Page 1

SINGLE LINE MAINSAIL REEFING SYSTEM

430

(For boats 22 - 27 ft (6 - 8 m) with mainsails under 150 ft

Installation Manual – Intended for specialized personnel or expert users

2

(14 m2)

4171 12/13

Reef Mainsail with One Line

Easy to Install

Reef From Cockpit in Seconds

Use with Regular or Full-Length Battens

Track Allows Easy Adjustment of Block for Best Sail Shape

No Modification to Sails with Reef Points

Please read these instructions carefully before installing, servicing, or operating the equipment.

This manual may be modified without notice. See: www.harken.com/manuals for updated versions.

PLEASE SAVE THESE INSTRUCTIONS

Page 2

Parts (Included) Drill/Tap Sets You Must Supply

Clew Track Assembly

1 HSB60 Clew Slider Assembly

1 H-24294C Track

1 833 Blue Loctite® (Threadlocker 242)

6 HFS566 5/16-18 x 3/4” Flathead Screws (1 Extra)

6 HFS841 M8 x 1.25 x 20 mm Flathead Screws (1 Extra)

Mid-Boom Fairlead

1 137 Eyestrap

3 HFS104 #10-32 x 3/8” Trusshead Screws (1 Extra)

3 HFS842 M5 x .80 x 10 mm Panhead Screws (1 Extra)

3 HFS125 #10 x 3/8” Self-Tapping Panhead Screws (1 Extra)

Mast Mounted Tack Block Assembly

1 168 Big Bullet Block/071 Spring/137 Eyestrap

2 HFS104 10-32 x 3/8” Trusshead Screws

2 HFS842 M5 x .80 x 10 mm Panhead Screws

2 HFS125 #10 X 3/8” Self-Tapping Panhead Screws

Mast Mounted Bullseye

1 H-24675A Bullseye

3 HFS259 10-32 x 11/4” Roundhead Screws (1 Extra)

3 HFS843 M5 x .80 x 30 mm Panhead Screws (1 Extra)

3 HFS840 #10 x 11/4” Self-Tapping Screws (1 Extra)

Deck Blocks

1 132 Big Bullet Cheek Block

1 168 Big Bullet Block/071 Spring/137 Eyestrap

5 HFS106 10-32 x 1-1/2” Roundhead Screws (1 Extra)

5 HFS110 10-32 18-8 Nuts (1 Extra)

5 HFS111 Washer (1 Extra)

5 HFS112 Lockwasher (1 Extra)

Tools You Must Supply

Electric Drill

Drill Bits

Screwdrivers

Slotted

Phillips

Wrench – 3/8” (9.5 mm) or Adjustable

Hammer

Center Punch

Pencil or Fine Point Marker

US Drill Bits

5/32” for 10-32 Tap Set and for Self-Tapping #10 Screws

13/64” for Deck Clearance Holes for #10 Screws*

17/64” for 5/16-18 Tap Set

*Used for mounting mast base block to deck, not used if shackling to mast

collar. Also used for deflector block, not used if using deck organizer.

US Tap Sets

10-32 optional - you can also use self-tapping screws

5/16-18 required for mounting track

Metric Drill Bits

4 mm

for 10-32 Self-Tapping Screws

5 mm for Deck Clearance Holes for #10 Screws*

4.2 mm for 5 x .80 mm Tap Set (Optional)

6.8 mm for 8 x 1.25 mm Tap Set

*Used for mounting mast base block to deck, not used if shackling to mast

collar. Also used for deflector block, not used if using deck organizer.

Metric Tap Sets

5 x .80 mm

8 x 1.25 mm

Optional-you can also use self-tapping screws

Required for mounting track

Parts You Must Supply

• Reefing line – 5/16” (8mm) double braided Dacron

line. Use formula below to calculate length.

• Cleat or stopper to secure reefing line.

• High quality marine sealant for mounting deck

hardware.

• Back-up plate or large diameter washers for

backing up deck hardware screws.

• Topping lift.

• For most effective reefing, the main halyard

should be led back to the cockpit.

• Feeder cover plates for grooved spar so sail

slugs can pass mast feeder gap. See the bottom

of page 7.

