Page 1

MKIV HYDRAULIC JIB REEFING & FURLING

Unit 3

Installation Manual – Intended for specialized personnel or expert users

Preassembly

Safety Precautions 2

Parts Descriptions 2 - 3

Size Check 3

Parts 4-5

Rigging Parts Check/Tools 6

Hydraulic System 7 - 8

Toggle Deductions/Stay Into Foil Options 9

Top Foil Lengths 10 - 11

Short Top Foil 11

Confirm Foil Length 12

Assembly

Foils/Connectors 13 - 18

Bottom Foil/Connectors/Halyard Swivel 19

Lower Unit to Foil 20

Rod Rigging: Rod Adapter Stud 21

Attach Turnbuckle/Toggle 22 - 23

Attach Hydraulic Cylinder 23 - 24

Feeder/Final 25

4379 12/13

Commissioning

Turnbuckle on Boat 26

Halyard Swivel Height/Lead Angle 27

Halyard Restrainer/Tension 28

Operation

Halyard: Headstay Tension 29

Reefing/Secure Sail 30

Manual Operation 31

Race Conversion 32

Maintenance/Inspection/Decommissioning 33

Troubleshoot/Warranty 34

Appendix

Component Part Number List 35 - 37

Toggle Dimensions 38

Dimensions/Sailmaker's Instructions 39

WARNING! Strictly follow all instructions

to avoid an accident, damage to your vessel,

personal injury or death. See www.harken.com

Please read these instructions carefully before installing, servicing, or operating the equipment.

This manual may be modified without notice. See: www.harken.com/manuals for updated versions.

PLEASE SAVE THESE INSTRUCTIONS

for additional safety information.

Page 2

Safety Precautions/Parts Description

Introduction

This manual gives technical information on installation and service. This information is destined exclusively for

specialized personnel or expert users. Installation, disassembling, and reassembling by personnel who are not

experts may cause serious damage to property or injury to users and those in the vicinity of the product. If you

do not understand an instruction contact Harken.

The user must have appropriate training in order to use this product.

Harken accepts no responsibility for damage or harm caused by not observing the safety requirements and

instructions in this manual. See limited warranty, general warnings, and instructions in www.harken.com/manuals.

Purpose

®

Harken

Jib Reefing and Furling is designed for rolling sails on sailboats to reduce sail size or to completely roll

so wind has little effect on the sail. Use of this product for other than normal sailboat applications is not covered

by the limited warranty.

Safety Precautions

WARNING! This symbol alerts you to potential hazards that may kill or hurt you and others

if you don't follow instructions. The message will tell you how to reduce the

chance of injury.

CAUTION! This symbol alerts you to potential hazards that may hurt you and others if

you do not follow instructions. The message will tell you how to reduce the

chance of injury.

WARNING! Strictly follow all instructions to avoid potential

hazards that may kill or hurt you and others. See www.harken.com/

manuals, for general warnings and instructions.

9

8

5

7

3

2

1

6

4

11

10

3

1

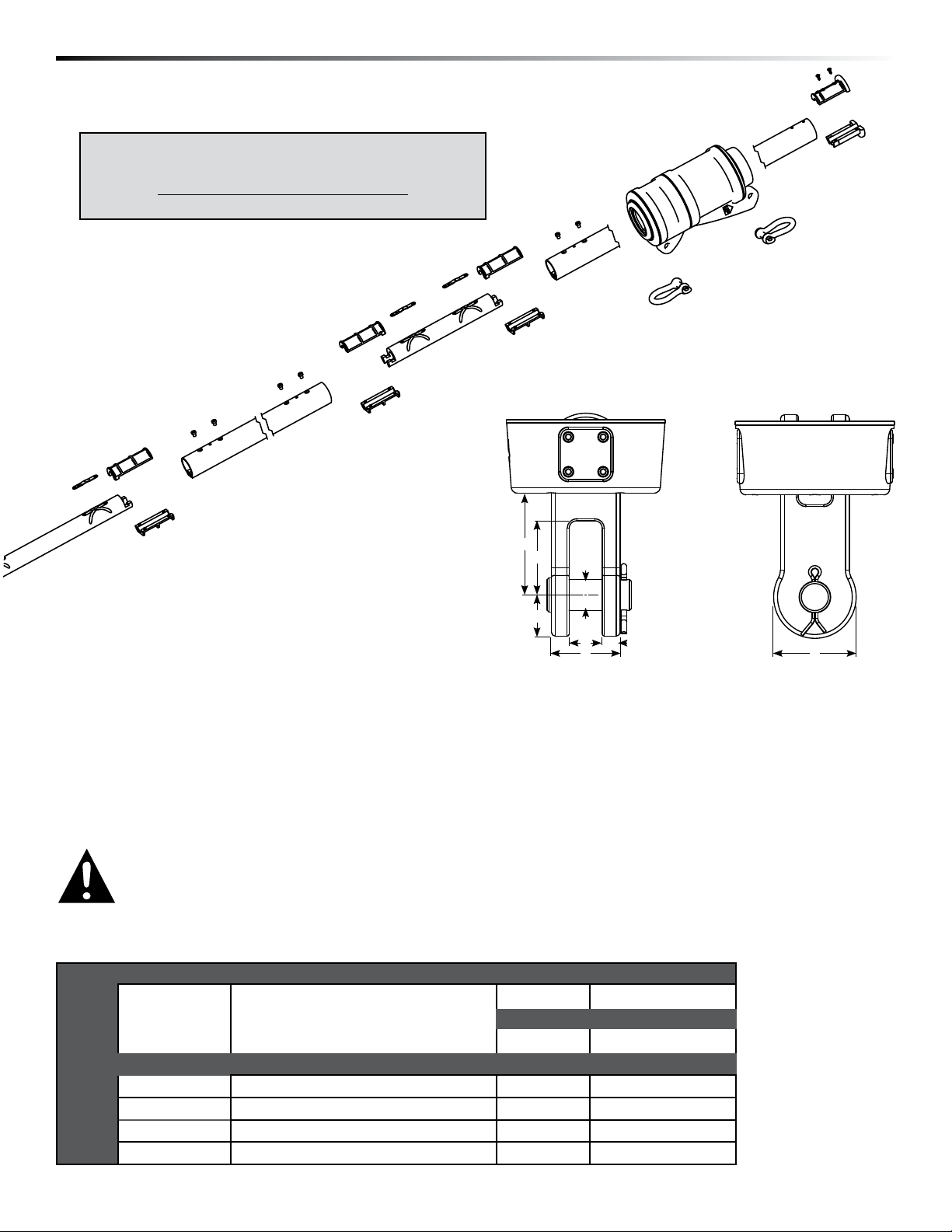

Parts Descriptions

1) Jaw/Jaw Toggle

2) Toggle Housing

3) Toggle Housing Insulator

4) Hydraulic Cylinder

2 MKIV Hydraulic Unit 3

5) Lower Unit

6) Calibrated Guide

7) Shackles

8) Foil Clamp

9) 2' (610 mm) Bottom Foil

10) Feeder

11) Connector Bushing

12) Bottom Connector

13) 7' (2.13 m) Foil

14) Connector Screws

15) Connector Wedge

16) Connector

17) Halyard Swivel

18) Trim Cap

19) Trim Cap Screws

Page 3

Preassembly Sizing Check

19

18

12

Online Product Registration

www.harken.com/FurlingWarranty

15

14

13

11

16

17

A

B

See page 39 for all

toggle dimensions.

C

D

GE

F

H

Size Check

1. Check headstay and clevis pin dimensions in chart below.

2. Harken does not recommend drilling boat’s chainplate or toggle. Bushings may be required to fit boats with

smaller clevis pin sizes.

WARNING! Do not drill boat's chainplate or toggle. This may result in rig failure.

Use the correct size toggle and clevis pin.

3. Will lower unit fit on bow? See page 9. If necessary, use an additional toggle to slightly raise unit.

Unit Part No. Description Wire Ø

7

7413.15

7413.16

MKIV Hydraulic Unit 3 (Aluminum Foils)

MKIV Hydraulic Unit 3 (Carbon Foils)

Toggle Part No. Description Toggle Clevis Ø

7413.25 3/4

UNIT 3

7413.25 7/8

7413.26 3/4

7413.26 7/8

MKIV Hydraulic Unit 3 3

Toggle Assembly

Toggle Assembly

Hydraulic Cylinder/Toggle

Hydraulic Cylinder/Toggle

/16", 1/2" 11 mm, 12 mm

Rod Ø

-22, -30 9.53 mm, 11.10 mm

3

/4" 19.1 mm

7

/8" 22.2 mm

3

/4" 19.1 mm

7

/8" 22.2 mm

Page 4

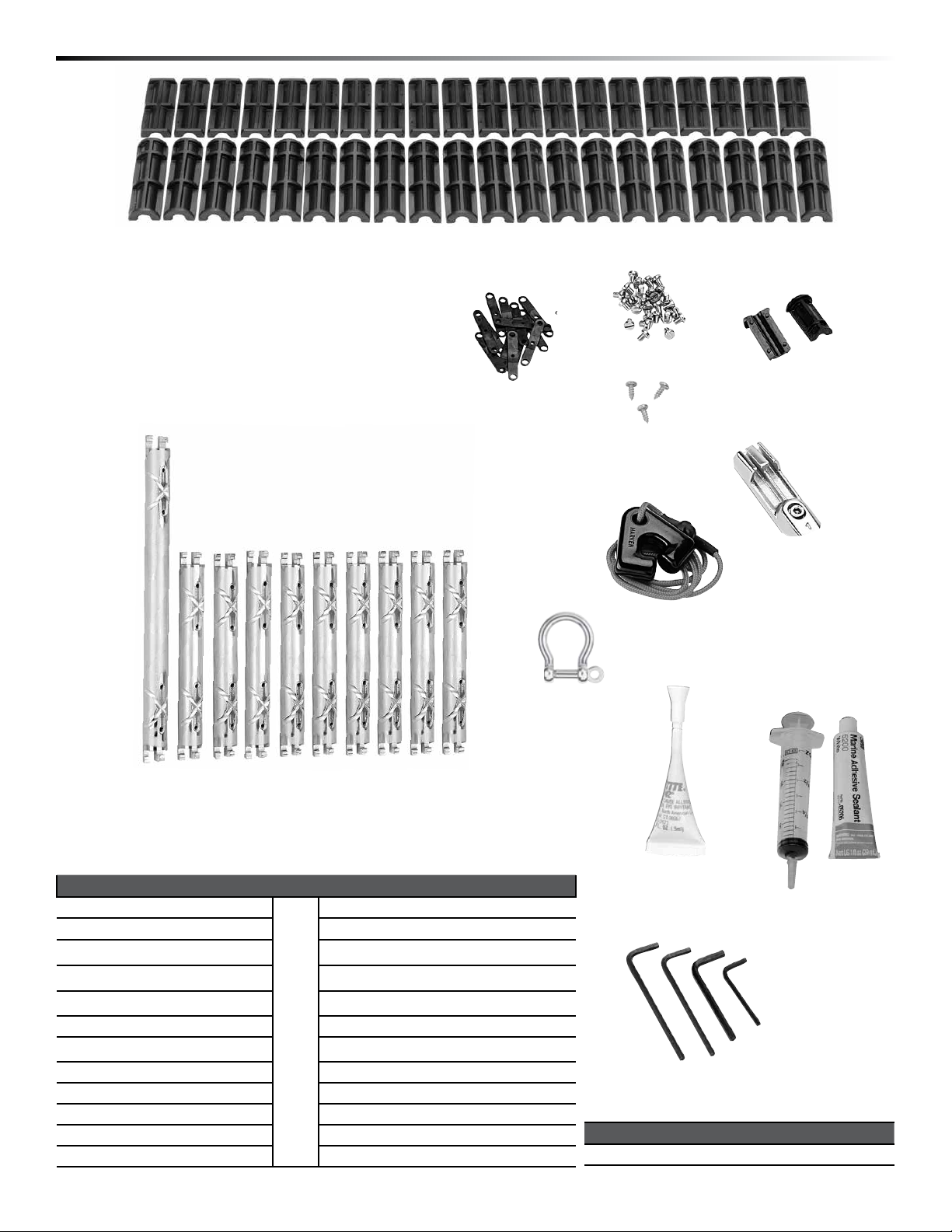

Preassembly Parts

2' (610 mm)

