Page 1

Cruising

Jib Reefing & Furling

Installation Manual

Unit 1, 2

WARNING! Strictly follow all instructions to avoid an

accident, damage to your vessel, personal injury, or death.

See www.harken.com for additional safety information.

Page 2

Table of Contents

Preassembly

Parts 4–5

Tools 6

Dimensions/Sailmaker's Instructions 7

Toggle Deductions, Stay Into Foil Options 8

Top Foil Length Worksheet—Unit 1 9

Top Foil Length Worksheet—Unit 2 10

Short Top Foil 11

Foil Length 12

Assembly

Foils/Connectors 13–15

Halyard Swivel 13

Drum Assembly 13

Rod Rigging 14

Adjust Turnbuckle 17

Toggle 17–18

Final 17–18

Commissioning

Turnbuckle 20

Line to Cockpit 21

Halyard Swivel Height/Angle 22–23

Halyard Restrainer/Tension 21

Operation

Halyard/Headstay Tension 24

Raise Sails 25

Furl/Reef 23–24

Secure Sail 26

Maintenance

Clean 27

Inspect 27

Replace Line 27

Storage 27

Remove Furler 27

Troubleshooting

Warranty

Parts

7

6

5

3

4

1

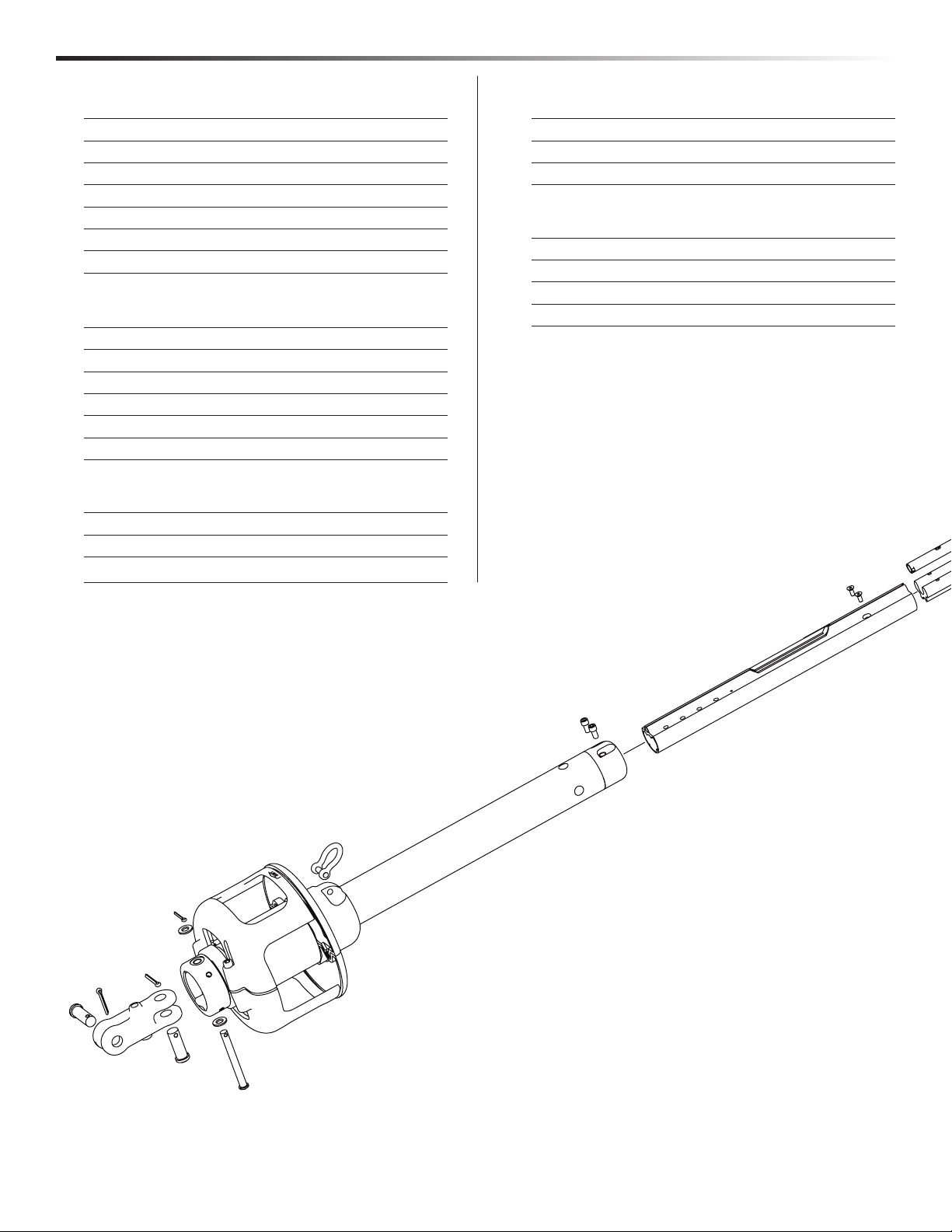

Parts Descriptions

1) Toggle Assembly

2) Crosspin

3) Shackle

4) Drum Assembly

2 Unit 1, 2 Cruising 08/23/10

2

5) Foil Clamp Screws

6) 2' (610 mm) Bottom Foil

7) Connector Isolator

8) Connector

9) 7' (2.13 m) Foil

10) Connector Screws

11) Halyard Swivel

12) Trim Cap

13) Trim Cap Screws

Page 3

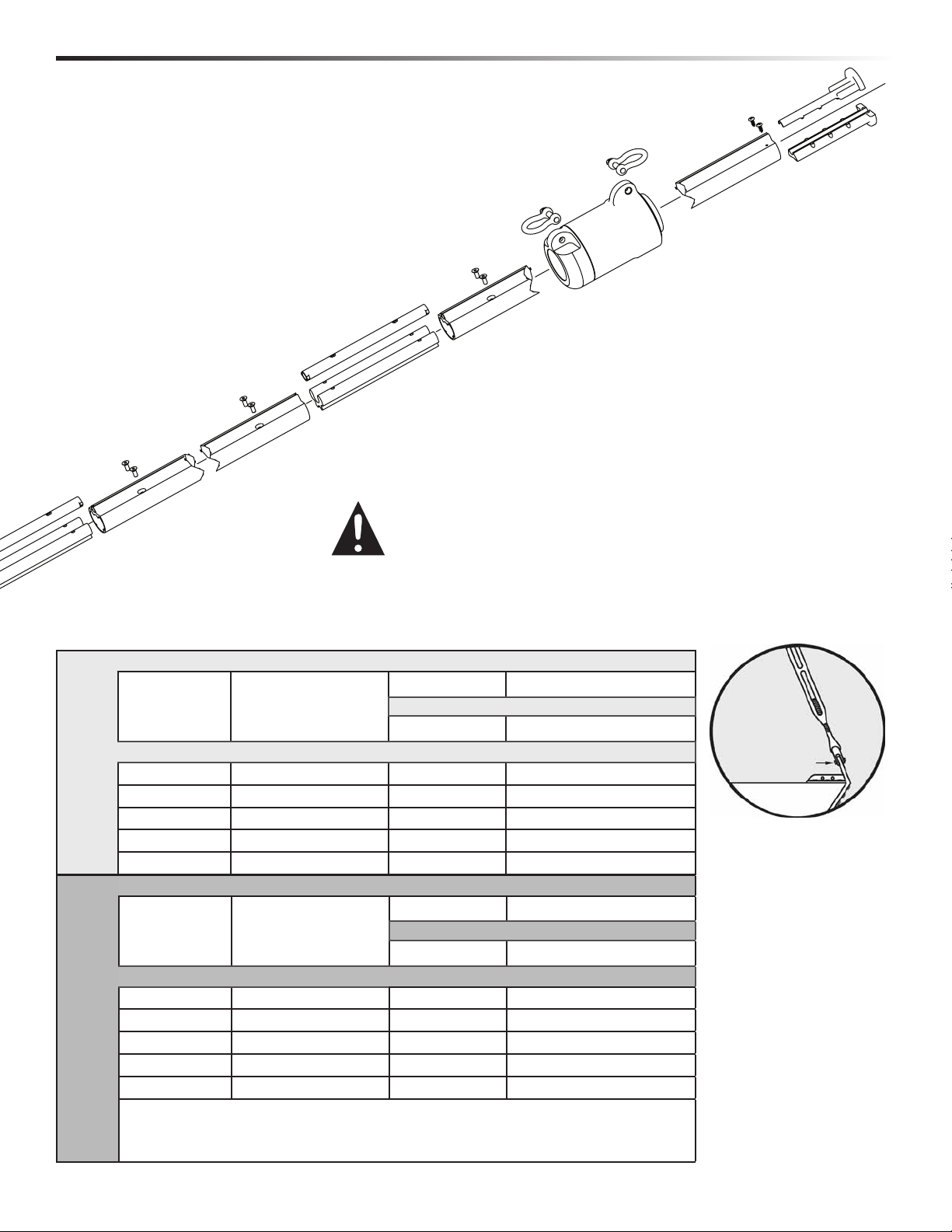

Preassembly Sizing Check

13

12

11

10

Check headstay and clevis pin dimensions in chart below.

Size Check

7

9

WARNING! Harken does not recommend drilling boat's chainplate

or toggle as this may result in rig failure which will cause an accident,

damage to your vessel, personal injury, or death. See www.harken.

com for additional safety information.

8

Will drum fit on bow? See page 7. If necessary use an additional toggle

to slightly raise the unit. To clear anchor use Harken Long Link Plates,

which can be cut to various lengths.