Figuring Line Length

1 Reef height X 5 ................. ____________

2 Sail foot length X 2.............. ____________

3 Add 7 feet (2.2 m) ..............+ 7 feet (2.2 m)

Total length of reefing line.......... ____________

Sail Work

In most cases your mainsail needs no alteration. Check

to make sure your sail is fitted with tack and clew reef

grommets. Intermediate reef points are used

as required.

2

Page 3

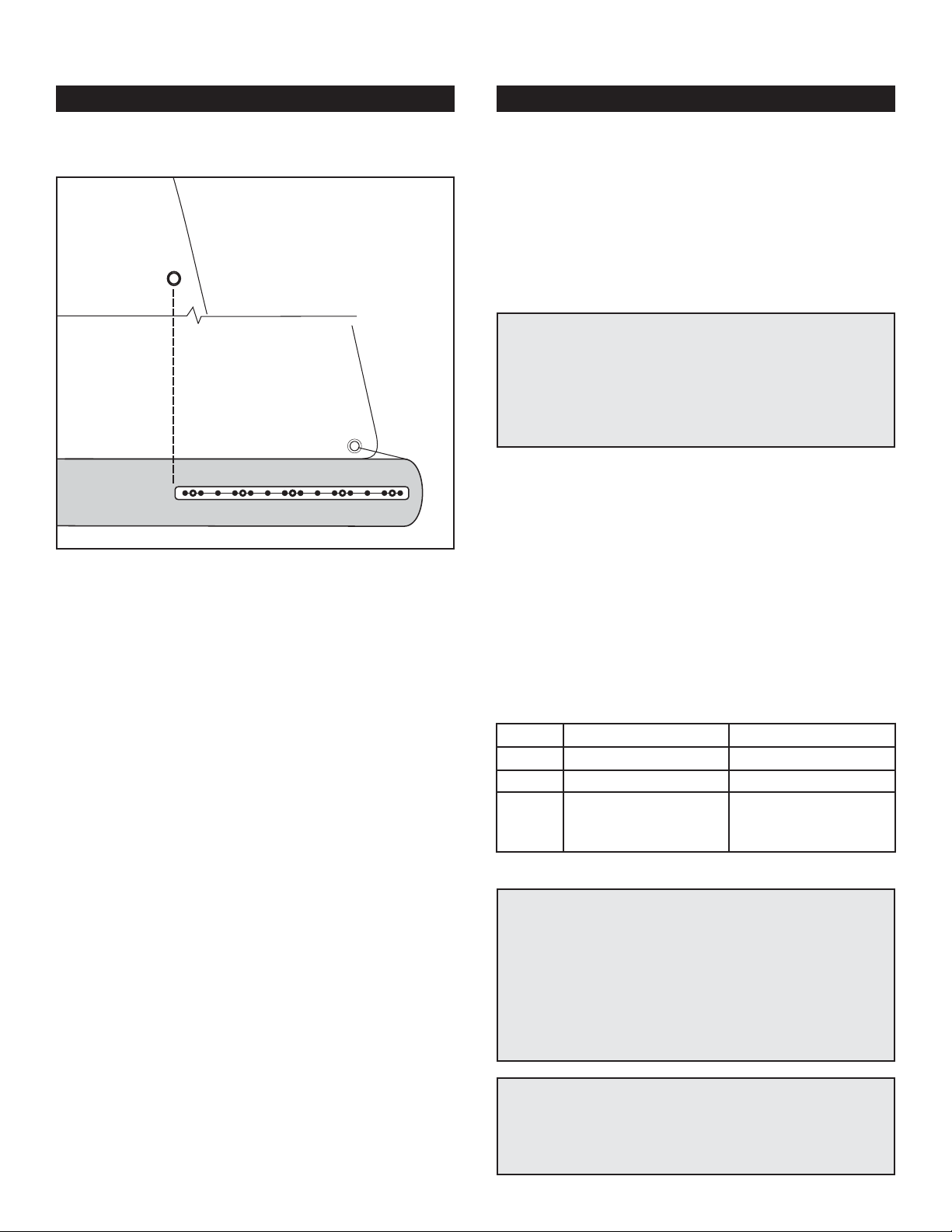

Step 1 Mounting Track on Boom

General Instructions Detailed Instructions

A. Decide whether to place the system on the port or

starboard side of the boom.