Bottom Foil

10—7' (2.13 m) Foils

Drill Adapter for

Manual Drive

Emergency

Crank Handle

Halyard Swivel

Unit 3H

Lower Unit

Unit 3H

Remote Switch w/Guard

(Order Separately)

4 MKIV Hydraulic Unit 3

Main Components

Description Part No. Qty

Lower Unit

2'(610 mm) Bottom foil

7'(2.13 m) Foil

Halyard Swivel

Emergency Crank Handle

Drill Adapter for Manual Drive

See Parts List

7413.33

7413.31

H-39392

7430

7431

1

1

10

1

1

1

Page 5

Preassembly Parts

Connector Bushings

Foil Screws

Trim Cap

Plastic

Connector

Wedges

Trim Cap Screws

Feeder

Prefeeder

Bow Shackles

Bottom

Connectors

Connector

Other Components

Blue Loctite

Description Unit Part No. Qty Size

Connectors

Bottom Connector

Connector bushing set

Plastic connector wedge set

Foil screw set

Trim cap set

3E

Trim cap screw set

Prefeeder

Feeder with screw and tab

10 mm Bow shackle

Blue Loctite

®

Injector, 1 oz. 5200 Adhesive

MKIV Hydraulic Unit 3 5

7413.31F

7413.32F

HFG297

(20 EA H-42073/H-42074)

HFG324

(22 EA H-39487)

HFG349

( 46 EA HFS1106)

HFG682

HFG672

( 3 EA HFS1127)

947

H-39756

2124

833

HFG725

9 9.75" (248 mm)

1 14" (356mm)

1 —

1

1

—

—

1 —

1

—

1 —

1 —

3 10 mm

1

1

.017 oz.

1 oz.

Tools

Description Unit Qty

3, 4, 6, 10 mm Hex wrenches 3 1 Each

®

5200

Adhesive

Injector

3,4, 6, 10 mm

Page 6

Preassembly Rigging Parts Check/Tools/Adhesive

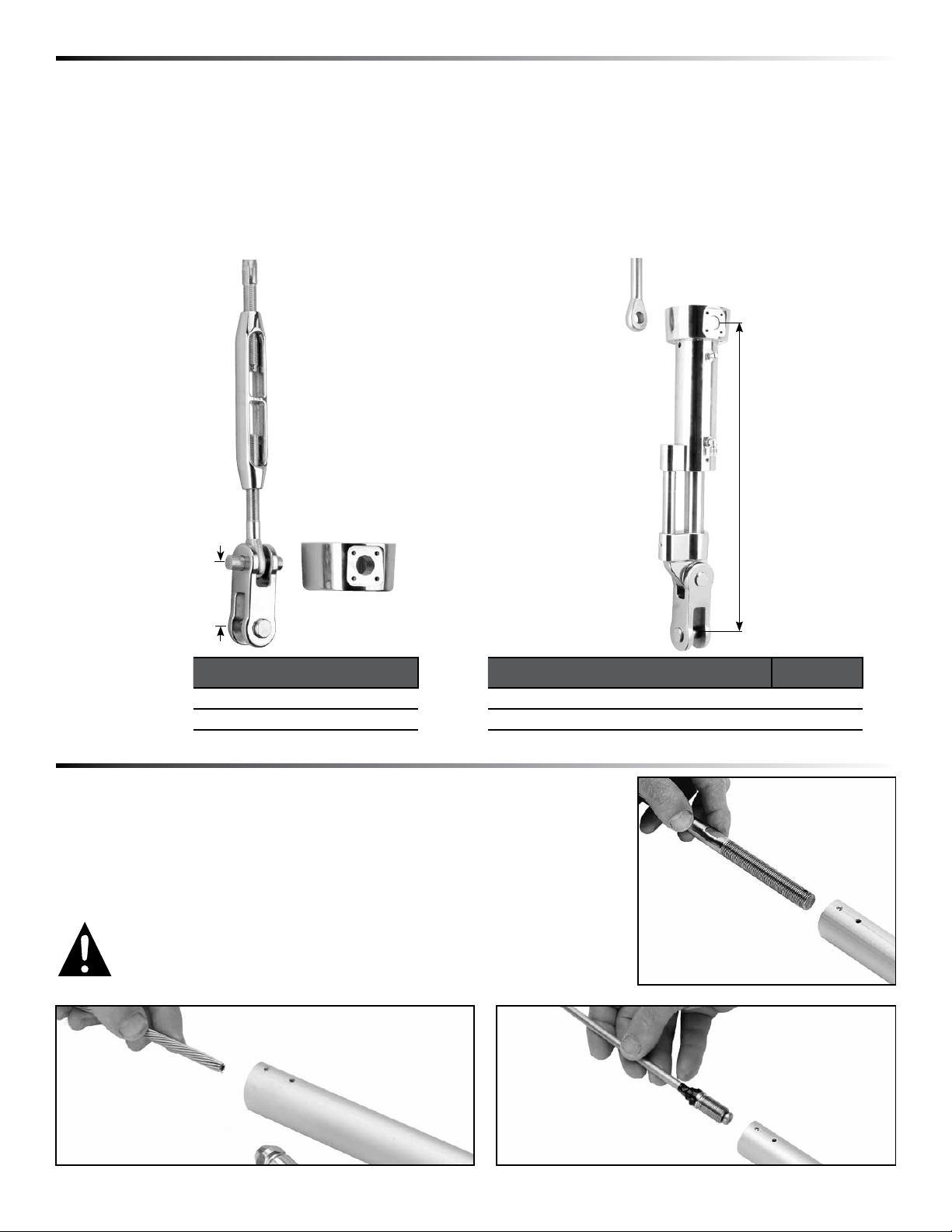

Toggle Assembly

1. Harken toggle assembly or hydraulic cylinder required. Sold separately.

2. Mating turnbuckle components, with eye at lower end, must be purchased

separately. See page 10.

3. Headstay may require cutting and shortening to fit Harken toggle. Some

headstays may remain uncut by replacing lower stud of turnbuckle with

stud/eye thus eliminating extra toggle.

4. Rod rigging requires Harken rod adapter stud.

Harken Toggle

WARNING! A stay that is old or damaged may break suddenly, causing an accident. Headstay condition should

Assembly Housing

(Sold Separately)

be checked by a professional rigger before reusing.

Hydraulic Hoses

Hoses are not supplied with furler. Use SAE 100 R1 or R2 hoses.

Size depends on the distance that hoses will run and the power

source. For shorter runs use two hoses: -6 (3/8" ID). Contact

Harken for further hose size recommendations.

Hose End Fittings

Use SAE straight thread O-ring male hose end fittings - 9/16-18.

Unit Part No.

3H

Hydraulic cylinder uses a -4JIC end fitting.

7413.25 3/4

7413.25 7/8

Hydraulic Length-

Adjusting Cylinder

(Sold Separately)

Unit Part No.

7413.26 3/4

3H

7413.26 7/8

ROD RIGGING

Harken Rod Adapter

Stud Required

(Sold Separately)

Unit Part No.

7426 -22

3H

7427 -30

Tools You Will Need

3

10

16

4

12

13

11

1

2

8

6

7

1. Long tape measure 6. Side cutters 11. Center punch

2. Short tape measure 7. Rat-tail file 12. Rigging or black tape

3. Power drill 8. Hex wrenches (provided) 13. Scissors

4. Drill bit – 5/32" (4 mm) 9. Slotted/phillips screwdrivers 14. Metal straight edge

5. Hacksaw 10. Needle-nose pliers 15. Hammer

16. 6 mm Ball-end hex wrench (recommended but not required)

6 MKIV Hydraulic Unit 3

9

5

14

15

Adhesive Alert

MKIV Furlers are shipped with 3M 5200

adhesive. Use adhesives on dry connectors

and foils using the special injection system

described in the assembly section. Parts

may immediately be exposed to rain. Cure

is best at 70 F (22 C) with 50% humidity.

Do not apply at temperatures below 40 F

(5 C) and above 100F (38 C).

Although adhesive has not cured it will

remain in place on foil joints whether

they are left on the ground or raised up

on boat. Foils can be raised immediately

after assembly and sails fitted.

Note: A small amount of adhesive may

bulge out of injection ports. If possible

let system sit for a couple days before

sailing. If adhesive gets on sails remove

using acetone. For faster-curing adhesive,

purchase 4200 Fast Cure.

Note: Damaged foils can be repaired.

Use a hand-held propane torch to heat

joints until foils can be pulled apart.

