Page 1

INSTALLATION SHEET

6061 Furling Main Clew Block

N15W24983 Bluemound Rd.,Pewaukee, WI 53072 U.S.A.

Web: www.harken.com; www.harkenstore.com • Email: harken@harken.com

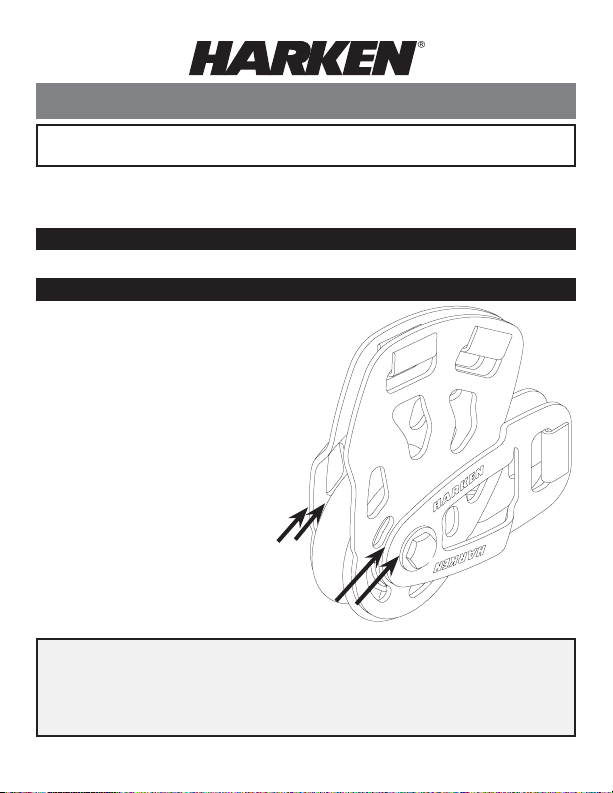

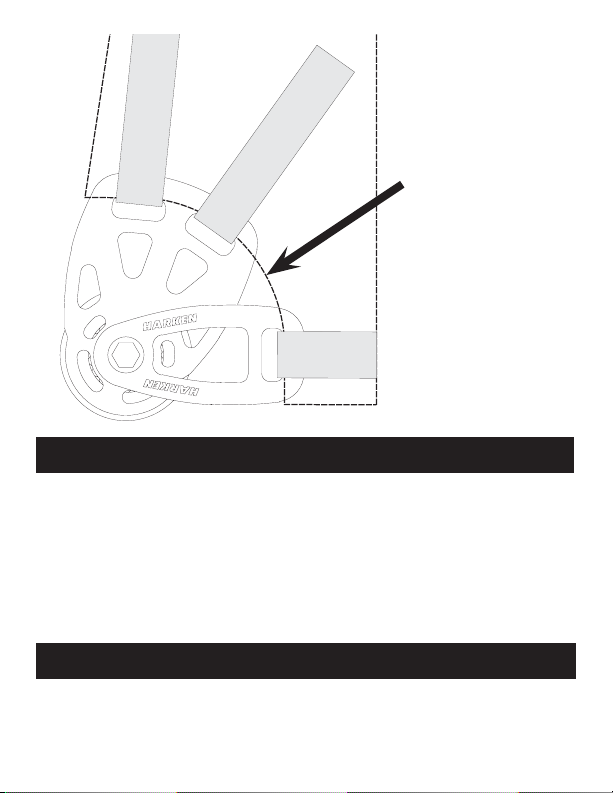

Cut sail for clew block and strap through block as shown on reverse side.

If you remove sheave, retain clear

plastic washers to prevent corrosion

and to maintain proper spacing.

Nut and bolt must be tight for

proper operation. If too loose, inner

metal sleeve may spin and cause

undue wear. Replace

locking nut when it becomes

ineffective.

Important! If you remove sheave from clew block assembly be sure to

retain and reinstall clear plastic washers to maintain proper spacing.

Nut and bolt must be tight for proper operation. If too loose, inner metal

sheave may spin and cause undue wear.

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Sail Cutout for Clew Block

IMPORTANT — If You Remove Clew Block Sheave

3

/8-16 nylon

Clear Plastic Washers

HCP374

Page 2

Cut sail for clew block

and strap through

block as shown.

Maintenance

Harken equipment requires minimal maintenance, but some is required to give the best

service and to comply with Harken’s limited warranty.

Keep equipment clean by frequent flushing with fresh water. Periodically clean with mild

detergent and water solution. Spin sheaves to distribute soap solution evenly.

In corrosive atmospheres, stainless parts may show discoloration around holes, rivets

and screws. This is not serious and may be removed with a fine abrasive.

Important! Exposure to some teak cleaners and other caustic solutions can result in

discoloration of part and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken

®

catalog.

Printed in USA 4929 12/13

Loading...

Loading...