B. Mount track at the aft end of the boom.

A. Each boat is different. Choose the best side by deter-

mining if you have room on the boom and where the

line will lead on the cabin house. Remember, the line

runs down the opposite side of the mast as the track is

mounted to the boom. If the track is on starboard, the

line will run down the port side of the cabin top. You

will need 19” (483 mm) on the aft end of the boom to

mount the track.

Installation Tip – Plan the Location of All Hardware

Before Installation

Look at the mast area to see if the tack block and bullseye will

fit easily. Look at the mast base area. Is there a good spot for

mounting the mast base block? Where is the main halyard cleat?

If possible, locate the single line cleat near the halyard cleat in

easy reach of the cockpit.

B. Place the track so the front edge is behind the aft

mainsail reefing grommet. If the boom is not long

enough for this, position the track as far aft as

possible.

Carefully mark the holes, drill, tap and mount track.

See tips below.

US Metric

Drill

Tap

5 Screws

(Use Blue Loctite on Screws)

Installation Tip – Lining Up Holes with Track

If holes in boom do not line up with track holes, it will be very

difficult to install screws. After marking each hole, drill and tap

the forward hole and use a screw to secure the track. Use a center punch to start the other holes. If any dimples do not line up,

relocate them before drilling holes. Loosen screw and let track

pivot out of the way and drill the other holes. Do not drill holes

through track; remove track before drilling.

Installation Tip – Drilling

Hold the drill perpendicular to the face of the boom. Do not angle

the drill or it will be very difficult to install the screws flush with

the track.

3

17/64” 6.8 mm

5/16-18 8 x 1.25 mm

5/16 -18 x 3/4”

Flathead Machine Screws

Flathead Machine Screws

(Use Blue Loctite on Screws)

8 x 1.25 x 20 mm

Page 4

Step 2 Mounting Clew Slider

General Instructions Detailed Instructions

A. Install the clew slider on the track, so it’s aft of the

reef outhaul grommet.

Starboard Installation

Port Installation

Port-Side Installation

If installing on port side, flip block around.

Step 3 Installing Tack Block

General Instructions Detailed Instructions

A. Load the clew slider on the track so the eyestrap

is down. Secure by tightening the set screw into a

positioning hole. This may be adjusted later while

adjusting the system at the dock with the sail hoisted.

Port-Side Installation

The car is shipped ready for installation on the starboard side. If installing on the port side of the boom

remove the cheek block and reinstall so sheave faces

forward.

A. Mount the reefing tack block to the mast on the same

side as the track is mounted to the boom. Position the

block so the line pulls down and forward at 45° when

reefed.

Mast

7:oo

5:oo

A. Choose the same side as the track is mounted to

the boom. Position the reefing tack block so it’s aft of

the side of the mast. Looking down from above it will

be pointed to 5:00 or 7:00 o’clock depending whether

it’s mounted on the starboard or port side respectively.

Looking from the side, the top of the block should be

just below the level of the bottom of the boom. Position

the eyestrap, parallel to the load (see diagram).

Self-Tapping

US Metric

Drill

2 Screws

Drill

Tap

2 Screws

#10 x 3/8”

Roundhead Self-Tapping Screws

(Use Blue Loctite on Screws)

Drilling and Tapping

10-32 x 3/8”

Roundhead Machine Screws

(Use Blue Loctite on Screws)

Trusshead Machine Screws

(Use Blue Loctite on Screws)

4 mm5/32”

MetricUS

4.2 mm5/32”

5 x .80 mm10-32

5 x .80 x 10 mm

Position the

eyestrap so it

aligns with

the load.

Installation Tip – Internal Halyards

To keep screw from snagging internal halyards, first install, then

remove, nip off the end and reinstall.

4

Page 5

Step 4: Installing Tack Bullseye

General Instructions Detailed Instructions

A. Mount the reefing tack bullseye so it is on the opposite

side from the tack block. Position the bullseye so the line

pulls down and forward at 45° when reefed.

Mast

7:oo

5:oo

A. Position the reefing tack bullseye so it is on the

opposite side from the tack block. Looking down from

above it will be pointed to 7:00 or 5:00 o’clock depending whether it’s mounted on the port or starboard side

respectively. Looking from the side, the bullseye should

be just below the level of the bottom of the boom.

