Page 1

INSTALLATION SHEET

6070, 6074, 6076, 6077, 6078, 6079, 6091, 6092, 6093, 6106 Cruising ESP Footblocks

Telephone: (262) 691-3320 • Fax: (262) 701-5780 • Web: www.harken.com • Email: harken@harken.com

Strictly follow all instructions to avoid an accident, damage to your vessel, personal injury,

or death. See www.harken.com/manuals for additional safety information.

Part

No.

6070 2

6074 3 75

6076 2

6077 2

6078 3 75

6079 3 75

6091 2

6092 3 75

6093 4 100

6106 1

Sheave ØMax line

in mm in mm lb kg lb kg lb kg in mm

1

/4575/816 2500 1135 5000 2272 650 295

1

/4575/816 2500 1135 5000 2272 — —

1

/4575/816 2500 1135 5000 2272 1200 550

1

/4575/816 2500 1135 5000 2272 — —

9

/16401/212 1250 567 2500 907 — —

WARNING! You must mount to solid deck construction using specified fasteners in all

mounting holes and nuts, washers or backing plates to achieve correct maximum working

load to avoid a failure leading to an accident.

Use “lock-off” to temporarily secure sheet. Do not use in place of a clutch, jammer or line stopper.

N15W24983 Bluemound Road • Pewaukee, WI 53072 U.S.A.

Ø

3

/419 3500 1587 7000 3175 750 340

3

/419 3500 1587 7000 3175 1200 550

3

/419 3500 1587 7000 3175 — —

3

/419 3500 1587 7000 3175 — —

3

/419 7500 3402 15000 6804 — —

working load

Maximum

Breaking

load

Max lockoff

load

Mounting Instructions

Using Lock-Off—6070/6074/6077/6078

Fasteners (FH)

A4 (316) or A2 (18-8)

stainless steel

3

/

8

3

/

8

3

/

8

5

/

16

5

/

16

3

/

8

5

/

16

5

/

16

1

/

2

5

3

/

16,

/

8

10

10

10

8

8

10

8

8

12

8, 4

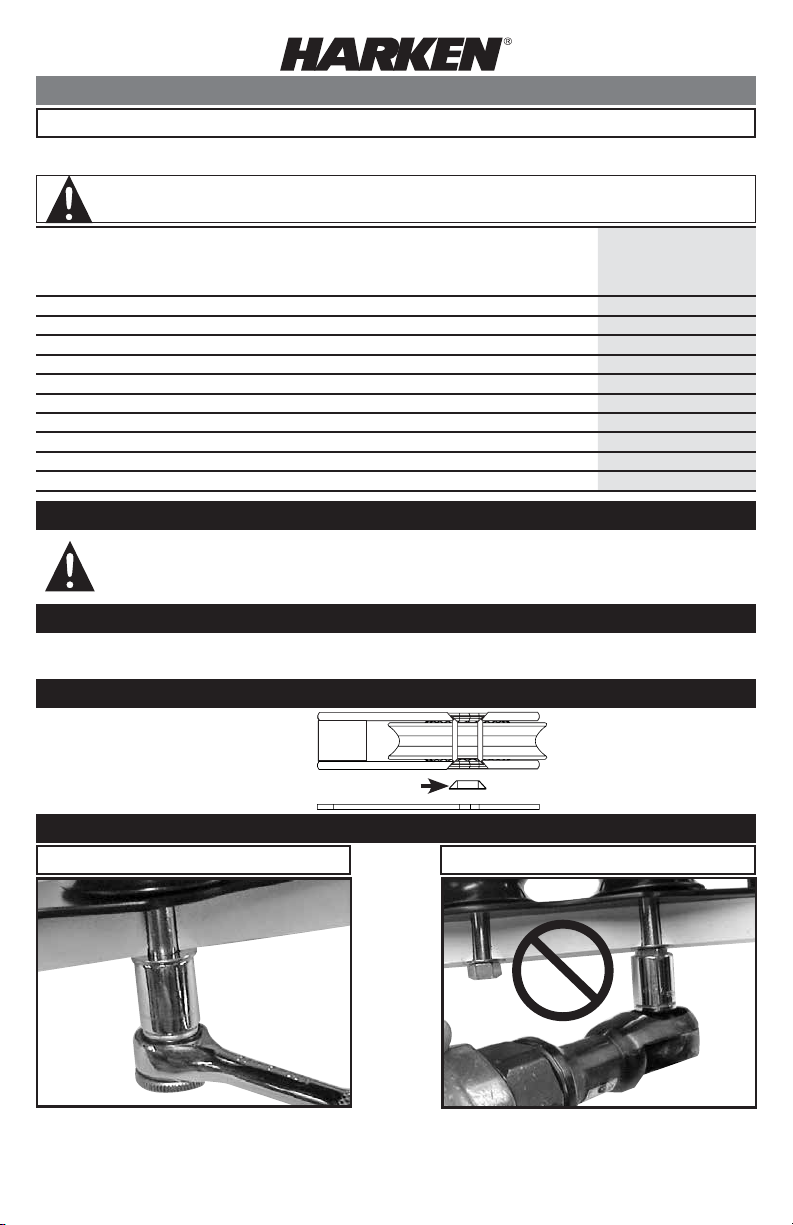

Mounting Instructions—6093 Only

Mount H-42862 on underside of

block to support axle area.

