Page 1

7801: 60 lb (27 kg) system

7802: 90 lb (41 kg) system

7803: 145 lb (66 kg) system

7806: 200 lb (91 kg) system

Harken, Inc. • N15W24983 Bluemound Rd, Pewaukee, WI 53072-4974 • Tel: 262-691-3320 • Fax: 262-701-5780• Email: hoister@hoister.com • Web: www.hoister.com

WARNING! Strictly follow all instructions to avoid an accident, damage to property,

personal injury, or death. See www.harken.com/manuals for additional safety information.

WARNING! Do not use this product for human suspension. Components can fail causing person to fall,

possibly resulting in serious injury or death.

SAVE TIME! READ THE ENTIRE MANUAL BEFORE BEGINNING HOISTER INSTALLATION.

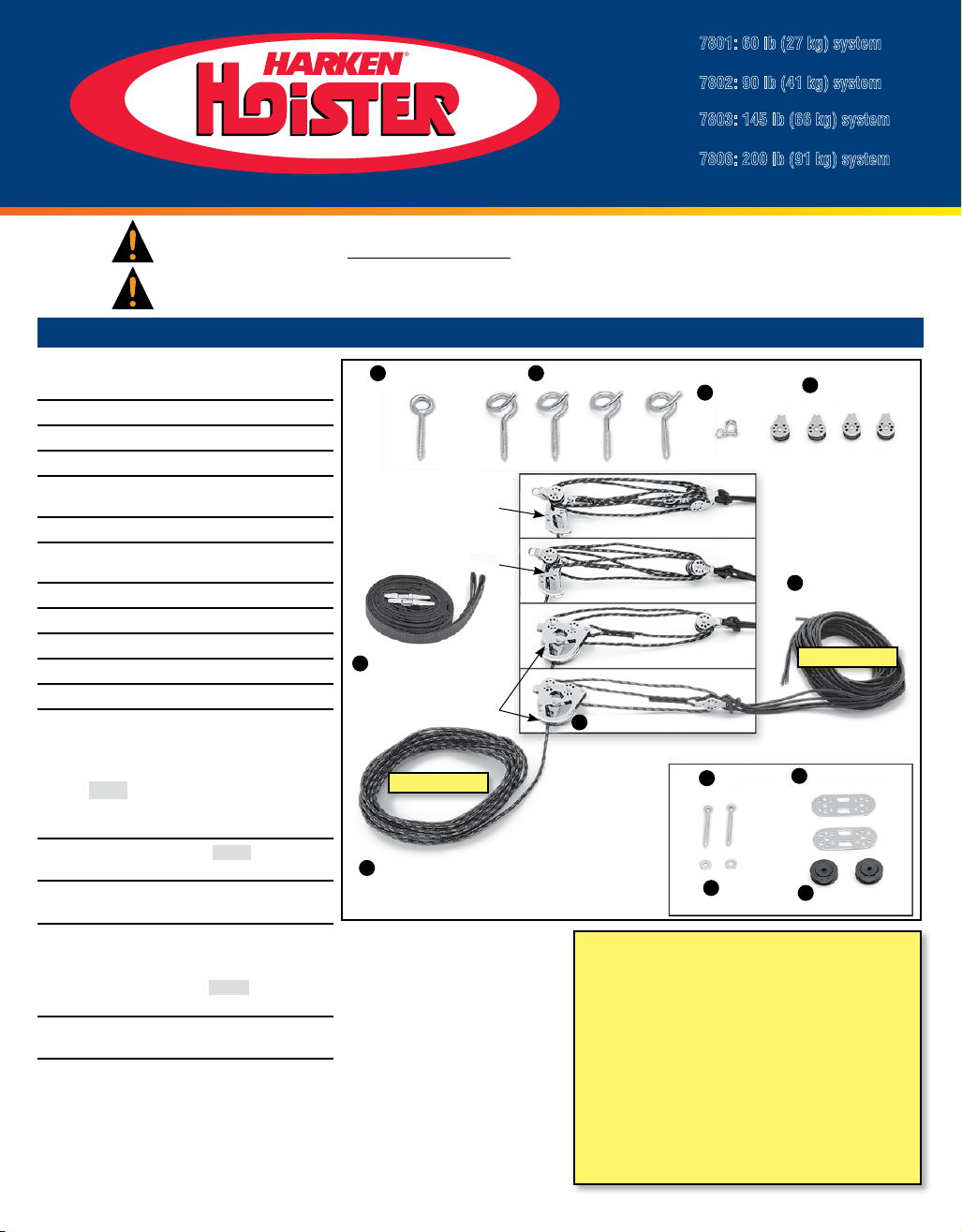

KIT INCLUDES

1 welded screw eye

A

4 pigtail lag screws

B

1 shackle

C

4 pulleys

D

2 webbing straps with buckles

E

7' (2.13 m)

1 single black/red hoisting rope

F

1 block and tackle with

G

cleat (G1) and rope

4 black drop ropes: 2 long, 2 short

H

4 lag bolts 1/4" x 21/2" (6 x 63 mm)

I

4 washers

J

2 organizer plates

K

2 organizer pulleys

L

1

/4" (6 mm)

Welded screw eye

A

HCP1443

(G1) Cleat 7757ASSY

(G1) Cleat 7753ASSY

E

Webbing straps with buckles

HCP1459.SET

PURCHASE SEPARATELY IF NEEDED

See “note” Step 1B, page 6.

1 pine board (riser) (grade 2)

2" x 6" x 7" (50 mm x 152 mm

DO NOT UNTIE

x 180 mm). Do not use for rafters

running sideways.

2 pine boards (grade 2) 2" x 6" x 6'

F

(50 mm x 152 mm x 1.83 m)

8 lag bolts and washers

5

/16" x 4"

Single black/red hoisting rope

HCP1483**

(8 x 100 mm)

*NOTE: (G) Block and tackle varies

PURCHASE ADDITIONAL FOR RAFTERS

RUNNING SIDEWAYS See Step 2A, page 7.

1 pine board (grade 2) 2" x 4" x 6'

(50 mm x 100 mm x 1.83 m)

2 lag bolts and washers

5

/16" x 31/2"

by system size. Refer to Hoister

part number for specific cleat style.

**NOTE: (H) and (F) ropes in 12'

(3.6 m) and 16' (4.9 m) ceiling

models have different part numbers.

(8 mm x 90 mm)

TOOLS

Drill Plumb line Safety glasses

Drill bits:

5

/

32

" (4 mm)

7

/

32

" (5.5 mm)

5

/

16

" (8 mm)

Pencil Tape measure

Stud finder Wrench (box end or

Stepladder

ratcheting)

7

(G1) Cleat

7754ASSY

/

16

" (11 mm)

Pigtail lag screws

B

HCP1444

G

Block and tackle*

229/234A

228A

226A

225A

C

Shackle

072

7806

7803

7802

7801

Rope organizer components

I

Lag bolts

HFS908

Washers

J

HFS913

HCP1447/HCP1448**

IMPORTANT SAFETY INFORMATION

• NEVER USE TO LIFT A PERSON

• DISABLE AUTOMATIC GARAGE DOOR OPENER

when installing, raising, or lowering Hoister.

• READ ENTIRE MANUAL CAREFULLY BEFORE

starting installation. It will save you time.

• DO NOT RAISE OR LOWER HOISTER

with anyone standing under object.

• DO NOT UNTIE ANY ROPES

System comes ready to install.

Leave F, G, and H together.