Position the bullseye so the mounting holes run side

to side.

Self-Tapping

US Metric

Drill

#10 x 1-1/4”

2 Screws

Drill

Tap

10-32 x 1-1/4”

2 Screws

Installation Tip – Internal Halyards

To keep screw from snagging internal halyards, first install, then

remove, nip off the end and reinstall.

Roundhead Screws

(Use Blue Loctite on Screws)

Roundhead Screws

(Use Blue Loctite on Screws)

Drilling and Tapping

Trusshead Machine Screws

(Use Blue Loctite on Screws)

4 mm5/32”

MetricUS

4.2 mm5/32”

5 x .80 mm10-32

5 x .80 x 30 mm

Step 5 Installing Mid-Boom Fairlead Eyestrap

General Instructions Detailed Instructions

A. Install the eyestrap half way between the clew slider

and the mast.

Halfway

Keep friction to a minimum,

by positioning eyestrap

so reefing line will lead

smoothly to tack block.

A. The eyestrap is used to help hold the reefing line

from drooping when it is not tensioned.

Position the eyestrap so the reefing line runs directly

through the eyestrap as it runs from the clew slider to

the mast. Choose one of the mounting methods below

and install.

Self-Tapping

Metric

4 mm

MetricUS

4.2 mm5/32”

5 x .80 mm10-32

5 x .80 x 10 mm

Drill

2 Screws

Drill

Tap

2 Screws

US

5/32”

#10 x 3/8”

Roundhead Self-Tapping Screws

(Use Blue Loctite on Screws)

Drilling and Tapping

10-32 x 3/8”

Roundhead Machine Screws

(Use Blue Loctite on Screws)

Trusshead Machine Screws

(Use Blue Loctite on Screws)

Installation Tip – Internal Halyards

To keep screw from snagging internal halyards, first install, then

remove, nip off the end and reinstall.