UniPart No. Description Wire Ø

1/4", 9/32", 5/16" 6 mm, 7 mm, 8 mm

7311.10 Cruising Unit 1

-8, -10 5.72 mm, 6.35 mm

Toggle Part No. Description Chainplate Clevis Ø

7411.20 1/2 Eye/jaw reversible 1/2" 12.7 mm

UNIT 1

7311.20 1/2 Jaw/jaw 1/2" 12.7 mm

7311.20 5/8 Stud/jaw 5/8" 15.9 mm

7311.21 1/2 Long link plate w/toggle 1/2" 12.7 mm

7311.21 5/8 Long link plate w/toggle 5/8" 15.9 mm

Part No. Description Wire Ø

5/16", 3/8", 7/16" 8 mm, 10 mm, 11 mm, 12 mm*

7312.10 Cruising Unit 2

-12, -17, -22 7.14 mm, 8.38 mm, 9.53 mm

Toggle Part No. Description Chainplate Clevis Pin Ø

7412.20 5/8 Eye/jaw reversible 5/8" 15.9 mm

7312.20 5/8 Jaw/jaw 5/8" 15.9 mm

7312.20 3/4 Stud/jaw 3/4" 19.1 mm

UNIT 2

7312.21 5/8 Long link plate w/toggle 5/8" 15.9 mm

7312.21 3/4 Long link plate w/toggle 3/4" 19.1 mm

7

/16", 11 mm and 12 mm requires large bore H-41009 isolators. They have a “12” stamped on

*

the outside. H-41009 Isolators are shipped with 7412.20 3/4 stud jaw toggle and 7312.21 3/4

long link plate assembly

Rod Ø

Chainplate Clevis Pin

Rod Ø

08/23/10 Unit 1, 2 Cruising 3

Page 4

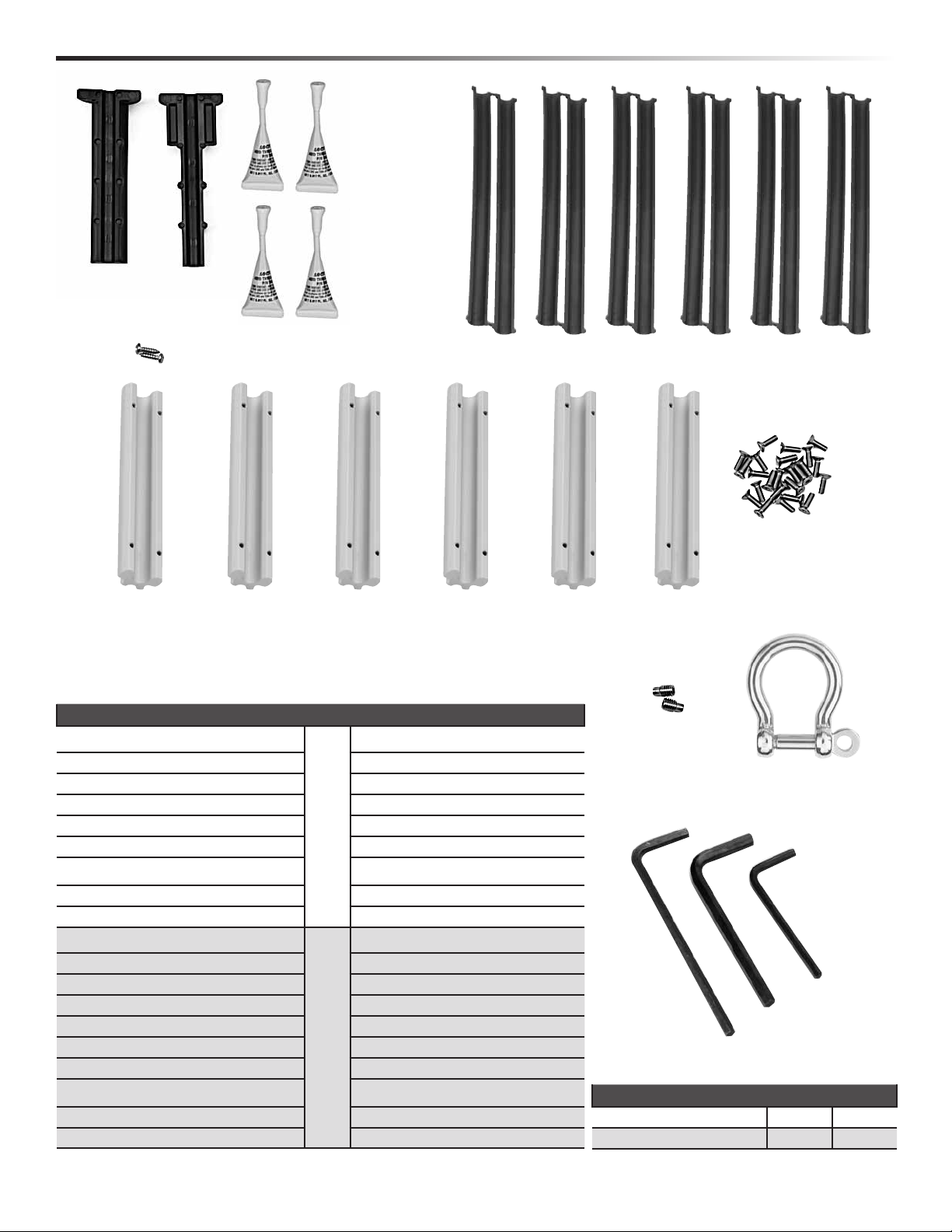

Parts

Bottom Foil

w/Feeder

Foils

Halyard Swivel

Line

Drum Assembly

Main Components

Description Unit Part No. Qty

Drum Assembly

2'(610 mm) Bottom foil 7311.33 1

7'(2.13 m) Foil 7311.30 6

Halyard Swivel H-36596C 1

7mm Double braid polyester line HFG233 70'(21.3 m)

Drum Assembly

2'(610 mm) Bottom foil 7312.33 1

7'(2.13 m) Foil 7312.30 8

Halyard Swivel H-37317C 1

8mm Double braid polyester line HFG235 100' (30.4 m)

4 Unit 1, 2 Cruising 08/23/10

1

2

HFG146 1

HFG188 1

Page 5

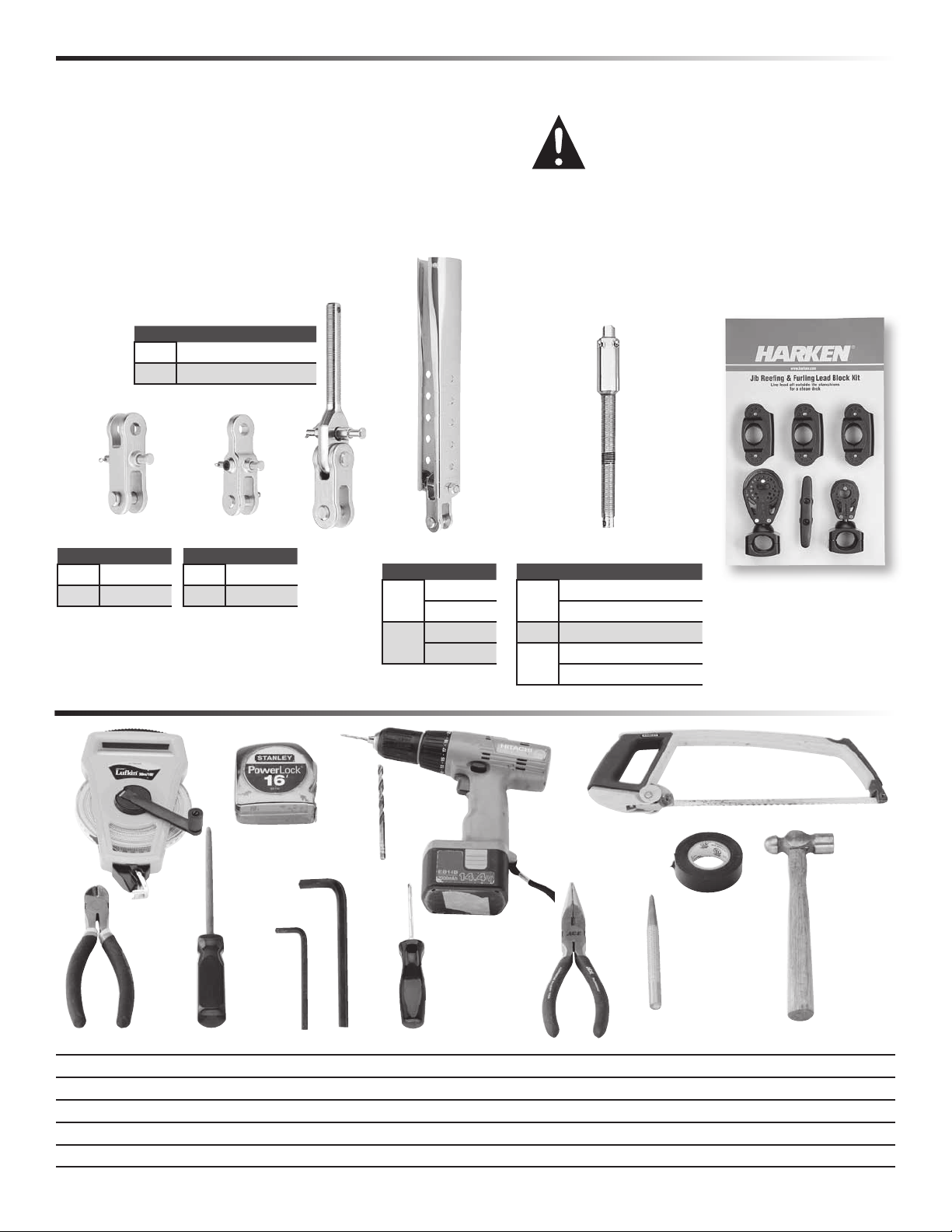

Parts

Trim Cap Set

Trim Cap

Screw Set

Red Loctite

Blue Loctite

®

®

Connector Isolators

Connector Screw Set

Connectors

Foil Clamp

Screw Set

Other Components

Description Unit Part No. Qty Size

Trim cap set

Trim cap screw set

Red Loctite

Blue Loctite

®

(foil screws)

®

(foil clamp screws)

Connectors

Connector isolators

Connector screw set

Foil clamp screw set

Bow shackles

Trim cap set

Trim cap screw set

Red Loctite

Blue Loctite

®

(foil screws)

®

(foil clamp screws)

Connectors

Connector isolators

Connector isolator for 7/16", 11 mm, 12 mm Wire*

Connector screw set

Foil clamp screw set

Bow shackles

1

2

HFG182

(H-37443B/H-37444B)

HFS1127

HFG739

833

7311.31F

H-41008

HFG149

(30 - HFS980)

H-41153

2110

HFG197

(H-37445B/H-37446B)

HFS1127

HFG739

833

7312.31F

H-37330C

H-41009

HFG196

(38 - HFS1060)

H-41154

2117

1 —

3

2

1

—

—

—

6 6" (152 mm)

6

1

3

—

—

—

3 6 mm

1

3

2

1

—

—

—

—

8 9" (229 mm)

8

9

1

3

—

—

—

—

3 8 mm

Bow Shackles

Allen Wrenches

Allen Wrenches (Supplied)

Description Unit Qty

M2.5, M4, M5 1 1 Each

M3, M4, M6 2 1 Each

*H-41009 Connectors are shipped with 7312.20 3/4 stud/jaw toggle and 7312.21 3/4 long link plate w/toggle for use with 7/16", 11 mm or 12 mm wire.

10/19/10 Unit 1, 2 Cruising 5

Page 6

Preassembly Rigging Parts Check/Tools

1. Harken toggle assembly required. Sold separately.

2. Mating turnbuckle components must be purchased separately.

3. Headstay may require cutting and shortening to fit Harken

toggle. Headstay may remain uncut by replacing lower stud

of turnbuckle with stud/eye thus eliminating extra toggle.

4. Rod rigging requires Harken rod adapter stud.

WARNING! Headstay condition should be

checked by a professional rigger before

reusing. Wire that is old or damaged

may break suddenly causing an accident,

damage to your vessel, personal injury,

or death. See www.harken.com for

additional safety information.

5. Order Harken 7404 Lead Block Kit and one additional 7403 if necessary. Fits 1" (25 mm) stanchions.

Harken Toggle (Sold Separately)

ALL UNITS

Stud/Jaw Toggle

Unit Part No. Thread Ø

7311.20 5/8

1

2

7312.20 3/4*

5

/8" - 18LH

3

/4" - 16LH

ROD RIGGING

Harken Rod Adapter

Stud Required

(Sold Separately)

7404 Lead Block Kit

(Sold Separately)

Jaw/Jaw Toggle

Unit Part No.