Page 7

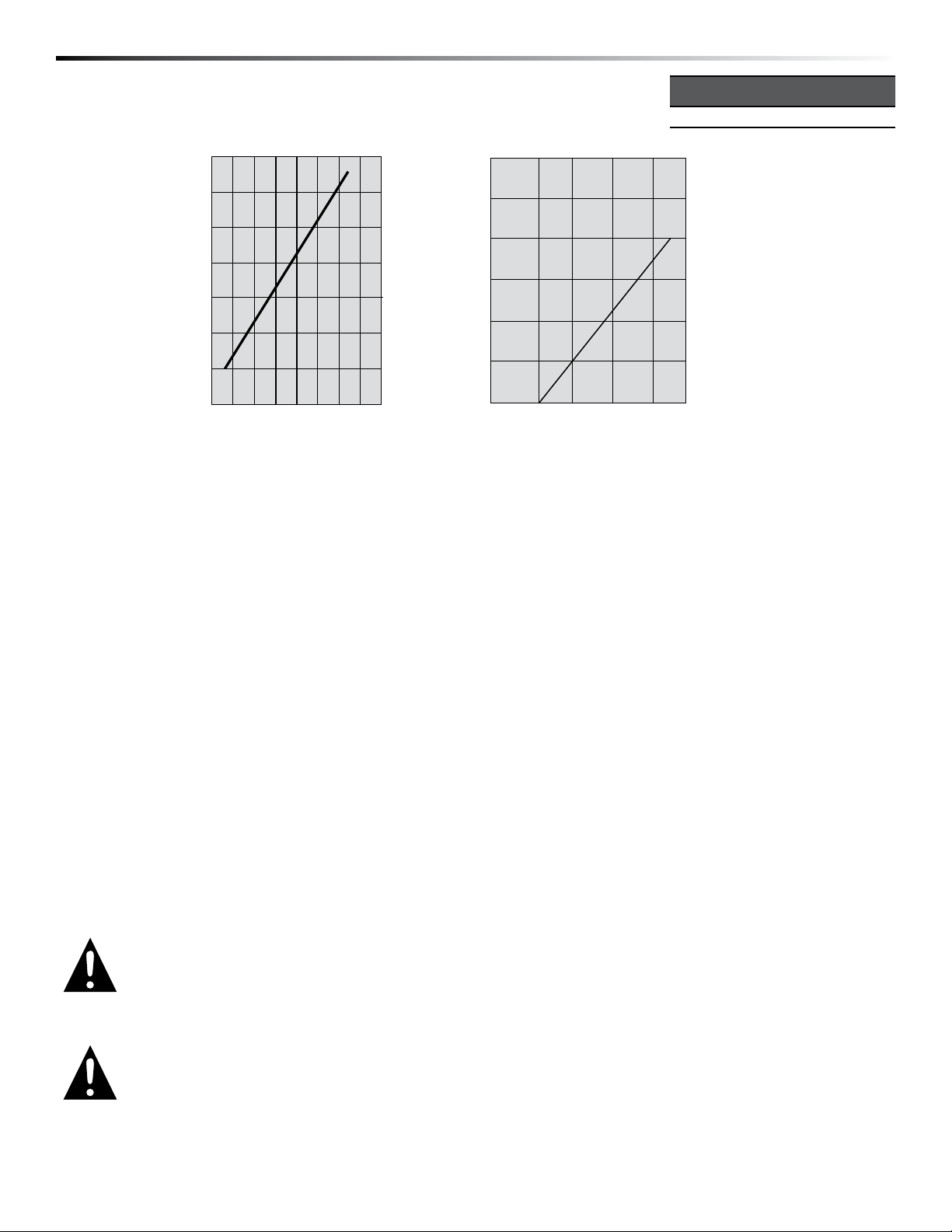

Hydraulic General Specifications/Valves/Operation Pressure/Oil

Furler Power Requirements

The furling unit and hydraulic tensioning cylinder will work with all current Harken

Unit

3 4 g/m 15 l/m

Recommended

Flow Rate

hydraulic power plants. They are designed to provide 4 g/m (15 l/min) at load.

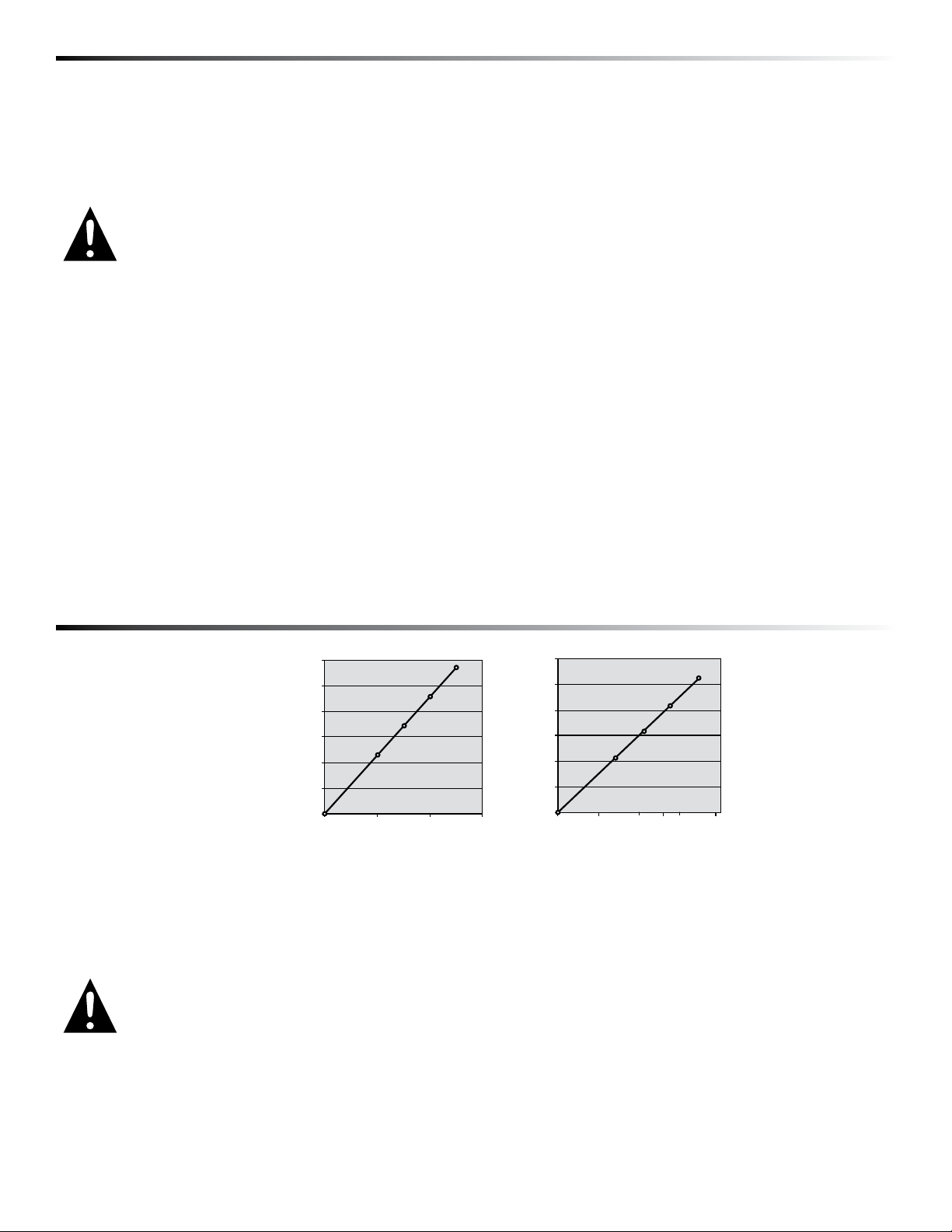

70

60

50

40

30

Furling speed RPM

20

10

1 2 3 4 5 6 7 8

Flow GPM

3000

2500

2000

1500

1000

Furling torque M - LB

500

500 1000 1500 2000 2500

Pressure PSI

Maximum Operating Pressure

Set relief valve on power plant at 140 Bar or 2000 PSI. Harken power packs ship with valves set at 140 Bar.

Valves on Power Unit

Furler can be used with open or closed center, 4-way, 3-position control valves.

Gear Oil Specifications

Unit is sealed with a light bath of ISO 68 gear oil.

IMPORTANT! The only parts of furler to be disassembled by installer are the Torque Tube Clamp and Toggle

Housing. All other work should be performed by factory-authorized personnel. Work performed by unauthorized

personnel may void the Harken limited warranty.

Hose and Fitting Selection Recommendation

Required hose type - SAE 100 R2 or SAE 100 R8. Hose size is determined by flow and run length between power

unit and furler.

Measure hydraulic hose runs.

Remember these important points when measuring runs.

1) Short straight runs between HPU and function are best.

2) Avoid sharp edges which may chafe the hose.

3) Minimize fittings/connections throughout the run to avoid possible leak points.

4) Minimize 90° bends, which increase system losses and decrease performance. If unavoidable use a 90° swept

fitting, Do not use a 90° elbow fitting.

CAUTION! Do not exceed the manufacturer specified minimum bend radius.

When ordering, specify that all hoses are flushed, filled with clean oil and capped at point of purchase. HARKEN

recommends ISO 46 grade oil. If hoses are shipped, they may not contain oil.

CAUTION! Always ensure pressure rating for selected hose is equal to or greater than 2000psi/140 bar.

Note: Hose Shortening - Hydraulic hoses typically shorten 2% to 4% of total length when pressurized. When routing

and measuring hose lines ensure extra hose length is added to compensate for the hose shortening under pressure.

MKIV Hydraulic Unit 3 7

Page 8

Hydraulic General Specifications/Valves/Operation Pressure/Oil

Hydraulic Connection to Furling Unit

Use Stainless Steel -6 ORB to -6 JIC Adapters.

Important: Do not use PTFE tape or sealant on threaded connections to Harken ports. Using PTFE tape can damage threads.

Hydraulic Oil

Use only hydraulic oil ISO 46 grade or equivalent.

CAUTION! Hydraulic oil may cause skin irritation.

Important: Hydraulic oil may damage paint and some surfaces.

Leak Check

To perform leak check, run furler in a single direction for 5 – 10 seconds. If installation was completed with empty

hoses, increase the run time to 10 – 30 seconds. Perform the following:

1) Confirm hose run is correct by verifying operation of intended function.

2) Inspect each fitting for leakage.

3) Tighten fitting as necessary.

4) Repeat procedure for all functions.

IMPORTANT: If installation was completed with empty hoses, check the oil level indicator after, and add oil as necessary.

One-Way Function Flush

Flush the pump motor through the power unit system filter by running furler in a single direction. Run in same

direction as previous step. This process helps ensure system cleanliness by depositing any contaminates into the

power unit system filter.