D

Pulleys

224A

H

Drop black ropes

DO NOT UNTIE

Organizer plates

K

H-28375A

Organizer pulleys

L

H-52010

1

Page 2

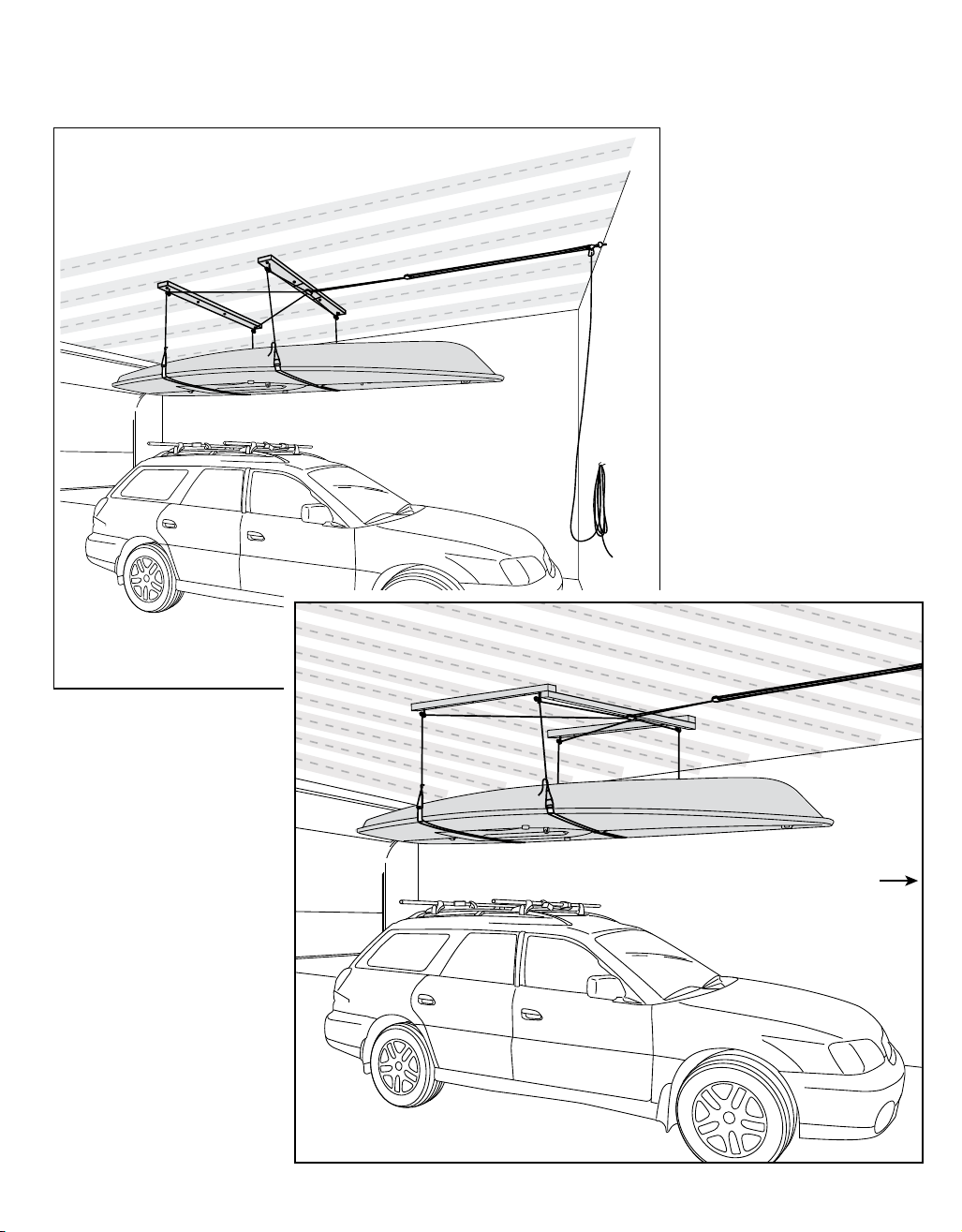

BEFORE STARTING INSTALLATION

Determine the rafter direction and follow the instructions for rafters running: FRONT-TO-BACK or SIDEWAYS

RAFTERS RUNNING FRONT-TO-BACK

Garage door

RAFTERS RUNNING SIDEWAYS

Garage door

Front wall

Front wall

2

Page 3

INSTALLATION OVERVIEW

Organizer

Garage door

Front wall

Top plate

Pigtail

lag screw

Pigtail

lag screw

Pigtail

lag screw

Pigtail

lag screw

Rafter

2" x 6" x 6' (50 mm x 152 mm x 1.83 m) mounting board

2" x 6" x 7"

riser board

(50 mm x 152 mm x 180 mm)

2" x 6" x 6' (50 mm x 152 mm x 1.83 m) mounting board

Rafter

center-to-center

distance

Mounting boards

2" X 4"

(50 mm x 100 mm)

for mounting organizer –

no riser board used

Alternate position for rafters that run sideways.

Front

wall

2" x 6"