7311.20 1/2

1

2

7312.20 5/8

*Includes 9 H-41009 large bore connector isolators

for use with 7/16", 11 mm or 12 mm wire.

** Requires drum assembly with four threaded holes

in base. See page 16.

Eye/Jaw Toggle

Unit Part No.

7411.20 1/2

1

2

7412.20 5/8

Tools You Will Need

2

1

Long Link

Plate w/Toggle

Unit Part No.

7311.21 1/2

1

7311.21 5/8

7312.21 5/8

2

7312.21 3/4*

3

Rod Adapter Stud

Unit Part No. Thread Ø

7422 -8

1

7423 -10

1 & 2

7424 -12

7425 -17

2

7426 -22

1

/2" - 20RH

1

/2" - 20RH

5

/8" - 18RH

5

/8" - 18RH

3

/4" - 16RH

Includes 3 x 7403; 1 x 7401;

1 x 7402; 1 Horn Cleat

5

12

4

6

7

8

9

10

11

13

1. Long tape measure 6. Side cutters 11. Center punch

2. Short tape measure 7. Rat-tail file 12. Rigging or black tape

3. Drill bit – 1/8" (3 mm) 8. Allen wrenches (provided) 13. Hammer

4. Power drill 9. Phillips screwdriver

5. Hacksaw 10. Needle-nose pliers

6 Unit 1, 2 Cruising 10/19/10

Page 7

Preassembly Sailmaker's Instructions

Luff Length

Note offsets above and below sail.

C

A shorter luff may be required if a halyard restrainer is necessary

(page 23) or a toggle or long toggle assembly is used to raise drum.

If luff of sail is not long enough to put halyard swivel near top of head-

B

stay foil, make sure a pendant must be added. (See page 22).

A

Tack Setback

Note setback for tack shackle and cut the sail accordingly.

Luff Tape Size

6

Both units require #6 (

/32" or 5 mm) luff tape.

Luff Tape Length

Note feeder height and extend bottom of luff tape downward so it is

below feeder. This will prevent luff tape from catching in feeder as sail

is lowered.

Tack and Head Shackles

Make sure tack and head shackles fit

sail rings. Minimum inside dimensions

of standard head and tack shackles are:

Unit A B

1

1

1

/16" (27 mm)1/2" (13 mm)

3

2

/4" (44 mm)11/16" (17 mm)

1

A

B

Suncover

E

Suncovers may be installed on either side of sail. Be

sure to match other sails in the customer's inventory.

D

Note: If a long link plate is used, add the following dimensions to feeder,

shackle and drum height (based on whether plate is used full-length or

shortened to one of five hole positions). Do not add to halyard swivel or

H

top terminal dimensions.

1/2" (12.7 mm) Clevis Pin Add 131/2" to 65/8" (343 mm to 168 mm)

/8"

1

/4" to 43/8" (286 mm to 111 mm)

9

/16" to 511/16" (344 mm to 144 mm)

Min 2

31/16"

78 mm

Max 51/16" (129 mm)**

313/16"

97 mm

Min 33/8" (86 mm)*

Max 61/2" (165 mm)**

7

/8" (71 mm)*

*1

/2" (12.7 mm)

**5/8" (15.9 mm)

*5

/8" (15.9 mm)

**3/4" (19.1 mm)

I

J

Unit A B C Max D E F G H I J Toggle Used

5

1

3

/8"

6"

12"

16"

13/8"

35 mm

111/16"

42 mm

92 mm

152 mm

305 mm

1

2

4

/2"

114 mm

11/01/10 Unit 1, 2 Cruising 7

8"

203 mm

406 mm

F

G

Min 331/2" (851 mm)

Max 407/16" (1027 mm)

Min 427/16"(1078 mm)

Max 503/4"(1289 mm)

Min 91/2" (241 mm)

Max 117/8" (302 mm)

Min 113/4" (298 mm)

Max 147/8" (378 mm)

Unit 1

5/8" (15.9 mm) Clevis Pin Add 11

5/8" (15.9 mm) Clevis Pin Add 161/8" to 81/4" (410 mm to 210 mm)

Unit 2

3/4" (19.1 mm) Clevis Pin Add 13

Min 81/2"( 216 mm)

Max 1013/16" (275 mm)

Min 103/8" (264 mm)

Max 131/2" (343 mm)

5

6

167 mm

83/16"

208 mm

Page 8

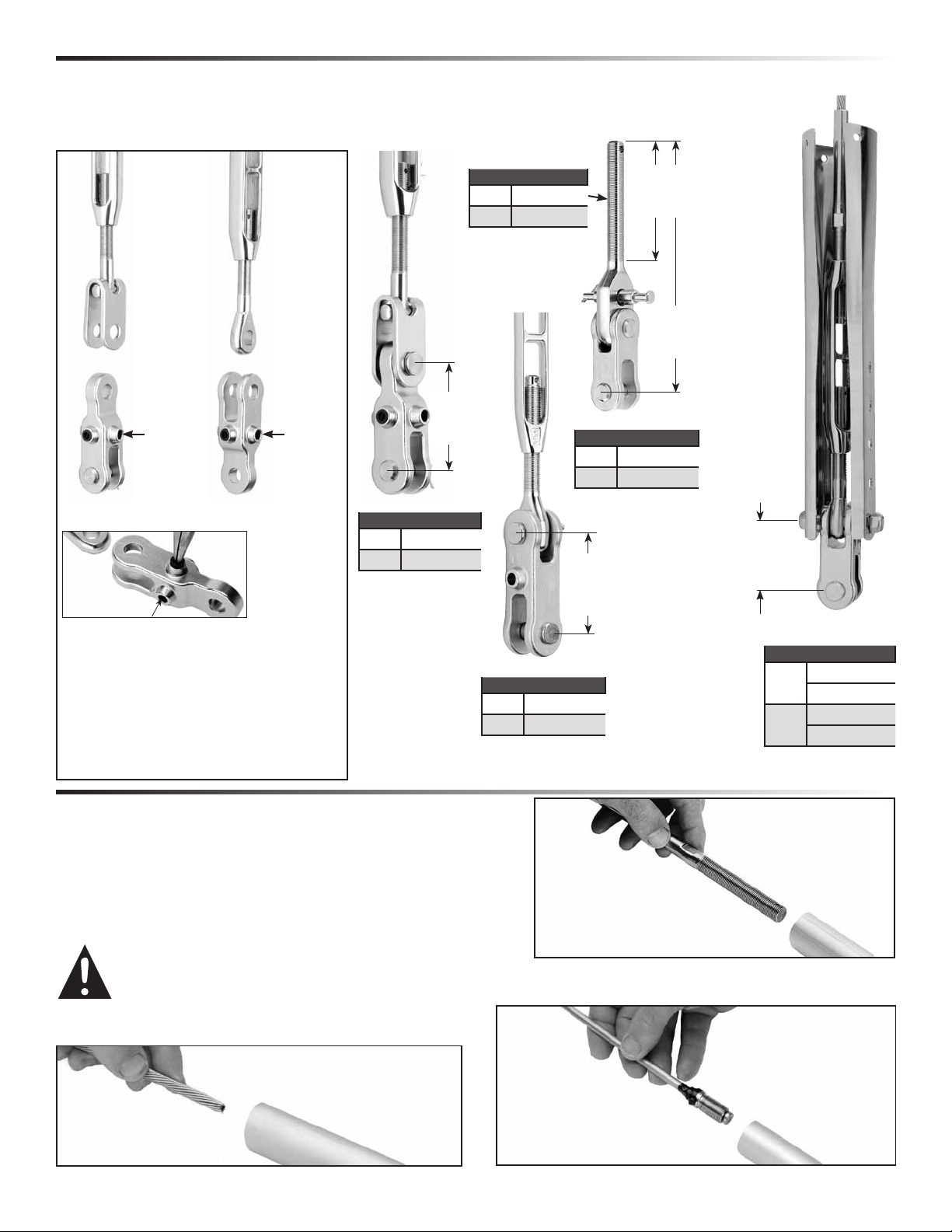

Preassembly Toggle Deductions/Stay Into Foil Options

Use dimensions of the Harken toggle below to build stay to correct length.

Tip: Turnbuckles should be 1/2 to 2/3rds open to allow shortening for

new wire stretch and allows fine tune adjustment of mast rake.

Unit Thread

1

5/8" - 18LH

2

3/4" - 16LH

Unit 1

7

/8" (98 mm)

3

Unit 2

1

/4" (133 mm)

5

7

/8" (225 mm)

8

5

/8" (295 mm)

11

Unit 1

Unit 2

Eye/Jaw Reversible Toggle

Unit 1

1

/4" (83 mm)

3

Unit 2

4" (102 mm)

Fork

Attachment

Crosspin

Tang

Attachment

For tang-down

installations,

Crosspin

Eye/Jaw Reversible

Unit Clevis Pin

1

1/2" (12.7 mm)

2

5/8" (15.9 mm)

switch plugs

to this position.

3

Most boats have a chainplate with

a single tang. If boat has two plates

forming a jaw, reverse eye/jaw

toggle so eye is down.

Important: Remove black plastic

caps and install them so that crosspin

will be 90 degrees to main clevis pin.

Options for Snaking Stay into Foils

Jaw/Jaw

Unit Clevis Pin

1

1/2" (12.7 mm)

2

5/8" (15.9 mm)

Make sure your

toggle looks like this!

Stud/Jaw

Unit Clevis Pin

1

3/4" (19.1 mm)

2

5/8" (15.9 mm)

Make sure your

toggle looks like this!

Unit 1

3" (76 mm)

Unit 2

9

/16" (90 mm)

5

/16" (59 mm)

*2

11

/16" (68 mm)

**2

5

/8" (67 mm)

*2

1

/4" (83 mm)

**3

Unit 1

Unit 2

Plate w/Toggle

Unit Clevis Pin

1

2

Long Link

1/2" (12.7 mm)*

5/8" (15.9 mm)**

5/8" (15.9 mm)*

3/4" (19.1 mm)**

1. Swage stud at end of wire.

®

2. Open end of wire and install Norseman or Sta-Lok

stud after foil is assembled.

3. When using smaller wires, marine eye may fit. See page 14.

4. Rod adapter nosepiece for Harken rod adapter stud.

WARNING! Using a threaded nosepiece with only

adhesive at the upper rod eye terminal may result

in headstay system failure which can cause an

accident, damage to your vessel, personal injury,

or death. See www.harken.com for additional

safety information.

8 Unit 1, 2 Cruising 10/11/10

Page 9

UNIT 1

Preparation for Assembly Top Foil Length Worksheet

Measure A and add to this chart

and “length chart” below

Inches mm

A

B .5 13

E 24.0 610

F 16

G

Total A+B+E+F+G

.4

416

Length Check

After completing worksheet above fill in A, C, D and G below. Add

Make sure upper

measurement points

of A and pin-to-pin

Alternate

Measurement

Point

A

are the same.

1

2

3

4

To find “D” pick number from chart below that is closest to,

but not greater than total from step 3.

