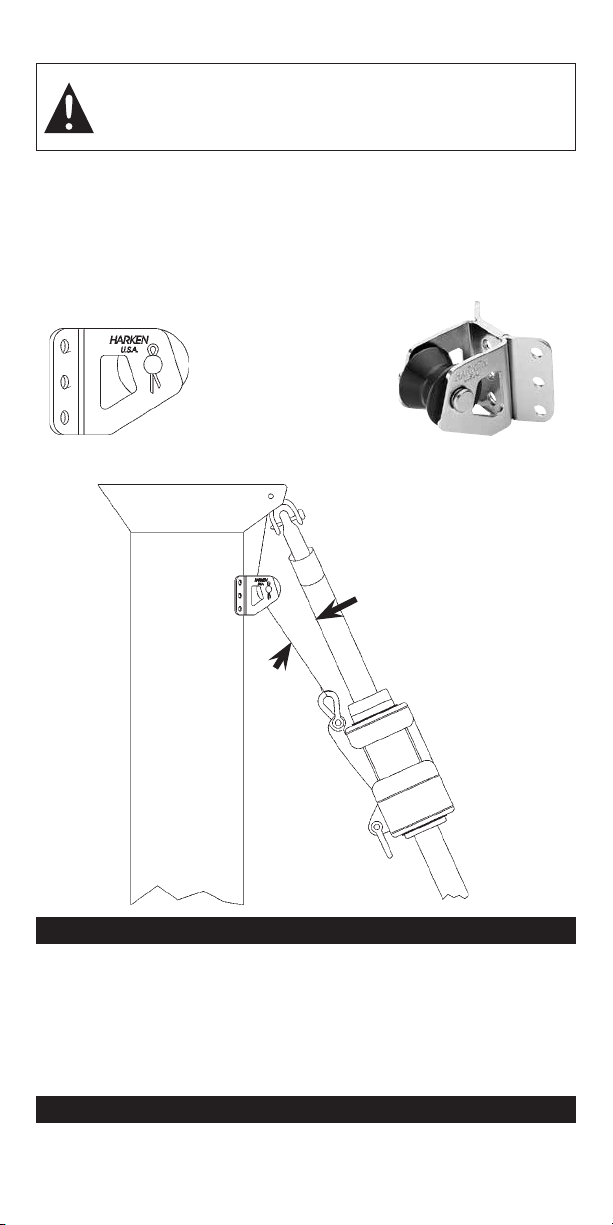

3. Position restrainer on mast so halyard is at a 7 to 10° angle to

headstay. See drawing on reverse side.

If necessary have a sailmaker cut down top of sail to create a 7 to 10°

angle between halyard and headstay.

With restrainer installed, halyard swivel will ride lower than installations

without restrainers. This is necessary to achieve correct halyard angle.

Page 2

4. Mark position of holes and drill.

WARNING! Drilling or fastening into mast may snag halyards

holding the installer aloft seriously reducing strength. Limit drill

depth and avoid fasteners protruding into mast where they may

interfere with halyards.

5. Ease halyard. Install fasteners in all six holes.

6. Tension halyard and test furling system. Do not over-tension halyard

or system will be difficult to furl.

7. If a shorter-hoist sail is used, install a pendant between sail and

halyard swivel so halyard swivel is at same height as tallest sail.

This End Up

Install so

“HARKEN”

is up.

Angle between

halyard and

headstay must

be 7 to 10°

Maintenance

Harken equipment requires minimal maintenance, but some is required to give the best

service and to comply with Harken's limited warranty.

It is important to keep equipment clean by frequently flushing with fresh water. In

corrosive atmospheres, stainless parts may show discoloration around holes, rivets and

screws. This is not serious and may be removed with a fine abrasive.

With the exception of winches, do not use grease unless specifically recommended in

the instruction sheets.

Warranty

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken® catalog.

Printed in USA. 4410 04/14

Loading...

Loading...