50 mm x 152 mm

Rafters

Organizer

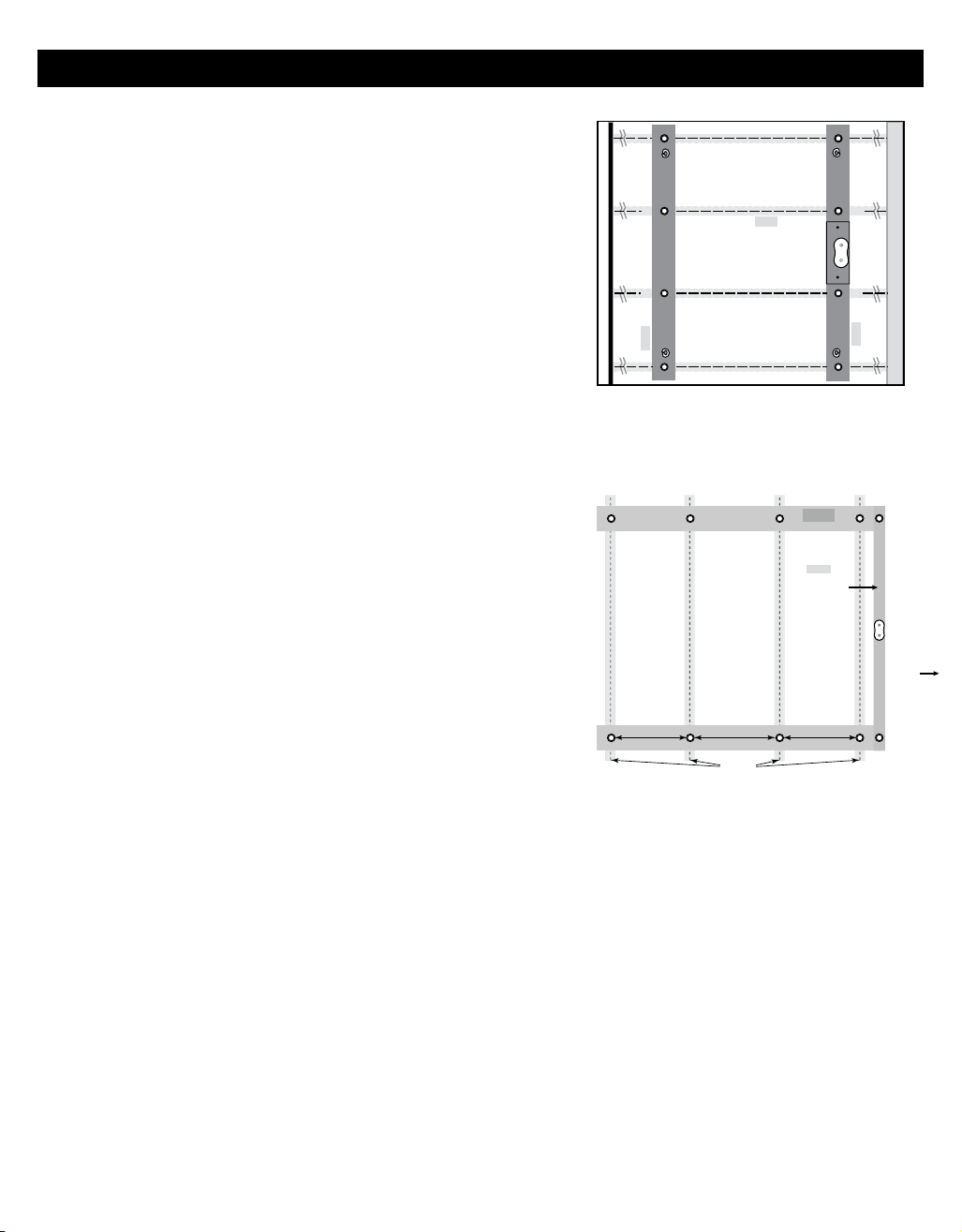

PART 1: ASSEMBLY FOR RAFTERS RUNNING FRONT-TO-BACK

INSTALLATION OVERVIEW Page 4

STEP 1: Determine Hoister location Page 5 - 6

STEP 2: Install mounting boards Page 7

STEP 3: Install pigtail lag screws Page 8

STEP 4: Install rope organizer Page 9

STEP 5: Assemble Hoister system Page 9

PART 2: ASSEMBLY FOR RAFTERS RUNNING SIDEWAYS

INSTALLATION OVERVIEW Page 10

STEP 1: Determine Hoister location Page 11 - 12

STEP 2: Install mounting boards Page 13

STEP 3: Install pigtail lag screws Page 13 - 14

STEP 4: Install rope organizer Page 14

STEP 5: Assemble Hoister system Page 15

PART 3: FOR ALL ASSEMBLIES

STEP 6: Assemble Hoister systems continued Page 16 - 17

STEP 7: Operating Hoister systems Page 18

Appendix, maintenance, and warranty Page 19

VIEWED FROM BELOW

VIEWED FROM BELOW

3

Page 4

PART 1: ASSEMBLY FOR RAFTERS RUNNING FRONT-TO-BACK

Organizer

Garage door

Front wall

Top plate

Pigtail

lag screw

Pigtail

lag screw

Pigtail

lag screw

Pigtail

lag screw

Rafter

2" x 6" x 6' (50 mm x 152 mm x 1.83 m) mounting board

2" x 6" x 7"

riser board

(50 mm x 152 mm x 180 mm)

2" x 6" x 6' (50 mm x 152 mm x 1.83 m) mounting board

INSTALLATION OVERVIEW

STEP 1: Determine Hoister location Page 5 - 6

STEP 2: Install mounting boards Page 7

STEP 3: Install pigtail lag screws Page 8

STEP 4: Install rope organizer Page 9

STEP 5: Assemble Hoister system Page 9

Pigtail lag

screw (B)

Rope organizer on 2" x 6" x 7"

(50 mm x 152 mm x 180 mm) riser board

Pulleys (L) Plates (K) Lag bolts (I) Washers (J)

Long black

drop ropes

(H)

Pulley

(D)

(50 mm x 152 mm x 1.82 m)

Back 2" x 6" x 6'

mounting board

Front 2" x 6" x 6'

(50 mm x 152 mm x 1.82 m)

mounting board

VIEWED FROM BELOW

Welded

screw eye

(A)

Block and tackle (G)

Shackle

(C)

4

Garage door

Webbing straps (E)

Short black

drop ropes

(H)

Cleat

(G1)

Single black/red

hoisting rope

(F)

Front wall

Page 5

Opened

garage door

STEP 1: DETERMINE HOISTER LOCATION; RAFTERS RUNNING FRONT-TO-BACK

Opened

garage door

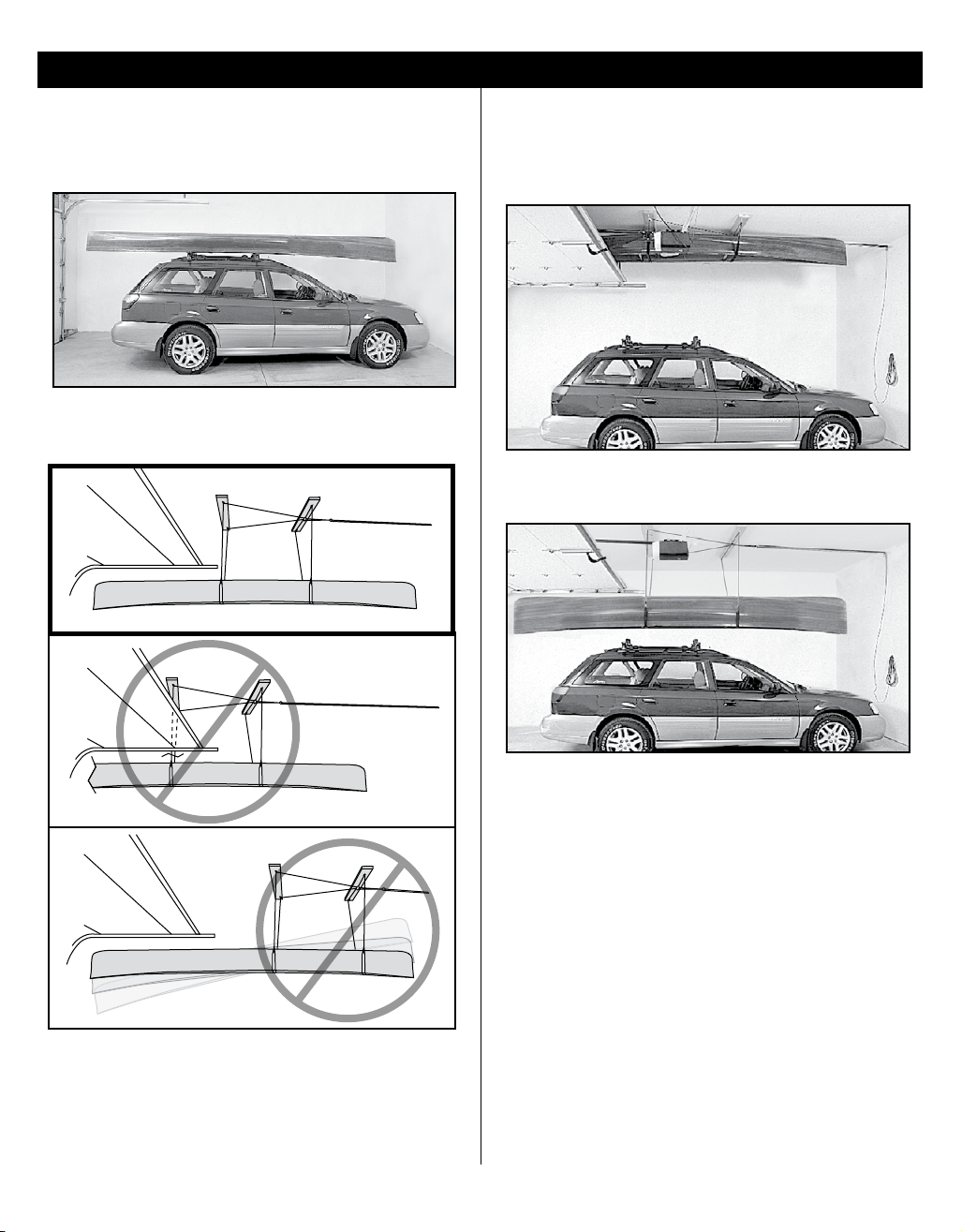

A. PLAN INSTALLATION

Pull car into garage with object on car rack.

