Page 1

SMALL BOAT UNDERDECK FURLER

477, 493, 478

Installation and User Manual – Intended for specialized personnel or expert users

Preassembly

Safety Precautions/Terms/General Information 2

Parts Descriptions/Specifications 3

Planning Installation

Hoistable Halyard Swivel 4

Tools 4

Furler Requires Drained Compartment 5

Assembly

Stay Loading 5

Stay Angle 5

Deck Plate 6

Commissioning

Furling Line 7

Upper Swivel 8

4428 01/14

Operation

Unfurling/Furling 8

Maintenance

Clean 8

Inspect 8

Maintenance 8

Deck Drill Templates

477 Small Boat Underdeck Furler 9-10

493 Medium Underdeck Furler 11-12

478 Small Boat Underdeck Furler 13-14

Appendix

Sailmaker Instructions 15

Addresses

Please read these instructions carefully before installing, servicing, or operating the equipment.

This manual may be modified without notice. See: www.harken.com/manuals for updated versions.

PLEASE SAVE THESE INSTRUCTIONS

Page 2

Safety Precautions/Terms/General Information

Introduction

This manual gives technical information on installation and service. This information is destined exclusively for

specialized personnel or expert users. Installation, disassembling, and reassembling by personnel who are not

experts may cause serious damage to property or injury to users and those in the vicinity of the product. If you

do not understand an instruction, contact Harken.

The user must have appropriate training in order to use this product.

Harken accepts no responsibility for damage or harm caused by not observing the safety requirements and

instructions in this manual. See limited warranty, general warnings, and instructions in www.harken.com/manuals.

Purpose

®

Harken

Jib Furling is designed to roll sails on sailboats so wind has little effect on the sail. Use of this product for

other than normal sailboat applications is not covered by the limited warranty.

Safety Precautions

WARNING! Strictly follow all instructions to avoid potential hazards

that may kill or hurt you and others. See www.harken.com/manuals

for general warnings and instructions.