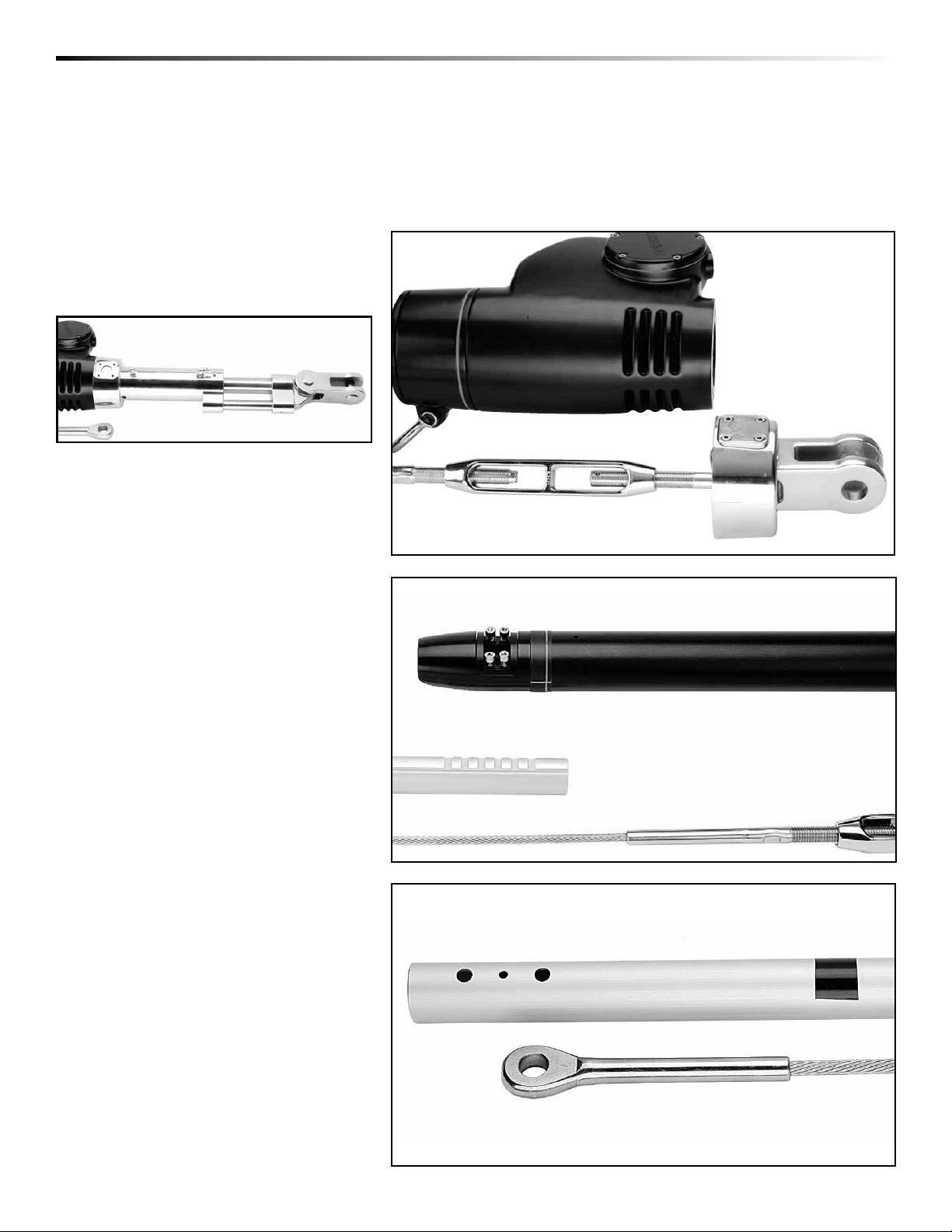

Hydraulic Length Adjusting Cylinder (Optional)

Specifications:

Stroke: Unit 3: 4" (100 mm)

CYLINDER PULL FORCE LBS

12000

10000

CYLINDER PULL FORCE KG

6000

5000

Performance:

4000

3000

2000

Cylinder pull in KG

1000

0

0

Hydraulic pressure in BAR

100

200

300

400

Pressure Requirements

8000

6000

4000

Cylinder pull in LBS

2000

0

0

Hydraulic pressure in LBS

600040002000

The hydraulic length adjusting cylinder requires a pressure of Max. 5,000 pounds (350 Bar) to develop rated pull

force on the headstay. The hydraulic pressure for the cylinder can be provided by a high pressure manual system or

the boats power unit. If the cylinder is used with a power unit providing less than 5,000 psi (350 Bar), a hydraulic

intensifier is required to step up the pressure. Either power source requires the use of a zero leak control valve so

the pressure to the cylinder doesn’t bleed down over time.

WARNING! Relieve all pressure prior to disconnecting. Only work on cylinder and connections

if you are a hydraulic technician.

Hydraulic Cylinder Hose Connection

The cylinder has a -4 JIC fitting. Choose appropriate hose and end fitting.

Cylinder Gas

Cylinder is shipped without gas. Fill fitting is a Schroeder type. For best clean performance use Nitrogen or Argon

gas pressurized to 50 - 65 lbs.

8 MKIV Hydraulic Unit 3

Page 9

Preassembly Toggle Deductions/Stay Into Foil Options

Use dimensions of Harken toggles or cylinders shown below to build stay to correct length.

Toggle Assembly

Turnbuckles should be 1/2 to 2/3rds open to allow shortening for new wire stretch and for fine-tuning mast rake and

to help connect the stay.

Hydraulic Cylinder

Length for hydraulic cylinder can be determined at 1/2 to 2/3rds open to allow to allow shortening for new wire

stretch and for fine-tuning mast rake and to help connect the stay. Stroke length for unit 3 cylinder is 4" (100 mm).

Toggle

Part No.

7413.25 3/4

7413.25 7/8

Clevis Pin ØPin-to-Pin

3

/4" (19.1 mm) 31/4" (83 mm)

7

/8" (22.2 mm) 37/8" (98 mm)

Length

Hydraulic Cylinder

Part No.

7413.26 3/4

7413.26 7/8

Clevis Pin ØMax. Pin-to-Pin

3

/4" (19.1 mm) 20" (50 mm) 16" (400 mm)

7

/8" (22.2 mm) 201/2" (525 mm) 161/2" (420 mm)

Length

Min. Pin-to-Pin

Length

Options for Snaking Stay into Foils

1. Swage stud at end of wire.

2. Open end of wire and install Norseman or Sta-Lok

®

stud after foil is assembled.

3. Rod adapter nosepiece for Harken rod adapter stud: Threaded nosepiece must

have a positive lock of as well as adhesive. Use Harken stud with cotter pins.

See page 22.

WARNING! Using a threaded nosepiece with only adhesive at the

upper rod eye terminal may result in headstay failure. Make

sure there is a mechanical lock.

MKIV Hydraulic Unit 3 9

Page 10

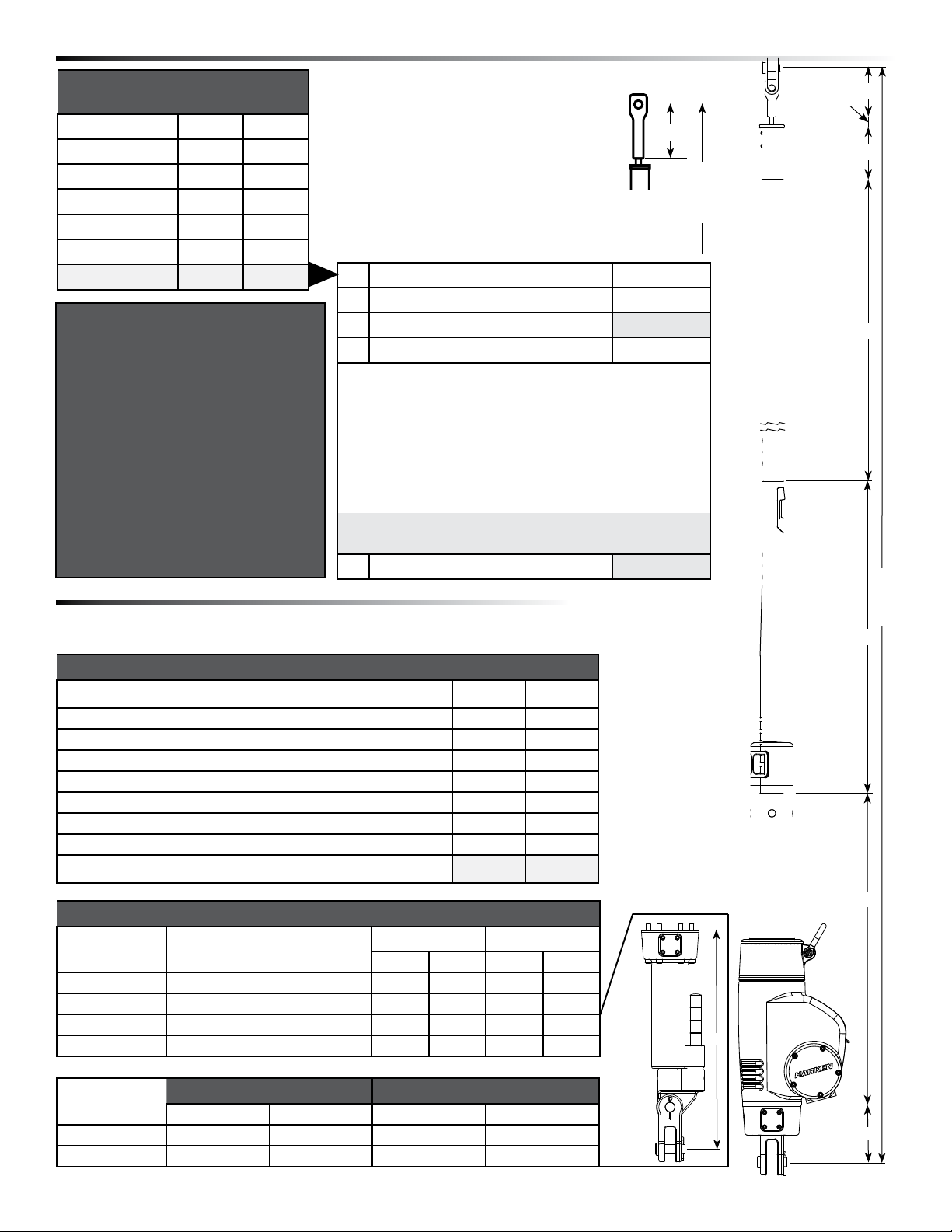

Preassembly Top Foil Length

Measure A and add to this chart

and length chart below

Inches mm

A

B 1 25

E 24 610

F 23.18 589

G

Total A+B+E+F+G

UNIT 3H

Make sure upper

measurement points

of A and Pin-to-Pin

are the same.

TOP FOIL LENGTH WORKSHEET

1

2

3

4

To find “D” pick number from chart below that is closest to,

but not greater than total from step 3.

800 inches “D” = 756 inches 20,000 mm “D” = 19,202 mm

5

Result (Pin-to-Pin – ABEFG)

Inches mm

7 x 84 = 588

8 x 84 = 672

9 x 84 = 756

10 x 84 = 840

11 x 84 = 924

Example–If result from Step 3 is:

Result (C) Top Foil Length

Pin-to-Pin Length

Subtract ABEFG

Length Check

After completing worksheet above fill in A, C, D and G below. Add

“A” through “G” to confirm total equals your pin-to-pin measurement.