Measure length of object. Plan to position Hoister

so garage door can open with object lowered.

Opened

garage door

STORAGE OPTIONS

Measure height of object. Make sure object can

be stored above or below the open garage door.

OPTION 1. Above garage door: Make sure there is enough

clearance to lift and store object above open garage door.

Opened

garage door

Opened

garage door

DIAGRAM 1. Plan to position object above car with clearance

to open garage door. If Hoister is mounted too close to garage

door, there may not be clearance to open door. Mounted too

far forward, object may not balance or lower onto car.

OPTION 2. Below garage door: Use if not enough clearance

for above garage door storage (Option 1). Object has clearance

to lift and store below open garage door.

5

Page 6

STEP 1B

1) Measurement between

center points on

mounting boards _________

(calculation above)

STEP 5A

2) Measurement from center

of front mounting board

to front wall _________

3) Measurement from front

mounting board to

lowest drop point _________

If measurement 2 is less than

measurement 3, refer to

Step 5A, Diagram 12 (page 7).

Garage door

Front

wall

Step 1B

Mounting board

placement

Step 5A

Welded screw eye

placement

Ceiling

Plan location of mounting boards and welded screw eye

2

3

1

Front mounting board

Back mounting board

Top plate

STEP 1 CONTINUED: DETERMINE HOISTER LOCATION; RAFTERS RUNNING FRONT-TO-BACK

B. PLAN LOCATION OF MOUNTING BOARDS

Mounting boards are used to position Hoister

directly above object to be lifted.

7806 Hoister (200 lb/91 kg system) requires

mounting boards to span minimum three rafters.

WARNING! Do not screw into laminated rafters.

They are not intended to accept fasteners. Consult

rafter maker for recommendations. Screwing into

laminated rafters may considerably weaken system,

causing load to fall and cause an accident.

Note: Mounting boards may not be necessary for

installation in ceiling with exposed rafters. In ceilings

with exposed rafters, system can be installed on

rafters. Position Hoister directly above object to be

lifted. If installing without mounting boards, go to

Step 3 (page 8).

DISTANCE BETWEEN MOUNTING BOARDS

Distance between mounting boards should be

35% of the object's length.

Exception: Distance between mounting boards for long, light weight

canoes/sea kayaks will be less than 35% of the object’s length.

Calculate distance between mounting boards using formula

or chart below.

_________________ x .35 = _________________

Object length 35% Mounting distance

Tip: The distance does not have to be exactly 35%.

Greater distance is okay and distance for long canoes

and sea kayaks can be less as stated above.

LOCATE CEILING MOUNTING BOARD POSITION

6

DIAGRAM 3. Distance of mounting boards from front wall is important, as it affects the position of the welded screw eye in Step 5A (page 9).

DIAGRAM 2. Center object under mounting points.

Position mounting boards so lifted object is balanced.

(page 9).

Page 7

Rafters

Rafter

center-to-center

distance

Rafter

center-to-center

distance

Rafter

center-to-center

distance

Mounting

boards

STEP 2: INSTALL MOUNTING BOARDS; RAFTERS RUNNING FRONT-TO-BACK

A. DRILL CEILING RAFTER ATTACHMENT POINTS

LOCATE CEILING RAFTERS

Mounting boards must attach to ceiling rafters

(Diagram 4). On finished ceilings, locate rafters

using stud finder. Follow manufacturer's instructions.

Mark center of ceiling rafters. Drill

7

/

32

" (5.5 mm)

holes in a straight line square to the rafters.

See Diagram 4 below.

Always wear safety glasses.

DIAGRAM 4A.

7

/32" (5.5 mm) hole in rafter

5

/16" (8 mm) clearance hole in 2" x 6" mounting board

SIDE VIEW

B. DRILL MOUNTING BOARD

Measure center-to-center distance between

(5.5 mm) rafter holes. Mark distance on mounting

boards. Mark drill points in the center of board. Drill

5

/

16

" (8 mm) holes completely through the mounting

boards. See Diagram 4A below.

7

/

32

C. ATTACH MOUNTING BOARDS TO CEILING

Attach mounting boards using

lag bolts and washers (not included).

Do not overtighten.

5

/

16

" (8 mm)

"

VIEWED FROM BELOW

DIAGRAM 4. Mark center-to-center distance between rafters on mounting boards. Attach mounting boards to rafters.

7

Page 8

2"

(50 mm)

Object width

2"

(50 mm)

Plumb lines

Ceiling

Plumb lines

Front view

Object

STEP 3: INSTALL PIGTAIL LAG SCREWS; RAFTERS RUNNING FRONT-TO-BACK

Overtightened

past top

thread

Mounting board

Top

thread

Mounting board

Overtightened

past top

thread

Mounting board

A. DETERMINE PIGTAIL LAG SCREW (B) LOCATION

PULL VEHICLE INTO GARAGE

Pull vehicle into garage with object on car rack.

Disconnect automatic garage door.

MARK LOCATION POINTS

Use plumb line to locate four lifting points on mounting

boards above vehicle.

DRILL 2 HOLES ON EACH MOUNTING BOARD

Drill hole

point

Pigtail lag

screw holes

Mounting

board

Object width

2"

(50 mm)

Add 2"

(50 mm) outside

Drill 7/

32

"

(5.5 mm) hole at

each outside point

2"

Drill hole

point

VIEWED FROM BELOW

DIAGRAM 6. Add 2" (50 mm) outside each mark. Drill a

hole at each drill point on mounting boards. Always wear safety glasses.

(50 mm)

7

/32" (5.5 mm)

INSTALL PIGTAIL LAG SCREWS

DIAGRAM 5. Mark object width on mounting boards.

8

Mounting board

Top

thread

Mounting board

thread

Mounting board

Top

DIAGRAM 7. Install a pigtail lag screw (B) in each hole.

Threads should disappear into mounting board.

WARNING! Do not overtighten pigtail lag screw

past top thread. This can weaken fastener hold

which can considerably weaken system, causing

load to fall and cause an accident.

Overtightened

past top

thread

Page 9

Front

wall

Top

plate

Pigtail lag

screw

Pigtail lag

screw

Rope

organizer

Welded

screw eye

Front mounting board

STEP 4: INSTALL ROPE ORGANIZER; RAFTERS RUNNING FRONT-TO-BACK

A. MOUNT RISER BOARD AND DRILL HOLES

IMPORTANT! Use smaller drill bit in this step.

DIAGRAM 9

FRONT WALL

Mount 2" x 6" x 7" (50 mm x 152 mm x 180 mm) riser

board on front mounting board centered between the

two pigtail lag screws (B). Drill

5

/

32

" (4 mm) holes.

Always wear safety glasses. Attach riser boards using

1

two

/

4

" (6 mm) lag bolts (l) and washers (J) (included).

Do not overtighten.

DIAGRAM 8. Hold rope organizer plate (K) on riser board near

the side toward the front wall. Use plate as template to mark

center holes. Drill two 5/32" (4 mm) holes.

STEP 5: ASSEMBLE HOISTER SYSTEM; RAFTERS RUNNING FRONT-TO-BACK

A. INSTALL WELDED SCREW EYE (A)

PLACEMENT ON FRONT WALL

Ceiling

2

3

B. ASSEMBLE ROPE ORGANIZER

Rope organizer

Rope organizer

pulleys (L)

Washer (J)

Lag bolt

(I)

DIAGRAM 10. Assemble rope organizer using plate (K)

and pulleys (L). Fasten to mounting board with lag bolts (I)

and washers (J).