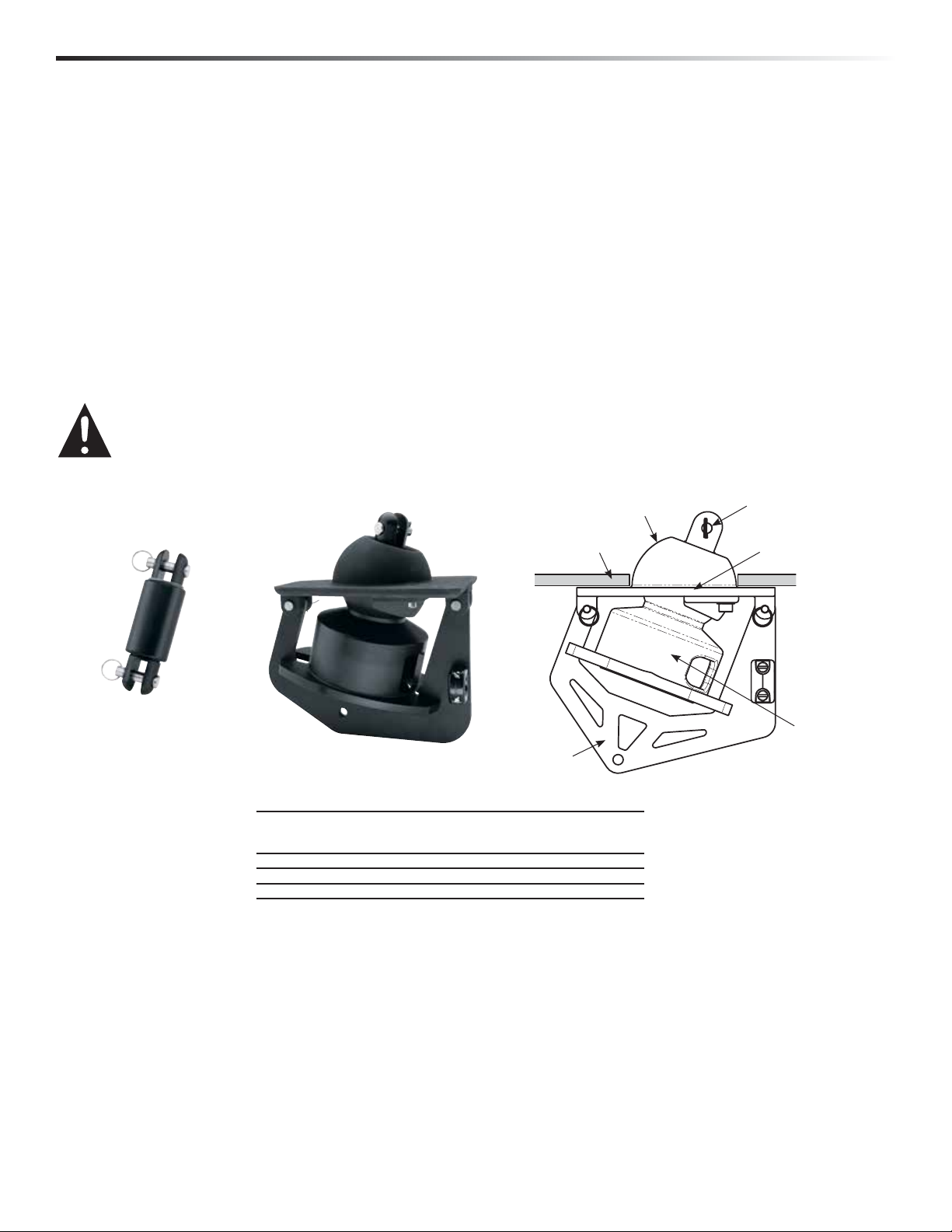

Swivel Assembly

Drum

Assembly

Furler Description

477 Underdeck furler/small

493 Underdeck furler/medium

478 Underdeck furler/large

Deck Plate Ball

Deck

Bridge

Clevis pin ØMaximum

in mm lb kg in mm

1

/46 950 4311/8–5/323–4

5

/

16

7

/1611 3000 13613/16–1/45–6

working load

8 2000 9075/32–3/164–5

Line

Ø

Clevis Pin

Deck Plate

Bullseye

Spool

2 477, 478, 493 Small Boat Underdeck Furler

Page 3

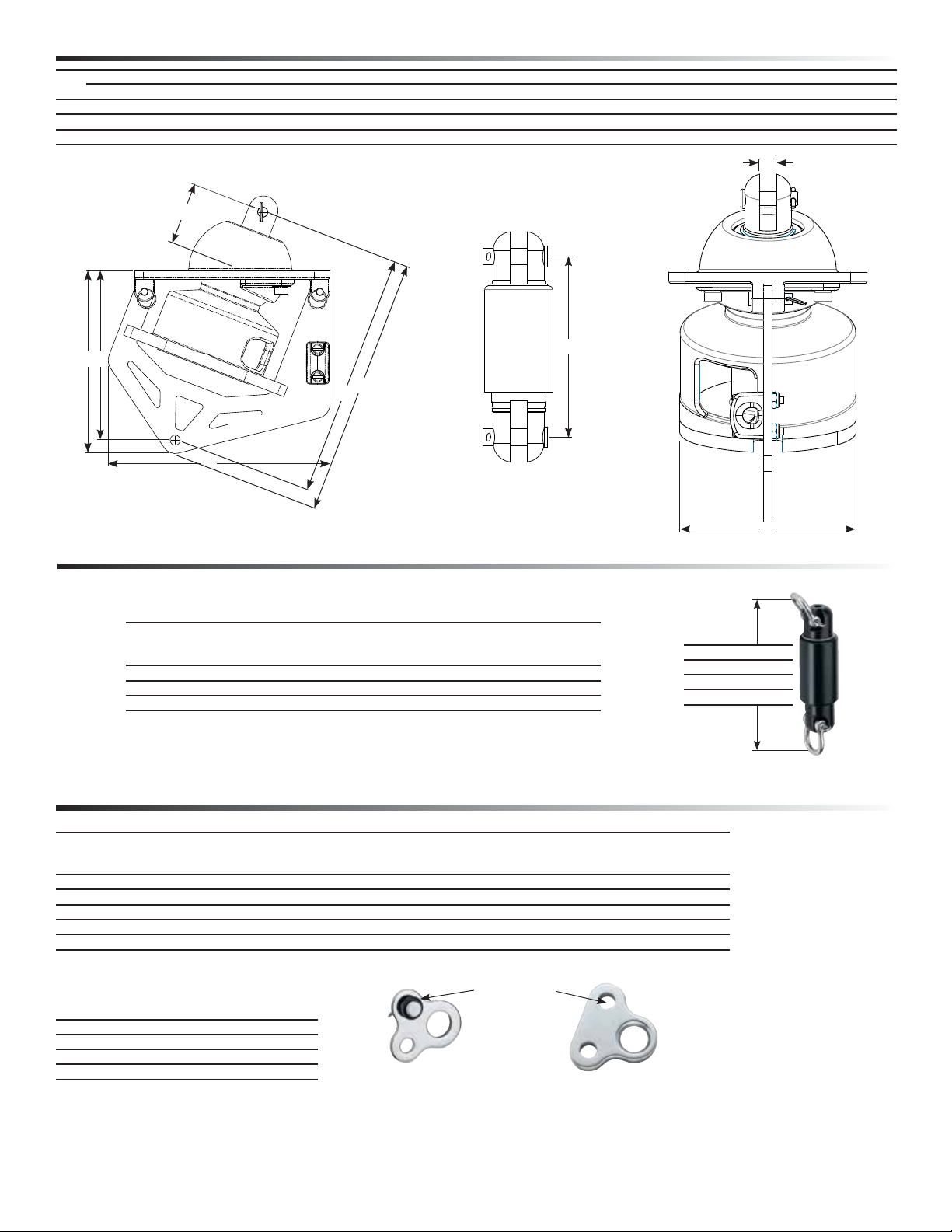

Parts Descriptions and Specifications

Furler

477

493

478

A B C D E F G H I

in mm in mm in mm in mm in mm in mm in mm in mm in mm

5

/8118 45/

4

11

/16144 55/

5

7 177 5

16

16

3

/

4

147 19/

135 113/

147 27/

16

40 55/

16

45 7 179 73/

16

61 93/

8

8

143 63/

238 81/

16

8

2

157 69/

188 713/

215 91/

16

166 21/

16

198 4 102

2

240 43/

2

4

121

5

64

/

16

3

7

8 3 76

/

8

9.5 4 100

/

16

11.5 51/

H

C

G

A B

F

E

477

D

2

140

Components

Upper

swivel

Furler

Part No.

477 164 464* HC9226 2.6 74 2.9 82 24 680

493 207 465* HC10893 9.2 261 8.9 252 42.6 1201

478 HCP141 482* HC9976 15 431 16.8 477 81 2296

*Hoistable halyard swivels (464, 465, 482) are not included in 477, 493, or 478.

Hoistable

swivel

Part No.

Drum

Part No.

Tangs for Attaching Sail to Lower Unit

Tack

adapter tang

Furler

Part No.

477 HCP649*

493 489 1

478 479 1