500 inches “D” = 420 inches 12,000 mm “D” = 10,668 mm

5

Result (Pin-to-Pin – ABEFG)

Inches mm

3 X 84 = 252

4 X 84 = 336

5 x 84 = 420

6 x 84 = 504

7 x 84 = 588

8 x 84 = 672

Example–If result from Step 3 is:

Result (C) Top Foil Length

Pin-to-Pin Length

Subtract ABEFG

Subtract D

3 x 2133.6 = 6400.8

4 x 2133.6 = 8534.4

5 x 2133.6 = 10668.0

6 x 2133.6 = 12801.6

7 x 2133.6 = 14935.2

8 x 2133.6 = 17068.8

–

–

If top foil length is

63/4" (171 mm) or

less, go to page 11

Pin

to

Pin

A

B

C

D

Pin

Pin

“A” through “G” to confirm total equals your pin-to-pin measurement.

to

Pin-to-Pin Length Worksheet

Dimensions Inches mm

A Center of Pin to Bottom of Terminal

B Bottom of Terminal to Top of Foil

C Top Foil Length

D Number of Foils ________ x 84" (2133.6 mm)

E Bottom Foil 24.0 610

F Bottom of Foil to Crosspin 16.4 416

G Crosspin to Clevis Pin

.5

13

E

Pin-to-Pin Length

G Toggle Distance from Lower Clevis Pin to Crosspin Hole

Toggle Part No. Type Clevis Pin G Distance

1

7411.20 1/2 Eye/Jaw Reversible

7311.20 1/2 Jaw/Jaw

7311.20 5/8 Stud/Jaw

7311.21 1/2 Long Link Plate w/Toggle

7311.21 5/8 Long Link Plate w/Toggle

Note: If long link plate is shortened, dimension must be changed or foil will be too short.

Measure distance from crosspin down to where clevis pin attaches toggle to boat and

use this dimension in G above.

08/23/10 Unit 1 Cruising 9

/2" 12.7 mm 1.75" 44 mm

1

/2" 12.7 mm 1.75" 44 mm

5

/8" 15.9 mm 4.00" 102 mm

1

/2" 12.7 mm 15.00" 381 mm

5

/8" 15.9 mm 15.25" 387 mm

F

G

Page 10

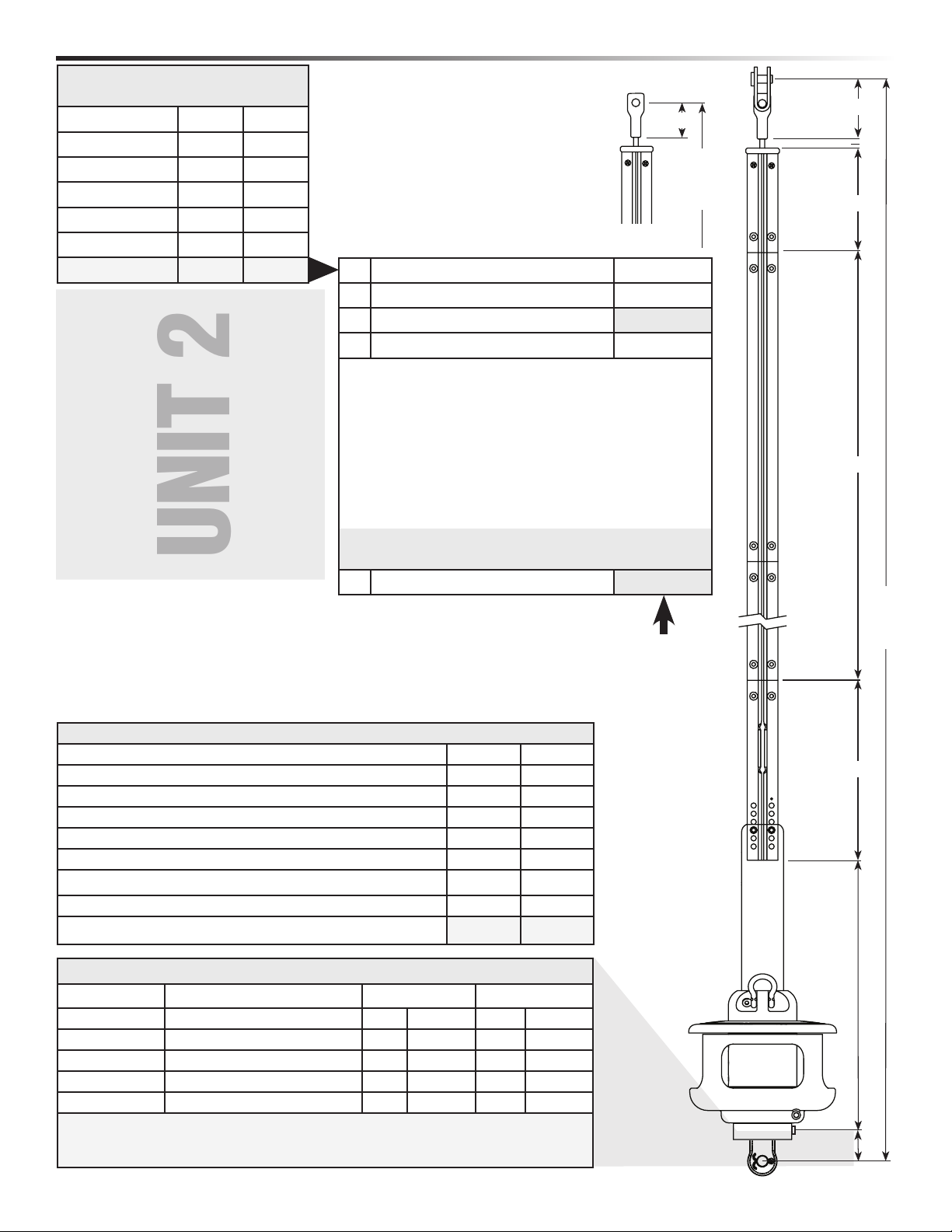

UNIT 2

Preparation for Assembly Top Foil Length Worksheet

Measure A and add to this chart

and “length chart” below

Inches mm

A

B .7 18

E 24.0 610

F 19.1 484

G

Total A+B+E+F+G

Length Check

After completing worksheet above fill in A, C, D and G below. Add

Make sure upper

measurement points

of A and pin-to-pin

Alternate

Measurement

Point

A

are the same.

1

2

3

4

To find “D” pick number from chart below that is closest to,

but not greater than total from step 3.

500 inches “D” = 420 inches 12,000 mm “D” = 10,668 mm

5

Result (Pin-to-Pin – ABEFG)

Inches mm

4 X 84 = 336

5 x 84 = 420

6 x 84 = 504

7 x 84 = 588

8 x 84 = 672

9 x 84 = 756

Example–If result from Step 3 is:

Result (C) Top Foil Length

Pin-to-Pin Length

Subtract ABEFG

Subtract D

4 x 2133.6 = 8534.4

5 x 2133.6 = 10668.0

6 x 2133.6 = 12801.6

7 x 2133.6 = 14935.2

8 x 2133.6 = 17068.8

8 x 2133.6 = 1920.4

–

–

If top foil length is

91/8" (232 mm) or

less, go to page 11

Pin

to

Pin

A

B

C

D

Pin

Pin

“A” through “G” to confirm total equals your pin-to-pin measurement.

to

Pin-to-Pin Length Worksheet

Dimensions Inches mm

A Center of Pin to Bottom of Terminal

B Bottom of Terminal to Top of Foil

C Top Foil Length

D Number of Foils ________ x 84" (2133.6 mm)

E Bottom Foil 24.0 610

F Bottom of Foil to Crosspin 19.1 484

G Crosspin to Clevis Pin

.7

18

E

Pin-to-Pin Length

G Toggle Distance from Lower Clevis Pin to Crosspin Hole

Toggle Part No. Type Clevis Pin G Distance

5

7412.20 5/8 Eye/Jaw Reversible

7312.20 5/8 Jaw/Jaw

7312.20 3/4 Stud/Jaw

7312.21 5/8 Long Link Plate w/Toggle

7312.21 3/4 Long Link Plate w/Toggle

Note: If long link plate is shortened, dimension must be changed or foil will be too short.

Measure distance from crosspin down to where clevis pin attaches toggle to boat and

use this dimension in G above.

10 Unit 2 Cruising 08/23/10

/8" 15.9 mm 2.00" 51 mm

5

/8" 15.9 mm 2.00" 51 mm

3

/4" 19.1 mm 5.10" 130 mm

5

/8" 15.9 mm 18.10" 460 mm

3

/4" 19.1 mm 18.75" 476 mm

F

G

Page 11

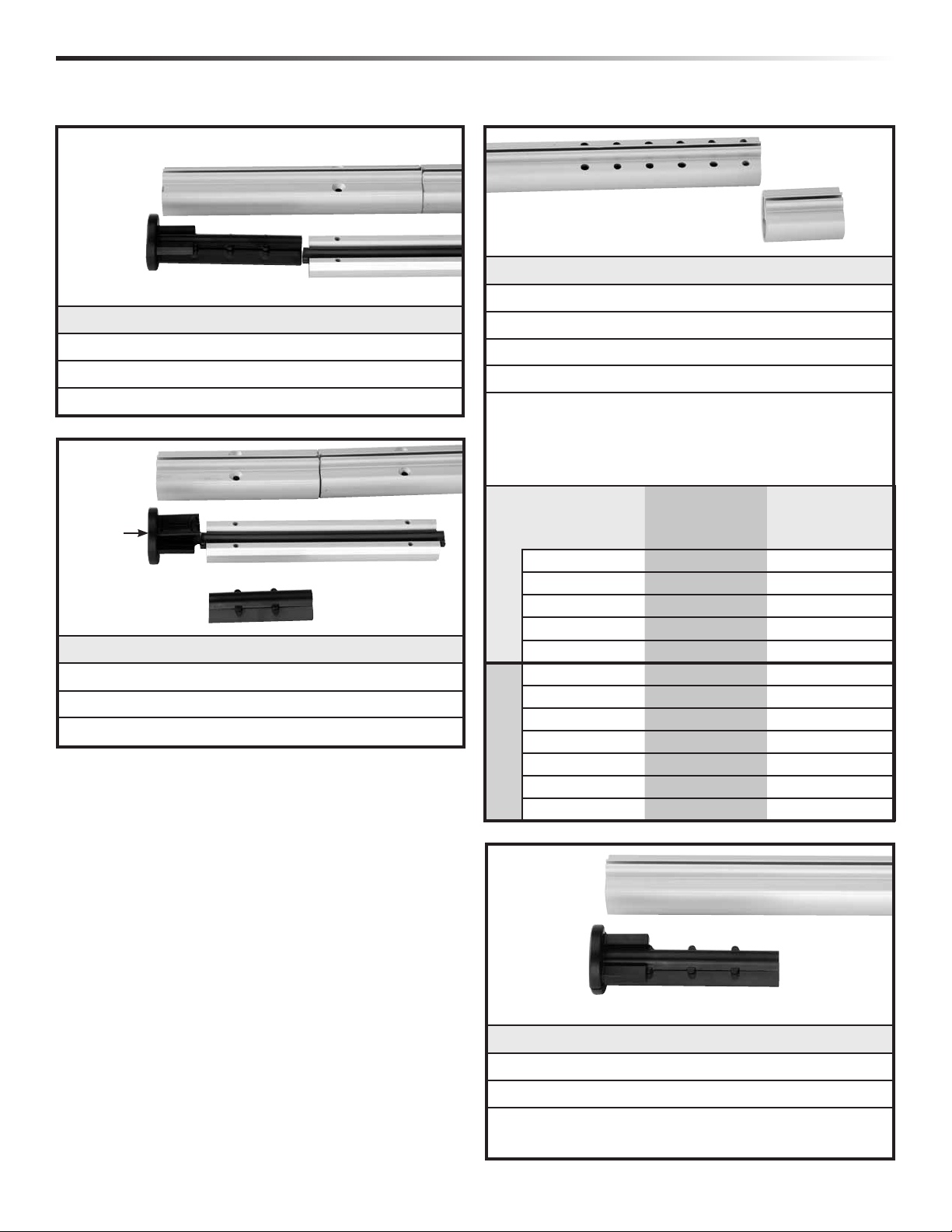

Preassembly Short Top Foil

Use one of the following special techniques for short foils to ensure sufficient bearing surface for foil in area of

halyard swivel.