IMPORTANT! Do not overtighten bolts. This can keep

rope organizer pulleys (L) from turning properly.

plates (K)

Washer (J)

Lag bolt

(I)

VIEWED FROM BELOW

DIAGRAM 12. If distance

to front wall is less than

distance needed to lift

object, move the welded

screw eye (A) along the

front wall until distance

2 is equal to distance 3

(see Diagram 11).

DIAGRAM 11. Distance 2 must be equal or somewhat

greater than distance 3. See chart below. For a larger view,

see Diagram 3 (page 6).

MAXIMIZING LOWERING OF OBJECT

You may want to lower object to floor or onto sawhorses.

If distance 2 is much greater than 3, the distance object

can be lowered will be limited by length of rope supplied.

If distance 2 is distance 3 will be If distance 2 is distance 3 will be

10 10 14 6

11 9 15 5

12 8 16 4

13 7 17 3

When distance 2 is much greater than 3, purchase longer rope

for drop ropes (H) to maximize distance object can be lowered.

Front

wall

Drill a 7/32" (5.5 mm) hole into top plate of garage for mounting

welded screw eye. Always wear safety glasses. Screw welded

screw eye into top plate until threads just disappear into top

plate. Do not overtighten. See procedure and warnings for

Install Pigtail Lag Screws.

LEADING BLOCK AND TACKLE TO SIDE WALL

If distance to front wall is still too short, consider

running block and tackle to the side of to the object

instead of lengthwise.

SEE APPENDIX — PAGE 19.

9

Page 10

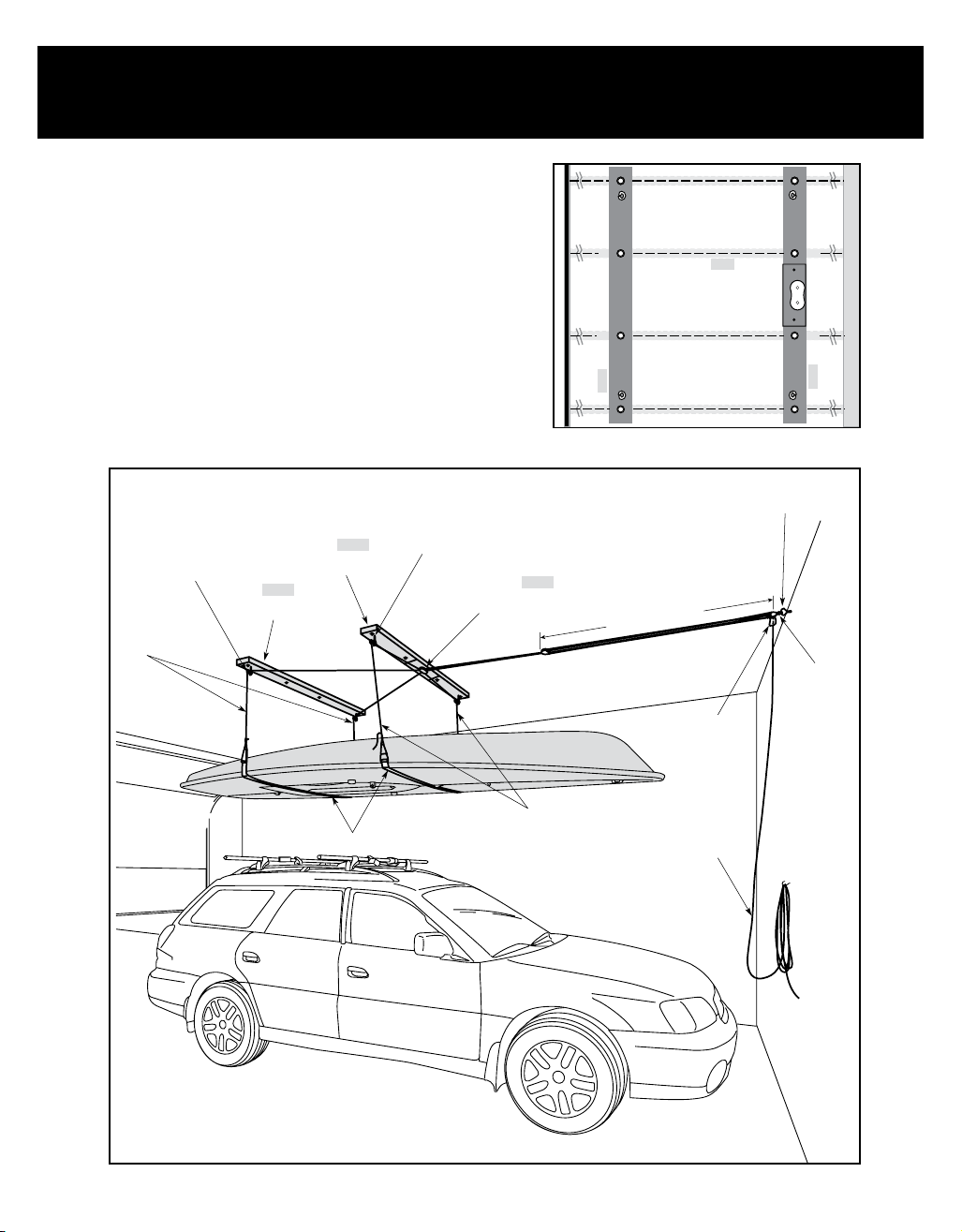

PART 2: ASSEMBLY FOR RAFTERS RUNNING SIDEWAYS

Rafter

center-to-center

distance

Mounting boards

2" X 4"

(50 mm x 100 mm)

for mounting organizer –

no riser board used

Alternate position for rafters that run sideways.

Front

wall

2" x 6"

50 mm x 152 mm

Rafters

Organizer

INSTALLATION OVERVIEW

STEP 1: Determine Hoister location Page 11 - 12

STEP 2: Install mounting boards Page 13

STEP 3: Install pigtail lag screws Page 13 - 14

STEP 4: Install rope organizer Page 14

STEP 5: Assemble Hoister system Page 15

2" x 6" x 6'

(50 mm x 152 mm x 1.82 m)

Pigtail lag screw (B)

with pulley (D)

Long black

drop ropes

(H)

mounting boards

Rope organizer on 2" x 4" x 6"

(50 mm x 100 mm x 1.83 m)

Pulleys (L) Plates (K) Lag bolts (I) Washers (J)

VIEWED FROM BELOW

Welded

screw eye

(A)

board

Block and tackle (G)

Shackle

(C)

Garage door

10

Cleat

(G1)

Short black

Webbing straps (E)

drop ropes

(H)

Single black/red

hoisting rope

(F)