478 480 1

478 481 1

*See parts required below. **Upper tang hole pin size listed.

*The following parts must be ordered with the HCP649

Part No. Qty Description

HCP650 2 Neoprene O-ring

HFS118 1 Cotter pin 1/16X.500 18-8

HSB99 1 Clevis pin 1/4 X .672 SS

Pin-to-pin

length

in mm in mm in mm oz g lb kg

3

/

4

3

/

1

/

1

/

1

/

19

8

35

2

38

2

38

2

38

1

/

8

5

/

32

5

/

32

3

/

16

7

/

32

Wire

Ø

Upper swivel Hoistable swivel Drum

Weight

oz g oz g oz g

Clevis pin

Ø Weight

3

4

4

5

6

1

/4** 6** — — — —

5

/16** 8** — — — —

5

/16** 8** 5.2 147 3000 1361

3

/8** 10** 5.2 147 3000 1361

7

/16** 11** 5.2 147 3000 1361

Upper

Adapter Tang

Hole

HCP649 Tang

Part No. in mm

Maximum

working load

479

480

481

489

464 4

465 5

482 7

3

/16124

11

/16144

19

/32193

I

477, 478, 493 Small Boat Underdeck Furler 3

Page 4

Planning Installation Hoistable Halyard Swivel

An optional hoistable ball bearing halyard swivel can be installed

on your headstay so you can raise or lower the sail without removing

the headstay. Hoistable halyard swivels are independent of the headstay, allowing you to tension the luff separately from the mast rake.

Hoistable swivels work along with your standard Harken Small

Boat furler.

IMPORTANT! Hoistable halyard swivel must be loaded on stay before

terminals are made. Make sure the end with circlip is facing up.