5

Page 6

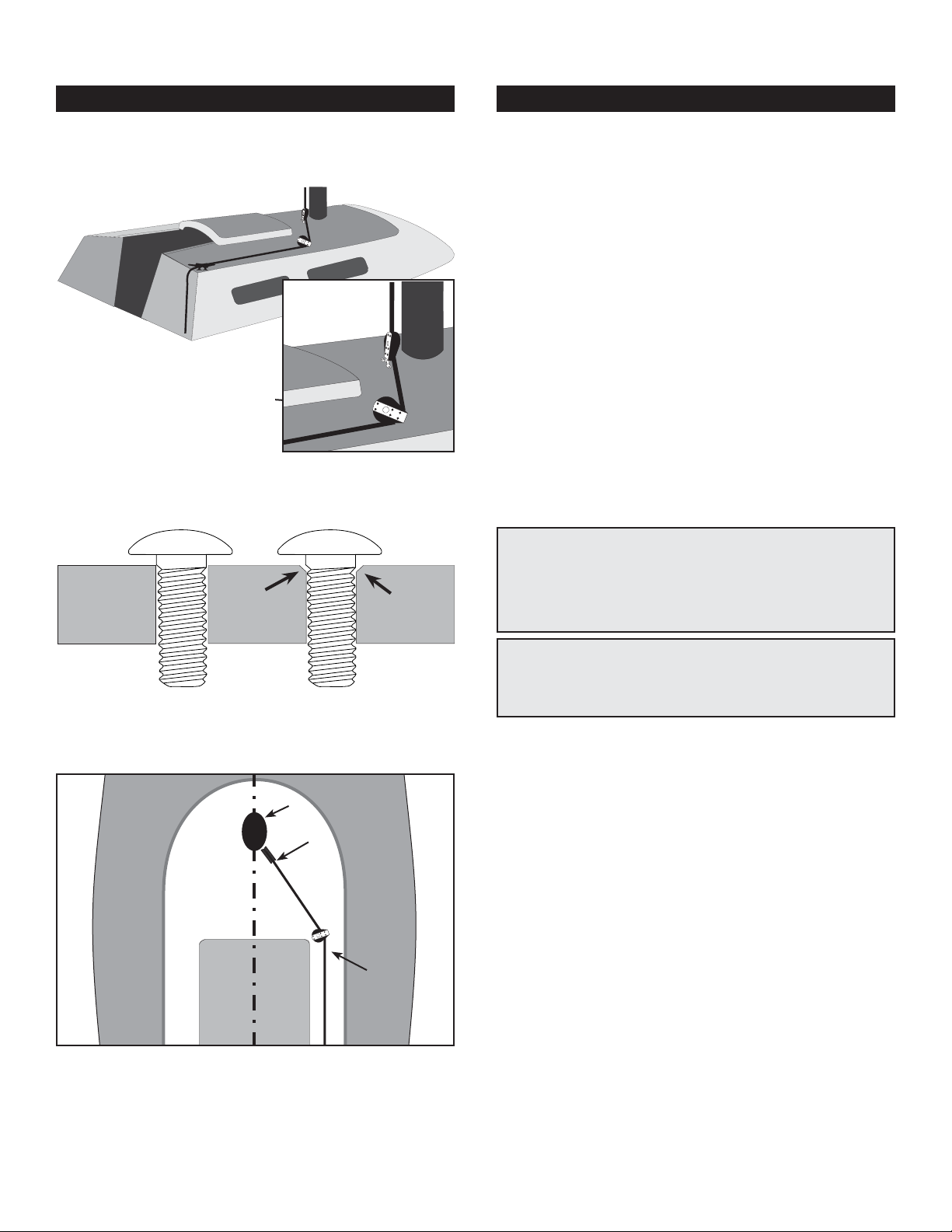

Step 6 Installing Deck Hardware

General Instructions Detailed Instructions

A. Mount mast base block directly below the bullseye

and position so block is angled towards the deflector

block or deck organizer.

Mount so it bisects

line angle and is aft

and inboard to reduce

load on block.

Beveling Top Edge of Hole

Deck

A. If there is a mast collar, remove the eyestrap and

shackle the block to the collar. Alternatively, install the

block with eyestrap to the deck.

Position the eyestrap on the deck below the bullseye.

Align the legs of the eyestrap so they are in line with

the line direction to the deflector block or deck organizer. Consider the location of the back-up nuts below

deck when planning the block’s location of the mast

base block. See tip below.

Drill holes and apply a high quality marine sealant to

the holes. See tip below. Install the block assembly. Use

a back-up plate or large diameter washers inside the

cabin top to back up the hardware.

Drill size - 13/64” (5mm)

Mounting Hardware

2 10-32 X 11/2” Roundhead screws

2 Washers

2 Lockwashers

2 10-32 Nuts

Marine Sealant – Use to seal holes - See tip below.

Installation Tip – Planning Location of Deck Hardware

It is important to plan the location of all deck hardware before

mounting the mastbase block, deflector block and cleat. The

position of one block depends on the location of the other block

or cleat. In addition, you must consider the location and

accessibility of back up hardware inside the cabin top.

Before After

B. Install deflector block so line runs in fore/aft direction

to cleat.

Mast

Mast base

block

Keep

block aft

C. Install cleat or line stopper at a convenient spot on

the cabin top near the main halyard cleat.

Installation Tip – Beveling Top Edge of Hole

After drilling through deck, slightly round off the top edge of the

holes with a small knife. This way, when the sealant is applied, it

will mass around the screw providing a good durable water seal.

B. The deflector block is used to turn the reefing line so

it does not interfere with the companionway hatch or

other obstructions on the cabin top:

1) Place so line runs in straight fore/aft direction to cleat.

2) Keep block aft and inboard to reduce load.

3) Check for suitable position for back-up nut and washers.

4) Rotate so it bisects line angle.

Drill holes, apply marine sealant and install using:

Drill size - 13/64” (5mm)

Mounting Hardware

2 10-32 X 11/2” Roundhead screws

2 Washers

2 Lockwashers

2 10-32 Nuts

Marine sealant – Use to seal holes.

C. You will need to supply a cleat or line stopper for

the Single Line Reefing system and hardware to mount

it. Mount the cleat in a convenient spot within easy

reach of the cockpit, near the main halyard cleat if possible. Make sure the cleat or line stopper is throughbolted and has a suitable back-up plate or washers.

6

Page 7

Step 7 Reeving the Control Line

General Instructions Detailed Instructions

A. Hoist the mainsail.

B. Starting at the eyestrap at the clew slider reeve the

line through the sail and blocks.