Front wall

Page 11

Opened

garage door

STEP 1: DETERMINE HOISTER LOCATION; RAFTERS RUNNING SIDEWAYS

Opened

garage door

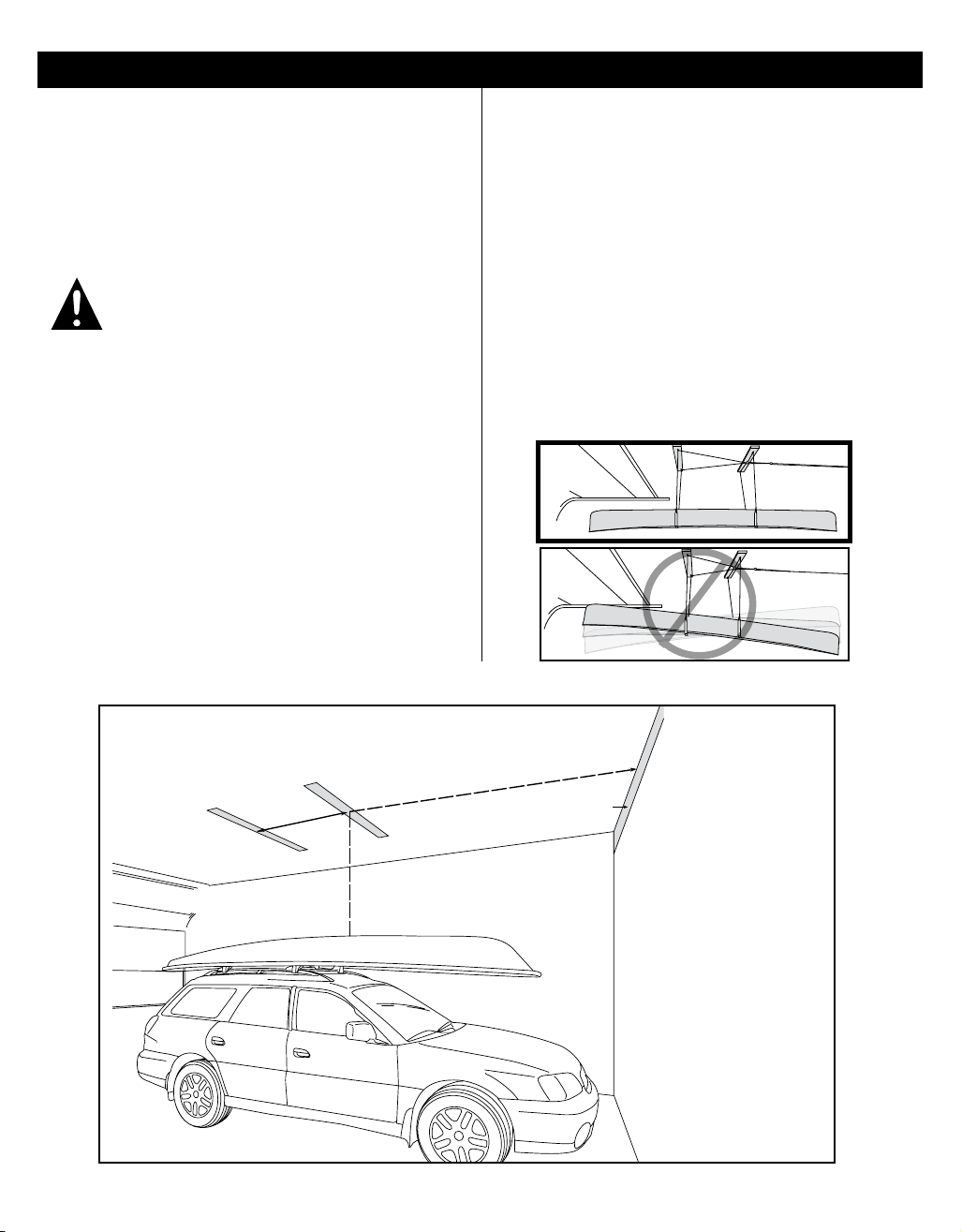

A. PLAN INSTALLATION

Pull car into garage with object on car rack.

Measure length of object. Plan to position Hoister

so garage door can open with object lowered.

Opened

garage door

STORAGE OPTIONS

Measure height of object. Make sure object can be

stored above or below the open garage door.

OPTION 1. Above garage door: Make sure there is enough

clearance to lift and store object above open garage door.

Opened

garage door

Opened

garage door

DIAGRAM 13. Plan to position object above car with clearance

to open garage door. If Hoister is mounted too close to garage

door, there may not be clearance to open door. Mounted too

far forward, object may not balance or lower onto car.

OPTION 2. Below garage door: Use if not enough clearance for

above garage door storage (Option 1). Object has clearance to

lift and store below open garage door.

11

Page 12

STEP 1 CONTINUED: DETERMINE HOISTER LOCATION; RAFTERS RUNNING SIDEWAYS

Garage

door

Front

wall

2

3

1

Ceiling

B. PLAN LOCATION OF MOUNTING BOARDS

Mounting boards are used to position Hoister

directly above object to be lifted.

7806 Hoister (200 lb/91 kg system) requires

mounting boards to span minimum three rafters.

WARNING! Do not screw into laminated rafters.

They are not intended to accept fasteners. Consult

rafter maker for recommendations. Screwing into

laminated rafters may considerably weaken system,

causing load to fall and cause an accident.

Note: Mounting boards may not be necessary for

installation in ceiling with exposed rafters. In ceilings

with exposed rafters, system can be installed on

rafters. Position Hoister directly above object to

be lifted. If installing without mounting boards,

go to Step 3 (page 13).

LENGTH OF 2" X 6" MOUNTING BOARDS

Length of mounting boards should be at least

35% of the object's length.

Exception: Length of mounting boards for long, lightweight

canoes/sea kayaks will be less than 35% of the object’s length.

Calculate length of mounting boards using formula or chart below.

_________________ x .35 = ______________________

Object length 35% Length of mounting board

Tip: The distance does not have to be exactly 35%.

Greater distance is okay and distance for long canoes

and sea kayaks can be less as stated above.

LOCATE CEILING MOUNTING BOARD POSITION

+ 8" (200 mm)

DIAGRAM 14. Center object under mounting points.

Position mounting boards so lifted object is balanced.

Plan location of mounting boards and welded screw eye.

2" x 4"

DIAGRAM 15. Check to make sure 2" x 6" boards are long enough.

Distance of 2" X 4" from front wall is important, as it affects the position of the welded screw eye in Step 5A (page 15).

12

STEP 1B

1) Length of mounting boards.

________________________

(calculation above)

STEP 5A

2) Measurement from

center of 2" X 4" to

front wall. __________

3) Measurement from

2" X 4" to lowest drop point.

____________

If measurement 2 is less than

measurement 3, refer to step

5A Diagram 21 (page 15).

Page 13

STEP 2: INSTALL MOUNTING BOARDS; RAFTERS RUNNING SIDEWAYS

2"

(50 mm)

Object width

2"

(50 mm)

Plumb lines

Ceiling

Plumb lines

Front view

Object

Top

view

Rafter

center-to-center

distance

Mounting boards

2" X 4"

(50 mm x 100 mm)

for mounting organizer –

no riser board used

Alternate position for rafters that run sideways.

2" x 6"

50 mm x 152 mm

Rafters

Organizer

Front

wall

A. DRILL CEILING RAFTER ATTACHMENT POINTS

LOCATE AND DRILL CEILING RAFTERS

Mounting boards must attach to ceiling rafters (see

Diagram 16). On finished ceilings, locate rafters using

stud finder. Follow manufacturer's instructions. Mark

center of ceiling rafters. Drill

straight line square to the rafters. Always wear safety

glasses. See Diagram 4 below.

Note: Mount boards so that object width

is at or about 3/4" from inside edge.

Object Width

VIEWED FROM BELOW

DIAGRAM 16. Attach board for mounting organizer using

(8 mm) 31/2" (90 mm) lag bolts and washers (not included).

See Step 3A to determine distance between mounting boards.

7

/

32

" (5.5 mm) holes in a

5

B. DRILL MOUNTING BOARD

Measure center-to-center distance between

rafter holes. Mark distance on mounting boards. Mark

drill points in the center of board. Drill

completely through the mounting boards.

7

/32" (5.5 mm) hole in rafter

5

/16" (8 mm) clearance hole in 2" x 6" mounting board

SIDE VIEW

7

/

32

" (5.5 mm)

5

/

16

" (8 mm) holes

C. ATTACH MOUNTING BOARDS TO CEILING

Attach mounting boards using

lag bolts and washers (not included). Do not overtighten.