When using Hoistable Halyard Swivel adapter tangs provide

a “Y” attachment to connect both stay and sail tack to the

lower unit. A Sailmaker Eye may also be used. The eye

consists of a swage marine eye with a hole designed

for lashing or shackling the tack to the terminal.

Sail Tack

Securing Points

Adapter Tang

Sailmaker Eye

Circlip

Hoistable swivel

End of halyard

swivel with

circlip faces up

Upper swivel

Halyard

Unfurl

Furl

Tools/Parts You Will Need

4

1

5

3

2

1. Hole saw 5. Deck sealant

2. Center punch 6. File for beveling

3. Scissors 7. Wrench for deck plate bolts

4. Rigging or black tape 8. Power drill/drill bit for pilot holes

6

8

7

B

A

C

or

Fasteners for Mounting Unit to Deck (Not Supplied)

Unit Fastener Ø C–Deck Plate Thickness*

477

493

478

*Add deck thickness to this measurement

4 477, 478, 493 Small Boat Underdeck Furler

5 mm

5 mm

6 mm

1

/4" (6 mm)

1

/4" (6 mm)

3

/8" (10 mm)

Hole Saw Size – Refer to information below and choose hole saw for deck plate.

Deck Plate Ball Ø Recommended Hole Saw Ø

Unit in mm in mm in mm in mm

477

493

478

* A smaller hole than listed may be used to fashion a socket in the deck to conform to the ball shape. This can improve the

appearance and reduce the amount of sealant required. See drilling template in Appendix.

A B Requires Some Beveling Requires No Beveling

2.6 66 2.7 68.5 2.5 or smaller* 65 or smaller* 2.75 70

3 76 3.25 83 3 or smaller* 75 or smaller* 3.25 85

4.25 108 4.5 114 4.25 or smaller* 110 or smaller* 4.5 115

Page 5

Planning Installation Furler Requires Drained Compartment

The drum assembly is designed to keep much of the water from entering the bow compartment. Water will drip

through the furler during rain or when sailing in heavy weather.

IMPORTANT! Furling compartment must drain.