Cut-Offs

Do Not Use

Unit 1 Unit 2

Top foil length from worksheet:

Unit 1 Unit 2

Top foil length from worksheet:

3

/4" (171 mm) 91/8" (232 mm)

6

No change necessary.

1

/2" - 11/2" (89 - 38 mm) 51/2" – 21/2" (89 - 64 mm)

3

Actual Top Foil

3

4" (102 mm) 5

/4" (146 mm)

Do not cut top foil to length from worksheet. Cut top

3

foil to 4" (102 mm) or 5

/4" (146 mm) and shorten trim

cap as shown in middle photo above. Shorten bottom

foil per chart below.

Shorten bottom of

bottom foil by this

amount

Cut top

trim cap

Cut-Offs

Do Not Use

Unit 1 Unit 2

Top foil length from worksheet:

1

/2" – 4" (165 – 102 mm) 9" - 53/4" (229 - 146 mm)

6

Cut top trim cap as shown above.

Top foil length

from worksheet Actual top foil

in mm in mm in mm

31/2 89 4 102 0 0

3 76 4 102 1 25

1

2

/2 64 4 102 11/2 38

UNIT 1

2 51 4 102 2 51

1

1

/2 38 4 102 21/2 64

51/2 140 53/4 146 0 0

5 127 5

1

4

/2 114 53/4 146 11/2 38

4 102 5

UNIT 2

1

3

/2 89 53/4 146 21/2 64

3 76 5

1

2

/2 64 53/4 146 31/2 89

3

/4 146 1 25

3

/4 146 2 51

3

/4 146 3 76

Unit 1 Unit 2

Top foil length from worksheet:

1

/2" (25 – 13 mm) 2" - 1/2" (51 – 13 mm)

1" -

Do not use short top foil. Use full length foil and

clamp foil higher in drum assembly.

08/23/10 Unit 1, 2 Cruising 11

Page 12

Preassembly Foil Length

Confirm foil length by laying foils alongside

stay with turnbuckle components.

Pull stay out so it is straight. Attach Harken

toggle to bottom of stay. Adjust turnbuckle

so that length of stay with Harken toggle

will fit boat. Ideally, turnbuckle will be

half to two-thirds open to allow for rig

adjustment.

Line up drum assembly so holes below

drum line up with holes in Harken toggle.

Make sure toggle is tensioned when

measuring.

Line up bottom foil so clamp screw holes

are lined up with third row of holes as

shown.

Note: Mark top foil so foil with trim cap will

ride 1/2" (12 mm) below terminal. If wire

fitting at top of stay is swage, foil must ride

just below shoulder of swage. Mark cut line

on foil. Wrap tape around foil as a guide

so cut is straight. Check length to see

if it matches results from chart on

page 9 (Unit 1) or page 10 (Unit 2).

12 Unit 1, 2 Cruising 08/23/10

Page 13

Assembly Cut Top Foil/Slide Foil on Stay/Assemble Trim Cap

Cut foil to length using hacksaw.

Deburr inside edge

using rat-tail file.

Insert trim cap. Use centerpunch to mark

two top foil trim cap holes ½" (12 mm)

down from top of foil on each side of

sail groove.

Remove trim cap. Drill two 1/8" (3 mm)

holes in foil for self-tapping screws.

08/23/10 Unit 1, 2 Cruising 13

Page 14

Assembly Assemble Trim Cap

Smaller Wires Larger Wires

Unit Wire Ø

1/4", 6 mm, 9/32", 7 mm

1

2

5/16", 8 mm, 3/8", 10 mm

Unit Wire Ø

1

2

5/16", 8 mm

7/16", 11 mm, 12 mm

Slide foils on stay starting from bottom or top. In most

cases marine eye will fit through foil.

Place halves of trim cap over wire and

insert into top foil.

Tip: With foil groove up, have

rectangular pieces on the upper half.

Install self-tapping trim cap screws.

Fold halves of plastic isolator over wire.

Note: Use H-41009 Isolators for use

with 7/16", 11 mm or 12 mm wire. Nine

H-41009 isolators are shipped with

3/4"(19mm) Harken Toggles. Look

for “12” molded on the outer side.

Swage stud fitting or wire end must pass through foil.

Use Norseman-/Sta-Lok-type terminal with wire end.

Rectangular pieces

14 Unit 1, 2 Cruising 10/19/10

Page 15

Assembly Assemble Connector/Assemble Foil/Slide on Halyard Swivel

Place connector over plastic isolator

so tabs on isolator are to side.

Put red Loctite

®

in screw holes and

assemble. Continue with rest of foils.

Make sure bottom foil with feeder gap

will be at bottom.

Slide halyard swivel onto foils so swivel

portion is towards top of stay.

Tip: Taller “half” will be facing up.

Slide drum assembly onto foils.

Red

Loctite

®

7/01/08 Unit 1, 2 Cruising 15

Page 16

Assembly Rod Rigging: Rod Adapter Stud

Apply a few drops of red

®

Loctite

nosepiece.

Screw main threaded stud

portion onto bronze nosepiece

until flats align with two cotter

pin holes in terminal body.

Tip: Turn nosepiece

completely into threaded

stud portion. Flats will be

close and may only require

a small half turn to align

with cotter pin holes.

to threads of

Insert two cotter pins and

®

spread. Clean excess Loctite

from terminal body using

special care to ensure that

there is no red Loctite

on threaded stud.

®

ROD RIGGING

16 Unit 1, 2 Cruising 5/30/08

Page 17

Assembly Attach Turnbuckle/Toggle

Assemble turnbuckle and attach Harken

toggle.

®

Note: If using Sta-Lok

or Norseman®

stud, you must use a washer above

stud as shown below. Use a fender

washer to fit large-diameter cruising foil.

Washer

Eye/Jaw Toggle Assembly

Up

Make sure shallow jaw is up.

Down

Jaw/Jaw Toggle Assembly

Stud/Jaw Toggle AssemblyEye/Jaw Toggle Assembly

5/30/08 Unit 1, 2 Cruising 17

Page 18

Assembly Attach Toggle/Long Link Plate

Make sure drum assembly

has four threaded holes

in base.

Determine height of long link

plates to provide anchor

clearance and cut to length.

Cut at scribe mark. Deburr

edges.

Make sure shallow jaw is up.

Connect eye to toggle jaw

using special clevis pin.

Secure using cotter pin.

Toggle For Long Link Plates

Apply Isolator.

Fasten one long link plate to drum assembly

®

using fasteners. Use blue Loctite

on screws.

Fasten second long link plate to drum

assembly and secure to clevis pin using

locknuts.

WARNING! Stay must attach

to toggle. Do not attach stay

to crosspin at drum assembly

because crosspin and plates

may fatigue and break causing

an accident, damage to your

vessel, personal injury, or death.

See www.harken.com for

additional safety information.

18 Unit 1, 2 Cruising 08/23/10

Page 19

Assembly Attach Foil to Drum Assembly

Slide lower drum assembly over turnbuckle

and attach using long crosspin. Use plastic

washers provided.

WARNING! Crosspin must be

90 degrees to clevis pin that

attaches unit to boat. If pins run

same direction toggle will fatigue

and could break suddenly causing

an accident, damage to your

vessel, personal injury, or death.

See www.harken.com for

additional safety information.

Lift foils so top of foils ride about

½" (12 mm) below upper terminal.

Crosspin at 90°

to Clevis Pin

Clevis Pin

Lining these holes

up with top of drum

assembly insures

screws are lined

up with foil holes.

1

/2" (12 mm)

Use blue Loctite® on

screws to secure foils

in a lifted position.

08/23/10 Unit 1, 2 Cruising 19

Page 20

Commissioning Adjust Turnbuckle on Boat

Have extra cotter pins on hand to replace used ones at base

of unit and for turnbuckle. Hold foils and remove foil clamp

screws. Lower foils.

Remove crosspin holding lower unit to turnbuckle. Raise

drum assembly and use halyard to hold unit at about

5' (1.5 m) above deck. Raise foils and secure with second

halyard. Allow room above for turnbuckle take up.

WARNING! To avoid injury, make sure drum

assembly and foils are securely lifted using a

halyard before adjusting turnbuckle. Failure to do

so may result in furler dropping suddenly, causing

damage to the furler, or severe injury. See www.

harken.com for additional safety information.

Adjust turnbuckle. Use sidecutters or needlenose pliers to

bend cotter pin. Replace used cotter pins. Lower unit and

install crosspin and new cotter pin.

1

Lift foils so top is

Use blue Loctite

/2" (12 mm) below upper terminal.

®

on foil clamp screws when you replace them.

WARNING! Stay must attach to toggle. Do not attach stay to crosspin at drum assembly because

crosspin and plates may fatigue and break causing

an accident, damage to your vessel, personal

injury, or death. See www.harken.com for

additional safety information.

Crosspin

20 Unit 1, 2 Cruising 08/23/10

Page 21

Commissioning Lead Line to Cockpit

Run line through enclosed window in guard and into

hole in bottom plate of spool. Tie a small overhand

knot and pull it up under drum assembly.

WARNING! If line is led through opening

between two enclosed windows it can ride

above lineguard and jam furler. This can

cause an accident, damage to your vessel,

Enclosed

Window

personal injury, or death. See www.harken.

com for additional safety information.

Note location of sun cover. Charge system by rotating furler to wrap line on drum.

Tip: Sun cover to starboard—turn clockwise to charge. Sun cover to port—turn counter-clockwise. Tension line

while charging.

Mount Lead Blocks

Furling line can be led down either side of boat. If boat is in slip, consider mounting opposite dock.

Remove four screws on stanchion blocks. Clamp blocks to stanchions. See instructions below.

Tip: Start all four screws before tightening.