5

/

16

" x 4" (8 mm x 10 mm)

D. ATTACH 2" X 4" TO MOUNTING BOARDS

Hold 2" x 4" up to ends of mounting boards and mark

screw location on each side. Lower and drill 5/16" (8 mm)

holes. Hold 2" x 4" in place and mark holes in ends of

mounting boards. Leave room for pigtail lag screws

shown in Diagram 17. Drill a 7/32" (5.5 mm) hole in the

end of each mounting board. Attach 2" x 4" mounting

/

16

"

boards using

washers (not included). Do not overtighten.

5

1

/

16

" x 3

/

2

" (8 mm x 90 mm) lag bolts and

STEP 3: INSTALL PIGTAIL LAG SCREWS; RAFTERS RUNNING SIDEWAYS

A. DETERMINE PIGTAIL LAG SCREW (B) LOCATION

PULL VEHICLE INTO GARAGE

Pull vehicle into garage with object on car rack.

Disconnect automatic garage door.

MARK LOCATION POINTS

Use plumb line to locate four lifting points on mounting

boards above vehicle.

13

Page 14

STEP 3 CONTINUED: INSTALL PIGTAIL LAG SCREWS; RAFTERS RUNNING SIDEWAYS

Overtightened

past top

thread

Mounting board

Overtightened

Top

thread

Mounting board

Overtightened

past top

thread

Mounting board

INSTALL PIGTAIL LAG SCREWS

Mounting boards

Top view

DIAGRAM 17. Drill pigtail lag screw holes on 2" x 6" (50 mm x

152 mm) as shown.

2" x 6"

50 mm x 152 mm

Pigtail lag

screw holes

2" X 4"

(50 mm x 100 mm)

for mounting organizer –

no riser board used

Front

wall

Mounting board

Top

thread

Mounting board

Top

thread

DIAGRAM 18. Install a pigtail lag screw (B) in each hole.

Threads should disappear into mounting board.

WARNING! Do not overtighten pigtail lag screw past

top thread. This can weaken fastener hold which can

considerably weaken system, causing load to fall and

cause an accident.

STEP 4: INSTALL ROPE ORGANIZER

A. DRILL HOLES FOR ORGANIZER

IMPORTANT! Use smaller drill bit in this step.

Use rope organizer plate (K) as a template to mark

holes on 2" x 4". See Diagram 17. Drill 5/32" (4 mm)

holes. Always wear safety glasses.

Mounting board

past top

thread

B. ASSEMBLE ROPE ORGANIZER

Rope organizer

Rope organizer

pulleys (L)

Washer (J)

Lag bolt

(I)

DIAGRAM 19. Assemble rope organizer as shown in Diagram 17

using plate (K) and pulleys (L). Fasten to 2" x 4" (50 mm x 100 mm)

with lag bolts (I) and washers (J).

Do not use riser board.

IMPORTANT! Do not overtighten bolts. This can keep

rope organizer pulleys (L) from turning properly.

14

plates (K)

Washer (J)

Lag bolt

(I)

Page 15

Front

wall

Top

plate

Pigtail lag

screw

Pigtail lag

screw

Rope

organizer

Welded

screw eye

Front

mounting

board

STEP 5: ASSEMBLE HOISTER SYSTEM; RAFTERS RUNNING SIDEWAYS

A. INSTALL WELDED SCREW EYE (A)

PLACEMENT ON FRONT WALL

1

Ceiling

3

DIAGRAM 20. Distance 2 must be equal or somewhat

greater than distance 3. See chart below. For a larger view,

see Diagram 15 (page 12).

MAXIMIZING LOWERING OF OBJECT

You may want to lower object to floor or onto sawhorses.

If distance 2 is much greater than 3, the distance object

can be lowered will be limited by length of supplied rope.

2

Front

wall

If distance 2 is distance 3 will be If distance 2 is distance 3 will be

10 10 14 6

11 9 15 5

12 8 16 4

13 7 17 3

When distance 2 is much greater than 3, purchase longer rope

for drop ropes (H) to maximize distance object can be lowered.

VIEWED FROM BELOW

DIAGRAM 21. If distance to front wall is less than distance needed

to lift object, move the welded screw eye (A) along the front wall

until distance 2 is equal to distance 3 (see Diagram 20).

Drill a 7/32" (5.5 mm) hole into top plate of garage for mounting

welded screw eye. Always wear safety glasses. Screw welded

screw eye into top plate until threads just disappear into top

plate. Do not overtighten. See procedure and warnings for

Install Pigtail Lag Screws.

LEADING BLOCK AND TACKLE TO SIDE WALL

If distance to front wall is still too short, consider

running block and tackle to the side of the object

instead of lengthwise.

SEE APPENDIX—PAGE 19.

15

Page 16

PART 3: FOR ALL ASSEMBLIES

STEP 6: ASSEMBLE HOISTER SYSTEM FOR ALL ASSEMBLIES

Ceiling

Front

wall

DIAGRAM 22. Avoid installing welded screw eye above tall shelves.

Rope must point down to lock.

B. ATTACH PULLEYS

Place one pulley (D) on each pigtail lag screw (B).

ATTACH BLOCK AND TACKLE (G)

Attach block and tackle system (G) to welded screw

eye (A) with shackle (C). Remove ring from shackle

like a key ring. Put pin through top of cleat (G1).

Put ring back on to secure shackle (C).

INSTALL WELDED SCREW EYE (A) ON FRONT WALL

Use stud finder to locate solid wood of top plate.

7

Drill

/

32

" (5.5 mm) hole. Screw welded screw eye (A)

into top plate of front wall (near top of ceiling).

Front view

Top plate of front wall

Studs

DIAGRAM 23. Top plate of front wall.

16

Block and tackle cleat (G1)

*

7801

7802

Single black/red

hoisting rope (F)

DIAGRAM 24. Single black/red

hoisting rope must face down.

*NOTE: Appearance of cleat (G1)

varies by system size. Refer to

system part number for specific

block and tackle cleat.

Welded screw eye (A)

Shackle (C)

7803

7806

Page 17

Tie knots below top of object

so load can be lifted to ceiling.

Object

Ceiling

STEP 6 CONTINUED: ASSEMBLE HOISTER SYSTEM FOR ALL ASSEMBLIES

C. INSTALL ROPE

VIEWED FROM BELOW

Short

Organizer

Short

drop

drop

rope

rope

Pulley

(D)

Pulley

(D)

Block & tackle

Front

wall

Pulley

(D)

Long drop rope

Long drop rope

Pulley

(D)

DIAGRAM 25. Put all four black drop ropes through organizer.

Put two shorter black drop ropes through pulleys (D) on mounting

board with rope organizer.

Put two longer black drop ropes through pulleys (D) on remaining

mounting board.

Top

plate

POSITION WEBBING STRAPS

Place object in position under system. Place webbing

straps (E) under object to be lifted. Push buckles

together to lock.

FRONT VIEW

DIAGRAM 26. Tie knots below top of object so object can be lifted

to ceiling. Adjust strap length in buckle as needed.

D. ATTACH STRAPS TO ROPE

TIE ROPE TO WEBBING STRAPS

Keep knot as close to webbing strap (E) eye as possible.

Webbing strap eye

5

1

6

4

DIAGRAM 27. Tie a black drop rope to each webbing strap (E)

using a figure-eight knot. Pass free end of rope through the sewn

webbing strap eye.

Webbing strap eye

11

15

10

14

9

12

DIAGRAM 28. Using free end of rope from webbing strap eye,

retrace original figure-eight knot in reverse. Tightly cinch all four

strands of rope exiting the knot.

Tighten knots. See www.harken.com/Knots for further knottying resources.

2

7

3

8

13

E. ADJUSTING LIFTING SYSTEM

ALIGN SCREW EYES

DIAGRAM 29. Align pigtail lag screws in direction of rope running

through pulley.