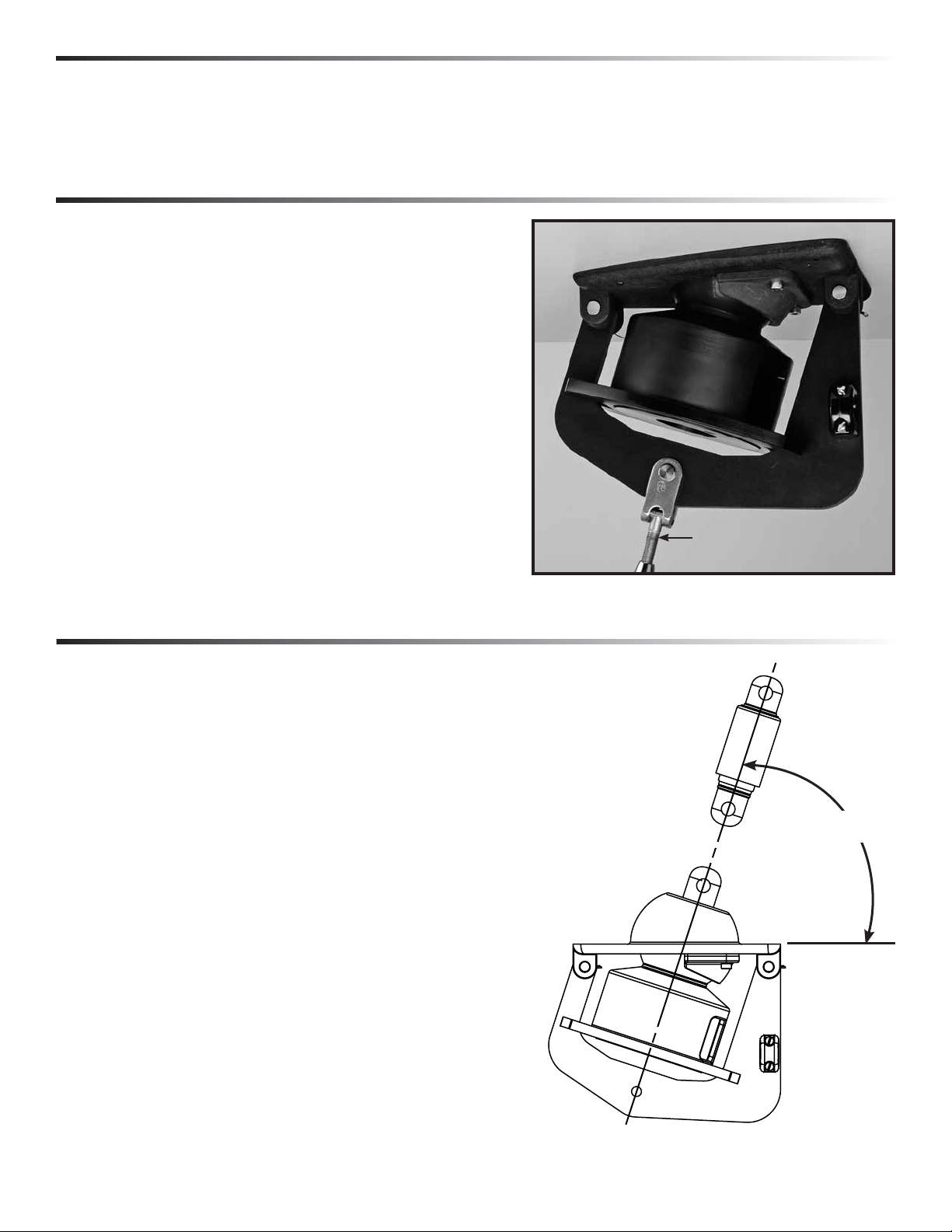

Assembly Stay Loading

The drum assembly is designed for either transferring the

headstay loads to the deck or for transferring the loads to

an underdeck chainplate.

If securing only to deck, make sure deck is strong enough

and designed for this purpose. A cored deck will not provide

adequate strength.

Use stay attachment below deck. A turnbuckle is used to

connect the chainplate to the bridge on the furler. It must

be carefully tensioned as the mast is tensioned to neutralize

the load on the deck.

Bridge

Turnbuckle

Turnbuckle to Bridge

Stay Angle

The Harken deck plate angle matches a stay angle of 72° when

compared to deck. Stay angle can vary between 71° and 73°.

IMPORTANT! If stay angle does not fall between 71° to 73° the

furler will be difficult to furl and may create excessive force on

deck and furler. To correct problem, change mast rake or make

shims using structural epoxy.

71°–73°

477, 478, 493 Small Boat Underdeck Furler 5

Page 6

Assembly Deck Plate

Carefully locate center point in deck to locate deck plate. Line from mast to underdeck chainplate must intersect this

center point. Mark center fore/aft and athwartships lines. Line up template accordingly. Mark four outer holes and center

pilot hole. Make sure closer pair of holes is forward. Mark center hole for drilling large hole.

If using an interior chainplate, check hole position by drilling a pilot hole

and running a low stretch line from mast head to chainplate.

Tip: After pilot drill bit clears deck, drill final hole from bottom using pilot

hole to line up hole drilled from top. This will prevent glass from chipping.

Tip: Run line through fairlead and dead end line into spool before mounting

lower unit.

Make sure hole is just large enough so deck plate bears against deck. It

is better to make hole slightly smaller and file opening larger to fit. Use

template to mark large hole and bolt holes. Once you are certain hole is

located in line with chainplate and any required shimming is done, drill

hole 90° to deck.

Use screws, washers, and deck sealant to

fasten lower unit to deck (see chart at right).

Note: Make sure there is sufficient thread

Furler

477, 493

478

Minimum thread

in deck plate

1

/4" (6 mm)

3

/8" (10 mm)

engagement into deck plate.

Deadend line before

mounting

6 477, 493, 478 Small Boat Underdeck Furler

Page 7

Commissioning Furling Line

To figure line length, measure the distance from the furler to the furling cleat. Add length indicated below.

Part

No.

477

493

478

Line Ø Measure distance from furler to cleat and add

in mm ft m

1

/8–5/

32

5

/32–3/

3

/16–1/

3–4 10 3

16

4–5 13 4

4

5–6 15 4.5

Feed the line through bullseye and into spool. Run down into deadend hole located on the lower flange of

the spool and add a stop knot. Tie an overhand or figure-8 knot in the end. Set up lead block so line runs

perpendicular to drum when it leaves bullseye.

