Page 1

INSTRUCTIONS

Trigger Cleat 418

N15W24983 Bluemound Road • Pewaukee, WI 53072 U.S.A.

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Web: www.harken.com • Email: harken@harken.com

Strictly follow all instructions to avoid an accident, damage to

your vessel, personal injury, or death. See www.harken.com

for additional safety information.

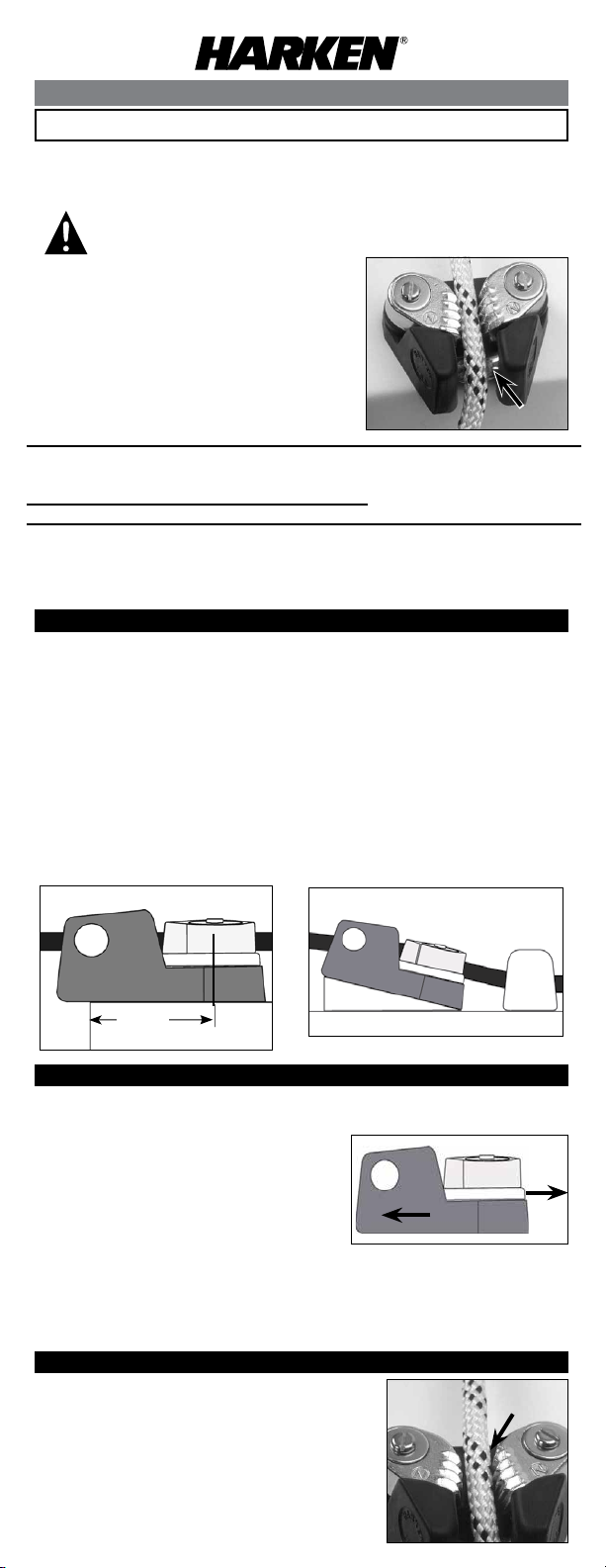

The 418 Trigger cleat allows easy

release of highly-loaded lines with

complete control. Pulling line down

on the trigger mechanism opens

cleat. Line never comes off cleat.

The trigger serves as a snubbing

surface to control release.

Trigger

Max line ØMin line ØMaximum

Part

No.

in mm in mm lb kg in mm

3

418

/16 5 1/2 12 500 227 2 51

working load

Fastener

spacing

Fastener size/

comments

5 mm (#10) PH/RH–ships w/1

screws and nuts to hold assembly.

OPTIONS: 419 eyestrap; 355 mounting bracket to attach cleat to Harken

Classic blocks: 052, 064, 152, and 411. See reverse side for mounting to

Carbo triple blocks.

Installing 418 Trigger Cleat

Placement

The angle of line from cleat to operator is important for efficient

release. For best operation, mount cleat at waist or chest height

in your normal operating position. If possible, mount cleat on

edge of deck, cockpit, or cabin.

3

Place mounting holes back 35 mm (1

13

Drill size 5 mm (

/64") or #12.

If line angle is too low, or if cleat cannot be mounted near an edge, mount

cleat on pad or bracket inclined 25°. Install bullseye fairlead or turning

block on the loaded side of the cleat to lead line into cleat parallel to cams.

35 mm

(13/8")

/8") from edge so cleat overhangs.

5

/8"

Adjusting Cleat to Fit Line Size

The Trigger cleat will accept most lines up to 12 mm (

To adjust cleat to fit larger size line,

loosen screws and lift cam cleat and

its platform slightly from base. Slide

base toward you, against spring

tension. Press cleat and platform

down and hold in place until screws

are tight.