DO NOT OVER-TIGHTEN BOLTS!

CORRECT

Tighten bolts wrist tight (10 ft-lb/14 N-m)

IMPORTANT! Tighten bolts only wrist tight (10 ft-lb/14 N-m) to remove play between block and deck. Do

not use a power driver. Over-tightening will permanently damage footblock and cause sheaves to bind.

DO NOT USE A POWER DRIVER.

INCORRECT

Page 2

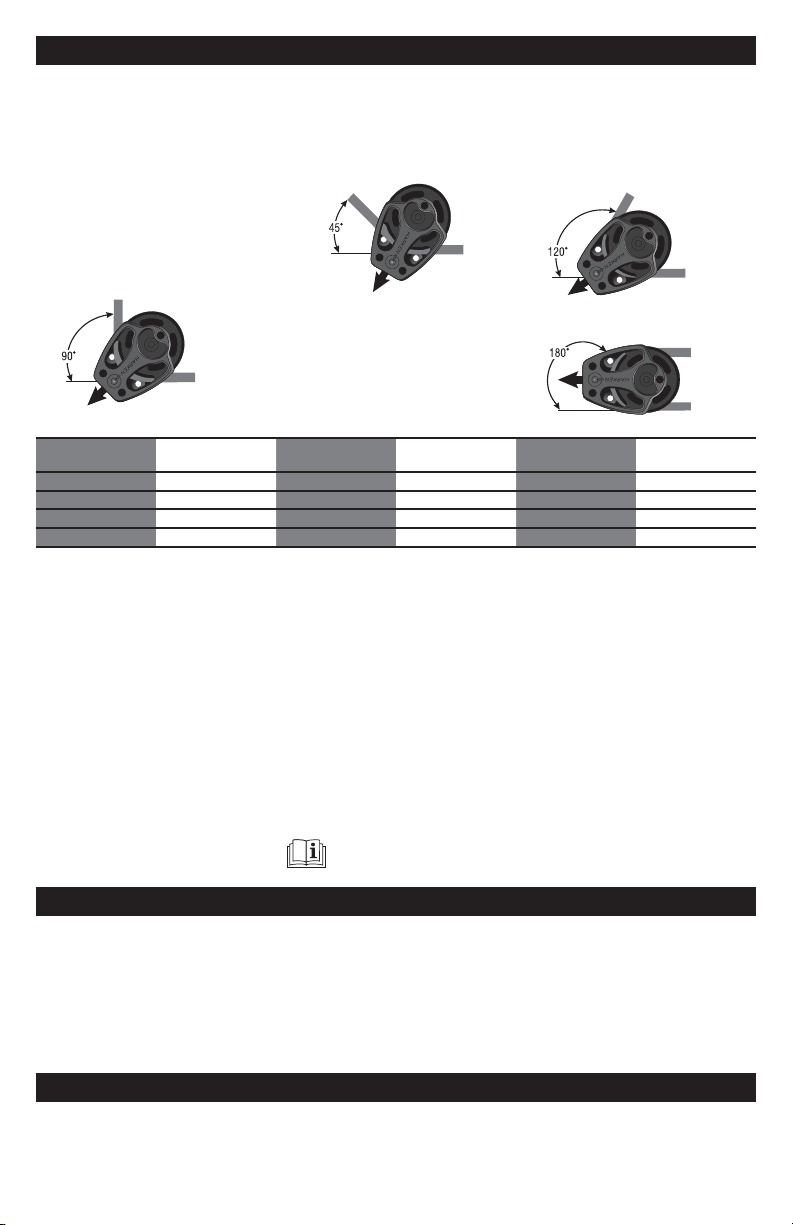

Block Loading vs Angle of Deflection

Block load is a combination of the load on the line passing through the block, plus a block-loading

factor, determined by the angle which the block turns the sheet. See loading example for a single

footblock below. IMPORTANT! When footblock is double-stacked upper block is rated at two-thirds

of listed maximum working and breaking load.

5000 lb

Example shows single

footblock with a sheet

load of 5000 lb (2268 kg)

5000 lb (2268 kg)

5000 lb

(2268 kg)

7000 lb (3175 kg)

Angle of

deflection Load factor

30° 52% 90° 141% 150° 193%

45° 76% 105° 159% 160° 197%

60° 100% 120° 173% 180° 200%

75° 122% 135° 185% — —

(2268 kg)

3800 lb (1723 kg)

Angle of

deflection Load factor

5000 lb

(2268 kg)

10000 lb

(4535 kg)

8650 lb (3923kg)

Angle of

deflection Load factor

5000 lb

(2268 kg)

5000 lb

(2268 kg)

5000 lb

(2268 kg)

5000 lb

(2268 kg)

Additional information:

www.harken.com/manuals

Maintenance

Harken equipment requires minimal maintenance, but some is required to give the best service and to comply with

Harken's limited warranty.

Keep equipment clean by frequent flushing with fresh water. Lubrication is not required.

In corrosive atmospheres, stainless parts may show discoloration around holes, rivets and screws. This is not serious

and may be removed with a fine abrasive.

IMPORTANT! Exposure to some teak cleaners and other caustic solutions can result in discoloration of part

and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance and warranty information see www.harken.com/manuals or the Harken® catalog.

Printed in USA 4638 03/14

Loading...

Loading...