The bullseye can correct small differences in line angle. Lead line aft using ball bearing blocks where line

makes a turn more than 30 degrees. Install cleat.

2

1. Run line out of hole in bottom of spool

and tie a single overhand knot.

Note: On the 493 the deadend hole is in

the hub.

2. Pull knot back up to seat at hole.

1

493 Deadend Hole

477, 478 Deadend Hole

Rotate the drum clockwise to charge the spool. Wind 10–15 ft (3–4.5 m) of line on spool.

477, 493, 478 Small Boat Underdeck Furler 7

Page 8

Commissioning Upper Swivel

Attach upper swivel to jib halyard. Fasten head of unfurled jib to upper swivel and attach tack to the top of drum.

Hoist sail with halyard, snug it up, and cleat. When using hoistable swivel, attach head of sail to shackle.

Operation Unfurling/Furling

To furl jib, pull the furling line to roll sail up around its own luff. To unfurl, uncleat furling line and pull

jib sheet.

Maintenance Inspect/Clean

Inspect

1) Unit for signs of chafe, wear, or damage.

2) Rigging components for signs of stress corrosion.

4) Turnbuckle below drum or inside torque tube for signs of loosening.

5) Headstay tension for signs of loosening.

6) All clevis pins, locking rings, and cotter pings to make sure they are secure.

7) Inspect wire for signs of wear or unraveling.

Maintenance

Keep unit clean. When you wash boat, flush unit with soap and fresh water.

Occasionally lower sail and flush halyard swivel with soap and fresh water.

To clean drum bearings, squirt a mild detergent and water solution into

the small gap between the plastic ball and the spool extension as shown at

right. Spin drum and let soak. Follow with a one minute flushing with hose.

Clean drum bearings

8 477, 493, 478 Small Boat Underdeck Furler

Page 9

477 Small Boat

Deck Drill Template

BOW

STERN

477 Small Boat Underdeck Furler Deck Drill Template

Hole Saw Size Recommendations. Read before drilling.

1

/2" (65 mm) – Requires some beveling of bottom edge of deck hole to provide a good fit. Alternatively, a smaller hole

2

may be used to fashion a socket in deck to conform to ball shape. This may improve appearance and reduce amount

of water that enters.

3

/4" (70 mm) – Use if no beveling to underside of deck is desired.

2

13/8" (35 mm)

!

Hole Saw Size

See Above

21/2" (65 mm)

Hole Saw Size

See Above

23/4" (70 mm)

43/16"

107 mm

31/4" (83 mm)

IMPORTANT! If you print this template from a computer file,

measure to confirm that template is the correct size.

477 Small Boat Underdeck Furler 9

Page 10

This Page Intentionally Left Blank

10 477 Small Boat Underdeck Furler

Page 11

493 Medium Underdeck Furler Deck Drill Template

493

Deck Drill Template

BOW

STERN

Hole Saw Size Recommendations

3" (75 mm) – Requires some beveling of bottom edge of deck hole to provide a good fit. Alternatively, a smaller hole may

be used to fashion a socket in deck to conform to ball shape. This may improve appearance and reduce amount of water

that enters.

1

3

/4" (85 mm) – Use if no beveling to underside of deck is desired.

. Read before drilling.

11/4" (31.75 mm)

!

Hole Saw Size

See Above

3" (75 mm)

Hole Saw Size

See Above

31/4" (85 mm)

5.53 (517/32")

140.5 mm

33/4" (95 mm)

IMPORTANT! If you print this template from a computer file,

measure to confirm that template is the correct size.

493 Small Boat Underdeck Furler 11

Page 12

This Page Intentionally Left Blank

12 493 Small Boat Underdeck Furler

Page 13

478 Small Boat Underdeck Furler Deck Drill Template

478 Small Boat

Deck Drill Template

BOW

STERN

Hole Saw Size Recommendations. Read before drilling.

1

4

/4" (110 mm) – Requires some beveling of bottom edge of deck hole to provide a good fit. Alternatively, a smaller

hole may be used to fashion a socket in deck to conform to ball shape. This may improve appearance and reduce

amount of water that enters.

1

4

/2" (115 mm) – Use if no beveling to underside of deck is desired.

33/8" (86 mm)

!