Tip: Mount screws through cleat and deck with nuts loosely threaded.

Screws should be ready to tighten before adjusting for larger line.

Cam base and cam platform have ridges and interlocking grooves

to help hold them in place until screws are tight.

1

/2").

Check for Proper Adjustment

With lever fully depressed, cam gap should be

slightly larger than line size. If gap is too small,

shift base to position for larger line size.

With line loaded in cams, lever should not

contact top of lever cavity. This will prevent

cams from closing tightly against line. If rope

slips when loaded, shift base to position for

smaller rope size.

Cam gap

Page 2

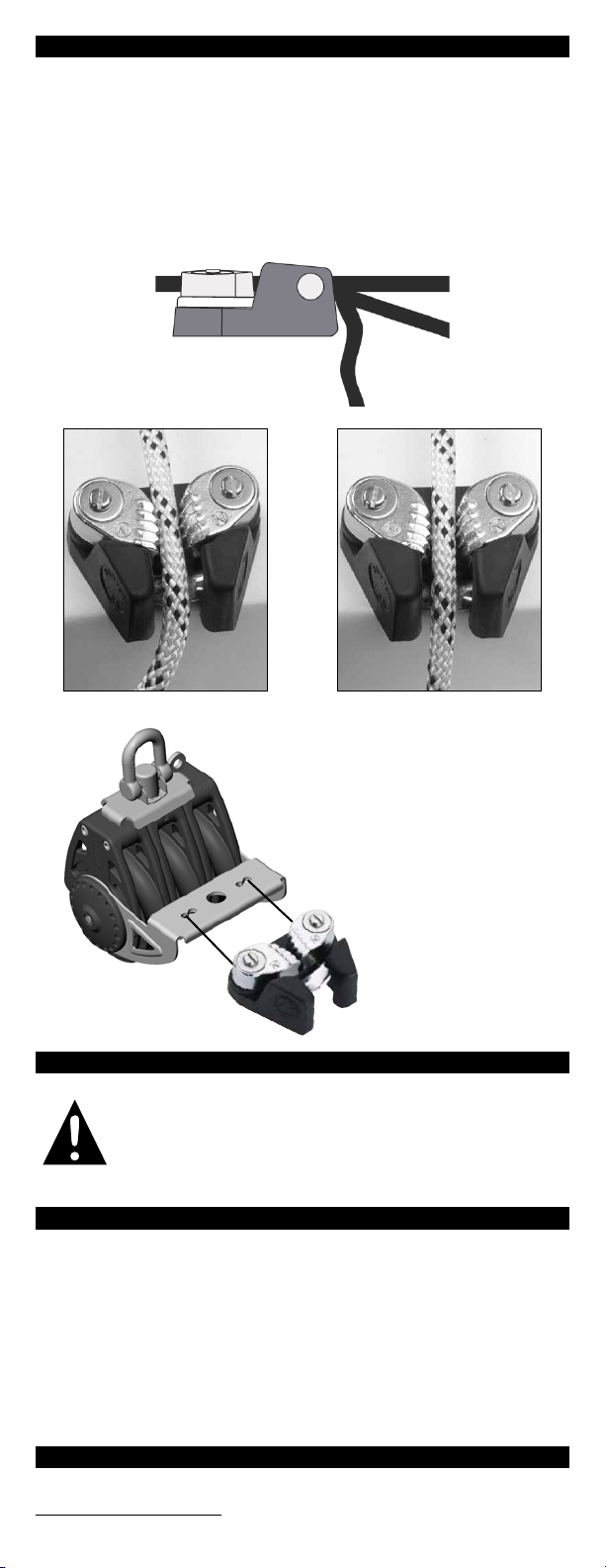

How Trigger Cleat Works

Pull line tail downward as in position B. The release lever opens cams so

line may be eased. By holding a downward angle, lever acts as a snubbing

surface for better control of heavily loaded lines.

Raise line tail (position C), or simply release line (position A).

Spring-loaded cams close to cleat line again.

Fairings around release lever allow cleating when tail leaves cleat at up

to 45° to either side of cleat axis. Line stays between cams at all times.

C

B

A

A B

Fitting triple carbo blocks

Use outer holes for mounting

57 mm or 75 mm Carbo block

triple cam arms.

Inspect Parts Each Time you Sail

WARNING! Parts must be inspected each time you sail.

If parts are under load during long passages, it is important

to inspect them carefully while in use. Failure to inspect and

correct block and loop or lashing can result in block breaking

under load causing an accident, or damage to your vessel.

Maintenance

Harken equipment is designed for minimal maintenance. However, some

upkeep is required to give the best service and comply with the Harken

limited warranty.

Keep your equipment clean and free-running by frequently flushing with

fresh water. Periodically clean with mild detergent and water solution.

Spin sheaves to distribute soap solution evenly. Flush with fresh water.

Important! Exposure to some teak cleaners and other caustic solutions can

result in discoloration of part and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance and warranty information see

www.harken.com/manuals or the Harken catalog.

Printed in USA. 4527/12-14

Loading...

Loading...