Alternate

Measurement

Point

–

Subtract D

7 x 2133.6 = 14935.2

8 x 2133.6 = 17068.8

9 x 2133.6 = 19202.4

10 x 2133.6 = 21336

11 x 2133.6 = 23470

–

A

B

A

C

Pin

to

Pin

D

Pin

to

Pin

E

Length Chart

Dimensions Inches mm

A Center of Pin to Bottom of Terminal

B Bottom of Terminal to Top of Foil

C Top Foil Length

D Number of Foils ________ x 84" (2133.6 mm)

E Bottom Foil 24.00 610

F Bottom of Foil to Top of Toggle Housing Insulator 23.18 589

G Top of Toggle Housing Insulator to Clevis Pin

1.00

Pin-to-Pin Length

G Toggle Distance from Lower Clevis Pin to Top of Toggle Housing Insulator

Toggle

Part No.

7413.25 3/4 Toggle Assembly

7313.25 7/8 Toggle Assembly

7413.26 3/4 Hydraulic Cylinder/Toggle

7313.26 7/8 Hydraulic Cylinder/Toggle

*Dimensions with cylinder 58% open

Cylinder Pin

Ø

3/4 17.00 432 21.00 533

7/8 17.67 449 21.67 550

10 MKIV Hydraulic Unit 3

G Distance (Closed) G Distance (Open)

Type

in mm in mm

Clevis Pin G Distance

in mm in mm

3

/4 19.1 4.39 112

7

/8 22.2 4.98 126

3

/4 19.1 19.32* 491*

7

/8 22.2 19.99* 508*

25

F

G

G

Page 11

Preassembly Short Top Foil

If top foil is shorter than 9

3

/4" (248 mm), use one of the following special techniques to ensure sufficient bearing

surface for the foil in the area of the halyard swivel.

/4" (248 mm)

3

9

93/4" (248 mm) No special treatment required.

/8" (244 – 181 mm)

1

Cut-Offs

/8" – 7

5

9

Do Not Use

95/8" – 71/8" (244 – 181 mm) Do not use plastic

bushing above top connector.

/2" (89 mm)

/2" (64 mm)

2

/2" (38 mm)

1

2" (51 mm)

1

1

1

3" (76 mm)

3

Cut-Offs

Do Not Use

31/2" – 11/2" (89 – 38 mm) Shorten top foil and adjoining

full length foil so two screws are used to assemble joint

instead of four. Do not use plastic bushings above top

connector.

Top Foil

Length from

Worksheet

1

3

/2"

(89 mm)

3"

(76 mm)

1

/2"

2

(64 mm)

2"

(51 mm)

1

/2"

1

(38 mm)

1. Initial

top foil

cut length

69/16"

(167 mm)

6

(154 mm)

69/16"

(167 mm)

5

(129 mm)

49/16"

(116 mm)

1

1

/16"

/16"

2. Cut through

middle hole in

top foil.*

Resulting Top

Foil Length Length

5"

(127 mm)

41/2"

(114 mm)

4"

(102 mm)

31/2"

(89 mm)

3"

(76 mm)

3. Shorten

full length

adjoining

foil by

cutting

through

middle

hole.*

4. Shorten

connector

(124 mm)

(124 mm)

(124 mm)

(111 mm)

(95 mm)

47/8"

47/8"

47/8"

43/8"

33/4"

5. Shorten

trim cap

No

No

No

Yes

Yes

/2" (178 – 140 mm)

1

7" – 5

Cut-Offs

Do Not Use

Cut-Off

Do Not Use

7" – 51/2" (178 – 140 mm) Do not use plastic bushing

above top connector. Shorten top of connector and if

necessary shorten trim cap.

*To allow for saw cut, position blade so upper half of

middle hole is preserved.

/2" (38 mm)

Cut-Offs – Do Not Use

/8" – 4" (137 – 102 mm)

3

5

53/8" – 4" (137 – 102 mm) Do not use plastic bushing

1

Under 1

above top connector. Cut connector right at cross formed

by glue dispersion channels. Use single foil screw in top

foil only.

MKIV Hydraulic Unit 3 11

Under 11/2" (38 mm) Eliminate top foil and run foil

higher in foil clamp.

Page 12

Preassembly Check Foil Length

Confirm foil length by laying foils alongside stay with turnbuckle components. Pull stay out so it is straight. Attach

Harken toggle to bottom of stay using crosspin. Adjust turnbuckle so that length of stay with Harken toggle will fit

boat. Ideally, turnbuckle will be half to two-thirds open to allow for rig adjustment.

Line up lower unit so base of unit lines up with toggle housing.

Attach one link plate to lower unit. Line up lower unit so link plate hole lines up with crosspin in Harken toggle.

Make sure toggle is tensioned when measuring.

Line up bottom foil so foil clamp is

centered or just below center of

notches in bottom foil.

Note: Position top foil so that with top

cap the foil will ride 1" (25 mm) below

terminal. If wire fitting at top of stay is

swage, foil must ride just below shoulder

of swage. Mark cut line on foil. Wrap tape

around foil as a guide so cut is straight.

12 MKIV Hydraulic Unit 3

Page 13

Assembly Top Foil

Cut foil to length using hacksaw.

Deburr inside edge using rat-tail file.

Prepare top foil for drilling.

Tip: Mark top foil to distinguish

from cutoff piece.

Scribe line on top of foil to mark drill

holes. Lay top foil alongside cutoff

piece and use a flat metal object

(i.e. metal ruler) to scribe top

line of foil.

MKIV Hydraulic Unit 3 13

Page 14

Assembly Top Foil

Cut out template at right. Line up template

with top of foil and scribed line. Tape in

place. Use center punch to mark holes.

Check center punch marks to confirm

3

they are 3/8" (10 mm) and 1

from top of foil.

Drill two (2) 5/32" (4 mm) holes for

trim cap.

/8" (35 mm)

!

Foil

3

Top

/8" (10 mm)

13/8" (35 mm)

Lay top foil in line with others. Slide stay

into top foil and down line of foils or slide

each foil up stay.

14 MKIV Hydraulic Unit 3

Page 15

Assembly Top Foil

Install trim cap. Place each side over wire.

Push trim cap into foil to start, then tap

in using hammer.

Install trim cap screws.

Place halves of plastic bushings on stay so

hooked part of longer section faces out.

Tip: With foil screw holes up as shown

below, place longer half of bushing

with hook on upper half.

MKIV Hydraulic Unit 3 15

Page 16

Assembly Top Foil/Connectors

Slip connector on wire, mating hook

of plastic bushing with connector.

Loading Injector with Adhesive

Tip: In cooler weather, keep sealed

adhesive in pocket to keep warm. Use

instructions below to fill injector less

than half way; you will only use a small

amount of adhesive. Refill if needed

but do not keep open sealant for long

periods. Use adhesive within 3 hours.

Use cap of adhesive to break seal. Remove

injector tip cap and plunger. Hold injector

at an angle with applicator tip facing down.

Squeeze adhesive into tube so lower half

of injector is full as shown. Keep tip free

of sealant to let air inside.

Adhesive in

lower half

16 MKIV Hydraulic Unit 3

Page 17

Assembly Foils/Connectors

Start plunger into injector and immediately

hold upright so plunger is down and

applicator tip is up.

As sealant runs down towards plunger an

air pocket will form near tip. Push plunger

to evacuate air. You are now ready to begin

injecting adhesive.

Put a drop of adhesive into screw holes.

Hold plastic wedge in place with thumb

as you insert into foil. Line foil holes

with connector screw holes.

MKIV Hydraulic Unit 3 17

Page 18

Assembly Foils/Connectors

Inject only a small amount of adhesive

into middle hole.

Unit Adhesive

3

1 to 1

1

/4 ml

Tip: When you see a small amount

of adhesive enter one screw

hole, stop. You have applied

enough adhesive.

Stop when you see a small

amount of adhesive enter

one screw hole.

Use “ml”

marks to

estimate 1

1

/4ml of

to 1

adhesive

Tighten screws into connector holes. Make

sure a drop of adhesive entered each screw

hole. If not, apply to screw.

Use bushings, connector, wedge and

adhesive in other screw hole and insert

1

into other foil. Use 1 to 1

18 MKIV Hydraulic Unit 3

/4 ml of adhesive.

Page 19

Assembly Bottom Foil/Connectors/Halyard Swivel

Continue installing connectors and wedges.

Make sure to use adhesive in screw holes.

Continue assembly. Use 14" (356 mm)

bottom connector to assemble bottom foil.

Slide halyard swivel onto foil above feeder

window. Make sure taller “half” is up as

shown.

MKIV Hydraulic Unit 3 19

Page 20

Assembly Lower Unit to Foil

Loosen foil clamp screws at top of

lower unit assembly.

Slide assembly onto foils.

Tip: Face clamp downward so it

clears foil notches during installation.

20 MKIV Hydraulic Unit 3

Page 21

Assembly Rod Rigging: Rod Adapter Stud

Apply a few drops of red

®

Loctite

Screw main threaded stud

portion onto bronze nosepiece

until flats align with two cotter

pin holes in terminal body.

Tip: Turn nosepiece completely

into threaded stud portion.

Flats will be close and may

only require a small half turn

to align with cotter pin holes.

to threads of nosepiece.

Insert two cotter pins and

®

spread. Clean excess Loctite

from terminal body using

special care to ensure that

there is no red Loctite

threaded stud.

®

on

ROD RIGGING

MKIV Hydraulic Unit 3 21

Page 22

Assembly Attach Turnbuckle/Toggle

Assemble turnbuckle. Slip toggle housing

insulator onto threaded eye. Remove toggle

plate. Use crosspin to capture eye and

tottle in toggle housing.

®

Note: If using Sta-Lok

or Norseman®

stud, you must use a washer above

stud as shown below.

Make sure shallow jaw is up.

Up

Down

Install cover plate using blue Loctite®

on screws.

If stay length is set use side cutters or

needle-nose pliers to bend cotter pin

to secure turnbuckle.

22 MKIV Hydraulic Unit 3

Page 23

Assembly Attach Toggle

Choose toggle orientation to match

chainplate—fore/aft or athwartships.

Line up insulator and secure toggle

assembly to lower unit using

®

blue Loctite

on screws.

Attach Hydraulic Cylinder

Slip toggle housing insulator onto eye terminal. Remove toggle plate. Use crosspin

to capture eye and toggle in housing.

Install cover plate using blue Loctite

®

on

screws.

MKIV Hydraulic Unit 3 23

Page 24

Assembly Attach Hydraulic Cylinder

Position cylinder to match chainplate direction.

Chainplate Runs Fore/Aft: Position the

guide rod so it is to the port side.

Hydraulic connections will be on the aft

side. Line up insulator and secure cylinder

®

assembly to lower unit using blue Loctite

on screws.

Chainplate Runs Athwartships: Position

the calibrated guide rod so it is aft.

Hydraulic connections will be on the

starboard side.