LEVEL OBJECT

All webbing straps and ropes must have equal tension

to keep object level. Check by slowly pulling the black/

red hoisting rope (F).

To level object, adjust tension by moving knot

or adjusting webbing strap at buckle.

17

Page 18

STEP 7: OPERATING HOISTER SYSTEM FOR ALL ASSEMBLIES

WARNING! Disable garage door opener when

installing, raising, or lowering the Hoister.

Do not raise or lower with anyone standing

under object. Keep area below Hoister clear.

If the load falls it can cause an accident.

A. RAISE OBJECT

Hoist in a series of pulls. Pull single black/red hoisting

rope (F) straight down.

WARNING! Do not use this product for human

suspension. Components can fail causing person

to fall, possibly resulting in serious injury or death.

With rope pointed down, the cleat will lock the rope.

Angle to release. Repeat until object is at desired height.

B. STORE OBJECT

With object in raised position, make sure single black/

red hoisting rope (F) is securely locked in cleat with

rope pointed down (Diagram 21). Coil loose rope end.

WARNING! Hang coiled rope where it will not

accidentally snag on persons or vehicle. Keep

coiled rope out of reach of children. Damage

or injury can result if rope is angled away from

wall with some tension; the object can come

down very quickly and cause an accident.

Tip: For additional security, use two 5/16" (8 mm) polyester safety

ropes. Securely tie ends to pigtail lag screws under object, parallel

with webbing straps (E). Remove safety ropes before lowering object.

C. LOWER OBJECT

Securely grip rope, apply tension, and angle it away

from front wall. Bring arm up to let rope out and then

back toward the wall to lock the rope. Repeat until

object is at desired height.

Locked

Rope (F) down

DIAGRAM 30. Locked (left): Single black/red hoisting rope (F) pointed

straight down locks cleat. Open (right): Angled rope opens cleat.

WARNING! Stop pulling as soon as object contacts

ceiling, or webbing strap knots stop at pulley (D).

Damage or injury can result from forcing the

system. If in doubt, stop hoisting, allow cleat to

lock by angling rope down. Stand back to see if

object is raised to the maximum, or if something

is jamming rope or object.

18

Open

Rope (F) angled

Lowering

(cleat open)

WARNING! When operating system, make sure

area below object is clear of persons. If object

comes down too quickly, this can cause an accident.

Tip: Use gloves to protect hands.

CAUTION! Avoid injury, do not let rope slip

through hands. Angle rope to wall to lock rope.

Locked

Page 19

WARRANTYAPPENDIX

BLOCK AND TACKLE RUNNING TO SIDE WALL

Rafters running front-to-back

Lead block and tackle at 90 degrees to a

conventional direction.

Organizer mounted to 2" X 4"

Block and tackle

Mount pigtail lag screws to 2" X 6" (50 mm x 152 mm)

mounting boards similar to Diagram 16 (page 13),

except block and tackle goes to side wall of garage.

Use a 2" X 4" (50 mm x 100 mm) as shown to mount

the organizer.

Rafters running sideways

Block and tackle

(50 mm x 100 mm)

Front wall

Organizer mounted to 2" X 6"

(50 mm x 152 mm) riser

Front wall

WARRANTY

What is covered – This warranty covers defects in

materials or workmanship.

Who is covered – The original purchaser.

For how long – Harken products are warranted for five

(5) years from the date of purchase.

After the end of any specific warranty period noted

above, HARKEN MAKES NO EXPRESS OR IMPLIED

WARRANTIES OF ANY KIND WITH RESPECT TO

THE PRODUCTS, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. Some states, or if you live outside the U.S.,

some countries, do not allow limitations on how long

an implied warranty lasts, so the above limitation may

not apply to you.

What is not covered – This warranty does not cover

any product that was: improperly installed; inadequately

inspected after installation; improperly maintained;

used in any application for which it was not intended;

used under load conditions exceeding the rating or

other recommendations published in the Harken

catalog; or subject to misuse, negligence, accident,

or unauthorized modification or repair. Ropes, buckles

and webbing are also not covered. Labor charges are

not covered. Separate warranty provisions may be

available from vendors on some of the above products.

Contact Harken for this warranty information.

CONSEQUENTIAL AND INCIDENTAL DAMAGES

ARE NOT RECOVERABLE UNDER THIS WARRANTY.

Some states do not allow the exclusion or limitation of

incidental damages, so the above limitation or exclusion

may not apply to you.

Use 2" X 6" (50 mm x 152 mm) mounting boards.

Mount the organizer on a 2" X 6" X 7" (50 mm x

152 mm x 180 mm) riser board.

MAINTENANCE

MAINTENANCE

Inspect rope (H and F), knots, and straps (E)

regularly for signs of chafe, wearing, or UV damage.

Replace immediately. Inspect knots for signs of

slipping. When attaching top, inspect webbing strap

buckles (E) to make sure spring clip functions properly.

Replace rope and hardware with Harken parts only.

How to get service – If something goes wrong,

contact Harken directly or your local Harken dealer

to arrange for warranty assistance. Your dealer has

Harken warranty return guidelines that provide you

with exact return procedures, depending on the product

involved. We will need, in writing, your name, address,

phone number, date of purchase, product involved,

application, an explanation of the defect, and conditions

under which the product was used. We are fair and we

do care when Harken products do not perform.

19

Page 20

CEILING LEVEL STORAGE

Each patented Hoister kit is complete and simple to install.

Easy one-person operation with a single control rope.

Self-locking cleat grips instantly if accidentally released.

Do not use this product for human suspension.

SELECT THE HARKEN HOISTER YOU NEED:

1. Determine maximum weight you will lift and select correct Hoister.

2. Standard Hoisters are designed for a maximum ceiling height of 10' (3 m). Contact Harken for taller ceilings.

3. Check distance between ceiling and top of garage door in open position. Will object fit in this space? If not, will object lift

and store under garage door in open position? If not, consider turning the object 90° and placing in the front of garage.

4. Hoisters 7801, 7802, 7803, 7806, and 7808 are designed to lift an object no wider than 5' (1.52 m). Width can increase if vertical lift

is lower or a taller ceiling model is used.

Part

No.

7801

7802

7803

7806

*7808

Storage

system (lb)

60

90

145

200

45

Mechanical

advantage

3:1

4:1

6:1

8:1

2:1

Lifting weight

Min Max

lb kg lb kg

15 7 60 27

25 11 90 41

45 20 145 66

75 34 200 91

10 4.5 45 20

*New SUP Hoister

Tools: Drill, drill bits:

tape measure, wrench:

20

5

/

32

" (4 mm),

7

/

16

7

/

32

" (5.5 mm),

"(11 mm) box end or ratcheting.

Qty Description Size Length

2

pine boards (grade 2)

1

pine boards (grade 2) 2"

8

lag bolts/washers

Rafters running sideways (purchase above plus following)

1

pine boards (grade 2)

2

lag bolts/washers

Harken, Inc. • N15W24983 Bluemound Rd, Pewaukee, WI 53072-4974 • Tel: 262-691-3320

Fax: 262-701-5780 • Email: hoister@hoister.com • Web: www.hoister.com

5

/

16

" (8 mm), plumb line, pencil, stud finder, stepladder, safety glasses,

Optional supplies

2"

x 6" (50 mm x 152 mm)

x 6" (50 mm x 152 mm)

5

/

16

" (8 mm)

2" x 4"

(50 mm x 100 mm)

5

/

16

" (8 mm)

6' (1.83 m)

7" (180 mm)

4

" (100 mm)

6' (1.83 m)

1

3

/

2

" ( 90 mm)

4907 01/15 Printed in USA

Loading...

Loading...