BOW

7401

FORWARD

STANCHION

BLOCK

OUTBOARD

STANCHION

7403

BLOCK

OUTBOARD

STANCHION

OUTBOARD

STANCHION

7403

BLOCK

7403

BLOCK

7401 Forward Stanchion Block

Position 7401 Forward Stanchion Block so line

enters drum at right angles to headstay and centers

vertically in opening. Install so line is inside stanchion.

Correct block position is critical to even

line spooling and ease of furling.

7403 Outboard Stanchion Blocks

Install 7403 Outboard Stanchion Blocks so line is

outside stanchions.

Number and placement of leads depends on boat

length and number/configuration of stanchions.

7402 Ratchet Stanchion Block

Mount 7402 Ratchet Stanchion Block as furthest-aft

lead to prevent line overrides in drum when unfurling.

Position ratchet block so line turns at least 90°.

Install so line is inside stanchion.

Lead line through block so ratchet makes

clicking sound when pulling line to furl sail.

Tip: Make sure ratchet switch is in “ON” position. If there is

no clicking sound, lead line through block in opposite direction.

Lead line to Furling Line Cleat in cockpit.

HCP168 Furling Line Cleat

Install so line is angled as shown.

7402

RATCHET

STANCHION

BLOCK

STERN

08/23/10 Unit 1, 2 Cruising 21

Use #10 (5 mm) fasteners.

Note: As furling line lead changes, make sure line

doesn’t chafe against line guard. Rotate line guard

if necessary.

Drum Full

(sail unfurled)

Drum Empty

(sail furled)

Page 22

Commissioning Halyard Wraps

Halyard Wrap

The most serious problem with furling systems occurs when the jib

halyard wraps around the headstay foil. Halyard wraps will keep you from

furling/unfurling and may cause serious damage to the unit and halyard.

WARNING! In severe cases, a halyard wrap can cause loss of

control of boat and/or headstay can break suddenly which can

cause an accident, damage to your vessel, personal injury, or

death. See www.harken.com for additional safety information.

To prevent wraps, the halyard must exert a slight pull to the rear. This

allows the foils to turn while halyard remains stationary.

Prevent Halyard Wraps

WARNING! Sail must be fitted to foil length before using to

prevent headstay loss which will cause an accident, damage

to your vessel, personal injury, or death. See www.harken.com

for additional safety information.

1. Halyard swivel should be within top 4" (100 mm) of foil unless a

halyard restrainer is used.

2. Halyard must pull slightly to rear (8–10°).

3. Halyard must be snug, but not too tight.

If halyard wraps, do not force unit to turn. Attempt to open sail by

carefully furling in and out a little at a time. If sail will unfurl, lower

8–10°

it by releasing jib halyard. Severe halyard wraps can only be cleared

by going aloft and freeing halyard.

If sail will not furl or unfurl, try to remove jib sheets and manually

wrap sail around headstay.

Testing at dock does not indicate halyard angle is correct. In wave

action, halyard may wrap if lead angle is not correct. The 8–10°

diverging angle shown at right is critical.

Pendants

If the your sail luff is not long enough to position the halyard swivel

properly, you must add a pendant. Pendants should be made of plasticcoated wire and be permanently attached so the sail height will be

correct. Adjustable length pendants are not acceptable as they

might not be adjusted correctly during a sail change.

Installing a Pendant

1. Raise sail, but do not attach tack shackle.

2. Position halyard swivel correctly near top of headstay.

3. Secure halyard.

4. Tie a piece of rope to sail tack.

5. Lead line through tack shackle on furling drum.

6. Tension sail.

7. Measure distance from tack shackle to sail tack and permanently

attach a pendant of this length to head of sail.

8. Repeat this procedure for every jib in your sail inventory.

22 Unit 1, 2 Cruising 08/23/10

Page 23

Commissioning Halyard Restrainer

Halyard Restrainer

To prevent wraps, jib halyard must pull slightly to rear. On most boats,

halyard lead angle is acceptable if halyard swivel is raised to top of foil.

On some boats halyard sheaves are located too close to headstay and

a halyard restrainer must be used.

Halyard restrainers should be used only when required by masthead

geometry. Restrainers tend to limit sail luff length and may cause

problems if not installed properly.

If your boat needs a halyard restrainer, use Harken part 944.

Restrainer should be mounted as high as possible on face of mast.

Position restrainer so that foils will not hit it when under load.

The restrainer should deflect halyard as little as possible or you may

experience difficulty in tensioning sail luff, friction when furling, and

possible damage to foils. To decrease deflection angles, shorten sail luff.

Tip: Boats used in charter service should have a halyard restrainer,

regardless of masthead geometry.

Halyard Tension

The jib halyard should be firm, but not too tight.

Tip: The luff foil system supports sail along its length so halyard tension is used only to shape sails, not to support them. Use enough

halyard tension to remove some wrinkles along luff of sail. Do not

tension halyard enough to cause vertical wrinkles in luff of sail.

Tension to adjust position of draft in sail to suit sailing conditions.

Halyard should be firm but not tight. If in doubt release halyard

tension. To protect sail, ease halyard when boat is not in use.

5/30/08 Unit 1, 2 Cruising 23

Page 24

Operation Halyards/Headstay Tension

Spinnaker Halyards

Spinnaker halyards occasionally cause problems

with furling.

WARNING! In severe cases, spinnaker

halyards can jam furler causing loss of control

of boat which can cause an accident, damage

to your vessel, personal injury, or death. See

www.harken.com for additional safety

information.

On many boats it will not be possible to attach

spinnaker halyard to bow pulpit or it may be

"sucked" into jib when furling.

On some boats the spinnaker halyard lays across

headstay and will catch on halyard swivel, foils, or

jib halyard. To prevent problems it may be necessary

to install a masthead bail to move spinnaker halyard

block forward and to one side.

Boats with external halyards may find it necessary to

flip both ends of spinnaker halyard behind spreaders

to prevent fouling with furling system.

Headstay Tension

A furling system will work best if headstay is tight.

A loose headstay is difficult to rotate and can cause

unusual wear on foil joints.

To adjust headstay tension, remove sail and furling line

from unit and follow instructions on page 24.

Tip: Before adjusting headstay tension, slack

mainsheet and vang.

Backstay Adjusters

Backstay adjusters allow headstay tension to be varied to change sail shape to match

conditions. They permit a very tight headstay to be eased when boat is not in use.

For best performance, consider adding a backstay adjuster; either a block and tackle,

a mechanical adjuster like those offered by Harken, or a hydraulic adjuster.

Remember to keep headstay tight for best performance when furling or reefing.

If your boat is fitted with an adjuster be sure that it is tensioned before the halyard

is tensioned. If not, backstay adjuster may increase halyard tension and could

damage the sail or furling system.

Racing boats often slack the headstay completely when sailing downwind. Check

to be sure that foil does not jam against upper headstay terminal when backstay is

released. It may be necessary to shorten foil slightly to prevent this.

24 Unit 1, 2 Cruising 08/23/10

Page 25

Operation Sail: Raise/Storm/Reef

Raise Sails

1) Shackle tack of sail to drum. Install shackle so screw pin head is on same

side as suncover.

2) Secure genoa sheets to clew of sail.

3) Attach genoa halyard to halyard swivel.

4) Pass luff tape through feeder into foil groove.

5) Attach head of sail or pendant at head of sail to halyard swivel.

6) Hoist sail.

Tip: New sails are often stiff and may hang up at feeder during

raising. Do not force sail when it hangs up—lower and remove

twist. Sails "break in" with use and will become easier to raise.

Storm Sails

Most people will use one multipurpose genoa for all their sailing, but it is not good seamanship to go offshore

without storm sails.

Heavy air working jibs and storm sails may be used with your unit. These sails need to have luff tape added to

allow them to be raised in headstay foils.

These sails will generally require pendants to ensure that halyard swivel is properly positioned at top of headstay.

See page 22.

Remember that heavy air working jibs and storm jibs may be reefed and furled like any other sail.

Furl and Reef

To furl or reef, ease the jib sheets and pull

furling line.

In very light air, it may be necessary to place

some tension on jib sheet to insure a tight furl.

In a breeze, you must completely luff sail by

totally slacking jib sheets before furling.

The furling line should pull readily. The amount

of force required is related to amount of wind,

but a Unit should never require use of a winch to

furl. If the sail will not furl, or if furling requires a

great deal of effort, there is a problem with system. Consult the Troubleshooting

Guide on page 28. Do not use a winch to force a system to turn.

You may use a winch to make furling easier, if you are certain that system is operating properly.

08/23/10 Unit 1, 2 Cruising 25

Page 26

Operation Reef/Secure Sail

Reef

A sail may be partially furled before you resume

sailing. This is known as reefing.

Many sailors find it helpful to place marks on

foot of sail so that they can reef to a variety of

predetermined jib sizes. This allows marks to be

placed on jib lead tracks or toe rail so that lead

block position can be changed to correspond

to reefed jib.

Sails are generally reefed to balance boat and to

reduce heeling moment. Sails may also be reefed

to improve visibility or to slow boat while sailing in

congested areas or while entering or leaving harbors.

Secure Sail

When furling prior to leaving your boat in slip or

on mooring, be sure that you get a tight furl and

continue furling system until sheets wrap around

rolled sail two or three times. Some people secure

sail with shock cord or sail ties. Be sure to securely

cleat furling line to a standard horn cleat.

You may also lock your system by aligning holes

in bottom of drum and basket and then using a

line to secure drum.

Be sure that mooring lines are not placed across

furling line where they may cause chafe.

26 Unit 1, 2 Cruising 5/30/08

Page 27

Maintenance Clean/Inspect/Remove Furler

Clean and Lubricate

Keep unit clean. When you wash boat, flush unit with soap

and fresh water. Occasionally lower sail and flush halyard

swivel with soap and fresh water.

At least twice a year unit should be cleaned more thoroughly

by removing line (first note direction of spool) and flushing

bearings with soap and fresh water. After unit has dried,

®

.

®

spray to

WARNING! Periodically inspect items listed

below and any others as necessary. Failure to

inspect can cause an accident, damage to your

vessel, personal injury, or death. See www.

apply a dry spray lubricant such as McLube

Foils may be cleaned by washing with soap and water. A

scrap of luff tape may be run up foil to scrub inside the

grooves. Foils may be sprayed with McLube

reduce friction during sail changes.

harken.com for additional safety information.

Inspect

1) Unit for signs of chafe, wear or damage.

2) Foil clamp screws for signs of loosening. Check headstay tension

for signs of loosening.

3) Swage fitting and lower toggle for signs of stress corrosion.

4) Norseman/Sta-Lok

®

terminal/rod terminal for signs of loosening.

5) All screws on unit to be sure they have not loosened.

6) Foil to make sure that it has not dropped into drum assembly.

7) Wire for signs of wear or unraveling.

Replace Line — Unit 1

Use HFG233 furling line or source a good quality line with good wear

characteristics. Use 9/32" (7 mm) line with break strength exceeding

2500 lbs (1130 kg). Smaller boats or smaller sails may allow

5/16" (8 mm) line.