Chainplate Fore/Aft Orientation

Chainplate Athwartships

Orientation

24 MKIV Hydraulic Unit 3

Page 25

Assembly Feeder/Final

Check foil height at top, set and secure

using hex wrench.

Slide halyard swivel above feeder. Place

feeder in foil recess. Push screw down

so tab catches under foil. Tighten screw.

Note: Screw will turn with some difficulty.

It is plastic coated to prevent loosening

due to vibration.

Important! When removing screw,

loosen no more than one full turn.

Slide screw up and remove feeder.

MKIV Hydraulic Unit 3 25

Page 26

Commissioning Turnbuckle on Boat

Have extra cotter pins and locknuts on hand to replace used

ones at base of unit and for turnbuckle.

Hold foils and loosen foil clamp screws until you can pull clamp

out to lower foils.

Lower foils.

Remove six toggle housing screws. Use halyards to securely lift

and hold foils and lower unit.

WARNING! Foils are heavy and can drop suddenly

on fingers. Only do this work at the dock, not

underway.

Adjust turnbuckle.

Replace used cotter pins and locknuts. Lower unit and install

clevis pin and new cotter pin.

Lift foils so top is 1" (25 mm) below upper terminal.

Raise lower unit and use

halyard to lift and hold it

about 5' (1.5 m). Raise foils

using second halyard and

secure. Allow room above

for turnbuckle take up.

26 MKIV Hydraulic Unit 3

Page 27

Commissioning Halyard: Swivel Height/Lead Angle

Halyard Wrap

The most serious problem with furling systems occurs when the jib

halyard wraps around the headstay foil. Halyard wraps will keep you

from furling or unfurling and may cause serious damage to the unit

and the halyard.

WARNING! In severe cases, a halyard wrap can cause loss

of control of boat and/or headstay can break suddenly.

Make sure halyard is clear of top foil before using system.

To prevent wraps, the halyard must exert a slight pull to the rear.

This allows the foils to turn while halyard remains stationary.

Prevent Halyard Wraps

WARNING! Sail must be fitted to foil length before using

to prevent headstay loss which will cause an accident.

1. Halyard swivel should be within top 4 - 6" (100 - 152mm) of foil

unless a halyard restrainer is used.

2. Halyard must pull slightly to rear (8 - 10°).

3. Halyard must be snug, but not too tight.

If halyard wraps, do not force unit to turn. Attempt to open sail by

carefully furling in and out a little at a time. If sail will unfurl, lower

it by releasing jib halyard. Severe halyard wraps can only be cleared

by going aloft and freeing halyard.

8 - 10°

If sail will not furl or unfurl, try to remove jib sheets and manually

wrap sail around headstay.

Testing at dock does not indicate halyard angle is correct. In wave

action, halyard may wrap if lead angle is not correct. The 8-10°

diverging angle shown at right is critical.

Pendants

If the your sail luff is not long enough to position halyard swivel properly,

you must add a pendant. Pendants should be made of plastic-coated wire

and be permanently attached so sail height will be correct. Adjustablelength pendants are not acceptable, as they might not be adjusted

correctly during a sail change.

1. Raise sail, but do not attach tack shackle.

2. Position halyard swivel correctly near top of headstay.

3. Secure halyard.

4. Tie a piece of rope to sail tack.

5. Lead line through tack shackle on lower unit.

6. Tension sail.

7. Measure distance from tack shackle to sail tack and permanently

attach pendant of this length to head of sail.

8. Repeat procedure for every jib in your sail inventory.

MKIV Hydraulic Unit 3 27

Page 28

Commissioning Halyard: Restrainer/Tension

To prevent wraps, jib halyard must pull slightly to rear. On most boats,

halyard lead angle is acceptable if halyard swivel is raised to top of foil.

On some boats halyard sheaves are located too close to headstay and

a halyard restrainer must be used.

Halyard restrainers should be used only when required by masthead

geometry. Restrainers tend to limit sail luff length and may cause

problems if not installed properly.

If your boat needs a halyard restrainer, use Harken Part No. 945 or 1988.

Restrainer should be mounted as high as possible on face of mast.

Position restrainer so that foils will not hit it when under load.

The restrainer should deflect halyard as little as possible or you may

experience difficulty in tensioning sail luff, friction when furling, and

possible damage to foils. To decrease deflection angles, shorten sail luff.

Tip: Boats used in charter service should have a halyard restrainer,

regardless of masthead geometry.

Halyard Tension

The jib halyard should be firm, but not too tight.

Tip: The luff foil system supports sail along its length so halyard

tension is used only to shape sails, not to support them. Use enough

halyard tension to remove some wrinkles along luff of sail. Do not

tension halyard enough to cause vertical wrinkles in luff of sail.

Tension to adjust position of draft in sail to suit sailing conditions.

Halyard should be firm but not tight. If in doubt, release halyard

tension. To protect sail, ease halyard when boat is not in use.

28 MKIV Hydraulic Unit 3

Page 29

Operation Halyard: Headstay Tension

Spinnaker Halyards

Spinnaker halyards occasionally cause problems

with furling.

WARNING! In severe cases, spinnaker

halyards can jam furler causing loss of

control of boat. Make sure all halyards

are clear of furling unit action.

On many boats it will not be possible to attach

spinnaker halyard to bow pulpit or it may be

"sucked" into jib when furling.

On some boats the spinnaker halyard lays across

headstay and will catch on halyard swivel, foils or

jib halyard. To prevent problems it may be necessary

to install a masthead bail to move spinnaker halyard

block forward and to one side.

Boats with external halyards may find it necessary to

flip both ends of spinnaker halyard behind spreaders

to prevent fouling with furling system.

Headstay Tension

A furling system will work best if headstay is tight.

A loose headstay is difficult to rotate and can cause

unusual wear on foil joints.

To adjust headstay tension, remove sail and follow

instructions on page 27.

Tip: Before adjusting headstay tension, slack

mainsheet and vang.

Using Hydraulic Length Adjuster

Use reference lines on guide rod to help repeat settings. Make sure mainsheet

and vang are eased. Use Adjuster to set length especially when using two furlers

to make sure the desired furler is tensioned when the backstay is tensioned.

Backstay Adjusters

Backstay adjusters allow headstay tension to be varied to change sail shape to

match conditions. They permit a very tight headstay to be eased when boat is

not in use. For best performance, consider adding a backstay adjuster; either a

mechanical adjuster like those offered by Harken, or a hydraulic adjuster.

Remember to keep headstay tight for best performance when furling or reefing.

If your boat is fitted with an adjuster be sure that it is tensioned before the halyard

is tensioned. If not, backstay adjuster may increase halyard tension and could

damage the sail or furling system.

Racing boats often slack the headstay completely when sailing downwind. Check

to be sure that foil does not jam against upper headstay terminal when backstay

is released. To prevent this, it may be necessary to shorten foil slightly.

MKIV Hydraulic Unit 3 29

Page 30

Operation Raise Sail/Storm Sail/Reefing

Raise Sails

1. Install prefeeder by securely tying end of line to a deck fitting or to toggle below

furler so it is 2' (610 mm) below feeder.

2. Shackle tack of sail to lower unit. Install shackle so screw pin head is on same side

as sun cover.

3. Secure genoa sheets to clew of sail.

4. Attach genoa halyard to halyard swivel.

5. Pass luff tape through prefeeder and feeder into foil groove.

6. Attach head of sail or pendant at head of sail to halyard swivel.

7. Hoist sail.

8. Attach genoa tack to Lower Unit shackle.

8. Once sail is raised, determine the direction of furling so suncover will shield sail

from UV rays when furled.

9. Suncover on port side of sail, furl clock-wise. Suncover on starboard, furl

counter-clockwise.

Tip: Once you have determined the direction of furl to match the suncover, mark

remote furler switches, i.e. “furl/unfurl” or “in /out”.

Tip: New sails are often stiff and may hang up on prefeeder during raising. Do

not force sail when it hangs up—lower and remove twist. Sails "break in" with

use and will become easier to raise.

Storm Sails

Most people will use one multi-purpose genoa for all their sailing, but it is not good seamanship to go offshore

without storm sails.

Heavy-air working jibs and storm sails may be used with your unit. These sails need to have luff tape added to allow

them to be raised in headstay foils.

These sails will generally require pendants to ensure that halyard swivel is properly positioned at top of headstay.

See page 28.

Remember that heavy-air working jibs and storm jibs may be reefed and furled like any other sail.

Furl and Reef

To furl or reef, ease jib sheets and press correct

switch to furl sail.

In very light air, it may be necessary to place

some tension on jib sheet to insure a tight furl.

To furl in a breeze, ease sheets gradually and furl

sail in smaller increments until sail is furled or

reefed.

When furling or reefing, make sure that nothing

is jammed. Review swivel height, lead angle, halyard restrainer information. Make sure operator has a good view of sail

and stops furling when sail is rolled and sheets have a wrap or two on the furled sail. Stop immediately if sheets jam or

halyard wraps. If operator does not have a good view, station a crew member with good visibility and communicate to

operator. If motor is laboring stop and check for reason. Consult the Troubleshooting Guide on page 35.

WARNING! A hydraulic furling system is very powerful and jammed parts can break suddenly at high

load. Stop furling immediately and correct problem.

30 MKIV Hydraulic Unit 3

Page 31

Operation Manual Operation

Before using the system, practice manual operation in case there is a loss of power. Make sure that the emergency

handle can rotate and not hit the bow pulpit.

Cordless drill adapters work well, but there must be a fully-charged cordless drill on hand at all times. Because

a cordless drill may lose power, always have an emergency handle onboard in a secure, easy-to-find location.

Communicate location as part of safety equipment orientation for all crewmembers.

WARNING! You must have a reliable manual

drive procedure in place before using the

system.

Drill Adapter for

Manual Drive

Emergency

Handle

WARNING! You must observe all personal safety

precautions including using a harness and

secure tether and personal flotation device

(PFD) when going forward.

1. Communicate to all crewmembers that you are going

to manually rotate the furler. Practice this emergency

procedure in controlled conditions so you and your

crew are prepared in the event of a power failure.

Explain procedure for controlling the boat and have

someone ease sheets as you rotate the handle.

2. Have an emergency handle available.

3. Using all personal safety precautions including PFD,

harness and tether, go forward.

4. Position shift lever on right side as shown in photo.

5. Use the emergency handle or a cordless drill to turn

the foil until the sail is reefed or furled.

Furling or Reefing with Manual Power

In the event of power failure it is necessary to go

forward and lower sail or furl by hand.

MKIV Hydraulic Unit 3 31

Page 32

Operation Reefing Tips/Secure Sail/Race Conversion

Reefing Tips

A sail may be partially furled before you resume sailing.

This is known as reefing.

Many sailors find it helpful to place marks on foot of sail

so that they can reef to a variety of predetermined jib

sizes. This allows marks to be placed on jib lead tracks

or toe rail so that lead block position can be changed

to correspond to reefed jib.