6

5

7

8

9

4

2

3

1

10

Step 8 Adjust Clew Car

General Instructions Detailed Instructions

A. Adjust the clew car to find optimum sail shape.

Mark halyard.

Topping Lift

B. You need to supply 5/16” (8 mm) double braided

Dacron line in a length as determined in the formula

on page 2:

1) Tie or splice line end to eyestrap on clew slider.

2) With sail hoisted, run line under the boom and up

through reefing grommet at clew.

3) Lead down through the block on clew slider.

4) Run line forward through eyestrap on boom.

5) Lead line up through big bullet block on mast.

6) Then up through the reefing tack grommet.

7) Down through bullseye on other side of mast.

8) Through the mast base big bullet block.

9) Through deflector block.

10) Back to cleat.

A. With the sail raised, move the clew slider to find the

optimum sail shape. Try reefing the system. The clew

line should pull down and aft at a 30 to 45° angle. It

is important to have a topping lift when reefing to prevent the boom from dropping down into the boat when

the halyard is eased.

Step 9 Reef

General Instructions Detailed Instructions

A. To reef, set the topping lift, ease the halyard, pull the

reef line, and tension the halyard if necessary. Test the

system before you need to use it.

Reefing Tip – Marking the Halyard

Mark the halyard so you know how far to ease it when lowering

the main in preparation for reefing. Start with the sail reefed and

the halyard tensioned. Mark the halyard at the cleat using a permanent marker. When reefing the sail, set the topping life, lower

the halyard to the mark and pull the reef line, and tension the

halyard if necessary.

A. Make sure the topping lift is set. Ease the halyard to

the mark that you have made and cleat it. Pull the reef

line until the clew and tack are down near the boom.

Keep pulling until the foot of the sail is tight and cleat

the reefing line. Check to make sure you can lower

slugs far enough to reef. Do not use stop above feeder

gap. Mount feeder plates so slugs pass below feeder.

Feeder plates are available from spar makers and are

screwed into the mast on either side of the feeder.

7

Page 8

Corporate Headquarters

N15W24983 Bluemound Rd, Pewaukee, WI 53072 USA

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Web: www.harken.com • Online Catalog: www.harkenstore.com

1B Green Street, Brookvale, N.S.W. 2100, Australia

Telephone: (61) 2-8978-8666 • Fax: (61) 2-8978-8667

Web: harken.com.au • Email: info@harken.com.au

ZA Port des Minimes, BP 3064, 17032 La Rochelle Cedex 1, France

Telephone: (33) 05.46.44.51.20 • Fax: (33) 05.46.44.25.70

Via Marco Biagi, 14, 22070 Limido Comasco (CO) Italy

Telephone: (39) 031.3523511 • Fax: (39) 031.3520031

30-36 Fanshawe Street, P.O. Box 1951, Auckland 1001, New Zealand

Telephone: (64) 9-303-3744 • Fax: (64) 9-307-7987

Web: harken.co.nz • Email: harken@harken.co.nz

ul. Rydygiera 8, budynek 3A, lokal 101, I pi

Tel: +48 22 561 93 93 • Fax: +48 22 839 22 75

Main Office and Harken Brandstore: Västmannagatan 81B

Telephone: (46) 0303 61875 • Fax: (46) 0303 61876

Mailing address: Harken Sweden AB, Box 64, SE -440 30 Marstrand

Bearing House, Ampress Lane, Lymington, Hampshire S041 8LW, England

Telephone: (44) 01590-689122 • Fax: (44) 01590-610274

Web: harken.co.uk • Email: enquiries@harken.co.uk

Email: harken@harken.com

Harken Australia Pty, Ltd.

Harken France

Web: harken.fr • Email: info@harken.fr

Harken Italy S.p.A.

Web: harken.it • Email: info@harken.it

Harken New Zealand, Ltd.

Harken Polska SP ZOO

ętro, 01-793 Warszawa, Poland

Web: harken.pl • Email: polska@harken.pl

Harken Sweden AB

SE-113 26 Stockholm Sweden

Web: harken.se • Email: harken@harken.se

Harken UK, Ltd.

Please visit: http://www.harken.com/locator.aspx

to locate Harken dealers and distributors

Printed in USA 4171 12/13

Loading...

Loading...