Replace Line — Unit 2

Use HFG235 furling line or source a good quality line with good wear characteristics. Use 5/16" (8 mm) line with

break strength exceeding 3740 lbs (1700 kg). Smaller boats or smaller sails may allow 3/8" (8 mm) line.

Replace Line — Both

If a larger diameter line is desired, consult with a rigger about using tapered line with a high strength core and cover

removed in forward part of line.

Storage – Mast Down

In areas where it freezes, do not store system where water can accumulate in foils. When water freezes it will rupture

aluminum. Store foils under cover, with grooves facing down or on an angle so water will run out.

Storage/Transporting

Do not store or transport system with drum assembly extending beyond mast. Remove masthead clevis pin and shift

furler up so drum assembly can be strapped securely to mast. Some people remove drum assembly and halyard swivel

for storage and transport.

After Storage or Transport

After storing or transporting unit, clean thoroughly including ball bearings. See instructions above.

Remove Furler

Foils can lock against upper stay terminal when backstay is released. To prevent this loosen foil clamp screws and

lower foil before loosening backstay.

08/23/10 Unit 1, 2 Cruising 27

Page 28

Troubleshoot

Problem Probable Cause Solution

Sail will not furl or

is difficult to furl.

Sail will not unfurl

or will not unfurl

completely.

Sail will not furl

completely.

Headstay rotates in

jerks or elliptically.

Sail does not stay

furled.

Sail will not go up.

Sail will not raise

completely or luff

will not tension.

Sail will not

come down.

Ultravoilet cover rolls

up inside of sail.

Line jams between

guard and plastic

spool plate.

Jib halyard is wrapping around headstay because

angle between mast and and halyard is too shallow

Jib halyard is wrapping around the headstay

because halyard swivel is too low.

Jib halyard is too tight. Ease jib halyard.

Foils riding on turnbuckle. Raise foils. See adjusting turnbuckle on page 20.

Foils too high, binding on swage eye. Lower foils until clear. See adjusting turnbuckle on page 20.

Spare halyard is wrapping in sail as it furls. Secure spare halyards away from furling headstay by flipping them behind spreaders

Salt or dirt in bearings. Flush bearings with fresh water and lubricate with dry spray lubricant such as McLube

Furling line tangled in drum. Overrides are best prevented by using a 7402 ratchet block as the last furling line lead to

Stop knot catching. Make sure knot is a single overhand and is pushed up inside drum.

Sail full of wind. Luff completely before furling or reefing.

Sail flogging too much. Release a short length of sheet, pull some furling line and repeat.

Jib sheets are not free. Free jib sheets.

Foil out of drum assembly. Reinstall foil in drum assembly and tighten foil clamp screws.

No wraps of furling line on drum. Remove sheets. Rotate stay wrapping as much furling line on drum as possible.

Lineguard assembly has slipped down. Tighten line guard assembly screws securely.

Line through 7402 ratchet backwards. Rerun line.

Halyard swivel installed upside down. Remount swivel corretly.

Jib halyard is wrapping around headstay because

angle between mast and halyard is too shallow.

Jib halyard is wrapping around the headstay

because the halyard swivel is too low.

Foils riding on turnbuckle. Raise foils. See adjusting turnbuckle on page 20.

Foils too high, binding on swage eye. Lower foils. See adjusting turnbuckle on page 20.

Jib halyard is too tight. Ease jib halyard.

Spare halyard is wrapping in sail as it furls. Secure spare halyards away from furling headstay by flipping them behind spreaders

Salt or dirt in bearings. Flush bearings with freshwater and lubricate with dry spray lubricant such as McLube

Furling line is not free. Free furling line.

Insufficient furling line on drum. Remove sheets. Rotate stay, wrapping as much furling line on drum as possible.

Too much line on drum. Adjust amount of line on drum or change position of forward lead block to allow line

Spare halyard catching in sail as it furls. Move halyards away from furling headsail as above.

Insufficient tension on headstay. Tighten headstay and/or backstay to eliminate sag in headstay.

Sail not furled tightly on stay. Maintain drag on sheets while furling.

Furling line not secure. Secure furling line.

Luff tape will not go into groove. Check luff tape for fraying.

Sail catching at prefeeder. Flake sail more loosely on deck.

Dirt in groove. Clean groove.

Halyard swivel is hitting end stop. Luff of sail is too long and must be recut.

Angle between halyard and mast is too sharp

and halyard is pulling too much to the rear.

Halyard is wrapping on headstay. Angle between headstay and halyard is too shallow and must be optimized per installation

Halyard swivel off foil. Sail luff too long or foil is too short or low and must be lengthened or raised.

Furling line is wrapped on drum in wrong direction. Remove sheets. Pull line to remove all furling line from drum. Turn stay to rewind line on

Line is not led through windows. Pull line through enclosed window.

See installation instructions regarding optimal halyard angle. It may be necessary

to mount a halyard restrainer on front of your mast to hold halyard to rear.

See installation instructions regarding optimal halyard swivel height. A wire pendant

may be needed at head of sail to raise halyard swivel to proper height.

maintain proper drag on line while unfurling.

See installation instructions regarding optimal halyard angle. It may be necessary to

mount a halyard restrainer on front of your mast to hold halyard to rear.

See installation instructions regarding optimal halyard angle.

to roll evenly on drum.

Check luff tape size.

Halyard must be routed from a point higher on mast. This may require that any halyard

turning blocks aloft be replaced or sail shortened.

instructions.

drum in opposite direction. Line guard and cowling alignment may need to be adjusted.

®

®

Warranty online at www.harken.com or call, write, email or fax Harken, Inc., Pewaukee, WI USA

28 Unit 1, 2 Cruising 08/23/10

Page 29

Cruising Unit 1 Parts

HFG687 HFG686

HFG688HFG145

HFS980

H-35665D

HFS980

H-35600C

H-35199E

HFS1052

H-41153

1

2

3

Description Order Part No

Top Cover Assembly w/Screws 1 HFG686

1

2

3

4

Top Cover 2 H-35665D

Top Cover Screw 2 HFS980

Bottom Flange Assembly w/Screws 1 HFG687

Flange 2 H-35600C

Bottom Flange Screw 2 HFS980

Guard Assembly 1 HFG688

Guard 2 H-35199E

Guard Screw 2 HFS1052

Torque Tube Screws 2 H-41153

Hub 1 HFG145

Ball Plugs 3 H-35144A

Delrin Ball Bearing 72 HBB152

Igus Crosspin Bushing 2 H-36636A

4

HBB152 (24)

H-35144A

HBB152 (24)

H-35144A

H-35144A

HBB152 (24)

H-36636A

1/06/10 Unit 1 Cruising 29

Page 30

Cruising Unit 1 Parts

Description Order Part No.

HFS1127

7311.10 FOILSET

HCP728

H-36602A

HBB14

H-36602A

HBB14

H-36602A

HFG182

H-36596C

7311.30

Trim Cap Set 1 HFG182

5

Trim Cap Screw 2 HFS1127

Halyard Swivel 1 H-36596C

Clip/Smally Ring 1 HCP728

Clip/Smally Ring for liners 2 H-36602A

Liner/Igus 3 H-36604A

Torlon Ball Bearings 42 HBB14

Foil Set (6)

Foil (7'/2.13 m Luff) 6 7311.30

Foil (2'/610 mm) Bottom w/Feeder 1

Connector Set (6)

Connector 6 7311.31F

Connector Screw Set (30) 1 HFG149

Connector Screw 30 HFS980

Connector Isolator 6

Connector w/isolator

1 7311.10 FOILSET

1 HFG937

7311.33

H-41008

7311.31

HFS980

HFG149

5

HFG937

7311.31

MKIV

Jib Reefing & Furling

Installation Manual

WARNING!: Strictly follow all instructions

to avoid an accident, damage to your vessel,

personal injury or death. See www.harken.com

for additional safety information.

7311.33

7311.31F

H-41008

Instruction Manual 1 4414

6

Shackle 3 2110

Red Loctite

Blue Loctite

7mm Double Braid Polyester (70', 21.3 m) 1 HFG233

Allen Wrenches

4414

Unit 0

M2.5 1 HCP1387

M4 1 HFG640

M5 1 HFG642

Description Order Part No

®

®

2 HFG739

1 833

2110

HFG739

6

833

HFG233

M5

M4

M2.5

30 Unit 1 Cruising 10/11/10

7404

944

884

7

Lead Block Kit 1 7404

7

29 mm Outboard Lead Assembly 3 7403

57 mm Carbo Ratchet Assembly 1 7402

40 mm Carbo Assembly 1 7401

Horn Cleat 1 HCP168

Halyard Restrainer 1 944

Sheave/SS Inner Race Only 1 944A

Clevis Pin (

Bracket-Large 1 HCP393

Cotter Pin (

Snap Shackle 1 884

Description Order Part No

1

/4" x 1.0625" 18-8) 1 HFG467

1

/16" x .500" 18-8) 1 HFS118

Page 31

Cruising Unit 1 Parts

No. Description Order Part No Part No

Rod Adapter Stud w/Nosepiece 1 7422 -8 7423 -10

8

2

3

7422 -8

7423 -10

7424 -12

8

1

1 Stud (Main Body) 1 H-41536 H-41536

2 Nosepiece 1 H-41534 H-41535

3 Cotter Pin 2 HFG193 HFG193

No. Description Order Part No

Rod Adapter Stud w/Nosepiece 1 7424 -12

1 Stud (Main Body) 1 H-41531

2 Nosepiece 1 H-41527

3 Cotter Pin 2 HFG193

4

1

6

5

2

3

4

5

5

4

7311.20 5/8

7

6

5

3

1

10/11/10 Unit 1 Cruising 31

7

2

3

10

5

3

6

2

7311.20 1/2

9

1

4

3

7

7411.20 1/2

6

8

5

8

8

8

7311.21 1/2

10

7311.21 5/8

2

2

6

3

11

No. Description Order Part No Part No

Long Link Plate w/Toggle 7311.21 1/2 7311.21 5/8

11

7

1

6

4

1 Jaw Jaw Toggle 1 H-42159 H-41300

2 Link Plate Straps 2 H-42178 H-42178

3 Cross Pin 1 H-42170 H-42171

4 Lower Clevis Pin 1 H-42395 H-42397

5 Isolator 2 H-42182 H-42182

6 Cotter Pin 2 HFS220 HFS203

7 Nylock Nut (M12) 2 HFS846 HFS846

8 Allen Cap Screws (M6 x 1 x 12mm) 4 HFS876 HFS876

No. Description Order Part No

Jaw/Jaw Toggle 1 7311.20 1/2

9

1 Toggle 1 H-42336

2 Crosspin 1 H-42396

3 Clevis Pin 2 H-42395

4 Cotter Pin 2 HFS220

5 Cotter Pin 1 HFS181

6 Nylon Washer 2 HFS1109

Eye/Jaw Toggle Reversible 1 7411.20 1/2

1 Toggle 1 H-37675C

2 Crosspin 1 H-42396

3 Nylon Washer 2 HFS1109

4 Cross Hole Plug 2 H-42049

5 Clevis Pin 1 h-42395

6 Cotter Pin 1 HFS220

7 Cotter Pin 1 HFS181

Stud/Jaw Toggle 1 7311.20 5/8

1 Jaw Jaw Toggle 1 H-41300

2 Crosspin 1 H-42396

3 Clevis Pin 2 H-42397

4 Stud 1 H-43207

5 Cotter Pin 3 HFS220

6 Cotter Pin 1 HFS181

7 Nylon Washer 2 HFS1109

Page 32

Cruising Unit 2 Parts

HFG690 HFG689

HFG691

HFS1060

H-35025D

HFS1060

H-35465C

H-33758E

HFS873

H-41154

1

2

3

Description Order Part No

Top Cover Assembly w/Screws 1 HFG689

1

2

3

4

Top Cover 2 H-35025D

Top Cover Screw 2 HFS1060

Bottom Flange Assembly w/Screws 1 HFG690

Flange 2 H-35465C

Bottom Flange Screw 2 HFS1060

Guard Assembly 1 HFG691

Guard 2 H-33758E

Guard Screw 2 HFS873

Torque Tube Screws 2 H-41154

Hub Assembly 1 HFG183

Ball Plugs 3 H-33860A

Delrin Ball Bearing 75 HBB153

Igus Crosspin Bushing 2 HCP1707

4

HFG183

HBB153 (25)