Sails are generally reefed to balance boat and to reduce

heeling moment. Sails may also be reefed to improve

visibility or to slow boat while sailing in congested

areas or entering or leaving harbors.

Secure Sail

When furling prior to leaving your boat in slip or on

mooring, be sure that you get a tight furl and continue

furling system until sheets wrap around rolled sail two

or three times. Some people secure sail with shock

cord or sail ties.

Race Conversion

Race conversion allows use of both grooves

for sail changes and tacking genoas on deck

for use of maximum luff length genoas.

Halyard Swivel Below Feeder

Use halyard to lift halyard swivel up, away

from feeder. Loosen screw one revolution

only. Slide screw up and hold. Remove

feeder carefully—bottom end first. Don’t

lose the feeder overboard! Lower swivel

onto lower unit. Replace feeder.

Remove Feeder

Loosen screw one revolution only. Slide screw up and hold.

To Remove

Feeder For

Racing

1.

2.

1. Loosen screw

one revolution only.

2. Slide screw up.

Remove feeder.

3. Lower halyard

swivel.

Carefully remove feeder–bottom end first.

Don't drop the feeder overboard!

32 MKIV Hydraulic Unit 3

Page 33

Maintenance Clean and Lubricate/Inspect/Storage

Clean and Lubricate

Keep unit clean. When you wash boat, flush unit with soap

and fresh water. Occasionally lower sail and flush halyard

swivel with soap and fresh water.

Foils may be cleaned by washing with soap and water.

A scrap of luff tape may be run up foil to scrub inside

®

grooves. Sail luff tapes may be sprayed with McLube

to reduce friction during sail changes.

®

Spray sails off boat so Mclube

spray does not contact deck.

WARNING! Decks sprayed with McLube® will

be very slippery which can lead to slipping and

falling overboard. Spray sails off boat so

®

Mclube

spray does not contact deck.

WARNING! Worn, damaged or corroded parts may

break suddenly. Periodically inspect items listed

below and any others as necessary.

Inspect

Inspect unit for signs of chafe, wear or damage.

Inspect clevis and cotter pins below and inside lower unit for

signs of loosening. Check headstay tension for signs of loosening.

Inspect swage fitting and lower toggle for signs of stress

corrosion.

Inspect Norseman or Sta-Lok terminal or rod terminal for

signs of loosening.

Inspect all screws on unit to be sure they have not loosened.

Inspect foil to make sure that it has not dropped into lower unit.

Periodically inspect wire for signs of wear or unraveling.

Storage – Mast Down

In areas where it freezes, do not store system where water can accumulate in foils. When water freezes it will rupture

aluminum. Store foils under cover, with grooves facing down or on an angle so water will run out.

Storage/Transporting

Do not store or transport system with lower unit extending beyond mast. Remove lower unit and halyard swivel for

storage and transport.

After Storage or Transport

After storing or transporting unit, clean thoroughly including tack and halyard swivel ball bearings. See instructions

above.

Loosen Foil Clamp Before Slacking Backstay

In order to prevent foils from locking against upper stay terminal when backstay is released, loosen foil clamp screws and

lower foil before loosening backstay.

MKIV Hydraulic Unit 3 33

Page 34

Troubleshoot

Problem Probable Cause Solution

Sail will not furl or

is difficult to furl.

Sail will not unfurl

or will not unfurl

completely.

Sail will not furl

completely.

Headstay rotates in

jerks or elliptically.

Sail does not stay

furled.

Sail will not go up.

Sail will not raise

completely or luff

will not tension.

Sail will not

come down.

Ultravoilet cover rolls

up inside of sail.

Loctite® is a registered trademark of Henkel AG & Company KGaA

™

is a registered trademark of McGee Industries, Inc.

McLube

®

is a registered trademark of Sta-Lok Terminals, Ltd.

Sta-Lok

®

is a registered trademark of Ultra Safety Systems, Inc.

Tef-Gel

™

is a registered trademark of Minnesota Mining and Manufacturing Company AkA 3M CORPORATION

3M

Jib halyard is wrapping around headstay because

angle between mast and and halyard is too shallow

Jib halyard is wrapping around the headstay

because halyard swivel is too low.

Jib halyard is too tight. Ease jib halyard.

Foils riding on turnbuckle. Raise foils. See adjusting turnbuckle on page 27.

Foils too high, binding on swage eye. Lower foils until clear. See adjusting turnbuckle on page 27.

Spare halyard is wrapping in sail as it furls. Secure spare halyards away from furling headstay by flipping them behind spreaders

Salt or dirt in bearings. Flush bearings with freshwater and lubricate with dry spray lubricant such as McLube

Sail full of wind. Luff completely before furling or reefing.

Sail flogging too much. Release a short length of sheet, furl a small amount and repeat.

Foil out of clamp. Reinstall foil in lower unit and tighten clamp screws.

Halyard swivel installed upside down. Remount swivel correctly.

Jib halyard is wrapping around headstay because

angle between mast and halyard is too shallow.

Jib halyard is wrapping around the headstay

because the halyard swivel is too low.

Foils riding on turnbuckle. Raise foils. See adjusting turnbuckle on page 27.

Foils too high, binding on swage eye. Lower foils. See adjusting turnbuckle on page 27.

Jib halyard is too tight. Ease jib halyard.

Spare halyard is wrapping in sail as it furls. Secure spare halyards away from furling headstay by flipping them behind spreaders

Salt or dirt in bearings. Flush bearings with freshwater and lubricate with dry spray lubricant such as McLube

Spare halyard catching in sail as it furls. Move halyards away from furling headsail as above.

Insufficient tension on headstay. Tighten headstay and/or backstay to eliminate sag in headstay.

Sail not furled tightly on stay. Keep some tension on sheets when furling in light air to get a tight, secure wrap.

Luff tape will not go into groove. Check luff tape for fraying.

Sail catching at prefeeder. Flake sail more loosely on deck.

Dirt in groove. Attach a halyard and downhaul to a small section of luff tape and clean groove by raising

Halyard swivel is hitting end stop. Luff of sail is too long and must be recut.

Angle between halyard and mast is too sharp

and halyard is pulling too much to the rear.

Halyard is wrapping on headstay. Angle between headstay and halyard is too shallow and must be optimized per installation

Halyard swivel off foil. Sail luff too long or foil is too short or low and must be lengthened or raised.

Wrong switch used to furl sail. Unroll sail and use other switch to furl. Alternatively, rewire switch if preferred. Once

See installation instructions regarding optimal halyard angle. It may be necessary

to mount a halyard restrainer on front of your mast to hold halyard to rear.

See installation instructions regarding optimal halyard swivel height. A wire pendant

may be needed at head of sail to raise halyard swivel to proper height.

See installation instructions regarding optimal halyard angle. It may be necessary to

mount a halyard restrainer on front of your mast to hold halyard to rear.

See installation instructions regarding optimal halyard angle.

Check luff tape size.

and lowering.

Halyard must be routed from a point higher on mast. This may require that halyard turning

block aloft be replaced or sail shortened.

instructions.

correct one is determined, label switch "furl" and the other "Unfurl."

®

®

Online Product Registration

www.harken.com/FurlingWarranty

34 MKIV Hydraulic Unit 3

Warranty

www.harken.com/manuals

or call, write, email or fax Harken, Inc.,

Pewaukee, WI USA

Page 35

Hydraulic Unit 3H Parts List

No. Description Order Part No.

Torque Tube Foil Clamp 1 H-42967

Torque Tube Screws M8 X 125 mm SHCS 4 HFS1107

1

H-42967

HFS1107

1

1

2

3

Red Ring 1 H-51510

Lower Unit 1 7413.15BASE

1 Smalley Ring 1 H-51494

2 Tack Swivel Top Washer 1 H-51493

1

3

/2" Torlon Ball 23 HBB21

4 Tack Swivel Body 1 H-51491

1

5

/2" Delrin Ball 23 HBB22

6 Tack Swivel Lower Washer 1 H-51492

4

5

6

7413.15BASE

H-51510

1

2

4

5

MKIV Hydraulic Unit 3 35

3

No. Description Order Part No.

2

2

6

7

8

9

1

Toggle Assembly Hydr

1 Toggle Plate Screws M5 X 16 mm SHCS 8 HFS982

2

2 Toggle Plate 2 H-51477

3 Toggle Housing Insulator 1 H-51475

4 Cross Pin

5 Toggle Housing

6 Toggle Housing Screws M8 X 70 mm SHCS 6 HFS1064

7 Cotter Pin

8 Clevis Pin

9 Jaw Jaw Toggle

Toggle Assembly Hydr 7/8" 1 7413.25 7/8

1 Toggle Plate Screws M5 X 16 mm SHCS 8 HFS982

2 Toggle Plate 2 H-51477

3 Toggle Housing Insulator 1 H-51475

4 Cross Pin

5 Toggle Housing

6 Toggle Housing Screws M8 X 70 mm SHCS 6 HFS1064

7 Cotter Pin

8 Clevis Pin

9 Jaw Jaw Toggle

3

/4" 1 7413.25 3/4

3

/4" 1 H-52246

3

/4" 1 H-52245

5

/32" X 1.25" 1 HFS203

3

/4" x 1.76" Grip Length 1 H-42403

3

/4" 1 H-41489

7

/8" 1 H-51476

7

/8" 1 H-51474

5

/32" X 1.25" 1 HFS203

7

/8" x 1.96" Grip Length 1 H-42404

7

/8" 1 H-41489

Page 36

Hydraulic Unit 3H Parts List

No. Description Order Part No.

3

1

2

3

4

4

3

5

Hydraulic Cylinder—3/4" Pin 1 7413.26 3/4

3

1 Toggle Housing Insulator 1 H-51475

2 Cross Pin

3 Toggle Plate 2 H-51477

4 Toggle Plate Screws M5 X 16 mm SHCS 8 HFS982

5 Toggle Housing Screws M8 X 70 mm SHCS 6 HFS1064

6 Clevis Pin

7 Jaw Jaw Toggle

8 Cotter Pin

Hydraulic Cylinder—

1 Toggle Housing Insulator 1 H-51475

2 Cross Pin

3 Toggle Plate 2 H-51477

4 Toggle Plate Screws M5 X 16 mm SHCS 8 HFS982

5 Toggle Housing Screws M8 X 70 mm SHCS 6 HFS1064

6 Clevis Pin

7 Jaw Jaw Toggle

8 Cotter Pin

3

/4" 1 H-52246

3

/4" x 1.76" Grip Length 2 H-42403

3

/4" 1 H-41489

5

/32" X 1.25" 1 HFS203

7

/8" Pin 1 7413.26 7/8

7

/8" 1 H-51476

7

/8" x 1.96" Grip Length 2 H-42404

7

/8" 1 H-41489

5

/32" X 1.25" 1 HFS203

7413.26 3/4

7413.26 7/8

6

7

8

9

2

3

7426 -22

7427 -30

4

1

36 MKIV Hydraulic Unit 3

No. Description Order Part No.