31/

4

3

8

/16"

208 mm

529/32"

(150 mm)

23/4" (70 mm)

Hole Saw Size

See Above

41/4" (110 mm)

Hole Saw Size

See Above

41/2" (115 mm)

IMPORTANT! If you print this template from a computer file,

measure to confirm that template is the correct size.

51/8" (130 mm)

67/16" (163 mm)

478 Small Boat Underdeck Furler 13

Page 14

This Page Intentionally Left Blank

14 478 Small Boat Underdeck Furler

Page 15

Appendix Sailmaker Instructions

Consult specifications for swivel and drum pin-to-pin lengths to determine luff length deductions. If using optional

hoistable halyard swivel, make sure to deduct for this.

Standard Upper Swivel Only

Sailmaker will often install a 1 x 19 stainless steel wire sewn into the luff with thimbles that are secured to the tack and

head so they will not turn while furling. In this case, the luff wire becomes the headstay. The jib remains on the boat in

its furled position when it is not in use and a cover protects the sail from UV exposure. Alternatively a temporary “mast

assist” line is used.

Direction of Wire Lay (All Installations)

When installing wire, coordinate the lay of the wire with the direction of furling so that the twist in the strands are

tightening when the sail is pulling aft as it is furled. Spool is charged clockwise. This means that the sail is rolled in

a counter-clockwise direction during furling. As a result, the wire should tighten when sail puts a clockwise load on

the strands.

Note: The outside of the roll will be on starboard. See diagram below.

Hoistable Halyard Swivel: If a hoistable halyard swivel is used, the sailmaker will use

a luff sleeve or small snap straps so that the sail can be hoisted onto a permanent stay

Circlip

and removed with the headstay left in place. Make sure the head and tack thimbles are

secured to the sail to handle furling loads.

IMPORTANT! Load hoistable halyard swivel onto stay before terminals are assembled.

Use tangs to provide a sail attachment to lower furler. A sailmaker eye may also be used.

End of halyard

swivel with

circlip faces up

Wire should tighten when

sail puts a clockwise load

on the strands. Outside

of roll is on starboard.

Attach headstay

to upper hole

Secure sail

here

Attach furler

to this hole

477, 478, 493 Small Boat Underdeck Furler 15

Page 16

Corporate Headquarters

N15W24983 Bluemound Rd, Pewaukee, WI 53072 USA

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Web: www.harken.com • Online Catalog: www.harkenstore.com

1B Green Street, Brookvale, N.S.W. 2100, Australia

Telephone: (61) 2-8978-8666 • Fax: (61) 2-8978-8667

Web: harken.com.au • Email: info@harken.com.au

ZA Port des Minimes, BP 3064, 17032 La Rochelle Cedex 1, France

Telephone: (33) 05.46.44.51.20 • Fax: (33) 05.46.44.25.70

Via Marco Biagi, 14, 22070 Limido Comasco (CO) Italy

Telephone: (39) 031.3523511 • Fax: (39) 031.3520031

30-36 Fanshawe Street, P.O. Box 1951, Auckland 1001, New Zealand

Telephone: (64) 9-303-3744 • Fax: (64) 9-307-7987

Web: harken.co.nz • Email: harken@harken.co.nz

ul. Rydygiera 8, budynek 3A, lokal 101, I pi

Tel: +48 22 561 93 93 • Fax: +48 22 839 22 75

Main Office and Harken Brandstore: Västmannagatan 81B

Telephone: (46) 0303 61875 • Fax: (46) 0303 61876

Mailing address: Harken Sweden AB, Box 64, SE -440 30 Marstrand

Bearing House, Ampress Lane, Lymington, Hampshire S041 8LW, England

Telephone: (44) 01590-689122 • Fax: (44) 01590-610274

Web: harken.co.uk • Email: enquiries@harken.co.uk

Email: harken@harken.com

Harken Australia Pty, Ltd.

Harken France

Web: harken.fr • Email: info@harken.fr

Harken Italy S.p.A.

Web: harken.it • Email: info@harken.it

Harken New Zealand, Ltd.

Harken Polska SP ZOO

ętro, 01-793 Warszawa, Poland

Web: harken.pl • Email: polska@harken.pl

Harken Sweden AB

SE-113 26 Stockholm Sweden

Web: harken.se • Email: harken@harken.se

Harken UK, Ltd.

Please visit: http://www.harken.com/locator.aspx

to locate Harken dealers and distributors

Printed in USA 4428 01/14

Loading...

Loading...