H-33860A

HBB153 (25)

H-33860A

H-33860A

HBB153 (25)

HCP1707

32 Unit 2 Cruising 1/06/10

Page 33

Cruising Unit 2 Parts

HFS1127

H-38028A

H-38027A

HBB7

H-38029A

HBB7

H-38027A

7312.10 FOILSET

HFG196

HFG197

H-37317C

7312.30

HFS1060

7312.33

5

Description Order Part No.

Trim Cap Set w/o Screws 1 HFG197

5

Trim Cap Screw 2 HFS1127

Halyard Swivel 1 H-37317C

Clip/Smally Ring 1 H-38028A

Clip/Smally Ring for liners 2 H-38027A

Liner/Igus 3 H-38029A

Torlon Ball Bearings 44 HBB7

Foil Set (8)

Foil (7'/2.13 m Luff) 8 7312.30

Foil (2'/610 mm) Bottom w/Feeder 1 7312.33

Connector Set (8)

Connector 8 7312.31F

Connector Screw Set (30) 1 HFG196

Connector Screw 30 HFS1060

Connector Isolator 8 H-37330C

Connector Isolator (7/16", 11 mm,

12 mm Wire)

Connector w/H-37330C 7312.31

1 7312.10 FOILSET

1 HFG938

9 H-41009

Description Order Part No.

Instruction Manual 1 4414

6

HFG938

7312.31F

Shackle 3 2117

Red Loctite

Blue Loctite

8mm Double Braid Polyester (100', 30.4 m) 1 HFG235

Allen Wrenches

®

®

M3 1 HCP1089

M4 1 HFG640

M6 1 HFG644

2 HFG739

1 833

Description Order Part No.

7312.31

H-41009

4414

H-37330C

MKIV

Jib Reefing & Furling

Installation Manual

Unit 0

WARNING!: Strictly follow all instructions

to avoid an accident, damage to your vessel,

personal injury or death. See www.harken.com

for additional safety information.

2117

7404

HFG739

833

6

HFG235

7

945

M6

M4

M3

10/11/10 Unit 2 Cruising 33

885

Lead Block Kit 1 7404

7

29 mm Outboard Lead Assembly 3 7403

57 mm Carbo Ratchet Assembly 1 7402

40 mm Carbo Assembly 1 7401

Horn Cleat 1 HCP168

Halyard Restrainer 1 945

Sheave/SS Inner Race Only 1 945A

Clevis Pin (

Bracket-Large 1 HCP394

Cotter Pin (

Snap Shackle 1 885

1

/4" x 1.0625" 18-8) 1 HCP208

1

/16" x .500" 18-8) 1 HFS181

Description Order Part No.

Lead Block Kit 1 7404

7

29 mm Outboard Lead Assembly 3 7403

57 mm Carbo Ratchet Assembly 1 7402

40 mm Carbo Assembly 1 7401

Horn Cleat 1 HCP168

Halyard Restrainer 1 945

Sheave/SS Inner Race Only 1 945A

Clevis Pin (

Bracket-Large 1 HCP394

Cotter Pin (

Snap Shackle 1 885

1

/4" x 1.0625" 18-8) 1 HCP208

1

/16" x .500" 18-8) 1 HFS181

Page 34

Cruising Unit 2 Parts

No. Description Order Part No.

Rod Adapter Stud w/Nosepiece 1 7424 -12

8

1 Stud (Main Body) 1 H-41531

7424 -12

7425 -17

7426 -22

8

1

2 Nosepiece 1 H-41527

3 Cotter Pin 2 HFG193

No. Description Order Part No.

Rod Adapter Stud w/Nosepiece 1 7425 -17 7426 -22

1 Stud (Main Body) 1 H-41531 H-41812

2 Nosepiece 1 H-41526 H-41811

3 Cotter Pin 2 HFG193 HFG319

4

1

6

5

2

8

3

4

5

5

4

7312.20 3/4

7

6

5

3

1

34 Unit 2 Cruising 10/19/10

7

2

3

10

5

3

6

2

7312.20 5/8

9

1

4

3

7

7412.20 5/8

6

8

8

10

8

9

5

8

7312.21 5/8

7312.21 3/4

2

2

11

11

6

3

7

1

6

4

No. Description Order Part No. Part No.

Long Link Plate w/Toggle 7312.21 5/8 7312.21 3/4

1 Jaw Jaw Toggle 1 H-41300 H-41489

2 Link Plate Straps 2 H-41304 H-41304

3 Cross Pin 1 H-41302 H-41525

4 Lower Clevis Pin 1 H-42397 H-42403

5 Isolator 2 H-41497 H-41497

6 Cotter Pin 2 HFS203* HFS203**

7 Nylock Nut (M12) 2 HFS937 HFS937

8 Allen Cap Screws

9 Large Bore Connector Isolator 9 H-41009*** —

* (5/8" x 11/2" 18-8); **(3/4" x 113/16" 18-8); *** Large Bore Connector Isolators for 7/16", 11 mm

or 12 mm wire

No. Description Order Part No.

Jaw/Jaw Toggle 1 7312.20 5/8

9

1 Toggle 1 H-42316

2 Crosspin 1 H-42398

3 Clevis Pin 2 H-42397

4 Cotter Pin 2 HFS203

5 Cotter Pin 1 HFS220

6 Nylon Washer 2 HFS1005

Eye/Jaw Toggle Reversible 1 7412.20 5/8

1 Toggle 1 H-37647C

2 Crosspin 1 H-42398

3 Nylon Washer 2 HFS1005

4 Cross Hole Plug 2 H-42045

5 Clevis Pin 1 H-42397

6 Cotter Pin 1 HFS203

7 Cotter Pin 1 HFS220

Stud/Jaw Toggle 1 7312.20 3/4

1 Jaw JawToggle 1 H-41489

2 Crosspin 1 H-42398

3 Clevis Pin 2 H-42403

4 Stud 1 H-43210

5 Cotter Pin 3 HFS203

6 Cotter Pin 1 HFS220

7 Nylon Washer 2 HFS1005

8 Large Bore Connector Isolator 9 H-41009*

*Large Bore Connector Isolators for 7/16", 11 mm or 12 mm wire

(M8x1.25x16 A4 (SH) 4 HFS336 HFS336

Page 35

Jeanneau Sun Odyssey 52DS — Photo courtesy Jeanneau

MAKE CRUISING SAFER AND EASIER

Add a

Harken ball bearing traveler

The difference in performance will be night and day.

Harken free-running travelers provide

control in all conditions.

the traveler to power up the main. Wind howling?

Safely depower by easing the car to reduce heel

and maintain speed—

releasing and retrimming the sheet.

Harken captive ball traveler cars are modular

with 2:1 to 6:1 purchases

sail.

Systems can be tailored for end-boom— mounted on bridge decks—or for mid-boom

configurations with risers and high-beam track to move the traveler out of the cockpit.

faster and safer

Wind light? Adjust

so a small crew can play a highly loaded main-

to your boat.

smooth sail

than

TRAVELERS

TECH TIP

To reduce heel: Slack the windward adjuster line so the

traveler car slides to the boat’s low side, depowering the

leech and spilling air from the main. After tacking make the

same adjustment. Mark both lines at the cam for no-guess

trimming when it's windy.

1251 E. Wisconsin Ave., Pewaukee, WI 53072, Tel: 262-691-3320, Fax: 262-691-3008, Email: harken@harken.com, Web: www.harken.com

Page 36

1251 East Wisconsin Avenue, Pewaukee, Wisconsin 53072-3755 USA

01

97653 15322

Telephone: (262) 691-3320 • Fax: (262) 691-3008

Web: www.harken.com • Online Catalog: www.harkenstore.com

ZA Port des Minimes, BP 3064, 17032 La Rochelle Cedex 1, France

Telephone: (33) 05.46.44.51.20 • Fax: (33) 05.46.44.25.70

Via Marco Biagi, 14, 22070 Limido Comasco (CO) Italy

Telephone: (39) 031.3523511 • Fax: (39) 031.3520031

Bearing House, Ampress Lane, Lymington, Hampshire S041 8LW, England

Tel: (44) 01590-689122 • Fax: (44) 01590-610274

Web: www.harken.co.uk • Email: enquiries@harken.co.uk

Ul Lisa Kuli 4 Lok 1, 01-512 Warsaw, Poland

Telephone: +48 22 561 93 93 • Fax: +48 22 839 22 75

Main Office and Harken Brandstore: Västmannagatan 81B

Telephone: +46 303 618 75 • Fax:+46 303 618 76

Mailing address: Harken Sweden AB, Box 64, SE -440 30 Marstrand

Web: www.harken.si • Email: info@harken.si

1B Green Street, Brookvale, N.S.W. 2100, Australia

Telephone: (61) 2-8978-8666 • Fax: (61) 2-8978-8667

Web: www.harken.com.au • Email: info@harken.com.au

30-36 Fanshawe Street, P.O. Box 1951, Auckland 1001, New Zealand

Telephone: (64) 9-303-3744 • Fax: (64) 9-307-7987

Web: www.harken.co.nz • Email: harken@harken.co.nz

Corporate Headquarters

Email: harken@harken.com

Harken France

Web: www.harken.fr • Email: info@harken.fr

Harken Italy S.p.A.

Web: www.harken.it • Email: info@harken.it

Harken UK, Ltd.

Harken Polska SP ZOO

Email: polska@harken.com

Harken Sweden AB

SE-113 26 Stockholm Sweden

Email: harken@harken.se

Harken Adriatik d.o.o.

Obala 107, 6320 Portoroz, Slovenia

Telephone/Fax: (386) 5-6774122

Harken Australia Pty, Ltd.

Harken New Zealand, Ltd.

Please visit: http://www.harken.com/dealers/dealers.php

for an up-to-date list of Harken dealers and distributors

Printed in USA 4414/11-01-10

Loading...

Loading...