Rod Adapter Stud w/Nosepiece -22 Rod 1 7426 -22

4

1 Stud (Main Body) 1 H-41812

2 Nosepiece -22 1 H-41811

3 Cotter Pin

Stud Cap

Rod Adapter Stud w/Nosepiece -30 Rod 1 7427 -30

1 Stud (Main Body) 1 H-41814

2 Nosepiece -30 1 H-41813

3 Cotter Pin

Stud Cap

3

/32" x 1.750" 2 HFG319

7

/8" ID 1 HFG303

3

/32" x 1.750" 2 HFG319

7

/8" ID 1 HFG303

Page 37

Hydraulic Unit 3H Parts List

PLEASE SAVE THESE INSTRUCTIONS

HFG672

7413FOILSET

H-39916

HBB21

HBB21

HBB21

H-39916

HFG349

HFG682

H-39392

7413.30

7413.31F

H-42073

H-42074

5

Description Order Part No.

Trim Cap Set w/o Screws 1 HFG682

5

Trim Cap Screw Set 1 HFG672

Trim Cap Screw 2 HFS1127

Halyard Swivel 1 H-39392

Clip/Smally Ring for Balls 2 H-39916

Torlon Ball Bearings 88 HBB21

Foil Set 1 7413FOILSET

Foil (7'/2.13 m Luff) 10 7413.31

Foil (2'/610 mm) Bottom 1 7413.33

Foil Screw Set 1 HFG349

Foil Screw 46 HFS1106

Connector Set 1 HFG627

Connector 9 7413.31F

Bottom Connector (9

3

/4"/247 mm) 1 7413.32F

Connector Bushing Set 1 HFG297

Connector Bushing Top (Curved/Longer) 20 H-42073

Connector Bushing Bottom (Flat/Shorter) 20 H-42074

Plastic Connector Wedge Set 1 HFG324

Plastic Connector Wedge 22 H-39487

Feeder with Screw and Tab 1 H-39756

Feeder Tab 1 H-38372A

Screw 1 HFS1130

7413.32F

HFG349

H-39756

HFG324

7413.33

Description Order Part No.

HFG627

MKIV HYDRAULIC JIB REEFING & FURLING

Unit 3

Installation Manual – Intended for specialized personnel or expert users

4379 12/13

Preassembly

Safety Precautions 2

Parts Descriptions 2 - 3

Size Check 3

Parts 4-5

Rigging Parts Check/Tools 6

Hydraulic System 7 - 8

Toggle Deductions/Stay Into Foil Options 9

Top Foil Lengths 10 - 11

Short Top Foil 11

Confirm Foil Length 12

Assembly

Foils/Connectors 13 - 18

Bottom Foil/Connectors/Halyard Swivel 19

Lower Unit to Foil 20

Rod Rigging: Rod Adapter Stud 21

Attach Turnbuckle/Toggle 22 - 23

Attach Hydraulic Cylinder 23 - 24

Feeder/Final 25

Commissioning

Turnbuckle on Boat 26

Halyard Swivel Height/Lead Angle 27

Halyard Restrainer/Tension 28

Operation

Halyard: Headstay Tension 29

Reefing/Secure Sail 30

Manual Operation 31

Race Conversion 32

Maintenance/Inspection/Decommissioning 33

Troubleshoot/Warranty 34

Appendix

Component Part Number List 35 - 37

Toggle Dimensions 38

Dimensions/Sailmaker's Instructions 39

WARNING! Strictly follow all instructions

to avoid an accident, damage to your vessel,

personal injury or death. See www.harken.com

Please read these instructions carefully before installing, servicing, or operating the equipment.

for additional safety information.

This manual may be modified without notice. See: www.harken.com/manuals for updated versions.

4379

833

945

2124

M10

HFG722

6

7

M6

M4

HFG947

M3

HFG200/HFG201

MKIV Hydraulic Unit 3 37

Instruction Manual 1 4379

6

Blue Loctite

®

1 833

5200 Adhesive Set 1 HFG725

5200 Marine Adhesive Sealant 1 HFG722

Injector 1

Prefeeder 1 947

Description Order Part No.

Halyard Restrainer (Optional) 1 945

7

Sheave/SS Inner Race Only 1 945A

Clevis Pin (

1

/4" x 1.0625" 18-8) 1 HCP208

Bracket-Large 1 HCP394

Cotter Pin (

1

/16" x .500" 18-8) 1 HFS181

Shackle 3 2124

Hex Wrenches

M10 1 HFG647

M6 1 HFG644

M4 1 HFG640

M3 1 HCP1089

HFG200

HFG201

Page 38

Hydraulic Unit 3H Toggle Dimensions

A

B

Unit Part No.

3

7413.25

3H

C

D

7413.25 7/

/

4

8

Unit Part No.

7413.26

3H

7413.26 7/

GE

F

H

Toggle Dimensions*

A B C D E F G H

in mm in mm in mm in mm in mm in mm in mm in mm

7413.25 3/

2.08 52.83 1.739 44.17 1.024 26.01 0.744 18.90 0.814 20.68 1.746 44.35 0.468 11.89 2 50.8

7413.25 7/8, 7413.26 7/

2.662 67.61 2 50.80 1.156 29.36 0.868 22.05 0.94 23.88 1.938 49.23 0.499 12.67 2.312 58.72

*Toggle dimensions apply to standard toggle and cylinder option except A does not apply to cylinder

4,

7413.26 3/4*

8

3

/

4

8

38 MKIV Hydraulic Unit 3

Page 39

Preassembly Dimensions/Sailmaker's Instructions

Luff Length

Note offsets above and below sail.

A shorter luff may be required if a halyard restrainer is used or an

C

additional toggle assembly is used to raise unit.

If luff of sail is not long enough to put halyard swivel near top of

headstay foil, a pendant must be added. See page 28.

B

Tack Setback

A

Note setback for tack shackle and cut sail accordingly.

Luff Tape Size

6

Unit 3H requires #6 (

/32" or 5 mm) luff tape.

Luff Tape Length

Cut off top of luff tape so it is 18 to 24" (450 to 600 mm) below head

of sail. This allows head to lag behind rest of sail to help flatten sail.

It will also help head to roll more smoothly.

Note feeder height and extend bottom of luff tape downward so it is

below feeder. This will prevent luff tape from catching in feeder as

sail is lowered.

Tack and Head Shackles

Make sure tack and head shackles fit sail

rings. Minimum inside dimensions of

A

standard head and tack shackles are:

7

/8" (48 mm)

D

E

F

(A) 1

13

/16" (21 mm)

(B)

Sun Cover

B

Sun covers may be installed on either side of sail. Be

sure to match other sails in the customer's inventory.

G

H

I

J

K

See page 39

for all toggle

dimensions

MKIV Hydraulic Unit 3 39

J

I

Toggle/Pin

Ø

7413.25 ¾ Std

7413.25 7/8 Std

7413.26 ¾ Cylinder

7413.26 7/8 Cylinder

Toggle/Pin

Ø

7413.25 ¾ Std 32

7413.25 7/8 Std 32

7413.26 ¾ Cylinder 49 1245 45 1142 34

7413.26 7/8 Cylinder 49

7413.25 7/8 Std

7413.26 ¾ Cylinder

7413.26 7/8 Cylinder

*Height of threaded hydraulic ports

A B C D E Max E Min

in mm in mm in mm in mm in mm in mm

5

7

/16186 115/8296 18 457

5

7

/16186 115/8296 18 457

5

7

/16186 115/8296 18 457

5

7

/16186 115/8296 18 457

F Max F Min G Max G Min

in mm in mm in mm in mm in mm in mm

5

/16821 — — 18 446 — —

7

/8836 — — 189/16472 — —

5

/81260 455/81159 351/4895 311/4794

Toggle/Pin

Ø

7413.25 ¾ Std

I Max* I Min* J Max J Min K

in mm in mm in mm in mm in mm

5

/8118

4

3

/16132

5

1

/4 540 171/4438 117/16291 77/16 189 81/4209

21

7

/8556 177/8455 121/16306 81/16205 81/4209

21

7

/898 47 1194 — —

3

7

/898 479/161209 — —

3

7

/898 635/81616 595/81515

3

7

/898 641/41632 601/41530

3

5

/8879 305/8778

— —

— —

2 51

29/1665

H Max H Min

1

/8409

16

11

/16424

16

3

/4832 283/4730

32

3

/8848 293/8747

33

— —

— —

81/4209

81/4209

— —

— —

Page 40

N15W24983 Bluemound Rd, Pewaukee, WI 53072 USA

01

Web: www.harken.com • Email: harken@harken.com

1B Green Street, Brookvale, N.S.W. 2100, Australia

Telephone: (61) 2-8978-8666 • Fax: (61) 2-8978-8667

ZA Port des Minimes, BP 3064, 17032 La Rochelle Cedex 1, France

Telephone: (33) 05.46.44.51.20 • Fax: (33) 05.46.44.25.70

Via Marco Biagi, 14, 22070 Limido Comasco (CO) Italy

Telephone: (39) 031.3523511 • Fax: (39) 031.3520031

158 Beaumont Street, Westhaven, P.O. Box 90689, Victoria St. West, Auckland 1142, New Zealand

Telephone: (64) 9-303-3744 • Fax: (64) 9-307-7987

ul. Rydygiera 8, budynek 3A, lokal 101, I pi

Main Office and Harken Brandstore: Västmannagatan 81B

Telephone: (46) 0303 61875 • Fax: (46) 0303 61876

Mailing address: Harken Sweden AB, Box 64, SE -440 30 Marstrand

Bearing House, Ampress Lane, Lymington, Hampshire S041 8LW, England

Telephone: (44) 01590-689122 • Fax: (44) 01590-610274

Web: harken.co.uk • Email: enquiries@harken.co.uk

Corporate Headquarters

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Harken Australia Pty, Ltd.

Web: harken.com.au • Email: info@harken.com.au

Harken France

Web: harken.fr • Email: info@harken.fr

Harken Italy S.p.A.

Web: harken.it • Email: info@harken.it

Harken New Zealand, Ltd.

Web: harken.co.nz • Email: harken@harken.co.nz

Harken Polska SP ZOO

Tel: +48 22 561 93 93 • Fax: +48 22 839 22 75

Web: harken.pl • Email: polska@harken.pl

Harken Sweden AB

SE-113 26 Stockholm Sweden

Web: harken.se • Email: harken@harken.se

Harken UK, Ltd.

ętro, 01-793 Warszawa, Poland

Please visit: http://www.harken.com/locator.aspx

to locate Harken dealers and distributors

97653 21428

Printed in USA 4379 12/13

Loading...

Loading...